Page 1

http://cxema.ru

SPECIFICATIONS

ORDER NO. VRD0006016C2

Digital Video Cassette Recorder

NV-DV2000EC

DJ-MECHANISM

© 2000 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a violation of

law.

Page 2

http://cxema.ru

1. INTRODUCTION

This service manual contains technical information which will allow service personnel to understand and

service this model.

If the circuit is changed or modified, this information will be followed by supplementary service manual to be

filed with original service manual.

NOTE:

Adjustment procedures, Disassembly Procedures and Assembly Procedures for Mechanism Chassis are separated

volume from this Service Manual.

Please refer to the Service Manual for DJ-Mechanism Chassis. (Order No. VMD9706005A8)

1.1. CMPONENT REFERRENCE TABLE

If you have the reference number of each component and have no idea where it is, use the following table to

find out the C.B.A. and/or diagram.

Reference-Series- Located C.B.A. Name of Diagram Remarks

1000 Series VEP06D55A RF I/F SECTION IN MAIN

1100 Series

1200 Series

1100 Series

1200 Series

1500 Series VEP06D55A RF I/F SECTION IN MAIN

1500 Series VEP000D5B MOTOR DRIVE<DIGITAL (SYSTEM CONTROL&

2000 Series VEP03F39A DIGITAL (LSI MICON SECTION)

2500 Series VEP03F39A DIGITAL (SYSTEM CONTROL& SERVO SECTION)

3000 Series VEP03F39A DIGITAL (VIDEO 1 SECTION)

3100 Series VEP03F39A DIGITAL (VIDEO 1 SECTION)

3200 Series VEP03F39A DIGITAL (VIDEO 2 SECTION)

3600 Series VEP06D55A VIDEO SECTION IN MAIN

3700 Series VEP03F39A DIGITAL (DIGITAL I/F SECTION)

3900 Series VEP03F40A INPUT/OUTPUT

4000 Series VEP06D55A RF I/F SECTION IN MAIN

4200 Series VEP03F39A DIGITAL (VIDEO 1 SECTION)

4300 Series VEP06D55A AUDIO SECTION IN MAIN

4500 Series VEP03F39A DIGITAL (VIDEO 1 SECTION)

4700 Series VEP06D55A VIDEO SECTION IN MAIN

4800 Series VEP07A24A TIMER

4900 Series VEP06D55A RF I/F SECTION IN MAIN

4900 Series VEP03F40A INPUT/OUTPUT

4950 Series VEP06D55A RF I/F SECTION IN MAIN

5000 Series VEP05352A HEAD/ REC AMP

VEP06D55A POWER SECTION IN MAIN

VEP01868A SUB POWER<POWER SECTION IN MAIN>

SERVO SECTION)>

Page 3

http://cxema.ru

6000 Series

6100 Series

6200 Series VEP06D55A RF I/F SECTION IN MAIN

7500 Series VEP07A24A TIMER

7600 Series VEP06D55A RF I/F SECTION IN MAIN

7650 Series VEP07A04A DV JACK<RF I/F SECTION IN MAIN>

ґ---- VEP000D6A SW<DIGITAL (SYSTEM CONTROL& SERVO

30000 Series VEP03F41A ANALOG Y/C

VEP03F39A DIGITAL (SYSTEM CONTROL& SERVO SECTION)

SECTION)>

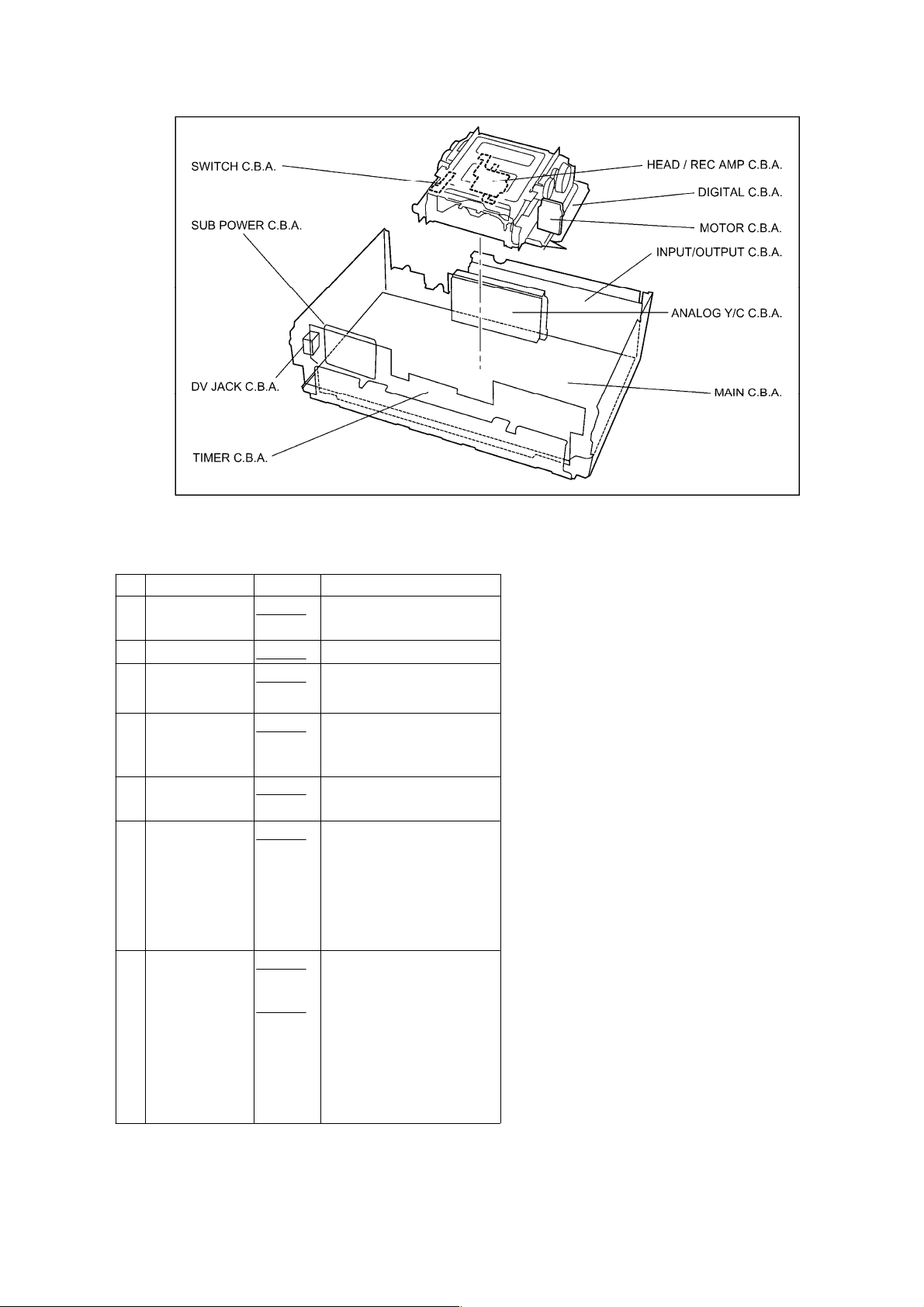

2. GENERAL DESCRIPTIONS

2.1. SERVICE POSITION

2.1.1. Extension Cables

Use the following Extension Cables when checking individual circuit boards.

No. Part No. Part Name Connection

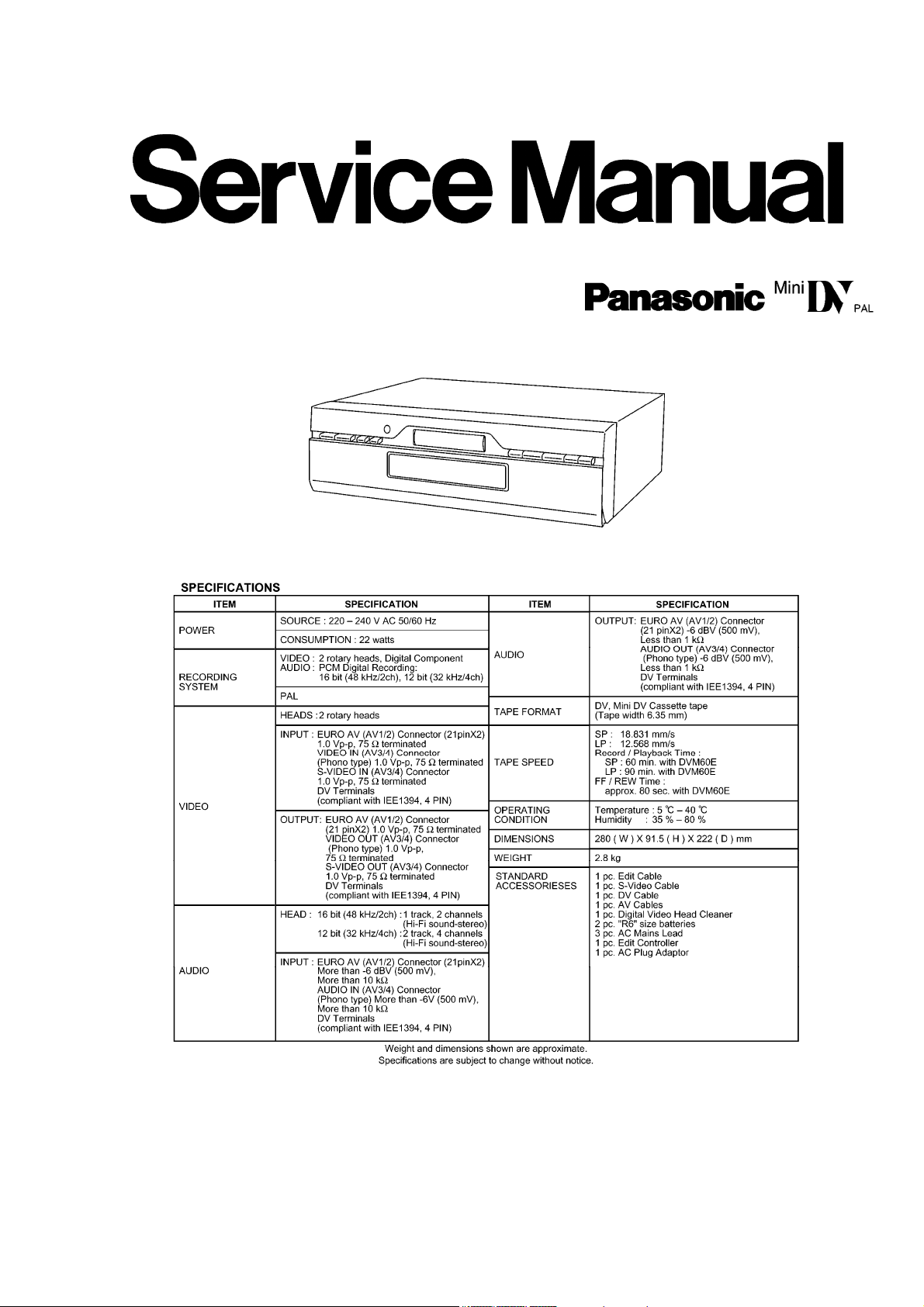

1 VFK1507P ANALOG Y/C Connection

C.B.A.

2 VFK1509 36P Flat Cable

3 VFK1508 32P Flat Cable

4 VFK1509 36P Flat Cable

5 VFK1174 30P Flat Cable

6 VFK1284 24P Flat Cable

7 VFK1292 9P Flat Cable

8 VFK1282 22P Flat Cable

9 VFK1446 32P Flat Cable

10 VFK1445 26P Flat Cable

11 VFK1527 3P Extension Cable

12 VFK1529 2P Extension Cable

13 VFK1530 30P Flat Cable Mech. Flex. (VES0914) 1 for Emagency Tape

Main C.B.A.→ Analog Y/C

C.B.A.

Main FP3401→ Digital FP3201

Main FP3402→ Digital FP3202

Main FP6201→ Digital FP6002

Digital FP6003→ Mech. Flex.

(VES0914)

Digital FP3203→ Mech. (Head

Amp)

Digital P2501→ Mech.

(Cylinder)

Digital P2502→ Mech.

(Capstan)

Main P7901→ Timer P7502

Main P7902→ Timer P7501

Digital P6001→ Switch P1502

Digital P6002→ Motor P1501

Q‘ty

1

1

1

1

1

1

1

1

1

1

1

1

Ejection

Remarks

Fig. 2-1 Extension Cable

2.1.2. Service Position

2.1.2.1. Service Position for Analog Y/C C.B.A.

Fig. 2-2 Service Position for Analog Y/C C.B.A.

Page 4

http://cxema.ru

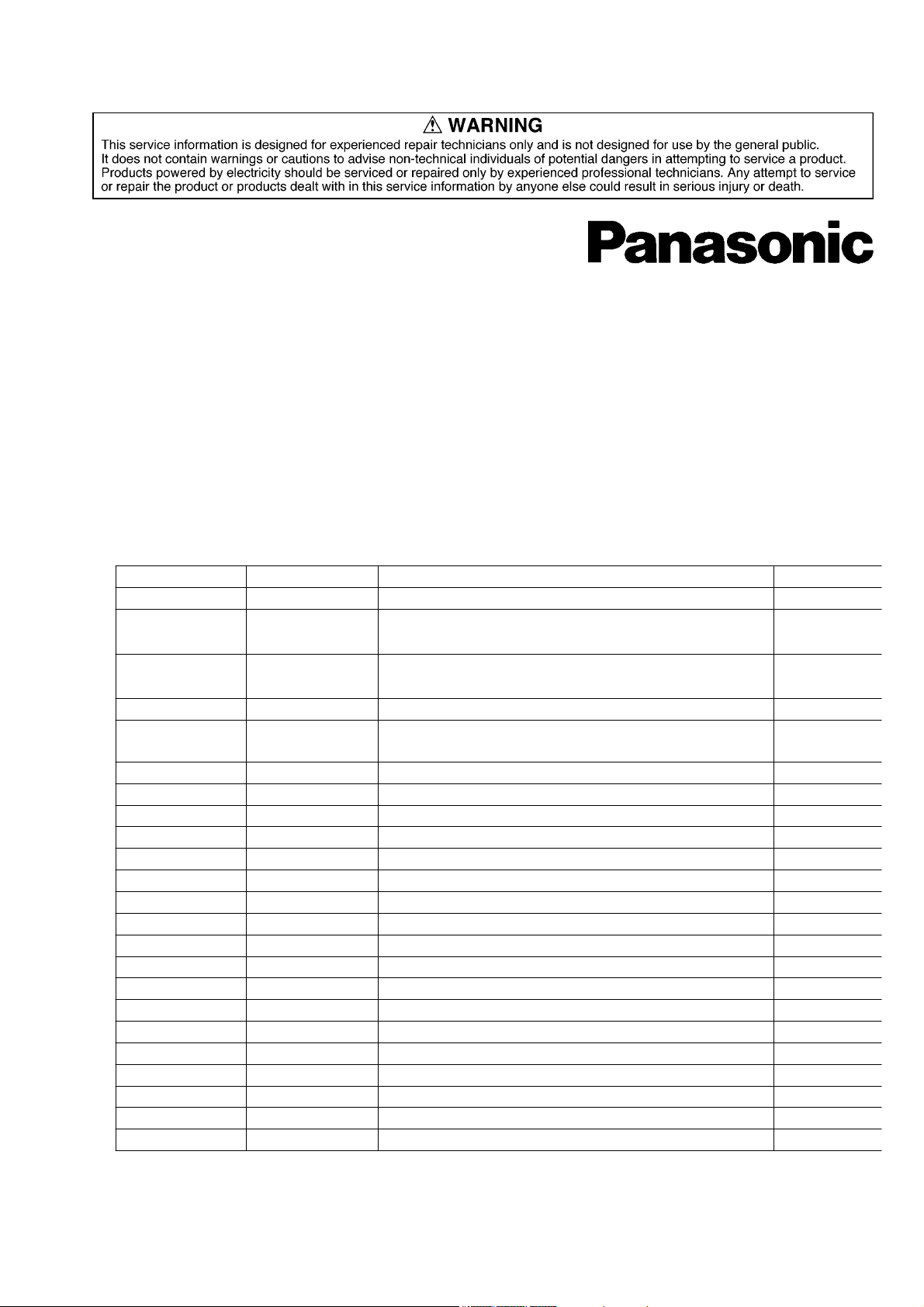

2.1.2.2. Service Position for Digital C.B.A.

When checking the Digital C.B.A., remove the Mechanism unit with Digital C.B.A. from the frame. Then,

connect the extension cables as shown in

Mechanism unit.

Fig. 2-3 Service Position for Digital C.B.A.

Fig. 2-3 Service Position for Digital C.B.A. and turn overthe

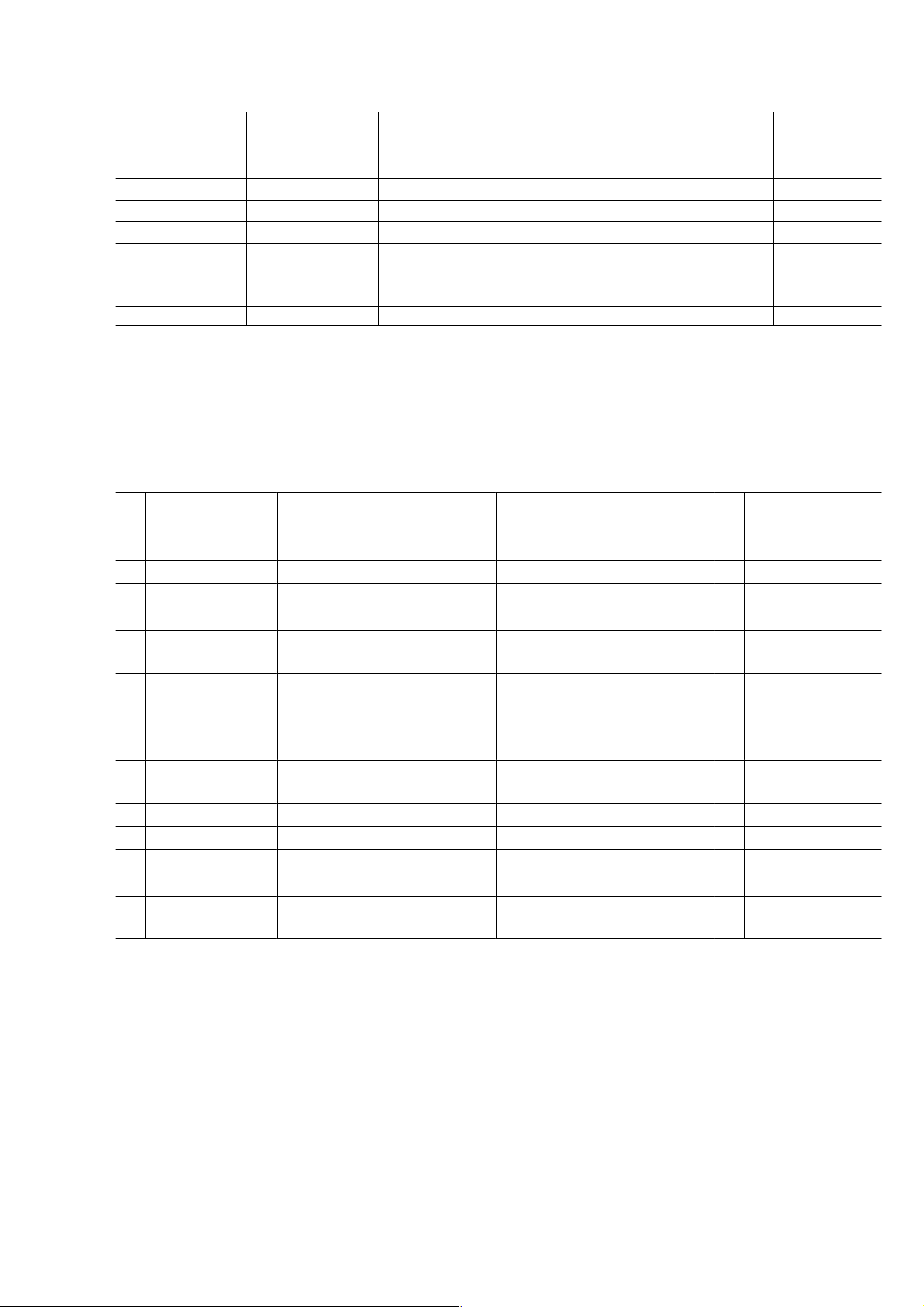

2.1.2.3. Service Position for Main C.B.A.

When checking the Main C.B.A., take out the Mechanism unit with Digital C.B.A. and Main C.B.A. from the

frame. Then, connect extension cables as shown in

Main C.B.A..

Fig. 2-4 Service Position for Main C.B.A. and turnover the

Fig. 2-4 Service Position for Main C.B.A.

