Panasonic MS KX-MB283BR Schematic

Multi-Function printer

KX-MB283BR

(for Brazil)

ORDER NO. KMF0711134CE

© 2007 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and distribution is a violation of law.

KX-MB283BR

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. FOR SERVICE TECHNICIANS ------------------------3

1.2. AC CAUTION -----------------------------------------------3

1.3. PERSONAL SAFETY PRECAUTIONS --------------4

1.4. SERVICE PRECAUTIONS------------------------------4

2Warning--------------------------------------------------------------5

2.1. ABOUT LEAD FREE SOLDER (PbF: Pb free)-----5

2.2. Discarding of P. C. Board --------------------------------5

2.3. INSULATION RESISTANCE TEST--------------------6

2.4. BATTERY CAUTION--------------------------------------6

2.5. LASER BEAM AND FUSER UNIT SECTION ------6

3 Specifications------------------------------------------------------7

4 General/Introduction---------------------------------------------8

4.1. OPTIONAL ACCESSORIES----------------------------8

4.2. Translation Lists--------------------------------------------9

5Features------------------------------------------------------------10

5.1. General Features-----------------------------------------10

5.2. HARDWARE REQUIREMENTS FOR MULTIFUNCTION SOFTWARE-------------------------------10

6 Technical Descriptions----------------------------------------11

6.1. CONNECTION DIAGRAM-----------------------------11

6.2. GENERAL BLOCK DIAGRAM------------------------12

6.3. MAIN BOARD SECTION-------------------------------14

6.4. CIS CONTROL SECTION -----------------------------23

6.5. MOTOR DRIVE SECTION-----------------------------24

6.6. TIMING CHART AND WAVE FORM OF

SCANNER MOTORS -----------------------------------28

6.7. FAN MOTOR SECTION--------------------------------31

6.8. SOLENOID DRIVER SECTION----------------------33

6.9. LSU (Laser Scanning Unit) SECTION--------------34

6.10. SENSORS AND SWITCHES SECTION----------- 36

6.11. OPERATION BOARD SECTION---------------------44

6.12. LCD SECTION--------------------------------------------45

6.13. HVPS (High Voltage Power Supply)

SECTION---------------------------------------------------46

6.14. HEAT LAMP CONTROL CIRCUIT-------------------48

6.15. Main Board Section--------------------------------------53

6.16. POWER SUPPLY BOARD SECTION --------------56

6.17. Mechanical Operation-----------------------------------57

7 Location of Controls and Components------------------59

7.1. OVERVIEW------------------------------------------------59

7.2. CONTROL P ANEL---------------------------------------60

8 Installation Instructions---------------------------------------61

8.1. INSTALLATION-------------------------------------------61

8.2. CONNECTIONS------------------------------------------72

9 T est Mode----------------------------------------------------------73

9.1. TEST FUNCTIONS--------------------------------------73

10 Service Mode -----------------------------------------------------77

10.1. PROGRAMMING AND LISTS ------------------------77

10.2. USER MODE (The list below is an example of

the SYSTEM SETUP LIST the unit prints out.)---80

10.3. HISTORY (Example of a printed out list) ---------81

11 Troubleshooting Guide----------------------------------------83

11.1. USER RECOVERABLE ERRORS ------------------83

1 1 .2. TROUBLESHOOTING DETAILS---------------------85

11.3. DOCUMENT JAMS (AUTO DOCUMENT

FEEDER)------------------------------------------------- 144

1 1 .4. RECORDING PAPER JAM-------------------------- 146

12 Service Fixture & Tools--------------------------------------154

13 Disassembly and Assembly Instructions -------------155

13.1. ADF SECTION ------------------------------------------156

13.2. REMOVE ADF SECTION (1)------------------------157

13.3. REMOVE ADF SECTION ----------------------------158

13.4. REMOVE TOP COVER SECTION-----------------159

13.5. REMOVE SCANNER GLASS SECTION---------160

13.6. REMOVE OPERATION PANEL SECTION ------161

13.7. LEFT SIDE SECTION---------------------------------162

13.8. REMOVE MAIN BOARD -----------------------------162

13.9. REMOVE GEAR CHASSIS SECTION------------163

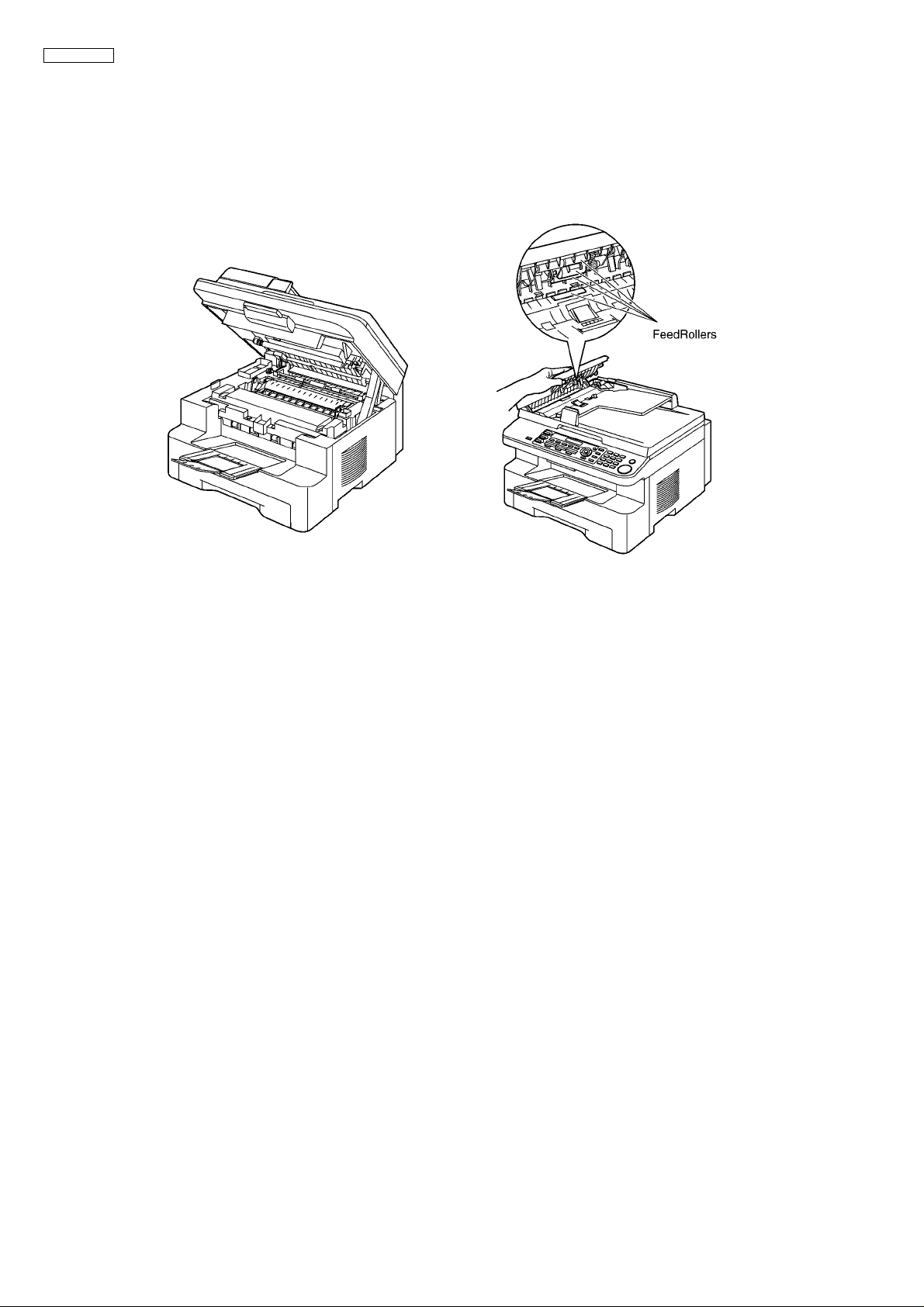

13.10. REMOVE PAPER FEED ROLLER-----------------164

13.11. RIGHT SIDE SECTION-------------------------------164

13.12. REMOVE RIGHT SIDE COVER SECTION------165

13.13. LOWER SIDE CABINET SECTION ---------------166

13.14. REMOVE RIGHT CASSETTE GUIDE------------167

13.15. REMOVE PICK UP BOARD-------------------------167

13.16. REMOVE HIGH VOLTAGE POWER BOARD---168

13.17. REMOVE PICK UP ROLLER UNIT----------------169

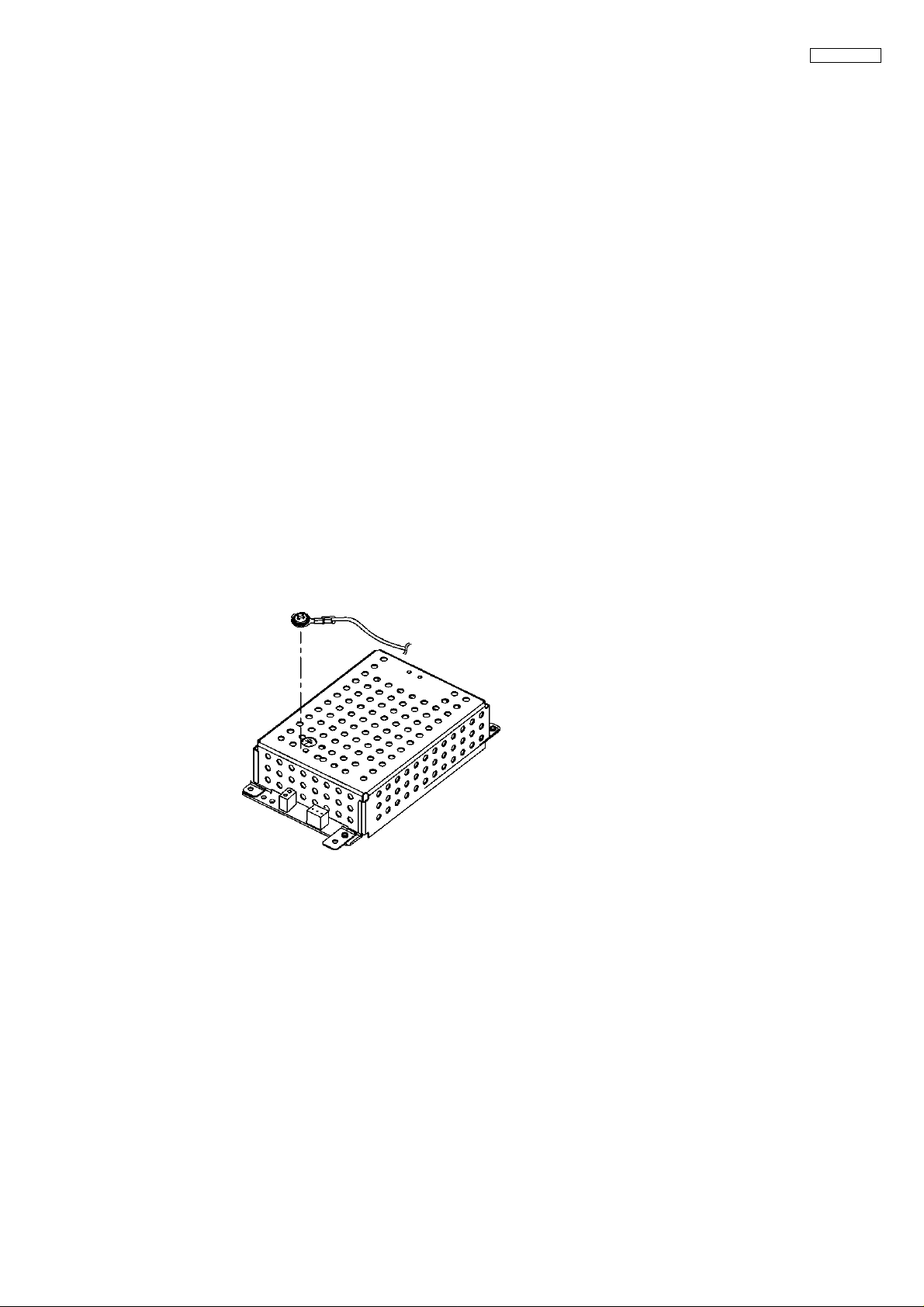

13.18. REMOVE LOW VOLTAGE POWER BOARD ---170

13.19. REMOVE FUSER UNIT-------------------------------171

13.20. Installation Position of The Lead--------------------172

14 Maintenance-----------------------------------------------------178

14.1. MAINTENANCE ITEMS AND COMPONENT

LOCATIONS---------------------------------------------178

14.2. MAINTENANCE-----------------------------------------180

14.3. PRINTING OPERATION PRINCIPLE-------------185

14.4. TERMINAL GUIDE OF THE ICs

TRANSISTORS AND DIODES----------------------190

14.5. HOW TO REPLACE THE FLAT PACKAGE IC -192

14.6. MAIN BOARD SECTION -----------------------------194

14.7. TEST CHART--------------------------------------------196

15 Schematic Diagram-------------------------------------------198

15.1. For Schematic Diagram-------------------------------198

15.2. MAIN BOARD -------------------------------------------199

15.3. OPERATION BOARD ---------------------------------209

15.4. SENSOR BOARD --------------------------------------210

16 Printed Circuit Board-----------------------------------------212

16.1. MAIN BOARD -------------------------------------------212

16.2. OPERATION BOARD ---------------------------------214

16.3. SENSOR BOARD --------------------------------------216

17 Exploded View and Replacement Parts List----------219

17.1. CABINET, MECHANICAL AND ELECTRICAL

PARTS LOCATION-------------------------------------219

17.2. REPLACEMENT PARTS LIST ----------------------232

2

KX-MB283BR

1 Safety Precautions

1. Before servicing, unplug the AC power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer's recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance test to prevent

the customer from being exposed to shock hazards.

1.1. FOR SERVICE TECHNICIANS

• Repair service shall be provided in accordance with repair technology information such as service manu al so as to prevent fires, injury or electric shock, which can be caused by improper repair work.

6. When repair services are provided, neither the products nor their parts or members shall be remodeled.

7. If a lead wire assembly is supplied as a repair part, the lead wire assembly shall be replaced.

8. FASTON terminals shall be plugged straight in and unplugged straight.

• ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

1.2. AC CAUTION

For safety, before closing the lower cabinet, please make sure of the following precautions.

1. The earth lead is fixed with the screw.

2. The AC connector is connected properly.

3

KX-MB283BR

1.3. PERSONAL SAFETY PRECAUTIONS

1.3.1. MOVING SECTIONS OF THE UNIT

Be careful not to let your hair, clothes, fingers, accessories, etc., become caught in any moving sections of the unit.

The moving sections of the unit are the rollers and a gear. There is a separation roller and a document feed roller which are rotated

by the document feed motor. A gear rotates the two rollers. Be careful not to touch them with your hands, especially when the unit

is operating.

1.3.2. LIVE ELECTRICAL SECTIONS

All the electrical sections of the unit supplied with AC powe r by the AC power cord are live.

Never disassemble the unit for service with the AC power supply plugged in.

CAUTION:

AC voltage is supplied to the primary side of the power supply unit. Therefore , always unplug the AC power cord before disassembling for service.

1.4. SERVICE PRECAUTIONS

1.4.1. PRECAUTIONS TO PREVENT DAMAGE FROM STATIC ELECTRICITY

Electrical charges accumulate on a person. For instance, clothes rubbing together can damage electric elem ents or change their

electrical characteristics. In order to prevent static electricity, touch a metallic part that is grounded to release the static electricity.

Never touch the electrical sections such as the power supply unit, etc.

4

KX-MB283BR

2Warning

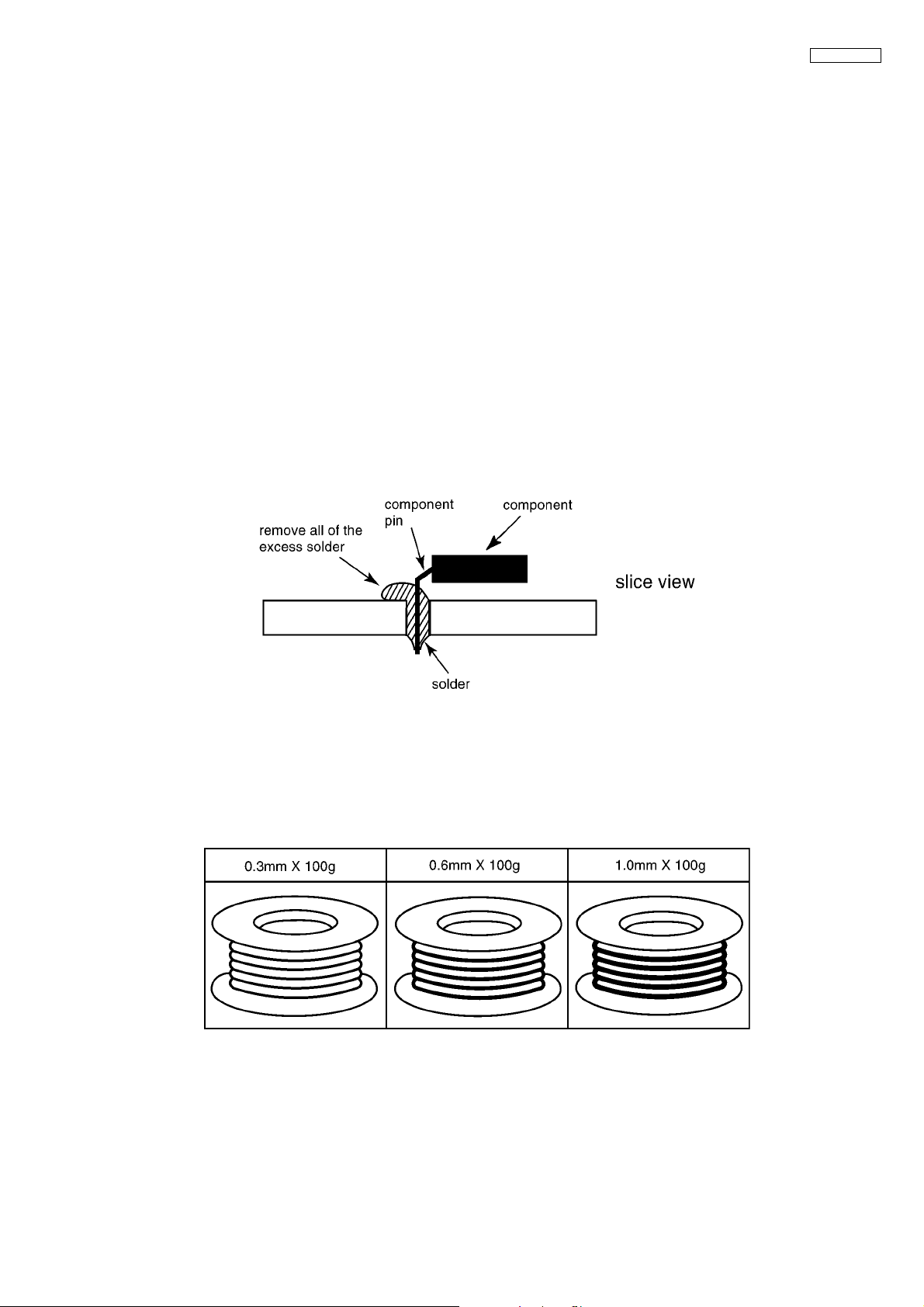

2.1. ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin, (Sn),

Silver, (Ag), and Copper, (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

• PbF solder has a melting point that is 50° ~ 70° F, (30° ~ 40°C) higher than Pb solder. Please use a soldering iron with temperature control and adjust it to 700° ± 20° F, (370° ± 10°C). In case of using high temperature soldering iron, please be careful not to

heat too long.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F, (600°C).

