panasonic PV-DV100, PV-DV200, PV-DV400, PV-DV600, PV-DAC10 Service Manual

ORDER NO. MKE0001400C1

Digital Video Camcorder

TM

Mini

Models:PV-DV100/ PV-DV200

PV-DV400/ PV-DV600

ITEM SPECIFICATION 1 2 3 4

Power

Source

Power

Consumption

Video Signal

Video

Recording

System

Audio

Pick-Up

System and

Device

Lens

1. PV-DV100

2. PV-DV200

3. PV-DV400

4. PV-DV600

Digital Video Camera: 7.2 V DC (Battery)

AC Adaptor: 110/120/220/240 V AC, 50/60 Hz

Battery: Lithium-Ion Type DC 7.2 V

Digital Video Camera: 7.2 V DC 6.5 W (Max. 9.5 W)

AC Adaptor: 18 W

EIA Standard (525 lines, 60 fields) NTSC color signal

2 rotary heads. helical scanning system

12 bit (32 kHz) 4 tracks

16 bit (48 kHz) 2 tracks

One integral color filter Charge Coupled Device (CCD)

18:1 zoom lens, F1:1.6 with auto iris control

Focal length: 3.9 mm-70.2 mm

Power zoom function

Lens filter diameter: 49 mm

7.8 V DC (AC Adaptor)

1 W (when not in use.)

R

PV-DV100

PV-DV200

PV-DV400

PV-DV600

AC Adaptor

PV -DAC10

Model: PV-DAC10

ITEM SPECIFICATION 1234

Viewfinder

LCD Monitor

Minimum

Illumination

Required

Operating

Condition

Weight

Dimensions

Designs and specifications are subject to change without notice.

10.2 mm (0.4 inch) Electronic Viewfinder ––

11.2 mm (0.44 inch) Liquid Crystal Electronic Viewfinder – –

63.5 mm (2.5 inch) Liquid Crystal Display ––

76.2 mm (3.0 inch) Liquid Crystal Display – –

5 lx (F1:1.6) 0.5 footcandles

0 lx (IR Filter ON) – –

0 °C-40 °C (32 °F-104 °F) (Temperature)

10 %-75 % (Humidity)

Digital Video Camera: 0.7 kg (1.54 lbs.) –––

0.71 kg (1.57 lbs.) – ––

0.68 kg (1.5 lbs.) – – –

0.69 kg (1.52 lbs.) – – –

AC Adaptor: 0.18 kg (0.4 lbs.)

Digital Video Camera:

85 mm x 107.5 mm x 188 mm (W x H x D) ––

(3-3/8 inch x 4-1/4 inch x 7-3/8 inch)

85 mm x 107.5 mm x 163 mm (W x H x D) – –

(3-3/8 inch x 4-1/4 inch x 6-3/8 inch)

AC Adaptor: 103 mm x 40 mm x 79 mm (W x H x D)

(4 inch x 1-5/8 inch x 3-1/8 inch)

Weight and dimensions shown are approximate.

R

© 2000 Matsushita-Kotobuki Electronics Industries LTD.

All rights reserved. Unauthorized copying and distribution

is a violation of law.

! WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

Use Marks shown in the chart below to distinguish the

different models included in this Service Manual.

MODEL MARK

PV-DV100 A

PV-DV200 B

PV-DV400 C

PV-DV600 D

NOT USED Z

TABLE OF CONTENTS

SAFETY PRECAUTIONS................................................ 1-1

PREVENTION OF ESD TO ES DEVICES....................... 1-1

X-RADIATION (MODEL: A, B)........................................ 1-2

SERVICE NOTES ............................................................ 1-3

IC, Transistor and Chip Part Information .................... 1-12

DISASSEMBLY/ASSEMBLY PROCEDURES

Cabinet Section ............................................................ 2-1

Mechanism Section .................................................... 2-17

ADJUSTMENT PROCEDURES

Service Fixtures & Tools............................................... 3-1

Electrical Adjustment .................................................... 3-3

Tape Path Alignment with L.I.S.T.A............................ 3-12

SCHEMATIC DIAGRAMS

Schematic Diagram

and Circuit Board Layout Notes ................................ 4-1

Main I (Overall) Schematic Diagram............................. 4-2

Main II (Control) Schematic Diagram ........................... 4-3

Main III (Camera Signal Process)

Schematic Diagram (A) ............................................. 4-4

Main III (Camera Signal Process)

Schematic Diagram (B, C, D) .................................... 4-5

Main IV (Video I) Schematic Diagram .......................... 4-6

Main V (Video II) Schematic Diagram .......................... 4-7

Main VI (Audio) Schematic Diagram ............................ 4-8

Main VII (Drive) Schematic Diagram ............................ 4-9

Main VIII (Sub Power) Schematic Diagram ................ 4-11

Jack Schematic Diagram............................................ 4-12

S-Jack Schematic Diagram ........................................ 4-12

Head Amp Schematic Diagram .................................. 4-13

Analog Schematic Diagram (D) .................................. 4-14

Power Schematic Diagram ......................................... 4-15

Microphone Unit/ Front Schematic Diagram............... 4-16

CCD Schematic Diagram............................................ 4-17

EVF Schematic Diagram (A, B) .................................. 4-18

Color EVF A/ B Schematic Diagram (C, D) ................ 4-19

LCD Schematic Diagram ............................................ 4-20

Interconnection Schematic Diagram........................... 4-21

Signal Waveform ........................................................ 4-22

Voltage Chart.............................................................. 4-23

CIRCUIT BOARD LAYOUT

Main C.B.A. (A)............................................................. 5-1

Main C.B.A. (B, C, D).................................................... 5-5

S-Jack C.B.A. ............................................................... 5-9

Head Amp C.B.A. ......................................................... 5-9

Jack C.B.A. ................................................................. 5-10

