Panasonic PT- 65WX51E, PT- 56WX51E, PT- 56WX51CE Service Manual

ORDER NO. MTNC010631A1

B2

Service Manual

HDTV MONITOR

Simplified Manual

Simp

lifie d

P5PW

Panasonic

Models

PT- 65WX51E EP820

PT- 56WX51E EP820

PT- 56WX51CE EP820

Chassis

PT-65WX51E

This Simplified Service Manual is issued to add listed models to the Simplified Service Manual order No.

MTNC010522A1 (PT-47WX51E). Incl ud ed in this ma nual are schematics that are un iq ue to the listed models, unique

disassembly proce dures, and a c omplete parts list for th e serviceable boards are included i n this Simpl ified Manua l.

Please file and use this manual together with Simplified Service Manual, order No. MTNC010522A1 (PT-47WX51E).

“WARNING! This Service Man ual is desig ned for expe rienced repa ir technici ans only and is not designed f or use by t he general p ublic.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired onl y by experienced pro fessional technicians. Any attempt to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is required to read and follow the “Safety Precautions” and “Important Safety Notice” in this Manual.

Copyright 2001 by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

and distribution is a violation of law.

Important Safety Notice

Special components are used in this projection television that are important for safety. These components are

identified on the schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is

essential that these criti cal parts be repla ced with the manufactur er’s specifie d replacement part to pre vent x-ray

radiation, shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety Precautions

General Guidelines

An

isolation transformer

during the servicing of a PTV whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating a s this protects the techn ician

from accidents resulting in personal injury from

electrical shocks. It will also p rotect the PTV from being

damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices, such as

fishpaper, isolation resistors and capacitors, and

shields after servicing the PTV. Use only

manufacturer ’s recommended ra ting for fuses, c ircuits’

breakers, etc.

High potentials, as high as 32kV, are present when this

PTV is operating. Operation of the PTV without the rear

cover introduces danger for elect rical shock. S ervicing

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be pr acticed when handling the

picture tube

due to atmospheric pressure. (14.7 lbs. per sq. in.). Do

not nick or scratch the glass or subject it to any undu e

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture

tube by shorting the anode to chassis ground (not to

the cabinet or to other mounting hardware). When

discharging, connect cold ground (i.e. DAG ground

lead) to the a node with a well-insulated wire or use a

grounding probe.

. Rough handling may caus e it to implod e

should always be used

X-ray Precautions

The front area (between the projection tube and the

lens) is enclosed by a metal box to ensure positive

safety during normal and abnormal conditions when

checking and repairing. To fully ensure safety, the

following precautions must be observed.

1. Do not remove the lens or metal box.

2. Make sure to turn the power OFF when the le ns is

removed or when checkin g the cleanliness of the

lens.

3. Do not remove the lens or metal box to check the

projection tube for operation by w atching it directly.

Use a mirror or paper to view the image.

Before returning a se rviced PTV to the owner, the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage Current Cold Check

Unplug the AC cord and connect a jumper between the

two plug prongs. Press the POW ER swit ch ON.

Measure the resistance between the jumpered AC plug

and expose metallic parts such as screw heads,

Service Manual

antenna terminals, control shafts, etc. If the exposed

metallic part has a return path to the chassis, the

reading should be between 240k

exposed metall ic part does not have a re turn path to

the chassis, the re adi ng sh oul d be infinite.

