Panasonic PAW560MAH2L, PAW560MAH2, PAW280PAH2L, PAW280PAH2, PAW280MAH2L Installation Instructions Manual

...

Air Handling Unit Kit

Installation Instructions

SET

AL1

OUT

ATU

PV

SV

ºC

ºC

3

Air Handling Unit Kit

Installation Instructions

Original Installation Instructions (English)

Preliminary version as at December 2014

COPYRIGHT

© Panasonic Marketing Europe GmbH 2014. All rights reserved.

.

4

Table of Contents

1 General information and safety instructions .................................................... 6

1.1 Introduction ......................................................................................................................... 6

1.2 Structure and meaning of notices and symbols .............................................................. 7

1.3 Safety instructions .............................................................................................................. 8

1.4 Warranty policy ................................................................................................................... 9

2 Ventilation theory and air handling units .......................................................... 10

2.1 Purpose of air-conditioning ............................................................................................... 10

2.2 Purpose of ventilation ........................................................................................................ 10

2.3 Mechanical ventilation systems ........................................................................................ 12

2.4 Air handling units ................................................................................................................ 13

3 Product description ............................................................................................. 17

3.1 General description ............................................................................................................ 17

3.2 Scope of supply .................................................................................................................. 17

3.3 System lineup ...................................................................................................................... 20

3.4 AHU Kit dimensions and exterior view ............................................................................. 21

3.5 Wiring layout ....................................................................................................................... 23

3.6 AHUKitenclosureconguration ....................................................................................... 27

3.7 System Overview ................................................................................................................ 28

3.8 Technical data and limitations ........................................................................................... 32

4 Installation ............................................................................................................ 37

4.1 Installation of AHU Kit ........................................................................................................ 37

4.2 Installation of refrigerant piping ........................................................................................ 40

4.3 Installation of expansion valve .......................................................................................... 41

4.4 Installation of thermistors .................................................................................................. 42

4.4.1 Installation of thermistor on gas pipe ........................................................................ 43

4.4.2 Installation of thermistor on liquid pipe ..................................................................... 45

4.4.3 Installation of thermistor on heat exchanger pipe middle ......................................... 46

4.4.4 Installation of thermistor for suction and discharge air stream ................................. 47

4.5 Disconnection of jumper on outdoor unit PCB ................................................................ 47

5 Electrical Wiring ................................................................................................... 49

5.1 General precautions on wiring .......................................................................................... 49

5.2 Recommended wire lengths and diameters ..................................................................... 50

5.3 Wiring system diagrams ..................................................................................................... 51

5.4 Terminal block layout ......................................................................................................... 54

5.5 Connection of wiring to terminals ..................................................................................... 55

5

5.6 Connection of external signal lines................................................................................... 57

5.7 Electric circuit examples .................................................................................................... 59

6 Test Run ................................................................................................................ 60

7 Control .................................................................................................................. 61

7.1 Remote controller ............................................................................................................... 61

7.2 Thermostat........................................................................................................................... 61

7.2.1 Control and display elements ................................................................................... 61

7.2.2 Operation .................................................................................................................. 62

7.2.3 Initial Settings ........................................................................................................... 67

7.2.4 Error Codes .............................................................................................................. 72

7.2.5 Maintenance and Service ......................................................................................... 72

7.2.6 Technical data ........................................................................................................... 73

6

General information and safety instructions

1 General information and safety instructions

1.1 Introduction

This document contains the installation instructions for the Panasonic AHU Kits.

The following products are covered in this documentation:

● PAW-160MAH2 / PAW-160MAH2L

● PAW-280MAH2 / PAW-280MAH2L

● PAW-560MAH2 / PAW-560MAH2L

● PAW-280PAH2 / PAW-280PAH2L

AHU Kits connect Panasonic ECOi, ECO G and PACi outdoor units to third-party air handling

unit systems, using the same refrigerant circuit as the VRF system.

Application examples for Panasonic AHU Kits are hotels, ofces, server rooms or all large buildings where air quality control such as humidity control and fresh air is needed.

The installation should be performed only by qualied electricians in strict accordance with the

installation instructions and especially with the safety instructions given in this document.

Where information in this document does not apply to all three VRF system ranges, but only to

either ECOi, ECO G or PACi systems, this will be indicated by the relevant product range logos:

Important: Validity of this document

Due to the ongoing development and innovation of Panasonic products, this document and all

the information contained herein is preliminary (as at December 2014). It may not reect the

current status of the relevant products. Preliminary or missing information will be updated and

added on an ongoing basis and published at the discretion of Panasonic.

i

7

General information and safety instructions

1.2 Structure and meaning of notices and symbols

Safety notices

WARNING

This indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

This indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

NOTICE

This indicates a hazardous situation which, if not avoided, could result in property damage.

Other notices

Important

This indicates other important information or references to other useful sources of technical data

and descriptions.

!

i

8

General information and safety instructions

1.3 Safety instructions

WARNING

The following precautions need to be followed strictly, in order to avoid hazardous situations,

which could result in death or serious injury.

Electricshockorremayresultfrominadequateorincorrectinstallationorwiring

procedures.

► System installation must only be performed by an experienced electrician.

► Arrange installation at the dealer where the system was purchased or use a

professional installer.

► System installation must be performed in strict accordance to the installation

procedures described in this document.

Damagetothecircuitbreakersmayresultfromincorrectelectricalwiring,insufcient

electrical circuit capacity or use with other electrical devices.

► Always use a dedicated branch circuit for electrical wiring.

► Strictly avoid using other electrical devices within the same electrical circuit.

► Make sure the electrical circuit used has sufcient capacity.

Overheatingorremayresultifconnectionsorattachmentsarenotsecure.

► Use the specied cables (type and wiring diameter) for the electrical connec-

tions, and securely connect the cables.

► Run and fasten the cables securely so that external forces or pressure placed

on the cables will not be transmitted to the connection terminals.

Suffocation can result if refrigerant gas leaks and exceeds the limit density in a small

room.

► Installation of the refrigerant piping must only be performed by an experienced,

qualied installer to minimize the risk of leaks.

► Install so that even if refrigerant gas leaks into the room, it will not exceed the

limit density of 0.44 kg/m3, in accordance with the local regulatioins for facility

air conditioning equipment.

► If the refrigerant gas concentration does exceed the limit density, do one of the

following:

● install an opening in a neighbouring room

● or install ventilation equipment triggered by gas leak detection sensors

● or install an automatic pump-down system provided by the manufacturer of

the equipment

Poisonousgascanresultifrefrigerantgascomesintocontactwithre.

► After installation of refrigerant pipes, perform a dry nitrogen gas sealing test to

check that there are no leaks.

► Ventilate the work area if refrigerant gas leaks during installation.

9

General information and safety instructions

► Prevent the refrigerant gas from coming into contact with a fan heater, stove,

range, or other source of re.

Incorrectinstallationcanresultinfallingequipmentcausingdamage,injuriesorother

accidents.

► Install in a location that is fully strong enough to support the weight of the

equipment.

► Perform installation that is secure enough to withstand earthquakes, whirlwinds,

storms and other strong winds.

Frostbite injuries may result from coming into direct contact with the refrigerant gas.

► When handling refrigerant gas, be careful not to touch the refrigerant gas

directly.

CAUTION

The following precautions need to be followed strictly, in order to avoid hazardous situations,

which could result in minor or moderate injury.

Electricshock,shockandresmayresultfromincompletegroundingoftheequipment

or failure to install an earth leakage breaker.

► Be sure to ground equipment properly.

► Do not attach ground wires to gas pipes, water pipes, lightning arresters, or

telephone ground lines.

► Always install an earth leakage breaker.

Ignitionofammablegasorinammablematerialsmayresultfrominstallingthesystem

inlocationswhereammablegascangenerate,enter,buildup,orleak.

► Do not install the system in locations where ammable gas can occur in any

way.

► Do not install in locations where volatile inammable materials are handled.

1.4 Warranty policy

We can be held responsible for the quality and performance of the AHU Kit we supply.

