Panasonic PT-M1083U, PT-M1085U Service Manual

. THESE MODELS COMPLY WITH DHHS RUlGS 21 CFR SUBCHAPTER J APPLICABLE AT DATE OF

MANUFACTURE.

There are special components used in Panasonic Color Video/Data projector which are important for safety. These parts

are shaded on the schematic diagram. 1\ is essential that these critical parts should be replaced with manufacturer's

specified parts to prevent X-RADIATION, shock, !ire, or other hazards. Do nol modify the original design without

permission of PANASONIC BROADCAST & TELEVISION SYSTEMS COMPANY.

PRECAUTION: To prevent permanent burning of the picture tubes do not operate the projector wilh a still picture for an

extended time period when not necessary and be certain to turn power off when not in use.

Burne9 picture tubes are not covered under warranty.

SAFETY PRECAUTION

GENERAL GUIDELINES

, ,

1. II is advisable to use an isolation transformer in the AC line

, supply before servicing this model.

2. . When servicing observe the original lead dress, especially

in the high vollage circuit. In case of a short circuit, replace

every part which has overheated.

3. Alter servicing observe thai all protective devices such as

rnsulation barriers, fish paper, shields, isolation networks

and fuses are properly installed.

'1, Beiore turning the receiver on, the resistance between the

B+ line and chassis ground should be checked. Coonect

the :. side of an ohmmeter to the B+ lines and the (B side

, ,

10 chassis ground.

Each line' should have more resistance than specified, as

'shown in Table 1:

5 Ir the set is not intended to be used ror a long time: the

power cord Should be unplugged from ihe AC line outlet.

6. Potentials. as high as 34.3kV are present when this set is

in operation. Removal of the covers involves the danger or

. a shock hazard rrom the set's power supply. Servicing

should not be attempted by anyone who is not thoroughly

familiar with the precautions necessary when working on

higll-voliage equipment

Always discharge the anode of theprojeclion tube to the

sel chassi.s before handling the tube. .

7 - . Alter servicing, make the leakage current checks 10 prevent

a shock hazard.

IMPORTANT SAFETY NOTICE

.....

,

~

* : Connect the (f) side or an ohmmeter to the B- Ijne and the

.:~:I side to (;hassls ground. --"

Table 1

1

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two

plug prongs.

Turn on the set.

Measure the resistance value with an ohmmeter between

the jumpered AC plug and each exposed metallic part such

as screwheads, inpullerminals, control shafts, etc.

. When the exposed metallic part has. a return path to the

chassis. the reading should be between 490~2 and 9M!1.

3.

When Ihe exposed melal does not have a return path to

the chassis. the reading must be infinite. .

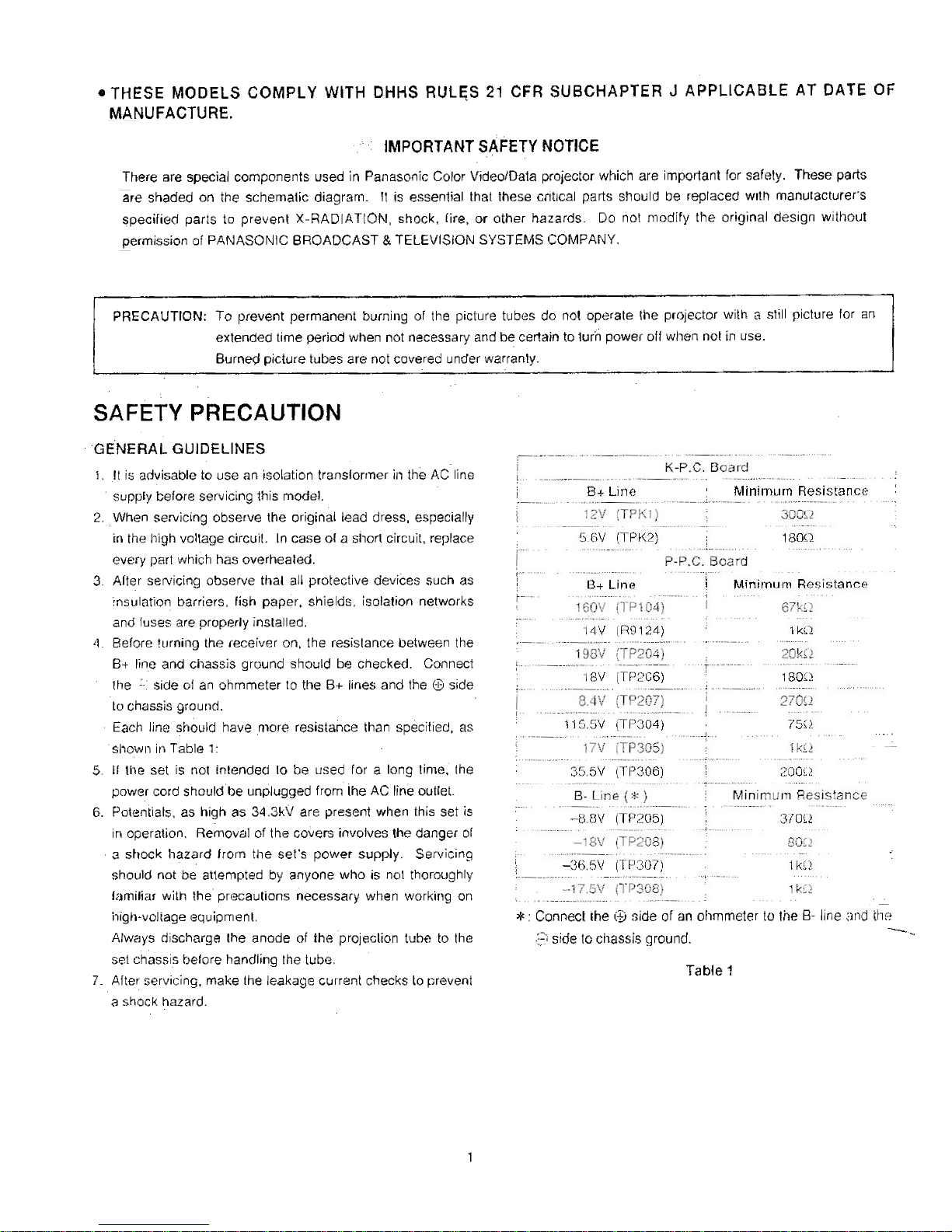

LEAKAGE CURRENt HOT CHECK (See Fig. 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer during this check.

2. Connect a L5k!2, 10 watts resistor, in parallel with a

O. 15~F capacitor between each exposed metallic part and

an ground. Use a good ground, for example, a water pipe.

3. Use a Iligh impedance AC voltage meter (VTVM) to

measurelhe potential across the resistor.

4. Move the resistor connection to each exposed metallic part

. .

and measure the. voltage present. '.

5. Check .that any potential does not exceed 0.75 vol! RMS.

. ..

A leakage current tester (Simposon Model 229 or equiv-

alent) may be used in the above hot check, in which case

any currenl measured must not exceed 1/2 milliamp. In

. case any measurement is out of Ihe iimits specified. there

is a possibility of a shock hazard arid the set should

be repaired and rechecked before it is returned to the

customer.

~~

r-'--"-'-'

; Hot-Check Circuit AC VOLTMETER

(i.-:J

I

I

1 O.15~F . t TO COL.D

j INSTRUMENT'S WATER PIPE

l EXPOSED l_.~ (EARTH GROUNO)

METAL PIIRTS 1.5110. lOW

. -.-

Fig. 1

Fig. 1

.-~.

~~~

X-RADIATION

WARNING: The potential source of X-Radiation in the color

video projector is the High voltage section and

the projection lubes.

NOTE: It is important to use an accurate, periodically,

calibrated high voltage meter.

1. Set to the bright mode by using menu selector button on

the projector.

Minimize Brightness by using control level adjustment

button.

2. Measure the High Voltage. The high voltage meter should

indiCate 32kV:!:O.5kV. If the upper meter indication is oul of

tolerance, immediate service and correction is required to

prevent the possibility of premature component railure.

(Refer to high voltage adjustment in the manual.)

3. To prevent an X-Radiation possibility, it is essential to use

the specified projection tube only.

4. To prevent exposure to X-Radiation, the projection tube

shield must be kept in place with power applied to the set.

WARNING: When using a projection tube test jig lOt service,

ensure that jig is capable of handling 32.5kV

without causing X-Radiation.

HORIZONTAL OSC. DISABLE CIRCUIT TEST

This test must be made as a final check before the set is

returned to the customer. .

1. With the chassis case removed. supply a nominal 120V AC

to the set, turn on the set.

2. Set the customer controls to normal operating positions.

3. Press the TEST button once on the remole control and

display Internal crosshatch of NTSC sync.

4. Short the C6046 with a jumper wire.

5. Short theA6068 wilh a jumper wire.

Confirm vanish the high voltage. and reaster stop. and

120V:t10V on the voltmeter.

6. If this does not occur, the Horizontal Ose. Disable Circuit is

nol operating. Follow the Horizontal Ose. Disable Circuit

Repair Procedures before the set is returned 10 the

customer.

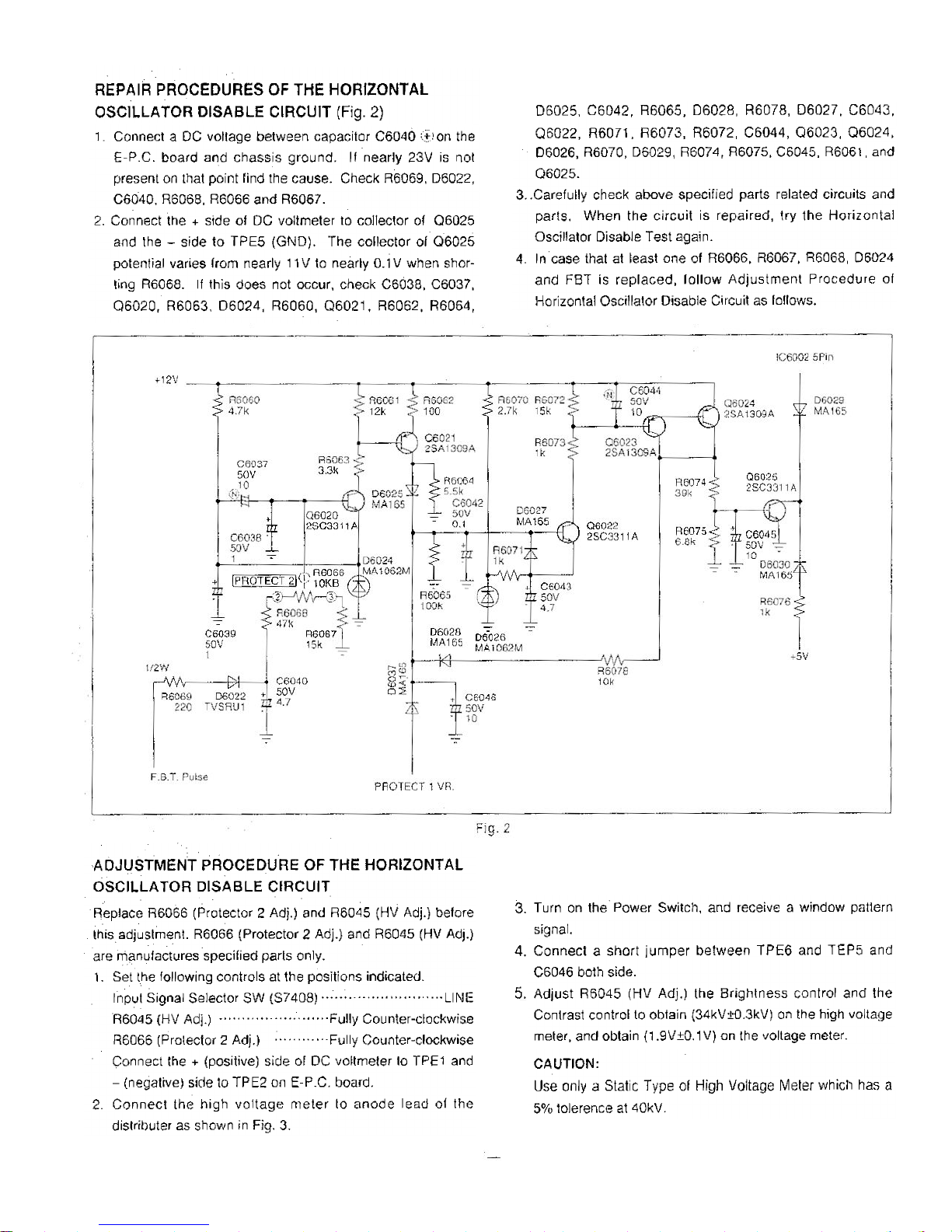

REPAIR PROCEDURES OF THE HORIZONTAL

OSCILLATOR DISABLE CIRCUIT (Fig. 2)

1. Connect a DC vOltage between capacitor C604Q ::t) on the

E-P.C. board and chass.is ground. If nearly 23V is not

present on that point find the cause. Check R6069. D6022,

C6040, R6D68, R6D66 and R6067,

2. Connect the + side 01 DC voltmeter to collector of 06025

and the - side to TPE5 (GND). The collector of 06025

potential varies Irom nearly 11 V \0 nearly 0.1 V when shor-

ling R6D68. If this does not occur, check C6038, C6037 ,

Q6020, R6063. 06024, R6060, Q6021 , R6062, R6064,

.ADJUSTMENT PROCEDURE OF THE HORIZONTAL

OSCILLATOR DISABLE CIRCUIT

. .. .

Replace R6066 (Protector 2 Adj.) and R6045 (HV Adj.) before

. .

this adjustment. R6066 (Protector 2 Adj.) and R6045 (HV Adj.)

are in~nulactures specified parts only.

1. 8et the following controls at the positions indicated.

Input Signal Selector SW (87408) LlNE

R6045 (HV Adj.) """"""""""""Fully Counter-clockwise

R6066 (Pro/ector 2 Adj.) """"""Fully Counter-clockwise

Connect the + (positive) side or DC voltmeter to TPE1 and

- (negalive) side to TPE2 on E-P.C. board.

2. Connect the high voltage meter to anode lead of the

distributer as shown in Fig. 3.

06025. C6042. R6065. 06028, R6078. 06027. C6043.

Q6022. R6071. R6073. R6072, C6044. Q6023, Q6024.

. D6026. R6D70. D6O29, R6074.R6075,C6045. R6061,and

Q6025.

3. .Carefully check above specified parts related circuits and

parIs. When the circuit is repaired. try 1he Horizontal

Oscillator Disable Test again.

4. In case that at least one of R6066, R6067, R6068, D6024

and FBT is replaced. follow Adjustment Procedure of

Horizontal Oscillator Disable Circuit as follows.

Turn on the Power Switch. and receive a window pattern

signal.

Connect a short jumper between TPE6 and TEPS and

C6046 both side.

Adjust R6045 (HV Adj.) the Brightness control and the

Contrast control to obtain (34kV:tO.3kV) on the high voltage

meier, and obtain (1 .9V.:!:O.1V) on the voltage meter.

3.

4.

5.

CA UTION:

Use only a Stalic Type 01 High Voltage MeIer whicJ1 has a

5% tolerence at 40kV-

Adjust R6066 (Protector 2 Adj.) slowly clockwise unit shut-

6.

down occurs and hold that position.

7. Turn oilihe power switch.

B. Adjust R6045 (HV Adj.) slightly counler-elockwise.

9.

Turn on the power switch.

10. Adjust R6045 (HV Adj.) slowly clockwise until shut-down

occurs High VoHage should be 34kV:!:O.5kV, and 1.9V

t.O.1 V on the voltage meter just before shut-down.

, 1. " the readings in step 10 are not confirmed. repeat steps

5 to 10.

Turn ofl the power SWItch.

13. Disconnect the short jumper between TPE6 and TPE5.

and C6046 both sides.

Turn on the 'power switch, and adjust (hal the high voltage

is 32.0kV:!:O.5kV with R6045.

15: Confirm that the high voltage does not ctiange by iurnlng

. .' the Brightnessand Contrast controls.

16. Fix R6066 (Protector 2 Adj.) and R6045 (HV Adj.) with

.' .

bond as illustrated below. (Fig. 4)

Fig. 4

tt;~!';:t;;;'- : 5'/,;<" "'~:

X-RAY PRECAUTIONS

The Iront area (between the projection tube and the lens.) is

enclosed by a metal box to ensure positive safety during

abnormal and normal conditions when checkinQ and doing

repair work. To fully ensure safety, however. the following

precautions must be observed.

(1) Do not remove the lens.

(2} Be sure to lurn OFF the power when the lens must be

removed and when yO~t could be exposed \0 X.rays

during cleaning and other routine servicing.

(3) Do not remove the lens to check the projection tube for

operation by watching it directly.

(4) Do not remove Ihe LEAD TAPE on the CRTs. (Fig. 5)

(5) Do not remove the METAL COVEA on the CATs. (Fig. 5)

(6) Do not remove the LEAD TAPE LENSes. (Fig. 5)

Fig. 5

~

RCUJT EXPLANATIONCI

~

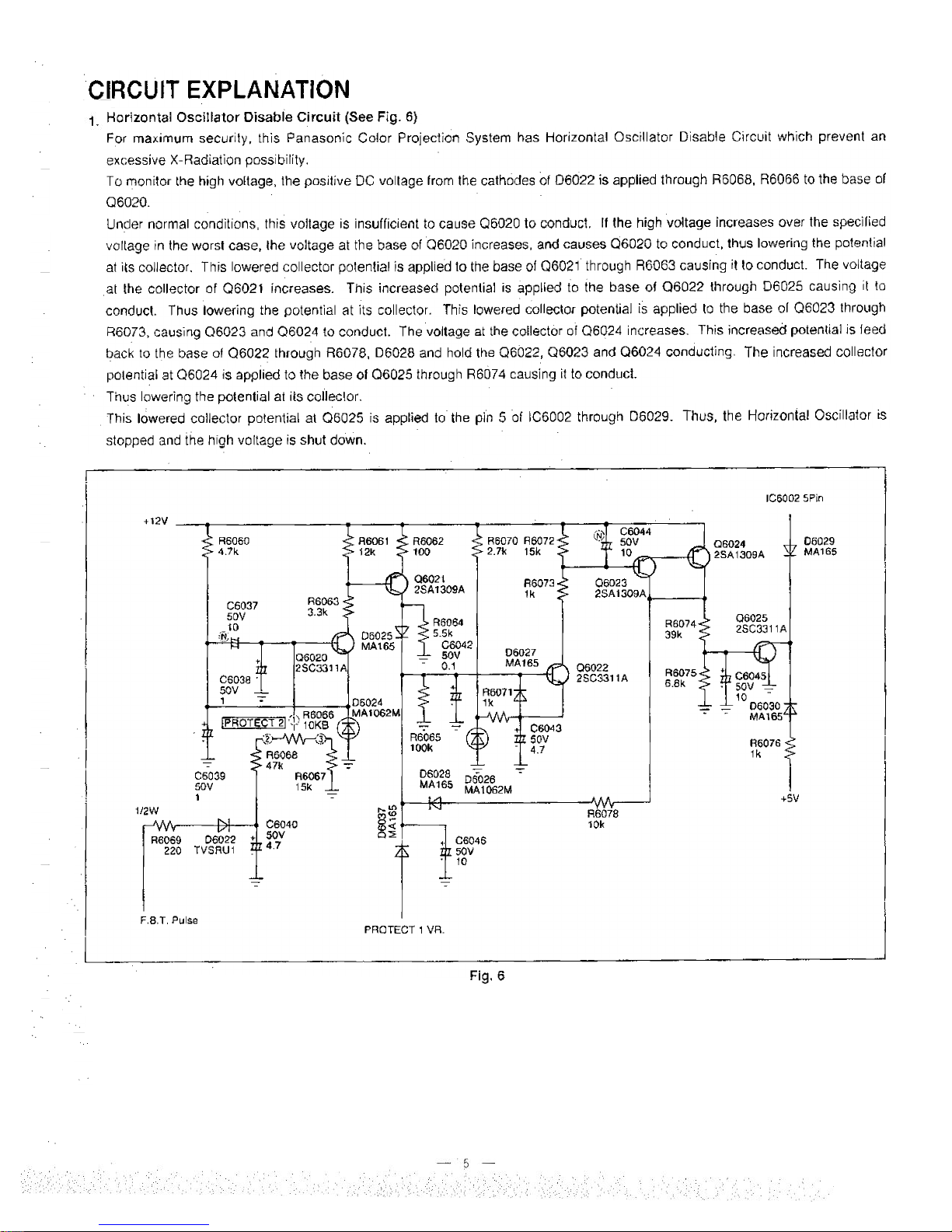

Horizontal Oscillator Disabie Circuit (See Fig. 6)

For maximum security, this Panasonic Color Projection System has Horizontal Oscillator Disable Circuit which prevent an

excessive X-Radiation possibility. .

To monitor the high voltage. the positive DC voltage Irom the cathodes of 06022 is applied through R6D68, R6D66 to the base of

06020.. ..

Under normal conditions, this voltage is insufficient to cause 06020 to conduct. If the high voltage increases over the specified

voltage in the worst case, the voltage at the base of 06020 increases, and causes Q6020 to conduct. thus lowering the potential

at its collector. This lowered collector potential is applied to the base of 06021 through R6063 causing it to conduct. The voltage

al the collector of 06021 increases. This increased potential is applied to the base of 06022 through 06025 causing it to

conduct. Thus lowering the potential at its collector. This lowered Collector potential is applied to the base 01 06023 through

R6073. causing Q6023 and 06024 to conduct. The voltage at the collector of Q6024 increases. . This increased potential isleed

back to the base of Q6022 through R6078, 06028 and hold the 06022,06023 and 06024 conducting. The increased collector

--. --.:-. -> ""<on,., A ,- ---"--' .- k__- _I ,."",n,.,.c: 11 .~... co:!n7 A --. ,_I_~ H In n~ft"" ""I