Page 5

http://cxema.ru

2.2. SERVICE MODE

e

a

e

S

2.2.1. Setting the Service Mode

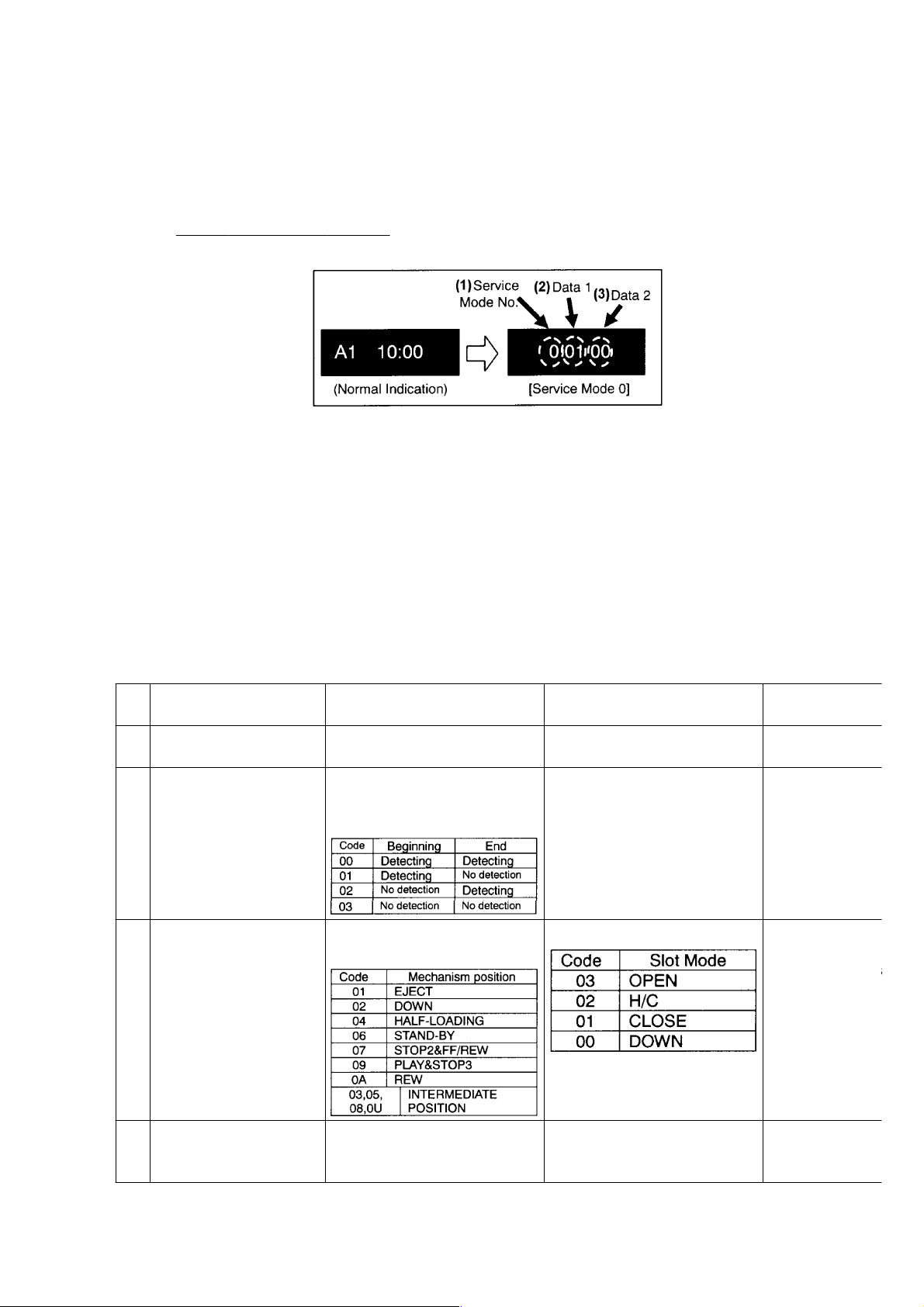

This VTR is equipped with the Service Mode, which is effective for servicing.To turn on the Service Mode,

press FF and EJECT button simultaneously in 3 seconds.(Indication of Front Panel Display is changed as

shown in

2.2.2. How to use the Service Mode

There are 8 kinds of Service Mode and the subject of each Service Mode is listed below.

Mode 0: Mevhanism process/position

Mode 1: Tape Beg/End Sensor& Receiving key command

Mode 2: Mechanism position& slot mode

Mode 3: Self-Diagnosed record 1 (Latest)

Mode 4: Self-Diagnosed record 2 (2nd Latest)

Mode 5: Self-Diagnosed record 3 (3rd Latest)

Mode 6: Receiving command at LSI

Mode 7: Mechanism Manual operation

The following chart shows the meaning of the each code.

To read/decode the Service Mode, use following chart.

Fig.2-5 Service Mode (Sample).)

Fig. 2-5 Service Mode (Sample)

(1)

No.

0 Mechanism position. VCR (Deck) Mode [Real-time] Mechanism driving position

1 Tape Beg/End sensor

checkup& Receiving

key Command checkup

2 Mechanism position&

slot mode checkup

3 Self-Diagnosed record 1

(Latest)

Group (2) Data 1 (3) Data 2 Remarks

process code. [Real-time]

Tape Beginning/End Detection

data.

[Real-time]

Mechanism position

[Real-time]

Refer to the Fig. 2-8

Receiving Key command from

both Remote controller& VCR.

[Real-time]

Slot mode [Real-time]

These two digits (Data2) are

meaningless although it might

be changed.

At this mode, wh

the Eject key is

pressed mode th

3 seconds, it will

the Electrical

Adjustment Mod

Refer to the

SELFDIAGNOSI

MODE.

Page 6

http://cxema.ru

(1)

S

S

Group (2) Data 1 (3) Data 2 Remarks

No.

4 Self-Diagnosed record 2

(2nd Latest)

5 Self-Diagnosed record 3

(3rd Latest)

(To be continued.)

Refer to the Fig. 2-8

Refer to the Fig. 2-8

These two digits (Data2) are

meaningless although it might

be changed.

These two digits (Data2) are

meaningless although it might

be changed.

Refer to the

SELFDIAGNOSI

MODE.

Refer to the

SELFDIAGNOSI

MODE.

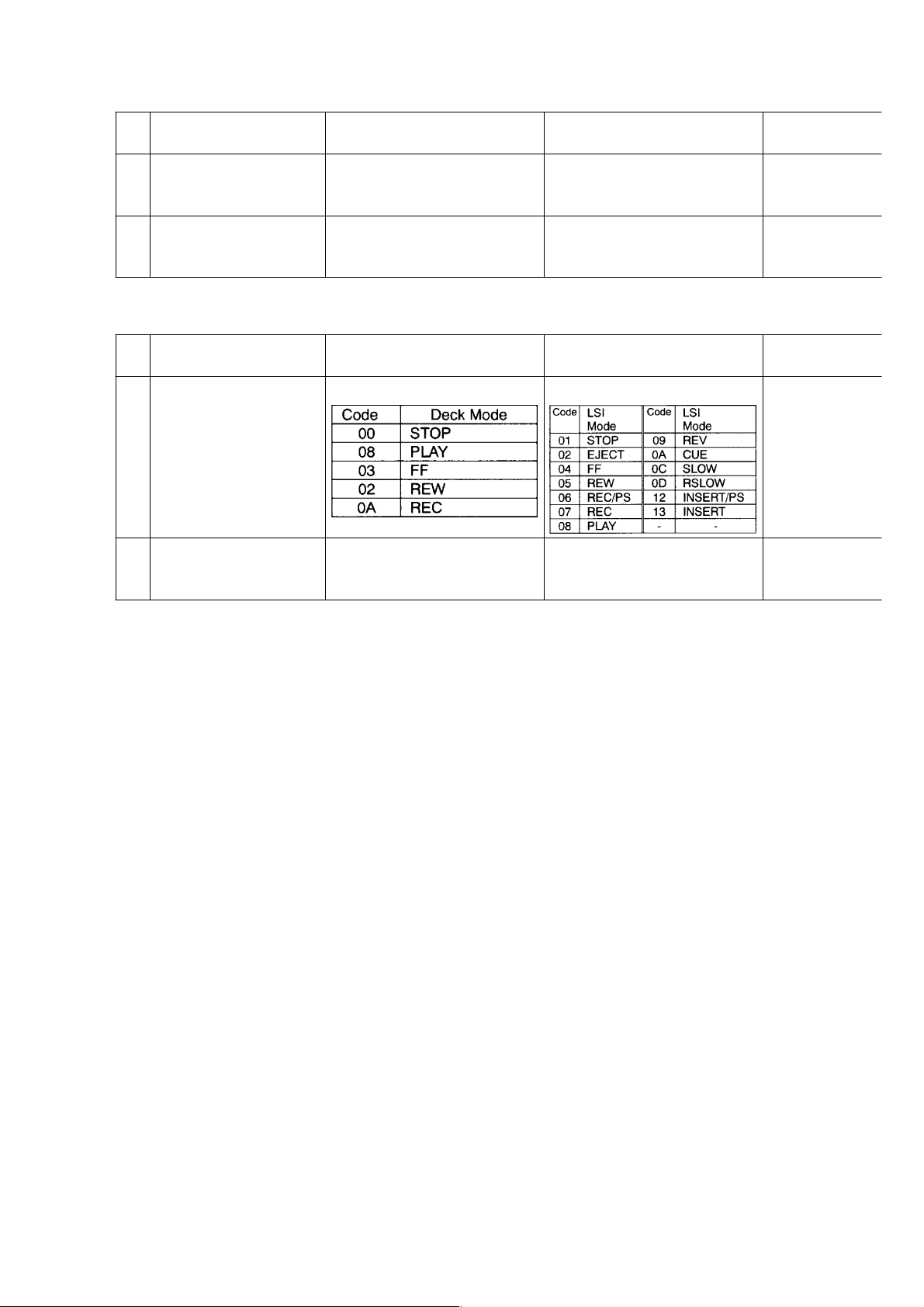

(1)

Group (2) Data 1 (3) Data 2 Remarks

No.

6 LSI receiving command

Deck Mode LSI Mode [Real-time]

checkup

7 Mechanism Manual

operation

Mechanism Position

(Real-time) (Same data with

Slot mode (Real-time (Same

data with Service Mode 2)

Service Mode 2)

Fig. 2-6 Service Mode Decoding Table

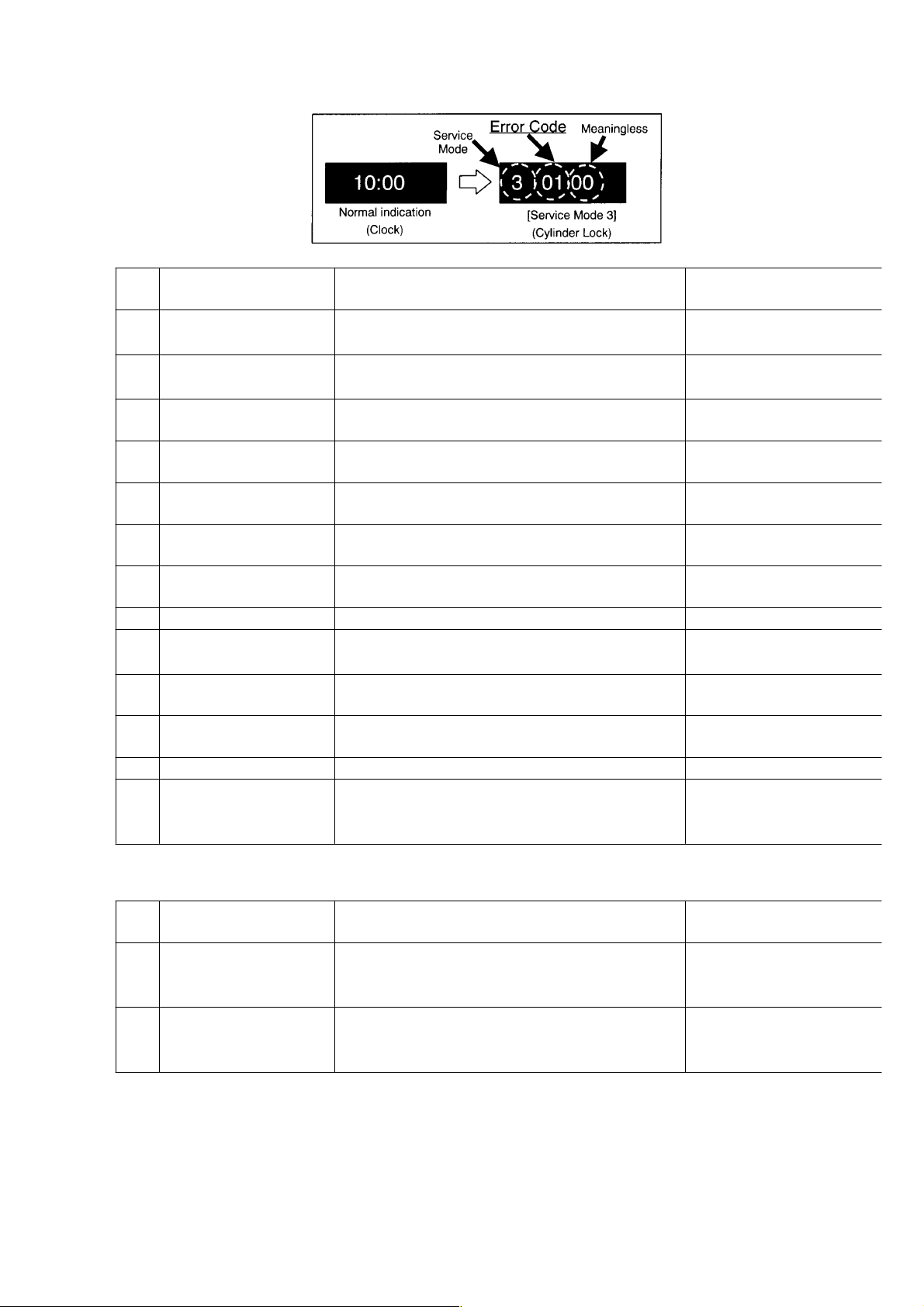

2.2.3. Self- Diagnosis Mode

This VTR has a Self-Diagnosis function, which detects troubles when undesirable condition occurred.When

one of the following listed trouble is detected, Power is automatically turns off and its error is saved as the

"Error-Code" in Timer microprocessor (IC7501).(Threeerror codes can be memorized in historical order and

are backed up by the Lithium Battery;B7901.)

NOTE:

It is not automatically displayed on the Front Panel Display although trouble has been detected. (It means that user can

not be recognized what is happened.)

2.2.3.1. How To Confirm The "Error Code".

The Error Code can be confirmed on the Front Panel Display by placing the unit to the Service Mode 3, 4

and/or 5.

1. Turn on the Service Mode by pressing "FF" and "EJECT" buttons simultaneously in more than 3 seconds.

2. Select the Service Mode 3, 4 or 5 by pressing the "FF" and "EJECT" buttons simultaneously in certain time.The error

codes can be displayed Service Mode 3, 4 and 5 in historical order.

Service Mode 3 displays the last Error Code on the FIP.

Service Mode 4 displays the Error Code on the FIP, which is just before the error code displayed in Service Mode 3.

Service Mode 5 displays the Error Code on the FIP, which is just before the error code displayed in Service Mode 4.

NOTE:

Although same errors are occurred in several times, only first error code is memorized.(When the error is occurred, it is

compared with the memorized data. If the just occurred error is same as the memorized one, it is skipped to be

memorizing.)

Fig. 2-7 Error Code is displayed in F.I.P. (Example)

Page 7

http://cxema.ru

Error

Code

01 Cylinder Lock The cylinder does not rotate or Cylinder lock has

02 Capstan Lock FG signal does not existed in the Cassette down

03 Loading Lock Mechanism Lock has been detected during

04 Unloading Lock Mechanism Lock has been detected during

05 Reel FG NG Abnormal Reel FG has been detected during

07 Slot Motor Lock Slot motor lock has been detected during slot

09 Communication Error

(Sys-Timer)

11 Head Clogging Head clogging has been detected. Head cleaning

14 Mode error Cassette down position has been detected during

17 S-Reel Lock S-Reel Lock has been detected during normal

18 T-Reel Lock T-Reel Lock has been detected during normal

19 Fan Motor Lock Fan motor does not rotate after turning power ON. Fan motor

51 S-Photo Tr Adj. Error

Condition Description Remedy/Check

Check the Cylinder

been detected during normal rotation.

position (Eject-Rev.).

loading operation.

unloading operation.

loading/unloading operation.

in/out operation.

"SYSCON-TIMER" Communication error has

been detected.

unloading operation.

rotation.

rotation.

Adjustment Error.

(Adjustment error of S-Photo Transistor sensitivity

Adjustment.)

Cylinder Drive IC

Check the Capstan

Capstan Drive IC

Loading Post

Loading Post

Reel FG line

Slot Motor

Communication-line

Loading Motor Drive

Mode Switch

S-Reel

T-Reel

Re-adjustment is required.

(Tape End Sensor

Adjustment.)

(To be continued.)

Error

Code

52 T-Photo Tr Adj. Error

53 S/T-Photo Tr Adj. Error

Fig. 2-8 Error Code (Displayed in Service Mode 3, 4 and 5)

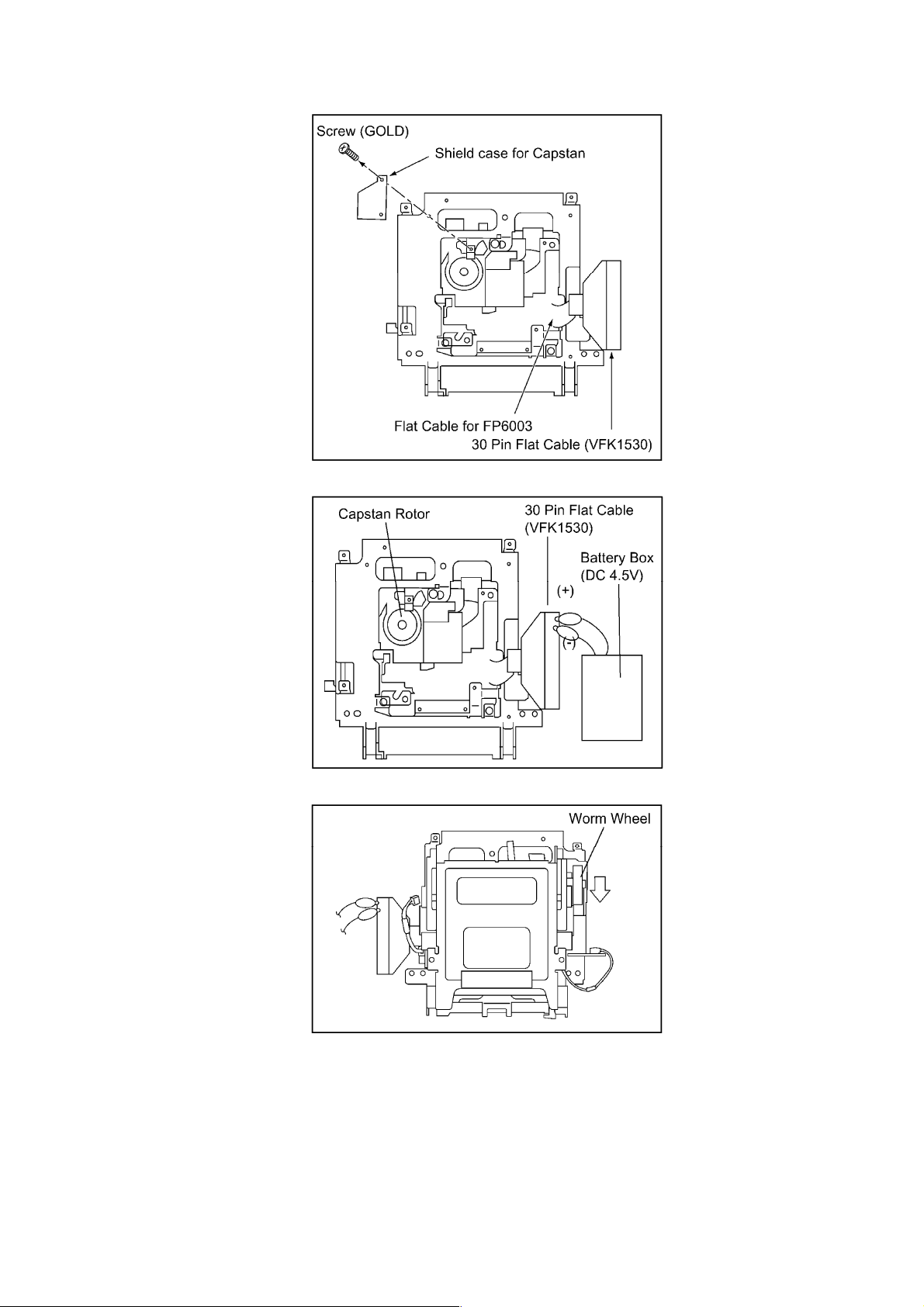

2.2.4. Emergency Tape Ejection

If the electric circuit defects and no Tape ejection can be made in regular way, try following methods.There are

two methods to achieve the emergency tape ejection.

Condition Description Remedy/Check

Adjustment Error.

(Adjustment error of T-Photo Transistor sensitivity

Adjustment.)

Adjustment Error.

(Adjustment error of S/T-Photo Transistor

sensitivity Adjustment.)

Re-adjustment is required.

(Tape Beg. Sensor

Adjustment.)

Re-adjustment is required.

(Tape End/Beg. Sensor

Adjustment.)

Page 8

http://cxema.ru

1. Utilizing the Service Mode 7.

2. Utilizing the Extra DC power (batteries).

2.2.4.1. Utilizing the Service Mode 7

Procedures:

1. Remove the Top panel.

[Refer to the "Disassembly Procedures" section.]

2. Turn on the Service mode and select mode 7.

[Refer to the "Service Mode" section.]

In this mode, when the "STOP" button is pressed, loading motor rotates unloading direction.

Also when the "PLAY" button is pressed, loading motor rotates loading direction.

This action is effective only while either "STOP" or "PLAY" button is being pressed.

NOTE:

While loading/unloading operation, pay attention to the tape slack.

3. Press the "STOP" button until "7 02 00"(Cassette Down position) is displayed on the F.I.P. display.

Fig. 2-9

4. Be sure to confirm no tape slack and take up the tape slack by rotating Capstan with hand if necessarily.

5. Press the "STOP" button until "7 02 03"(Cassette Eject position) is displayed on the F.I.P. display.

Fig. 2-10

6. Take out the tape carefully.

2.2.4.2. Utilizing the Extra DC power (batteries)

Procedures:

1. Remove the Mechanism unit from the chassis.

[Refer to the "Disassembly Procedures" section.]

2. Remove the Digital C.B.A. from the Mechanism unit.

3. Remove the shield case of capstan unit.

4. Connect the Flexible card (VFK1530).

5. Supply the+B (4.5V) to VFK1530 to activate the unloading operation.

Loading.............Pin25,26 (+4.5V) Pin27,28 (GND)

Unloading.........Pin25,26 (GND) Pin27,28 (+4.5V)

In this case, stop supplying the power at just before the mechanism to be the unloading complete position (Tension post

is not retracted fully), otherwise, the tape slack can not be taken although capstan is rotated with hand.

6. Confirm that no tape slack and supply the power again to make full unloading position (Tension post is retracted fully).

Take up the tape slack by rotating Capstan with hand if necessarily.

