Panasonic S-125PU1R5, S-60PU1R5, S-140PU1R5, S-60PE1R5, S-71PE1R5 Service Manual

...

TECHNICAL DATA

&

SERVICE MANUAL

8546484931000

REFERENCE NO.

SM830210-00

■

R410A Models

Model No.

Indoor Units

Type Indoor Units Type 60 71 100 125 140

U1 4-Way Cassette

S-60PU1R5 S-71PU1R5 S-100PU1R5 S-125PU1R5 S-140PU1R5

E1 Ducted

S-60PE1R5 S-71PE1R5 S-100PE1R5 S-125PE1R5 S-140PE1R5

Outdoor Units

Type

Outdoor Units

Type

60 71 100 125 140

PE1

Single Split

(1-phase)

U-60PE1R5 U-71PE1R5 U-100PE1R5 U-125PE1R5 U-140PE1R5

Single Split

(3-phase)

– – U-100PE1R8 U-125PE1R8 U-140PE1R8

Indoor Unit Outdoor Unit

4-Way Cassette

Ducted

Cover.indd1Cover.indd1 2012/02/2811:59:572012/02/2811:59:57

i

IMPORTANT!

Please Read Before Starting

This air conditioner must be installed by the sales dealer

or installer.

This information is provided for use only by authorized

persons.

For safe installation and trouble-free operation, you must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as shown.

●

This air conditioner shall be installed in accordance with

National Wiring Regulations.

●

Pay close attention to all warning and caution notices

given in this manual.

WARNING

This symbol refers to a hazard or unsafe

practice which can result in severe

personal injury or death.

CAUTION

This symbol refers to a hazard or unsafe

practice which can result in personal injury

or product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

• Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this

system.

Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or

death.

• Connect all wiring tightly. Loose wiring may cause

overheating at connection points and a possible fire

hazard.

• Provide a power outlet to be used exclusively for each

unit.

• Provide a power outlet exclusively for each unit, and

full disconnection means having a contact separation

in all poles must be incorporated in the fixed wiring in

accordance with the wiring rules.

• To prevent possible hazards from insulation failure,

the unit must be grounded.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges

or thin aluminum fins on the air conditioner can cut your

fingers.

When Installing…

Select an installation location which is rigid and strong

enough to support or hold the unit, and select a location

for easy maintenance.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

CAUTION

Keep the fire alarm and the air outlet at least

1.5 m away from the unit.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide

a solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

…At least 2.5 m

Indoor unit of this air conditioner shall be installed in a

height of at least 2.5 m.

…In laundry rooms

Do not install in laundry rooms. Indoor unit is not drip proof.

When Connecting Refrigerant Tubing

WARNING

•

When performing piping work do not

mix air except for specified refrigerant

(R410A) in refrigeration cycle. It

causes capacity down, and risk of

explosion and injury due to high

tension inside the refrigerant cycle.

• Refrigerant gas leakage may cause

fire.

• Do not add or replace refrigerant

other than specified type. It may

cause product damage, burst and

injury, etc.

• Ventilate the room well, in the event that is refrigerant

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Apply refrigerant lubricant to the matching surfaces

of the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leak-free

connection.

• Check carefully for leaks before starting the test run.

Cover.inddSec1:iCover.inddSec1:i 2012/02/2811:59:582012/02/2811:59:58

ii

• Do not leak refrigerant while piping work for an

installation or re-installation, and while repairing

refrigeration parts.

Handle liquid refrigerant carefully as it may cause

frostbite.

When Servicing

• Turn the power OFF at the main power box

(mains) before opening the unit to check or repair

electrical parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit being serviced.

WARNING

• Do not clean inside the indoor and

outdoor units by users. Engage

authorized dealer or specialist for

cleaning.

• In case of malfunction of this

appliance, do not repair by yourself.

Contact the sales dealer or service

dealer for repair.

CAUTION

• Do not touch the air inlet or the

sharp aluminum fins of the

outdoor unit. You may get injured.

•

Ventilate any enclosed areas when

installing or testing the refrigeration

system. Escaped refrigerant gas, on

contact with fire or heat, can produce

dangerously toxic gas.

•

Confirm after installation that no

refrigerant gas is leaking. If the gas

comes in contact with a burning stove,

gas water heater, electric room heater

or other heat source, it can cause the

generation of poisonous gas.

Others

CAUTION

• Do not touch the air inlet or

the sharp aluminum fins of the

outdoor unit. You may get injured.

• Do not sit or step on the unit,

you may fall down accidentally.

• Do not stick any object into

the FAN CASE.

You may be injured and the

unit may be damaged.

Cover.inddSec1:iiCover.inddSec1:ii 2012/02/2811:59:592012/02/2811:59:59

iii

RoHS

· This product does not contain any hazardous

substances prohibited by the RoHS Directive.

WARNING

· You are requested to use RoHS compliant for

maintenance or repair.

2. The standards for minimum room volume are as follows.

(1) No partition (shaded portion)

(2) When there is an effective opening with the adjacent room

for ventilation of leaking refrigerant gas (opening without

a door, or an opening 0.15% or larger than the respective

floor spaces at the top or bottom of the door).

(3) If an indoor unit is installed in each partitioned room and

the refrigerant tubing is interconnected, the smallest room

of course becomes the object. But when mechanical

ventilation is installed interlocked with a gas leakage

detector in the smallest room where the density limit is

exceeded, the volume of the next smallest room becomes

the object.

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows (for room with

2.7 m high ceiling):

40

35

30

25

20

15

10

5

0

10 20 30

m

2

Check of Density Limit

The room in which the air conditioner is to be installed

requires a design that in the event of refrigerant gas

leaking out, its density will not exceed a set limit.

The refrigerant (R410A), which is used in the air conditioner,

is safe, without the toxicity or combustibility of ammonia, and

is not restricted by laws imposed to protect the ozone layer.

However, since it contains more than air, it poses the risk of

suffocation if its density should rise excessively. Suffocation

from leakage of refrigerant is almost non-existent. With the

recent increase in the number of high density buildings,

however, the installation of multi air conditioner systems is

on the increase because of the need for effective use of floor

space, individual control, and energy conservation by curtailing

heat and carrying power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners. If a single unit of the

multi air conditioner system is to be installed in a small room,

select a suitable model and installation procedure so that if the

refrigerant accidentally leaks out, its density does not reach the

limit (and in the event of an emergency, measures can be made

before injury can occur).

In a room where the density may exceed the limit, create an

opening with adjacent rooms, or install mechanical ventilation

combined with a gas leak detection device. The density is as

given below.

Total amount of refrigerant (kg)

Min. volume of the indoor unit installed room (m

3

)

< Density limit (kg/m

3

)

The density limit of refrigerant which is used in multi air

conditioners is 0.3 kg/m

3

(ISO 5149).

NOTE

1. If there are 2 or more refrigerating systems in a single

refrigerating device, the amount of refrigerant should be as

charged in each independent device.

For the amount of charge in this example:

The possible amount of leaked refrigerant gas in rooms A,

B and C is 10 kg.

The possible amount of leaked refrigerant gas in rooms D,

E and F is 15 kg.

e.g., charged

amount (10 kg)

Indoor unit

Outdoor unit

e.g., charged

amount (15 kg)

Room A Room B Room C Room D Room E Room F

Outdoor unit

Refrigerant tubing

Indoor unit

Mechanical ventilation device – Gas leak detector

Refrigerant tubing

Outdoor unit

Indoor unit

Very

small

room

Small

room

Medium

room

Large room

Total amount of refrigerant

Min. indoor floor space

Range above the

density limit of 0.3 kg/m

3

(countermeasures needed)

kg

Range below the

density limit of 0.3 kg/m

3

(countermeasures not

needed)

Cover.inddSec1:iiiCover.inddSec1:iii 2012/02/2812:00:012012/02/2812:00:01

1-1

1

1. SPECIFICATIONS

1-1. Unit Specifications................................................................................................... 1-2

4-Way Cassette Type ............................................................................................................................ 1-2

Ducted Type .......................................................................................................................................... 1-7

1-2. Dimensional Data ..................................................................................................... 1-15

(A) Indoor Units ..................................................................................................................................... 1-15

(B) Outdoor Units .................................................................................................................................. 1-18

1-3. Refrigerant Flow Diagram ....................................................................................... 1-20

1-4. Operating Range ...................................................................................................... 1-21

1-5. Capacity Correction Graph According to Temperature Condition ...................... 1-22

1-6. Noise Criterion Curves ............................................................................................ 1-27

1-7. Indoor Fan Performance .......................................................................................... 1-32

1-8. Airflow Distance Chart ............................................................................................ 1-33

1-9. Intaking Fresh Air of 4-Way Cassette Type ............................................................ 1-35

1-10. Electrical Wiring ....................................................................................................... 1-37

1-11. Installation instructions .......................................................................................... 1-40