However, we cannot be held responsible for the performances, operations and machine controls

of your complete AHU system which incorporates our AHU Kit, nor for the components used in

the refrigerant cycle of your AHU system (including, but not limited to, compressors, high-pressure switches, check valves, strainers, expansion valves, solenoid valves, 4-way valves, capil-

lary tubes, accumulator tanks, and heat exchanger tubes), nor for any damages and defects

caused in the process of installing our AHU Kit, by the system design and/or during assembly of

your AHU system.

We do not publish the certicate to show conformity to the EMC and the product safety requirements applicable to your complete AHU system.

10

Ventilation theory and air handling units

2 Ventilation theory and air handling units

2.1 Purpose of air-conditioning

The purpose of air-conditioning is to provide comfortable indoor air conditions for the room occupants and to provide energy saving potentials for the owner.

Comfort

If room occupants feel “comfortable“ in a given room, depends mainly on the following two

factors:

● air temperature

● relative air humidity

However, optimum working or living conditions do not only exist at a specic setpoint of room

temperature and room humidity, but also within a certain band width of the setpoint.

A temperature setpoint of 22 °C and a relative humidity setpoint of 45 % with variations of ±2 °C

and ±15 %rh respectively are typical levels used for ofce spaces. Also, at high temperatures,

maximum limitation of absolute humidity should be provided to avoid “muggy” conditions. Typically, this limit value lies at about 10 g/kg (H2O).

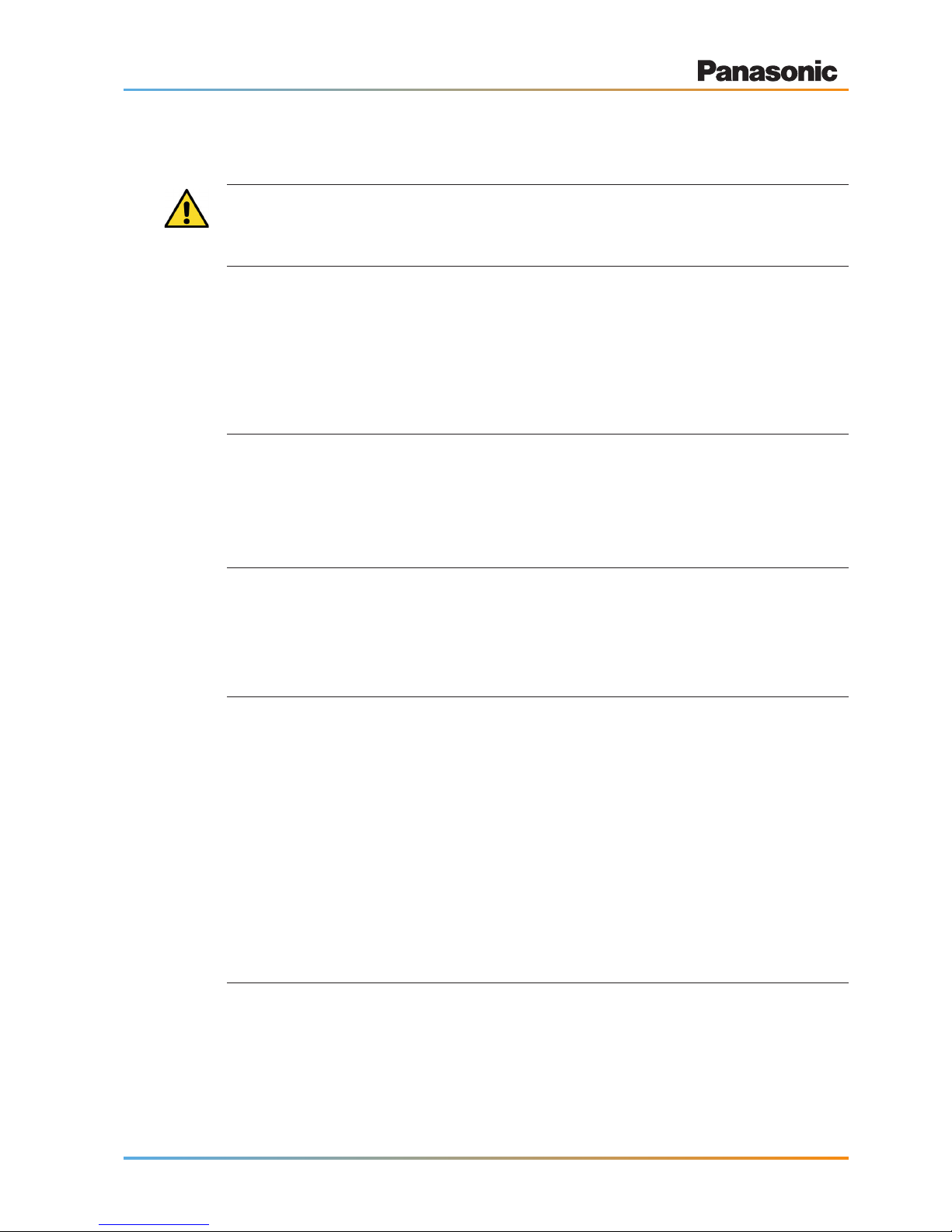

Absolute humidity

rh = relative humidity

Temperature

Cooling and

humdifying

Heating and

humdifying

Humdifying and

reheating, if required

Humdifying only

Comfort range

35 %rh

24 °C

20 °C

65 %rh

Cooling only

Heating only

Energy savings

Besides the advantages in terms of indoor air quality, air conditioning offers also an energy saving potential. For example, while uncontrolled ventilation through open windows leads to large

amounts of heat being lost to the outside during the heating season or gained from the outside

during the cooling season, air conditioning systems provide possibilities to utilize the extra “free”

energy in heat recovery modules so that overall operating costs will be reduced.

The larger the area of the comfort range, the better the energy saving opportunities.

2.2 Purpose of ventilation

The purpose of ventilation is to introduce fresh air from outside into a building or room, in order

to control indoor air quality and thermal comfort.

11

Ventilation theory and air handling units

Ventilation demands

Ventilation must meet the following demands:

● Provide outside air (oxygen) for breathing

● Control of indoor air contaminants

● Covering of the building’s thermal loads (temperature and humidity control)

● Setting of uniform conditions in the occupied zone

As the outside or ambient air varies in temperature, humidity, contamination etc., it must be specically conditioned before being supplied to the target room, so that it meets the dened indoor

air requirements. “Conditioning” means treating the ambient air by ltering, heating, cooling,

humidifying, dehumidifying etc.

Room with defined requirements:

· Temperature

· Humidity

· Pressure

· Ventilation

Return airSupply air

While the conditioned air (supply air) is being introduced to the building or room, return air,

which no longer meets the dened indoor air requirements (e.g. in terms of temperature or humidity) is withdrawn from the room and rejected to the outside.

Thus, a constant indoor air exchange is maintained by the mechanical ventilation system.

Recommendedindoorairrequirements

Organizations concerned with setting quality standards for the HVAC industry (Heating, Ventila-

tion and Air Conditioning), like e.g. ASHRAE or Eurovent, give recommendations for indoor air

quality criteria depending on the intended use of the room.

The ASHRAE recommendations for residential and commercial applications are as follows:

● Temperature: ranging from 20 to 24 °C

● Humidity: ranging from 35 to 65 %rh

● Pressure: slightly positive pressure to reduce outside air inltration

● Ventilation: ranging from 4 to 8 complete air changes per hour

In order to full the ventilation demands and to meet the recommended indoor air requirements,

mechanical ventilation systems comprising air lters, supply and return air ventilators, cooling

12

Ventilation theory and air handling units

and heating coils, variable air volume (VAV) valves, thermostats and other air-handling equipment are used.

