Page 1

Operation

Indicator LED

MQ-W3 type

MW-W20 type

Distance adjustment dial

Adjustment

indicator LED

Adjustment

indicator LED

Operation

Indicator LED

MQ-W70 type

Distance adjustment dial

MQ-W

08/2005

SERIES

Triple Beam Trigonometric

Area Reflective Photoelectric Sensors

Very accurate detection by triple beam triangulation sensing method in a compact package.

Environmental resistance

Immersion protected construction

(equivalent to IEC IP67)

High speed detection: Max. 2 ms

Light-ON/Dark-ON output is wire

selectable.

Operating voltage of 12 to 24 V DC

Adjuster and Indicators

(Comply with EMC directive MQ-W-EM type only)

FEATURES

Accurate detection regardless of

color, material, or shape of objects

Area reflective type sensor can detect

white or black object at the same distance. In case of diffuse reflective type,

it is difficult to detect objects of various

color with the same sensitivity setting.

MQ-W area reflective type sensor is

useful for such a case.

No-miss operation regardless of

back-grounds

Area reflective type sensor does not

detect objects beyond the set range.

Resistant to lens surface soiling

Area reflective type sensor detects the

distance by the angle, not the intensity

of received light. Even if the lens surface is soiled by dust or any powdery

material, there is a little variation of

sensing range.

SENSING RANGES

Sensing range (m ft.)

0.03 .098 0.2 .656 0.7 2.297

MQ-W3 types

MQ-W20 types

MQ-W70 types

PRODUCT TYPE

Detection method

Triple beam area

reflective type

1

These suffix EM types conform to CE. These types have the grounding connection inside of housing

*

Range

0.03 m .098 ft.

0.2 m .656 ft.

0.7 m 2.297 ft.

Rated operating voltage

12 to 24 V DC

Control output Light source Part number *1 CE types

NPN

PNP

NPN

PNP

NPN

PNP

Infrared LED MQ-W3A-DC12-24V

Red LED

Infrared LED

Red LED

Infrared LED

Red LED

Infrared LED

Red LED

Infrared LED

MQ-W3AR-DC12-24V

MQ-W3C-DC12-24V

MQ-W3CR-DC12-24V

MQ-W20A-DC12-24V

MQ-W20AR-DC12-24V

MQ-W20C-DC12-24V

MQ-W20CR-DC12-24V

MQ-W70A-DC12-24V

MQ-W70C-DC12-24V

MQ-W3A-DC12-24VEM

MQ-W3AR-DC12-24VEM

MQ-W3C-DC12-24VEM

MQ-W3CR-DC12-24VEM

MQ-W20A-DC12-24VEM

MQ-W20AR-DC12-24VEM

MQ-W20C-DC12-24VEM

MQ-W20CR-DC12-24VEM

MQ-W70A-DC12-24VEM

MQ-W70C-DC12-24VEM

266

Page 2

SPECIFICATIONS

08/2005

1) Ratings

MQ-W

Operating side

Rated operating voltage

Rated current consumption

Output current capacityLoad side

12 to 24 V DC

30 mA or less (excluding load)

100 mA or less

2) Performance

Detection principle Triple beam triangulation sensing method

Detection method Area reflective type

Type Amplifier selfcontained DC type

MQ-W3A-DC12-24V

Part number

Sensing range 0.03 m .098 ft. 0.2 m .656 ft. 0.7 m 2.297 ft.

Detectable distance 0.02 to 0.04 m .066 to .131 ft. 0.04 to 0.2 m .131 to .656 ft. 0.2 to 0.7 m .656 to 2.297 ft.

