Panasonic SAPM-31-P, SAPM-31-PC Service manual

A

CD Stereo System

SA-PM31P

SA-PM31PC

Colour

(S)... Silver Type

ORDER NO. MD0412578C1

A6

Specification

n Amplifier Section

Power output

10% Total harmonic distortion

60 Hz - 3 kHz, both channels driven

(Low channel) 35 W per channel (6 Ω)

3 kHz - 16 kHz, both channels driven

(High channel) 35 W per channel (6 Ω)

Total Bi-Amp power 70 W per channel

Power output

10% Total harmonic distortion

1 kHz, both channels driven

(Low channel) 40 W per channel (6 Ω)

8 kHz, both channels driven

(High channel) 40 W per channel (6 Ω)

Total Bi-Amp power 80 W per channel

Output Impedance

Headphone 16 Ω -32Ω

n FM Tuner Section

Frequency range 87.5 MHz - 108.0 MHz

(100 kHz steps)

87.9 MHz - 107.9 MHz

(200 kHz steps)

Sensitivity 1.02 µV (IHF)

S/N 26 dB 1.00 µV

ntenna terminal(s) 75 Ω (unbalanced)

n AM Tuner Section

Frequency range 520 kHz - 1710 kHz (10 kHz

steps)

Sensitivity

S/N 20 dB (at 1000 kHz) 900 µV/m

n Cassette Deck Section

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s

Overall frequency response (+3 dB, -6 dB at DECK OUT)

NORMAL (TYPE I) 35 Hz - 14 kHz

S/N RATIO 42.64 dB (A weighted)

Wow and flutter 0.08% (WRMS)

Fast forward and rewind time Approx. 120 seconds with C-60

cassette tape

n CD Section

Disc

© 2004 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SA-PM31P / SA-PM31PC

CD, CD-R, CD-RW, MP3 8 cm/12 cm (3-3/20” / 4-

Sampling frequency 44.1 kHz

Decoding 16/20/24 bit linear

Beam source/wavelength Semiconductor laser / 780 nm

Number of channels Stereo

Frequency response 20 Hz - 20 kHz (+1dB, -2dB)

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

MP3

Bit rate 32 kbps - 320 kbps

Sampling frequency 32kHz, 44.1kHz, 48kHz

n General

Power supply AC 120 V, 60 Hz

73/100”)

Power consumption 135 W

Dimensions (W x H x D) 175 x 254 x 390.7 mm

(6-89/100” x 10” x 15-19/50”)

Mass 5.44 kg (11.99 lbs.)

Power consumption in standby mode: 0.4 W

n System: SC-PM31P-S

n System: SC-PM31PC-S

Notes:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

3. The labels “HIGH” and “LOW” on the rear of the speakers refer

to High frequency and Low frequency.

Music Center: SA-PM31P-S

Speaker: SB-PM31P-SJ

Music Center: SA-PM31PC-S

Speaker: SB-PM31P-SJ

CONTENTS

Page Page

1 Safety Cautions

1.1. GENERAL GUIDELINES

2 Before Repair and Adjustment

3 Protection Circuitry

4 Handling the Lead-free Solder

4.1. About lead free solder (PbF)

5 Precaution of Laser Diode

6 Handling Precautions For Traverse Deck

7 Accessories

8 Operating Procedures

9 Assembling and Disassembling

9.1. Disassembly flow chart

9.2. Disassembly of Side Panel L & R

9.3. Disassembly of Top Cabinet Unit

9.4. Disassembly of Deck P.C.B. and Tape Eject P.C.B.

9.5. Disassembly of Front Panel Assembly

9.6. Disassembly of Main Control P.C.B., Function P.C.B. and

Power-In P.C.B.

9.7. Disassembly of Panel P.C.B.

9.8. Disassembly of Rear Panel

9.9. Disassembly of Main P.C.B.

9.10. Disassembly of Transforme r P.C.B.

9.11. Disassembly of Tuner Pack

9.12. Disassembly of Power P.C.B

9.13. Disassembly of CR16 Mechanism

9.14. Replacement of CD Lid

9.15. Replacement of Cassette Lid

9.16. Replacement of the Power IC and Transistors.

4

4

5

5

5

5

6

7

8

9

11

11

12

12

12

13

14

14

15

15

16

16

17

17

18

19

20

9.17. Procedure for Replacing Pinch Roller and Head Block

(Cassette Mechanism Unit)

9.18. Procedure for Replacing Motor, Capstan Belt A, Capstan

Belt B, and Winding Belt (Cassette Mechanism Unit)

9.19. Procedure for Replacing Parts on Mechanism PCB

9.20. Replacement of CD traverse deck

9.21. Replacement of optical pickup unit (CD mechanism)

9.22. Replacement of a traverse gear A and a traverse gear B

9.23. Procedure for removing CD loading mechanism

9.24. CR16 mechanism disassembly procedure

9.25. CR16 MECHANISM ASSEMBLY PROCEDURE

9.26. Disassembly of traverse mechanism

9.27. Handling of Cassette Tape jam

10 Service Positions

10.1. Checking procedure

10.2. Checking the major P.C.B.

11 Self-Diagnostic Display Function

11.1. Entering into Self-Diagnostic Mode

11.2. Clearing Self-Diagnostic Memory

11.3. Displaying Self-Diagnostic Results

11.4. Error Code Table

11.5. Cassette Mechanism Self-Diagnostic Mode

11.6. Changer Reliability Test Mode

11.7. Changer Operation Checking

11.8. CR16 Mechanism Ageing Mode

12 Procedure for Checking Operation of Individual Parts of

Cassette Mechanism Unit

12.1. Operation Check with Cassette Tape

2

21

21

23

23

25

26

27

27

34

46

47

48

48

48

49

49

51

51

52

52

53

53

54

55

55

12.2. Operation Check without Cassette Tape 55

13 Measurement And Adjustments

13.1. Tuner/CD Sections

13.2. Cassette Deck Section

14 Voltage Measurement and Waveform Chart

14.1. Waveform

15 Block Diagram

15.1. CD Servo Block

15.2. Main Block

16 Notes of Schematic Diagram

17 Schematic Diagram

17.1. CD Servo Circuit

17.2. Main Circuit

17.3. Main Control Circuit, Panel Circuit, Power-In Circuit and

Function Circuit

17.4. Deck Circuit, Deck Mechanism Circuit and Tape Eject

Circuit

17.5. Power Circuit

17.6. Transformer Circuit

17.7. CD Loading Circuit

18 Printed Circuit Board

18.1. CD Servo P.C.B.

18.2. Main P.C.B.

18.3. Main Control P.C.B. and Panel P.C.B.

57

57

57

59

62

63

63

65

70

71

71

73

18.4. Power In P.C.B., Function P.C.B. and Deck Mechanism

P.C.B.

18.5. Deck P.C.B. and Tape Eject P.C.B.

18.6. CD Loading P.C.B.

18.7. Power P.C.B.

18.8. Transformer P.C.B.

19 Wiring Connection Diagram

20 Illustration of IC 痴, Transistors and Diodes

21 Terminal Function of ICエs

21.1. IC702 (MN6627953HB) Servo processor/ Digital signal

processor/ Digital filter/ D/A converter

21.2. IC703 (BA5948FP E2) IC 4CH DRIVE

21.3. IC302 (C2CBJG000574) MICRO PROCESSOR

22 Troubleshooting Flowchart (CD Section Circuit)

77

23 Parts Location and Replacement Parts List

79

81

84

85

86

86

23.1. Deck Mechanism

23.2. CD Loading Mechanism

23.3. Cabinet

23.4. Electrical Part List

23.5. Packaging Materials & Accessories Parts List

23.6. Packaging

87

SA-PM31P / SA-PM31PC

89

90

91

92

93

94

95

97

98

98

98

99

101

103

104

106

111

114

122

122

3

SA-PM31P / SA-PM31PC

1 Safety Cautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

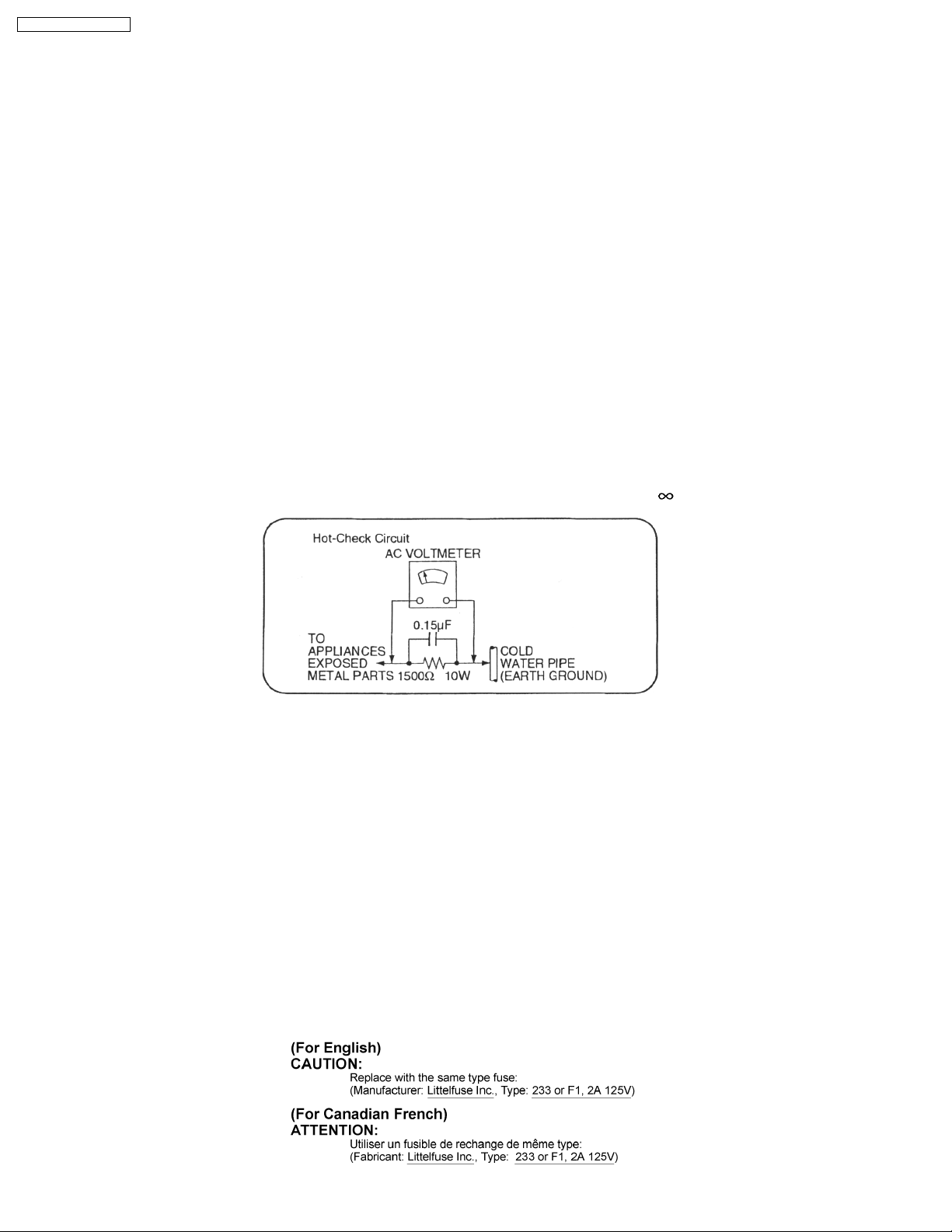

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩand 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. Should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

1.1.3. CAUTION FOR FUSE REPLACEMENT

4

SA-PM31P / SA-PM31PC

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C506, C507, C508, C600, C601, C602, C620 through a 10Ω,1W

resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

· Current consumption at AC 120V, 60 Hz in NO SIGNAL mode (volume min) should be ~300 mA.