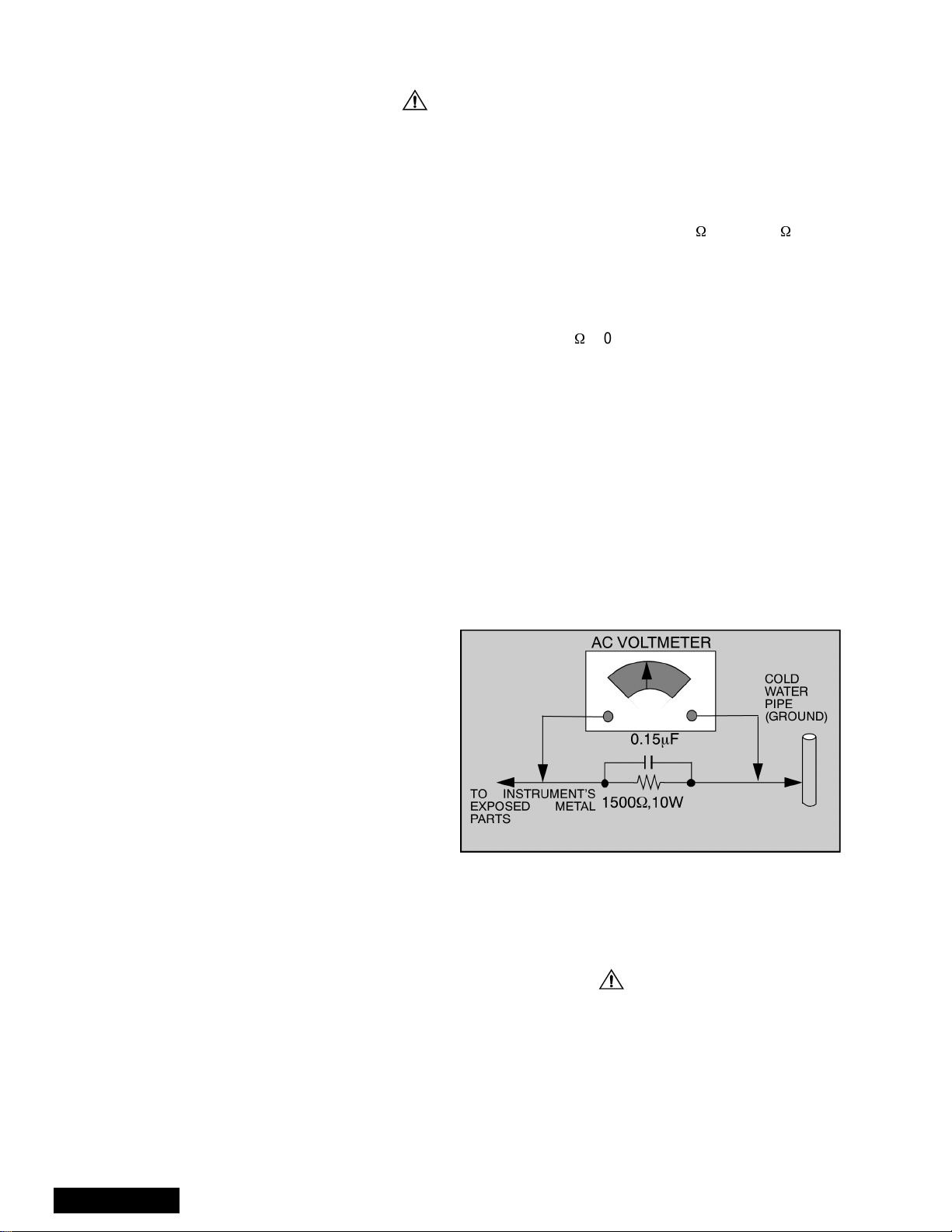

Leakage Current Hot Check

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5k

0.15mF capacitor between and exposed metallic part

and ground. Use earth ground, for example a water

pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other expose metallic parts.

Verify any potential does not exceed 0.75 vo lt RMS. A

leakage current tester (such a Simpson Model 229,

Sencore Model PR57 or equivalent) may be used in

the above procedure, in which case any current

measure must not exceed 0.5 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the PTV must be

repaired and rechecked before it is returned to the

customer.

10-watt resistor in parallel with a

Ω

Figure 1. Hot Check Circuit

and 5.2MΩ. If the

Ω

(See Fig. 1)

Insulation Test

Connect an insulation tester between an exposed

metallic part and AC line.

Apply 1080VAC/60Hz for 1 second. Confirm that the

current measurement is 0.5mA ~ 2.0mA. Repeat test

with other metallic exposed parts.

X-ray Radiation

WARNING: The potential source of X-ray radiation in the

PTV is in the high voltage section and the picture tube.

Note: It is important to use calibrated equipment.

Apply all black video signals (1080i) and confirm high

voltage measures 31.5 ± 1.0kV. If the high voltage is

not within the range, c hange C51 4 to 1800p F, 2000pF,

2400pF or 2700pF until the desired value is obtained.

Apply NTSC Lion Head Pattern and confirm the high

voltage measures 3 0.1 ± 1.5kV.