7. Rotate the worm wheel with hand in counterclockwise, then take out the tape carefully.

Fig. 2-11

Page 9

http://cxema.ru

Fig. 2-12

Fig. 2-13

2.3. OPERATING GUIDE

2.4. CAUTION FOR AC MAINS LEAD (FOR UK)

2.5. HOW TO REPLACE THE LITHIUM BATTERY

Page 10

http://cxema.ru

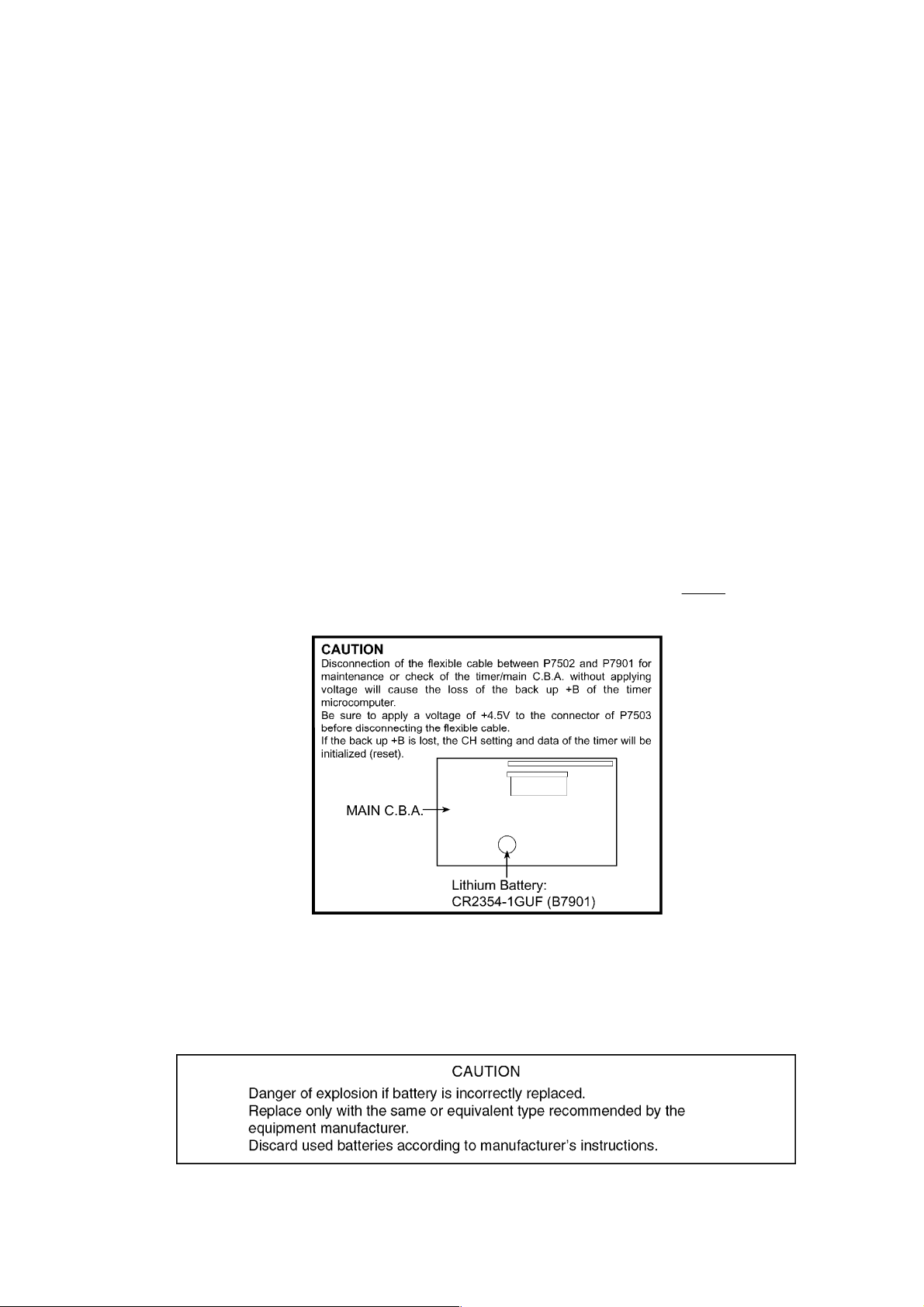

2.5.1. Backup Battery B7901

This VTR equipped with the Backup Battery (B7901) to backup the following memorized data in the Timer

microprocessor (IC7501).

1. Setting condition of "VCR Functions"

OSD(AUTO/ON/OFF)

VCR display(ON/OFF/DIMMED)

Colour Mode(COLOUR/ B/W)

Comb filter (ON/OFF)

E-TBC (ON/OFF)

REC-DNR (LEVEL1/LEVEL2)

PB-DNR (LEVEL1/LEVEL2)

Remote (VCR1/VCR2/VCR3)

2. Setting condition of "Edit Functions"

Search with Sound (OFF/EDIT ONLY/ALWAYS ON)

Audio Mode(12bit/16bit)

One-Touch-Edit(OFF/ON)

Still Album(3-20seconds adjustable)

3. Clock& Date data

4. Self-Diagnosed Result Record (3 records)

2.5.2. Replacement Procedure

1. Remove the Top Panel and Mechanism unit with DIGITAL C.B.A.(VEP03F39A).(Refer to Disassembly Procedures).

2. Unsolder the Lithium Battery;B7901"CR2354-1GUF" and then replace it into new one.(See

Fig. B1)

Fig. B1

CAUTION:

The lithium battery is a critical component (Type No.: CR2354-1GUF Manufactured by Panasonic.) / It must never be

subjected to excessive heat or discharge. / It must therefore only be fitted in equipment designed specifically for its use. /

Replacementbatteries must be of the same type and manufacture. / They must be fitted in the same manner and location

as the original battery, with the correct polarity contacts observed. / Do not attempt to re-charge the old battery or re-use it

for any otherpurpose. / It should be disposed of in waste products destined for burial rather than incineration.

Page 11

http://cxema.ru

3. ADJUSTMENT PROCEDURES

3.1. DISASSEMBLY/ ASSEMBLY PROCEDURES FOR CABINET PARTS,

C.B.A. AND MECHANISM UNIT

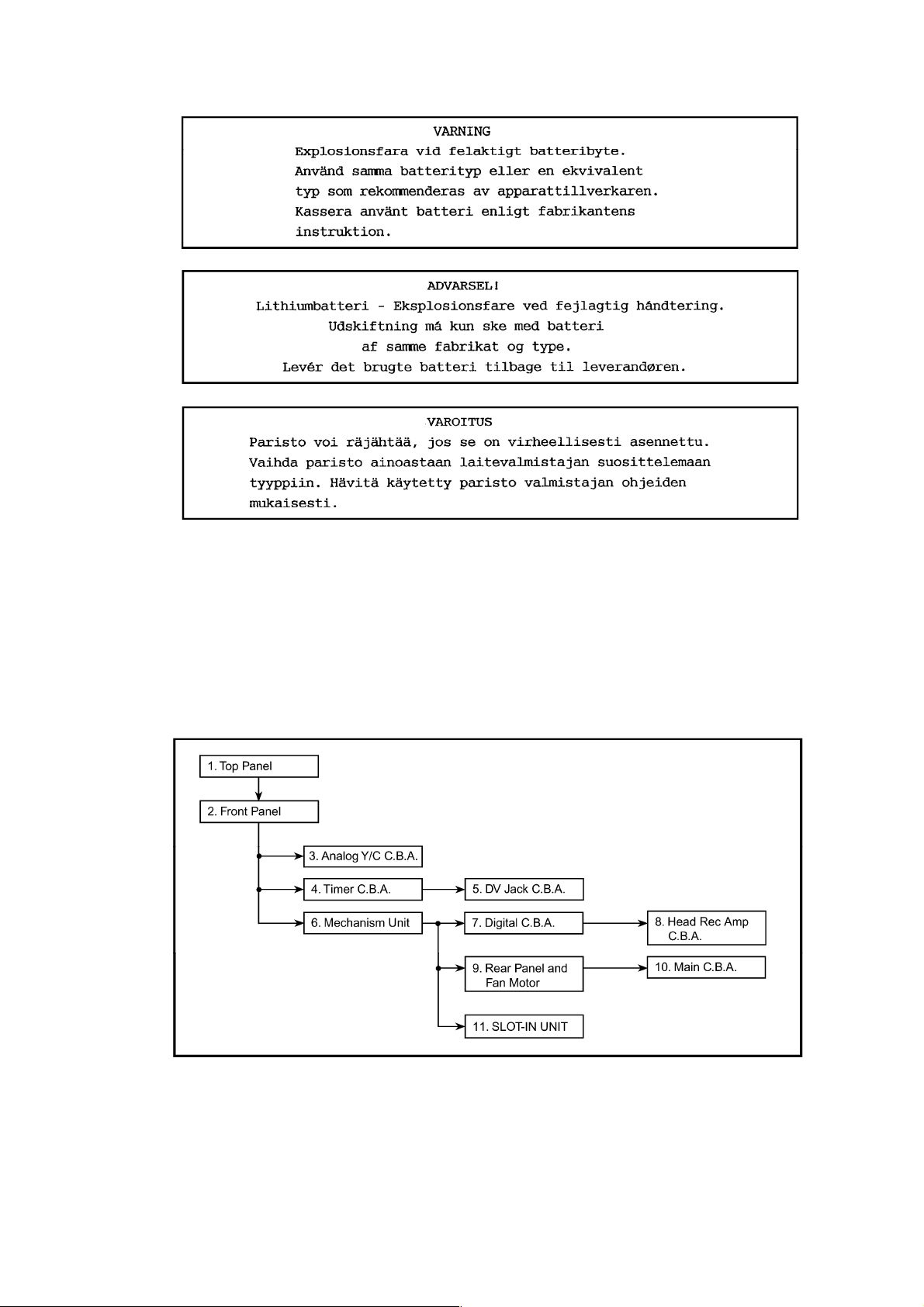

3.1.1. Disassemble Flow Chart for cabinet parts, C.B.A. and Mechanism Unit.

This flow chart indicates the disassembly steps the cabinet parts, C.B.A. and Mechanism Unit in order to

access to items to be serviced. When reinstalling, perform the steps in reverse order.

Fig. 3-1 Flow Chart

Fig. 3-2

Page 12

http://cxema.ru

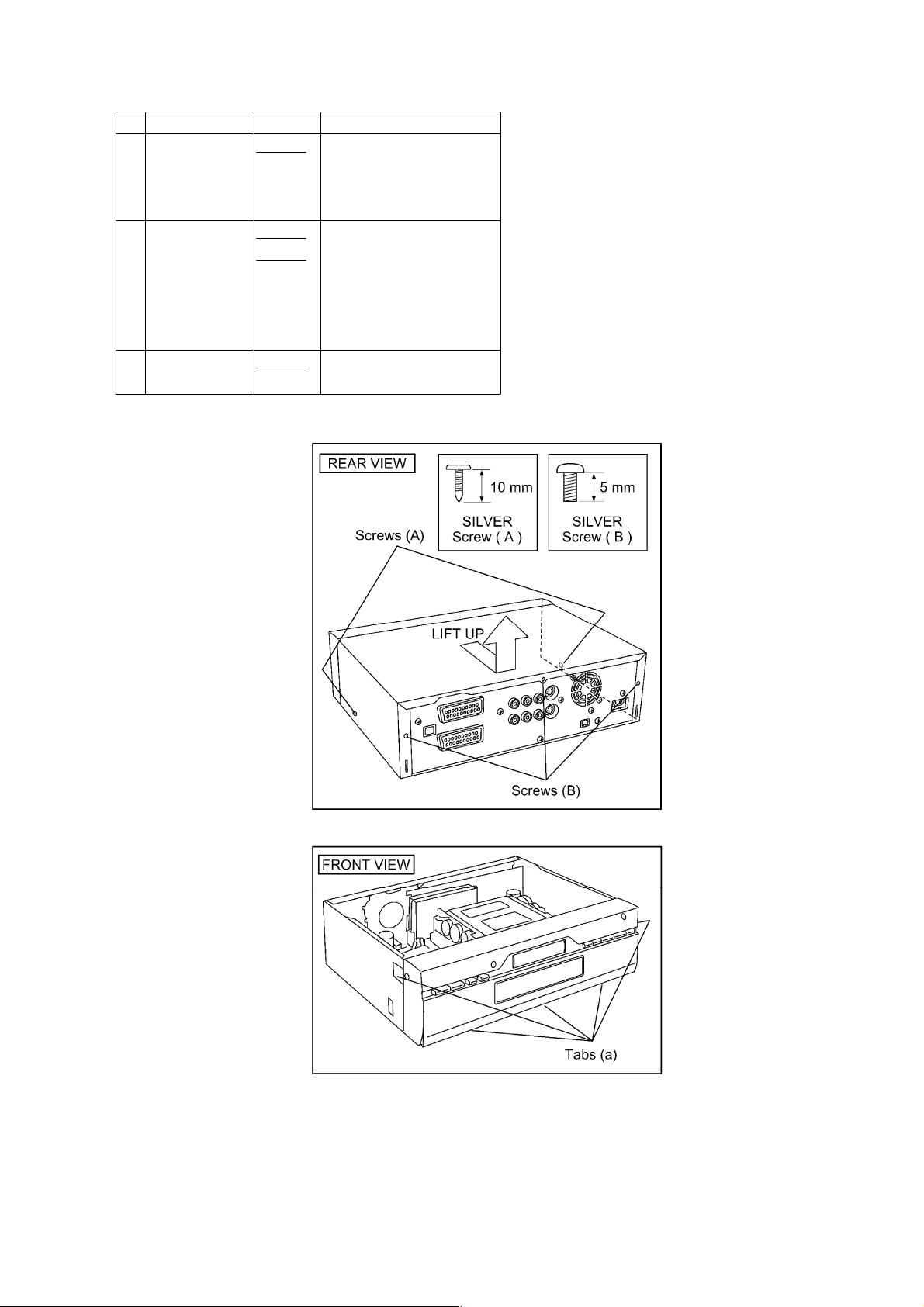

3.1.2. Assemble/ Disassemble Procedures (for cabinet parts, C.B.A. and Mechanism

Unit)

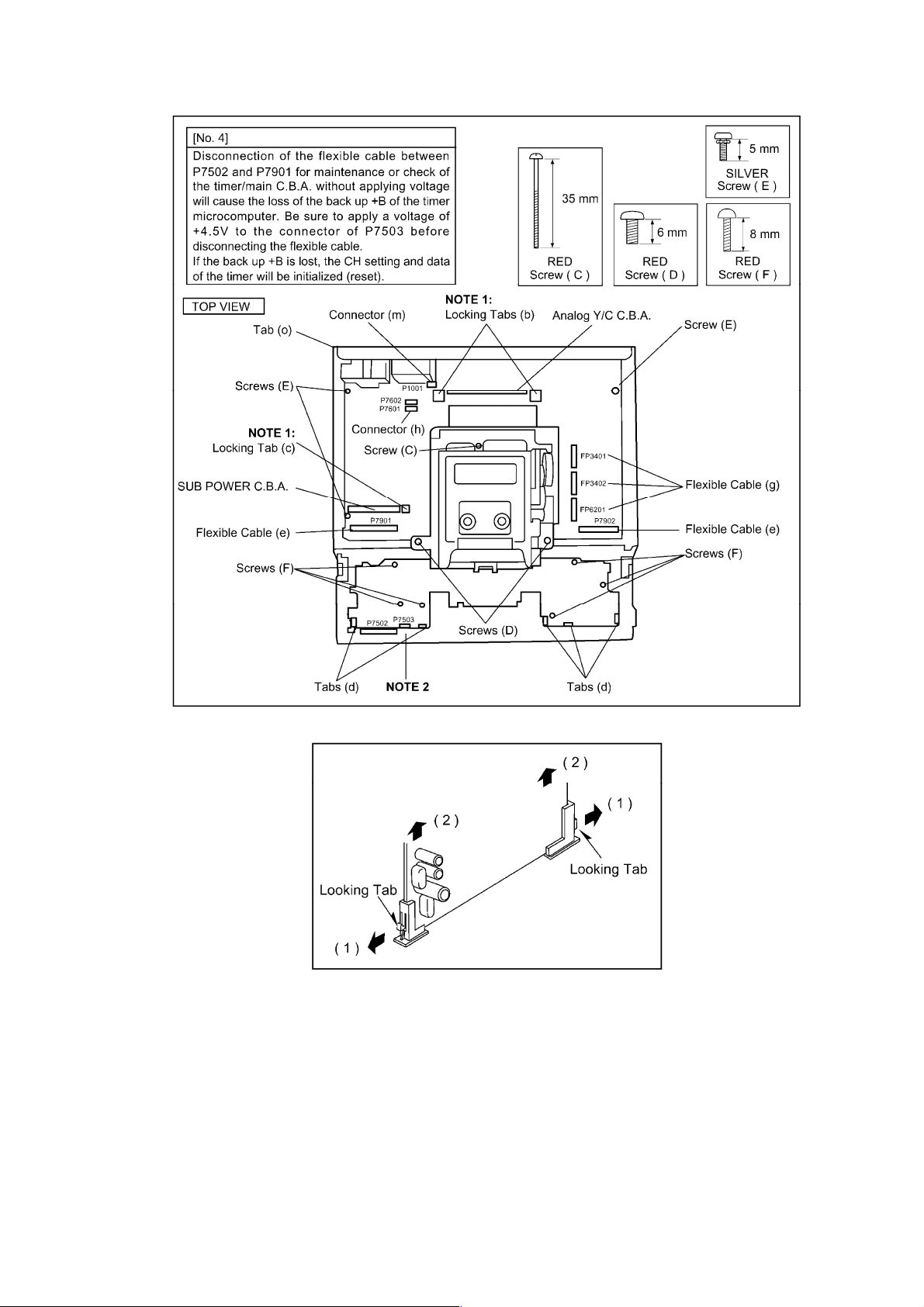

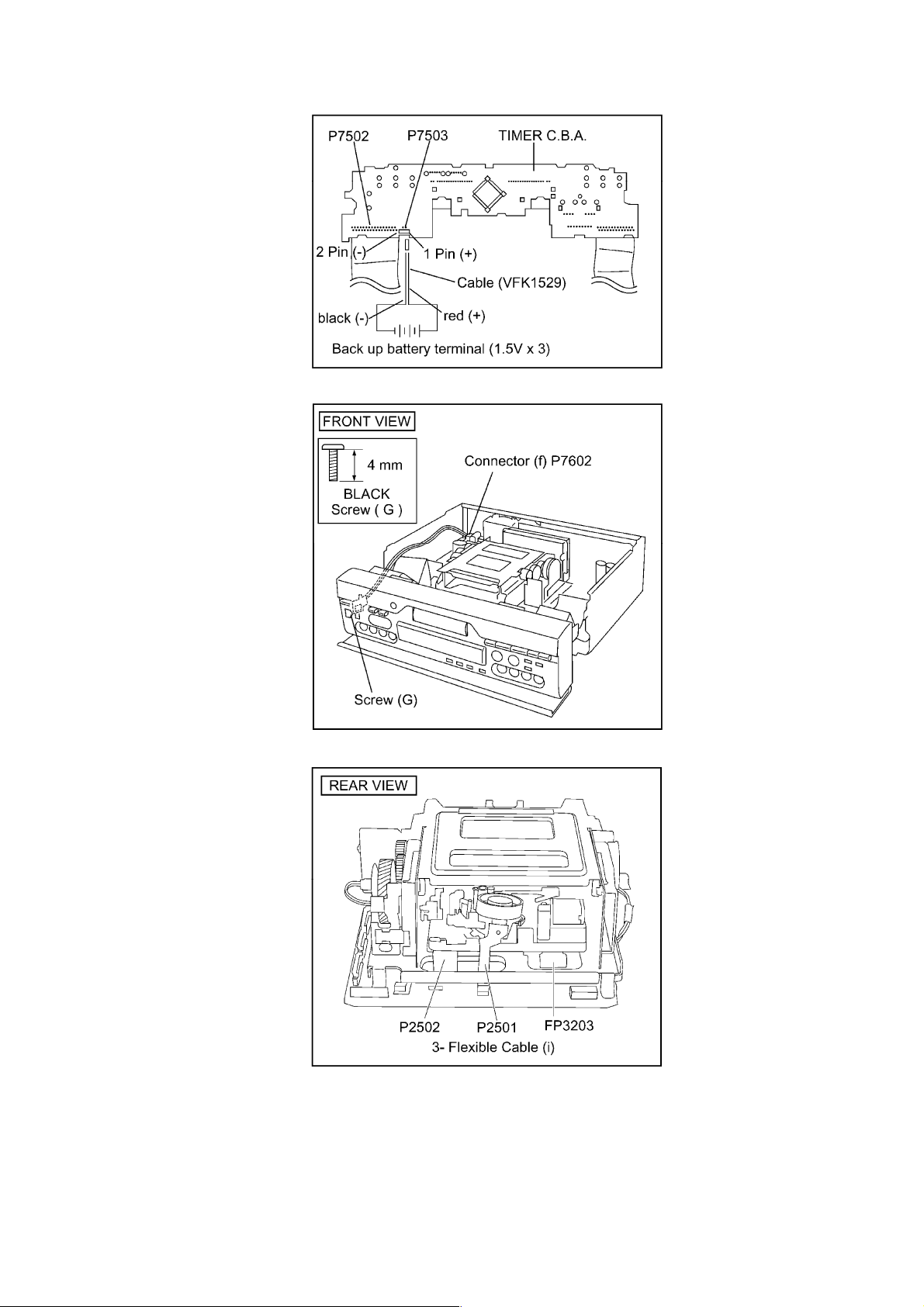

No. ITEM/PART FIGURE REMARKS

1 Top Panel

2 Front Panel

3 Analog Y/C

C.B.A.

4 Timer C.B.A

5 DV Jack

C.B.A.