Exhaust

air

Outside

air

Dampers

Air handling unit (AHU)

Supply

air fan

Return

air fan

Return air

Filter

Cooling

Heating

Solar

radiation

Wind

ThermostatThermostat

VAV valve VAV valve

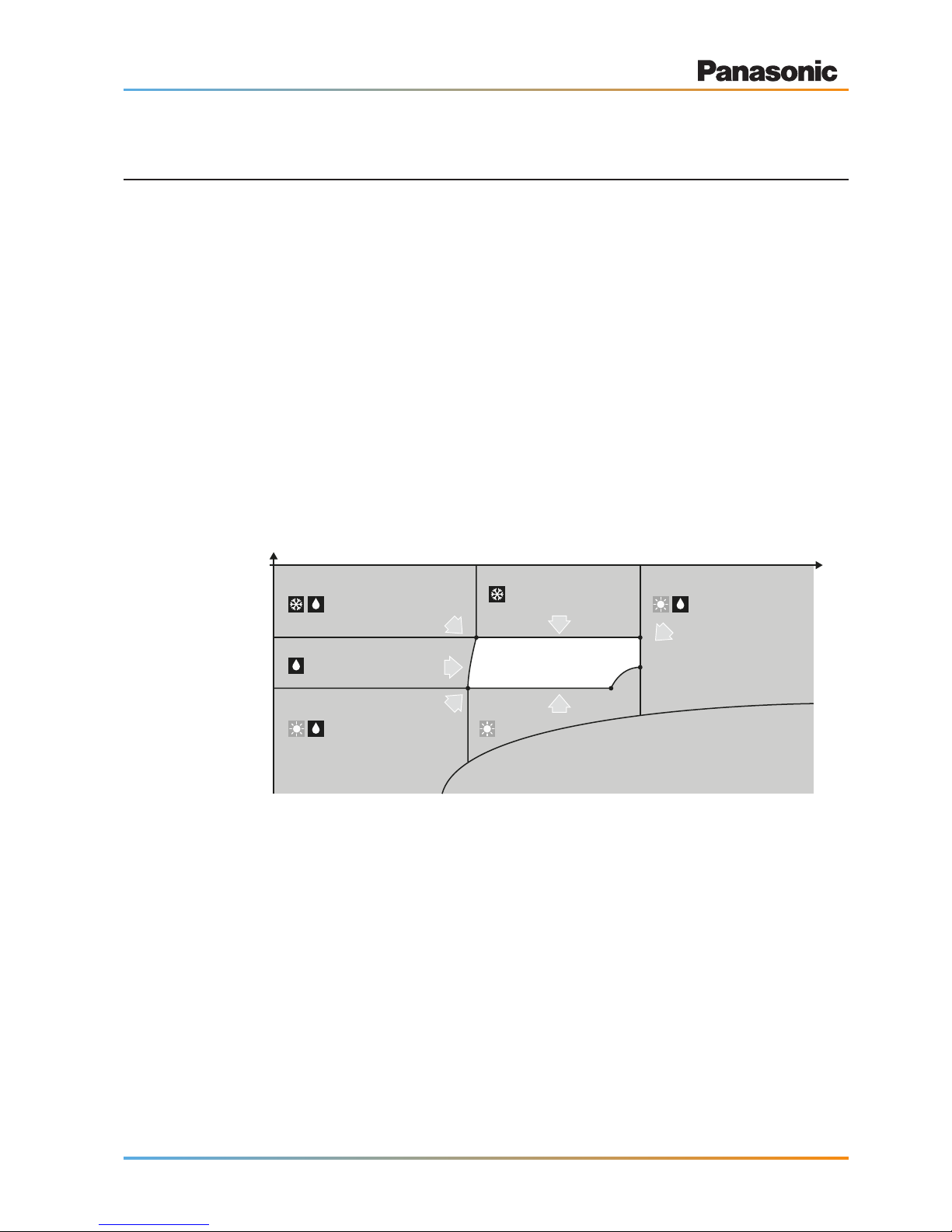

2.3 Mechanical ventilation systems

Main components of mechanical ventilation systems

The main components of a mechanical ventilation system are the following:

● Air handling unit (AHU)

● Air ducts

● Air distribution elements

Supply air

Outside air

Return air

Exhaust air

Types of mechanical ventilation systems

Mechanical ventilation systems can be subdivided based on the pressure relation between the

ventilated space and the ambient environment.

13

Ventilation theory and air handling units

In most cases, the pressure in ventilated spaces is equal to the atmospheric pressure of the

outside. This means that the air-ow delivered to a space equals the airow brought back from a

space. Such spaces are described as neutral or balanced.

However, in mechanical ventilation systems the supply air and return air ows might be

sized differently, when necessary. In these cases, a building can be either pressurized or

depressurized:

● Pressurized:

The pressure within the ventilated space is positive (higher) compared to the

outside pressure. This means, a certain amount of air is exltrated from the

space through openings and cracks.

Examples are clean rooms, operation theatres etc.

● Depressurized:

The pressure within the ventilated space is negative (lower) compared to the

outside pressure. This means, a certain amount of air is inltrated to the space

through openings and cracks.

Examples are kitchens, toilets, laboratories working with toxic substances etc.

2.4 Air handling units

Main components of air handling units

The main components of an air handling unit are shown in the following graphic.

Mixed air (MA)

Supply air fan

(SAF)

Supply air

(SA)

Outside air

(OA)

Return air

(RA)

Exhaust air

(EA)

Dampers

(D)

Dampers

(D)

Dampers

(D)

Cooling Coil

(CC)

Heating Coil

(HC)

Air handling unit (AHU)

Filter

(F)

Recirculated

air (CA)

14

Ventilation theory and air handling units

Air handling units can be manufactured targeted at the specic purpose for which they will be

used. Possible features comprise, but are not limited to the following non-exhaustive list of

characteristics:

● Construction: monoblock or split in separate delivery sections

● Installation location: indoor, outdoor

● Execution: horizontal, vertical, double deck or side-by-side

● Design: e.g. standard, hygienic, explosion-proof or anti-grease

● DX coil: with or without (see below the example of an AHU system with DX coil)