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4 Handling the Lead-free Solder

4.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please comple tely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

5

SA-PM31P / SA-PM31PC

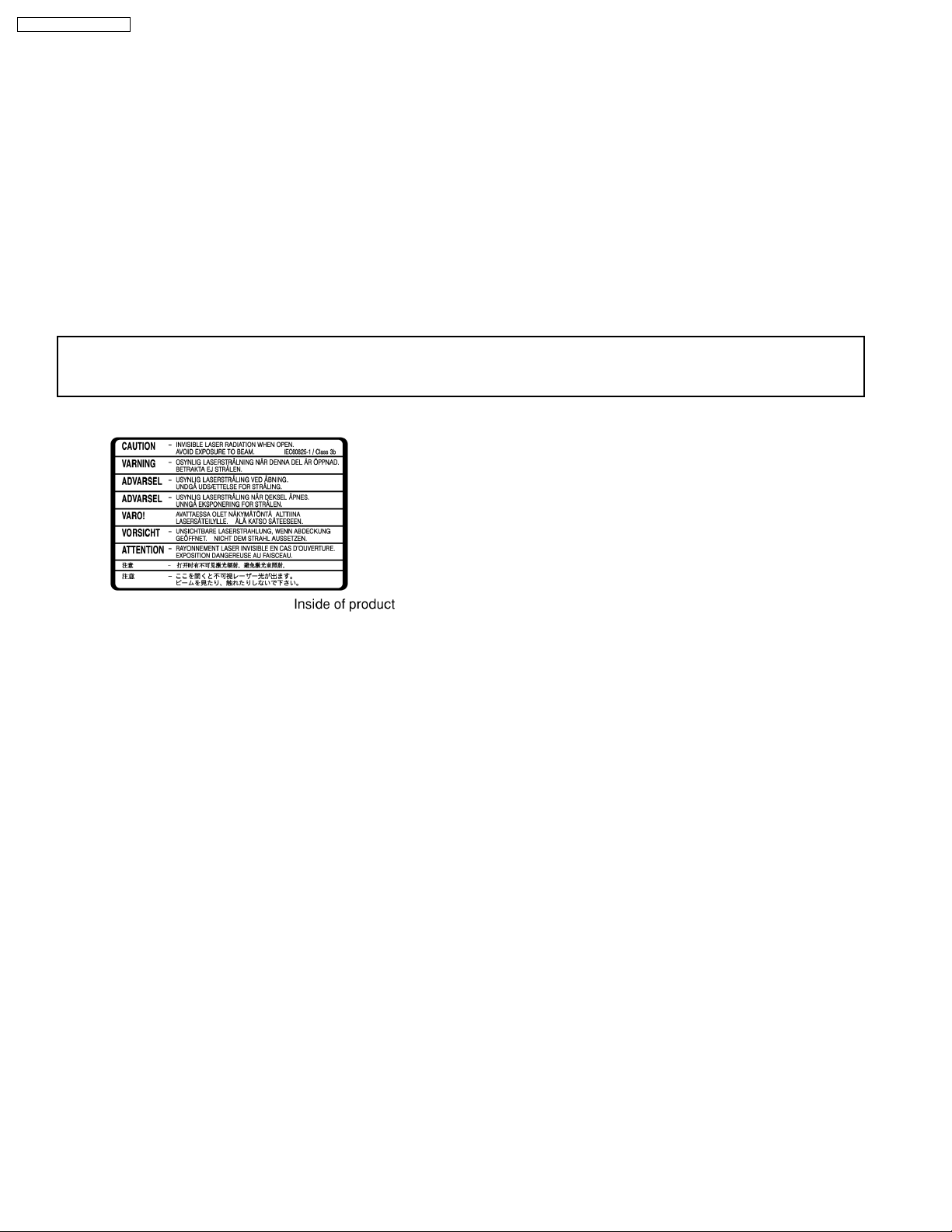

5 Precaution of Laser Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pickup lens.

When the unit is turned on:

1. Do not look directly into the pick up lens.

2. Do not use optical instruments to look at the pick up lens.

3. Do not adjust the preset variable resistor on the pickup lens.

4. Do not disassemble the optical pick up unit.

5. If the optical pick up is replaced, use the manufacturer’s specified replacement pick up only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of caution label (Except for U.S.A.)

6

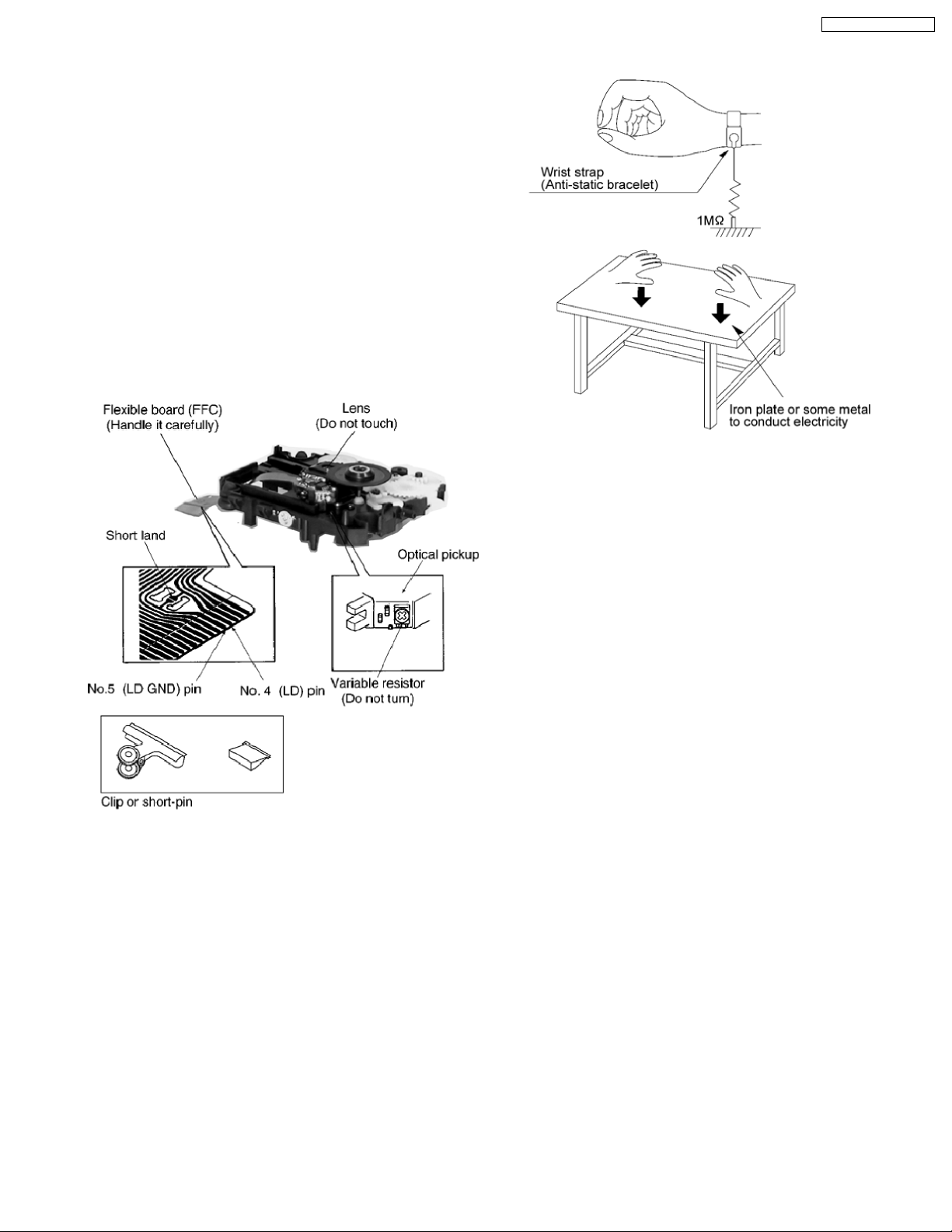

6 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

l Handling of CD traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to

static electricity as it is extremely sensitive to electrical

shock.

2. The short land between the No.4 (LD) and No.5 (GND)

pins on the flexible board (FFC) is shorted with a solder

build-up to prevent damage to the laser diode (Fig 1).

3. Take care not to apply excessive stress to the flexible

board (FPC board).

4. Do not turn the variable resistor (laser power

adjustment). It has already been adjusted.

Caution when Replacing the Optical Pickup :

The traverse has a short point shorted with solder to protect

the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making

connections.

SA-PM31P / SA-PM31PC

Fig 2

Fig 1

l Grounding for electrostatic breakdown prevention

1. Human body grounding (Fig 2)

Use the anti-static wrist strap to discharge the static

electricity from your body.

2. Work table grounding (Fig 2)

Put a conductive material (sheet) or steel sheet on the

area where the traverse deck (optical pickup) is placed,

and ground the sheet.

Caution :

The static electricity of your clothes will not be grounded

through the wrist strap. So, take care not to let your

clothes touch the traverse deck (optical pickup).

7

SA-PM31P / SA-PM31PC

7 Accessories

Note : Refer to Packaging Materials & Accessories for the part number.