Microphone Unit/ Front C.B.A..................................... 5-10

Power C.B.A. .............................................................. 5-11

Analog C.B.A. (D) ....................................................... 5-12

EVF C.B.A. (A, B) ....................................................... 5-13

Color EVF A C.B.A. (C, D).......................................... 5-14

Color EVF B C.B.A. (C, D).......................................... 5-14

CCD C.B.A.................................................................. 5-14

LCD C.B.A. ................................................................. 5-15

BLOCK DIAGRAMS

CCD Drive Block Diagram ............................................ 6-1

Video Signal Process I Block Diagram ......................... 6-2

Video Signal Process II Block Diagram ........................ 6-4

Analog Video I/F Block Diagram................................... 6-5

Audio Signal Process Block Diagram ........................... 6-6

System Control Block Diagram..................................... 6-7

Servo Block Diagram .................................................... 6-9

AF Block Diagram....................................................... 6-10

LCD Block Diagram .................................................... 6-12

EVF Block Diagram .................................................... 6-13

Color EVF Block Diagram........................................... 6-14

Power Supply Block Diagram ..................................... 6-15

Troubleshooting Hints................................................. 6-16

EXPLODED VIEWS

1. Main Parts Section ................................................... 7-1

2. Side Case L Section ................................................. 7-2

3. Top Case and EVF Section (A, B) ............................ 7-3

3. Top Case and Color EVF Section (C, D) .................. 7-4

4. Lens Section ............................................................. 7-5

5. Side Case R and LCD Section ................................. 7-6

6. Front Case Section................................................... 7-7

7. Mechanism Section .................................................. 7-8

8. Packing Parts and Accessories Section ................... 7-9

REPLACEMENT PARTS LISTS

Replacement Notes ...................................................... 8-1

Mechanical Replacement Parts List ............................. 8-2

Electrical Replacement Parts List ................................. 8-5

AC ADAPTOR SECTION

DISASSEMBLY/ASSEMBLY PROCEDURES................ 9-1

ELECTRICAL ADJUSTMENT......................................... 9-2

SCHEMATIC DIAGRAM

AC Adaptor Schematic Diagram................................... 9-3

CIRCUIT BOARD LAYOUT

AC Adaptor C.B.A......................................................... 9-4

BLOCK DIAGRAM

AC Adaptor Block Diagram........................................... 9-5

EXPLODED VIEWS

1. AC Adaptor Section .................................................. 9-6

2. Packing Parts and Accessories Section ................... 9-7

REPLACEMENT PARTS LISTS

Replacement Notes ...................................................... 9-8

Mechanical Replacement Parts List ............................. 9-8

Electrical Replacement Parts List ................................. 9-9

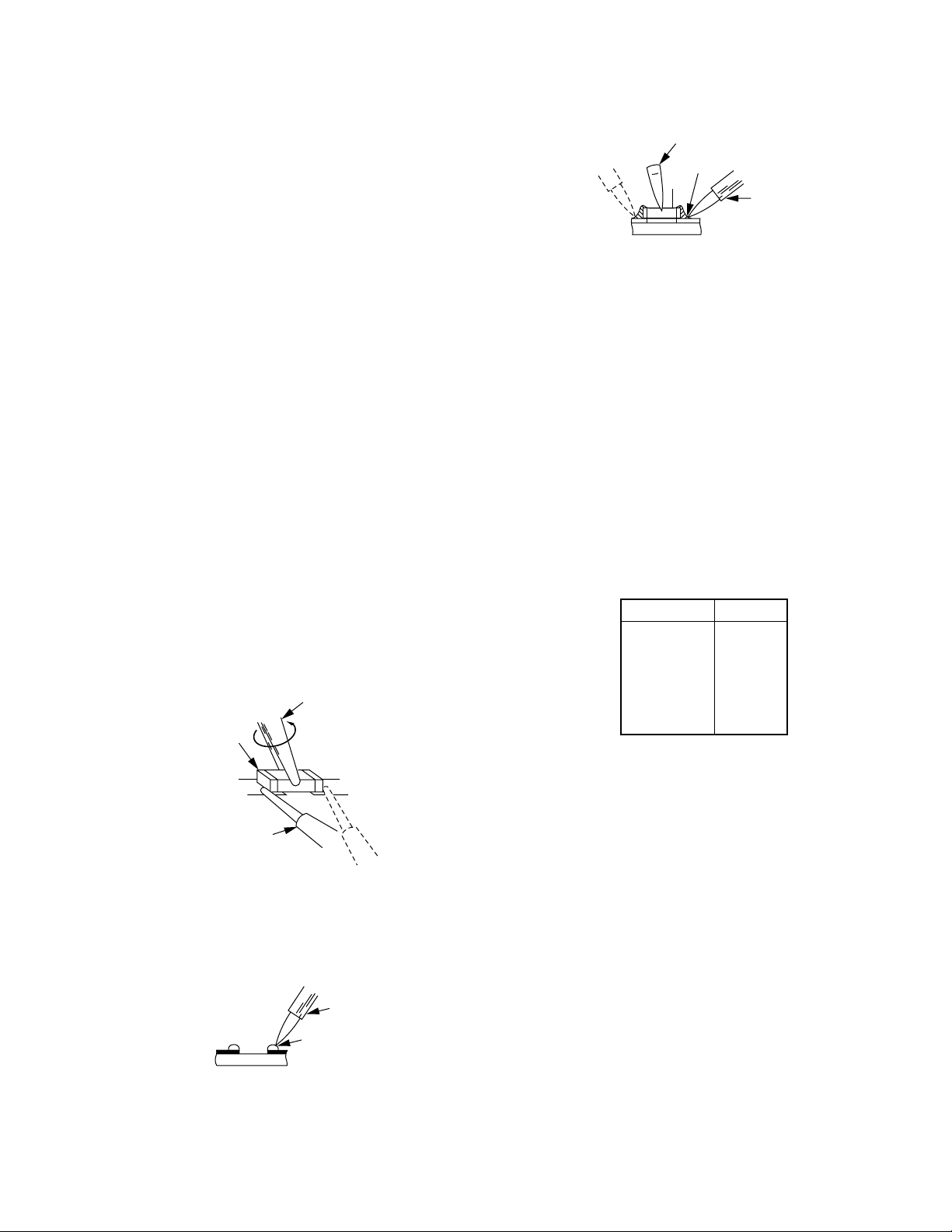

SAFETY PRECAUTIONS

EARTH GROUND

AC VOLTMETER

Hot-Check Circuit

TO

APPLIANCES

EXPOSED

METAL PARTS

GENERAL GUIDELINES

1. IMPORTANT SAFETY NOTICE

2. An Isolation Transformer should always be used during the

3. When servicing, observe the original lead dress. If a

4. After servicing, see to it that all the protective devices

5. After servicing, make the following leakage current

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two

2. Measure the resistance value, with an ohmmeter, between

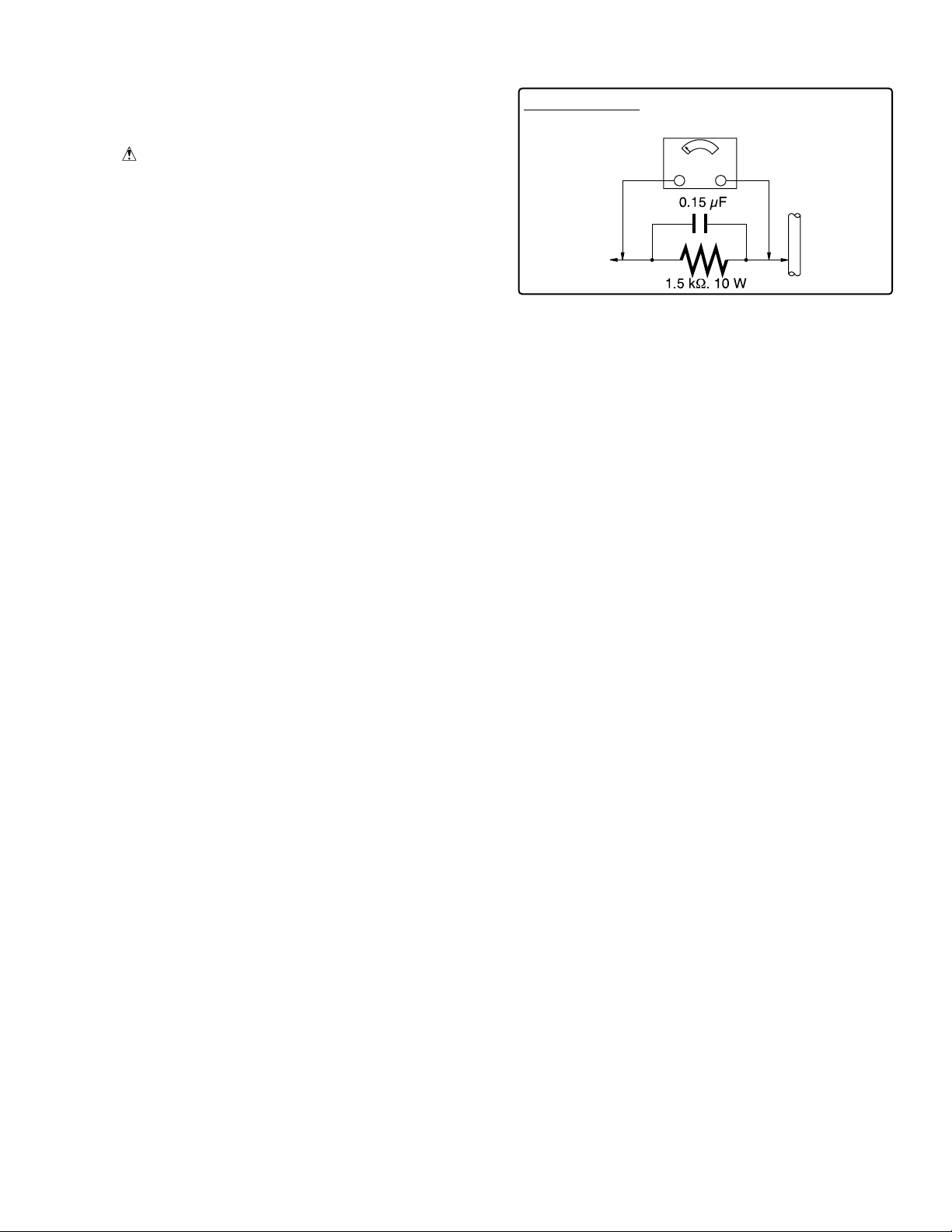

LEAKAGE CURRENT HOT CHECK

(See figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 µF

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

4. Check each exposed metallic part, and measure the volt-

5. Reverse the AC plug in the AC outlet and repeat each of the

6. The potential at any point should not exceed 0.75 V RMS.

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential

that these critical parts should be replaced with

manufacturer's specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

servicing of AC Adaptor whose chassis is not isolated from

the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents resulting

in personal injury from electrical shocks. It will also protect

AC Adaptor from being damaged by accidental shorting

that may occur during servicing.

short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

such as insulation barriers, insulation papers shields are

properly installed.

checks to prevent the customer from being exposed to

shock hazards.

prongs on the plug.

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1 MΩ and 5.2 MΩ. When the exposed metal does not have

a return path to the chassis, the reading must be infinity.

isolation transformer for this check.

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in figure 1.

measure the potential across the resistor.

age at each point.

above measurements.

A leakage current tester (Simpson Model 229 or equiva-

lent) may be used to make the hot checks, leakage current

must not exceed 1/2 mA. In case a measurement is outside

of the limits specified, there is a possibility of a shock

hazard, and the equipment should be repaired and rechecked before it is returned to the customer.

Figure. 1

PREVENTION OF ELECTRO

STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY

SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

ESD on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified as "antistatic (ESD protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity (ESD) sufficient to damage an ES device).

1-1

X-RADIATION (MODEL: A,

B)

WARNING :

1. The potential source of X-Radiation in EVF sets is the High

Voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure that

jig is capable of handling 10 kV without causing X-Radiation.

NOTE :

It is important to use an accurate periodically calibrated

high voltage meter.

3. Measure the High Voltage. The meter (electrostatic type)

reading should indicate 2.2 kV±0.1 kV. If the meter indication

is out of tolerance, immediate service and correction is

required to prevent the possibility of premature component

failure. To prevent an X-Radiation possibility, it is essential

to use the specified picture tube.

1-2

SERVICE NOTES

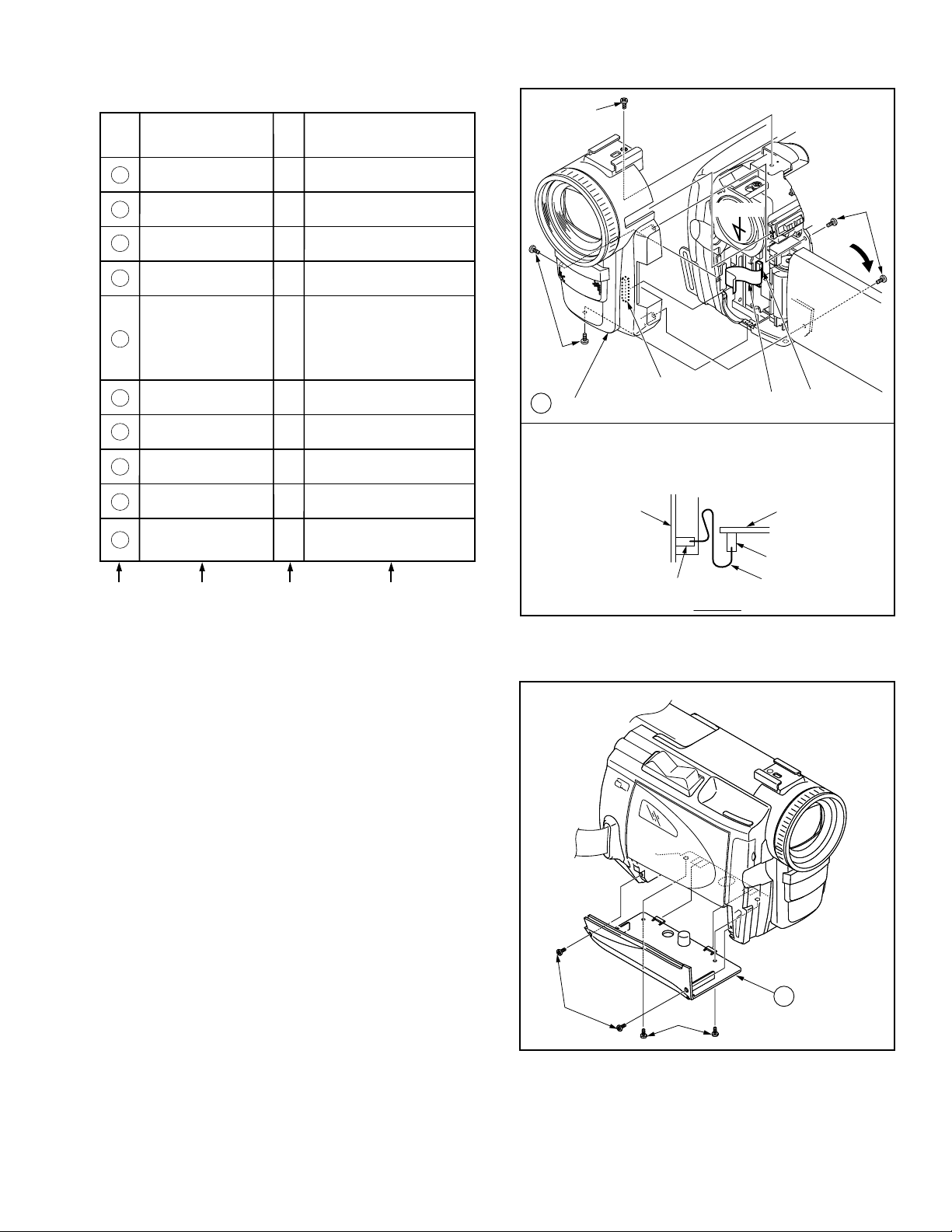

NO.

1

2

3

4

PART NUMBER

LSUA0028

LSUA0020

LSUA0019

LSUA0029

PART NAME

32Pin Extension Cable

20Pin Extension Cable

8Pin Extension Cable

40Pin Extension Cable

CONNECTION

FP301 on Main C.B.A. ~ CCD F.P.C. on Lens Unit

FP701 on Main C.B.A. ~ Lens F.P.C. on Lens Unit

FP1 on Main C.B.A. ~ Mechanism Sensor F.P.C. on Mechanism Chassis Ass'y

B2 on Main C.B.A. ~ B3501 on Analog C.B.A.

NO.

5

6

7

8

9

PART NUMBER

VUVS0015

LSUA0017

LSUA0016

LSUA0018

LSUA0020

PART NAME

28Pin Extension Cable

18Pin Extension Cable

10Pin Extension Cable

24Pin Extension Cable

20Pin Extension Cable

CONNECTION

FP7 on Main C.B.A. ~ LCD F.P.C.

FP4 on Main C.B.A. ~ Capstan F.P.C. on Mechanism Chassis Ass’y

FP3 on Main C.B.A. ~ Cylinder F.P.C. on Mechanism Chassis Ass’y

FP5 on Main C.B.A. ~ Head Amp F.P.C. on Mechanism Chassis Ass’y

FP2 on Main C.B.A. ~ Mechanism F.P.C. on Mechanism Chassis Ass’y

EXTENSION CABLES FOR SERVICE POSITION

Using the following Extension Cables (No.1 ~ No.4), place the unit as shown for check and service as shown in Fig. 1-1.

Extension Cables (No.5 ~ No.9) are used for improving serviceability as shown in Fig. 1-2. (They are not necessarily used.)

Note :

1. The LCD open/close SW. is for changing between LCD Display or EVF Display. When turning on LCD Display, place some paper

or tape, etc. on LCD open/close SW. so that this SW. stays ON.

2. Use a grounded ESD wrist strap while disassembling the Lens portion.

3. Use extreme care when unplugging or plugging in connectors.

Note: marked parts are supplied as service fixtures.

Lens Unit

Lens F.P.C.

20P

(LSUA0020)

Jack C.B.A.

Front C.B.A.

Note 1

LCD open/close SW.

LCD C.B.A.

Tape

CCD F.P.C.

40P

(LSUA0029)

32P

(LSUA0028)

FP701

FP6

FP9

FP10

B2

FP2

Top F.P.C.

FP1

FP5

Main

C.B.A.

Top Operation Unit

Slide

Eject Switch

FP8

FP7

FP3

FP302

FP4

8P

(LSUA0019)

Mechanism Chassis Ass’y

FP301

B1

Power C.B.A.

Zoom Switch Unit

EVF Unit

(Model: A, B)

Or,

Color EVF Unit

(Model: C, D)

MMC Connector Unit

(Model: B, C, D)

Mechanism Sensor F.P.C.

B3501

Fig. 1-1

1-3

Analog C.B.A.

(Model: D)

Note: marked parts are supplied as service fixtures.

Lens Unit

Lens F.P.C.

20P

(LSUA0020)

32P

(LSUA0028)

24P

(LSUA0018)

28P

(VUVS0015)

20P

(LSUA0020)

Jack C.B.A.

Front C.B.A.

FP6

FP10

B2

FP2

40P

(LSUA0029)

CCD F.P.C.

FP701

FP9

Top F.P.C.

Main

C.B.A.

FP1

FP3

FP5

Eject Switch

Slide

FP4

18P

(LSUA0017)

Top Operation Unit

FP8

FP301

FP7

B1

Power C.B.A.

FP302

Zoom Switch Unit

8P

(LSUA0019)

10P

(LSUA0016)

EVF Unit

(Model: A, B)

Or,

Color EVF Unit

(Model: C, D)

MMC Connector

Unit

(Model: B, C, D)

LCD C.B.A.

LCD F.P.C.

Note 1

LCD open/close SW.

Tape

Head Amp F.P.C.

Cylinder F.P.C.

Mechanism F.P.C.

B3501

Analog C.B.A.

(Model: D)

Fig. 1-2

Head Amp C.B.A.

Mechanism Sensor F.P.C.

Capstan F.P.C.

Mechanism Chassis Ass’y

1-4

INTERCONNECTION OF EXTENSION CABLES

Lens Unit

CCD F.P.C.

Lens F.P.C.

Capstan F.P.C.

Cylinder F.P.C.

Mechanism Sensor F.P.C.

Head Amp F.P.C.

Head Amp C.B.A.

Mechanism

F.P.C.

LCD F.P.C.

LCD C.B.A.

Jack C.B.A.

Front C.B.A.

Mechanism Chassis Ass'y

Main C.B.A.

Power C.B.A.