Apply HD 1081I Monoscope Pattern and confirm the

high voltage measures 30.1 ± 1.5kV

- 2 -

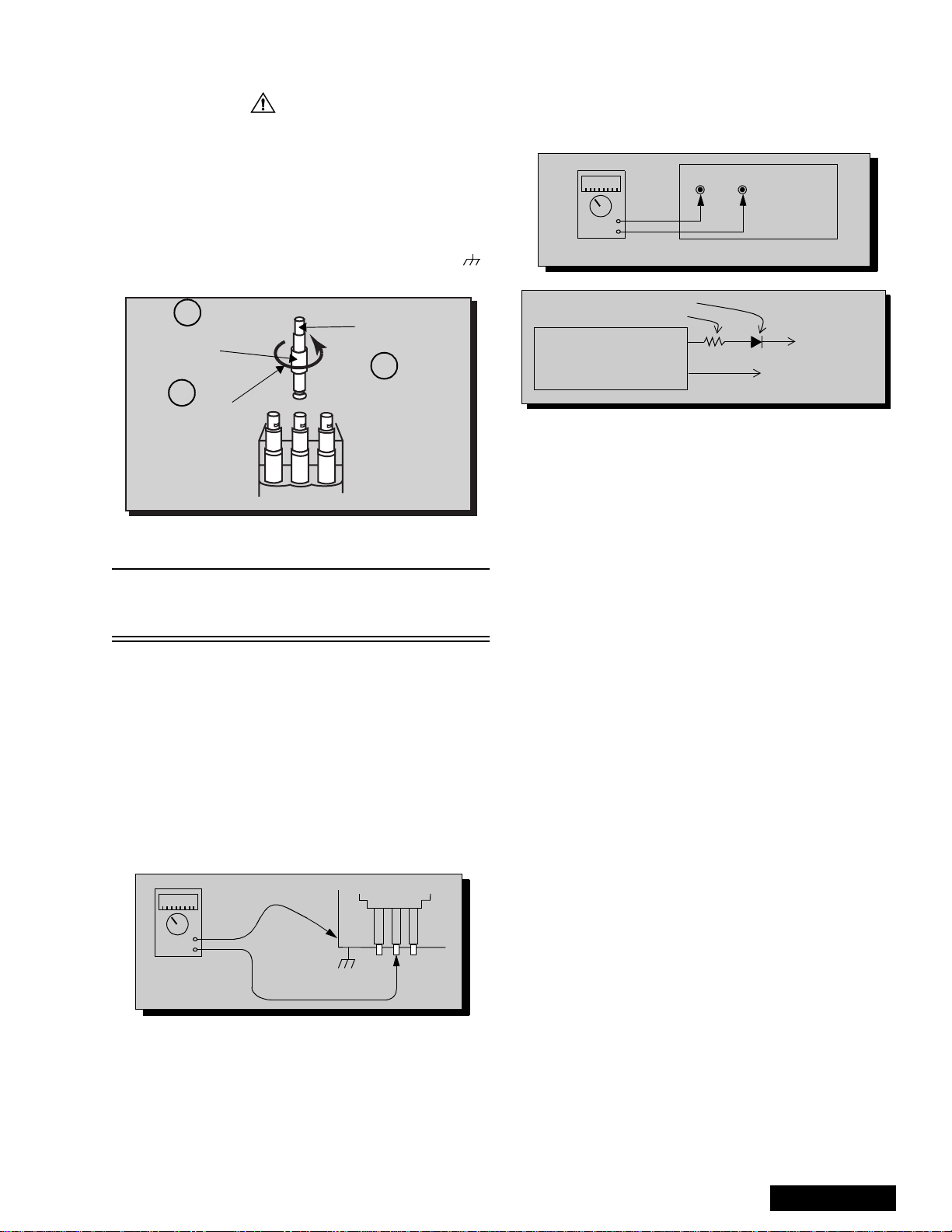

Important Safety Tests

Measuring H.V.

The anode caps are cemented to the CRTs. To gain

access for high vo ltage measurem ent, remove the re d

CRT’s anode lead from the flyback transformer

distributor. Grasp the anode lead protective cap at its

bottom and squeeze it against the locking cap body

inside, Rotate 1/4 turn count er clockwise and pull the

anode lead sleeve out of the FBT distributor. Connect a

high voltage lead (+) from your H.V. meter to the FBT

distributor, and the common (-) to cold ground ( ).

(See Fig. 2).

1

Grasp protective

Anode lead

rubber cap

3

2

Push & rotate

Discharge to

CRT Chassis

cap counterclockwise

to remove

FBT Distributor

Figure 2. Removal of FBT leads

Note: Reinsert the anode lead into the FBT

distributor until it is tightly and fully seated.

T urn the locking cap clockwise to lock in place.

(EHT) Protector Operation Check

With the cabinet ba ck removed, apply a n ominal 120V

AC to the PTV.

Over Voltage Test

Preparation:

1. Turn PTV “OFF”

2. Connect an NTSC signal generator to the

antenna terminal.

3. Connect DVM (+) TPD50 and (-) TPD51 on

D Board. (See Fig. 4)

4. Connect a H.V. meter (static type, class 0.1 ) with

high voltage leads to high voltage distributor

on FBT. (See Fig. 4)

TPD51 TPD50

-

+

D-Board

DVM

D-Board

IC802 PIN 2

OR TPD8

Variable

Power

Supply

MA150

100Ω 1/2 W

(+)

(15~25DC)

(-)

HEAT SINK OF Q551

Figure 4. DVM & Power supply connection.

Connect the 15 ~ 25 V DC variable power supply to (+)

TPD8 or IC802 pin 2 (D-Board) and (-) heat sink of

Q551 (See Fig. 4).

Procedures:

1. Apply a monoscope pattern.

2. Turn PTV ON.

3. Adjust the Picture or Brightness controls so that the

DVM reads 12.4 volts ± 0.4 volts.

4. Increase the variabl e power supply until set turns

off. The set should turn off at 12.4 volts ± 0.4 volts

(DVM) and high voltage le ss th an 3 6.4k V.

5. If the DVM reading is other than 12.4 volts (± 0.4

volts), readjust picture or brightness control and

repeat steps 3.

6. Turn off the variable supply and confirm that the set

will turn on with the Remote Control.

-

+

H.V. METER

Cold Ground

FBT Distributor

CRT

CHASSIS

Figure 3. Measuring H.V.