AC power cord

FM indoor antenna

AM loop antenna

Remote control

8

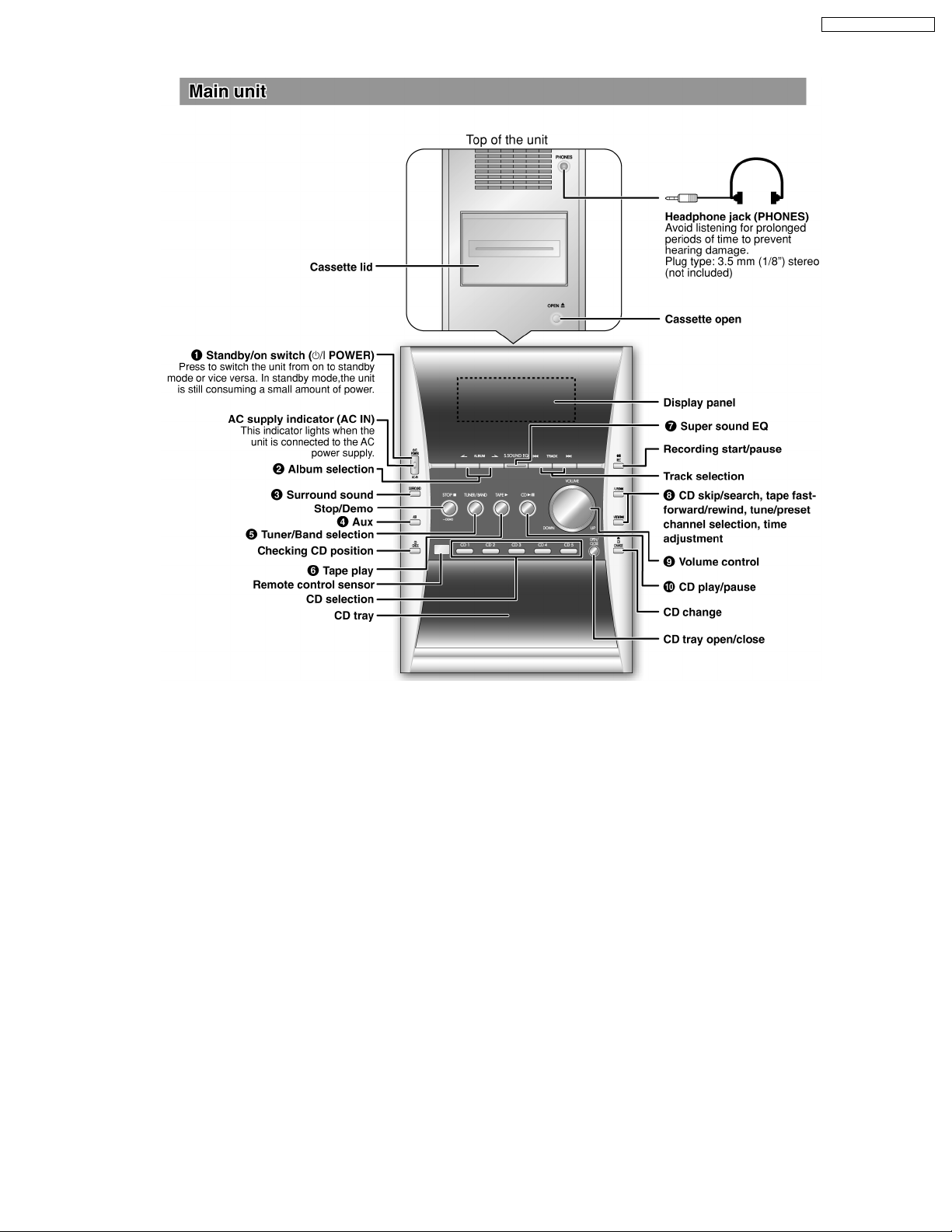

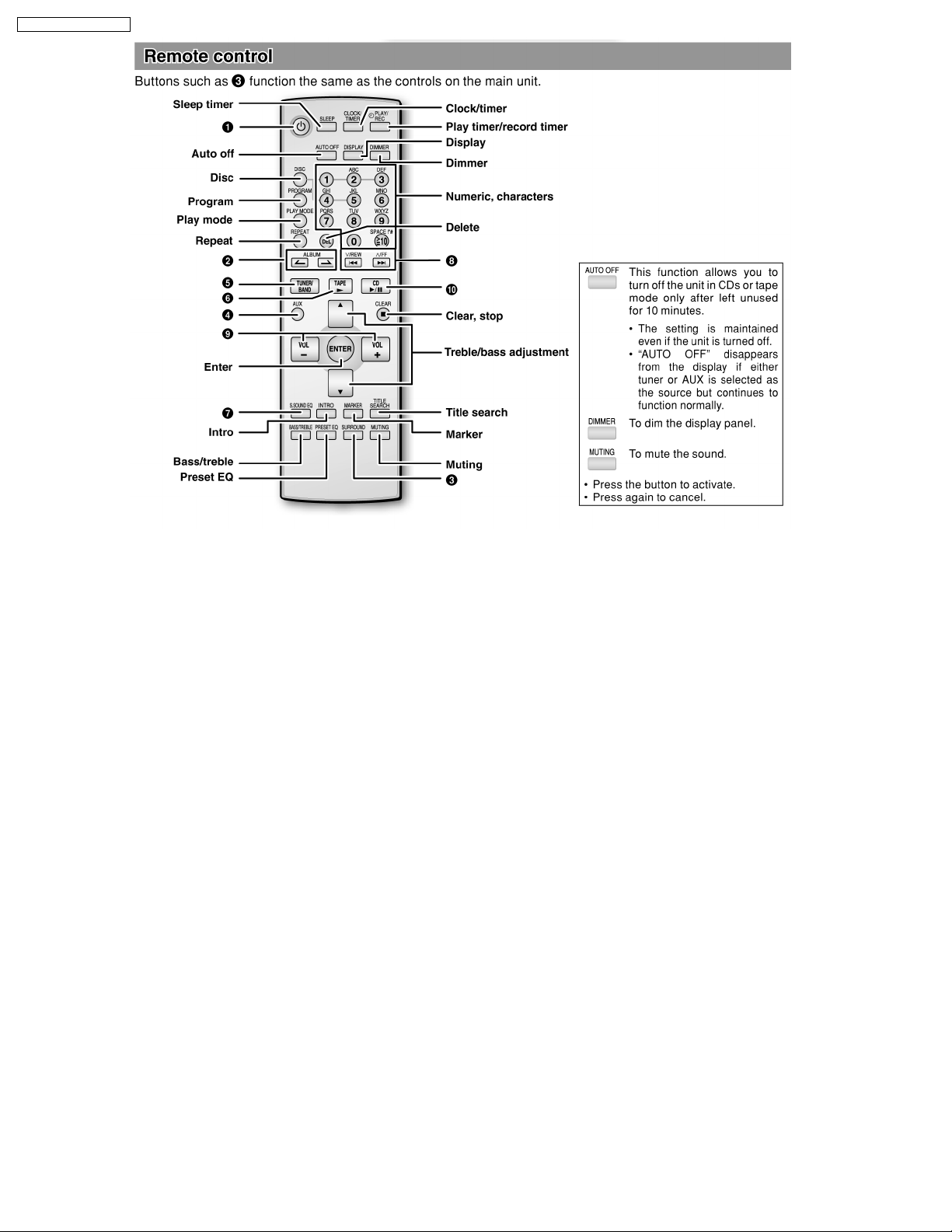

8 Operating Procedures

SA-PM31P / SA-PM31PC

9

SA-PM31P / SA-PM31PC

10

SA-PM31P / SA-PM31PC

9 Assembling and Disassembling

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to “Precaution of Laser Diode”.

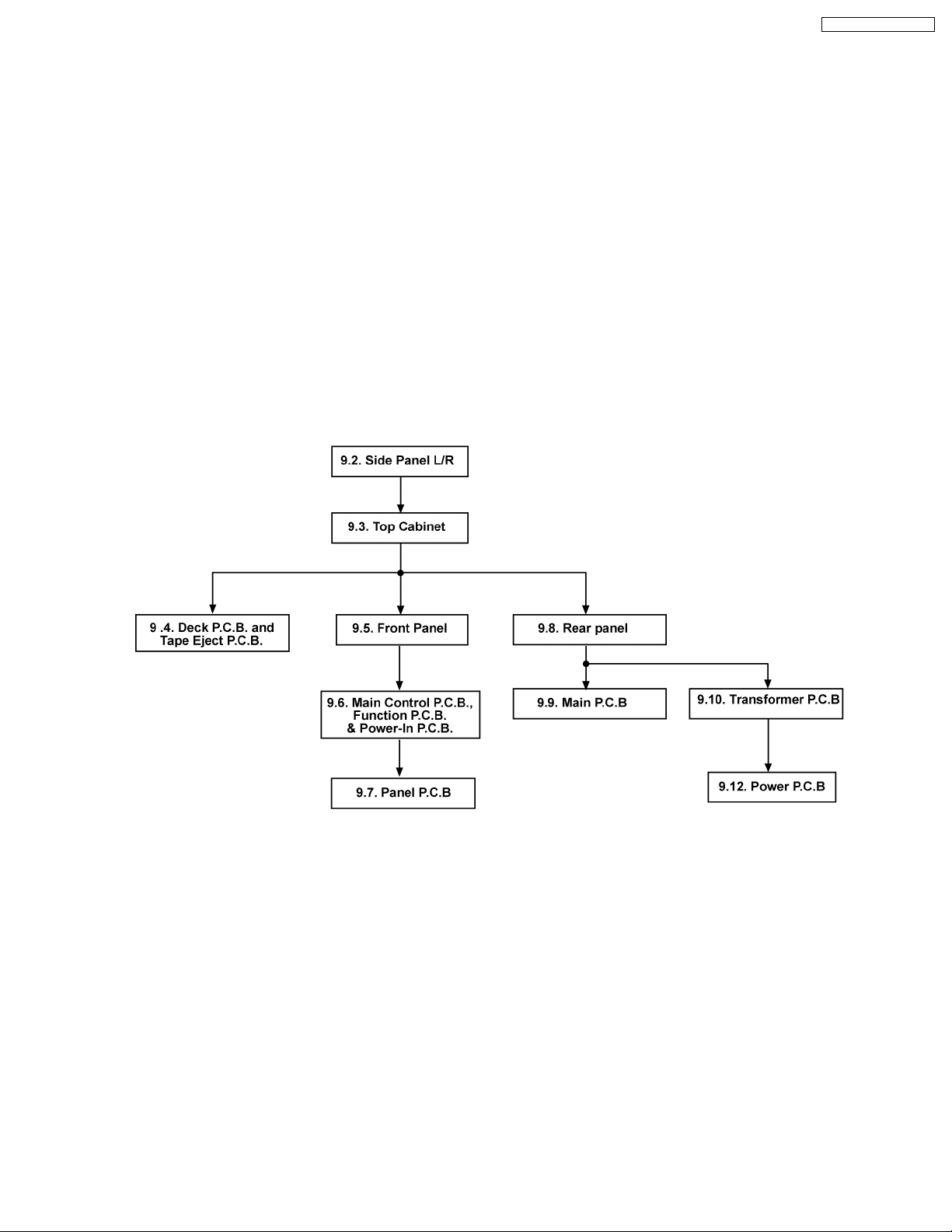

9.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

11

SA-PM31P / SA-PM31PC

9.2. Disassembly of Side Panel L &

R

Step 1 : Remove 5 screws.