Analog C.B.A.

(Model: D)

Eject Switch

FP8

B1

FP301

FP1

FP9

FP701

FP6

FP10

B3501

B2

FP2

FP5

FP3

FP4

FP7

FP302

20P

(LSUA0020)

32P

(LSUA0028)

18P

(LSUA0017)

10P

(LSUA0016)

8P

(LSUA0019)

20P

(LSUA0020)

40P

(LSUA0029)

24P

(LSUA0018)

28P

(VUVS0015)

Top F.P.C.

Top

Connector

Cable

Zoom Switch Unit

EVF Unit

(Model: A, B)

Color EVF Unit

(Model: C, D)

MMC Connector Unit

(Model: B, C, D)

Note:

marked parts are supplied as service fixtures.

Fig. 2

1-5

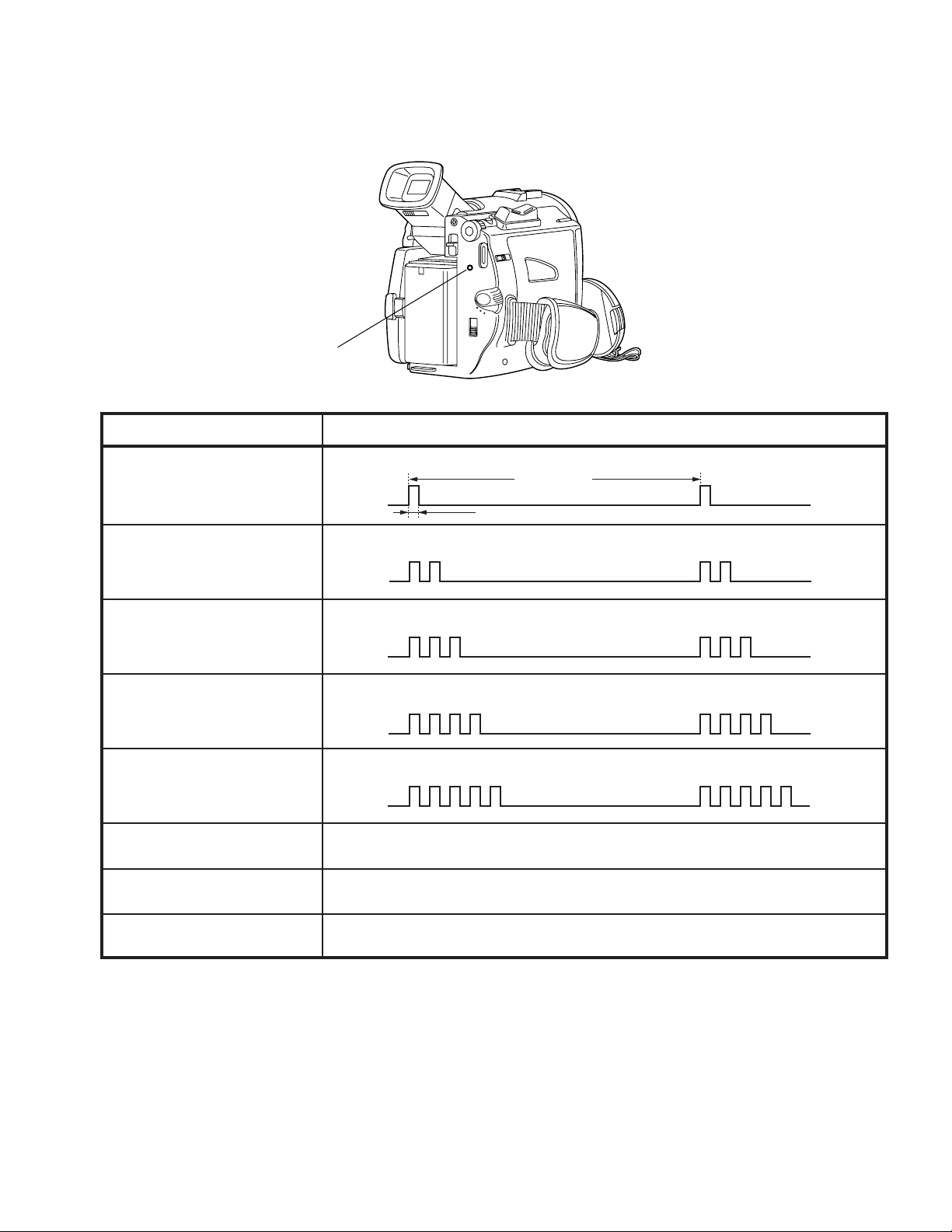

SIMPLIFIED FAULT FINDING DATA (SELF-DIAGNOSTIC SYSTEM)

When following conditions occur, the Power LED will flash according to the condition.

Power LED

CONDITION

T-Reel Lock

S-Reel Lock

Unloading Lock

Loading Lock

Cylinder Lock

Focus Motor Lock

POWER LED FLASHING TIMING & POWER OFF TIMING

After 1 minute flash, power will be turned off.

T = 2.56 sec

0.16 sec

After 1 minute flash, power will be turned off.

After 1 minute flash, power will be turned off.

After 1 minute flash, power will be turned off.

After 1 minute flash, power will be turned off.

Power LED flashes at 1 Hz timing.

Zoom Motor Lock

Dew Detection

Power LED flashes at 1 Hz timing.

After 18 seconds flash at 1 Hz timing, power will be turned off.

Fig. 3

1-6

SHORT JIG C.B.A.

DC Power Supply

(+3 VDC)

"a"

"b"

Loading

Motor

Loading

Posts

CAUTION:

Be sure to attach the Short JIG C.B.A. to protect the

microcontrollers (IC6001 and IC302) after servicing.

(1) Open the LCD Unit.

(2) Remove 2 Screws (A). Then open the Right Cover Unit.

(3) Install the Short JIG C.B.A. to Connector B3.

LCD Unit

B3

direction

Screws (A)

Right Cover

Unit

Fig. 4

Short JIG C.B.A.

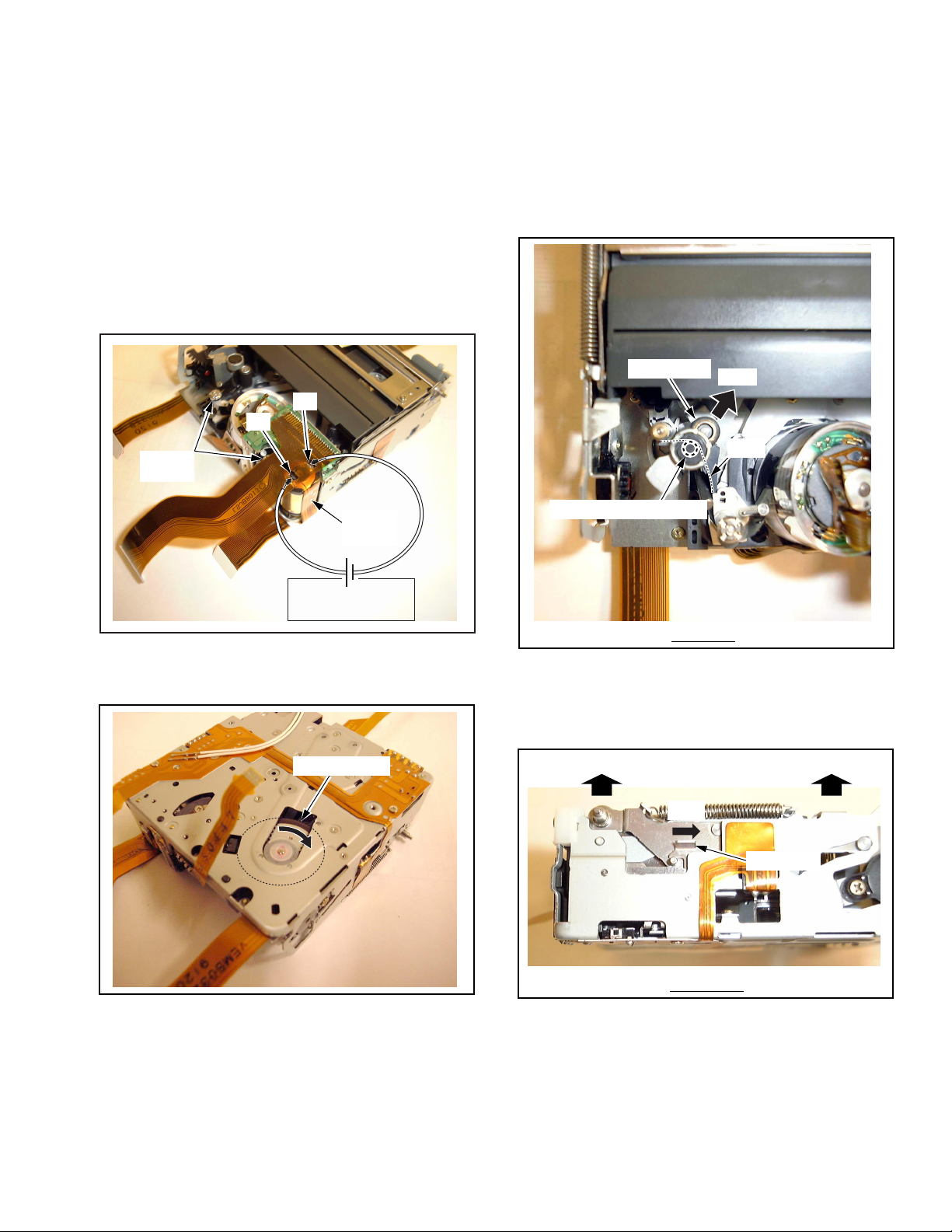

METHOD FOR LOADING/UNLOADING OF

MECHANISM

CAUTION:

If loading does not start after DC Power Supply is applied,

DO NOT continue to applying DC Power Supply.

Apply +3 VDC Power Supply to the Loading Motor terminals.

Loading:

DC - to Portion "a," DC + to Portion "b"

Unloading:

DC + to Portion "a," DC - to Portion "b"

Fig. 5

1-7

HOW TO REMOVE A JAMMED TAPE

Electrical Method

CAUTION:

If loading does not start after DC Power Supply is applied,

DO NOT continue to applying DC Power Supply. In this

case, perform in Manual Method.

Remove a jammed tape as follows:

(1) Remove the Cabinet Parts. Refer to "CABINET SECTION"

in DISASSEMBLY/ASSEMBLY PROCEDURES.

(2) Apply +3 V DC Power Supply to the Loading Motor terminals.

(3) When the Loading Posts reach the fully unloaded position,

remove the Power Supply immediately.

Note:

DO NOT let eject the Garage Unit. If the Garage Unit is in

the up position, the DV Cassette Tape may be damaged.

Manual Method

(1) Remove the Cabinet Parts. Refer to "CABINET SECTION"

in DISASSEMBLY/ASSEMBLY PROCEDURES.

(2) Remove the Head Amp C.B.A. from Mechanism. Refer to

"MECHANISM SECTION" in DISASSEMBLY/ASSEMBLY

PROCEDURES.

(3) Move the Pinch Roller Unit out so that the Pinch Roller is

separated from the Capstan Rotor Unit shaft. Then, remove

the tape from the tape path and all posts.

"b"

"a"

Loading

Posts

Loading

Motor

DC Power Supply

(+3 VDC)

Fig. 6-1

(4) Rewind the tape into the DV Cassette Tape by turning the

Capstan Rotor clockwise.

Capstan Rotor

Pinch Roller

Capstan Rotor Unit shaft

Top View

(4) Rewind the tape into the DV Cassette Tape by turning the

Capstan Rotor clockwise.

(5) Eject the DV Cassette Tape by sliding the Lock Lever.

Eject Eject

Slide

Move

Tape

Fig. 6-3

Fig. 6-2

(5) Eject the DV Cassette Tape by applying +3 VDC Power

Supply again.

(6) Take out the DV Cassette Tape from the Garage Unit.

Lock Lever

Side View

Fig. 6-4

(6) Take out the DV Cassette Tape from the Garage Unit.

1-8

EEPROM DATA

CAUTION:

Be sure to save the EEPROM data using PC-EVR

Adjustment Program before service and adjustment in

order to make sure to avoid an accidental data loss, etc. as

follows.

There are two EEPROM in this unit.

EEPROM IC

C.B.A.s EEPROM IC Ref. No.

Main C.B.A. (Camera)

Main C.B.A. (Video)

1 How to save the EEPROM data to your PC

1. How to save the EEPROM data for Camera Circuit

1) Start up the PC-EVR Adjustment Program.

2) Select “3. Check [Camera].” in Main menu, and then

press “Enter” key.

3) Select “3. Read (Save)/Write AII EEPROM data” in

Camera check menu, and then press “Enter” key.

4) Select “3. Save all data of EEPROM” in Read (Save)/

Write All EEPROM data menu, and then press “Enter”

key.

5) Input the File name, and then press the “Enter” key. The

data of EEPROM IC will be stored to your PC.

2. How to save the EEPROM data for Video Circuit

1) Start up the PC-EVR Adjustment Program.

2) Select “2. Check [Video].” in Main menu, and then press

“Enter” key.

3) Select “3. Read (Save)/Write All EEPROM data” in

Video check menu, and then press “Enter” key.

4) Select “3. Save all EEPROM data” in Read (Save)/

Write All EEPROM data menu, and then press “Enter”

key.