● Heat recovery: with or without

● Size: ranging from 150 m3/h to 100000 m3/h

● Applying European standards: EN1886; EN13053

RA

EA

OA

SA

Casing

HumidifierAir filterDamper

Sirocco fan

Air flow DX coil

Turbo fan

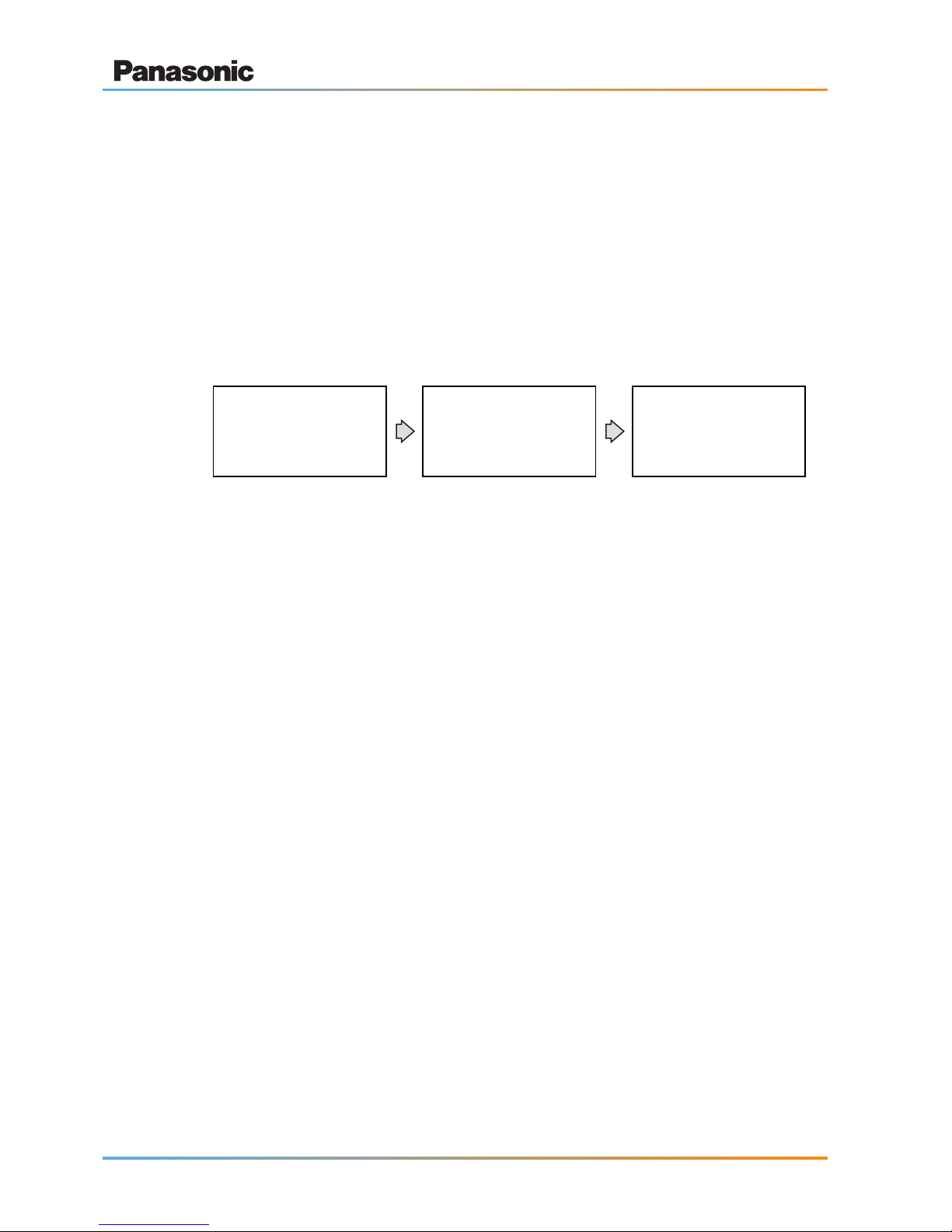

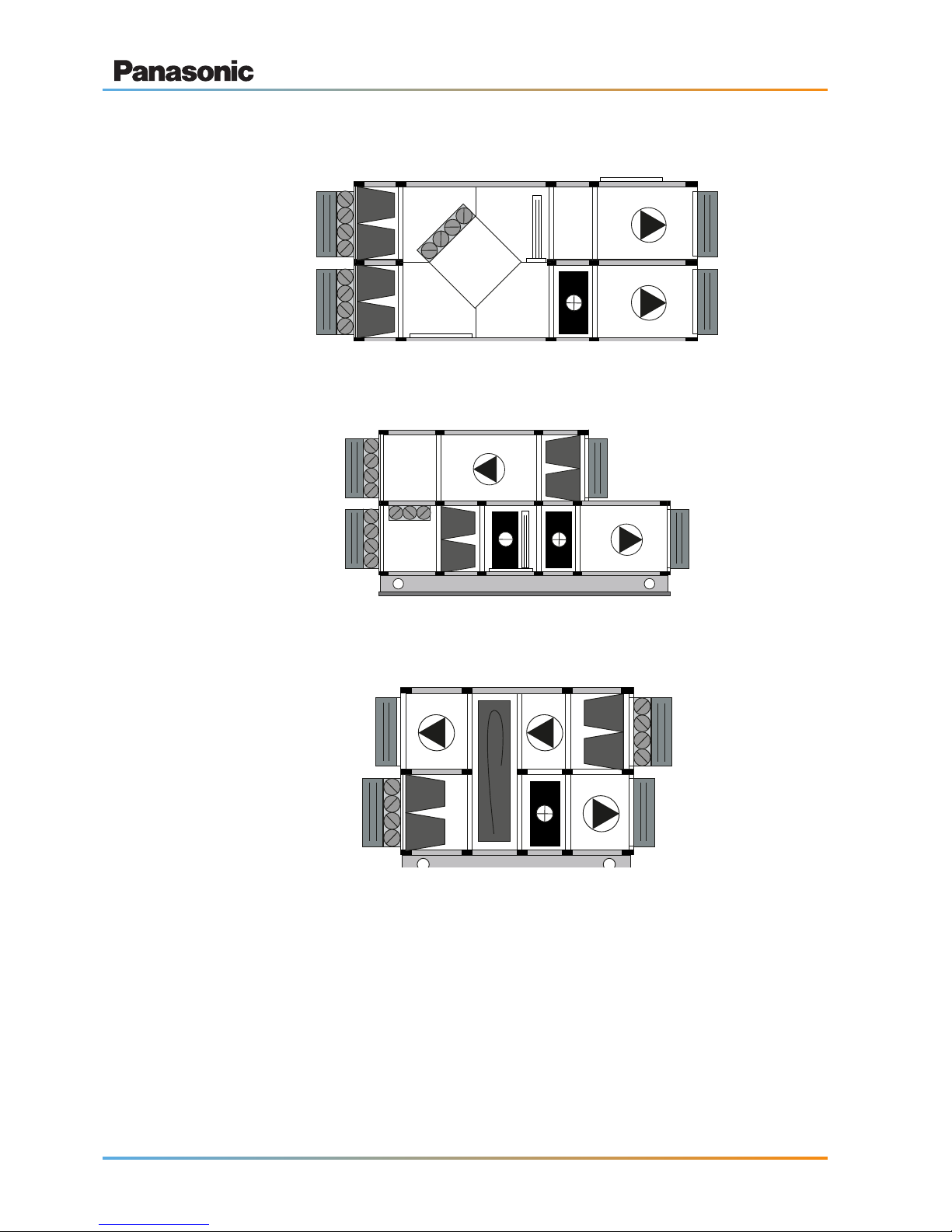

Main types of air handling units

Supply type

Exhaust type

15

Ventilation theory and air handling units

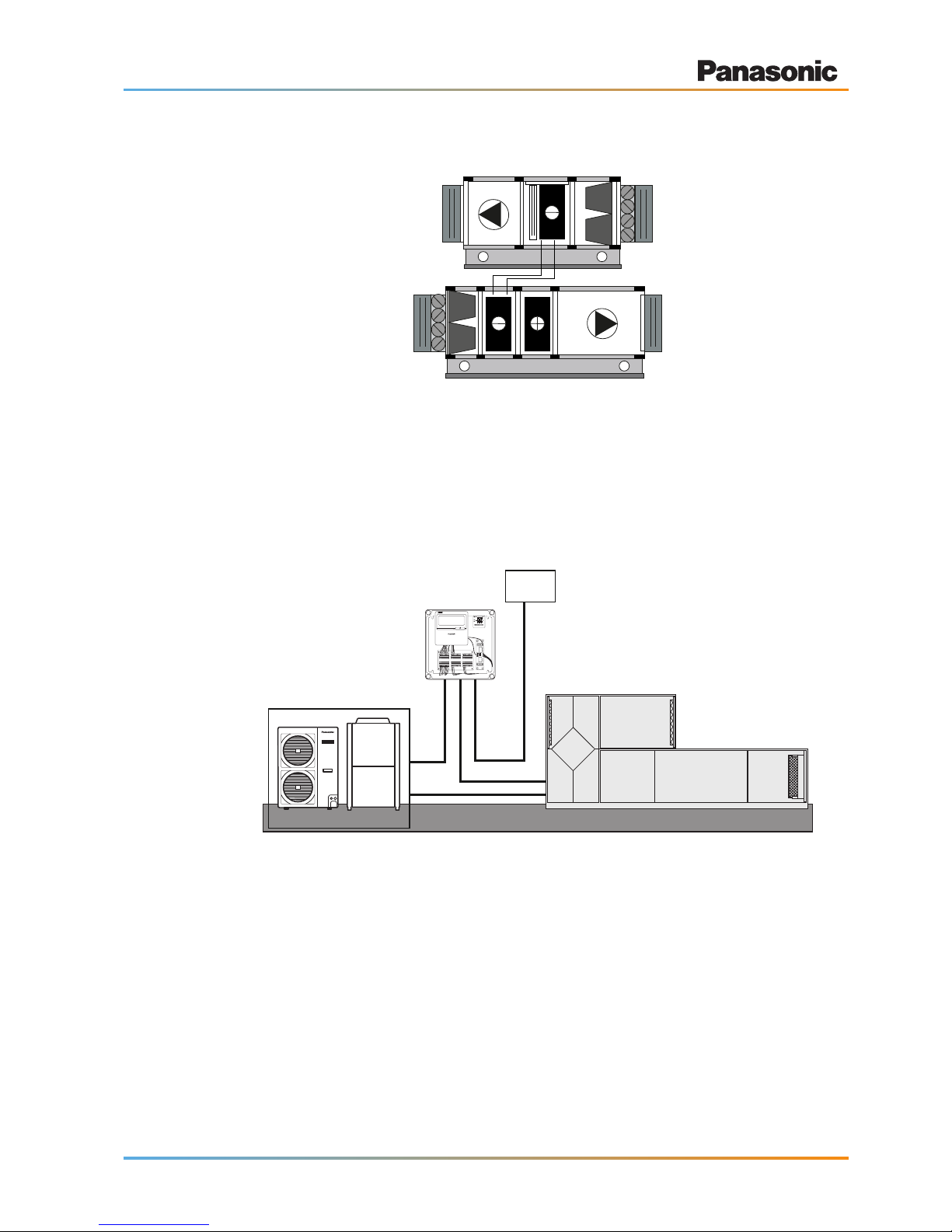

Supply/Exhausttypewithcross-owheatexchanger

Supply/Exhaust type with mixing chamber

Supply exhaust type with rotary heat exchanger

16

Ventilation theory and air handling units

Supply/Exhaust type with glycol heat exchanger

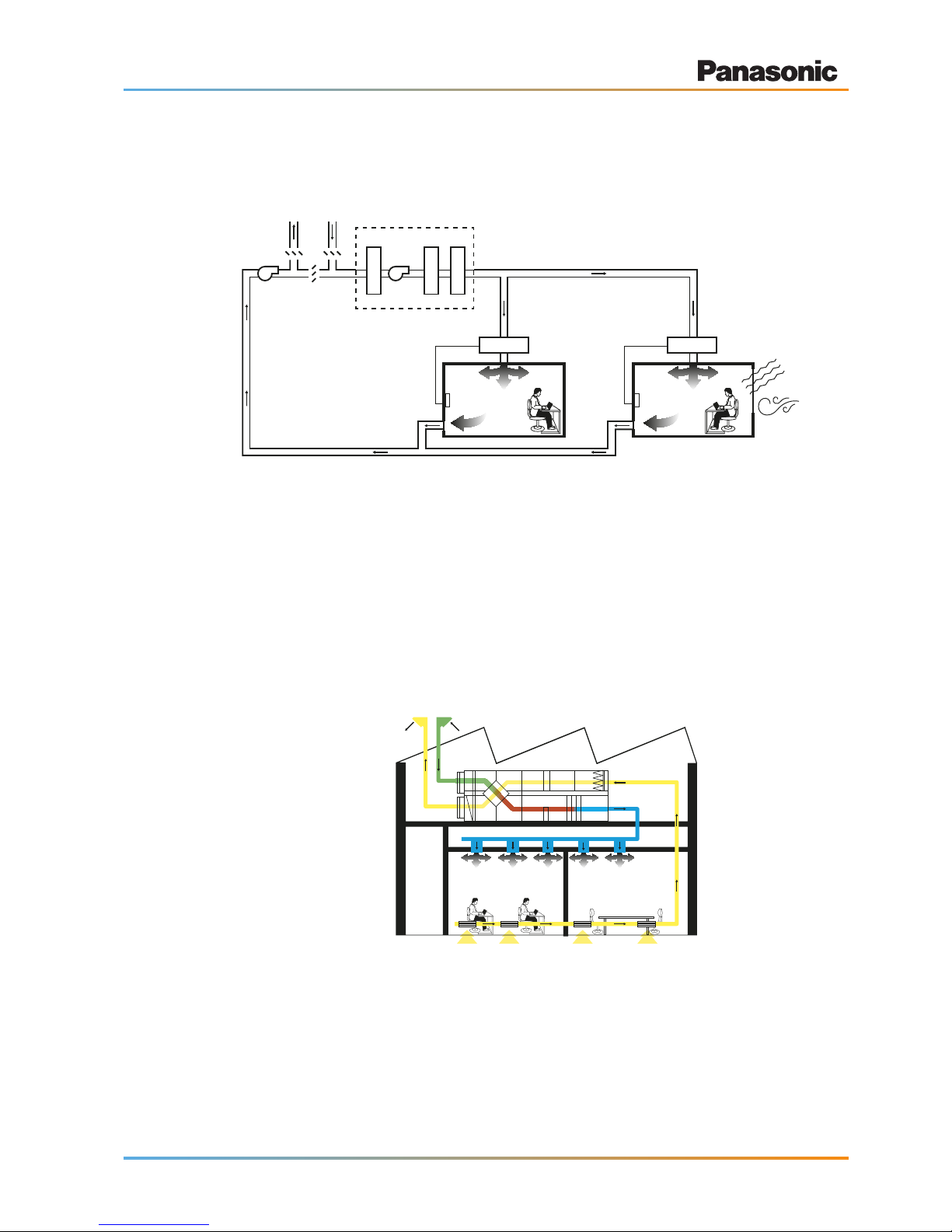

Connecting AHU systems via the AHU Kit to ECOi/ECO G or PACi outdoor

units

The following graphic shows an example for connecting a third-party air handling unit via the

Panasonic AHU Kit to Panasonic ECOi/ECO G or PACi outdoor units.

PACi or ECOi/ECO G outdoor unit

Demand control on the outdoor unit

managed by external 0–10 V signal

Air Handling Unit (AHU)

AHU control kit

External BMS

0 – 10V capacity control

1 This schematic layout applies to the advanced AHU Kit version only, because it features an in-built CZ-CAPBC2

interface handling the 0–10 V control. This enables two control alternatives:

● Capacity control through external BMS via 0–10 V signal

● Capacity control through in-built supply air or ambient temperature sensor

2 As the “light” version of the AHU Kit does not include an in-built CZ-CAPBC2 interface for handling the 0–10 V con-

trol, this schematic layout does not apply to the “light” AHU Kit version.

17

Product description

3 Product description

3.1 General description

AHU Kits connect Panasonic ECOi, ECO G and PACi outdoor units to third-party air handling

unit systems, using the same refrigerant circuit as the VRF system.

Application examples for Panasonic AHU Kits are hotels, ofces, server rooms or all large buildings where air quality control such as humidity and temperature control and fresh air is needed.

The Panasonic AHU Kits offer a wealth of connectivity possibilities so that they can be easily

integrated into many systems.

The new AHU Kit has been developed to better meet customer demand:

● Two versions available depending on the required functionality (light or advanced version)