Standard target

Detectable target Opaque, translucent

Hysteresis 10% or less the set range 20% or less of the set range

Operating voltage range 9.6 to 30 V DC ripple (P-P) included

Response time (freq.) 2 ms or less (250 times per second or less)

Initial insulation resistance Min. 20 MΩ between a lead wire and external housing (at 500 V DC)

Initial breakdown voltage Between a lead wire and external housing: 500 Vrms for 1 min

Vibration resistance 10 to 55 Hz (1 cycle/min), double amplitude 1.5 mm .059 inch (2 h each on 3 axes)

Shock resistance 980 m/s2{approx. 100 G} (6 times each on 3 axes)

Protective construction Diecast case immersion protected (equivalent to IEC IP67)

Usable ambient

light level

Ambient temperature –25 to 55°C –13 to +131°F (non-icing condition)

Ambient humidity Max. 85% RH (non-condensing condition)

Storage temperature –25 to 55°C –13 to +131°F

Indicator

Light source

Note: Unless otherwise specified, the measurement conditions comprise rated operating voltage, power supply by battery, 20°C 68°F ambient

temperature, standard target and 200 lux or less illuminance on the receiver surface.

Incandescent lamp

Sunlight 30,000 lux or less

MQ-W3AR-DC12-24V

MQ-W3C-DC12-24V

MQ-W3CR-DC12-24V

White drawing paper

11 cm .394.394 inch

Operation indicator: Red LED ON with light entry

Adjustment indicator: Red LED ON with sufficient volume of lights

Infrared LED/Red LED (R is added to the suffix of W3(20)A(C) in the part No.)