5) Input the File name, and then press “Enter” key. The

data of EEPROM IC will be stored to your PC.

2 How to write the EEPROM data which was

stored in your PC to EEPROM IC

When it becomes impossible to adjust during service and

adjustment, write the EEPROM data which was stored in

your PC to EEPROM IC as follows. And readjust the

camcorder.

1. How to write the EEPROM data which was stored

for Camera circuit

1) Start up the PC-EVR Adjustment Program.

2) Select “3. Check [Camera].” in Main menu, and then

press “Enter” key.

3) Select “3. Read (Save)/Write AII EEPROM data” in

Camera check menu, and then press “Enter” key.

4) Select “4. Data write using stored file” in Read [Save]/

Write All EEPROM data menu, and then press “Enter”

key.

5) Input the saved file name, and then press “Enter” key.

The data will be written in EEPROM IC.

2. How to write the EEPROM data which was stored

for Video circuit

1) Start up the PC-EVR Adjustment Program.

2) Select “2. Check [Video].” in Main menu, and then press

“Enter” key.

3) Select “3. Read (Save)/Write All EEPROM data” in

Video check menu, and then press “Enter” key.

4) Select “4. Writing from stored data files” in Read (Save)/

Write All EEPROM data menu, and then press “Enter”

key.

5) Input the saved file name, and then press “Enter” key.

The data will be written in EEPROM IC.

IC301

IC6009

3 How to initialize the EEPROM IC

When the EEPROM IC or Main C.B.A. is replaced, be sure

to write the initial data to EEPROM IC. And adjust the

camcorder.

1) Start up the PC-EVR Adjustment Program.

2) Select “3. Check [Camera].” in Main menu, and then

press “Enter” key.

3) Select “3. Read (Save)/Write AII EEPROM data” in

Camera check menu, and then press “Enter” key.

4) Select “4. Data write using stored file” in Read (Save)/

Write All EEPROM data menu, and then press “Enter”

key. Input the saved file name, and then press “Enter”

key.

OR;

Select “5. Data write with initial data,” and then press

“Enter” key. And press “Enter” key once again.

5) Select “2. Check [Video].” in Main menu, and then press

“Enter” key.

6) Select “3. Read (Save)/Write All EEPROM data” in

Video check menu, and then press “Enter” key.

7) Select “4. Writing from stored data files.” in Read

(Save)/Write All EEPROM data menu, and then press

“Enter” key. Input the saved file name, and then press

“Enter” key.

OR;

Select “5. Writing of initial data,” and then press “Enter”

key. And press “Enter” key once again. Then, input ID

Number as follows.

4 How to input ID Number

The ID number is in the EEPROM.

There are two ways to write the data of EEPROM IC after

replacing Main C.B.A. as follows:

• Selecting “4. Writing from stored data files,” ID Number with

stored data file will be written automatically.

• Selecting “5. Writing of initial data,” ID Number needs to be

input. There are two methods, “a” or “b,” to input ID Number

as follows.

a When writing ID Number from the saved data which

is stored in 1-2:

1. Select “2. Check [Video].” in Main menu, and then press

“Enter” key.

2. Select “3. Read (Save)/Write All EEPROM data” in

Video check menu, and then press “Enter” key.

3. Select “6. Writing ID from stored file.” in Read (Save)/

Write All EEPROM data menu, and then press “Enter”

key. Input the saved file name, and then press “Enter”

key. ID Number will be written automatically.

b When the original ID information can not be read

because of destruction of EEPROM etc.:

1. Select “4. Adjust [Video].” in Main menu, and then press

“Enter” key.

2. Select “7. Write products ID” in Video adjustment menu,

and then press “Enter” key. ID Number will be written

automatically.

1-9

HOW TO USE THE DVC HEAD CLEANING TAPE / LSUQ0003

Please use the cleaning tape as described below.

Note: This cleaning tape has a total playback time of 45 minutes. Once used, it is not reusable.

1. Confirm the picture.

NG

2. Playback the cleaning tape for 20 seconds.

3. Confirm the picture again.

NG

4. Playback the cleaning tape for 20 seconds.

5. Confirm the picture again.

NG

6. Playback the cleaning tape for 20 seconds.

7. Confirm the picture again.

NG

8. Replace the Cylinder Unit

OK

The picture will look like this in case of clogged video head.

OK

OK

OK

Playback any normal DVC tape

for 20 minutes or over.

Fig. 7

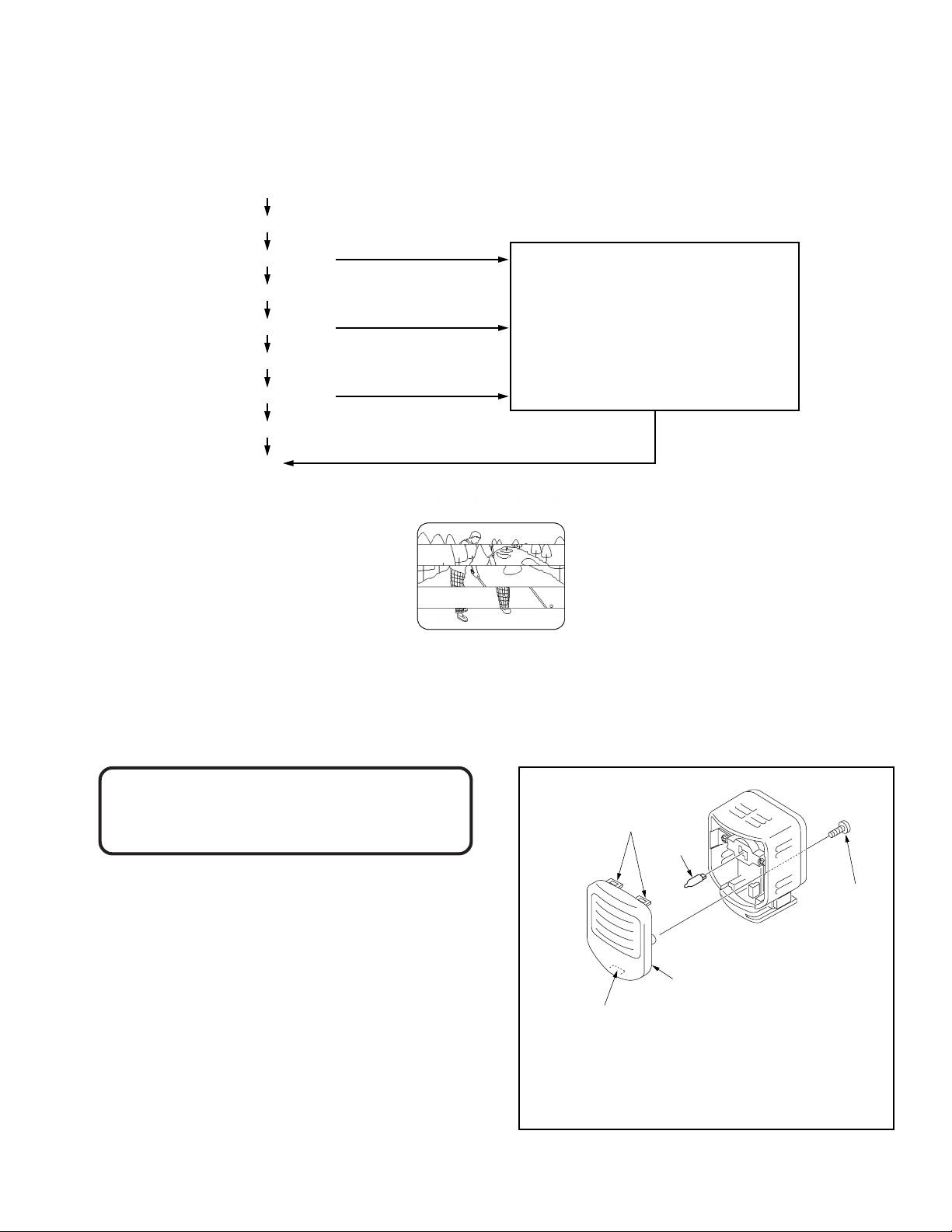

HOW TO REPLACE THE LAMP (VLLW0023) OF ENHANCEMENT LIGHT UNIT (MODEL: D)

DANGER:

To prevent possible burn hazard, disconnect this unit and

allow lamp to cool before replacing. Replace only with

VLLW0023 lamp, to reduce the risk of fire.

Note :

When installing the Lamp, do not touch the surface of

Lamp directly. Use a clean cloth or tissue to install the

Lamp.

Locking Tabs

Lamp

Screw

Light Case

Locking Tab

1-10

Fig. 8

REPLACEMENT PROCEDURE FOR

MODEL

PV-DV100

PV-DV200

PV-DV400

PV-DV600

NOT USED

A

B

C

D

Z

MARK

Note:

Refer to Item 3 of Schematic Diagram Notes of Schematic

Diagram and Circuit Board Layout Notes, for Mark "Z."

Tweezers

Soldering Iron

Solder

LEADLESS (CHIP) COMPONENT

The following procedures are recommended for the replacement

of the leadless components used in this Unit.

1. Preparation for replacement

a. Soldering Iron

Use a pencil-type soldering iron using less than 30

watts.

b. Solder

Eutectic Solder (Tin 63 %, Lead 37 %) is

recommended.

c. Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before

installation.

(130 °C ~ 150 °C, for about 2 minutes.)

Note:

a. Leadless component must not be reused after removal.

b. Excessive mechanical stress and rubbing of the

component electrode must be avoided.

2. Removing the leadless component

Grasp the leadless component body with tweezers and

alternately apply heat to both electrodes. When the solder

on both electrodes is melted, remove leadless component

with a twisting motion.

Note:

a. Do not attempt to lift the component off the board until

the component is completely disconnected from the

board by a twisting action. The leadless component is

attached to the PCB with glue. So carefully twist the

component when removing it so as not to break or

damage any fail under the component.

b. Take care not to break the copper foil on the printed

board.

b. Press the part downward with tweezers and solder both

electrodes as shown below.

Fig. 9-3

Note:

Do not glue the replacement leadless component to the

circuit board.

SPECIAL NOTE

All integrated circuits and many other semiconductor devices

are electrostatically sensitive and therefore require the special

handlings techniques described under the

"ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section

of this service manual.

MODEL NO. IDENTIFICATION MARK

Use Marks shown in the chart below to distinguish the different

models included in this Service Manual.

Tweezers

Chip

Soldering Iron

Fig. 9-1

3. Installation of the leadless component

a. Presolder the contact points of the circuit board.

Soldering Iron

Presolder

Fig. 9-2

1-11

IC, TRANSISTOR AND CHIP PART INFORMATION

B

E

C

C

E

B

R1

R2

GENERAL C.B.A./ASS'Y PARTS

1

ADM3202ARU, AK4516AVF-E1, AK6480AF-E1,

AN2516S-EV1, AN8021NS-E1, BA6289F-E2,

BA10324AFVE1, BR9040FV-DE2,

LB1837MTEL3, LB1837MLTEL3, LB1837M-TE-L,

LM324DB, M5223FP-720C, M52684BFP,

M62366GP, MM1093NFBE, MN31121SAE1,

NJM2112V-TE1, NJM2115V-TE1,

NJM2151AVTE1, NJM2151V-TE1, NJM2285VTEL1, NJM2407R-TE1, NJM2538VTE2, S29453AFE, S3514AEFSTB, S93C66AMFNTB,

SNLV125APW, SNLV244APW, SNLV4053AFE,

TC7W32FU, TC4W66F, TC4W53FUTEL,

TC90A45F-ELP, UN224-TX, UPD6462GS712,

Z4C2973

MAIN C.B.A.

TSB13LV21GHE MN2MP0006F,

MN103004KBA1

5

4

1

2

3

S814A24AUC

1

2

3

S81333HGKFT1

1

AD80008BUS, AN2109NFHQ,

AN2536FHQ, AN2545FHQ,

AN3742FHN-EB, AN3732FHQ,

BH7086KV, BA9737KV,

F712525APBW, M2-855,

M34521, M5238FP, MN5293-1,

MN102L62GBA, T3W23XB,

TB6534F

E

C

B

2SB1073,

2SB1386T100R,

2SB1386T100Q,

2SD968A

4

3

1

2

PST9328UR

C

B

E

2SD1819, 2SD1819A,

2SC4081T106R, MSB1218A,

2SA1576T106R, 2SB1218A,

2SB1218AI, 2SB1585, 2SB970,

2SA1037K146R, 2SB709A,

2SC3931, 2SK1580, 2SD1119,

2SD2150T100R, 2SD601A,

2SC4617, 2SC2412K1,

2SD2216J, 2SK1958,

2SA1576T106R, 2SC3938,

2SD2436, 2SD1820A, 2SD1328,

2SB1462J, 2SA1774-TLR

1

5

XC6365C503MR,

RN5RG46AATR,

TA75S558FTEL,

NJM2125F-TE2,

NJM2380AFTE1

AC ADAPTOR

4

1

PC357N2N

3

2

UN5114 (R1=10K, R2=47K),

UN5115 (R1=10K, R2=OPEN),

UN9111J (R1=10K, R2=10K),

UN9115J (R1=10K),

DTA114YU (R1=10K, R2=47K),

DTA114TU (R1=10K),

DTA114EE (R1=10K, R2=10K),

DTA114TE (R1=10K),

C

B

E

B

UN2211 (R1=10K, R2=10K),

UN5212 (R1=22K, R2=22K),

UN5213 (R1=47K, R2=47K),

UN9212J (R1=22K, R2=22K),

UN9213J (R1=47K, R2=47K),

DTC144EU (R1=47K, R2=47K),

DTC124EE (R1=22K, R2=22K),

DTC124EU (R1=22K, R2=22K),

DTC144EE (R1=47K, R2=47K)

C

R1

E

R2

CCD C.B.A.