- 3 -

Service Manual

Important Safety Notice. . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . 2

General Guidelines . . . . . . . . . . . . . . . . . 2

X-ray Precautions . . . . . . . . . . . . . . . . . . 2

Leakage Current Cold Check . . . . . . . . . 2

Leakage Current Hot Check . . . . . . . . . . 2

Insulation Test . . . . . . . . . . . . . . . . . . . . . 2

X-ray Radiation . . . . . . . . . . . . . . . . . . . . 2

Important Safety Tests. . . . . . . . . . . . . . . . . . . . 3

Measuring H.V. . . . . . . . . . . . . . . . . . . . . 3

(EHT) Protector Operation Check . . . . . . 3

Leadless Chip Component

(surface mount). . . . . . . . . . . . . . . . . 5

Component Removal. . . . . . . . . . . . . . . . 5

Chip Component Installation . . . . . . . . . . 5

How to Replace Flat-IC . . . . . . . . . . . . . . 5

Feature Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PCBs Designation . . . . . . . . . . . . . . . . . . . . . . . 7

PTV - Location of Controls . . . . . . . . . . . . . . . . 8

Quick Reference Control Operation . . . . 8

Remote - Location of Controls

Basic Operation . . . . . . . . . . . . . . . . . . . . . . 9

Disassembly for Service . . . . . . . . . . . . . . . . . 10

PTV Frame Assembly. . . . . . . . . . . . . . . . . . . . 10

PTV Screens Preparation. . . . . . . . . . . . . . . . . 11

Placement of Screens in PTV

Screen Frame . . . . . . . . . . . . . . . . . . . . . . . 12

Frame and Customer Controls

Panel Installation . . . . . . . . . . . . . . . . . . . . 13

Cabinet Top and Mirror Panel Installation . . . 14

G, K-Board schematics. . . . . . . . . . . . . . . . . . . . 25

G, K-Board PCBs. . . . . . . . . . . . . . . . . . . . . . . .26

Service Manual

- 4 -

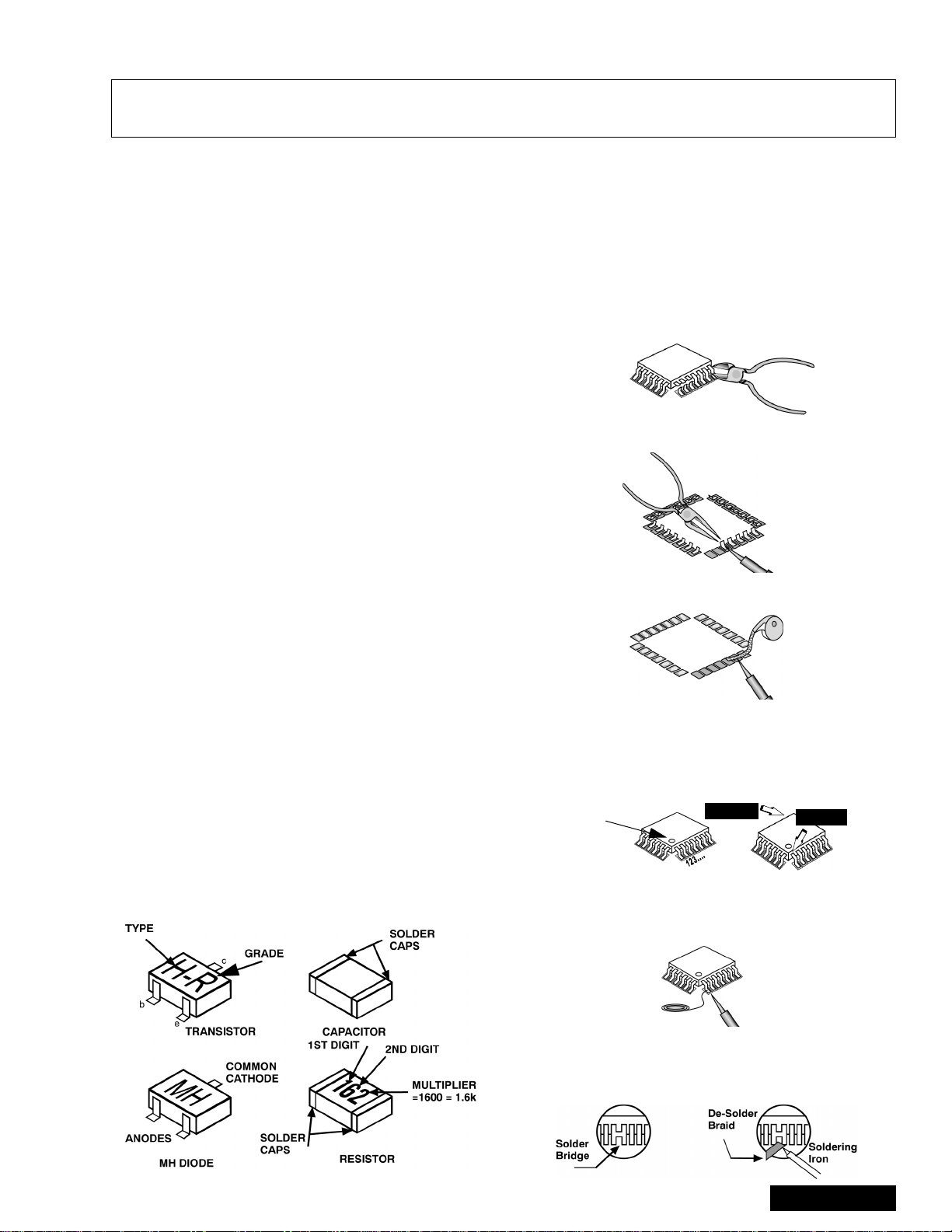

Service Notes

Note: Some components may be affixed wit h glue. Be caref ul not to break or dama ge foil under the com ponent

or at the pins of th e ICs when removing . Usually applying heat to the component for a short time while

twisting with tweezers will break the component loose.

Leadless Chip Component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track sp acing. There are no holes in

the board to mount standard transistors or diodes.

Some chips, capacitor or resistor board solder pads

may have holes thr ough the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistors have a three-digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kW resistor, 0 = 0W