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible and

be sure that any remaining is melted prior to applying the Pb solder.

• When applying PbF solder to double layered bo ards, please check the component side for excess which may flow onto the

opposite side (See figure, below).

2.1.1. SUGGESTED PBF SOLDER

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper,

(Sn+Ag+Cu), you can also use Tin and Copper, (Sn+Cu), or Tin, Zinc, and Bismuth, (Sn+Zn+Bi). Please check the manufacturer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

2.2. Discarding of P. C. Board

When discarding P. C. Board, delete all personal information such as telephone directory and caller list or scrap P. C. Board.

5

KX-MB283BR

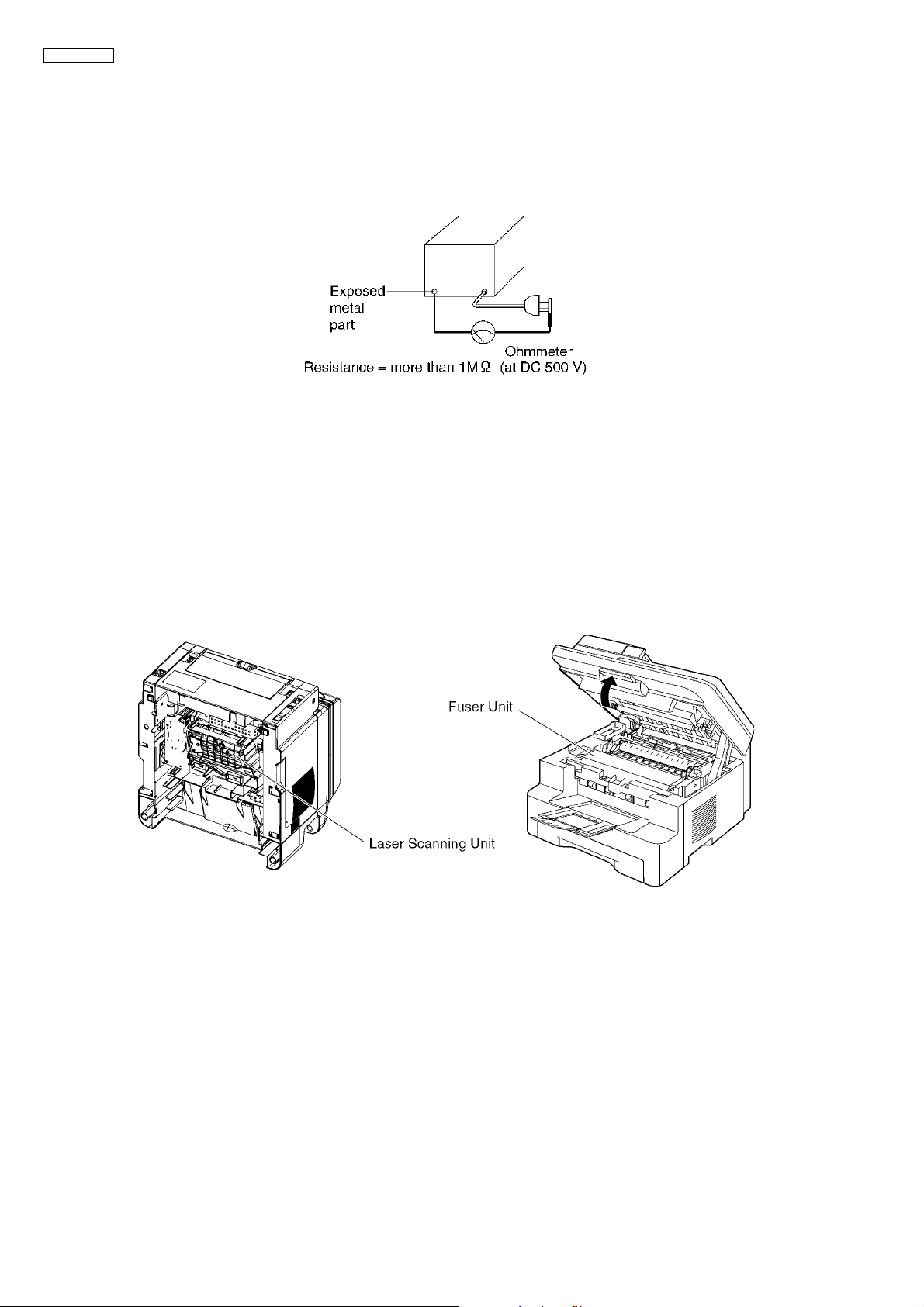

2.3. INSULATION RESISTANCE TEST

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the pow e r switch .

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part

(screw heads, control shafts, bottom frame, etc.).

Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

2.4. BATTERY CAUTION

CAUTION

Danger of explosion if the battery is replaced incorrectly. Replace only with the same or equivalent type recommended by the

manufacturer. Dispose used batteries according to the manufacturer’s instructions:

The lithium battery is a critical component (typ e No.CR2354). Please observe for the proper pol arity and exact location when

replacing it and the soldering the replacement litium battery in.

2.5. LASER BEAM AND FUSER UNIT SECTION

• The printer of this unit utilizes a laser. Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• The fuser unit is inside of the unit and gets hot. Do not touch it when removing the jammed paper or cleaning the lower glass.

6

3 Specifications

Applicable Lines: Public Switched Telephone Network

Document Size: Max. 216 mm in width

Effective Scanning Width: 208 mm

Effective Printing Width: Letter/ Legal: 208 mm

Tran sm ission Time*: Approx. 4 s/page (ECM-MMR Memory transmission)**

Scanning Density: Scanning resolution:

Photo resolution: 64-level

Scanner Type: Color Contact Image Sensor

Printer Type: Laser printer

Data Compression System: Modified Huffman (MH), Modified READ (MR), Modified Modified READ (MMR)

Operating Environment: 10 °C—32.5 °C, 20—70 % RH (Relative Humidity)

Dimensions: Approx. height 305 mm × width 420 mm × depth 445 mm

Mass (Weight): Approx. 13 kg

Power Consumption: Standby: Approx. 5.5 W

Power Supply: 127V AC, 60Hz

Memory Capacity (for operation and

storing memory):

Laser diode properties: Laser output: Max. 5 mW

Print Speed: Approx. 18 ppm (pages per minute)

Printing Resolution: 600 × 600 dpi

Max. 600 mm in length

A4: 202 mm

Up to 600 × 1,200 dpi (Optical)

Up to 9,600 × 9,600 dpi (Interpolated)

Copy resolution:

Up to 600 × 600 dpi (Scanner Glass)

Up to 600 × 300 dpi (Auto Document Feeder)

Preheat: Approx. 65 W

Copy: Approx. 320 W

Maximum: Approx. 900 W (When the fuser lamp turns on)

32 MB

Wave length: 760 nm—810 nm

Emission duration: Continuous

KX-MB283BR

* Transmission speed depends on the contents of the pages, resolution, telephone line conditions and capability of the other party’s

machine.

** Transmission speed is based on the ITU-T No. 1 Test Chart with original mode. (Refer to ITU-T No.1 TEST CHART (P.196).) If

the capability of the other party's machine is inferior to your unit, the transmission time may be longer.

Note:

• Design and specifications are subject to change without notice.

• The pictures and illustrations in these instructions may vary slightly from the actual product.

• The accuracy of the clock is approximately ±60 seconds a month.

7

KX-MB283BR

4 General/Introduction

4.1. OPTIONAL ACCESSORIES

Model No. Description Specifications

KX-FAT92A Replacement toner cartridge 1 toner cartridge

KX-FAD93A Replacement drum unit 1 drum unit

8

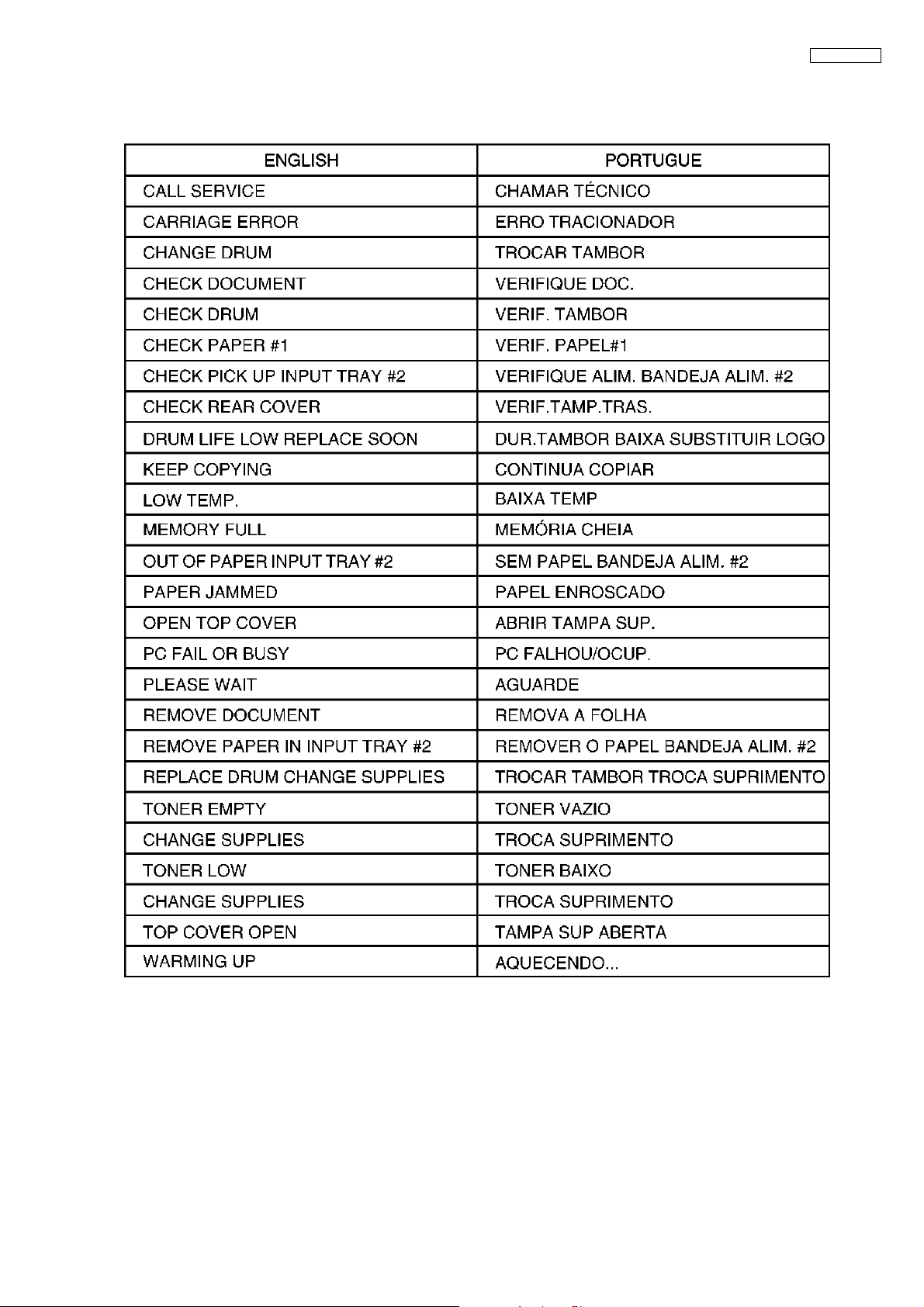

4.2. Translation Lists

4.2.1. Error Message (Display)

KX-MB283BR

9

KX-MB283BR

5Features

5.1. General Features

General

• LCD (Liquid Crystal Display) readout

250-sheet paper capacity (60 g/m

Distinctive ring detection.

2

~ 75 g/m2)

Plain Paper Facsimile Machine

Output tray (approx. 150 sheets)

Letter/A4/Legal, G3 compatible

Automatic document feeder (Up to 20 sheets)

Quick scan

Resolution: Standard/Fine/Super fine/Photo (64 level).

STANDARD: For normal-sized characters.

FINE: For small-sized characters.

SUPER FINE: For very small-sized characters.

PHOTO: For photographs, shaded drawings, etc.

Broadcast

Large Memory... Performed by DRAM

Approx. 150 pages of memory transmission

Approx. 170 pages of memory reception

Enhanced Copier Function

Multi-copy function (up to 99 copies)

Enlargement and reduction

Collate

64-Level halftone

5.2. HARDWARE REQUIREMENTS FOR MULTI-FUNCTION SOFTWARE

To use Multi-Function Station on your computer, the following are required:

Operating System:

Windows 98 / Windows Me / Windows 2000 / Windows XP / Windows Vista

CPU:

Windows 98: Pentium® 90 MHz or faster

Windows Me: Pentium 150 MHz or faster

Windows 2000: Pentium 166 MHz or faster

Windows XP: Pentium 300 MHz or faster

Windows Vista: Recent Processor (x86) 800 MHz or higher processor

RAM:

Windows 98: 24 MB (32 MB or more recommended)

Windows Me: 32 MB (64 MB or more recommended)

Windows 2000: 64 MB or more

Windows XP: 128 MB or more

Windows Vista: 512 MB or more

Other Hardware:

CD-ROM drive

Hard disk drive with at least 150 MB of available space

USB interface

LAN interface (10Base-T / 100Base-TX)

Other:

Internet Explorer® 5.0 or later

TM

operating system

10

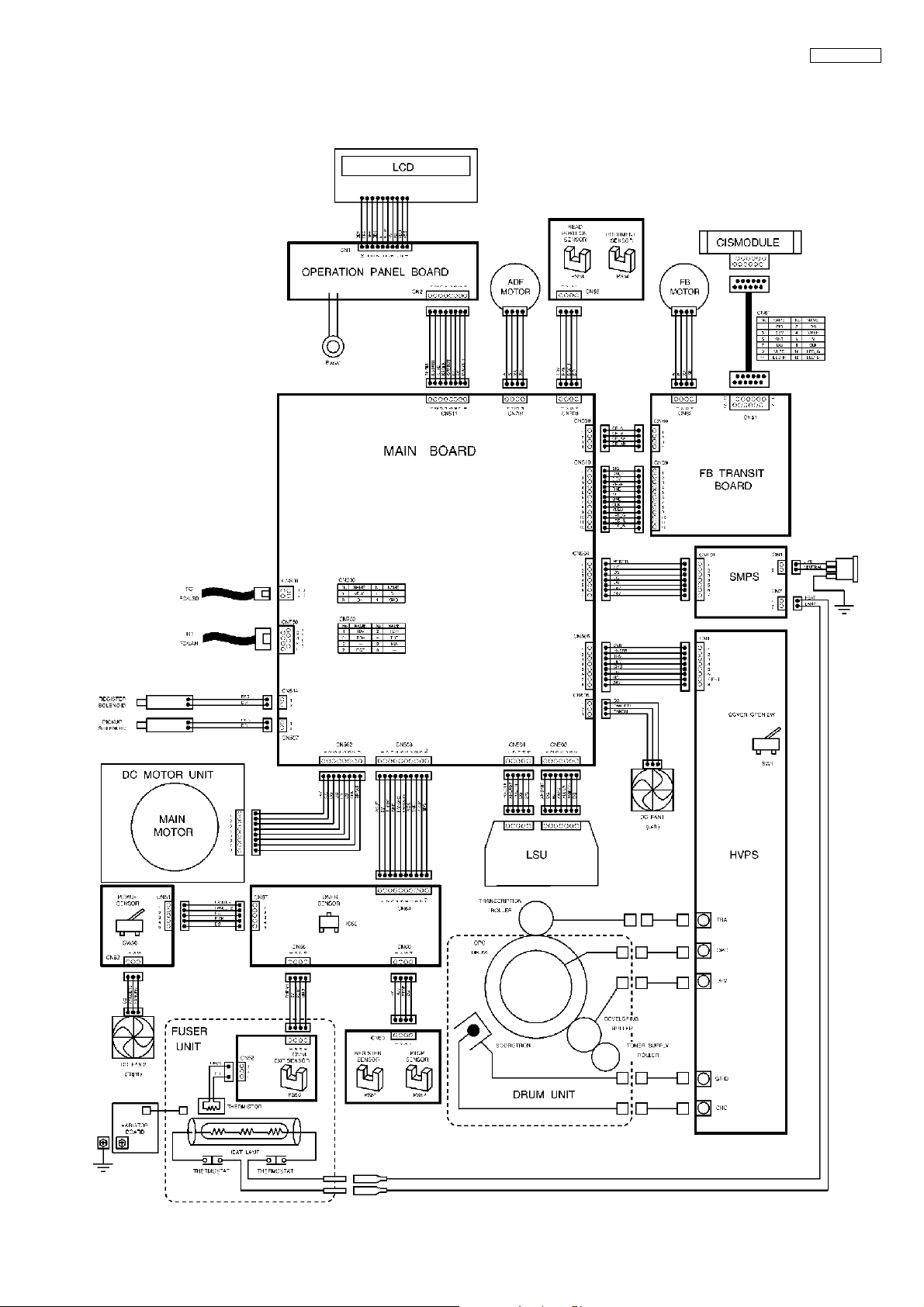

6 Technical Descriptions

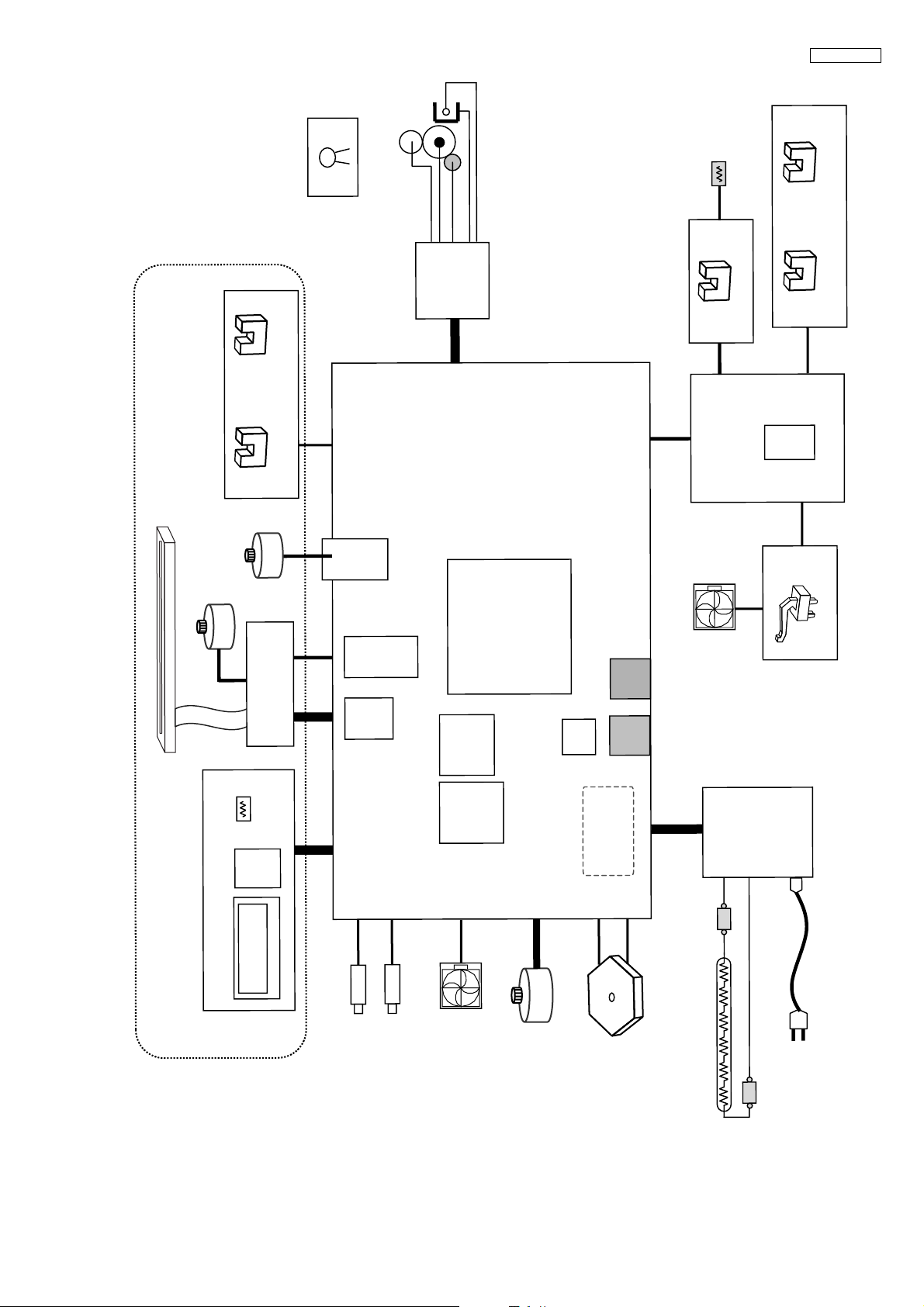

6.1. CONNECTION DIAGRAM

KX-MB283BR

11

KX-MB283BR

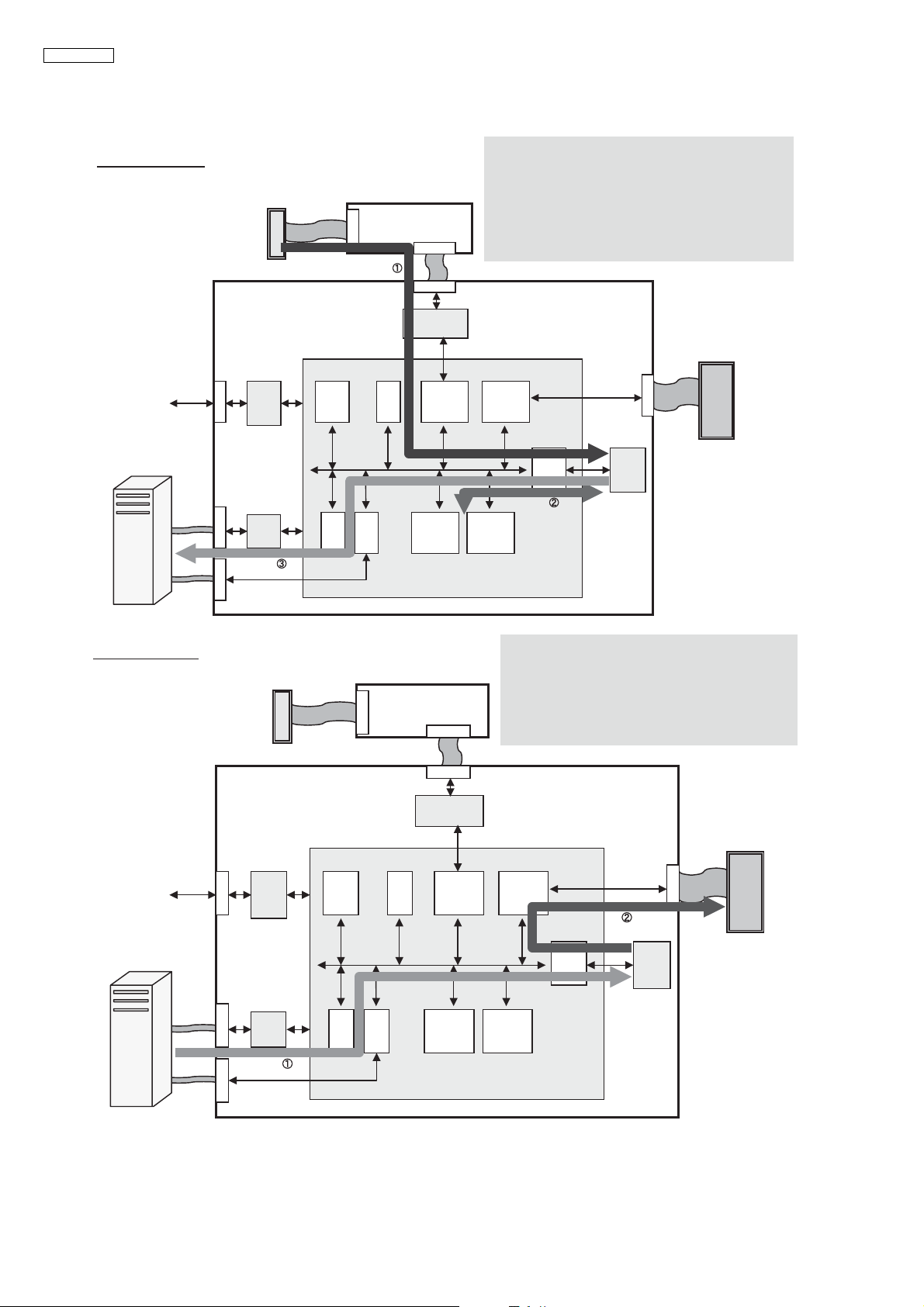

6.2. GENERAL BLOCK DIAGRAM

MAIN UNIT

SOC (IC300)

This custom IC is used for general MFP operations.

1) CPU ARM9 operating at 250MHz.

2) SDRAM Controller Controls SDRAM Memory.

3) USB Controller with PHY Apply to USB2.0 HS

4) Scanner I/F Controls the CIS and AFE, and process the scan images.

5) LSU I/F Controls the polygon motor and outputs the VIDEO signal to LSU.

6) MOTOR I/F Controls the DC motor and Stepping Motor.

7) FAN I/F Controls FAN MOTOR and detect the rotation of FAN MOTOR.

8) OPERATION PANEL I/F Serial interface with Operation Panel.

9) SENSOR I/F Detects the sensor signal.

10) I/O PORT I/O Port Interface.

11) A/D, D/A converter Sends beep tones, etc.

Convert the analog signal to the digital signal.

12) RTC Real time clock.

15) LAN Controller Ethernet Control.

ROM (IC402)

This 8MB FLASH ROM contains all of the program instructions on the unit operations.

SYNCHRONOUS DYNAMIC RAM (IC400)

This 256Mbit SDRAM is used for CPU work and receiving memory and page memory.

POWER SUPPLY

DC-DC converters generate 3.3V and 1.2V for system power.

Regurator generates 5V for peripheral devices.

READ SECTION

CIS Unit to read transmitted documents.

CIS Unit is connected to FLATBED transit Unit.

Scan data is converted by AFE(IC503).

MOTOR

This model has 1 DC motor and 2 stepping motors.

IC300 drives the DC motor for printing.

IC502 and IC700 drive the stepping motor for Auto Document Feeder motor and CIS carriage.

LSU

Forms the images on the OPC DRUM by rotating polygon motor and reflecting the laser beam against polygon.

SENSORS

Composed of 2 switches and 5 sensors.

POWER SUPPLY BOARD

Supplies +24V and +7V to the Main unit and controls the Heat Lamp.

HIGH VOLTAGE POWER SUPPLY BOARD

Supplies bias need for the printing operation: bias of the DRUM, Developing and Transcription.

FIXING UNIT

Composed heat lamp, thermistor and thermostats.

12

Varistor

Thermistor

KX-MB283BR

ePTOP S nsor

ater)

(He

CN52

or

Sens

tr

HVU

CN1

nRP Se sor

sor

CN56

CN700

CN505

8

CN50

Document Sen

t)

r (righ

AN moto

F

CN300

ADF motor

CN701

Motor

Driver

(ADF)

IC700

ge motor

Carria

er

CN60

Color CIS

nsit

CN509

Motor

Driv

(FB)

IC502

SoC

(sirius

IC300

Lite)

USB

IT SensorEX

CN53

CN65

CN64

Hole

CN63

egis e

R

CN50

CN66

or

IC

IC50

oner Sens

T

CN67

51

CN

p Sensor

Pick U

ed

ed

Flat B

Flat B

ard

Ope

2Line

eration Panel Bo

Op

CN61 CN62

Thermistor

G/A

LCD

FB Tra

CN59

(Room)

CN2

IC1

510

CN

AFE

IC503

ard

Main Bo

CN511

CN507

CN514

)

bit

IC400

(256M

SDRAM

)

FLASH

(32/64Mbit

CN506

IC402

Phy

LAN

0

CN75

t

CN504

CONVERTER

DC-DC

CN500

CN502

CN501

CN101

SWPS

inle

AC

Thermostat

rd set

AC co

lenoid

Resist So

DC motor

Pick-up Solenoid

FAN motor (left)

lygon motor

Po

(LSU)

Heater lamp

ostat

Therm

13

KX-MB283BR

6.3. MAIN BOARD SECTION

6.3.1. Data Flow

[PC Scan]

CISunit

CN61

FB transit Board

CN59

1. An analog image data is output from CISunit to IC503.

IC503 decode the analog data to digital data, and output to IC300.

Scanner I/F in IC300 process image data and store it in IC400

through SDRAM I/F.

2. If necessary, the data is compressed via DSP.

3. When you use the LAN, the data is output to PC

through the LAN I/F and PHY(IC750).

When you use the USB, the data is output to PC

through the USB I/F.

TEL

LINE

PC

LAN

USB

[PC print]

Main Board

IC100

IC101

DAA

CN100

IC750

PHY

CN750

CN300

CISunit

MODEM

LAN

I/F

USB

I/F

CPU

CN61

CN510

AFE

Scanner

I/F

FB transit Board

CN59

IC503

IC300

Print I/F

IC400

SDRAM

I/F

DSPJBIG

SDRAM

1.The print data is output from PC through LAN

and pass the PHY(IC750) and LAN I/F in IC300.

or

The print data is output from PC through USB

and pass the USB I/F in IC300.

then the data is stored in IC400 through SDRAM I/F.

Print I/F retrieve the data from IC400 and output it to LSU.

2.

LSU

CN500

PC

TEL

LINE

LAN

USB

Main Board

IC100

IC101

DAA

CN100

IC750

PHY

CN750

CN300

MODEM

LAN

I/F

USB

I/F

CPU

CN510

AFE

Scanner

IC503

IC300

DSPJBIG

Print I/F

SDRAM

I/F

I/F

CN500

IC400

SDRAM

LSU

14

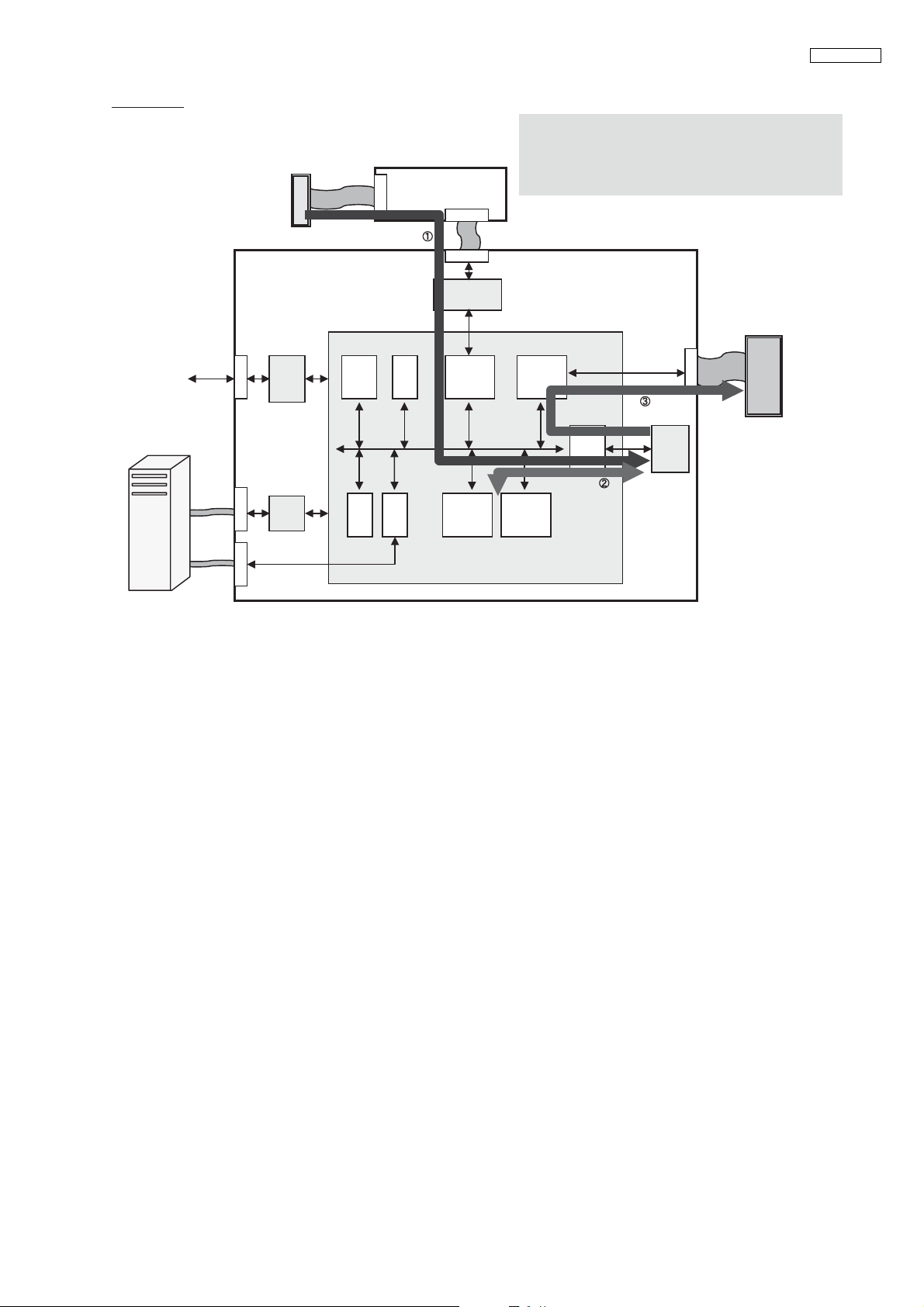

[Copy]

CISunit

CN61

FB transit Board

CN59

1. An analog image data is output from CISunit to IC503.

IC503 decode the analog data to digital data, and output to IC300.