~~~~

potential at 06024 is applied to the base 01 06025 through R6074 causing ilto conduct.

Thus lowering the potential at its collector. . .

. This lowered collector potential at 06025 is applied to the pin 5 'of IC6002 through 06029.

stopped and the high voltage is shut down. '.

~

IC6002 SPIn

+12V

~ C8044

R6O6O A6070 A6072 ~ty 5OV 06029

4.7k Vie 15k 10 MA1S5

A6073

1k

C6037

50V

10

iif;

C6O2O

25C3311 ~2

2SC3311A

C~39 D6028 D(rO26 ~

I5OV MA165 MAI062M

1 -=- +5V

112W {:):g R6O78

g< ,~

R6069 D6022 0 ~ ,. C6046

220 TVSRU1 5OV

. 10

- -

- -

F.B.T. Pulse PROTECT 1 VA.

Fig. 6

~~~~~~~~~~~~

The increased collector

Thus, the Horizontal Oscillator is

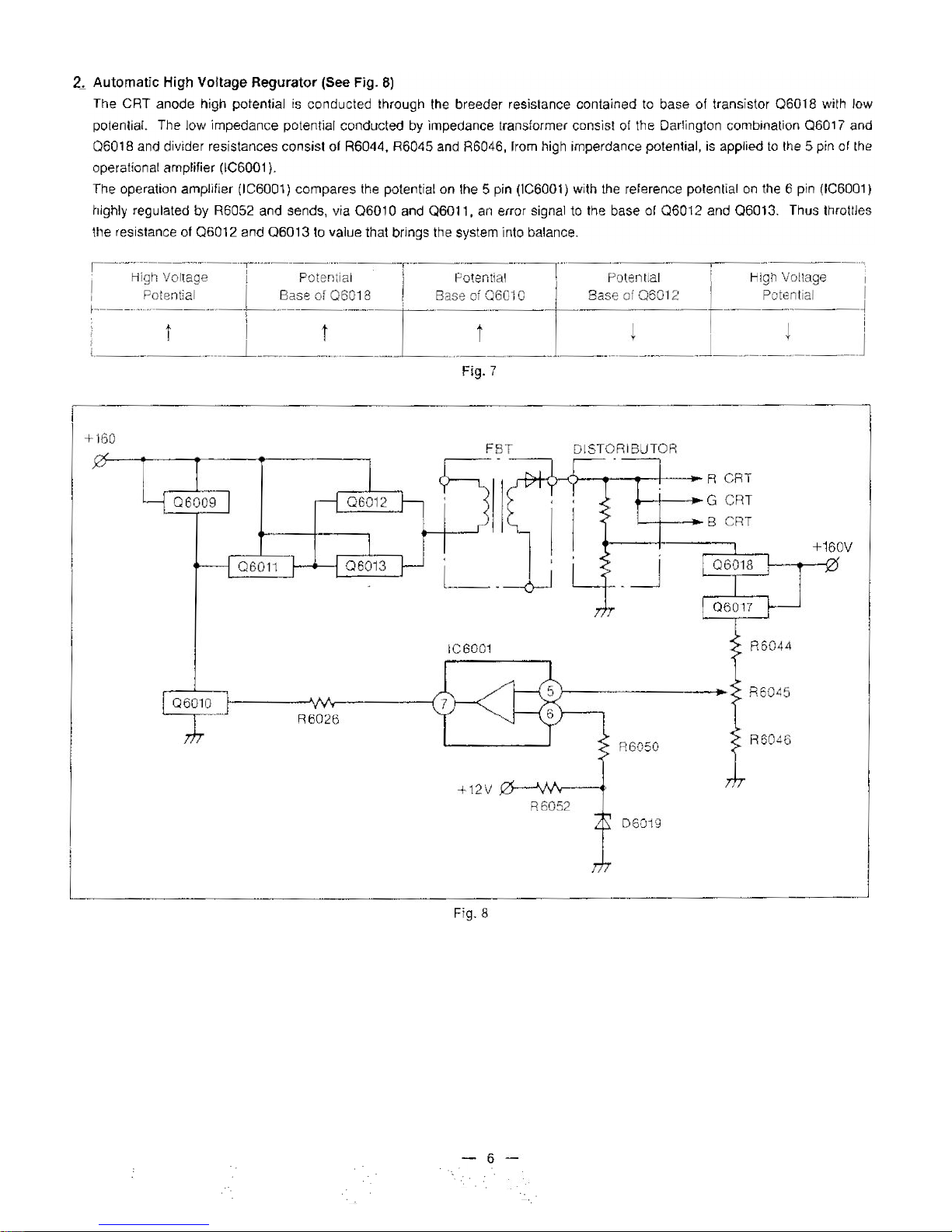

Automatic High Voltage Regurator (See Fig. 8)

The CRT anode high potential is conducted through the breeder resistance contained to base of transistor Q6018 with Jow

potentiaL The Jow impedance potential conducted by impedance transformer consist of the Darlington combination Q6017 and

Q6018 and divider resistances consist of R6044. R6045 and R6046, from high imperdance potential, is applied to Ihe 5 pin of the

operational amplifier (lC6001).

The operation amplifier (lC6001) compares the potential on the 5 pin (IC6001) with the reference potential on the 6 pin (IC6DD1}

highly regulated by R6052 and sends, via Q6010 and Q6011, an error signal to the base of Q6012 and 06013. Thus throttles

the resistance of Q6012 and 06013 to value that brings the system into balance.

2.

~~~

. 6-

~~~~~

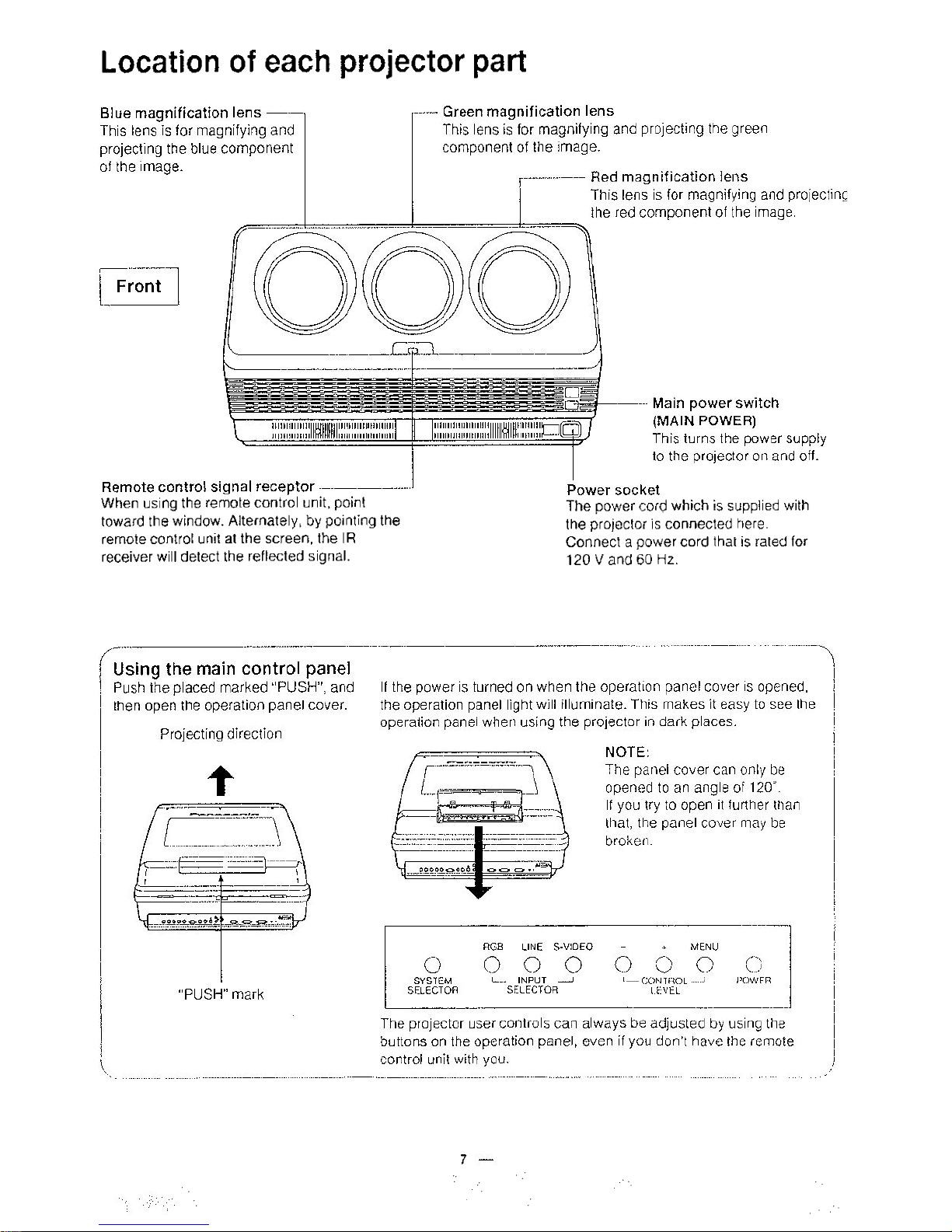

Location of each projector part

When using the remote control unit, poinl

toward the window. Alternately, by pointing the

remote control unit at the screen, the IR

receiver will detect the reflected signal.

~~

The power cord which is supplied with

the projector is connected here.

Connecl a power cord thai is raled for

120 V and 60 Hz.

7