(jumper).

Chip capacitors generally do not have the value

indicated on the capacito r. The color of the component

indicates the general range of the capa ci tan ce .

Chip transistors are identified by a two-letter code. The

first letter indicates the type and the second l etter, the

grade of transistor.

Chip diodes have a two-letter identification code as per

the code chart and are a dual diode pack with either

common anode or comm on cathode. Check the parts

list for correct di ode num ber.

Component Removal

7. Use solder wick to remove s older fr om compo nent

end caps or termin al.

8. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

9. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area wi th a 30 watt iron

until solder flows. Do not appl y heat for more than

3 seconds.

Chip Components

How to Replace Flat-IC

- Required Tools -

• Soldering iron • De-solder braids

• Needle nose pliers • Magnifier

• Wire cutters (sharp & small)

1. Cut the pins of a defective IC with wire cutters.

Remove IC from boar d. If IC i s glued to the boa rd,

heat the IC and release the IC. See Note above.

Flat IC

2. Using soldering iron and needle nose pliers

remove the IC pins from the boa rd .

Soldering

Iron

3. Using de-soldering braid and soldering iron remove

solder from affected are on board (pads).

De-soldering

Braid

Soldering

Iron

4. Position the new Flat-IC in pl ace (apply the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Determine the positions of

the soldering pads and pins by correctly aligning

the polarity symbol. Solder pin #1 first, align the IC.

Polarity

symbol

Solder the pin op posite to pin #1. This will assist

positioning the IC.

5. Solder all pins to the soldering pads using a fine

tipped soldering iro n.

2nd solder

1st solder

Solder

6. Check with a magnifier fo r solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solde r bridge, use a de-solder

braid as shown in the figure below.

- 5 -

Soldering

Iron

Service Manual

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static

discharge, make cer tain that all ground wi res an d CRT

DAG wire are secu re ly conne cted.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when s ervicing the PTV to avoid

damage to the test equipment or to the chassis.

Connect the test equip ment to the proper ground or

when servicing, or incorrect voltages will be

measured.