Sec1.indb1Sec1.indb1 2012/03/0717:29:532012/03/0717:29:53

1-2

1

Single-Type

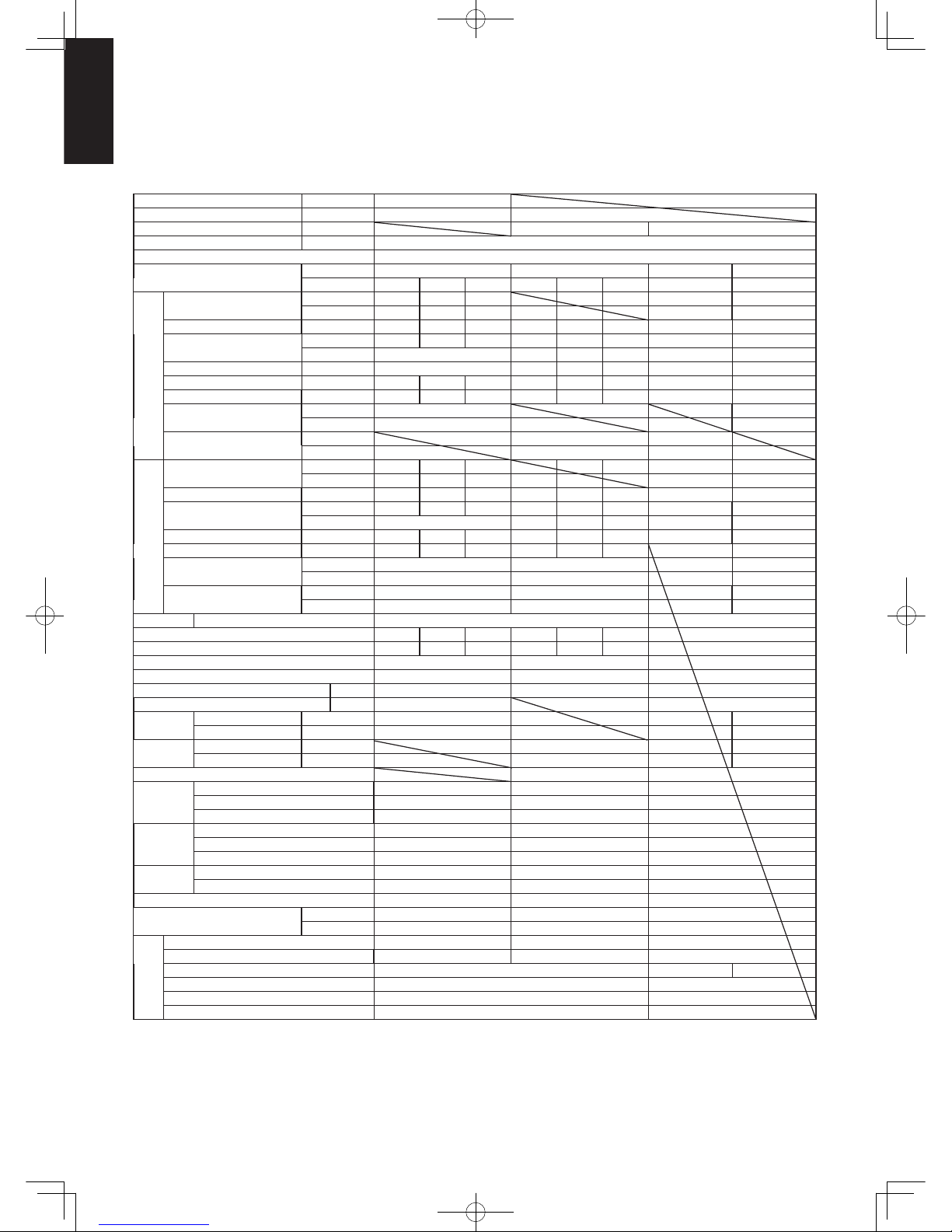

1-1. Unit Specifi cations

4-Way Cassette Type S-60PU1R5 / U-60PE1R5

INDOOR MODEL

S–60PU1R5

PANEL MODEL

CZ–KPU2

OUTDOOR MODEL

U–60PE1R5

Branch pipe MODEL

–

PERFORMANCE TEST CONDITION

ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz

1ø 50 Hz 1ø 50 Hz

V

230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW

6.0 6.0 2.5 7.1

BTU/h

20500 20500 8500 24200

CURRENT A

0.31 0.30 6.90 6.70 – –

INPUT POWER

W

35 35 1.445 k 1.445 k – –

TOTAL W

– 1.480 k 1.480 k 450 2.000 k

ANNUAL CONSUMPTION TOTAL W *

4

– 740 – – –

EER/AEER /STR RAT TOTAL (W/W)

–––

4.05/3.94/3.0

4.05 5.56 3.55

POWER FACTOR %

– – 91 90 – –

NOISE INDOOR

(H/M/L)

dB–A

36/31/28

Power Level dB

53/48/45

NOISE OUTDOOR

(H/L)

dB–A

48/–

Power Level dB

65/–

H

E

A

T

I

N

G

CAPACITY

kW

7.0 7.0 2.0 8.0

BTU/h

23900 23900 6800 27300

CURRENT A

0.30 0.29 8.20 7.95 – –

INPUT POWER

W

35 35 1.775 k 1.775 k – –

TOTAL W

– 1.810 k 1.810 k 400 2.480 k

COP/ACOP /STR RAT TOTAL (W/W)

–––

3.87/3.78/3.0

3.87 5.00 3.23

POWER FACTOR %

– – 94 93 – –

NOISE INDOOR

(H/M/L)

dB–A

36/31/28 – / /

Power Level dB

53/48/45 –

NOISE OUTDOOR

(H/L)

dB–A

– 50/– / /

Power Level dB

– 67/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

0.31/35 0.30/35

18.0/3.930 k 18.0/4.060 k

/

STARTING CURRENT(A)/COMP OUTPUT(W)

––

8.20/1.7 K

7.95/1.7 K

/

NETWORK IMPEDANCE(ΩMAX.)

––

FM OUTPUT (W)

60 90 /

MOISTURE REMOVAL VOLUME L/h(Pt/h)

3.4 (7.1) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min)

21 (742)

HEAT m3/min (ft3/min)

21 (742)

O/D AIR

FLOW

COOL m

3

/min (ft3/min)

60 (2119)

HEAT m3/min (ft3/min)

60 (2119)

REFRIGERANT TYPE, AMOUNT g(oz)

R410A 2.00 k (70.5) /

P

R

O

D

I

M

HEIGHT: H mm (inch)

256 (10–3/32) 996 (39-7/32) /

WIDTH: W mm (inch)

840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch)

840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm

298 1136 /

WIDTH: W mm

929 1055 /

DEPTH: D mm

929 485 /

MASS

(NET) kg(lb)

24(53) 68(150) /

(GROSS) kg(lb)

29(64) 76(168) /

LAYERS LIMIT (actually)

11(12) 2(3)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft)

fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft)

5 – 50 (16.4 – 164.0) – –

I/D&O/D HEIGHT DIRRERENCE m (ft)

15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft)

50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft)

30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

Sec1.indb2Sec1.indb2 2012/03/0717:29:542012/03/0717:29:54

1-3

1

Single-Type

1-1. Unit Specifi cations

4-Way Cassette Type S-71PU1R5 / U-71PE1R5

INDOOR MODEL

S–71PU1R5

PANEL MODEL

CZ–KPU2

OUTDOOR MODEL

U–71PE1R5

Branch pipe MODEL

–

PERFORMANCE TEST CONDITION

ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz

1ø 50 Hz 1ø 50 Hz

V

230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW

7.1 7.1 2.5 8.0

BTU/h

24200 24200 8500 27300

CURRENT A

0.33 0.32 8.10 7.90 – –

INPUT POWER

W

40 40 1.760 k 1.760 k – –

TOTAL W

– 1.800 k 1.800 k 450 2.650 k

ANNUAL CONSUMPTION TOTAL W *

4

– 900 – – –

EER/AEER /STR RAT TOTAL (W/W)

–––

3.94/3.85/2.5

3.94 5.56 3.02

POWER FACTOR %

– – – 94 93

NOISE INDOOR

(H/M/L)

dB–A

37/31/28

Power Level dB

54/48/45

NOISE OUTDOOR

(H/L)

dB–A

48/–

Power Level dB

65/–

H

E

A

T

I

N

G

CAPACITY

kW

8.0 8.0 2.0 9.0

BTU/h

27300 27300 6800 30700

CURRENT A

0.32 0.31 9.00 8.70 – –

INPUT POWER

W

40 40 1.960 k 1.960 k – –

TOTAL W

– 2.000 k 2.000 k 400 2.900 k

COP/ACOP /STR RAT TOTAL (W/W)

–––

4.00/3.91/3.0

4.00 5.00 3.10

POWER FACTOR %

– – 95 94 – –

NOISE INDOOR

(H/M/L)

dB–A

37/31/28 – / /

Power Level dB

54/48/45 –

NOISE OUTDOOR

(H/L)

dB–A

– 50/– / /

Power Level dB

– 67/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

– 0.33/40 0.32/40

18.0/3.930 k 18.0/4.060 k

/

STARTING CURRENT(A)/COMP OUTPUT(W)

–––

9.00/2.0 K

8.70/2.0 K

/

NETWORK IMPEDANCE(ΩMAX.)

––

FM OUTPUT (W)

60 90 /

MOISTURE REMOVAL VOLUME L/h(Pt/h)

4.2 (8.8) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min)

22 (777)

HEAT m3/min (ft3/min)

22 (777)

O/D AIR FLOW

COOL m

3

/min (ft3/min)

60 (2119)

HEAT m3/min (ft3/min)

60 (2119)

REFRIGERANT TYPE, AMOUNT g(oz)

R410A 2.35 k (82.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch)

256 (10–3/32) 996 (39-7/32) /

WIDTH: W mm (inch)

840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch)

840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm

298 1136 /

WIDTH: W mm

929 1055 /

DEPTH: D mm

929 485 /

MASS

(NET) kg(lb)

24(53) 69(153) /

(GROSS) kg(lb)

29(64) 77(170) /

LAYERS LIMIT (actually)

11(12) 2(3)

Operation

Condition

Cool (DBT)

18˚C – 32˚C -15˚C – 46˚C

Heat (DBT)

16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft)

fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft)

5 – 50 (16.4 – 164.0) – –

I/D&O/D HEIGHT DIRRERENCE m (ft)

15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft)

50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft)

30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

Sec1.indb3Sec1.indb3 2012/03/0717:29:542012/03/0717:29:54

1-4

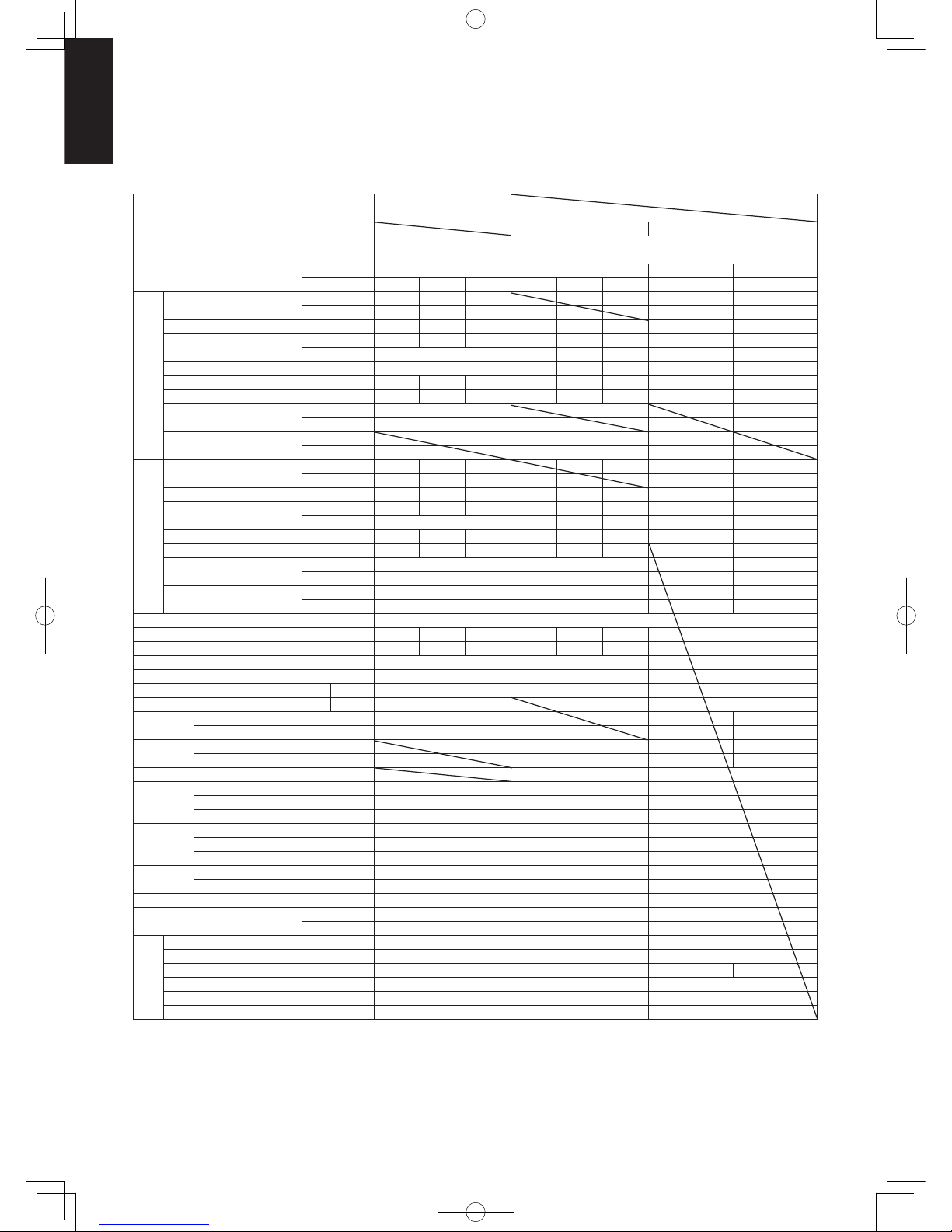

1

Single-Type

1-1. Unit Specifi cations

4-Way Cassette Type S-100PU1R5 / U-100PE1R5

INDOOR MODEL S–100PU1R5

PANEL MODEL CZ–KPU2

OUTDOOR MODEL U–100PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 10.0 10.0 3.3 12.5