Scanner I/F in IC300 process image data and store it in IC400

through SDRAM I/F.

2. If necessary, the data is compressed via JBIG.

3. Print I/F retrieve the data from IC400 and output it to LSU.

KX-MB283BR

PC

TEL

LINE

LAN

USB

Main Board

IC100

IC101

DAA

CN100

IC750

PHY

CN750

CN300

MODEM

LAN

I/F

USB

I/F

CPU

CN510

AFE

Scanner

I/F

IC503

DSPJBIG

Print I/F

IC300

SDRAM

I/F

LSU

CN500

IC400

SDRAM

15

KX-MB283BR

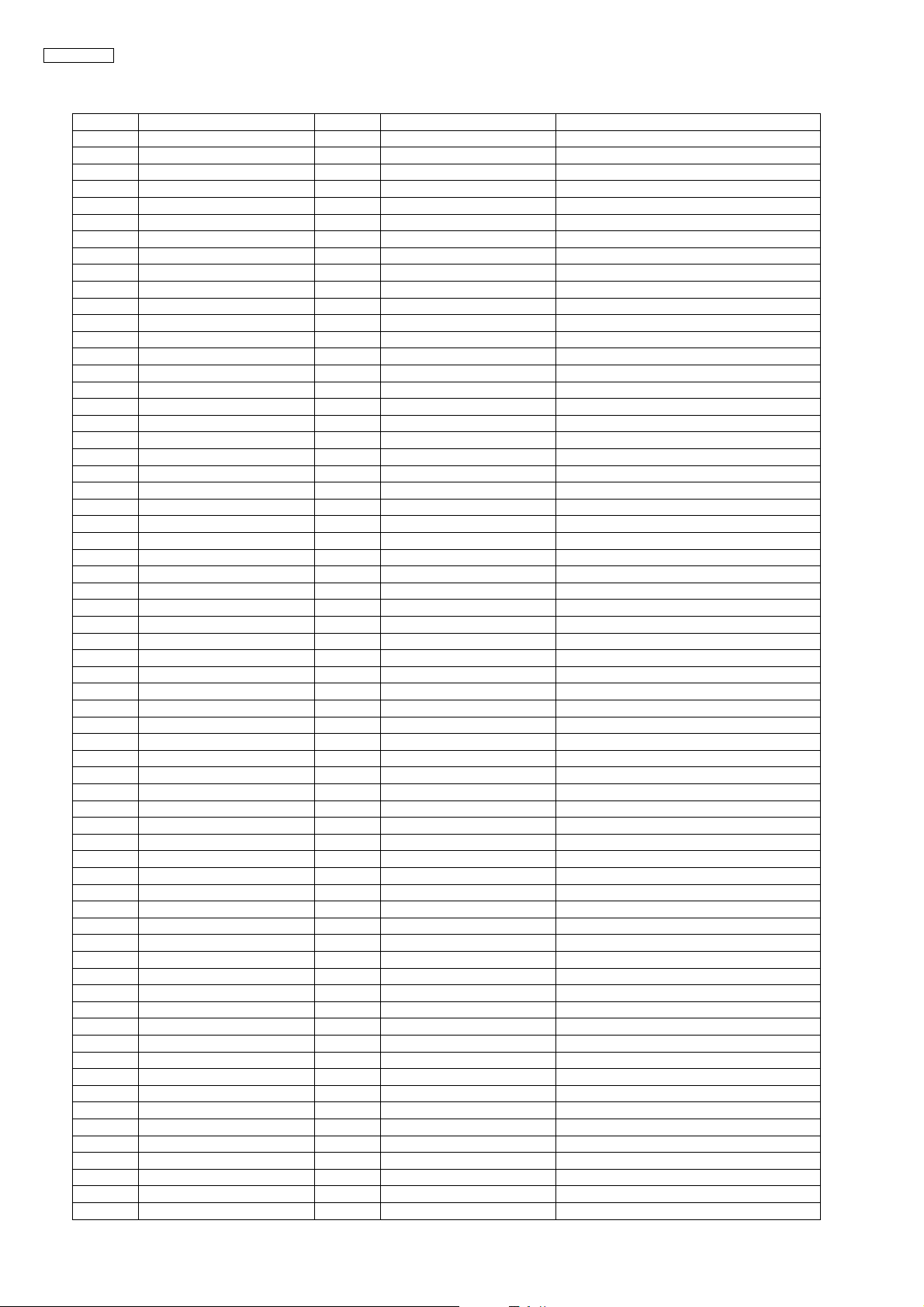

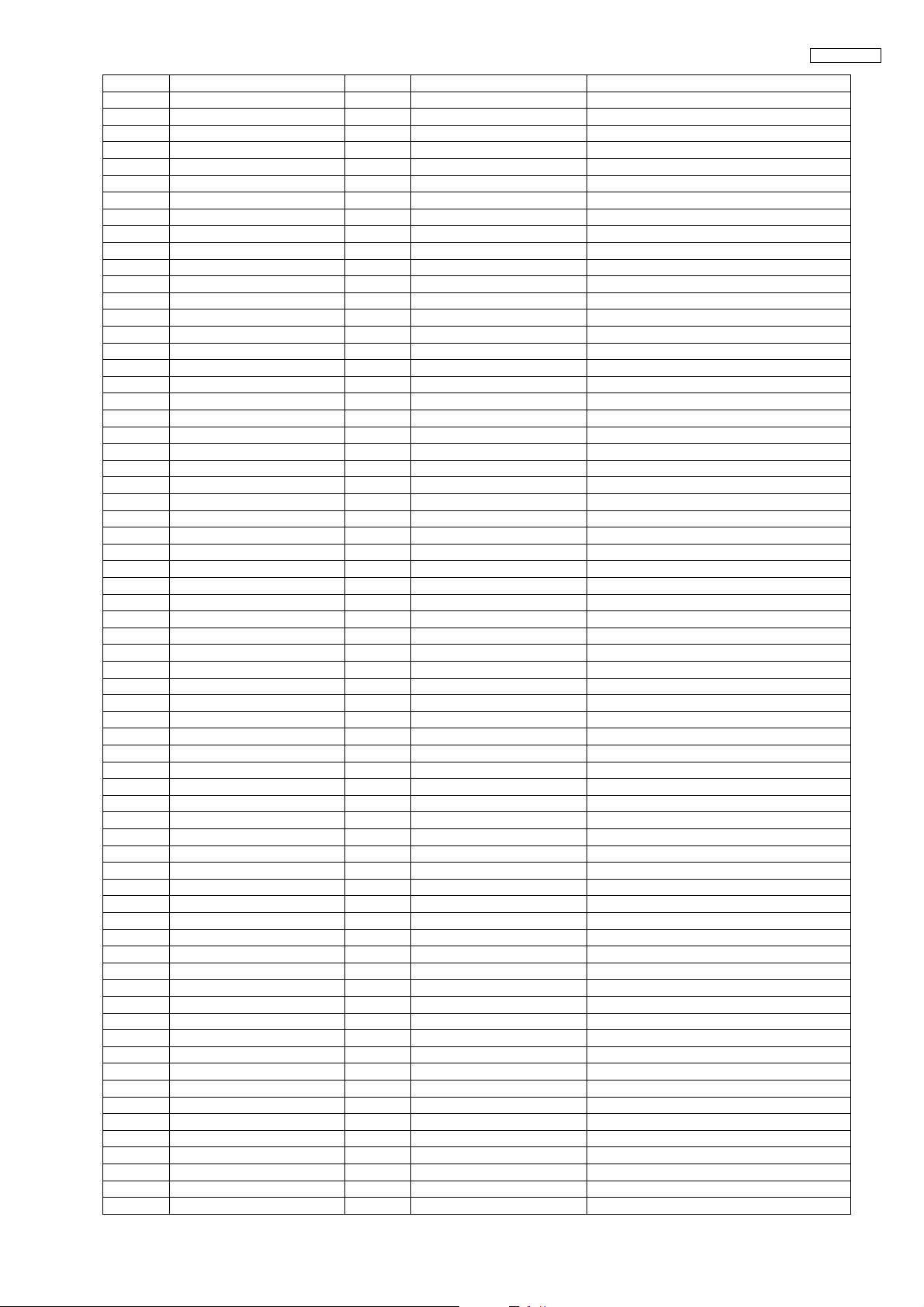

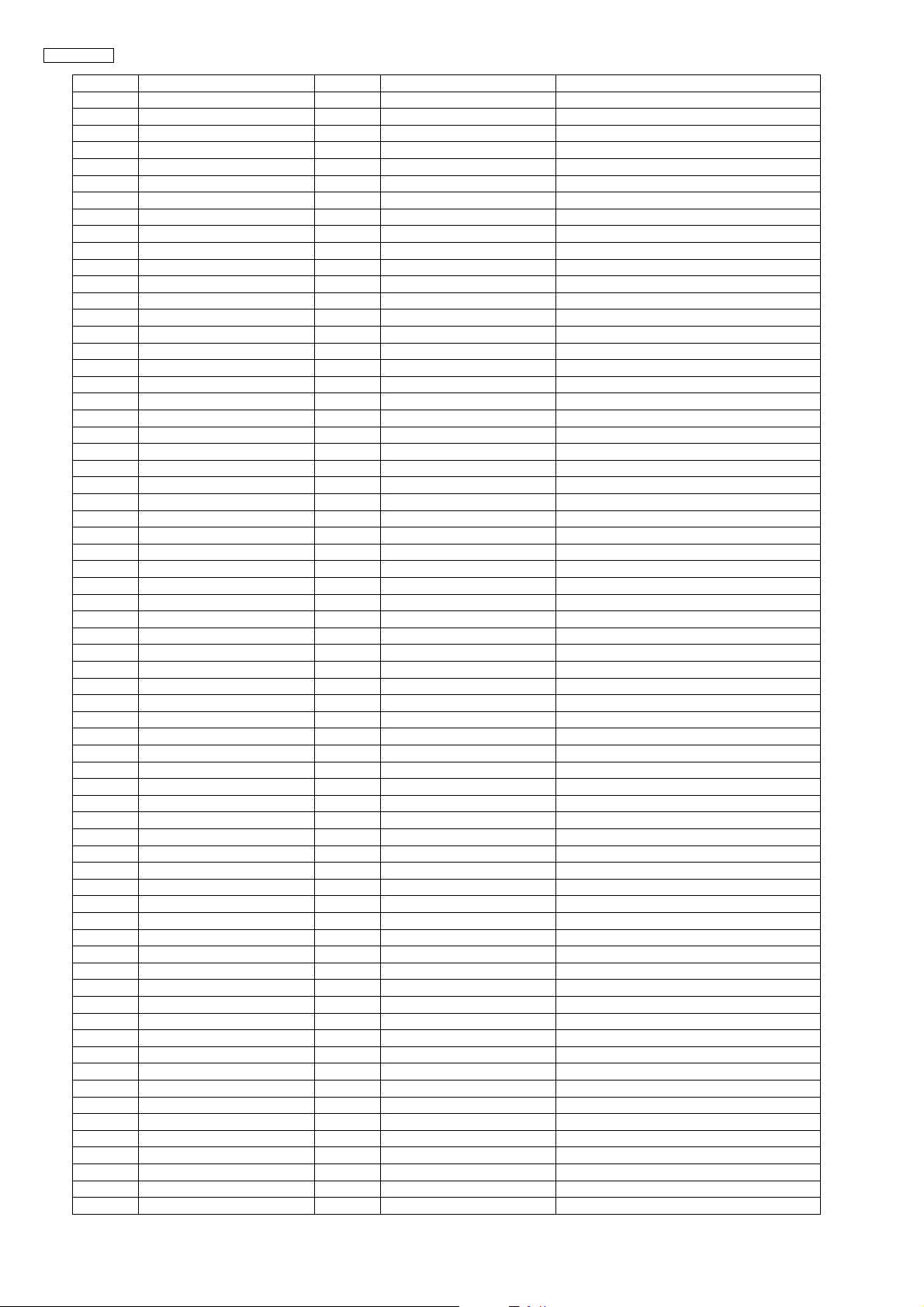

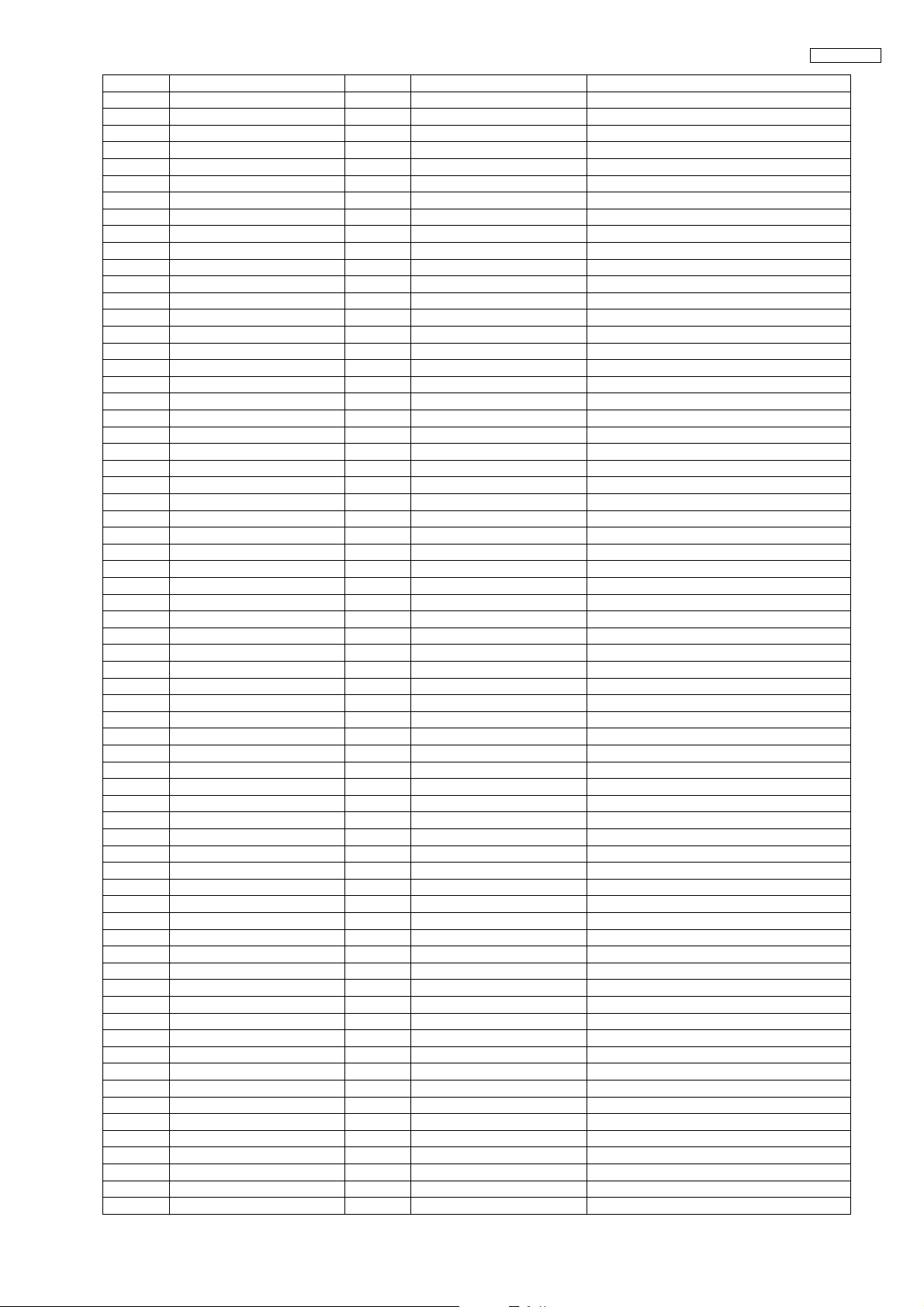

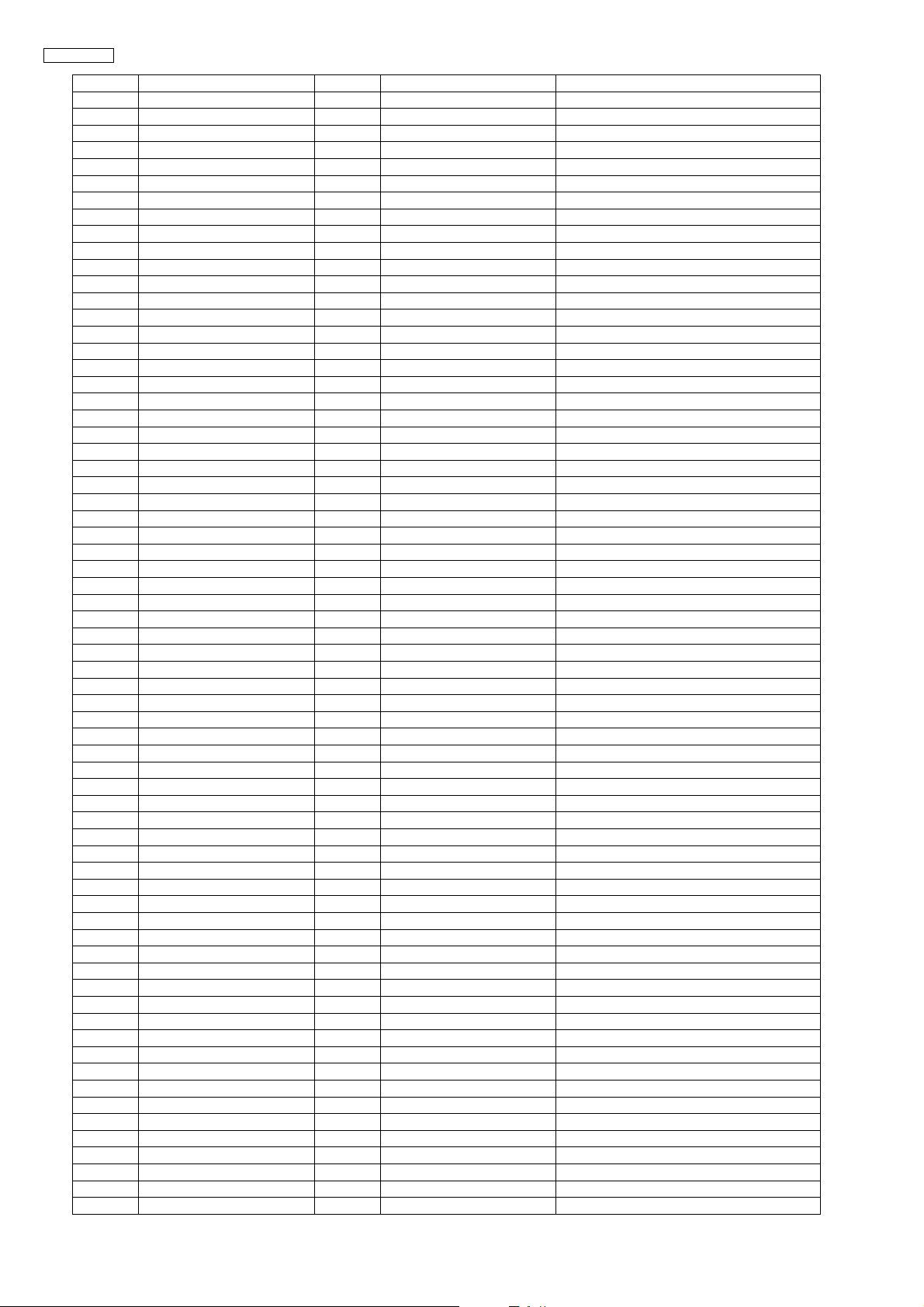

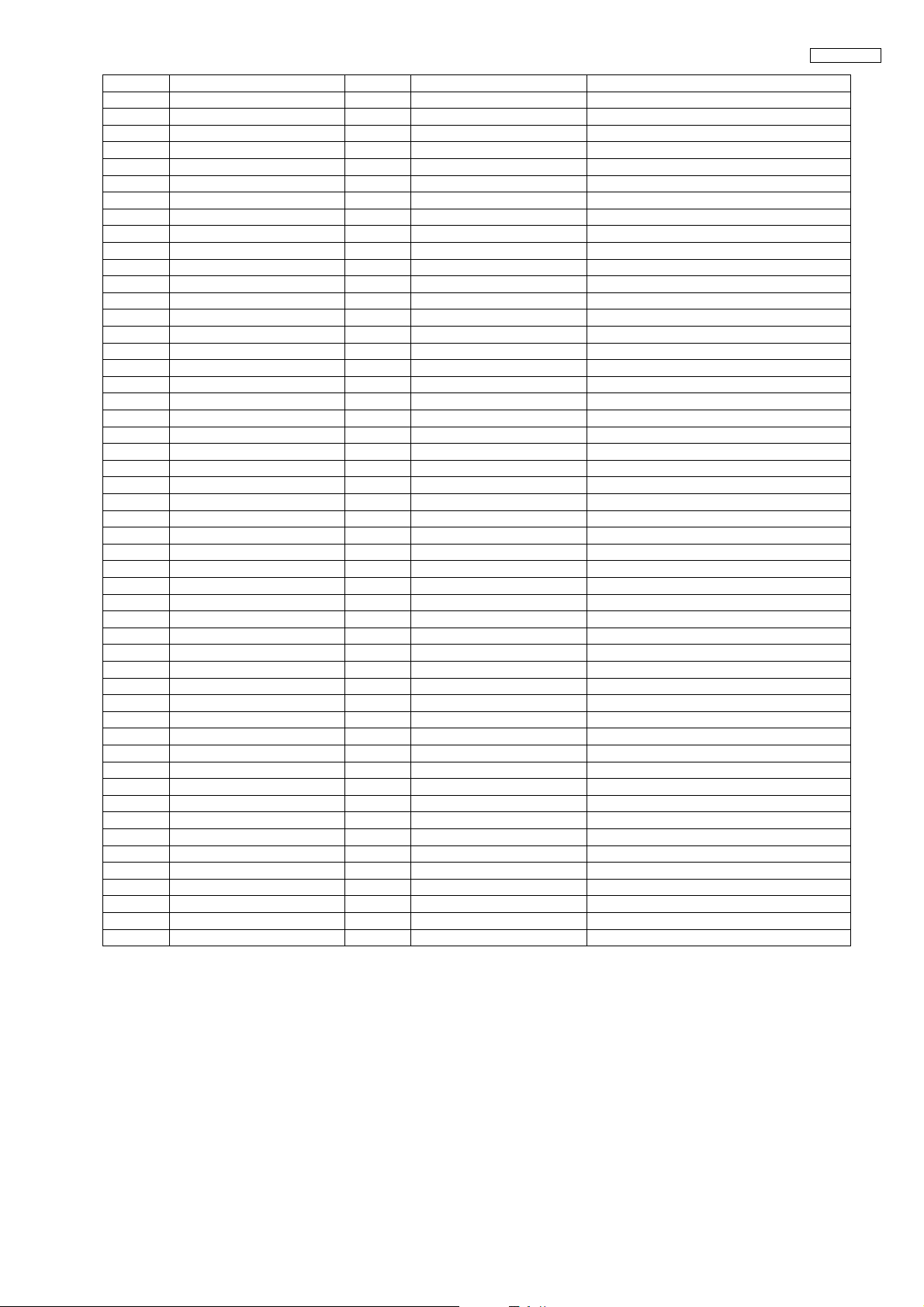

Description of Pin Distribution (IC300) SOC (System On Chip)

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

A02 LEDONB O 3.3V SCANNER INTERFACE

A03 NCCDON O 3.3V SCANNER INTERFACE

A04 AFEMCLK O 3.3V SCANNER INTERFACE

A05 NCCDCP O 3.3V NOT USED

A06 CCDCLK O 3.3V NOT USED

A07 PIO29 O 3.3V OPERATION PANEL INTERFACE

A08 PIO57 O 3.3V CARRIAGE MOTOR INTERFACE

A09 PIO53 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

A10 PIO50 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

A11 PIO46 O 3.3V FAN1 CONTROL

A12 PIO42 O 3.3V DC MOTOR INTERFACE

A13 NFRCE O 3.3V FLASH MEMORY CHIP SELECT

A14 FRMD0 I/O 3.3V FLASH MEMORY DATA BUS 0

A15 FRMD3 I/O 3.3V FLASH MEMORY DATA BUS 3

A16 FRMD7 I/O 3.3V FLASH MEMORY DATA BUS 7

A17 FRMA3 O 3.3V FLASH MEMORY ADDRESS BUS 3

A18 FRMA6 O 3.3V FLASH MEMORY ADDRESS BUS 6

A19 FRMA10 O 3.3V FLASH MEMORY ADDRESS BUS 10

A20 THRMAVDD - 3.3V POWER SUPPLY

A21 FRMA11 O 3.3V FLASH MEMORY ADDRESS BUS 11

A22 FRMA15 O 3.3V FLASH MEMORY ADDRESS BUS 15

A23 FRMA17 O 3.3V FLASH MEMORY ADDRESS BUS 17

A24 FRMA20 O 3.3V FLASH MEMORY ADDRESS BUS 20

A25 FRMA22 O 3.3V FLASH MEMORY ADDRESS BUS 22

AA01 SDMD8 I/O 3.3V SDRAM DATA BUS 8

AA02 SDMD9 I/O 3.3V SDRAM DATA BUS 9

AA03 SDMA7 O 3.3V SDRAM ADDRESS BUS 7

AA04 SDMA6 O 3.3V SDRAM ADDRESS BUS 6

AA23 VDD1.2 - 1.2V POWER SUPPLY

AA24 AFERST O 3.3V NCU INTERFACE

AA25 RING I 3.3V NCU INTERFACE

AA26 EXTINT I 3.3V NCU INTERFACE

AB01 SDMD10 I/O 3.3V SDRAM DATA BUS 10

AB02 SDMD11 I/O 3.3V SDRAM DATA BUS 11

AB03 SDMA5 O 3.3V SDRAM ADDRESS BUS 5

AB04 VDD1.2 - 1.2V POWER SUPPLY

AB23 VSS - GND GND

AB24 BTXD O 3.3V NCU INTERFACE

AB25 BRXD I 3.3V NCU INTERFACE

AB26 AFECLK O 3.3V NCU INTERFACE

AC01 SDMD12 I/O 3.3V SDRAM DATA BUS 12

AC02 SDMD13 I/O 3.3V SDRAM DATA BUS 13

AC03 SDMA4 O 3.3V SDRAM ADDRESS BUS 4

AC04 VSS - GND GND

AC05 VSS - GND GND

AC06 VDD1.2 - 1.2V POWER SUPPLY

AC07 TXD0 O 3.3V ETHERNET INTERFACE

AC08 TX_ER O 3.3V ETHERNET INTERFACE

AC09 RXD1 I 3.3V ETHERNET INTERFACE

AC10 VDD3.3 - 3.3V POWER SUPPLY

AC11 TEST I 3.3V NOT USED

AC12 USBREXT I 3.3V USB INTERFACE

AC13 VDD1.2 - 1.2V POWER SUPPLY

AC14 VDD3.3 - 3.3V POWER SUPPLY

AC15 USBXIN I 3.3V CRYSTAL(12MHz) INPUT

AC16 LSI_SCAN_ENABLE I 3.3V NOT USED

AC17 VDD1.2 - 1.2V POWER SUPPLY

AC18 NWDTRST O 3.3V WATCH DOG TIMER RESET OUTPUT

AC19 LSI_TN I 3.3V NOT USED

AC20 PSCIO2 I 3.3V INPUT PORT (FANDET1)

AC21 PSCIO6 O 3.3V NOT USED

AC22 VDD1.2 - 1.2V POWER SUPPLY

AC23 VSS - GND GND

AC24 ATXD O 3.3V NCU INTERFACE

AC25 BBITCLK I/O 3.3V NCU INTERFACE

16

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

AC26 BSPCLK I/O 3.3V NCU INTERFACE

AD01 SDMD14 I/O 3.3V SDRAM DATA BUS 14

AD02 SDMD15 I/O 3.3V SDRAM DATA BUS 15

AD03 VSS - GND GND

AD04 NBATRST I 3.3V BATTERY RESET INPUT

AD05 VDD2RTC - 1.2V POWER SUPPLY

AD06 CRS I 3.3V ETHERNET INTERFACE

AD07 TXD1 O 3.3V ETHERNET INTERFACE

AD08 RX_DV I 3.3V ETHERNET INTERFACE

AD09 RXD2 I 3.3V ETHERNET INTERFACE

AD10 RX_ER I 3.3V ETHERNET INTERFACE

AD11 CLKSEL I 3.3V NOT USED