WARNING: This PTV has been designed to meet or

exceed applicable safety and X-ray radiation protection

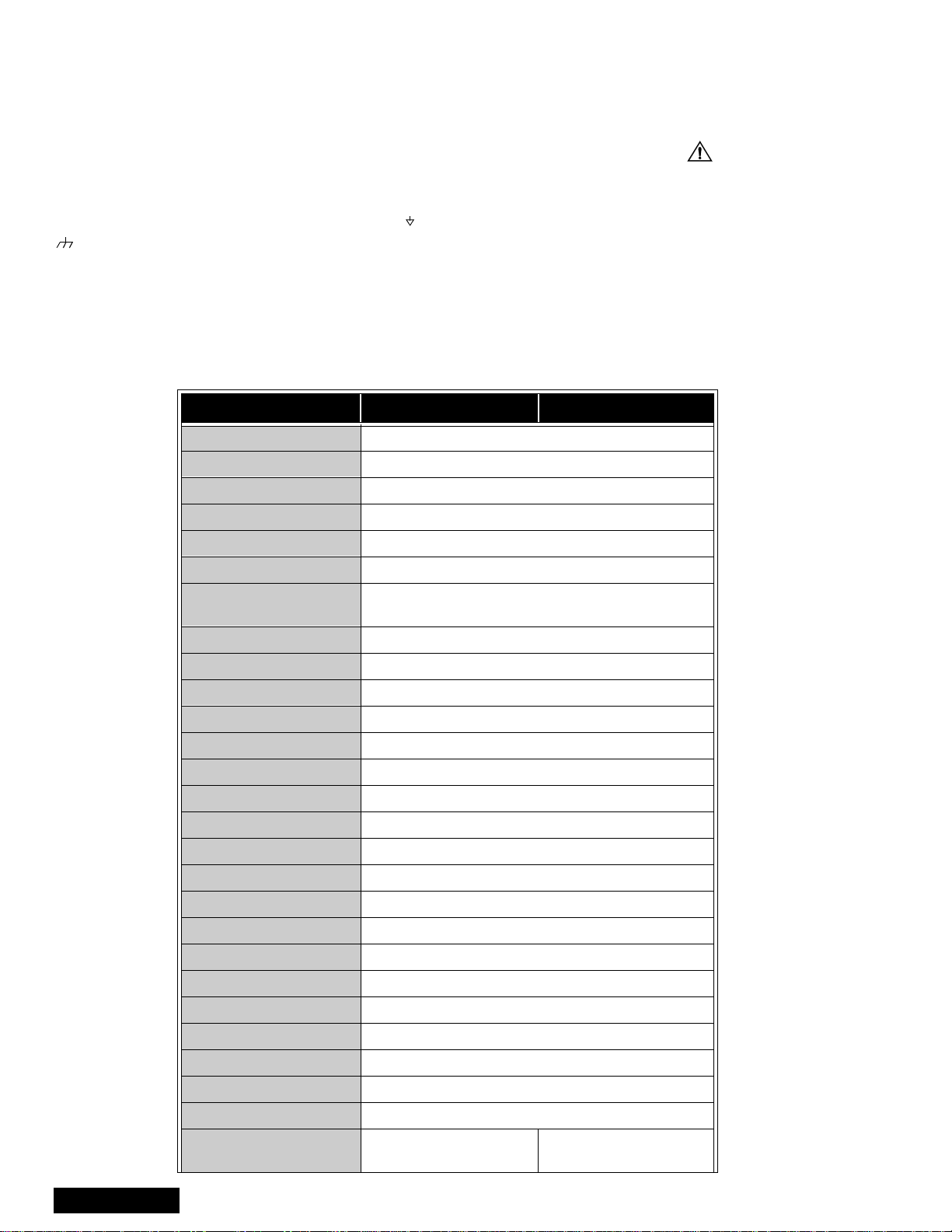

Feature Table

FEA TURE PT-65WX51E PT-56WX51E/CE

Chassis EP820

T uning sy stem 256K

# of channels 181

as specified by gover nment a gencies and ind ependen t

testing laboratories.

To maintain original product safety design standards

relative to X-ray radiation and shock and fire hazard,

parts indicated with th e symbol on the schematic

must be replaced with identical parts. Order parts from

the manufacturer’s parts center using the parts

numbers listed in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and readability, all other

parts should be rep laced with component s of identical

specification.

Menu language Eng/Span/Fr

Closed Caption X

V-Chip (USA/CANADA) X

Picture in Picture

2RF X

Comb Filter 3D Y/C

HEC / VEC Corrector Both

VM X

V/A Norm - Both Both

Color Temperature X

MTS/SAP/DBX X

AI Sound X

Bass/Bl/T re Contro l X

Surround X

BBE X

Built-in audio power 15W / CH (10%)

# of speakers 4

2 Tuner

Split Screen

Service Manual

A/V in (rear/front) 4 (3 / 1)

A/V Program Out X

S-VHS Input (rear/front) 2 / 1

Component Input 2

Audio Out (FAO & VAO) X

Dolby Center Channel In X

Dimensions mm

(WxDxH) in

1501x757x1545

59.1x29.8x60.8

- 6 -

1316x682x1401

51.8x26.9x55.2

FEATURE PT-65WX51E PT-56WX51E/CE

Weight (kg/lbs) 126.5/277.78 116/255.7

Power source (V/Hz) 120 / 60

Anode voltage 31.5 ± 1.0kV

Video input jack

Audio input jack 500mV RMS 47kΩ

Table 1: PTV Feature Table

Specifications are subject to change

without notice or obligation.

Dimensions and weights are approximate.

PCBs Designation

PART NUMBER

BOARD

PT-56WX51E/CE PT-65WX51E

A-Board TNPH0370AD

75Ω, phono jack

1V

p-p

BOARD DESCRIPTION

MAIN CHASSIS, VIDEO

PROCESSING, CONVERGENCE,

AUDIO PROCESSING

D-Board TNPH0371

DH-Board TNPA2033

POWER SUPPLY, VERTICAL

OUT, HORIZONTAL OUT

PIP PROCES SING , SPLIT,

SEARCH, FORMATS

G-Board TNP2AA090 TNP2AA092 Front A/V Connections

K-Board TNP2AA089 TNP2AA091 Customer Controls (Key board)

LR-Board TNPA1810 RED CRT Drive

LG-Board TNPA1811 GREEN CRT Drive

LB-Board T NPA1812 BLUE CRT Drive

R-Board TNPA0615AB IR Sensor

Table 2: PCB Des i gna tion

Note: The A-Board (

TNPH0370ADS

) and DH-Board (

TNPA2033S)

are Non-Serviceable. The Tuners, IC2302, IC7001, IC7002 and

IC870 are replaceable. If any other components on the A-Board

or DH-Board are defective, replace the en tire board with a new

one.

