Panasonic NN-SD987S, NN-SD967S, NN-SD957S, NN-SD997S, NN-SD977S User Manual

...

NN-SD997S

NN-SD987S

NN-SD967S

NN-SN977S

NN-SN957S

NN-SN947S

APH(USA)

CPH(CANADA)

ORDER NO.PHAMOS0701005A1

E1

Microwave Oven

Please file and use this specified manual together with the service manual for Model NN-T695 (ORDER NO.

PHAMOS0501001C7).

© 2007 Panasonic Home Appliances Microwave

Oven (Shanghai) Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation

of law.

NN-SD997S / NN-SD987S / NN-SD967S / NN-SN977S / NN-SN957S / NN-SN947S

2

NN-SD997S / NN-SD987S / NN-SD967S / NN-SN977S / NN-SN957S / NN-SN947S

3

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

CONTENTS

Page Page

1 SCHEMATIC DIAGRAM 5

1.1. APH

1.2. CPH

2 MEASUREMENTS AND ADJUSTMENTS

2.1. Adjustment of primary latch switch, secondary latch switch

and short switch.

2.2. Measurement of microwave output

3 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

3.1. Equipment

3.2. Procedure for measuring radiation leakage

3.3. Record keeping and notification after measurement

3.4. At least once a year, have the radiation monitor checked

for calibration by its manufacturer.