AD12 USBVSSA33_BIAS - GND GND

AD13 USBVSSA33 - GND GND

AD14 USBVDDA12_SQ - 1.2V POWER SUPPLY

AD15 USBVSSA12 - GND GND

AD16 LSI_TRSTN I 3.3V NOT USED

AD17 LSI_TDO O 3.3V NOT USED

AD18 NRST I 3.3V SYSTEM RESET INPUT

AD19 HTRCTL O 3.3V HEATER CONTROL

AD20 PSCIO3 I 3.3V INPUT PORT (POUT)

AD21 PSCIO7 O 3.3V NOT USED

AD22 PSCIO15 I 3.3V INPUT PORT (RPS)

AD23 NC - - NOT USED

AD24 VSS - GND GND

AD25 ASPCLK I/O 3.3V NCU INTERFACE

AD26 ARXD I 3.3V NCU INTERFACE

AE01 SDLDM1 O 3.3V SDRAM DQML1

AE02 VSS - GND GND

AE03 SYSPLLVSS1 - GND GND

AE04 RTCCLKOUT O 3.3V CRYSTAL(32.768KHz) OUTPUT

AE05 RTCPWRDWN I 3.3V RTC POWER DOWN

AE06 TX_CLKI I 3.3V ETHERNET INTERFACE

AE07 TXD2 O 3.3V ETHERNET INTERFACE

AE08 RX_CLKI I 3.3V ETHERNET INTERFACE

AE09 RXD3 I 3.3V ETHERNET INTERFACE

AE10 MDC O 3.3V ETHERNET INTERFACE

AE11 NC - - NOT USED

AE12 USBID O 3.3V NOT USED

AE13 USBDM I/O 3.3V USB INTERFACE

AE14 USBVSSA12_SQ - GND GND

AE15 USBVDDA12PLL - 1.2V POWER SUPPLY

AE16 USBVDDA12 - 1.2V POWER SUPPLY

AE17 LSI_TDI I 3.3V NOT USED

AE18 LSI_PROCMON O 3.3V NOT USED

AE19 LSI_IDDT I 3.3V NOT USED

AE20 PSCIO1 I 3.3V INPUT PORT (PICK)

AE21 PSCIO5 O 3.3V NOT USED

AE22 PSCIO13 I 3.3V INPUT PORT (TNR)

AE23 MDMCLKOUT O 3.3V CRYSTAL(24.576MHz) OUTPUT

AE24 MDMPLLVDD - 3.3V POWER SUPPLY

AE25 VSS - GND GND

AE26 ABITCLK I/O 3.3V NCU INTERFACE

AF02 SYSPLLVDD1 - 3.3V POWER SUPPLY

AF03 VDD3.3OSC - 3.3V POWER SUPPLY

AF04 RTCCLKIN I 3.3V CRYSTAL(32.768KHz) INPUT

AF05 COL I 3.3V ETHERNET INTERFACE

AF06 TX_EN O 3.3V ETHERNET INTERFACE

AF07 TXD3 O 3.3V ETHERNET INTERFACE

AF08 RXD0 I 3.3V ETHERNET INTERFACE

AF09 MDIO I/O 3.3V ETHERNET INTERFACE

AF10 MGTINT I 3.3V ETHERNET INTERFACE

AF11 USBVBUS O 3.3V USB INTERFACE

AF12 USBVDDA33_BIAS - 3.3V POWER SUPPLY

AF13 USBDP I/O 3.3V USB INTERFACE

AF14 USBVDDA33 - 3.3V POWER SUPPLY

AF15 USBVSSA12PLL - GND GND

KX-MB283BR

17

KX-MB283BR

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

AF16 USBXOUT I 3.3V CRYSTAL(12MHz) OUTPUT

AF17 LSI_TMS I 3.3V NOT USED

AF18 LSI_TCK I 3.3V NOT USED

AF19 LSI_CW_TAP I 3.3V NOT USED

AF20 PSCIO0 I 3.3V INPUT PORT (REGIST)

AF21 PSCIO4 O 3.3V NOT USED

AF22 PSCIO12 I 3.3V INPUT PORT (POUT)

AF23 PSCIO14 I 3.3V INPUT PORT (DOCU)

AF24 MDMCLKIN I 3.3V CRYSTAL(24.576MHz) INPUT

AF25 MDMPLLVSS - GND GND

B01 AFEADC0 I 3.3V NOT USED

B02 VSS - GND GND

B03 LEDONG O 3.3V SCANNER INTERFACE

B04 AFERSMP O 3.3V NOT USED

B05 AFEVSMP O 3.3V SCANNER INTERFACE

B06 NCCDRS O 3.3V SCANNER INTERFACE

B07 PIO30 I/O 3.3V OPERATION PANEL INTERFACE

B08 MMPWR O 3.3V NOT USED

B09 PIO54 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

B10 PIO51 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

B11 PIO47 O 3.3V NOT USED

B12 PIO43 O 3.3V DC MOTOR INTERFACE

B13 NFROE O 3.3V FLASH MEMORY CHIP OUTPUT ENABLE

B14 FRMD1 I/O 3.3V FLASH MEMORY DATA BUS 1

B15 FRMD4 I/O 3.3V FLASH MEMORY DATA BUS 4

B16 FRMA0 O 3.3V FLASH MEMORY ADDRESS BUS 0

B17 FRMA4 O 3.3V FLASH MEMORY ADDRESS BUS 4

B18 FRMA7 O 3.3V FLASH MEMORY ADDRESS BUS 7

B19 THRMAVSS - GND GND

B20 TONE O 3.3V ANALOG(TONE) OUTPUT

B21 FRMA12 O 3.3V FLASH MEMORY ADDRESS BUS 12

B22 FRMA16 O 3.3V FLASH MEMORY ADDRESS BUS 16

B23 FRMA19 O 3.3V FLASH MEMORY ADDRESS BUS 19

B24 FRMA21 O 3.3V FLASH MEMORY ADDRESS BUS 21

B25 VSS - GND GND

B26 DOTPLLVSS - GND GND

C01 AFEADC3 I 3.3V NOT USED

C02 AFEADC1 I 3.3V NOT USED

C03 VSS - GND GND

C04 LEDONR O 3.3V SCANNER INTERFACE

C05 OEB O 3.3V NOT USED

C06 CCDSH O 3.3V SCANNER INTERFACE

C07 PIO31 O 3.3V OPERATION PANEL INTERFACE

C08 OPMPWR O 3.3V NOT USED

C09 PIO55 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

C10 PIO52 O 3.3V CARRIAGE/ADF MOTOR INTERFACE

C11 PIO49 O 3.3V OUTPUT PORT(HSSPMUTE)