MQ-W20A-DC12-24V

MQ-W20AR-DC12-24V

MQ-W20C-DC12-24V

MQ-W20CR-DC12-24V

White drawing paper

22 cm .787.787 inch

10,000 lux or less

MQ-W70A-DC12-24V

MQ-W70C-DC12-24V

White drawing paper

7.57.5 cm 2.9532.953 inch

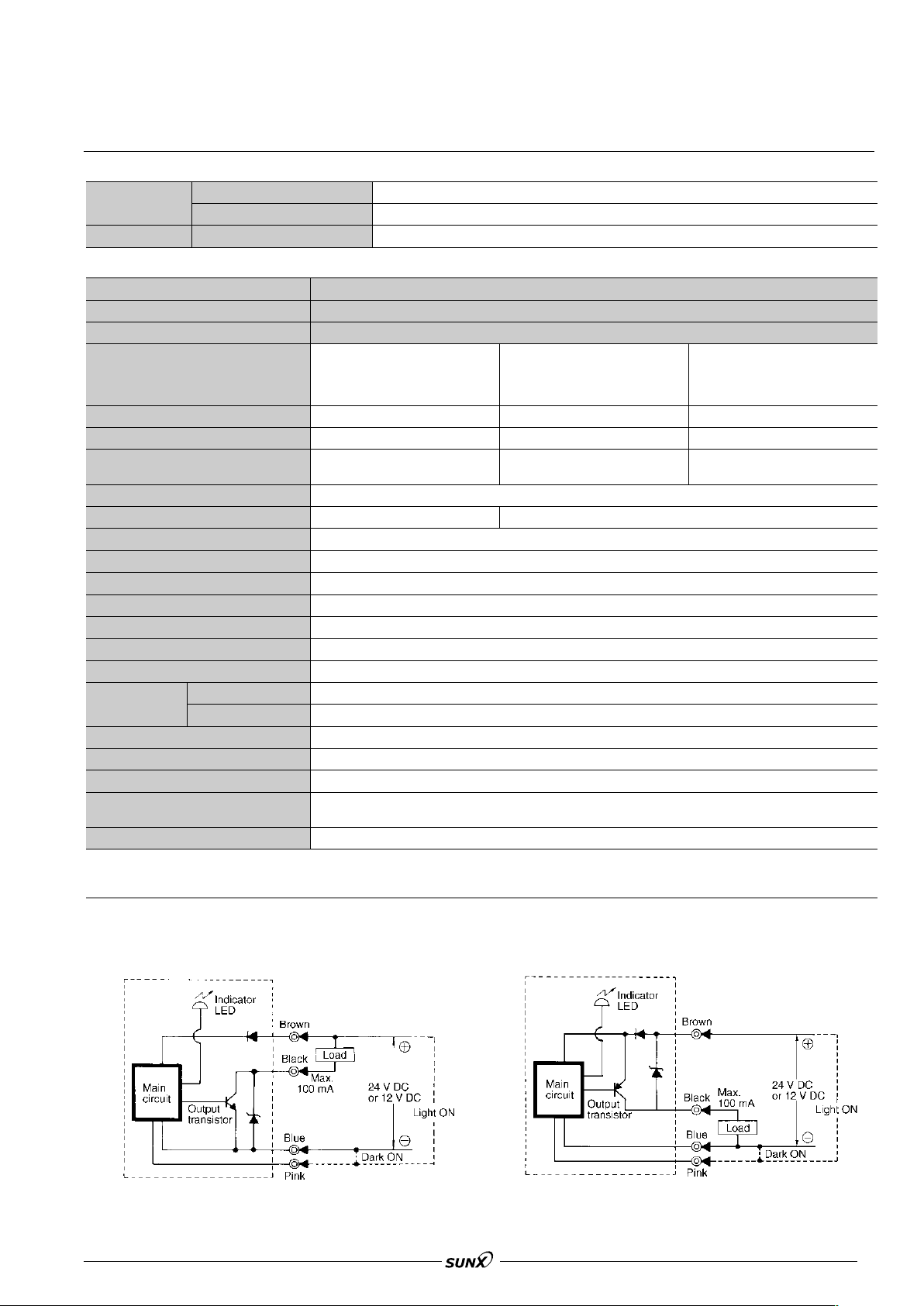

3) Output circuit diagram

NPN Output type PNP Output type

267

Page 3

MQ-W

40

.131

For 40 mm .131 ft.

For 30 mm .098 ft.

For 20 mm .066 ft.

Operating range (mm)

(inch)

Moving direction

Standard target

(white drawing paper

10×10 mm .394×.394 inch)

(mm)

(ft.)

Operating

distance

30

.098

20

.066

10

.394

10

.394

5

.1975.197

0

200

.656

150

.492

100

.328

50

.164

For 150 mm .492 ft.

For 200 mm .656 ft.

For 100 mm .328 ft.

For 50 mm .164 ft.

Operating range (mm)

(inch)

Moving direction

Standard target

(white drawing paper 20×

20 mm .787×.787 inch)

(mm)

(ft.)

Operating

distance

10

.394

10

.394

5

.1975.197

0

200

.656

600

1.969

400

1.312

For 500 mm 1.641 ft.

For 700 mm 2.297 ft.

For 300 mm .984 ft.

Operating range (mm)

(inch)

Moving direction

Standard target

(white drawing paper 75×

75 mm 2.953×2.953 inch)

(mm)

(ft.)

Operating

distance

10

.394

10

.394

5

.1975.197

0

(mm

inch)

2.5 dia.

.098

2.3 dia.

.091

4.0 dia.

.157

(mm ft.)20

.06630.09840.131

0

(mm

inch)

6.9 dia.

.272

6.7 dia.

.264

7.4 dia.

.291

8.3 dia.

.327

(mm ft.)100

.328

50

.164

150

.492

200

.656

0

(mm

inch)

23.0 dia.

.906

33.0 dia.

1.299

39.0 dia.

1.535

(mm ft.)300

.989

500

1.641

700

2.287

0

10

0.015

20

.066

30

.098

40

.131

0

100

0.155

Distance setting 40 mm

.131 ft.

Distance setting 30 mm

.098 ft.

Distance setting 20 mm

.066 ft.

Target size (mm

2

inch2)

Distance range (mm ft.)

Standard target

(white drawing paper 10×10 mm

.394×.394 inch)

100

.328

200

.656

300

.984

400

1.132

500

1.641

600

1.969

Distance range (mm ft.) × : Impossible

Former pruduct

White drawing

paper

Corrugated

carton

Veneer panel

Black rubber

Black frosted

finish

Aluminum

panel

Mirror

Copper clad

printed circuit

board

×

×

Triple beam type (MQ-W20A)

10

.03320.06630.09840.131

Distance range (mm ft.)

White

drawing

paper

Black

drawing

paper

Corrugated

paper

Veneer panel

Black rubber

Non-glossy target

Semi-glossy target

Glossy target

Mirror

Blue acrylic

White acrylic

Copper clad

printed circuit

board

50

.164

100

.328

150

.492

200

.656

Distance range (mm ft.)