4 SIMPLE WAY OF H.V. INVERTER/MAGNETRON

TROUBLESHOOTING

5 H.V.INVERTER BOARD MAIN PARTS LIST (F606Y8M00AP)

5

6 EXPLODED VIEW AND PARTS LIST

6

7

7

7

8

8

8

8

8

9

6.1. EXPLODED VIEW

6.2. PARTS LIST

6.3. ESCUTCHEON BASE ASSEMBLY

6.4. PACKING AND ACCESSORIES

6.5. DOOR ASSEMBLY

6.6. WIRING MATERIALS

7 DIGITAL PROGRAMMER CIRCUIT

7.1. NN-SD997S APH/CPH, SD987S/SB APH

7.2. NN-SD967S APH

7.3. NN-SN977S APH

7.4. NN-SN957S APH

7.5. NN-SN947S APH

7.6. PARTS LIST

9

10

10

11

12

16

17

17

18

18

20

22

24

26

28

4

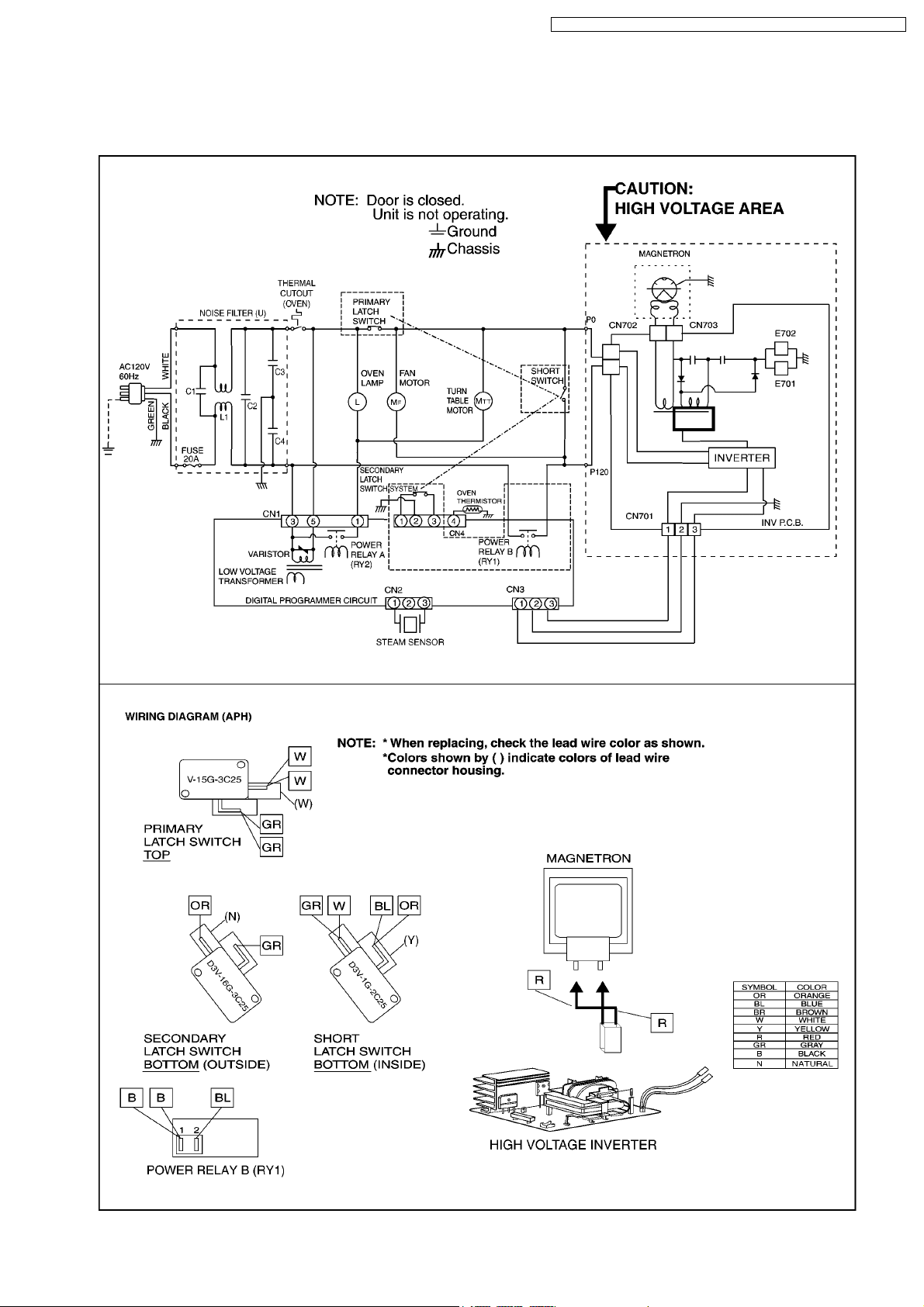

1 SCHEMATIC DIAGRAM

1.1. APH

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

5

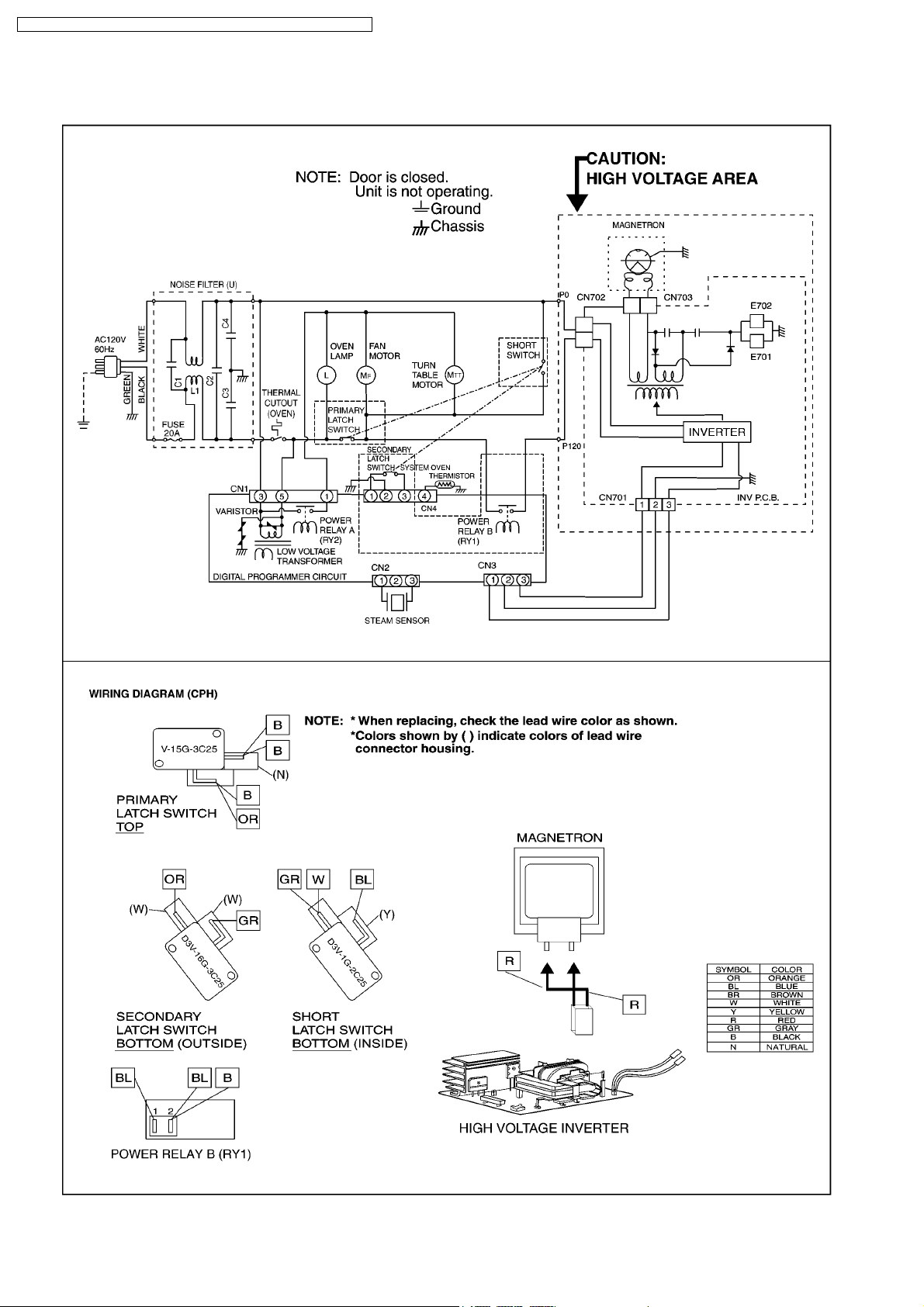

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

1.2. CPH

6

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

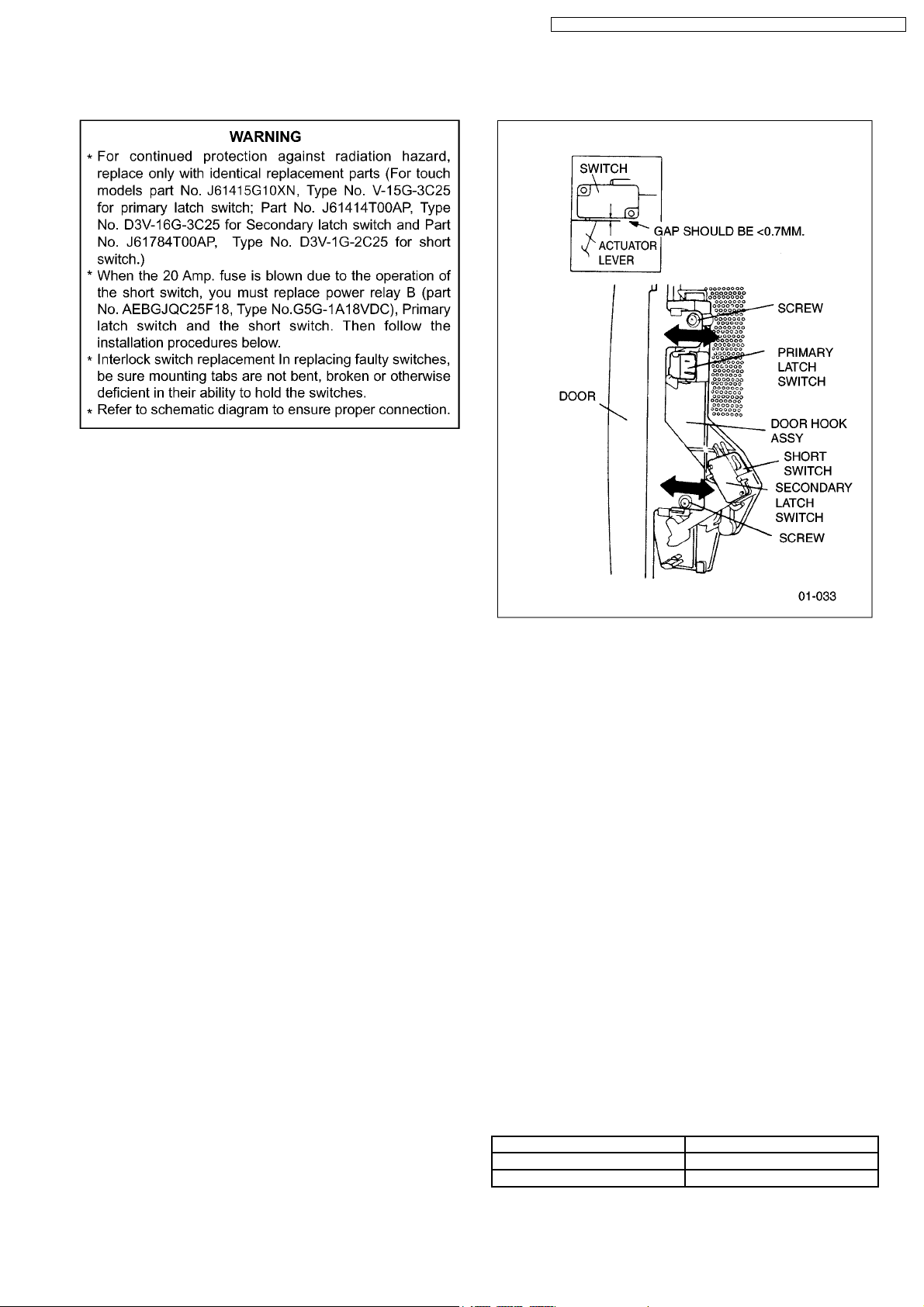

2 MEASUREMENTS AND ADJUSTMENTS

2.1. Adjustment of primary latch