C12 PIO45 O 3.3V DC MOTOR INTERFACE

C13 NFRWE O 3.3V FLASH MEMORY CHIP WRITE ENABLE

C14 FRMD2 I/O 3.3V FLASH MEMORY DATA BUS 2

C15 FRMD6 I/O 3.3V FLASH MEMORY DATA BUS 6

C16 FRMA2 O 3.3V FLASH MEMORY ADDRESS BUS 2

C17 FRMA5 O 3.3V FLASH MEMORY ADDRESS BUS 5

C18 FRMA9 O 3.3V FLASH MEMORY ADDRESS BUS 9

C19 THRMSTR0 I 3.3V ANALOG INPUT(THERMISTOR)

C20 TONEAVDD - 3.3V POWER SUPPLY

C21 FRMA14 O 3.3V FLASH MEMORY ADDRESS BUS 14

C22 FRMA18 O 3.3V FLASH MEMORY ADDRESS BUS 18

C23 FRMA23 O 3.3V FLASH MEMORY ADDRESS BUS 23

C24 VSS - GND GND

C25 DOTPLLVDD - 3.3V POWER SUPPLY

C26 DOTCLKIN I 3.3V CRYSTAL(20MHz) INPUT

D01 AFEADC5 I 3.3V SCANNER INTERFACE

D02 AFEADC4 I 3.3V SCANNER INTERFACE

D03 AFEADC2 I 3.3V NOT USED

D04 VSS - GND GND

D05 VSS - GND GND

18

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

D06 VDD1.2 - 1.2V POWER SUPPLY

D07 PIO32 O 3.3V OPERATION PANEL INTERFACE

D08 CRMPWR O 3.3V MOTOR CURRENT CONTROL

D09 PIO56 O 3.3V ADF MOTOR INTERFACE

D10 VDD1.2 - 1.2V POWER SUPPLY

D11 PIO48 O 3.3V FAN2 CONTROL

D12 PIO44 O 3.3V DC MOTOR INTERFACE

D13 VDD3.3 - 3.3V POWER SUPPLY

D14 VDD1.2 - 1.2V POWER SUPPLY

D15 FRMD5 I/O 3.3V FLASH MEMORY DATA BUS 5

D16 FRMA1 O 3.3V FLASH MEMORY ADDRESS BUS 1

D17 VDD3.3 - 3.3V POWER SUPPLY

D18 FRMA8 O 3.3V FLASH MEMORY ADDRESS BUS 8

D19 THRMSTR1 I 3.3V ANALOG INPUT(THERMISTOR)

D20 TONEAVSS - GND GND

D21 FRMA13 O 3.3V FLASH MEMORY ADDRESS BUS 13

D22 VDD1.2 - 1.2V POWER SUPPLY

D23 VSS - GND GND

D24 NC - - NOT USED

D25 DOTCLKOUT O 3.3V CRYSTAL(20MHz) OUTPUT

D26 PIO66 O 3.3V NOT USED

E01 SDUDM0 O 3.3V SDRAM DQMU0

E02 AFEADC7 I 3.3V SCANNER INTERFACE

E03 AFEADC6 I 3.3V SCANNER INTERFACE

E04 VSS - GND GND

E23 VDD1.2 - 1.2V POWER SUPPLY

E24 FRMA24 O 3.3V FLASH MEMORY ADDRESS BUS 24

E25 PIO65 O 3.3V NOT USED

E26 PIO64 O 3.3V NOT USED

F01 SDMD16 I/O 3.3V SDRAM DATA BUS 16

F02 SDMD17 I/O 3.3V SDRAM DATA BUS 17

F03 AFESIFCLK O 3.3V SCANNER INTERFACE

F04 VDD1.2 - 1.2V POWER SUPPLY

F23 PIO24 I 3.3V LSU INTERFACE

F24 PIO61 O 3.3V OUTPUT PORT(SPMUTE)

F25 PIO60 O 3.3V NOT USED

F26 PIO3 O 3.3V LSU INTERFACE

G01 SDMD18 I/O 3.3V SDRAM DATA BUS 18

G02 SDMD19 I/O 3.3V SDRAM DATA BUS 19

G03 AFESIFDIN I 3.3V SCANNER INTERFACE

G04 AFESIFEN O 3.3V SCANNER INTERFACE

G23 PSCIO24 I 3.3V LSU INTERFACE

G24 PIO2 O 3.3V LSU INTERFACE

G25 PIO59 O 3.3V LAN CONTROLLER RESET

G26 PIO58 O 3.3V OUTPUT PORT(CIDRLY)

H01 SDMD20 I/O 3.3V SDRAM DATA BUS 20

H02 SDMD21 I/O 3.3V SDRAM DATA BUS 21

H03 NSDCS2 O 3.3V SDRAM CHIP SELECT 2

H04 AFESIFDOUT O 3.3V SCANNER INTERFACE

H23 PIO63 O 3.3V LSU INTERFACE

H24 PIO62 O 3.3V LSU INTERFACE

H25 PIO28 O 3.3V NOT USED

H26 PIO21 O 3.3V LSU INTERFACE

J01 SDMD22 I/O 3.3V SDRAM DATA BUS 22

J02 SDMD23 I/O 3.3V SDRAM DATA BUS 23

J03 SDMA3 O 3.3V SDRAM ADDRESS BUS 3

J04 SDMA2 O 3.3V SDRAM ADDRESS BUS 2

J23 PIO6 O 3.3V HIGH VOLTAGE UNIT INTERFACE

J24 PIO27 O 3.3V NOT USED

J25 PIO5 O 3.3V HIGH VOLTAGE UNIT INTERFACE

J26 PIO4 O 3.3V HIGH VOLTAGE UNIT INTERFACE

K01 VSS - GND GND

K02 SDCLK2 O 3.3V SDRAM CLOCK 2

K03 VSS - GND GND

K04 VDD3.3 - 3.3V POWER SUPPLY

K23 VDD1.2 - 1.2V POWER SUPPLY

K24 PIO41 O 3.3V NOT USED

KX-MB283BR

19

KX-MB283BR

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

K25 PIO40 O 3.3V NOT USED

K26 PIO39 O 3.3V NOT USED

L01 SDMD24 I/O 3.3V SDRAM DATA BUS 24

L02 SDMD25 I/O 3.3V SDRAM DATA BUS 25

L03 SDMA1 O 3.3V SDRAM ADDRESS BUS 1

L04 SDMAÇO O 3.3V SDRAM ADDRESS BUS 0

L11 VSS - GND GND

L12 VSS - GND GND

L13 VSS - GND GND

L14 VSS - GND GND

L15 VSS - GND GND

L16 VSS - GND GND

L23 PIO37 I 3.3V INPUT PORT (RING)

L24 PIO38 O 3.3V NOT USED

L25 PIO36 O 3.3V NOT USED

L26 PIO35 O 3.3V NOT USED

M01 SDMD26 I/O 3.3V SDRAM DATA BUS 26

M02 SDMD27 I/O 3.3V SDRAM DATA BUS 27

M03 SDMA10 O 3.3V SDRAM ADDRESS BUS 10

M04 SDBA1 O 3.3V SDRAM BANK ADDRESS 1

M11 VSS - GND GND

M12 VSS - GND GND

M13 VSS - GND GND

M14 VSS - GND GND

M15 VSS - GND GND

M16 VSS - GND GND

M23 PIO33 O 3.3V NOT USED

M24 PIO34 O 3.3V NOT USED

M25 PIO26 O 3.3V NOT USED

M26 PIO25 O 3.3V OUTPUT PORT(CNGMUTE)

N01 SDMD28 I/O 3.3V SDRAM DATA BUS 28

N02 SDMD29 I/O 3.3V SDRAM DATA BUS 29

N03 SDBA0 O 3.3V SDRAM BANK ADDRESS 0

N04 VDD1.2 - 1.2V POWER SUPPLY

N11 VSS - GND GND

N12 VSS - GND GND

N13 VSS - GND GND

N14 VSS - GND GND

N15 VSS - GND GND

N16 VSS - GND GND

N23 VDD3.3 - 3.3V POWER SUPPLY

N24 PIO23 O 3.3V NOT USED

N25 PIO22 O 3.3V NOT USED

N26 PIO20 O 3.3V NOT USED

P01 SDMD30 I/O 3.3V SDRAM DATA BUS 30

P02 SDMD31 I/O 3.3V SDRAM DATA BUS 31

P03 NSDCS O 3.3V SDRAM CHIP SELECT 1

P04 VDD3.3 - 3.3V POWER SUPPLY

P11 VSS - GND GND

P12 VSS - GND GND

P13 VSS - GND GND

P14 VSS - GND GND

P15 VSS - GND GND

P16 VSS - GND GND

P23 VDD1.2 - 1.2V POWER SUPPLY

P24 PIO16 O 3.3V NOT USED

P25 PIO17 O 3.3V NOT USED

P26 PIO18 I 3.3V HIGH VOLTAGE UNIT INTERFACE

R01 SDUDM1 O 3.3V SDRAM DQMU1

R02 SDLDM0 O 3.3V SDRAM DQML0

R03 BZVDD33 - 3.3V POWER SUPPLY

R04 BZRST33 - 3.3V POWER SUPPLY

R11 VSS - GND GND

R12 VSS - GND GND

R13 VSS - GND GND

R14 VSS - GND GND

R15 VSS - GND GND

20

PIN NO. PinName I/O POWER SUPPLY VOLTAGE EXPLANATION

R16 VSS - GND GND

R23 PIO13 O 3.3V NOT USED

R24 PIO12 O 3.3V NOT USED

R25 PIO14 O 3.3V NOT USED

R26 PIO15 O 3.3V NOT USED

T01 SDMD0 I/O 3.3V SDRAM DATA BUS 0

T02 SDMD1 I/O 3.3V SDRAM DATA BUS 1

T03 NSDCAS O 3.3V SDRAM CAS

T04 NSDRAS O 3.3V SDRAM RAS

T11 VSS - GND GND

T12 VSS - GND GND

T13 VSS - GND GND

T14 VSS - GND GND

T15 VSS - GND GND

T16 VSS - GND GND

T23 PIO9 O 3.3V OUTPUT PORT(SNPICK)

T24 PIO8 O 3.3V NOT USED

T25 PIO10 O 3.3V NOT USED

T26 PIO11 O 3.3V OUTPUT PORT(SNREG)

U01 SDMD2 I/O 3.3V SDRAM DATA BUS 2

U02 SDMD3 I/O 3.3V SDRAM DATA BUS 3

U03 NSDWE O 3.3V SDRAM WRITE ENABLE

U04 VDD1.2 - 1.2V POWER SUPPLY

U23 VDD3.3 - 3.3V POWER SUPPLY

U24 PIO0 I 3.3V INPUT PORT (HOOK)

U25 PIO1 O 3.3V OUTPUT PORT(EXTRLY)

U26 PIO7 O 3.3V NOT USED

V01 SDMD4 I/O 3.3V SDRAM DATA BUS 4

V02 SDMD5 I/O 3.3V SDRAM DATA BUS 5

V03 SDCKE O 3.3V SDRAM CLOCK ENABLE

V04 SDMA12 O 3.3V SDRAM ADDRESS BUS 12

V23 PSCIO20 O 3.3V NOT USED

V24 PSCIO21 O 3.3V NOT USED

V25 PSCIO22 O 3.3V NOT USED

V26 PSCIO23 O 3.3V NOT USED

W01 SDMD6 I/O 3.3V SDRAM DATA BUS 6

W02 SDMD7 I/O 3.3V SDRAM DATA BUS 7

W03 SDMA11 O 3.3V SDRAM ADDRESS BUS 11

W04 SDMA9 O 3.3V SDRAM ADDRESS BUS 9

W23 PSCIO16 O 3.3V NOT USED

W24 PSCIO17 I 3.3V INPUT PORT (FANDET2)

W25 PSCIO18 I 3.3V INPUT PORT (TOPCVR)

W26 PSCIO19 I 3.3V INPUT PORT (PSTART)

Y01 VSS - GND GND

Y02 SDCLK O 3.3V SDRAM CLOCK 1

Y03 SDMA8 O 3.3V SDRAM ADDRESS BUS 8

Y04 VSS - GND GND

Y23 AFESEL0 I 3.3V NCU INTERFACE

Y24 AFESEL1 I 3.3V NCU INTERFACE

Y25 EXMDMCS O 3.3V NOT USED

Y26 DP O 3.3V NCU INTERFACE

KX-MB283BR

21

KX-MB283BR

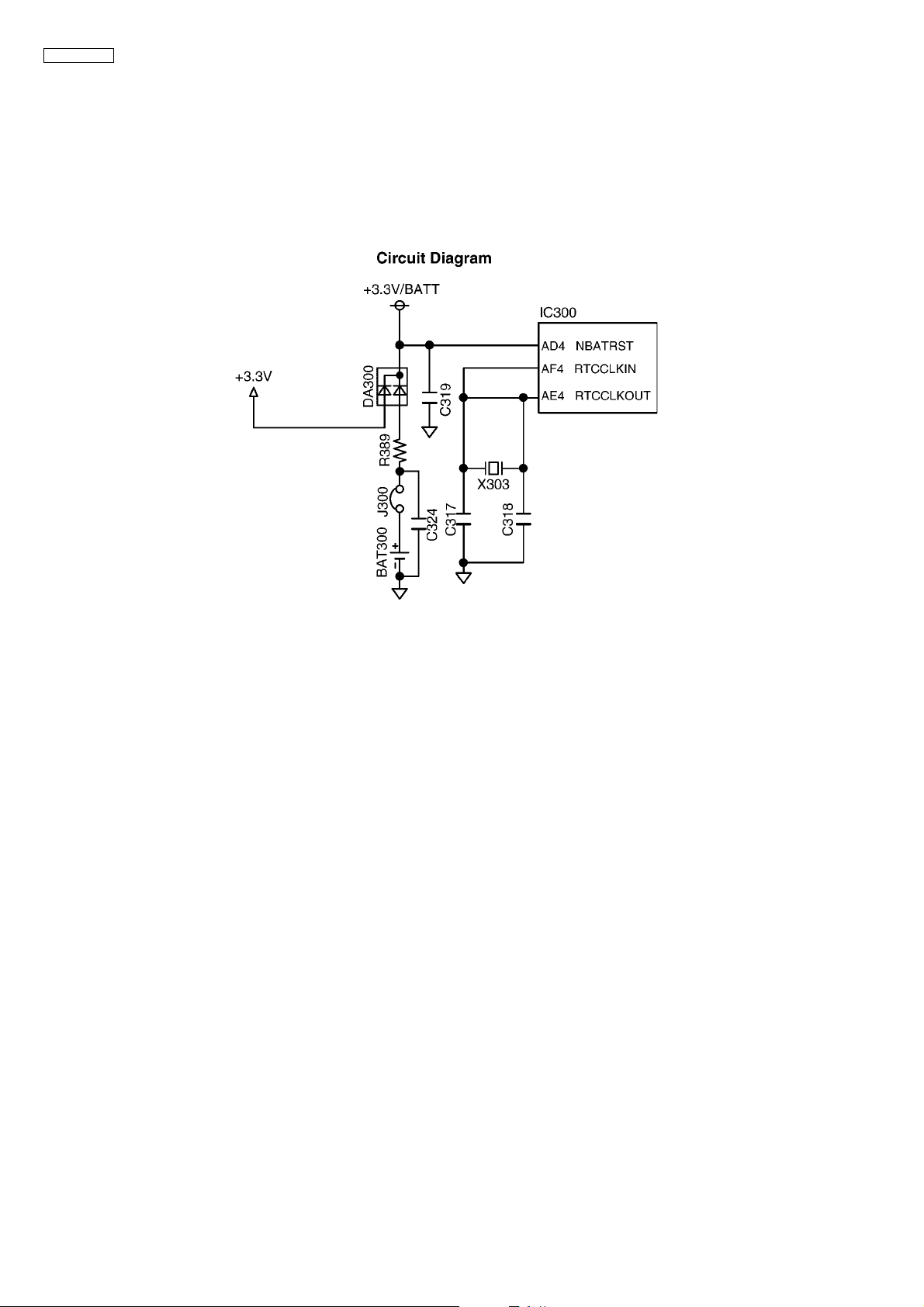

6.3.2. RTC BACKUP CIRCUIT

1. Function

This unit has a lithium battery (BAT300) which works for the Real Time Clock IC (RTC: inside IC300).

The RTC continues to work, backed up by a lithium battery even when the power switch is OFF.

2. RTC Inside (IC300) Backup Circuit Operation

When the power switch is turned ON, power is supplied to the RTC (inside IC300). At this time, the voltage at pin AD4 of the

IC300 is +3.3V . When the power switch is turned OFF, the BA T300 supplies power to RTC through DA300.

When the power switch is OFF and the voltage of +3.3V decreases, pin AD4 of RTC (IC300) becomes roughly the same voltage as the battery voltage. RTC goes into the backup mode, in which the power consumption is lower.

22

KX-MB283BR

6.4. CIS CONTROL SECTION

The scanning block of this device consists of a control circuit and a CIS (contact image sensor), and AFE (Analog Front End)

include A/D Converter.

When an original document is inserted and the start button pressed, pin A3 o f IC300 goes to a low level and the transistor Q51 8

turns on. This applies voltage to the CIS. The CIS is driven by e ach of the CCDSH , CCDCLK signals output from IC300, and the

original image illuminated by the LED to output an analog image signal.

The analog image signal is input to the AFE on VINP(20pin of IC503 ) and converted into 16-bit data by the A/D conve rter inside

IC503. Then this signal undergoes digital processing in order to obtain a high-quality image.