White

drawing

paper

Black

drawing

paper

Corrugated

paper

Veneer panel

Black rubber

Non-glossy target

Semi-glossy target

Glossy target

Mirror

Blue acrylic

White acrylic

Copper clad

printed circuit

board

1000

1.55

100

.328

200

.656

0

100

0.155

Distance setting 200 mm

.656 ft.

Distance setting 100 mm

.328 ft.

Distance setting 40 mm

.131 ft.

Target size (mm

2

inch2)

Distance range (mm ft.)

Standard target

(white drawing paper 20×20 mm

.787×.787 inch)

1,000

1.55

100

.328

200

.656

300

.984

400

1.312

500

1.641

600

1.969

700

2.297

0

10,000

15.5

Distance setting 700 mm

2.297 ft.

Distance setting 400 mm

1.312 ft.

Distance setting 200 mm

.656 ft.

Target size (mm

2

inch2)

Distance range (mm ft.)

Standard target

(white drawing paper 75×75 mm

2.953×2.953 inch)

08/2005

DATA

1. Operating range characteristics

MQ-W3 types MQ-W20 types MQ-W70 types

2. Projector beam diameter characteristics

Light beam diameter is determined as the region where the amount of light is decreased to 1/e2(e]2.72) when the largest amount of light is

assumed as 1.

MQ-W3 types MQ-W20 types MQ-W70 types

3 Detectable target characteristics

MQ-W3 types MQ-W20 types MQ-W70 types

4. Material characteristics

Comparision between MQ-W20A and former product

Condition: Target (4060 mm 1.5752.362 inch),

target assumed as natural shape

For the former product (diffuse reflective type),

depending upon the object material, the operating

range varied greatly, but for the triple beam type

there a little variation.

MQ-W3 types

Condition: Target (4060 mm 1.5752.362

inch), natural shape

MQ-W20 types

Condition: Target (4060 mm 1.5752.362

inch), natural shape

268

Page 4

DIMENSIONS mm inch

12.2

.480

11.7

.461

3.3

.130

2,000

78.74

3.3

.130

3.3

.130

4.4

.173

4.4

.173

44.8

1.764

24

.945

10.9

.429

1.4

.055

4

.157

16.6

.654

25.4

1 inch

4

.157

2.2

.087

10.7

.421

6.3

.248

7.3

.287

24.4

(1 inch)

(17)

(.669)

25.4±0.2

1 inch

25.4±0.2

1 inch

6.3

.248

32

1.260

6.3

.248

1

.039

4.2 DIA.

.165

12.6

.496

Distance adjustment dial Operation indicator LED

2-M4 (P = 0.6) tapped

M.S.:* M4 or #6

Adjustment indicator LED

Dimensions with the mounting bracket**

attached

Outline dimensions

12.2

.480

3.3

.130

2,000

78.74

3.3

.130

3.3

.130

4.4

.173

4.4

.173

44.8

1.764

24

.945

10.9

.429

1.4

.055

4

.157

16.6

.654

25.4

1 inch

4

.157

2.2

.087

10.7

.421

6.3

.248

7.3

.287

24.4

(1 inch)

(17)

(.669)

25.4±0.2

1 inch

25.4±0.2

1 inch

7.5

.295

7.5

.295

10.5

.413

32

1.260

1

.039

4.2 DIA.

.165

12.6

.496

Distance adjustment dial Operation indicator LED

2-M4 (P = 0.6) tapped

M.S.:* M4 or #6

Adjustment indicator LED

Dimensions with the mounting bracket**

attached

Outline dimensions

18.2

.717

2,000

78.74

3.5

.138

3.5

.138

3.5

.138

4.4

.173

4.4

.173

4

.157

68.2

2.685

12.5

.492

12.5

.492

24

.945

12.4

.488

1.6

.063

17.4

.685

36.6

1.441

45

1-49/64

45.0

1.772

12.7

.500

4.5 DIA.

.177

9.1

.358

8.1

.319

44

(1-3/4 inch)

(22)

(.866)