6 Mechanism

Unit

7 Digital C.B.A.

Fig. D1 2-Screws (A)

3-Screws (B)

Fig. D2

Fig. D3

Fig. D3 6-Screws (F) / 5-Tabs

Fig. D4 1-Connector (f) (P7602)

Fig. D3 3-Flexible Cable (g)

Fig. D5

Fig. D6

5-Tabs (a)

Note1:

2-Locking Tabs (b)

(d) / 2-Flexible Cable (e)

/ (P7901, P7902)

1-Screw (G)

(FP3401, FP3402,

FP6201)

1-Screw (C)

2-Screws (D)

1-Connector (h) (P7601)

3-Flexible Cable (i)

(FP3203, P2501, P2502)

2-Screws (H)

2-Screws (I)

1-Flexible Cable (j)

(FP6003)

2-Connectors (k)

(P6001, P6002)

Page 13

http://cxema.ru

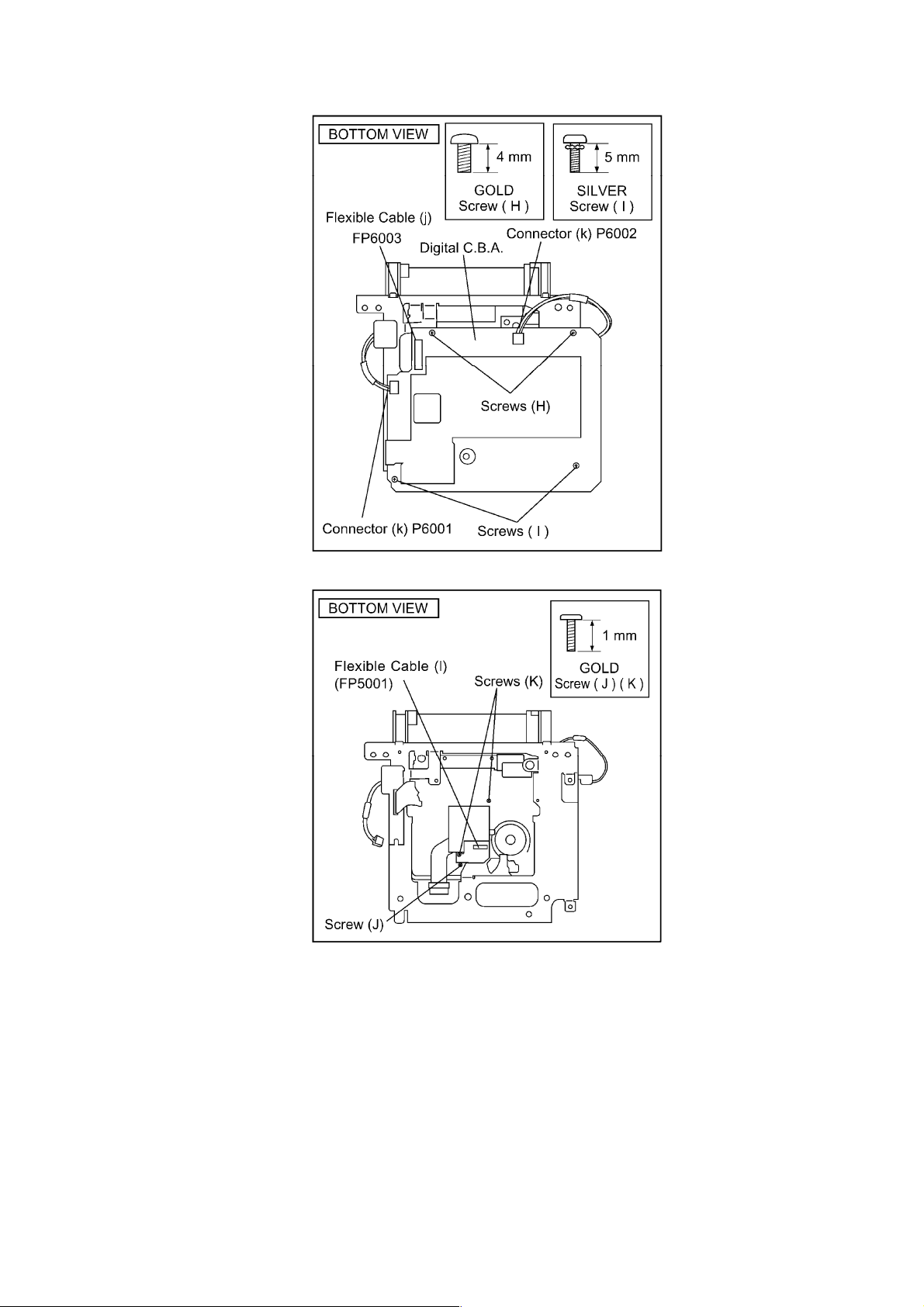

No. ITEM/PART FIGURE REMARKS

8 Head Rec

Amp C.B.A.

9 Rear Panel

and Fan Motor

10 Main C.B.A.

Fig. D7 1-Screw (J)

2-Screws (K)

1-Flexible Cable (l)

(FP5001)

Fig. D3

Fig. D8

Fig. D3 3-Screws (E)

1-Connector (m)

(P1001)

1-Screw (L)

7-Screws (M)

2-Tabs (n)

2-Tabs (p)

1-Tabs (o)

Fig. D1

Fig. D2

Fig. D3

Page 14

http://cxema.ru

NOTE 1

NOTE 2

Page 15

http://cxema.ru

Fig. D4

Fig. D5

Fig. D6

Page 16

http://cxema.ru

Fig. D7

Fig. D8

Page 17

http://cxema.ru

3.1.3. Assemble/ Disassemble Procedures of Slot-in Unit

3.1.3.1. Disassemble Section

Before proceeding the disassembling of the Slot-in unit, remove the mechanism unit from the chassis and

remove the DIGITAL C.B.A. from the mechanism by referring the disassemble procedure describing in the

previous section.

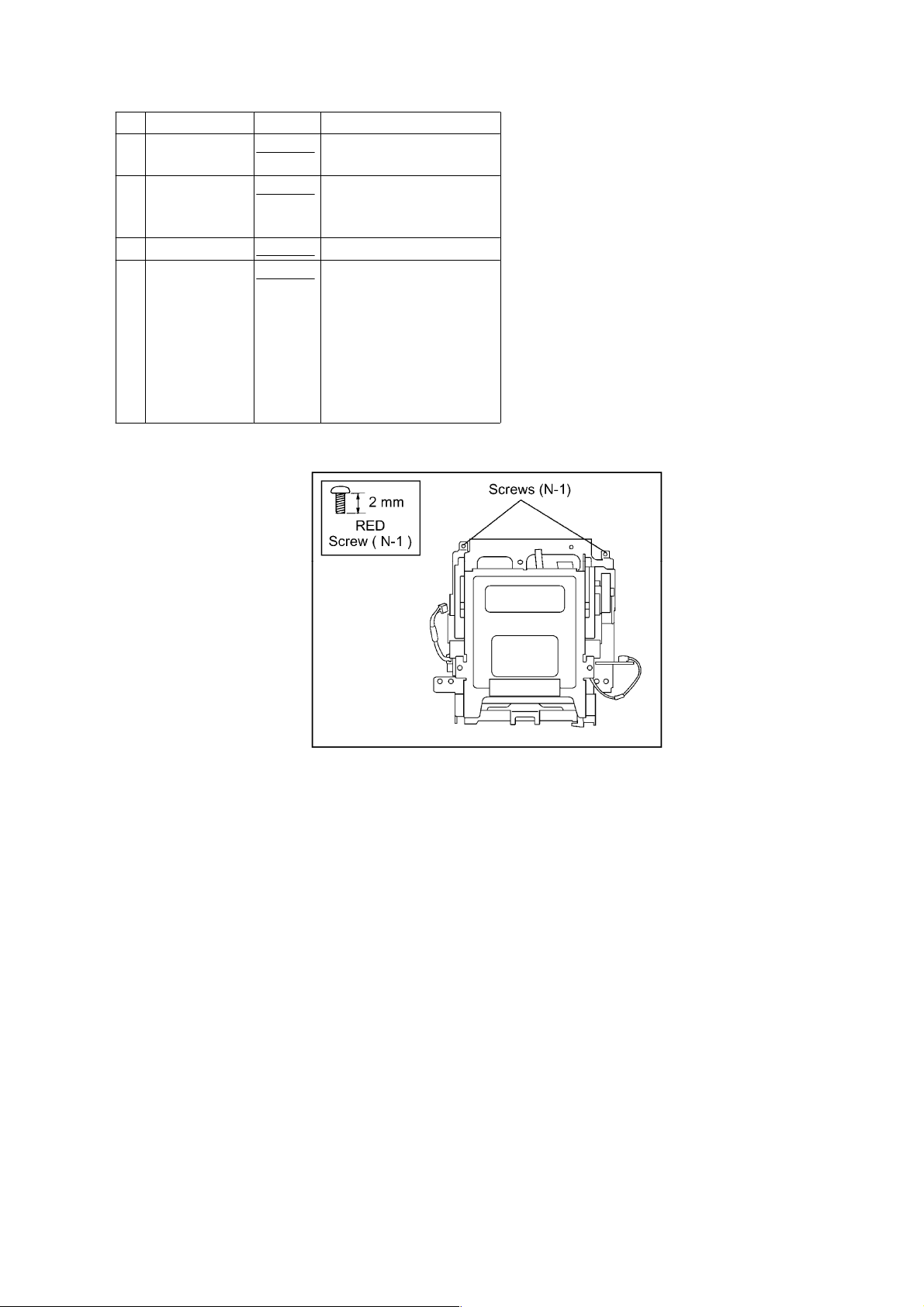

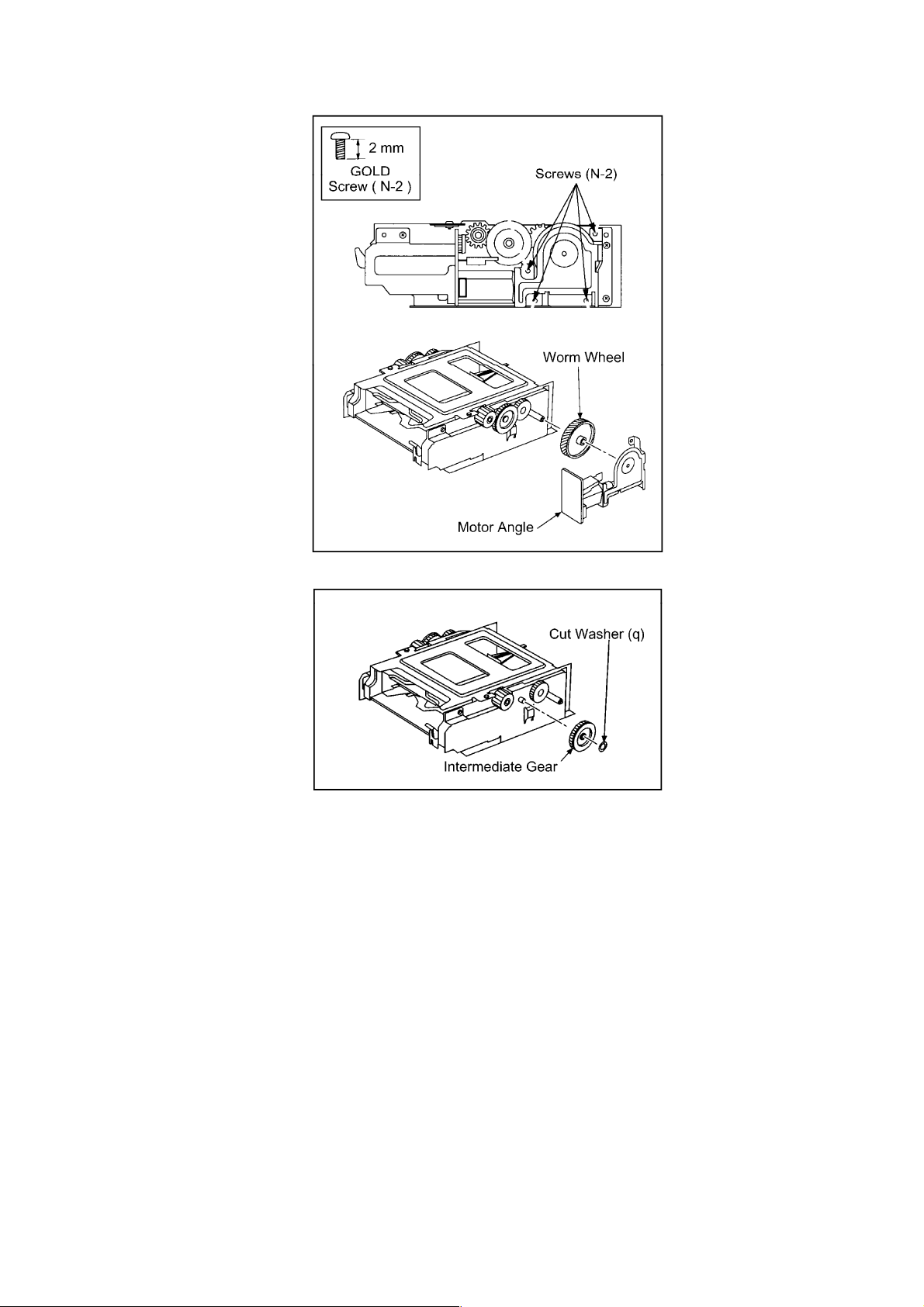

No. ITEM/PART FIGURE REMARKS

11 SLOT-IN

UNIT/MOTOR

ANGLE/WORM

WHEEL

12

INTERMEDIATE

GEAR

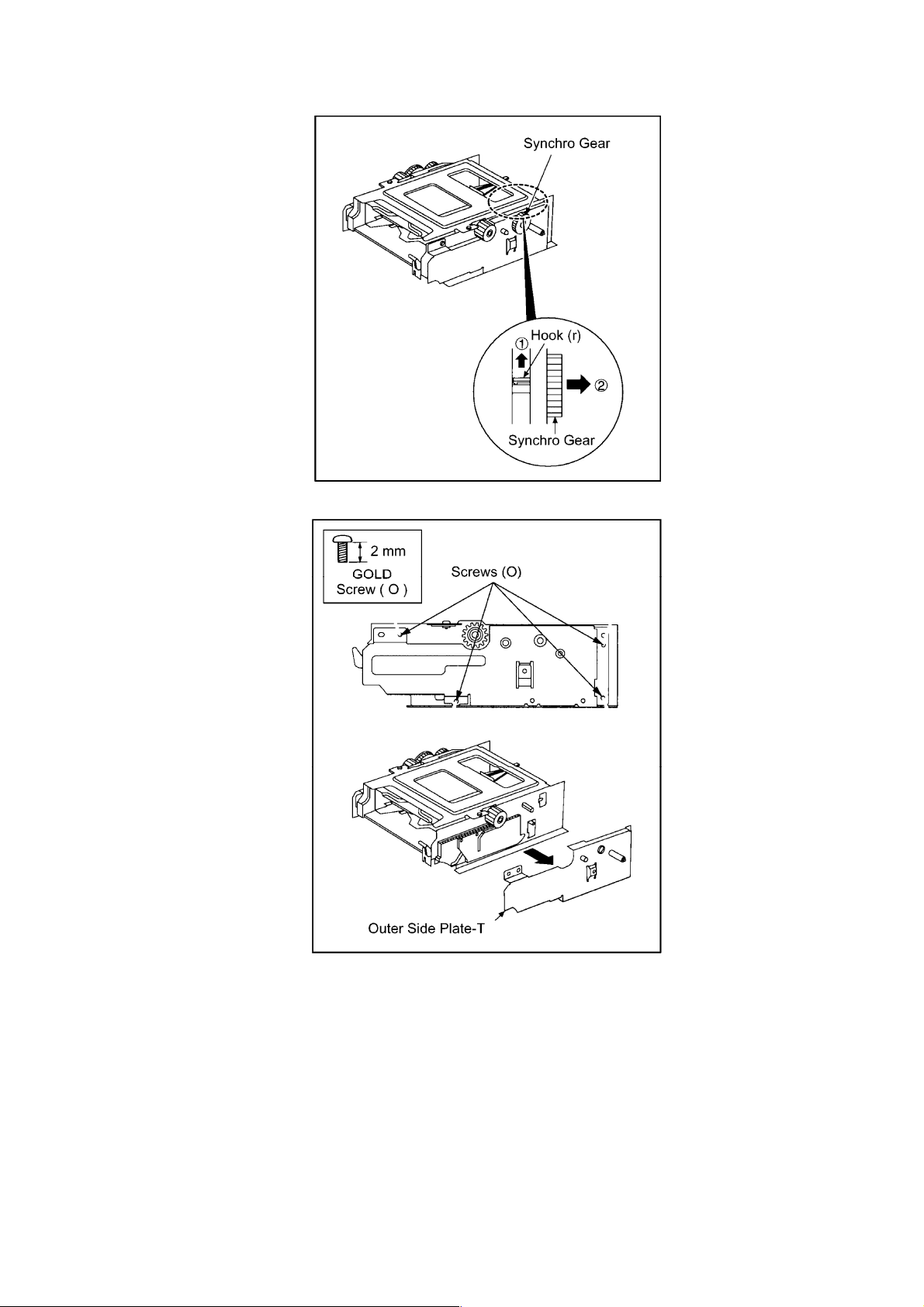

13 SYNCHRO

-GEAR

14 OUTER SIDE

PLATE-T

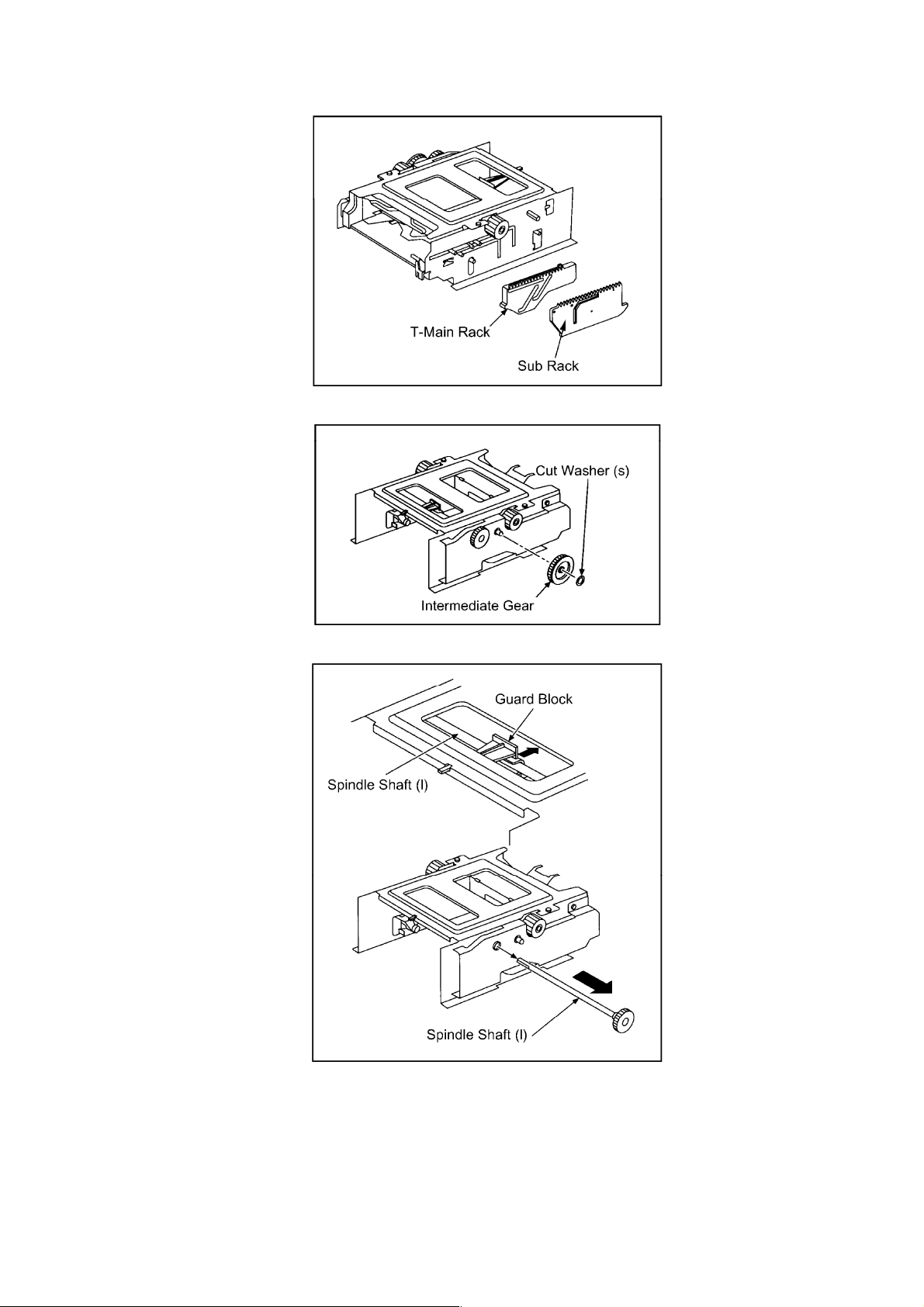

15 SUB

RACK/T-MAIN

RACK

16

INTERMEDIATE

GEAR

17 GUARD

BLOCK /

SPINDLE

SHAFT (I)

Fig.

D9-1

Fig.

D9-2

Fig. D10

Fig. D11

Fig. D12

Fig. D13

Fig. D14

Fig. D15

2-Screws (N-1)

4-Screws (N-2)

1-Cut washer (q)

1-Hook (r)

4-Screws (O)

1-Cut washer (s)

Slide the guard block to

arrow direction.