BTU/h 34100 34100 11300 42700

CURRENT A 0.71 0.71 10.3 9.90 – –

INPUT POWER

W 95 95 2.285 k 2.285 k – –

TOTAL W – 2.380 k 2.380 k 840 3.700 k

ANNUAL CONSUMPTION TOTAL W *

4

–1190–––

EER/AEER /STR RAT TOTAL (W/W) – –

4.20/4.13/3.0

4.20 3.93 3.38

POWER FACTOR % – – 96 96 – –

NOISE INDOOR

(H/M/L)

dB–A 44/38/32

Power Level dB 62/55/49

NOISE OUTDOOR

(H/L)

dB–A 52/–

Power Level dB 69/–

H

E

A

T

I

N

G

CAPACITY

kW 11.2 11.2 4.1 14.0

BTU/h 38200 38200 14000 47800

CURRENT A 0.65 0.64 11.4 11.0 – –

INPUT POWER

W 85 85 2.515 k 2.515 k – –

TOTAL W – 2.600 k 2.600 k 900 4.400 k

COP/ACOP /STR RAT TOTAL (W/W) – –

4.31/4.24/4.0

4.31 4.56 3.18

POWER FACTOR % – – 96 95 – –

NOISE INDOOR

(H/M/L)

dB–A 44/38/32 – / /

Power Level dB 62/55/49 –

NOISE OUTDOOR

(H/L)

dB–A – 52/– / /

Power Level dB – 69/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W) 0.71/95 0.71/95

25.0/5.550 k 25.0/5.750 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

10.8/3.0 K

10.4/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 6.0 (12.6) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 33 (1165)

HEAT m

3

/min (ft3/min) 33 (1165)

O/D AIR

FLOW

COOL m

3

/min (ft3/min) 110 (3885)

HEAT m3/min (ft3/min) 95 (3355)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch) 840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch) 840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 361 1556 /

WIDTH: W mm 929 1055 /

DEPTH: D mm 929 485 /

MASS

(NET) kg(lb) 27(60) 98(216) /

(GROSS) kg(lb) 33(73) 108(238) /

LAYERS LIMIT (actually) 11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid) ø9.52(3/8) (Gas) ø15.88(5/8) (Liquid) ø9.52(3/8) (Gas) ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

Sec1.indb4Sec1.indb4 2012/03/0717:29:542012/03/0717:29:54

1-5

1

Single-Type

1-1. Unit Specifi cations

4-Way Cassette Type S-125PU1R5 / U-125PE1R5

INDOOR MODEL

S–125PU1R5

PANEL MODEL

CZ–KPU2

OUTDOOR MODEL

U–125PE1R5

Branch pipe MODEL

–

PERFORMANCE TEST CONDITION

ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz

1ø 50 Hz 1ø 50 Hz

V

230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW

12.5 12.5 3.3 14.0

BTU/h

42700 42700 11300 47800

CURRENT A

0.76 0.73 15.3 14.8 – –

INPUT POWER

W

100 100 3.370 k 3.370 k – –

TOTAL W

– 3.470 k 3.470 k 840 4.600 k

ANNUAL CONSUMPTION TOTAL W *

4

– 1735 – – –

EER/AEER /STR RAT TOTAL (W/W)

––

3.60/3.56/2.0

3.60 3.93 3.04

POWER FACTOR %

– – 96 95 – –

NOISE INDOOR

(H/M/L)

dB–A

45/39/33

Power Level dB

63/56/50

NOISE OUTDOOR

(H/L)

dB–A

53/–

Power Level dB

70/–

H

E

A

T

I

N

G

CAPACITY

kW

14.0 14.0 4.1 16.0

BTU/h

47800 47800 14000 54600

CURRENT A

0.73 0.73 15.4 14.9 – –

INPUT POWER

W

100 100 3.400 k 3.400 k – –

TOTAL W

– 3.500 k 3.500 k 900 5.200 k

COP/ACOP /STR RAT TOTAL (W/W)

––

4.00/3.95/3.0

4.00 4.56 3.08

POWER FACTOR %

– – 96 95 – –

NOISE INDOOR

(H/M/L)

dB–A

45/39/33 – / /

Power Level dB

63/56/50 –

NOISE OUTDOOR

(H/L)

dB–A

– 53/– / /

Power Level dB

– 70/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

– 0.76/100 0.73/100 –

28.0/6.200 k 28.0/6.400 k

/

STARTING CURRENT(A)/COMP OUTPUT(W)

––––

15.7/3.0 K 15.2/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.)

––

FM OUTPUT (W)

90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h)

7.9 (16.6) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min)

35 (1236)

HEAT m

3

/min (ft3/min)

35 (1236)

O/D AIR

FLOW

COOL m3/min (ft3/min)

130 (4591)

HEAT m

3

/min (ft3/min)

110 (3885)

REFRIGERANT TYPE, AMOUNT g(oz)

R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch)

319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch)

840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch)

840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm

361 1556 /

WIDTH: W mm

929 1055 /

DEPTH: D mm

929 485 /

MASS

(NET) kg(lb)

27(60) 98(216) /

(GROSS) kg(lb)

33(73) 108(238) /

LAYERS LIMIT (actually)

11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft)

fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft)

5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft)

15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft)

50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft)

30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

Sec1.indb5Sec1.indb5 2012/03/0717:29:552012/03/0717:29:55

1-6

1

Single-Type

1-1. Unit Specifi cations

4-Way Cassette Type S-140PU1R5 / U-140PE1R5

INDOOR MODEL

S–140PU1R5

PANEL MODEL

CZ–KPU2

OUTDOOR MODEL

U–140PE1R5

Branch pipe MODEL

–

PERFORMANCE TEST CONDITION

ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz

1ø 50 Hz 1ø 50 Hz

V

230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW

14.0 14.0 3.3 15.5

BTU/h

47800 47800 11300 52900

CURRENT A

0.89 0.87 19.0 18.4 – –

INPUT POWER

W

115 115 4.195 k 4.195 k – –

TOTAL W

– 4.310 k 0.000 k 840 6.000 k

ANNUAL CONSUMPTION TOTAL W *

4

– 2155 – – –

EER/AEER /STR RAT TOTAL (W/W)

––

3.25/3.22/1.5

3.25 3.93 2.58

POWER FACTOR %

– – 96 95 – –

NOISE INDOOR

(H/M/L)

dB–A

46/40/34

Power Level dB

64/57/51

NOISE OUTDOOR

(H/L)

dB–A

54/–

Power Level dB

71/–

H

E

A

T

I

N

G

CAPACITY

kW

16.0 16.0 4.1 18.0

BTU/h

54600 54600 14000 61400

CURRENT A

0.80 0.79 19.2 18.6 – –

INPUT POWER

W

105 105 4.225 k 4.225 k – –

TOTAL W

– 4.330 k 4.330 k 900 5.900 k

COP/ACOP /STR RAT TOTAL (W/W)

––

3.70/3.66/2.5

3.70 4.56 3.05

POWER FACTOR %

– – 96 95 – –

NOISE INDOOR

(H/M/L)

dB–A

46/40/34 – / /

Power Level dB

64/57/51 –

NOISE OUTDOOR

(H/L)

dB–A

– 55/– / /

Power Level dB

– 71/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

0.89/115 0.87/115

30.0/6.650 k 30.0/6.850 k

/

STARTING CURRENT(A)/COMP OUTPUT(W)

––

19.5/3.0 K 19.0/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.)

––

FM OUTPUT (W)

90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h)

9.0 (18.9) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min)

36 (1271)

HEAT m3/min (ft3/min)

36 (1271)

O/D AIR

FLOW

COOL m

3

/min (ft3/min)

135 (4767)

HEAT m3/min (ft3/min)

120 (4238)

REFRIGERANT TYPE, AMOUNT g(oz)

R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch)

319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch)

840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch)

840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm

361 1556 /

WIDTH: W mm

929 1055 /

DEPTH: D mm

929 485 /

MASS

(NET) kg(lb)

27(60) 98(216) /

(GROSS) kg(lb)

33(73) 108(238) /

LAYERS LIMIT (actually)

11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft)

fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft)

5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft)

15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft)

50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft)