~~~~~~~

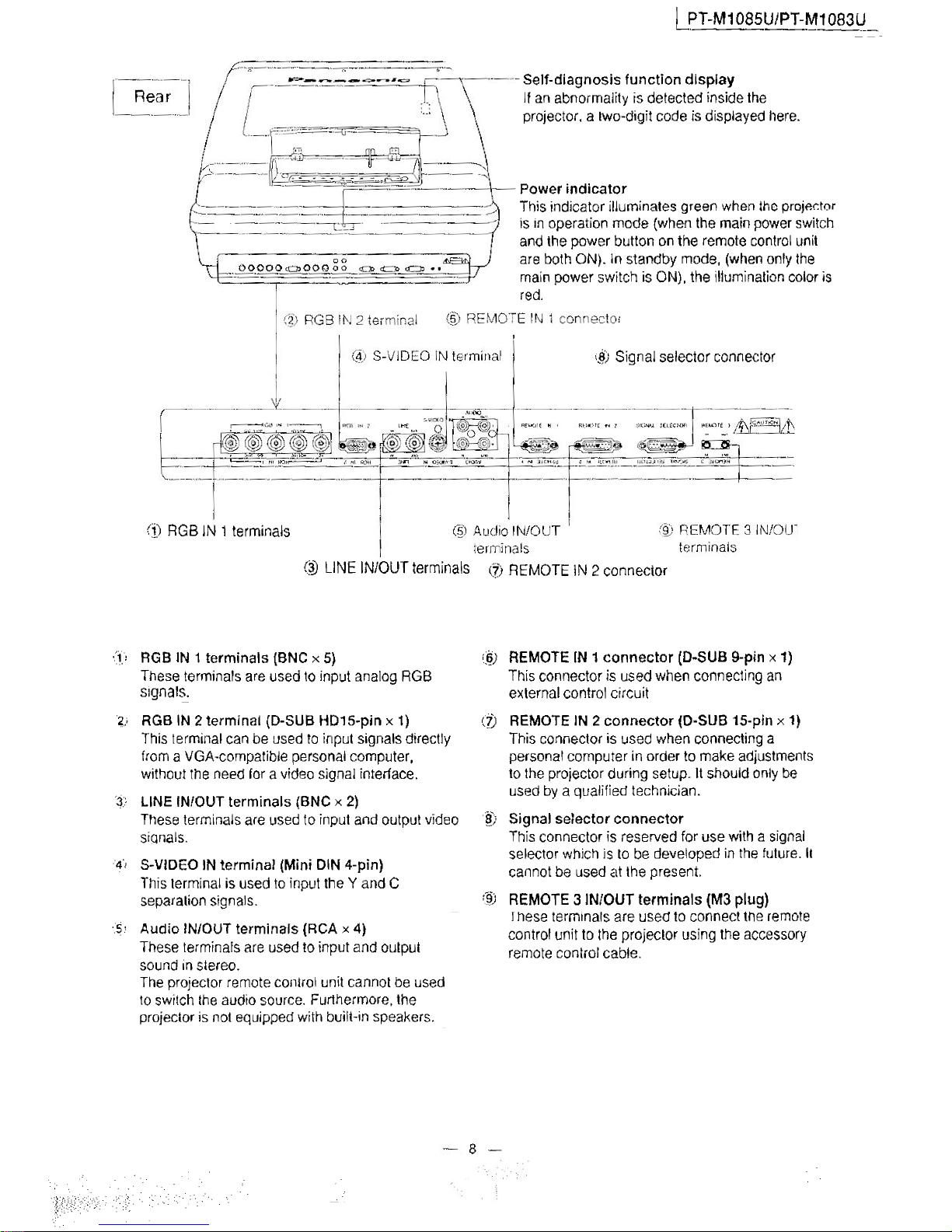

(j) AGB IN 1 terminals

-'1' RGB IN 1 terminals (BNC x 5)

These terminals are used to input analog RGB

signals.

2.) RGB IN 2 terminal (D-SUB HD15-pin x 1)

This terminal can be used to input signals directly

from a VGA-compatible personal computer,

without the need for a video signal interface.

~: LINE IN/OUT terminals (BNC x 2)

These terminals are used 10 input and output video

siQnals.

4" S-VIDEO IN terminal (Mini DIN 4-pin)

This terminal is used to input the Y and C

separation signals.

'5' Audio IN/OUT terminals (RCA x 4)

These terminals are used to input and output

sound in stereo.

The projector remote control unit cannot be used

\0 switch the audio source. Furthermore. the

projector is not equipped with built.in speakers.

:'. . " '"

. . ' .

'}~iiri{'l:'; :~~';ii:: " ::,..: :~' :',

~~

U>T-M1085U1PT-M1083U

Self-diagnosis function display

If an abnormality is detected inside the

projector, a Iwo-digit code is displayed here.

Power indicator

This indicator illuminates green when tho proj~tor

is in operation mode (when the main power switch

and the power button on the remote control unit

are both ON). In standby mode. (when only the

main power switch is ON). the illumination color is

red.

I§) Signal selector connector

(I) REMOTE IN 2 connector

@ LINE IN/OUT terminals

@

REMOTE IN 1 connector (D-SUB 9-pln x 1)

This connector is used when connecting an

exlernal control circuit.

ev

REMOTE IN 2 connector (D-SUB 15-pin x 1~

This connector is used when connecting a

personal computer in order to make adjustments

to the projector during setup- It should only be

used by a qualified technician.

Signal selector connector

This connector is reserved for use with a signal

selector which is to be developed in the future. \I

cannot be used at Ihe present.

ID

@

REMOTE 3 IN/OUT terminals (M3 plug)

These terminals are used to connect the remote

control unit to the projector using the accessory

remote control cable.

8

~~~

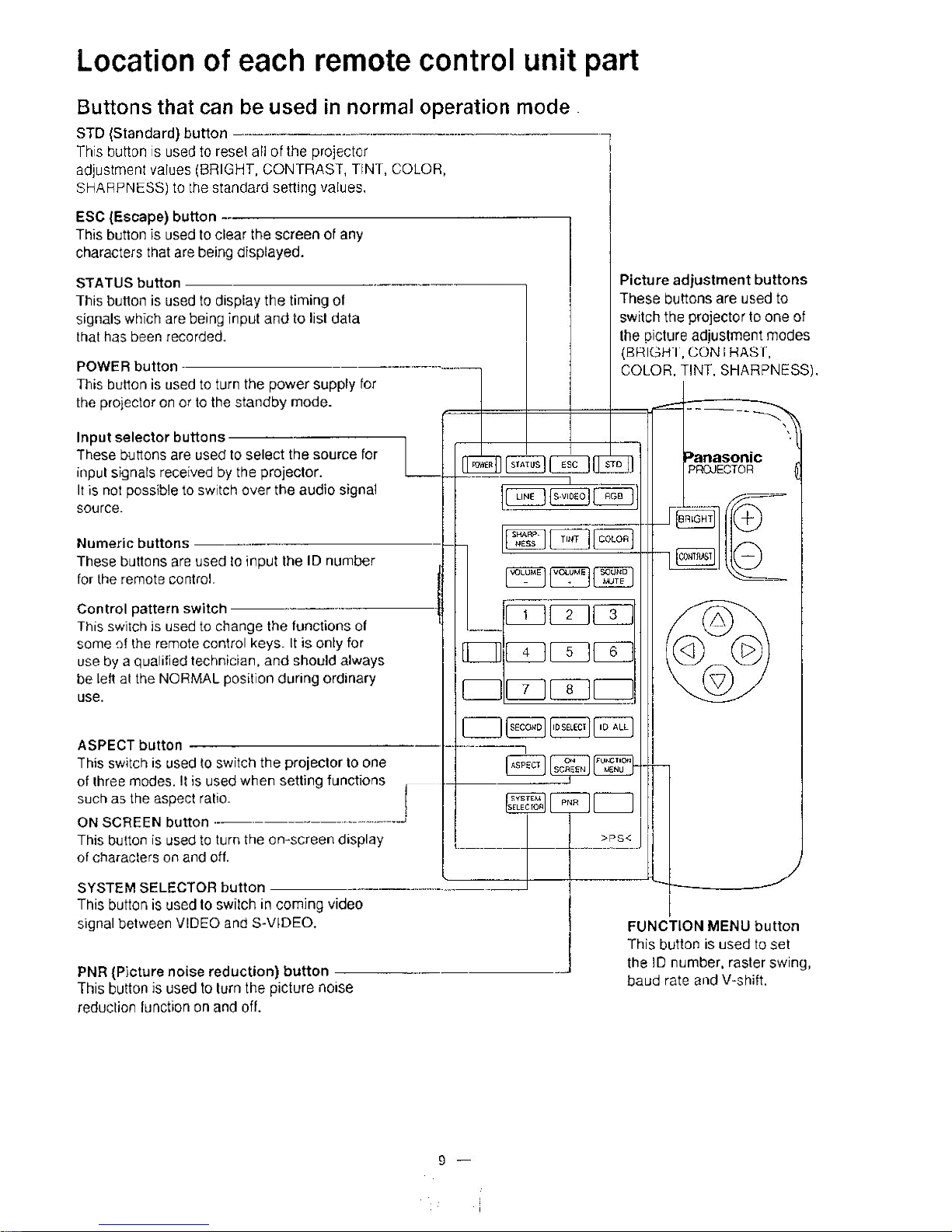

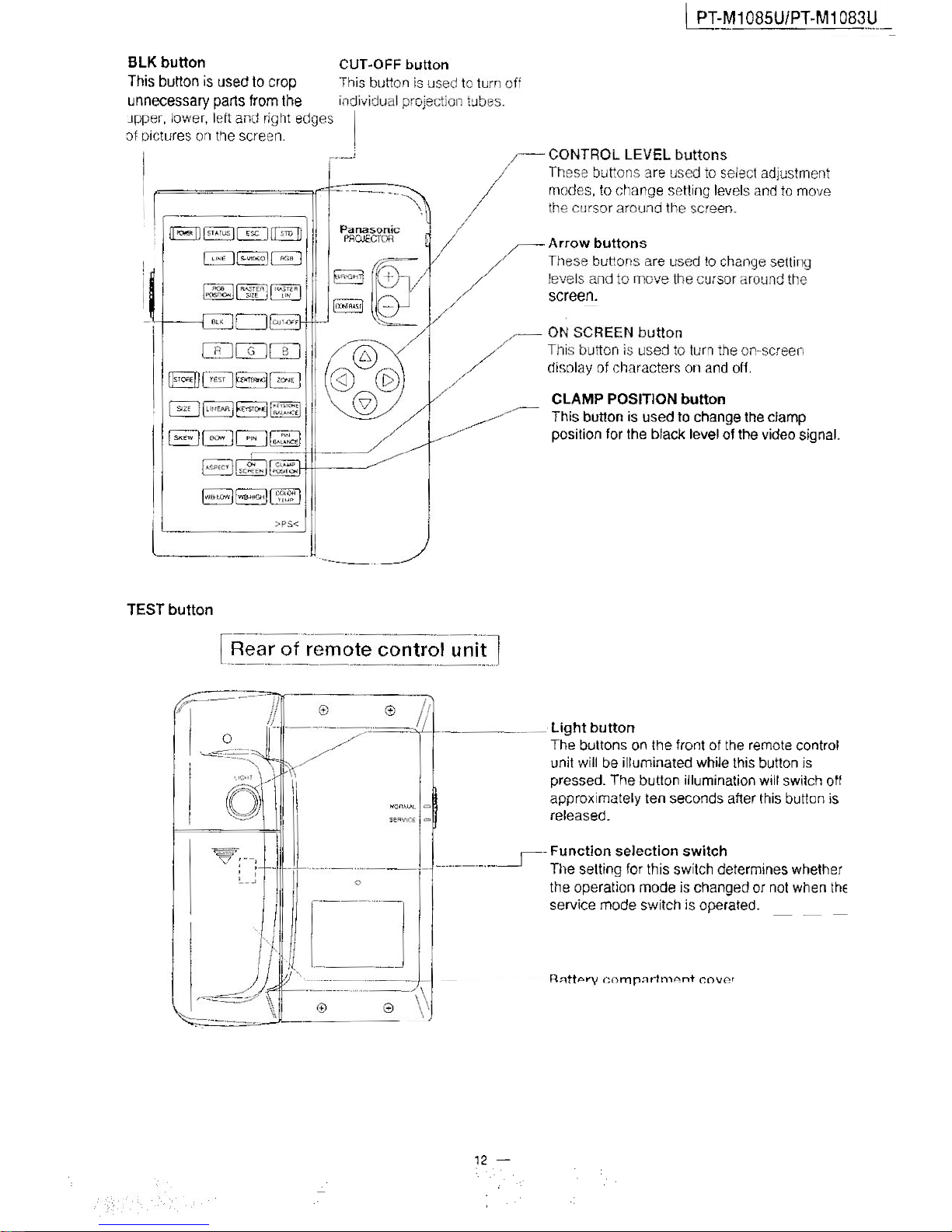

Location of each remote control unit part

ESC (Escape) button --

This button is used to clear the screen of any

characters that are being displayed.

STATUS button ---

IThis button is used 10 display the timing of

signals which are being input and to list data

that has been recorded.

POWER button" ..-.....---..-

This button is used to turn the power supply for

the projector on or to the standby mode.

Input selector buttons L

These buttons are used to select the source for

input signals received by the projector.

It is not possible to switch over the audio signal

source"

Numeric buttons --.---..

These buttons are used 10 input the ID number

Ifor the remote control. -

Control pattern switch "_'_00""'" -;

This switch is used to change the functions of

some of the remote control keys" It is only for

use by a qualified technician, and should always

be left al the NORMAL position during ordinary

use.

ASPECT button

This switch is used to switch the projector to one

of three modes. II is used when setting functions

Isuch as the aspect ralio"

ON SCREEN button oo ,,---J

This button is used to turn the on-screen display

of characlers on and off.

SYSTEM SELECTOR button ......-.-..............-

signal between VIDEO and S-VIDEO. I

PNR (Picture noise reducUon) button - .J

This button is used to swilch in coming video

This button is used to lurn the picture noise

reduclion function on and off.

Picture adjustment buttons

These buttons are used to

switch the projector to one of

the picture adiustment modes

I

FUNCTION MENU button

This button is used to set

the 10 number, raster swing,

baud rate and V-shift.

9

~

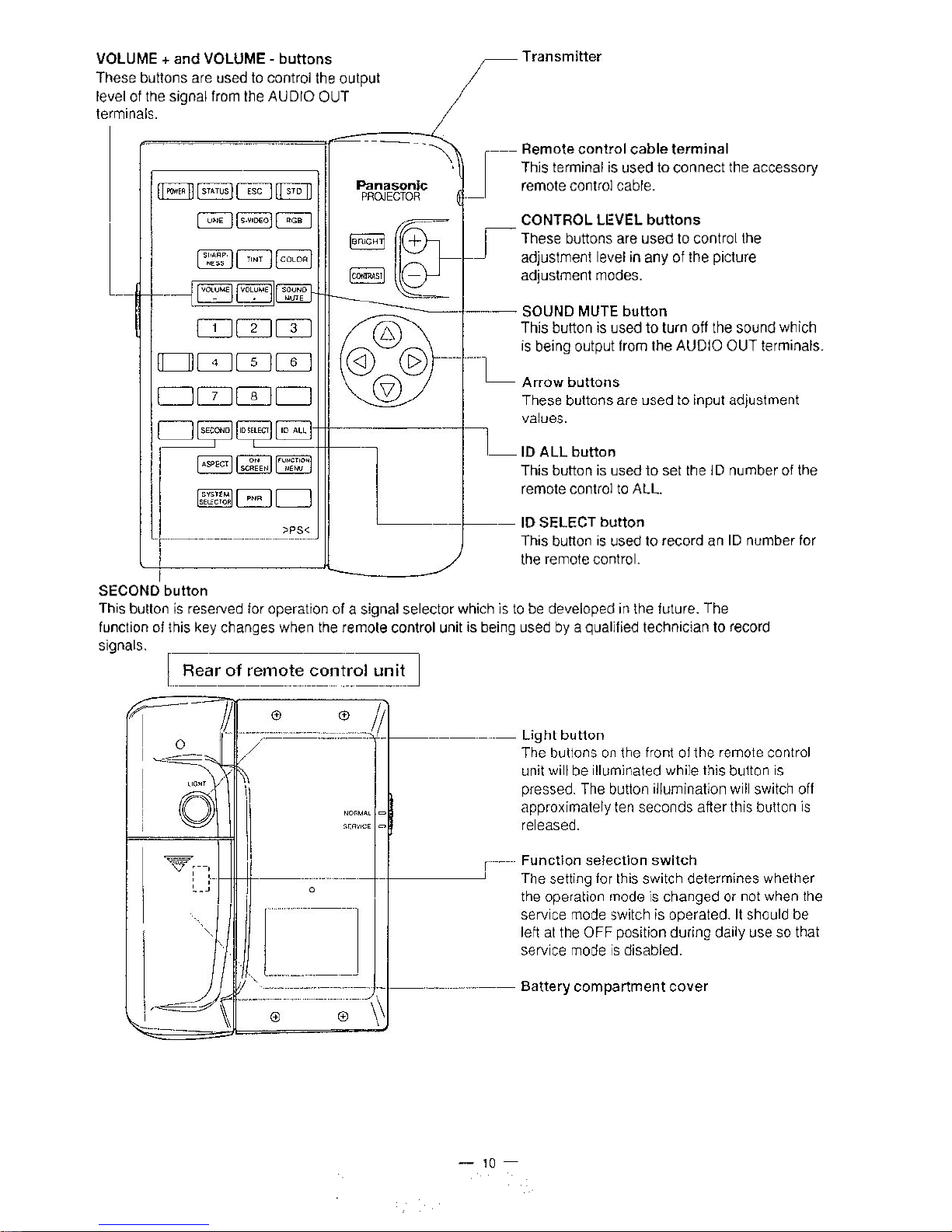

VOLUME + and VOLUME - buttons

These buttons are used to control the output

level of the signal from the AUDIO OUT

I

SECOND button

This button is reserved lor operation of a signal selector which IS to be developed in the future. The

function ollhis key changes when the remole control unit is being used by a qualJfied technician to record

signals.

Remote control cable terminal

This terminal is used to connect the accessory

remote control cable.

CONTROL LEVEL buttons

These buttons are used to control the

adjustment level in any of the picture

adjustment modes.

This button is used to turn off the sound which

is being output from the AUDIO OUT terminals.

ID ALL button

This button is used to set the 10 number of the

remote control to ALL.

ID SELECT button

This button is used to record an 10 number for

the remote control.

10