Page 18

http://cxema.ru

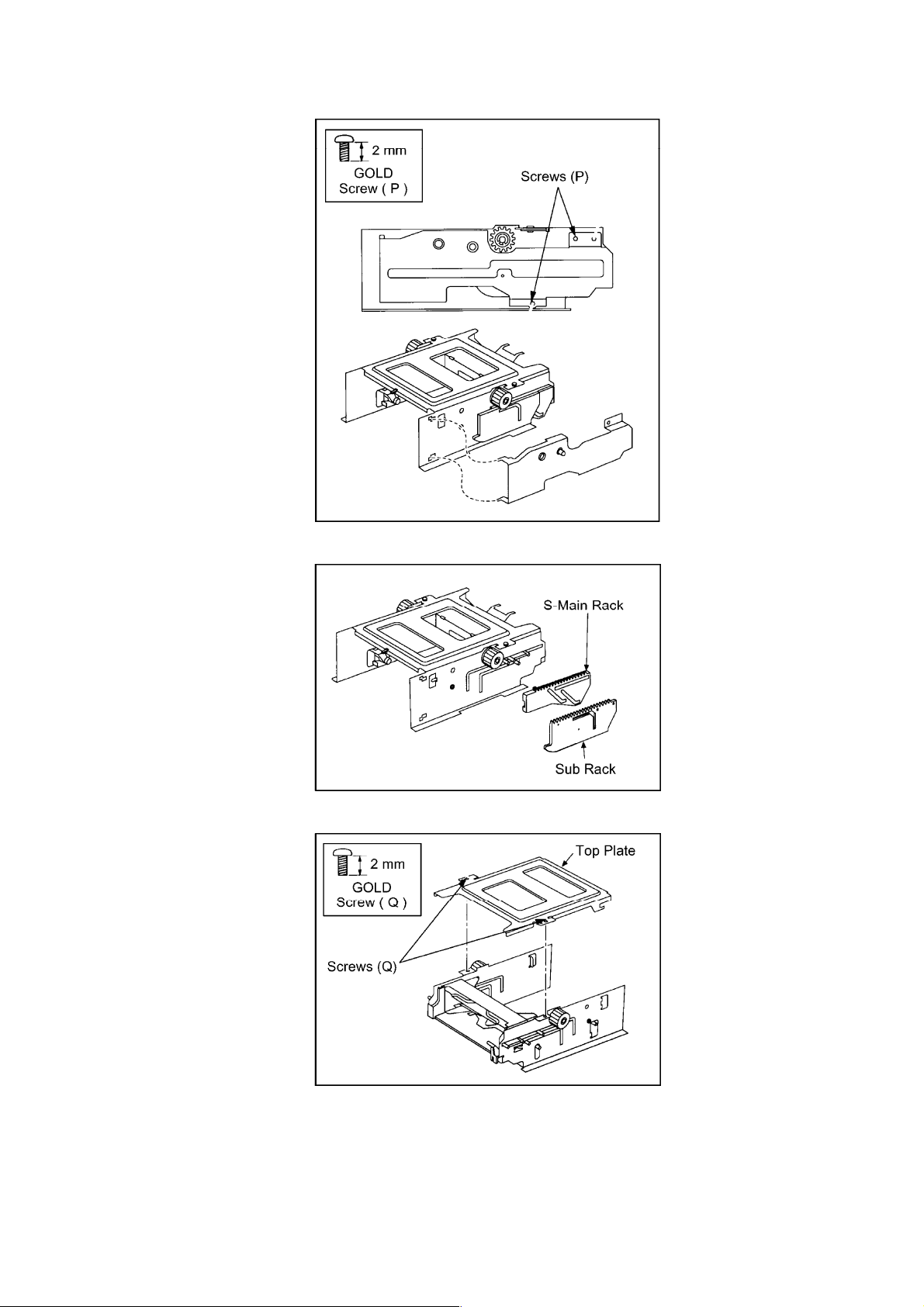

No. ITEM/PART FIGURE REMARKS

18 OUTER SIDE

PLATE-S

19 SUB

RACK/S-MAIN

RACK

20 TOP PLATE

21 SIDE PLATE

S& T/GUARD

PANEL /

CASSETTE

HOLDER

UNIT/FRONT

GUIDE/BLIND

LEVER

Fig. D16

Fig. D17

Fig. D18

Fig. D19

2-Screws (P)

2-Screws (Q)

Fig. D9-1

Fig. D9-2

Page 19

http://cxema.ru

Fig. D10

Fig. D11

Page 20

http://cxema.ru

Fig. D12

Fig. D13

Page 21

http://cxema.ru

Fig. D14

Fig. D15

Fig. D16

Page 22

http://cxema.ru

Fig. D17

Fig. D18

Fig. D19

Page 23

http://cxema.ru

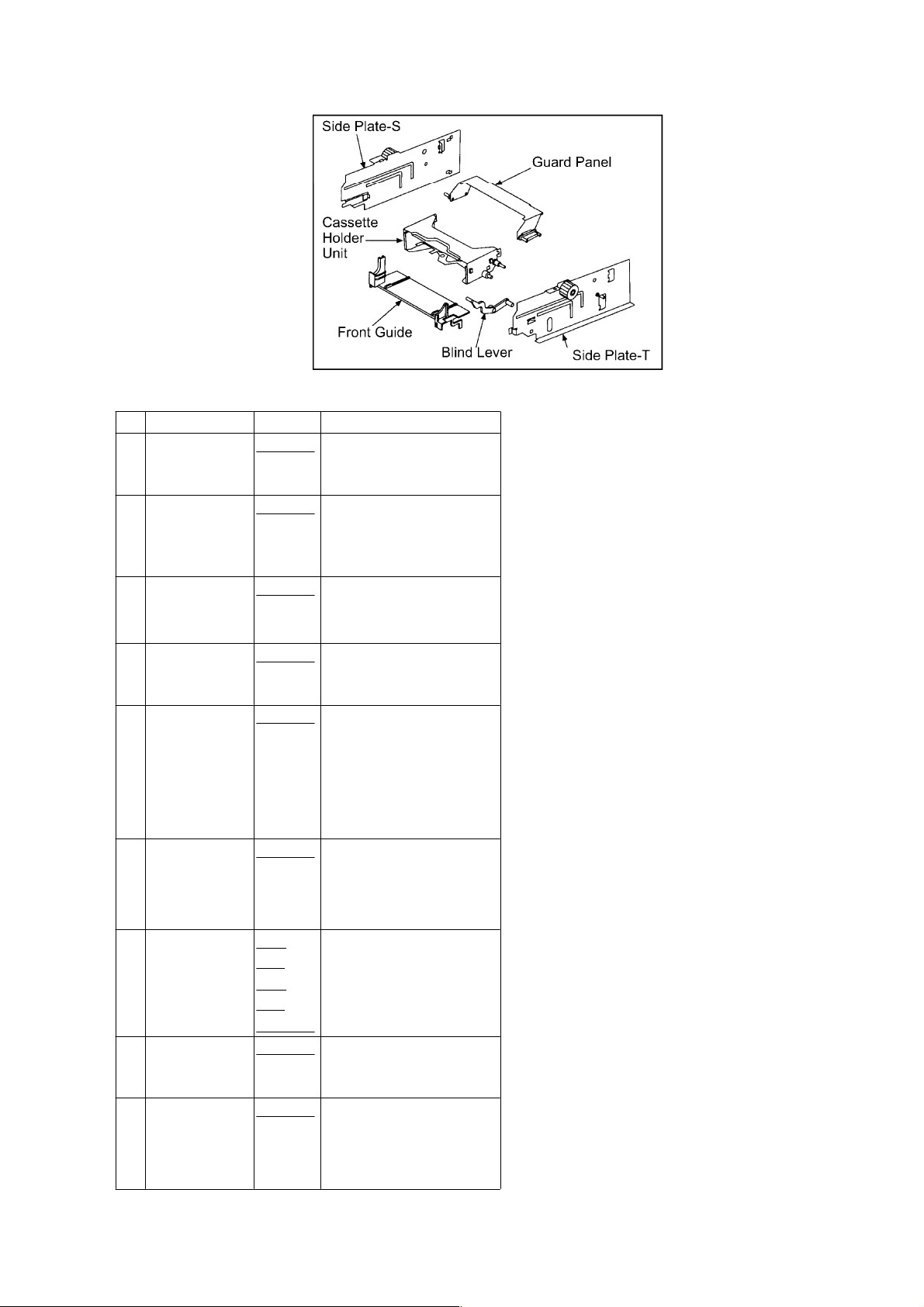

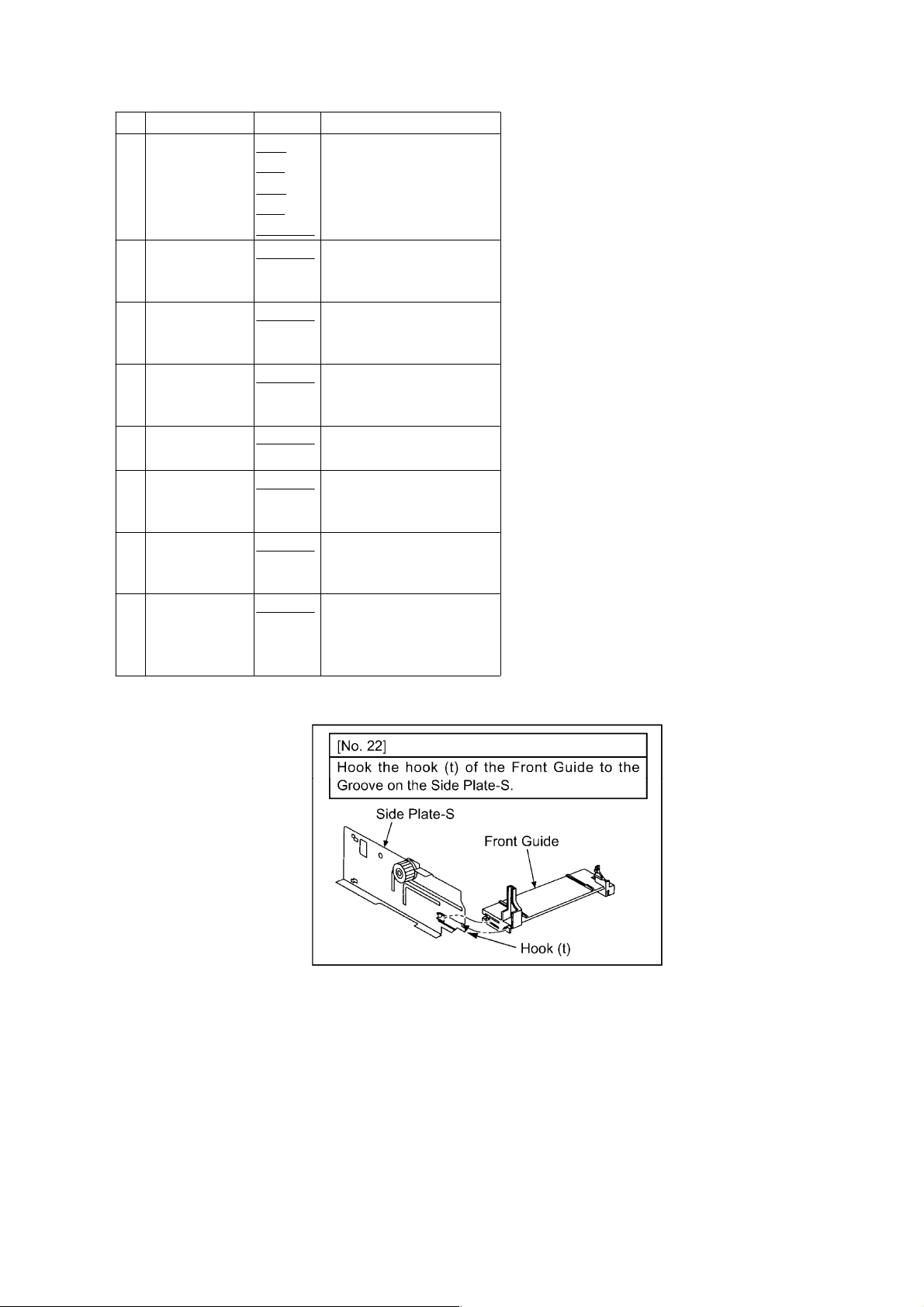

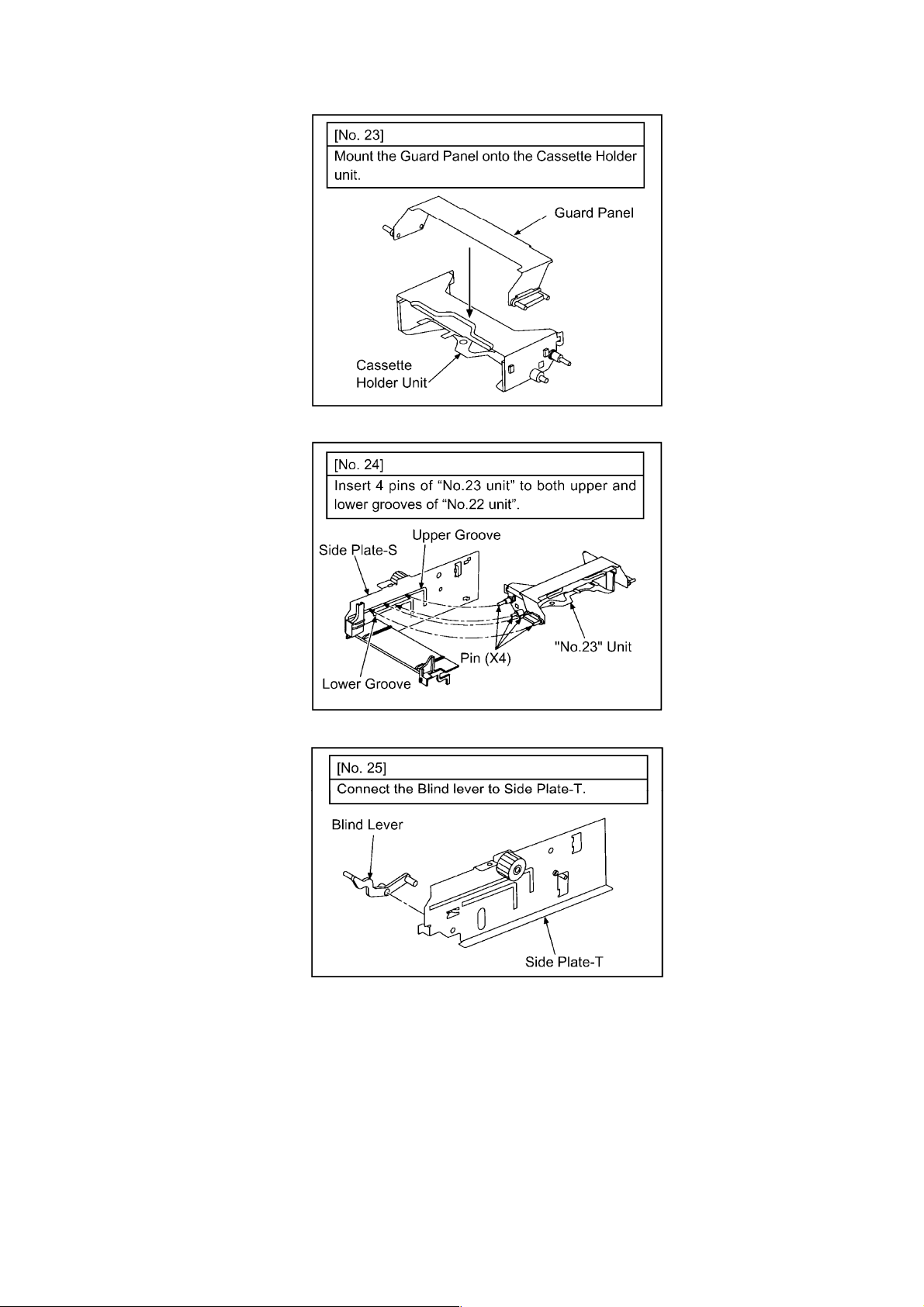

3.1.3.2. Assemble Section

No. ITEM/PART FIGURE REMARKS

22 FRONT

GUIDE/SIDE

PLATE-S

23 CASSETTE

HOLDER

UNIT/GUARD

PANEL

24 "No.22"

unit/"No.23"

unit

25 SIDE

PLATE-T/BLIND

LEVER

26 "No.24"

unit/"No.25"

unit

27 "No.26"

unit/TOP

PLATE

28 "No.27"

unit/S-MAIN

RACK

29 "No.28"

unit/SUB

RACK

30 "No.29"

unit/OUTER

SIDE

PLATE-S

Fig. D20

Fig. D21

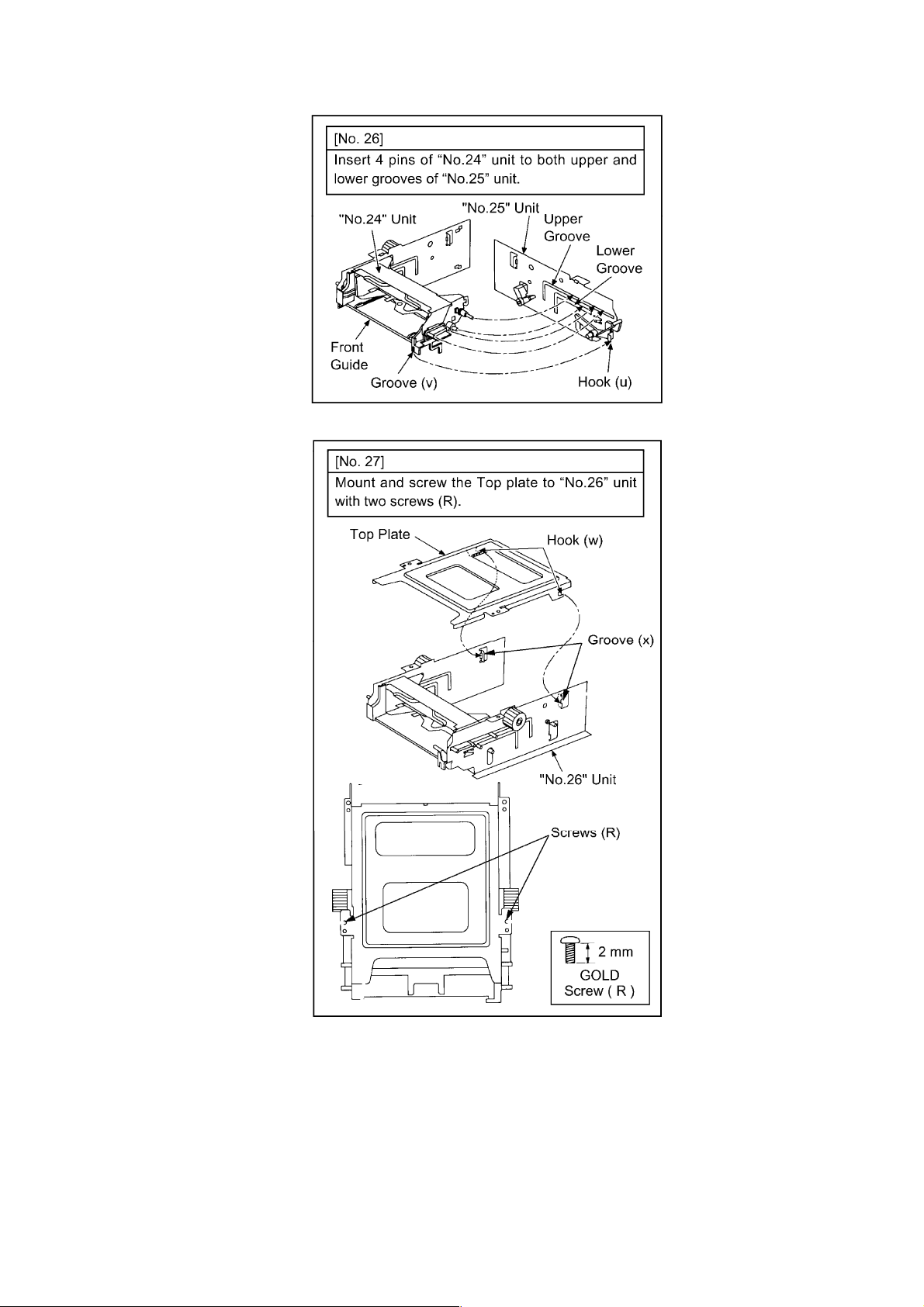

Fig. D22 4-Pins

Fig. D23 1-Pin

Fig. D24 4-Pins

Fig. D25 2-Hook (w)

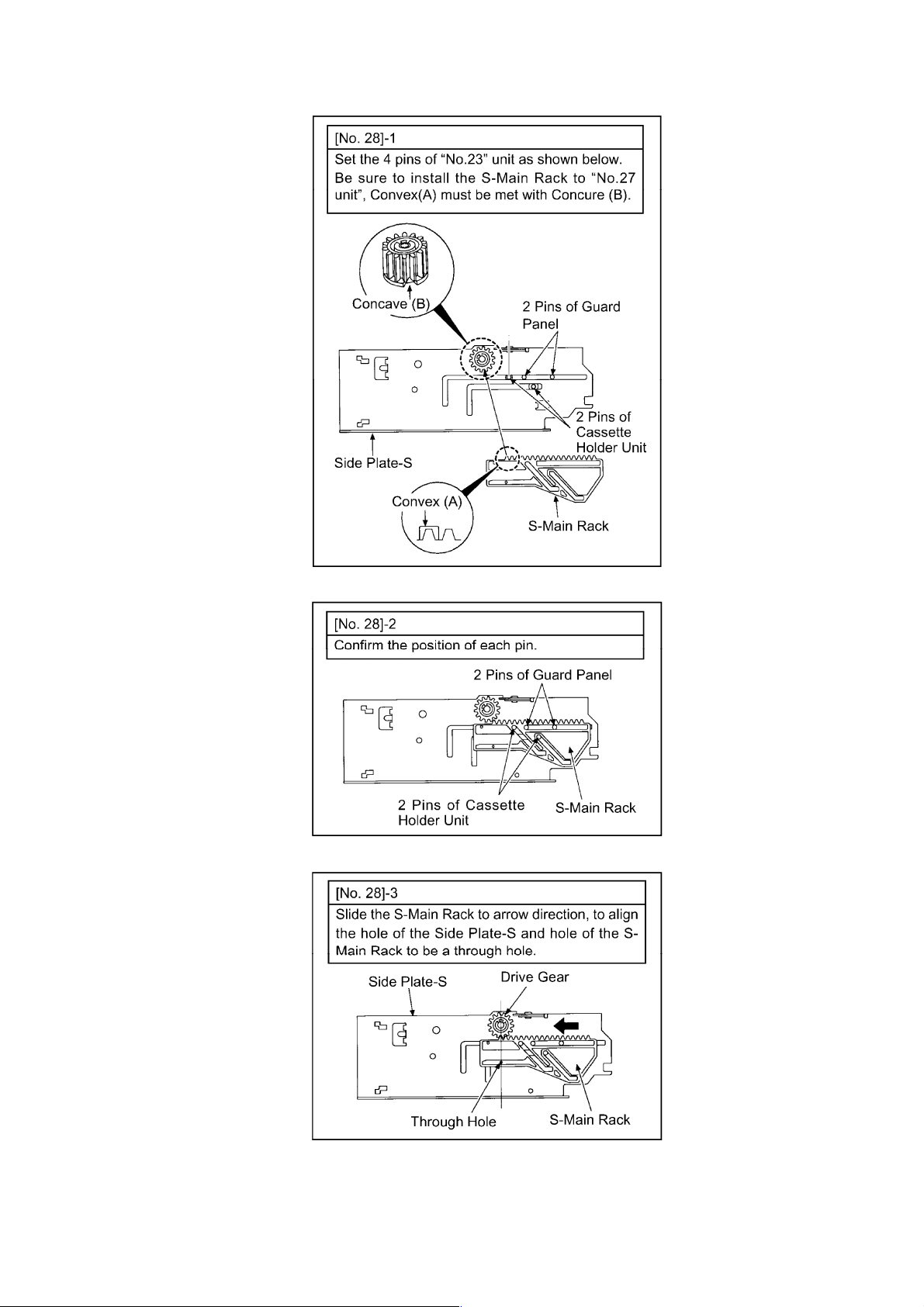

Fig.

D26

Fig.

