Panasonic SAAK-250-GCP Service manual

A

A

A

A

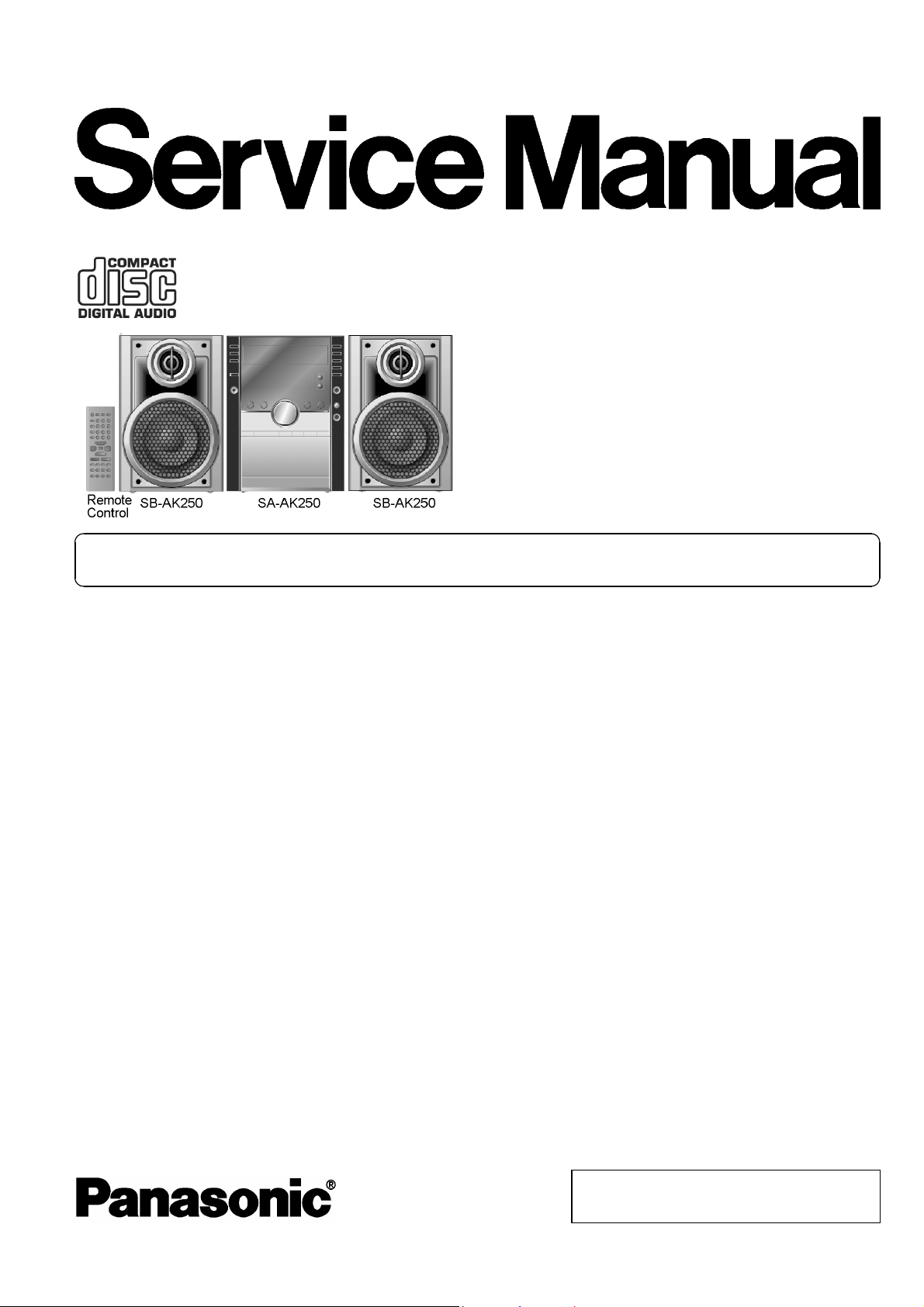

CD Stereo System

SA-AK250GCP

Colour

(S)... Silver Type

ORDER NO. MD0704056CE

Notes: This model’s CD mechanism changer unit is CRS1. Please refer to the original Service Manual

(Order No. MD0509368C0) for this mechanism.

Specifications

n AMPLIFIER SECTION

RMS output power

THD 10%, both channels driven

1 kHz 115 W per channel (3 Ω)

Total output power 230 W

n FM/AM TUNER, TERMINALS SECTION

Preset station FM 20 stations

AM 15 stations

Frequency Modulation (FM)

Frequency range

87.50 to 108.00 MHz (50 kHz steps)

Sensitivity 4.0 µV (IHF)

S/N 26 dB 2.2 µV

ntenna terminal(s) 75 Ω (unbalanced)

mplitude Modulation (AM)

Frequency range 522 to 1629 kHz (9 kHz step)

520 to 1630 kHz (10 kHz step)

Sensitivity

S/N 20 dB (at 999 kHz) 560 µV/m

udio performance (Amplifier)

Input Sensitivity/ Input Impedance

ux 250 mV, 14.7 kΩ

Music Port input jack

Terminal Stereo, 3.5 mm jack

Sensitivity 100 mV, 4.7 kΩ

Phone jack

Terminal Stereo, 3.5 mm jack

Mic jack

Terminal Mono, 3.5 mm jack

Sensitivity 0.7 mV, 680 Ω

n CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s

Overall frequency response (+3, -6 dB) at DECK OUT

NORMAL 35 Hz to 14 kHz

S/N ratio 50 dB (A weighted)

Wow and flutter 0.18 % (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

n DISC SECTION

Disc played [8 cm or 12 cm]

© 2007 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

A

SA-AK250GCP

(1) CD-Audio (CD-DA)

(2) CD-R/RW (CD-DA, MP3* formatted disc)

(3) MP3*

*MPEG-1 Layer 3, MPEG-2 Layer 3

Bit rate

MP3 32 kbps to 320 kbps

Sampling frequency

MP3 32 kHz, 44.1 kHz, 48 kHz

CD-DA 44.1 kHz

Decoding 16 bit linear

Digital filter 8fs

D/A converter MASH (1 bit DAC)

Pick up

Wavelength 780 nm

Beam Source Semiconductor laser

udio output (Disc)

Number of channels 2 (Stereo) (FL, FR)

n GENERAL

Power supply

AC 110 to 127/220 to 240 V, 50/60Hz

Power consumption 95 W

Power consumption in standby

mode

Dimensions (W x H x D) 250 x 330 x 323 mm

Mass 7.1 kg

Operating temperature range +5 to +35°C

Operating humidity range 5 to 90% RH (no condensation)

n SYSTEM

SC-AK250 (GCP) Music center: SA-AK250 (GCP)

Speakers: SB-AK250 (PL)

For Information on speaker system, plesae refer to the original

Service Manual (Order No. MD0704055CE) for SB-AK250PL-S.

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

0.7 W (Approx.)

CONTENTS

Page Page

1 Safety Precautions 4

1.1. General Guidelines

1.2. Before Use

1.3. Before repair and adjustment

1.4. Protection Circuitry

1.5. Safety Part Information

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Handling Precautions For Traverse Unit

4 Precaution of Laser Diode

5 About Lead Free Solder (PbF)

5.1. Service caution based on legal restrictions

6 Accessories

7 Operating Procedures

7.1. Main Unit Key Buttons Operations

7.2. Remote Control Key Buttons Operations

8 New Features

8.1. Using the Music Port

9 Self diagnosis and special mode setting

9.1. Service Mode Summary Table

9.2. Special Mode Table 1

9.3. Reliability Test Mode (CRS1 Mechanism)

9.4. Error code Table Display

10 Assembling and Disassembling

10.1. Caution

10.2. Disassembly flow chart

10.3. Main Parts Location

10

10

11

12

12

13

14

14

16

16

16

19

21

26

26

27

28

4

4

4

4

5

5

7

9

10.4. Disassembly of Top Cabinet

10.5. Disassembly of CD Changer Unit (CRS1)

10.6. Disassembly of Rear Panel

10.7. Disassembly of Main P.C.B.

10.8. Disassembly of Transformer P.C.B.

10.9. Disassembly of Power P.C.B.

10.10. Disassembly of Front Panel Unit

10.11. Disassembly for Panel P.C.B.

10.12. Disassembly of Tact Switch P.C.B.

10.13. Disassembly of Deck mechanism unit

10.14. Disassembly of Deck P.C.B.

10.15. Disassembly of Traverse Unit

10.16. Disassembly for Deck Mechanism

10.17. Disassembly of Deck Mechanism P.C.B.

10.18. Disassembly of cassette lid

10.19. Rectification for tape jam problem

11 Service Fixture and Tools

12 Service Positions

12.1. Checking and Repairing of Main P.C.B.

12.2. Checking and Repairing of Transformer P.C.B.

12.3. Checking and Repairing of Panel, Deck & Deck

Mechanism P.C.B.

12.4. Checking and Repairing of Power P.C.B.

13 Procedure for Checking Operation of Individual Parts of Deck

Mechanism Unit

13.1. Operation Check with Cassette Tape

13.2. Operation Check without Cassette Tape

29

29

30

31

31

32

32

33

34

34

34

35

36

39

40

40

42

42

42

43

43

44

45

45

45

2

SA-AK250GCP

14 Measurement And Adjustments 47

14.1. Cassette Deck Section

15 Voltage and Waveform Chart

15.1. CD Servo P.C.B.

15.2. Deck P.C.B. & Deck Mechanism P.C.B.

15.3. Main P.C.B.

15.4. Panel P.C.B. & Transformer P.C.B.

15.5. Power P.C.B.

15.6. Waveform Chart

16 Wiring Connection Diagram

17 Block Diagram

17.1. CD Servo Diagram

17.2. Deck/ Deck Mechanism Diagram

17.3. Main Diagram

17.4. Panel Diagram

17.5. Power Diagram

17.6. Transformer Diagram

18 Notes Of Schematic Diagram

19 Schematic Diagram

19.1. (A) CD Servo Circuit

19.2. (B) Main Circuit

19.3. (C) Panel Circuit

19.4. (D) Sub Panel Circuit & (G) Deck Mechanism Circuit

47

49

49

49

50

51

51

52

53

55

55

56

57

59

60

61

63

65

65

66

70

71

19.5. (E) Power Circuit

19.6. (F) Deck Circuit

19.7. (H) Transformer Circuit

20 Printed Circuit Board

20.1. (A) CD Servo P.C.B., (F) Deck P.C.B. & (G) Deck

Mechanism P.C.B.

20.2. (B) Main P.C.B.

20.3. (C) Panel P.C.B.

20.4. (D) Sub Panel P.C.B.

20.5. (E) Power P.C.B.

20.6. (H) Transformer P.C.B.

21 Illustration of ICs, Transistors and Diodes

22 Terminal Function of IC's

22.1. IC7001 (MN6627954MA) Servo Processor,Digital Signal

Processor/Digital filter and D/A Converter

22.2. IC7002 (BA5948FPE2) IC 4CH Drive

22.3. IC2801 (C2CBYY000482) System Microprocessor

23 Exploded Views

23.1. Cabinet Parts Location

23.2. Deck Mechanism Parts Location (RAA4403-S)

23.3. Packaging

24 Replacement Parts List

72

74

75

77

78

79

80

81

82

83

85

86

86

87

87

89

89

91

92

93

3

SA-AK250GCP

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers and insulation papers shields are properly

installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each expose d metallic cabine t part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