23

KX-MB283BR

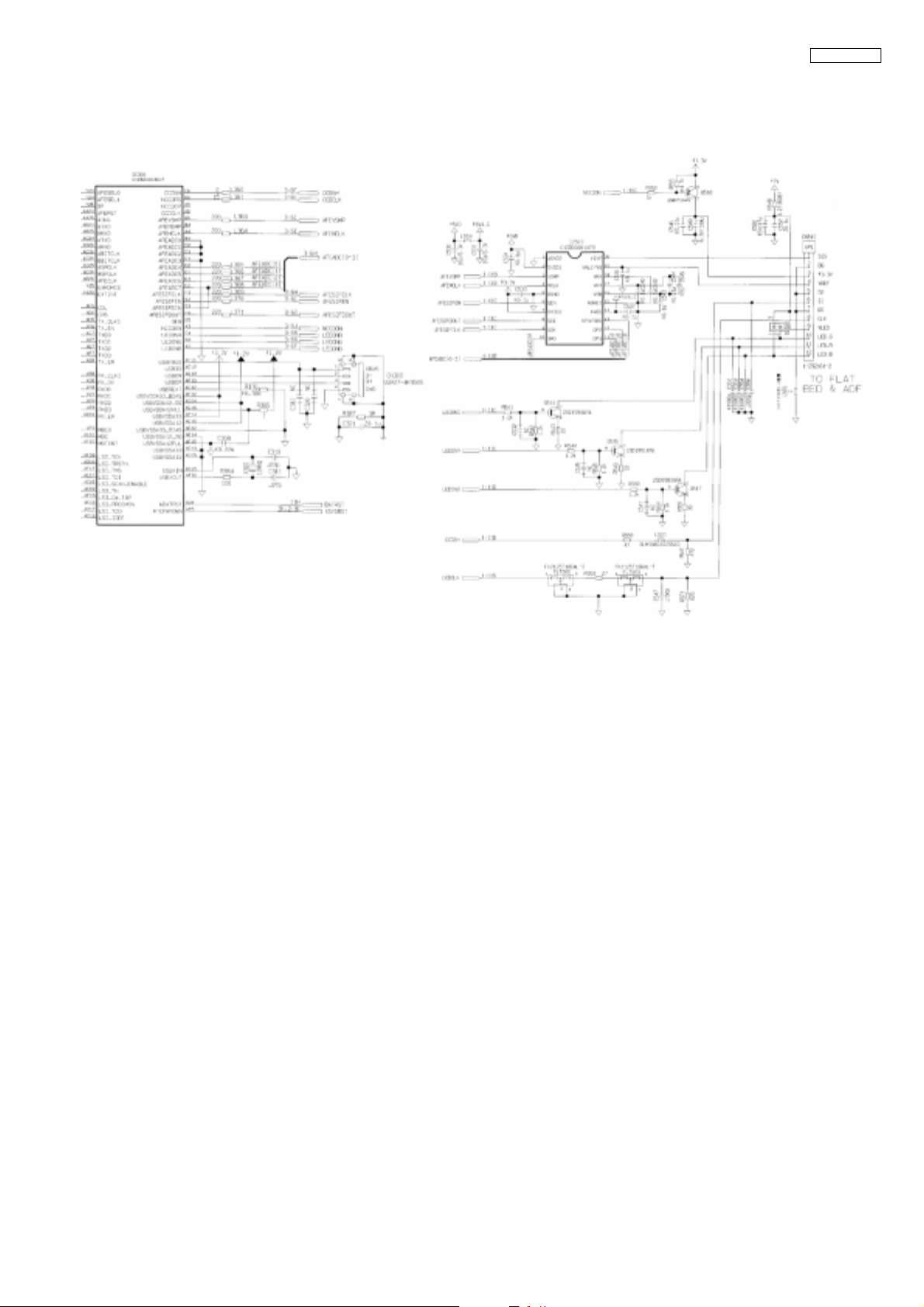

6.5. MOTOR DRIVE SECTION

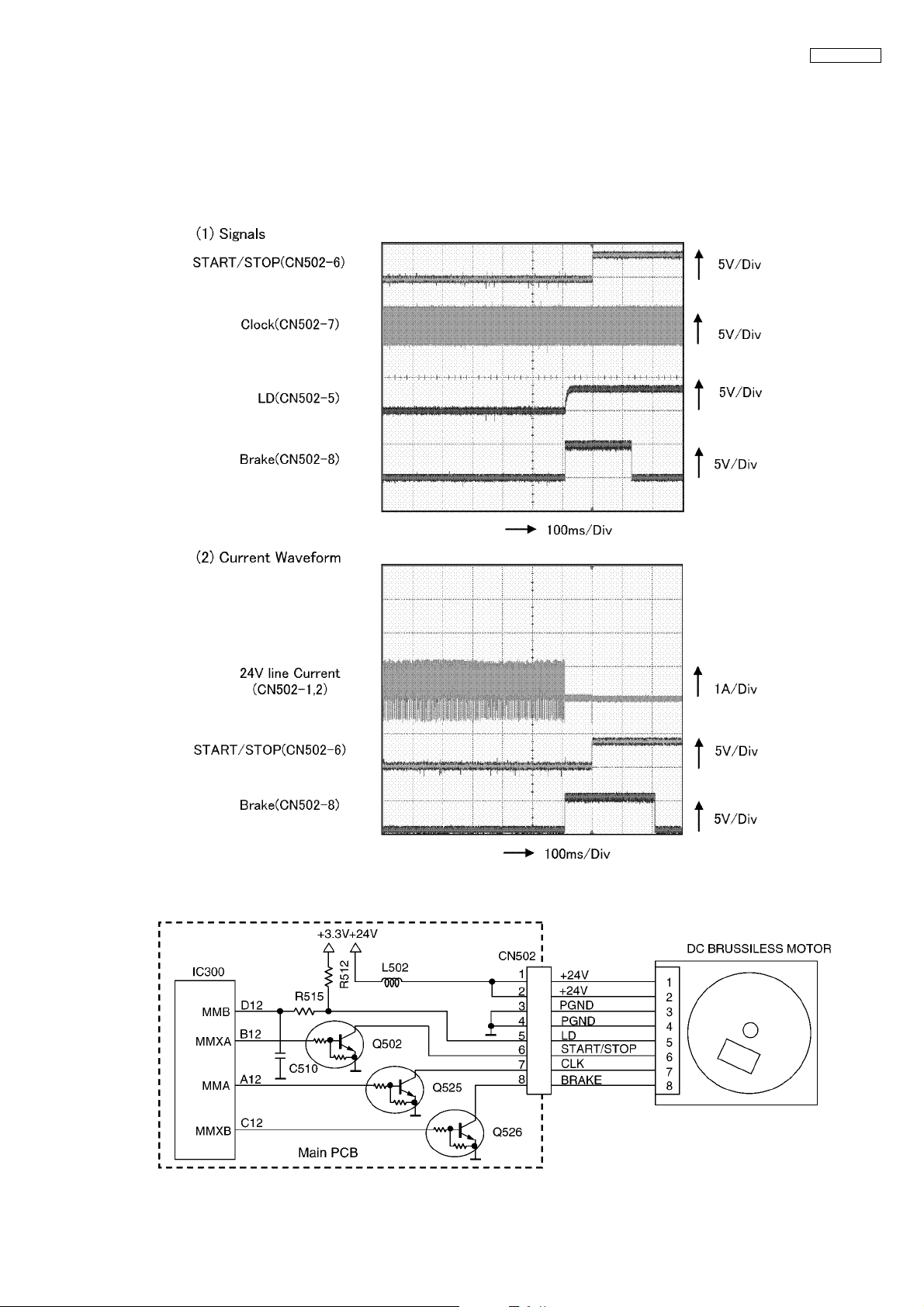

6.5.1. Engine Motor Control Circuit

1. Functions

All driving forces of printer engine part are supplied by this engine motor.

Engine motor is controlled so as to rotate at constant speed during printing and copying.

2. Motor operation

<Start operation>

In order to start the motor rotation, following 3 signals are supplied from IC300.

1. SS signal (Output pin: Pin B12/Output Signal: "H")

When this signal is inverted by transistor Q502 and becomes "L", motor recognize this signal as "start" signal.

2. Clock signal (Output pin: Pin A12/Output Signal: Pulse)

Pulse frequency :approx. 1.9KHz (at normal printing speed, )

Pulse frequency :approx. 0.5KHz.(at half printing speed)

This signal is also inverted by transistor Q525, and supplied to motor as "clock" signal .

3. Brake signal (Output pin: Pin C12/Output Signal: "H")

When this signal is inverted by transistor Q526 and becomes "L", motor recognize this signal as "brake off" signal.

When motor reaches constant speed, "L" signal is supplied from motor to IC300 pin B12 as "Lock detect (LD)" signal.

if "LD" signal does not becomes "L" within predetermined period after "SS" signal becomes "H", or if "LD" signal becomes

"H" during rotation, it is judged that motor Error occurred.

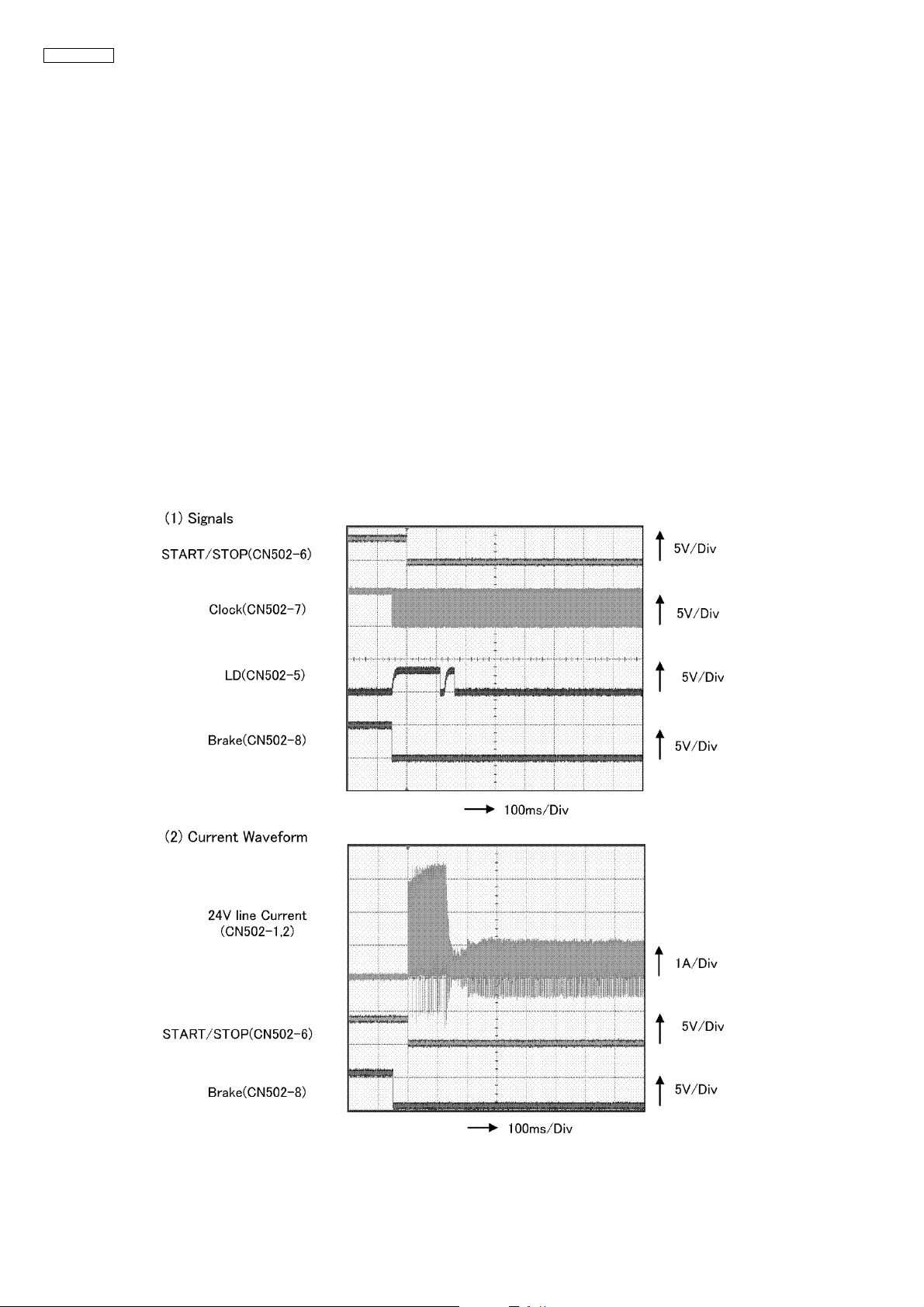

Timing Chart of Start operation

24

KX-MB283BR

<Stop operation>

In order to stop the motor rotation, following 2 signals are supplied from IC300.

1. SS signal (Output pin: Pin B12/Output Signal: "L")

When this signal is inverted by transistor Q502 and becomes "H", motor recognize this signal as "stop" signal.

2. Brake signal (Output pin: Pin C12/Output Signal: "L")

When this signal is inverted by transistor Q526 and becomes "H", motor recognize this signal as "brake on" signal.

Timing Chart of Stop operation

6.5.1.1. ENGINE MOTOR DRIVE CIRCUIT

25

KX-MB283BR

6.5.2. SCANNER MOTOR DRIVE CIRCUIT

General

Scanner motor drive circuit is consist of motor current control circuit ,FB (Flat Bed) motor driver and ADF (Auto Document Feeder:

equipped model only) motor driver .

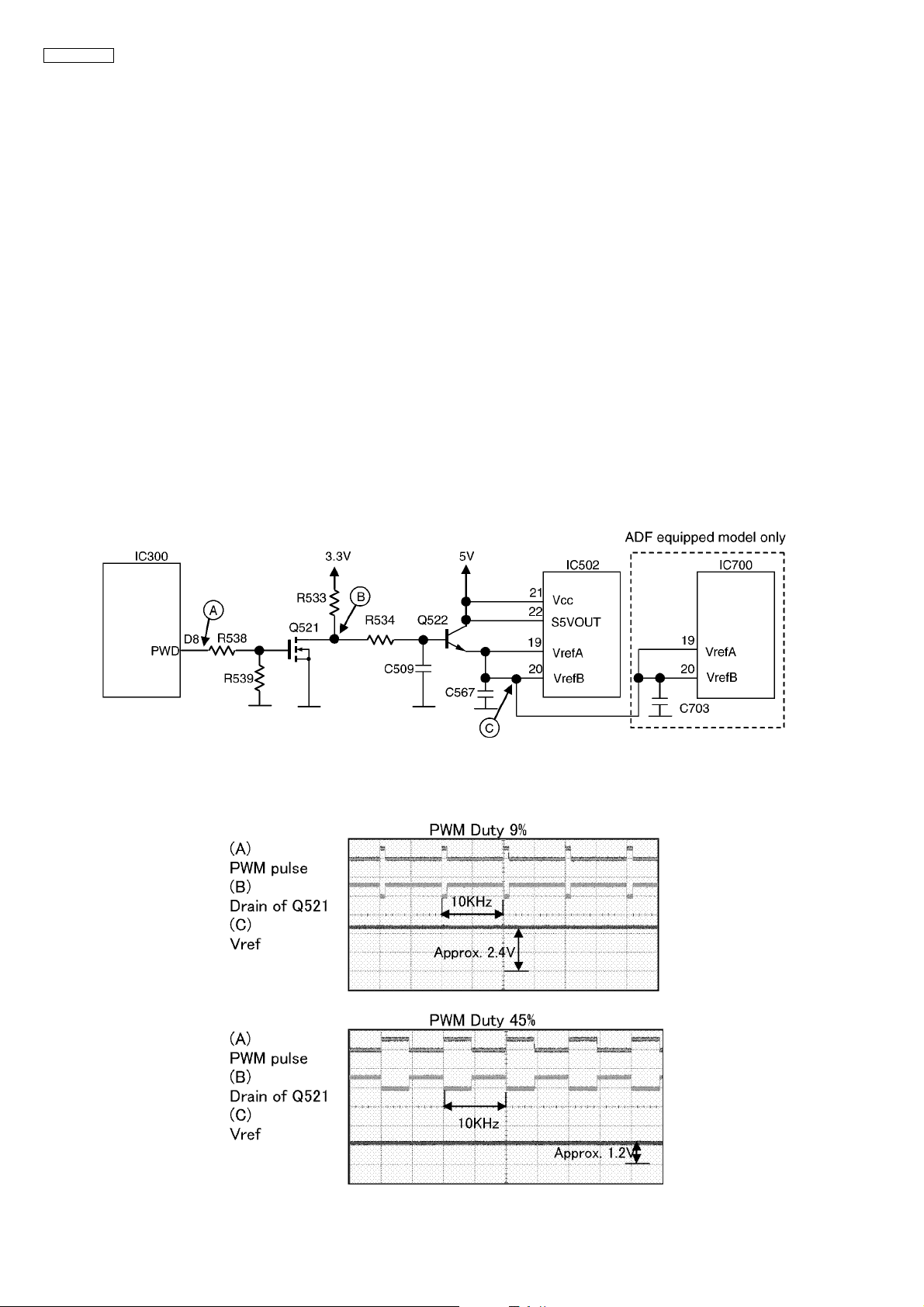

6.5.2.1. MOTOR CURRENT CONTROL CIRCUIT

1. Circuit explanation

According to the scan speed, each motor current is controlled for appropriate value.

When scan speed is low, motor current is reduced to prevent the vibration during motor rotation.

When scan speed is high, motor needs much driving force. so much current should be supplied.

For the control of motor current, Vref voltage of each motor driver is controlled.