-

~~~~~

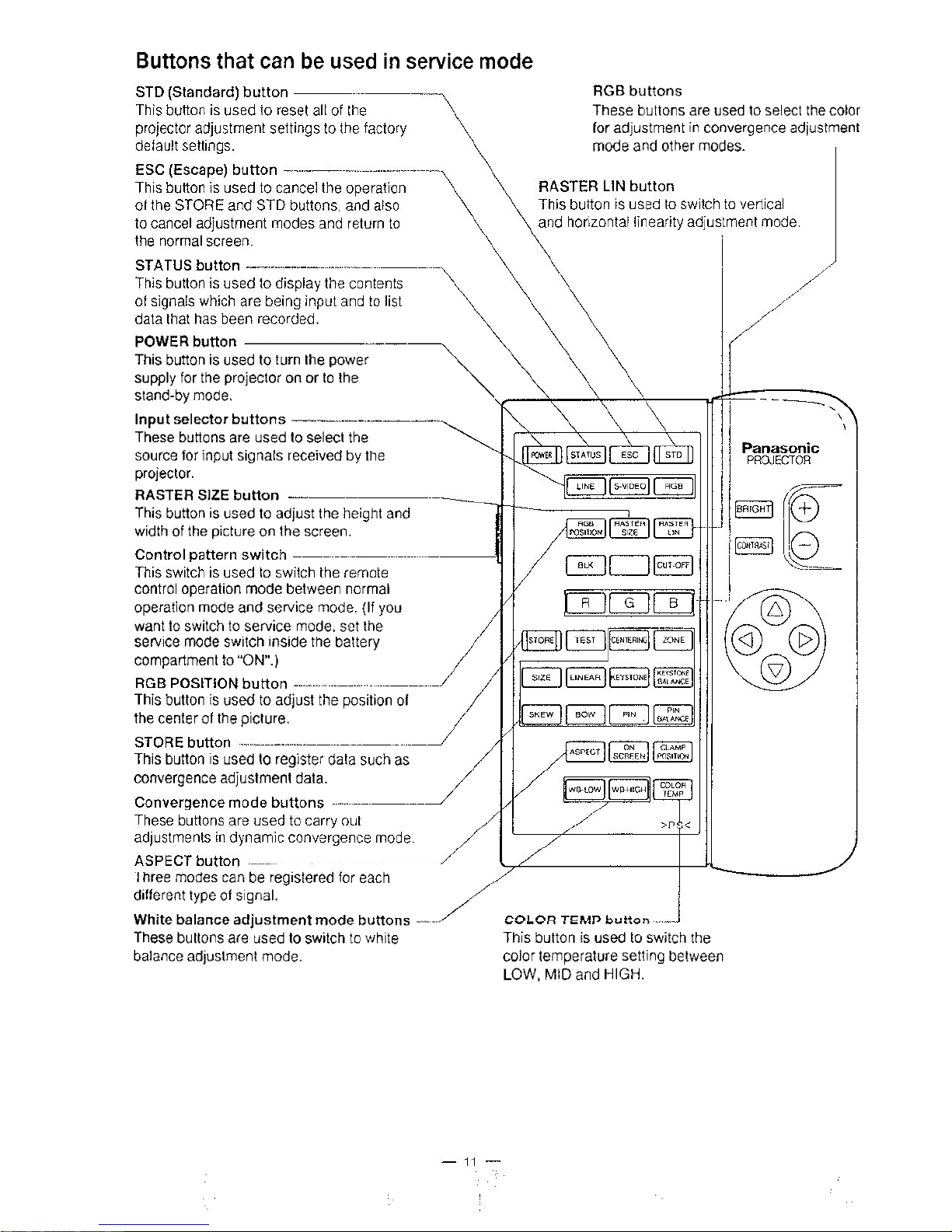

Buttons that can be used in service mode

POWER button ~This button is used to turn the power

supply for the projector Dn Dr tD Ihe

stand-by mode.

Input selector buttons -'-'-"-"'--' '-"'",-

These buttons are used to select the ~

source for input signals received by the

proj ector.

RASTER SIZE button

This button is used to adjust the height and

width of the picture on the screen.

control operation mode between normal

operation mode and service mode. (If you

want to switch to seNice mode. set Ihe

service mode switch inside the battery

compartment to "ON".)

This butlon is used to adjust the position 01

the center of the picture.

This button is used to register dala such as

convergence adjustment data.

Three modes can be registered for each '"

different type of signal.

/White balance adjustment mode buttons -.----

These bullons are used to switch to white

balance adjustmenl mode.

~

RGB buttons

These buttons are used to select the color

ror adjustment In convergence adjustment

mode and other modes.

"' "" , 1 . " .."'.,

This button is used to switch the

color temperature setting belween

LOW, MID and HIGH.

~~~~~

BlK button

This button is used to crop

unnecessary parts from the

TEST button

~

I PT-M1085U1PT-M1083U

screen.

'" CLAMP POSITION button

~ This button is used to change the clamp

~ position for the black level of the video signal.

)1 unit I

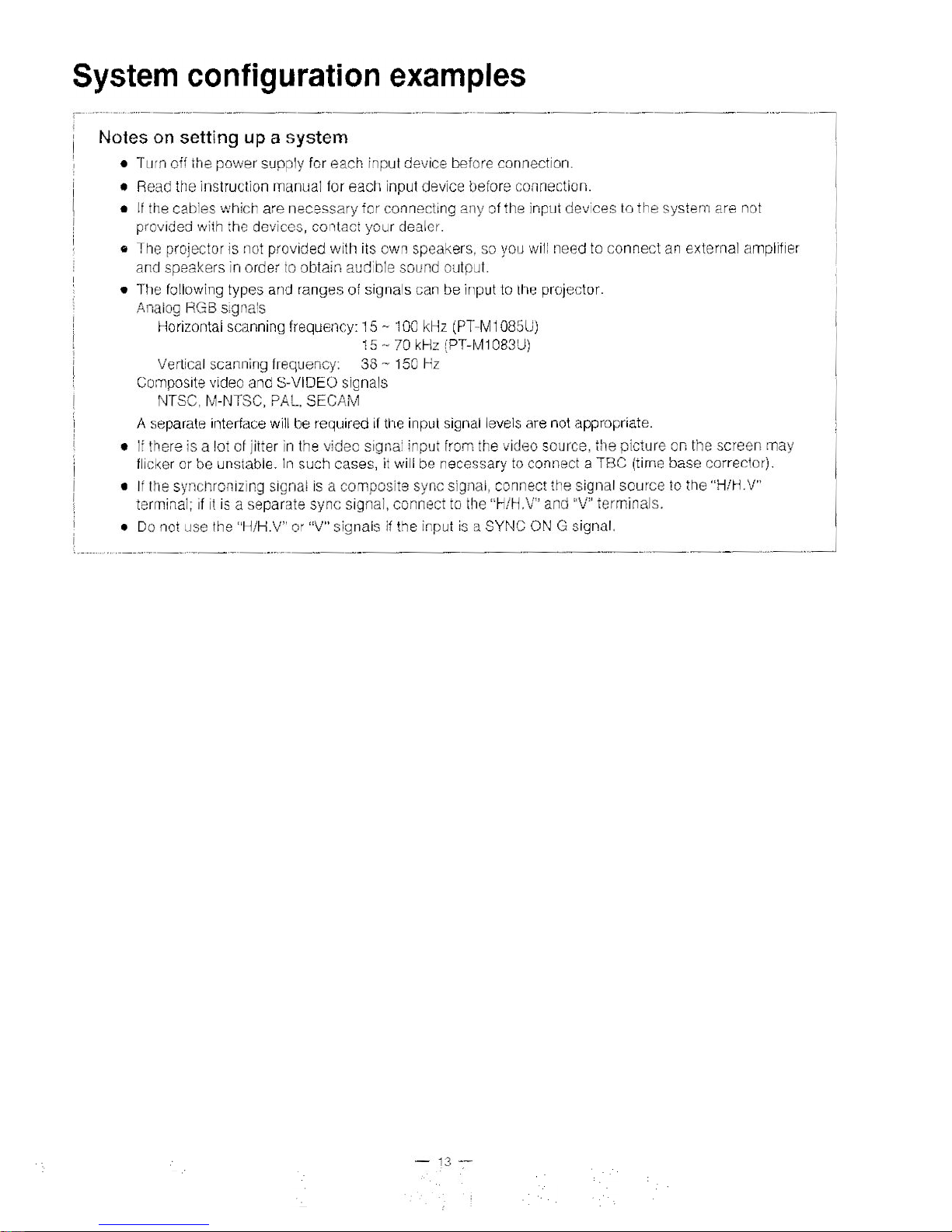

Light button

The buttons on the front of the remote control

unit will be illuminated while this button is

I pressed. The button illumination will switch off

approximately ten seconds after this button is

released.

~ Function selection switch

-. TIle setting for this switch determines whether

the operation mode is changed or not when the

service mode switch is operated.

12 -

I