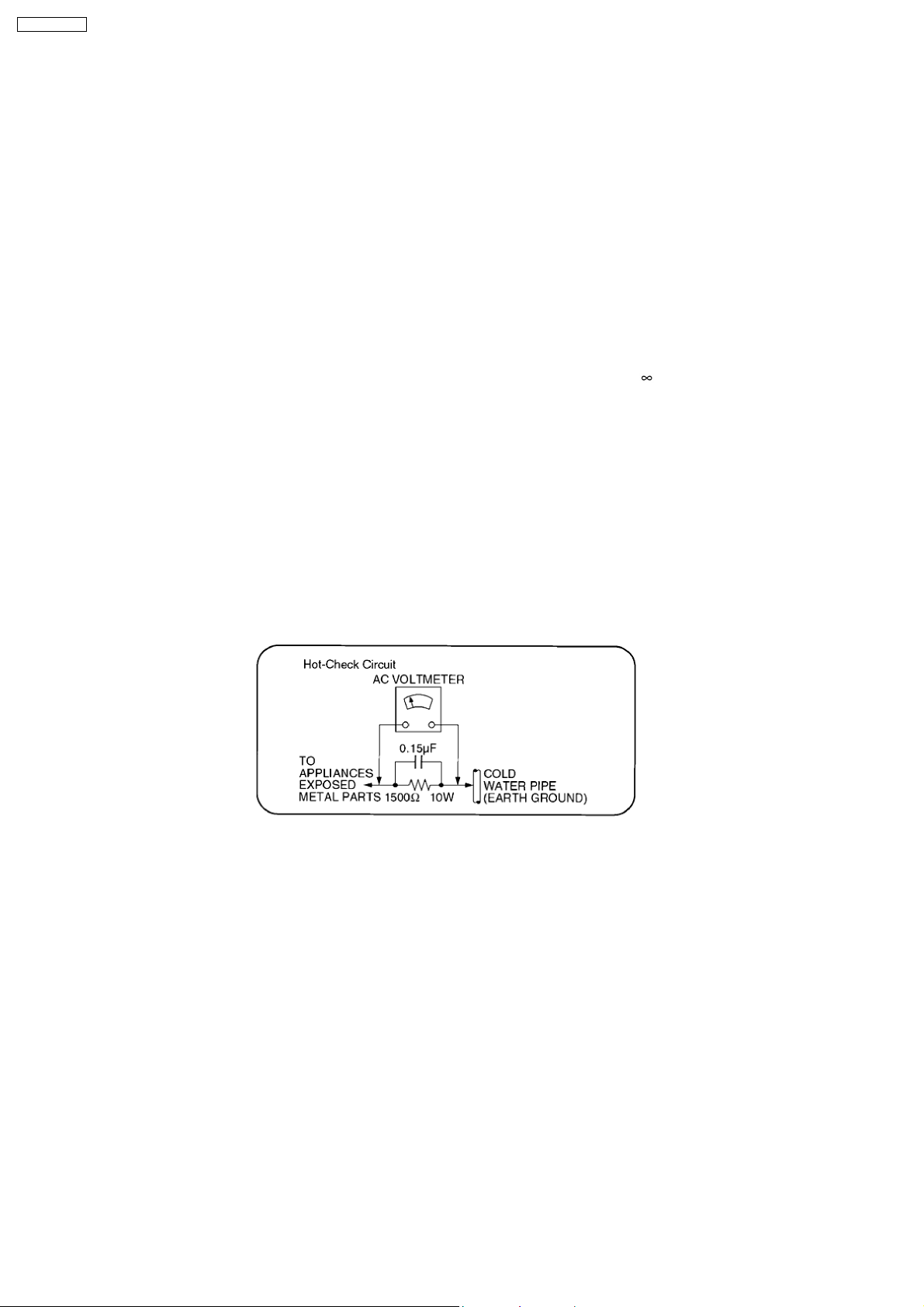

1.1.2. Leakage Current Hot Check (See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. Should the measurement is out of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

.

Fig. 1

1.2. Before Use

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will

be used. (If the power supply in your area is 110V or 127V, set to the “127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

1.3. Before repair and adjustment

Disconnect AC power, discharge power capacitors C5101 , C5104, C5171 , C5172, C5920, C5940 and C5950 through a 10Ω,5W

resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 110 ~ 127V, 50 Hz in NO SIGNAL mode (at volume min at CD mode) should be ~ 500mA.

Current consum ption at AC 220 ~240V, 60 Hz in NO SIGNAL mode (at volume min at CD mode) should be ~ 350mA.

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

4

SA-AK250GCP

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outline s below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.5. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by

be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without

permission of manufacturer.

Table 1

Reference No. Part No. Part name & Description Remarks

in the Schematic Diagrams & Replacement Parts List. It is essential that these critical parts should

360 RAE0165A-V TRAVERSE UNIT

L5601 G0B9R5K00001 CHOKE COIL

L5602 G0B9R5K00001 CHOKE COIL

S5950 K0ABLB000003 SW VOLTAGE SELECTOR

T5950 G4CYAYY00135 MAIN TRANSFORMER

T5951 G4C2AAJ00005 SUB TRANSFORMER

Z5950 ERZV10V511CS ZENER

RL5950 K6B1AEA00015 POWER RELAY

F1 K5D312BLA015 FUSE

F2 K5D162BLA013 FUSE

FP5920 K5G702A00009 FUSE PROTECTOR

FP5940 K5G702Z00004 FUSE PROTECT OR

FP5950 K5G402A00025 FUSE PROTECTOR

JK5950 K2AA2B000011 JK AC INLET

A2 K2CQ2CA00006 AC CORD

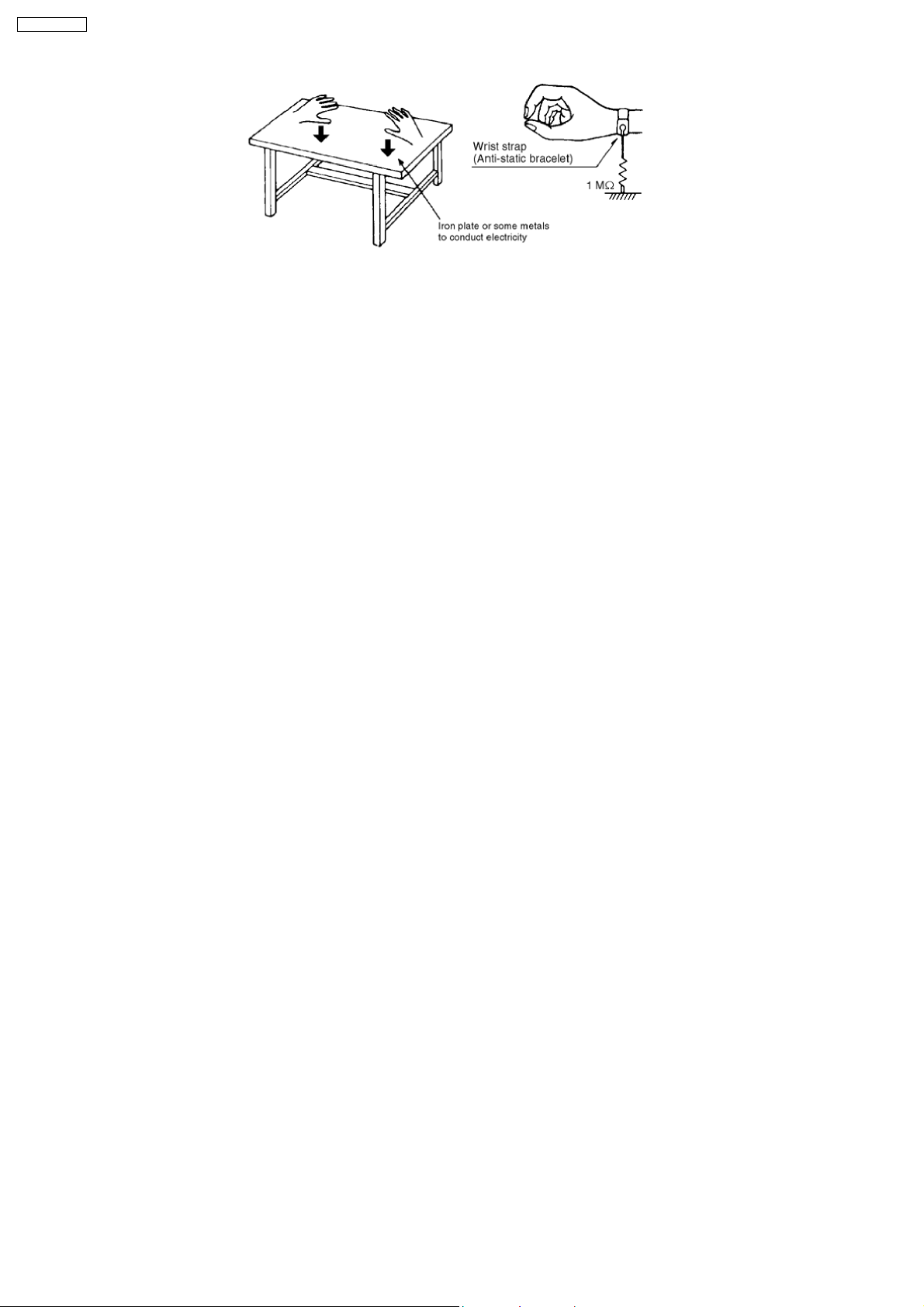

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handlin g any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potent ial shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposu re of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installe d.

5

SA-AK250GCP

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

6

SA-AK250GCP

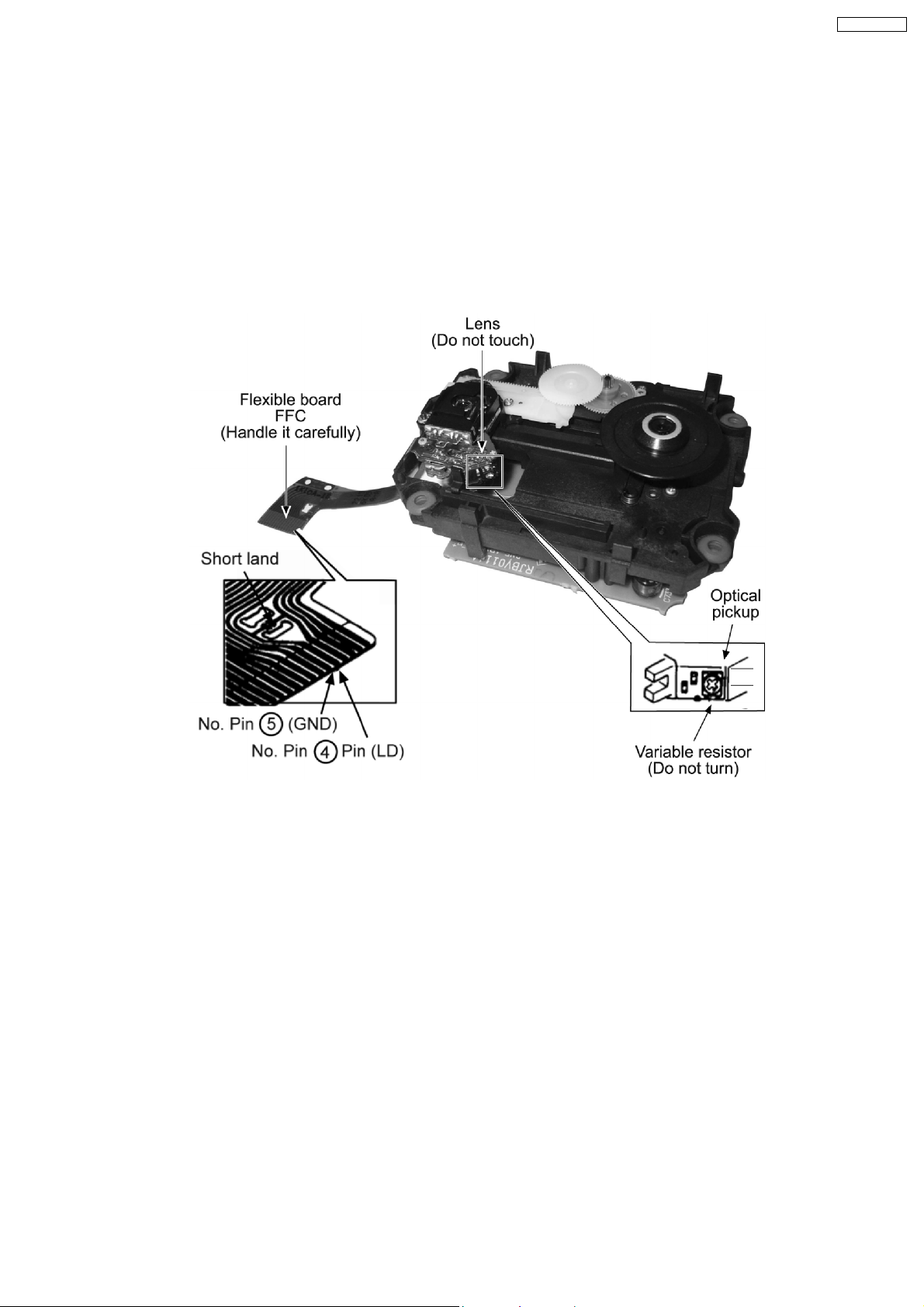

3 Handling Precautions For Traverse Unit

The laser diode in the traverse unit (with optical pickup) may break down due to potent ial differe nce caused by the static electricity

of clothes or our human body.

So, be careful of electrostatic breakdown during repair of the traverse unit (with optical pickup).

· Way of handling the traverse unit (with optical pickup)

1. Do not subject the traverse unit (with optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Do not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish the job

in as short time as possible.

4. Do not turn the variable resistor for laser power adjustment. (It is pre-adjusted during production time)

Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse unit (with optical pickup) is place, and ground

the sheet.

Caution :

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse unit (with optical pickup).