When Vref voltage is high, motor current is increased, and the voltage is low, motor current is reduced.

In order to control Vref voltage, PWM pulse is supplied from IC300 pin D8 .

PWM pulse is inverted by Q521 and integrated by R533, R534, and C567, then convert to DC voltage.

This DC voltage is supplied to Vref pin of each motor driver through Q522.

When duty of PWM pulse is high, Vref voltage is decreased and when duty is low, Vref voltage is increased.

For FB motor, motor current is controlled approx. 0.1A-0.25A.

For ADF motor, motor current is controlled approx. 0.2A-0.35A (ADF epuipped model only).

2. Circuit diagram

3. Timing chart

Following timing charts are the example when PWM pulse duty are approx 9% and 45%.

26

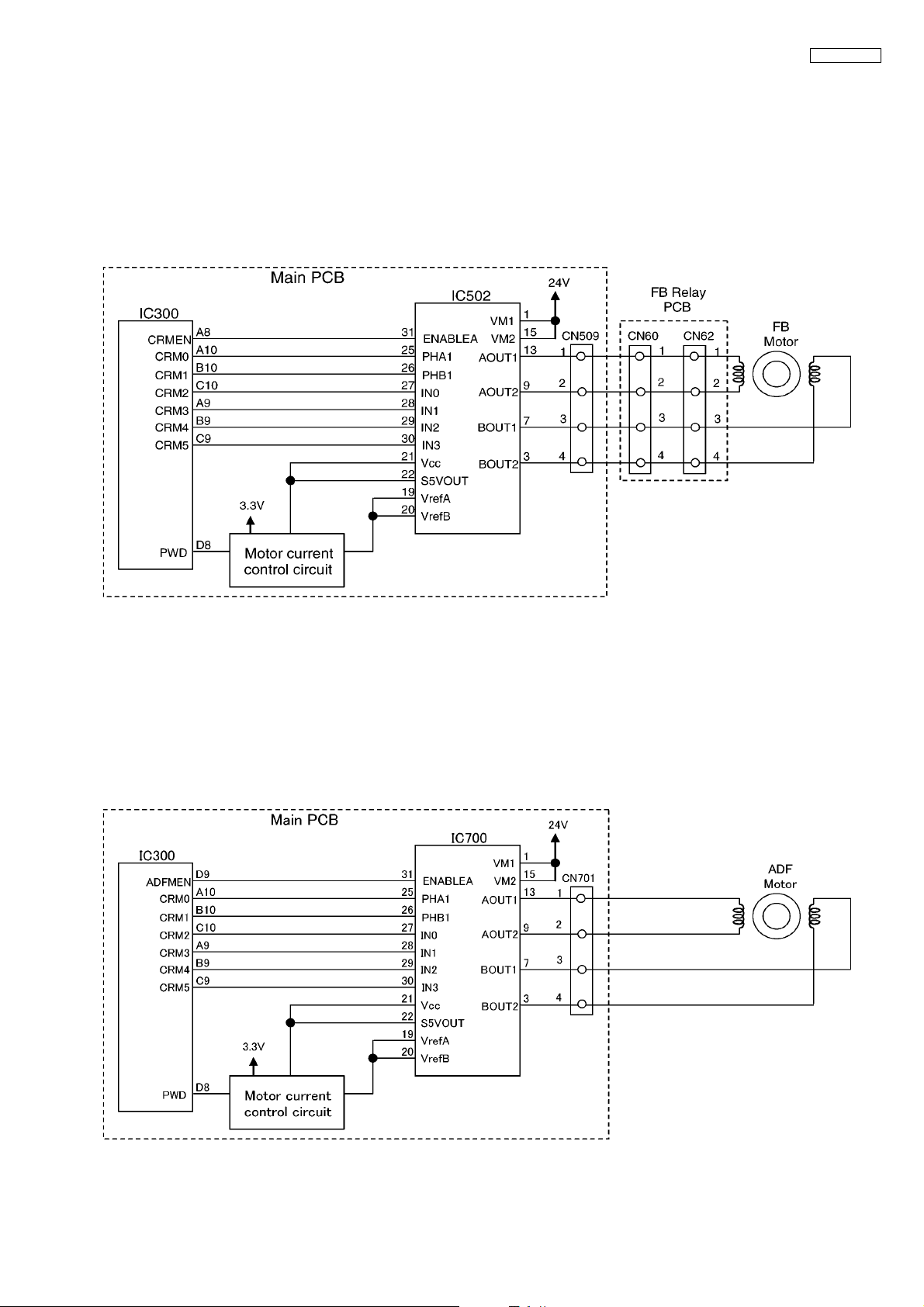

6.5.2.2. FB (FLAT BED) MOTOR DRIVE CIRCUIT

1. Functions

This motor functions for main operations including FB copy and PC scan.

This motor feeds CIS unit with synchronizing for reading.

2. Motor operation

During motor driving, pin A8 of IC 300 become low level, then motor driver IC502 is activated.

Stepping pulses are output from IC300 pins A9, B9, C9,A10, B10, and C10, causing driver IC502 pin 3, 7, 9 and 13 to dri ve

the motor coil.

A 1-step rotation of this motor feeds 0.021 mm of CIS unit.

3. Circuit Diagram

KX-MB283BR

6.5.2.3. ADF (AUTO DOCUMENT FEEDER) MOTOR DRIVE CIRCUIT

1. Functions

This motor functions for main operations including ADF copy and PC scan.

This motor feeds document which are set to ADF with synchronizing for reading.

2. Motor operation

During motor driving, pin D9 of IC 300 become low level, then motor driver IC700 is activated.

Stepping pulses are output from IC300 pins A9, B9, C9, A10, B10, and C10, causing driver IC700 pin 3, 7, 9 and 13 to dr ive

the motor coil.

A 1-step rotation of this motor feeds 0.04 2 mm of doc ument.

3. Circuit Diagram

27

KX-MB283BR

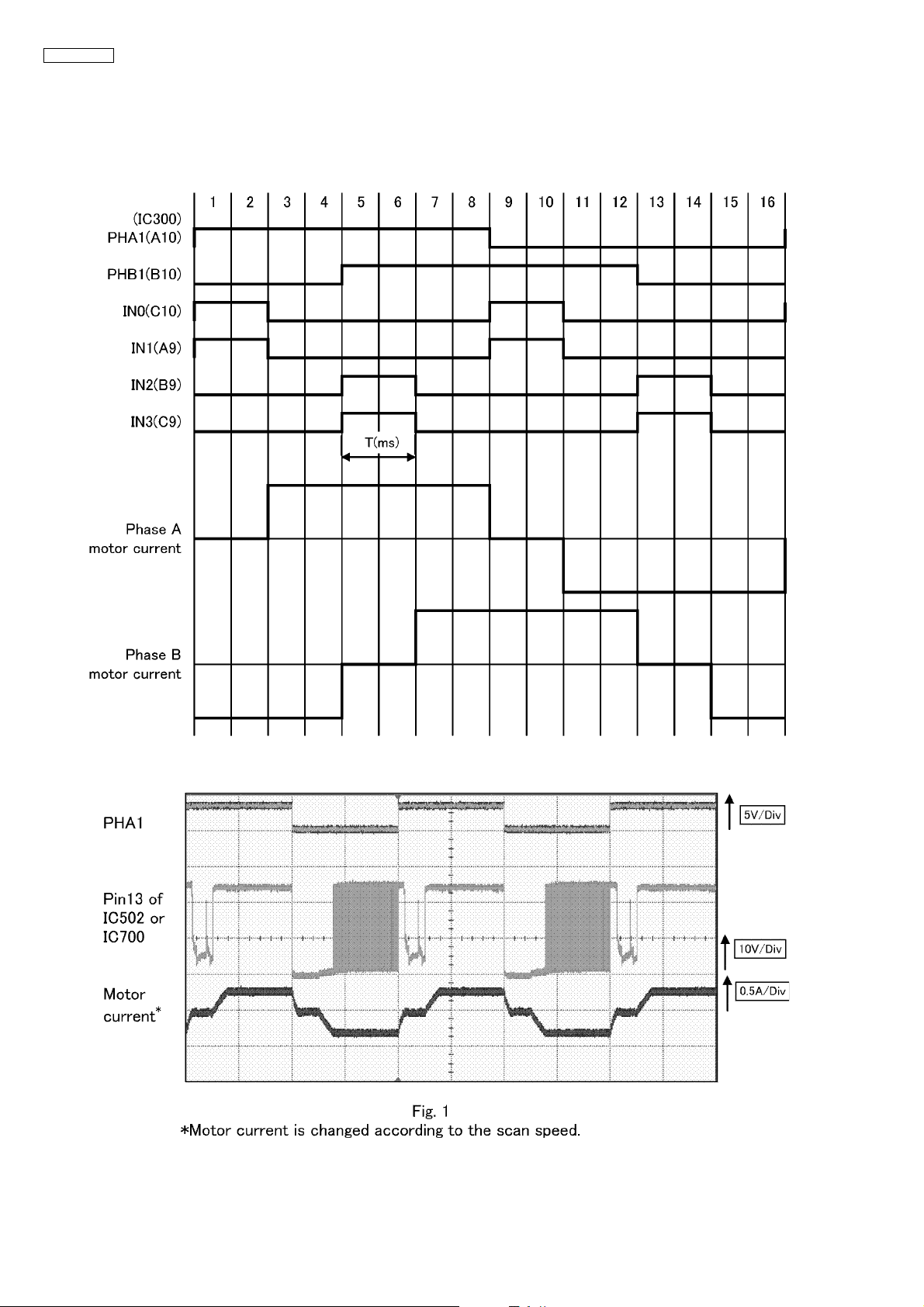

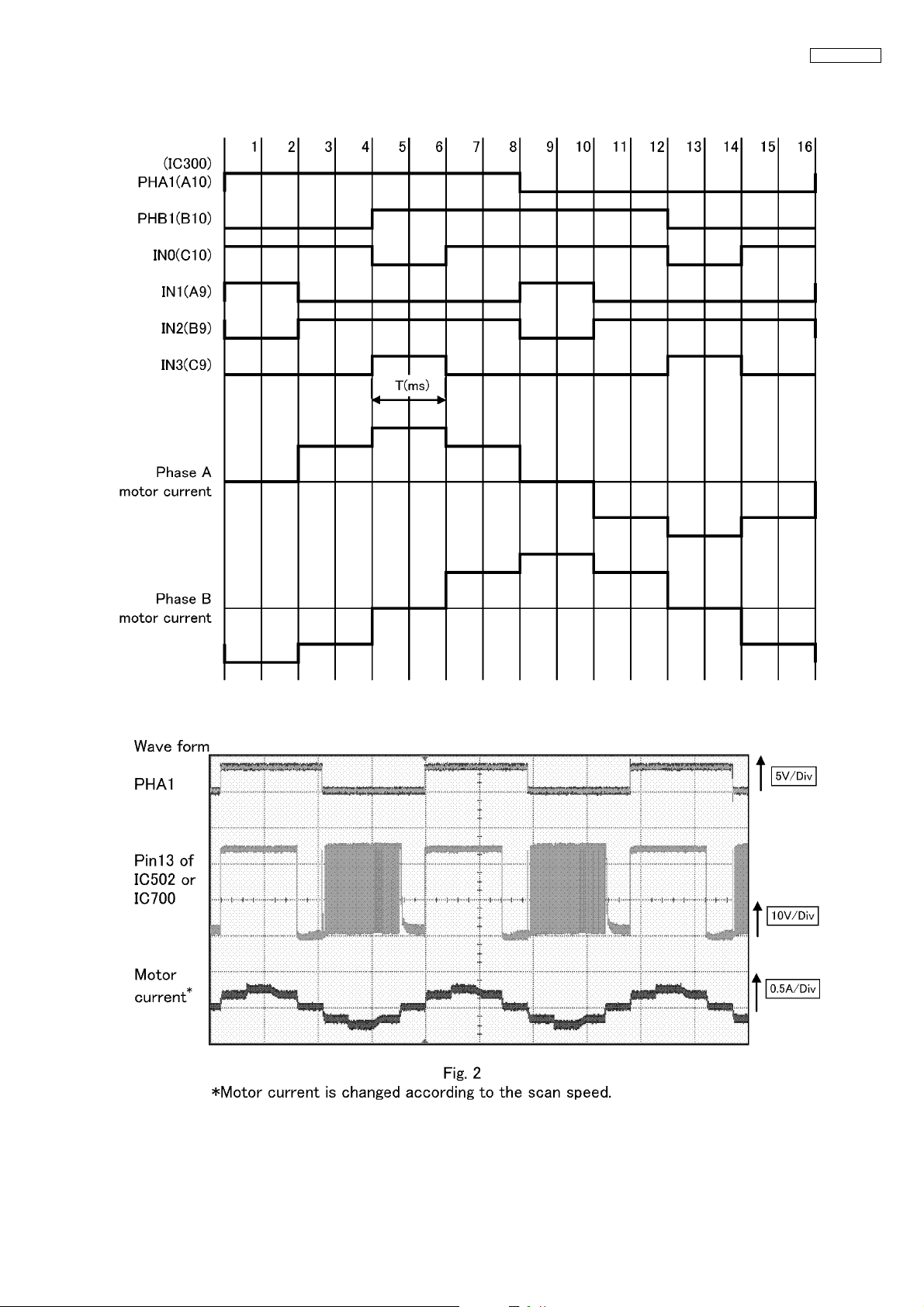

6.6. TIMING CHART AND WAVE FORM OF SCANNER MOTORS

Control sequence and waveform of both FB and ADF motor are almost same.

6.6.1. NORMAL 1-2 PHASE EXCIT ATION (HALF STEP)

1. Timing chart

2. Wave form

28

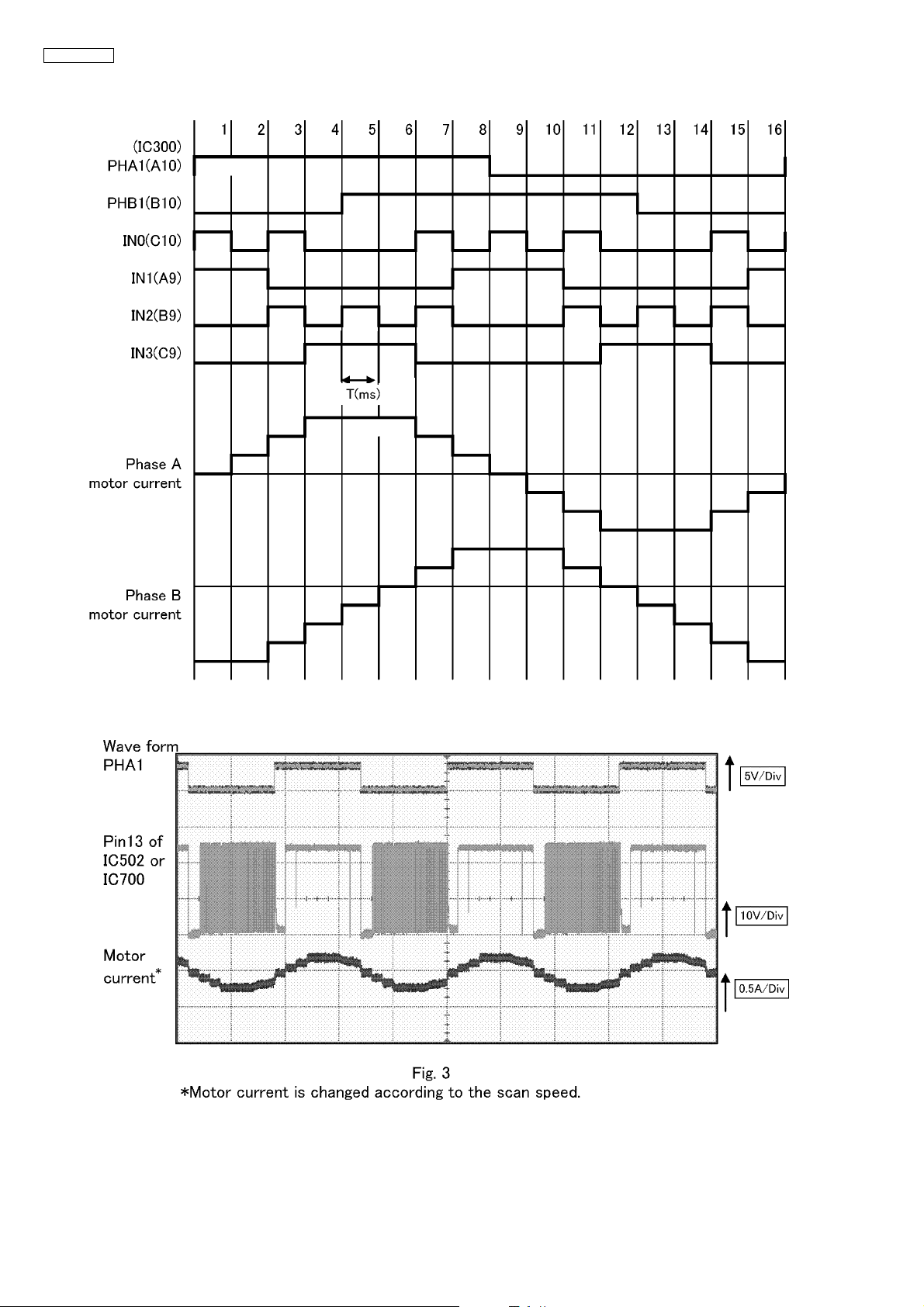

6.6.2. FLAT TORQUE 1-2 PHASE EXCITATION (HALF STEP)

1. Timing chart

KX-MB283BR

2. Wave form

29

KX-MB283BR

6.6.3. W 1-2 PHASE EXCITATION (QUARTER STEP)

1. Timing chart

2. Wave form

30

Loading...

Loading...