1

MN37290FT

HOW TO READ THE IDENTIFICATION

MARK OF CHIP COMPONENTS.

MARKING PART NO. MARKING PART NO.

B

2SC4081T106R

B 2SB709A

6D UN5114

F

2SA1037L146R

8C UN5213

8B UN5212

6E UN5115

Z 2SD601A

G 2SK1958

Z 2SD1819A

Y 2SD1819

B 2SB1218A

1R 2SB970

U 2SC3931

1X 2SC3938

S 2SC3929

1R 2SB1585

T 2SD1119

MC MA143

1B MA111

1-12

MARKING

BE

UN5212

C

8B

hfe classification

MARKING

C

A

Q

BE

2SB709

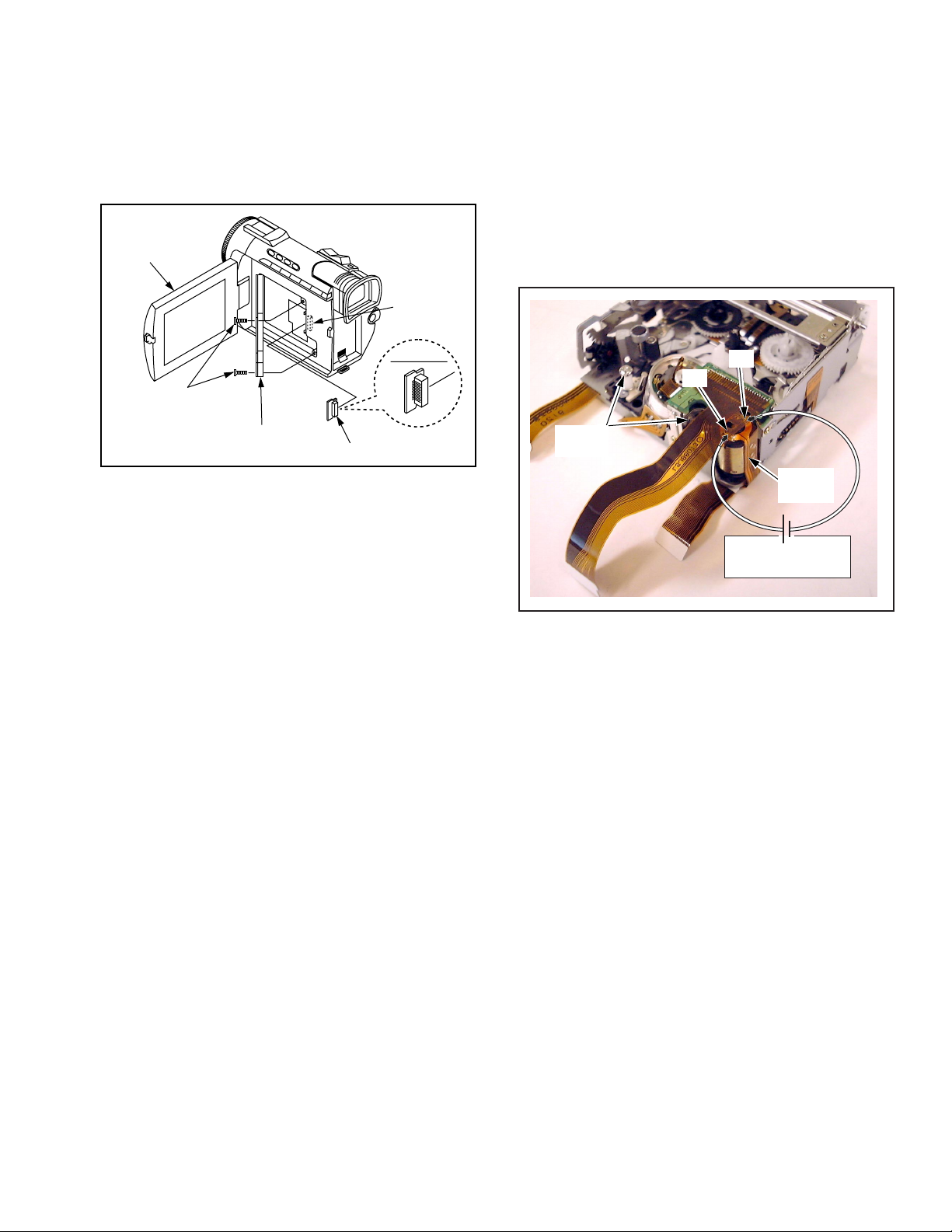

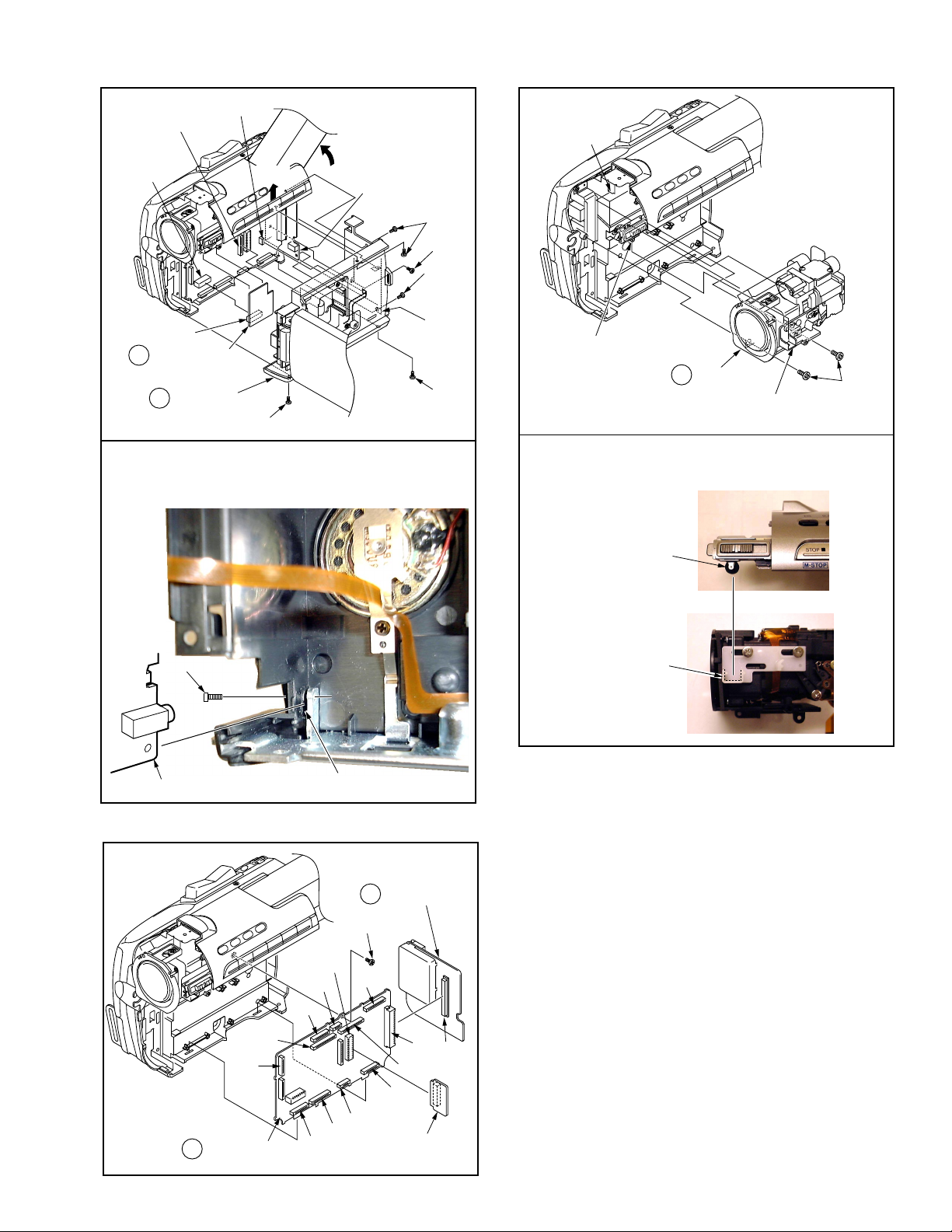

DISASSEMBLY/ASSEMBLY PROCEDURES

CABINET SECTION

Disassembly Flowchart

This flow chart indicates the disassembly steps of the cabinet parts and the P.C.Boards in order to gain access to item (s) to be

serviced. When reassembling, perform the step (s) in the reverse order. Bend, route and dress the wires as they were originally.

1 Front Case Unit

2 Left Cover

3 Side Case R Unit

4 Analog C.B.A.

(Model: D)

5 Main C.B.A.

6 Power C.B.A.

7 Lens Unit

8 Cassette Cover Unit

9 Mechanism Chassis Ass’y

10 Top Case Ass’y

LENS PORTION A

1 CCD C.B.A.

2 Filter Rubber

3 Optical Filter

LENS PORTION B

1 Lens Piece Unit

2 Lens Insulator

3 IR Filter Plate

(Model: C, D)

4 Focus Motor Unit

5 Zoom Motor Unit

FRONT CASE UNIT PORTION

1 Front C.B.A.

2 Shoe

3 Hood Screw

4 IR Panel

(Model: C,D)

SIDE CASE R UNIT PORTION

1 LCD Case Unit

2 Right Cover Unit

3 Speaker Unit

4 Toripod Frame

LCD PORTION

1 LCD Case A Unit

2 LCD Shield Case

3 LCD Shaft Unit

4 LCD Case B

5 LCD C.B.A.

6 LCD Panel Unit

7 LCD Lamp Unit

SIDE CASE L UNIT PORTION

1 Jack Ass’y

2 Strap Angle

3 Jack Cover

4 IN/OUT Knob

5 Jack F.P.C.

6 S-Jack C.B.A.

7 Jack C.B.A.

8 Jack Angle

9 Battery Eject Piece

10 Zoom Switch Unit

11 Hand Strap

TOP CASE UNIT PORTION

1 Top Case Unit

2 Color EVF Unit

or EVF Unit

3 Top Angle

4 Top Connector Cable

5 Top Operation Unit

EVF PORTION (Model: A,B)

1 Eye Cap Unit

COLOR EVF PORTION

(Model: C,D)