Caution when replacing the Traverse Unit

The traverse unit has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

7

SA-AK250GCP

8

SA-AK250GCP

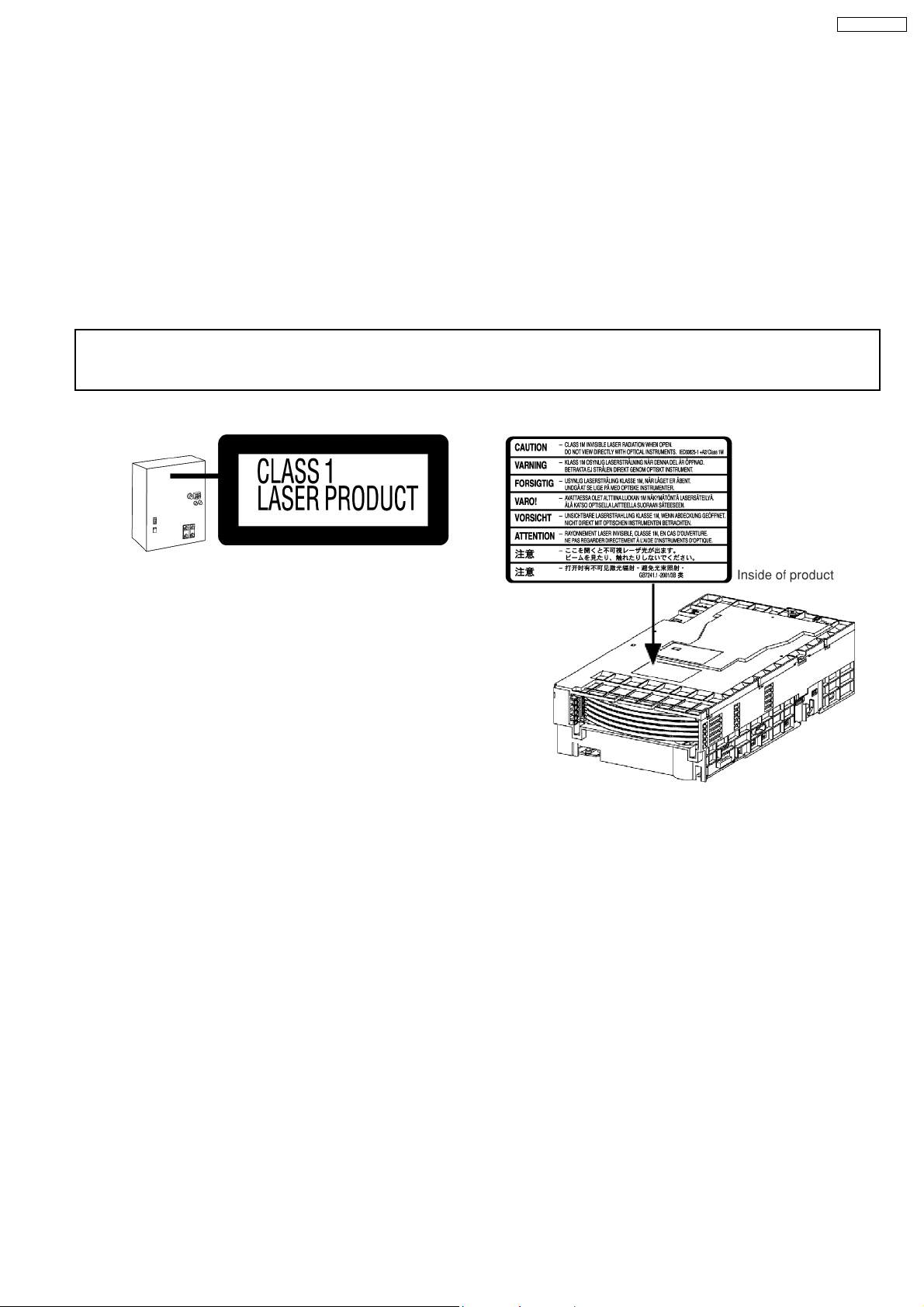

4 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

9

SA-AK250GCP

5 About Lead Free Solder (PbF)

5.1. Service caution based on legal restrictions

5.1.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

10

6 Accessories

Note: Refer to “Replacement Parts List” (Section 24) for part number.

Remote Control

FM Antenna Wire

SA-AK250GCP

AC Cord

AM Loop Antenna

Power Plug Adapter

11

SA-AK250GCP

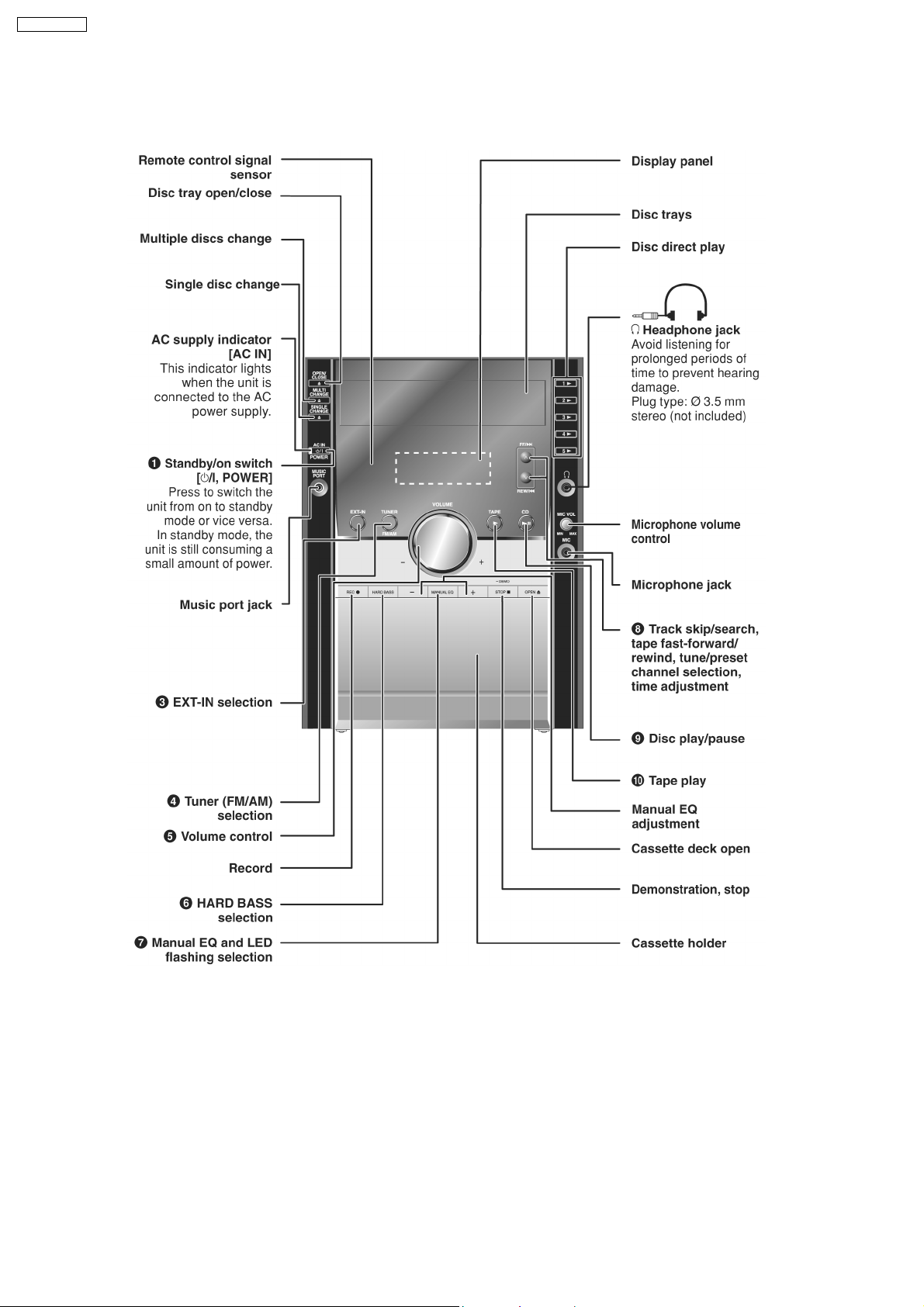

7 Operating Procedures

7.1. Main Unit Key Buttons Operations

12

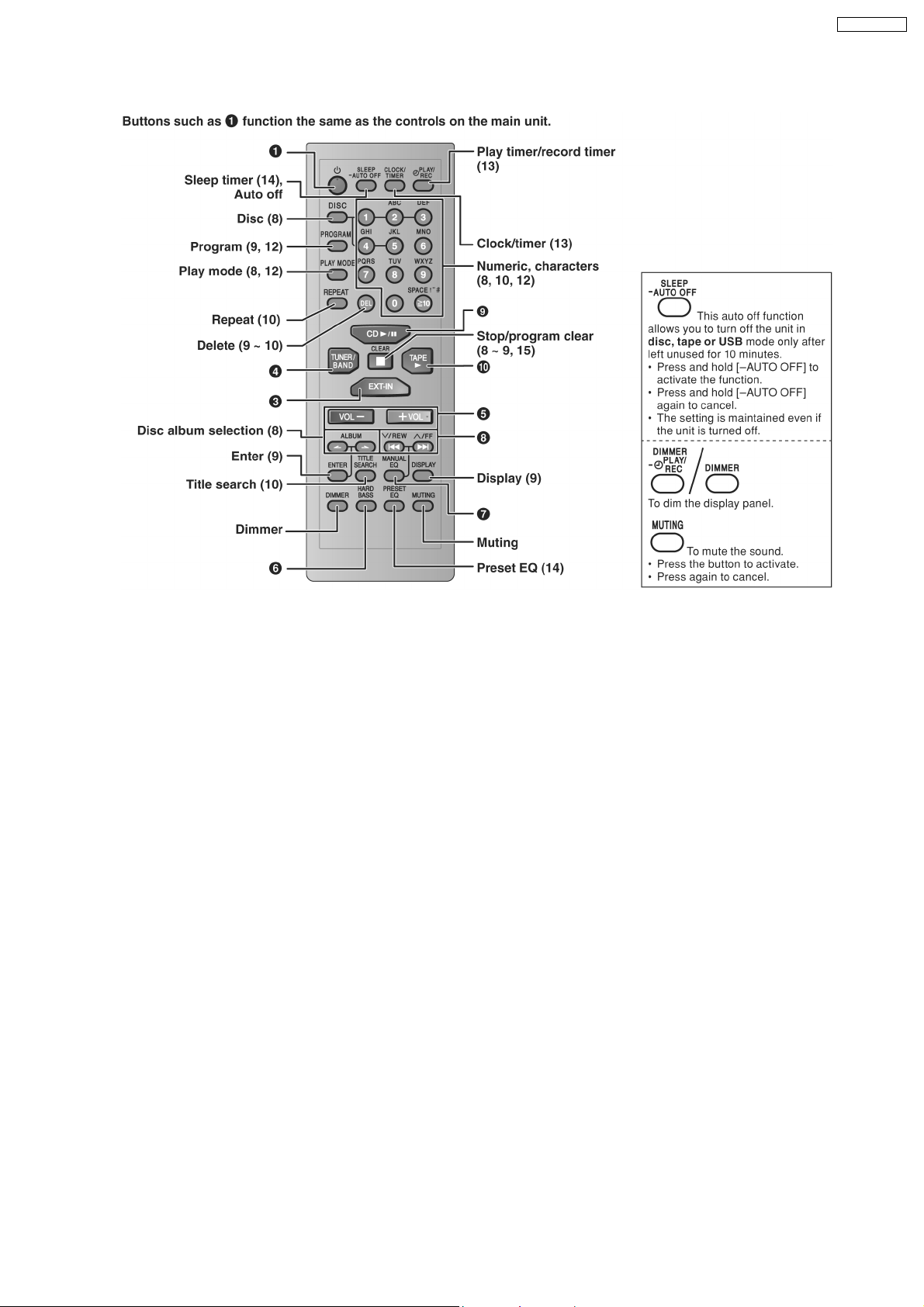

7.2. Remote Control Key Buttons Operations

SA-AK250GCP

13

SA-AK250GCP

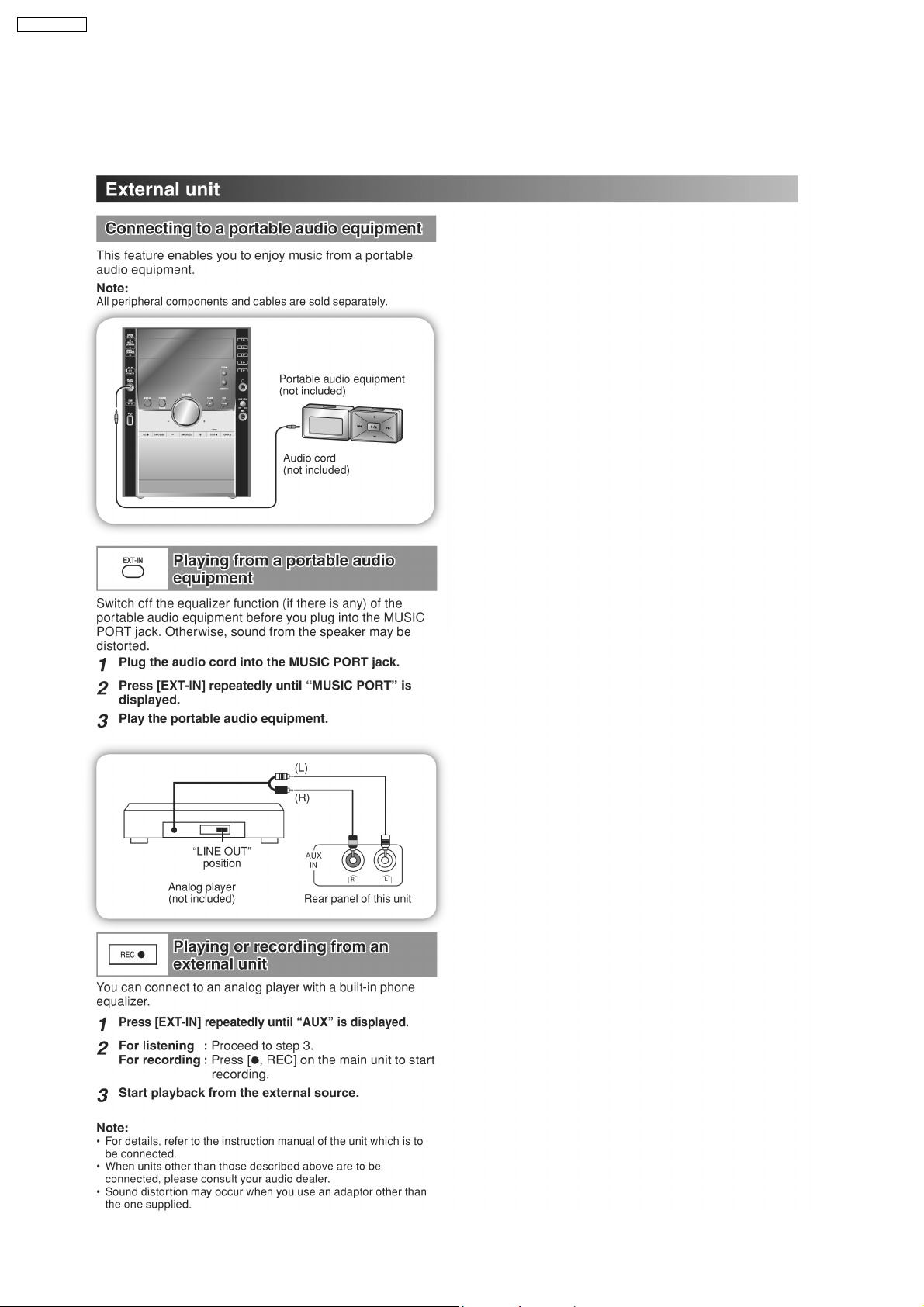

8 New Features

8.1. Using the Music Port

This feature enables you to enjoy music from a portable audio equipment.