Step 2 : Remove 1 screw.

Step 3 : Remove the side panel as arrow shown (Be careful of

the catches).

Step 1 : Remove 1 screw.

Step 2 : Lift up the top Cabinet as arrow shown (be careful of

the catches).

Step 4 : Remove 5 screws.

Step 5 : Remove 1 screw.

Step 6 : Remove the side panel as arrow shown (Be careful of

the catches).

9.3. Disassembly of Top Cabinet

Unit

· Follow the (Step 1) - (Step 6) of Item 9.2.

Step 3 : Place the top cabinet as shown and detach the

connector CN1305.

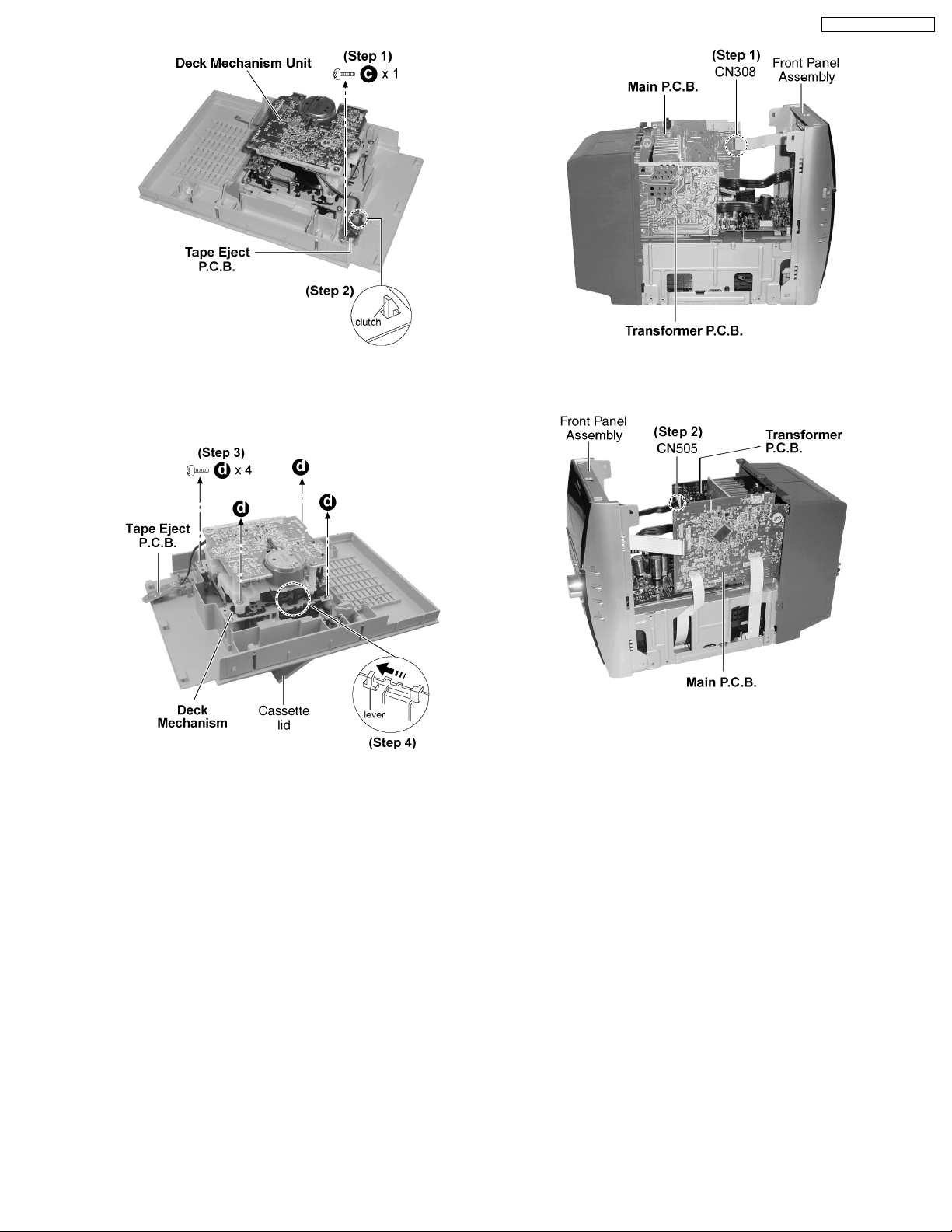

9.4. Disassembly of Deck P.C.B.

and Tape Eject P.C.B.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

12

SA-PM31P / SA-PM31PC

Step 1 : Remove 1 screw.

Step 2 : Release the clutch.

Step 3 : Remove 4 screws.

Step 4 : Push the lever as arrow shown to open the cassette lid

and remove the Deck Mechanism Unit.

Step 1 : Detach the connector CN308.

Step 2 : Detach the connector CN505.

9.5. Disassembly of Front Panel

Assembly

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

13

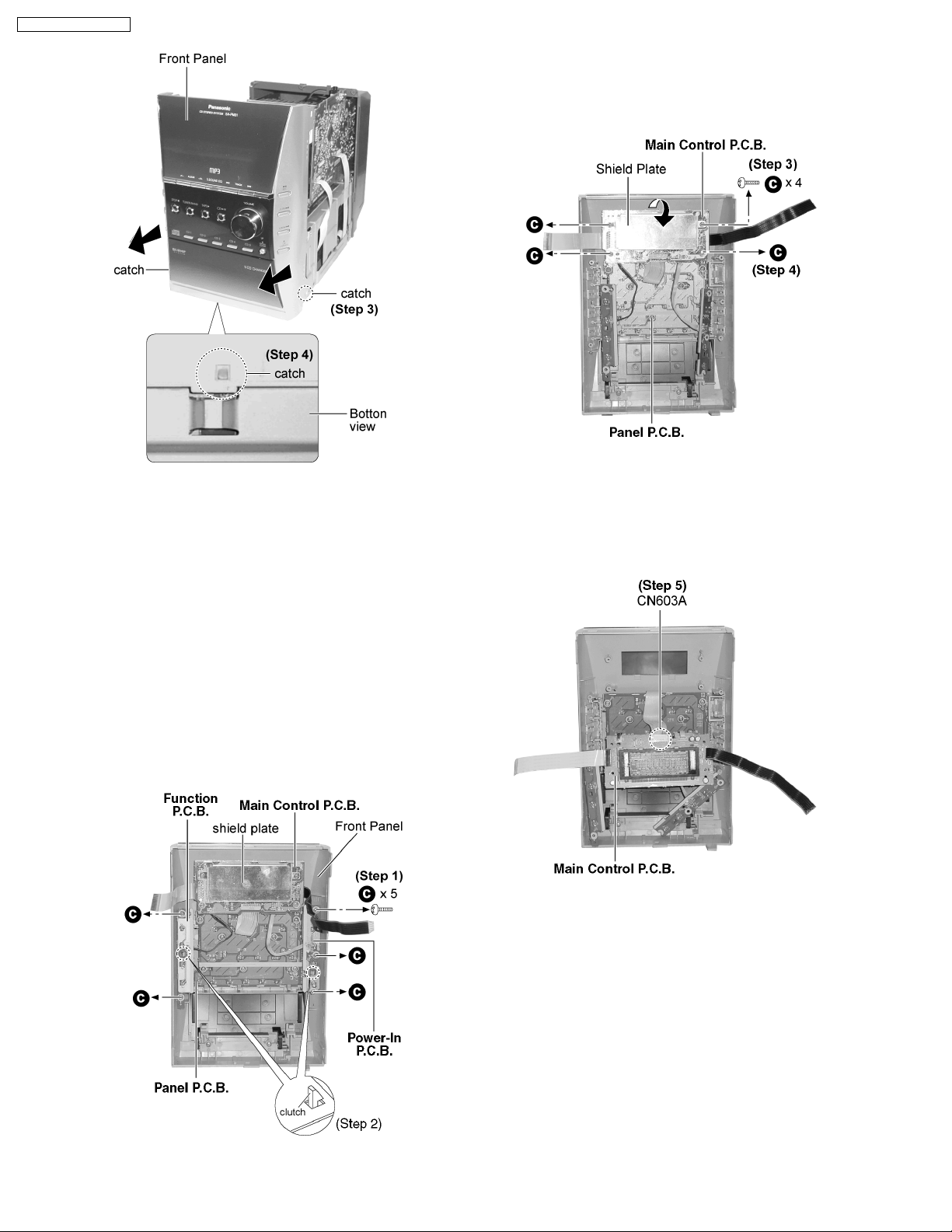

SA-PM31P / SA-PM31PC

Step 2 : Release 2 clutches and remove both Function P.C.B.

and Power-In P.C.B.

· Disassembly of Main Control P.C.B.

Step 3 : Release 2 catches and remove the front panel as

arrows shown.

Step 4 : Release the catch at the bottom cabinet as shown.

9.6. Disassembly of Main Control

P.C.B., Function P.C.B. and

Power-In P.C.B.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Disassembly of Function P.C.B. and Power-In P.C.B.

Step 3 : Remove 2 screws to remove the shield plate.

Step 4 : Remove 2 screws and flip the Main Control P.C.B. as

arrow shown.

Step 5 : Detach the connector CN603A.

Step 1 : Remove 5 screws.