1 Eye Cap Unit

2 LCD EVF Case A

3 EVF Panel Unit

4 EVF F.P.C. Unit

5 EVF Fixing Angle

6 LCD EVF Case

7 EVF F.P.C.

8 LCD EVF Angle Unit

9 Color EVF A C.B.A.

10 EVF Protect A

11 Protect Plate

12 Color EVF B C.B.A.

13 LED Diffusion Plate

14 LED Lens

15 EVF LCD Holder

16 LCD Panel

17 EVF Rubber

18 EVF Protect B

Fig. D1

2-1

2 EVF Angle Unit

3 EVF F.P.C. Holder

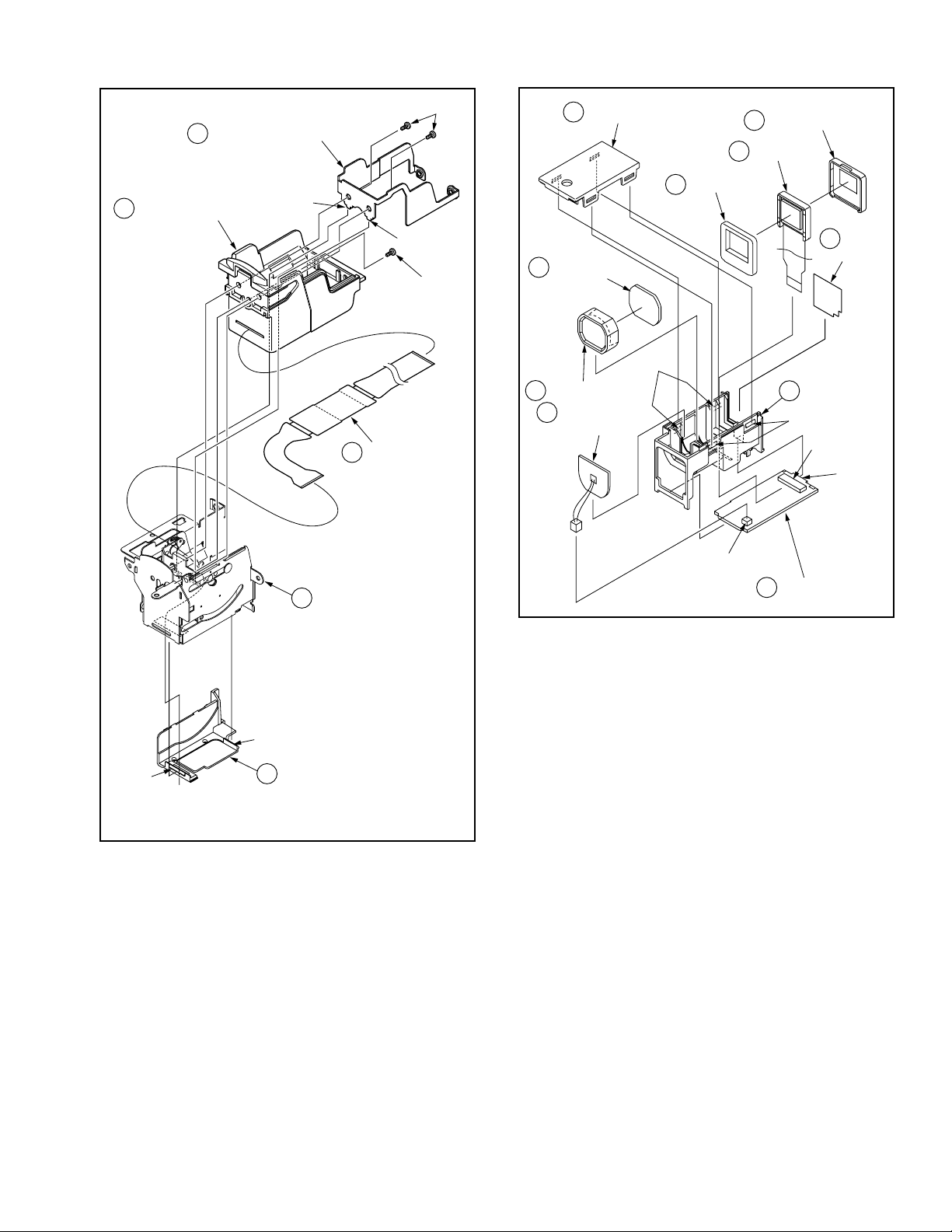

4 EVF Case A Unit

5 Dust Cover

6 EVF ESD Angle Unit

7 EVF Case B

8 EVF F.P.C.

9 CRT

10 Deflection Yoke

11 EVF C.B.A.

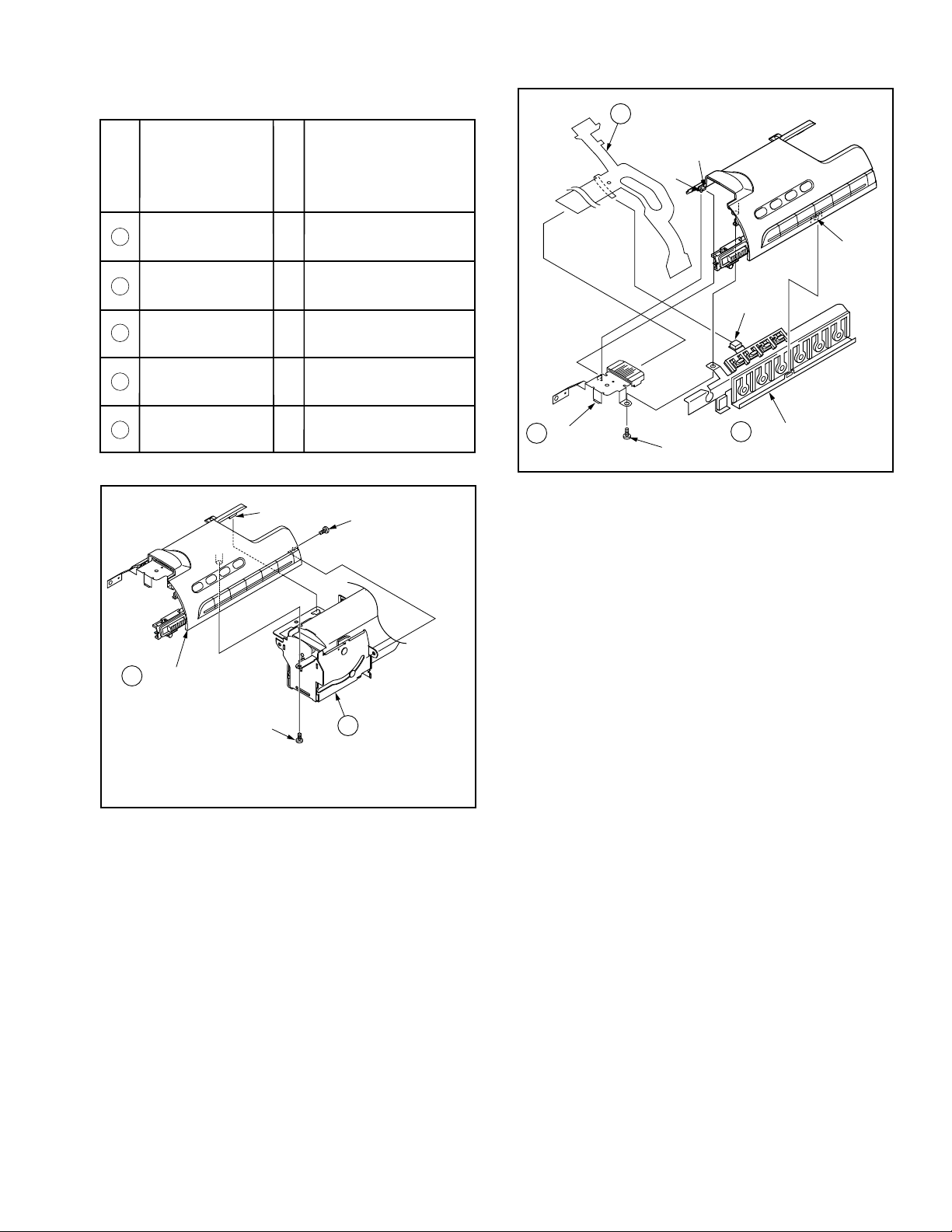

Main Parts Portion

STEP

/LOC.

No.

1

PART REMOVE

Front Case Unit D2 3(S-1), 2(S-2), FP4801

Fig.

No.

(S-1)

Left Cover D3 2(S-3), 2(S-4)

2

Side Case R Unit D4

3

Analog C.B.A. D4 B3501

4

Main C.B.A. D5

5

Power C.B.A. D5 B1001

6

Lens Unit D6 2(S-8), (L-1)

7

Cassette Cover

8

Unit

Mechanism Chassis

9

Ass’y

Top Case Ass’y D8

10

5(S-5), (S-6),

FP7, FP302

(S-7),

FP1, FP2, FP3, FP4, FP5,

FP6, FP8, FP9, FP301,

FP701, B3,

Short JIG C.B.A.

D7 ------

D7 3(S-9)

2(S-10), 2(S-11),

Top F.P.C.

A B C D

How to read chart shown above:

A: Order of steps in Procedure

When reassembling, perform the step(s) in the reverse

order. These numbers are also used as the identification

(location) No. of parts in Figures.

B: Part to be removed or installed.

C: Fig. No. showing Procedure or Part Location.

D: Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped, or unsoldered.

2(S-1)=2 Screws (S-1), 2(L-1)=2 Locking Tabs (L-1)

View A

(S-2)

Open

(S-1)

FP4801 of Front C.B.A.

1

Front Case Unit

Front

Cable

FP10 of

Main C.B.A.

Reassembly Note:

When installing the Front Case Unit, connect it between

FP10 and FP4801 so that the Front Cable is positioned

correctly as shown.

Front C.B.A.

Main C.B.A.

FP10

FP4801

Front Cable

View A

Fig. D2

Note :

a. When removing the cabinet, work with care so as not to

break the Locking Tabs.

b. Place a cloth or some other soft material under the P.C.

Boards or Unit to prevent damage.

c. When reinstalling, ensure that the connectors are connected

and electrical components have not been damaged.

d. Do not supply power to the unit during disassembly and

reassembly.

2-2

(S-3)

(S-4)

Fig. D3

2

Left Cover

B2

FP7

FP302

(L-1)

up

raise

Power C.B.A.

(S-5)

(S-6)

(S-5)

B3501

Slot A

Analog C.B.A.

4

(Model: D)

3

Side Case

R Unit

(S-5)

(S-5)

Reassembly Note:

When installing the Side Case R Unit, install so that the

Power C.B.A. inserts to the Slot A. Then, tighten Screw

(S-5).

(S-5)

Power C.B.A.

Slot A

Rubber of

IR Filter Knob

(Model: C, D)

7

Lens Unit

Slot of IR Filter Plate

(S-8)

(Model: C, D)

Reassembly Note:

When installing the Lens Unit, install so that the Rubber of

IR Filter Knob inserts to Slot of IR Filter Plate.

Rubber of

IR Filter Knob

(Model: C, D)

Slot of IR

Filter Plate

(Model: C, D)

Fig. D6

FP6

5

Main C.B.A.

Fig. D4

FP9

Fig. D5

FP701

FP1

FP2

B3

FP5

6

Power C.B.A.

(S-7)

FP8

FP4

FP3

Short JIG

C.B.A.

B1

FP301

B1001

2-3

Slot B

Boss A

Slot B

Pin B

8

Cassette Cover Unit

Garage

Boss A

Unit

Pin B

Lock Lever

Slide

Cylinder F.P.C.

Hooking Portion

FRONT CASE UNIT PORTION

STEP

/LOC.

No.

1

2

3

4

PART REMOVE

Front C.B.A.

Shoe

Hood Screw

IR Panel

Fig.

No.

2(S-1)

D9

D10

(S-2)

3(S-3), Lens Ring,

D10

Hood Piece

2(L-1)

D10

9

Mechanism

Chassis Ass’y

Slot A

(S-9)

Slot A

(S-9)

Note:

Remove both the Cassette Cover Unit and the Mechanism

Chassis Ass’y.

Reassembly Note:

(1) Install the Mechanism Chassis Ass’y, and then tighten

3 Screws (S-9).

(2) Eject the Garage Unit by sliding the Lock Lever of

Mechanism Chassis Ass’y.

(3) Install the Cassette Cover Unit so that 2 Slot B are

inserted to 2 Pin B. Then, insert 2 Boss A to 2 Slot A.

Fig. D7

Connector

of Zoom Switch

(S-10)

(S-11)

Unit

Side Case L

Unit

Top F.P.C.

Front Case Unit

Fig. D9

1

Front C.B.A.

(S-1)

(S-11)

Fig. D8

(S-10)

10

Top Case Ass’y

2-4

(L-1)

4

IR Panel

(Model: C, D)

3

Hood Screw

Lens Ring

Front Case

Unit

Hood Piece

Fig. D10

2

Shoe

(S-2)

(S-3)

SIDE CASE R UNIT PORTION

STEP

/LOC.

No.

1

PART REMOVE

LCD Case Unit

Fig.

No.

D11

2(S-1), (L-1), Unsolder

3

Speaker Unit

2

Right Cover Unit

Open

(S-2)

(S-2)

(L-2)

Right Cover Unit 2(S-2), (S-3), 2(L-2)

2

Speaker Unit (S-4)

3

Toripod Frame

4

1

D12

D12

D12

(S-5)

LCD Case Unit

(L-1)

Unsolder

(S-1)

(S-4)

(S-3)

(S-5)

Fig. D12

Boss

4

Toripod Frame

Slot

Slot

Slot

Bosses

Side Case R Unit

Note:

(1)To gain access 2 Screws (S-1), close the LCD Case

Unit, or turn it to the right or left.

(2)Work carefully so as not to damage F.P.C.

Fig. D11

2-5

LCD PORTION

(LCD Case B Unit)

Slots

LCD Case B

4

STEP

/LOC.

No.

LCD Case A Unit

1

2

LCD Shaft Unit

3

LCD Case B

4

LCD C.B.A.

5

LCD Panel Unit

6

LCD Lamp Unit

7

PART REMOVE

LCD Shield Case

Fig.

No.

D14

2(S-1), 6(L-1)

D15

2(S-2)

FP8001

D15

D15

2(S-3)

D16

FP8003, Unsolder

D16

8(L-2)

3(L-3), LCD Sheet Unit

D17

LCD Unit

(S-3)

Case

LCD Shield

2

raise

FP8001

(S-2)

LCD Shaft Unit

3

(S-3)

Note:

When removing the LCD Case B, pull the LCD Unit out of

the slots while raising the lower portion of LCD Unit as

indicated by the arrow.

Fig. D15

(LCD Case Unit)

LCD Case B Unit

Turn

LCD Shaft

Unit

(S-1)

Note:

To gain access to 2 Screws (S-1), turn the LCD Shaft Unit

to the right or left.

Fig. D14

1

LCD Case A Unit

(L-1)

(L-1)

(L-1)

2-6

6

7 LCD Lamp Unit

LCD Lamp Unit

LCD Panel Holder

LCD Panel

Holder

LCD

Reflect

Sheet

LCD Reflect Sheet

Open

Lead Light Panel

(Lead Light Panel Unit)

Lead Light Panel

When installing the LCD Lamp Unit, confirm that the

LCD Lamp Unit is positioned as shown below.

Use extreme care when handling the Lead Light Panel

and the LCD Sheet Unit to avoid damage, dust, and

spots (especially fingerprints, etc.).

Reassembly Note:

(1)

(2)

LCD Sheet

Unit

LCD

Sheet

Unit

(L-3)

(L-3)

View A

View A

LCD Panel Unit

(L-2)

Lead Light Panel Unit

(L-2)

5

(L-2)

LCD C.B.A.