14

With reference to page 15 of the operating instruction manual.

SA-AK250GCP

15

SA-AK250GCP

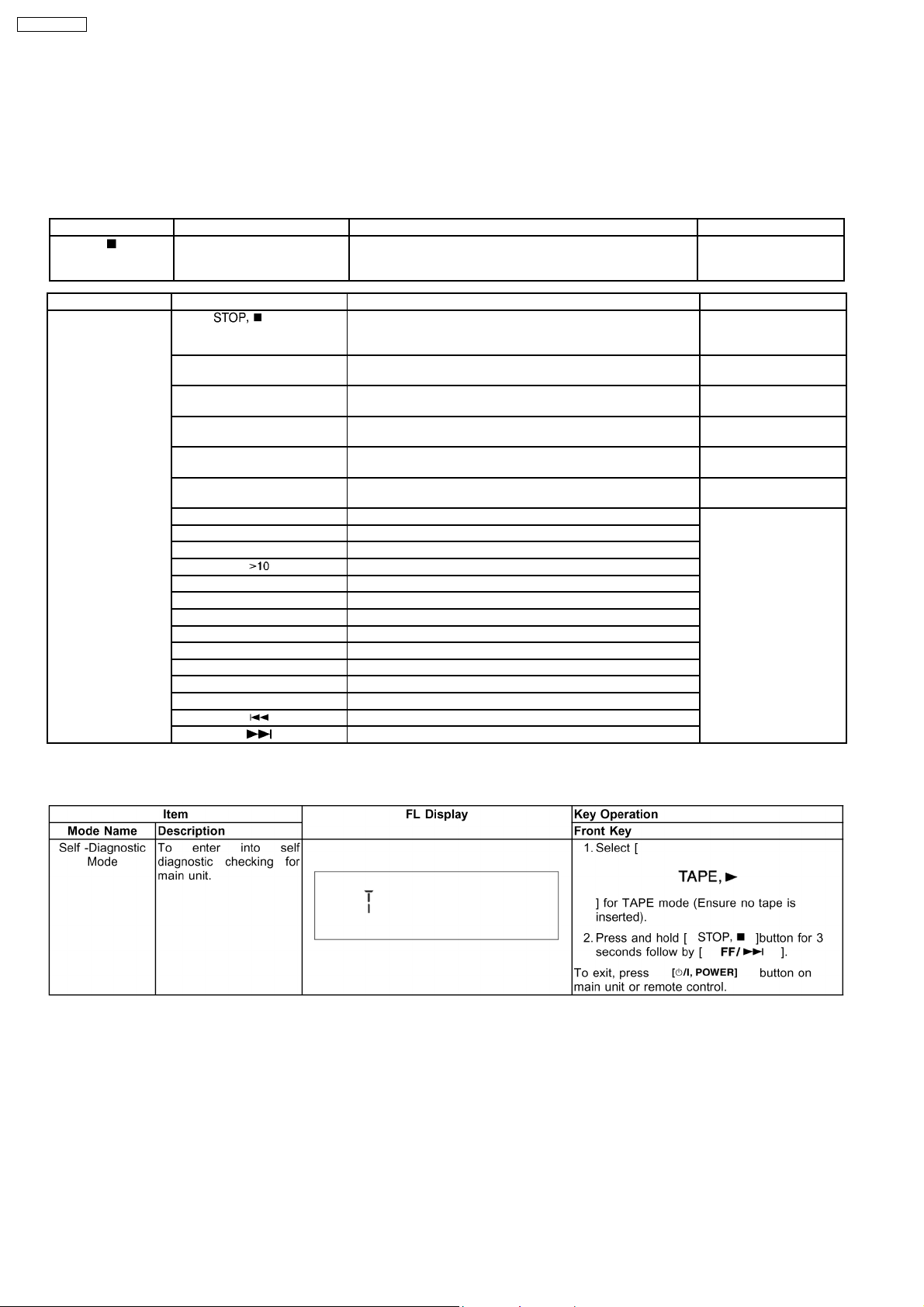

9 Self diagnosis and special mode setting

This unit is equipped with functions for checking and inspecting namely: Self-Diagnostic and Test Mode.

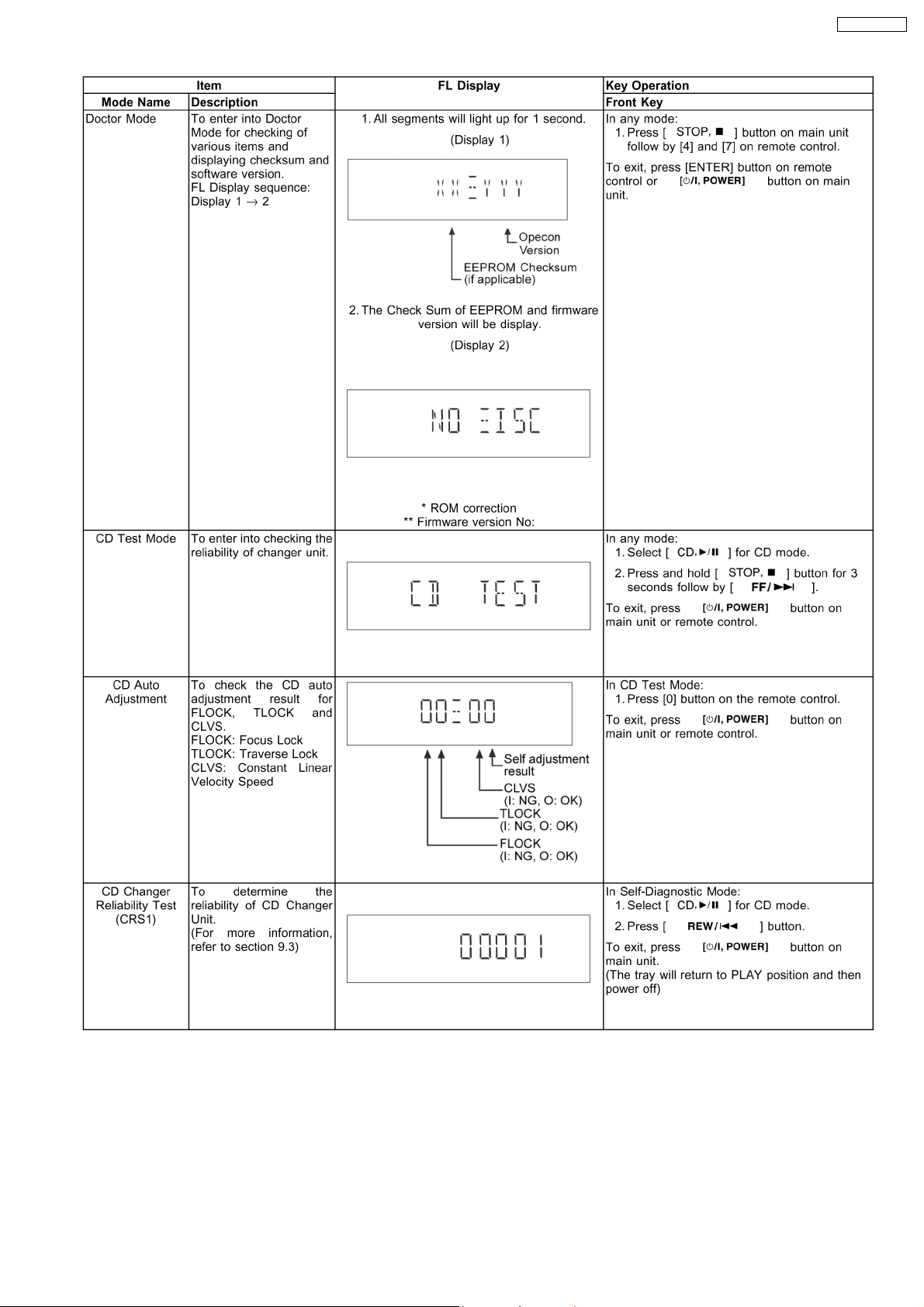

9.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the main unit and remote control unit. Below is the

summary for the various modes for checking:

Player button Remote control button unit Application Note

[ ] [4], [7] Entering into Doctor Mode Refer to the section, “9.2

Mode Remote control button unit Application Note

In Doctor Mode [ ], [4]+[7] Display firmware version & EEPROM checksum Refer to the section,

[4] <Set for cold start when reset start is executed the next time> Refer to the section, “9.2

[Muting] Clock Setting Refer to the section, “9.2

[0] Tape Eject Test Refer to the section, “9.2

[DIMMER] All segment display for the FL Refer to the section, “9.2

[DISC] CRS1 Inspection Refer to the section, “9.2

[7] Volume 50 Setting check

[8] Volume 41 Setting check

[9] Volume 35 Setting check

[ ] Volume 0 Setting check

[PRESET EQ] EQ Off

[H. Bass] EQ Heavy

[PROGRAM] HIC force MUTE ON/ OFF

[5] CD To Tape recording Inspection

[6] Tape record’s playback

[SLEEP] TPS Inspection

[<] FM Tuning check

[>] Tuner STEREO/ forced MONO

[ ] FM Checking

[ ] AM Checking

Special Mode Table 1 for

more information.

“9.2.1 for more

information.

for more information.

for more information.

for more information.

for more information.

for more information.