~~~~~~

System configuration examples

~~~~~~~~~

PT.M1085U1PT-M1083U I

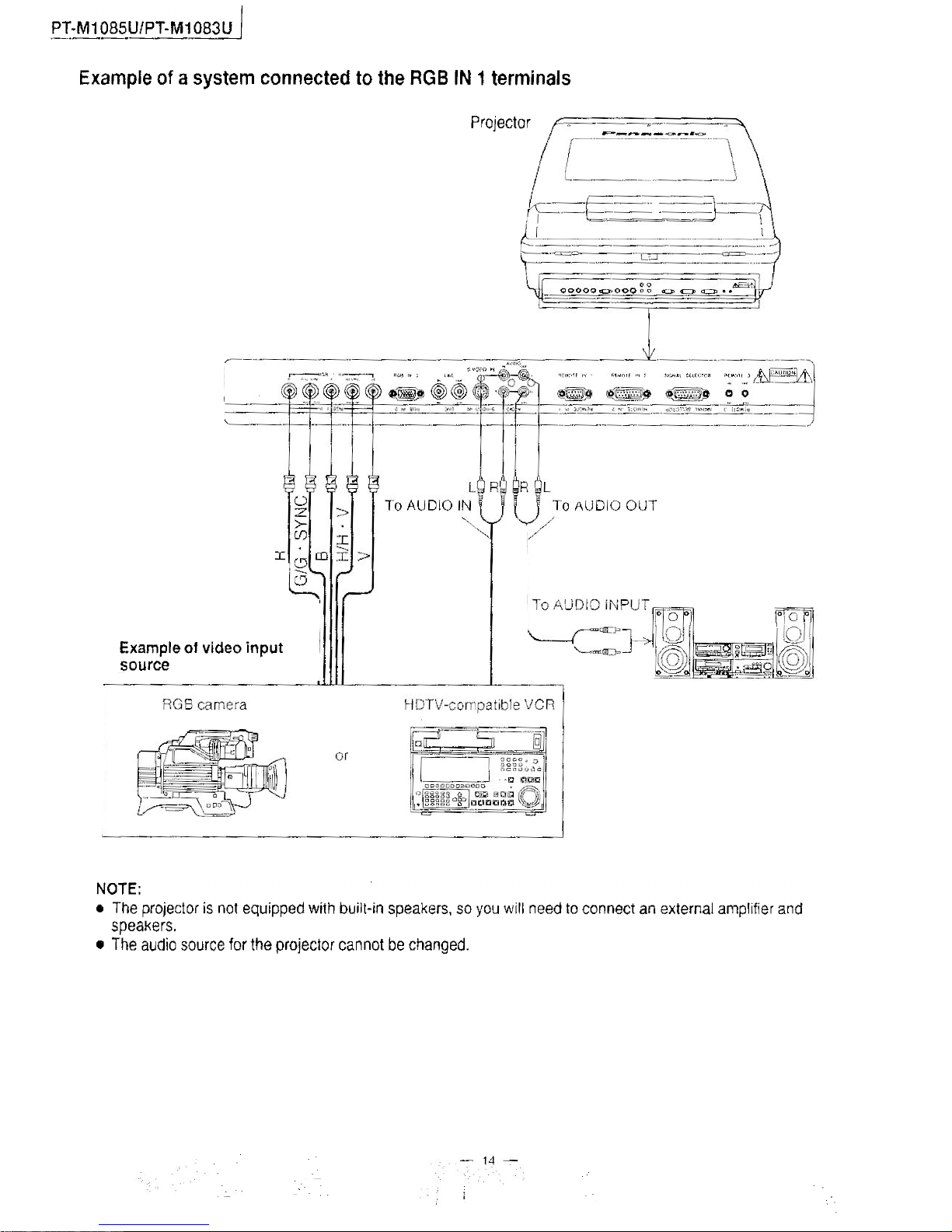

Example of a system connected to the RGB IN 1 terminals

Example of video input

source

NOTE:

. The projector is nol equipped with built-in speakers, so you will need to connect an external amplifier and

speakers.

The audio source for the projector cannot be changed.

.

~~~~~~

Projector

~~i~

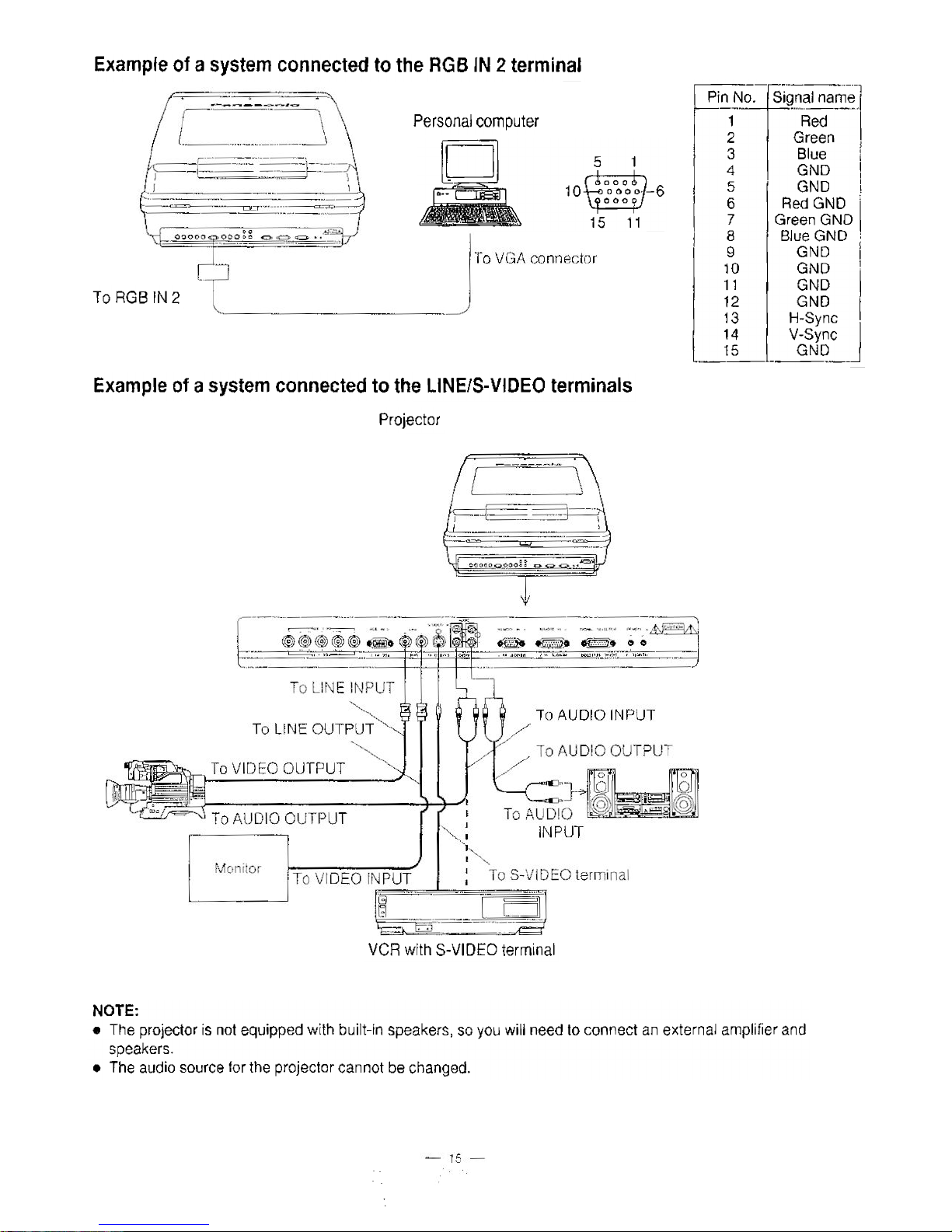

Example of a system connected to the RGB IN 2 terminal

ToRGBIN2

Example of a system connected to the LlNE/5-VIDEO terminals

NOTE:

. The projector is not equipped with built-in speakers, so you will need to connect an external amplifier and

speakers.

. The audio source for the projector cannot be changed.

Pin1N~.- Sign:~a~~-

12 Green

3 Blue

I4 GND

5 GND!

6 Red GND

I7 Green GND

8 Blue GND :

9 GND I

10 GNO

11 GND

12 GND

13 H-Sync

14 V-Sync

15 GND

Personal computer

& 10 5 1

Projector

VCR with S-VIDEO terminal

~~

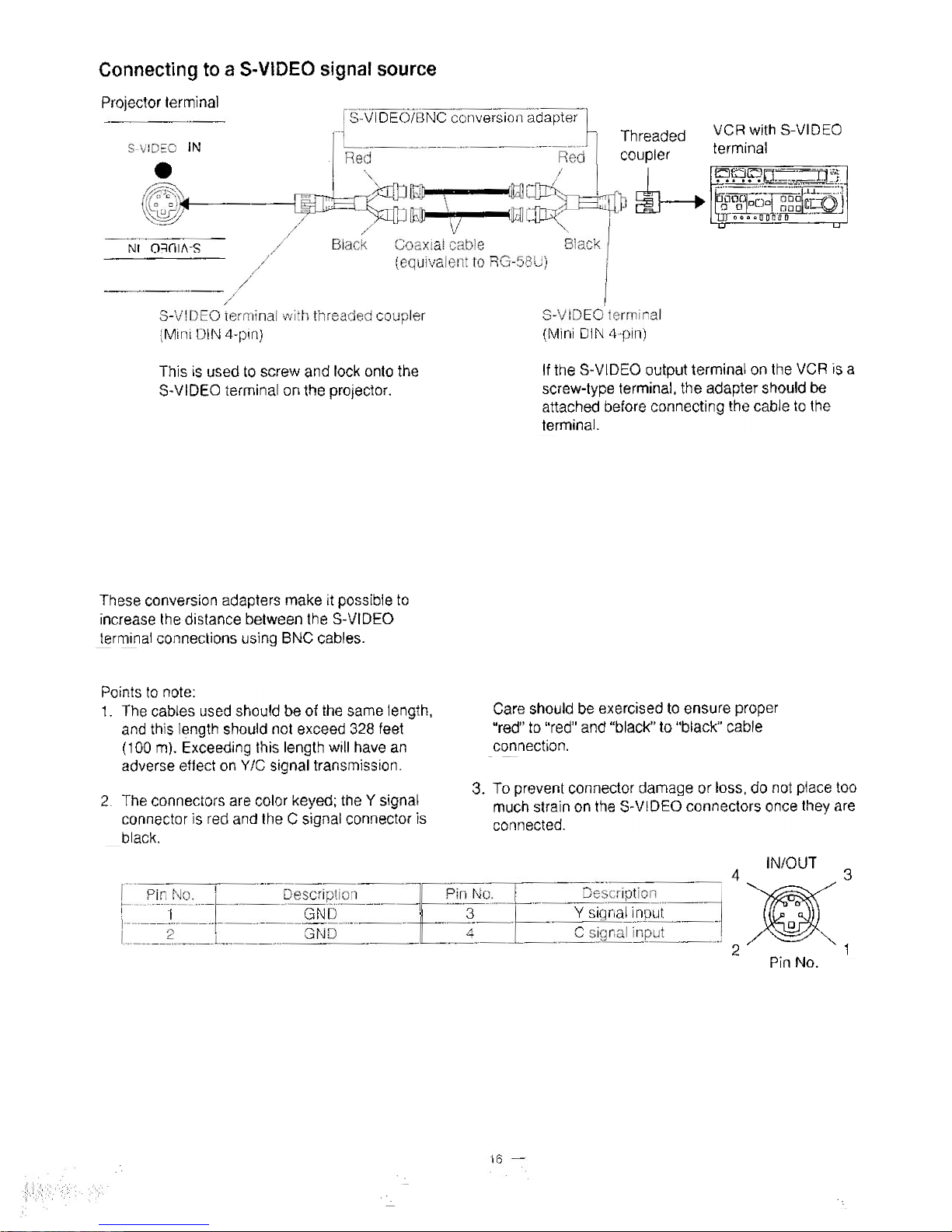

Connecting to a S-VIDEO signal source

Projector terminal

IN

NI 0=1011\0£

This is used to screw and lock onto the

S.vIDEO terminal on the projector.

These converSion adapters make it possible to

increase the distance between the S-VIDEO

terminal connections using BNC cables.

Points to note:

1. The cables used should be of the same length.

and this length should not exceed 328 feet

(100 m). Exceeding this length will have an

adverse effect on Y/C signal transmission.

2. The connectors are color keyed; the Y signal

connector IS red and the C signal connector IS

black.

~

VCR with S-VIDEO

terminal

If the S-VIDEO output terminal on the VCR is a

screw-type terminal. the adapter should be

attached before connecting the cable to the

terminal.

Care should be exercised to ensure proper

"red" to "red" and "black" to "black" cable

connection.

To prevent connector damage or loss, do not pi ace too

much strain on the S-VIDEO connectors once they are

connected.

3.

IN/OUT

4

-

3

1

.:0:

2 Pin No.

~~~

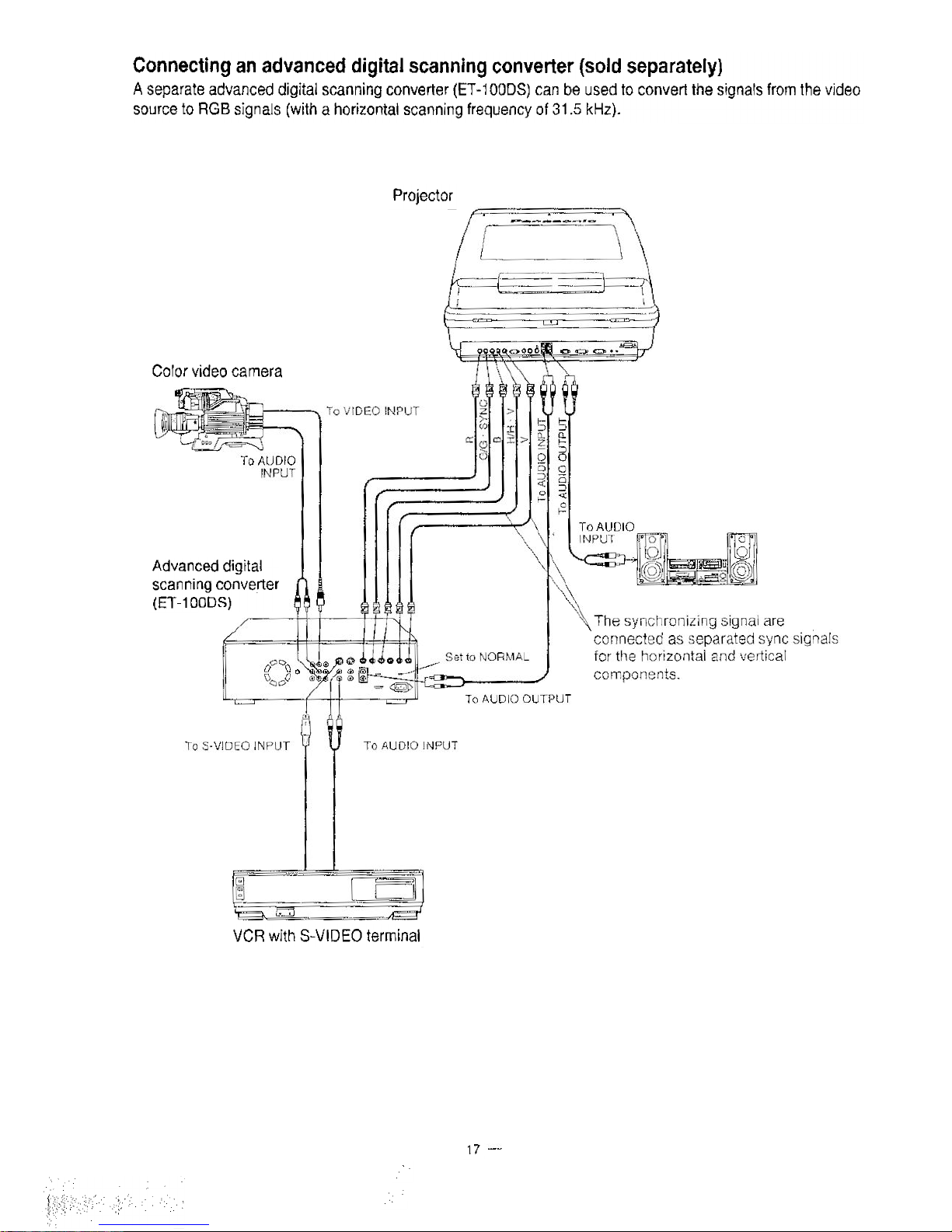

Connecting an advanced digital scanning converter (sold separately)

A separate advanced digital scanning converter (ET-100DS) can be used to convert the signals from the video

source to RGB signals (with a horizontal scanning frequency of 31.5 kHz).

Color video camera

Advanced digital

scanning converter

(ET-100DS)

VCR with S-VIDEO terminal

. .

, ,", "

", ,

"!.~'~'}'::}<": ...;1:"> :' ."':. :

Projector

17

'.

~

PT-M1085U1PT-M1083U I

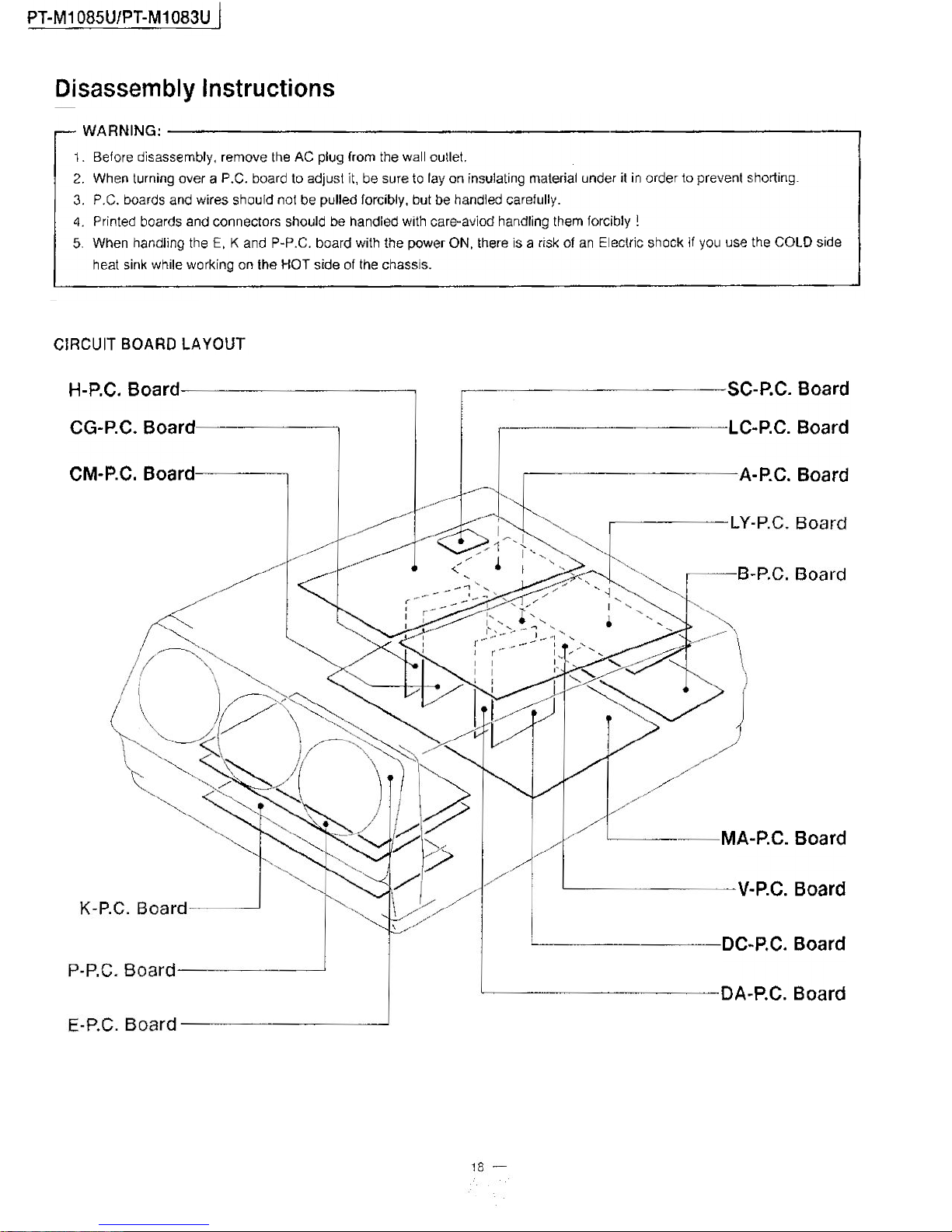

Disassembly Instructions

WARNING:

1. Before disassembly. ramove the AC plug from the wall oullet.

2. When turning over a P.C. board to adjust it. be sure to lay on insulating material under it in order to prevent shorting.

3. P.C. boards and wires should not be pulled forcibly, but be handled carefully.

4. Printed boards and connectors should be handled with care-aviod handling them forcibly!

5. When handling the E, K and P-P.C. board with the power ON. there is a risk of an Electric shock if you use the COLD side

heat sink while working on the HOT side of the chassis.

CIRCUIT BOARD LAYOUT

H-P.C. Board-

CG-P.C. Board

CM-P.C. Board

.SC-P.C. Board

-LC-P.C. Board

-A-P.C. Board

MA-P.C. Board

- V-P.C. Board

'DC~P.C. Board

DA.P.C. Board

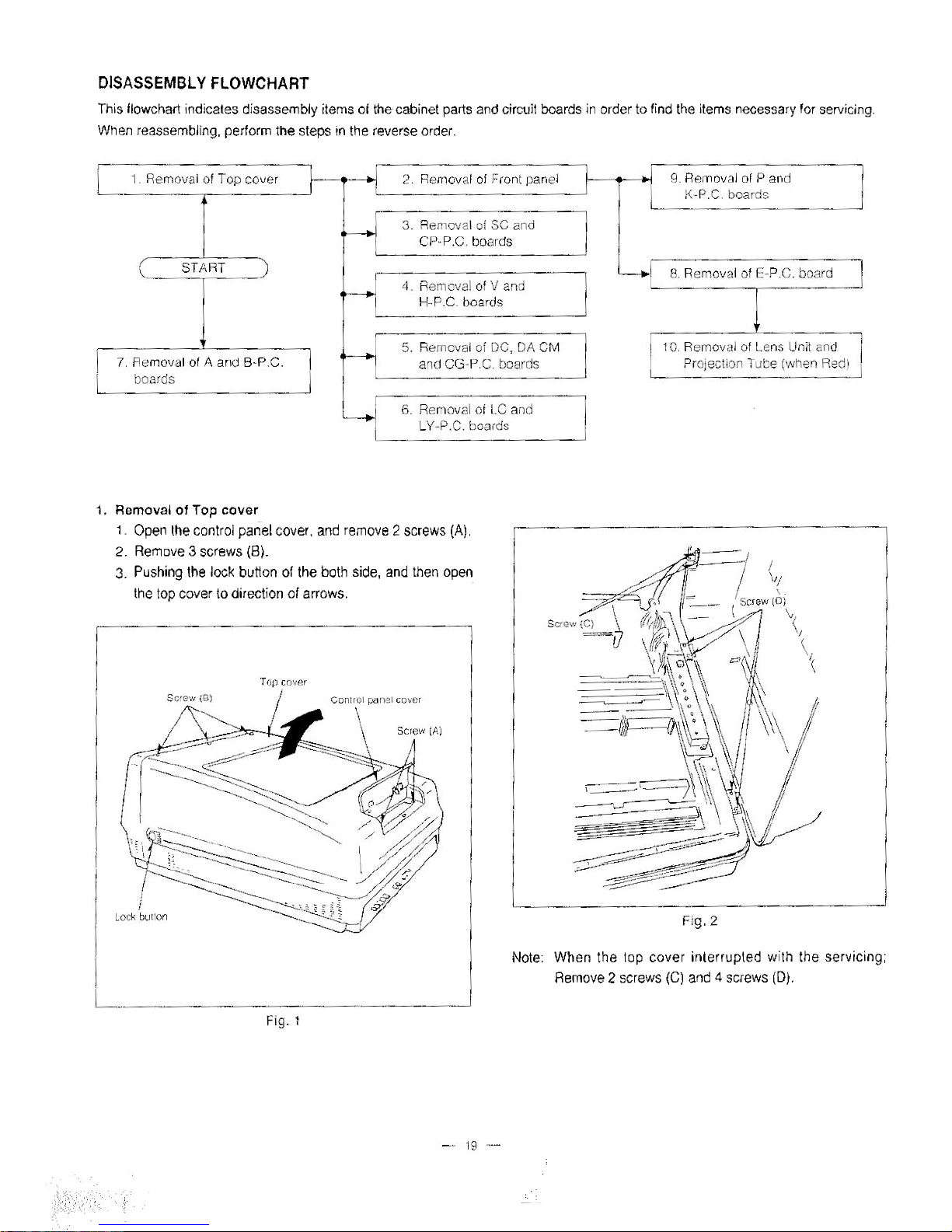

DISASSEMBLY FLOWCHART

This flowchart indicates disassembly items of the cabinet parts and circuit boards in order to find the items necessary for servicing.

When reassembling. perform the steps in the reverse order.

1. Removal of Top cover

Open the control panel cover, and remove 2 screws (A).

1.

2.

3.

Remove 3 screws (8).

Pushing the lock button of the both side. and then open

the top cover 10 direction of arrows.

Note: When the top cover interrupted with the servicing;

Remove 2 screws (C) and 4 screws (D).

;

~

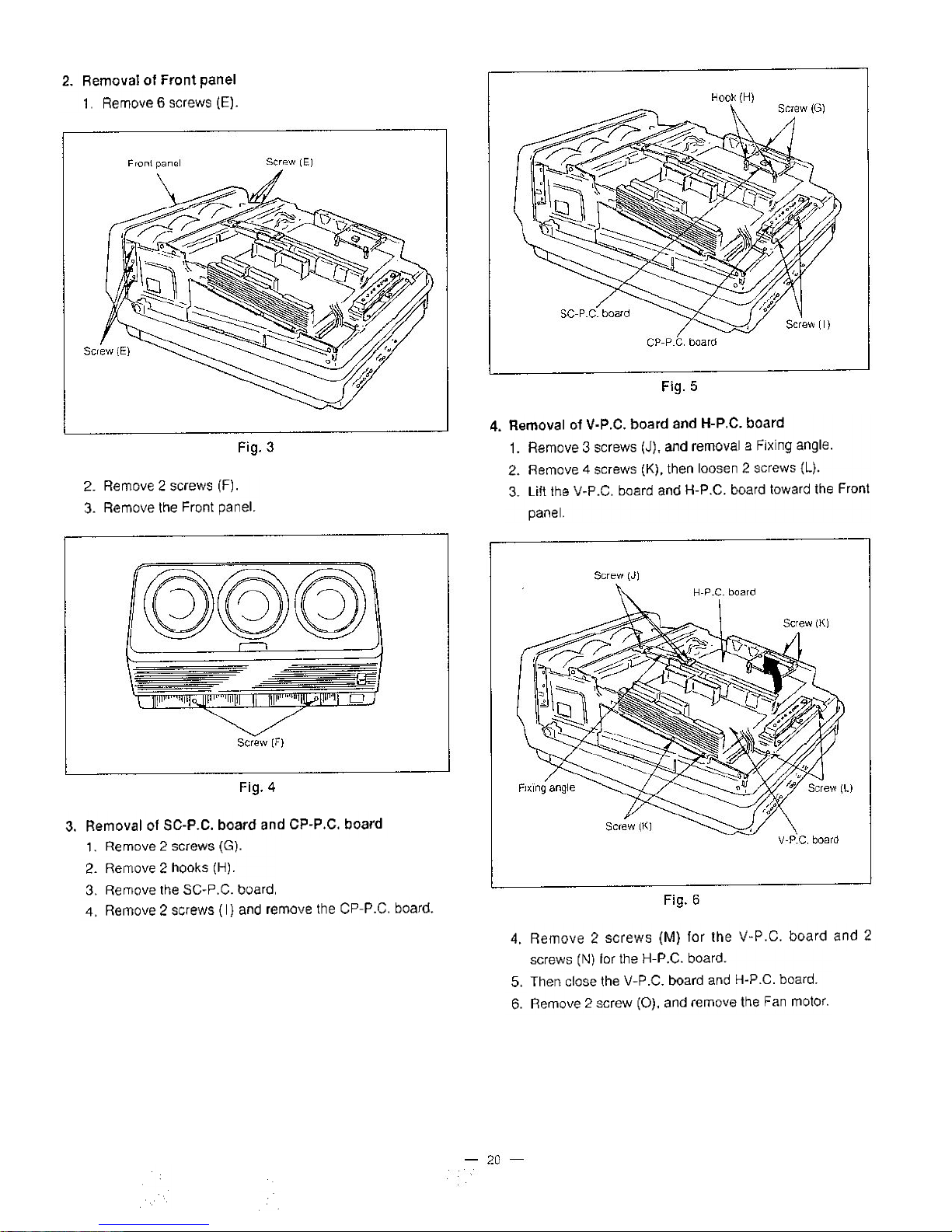

2. Removal of Front panel

1. Remove 6 screws (E).

Remove 2 screws (F).

Remove the Front panel.

2.

3.

3. Removal of SC-P.C. board and CP-P.C. board

Remove 2 screws (G).

Remove 2 hooks (H).

Remove the SC-P.C. board.

1.

2.

3.

4.

Remove 2 screws {I} and remove the CP-P.C. board.

~~

4.

Removal of V-P.C. board and H-P.C. board

1. Remove 3 screws (J). and removal a Fixing angle.

2. Remove 4 screws (K). then loosen 2 screws (L).

3. Lilt the V-P.C. board and H-P.C. board toward the Front

panel.

4. Remove 2 screws (M) fo r the V -P. C. board and 2

screws (N) lor the H-P.Co board.

Then close the V-PoCo board and H-P.Co board.

Remove 2 screw (0), and remove the Fan motor.

5.

6.

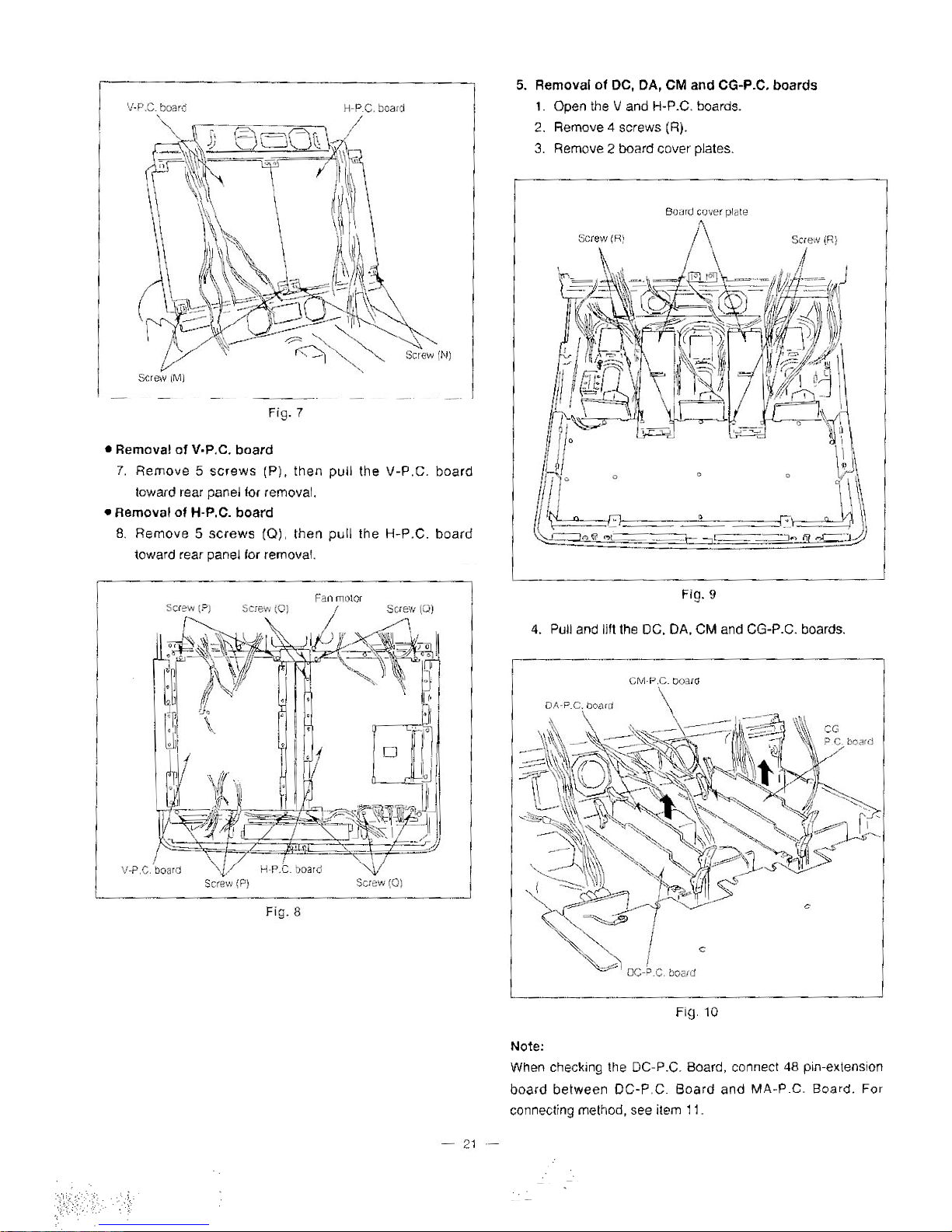

. Removal of V.P.C. board

7. Remove 5 screws (P). then pull the V-P .C. board

toward rear panel for removal.

. Removal of H-P.C. board

8. Remove 5 screws (Q), then pull the H-P.C. board

toward rear panel ror removal.

~

:~W~~~:>1,~,~, "",l'

",

5. Removal of DC, DA, CM and CG-P .C. boards

1. Open the V and H-P.C. boards.

2. Remove 4 screws (R).

3. Remove 2 board cover plates.

4. Pull and Uft the DC. DA. CM and CG-P.C. boards.

Note:

When checking the DC-P .C. Board. connect 48 pin-extension

board between DC-P,C. Board and MA-P.C. Board. For

connecting method, see item 11.