LCD Lamp

Unit

Note:

(1)

When replacing the Lead Light Panel Unit, make sure

to remove Protection Sheet as shown below.

(2)

Use extreme care when handling the Lead Light Panel

Unit and the LCD Panel Unit to avoid damage, dust,

and spots (especially fingerprints, etc.).

The use of clean cotton gloves when available is

highly recommended.

Be careful not to apply any pressure to Portion "a" and

(3)

"b" of the LCD Lamp Unit as shown below.

Portion "a"

After replacing the Lead Light Panel Unit, confirm

(4)

that the Terminal of LCD Lamp Unit is soldered

correctly as shown below.

(L-2)

LCD Lamp Unit

Lead Light Panel Unit

Solder

Unsolder

FP8003

Unsolder

Portion "b"

Protection Sheet

Fig. D17

LCD C.B.A.

Hole of

Lead Light

Panel Unit

1~1.4mm

Fig. D16

Terminal of

LCD Lamp Unit

2-7

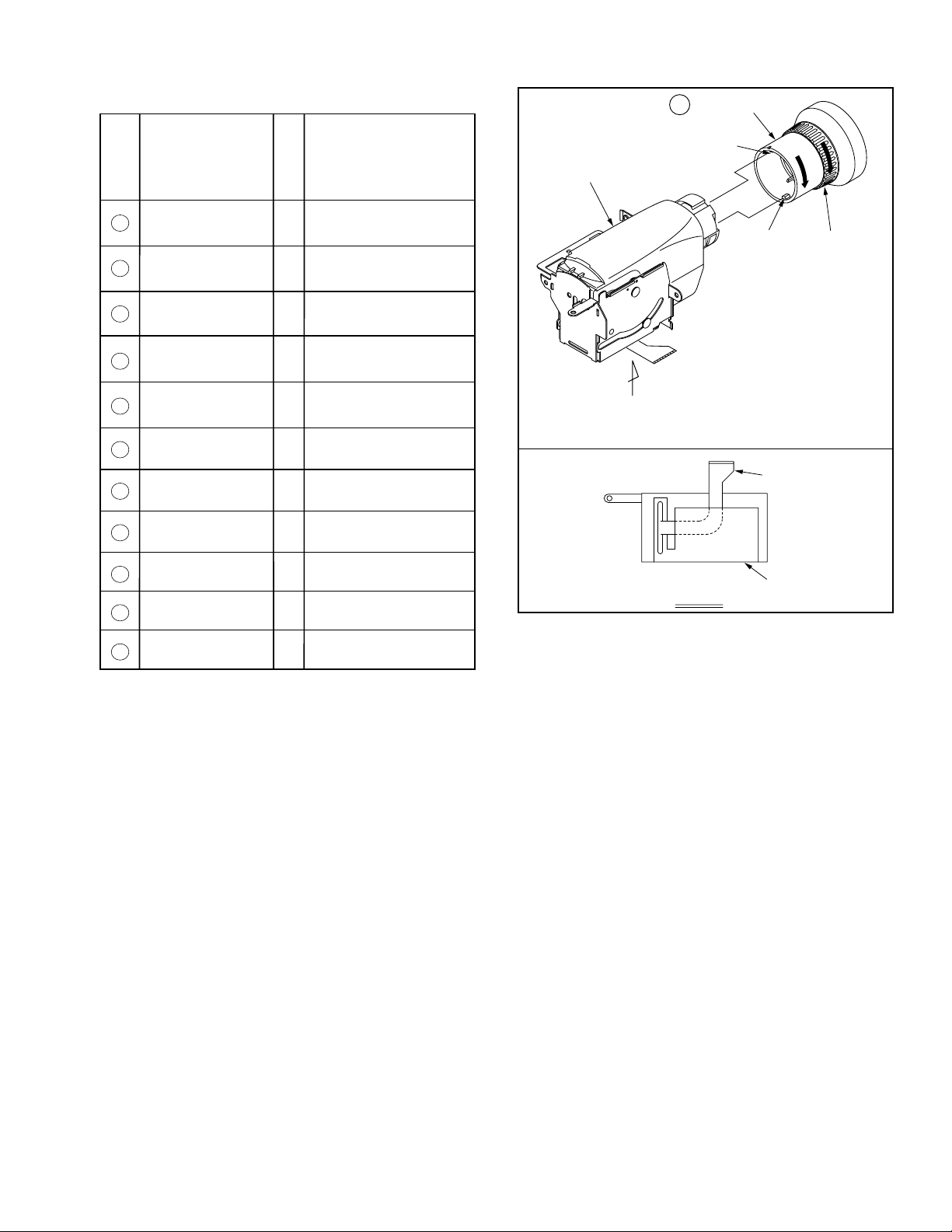

LENS PORTION A

Optical

Filter

Filter

Rubber

Filter

Rubber

View B

View B

CCD

Surface

Plate

CCD

F.P.C.

Hole

(B)

Hole

(B)

Hole (A)

Hole (A)

CCD

CCD

CCD

C.B.A.

Thinnest layer

(Model: A, B)

(Model: C, D)

Lens

Unit

(S-1)

Lens

Unit

Note:

This Optical Filter

is reversible to use.

Reassembly Note:

1. Installation of the Optical Filter

(1) Install the Optical Filter in the Lens Unit correctly.

Note:

(Model: A, B)

Be sure to install the Optical Filter with the thinnest

layer of the Optical Filter facing toward the Lens Unit.

Make sure that no dust gets on the Optical Filter and

in the Lens Unit. Clean the Optical Filter with lens

cleaning paper dampened with lens cleaner if

necessary.

2. Installation of the Filter Rubber

(1) Install the Filter Rubber in the Lens Unit correctly as

shown bellow.

Note:

Make sure that no dust gets on the Filter Rubber.

3. Installation of the CCD C.B.A.

(1) Place the CCD Surface Plate so that Holes (A) are

aligned with Holes (B) on the CCD F.P.C.

(2) Carefully install the CCD onto the CCD F.P.C. by

soldering.

Note:

Do not apply heat to the CCD directly when soldering.

Keep soldering time to a minimum to prevent damage

to the CCD.

Install the CCD and CCD Surface Plate so that there

are no gaps between them.

When installing, do not touch the CCD window surface

and make sure that no dust gets on the CCD. Clean

the CCD window surface with lens cleaning paper

dampened with lens cleaner if necessary.

(3) Install the CCD C.B.A. to the Lens Unit. Then, secure

2 Screws (S-1) while keeping the CCD C.B.A. pressed

toward the upper right corner.

Solder

STEP

/LOC.

No.

1

2

3

PART

CCD C.B.A.

Filter Rubber

Optical Filter

Fig.

No.

D18

D18

D18

2(S-1)

-----

-----

Lens Unit

Optical Filter

3

Filter Rubber

2

CCD

CCD

Pin

1

CCD

C.B.A.

Unsolder

Note:

1. Removal of the CCD and the CCD Surface Plate

(1) Unsolder the CCD Pins on the CCD F.P.C.

(2) Remove the CCD and the CCD Surface Plate from the

(S-1)

CCD F.P.C.

CAUTION:

(1) When removing the CCD C.B.A., take care so that the

Optical Filter does not fall out.

(2) Take extreme care when removing the CCD because

it is easily damaged by static electricity.

Use a Wrist Strap while removing and installing.

(3) Do not apply heat to the CCD directly when soldering.

Keep soldering time to a minimum to prevent damage

to the CCD.

(4) Do not touch the CCD window surface when servicing.

Fig. D18

REMOVE

CCD

Surface

Plate

CCD

F.P.C.

Fig. D19

2-8

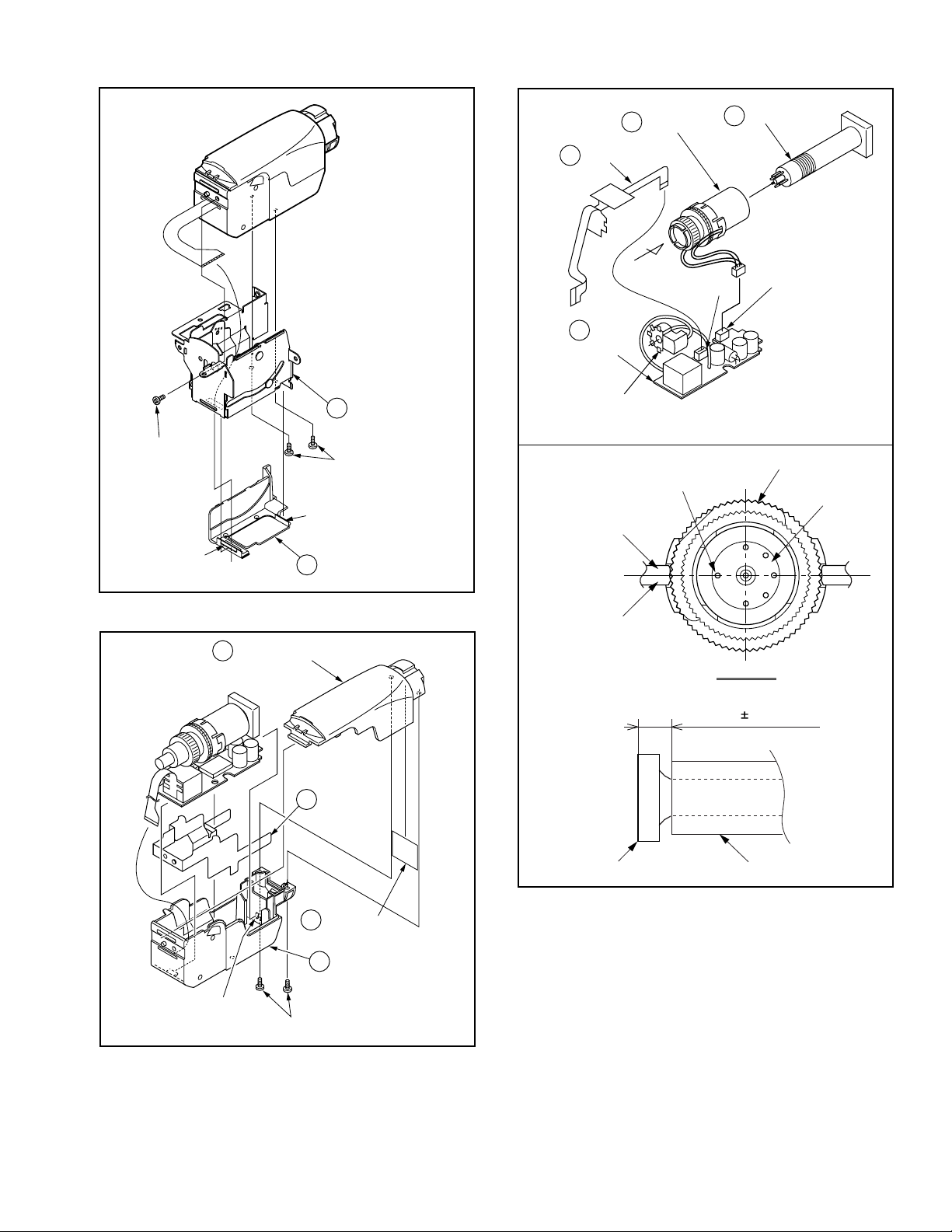

LENS PORTION B

STEP

/LOC.

No.

1

PART REMOVE

Lens Piece Unit

Fig.

No.

D20

3(S-1)

5

Zoom Motor Unit

(S-3)

Unsolder

Portion A

4

Focus

Motor

Unit

Holder

Slots of Holder

Lens Insulator -----

2

IR Filter Plate 2(S-2)

3

Focus Motor Unit

4

5

D20

D20

D21

D21

2 Lens Insulator

(S-1)

(S-1)

1

Lens Piece

Unit

3 IR Filter Plate

2(S-3), Unsolder

2(S-4), UnsolderZoom Motor Unit

Lens Unit

(Model: C, D)

Pin of IR

Lever

(Model: C,D)

Slot

(S-2)

(S-4)

View A

Unsolder

Reassembly Note:

When installing the Zoom Motor Unit, install so that the

Portion A of Zoom Motor Unit is inserted to Slots of Holder

by sliding the Holder.

Slide

Slots of

Holder

Holder

View A

Fig. D21

Note:

When installing the IR Filter Plate, install so that the Pin of

IR Lever is inserted to Slot of IR Filter Plate. After installing,

confirm that the IR Filter Plate and IR Lever are slide correctly.