switch, secondary latch switch

and short switch.

1. Mount the Primary latch switch, the Secondary latch switch

and the short switch to the door hook assembly as shown in

ILL.

NOTE:

No specific individual adjustments during

installation of the Primary latch switch, Secondary

latch switch or Short switch to the door hook are

required.

2. When mounting the door hook assembly to the oven

assembly, adjust the door hook assembly by moving it in

the direction of the arrows in the illustration so that the oven

door will not have any play in it. Check for play in the door

by pulling the door assembly. Make sure that the latch keys

move smoothly after adjustment is completed. Completely

tighten the screws holding the door hook assembly to the

oven assembly.

3. Reconnect the short switch and check the continuity of the

monitor circuit and all latch switches again by following the

component test procedures.

2.2. Measurement of microwave

output

The output power of the magnetron can be determined by

performing IEC standard test procedures. However,due to the

complexity of IEC test procedures, it is recommended to test

the magnetron using the simple method outlined below.

Necessary Equipment:

*1 liter beaker *Glass thermometer

*Wrist watch or stopwatch

NOTE:

Check the line voltage under load.Low voltage will

lower the magnetron output. Take the temperature

readings and heating time as accurately as possible.

1. Fill the beaker with exactly one liter of tap water.Stir the

water using the thermometer and record the water’s

temperature. (recorded as T1).

2. Place the beaker on the center of glass tray.

Set the oven for High power and heat it for exactly one

minute.

3. Stir the water again and read the temperature of the water.

(recorded as T2).

4. The normal temperature rise at High power level for each

model is as shown in table.