45±0.2

1-49/64

45±0.2

1-49/64

13

.512

13

.512

15.5

.610

52

2.047

1

.039

4.2 DIA.

.165

18.6

.732

Distance adjustment dial Operation indicator LED

2-M4 (P = 0.6) tapped

M.S.:* M4 or #6

Adjustment indicator LED

Dimensions with the mounting bracket**

attached

Outline dimensions

08/2005

1. MQ-W3 types

MQ-W

2. MQ-W20 types

3. MQ-W70 types

General tolerance:

±0.5 .020

General tolerance:

±0.5 .020

CONNECTING DIAGRAM

*M.S.: mounting screw

Make connection to B side with pink wire for

Light ON

Make connection to v side with pink wire for

Dark ON

Note: When switching a power source, make

ground connection to the frame ground terminal or to the ground terminal. This will assure

more stable operation.

General tolerance:

**The mounting bracket is enclosed in the inner carton.

Operating condition

With light

intercepted ON

With light

entering ON

Lights with light entering

Output transistor

Operation

indicator LED

±0.5 .020

Common use

269

Page 5

MQ-W

08/2005

OPERATING PRINCIPLES

Detection principle of new triple beam area reflective series

$ Optical triangulation sensing method

The light beam projected by the LED,

passing through the condensing lens of

the light projector, is applied to the surface of the target to be detected. One

part of the diffused reflected light rays

passes through the light receiver lens

producing a spot on the position sensitive device. When the detectable target

is at a position A that is at a compara-

$ Triple beam type range sensing principle

The MQ photoelectric sensor area

reflective type has adapted this optical

triangulation range measurement principle, but in order to improve the reliability of the detection of the sensor, a

more elaborate method has been

devised. First, light receivers are positioned symmetrically on either side of

the axis of the light projector, composing a triple beam arrangement. As

shown in Fig. 2, when the moving

detectable target is at the edge of the

projected light beam, the spot reflected

from the target is at a location different

tively near distance as shown in Fig. 1,

a spot is produced at (a). When the target is at a position B that is far, a spot

is produced at (b). Accordingly, if any

spot position on the position sensitive

device is detected, the distance to the

target can be determined. This is the

principle of optical triangulation range

measurement.

from the point where the spot is produced when the beam is completely

intercepted, generating a range measurement difference of +

the triple beam composition, the symmetrically arranged position sensitive

device (2) has a spot produced conversely at a –

and by means of averaging both range

measurement signals, the correct range

measurement can be made. This

results in significantly improved

repeatability and background suppression.

∆

X difference position,

∆

X, but with

Fig. 1 Optical triangulation range

measurement method

Other examples of this method are

the automatic focusing and camera

range measurement systems.

Fig. 2 Triple beam range measurement method

By averaging the range measurement signals of the 2 light receiving

systems, the range measurement

difference is cancelled.

$ Optical system of the triple beam photoelectric sensor

In the MQ photoelectric sensor area

reflective type, it is necessary to give

special consideration to the lens. In

order to improve the precision, an

aspherical lens, having limited spherical

and coma aberration, is used.

In addition, as shown in Fig. 4, a photo

diode having 2 output terminals is used.

By comparing the output currents from

the 2 PSDs, there is no relationship to

the level of the incident light. Thus, the

ratio of reflection from the detectable

target exerts no influence and the

range measurement and detection can

be interpreted accuracy.

Fig. 3 Light beam trace of the lens

(a) is a spherical lens, and (b) is the

aspherical lens. Because there is no

aberration in (b), range measurement precision is high.

$ Operating principle of area reflective method

The operation of the MQ photoelectric

sensor area reflective type is explained

in Fig. 5. After the output from the 2

PSD elements is added, the I/V value is

converted and the logarithm determined. By subtraction, the distance signal in (I

1/I2) is obtained. This can be

optionally set, and with the distance

adjustment control, comparison with the

produced value can be made to detect

whether the target is or is not within the

distance range.

Fig. 4 PSD (position sensitive

device) construction

By making a calculation of the ratio

of I

1 and I2, the light spot position

can be detected.