30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

Sec1.indb6Sec1.indb6 2012/03/0717:29:552012/03/0717:29:55

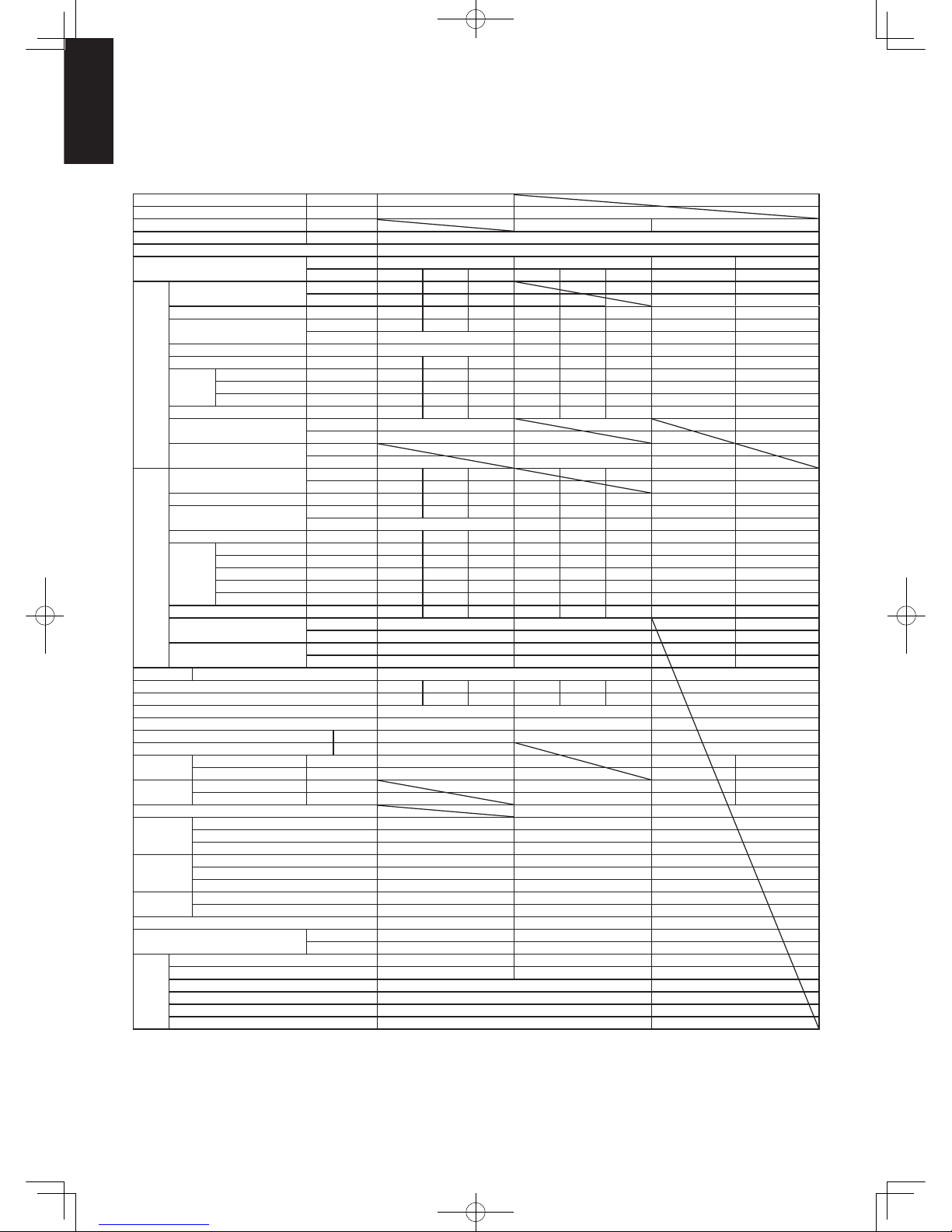

1-7

1

Single-Type

1-1. Unit Specifi cations

Ducted Type S-60PE1R5 / U-60PE1R5

INDOOR MODEL S–60PE1R5

PANEL MODEL –

OUTDOOR MODEL U–60PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 6.0 6.0 2.5 7.1

BTU/h 20500 20500 8500 24200

CURRENT A 0.85 0.86 7.85 7.65 – –

INPUT POWER

W 190 200 1.660 k 1.650 k – –

TOTAL W – 1.850 k 1.850 k 605 2.155 k

ANNUAL CONSUMPTION TOTAL W *

4

– 925 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.24/3.17/–

3.24 4.13 3.29

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 92 90 – –

NOISE INDOOR

(H/L)

dB–A 43/40

Power Level dB 60/57

NOISE OUTDOOR

(H/L)

dB–A 48/–

Power Level dB 65/–

H

E

A

T

I

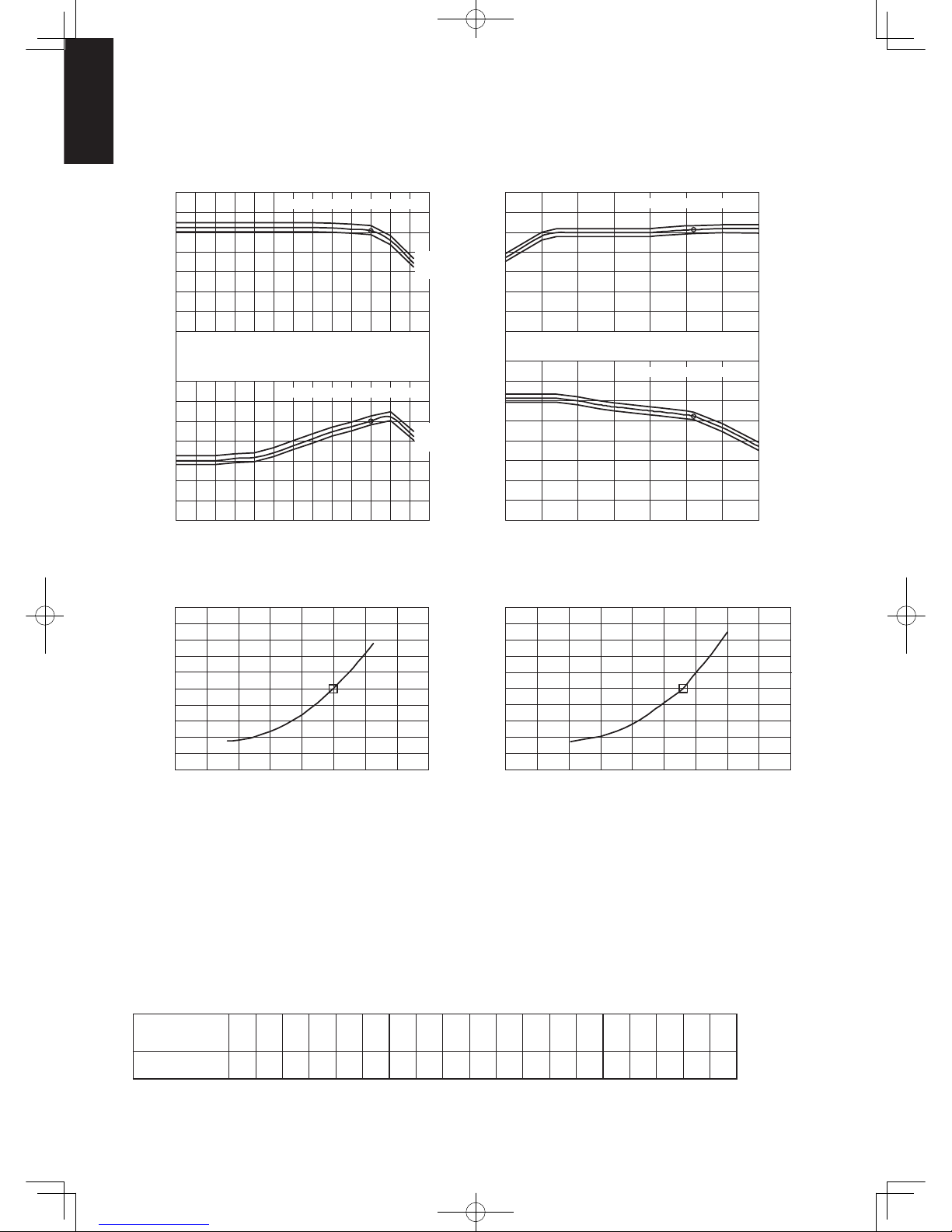

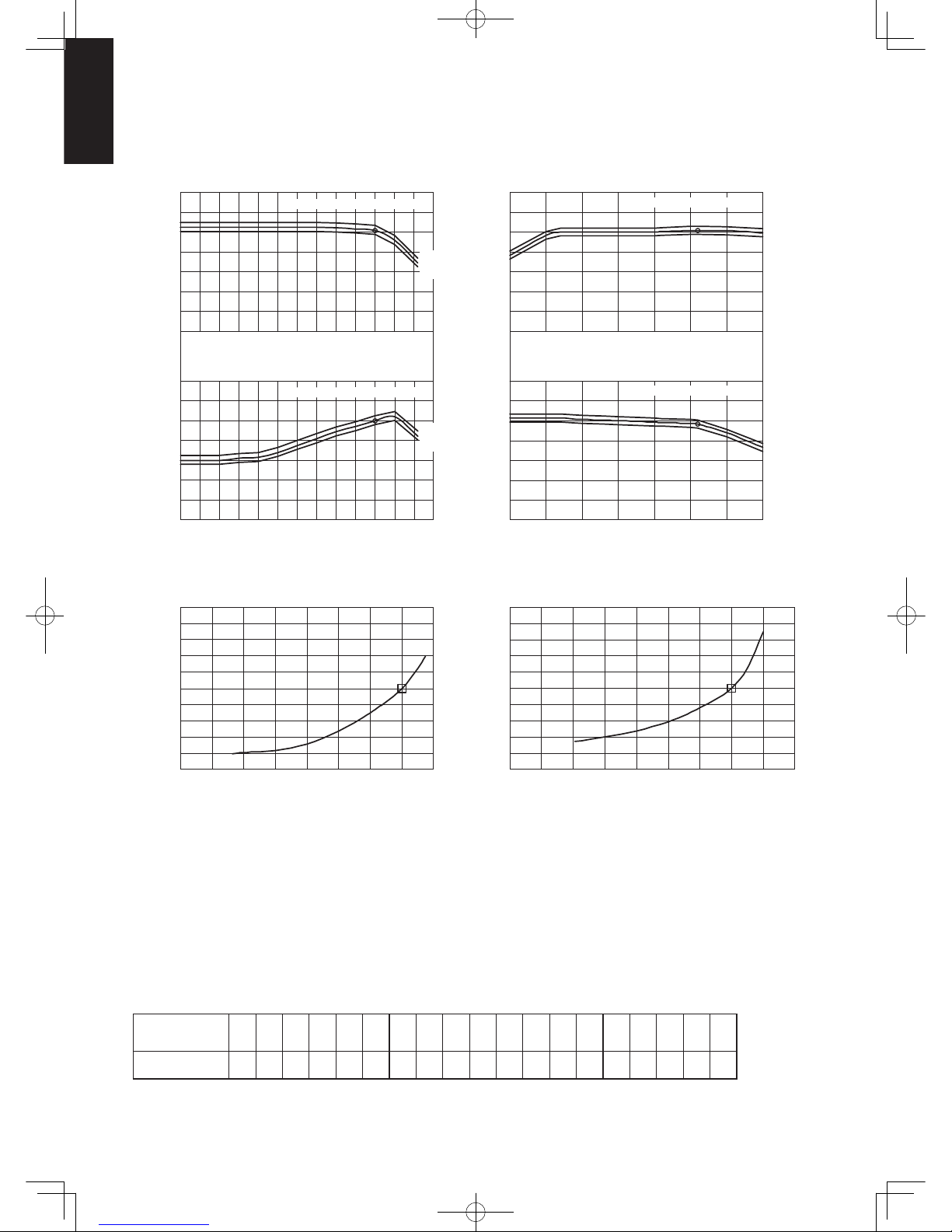

N

G

CAPACITY

kW 7.0 7.0 2.0 8.0

BTU/h 23900 23900 6800 27300

CURRENT A 0.85 0.86 8.8 8.6 – –

INPUT POWER

W 190 200 1.860 k 1.850 k – –

TOTAL W – 2.050 k 2.050 k 555 2.635 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.41/3.34/–

3.41 3.60 3.04

Erp *

6

Pdsign kW – –––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 92 90 – –

NOISE INDOOR

(H/L)

dB–A 43/40 – / /

Power Level dB 60/57 –

NOISE OUTDOOR

(H/L)

dB–A – 50/– / /

Power Level dB – 67/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

0.89/0.200 k 0.90/0.210 k 18.0/3.93 k 18.0/4.060 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

8.8/1.7 K 8.6/1.7 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 90 90 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 3.4 (7.1) –

Extarnal static pressure

Pa (mmAq)

70 (MIN10 – MAX100)

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 22 (777)

HEAT m3/min (ft3/min) 22 (777)

O/D AIR

FLOW

COOL m3/min (ft3/min) 60 (2119)

HEAT m

3

/min (ft3/min) 60 (2119)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 2.00 k (70.5) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 290 (11–13/32) 996 (39–7/32) /

WIDTH: W mm (inch)

1100(+100)

(

43–5/16(+3–15/16))