TABLE (1L-1min.test)

RATED OUTPUT TEMPERATURE RISE

1200W Min. 18.5°F(10.3°C)

1300W Min. 19.8°F(11.1°C)

7

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

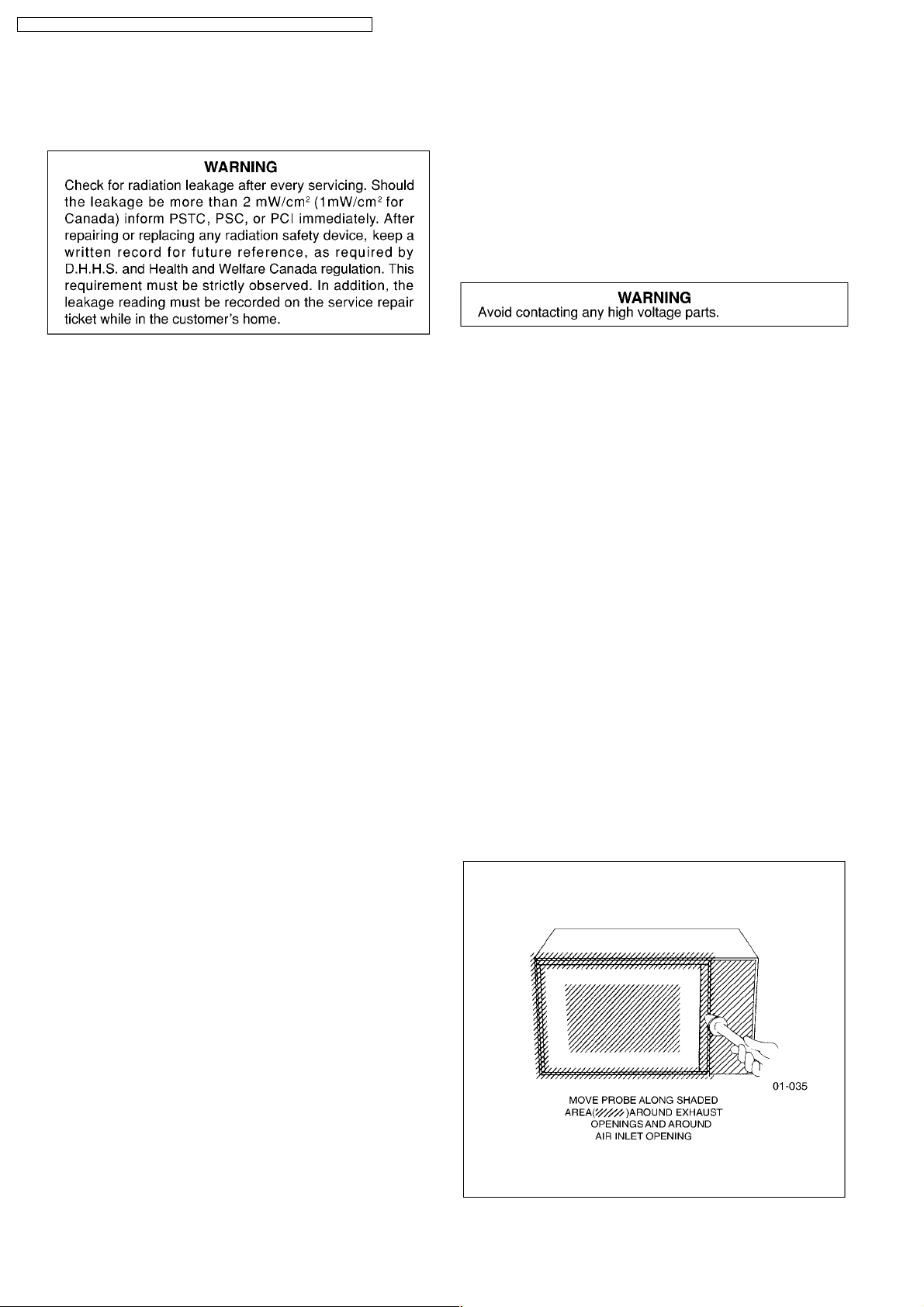

3 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

3.2.1. Measurement with the outer panel

removed.

Whenever you replace the magnetron, measure for radiation

leakage before the outer panel is installed and after all

necessary components are replaced or adjusted. Special care

should be taken in measuring around the magnetron.