Fig. 5 Signal processing circuit block diagram

270

Page 6

CAUTIONS

Operation

Indicator LED

MQ-W3 type

MW-W20 type

Distance adjustment dial

Adjustment

indicator LED

Adjustment

indicator LED

Operation

Indicator LED

MQ-W70 type

Distance adjustment dial

08/2005

MQ-W

These products are not

safety sensors and are

not designed or intended

to be used to protect life

and prevent bodily injury

or property damage.

1. Ambient environment

1) Use within the range of ambient

temperature of –25 to +55°C –13 to

+131°F.

2) Use within a range of 9.6 V to 30 V

DC (ripple P-P included) for operating

voltage.

3) Use with an ambient light level at the

light receiving surface of less than

10,000 lux for incandescent lamp and

less than 30,000 lux for sunlight.

4) Use a surge absorber as the internal

circuit may be damaged if external

surge voltage exceeds 500 V

[±(1.250) µs of single polarity fullwave voltage].

5) Avoid using in a location with high

concentrations of steam, dust, or corrosive gas.

6) The sensor is of immersion protected

type, but this does not mean that it can

be used in water or where there is

direct impingement of rain for detecting

objects.

2. Connections

1) Check all wiring before applying

power since incorrect wiring may damage the internal circuit.

2) Use a load relay with a rated operating voltage of 12 V DC or 24 V DC. The

voltage applied to the load relay is the

operating voltage of the photoelectric

sensor minus the internal voltage drop

(1.2 V). Voltage fluctuations should be

taken into account.

3) If a load greater than 100 mA is connected, the output section will be

damaged, so sufficient care should be

taken.

4) If the wiring to the photoelectric sensors run parallel to high voltage or

power lines, due to inductive noise,

mis-operation or damage can occur.

Wiring should be run in separate.

5) Wire 0.3 mm

2

.0005 inch2AWG22 or

larger should be used for wiring up to a

length of 100 m 328 ft..

6) When the photoelectric sensors

being mounted, if the unit is struck by a

hammer or other heavy tool, the function can be impaired. Sufficient care

should be taken.

7) The changeover from Light-ON (light

entry ON) to Dark-ON (light intercepted

OFF) can be carried out with the pink

lead wire. For Light-ON, connect the

pink wire to the B side, and for DarkON, connect the pink wire to the v

side.

3. Distance adjustment

1) Set the detecting surface of the photoelectric sensor in the detecting direction and temporarily fasten it.

2) While no target in the detection

region, set the distance adjustment dial

to maximum (FAR) and slowly turn it

counterclockwise.

Continue turning the control counterclockwise until the operation indicator

LED (OPE.) is extinguished. This is the

adjustment position. If the indicator

LED is extinguished at the maximum

position, that is the adjustment position.

3) With target in the detection area, set

the dial in the minimum position

(NEAR) and turn the control clockwise

to locate the position where the indicator LED turns ON. If the indicator LED

goes ON at the minimum position, then

NEAR is the adjustment position.

4) Set the control to a point midway

between the locations found in 2) and

3) above.

5) Securely fasten the photoelectric

sensor. When fastening, the sensor

should be sufficiently secure so that it

will not shift under vibration of shock.

Notes:

1. If the adjustment indicator LED does

not light in the adjustment of 3) as prescribed, or if the position between 2)

and 3) is less than 2 graduations,

change the position of the detection

surface and repeat the procedure of 1)

to 4), or try to determine the source of

external factors such as variation in

ambient temperature, variation in target

position, etc., that creating the problem.

2. The difference in detection distance

due to the colors of the target is virtually non-existent, but if the actual target is

one where the reflectivity is extremely

low (target which have a frosted finish

produced by black rubber), or where

the reflectivity is extremely high (mirror,

glass, or truly reflectting target), confirmation should be done with the actual

target.

4. Detector

1) Keep the detector surface clean as

excessive dust or dirt on the detector

surface will decrease the margin of the

distance range.

2) The front surface of the lens is made

of polycarbonate. This material is resistant to water, weak acids and alkalis,

aliphatic hydrocarbons, oils, etc., but it

is not resistant to ketones, esters, halogenated hydrocarbons, or aromatic

hydrocarbons.

271

Loading...

Loading...