D27

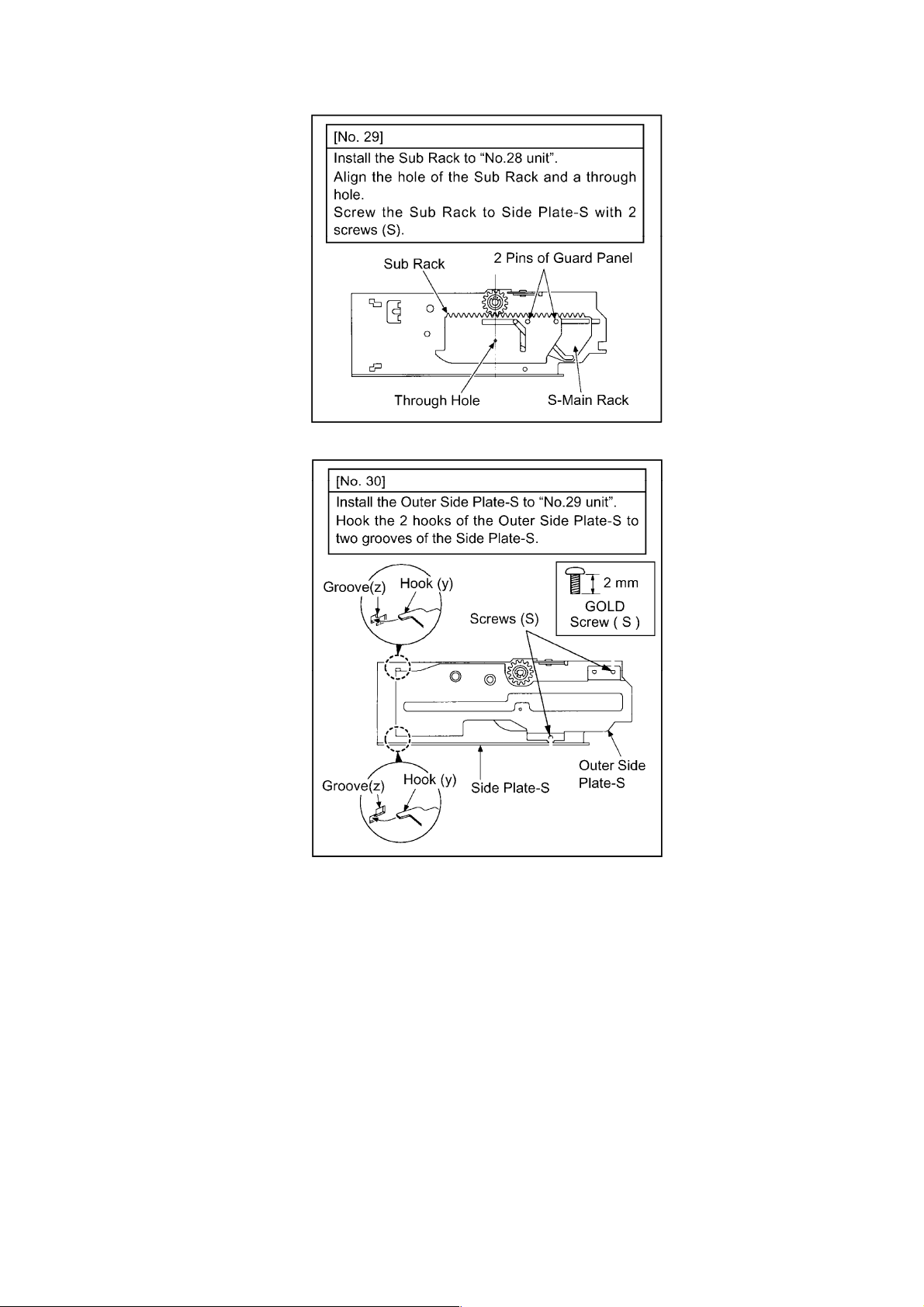

Fig. D28

Fig. D29

Fig. D30 2-Hook (y)

Hook (t)

Upper groove

Lower groove

1-Hole

Upper groove

Lower groove

-----------------------------------------Hook (u)

Groove (v)

2-Groove (x)

-----------------------------------------2-Screws (R)

Gear Phase Alignment

Gear Phase Alignment

2-Groove (z)

-----------------------------------------2-Screws (S)

Page 24

http://cxema.ru

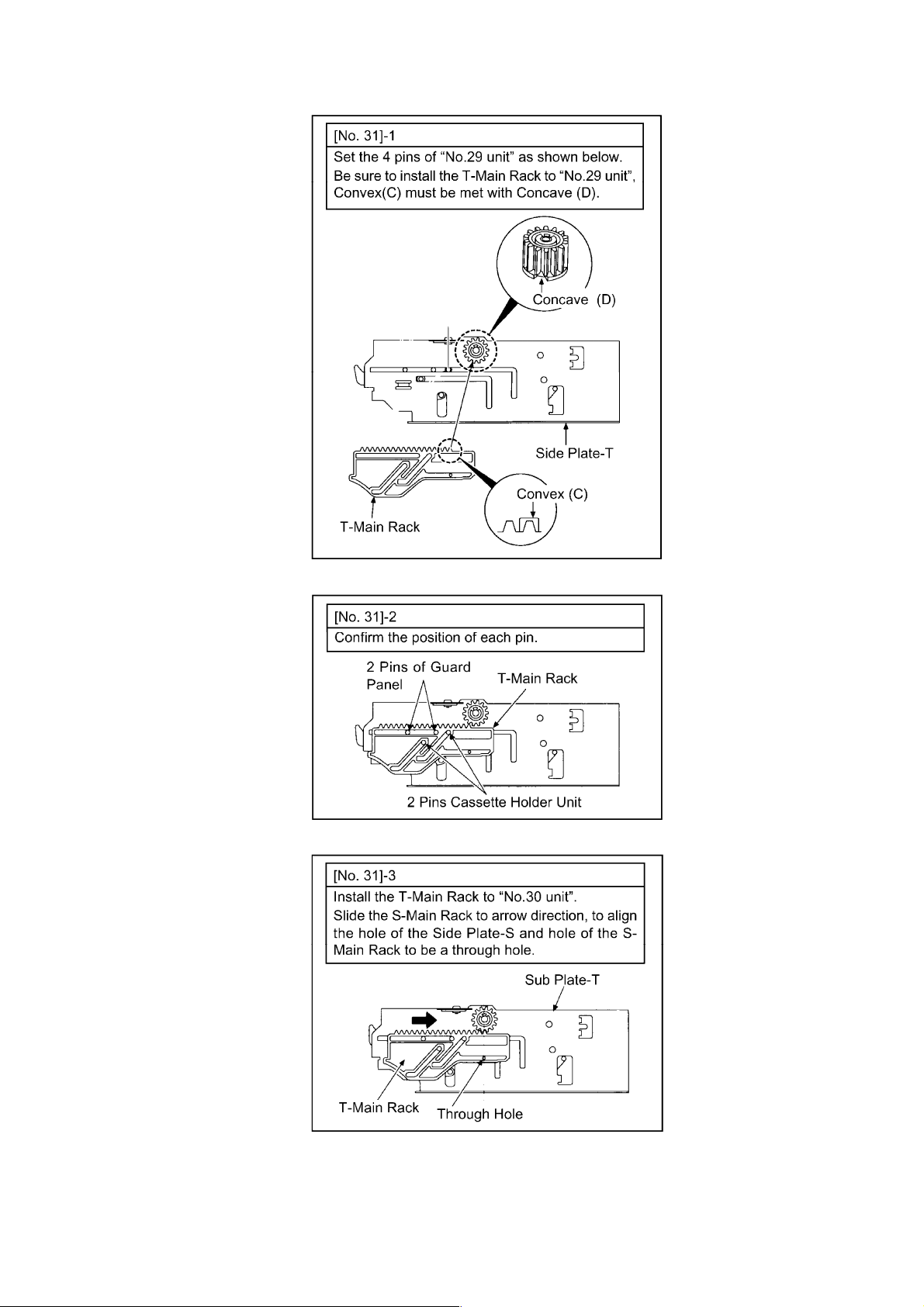

No. ITEM/PART FIGURE REMARKS

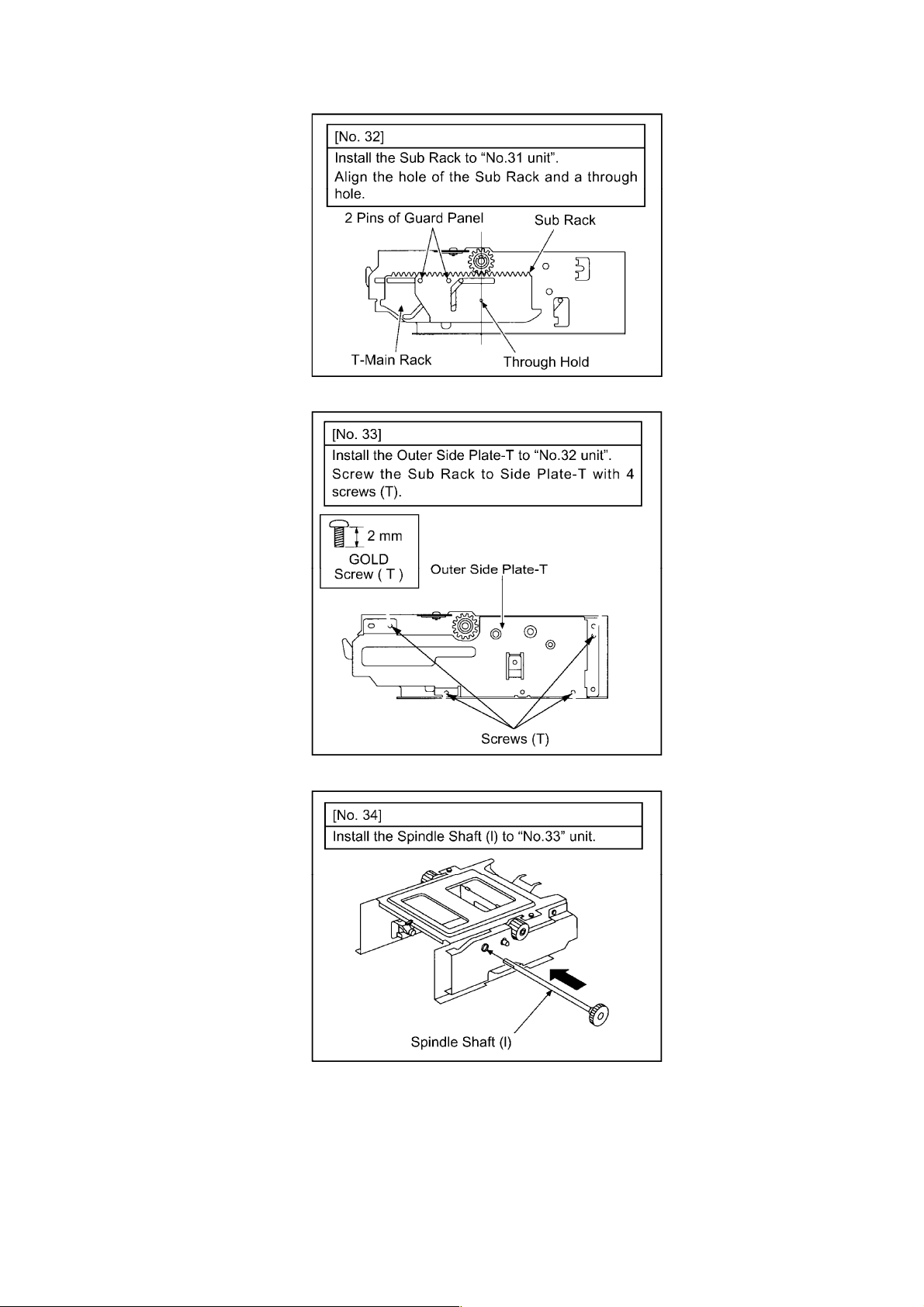

31 "No.30"

unit/T-MAIN

RACK

32 "No.31"

unit/SUB

RACK

33 "No.32"

unit/OUTER

SIDE PLATE-T

34 "No.33"

unit/SPINDLE

SHAFT (I)

35 "No.34"

unit/SYNCHRO-GEAR

36 "No.35"

unit/INTERMEDIATE

GEAR

37 "No.36"

unit/GUARD

BLOCK

38 "No.37"

unit/MOTOR

ANGLE/WORM

WHEEL

Fig.

D31

Fig.

D32

Fig. D33

Fig. D34

Fig. D35

Fig. D36

Fig. D37 1-Hook (a1)

Fig. D38 2-Cut washer (a3)

Fig. D39

Fig. D40

Gear Phase Alignment

Gear Phase Alignment

4-Screws (T)

1-Groove(a2)

Gear Phase Alignment

4-Screws (U)

Fig. D20

Fig. D21

Page 25

http://cxema.ru

Fig. D22

Fig. D23

Fig. D24

Page 26

http://cxema.ru

Fig. D25

Fig. D26

Page 27

http://cxema.ru

Fig. D27

Fig. D28

Fig. D29

Page 28

http://cxema.ru

Fig. D30

Fig. D31

Page 29

http://cxema.ru

Fig. D32

Fig. D33

Fig. D34

Page 30

http://cxema.ru

Fig. D35

Fig. D36

Fig. D37

Page 31

http://cxema.ru

Fig. D38

Page 32

http://cxema.ru

Fig. D39

Fig. D40

3.2. MECHANICAL ADJUSTMENT

Adjustment procedures, Disassembly Procedures and Assembly Procedures for Mechanism Chassis are

separated volume from this Service Manual.

Please Refer to the Service Manual for DJ-Mechanism Chassis.(VMD9706005A8)

3.3. ELECTRICAL ADJUSTMENT

As for this model, PC-EVR(Tatsujin) system is adopted for all Electrical Adjustments.

In achieving each adjustment, consult description in PC-EVR software for this model.

(All adjustments data is stored in IC2004 (EEPROM)).

Adjustment items are listed in the following table.

Page 33

http://cxema.ru

Circuit/Section Adjustment item Major Relative Components

ADJUST

MENT

OTHERS All Ave/Fix data Saving IC2004(EEPROM)

AV REC/PB RF EQ/ VITERBI Adjustment

REC/PB PG Shifter Adjustment

VIDEO REC/PB Video VCO Adjustment IC2004(EEPROM)

REC/PB E-E Y Level Adjustment 1 IC2004(EEPROM)

REC/PB E-E Y Level Adjustment 2 IC2004(EEPROM)

REC Video-In (Y Level) Adjustment IC2004(EEPROM)

REC Video-In (C Level) Adjustment IC2004(EEPROM)

PB Playback Y Level Adjustment IC2004(EEPROM)

PB Playback C Level Adjustment IC2004(EEPROM)

REC/PB Horizontal Screen Position

Adjustment

AUDIO Audio Level Meter Adjustment IC2004(EEPROM)

SYSTEM CONTROL Tape End/Beg. Sensor

Adjustment

All Ave/Fix data Overwriting IC2004(EEPROM)

Unit Unique ID Writing IC2004(EEPROM)

Function check -----

IC2004(EEPROM)

DD Cylinder, Capstan

Motor,Components on the Tape

Transportation

IC2004(EEPROM)

DD-CYLINER, Components on the

Tape Transportation

IC2004(EEPROM)

IC2004(EEPROM)

Fig. E1 Electrical Adjustment item list

3.3.1. How To Connect The PC-EVR.

Refer to the following figure to connect the VCR unit (NV-DV2000) and PC (Personnel Computer).

Before starting adjustment , confirm that all of the switch set to Normal Position.

No. Part No. Part Name Qty

1 VFK1317 30 Pin Flat card 2

2 VFK1395 232C(M3) I/F Cable 1

3 VFK1409 Measuring Board 1

4 VFK1410 EVR Connection Board 1

Fig. E2 Cable list for PC-EVR Adjustment

3.3.2. Measuring Equipment

1. OSCILLOSCOPE

(0.005-5V/Div. DC-More than 60MHz)

2. FREQUENCY COUNTER

(0 - 50MHz)

Fig. E3 Necessary connection for PC& the unit

Page 34

http://cxema.ru

3.4. SERVICING FIXTURES& TOOLS

Page 35

http://cxema.ru

4. ABBREVIATIONS

Page 36

http://cxema.ru

Page 37

http://cxema.ru

Page 38

http://cxema.ru

Page 39

http://cxema.ru

Page 40

http://cxema.ru

5. INPUT/OUTPUT CHART

5.1. INPUT/OUTPUT CHART FOR IC7501 [Timer Microprocessor]

Page 41

http://cxema.ru

Page 42

http://cxema.ru

5.2. INPUT/OUTPUT CHART FOR IC6001 [SYSCON/SERVO

Microprocessor]

Page 43

http://cxema.ru

Page 44

http://cxema.ru

Page 45

http://cxema.ru

5.3. INPUT/OUTPUT CHART FOR IC2001 [LSI Microprocessor]

Page 46

http://cxema.ru

Page 47

http://cxema.ru

Page 48

http://cxema.ru

Page 49

For your safety please read the following text carefully

This appliance is supplied with a moulded three pin mains plug

for your safety and convenience.

A 5 amp fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amps and that it is approved

by ASTA or BSI to BS 1362.

Check for the ASTA mark or the BSI mark on the body of

the fuse.

How to replace the Fuse

¡There are two types of the AC Mains Lead assembly:

A and B as shown below.

1Open the fuse compartment with a screwdriver.

2Replace the fuse and fuse cover.

TYPE A

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE

FOR THE SOCKET OUTLET IN YOUR HOME THEN

THE FUSE SHOULD BE REMOVED AND THE PLUG

CUT OFF AND DISPOSED OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL

SHOCK IF THE CUT OFF PLUG IS INSERTED INTO

ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt please consult a qualified electrician.

IMPORTANT

The wires in this mains lead are coloured in accordance with

the following code:

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the

terminal in the plug which is marked with the letter N or

coloured BLACK.

12

TYPE B

12

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstance should either of these wires be

connected to the earth terminal of the three pin plug, marked

with the letter E or the Earth Symbol .

Page 50

[ REF NO. 30000 SERIES ]

VIDEO MAIN SIGNAL PATH IN PLAYBACK MODE

R18

Q2

R2

L2

C3

68u

18P

E

R1

820

R19

1K

4.8

1.4

2.1

1.4

D

C

B

0

Q5

2SB1218(AMP)

R29

1K

R301KL13

2.1

1.5

0

Q9

2SB1218 (AMP)

PS2

C SYNC

V PULSE

IIC DATA

IIC CLK

H BLK

GND (D)

DNR C OUT

GND (D)

DNR Y OUT

GND (D)

DNR C IN

GND (D)

DNR Y IN

YC REG 5V

HSS

V BLK

TO VIDEO SECTION

IN MAIN PP3502

( D-1 )

PS1

GND

COMB OFF (L)

YC REG 5V

C SEP OUT

GND

Y SEP OUT

I/O -5V

FSC

I/O 5V

GND

CPN C IN

CPN (L)

CPN Y IN

GND

CPS V IN

TO VIDEO SECTION

IN MAIN PP3501

( C-1 )

R21

220

C4

68P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Q6

2SB1218

(AMP)

4.1

R20

100

C21

100PL95.6u

33u

C27

22P

LB4

LB5

LB6

L3

18u

L14

33u

C28

56P

LB4~6

VLP323A601T

A

1K

R3

1K

2.3

0

Q1

2SB1218(AMP)

R22

560

R24

33K

4.2

1.8

1.1

R23

240

R31

1K

C29

6V22

C30

22P

(A1)

(A2)

IC1

(A3)

MC14053BF

(A4)

(C/Y INPUT SELECT)

(A5)

(A6)

(A7)

(A8)

(A9)

(A10)

(A11)

(A12)

(A13)

2SB1218

(BUFFER)

R7

R5

33K

560

4.8

4.2

Q3

1.6

1.6

Q7

2SC3930

(BUFFER)

C22

6V22

R25

22K

R32

33K

R33

27K

0

VSS VEE INH

4.4 4.1 4.1 2.2 2.1 2.1 2.3 5.0

2SC3930

(AMP)

4.2

R4

180

1.1

R6

270

R26

C23

1100

22P

R35

560

2.0

L15

10u

C31

82P

R34

560

C2

0.1

-5.2

<0.2>

CBA

L10

33u

C5 0.1

1.8

4.1

1.3

R37

120

L

LH

R9

R8

1100

22K

L11

33u

C24

56P

4.8

4.1

2.3

Q10

2SC3930

(AMP)

R36

100

4 3 2 1

C

H

Y C VDD

1351261171089 14 15 16

L1

VLQ0319K330

C6

39P

L4

33u

Q8

2SC3930

(AMP)

R27

1k

L12

33u

C25

C26

56P

22P

Q11

2SB1218

(BUFFER)

2.3

Q12

2SB1218

(AMP)

2.300000

L

B

C7

33P

Q4

2SC3930

(AMP)

L5

39u

4.8

2.1

<2.6>

R38

1K

3.0

0

H

C1

0.1

4.8

2.0

<3.0>

2.8

<3.7>

R10

1K

R11

820

2.8<3.3>

R28

820

L17

VLP0319K

330

R44

5600

8 7

+V

1 2 3 41 2 3 4

4.5 0 0

R46

R51

100K

0

(A2) (A11) (A12)(A5)

VIDEO MAIN SIGNAL PATH IN REC MODE

C10

C8

6V100

C9

0.1

28 27 26 2552462372282192010191118121713161415

1 2 3 41234

3.3 0 0 0 0

TL1

L6

VLQ0319K

330

R45

22K

C38

1000P

X2

VSX1110

IC3

NJM2903M

(AMP)

65

2.9

R47

2700

D1

MA8027H

C32 0.01

R43

0

R95

470

0004.9

-V

C12

8200

2.8

<3.3>

VSS4

VDD4

VREF1

IC2

TC9090AF (3D IC INTERFACE)

VREFH

VSS1

ADIN

1.4

(1.5)

<1.9>

C33 50V0.47

C86

150P

R96

1M

C87

15P

C41

0.1

R48

390

C39

C40

0.1

6V47

0.01

R13

12K

C11 0.01

Y OUT

VDD1

1.44.8 4.8

C34 0.1

C35 16V10

L16

VLQ0319K

330

BIAS2

VREFL

D3

HVU17

R14 10K

C12 0.01

2.82.8

BIAS3

C OUT

BIASI

P/S

R39

C37 0.01

C36 0.01

47K

R97

100K

R98

33K

TL2

C89

0.1

C92

C93

0.1

0.1

C88

0.1

C100

0.1

16 15 14 1351261171089

VDD

IC4

TCHC4538AFEL (V PULSE MONO MULTI)

A

1 2 3 4

0 000 0

4.9 4.9 4.9

C43

470P

VR3

EVM7JSX30B54

H BLK

R15 10K

C13 0.01

C14 180P

1/2VDD

SDA

(TVSW1)

4.4 4.41.2

R40

3300

C90

470P

R63

0

B

R16 820

VFIL

SCL

(TVSW2)

C94

0.1

C16 120P

0

C15

0.01

C17

16V10

C18

0.1

00 0

CK IN

VDD2

RESET

(TVSW3)

TEST1

(VENH0)

00

QR1

UN5213

4.4

(COMP OFF L :OFF)

IC7

PST9142NR

(RESET)

R100

100K

4.94.94.9

L7

VLQ319K330L8VLQ319K330

C19

16V10

C20

0.1

4.84.84.8 2.32.33.4 1.91.6

VSS2

VSS3

VDD3

TEST2

(VENH1)

KILLER

PLLSEL

00.4

R42

0

R41

0

R17

0

000

3 2 1

SUB NC

GND

OUT

4.8 4.9

4 5

R101

150K

R99 1K

3

4.8

R109

0

IN

D2

MA142K

0000

VSS

LB2

VLP321A

300T

C57

6V22

R65

22K

1

2

R93

3300

R50

22K

R54

0

(A13)

(A6)

(A7) (A1) (A4)(A3)

LB7

VLP0321

A300T

C106

1u

(A8) (A15) (A16)

(A9) (A10) (A14)

C107

1u

C62

0.01

R64

33K

1.8

R66

560

4.2

1.1

R68

270

R74

33K

R75

22K

C63

0.1

LB1

VLP0321A300T

C84

0.1

C81 0.1

C82 0.1

C83 0.1

C97

6V100

Q15

2SB1218

(AMP)

4.2

Q14

2SC3930

(BUFFER)