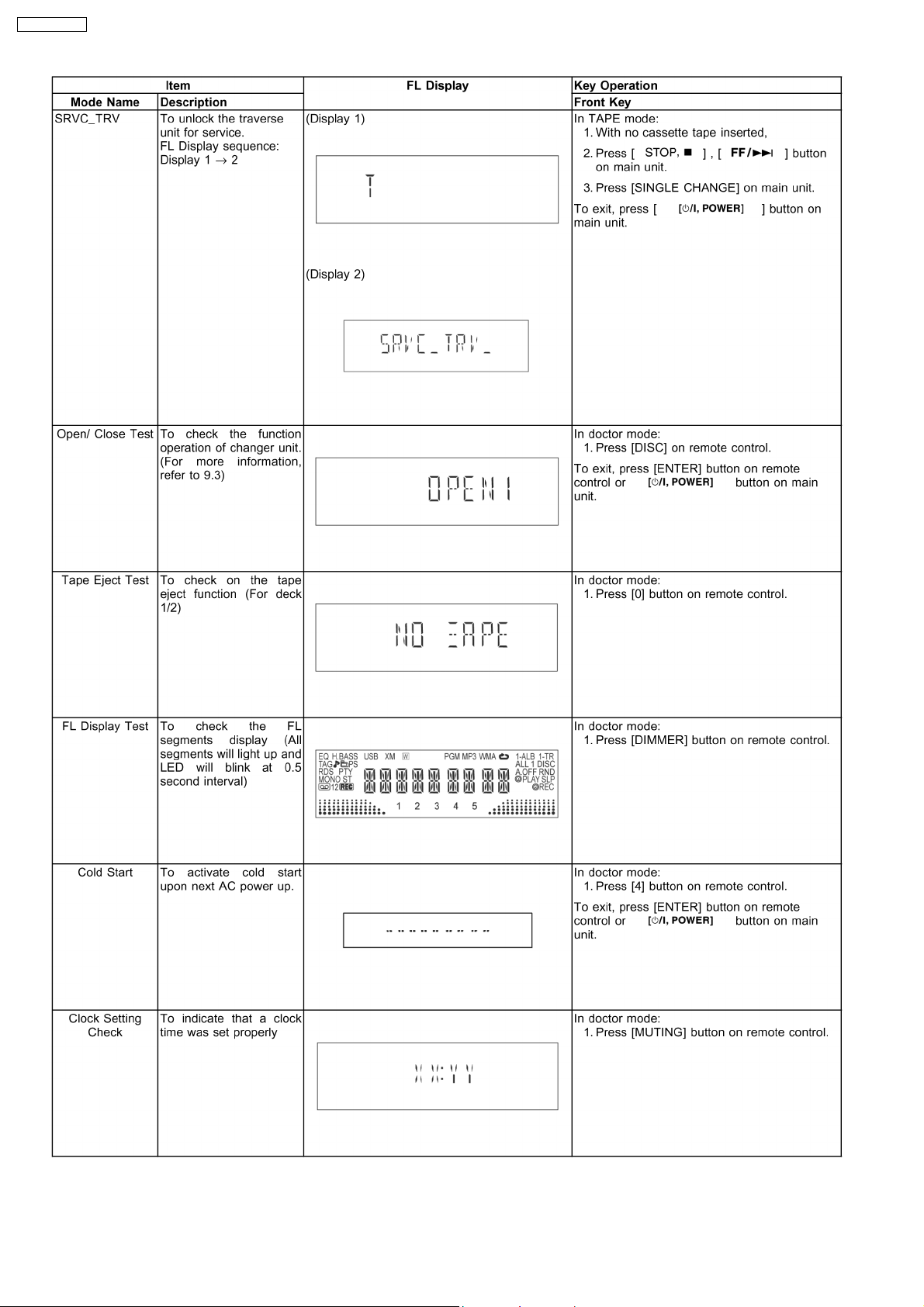

9.2. Special Mode Table 1

16

SA-AK250GCP

17

SA-AK250GCP

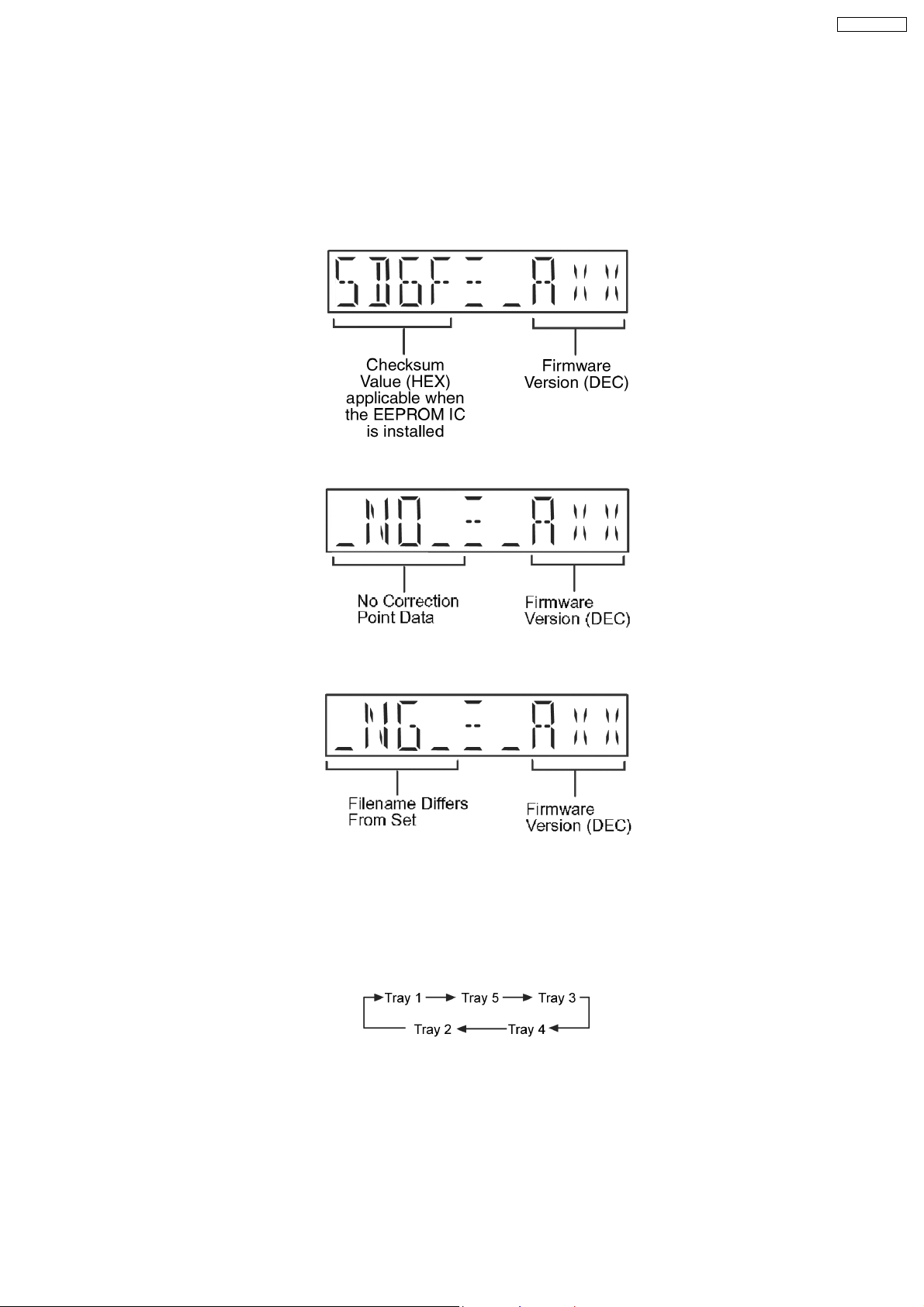

9.2.1. EEPROM Checksum (ROM Correction)

Purpose: To check for microprocessor firmware version and EEPROM checksum (ROM correction).

18

SA-AK250GCP

Below are the procedures for this mode.

Step 1: Enter into Doctor mode (for more information, refer to section 9.2 on the key operation to enter into this mode.

Step 2: Check for firmware version and EEPROM checksum (By pressing STOP button on main unit followed by “4” and “7” on

remote control).

· W hen entering into DOCTOR MODE, the firmware version and checksum data of EEPROM (if applicable) will appear on FL

display. Below is the information on the EEPROM IC (ROM correction) under 3 possible situations:

1. In the case that the correction point existence data is other than 0 (ie. correction file exists), EEPROM checksum display for

the microprocessor shall be made after calculating checksum by summing up the content of data area from EEPROM IC.

2. In the case when no EEPRO M IC is installed. It is display as below (no display of checksum data)

3. In cases that the filename is different even though a EEPROM is installed, or no correction file exists, [NG] shall be displayed

(the correction point existence data is set to 0 at this condition).

Note: Microprocessor firmware refers to version number for microprocessor IC located on PANEL P.C.B.. It is subject to change

which would be update d accordingly. ROM correction checksum refers to the HEX code that is display ed upon key button s pressed

if an EEPROM is loaded in the unit.

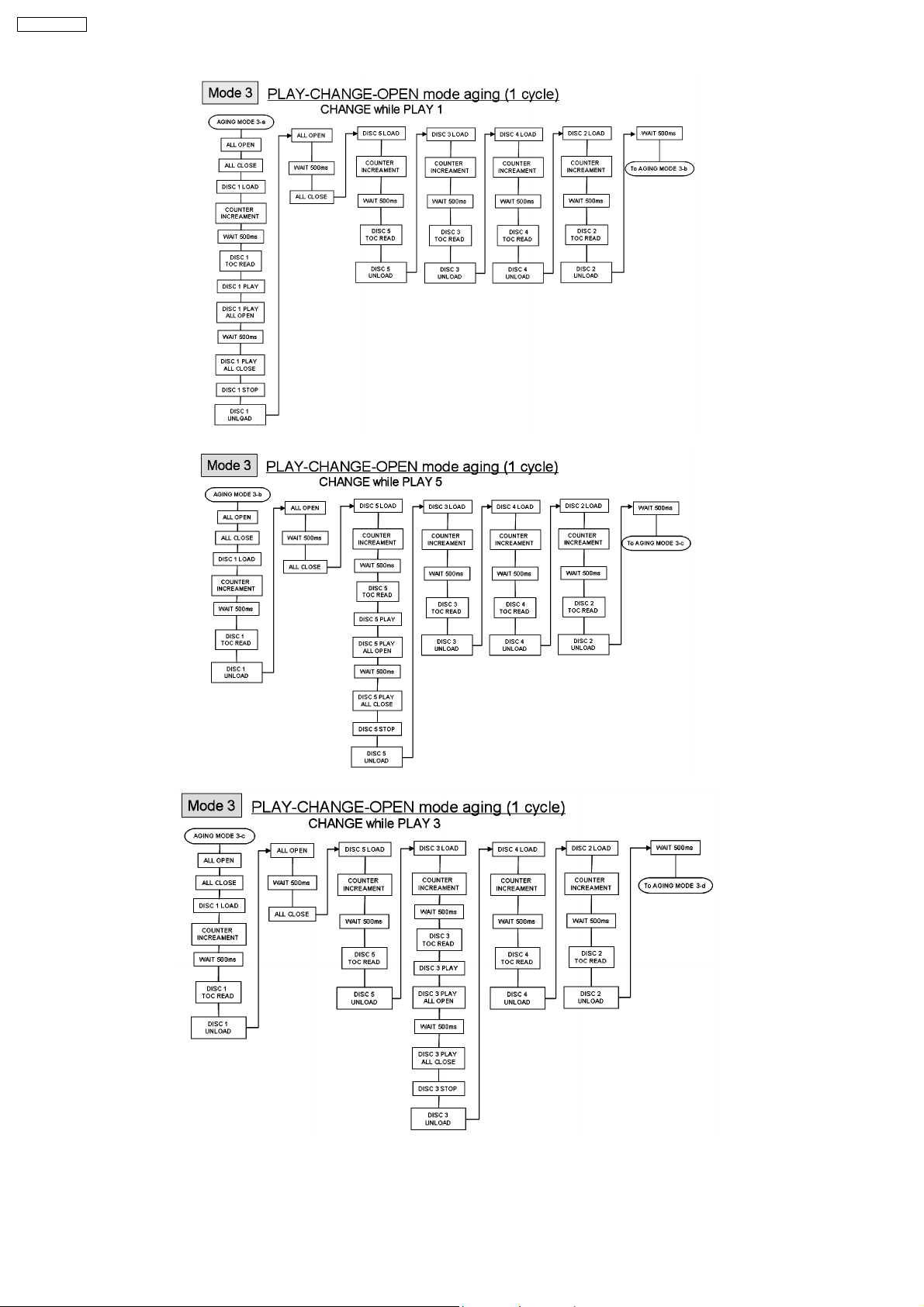

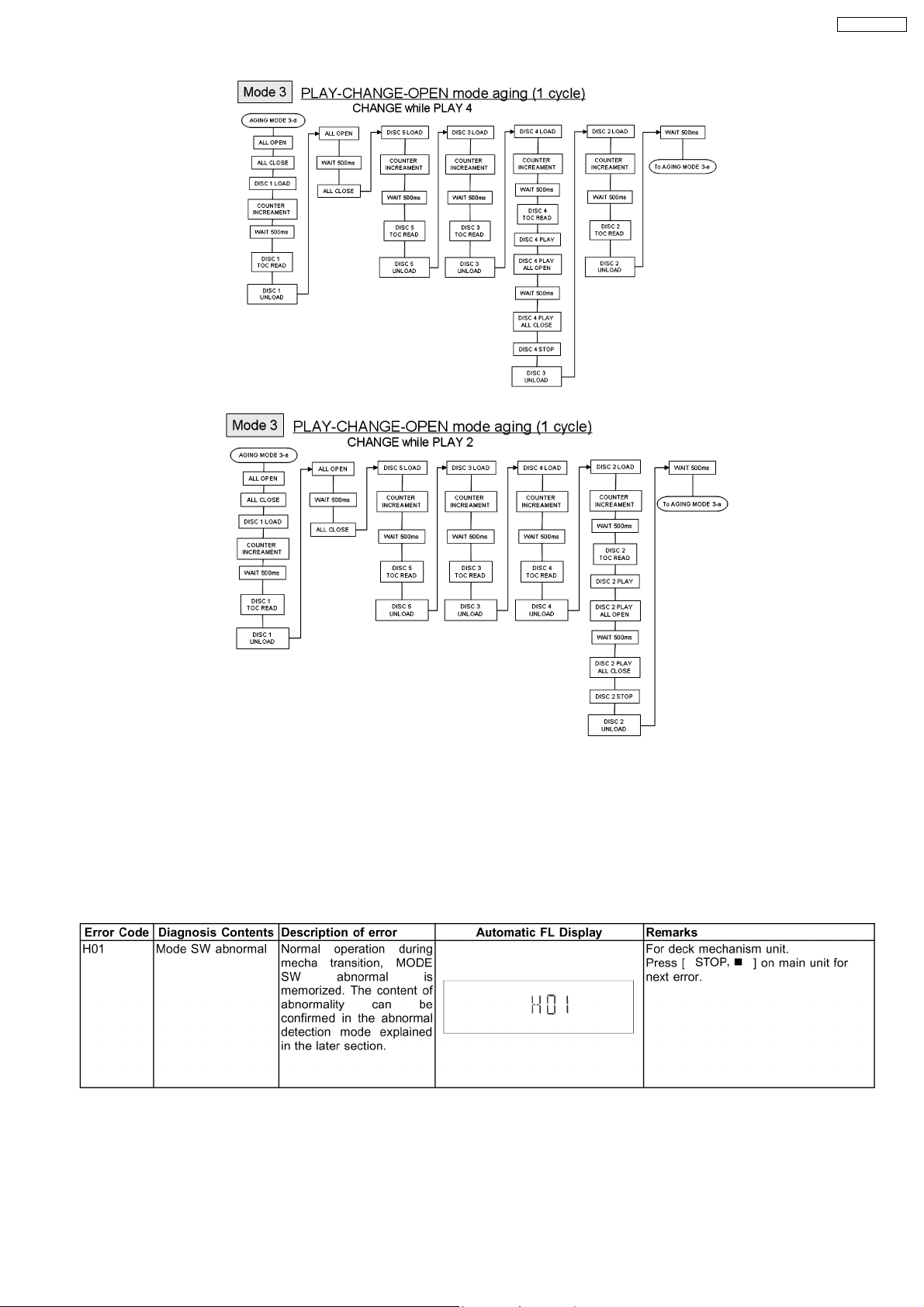

9.3. Reliability Test Mode (CRS1 Mechanism)

Below is the process flow chart of ageing for the CD changer unit. (CRS1)