Notice: When ordering any Board, add and” S” after the Board suffix

application for all models.

Example: If Order A-Board, should be ordered as:

TNPH0370AD

S.

- 7 -

Service Manual

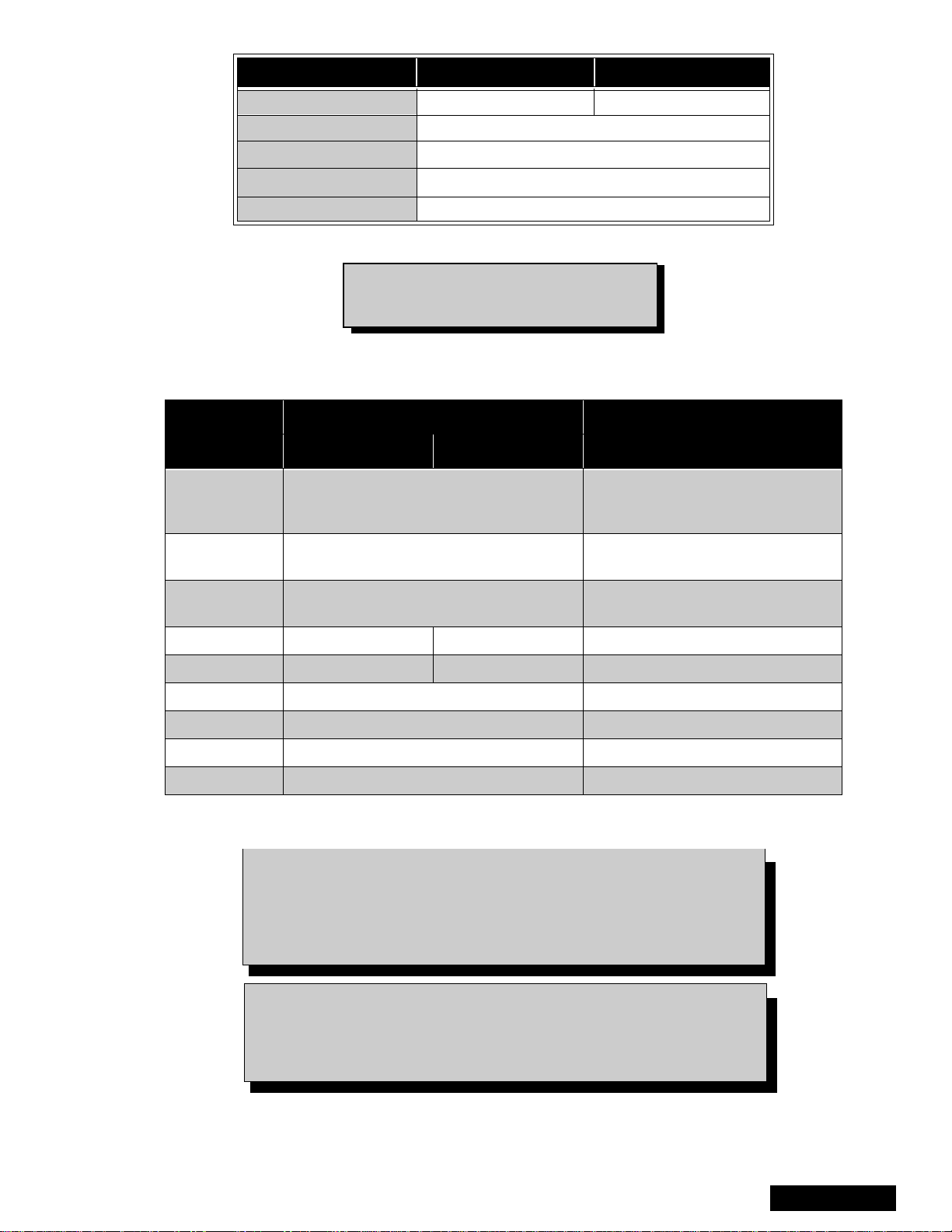

PTV - Location of Controls

PT-65WX51E

POWER VOLUME CHANNEL ACTION TV/VIDEO

1 2 4 53

Figure 5. Location of Control s PTV

Quick Reference Control Operation

Quick Reference Control Operation

1

2

3

Power - Press to turn ON or OFF.

Volume - Press to adjust Sound Level, or to adjust Audio Men us, Video Menus, and

select operating features when menus are displayed.

Channel - Press to s elect programm ed channels. Pres s to highlight desired features

when menus are displayed. Also use to select Cable Converter box channels after

programming Remote Control Infra red codes ( the TV/AUX /CABLE sw itch must be s et

in CABLE position).

4

5

Service Manual

Action - Press to displ ay Main Menu and access On Screen f eature and Ad justment

Menus.

TV/Video - Press to select TV or one of two Video Inputs, for the Main Picture or the

PIP frame (when PIP frame is displayed).