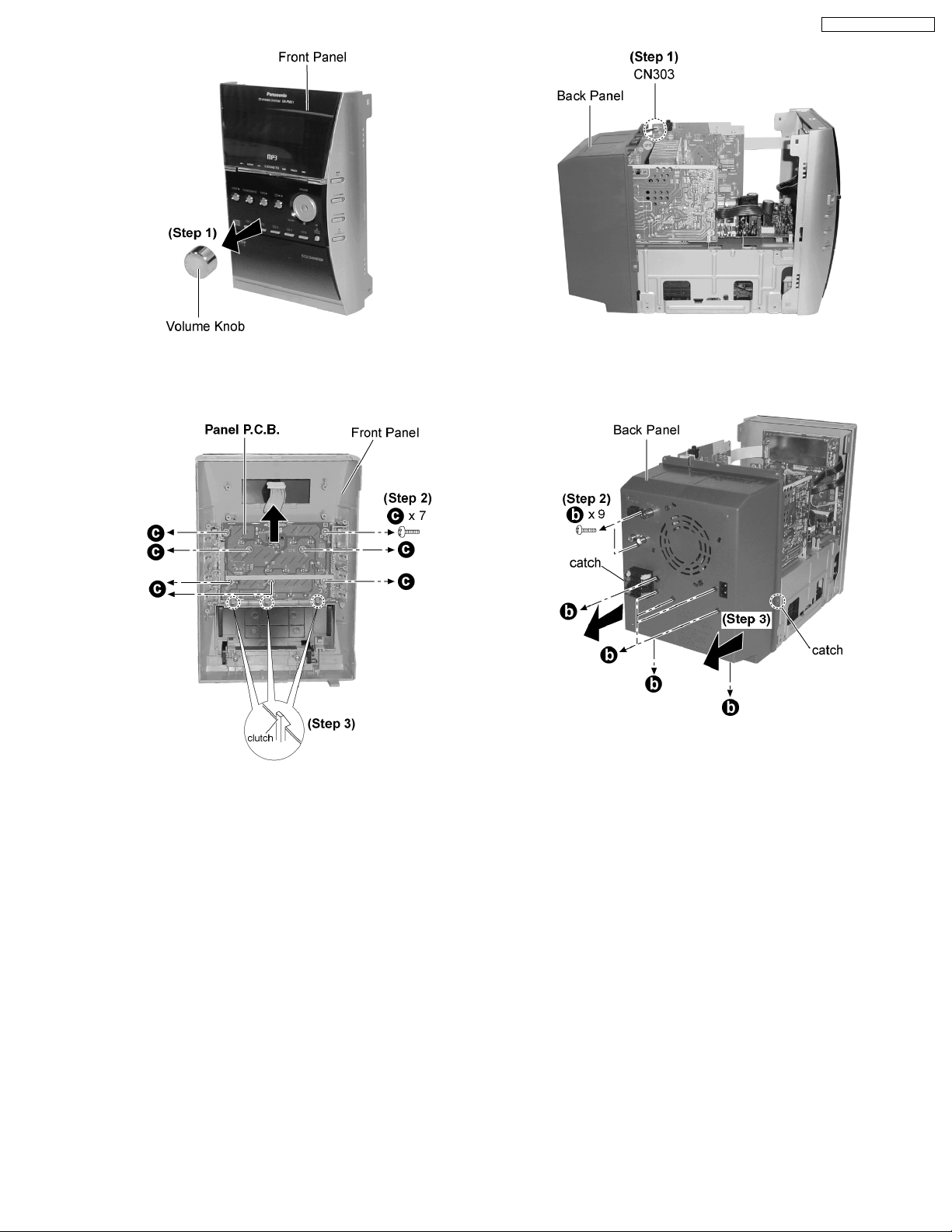

9.7. Disassembly of Panel P.C.B.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.6.

14

SA-PM31P / SA-PM31PC

Step 1 : Remove the volume knob.

Step 2 : Remove 7 screws.

Step 3 : Release 3 clutches and remove the Panel P.C.B. as

arrow shown.

Step 1 : Detach the connector CN303.

Step 2 : Remove 9 screws.

Step 3: Remove the rear panel as arrows shown (Be careful of

the catches).

9.9. Disassembly of Main P.C.B.

9.8. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 3) of Item 9.8.

15

SA-PM31P / SA-PM31PC

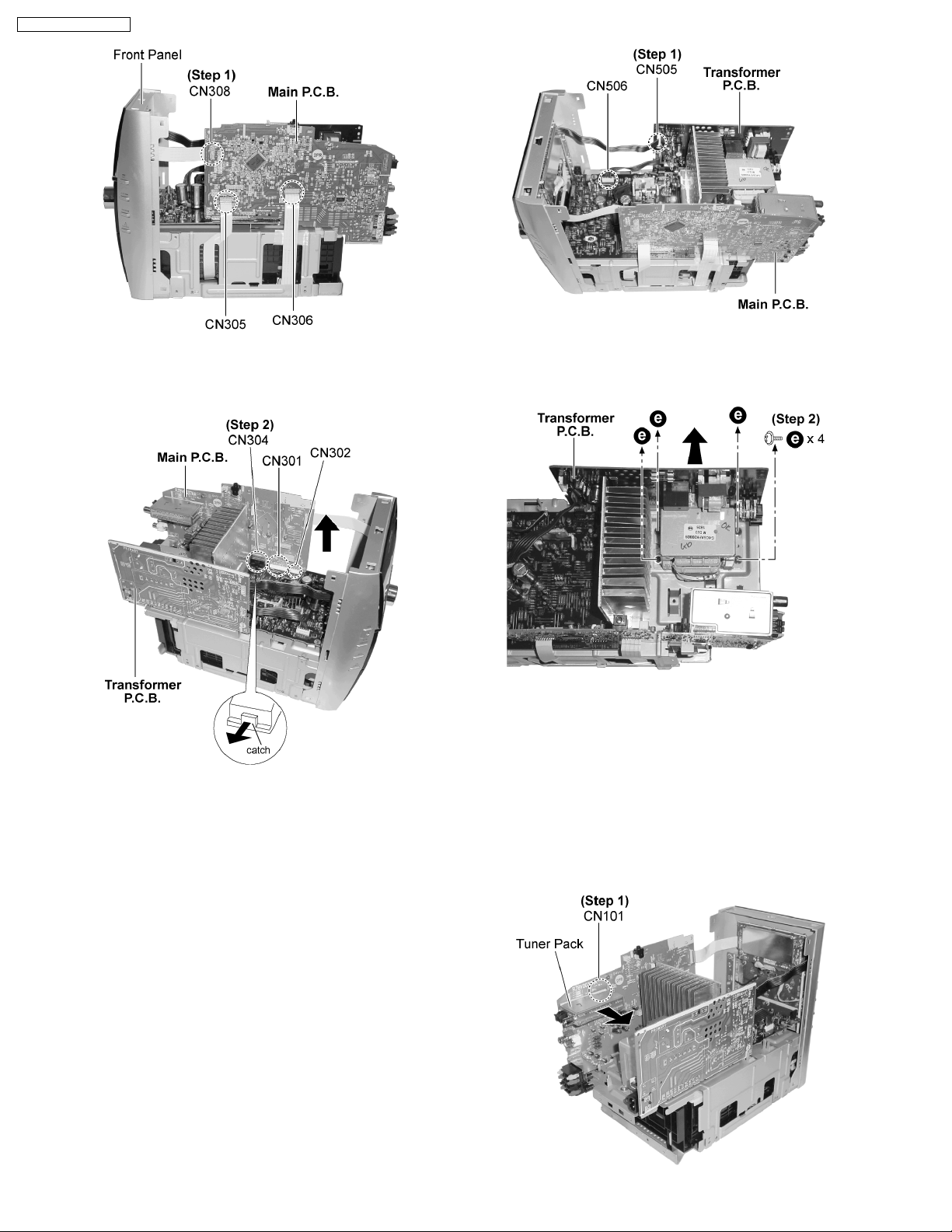

Step 1 : Detach the connectors CN308, CN305 and CN306 .

Step 1 : Detach the connectors CN505 and CN506.

Step 2 : Detach the connectors CN304 (pull the catch as arrow

shown), CN301 and CN302 and pull out the Main P.C.B as

arrow shown.

9.10. Disassembly of Transformer

P.C.B.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 3) of Item 9.8.

Step 2 : Remove 4 screws and pull out the Transformer P.C.B.

as arrow shown.

9.11. Disassembly of Tuner Pack

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 3) of Item 9.8.

16

Step 1 : Detach the connector CN101 and remove the tuner

pack as arrow shown.

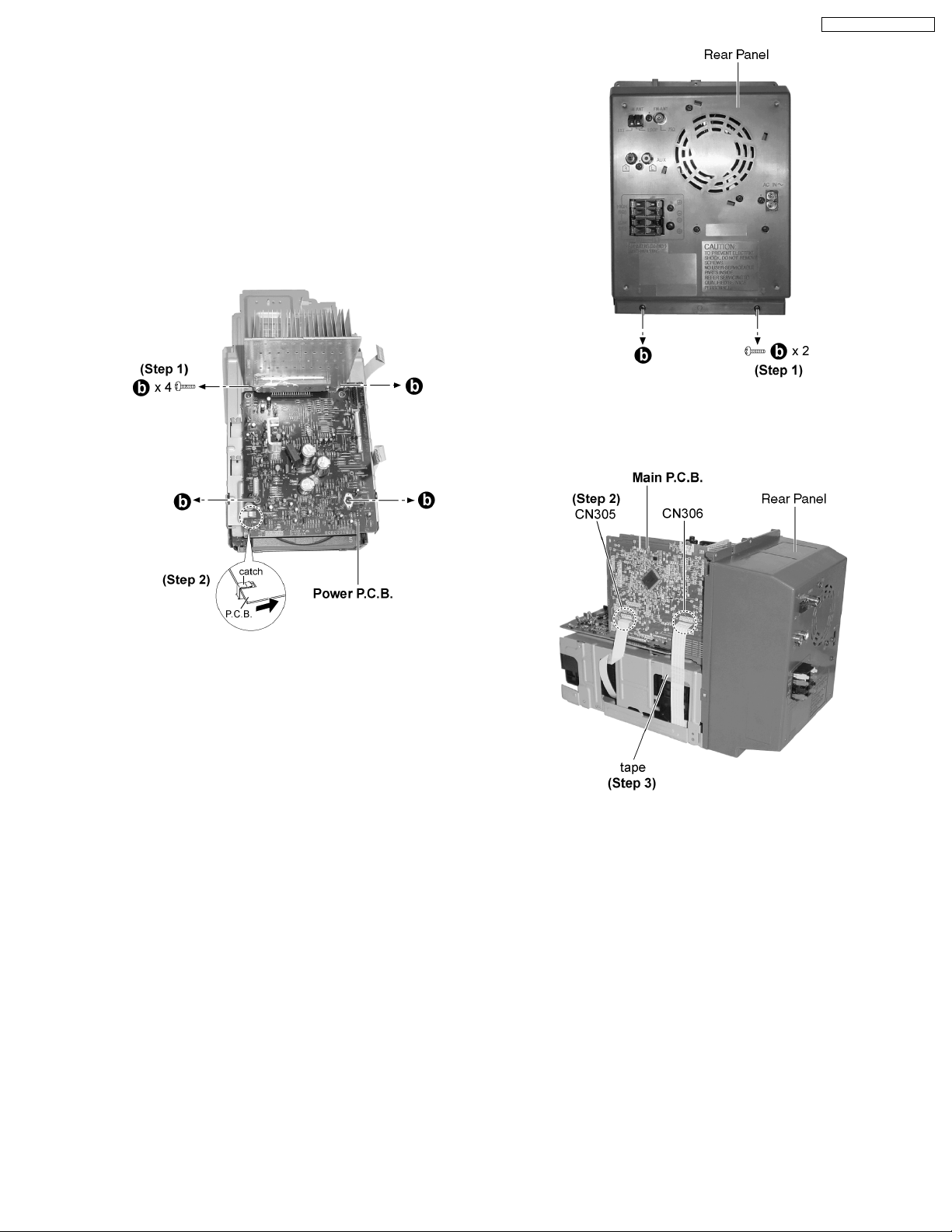

9.12. Disassembly of Power P.C.B

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 3) of Item 9.8.