19

SA-AK250GCP

20

SA-AK250GCP

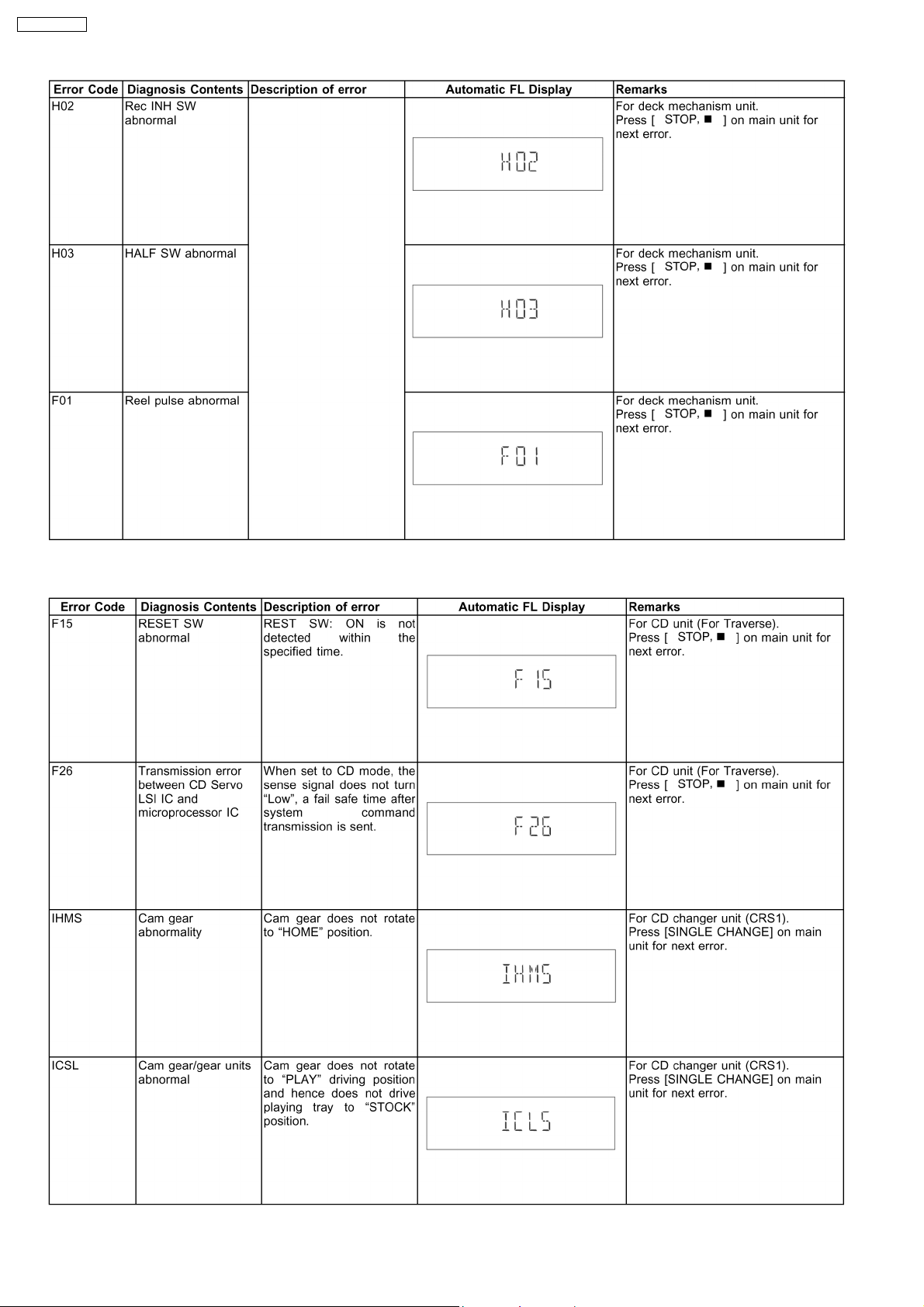

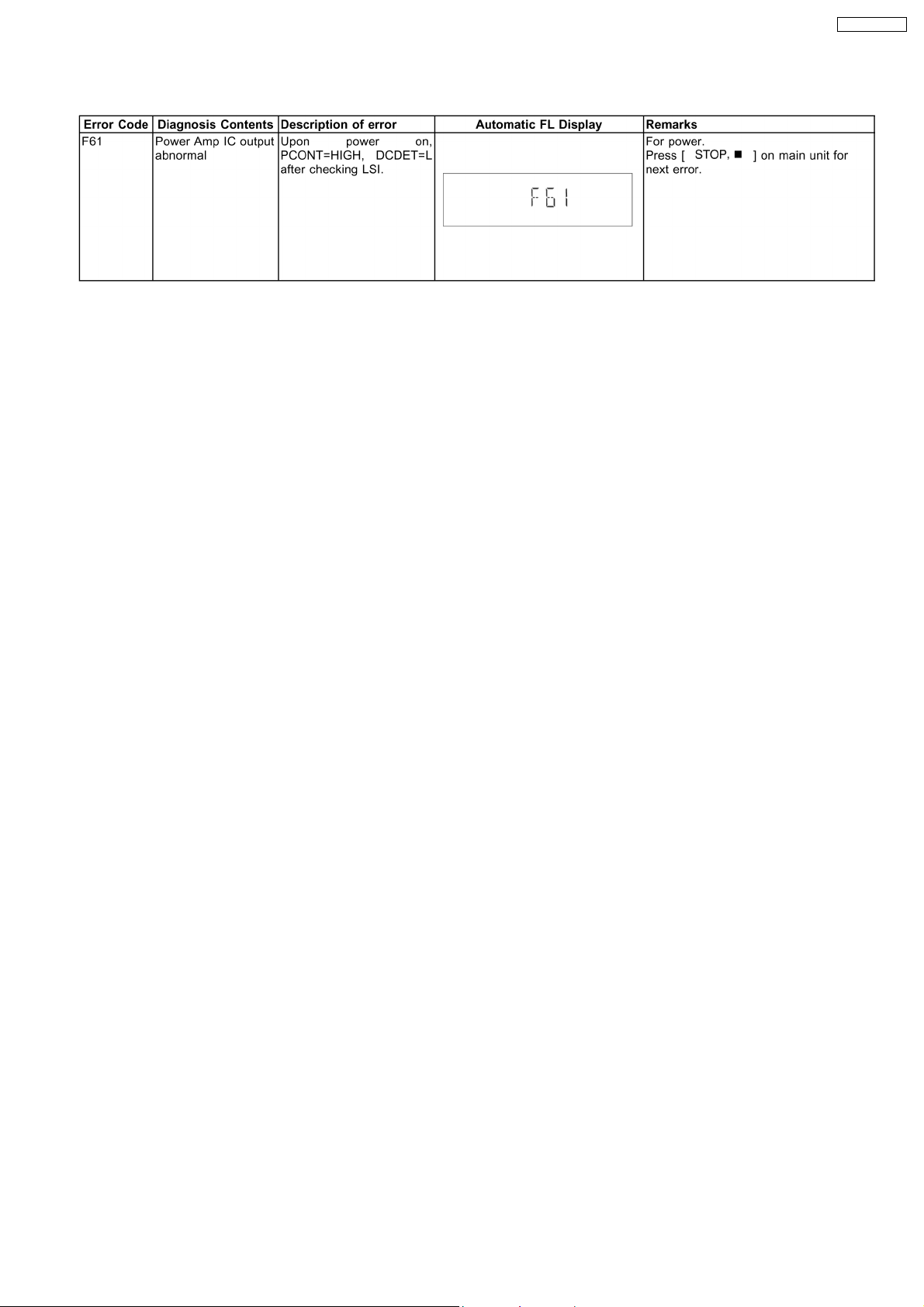

9.4. Error code Table Display

Self-Diagnosis Function (refer Section 9.2) provides information on any problems occuring for the unit and its respective

components by display ing the error codes. These error code such as U**, H** and F** are stored in memory and held unless it is

cleared.

The error code is automatically display after entering into self-diagnostic mode.