~~~~~

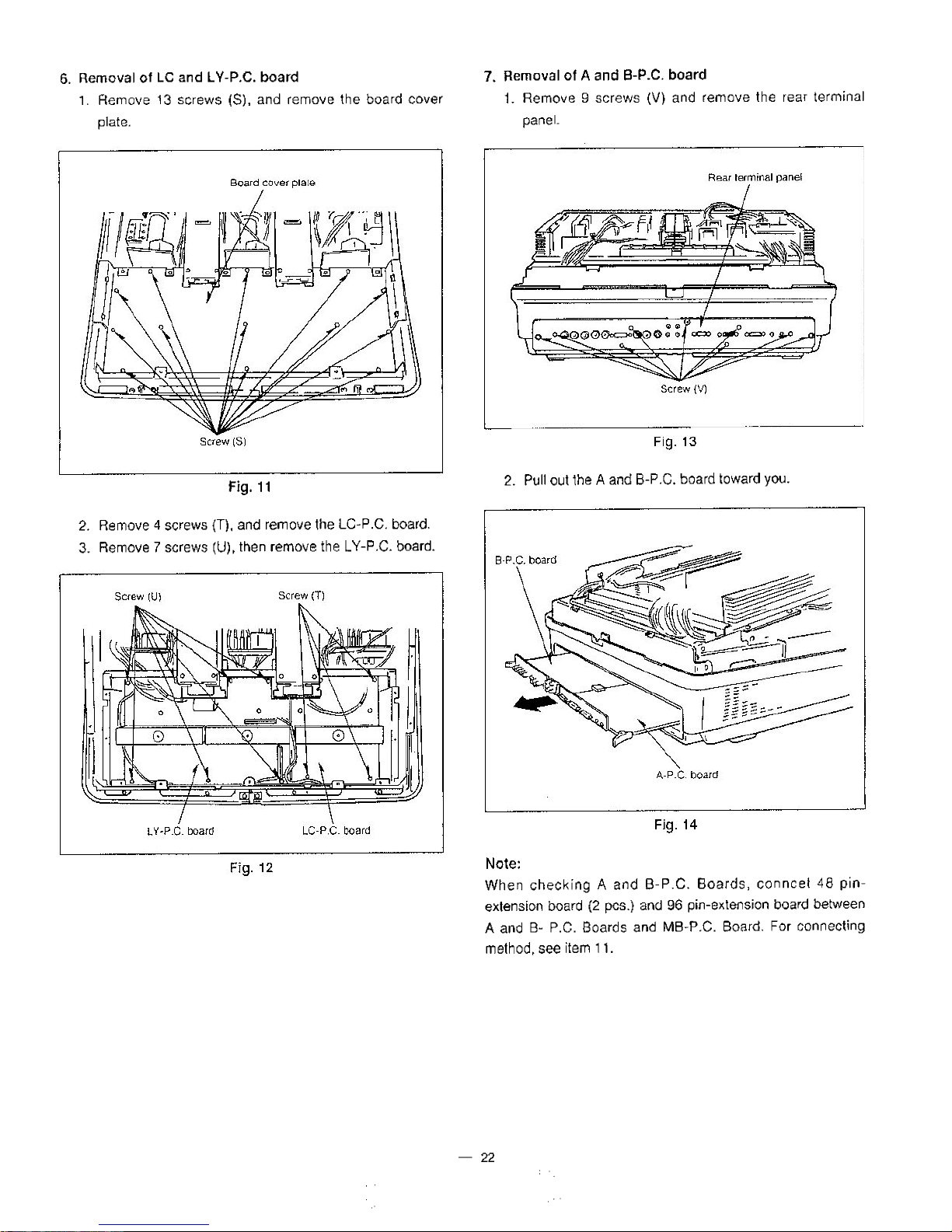

Removal of LC and L V-P.C. board

,. Remove 13 screws (5), and remove the board cover

plate.

6.

Fig. 11 2. Pu 11 out the A and B-P. C. board toward you.

2. Remove 4 screws (T). and remove the LC-P.C. board.

3. Remove 7 screws (U), then remove the L Y-P.C. board.

Removal of A and B-P.C. board

1. Remove 9 screws (V) and remove the rear terminal

paneL

7.

Note:

When checking A and B-P .C. Boards, conncel 48 pin-

extension board (2 pes.) and 96 pin-extension board between

A and B- PoCo Boards and MB-P.Co Board. For connecting

method, see item 11.

- 22

~~~~

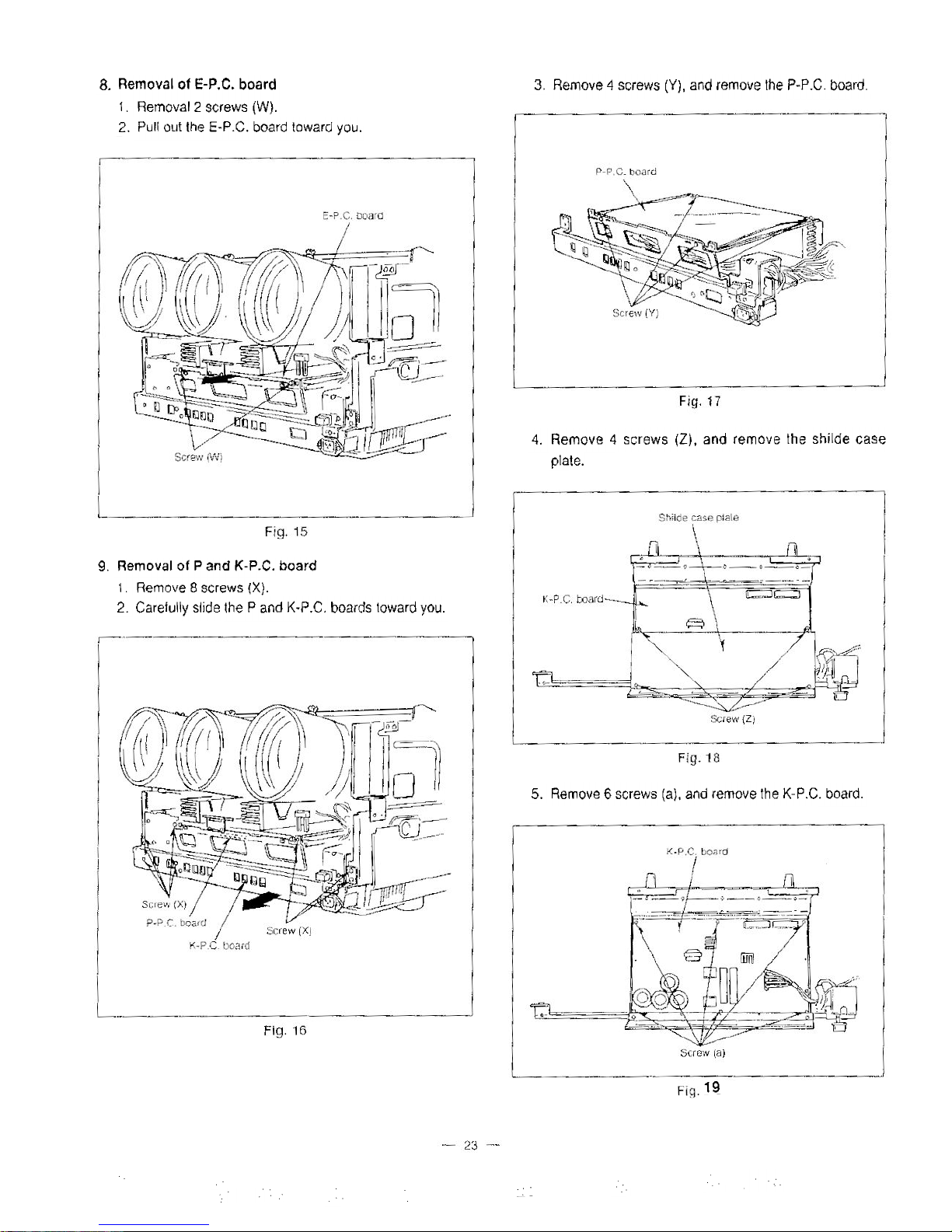

8.

Removal of E-P.C. board

1. Removal 2 screws (W).

Pull out the E-P.C. board toward you.2.

9.

Removal of P and K-P.C. board

1. Remove 8 screws (X).

Carefully slide the P and K.P.C. boards toward you.2-

~~~

Remove 4 screws (V), and remove the P-P.C. board.

3.

4. Remove 4 screws (2). and remove the shilde case

plate.

Remove 6 screws (a). and remove the K-P .C. board.5.