NOTE:

The U.S. Government standard is 5 mW/cm

customer’s home. 2mW/cm

voluntary standard. (1mW/cm

2

stated here is our own

2

for Canada)

2

while in the

3.1. Equipment

•••• Electromagnatic radiation monitor

•••• Glass thermometer 212°F or 100°C

•••• 600cc glass beaker

3.2. Procedure for measuring

radiation leakage

Note before measuring.

•••• Do not exceed meter full scale deflection. Leakage monitor

should initially be set to the highest scale.

•••• To prevent false readings the test probe should be held by

the grip portion of the handle only and moved along the

shaded area in Figure no faster than 1 inch/sec

(2.5cm/sec).

•••• Leakage with the outer panel removed ...... less than

5mW/cm

•••• Leakage for a fully assembled oven with door normally

closed ...... less than 2mW/cm

•••• Leakage for a fully assembled oven [Before the latch switch

(primary) is interrupted] while pulling the door ...... less than

2mW/cm

1. Pour 275 ± 15cc (9ozs

water in a beaker which is graduated to 600cc, and place in

the center of the oven.

2. Set the radiation monitor to 2450MHz and use it following

the manufacturer´s recommended test procedure to assure

correct results.

3. When measuring the leakage, always use the 2 inch (5cm)

spacer supplied with the probe.

4. Tap the start pad or set the timer and with the magnetron

oscillating, measure the leakage by holding the probe

perpendicular to the surface being measured.

2

.

2

(1mW/cm2for Canada).

2

.

s

± 1/2oz) of 20°C ± 5°C (68° ± 9°F)

3.2.2. Measurements with a fully

assembled oven.

After all components, including outer panel are fully assembled,

measure for radiation leakage around the door periphery, the

door viewing window, the exhaust opening, control panel and

air inlet openings.

3.3. Record keeping and

notification after measurement

•••• After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

A copy of this repair ticket and the microwave leakage

reading should be kept by repair facility.

•••• Should the radiation leakage be more than 2 mW/cm

(1mW/cm2for Canada) after determining that all parts are in

good condition, functioning properly, and genuine

replacement parts as listed in this manual have been used,

immediately notify PSTC, PSC or PCI.

3.4. At least once a year, have the

radiation monitor checked for

calibration by its

manufacturer.

2

8

NN-SD997S / NN-SD987S / NN-SD 967S / NN-SN 977S / NN-SN 957S / NN-SN947 S

4 SIMPLE WAY OF H.V. INVERTER/MAGNETRON

TROUBLESHOOTING

Purpose:

Simple way (3/37 seconds rule) of identifying whether it’s Magnetron, Inverter, or others.

Set-up:

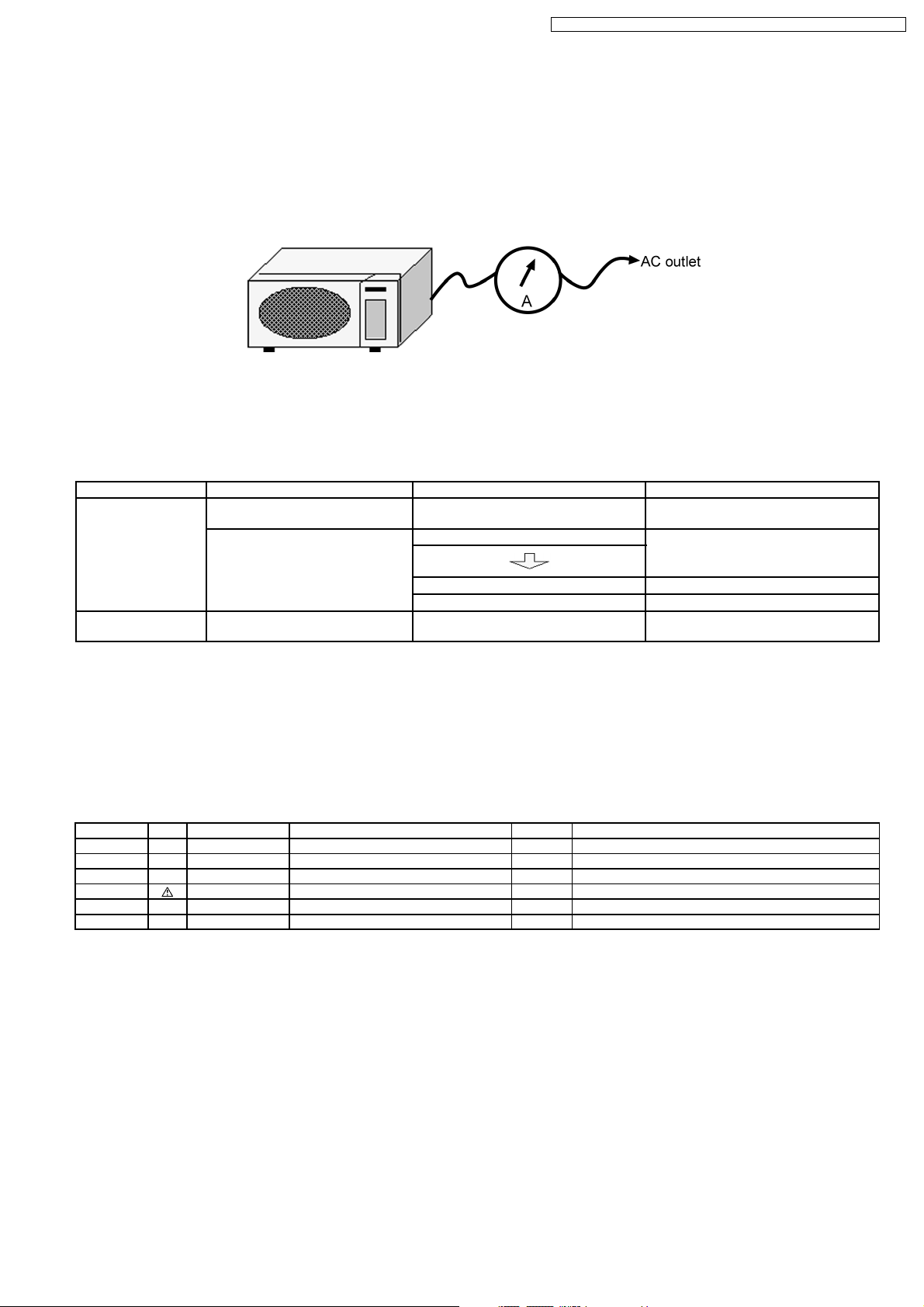

The unit under question is connected through the Ammeter as shown below.

Procedure:

Follow the matrix table below to identify the problem source.

Note:

Do not replace both Inverter board and Magnetron simultaneously and automatically without going through this

procedure.

Power will: Ammeter reading is: To do: Remedy:

Shut off in 37 seconds

after “Start”.

1. Between 0.5A and 1.0A. Check and repair open magnetron circuit Open magnetron wiring between Inverter

and magnetron terminal.

2. Between 1.0A and 2.0A. Check continuity of D702 in Inverter PCB.

1. D702 shorted Replace H.V.Inverter(F606Y8M00AP)

2. D702 is OK Replace magnetron

Shut off in 3 seconds

after “Start”

1. Less than 0.5A Check open circuit: Latch Switch, DPC,

Power Relay and CN701

Replace defective component(s), or

correct switch, cables and connectors.

5 H.V.INVERTER BOARD MAIN PARTS LIST

(F606Y8M00AP)

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

DB701 B0FBBS000001 BRIDGE DIODE 1 20A, 600V

L701 F50206G00AP CHOKE COIL 1

Q701 B1JAGV000015 TRANSISTOR SI 1 1000V

T701 A609A8M00AP H.V. TRANSFORMER 1 (INCLUDING D701,D702,C706,C707)

C701 ECWF5284N300 CAPACITOR 1 0.28µF/500V

C702 ECWF2455N644 CAPACITOR 1 4.5µF/250V

9

Loading...

Loading...