· Follow the (Step 1) - (Step 2) of Item 9.9.

· Follow the (Step 1) - (Step 2) of Item 9.10.

SA-PM31P / SA-PM31PC

Step 1 : Remove 2 screws.

Step 1 : Remove 4 screws.

Step 2 : Remove the Power P.C.B. as arrow shown (be careful

of the catch).

9.13. Disassembly of CR16

Mechanism

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

Step 2 : Detach the connectors CN305 and CN306.

Step 3 : Remove the tape which used to secure the FFC

connectors.

17

SA-PM31P / SA-PM31PC

Step 4 : Release the catches and remove the middle block as

arrow shown.

Step 1 : Remove 2 screws and the 2 CD lid supports.

Step 5 : Remove 2 screws and remove the CD Mechanism Unit

from the bottom chassis.

9.14. Replacement of CD Lid

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

Step 2 : Push the spring as arrow shown.

18

Step 3 : Remove the CD lid as arrow shown.

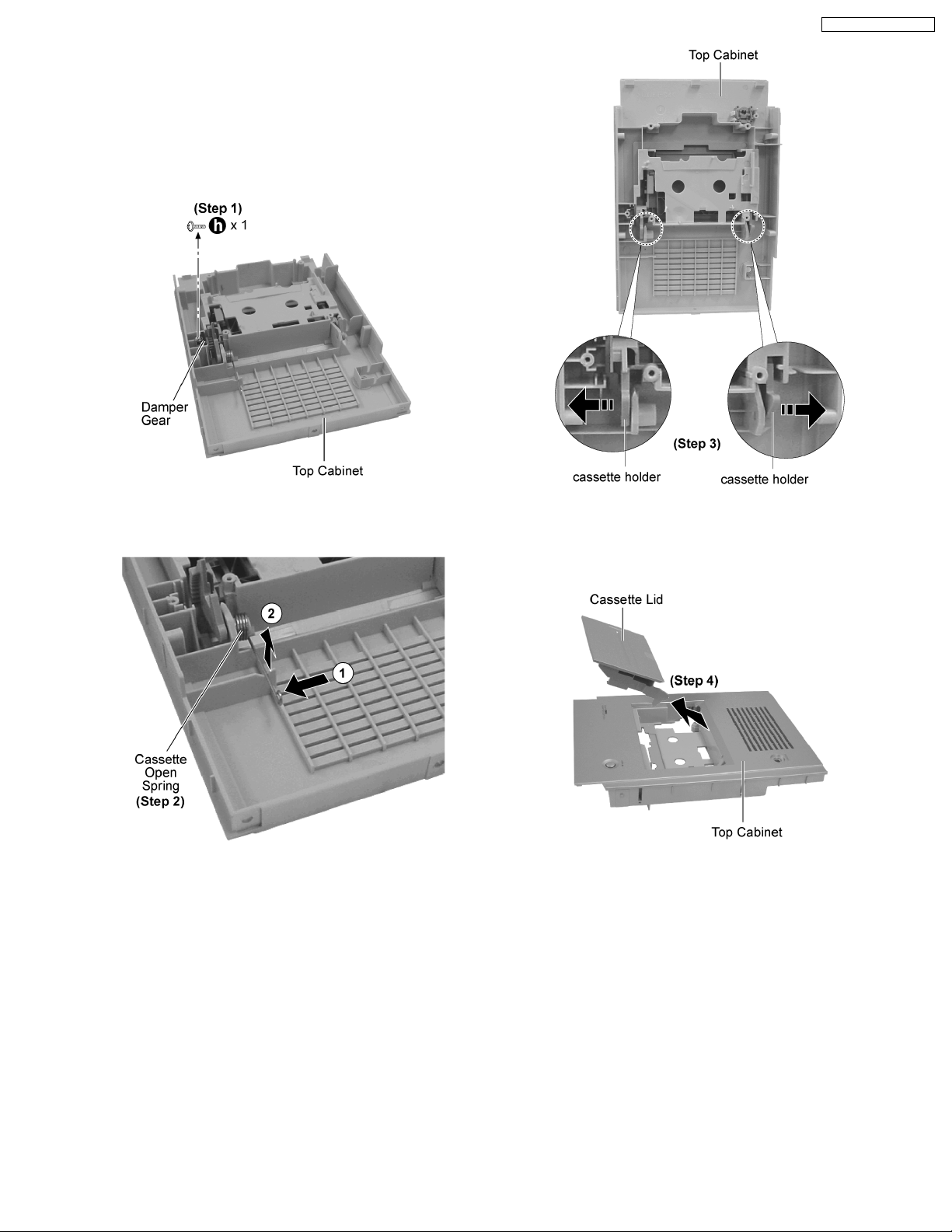

9.15. Replacement of Cassette Lid

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.4.

SA-PM31P / SA-PM31PC

Step 1 : Remove 1 screw and the damper gear.

Step 2 : Remove the cassette open spring as arrows shown in

order.

Step 3 : Pull both sides’ cassette holders to the direction of the

arrows shown.

Step 4 : Remove the cassette lid as arrow shown.

19

SA-PM31P / SA-PM31PC

9.16. Replacement of the Power IC and Transistors.

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 3) of Item 9.8.

· Follow the (Step 1) - (Step 2) of Item 9.9.

· Follow the (Step 1) - (Step 2) of Item 9.10.

· Follow the (Step 1) - (Step 2) of Item 9.12.

Step 1 : Remove 2 screws.

Step 2 : Remove 2 screws.

Step 3 : Unsolder the Power IC500.

Step 4 : Unsolder the Transistors Q501 and Q502.

20

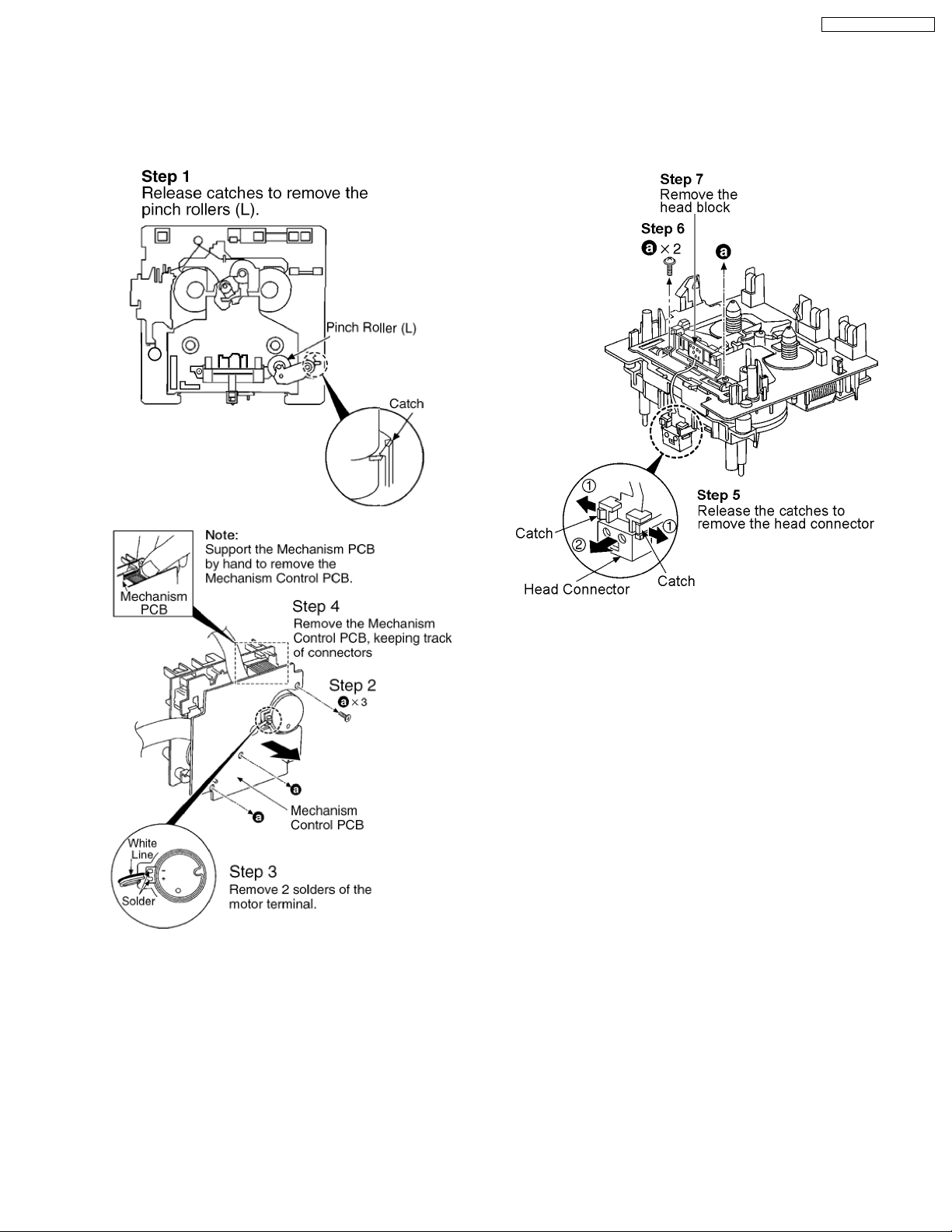

9.17. Procedure for Replacing Pinch Roller and Head Block (Cassette

Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.4.