940 (37–1/32) /

DEPTH: D mm (inch) 700 (27–9/16) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 375 1136 /

WIDTH: W mm 1315 1055 /

DEPTH: D mm 812 485 /

MASS

(NET) kg(lb) 35 68 /

(GROSS) kg(lb) 42 76 /

LAYERS LIMIT (actually) 6(7) 2(3)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 50 (16.4 – 164.0) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb7Sec1.indb7 2012/03/0717:29:552012/03/0717:29:55

1-8

1

Single-Type

1-1. Unit Specifi cations

Ducted Type S-71PE1R5 / U-71PE1R5

INDOOR MODEL S–71PE1R5

PANEL MODEL –

OUTDOOR MODEL U–71PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 7.1 7.1 2.5 8.0

BTU/h 24200 24200 8500 27300

CURRENT A 1.24 1.25 9.1 8.80 – –

INPUT POWER

W 275 290 1.925 k 1.910 k – –

TOTAL W – 2.200 k 2.200 k 685 2.855 k

ANNUAL CONSUMPTION TOTAL W *

4

–1100–––

EER/AEER /STR RAT TOTAL (W/W) – –

3.23/3.16/–

3.23 3.65 2.80

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 92 90 – –

NOISE INDOOR

(H/L)

dB–A 45/43

Power Level dB 62/60

NOISE OUTDOOR

(H/L)

dB–A 48/–

Power Level dB 65/–

H

E

A

T

I

N

G

CAPACITY

kW 8.0 8.0 2.0 9.0

BTU/h 27300 27300 6800 30700

CURRENT A 1.24 1.25 9.3 9.0 – –

INPUT POWER

W 275 290 2.025 k 2.010 k – –

TOTAL W – 2.300 k 2.300 k 635 3.135 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.48/3.41/–

3.48 3.15 2.87

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 95 93 – –

NOISE INDOOR

(H/L)

dB–A 45/43 – / /

Power Level dB 62/60 –

NOISE OUTDOOR

(H/L)

dB–A – 50/– / /

Power Level dB – 67/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

1.30/0.290 k 1.31/0.305 k 18.0/3.93 k 18.0/4.060 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

9.3/2.0 K 9.0/2.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 155 90 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 4.2 (8.8) –

Extarnal static pressure

Pa (mmAq)

100 (MIN10 – MAX150)

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 30 (1059)

HEAT m3/min (ft3/min) 30 (1059)

O/D AIR

FLOW

COOL m

3

/min (ft3/min) 60 (2119)

HEAT m3/min (ft3/min) 60 (2119)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 2.35 k (82.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 360 (14–5/32) 996 (39–7/32) /

WIDTH: W mm (inch)

1100(+100)

(

43–5/16(+3–15/16))

940 (37–1/32) /

DEPTH: D mm (inch) 700 (27–9/16) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 445 1136 /

WIDTH: W mm 1315 1055 /

DEPTH: D mm 812 485 /

MASS

(NET) kg(lb) 42 69 /

(GROSS) kg(lb) 50 77 /

LAYERS LIMIT (actually) 6(7) 2(3)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 50 (16.4 – 164.0) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb8Sec1.indb8 2012/03/0717:29:552012/03/0717:29:55

1-9

1

Single-Type

1-1. Unit Specifi cations

Ducted Type S-100PE1R5 / U-100PE1R5

INDOOR MODEL S–100PE1R5

PANEL MODEL –

OUTDOOR MODEL U–100PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 10.0 10.0 3.3 12.5

BTU/h 34100 34100 11300 42700

CURRENT A 1.72 1.74 11.8 11.40 – –

INPUT POWER

W 390 410 2.590 k 2.570 k – –

TOTAL W – 2.980 k 2.980 k 980 3.900 k

ANNUAL CONSUMPTION TOTAL W *

4

– 1490 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.36/3.31/–

3.36 3.37 3.21

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 95 94 – –

NOISE INDOOR

(H/L)

dB–A 48/44

Power Level dB 70/66

NOISE OUTDOOR

(H/L)

dB–A 52/–

Power Level dB 69/–

H

E

A

T

I

N

G

CAPACITY

kW 11.2 11.2 4.1 14.0

BTU/h 38200 38200 14000 47800

CURRENT A 1.72 1.74 12.7 12.3 – –

INPUT POWER

W 390 410 2.790 k 2.770 k – –

TOTAL W – 3.180 k 3.180 k 1050 4.600 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.52/3.47/–

3.52 3.90 3.04

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 96 94 – –

NOISE INDOOR

(H/L)

dB–A 48/44 – / /

Power Level dB 70/66 –

NOISE OUTDOOR

(H/L)

dB–A – 52/– / /

Power Level dB – 69/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W) 2.0/0.44 k 2.1/0.47 k

25.0/5.550 k 25.0/5.750 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

10.8/3.0 K 10.4/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 275 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 6.0 (12.6) –

Extarnal static pressure

Pa (mmAq)

100 (MIN10 – MAX150)

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 40 (1413)

HEAT m3/min (ft3/min) 40 (1413)

O/D AIR

FLOW

COOL m

3

/min (ft3/min) 110 (3885)

HEAT m3/min (ft3/min) 95 (3355)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 360 (14–5/32) 1416 (55–3/4) /

WIDTH: W mm (inch)

1100(+100)

(

43–5/16(+3–15/16))

940 (37–1/32) /

DEPTH: D mm (inch) 700 (27–9/16) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 445 1556 /

WIDTH: W mm 1315 1055 /

DEPTH: D mm 812 485 /

MASS

(NET) kg(lb) 44 98 /

(GROSS) kg(lb) 52 108 /

LAYERS LIMIT (actually) 6(7) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb9Sec1.indb9 2012/03/0717:29:552012/03/0717:29:55

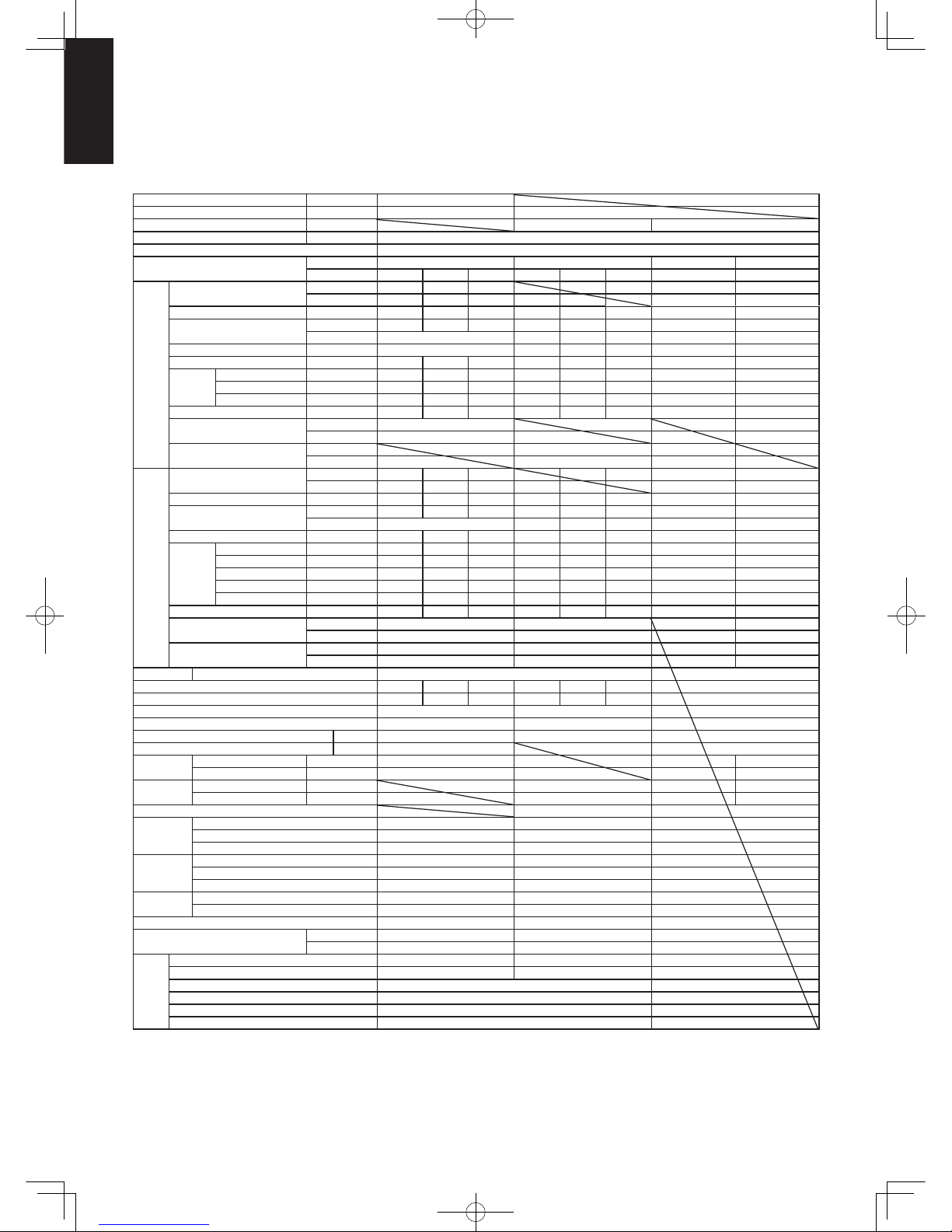

1-10

1

Single-Type

1-1. Unit Specifi cations

Ducted Type S-125PE1R5 / U-125PE1R5

INDOOR MODEL S–125PE1R5

PANEL MODEL –

OUTDOOR MODEL U–125PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 12.5 12.5 3.3 14.0

BTU/h 42700 42700 11300 47800

CURRENT A 1.82 1.84 16.0 15.4 – –

INPUT POWER

W 410 430 3.490 k 3.470 k – –

TOTAL W – 3.900 k 3.900 k 1000 4.800 k

ANNUAL CONSUMPTION TOTAL W *

4

– 1950 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.21/3.17/–

3.21 3.30 2.92

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 95 94 – –

NOISE INDOOR

(H/L)

dB–A 49/45

Power Level dB 71/67

NOISE OUTDOOR

(H/L)

dB–A 53/–

Power Level dB 70/–

H

E

A

T

I

N

G

CAPACITY

kW 14.0 14.0 4.1 16.0

BTU/h 47800 47800 14000 54600

CURRENT A 1.82 1.84 17.2 16.6 – –

INPUT POWER

W 410 430 3.750 k 3.730 k – –

TOTAL W – 4.160 k 4.160 k 1050 5.400 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.37/3.33/–

3.37 3.90 2.96

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 95 94 – –

NOISE INDOOR

(H/L)

dB–A 49/45 – / /

Power Level dB 71/67 –

NOISE OUTDOOR

(H/L)

dB–A – 53/– / /

Power Level dB – 70/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W) 2.1/0.47 k 2.2/0.50 k

28.0/6.200 k 28.0/6.400 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

15.7/3.0 K 15.2/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 310 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 7.9 (16.6) –

Extarnal static pressure

Pa (mmAq)

100 (MIN10 – MAX150)

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 50 (1766)

HEAT m3/min (ft3/min) 50 (1766)

O/D AIR

FLOW

COOL m3/min (ft3/min) 130 (4591)