● IP65 enclosure providing the possibility for outdoor installation

● 0–10 V demand control (included on the CZ-CAPBC2 interface)*

● Easy control by BMS

* Only available with ECOi and PACi Elite units from 6 kW up to 14 kW (for PACi Elite units from 20/25 kW available

on request)

Featuresandbenets

● The system is controlled by the air intake (or room return air) temperature in the

same way as a standard indoor unit. Selectable modes: Automatic / Cooling /

Heating / Fan / Dry (equivalent to Cooling).

● Easy integration into BMS or AHU control systems using demand control: 40 to

115 % (5 % steps) of nominal current by 0–10 V input signal (advanced version

only)

● Room supply air temperature can be controlled by the additional thermostat, its

supply air temperature sensor and the 0–10 V input signal for enhanced comfort

and efciency (advanced version only).

● Target temperature setting based on ambient temperature with CZ-CAPBC2

using 0–10 V signal (advanced version only).

● Connectable with P-LINK system.

● Fan control signal from the PCB can be used for controlling the air volume of an

external fan (High/Mid/Low and LL for Th-OFF). (Need to change the fan control

circuit wiring at eld.)

● Defrost operation signal, Thermo-ON/OFF states output

● Drain pump control (Drain-pump and the oat switch to be supplied in local)

● Basic humidier control output (humidier eld supplied)

● Alarm and operation output

3.2 Scope of supply

The AHU Kits are supplied in two versions, “light” or “advanced”, and can be selected based on

the required functionality.

18

Product description

The light version, denominated by the letter “L” in the model name, contains the following

components:

● IP65 case

● Control unit including transformer

● Relays

● Terminal boards

● Remote controller (CZ-RTC2)

● PCBs for the expansion and RAP valves

● PCB for T10 connection (PAW-T10)

● Expansion valve (only for ECOi and ECO G)

● Refrigerant temperature sensors (E1, E2/E3)

● Air intake and air outlet temperature sensors (TA, BL)

In addition to this, the advanced version, without the letter “L” in the model name, contains also

the following components:

● Thermostat including an additional temperature sensor to be used either for

room supply air or ambient air temperature

● Interface for 0–10 V control (CZ-CAPBC2)

The heat exchanger, fan and fan motor must be eld supplied.