9.4.1. Error Code Table for Deck Mechanism

21

SA-AK250GCP

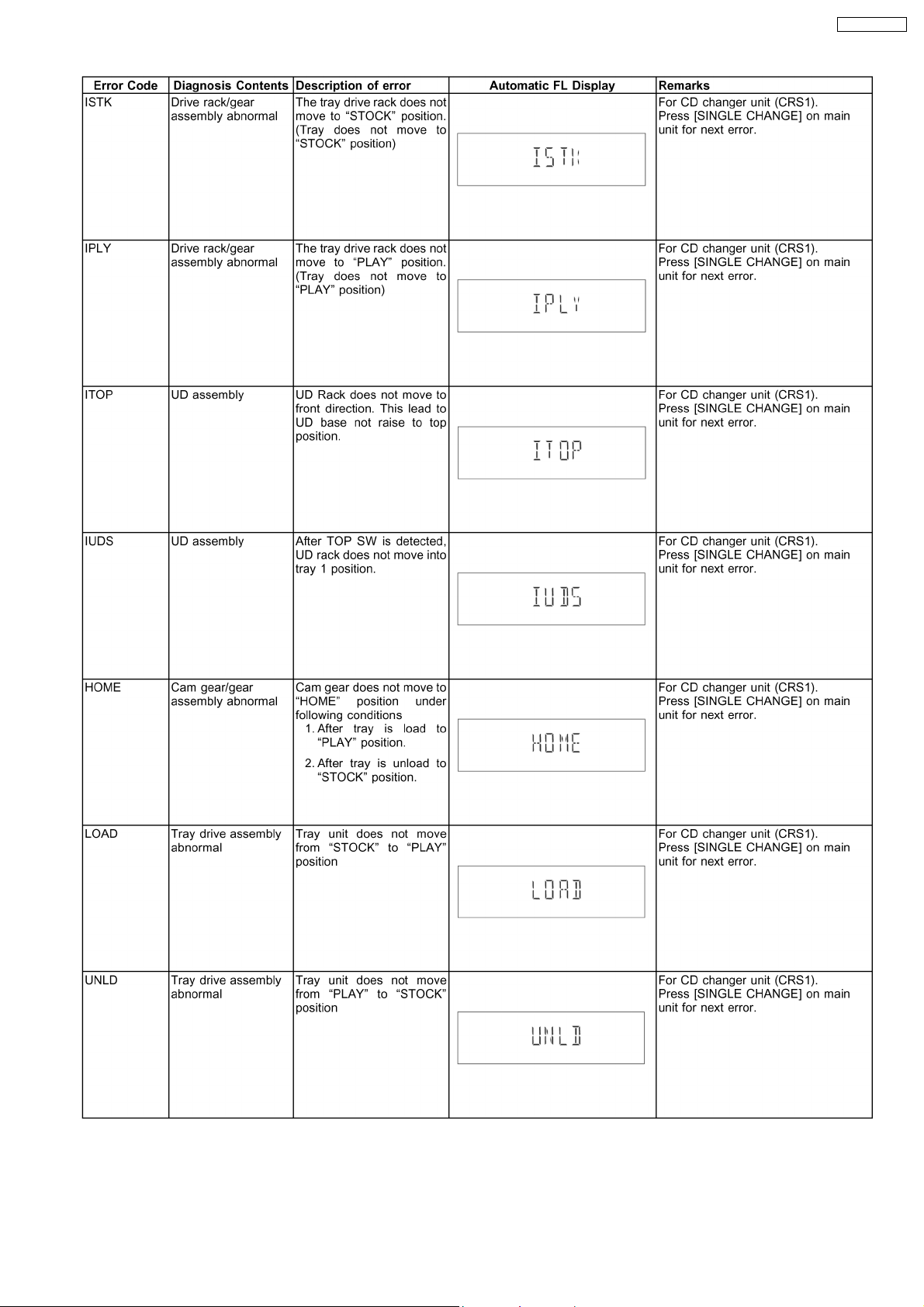

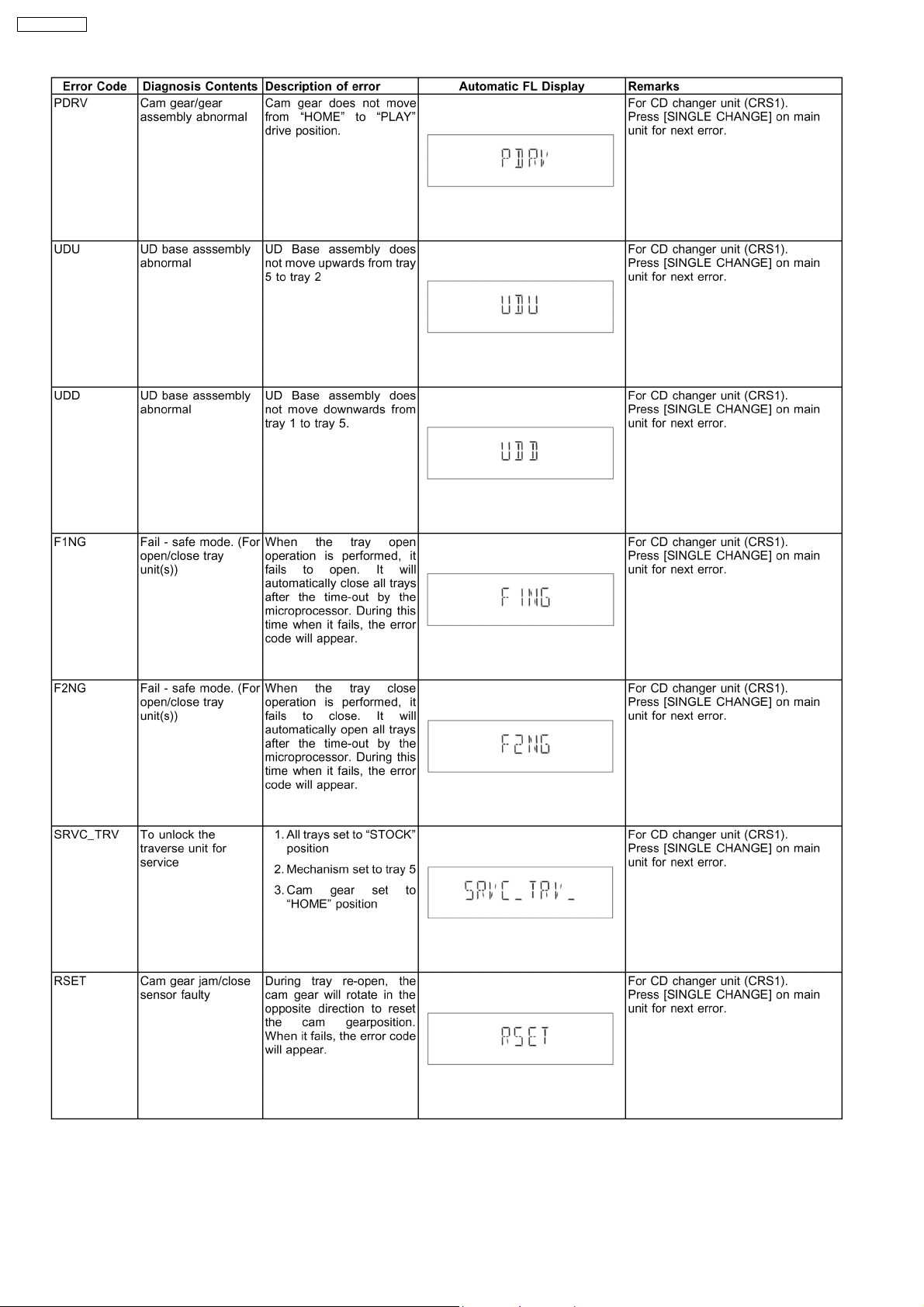

9.4.2. Error Code Table For CD Changer Block

22

SA-AK250GCP

23

SA-AK250GCP

24

SA-AK250GCP

9.4.3. Error Code Table For Power Supply

9.4.4. CRS1 Error Code display

CRS1 Error Code display

1. The errors that occured in CRS1 Mechanism can be recalled and displayed, in the order of the occurence under self-diagnostic

for procedures to enter this mode.

· Only the first 5 errors will be memorized (in backup memory). The subsequence error shall be ignored and not memorize.

For system with EEPROM as memory backup,memory space in EEPROM is neccesary.

2. To display all error code memorized

In CRS1 Self-Diagnostic mode, press [SINGLE CHANGE] to display subsequence error code.

It shall repeat after reaching error no. 5.

e.g.:

[1____IHMS]→ [SINGLE CHANGE]

[2____ITOP]→ [SINGLE CHANGE]

[3____HOME]→ [SINGLE CHANGE]

[4____LOAD]→ [SINGLE CHANGE]

[5_____UDD]→ [SINGLE CHANGE]

3. To clear the error code memory

In CRS1 Self-Diagnostic mode, long press [SINGLE CHANGE] key (2s or more)

25

SA-AK250GCP

10 Assembling and Disassembling

10.1. Caution

Special Note:

This model uses a new CD changer unit CRS1. In this following section does not contain the necessary disassembly &

assembly information for the CD changer unit (CRS1) except the disasembly & assembly of traverse unit. Kindly refer to the

original service manua l for the CD changer unit. (Order No. MD0509368C0).

“ATTENTION SERVICER”

Some chassis components may have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

4. Refer to the Parts No. on the page of “Parts Location and Replacement Parts List” (Section 24), if necessary.

Caution:

After replacing of CD Changer Unit, ageing test is necessary. Please confirm operation for CD Changer Unit.

Below is the list of disassembly sections

· Disasse mbly of Top Cabinet

· Disasse mbly of Rear Panel

· Disasse mbly of CD Changer Unit (CRS1)

· Disasse mbly of Main P.C.B.

· Disasse mbly of Transformer P.C.B.

· Disasse mbly of Power P.C.B.

· Disasse mbly of Front Panel Unit

· Disasse mbly of Panel P.C.B.

· Disasse mbly of Tact Switch P.C.B.

· Disasse mbly of Deck Mechanism Unit

· Disasse mbly for Deck P.C.B.

· Disasse mbly of Traverse Unit

· Disasse mbly of Deck Mechanism

· Disasse mbly of Deck Mechanism P.C.B.

· Disasse mbly of cassette lid

· Rectification for tape jam problem

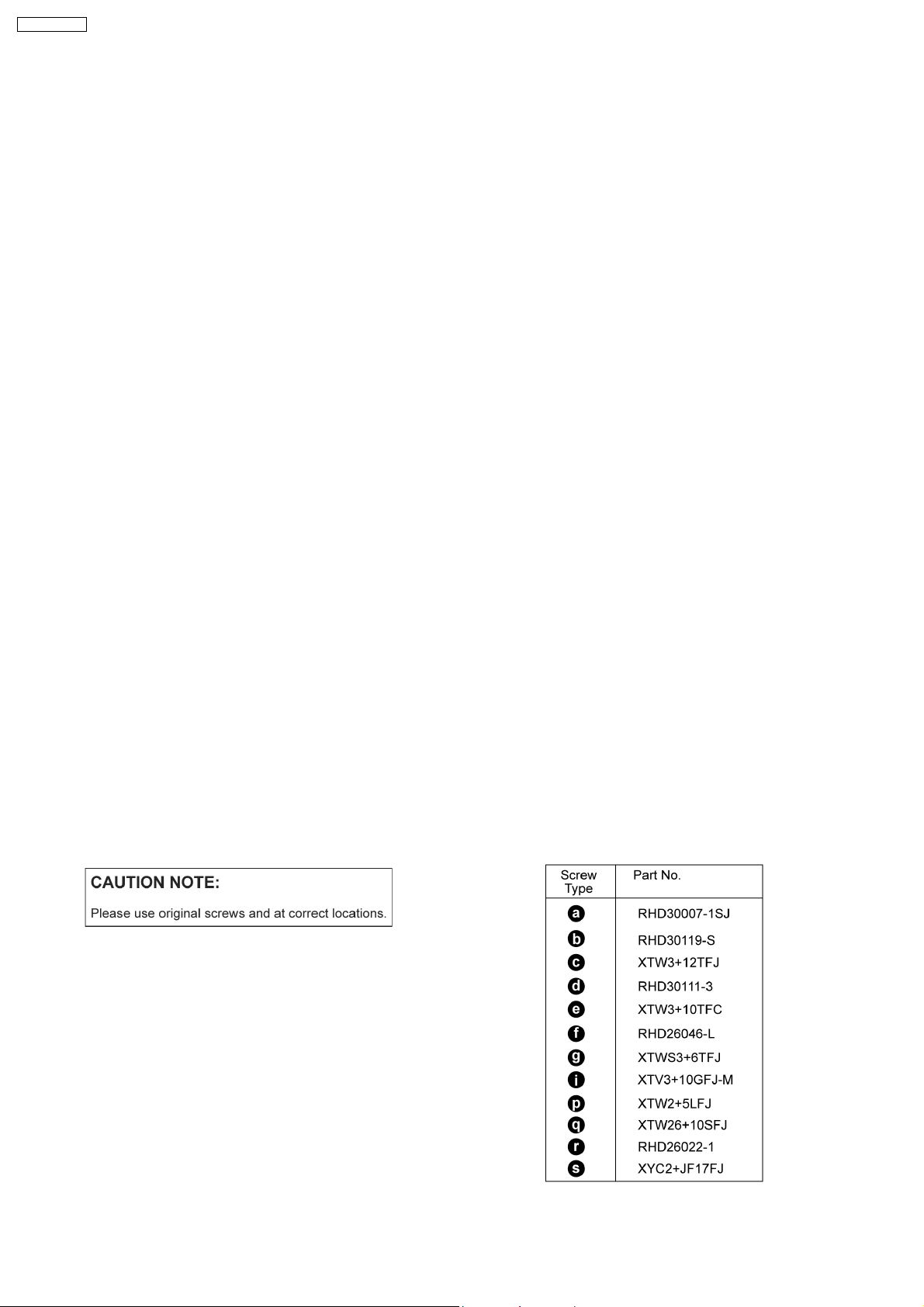

Below shown is part no. of different screws types used:

26

SA-AK250GCP

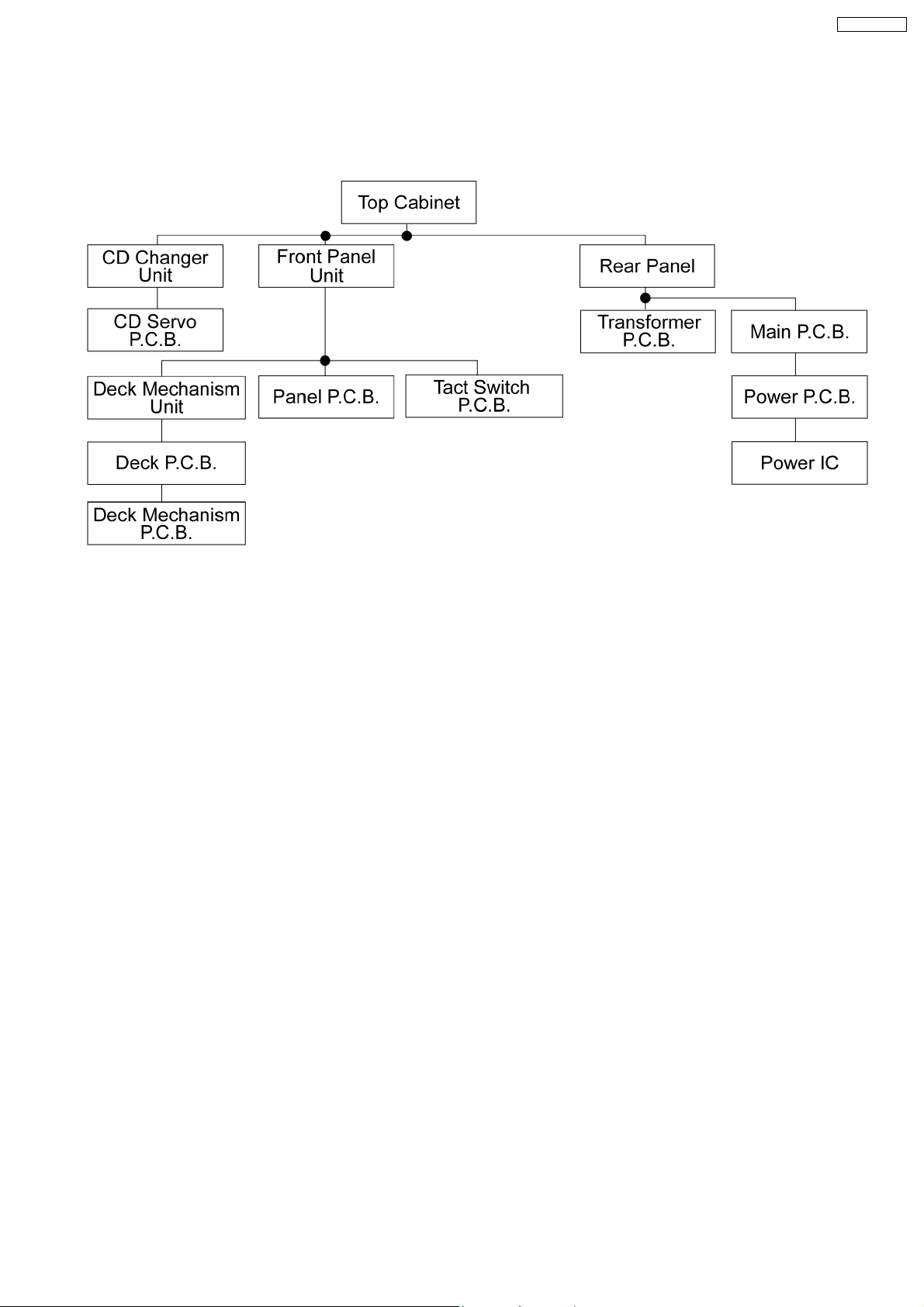

10.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as below.