SA-PM31P / SA-PM31PC

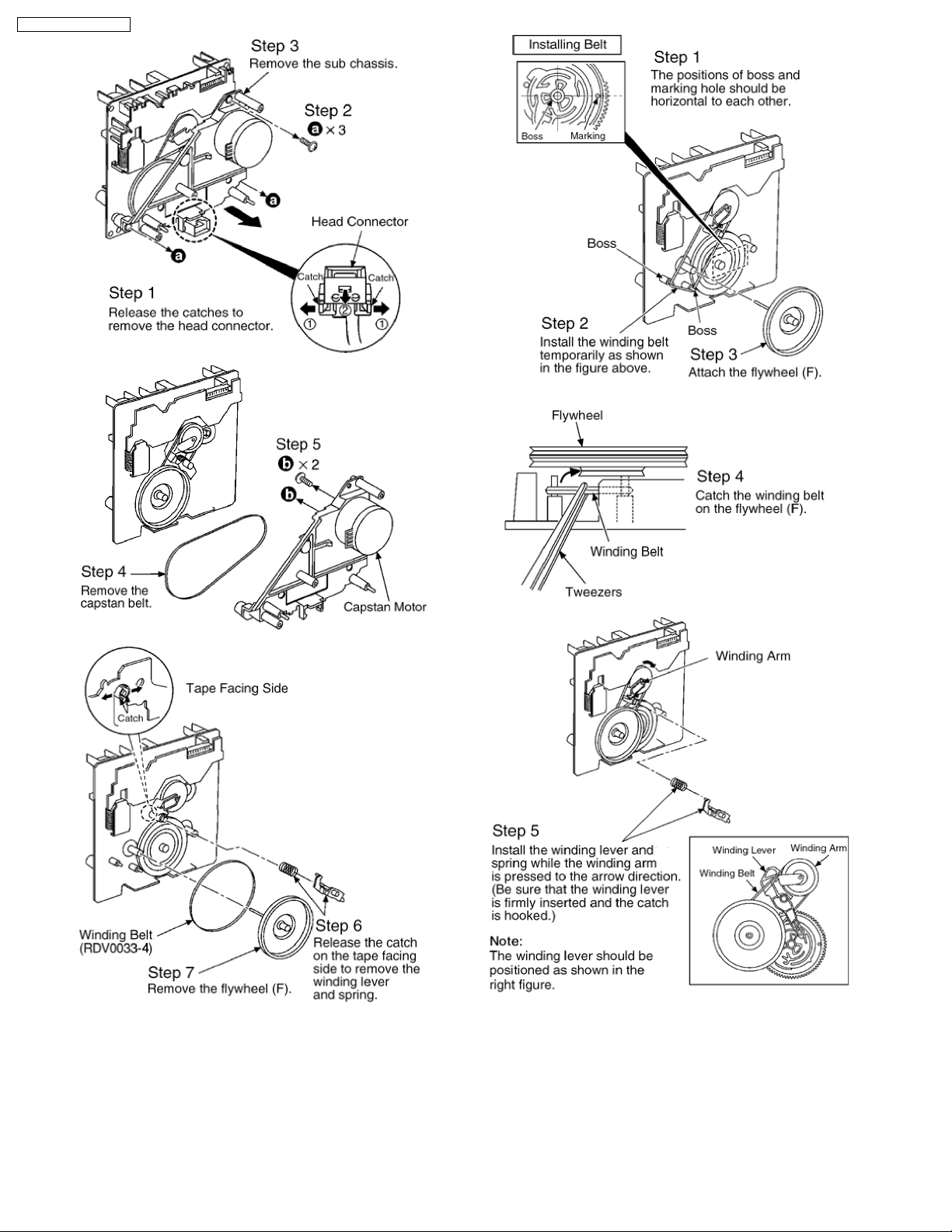

9.18. Procedure for Replacing Motor, Capstan Belt A, Capstan Belt B, and

Winding Belt (Cassette Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 1) - (Step 5) of Item 9.17.

21

SA-PM31P / SA-PM31PC

22

SA-PM31P / SA-PM31PC

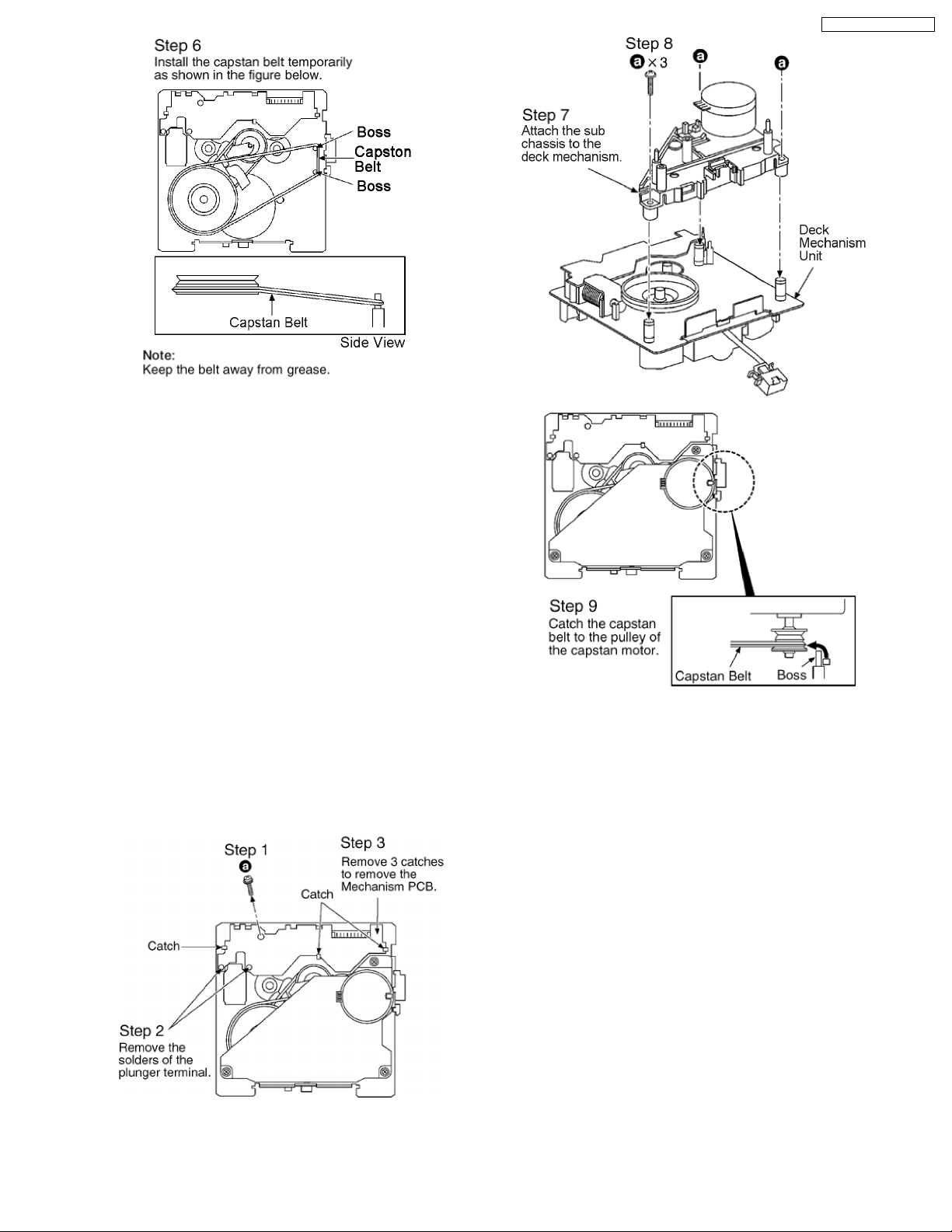

9.19. Procedure for Replacing Parts on Mechanism PCB

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 1) - (Step 5) of Item 9.17.

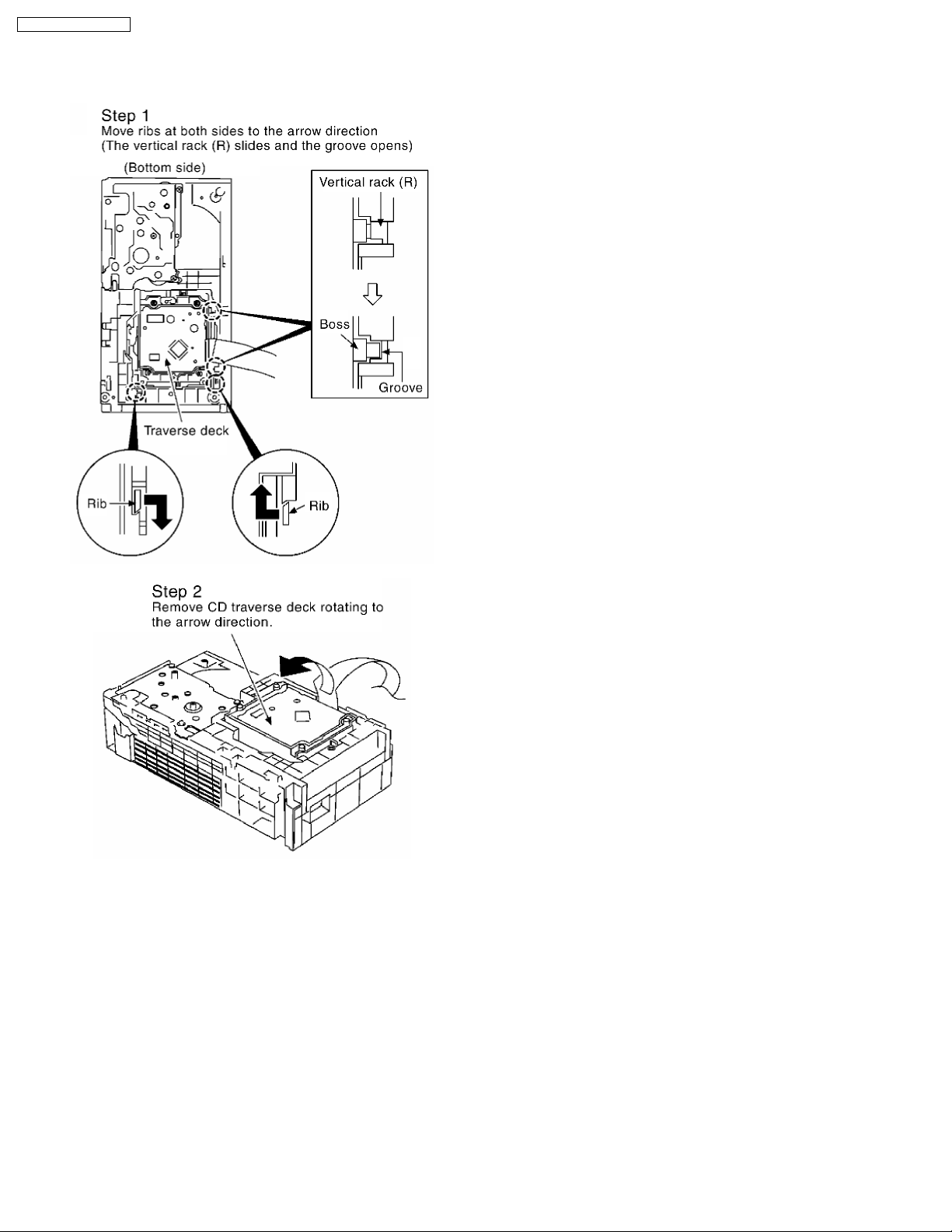

9.20. Replacement of CD traverse deck

· Follow the (Step 1) - (Step 6) of Item 9.2.