19

~~~~~~

~T.M1085U1PT.M1083U I

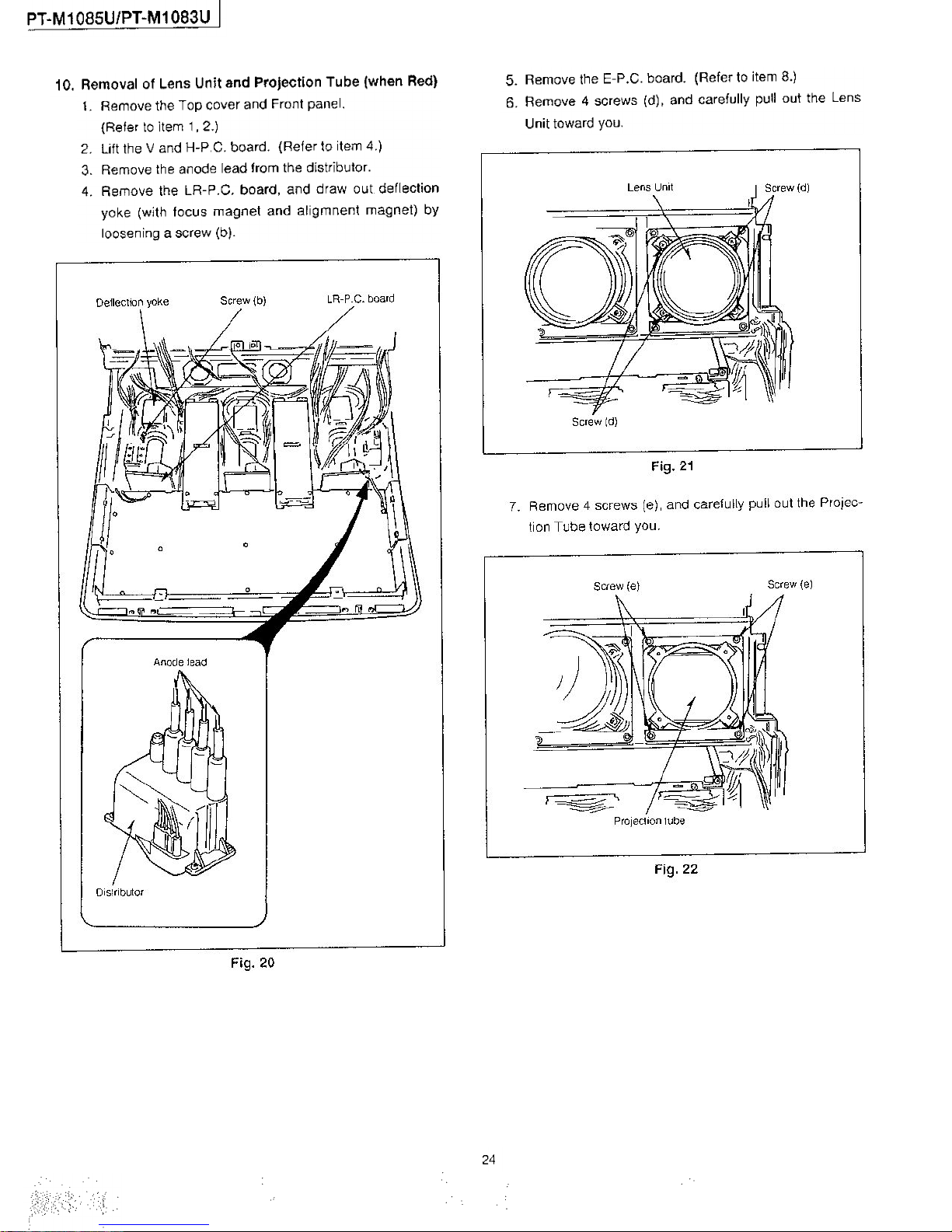

Removal of Lens Unit and Projection Tube (when Red)

1. Remove the Top cover and Front panel.

(Refer to Item 1,2.)

2. Lift the V and H-P.C. board. (Refer to item 4.)

3. Remove the anode lead from the distributor.

4. Remove the LR-P.C. board, and draw out deflection

yoke (with focus magnet and aligmnent magnet) by

loosening a screw (b).

10.

~~~

Remove the E-P.C. board. (Refer to item 8.)

Remove 4 screws (d). and carefully pun out the Lens

Unit toward you.

5.

6.

24

~~~~~

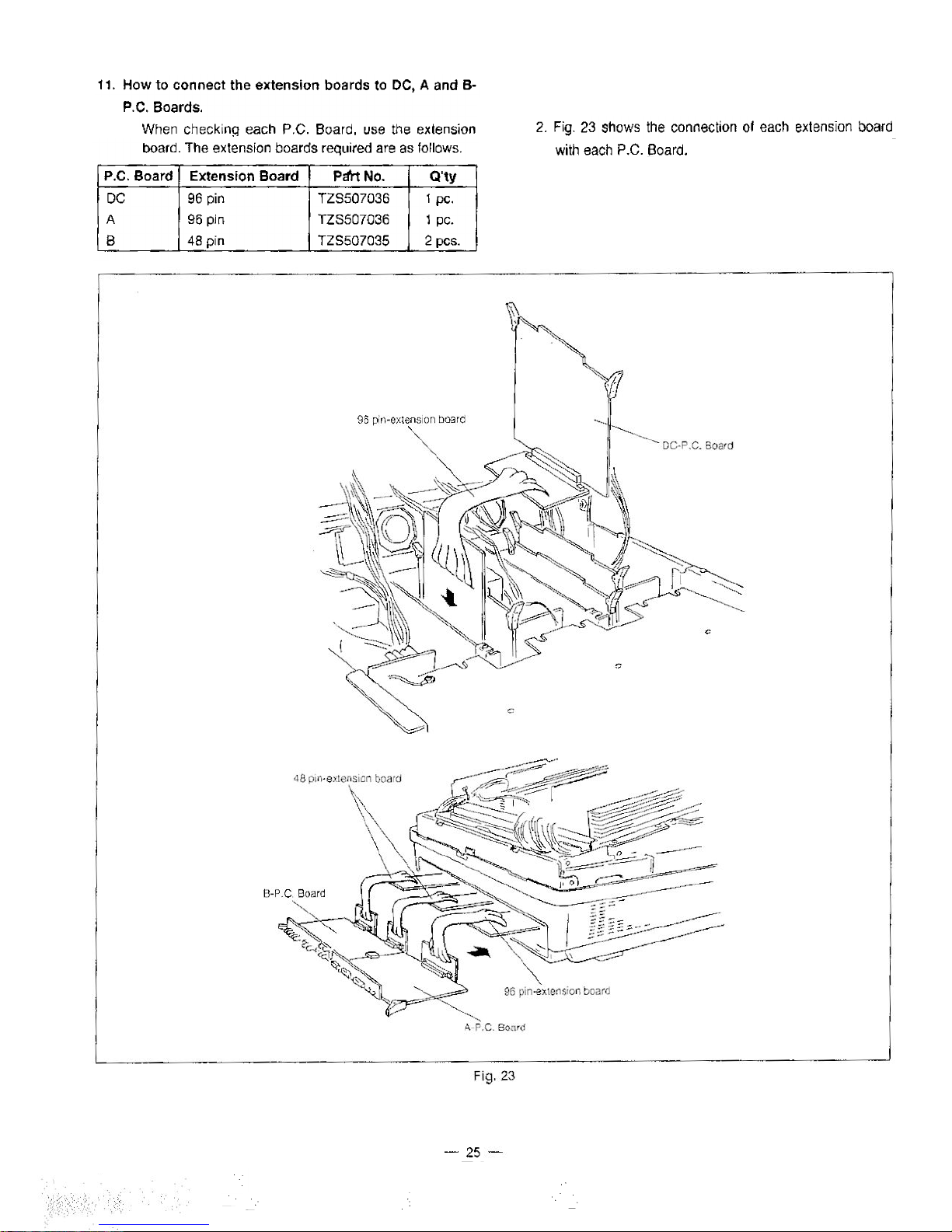

11. How to connect the extension boards to DC, A and BP.C. Boards.

1. When checking each P .C. Board, use the extension

board. The extension boards required are as fonows.

P.C, Board Extension Board pm No. Q'ty

DC 96 pin TZS5Q7036 1 pc.

A 96 pIn TZSSO7036 1 pc.

B 48 pin TZS507035 2 pes.

~~

23 shows the connection 01 each extension board

2. Fig. 23 shows the cor

with each P.C. Board.

25

~~~~

PT.M1085U/PT-M1083U I

~

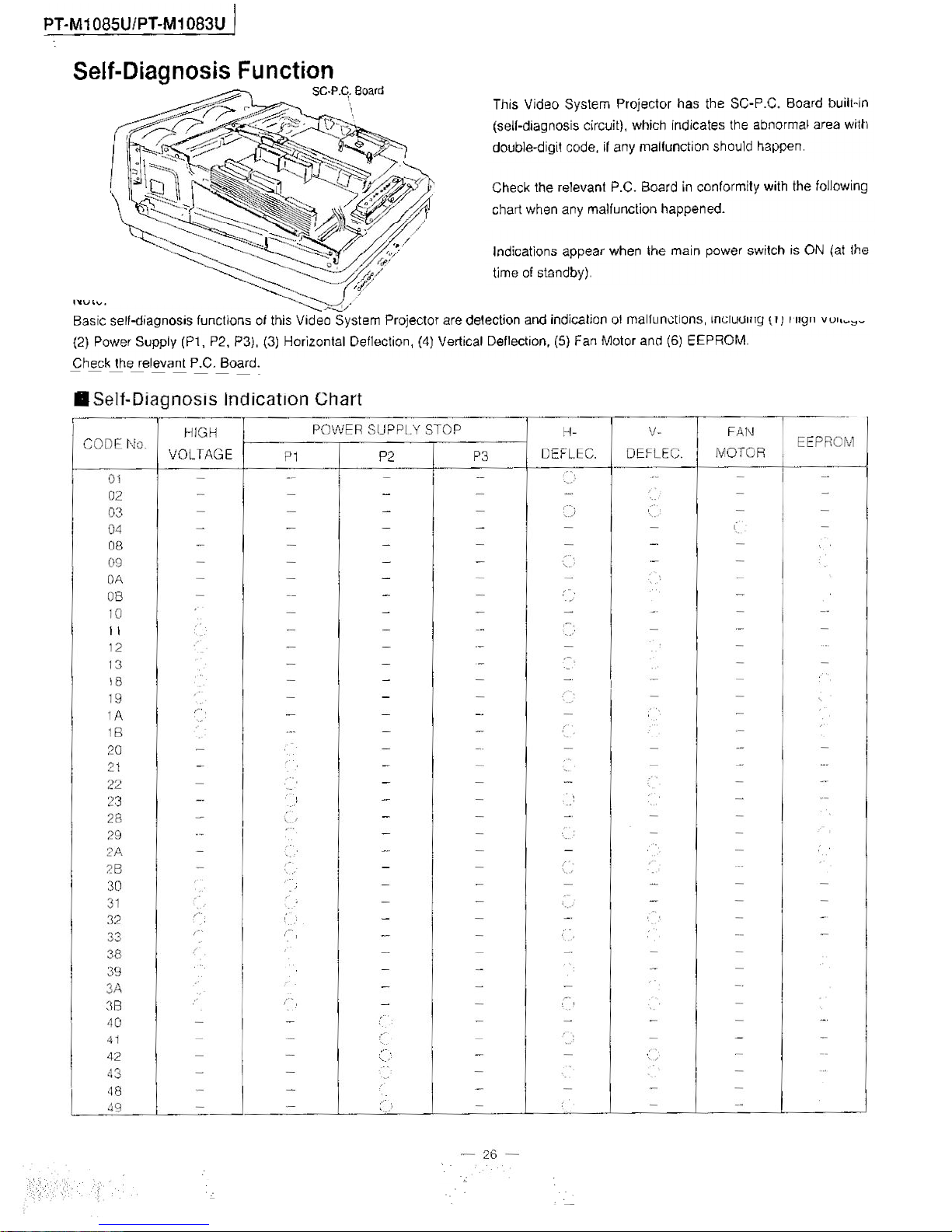

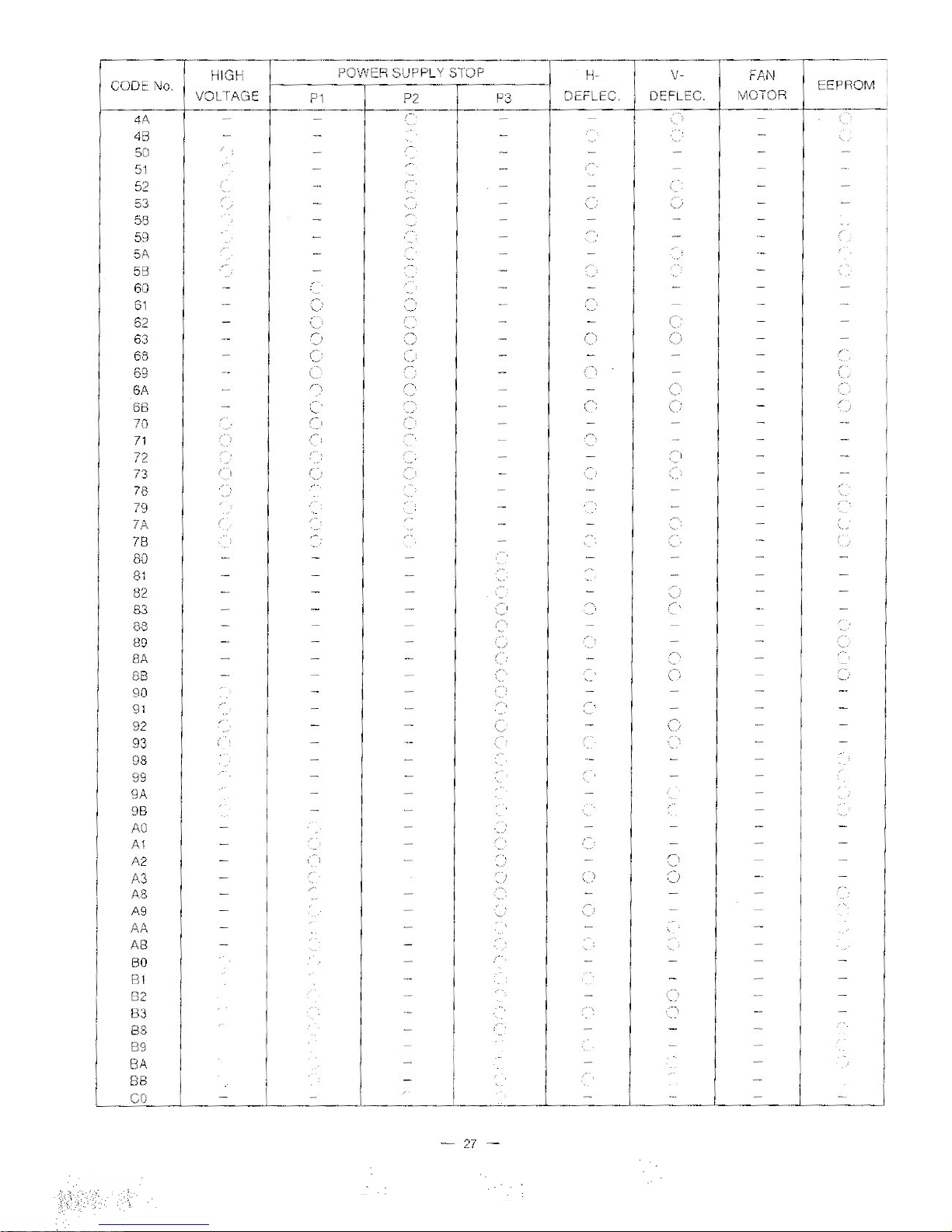

Self-Diagnosis Function

~ SC.P.q. Board

Basic self-diagnosis functions of this Video System Projector are detection and indication 01 malflln~tions, includillg (1) Iligh Voltage,

(2) Power Supply (P1, P2, P3), (3) Horizontal Deflection, (4) Vertical Deflection, (5) Fan Motor and (6) EEPROM.

Check the relevant P.C. Board.

~~

This Video System Projector has the SC-P.C. Board built-in

(self-diagnosls circuit), which indicates the abnormal area with

double-digit code, if any malfunction should happen.

Check the relevant P.C. Board in conformity with the following

chart when any malfunction happened.

Indications appear when the main power switch is ON (at the

time of standby).

~~~~~

, ~!0.):y{; :,' ' i:,;t

~~~~~~~~

Loading...

Loading...