R67

270

(2.0)

<1.7>

Q18

2SC3930

(BUFFER)

R55 0

C77 0.1

C78 0.1

C79 0.1

C80 0.1

R94

3300

C99

0.1

Q16

2SB1218

(AMP)

R76

560

1.8

R77

270

C56

6V47

C73

0.1

4.9

2.0

4.2

(0)

1.1

(2.6)

1.5(2.3)

1.5(2.3)

C85

0.1

C76

0.1

4.8

2.4

C61

50V1

C69

R80

10K

4.3

(2.3)

<2.5>

28 27 26 25 24 23 22 21 20 19 18 17 16 15

VDD

DIN4

1 2 3 4 5 6 7 8 9 10 11 12 13 14

0

0.1

(1.7)

<0>

(B11)

000000000

ADT2

ADT1

PST0

PST1

0.1

(B10) (B9) (B8) (B7)

2.6

2.5

(0)

2.9

(3.0)

<1.7>

<1.8>

<1.6>

DIN3

DIN2

DIN1

DIN5

DIN6

DIN7

0.1

0.1

00

(2.9)

(2.0)

<0>

<0>

(B12) (B13) (B14) (B1) (B2) (B18) (B17) (B16) (B15)

TL3

4.8

3.5(3.0)<3.2>

PWM

ADT0

RET0

POT7

D GND

PST2

PST3

PST4

PST5

PST6

L20

27u

C58

12P

R81

1K

R82

1K

2.5

0

4.9

0.9(1.3)<1.1>

1.1(2.3)<2.3>

VCXOVDD

A GND DA

0

1.6

2.2(3.1)

C98 0.1

R72

8200

R71

1K

C59

27P C60

Q21

2SD1819

(AMP)

R83

3300

C45

8P

L18

27u

C44

12P

IC8

MSM518221

(MEMORY)

C101

0.1

C91 0.01

4.9

0.8(1.2)

FS

DVDD

VCXOCK

(28) INV OUT

(29) INV IN

(30) VCXO GND

(51) C OUT

(52) AVDDDA

(53) VB1Y

Y OUT

AVSS

AVDD

000

4.8

R102 1K

R110

0

6V47

ADT7

D GND

BLNK

R103 1K

3.1

C46

12P

ADT6

PVPH

0

R111 0

Q17

2SD1819

(AMP)

4.8

2.5

ADT5

MOD0

MOD1

4.9

4.9

3.0

R79

10K

C64

0.01

R86

1K

C95

6V100

ADT4

IC6

TC90A11F

(3D Y/C SEP)

MOD2

R73

1K

(1.8)

ADT3

D GND

000000000

R69

1K

R70

820

2.6

2.0

0

4.9

4.2

Q19

2SB

1.9

1218

(AMP)

R78

1.9

270

Q20

2SB1218

(AMP)

0

2.3

30

4.8

4.8

3.4

1.4

1.3

4.9

1.4

2.4

3.4

3.3

1.6

2.4

29282726252423222120191817161514131211

VDD

31323334353637383940414244454647484950

0

VSS

0

LPH

0

FSC

0

AVSS

AVDD

CLAMP

0

A GND AD

V REF HY

A INY

V REF LY

BIAS

A VDD AD

43

V REF LC

A INC

V REF HC

0

A GND AD

VB2

VB1C

V REF

5152535455565758596061626364656667686970717273747576777879

3.5

4.9

LB3

VLP0321A300T

R84

1200

Q22

2SB1218

(2.5)

(AMP)

1.9

1.3

(1.8)

0

R88

1200

Q23

2SB1218

(AMP)

2.6

2.0

0

LB8

VLP0321A300T

(B19)

1.2

(1.1)

4.94.94.9

<0.9>

IE

NC

WE

DIN0

RSTW

SWCKNCREOEDOUT7

4.9

TL4

TL5

TL6

TL7

TL8

TL9

TL10

POT4

POT3

C SYNC

KILL

0

4.5

0(0.3)

R105 100

R106 100

R107 100

POT2

POT1

(1) WCK

(2) RSTW

(3) DVDD

(78) DVDD

(79) ATH

(80) RSTR

IICK

IIDT

4.2

R108 100

000000000

POT0

ACK

0

TL11

987654321

10

POT6

POT5

PST7

DOP

4.8

R104 10K

C67

R85

8P

1800

R90

4300

C71

R89

15P

10K

(B20) (B3) (B4) (B5) (B6)

2.9

1.4

2.0

(2.5)

(1.7)

(2.3)

00

<1.8>

<1.9>

<1.8>

RSTR

SRCK

DOUT0

DOUT1

DOUT6

0

1.3(1.1)<1.0>

D GND

FSC4

DVDD

0

TL13

MO0

MO1

MO2

MO3

MO4

MO5

MO6

MO7

RCK

0

DOUT5

1.9(2.3)<2.0>

MI0

1.8

MI1

2.2(2.5)<1.9>

MI2

3.3(1.6)<2.9>

MI3

2.5(2.8)<2.2>

2.4(2.8)<2.2>

3.1<2.6>

2.0(2.3)<3.9>

0

0

4.9

0.1(1.9)<0.4>

0.1(1.5)<0.4>

0.1(2.9)<0.4>

0.1(2.0)<0.4>

0(1.5)<0.1>

MI4

0(1.0)<0.1>

MI5

0(2.7)<0.1>

MI6

0(1.5)<0.1>

MI7

1.0

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 10 0

80

0

(1.3)0(2.6)0(1.1)0(1.3)

4.9

4.9

L21

47u

C70

3P

L22

47u

3.3

(1.5)

<1.5>

DOUT2

DOUT4

TL12

R87

1200

C68

3P

R91

1K

C72

8P

DOUT3

VSS

01.1 4.9

(B1)

(B2)

(B3)

(B4)

(B5)

(B6)

(B7)

(B8)

(B9)

(B10)

C96

0.1

(B11)

(B12)

(B13)

(B14)

(B15)

(B16)

(B17)

(B18)

(B19)

(B20)

(A16)

(A15) (A14)

NOTE: THE MEASURMENT MODE OF THE DC VOLTAGE OUT OF THE BRACKETS ON THIS DIAGRAM IS STOP MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

THE MEASURMENT MODE OF THE DC VOLTAGE IN THE BRACKETS ( ) ON THIS DIAGRAM IS PLAYBACK MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

THE MEASURMENT MODE OF THE DC VOLTAGE IN THE BRACKETS < > ON THIS DIAGRAM IS RECORD MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

1

24

3

5

6789

NOTE : DO NOT USE ANY PARTS NUMBER SHOWN ON THIS SCHEMATIC

DIAGRAM FOR ORDERING.

WHEN YOU ORDER A PART, PLEASE REFER TO PARTS LIST.

Page 51

AUDIO MAIN SIGNAL PATH IN PLAYBACK MODE

AUDIO MAIN SIGNAL PATH IN REC MODE

(A1)

R4335

22K

E

V

A IN (L)

V

A IN (R)

V

SS ON (H)

C4311

0.1

04.9 0 0

16 15 14 13

8 7 6 5

1 2 3 4

1

2 3 4

000

R4315

12K

C4379

33P

C4317

12K

D

IF

D REG 5V

V

IF

GND (D)

IF

A REG 5V

V

AUDIO DATA

V

AUDIO CLOCK

V

AUDIO ST1

IF

PCM OUT (L)

V

AUDIO ST2

IF

PCM IN (R)

IF

PCM IN (L)

V

EE MON (H)

IF

MIX VV (L)

IF

METER (L)

IF

METER (R)

IF

LINE OUT (R)

IFVV

C

V

V

IF

IF

IF

IF

LINE OUT (L)

LCH (H)

RCH (H)

LCH (L)

RCH (R)

PCM OUT (R)

GND (A)

(A1)

(A2)

(A3)

(A4)

(A5)

(A6)

(A7)

(A8)

(A9)

(A10)

(A11)

(A12)

(A13)

(A14)

(A15)

(A16)

R4390

10K

R4305

10K

R4307

18K

C4371

33P

04.9 0 0

16 15 14 13

8 7 6 5

1 2 3 4

1 2 3 4

000

R4316

10K

R4319

100K

R4306

18K

C4378

33P

R4320

10K

R4321

100K

IC4305

NJM4558M

-5.0

C4319

0.1

C4309

33P

IC4302

NJM4558M

-5.0

C4372

0.1

C4304

0.1

C4335

50V2.2

C4325

50V2.2

R4328 200K

C4323

16V10

IC4308

M62409FP

R4325

200K

R4322

200K

C4316

16V10

IC4306

M62409FP

R4318

200K

C4324

0.068

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

VCC1

1/2VCC

AGND

1/2VCC

OUT

12345678910111213141516

0 3.9 0 03.9 3.9 3.9 3.9 3.9 3.9 3.9 3.9 7.9 0 4.9 4.9

C4327

6V47

32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17

VCC1

1/2VCC

AGND

1/2VCC

OUT

12345678910111213141516

0 3.9 0 03.9 3.9 3.9 3.9 3.9 3.9 3.9 3.9 7.9 0 4.9 4.9

C4320

6V47

TIM2

TIM1

TIM2

TIM1

C4331

0.068

C4322

0.068

ZERO2

ZERO1

ZERO2

ZERO1

LB2

LB1

C4318

0.068

LB2

LB1

C4340

C4343

50V2.2

16V10

HB2

HB1

C4341

C4336

50V2.2

C4329

50V2.2

C4330

50V2.2

C4344

16V10

C4332

16V10

C4333

16V10

50V2.2

HB2

HB1

C4326

50V2.2

C4348

16V10

5.000000 3.93.93.93.93.93.93.93.93.9 7.9

A0

A1

DGND

VCCSTCLOCK

C4350

16V10

C4337

16V10

5.005.0000 3.93.93.93.93.93.93.93.93.9 7.9

A0

A1

DGND

VCCSTCLOCK

C4334

0.1

C4349

0.1

VDO

DATA

C4339

0.1

VDO

DATA

C4351

0.1

C4346

0.1

C4342

16V10

(A3) (A6) (A7) (A8)(A5)

(A2)

R4312 100

R4310 100

R4308 100

(A4)

R4396 100

R4336

10K

C4353

0.1

R4347

R4345

22K

10K

C4345

0.1

R4343

22K

R4402

5600

16 15 14 13 12 11 10 9

VDD X2 X1 X X0 X3 A B

Y0 Y2 Y Y3 Y1 INH VEE VSS

1 2 3 4

000000 0

R4401

5600

R4332

22K

004.9 0000 0

5 6 7 8

-5.0

3.1

0

0

QR4303

UN5213(MIX VV L :OFF)

IC4310

NJM4558M

R4354

22K

R4405

5600

R4403

5600

Q4315

0

2SD1819

(SS H :ON)

00

C4355

0.1

IC4309

MC14052BF

C4384

0.039

IC4311

NJM4558M

8 7 6 5

1

000

R4351

3900

C4381

33P

0

Q4314

2SD1819

0

(SS H :ON)

0

C4356

0.1

0 0 0 -5.0

R4357

36K

C4374

33P

C4406

5600

R4353

3900

C4380

33P

04.9 0 0

2 3 4

-5.0

C4352

10K

C4385

0.039

R4360

R4373

33P

04.9 0 0

8 7 6 5

1 2 3 4

R4359

10K

36K

R4356

10K

R4407

5600

R4367

10K

C4360

C4358

0.1

0.1

(A9)

(A11)

(A10) (A12)

R4359

0.1

IC4313

MC14052BF

C4362

0.1

R4388

10K

R4373

51K

5 6 7 8

R4355

22K

R4323

47K

R4324

47K

5 6 7 8

004.9 0000 0

-5.0

C4364

0.1

-5.0

16 15 14 13 12 11 10 9

VDD X2

X1 X X0X3A B

Y0 Y2 Y Y3 Y1 INH VEE VSS

1 2 3 4

000000 0

R4369

51K

04.9 4.94.90000

16 15 14 13 12 11 10 9

VDD X2 X1 X X0 X3 A B

Y0 Y2 Y Y3 Y1 INH VEE VSS

1 2 3 4

000000 0

(A13) (A15) (A16)

(A14)

4.9

QR4304

UN5213

(R CH L :OFF)

0

4.9

QR4305

UN5213

(L CH L :OFF)

IC4314

MC14052BF

C4368

0.1

0

0

0

R4385

100

R4381

100

05.0 0 0

-5.0

R4382

0

IC4315

NJM4558M

C4367

0.1

R4374

100

0

0

Q4310

2SD1819

0

R4386

1K

R4389

4700

IF

A MUT (H)

IF

UNREG 6V

IF

-8V

IF

8V

IF

B

REG 12V

IC4316

UPC1093J

2.4 0 8.5

A

: TO POWER SECTION IN MAIN

P

: TO VIDEO SECTION IN MAIN

V

: TO RF I/F SECTION IN MAIN

IF

1

R4397

0

C4321

0.01

IC4303

UPC78L05J

OUT GND IN

4.9 0 7.6

C4308

C4310

0.1

0.1

C4313

R4311

16V10

C4307

6V220

NOTE: THE MEASURMENT MODE OF THE DC VOLTAGE OUT OF THE BRACKETS ON THIS DIAGRAM IS STOP MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

THE MEASURMENT MODE OF THE DC VOLTAGE IN THE BRACKETS ( ) ON THIS DIAGRAM IS PLAYBACK MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

THE MEASURMENT MODE OF THE DC VOLTAGE IN THE BRACKETS < > ON THIS DIAGRAM IS RECORD MODE

WITH PAL COLOUR SIGNAL. (MINI DV:SP MODE) ·LINE IN SIGNAL LEVEL... -6dB 400Hz

1K

R4302

390

R4303

4700

Q4301

2SD1468

(REG)

8.5

R4301

10K

C4302

10V100

12.0

7.9

C4303

0.01

3

R4398

1K

ACR

24

C4306

0.1

IC4301

NJM79L05A

GND IN OUT

231 231

0 -7.5 -5.0

C4305

6V220

C4314

R43141KC4317

33P

C4313

18K

07.6 0 0

8 7 6 5

1 2 3 4

000

R4309

18K

C4312

33P

-7.5

5

16V10

IC4304

NJM4558M

C4315

0.1

C4352

16V100

R4348

680

D4302

MA153

3

21

QR4301

UN5119

(MUTE)

5.7 0

C4354

50V1

R4349

680

R4350

120K

5.7

5.7

0

0

QR4302

UN5212

(MUTE)

R4372

220

R4370

220

0

0

6789

R4366

10K

05.0 0

8 7 6 5

1 2 3 4

000

R4363

10K

R4364

10K

Q4305

2SD1819

0

R4368

1K

C4365

16V10

0

0

0

-5.0

C4361

0.1

Q4306

2SD1819

0

R4371

1K

IC4312

NJM4558M

C4366

16V10

0

0

R4377

10K

C4357

0.1

Q4307

2SD1819

0

R4375

1K

0

0

C4363

0.1

R4379

100

Q4308

2SD1819

0

R4387

4700

R4380

1K

8 7 6 5

1 2 3 4

000

R4376

0

Q4309

0

2SD1819

0

0

R4384

1K

(MUTE) (MUTE) (MUTE) (MUTE) (MUTE) (MUTE)

NOTE : DO NOT USE ANY PARTS NUMBER SHOWN ON THIS SCHEMATIC

DIAGRAM FOR ORDERING.

WHEN YOU ORDER A PART, PLEASE REFER TO PARTS LIST.

Page 52

IC6001

(SYSCON SERVO MICON)

CAPSTAN

UNIT

T -PHOT O Tr .

SOLENOID

LOADING MOTOR

MIC & S-TAB SW

[ BOTTOM SIDE VIEW ]

S1501

S1502

(CASSETTE DOWN)

(SAFETY TAB)

M

HEAD AMP

T-REEL

SENSOR

S-REEL SENSOR

P1502

3

P1502

1

P6001

3

P6001

1

FP6003

2

FP6003

7

FP6003

FP6003

30

FP6003

12

FP6003

25,26

FP6003

27,28

PHOTO LED

20

MODE

SW

(LOADING MOTOR DRIVE)

1

7

LOADING MOTOR

S-PHOTO Tr.

DETECTION SW

IC2501

CONTROL

CIRCUIT

P.OFF(L)

(TO POWER CONTROL CIRCUIT)

2KEY 1

1KEY 2

84KEY 3

P2501

P2501

P2502

FG1

FG2

P2501

3

7

P2501

1

2

5

6

8

9

P2502

22

5

3

1

S4801-4805,

S7503-7514

FG

PG

L (11.2um)

CYL

M

CAP

M

FG

R (11.2um)

19

20

18

QR1001,

QR1006,1007

P7501

8

P7501

7

P7501

9

Q7502,

QR7502

QR7501

YFGIN

YPGIN

YM3

YM1

H1+

CM3

CFG IN

CFG OUT

Q7501,

2

64

15

17

39

30

4

3

IC7501

(TIMER MICON)

59 S.CLK

60 S.DATA OUT

61 S.DATA IN

FP6002

51P.OFF(L)

81S.CLK

82S.DATA OUT

83S .DATA I N

28 OPEN

15CYL.ON(L)

29 CLOSE

30 DOWN

31 S.TAB

Q6001Q6002

4

5

32 SEN.LED

S.PHOTO

T.PHOTO

33 M.LOAD

34 M.UNLOAD

54CYL.FG

92CYL.ET

96DRV CLK

16CAP T.LIM

17CAP R/S/F

93CAP ET

IC3201

(EDA)

HID

57

TSR TSR

56

HIDI

93

97

CYL FG

CYL PG

ATF

DT0

DT15

48

103

120

1

FP6002

4

FP6002

14

FP6002

15

FP6201

40

FP6201

33

FP6201

23

FP6201

22

IC2503

(CYL/CAP DRIVE)

5 YSTB

60 YFG

7 YEC

55 YCLK

46 CTL

49 CRFS

48 CEC

59 YPG

P7902

P7902

P7902

S.REEL

SENSOR

T.REEL

SENSOR

SLOT-IN MOTOR

4

4

IC6002

(MOTOR DRIVE)

P6002

SW+3V

P1501

1

1

P15012P6002

2

FP6003

14

FP6003

15

M

23

1

23

1

24

CONTROL

CIRCUIT

15

IC6003

(T./S. REEL DRIVE)

2

6

6

8

1

7

36 S.LOAD

37 S.UNLOAD

59 T.REEL

60 S.REEL

CPU DATA OUT

73CPU CLK

75CPU DATA IN

74

55CAP FG

64FRP

IC2001

(LSI MICON)

73 CPU CLK

74 CPU DATA OUT

75 CPU DATA IN

IC2502

4

HID

57

DT15

139

154

DT0

IC2504

(FG AMP)

7

2

1

1

6

IC2505

(FG AMP)

2

7

IC3203

(EQ IC)

9

6

IC5001

(H.AMP)

2

57

IC3001

(DV I/O)

58

FRP

P.B.SIGNAL

FROM CYLINDER

Page 53

IC7501

(TIMER u-com)

IC6001

(SYSCON/SERVO u-com)

MAIN DATA / CLOCK TRANSMISSION

IC2001

(LSI u-com)

IC2004

(EEPROM)

SK

2

DO

DI

3

CS

1

4

IC2002

(DAC)

OSD CLK

62

D.OUT

64

S.CLK

S.DATA IN

S.DATA OUT

OSD

OSD CS

ON(H)

73

54

IC3606

(EDIT/OSD u-com)

IC3001

59

60

61

QR6020

81

S.CLK

82

S.DATA OUT

83

S.DATA IN

E.OSD

CLK

77

22

D.OUT

78

23

S.IN24CSCLK

CPU CLK

CPU D.OUT

CPU D.IN

CS

79

E.OSD

ON(L)

80

73

74

75

IC4701

(AY-u-com)

CPU CLK

73

75

CPU D.IN

74

CPU D.OUT

YC

CLK

77

64

YC

CLK

L YC

D.OUT

CYLINDER & CAPSTAN SERVO

YC

SBI

EE.CLK 99

EE.DI

100

EE.DO

103

EE.CS

104

106

DAC LD

69

com CLK

71

com D.IN

com RST

YC

CS

35

38

REM

CS

70

68

com D.OUT

L YC

D.IN

78

79

62

63

YC

SBO

CLK2

DI

1

LD3

IC2005

(com-u-com)

M.SCK

76

80

M.SDO

79

M.SDI

7

RST

DV-IN

A NA.Y-IN

INF

MCVS

REC.

V-Sync

COMPARISON

REFERENCE

COMPARISON

During Editing, Frame Servo is applied for Capstan Servo.

NOTE:

*

P.B.

25Hz

SPEED

ALL MODE

ROM DATACYLINDER REFERENCE

FG

ALL MODECAPSTAN

ROM DATA

FG

IC2001

V-PLL

PHASE

IC3005

VCO

(18MHz)

18MHz

IC3001 IC3003 IC3201

COUNT

DOWN

(25Hz)

FRP

COUNT

DOWN

SSP

(300Hz)

IC3201/IC2001

PHASE

REC/PB CUE/REV

TSR ROM

DATA

HID

PB REC/CUE/

REV/SLOW

ROM DATA

ATF INTERNAL

EFERENCE

FRP (25Hz)

COUNT

DOWN

REC./CUE/

REV/SLOW

IC6001

Over than

X1 tape speed

TSR(150Hz)

Less than

X1 tape speed

HID-3

HID-2

HID-1

AFT

AFT

(TRE)

P.B.

INT.REF.

ROM

ENVE

(Pilot f0-f2)

ROM Data

ROM CYL

FG-Pulse

TSR/ROM

IC3201

HID

GENERATOR

IC6001

ROM Data

ROM

FG-Pulse

ROM Data

ROM

(TRP0-3)

HID-1

(150Hz)

AFT

(TRE)

ENVE

FRP

SPEED

CYL

PHASE

CAP

SPEED

CAP

PHASE

FRAME

SERVO

(Other than Dubbing

(Copying)/Assemble.)