Control functions provided as standard by integral components

CZ-RTC2 Timer remote controller

● Operation-ON/OFF

● Mode selection

● Temperature setting

● Parameter settings

Additional Thermostat (advanced version only)

● Target temperature setting based on ambient temperature with proportional

integral logic*

● Demand control based on room supply air temperature to enhance comfort and

efciency*

* Only one of these two options can be chosen at a time.

19

Product description

CZ-CAPBC2 Mini seri-para I/O unit (advanced version only)

● Easy integration in external AHU control systems and BMS

● Demand control: 40 to 115 % (5 % steps) of nominal current by 0–10 V input

signal*

● Target temperature setting by 0–10 V or 0–140 Ω input signal*

● Room supply air temperature output by 4–20 mA signal

● Mode select or/and ON/OFF control

● Fan operation control

● Operation status output/ Alarm output

● Thermostat ON/OFF control

* Demand control by external BMS cannot be combined with the demand control or target temperature setting accom-

plished by the thermostat. However, if simultaneous demand control and target temperature setting is needed, this

can only be achieved by using a second (optional) CZ-CAPBC2 interface.

PAW-T10 PCB to connect to T10 connector

● Dry contact PCB for easy control of the unit

● Operation ON/OFF input signal

● Remote control prohibition

● Operation ON status output signal, maximum 230 V / 5 A (NO/NC)

● Alarm status output signal, maximum 230 V / 5 A (NO/NC)

PAW-OCT, DC12 V outlet, OPTION terminal

● Output signal for Cooling/Heating/Fan status

● Output signal for Defrost operation indication

● Output signal for Thermostat-ON status

Additional contacts available

● External humidier control (ON/OFF) 230 V AC 3 A

● External fan control (ON/OFF) 12 V DC

● External lter status signal potential free

● External oat switch signal potential free

● External leakage detection sensor or TH. OFF contact potential free (possible

usage for external blow out temperature control)

20

Product description

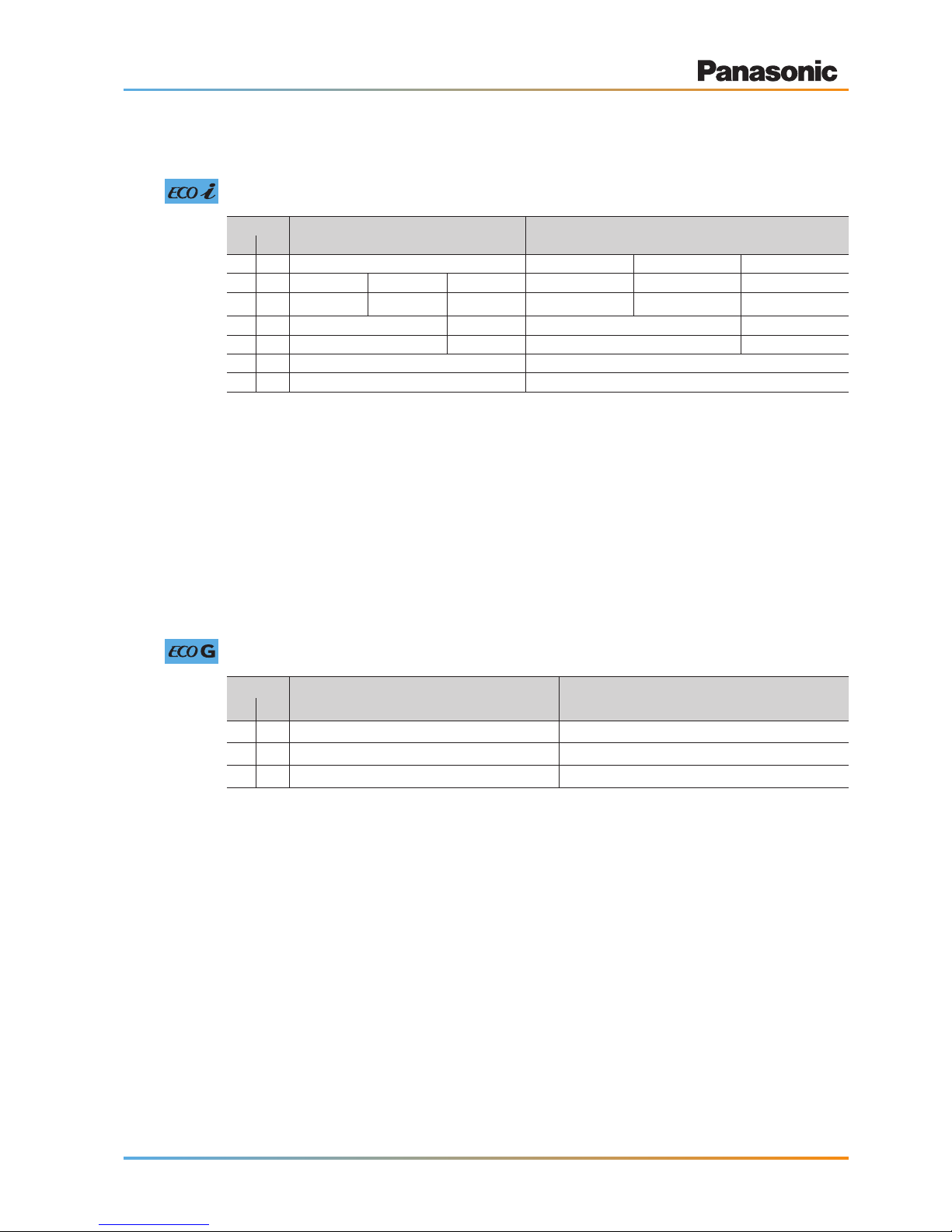

3.3 System lineup

System lineup – ECOi systems

Capacity Outdoor unit combination AHU Kit combination

HP kW

5 16 all ECOi outdoor units PAW-160MAH2(L)

1

– –

10 28 U-10ME1E81 – – PAW-280MAH2(L)

2

– –

20 56 U-20ME1E81 – – PAW-560MAH2(L)

3

– –

30 84 U-16ME1E81 U-14ME1E81 – PAW-560MAH2(L) PAW-280MAH2(L) –

40 112 U-20ME1E81 U-20ME1E81 – PAW-560MAH2(L) PAW-560MAH2(L) –

50 140 U-18ME1E81 U-16ME1E81 U-16ME1E81 PAW-560MAH2(L) PAW-560MAH2(L) PAW-280MAH2(L)

60 168 U-20ME1E81 U-20ME1E81 U-20ME1E81 PAW-560MAH2(L) PAW-560MAH2(L) PAW-560MAH2(L)

1 PAW-160MAH2(L):

● PAW-160MAH2(L) can be installed in combination with all ECOi 2-pipe and 3-pipe outdoor units like

any other standard indoor unit.

● Mixed installation with standard indoor units is possible. However, in this case one additional RAP

valve (CZ-P160RVK2) must be installed in the unit connection pipe, unless the unit is exclusively

used in cooling only operation.

2 PAW-280MAH2(L):

● Mixed installation with standard indoor units is possible. However, in this case two additional RAP

valves (2 x CZ-P160RVK2) must be installed in the unit connection pipe, unless the unit is exclusively used in cooling only operation.

● Connection to ECOi 3-way systems is not allowed.

3 PAW-560MAH2(L):

● Mixed installation with standard indoor units is not allowed.

● Connection to ECOi 3-way systems is not allowed.

System lineup – ECO G systems

Capacity Outdoor unit AHU Kit

HP kW

5 16

all ECO G outdoor units

PAW-160MAH2(L)

1

10 28

all ECO G outdoor units

PAW-280MAH2(L)

2

20 56 U-20GE2E5 PAW-560MAH2(L)

3

1 PAW-160MAH2(L):

● PAW-160MAH2(L) can be installed in combination with all ECO G outdoor units like any other stand-

ard indoor unit.

● Mixed installation with standard indoor units is possible. However, in this case one additional RAP

valve (CZ-P160RVK2) must be installed in the unit connection pipe, unless the unit is exclusively

used in cooling only operation.

2 PAW-280MAH2(L):

● PAW-280MAH2(L) an be installed in combination with all ECO G outdoor units like any other stand-

ard indoor unit.

● Mixed installation with standard indoor units is possible. However, in this case two additional RAP

valves (2 x CZ-P160RVK2) must be installed in the unit connection pipe, unless the unit is exclusively used in cooling only operation.