HEAT m

3

/min (ft3/min) 110 (3885)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 430 (16–15/16) 1416 (55–3/4) /

WIDTH: W mm (inch)

1100(+100)

(

43–5/16(+3–15/16))

940 (37–1/32) /

DEPTH: D mm (inch) 700 (27–9/16) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 515 1556 /

WIDTH: W mm 1315 1055 /

DEPTH: D mm 812 485 /

MASS

(NET) kg(lb) 48 98 /

(GROSS) kg(lb) 56 108 /

LAYERS LIMIT (actually) 6(7) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1: In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplie d by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb10Sec1.indb10 2012/03/0717:29:562012/03/0717:29:56

1-11

1

Single-Type

1-1. Unit Specifi cations

Ducted Type S-140PE1R5 / U-140PE1R5

INDOOR MODEL S–140PE1R5

PANEL MODEL –

OUTDOOR MODEL U–140PE1R5

Branch pipe MODEL –

PERFORMANCE TEST CONDITION ISO5151 / AS/NZS3823

POWER SUPPLY

ø, Hz 1ø 50 Hz 1ø 50 Hz

V 230 V 240 V 230 V 240 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 14.0 14.0 3.3 15.5

BTU/h 47800 47800 11300 52900

CURRENT A 2.62 2.70 17.8 17.2 – –

INPUT POWER

W 590 640 3.860 k 3.810 k – –

TOTAL W – 4.450 k 4.450 k 1000 6.200 k

ANNUAL CONSUMPTION TOTAL W *

4

– 2225 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.15/3.12/–

3.15 3.30 2.50

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 94 92 – –

NOISE INDOOR

(H/L)

dB–A 51/47

Power Level dB 73/69

NOISE OUTDOOR

(H/L)

dB–A 54/–

Power Level dB 71/–

H

E

A

T

I

N

G

CAPACITY

kW 16.0 16.0 4.1 18.0

BTU/h 54600 54600 14000 61400

CURRENT A 2.62 2.70 18.1 17.5 – –

INPUT POWER

W 590 640 3.960 k 3.910 k – –

TOTAL W – 4.550 k 4.550 k 1050 6.100 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.52/3.48/–

3.52 3.90 2.95

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 95 93 – –

NOISE INDOOR

(H/L)

dB–A 51/47 – / /

Power Level dB 73/69 –

NOISE OUTDOOR

(H/L)

dB–A – 55/– / /

Power Level dB – 71/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W) 2.9/0.66 k 3.0/0.71 k

30.0/6.650 k 30.0/6.850 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

19.5/3.0 K 19.0/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 440 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 9.0 (18.9) –

Extarnal static pressure

Pa (mmAq)

100 (MIN10 – MAX150)

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 60 (2119)

HEAT m3/min (ft3/min) 60 (2119)

O/D AIR

FLOW

COOL m3/min (ft3/min) 135 (4767)

HEAT m

3

/min (ft3/min) 120 (4238)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 430 (16–15/16) 1416 (55–3/4) /

WIDTH: W mm (inch)

1100(+100)

(

43–5/16(+3–15/16))

940 (37–1/32) /

DEPTH: D mm (inch) 700 (27–9/16) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 515 1556 /

WIDTH: W mm 1315 1055 /

DEPTH: D mm 812 485 /

MASS

(NET) kg(lb) 53 98 /

(GROSS) kg(lb) 61 108 /

LAYERS LIMIT (actually) 6(7) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb11Sec1.indb11 2012/03/0717:29:562012/03/0717:29:56

1-12

1

Single-Type

1-1. Unit Specifi cations

Single Split Type S-100PU1R5 / U-100PE1R8

INDOOR MODEL S–100PU1R5

PANEL MODEL CZ-KPU2

OUTDOOR MODEL U–100PE1R8

Branch pipe MODEL –

PERFORMANCE TEST CONDITION AS/NZS3823.1

POWER SUPPLY

ø, Hz 1ø 50 Hz 3ø 50 Hz

V 230 V 240 V 400 V 415 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 10.0 10.0 3.3 12.5

BTU/h 34100 34100 11300 42700

CURRENT A 0.71 0.71 3.50 3.40 – –

INPUT POWER

W 95 95 2.285 k 2.285 k – –

TOTAL W – 2.380 k 2.380 k 840 3.700 k

ANNUAL CONSUMPTION TOTAL W *

4

–1190–––

EER/AEER /STR RAT TOTAL (W/W) – –

4.20/4.13/–

4.20 3.93 3.38

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 94 93 – –

NOISE INDOOR

(H/L)

dB–A 44/32

Power Level dB 62/49

NOISE OUTDOOR

(H/L)

dB–A 52/–

Power Level dB 69/–

H

E

A

T

I

N

G

CAPACITY

kW 11.2 11.2 4.1 14.0

BTU/h 38200 38200 14000 47800

CURRENT A 0.65 0.64 3.85 3.75 – –

INPUT POWER

W 85 85 2.515 k 2.515 k – –

TOTAL W – 2.600 k 2.600 k 900 4.400 k

COP/ACOP /STR RAT TOTAL (W/W) – –

4.31/4.24/–

4.31 4.56 3.18

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 94 93 – –

NOISE INDOOR

(H/L)

dB–A 44/32 – / /

Power Level dB 62/49 –

NOISE OUTDOOR

(H/L)

dB–A – 52/– / /

Power Level dB – 69/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W) 0.71/95 k 0.71/95 k

9.0/5.850 k 9.0/6.100 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

3.85/3.0 K 3.75/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 6.0 (12.6) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 33 (1165)

HEAT m3/min (ft3/min) 33 (1165)

O/D AIR

FLOW

COOL m3/min (ft3/min) 110 (3885)

HEAT m

3

/min (ft3/min) 95 (3355)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch) 840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch) 840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 361 1556 /

WIDTH: W mm 929 1055 /

DEPTH: D mm 929 485 /

MASS

(NET) kg(lb) 27 98 /

(GROSS) kg(lb) 34 108 /

LAYERS LIMIT (actually) 11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb12Sec1.indb12 2012/03/0717:29:562012/03/0717:29:56

1-13

1

Single-Type

1-1. Unit Specifi cations

Single Split Type S-125PU1R5 / U-125PE1R8

INDOOR MODEL S–125PU1R5

PANEL MODEL CZ-KPU2

OUTDOOR MODEL U–125PE1R8

Branch pipe MODEL –

PERFORMANCE TEST CONDITION AS/NZS3823.1

POWER SUPPLY

ø, Hz 1ø 50 Hz 3ø 50 Hz

V 230 V 240 V 400 V 415 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 12.5 12.5 3.3 14.0

BTU/h 42700 42700 11300 47800

CURRENT A 0.76 0.73 5.15 5.00 – –

INPUT POWER

W 100 100 3.370 k 3.370 k – –

TOTAL W – 3.470 k 3.470 k 840 4.600 k

ANNUAL CONSUMPTION TOTAL W *

4

– 1735 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.60/3.56/–

3.60 3.93 3.04

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 94 94 – –

NOISE INDOOR

(H/L)

dB–A 45/33

Power Level dB 63/50

NOISE OUTDOOR

(H/L)

dB–A 53/–

Power Level dB 70/–

H

E

A

T

I

N

G

CAPACITY

kW 14.0 14.0 4.1 16.0

BTU/h 47800 47800 14000 54600

CURRENT A 0.73 0.73 5.20 5.05 – –

INPUT POWER

W 100 100 3.400 k 3.400 k – –

TOTAL W – 3.500 k 3.500 k 900 5.200 k

COP/ACOP /STR RAT TOTAL (W/W) – –

4.00/3.95/–

4.00 4.56 3.08

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 94 94 – –

NOISE INDOOR

(H/L)

dB–A 45/33 – / /

Power Level dB 63/50 –

NOISE OUTDOOR

(H/L)

dB–A – 53/– / /

Power Level dB – 70/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

0.76/100 k 0.73/100 k

10.0/6.500 k 10.0/6.750 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

5.20/3.0 K 5.05/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 6.0 (12.6) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 35 (1236)

HEAT m3/min (ft3/min) 35 (1236)

O/D AIR

FLOW

COOL m3/min (ft3/min) 130 (4591)

HEAT m

3

/min (ft3/min) 110 (3885)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch) 840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch) 840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 361 1556 /

WIDTH: W mm 929 1055 /

DEPTH: D mm 929 485 /

MASS

(NET) kg(lb) 27 98 /

(GROSS) kg(lb) 34 108 /

LAYERS LIMIT (actually) 11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb13Sec1.indb13 2012/03/0717:29:562012/03/0717:29:56

1-14

1

Single-Type

1-1. Unit Specifi cations

Single Split Type S-140PU1R5 / U-140PE1R8

INDOOR MODEL S–140PU1R5

PANEL MODEL CZ-KPU2

OUTDOOR MODEL U–140PE1R8

Branch pipe MODEL –

PERFORMANCE TEST CONDITION AS/NZS3823.1

POWER SUPPLY

ø, Hz 1ø 50 Hz 3ø 50 Hz

V 230 V 240 V 400 V 415 V Min Max

C

O

O

L

I

N

G

CAPACITY

kW 14.0 14.0 3.3 15.5

BTU/h 47800 47800 11300 52900

CURRENT A 0.89 0.87 6.45 6.20 – –

INPUT POWER

W 115 115 4.195 k 4.195 k – –

TOTAL W – 4.310 k 4.310 k 840 6.000 k

ANNUAL CONSUMPTION TOTAL W *

4

– 2155 – – –

EER/AEER /STR RAT TOTAL (W/W) – –

3.25/3.22/–

3.25 3.93 2.58

Erp *

6

Pdsign kW ––––––

SEER (W/W) ––––––

Class ––––––

POWER FACTOR % – – 94 94 – –

NOISE INDOOR

(H/L)

dB–A 46/34

Power Level dB 64/51

NOISE OUTDOOR

(H/L)

dB–A 54/–

Power Level dB 71/–

H

E

A

T

I

N

G

CAPACITY

kW 16.0 16.0 4.1 18.0

BTU/h 54600 54600 14000 61400

CURRENT A 0.80 0.79 6.50 6.25 – –

INPUT POWER

W 105 105 4.225 k 4.225 k – –

TOTAL W – 4.330 k 4.330 k 900 5.900 k

COP/ACOP /STR RAT TOTAL (W/W) – –

3.70/3.66/–

3.70 4.56 3.05

Erp *

6

Pdsign kW ––––––

Tbivalen ˚C ––––––

SCOP (W/W) ––––––

Annual consumption kWh ––––––

Class ––––––

POWER FACTOR % – – 94 94 – –

NOISE INDOOR

(H/L)

dB–A 46/34 – / /

Power Level dB 64/51 –

NOISE OUTDOOR

(H/L)

dB–A – 55/– / /

Power Level dB – 71/–

EXTRA LOW TEMP

TOTAL CAPACITY(kW)/INPUT POWER(W)/COP

–

MAX CURRENT(A)/MAX INPUT POWER(W)