IC2503

CYL-ET

FG-Pulse (Normal P.B.:600Hz)

PG-Pulse (Normal P.B.:150Hz)

ENVE.OUT(TRP0-3/PILOT f0-f2)

CAP-ET

Normal

(Other than left)

EDIT

(Normal P.B.:1,760Hz)

CYL

DRIVE

IC2503

CAP

DRIVE

FG-Pulse

CYLINDER

MOTOR

CAPSTAN

MOTOR

FG1

FG2

(Normal P.B.:880Hz)

FG MIX

IC2502

Page 54

7 8

FRONT

Í / I

¥

DV 2

AV4

IN

S-VIDEO

REAR

NORMAL

DV SELECT

2

VIDEO MAIN SIGNAL PATH IN REC MODE VIDEO MAIN SIGNAL PATH IN PLAYBACK MODE

AUDIO

STEREO

OUT

SERECT

EJECT

<

EDIT 8mm

1

2

VIDEO

L/MONO– AUDIO – R

RECORDER

PLAYER

PRINTER/

D.STILL PICTURE

EDIT CONTROL

PASSIVE

8mm

EDIT

DV

MIXING EDIT

SP/LP TBC 3D DNR PRINT

REW STOP

AUDIO REC LEVEL

010

S-VIDEO

STEREO1 STEREO2

VIDEO

STEREO1

AUDIO MIX

PLAY

100

STILL

ALBUM

INPUT SELECT

L– AUDIO – R

FF PAUSE

¥

REC/OTR

AV4

OUT

CPS-IN

(VIDEO)

IC3903 (VIDEO INPUT SELECT)

AV1-4

IC3002 (Y/C SEPA)

Y/C

SEPA

Y

C

9 10

Y

C

S-VIDEO OUT

AV1(TV

AV2(EXT

)

)

11 1

MONITOR OUT

R AUDIO L

VIDEO S-VIDEO

AV3 IN

6 5

CPN-IN

(S-VIDEO)

AC INT

SECTEUR

T

DIGITAL STILL

¥

DV1

PICTURE OUT

AV1-4Y

AV1-4C

IC3607 (S-VIDEO INPUT SELECT)

4 3

IC3001 (INPUT SEPA)

Y

C

IC3603 (EE/VV SELECT) IC30006 (3D-DNR) IC3601 (SELECTOR)

Y

C

P.B-Y

P.B-C

DV REC PB

PROCESS

DNR

Y

C

IC30008 (2MBF.MEMORY)

MEMORY

REC-Y

REC-C

IC3606 (EDIT/OSD) IC3610 (SELECTOR)

Y

(EDIT/OSD)

C

Y

C

Y

Y/C

C

4

1

2

5

6

8

3

7

9

10

AV3 V OUT

AV 1

NORMAL/

S-VIDEO

AV 2

NORMAL

AV 3 SV OUT

MONITOR OUT

AV 3 V OUT

MONITOR

AV 4 V IN

AV3 SV IN

AV4 SV IN

AV4 SV OUT

AV4 V OUT

AV3 VIDEO IN

JK3906

20

19

15

JK3901

JK3902

20

19

15

S OUT

JK3903

3 4

VIDEO OUT

JK3904

AV4 V IN

JK4851

JK3905

3 4

S IN

JK4852

3 4

S OUT

JK4853

3 4

JK4854

V IN

V OUT (Y.OUT)

C. OUT

V. IN

V. OUT

C

Y

C

Y

C

Y

C

Y

NORMAL

11

S-VIDEO

OUT SW

S3901

S-VIDEO NORMAL

Q3904,3905

Q3902,3903

Q3902 (AV2 OUT)

(H)

15

(L)

IC3901

(AV1 OUT)

(H)

15

(L)

1

2

11

10

9

1

2

11

10

9

IC7501

52 AV2 OUT

IC7501

51 TV (H)

PS3902 PP3402

19 19

PS3902 PP3402

17 13

PS3902 PP3402

13 17

PS3902 PP3402

15 15

P7502 P7901

27 6

PS3901 PP3401

18 18

PS3901 PP3401

16 16

P7502 P7901

29 4

P7502 P7901

31 2

P7501 P7902

21 6

P7501 P7902

20 7

P7501 P7902

23 4

IC3903 (VIDEO IN)

12

13

14

15

SW

AV4 V IN

AV3 S-C IN

AV3 S-Y IN

AV4 S-C IN

AV4 S-Y IN

CPN 2C OUT

CPN 2Y OUT

CPS 2V OUT

10

11

3

9

FRONT (H)

QR6202

QR6203

Q3907

IC3602 (AGC)

PS3901 PP3401

20 20

V IN

9

7

CLAMP

IC6001 45 A2 (L)

IC6001 44 A1 (L)

IC3607 (SELECTOR)

13

12

1

2

3

5

14

15

4

SELA

11

10

B/P (H)

9

C OUT

Y OUT

Y+C OUT

QR6203

IC6001

44 A1 (L)

IC7501

12 B/W (H)

IC3601 (SELECTOR)

3

Q3605

4

5

AV1-PIN 10

15

(H)

1

AV2-PIN 10

2

(L)

Q3606

IC7501 71

(QLINK ON H )

12

13

14

10

B

11

A

9

C

Q3610,3611 Q3617,3620,3622

11

12

14

Q3613,3614

Q3607

Q3623

IC4701

(AY-IN COM)

IIC CLK

IIC DATA

IC3603

(SELECTOR)

5

3

12

13

IC3606

(EDIT OSD CONTROLER)

C IN

2 27

1

Y IN

3 26

V IN

Q3608,3609

7

6

Q3604

4

Q3603

14

Y OUT

C OUT

PP3501 PS30001

PP3501 PS30001

PP3502

PP3502

Q3616,3618

Q3612,3615

15 15

13 13

PP3501

PS30001PP3501

PP3501

PS30002

4

PS30002

3

PP3502

PP3502

PP3502

PP3502

IC30002

Q30009-30012

CPS V IN

IC30001

(C/Y INPUT SELECTOR)

CPN Y IN

Y SEP OUT

6

CPN C IN

1111

C SEP OUT

4

4

3

DNR C IN

10

DNR Y IN

12

DNR Y OUT

8

DNR C OUT

6

IC3610

(IN/OUT SELECTOR)

1 14

3

11

12

Y IN

OSD Y IN

OSD C IN

C IN

CPN C OUT

CPN Y OUT

12 13

14

2

15

3

5

IC30006

(3D DIGITAL NOISE

REDUCTION)

75

IIC CLK

76

IIC DATA

45

A IN C

A IN Y

40

16

Y+C OUT

19

Q30005,30008

1

4

Q30004

100

MI 0

MI 17

82

51

C OUT

Y OUT

35

Q30001

Q30003

(DIGITAL Y/C SEPARA TOR)

3 AD IN

Y OUT

25

C OUT

23

IC30008

(2M BIT FIELD MEMORY)

Q3626

Q3625

Q3627

MEMORY

CPM 2C OUT

CPS 2V OUT

CPM 2Y OUT

Page 55

VIDEO MAIN SIGNAL PATH IN REC MODE VIDEO MAIN SIGNAL PATH IN PLAYBACK MODE

FP3401 FP3201 Y

6 31

FP3401 FP3201

8 29

35

46

Q3002 Q3001

FP3401 FP3201

10 27

FP3401 FP3201

12 25

Q3005,

3006

X3152

IC4201

(OP-AMP)

6PCM IN (R) 7

9 8PCM IN (L)

IC4210

(OP-AMP)

7PCM OUT (R) 6

1 2PCM OUT (L)

IC3004(AV-I/F)

Y

C

IC3004

(AV I/F)

Y

IN

OUT

C

C

IN

OUT

Q3004

IC3153,3154

IC2004

(EEPROM)

IC3001(DVIO) IC3002

Y

Y IN

C IN

Y OUT

C OUT

X IN

X OUT

A/D.

C

CONV

Y

D/A.

C

CONV

CLK 18M1

CLK 18/8M

CLK 18M2

CLK 450K

CLK 18 IN

27MHz

Y/C

MULTIPLEX.

68

DATA

IN/OUT

(8bit)

75

64 21

61

62

63

33

55

STP1

57

SDIO

56

SCLK

AV

I/F

IC3001

(DV I/O)

157

23

165

8

3

8

46

47

2

SK EE CLK

4

DO

3

DI

1

CS

(Shuffling Memory)

DV

TERMINAL

TO/FROM

AUDIO

SECTION

46

44

43

41

80

82

83

85

58

25

3

5

26

27

108

107

81

83

82

99

100

103

104

5Mb

MEMORY

IC4501

(PCM-AUDIO)

IC3002

(SHUFFLE MEMORY)

LBS

DATA

IN/OUT

(8bit)

SOC

SIC

IC3005

(VCO)

CLK 18

IC4501

(AUDIO I/F)

A IN R

A IN L

A OUT L

A OUT R

IC2001

(LSI MICON)

DCS STP2

DC STP1

DCS CLK

DCS DI

DCS DO

EE DI

EE DO

EE CS

LBS

DATA

IN/OUT

(8bit)

ADDRESS

IN

(8bit)

FS CLK

FS SEL 0

FS SEL 1

M CLK

LR CLK

S CLK

SDT 0

SDT 1

ADDRESS

COM CLK

COM DATA OUT

COM DATA IN

46

39

40

15

11

12

14

13

(15bit)

IC3003 (CAS) IC3201 (EDA)

DCT

Shuff.

MEMO.

CTL

IC3701

(DI/F)

35 12

33

32

30

91

93

94

96

97

98

1

9

67

79

154

DATA

139

69

70

71

IC3003

(CAS)

9

7

4

37

ADDRESS

IN

(18bit)

18

SHM225

1

CLK18

16

65

VCOI

68

FS0

67

FS1

79

SDIO

80

SCLK

78

STP2

95

DO MCK

94

DO LRCK

96

DO BCK

86

AI DAT

93

DO DATA

LBS

DATA

IN/OUT

(8bit)

VLC

IC3202

(EDA.M)

50

LBS

DATA

IN/OUT

(4bit)

47

ECC

EDA

MEMORY

(4M)

Desuf.

MEMORY

CTL

24-25

CONV.

151

154

103

120

MODU

VITERBI

(VITERBI-A/D)

IC3201

(EDA)

(REC DATA)

DATA

IN/OUT

(4bit)

ADDRESS

DATA

(15bit)

PB DATA IN

3

CLK 18M

2

CLK 450K

ATF 1

48

IC3202

(ECC MEMORY)

IC2005

(PC I/F)

76

M SCK

79

M SDI

80

M SDO

IC3204

HSE

REC CLK

REF CLK

PB CLK

PB DATA

(41.85M)

LSB

DATA IN

OUT

(15bit)

LSB

ADDRESS

OUT

(9bit)

LSB

ADDRESS

IN/OUT

(9bit)

LSB

DATA IN

IN/OUT

(15bit)

UART I

uART O

IC3203 (EQ)

A/D

CONV.

59

56

74

53

52

62

68

40

25

18

10

18

28

2

10

35

43

50

51

IC5001 (H.AMP)

TO RS-232C

CYLINDER

REC ONLY

PB ONLY

BOTH

IC3202

(EQ)

31 41.85M(REC)

41.85M/72

11

35

33

53 58

36

CLK

9

IC3701

(DIGITAL I/F)

130

DATA IN

(4bit)

133

102

ADDRESS

DATA

(15bit)

120

142

CLK 18M

VCO

LATCH

AGC IN

REF-EQ

LPF

TFIL

HD

ATF

BPF

ATF1

69

TPB-

70

TPB+

71

TPA-

72

TPA+

IC5001

FP3203 FP5002

13 12

62

17

18

59

2

4

5

FP3203 FP5002

16 9

FP3202 FP5002

14 11

7 29

64

57

HSE

AGC OUT

(PB DATA)

ATF OUT

AR 1

OUT

AR 2

OUT

HA 2

HA 1

PB H1

PB H2

MON 2

MON 1

31

36

IN

24

IN

Q5005

28

32

Q5006

34

IN

26

IN

(HR AMP)

RA 1 OUT

RA 2 OUT

Q5003

Q5002

FP5001

5

6

M CYL

7

4

IC3205 (GATE)

2

IC3204

(VITERBI A/D)

7

10

19

LBS

DATA

OUT

(7bit)

11

TO DV

TERMINAL

4

TO EVR

A/D

Page 56

ANALOG Y/C C.B.A.

Transistor

Q30001 B-2 (C)

Q30002 B-2 (C)

Q30003 B-1 (C)

Q30004 D-3 (F)

Q30005 C-3 (F)

Q30006 C-3 (F)

Q30007 B-2 (C)

Q30008 D-3 (F)

Q30009 A-2 (C)

Q30010 A-2 (C)

Q30011 A-2 (C)

Q30012 A-2 (C)

D

C

Q30014 A-4 (C)

Q30015 C-1 (F)

Q30016 C-1 (F)

Q30017 C-2 (F)

Q30018 A-3 (C)

Q30019 A-3 (C)

Q30020 C-2 (F)

Q30021 C-2 (F)

Q30022 C-2 (F)

Q30023 A-3 (C)

Transistor & Resistor

QR30001 B-2 (C)

Integrated Circuit

IC30001 A-2 (C)

IC30002 D-3 (F)

IC30003 A-2 (C)

IC30004 B-2 (C)

IC30006 D-2 (F)

IC30007 B-4 (C)

IC30008 B-3 (C)

(FOIL SIDE)

B

A

Test Land

TL30001 D-3 (F)

TL30002 B-3 (C)

TL30003 B-3 (C)

TL30004 B-3 (C)

TL30005 B-3 (C)

TL30006 B-3 (C)

TL30007 B-3 (C)

TL30008 B-3 (C)

TL30009 D-2 (F)

TL30010 D-2 (F)

TL30011 D-2 (F)

TL30012 D-2 (F)

TL30013 D-2 (F)

Test Point

TP30001 B-2 (C)

TP30004 B-2 (C)

TP30005 A-2 (C)

Adjstment

VR30001 C-3 (F)

VR30003 C-3 (F)

Connector

PS30001 A-2 (C)

PS30002 A-3 (C)

ADDRESS INFORMATION

(C) : COMPONENT SIDE

(F) : FOIL SIDE

(COMPONENT SIDE)

1

2

3

Page 57

Transistor Transistor & Resistor

Q2501 C-3 (F) QR2001 C-2 (F) QR6015 A-7 (C) IC2506 C-3 (F) IC4210 B-6 (C) TL6002 B-7 (C)

Q2502 C-3 (F) QR2002 C-2 (F) QR6016 A-7 (C) IC2507 C-3 (F) IC4501 B-6 (C) TL6003 B-7 (C)

Q2503 A-6 (C) QR2003 B-1 (F) QR6017 A-7 (C) IC2508 A-2 (F) IC6001 B-7 (C) TL6006 B-7 (C)

Q2504 A-6 (C) QR2501 A-6 (C) QR6019 A-7 (C) IC3001 B-4 (F) IC6002 A-2 (F) TL6007 B-7 (C)

Q3001 B-4 (F) QR2502 A-6 (C) QR6020 B-3 (F) IC3002 B-3 (F) IC6003 A-8 (C) TL6009 B-6 (C)

Q3002 B-4 (F) QR3001 C-6 (C) QR6021 A-3 (F) IC3003 B-3 (F) IC6004 A-8 (C) TL6010 B-6 (C)

Q3003 C-4 (F) QR3151 B-3 (F) QR6022 A-2 (F) IC3004 C-6 (C) IC6005 A-8 (C)

Q3004 B-4 (F) QR3152 B-3 (F) QR6023 A-7 (C) IC3005 C-3 (F)

Q3005 B-3 (F) QR3201 B-9 (C) QR6024 A-3 (F) IC3006 C-4 (F) FP3201 C-5 (F)

Q3006 B-4 (F) QR6001 A-2 (F) QR6025 A-3 (F) IC3007 C-4 (F) TL3002 B-7 (C) FP3202 B-5 (F)

Q3007 C-4 (F) QR6002 A-2 (F) IC3008 B-7 (C) TL3004 B-7 (C) FP3203 C-2 (F)

Q3151 B-3 (F) QR6003 A-2 (F) IC3009 C-4 (F) TL3006 B-8 (C) FP6002 A-5 (F)

Q3152 B-3 (F) QR6004 A-1 (F) IC2001 B-2 (F) IC3010 C-4 (F) TL3014 C-7 (C) FP6003 A-9 (C)

Q3201 B-9 (C) QR6005 A-1 (F) IC2002 B-1 (F) IC3011 C-6 (C) TL3020 B-4 (F) P2501 C-3 (F)

Q3202 B-9 (C) QR6006 B-7 (C) IC2003 C-2 (F) IC3012 C-5 (C) TL3024 B-4 (F) P2502 C-3 (F)

Q3203 B-8 (C) QR6007 B-7 (C) IC2004 B-1 (F) IC3153 B-3 (F) TL3026 C-6 (C) P3701 C-1 (F)

Q3204 B-9 (C) QR6008 B-7 (C) IC2005 B-2 (F) IC3154 B-3 (F) TL3027 C-6 (C) P6001 B-9 (C)

Q6001 A-2 (F) QR6009 B-7 (C) IC2006 A-1 (F) IC3201 B-8 (C) TL3028 C-6 (C) P6002 A-7 (C)

Q6002 A-2 (F) QR6010 B-3 (F) IC2501 A-2 (F) IC3202 A-8 (C) TL3201 B-9 (C) PS6001 C-4 (F)

Q6003 A-4 (F) QR6011 A-7 (C) IC2502 C-3 (F) IC3203 B-9 (C) TL3202 B-9 (C)

Q6004 A-3 (F) QR6012 A-3 (F) IC2503 C-7 (C) IC3204 B-8 (C) TL3207 B-8 (C)

QR6013 A-8 (C) IC2504 C-8 (C) IC3205 B-9 (C) TL3208 B-8 (C)

ADDRESS INFORMATION

(C) : COMPONENT SIDE

(F) : FOIL SIDE

QR6014 A-8 (C) IC2505 C-2 (F) IC3701 C-9 (C) TL6001 A-7 (C)

Integrated Circuit

DIGITAL C.B.A.

Connector

Test Land

C

B

A

(FOIL SIDE)

1

24

3

5

6789

(COMPONENT SIDE)

Page 58

123456

JK7651

24

67

13

58

P7651

Page 59

C5029

R5026

R5024

C5030

C5032

C5034

R5021

50

C5028

C5038

C5033

R5028

C5031

C5037

MR4

C5001

R5020

49

64

C5002

R5019

55

60

L5005

1

C5027

C5039

R5003

C5007

C5026

5

R5002

C5040

R5018

C5025

IC5001

C5004

R5004

R5005

R5025

10

Q5003

E

C

C5010

C5024

R5017

CKA7 CKA6

B

L5002

C5023

L5003

3335404548

32

30

25

C5019

C5014

20

17

15

16

MR1

L5007

C5036

R5015

R5014

R5016

Q5006

B

E

C5021

C5020

CKA5

Q5005

B

C5013

C5015

C5035

C

MR2

8

5

1

MR3

CKA2

R5010

CKA1

R5013

R5012

C5016

FP5001

C5018

C5017

C

B

CKA3

CKA4

Q5002

E

C

E

R5029

Page 60

INPUT/OUTPUT C.B.A.

Transistor

Q3901 A-3 TP3002 B-2

Q3902 A-3 TP3021 B-2

Q3903 A-3 TP3030 B-2

Q3904 A-3 TP3031 B-1

Q3905 A-3 TP3032 B-1

Q3907 A-4 TP3901 B-2

Q3908 B-4

Q3909 B-4

Transistor & Resistor

QR3901 A-2 PS3903 A-3

QR3902 B-4

QR3903 C-1

Integrated Circuit

IC3901 B-2

IC3902 A-2

IC3903 A-4

ADDRESS INFORMATION

Test Point

Connector

PS3901 A-2

PS3902 A-3

C

B

(FOIL SIDE)

A

(COMPONENT SIDE)

1

2 4

3

Page 61

MAIN C.B.A.

CAUTION

THE MARK INDICATES THE PRIMARY CIRCUIT TO

DISTINGUISH THE PRIMARY FROM THE SECONDARY CIRCUIT.

PAY ATTENTION NOT TO RECEIVE AN ELECTRIC SHOCK

E

DURING REPAIR AND SERVICE OF THE PRODUCTS.

HOT

D

C

B

(FOIL SIDE)

Transistor

Q1006 B-6

Q1009 C-3

Q1010 A-6

Q1011 A-6

Q3601 D-4

Q3605 D-4

Q3610 C-4

Q3611 C-4

Q3612 D-4

Q3615 D-4

Q3616 D-4

Q3618 D-4

Q3624 C-5

Q4004 C-6

Q4305 B-7

Q4306 B-7

Q4307 B-7

Q4308 B-7

Q4309 B-7

Q4310 B-8

Q4315 B-8

Transistor & Resistor

QR1002 B-6

QR1007 B-3

QR3601 D-4

QR3602 D-4

QR3606 D-6

QR4301 B-8

QR4302 B-8

QR4304 C-7

QR4305 C-7

QR6203 A-7

QR6210 A-5

QR6211 A-5

QR6212 A-5

Integrated Circuit

IC1005 B-3

IC3601 D-4

IC3603 D-3

IC3606 D-5

IC3607 D-5

IC3608 C-4

IC3609 C-5

IC3611 C-5

IC4304 A-7

IC4306 C-7

IC4308 D-7

IC4312 C-8

IC4315 B-7

IC4901 D-3

Test Land

TL7001 A-8

Adjstment

VC3601 C-5

VC3602 D-5

Connector

FP3401 C-7

FP3402 B-7

FP6201 B-7

ADDRESS INFORMATION

A

(FOIL SIDE)

1

24

3

5

678

Page 62

MAIN C.B.A.(COMPONENT SIDE)

IMPORTANT SAFETY NOTICE:

COMPONENTS IDENTIFIED WITH THE MARK HAVE THE SPECIAL CHARACTERISTICS

FOR SAFETY.

WHEN REPLACING ANY OF THESE COMPONENTS USE ONLY THE SAME TYPE.

E

THE MARK INDICATES THE PRIMARY CIRCUIT TO

DISTINGUISH THE PRIMARY FROM THE SECONDARY CIRCUIT.

PAY ATTENTION NOT TO RECEIVE AN ELECTRIC SHOCK

DURING REPAIR AND SERVICE OF THE PRODUCTS.

HOT

R DV

232C

D

C

B

A

CAUTION

Transistor

Q1001 B-3 IC1001 D-5

Q1002 B-3 IC1002 B-3

Q1003 B-3 IC1003 C-5

Q1004 B-5 IC1004 A-4

Q1005 B-5 IC1006 A-3

Q1007 B-5 IC1150 C-7

Q1008 C-5 IC1200 B-8

Q1012 A-3 IC1501 B-3

Q1013 A-2 IC3602 D-2

Q1014 A-4 IC3604 D-2

Q1015 B-3 IC3605 D-3

Q1016 A-4 IC3610 C-3

Q1200 C-8 IC3612 D-4

Q1501 B-2 IC3613 D-3

Q3602 D-2 IC4301 B-1

Q3603 D-5 IC4302 C-1

Q3604 D-5 IC4303 B-2

Q3606 D-4 IC4305 D-1

Q3607 D-2 IC4309 B-1

Q3608 E-1 IC4310 C-2

Q3609 E-1 IC4311 C-1

Q3613 D-4 IC4313 B-2

Q3614 C-4 IC4314 C-1

Q3617 D-4 IC4316 B-1

Q3619 D-4 IC4701 A-5