3 PAW-560MAH2(L):

● With PAW-560MAH2(L), only 1-to-1 installations are allowed (1 x U-20GE2E5 + 1 x PAW-

560MAH2(L)). Combinations with more than 1 outdoor unit or more than 1 AHU Kit are not possible.

● Mixed installation with standard indoor units is not allowed.

● Connection to ECO G 3-way systems is not allowed.

21

Product description

System lineup – PACi systems

Capacity

(kW)

Outdoor unit

1

AHU Kit

PACi Standard PACi Elite

Single-phase units Three-phase units Single-phase units Three-phase units

5.0 – – U-50PE1E5 –

PAW-280PAH2(L)

2

6.0 U-60PEY1E5 – U-60PE1E5A –

7.1 U-71PEY1E5 – U-71PE1E5A U-71PE1E8A

10.0 U-100PEY1E5 U-100PEY1E8 U-100PE1E5A U-100PE1E8A

12.5 U-125PEY1E5 U-125PEY1E8 U-125PE1E5A U-125PE1E8A

14.0 – U-140PEY1E8 U-140PE1E5A U-140PE1E8A

20.0 – – – U-200PE1E8

25.0 – – – U-250PE1E8

1 With PACi systems, only 1-to-1 installations are allowed (1 x PACi outdoor unit + 1 x PAW-280PAH2(L)). Combina-

tions with more than 1 outdoor unit or more than 1 AHU Kit are not possible.

2 Mixed installation with standard indoor units is not allowed.

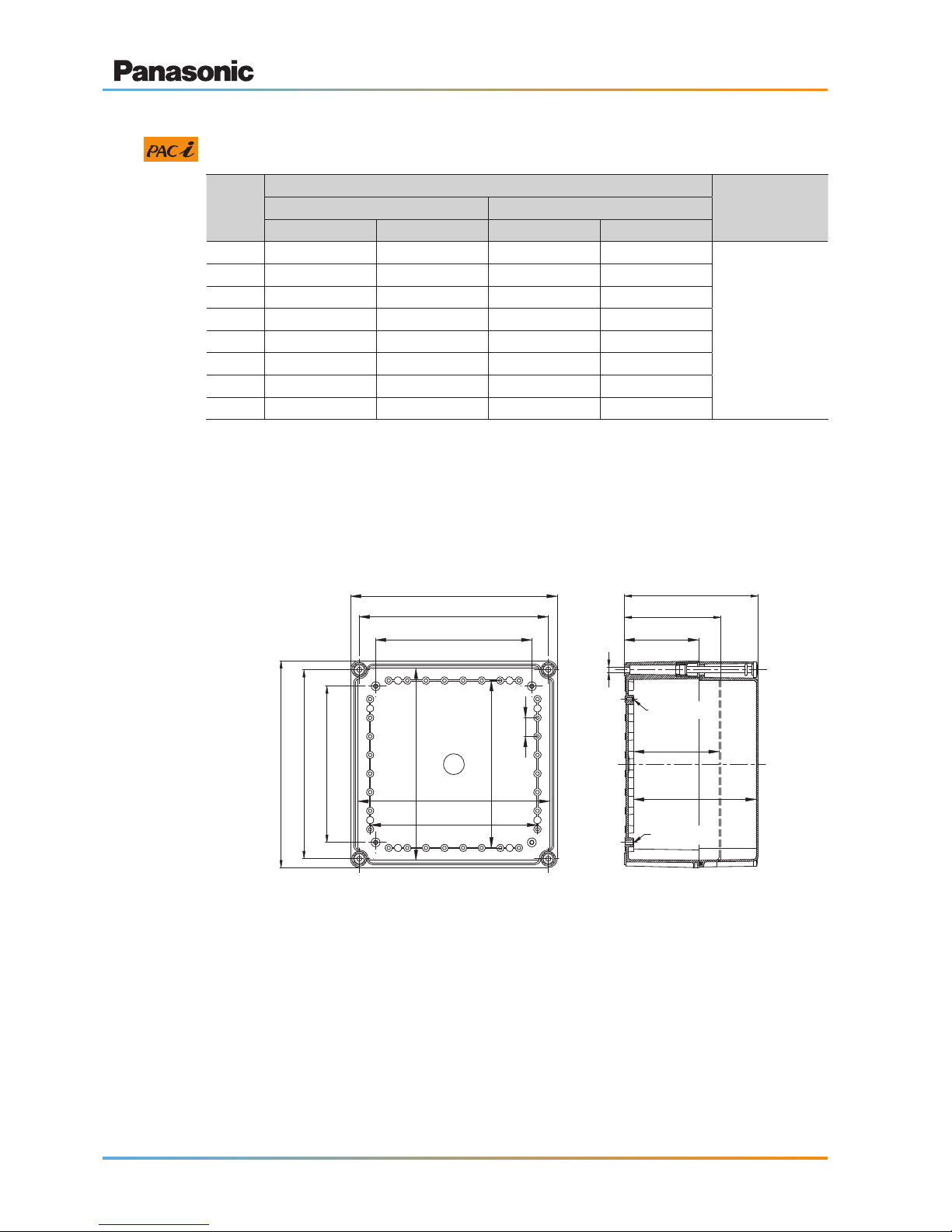

3.4 AHU Kit dimensions and exterior view

AHU Kit dimensions

Side view

210

254

278

210

254

278

225

257

225

257

100

130

180

165

115

Ø4.2 x 10

Ø5.2 x 11

25

Ø7

Front view (transparent cover removed)

22

Product description

Exterior view of the AHU Kit

AHU Kit including

PCB, power transformer, terminal block

Expansion

valve

Thermistor x2

(Refrigerant: E1, E2)

Thermistor x2

(Refrigerant: E1, E3)

Thermistor

(Air: TA)

Thermistor x2

(Air: TA, BL)

Note: AHU Kit shown with transparent front cover removed.