- 8 -

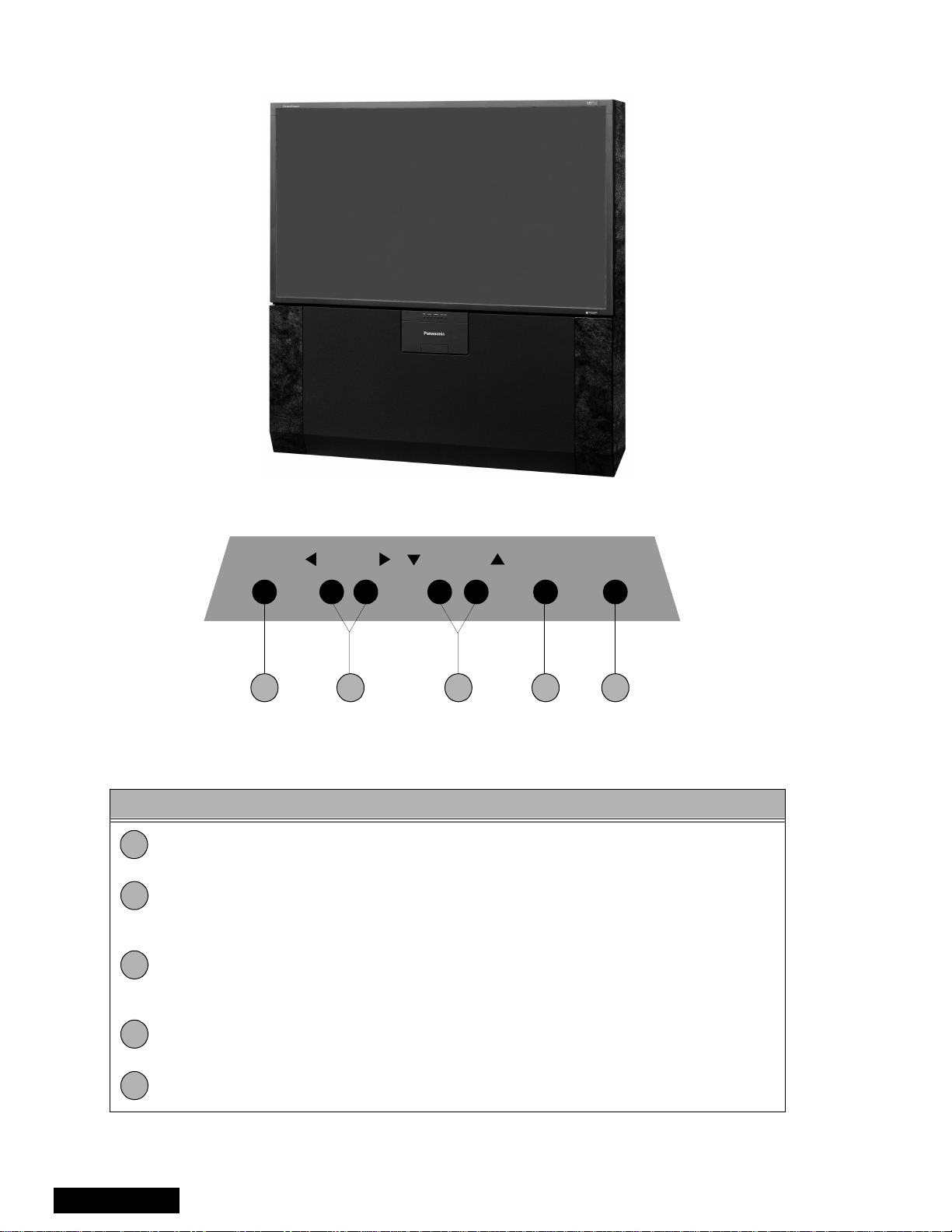

Remote - Location of Controls-Basic Operation

POWER Button

Press to turn ON and OFF.

MUTE Button

Press to mute sound.

A second press resumes sound.

Press also to access and delete

Closed Caption display.

TV, VCR, DVD, CBS/CBL

Component function buttons

VOL (volume) Buttons

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

R-TUNE (Rapid Tune) Button.

Press to switch to the previous

channel.

ACTION Button

Press to display Main Men u and access or

exit On Screen features

and Adjustment Menus.

REW, PLAY, FF, TV/VCR, STOP, PAUSE,

REC & VCR CHANNEL Buttons

Component function buttons.

DBS EXIT& DBS GUIDE Buttons

DBS function buttons.

LIGHT Button

Press to light remote control buttons.

SAP

Access second audio program

ASPECT

Select picture size (ratio) to match

programming format

MOVE, PIP, SPLIT/SIZE, FREEZE, SWAP,

SEARCH, PIP CHANNEL

EUR7603Z40

PIP function buttons

For additional information for this rem ote please refer

to the Remote Guide, listed on the parts li st.

Figure 6. Location of Controls

- 9 -

Service Manual

Loading...

Loading...