Fig. D20

2-9

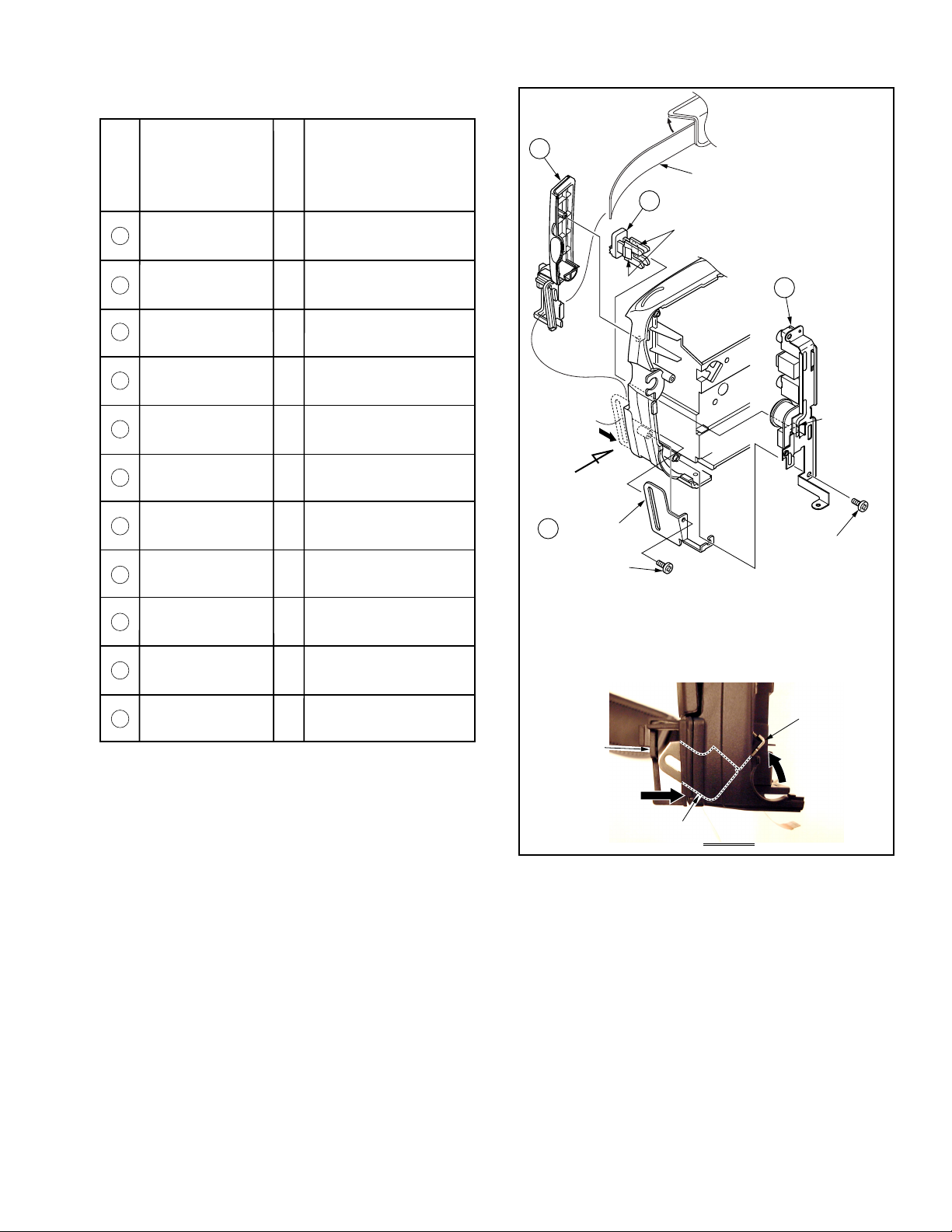

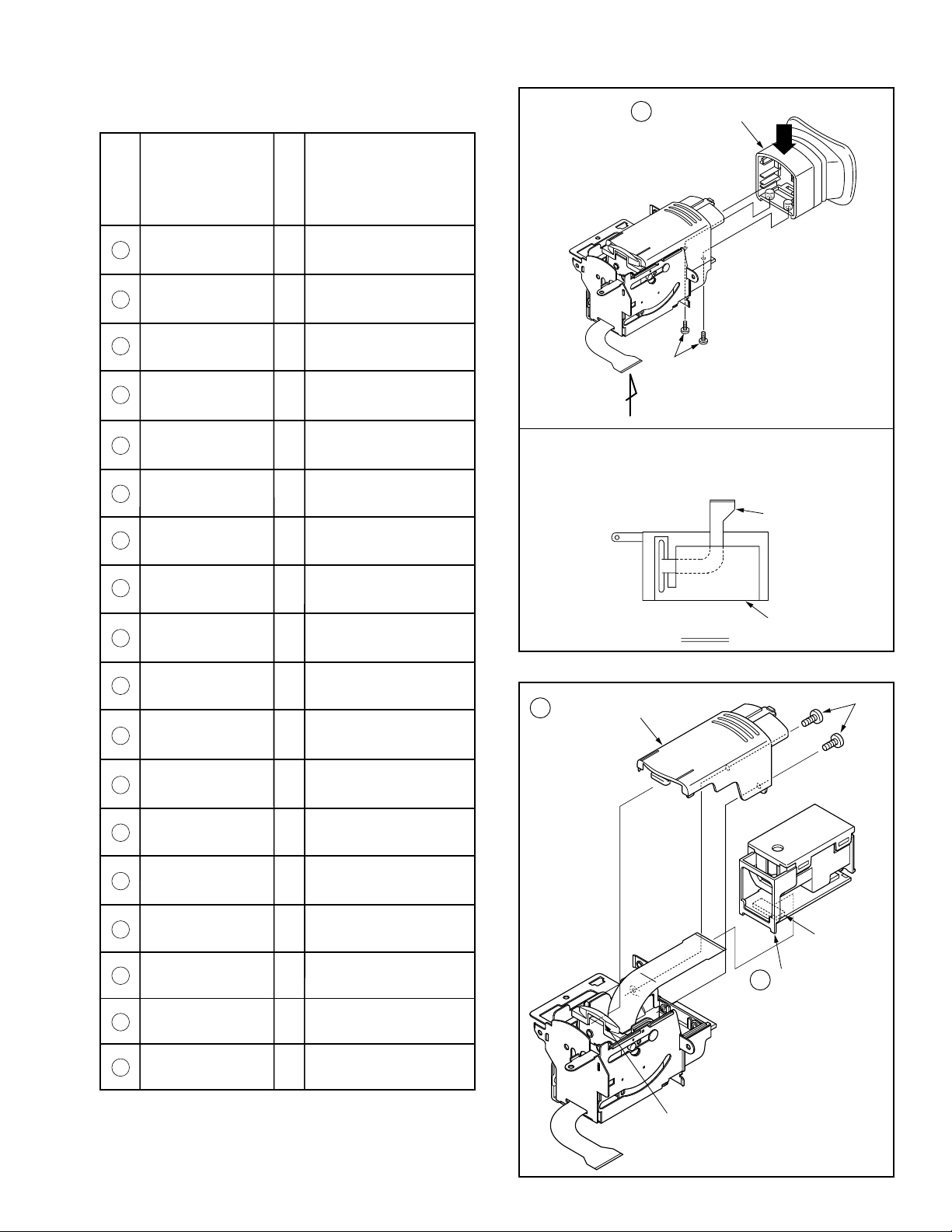

SIDE CASE L UNIT PORTION

STEP

/LOC.

No.

PART REMOVE

Fig.

No.

3

Jack Cover

Open

Hand Strap

4

IN/OUT Knob (Model: D)

Jack Ass’y

1

Strap Angle (S-2)

2

Jack Cover Hand Strap

3

IN/OUT Knob

4

5

6

7

8

9

10

D22

D22

D22

D22

D23

D23

D23

D23

D24

D24

(S-1)

2(L-1)

FP3701, FP3751Jack F.P.C.

(S-3)S-Jack C.B.A.

(S-4)Jack C.B.A.

-----Jack Angle

(S-5)Battery Eject Piece

2(S-6)Zoom Switch Unit

(L-1)

1

Jack Ass'y

IN/OUT

Push

Switch

(Model: D)

View A

2

Strap Angle

(S-1)

(S-2)

Note:

When removing the Strap Angle, push Strap Angle lower

portion to release as shown.

DO NOT remove the Jack Cover before removing the Strap

Angle.

11

D24

-----Hand Strap

Strap Angle

Jack Cover

Push

lower portion

View A

Fig. D22

2-10

8

Jack Angle

7

Jack C.B.A.

10

Zoom Switch Unit

(S-6)

(S-6)

Eject Plate

6

S-Jack C.B.A.

(S-3)

FP3751

Fig. D23

hole

5

Jack F.P.C.

(S-4)

FP3701

Portion A

Eject Knob Piece

Tab of Switch

(Model: B,C,D)

(S-5)

Portion B

9

Battery Eject

Piece

Slot of MMC Exchange Knob

(Model: B, C, D)

11

Hand Strap

Eject Knob Piece

Bosses

Eject Plate

Note: Work carefully so as not to damage the F.P.C.

Reassembly Note:

(1) When installing the Zoom Switch Unit, install Portion B

after installing Portion A.

(2) When installing Portion B, install so that the Tab of

Switch inserts to Slot of MMC Exchange Knob.

Slot of MMC

Exchange Knob

(Model: B, C, D)

Tab of Switch

(Model: B,C,D)

Fig. D24

2-11

TOP CASE UNIT PORTION

4

Top Connector Cable

STEP

/LOC.

No.

1

2

3

4

PART REMOVE

Top Case Unit

Color EVF Unit

or EVF Unit

Top Angle (S-3), (L-2)

Top Connector Cable

5

Fig.

No.

D25

D25

D26

D26

D26

(L-1)

(S-1), (S-2), (L-1)

-----

Connector

(L-3)Top Operation Unit

(S-2)

3

Top Angle

Boss

(S-3)

(L-2)

Connector

Fig. D26

5

Top Operation Unit

(L-3)

1

Top Case Unit

(S-1)

Fig. D25

2

Color EVF Unit

(Model: C, D)

or

EVF Unit

(Model: A, B)

2-12

EVF UNIT PORTION (Model: A, B)

1

Eye Cap Unit

STEP

/LOC.

No.

1

2

3

4

5

6

7

8

9

10

11

PART REMOVE

Eye Cap Unit

EVF Angle Unit (S-1), 2(S-2)

EVF F.P.C. Holder

EVF Case A Unit 2(S-3)

Dust Cover -----

EVF ESD Angle Unit -----

EVF Case B (L-3)

EVF F.P.C. FP801

CRT -----

Deflection Yoke P902, CRT Socket Unit

EVF C.B.A. -----

Fig.

No.

D27

D28

D28

D29

D29

D29

D29

D30

D30

D30

D30

2(L-1)

2(L-2)

(L-1)

Turn

EVF Case Unit

(L-1)

Eye Sight RIng

View A

Note:

The Eye Cap Unit is very tight. Use extreme so as not to

damage the unit.

EVF F.P.C.

EVF F.P.C. Holder

View A

Fig. D27

Note:

When disassembling or reassembling, make sure that no dust

gets in EVF Unit.

2-13

8

EVF F.P.C.

10

Deflection

Yoke

9

CRT

(S-1)

(L-2)

Fig. D28

4

EVF Case A Unit

2

EVF Angle Unit

(S-2)

(L-2)

3

EVF F.P.C. Holder

View A

11

EVF

C.B.A.

CRT

Socket

Unit

Lead (YELLOW)

Lead (BLUE)

FP801

Anode Pin

5.35 mm 1.35 mm

P902

Deflection Yoke

CRT

View "A"

(L-3)

(S-3)

Fig. D29

6

EVF ESD

Angle Unit

5

Dust Cover

7

EVF Case B

2-14

CRT

Deflection Yoke

Fig. D30

COLOR EVF UNIT PORTION (Model: C,

D)

1

Eye Cap Unit

Push

STEP

/LOC.

No.

1

2

3

4

5

6

7

8

PART REMOVE

Eye Cap Unit

LCD EVF Case A 2(S-2)

EVF Panel Unit FP901

EVF F.P.C. Holder

EVF Fixing Angle 3(S-3), 2(L-2)

LCD EVF Case -----

EVF F.P.C. -----

LCD EVF Angle Unit -----

Fig.

No.

D31

D32

D32

D33

D33

D33

D33

D33

2(S-1)

(S-1)

2(L-1)

View A

Reassembly Notes:

When installing the Eye Cap Unit, tighten 2 Screws (S-1)

while pushing as indicated by the arrow.

EVF F.P.C.

Color EVF A C.B.A. (L-3), P901, FP902

9

EVF Protect A 4(L-4)

10

Protect Plate -----

11

Color EVF B C.B.A. -----

12

LED Diffusion Plate -----

13

LED Lens -----

14

EVF LCD Holder -----

15

LCD Panel -----

16

EVF Rubber -----

17

EVF Protect B -----

18

D34

D34

D34

D34

D34

D34

D34

D34

D34

D34

2

LCD EVF Case A

View A

Fig. D31

EVF F.P.C. Holder

FP901

3

EVF Panel Unit

(S-2)

Note:

When disassembling or reassembling, make sure that no dust

gets in Color EVF Unit.

2-15

hole

Fig. D32

6

LCD EVF Case

5

EVF Fixing Angle

(L-2)

(L-2)

(S-3)

(S-3)

10

EVF Protect A

13

LED Diffusion

Plate

17

(L-4)

15

16

LCD Panel

EVF Rubber

EVF LCD Holder

11

Protect

Plate

7

EVF F.P.C.

8

LCD EVF Angle Unit

(L-1)

4

(L-1)

Note:

Work carefully so as not to damage the F.P.C.

EVF F.P.C. Holder

14

LED Lens

12

Color EVF B

C.B.A.

P901

Fig. D34

18

EVF

Protect B

(L-4)

FP902

9

Color EVF A

C.B.A.

(L-3)

Fig. D33

2-16

Loading...

Loading...