23

Product description

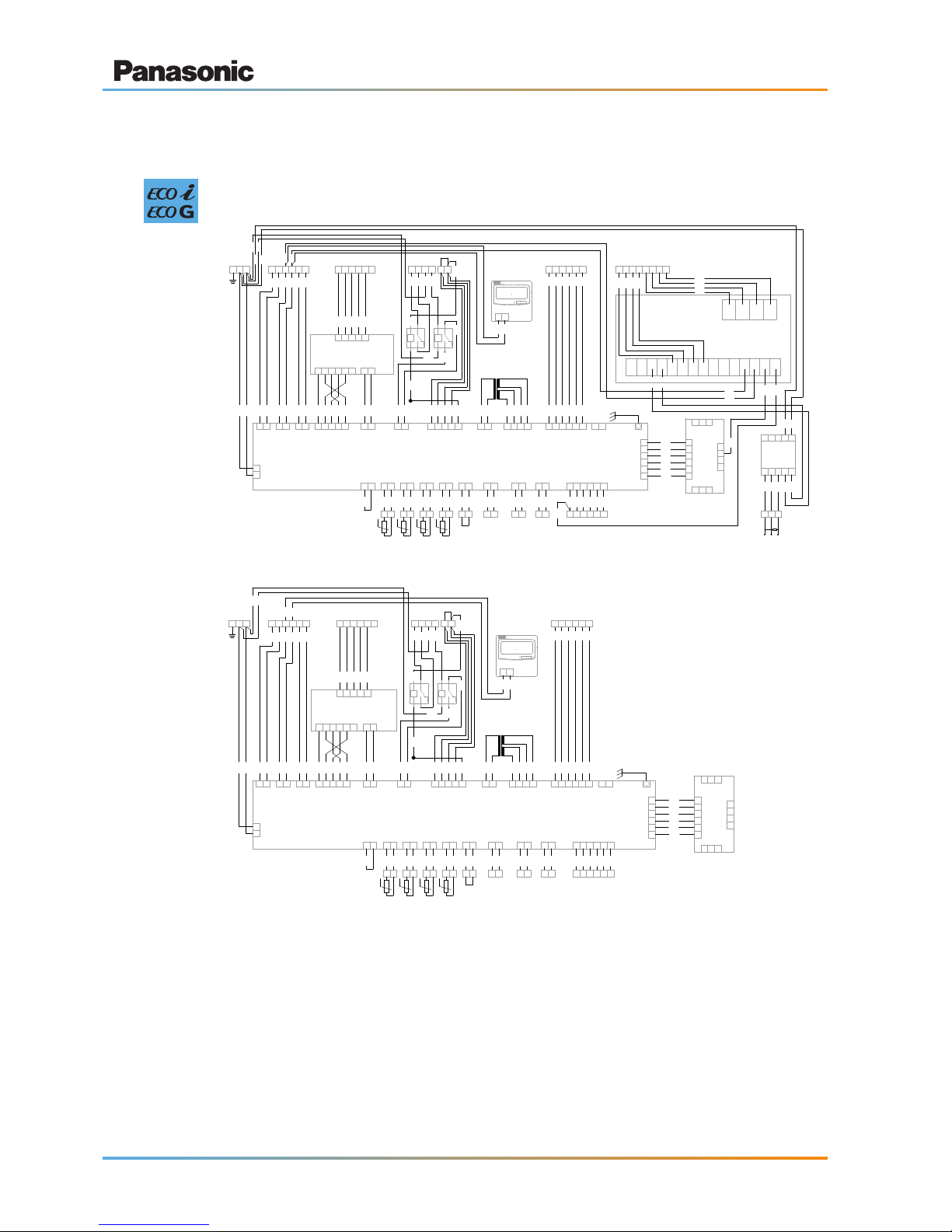

3.5 Wiring layout

Wiring layout – ECOi and ECO G systems

1

3

AC IN

(BLK)

1

2

OC

(BLU)

1

3

RC

(BLU)

1

2

EXCT

(RED)

1

2

3WAY

(BLK)

3

4

5 1

3

OP1

(YEL)

1

3

FAN

(WHT)

5

7

91

3

T20

(GRY)

1

3

TRANS-P

(WHT)

1

2

TRANS-S

(WHT)

3

4

BRN

BRN

WHT

WHT

RED

RED

TR1

1

2

PMV

(WHT)

3

4

5 6

ORG

RED

YEL

BLK

GRY

1

2

HBS

(YEL)

CR-UXRP71B-P

ORG

RED

YEL

BLK

GRY

1

2

TA

(YEL)

BLK

BLK

1

2

E1

(RED)

BLK

BLK

1

3

E3

(BRN)

BLK

BLK

1

2

BL

(GRN)

BLK

BLK

1

3

FS

(RED)

RED

1

2

PNL

(BRN)

GRN

1

2

FAN DRIVE

(WHT)

WHT

RED

BLK

BLU

PNK

BLU

WHT

BLK

RED

WHT

L N

U1 U2

R1 R2

EX1 EX2

YEL

BLU

BLK

WHT

RED

12345 1

3

3WAY (WHT)

POWER (WHT)

CR-SV80A

1

3

SV1/CN003 (RED)

5

7

9

BLK

WHT

RED

YEL

BLU

6

12345 6

CONNECTOR 6P

(YEL)

RED

WHT

BLK

1Z

7 5

8 3 1

2Z

7 5

8 3 1

TERMINAL

VLT

GRY

1Z5 1Z3

TERMINAL

OP3 2Z7 05 06

YEL

ORG

VLT

WHT

BRN

M1.1M1.2 M1.3M1.4 M1.5

TERMINAL

TA1 TA2 E1.1 E1.2 E3.1 E3.2 BL1 BL2 FS1 FS2

TERMINAL

FD1 FD2

1

2

FILTER

(WHT)

RED

WHT

FI1 FI2

1

3

HU1

(RED)

VLT

BRN

HU1 HU2

CZ-CAPBC2

COM DO2 COM DO1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

CN2

CN1

4POL

PK1-B

10

PK1-A

PAW-T10

T10

98

1

2

3

4

5

6

1

2

3

4

7 6 5

(WHT)

1

2

3

4

5

6

T10

(YEL)

+

E

1

2

OPTION

(WHT)

3

456

YEL

RED

WHT

BLK

BLU

ORG

ON1 ON2 ON3 ON4 ON5 ON6

TR-16

PT100

PE

COM DI1 DI2 DI3 COMDO2 COM DO1

TERMINAL

12345

678910

PT10PT9 PT8

TERMINAL

BLK

BLU

BRN

YEL

RED

WHT

RED

RED

WHT

+-

RED

BLK

BLK

ORG

RED

YEL

BLK

GRY

WHT

BLU

YEL

ORG

BRN

BRN

ORG

YEL

BLU

WHT

BLK

BLK

WHT

CZ-RTC2

R1 R2

WHT

BLK

ORG

ORG

VLT

GRY

WHT

RED

WHT

WHT

BLK

PNK

BLU

BLK

YEL

BLU

RED

t°

TH1t°TH2t°TH4t°TH5

M1.6

WHT WHT

BLK

BLU

WHT

RED

RED

RED

PAW-160MAH2

1

3

AC IN

(BLK)

1

2

OC

(BLU)

1

3

RC

(BLU)

1

2

EXCT

(RED)

1

2

3WAY

(BLK)

3

4

5 1

3

OP1

(YEL)

1

3

FAN

(WHT)

5

7

91

3

T20

(GRY)

1

3

TRANS-P

(WHT)

1

2

TRANS-S

(WHT)

3

4

BRN

BRN

WHT

WHT

RED

RED

TR1

1

2

PMV

(WHT)

3

4

5 6

ORG

RED

YEL

BLK

GRY

1

2

HBS

(YEL)

CR-UXRP71B-P

ORG

RED

YEL

BLK

GRY

1

2

TA

(YEL)

BLK

BLK

1

2

E1

(RED)

BLK

BLK

1

3

E3

(BRN)

BLK

BLK

1

2

BL

(GRN)

BLK

BLK

1

3

FS

(RED)

RED

1

2

PNL

(BRN)

GRN

1

2

FAN DRIVE

(WHT)

WHT

RED

BLK

BLU

PNK

BLU

WHT

BLK

RED

WHT

L N

U1 U2

R1 R2

EX1 EX2

YEL

BLU

BLK

WHT

RED

12345 1

3

3WAY (WHT)

POWER (WHT)

CR-SV80A

1

3

SV1/CN003 (RED)

5

7

9

BLK

WHT

RED

YEL

BLU

6

12345 6

CONNECTOR 6P

(YEL)

RED

WHT

BLK

1Z

7 5

8 3 1

2Z

7 5

8 3 1

TERMINAL

VLT

GRY

1Z5 1Z3

TERMINAL

OP3 2Z7 05 06

YEL

ORG

VLT

WHT

BRN

M1.1M1.2 M1.3M1.4 M1.5

TERMINAL

TA1 TA2 E1.1 E1.2 E3.1 E3.2 BL1 BL2 FS1 FS2

TERMINAL

FD1 FD2

1

2

FILTER

(WHT)

RED

WHT

FI1 FI2

1

3

HU1

(RED)

VLT

BRN

HU1 HU2

4POL

PK1-B

10

PK1-A

PAW-T10

T10

98

1

2

3

4

5

6

1

2

3

4

7 6 5

(WHT)

1

2

3

4

5

6

T10

(YEL)

+

E

1

2

OPTION

(WHT)

3

456

YEL

RED

WHT

BLK

BLU

ORG

ON1 ON2 ON3 ON4 ON5 ON6

PE

ORG

RED

YEL

BLK

GRY

WHT

WHT

BLK

CZ-RTC2

R1 R2

WHT

BLK

ORG

ORG

VLT

GRY

WHT

RED

WHT

WHT

BLK

PNK

BLU

BLK

YEL

BLU

RED

t°

TH1t°TH2t°TH4t°TH5

M1.6

WHT WHT

WHT

RED

RED

PAW-160MAH2L

TH1 Air intake temperature sensor

TH2 Indoor coil thermistor E1

TH4 Indoor coil thermistor E3

TH5 Air outlet temperature sensor

PT100* Supply air temperature sensor

CZ-RTC2 Remote controller

TR-16* Thermostat

CZ-CAPBC2* External signal control PCB

CR-SV80A RAP valve control PCB

CR-UXRP71B-P Main PCB

PAW-T10 External signal control PCB

1Z / 2Z Auxiliary power relay

TR1 Power transformer

* Not included in PAW-160MAH2L

Loading...

Loading...