0.89/115 k 0.87/115 k

11.0/7.150 k 11.0/7.450 k

/

STARTING CURRENT(A)/COMP OUTPUT(W) – –

6.50/3.0 K 6.25/3.0 K

/

NETWORK IMPEDANCE(ΩMAX.) – –

FM OUTPUT (W) 90 90 × 2 /

MOISTURE REMOVAL VOLUME L/h(Pt/h) 6.0 (12.6) –

Extarnal static pressure

Pa (mmAq)

–

I/D AIR

FLOW

COOL m

3

/min (ft3/min) 36 (1271)

HEAT m

3

/min (ft3/min) 36 (1271)

O/D AIR

FLOW

COOL m

3

/min (ft3/min) 135 (4767)

HEAT m3/min (ft3/min) 120 (4238)

REFRIGERANT TYPE, AMOUNT g(oz) R410A 3.40 k (119.9) /

P

R

O

D

I

M

HEIGHT: H mm (inch) 319 (12–9/16) 1416 (55–3/4) /

WIDTH: W mm (inch) 840 (33–3/32) 940 (37–1/32) /

DEPTH: D mm (inch) 840 (33–3/32) 340 (13–13/32) /

P

A

C

D

I

M

HEIGHT: H mm 361 1556 /

WIDTH: W mm 929 1055 /

DEPTH: D mm 929 485 /

MASS

(NET) kg(lb) 27 98 /

(GROSS) kg(lb) 34 108 /

LAYERS LIMIT (actually) 11(12) 1(2)

Operation

Condition

Cool (DBT) 18˚C – 32˚C -15˚C – 46˚C

Heat (DBT) 16˚C – 30˚C -20˚C – 24˚C

P

I

P

I

N

G

PIPE DIAMETER mm (inch)

(Liquid)ø9.52(3/8) (Gas)ø15.88(5/8) (Liquid)ø9.52(3/8) (Gas)ø15.88(5/8)

CONNECT METHOD, STD LENGTH m (ft) fl ared type, 5.0(16.4) fl ared type, 5.0(16.4)

PIPE LENGTH RANGE m (ft) 5 – 75 (16.4 – 246.1) – –

I/D&O/D HEIGHT DIRRERENCE m (ft) 15 (OD located lower)/30 (OD located higher) (49.2/98.4)

ADD GAS AMOUNT g/m (oz/ft) 50 (537.6)

PIPE LENGTH FOR ADDITIONAL GAS m (ft) 30 (98.4)

*1:In case it is necessary to indicate the air fl ow volume in (l/s), the value in (m3/min.) shall be multiplied by 16.7 and rounded down the decimal point.

*2

:

If the EUROVENT Certifi ed models can be operated under the “extra-low” temperature condition, -7°C dry bulb and -8°C wet–bulb temperatures with rated voltage

230 V shall be used.

*3:Network Impedance shall be applicable for EUROPE and CHINA models.

*4:The annual consumption is calculated by multiplying the input power at 230 V (400 V) by an average of 500 hours per year in cooling mode.

*5:EER and COP classification is at 230 V (400 V) only in accordance with EU directive 2002/31/EC.

*6

:

SEER and SCOP classification is at 230V (400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Other fiche data indicates in an attached sheet.

Sec1.indb14Sec1.indb14 2012/03/0717:29:572012/03/0717:29:57

1-15

1

1-2. Dimensional Data

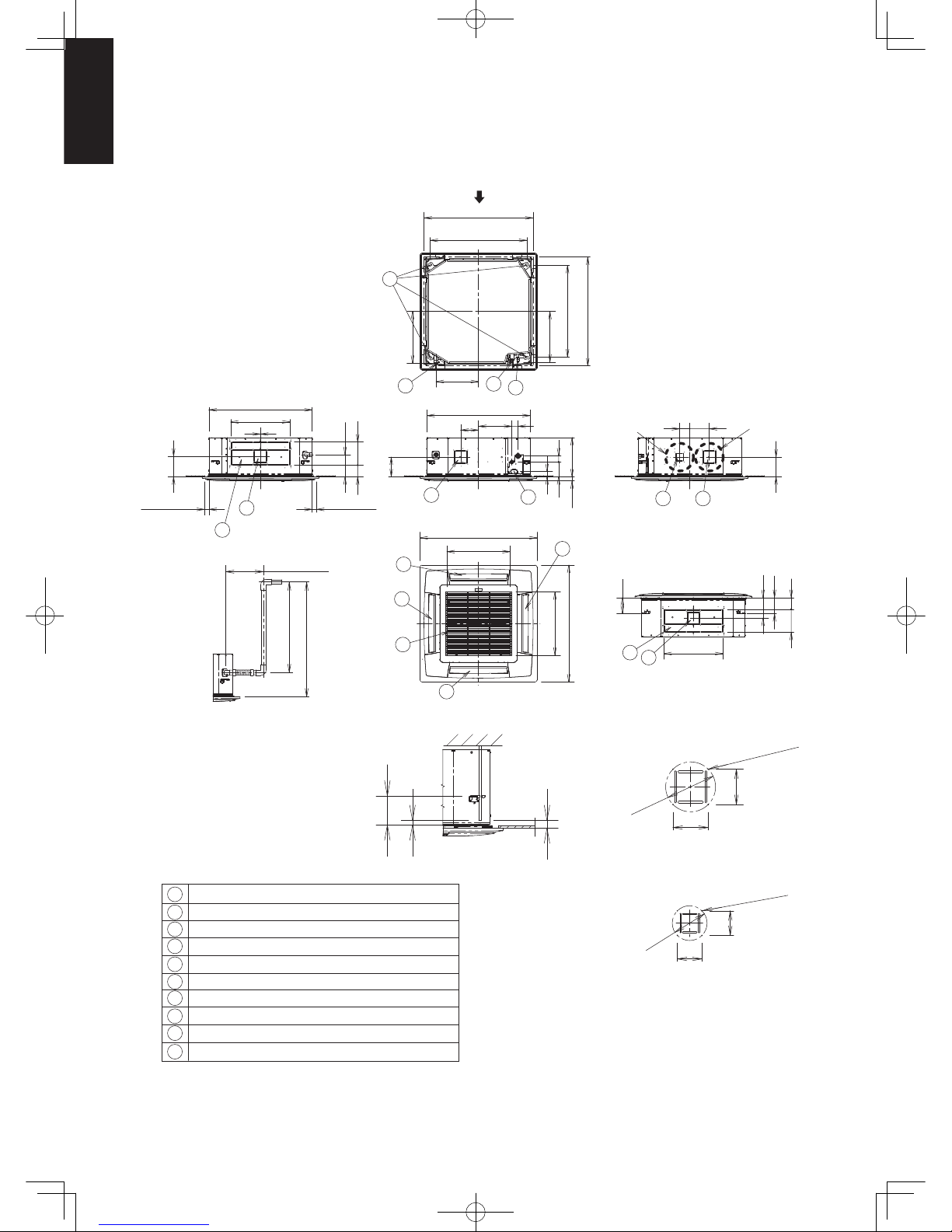

(A) Indoor Units: S-60PU1R5 / 71PU1R5

1

2

3

4

5

6

7

8

9

10

Air intake

Discharge outlet

Refrigerant tubing (liquid tube) ø9.52 (flared)

Refrigerant tubing (gas tube) ø15.88 (flared)

Drain tube connection port VP25 (outer dia. ø32)

Power supply port

Discharge duct connection port (ø150)

Vaporization-type humidifier (optional) installation area

Suspension bolt hole (4-12×30 elongated hole)

Fresh air intake duct connection port (ø100) *

345

9

5

3

4

7

7

8

6

2

2

2

2

1

10

7

7

8

421

(411)

745

(Suspension bolt pitch)

860~910

(Ceiling opening dimensions)

160

33.5

50121

42

840

50

271

145

160

16082

unit: mm

130

480

130

167

480

2

840

167

124

514

950

515

950

95

124

95

180

30

18

118

256

115

115

80

80

* Necessary to provide optional air intake kit.

<Filter dimension>

520 × 520 × 16

The length of the suspension bolts

should be selected so that there is

a gap of 30 mm or more below the

lower surface of the ceiling (18 mm

or more below the lower surface of

the main unit), as shown in the

figure at right. If the suspension

bolt is too long, it will contact

the ceiling panel and the unit

cannot be installed.

Raise dimension of drain tube

Detailed view Z

Detailed view Y

View X

X

ZY

860~910

786

(Ceiling opening dimensions)

(Suspension bolt pitch)

Less than 35

Less than 300

Less than 670

Less than 850

Less than 35

4 - ø3 burring hole

4 - ø3 burring hole

ø16

2

ø113

Sec1.indb15Sec1.indb15 2012/03/0717:29:572012/03/0717:29:57

1-16

1

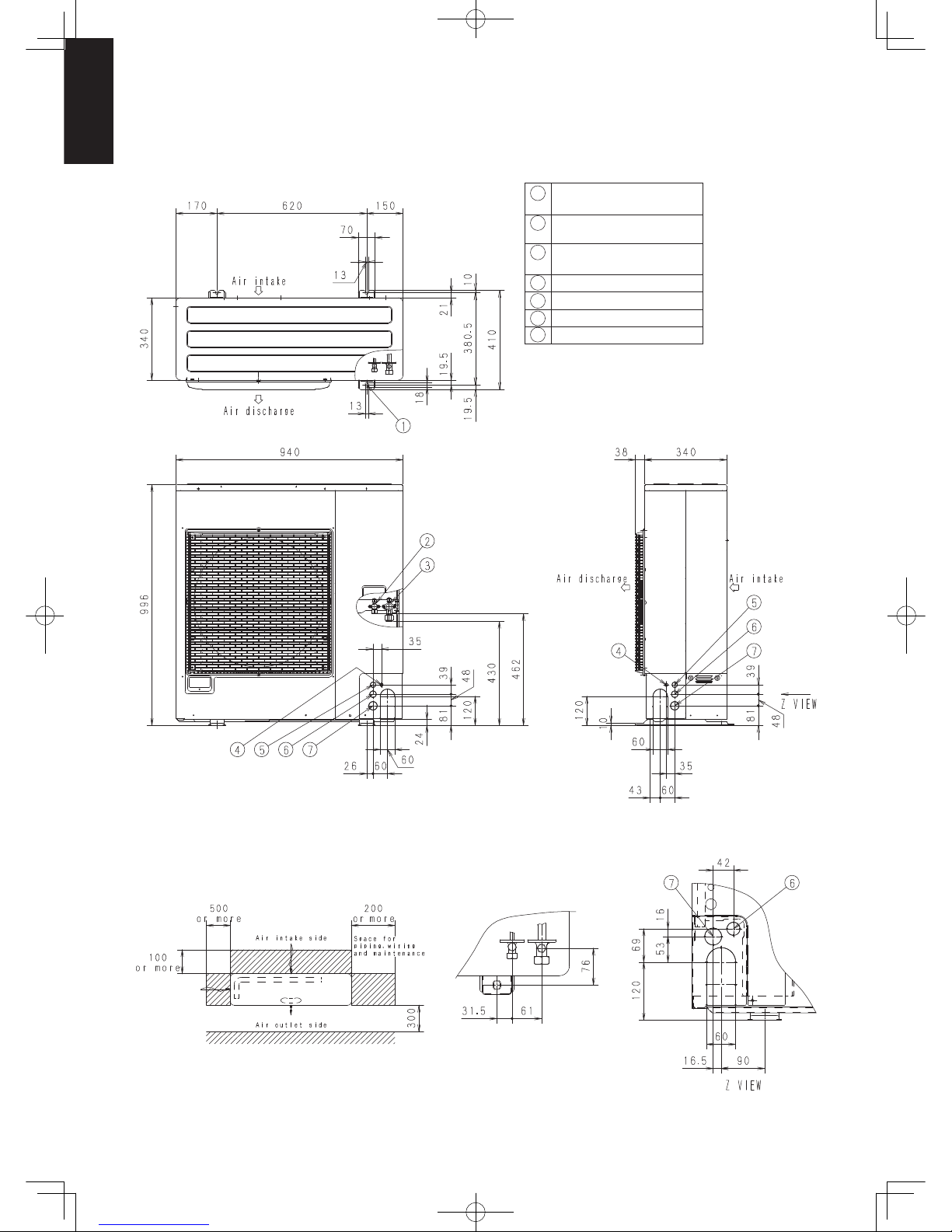

(A) Indoor Units: S-100PU1R5 / 125PU1R5 / 140PU1R5

unit: mm

30

18

118

187

2

480

840

167

187

180

319

95

80

80

1

2

3

4

5

6

7

8

9

10

Air intake

Discharge outlet

Refrigerant tubing (liquid tube) ø9.52 (flared)