23

SA-PM31P / SA-PM31PC

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.13.

24

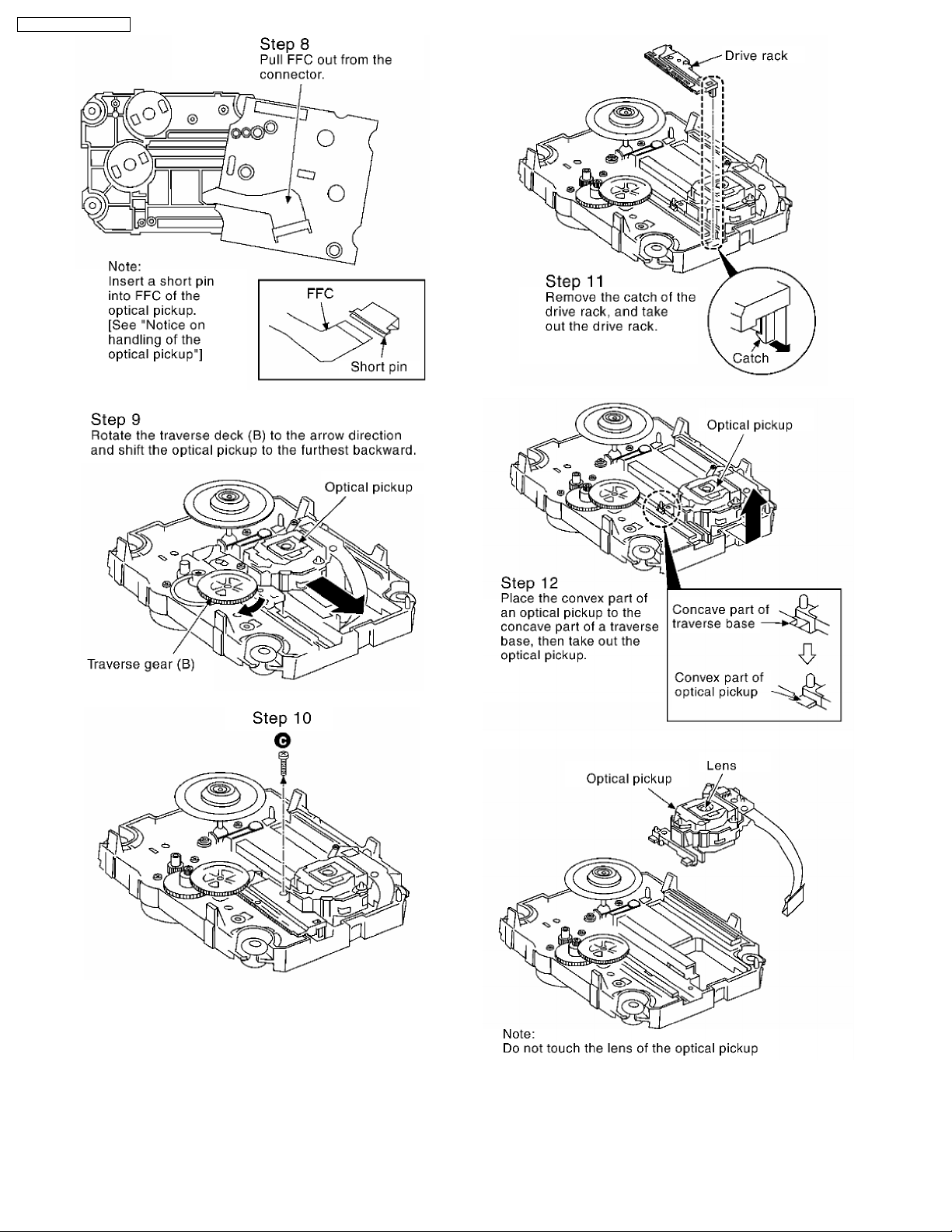

9.21. Replacement of optical pickup unit (CD mechanism)

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.13.

· Follow the (Step 1) - (Step 2) of Item 9.20.

SA-PM31P / SA-PM31PC

25

SA-PM31P / SA-PM31PC

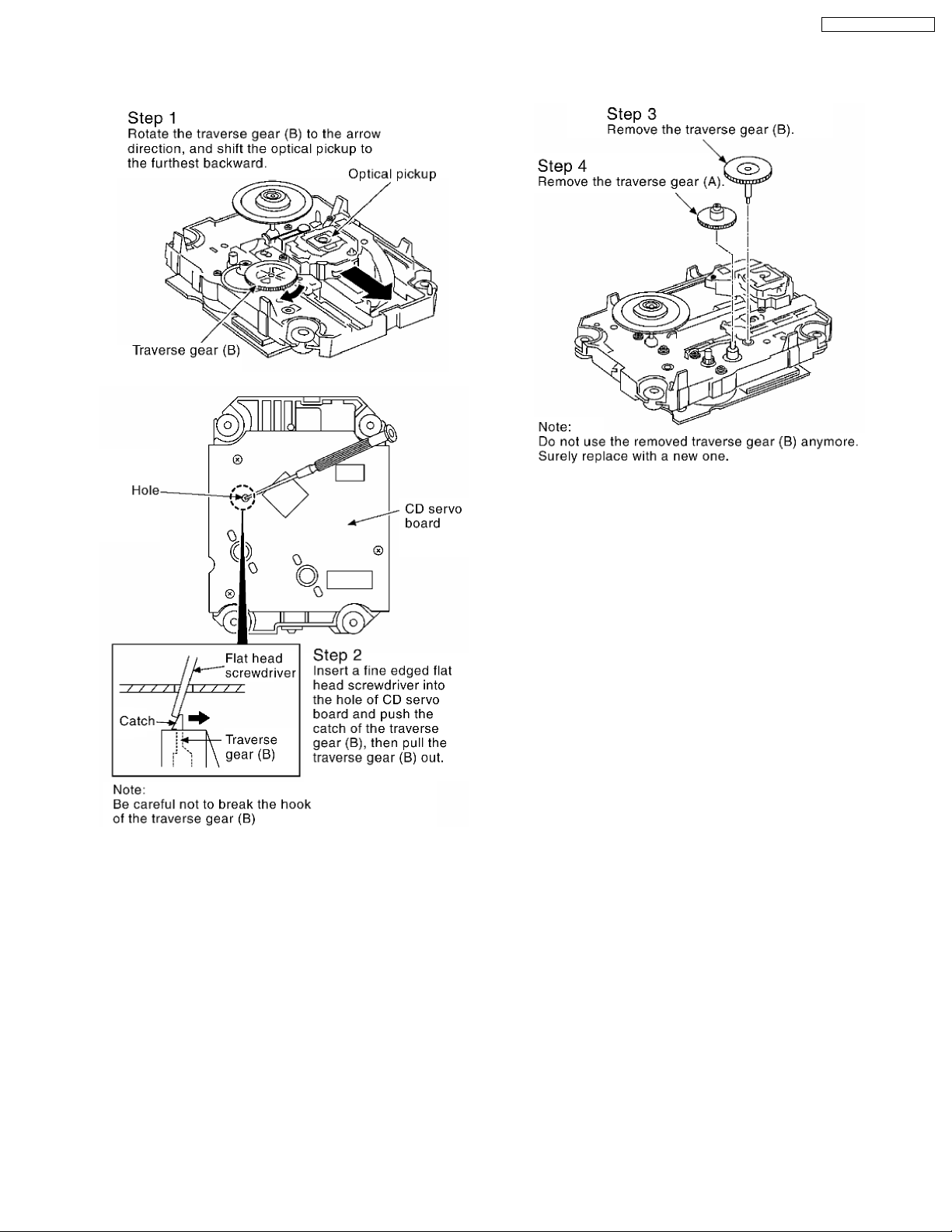

9.22. Replacement of a traverse gear A and a traverse gear B

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

26

· Follow the (Step 1) - (Step 5) of Item 9.13.

· Follow the (Step 1) - (Step 2) of Item 9.20.

· Follow the (Step 1) - (Step 12) of Item 9.21.

SA-PM31P / SA-PM31PC

9.23. Procedure for removing CD loading mechanism

1. Turn off by pressing power SW in the body.

2. Unplug AC power cord after the indication of [GOOD-BYE],

then disassemble the body.

3. Disassemble the body, and take out CD loading

mechanism.

4. Perform disassembly according to the following procedure

for disassembly.

9.24. CR16 mechanism disassembly procedure

9.24.1. Gear for servicing information

· This unit has a gear which used for checking items

(open/close of disc tray, up/down operation of traverse unit

by manually) when servicing. (For gear information, that is

described on the items for disassembly procedures.)

· For preparation of gear (for servicing), perform the

procedures as follows.

· In case of re-servicing the same set, the “ gear for servicing”

may be took off becaus e it had been used. So, the “gear for

servicing” must be stored.

1. Remove the gear attached to top cover of CD loading

mechanism.

27

SA-PM31P / SA-PM31PC

2. Insert the hexgonal wrench (2.5mm) into the gear.

9.24.2. Replacement for the disc tray

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.13.

28

SA-PM31P / SA-PM31PC

29

SA-PM31P / SA-PM31PC

9.24.3. Replacement for the traverse deck

· Follow the (Step 1) - (Step 6) of Item 9.2.

· Follow the (Step 1) - (Step 3) of Item 9.3.

· Follow the (Step 1) - (Step 4) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.13.

· Follow the (Step 1) - (Step 10) of item 9.24.2.

30

Loading...

Loading...