27

SA-AK250GCP

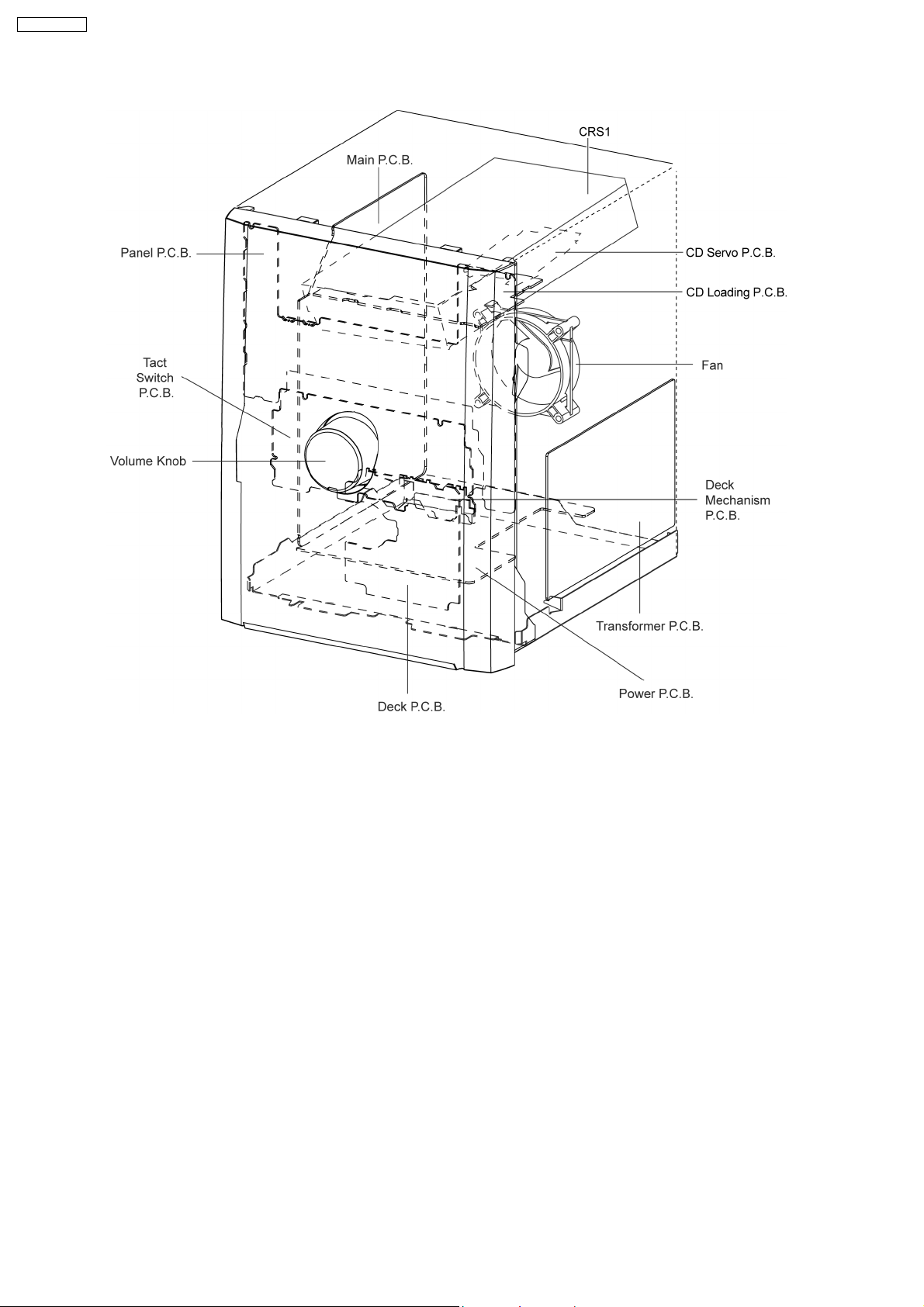

10.3. Main Parts Location

28

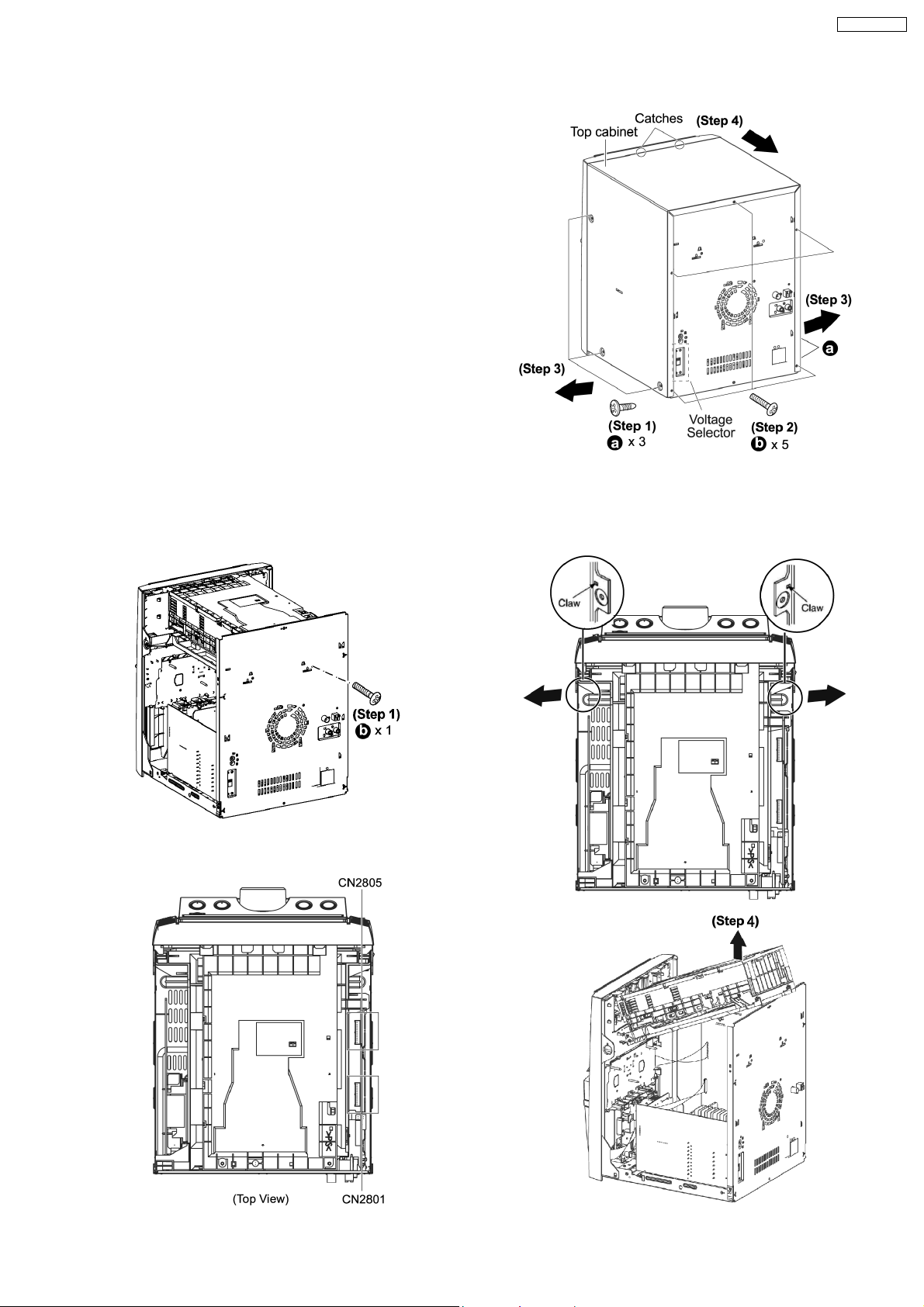

10.4. Disassembly of Top Cabinet

Step 1 Remove 3 screws on both sides on top cabinet.

Step 2 Remove 5 screws at the rear.

Step 3 Lift the sides of top cabine t outwards.

Step 4 Push the top cabinet backwards to release catches.

Step 5 Remove top cabine t.

SA-AK250GCP

10.5. Disassembly of CD Changer Unit (CRS1)

· Follow the (Step 1) - (Step 5) of Item 10.4

Step 1 Remove 1 screw at rear panel.

Step 2 Detach the FFC cables at connectors (CN2801 &

CN2805) on Main P.C.B..

Step 3 Release the claws outwards on both ends.

29

SA-AK250GCP

Step 4 Lift the CD changer unit upwards to remove it.

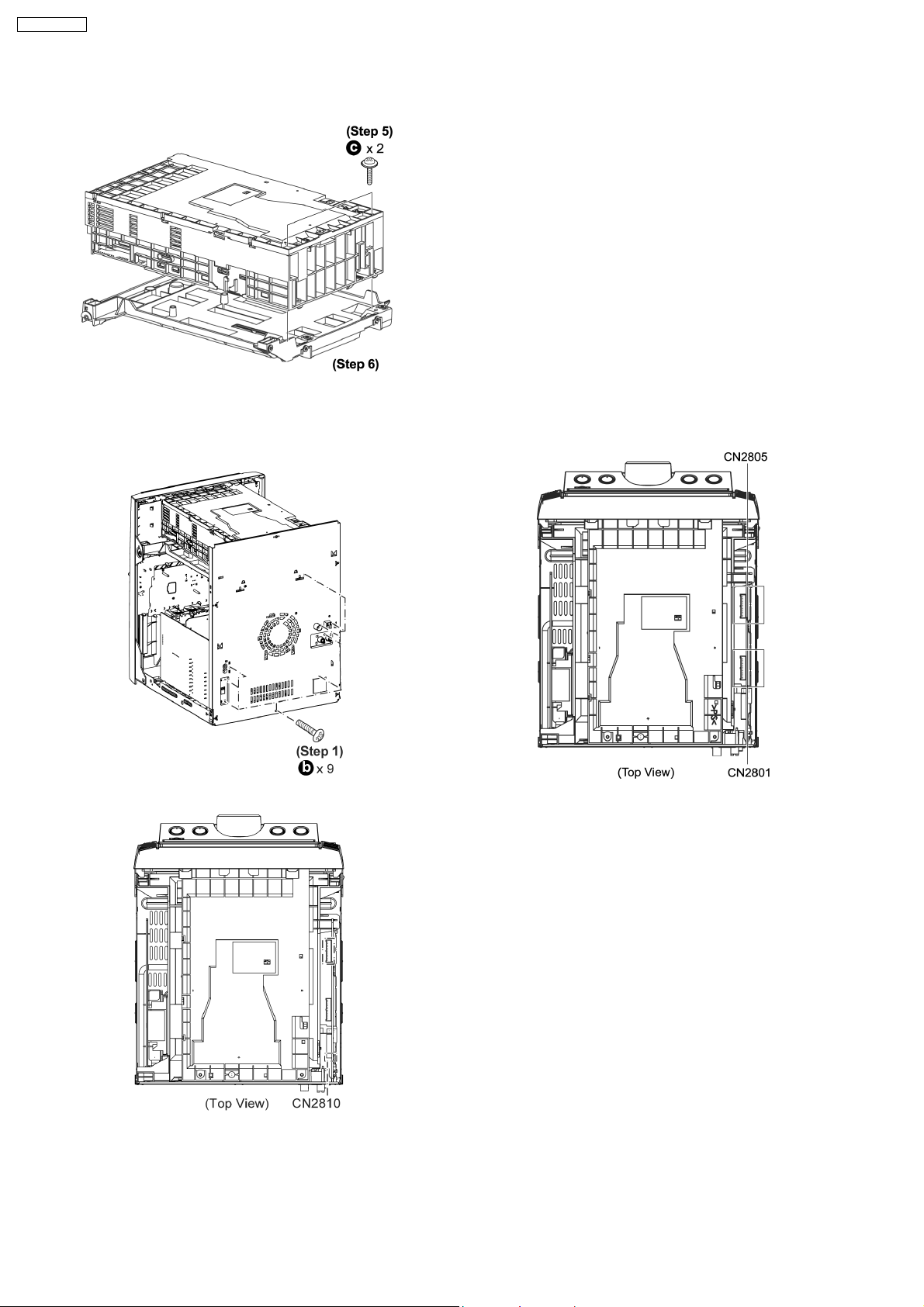

· Disasse mbly of Mecha Chassis

10.6. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 5) of Item 10.4

Step 1 Remove 9 screws.

Step 5 Remove 2 screws.

Step 6 Remove the Mecha Chassis.

Note:

For disassembly & assembly of traverse unit, please refer to

section 10.15 of this service manual. Please refer to original

Service Manual for the Disassembly and Assembly of the CD

Changer Unit (CRS1).

Step 2 Detach cable at connector CN2810 on Main P.C.B..

Step 3 Detach FFC cables at connectors (CN2801 & CN2805)

on Main P.C.B..

Step 4 Remove rear panel.

30

Loading...

Loading...