Refrigerant tubing (gas tube) ø15.88 (flared)

Drain tube connection port VP25 (outer dia. ø32)

Power supply port

Discharge duct connection port (ø150)

Vaporization-type humidifier (optional) installation area

Suspension bolt hole (4-12×30 elongated hole)

Fresh air intake duct connection port (ø100) *

* Necessary to provide optional air intake kit.

<Filter dimension>

520 × 520 × 16

115

115

Detailed view Z

Detailed view Y

4 - ø3 burring hole

4 - ø3 burring hole

ø162

ø113

The length of the suspension bolts

should be selected so that there is

a gap of 30 mm or more below the

lower surface of the ceiling (18 mm

or more below the lower surface of

the main unit), as shown in the

figure at right. If the suspension

bolt is too long, it will contact

the ceiling panel and the unit

cannot be installed.

7

8

130

480

130

167

95

View X

Less than 300

Less than 670

Less than 850

2

2

2

1

514

950

515

950

2

X

10

7

160

16082

ZY

7

6

160

33.5

50

121

42

840

50

271

145

7

8

Less than 35Less than 35

345

9

5

3

4

421

(411)

745

(Suspension bolt pitch)

860~910

(Ceiling opening dimensions)

860~910

786

(Ceiling opening dimensions)

(Suspension bolt pitch)

1-2. Dimensional Data

Sec1.indb16Sec1.indb16 2012/03/0717:29:572012/03/0717:29:57

1-17

1

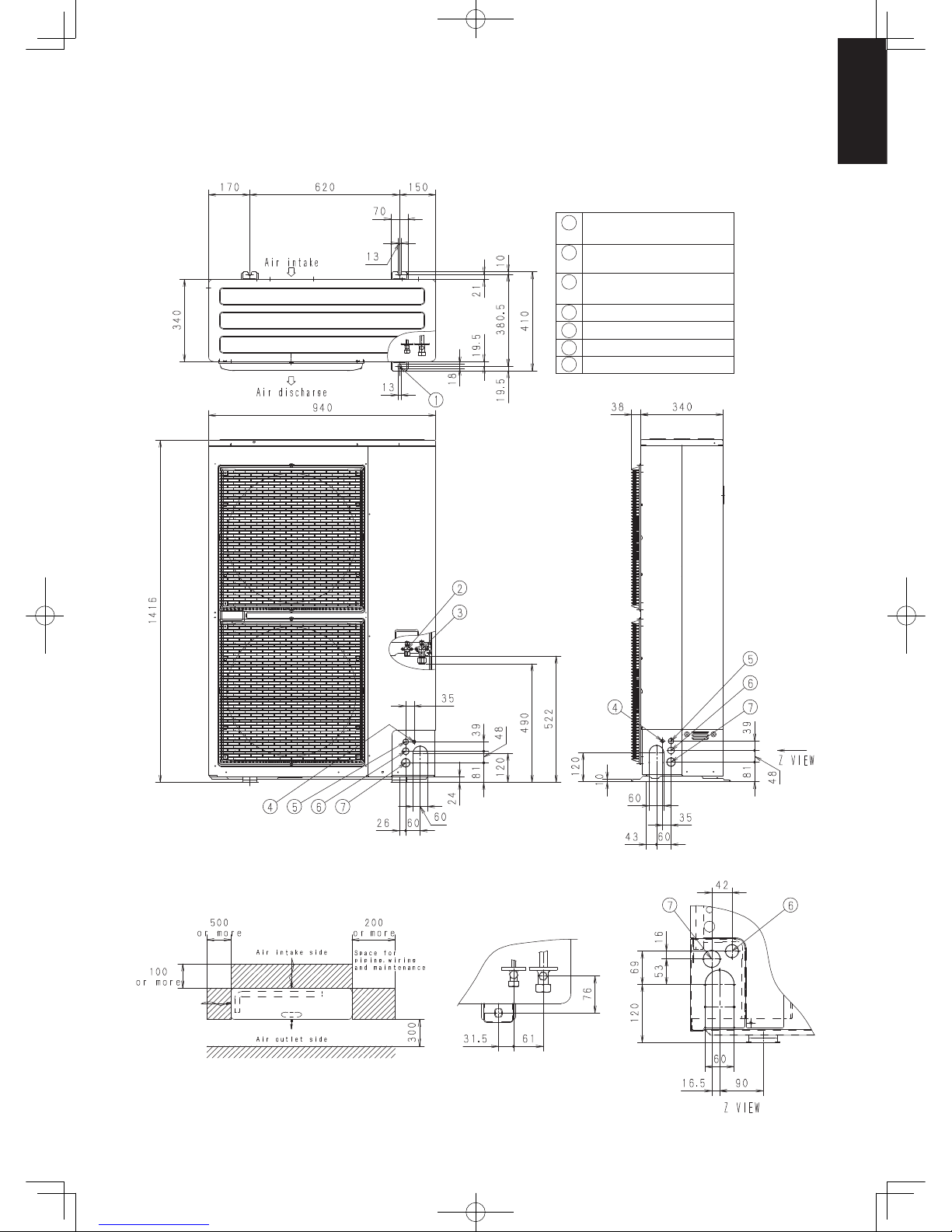

1-2. Dimensional Data

(A) Indoor Units: Ducted Type

S-60PE1R5 / S-71PE1R5 / S-100PE1R5 / S-125PE1R5 / S-140PE1R5

POSITION OF SUSPENSION BOLT

S-60PE1R5 1060

1060

110 0

110 0

540

540

700

unit : mm

700

S-71PE1R5

S-100PE1R5

S-125PE1R5

S-140PE1R5

S-60PE1R5

TYPE

130

195

33.1

35.7

290

360

118

ABCD

unit : mm

50

260 38.2 430 1215

S-71PE1R5

S-100PE1R5

S-125PE1R5

S-140PE1R5

Sec1.indb17Sec1.indb17 2012/03/0717:29:572012/03/0717:29:57

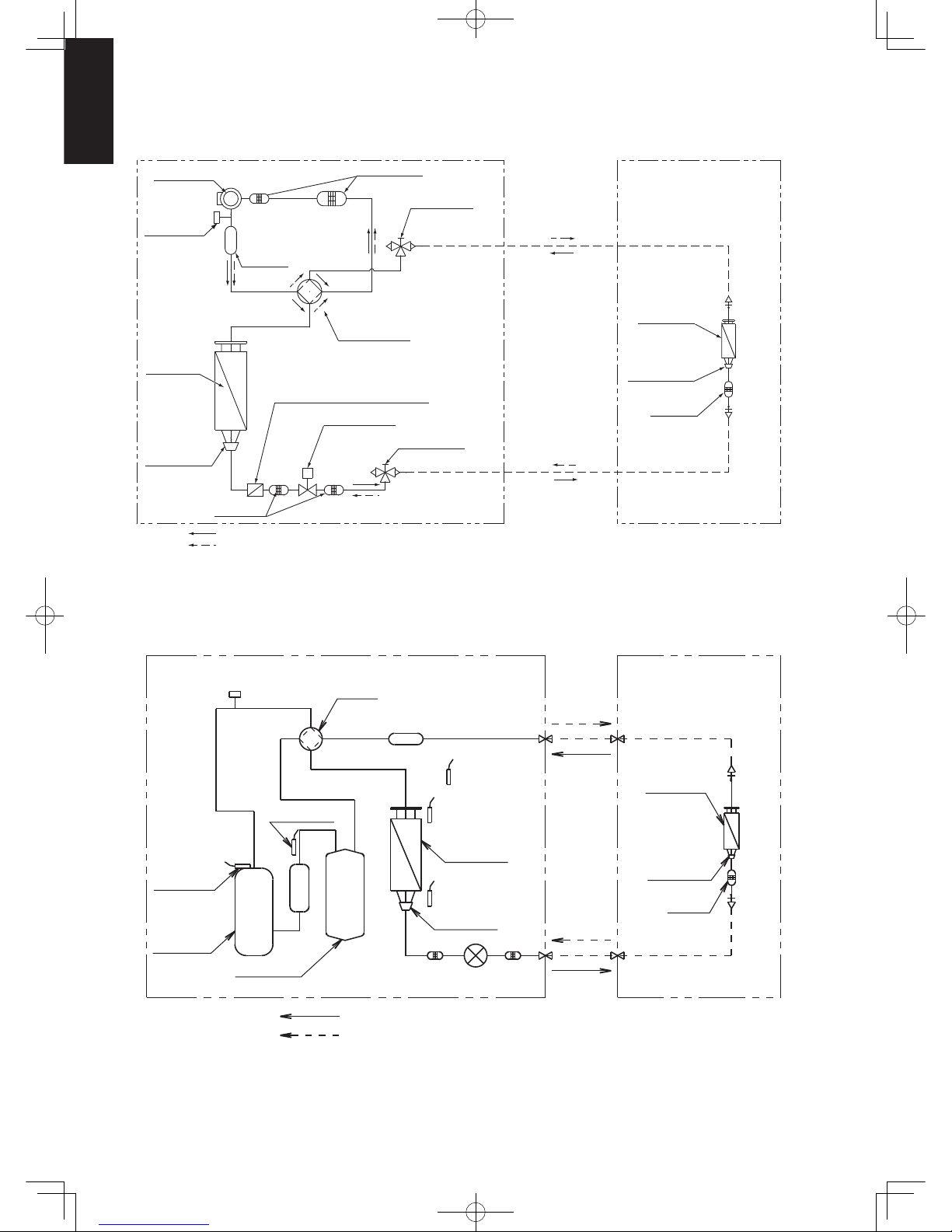

1-18

1

1-2. Dimensional Data

(B) Outdoor Units: U-60PE1R5 / U-71PE1R5

1

2

3

4

5

6

7

Mounting hole (4-R6.5),

anchor bolt: M10

Refrigerant piping (liquid pipe),

flared connection (ø9.52)

Refrigerant piping (gas pipe),

flared connection (ø15.88)