Panasonic Minas-LIQI Technical Reference

No. SR-ZSV00039

TECHNICAL REFERENCE

MODE L

Product name: AC Servo Amplifier

Product number: Minas-LIQI series

Issued on March 26, 2012

(REVISION . . )

Received by

Date:

CHECKED CHECKED CHECKED DESIGNED

Motor Business Unit, Appliances Company

Panasonic Corporation

7-1-1 Morofuku, Daito-City, Osaka 574-0044, Japan

REVISIONS

№SR-ZSV00039

Date Page Sym

Mar. 26, 2012

- -

REVISION Signed

NEWLY ISSUED

Kang,Wu

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039

Contents

1. Specification Overview.........................................................................................................................1

2. Specifications of Interface.....................................................................................................................2

2-1 Specifications of Input Signal of I/F Connector.................................................................................2

2-2 Specifications of Output Signal of I/F Connector..............................................................................4

2-3 Input/Output Signal Allocation ..........................................................................................................5

2-3-1 Allocation of Input Signal ..........................................................................................................5

2-3-2 Allocation of Output Signal .......................................................................................................8

3. Specifications of Front Panel ..............................................................................................................10

3-1 Rotary switch(RSW) ........................................................................................................................10

3-2 7 segment LED.................................................................................................................................11

4. Basic function .....................................................................................................................................12

4-1 Setting Rotational Direction.............................................................................................................12

4-2 Position control ................................................................................................................................13

4-2-1 Command Pulse Input ..............................................................................................................13

4-2-2 Command Scaling (Electronic Gear)........................................................................................15

4-2-3 Position Command Filter..........................................................................................................16

4-2-4 Pulse Regeneration...................................................................................................................18

4-2-5 Counter Clear (CL)...................................................................................................................21

4-2-6 In-position Output (INP) ..........................................................................................................22

4-2-7 Command Pulse Inhibition (INH) ............................................................................................23

4-3 Setting of Regenerative Resistor ......................................................................................................24

5. Gain Adjustment / Damping Control Functions .................................................................................25

5-1 Automatic Adjusting Function.........................................................................................................25

5-1-1 Real-time Auto Tuning.............................................................................................................26

5-1-2 Adaptive Filter..........................................................................................................................31

5-2 Manual Adjustment..........................................................................................................................33

5-2-1 Block Diagram of Position Control Mode................................................................................34

5-2-2 Gain Switching Function..........................................................................................................35

5-2-3 Notch Filter ..............................................................................................................................39

5-2-4 Damping Control......................................................................................................................41

5-2-5 Feed Forward Function ............................................................................................................44

5-2-6 3rd Gain Switching...................................................................................................................46

5-2-7 Friction Torque Compensation.................................................................................................47

6. Applied Functions ...............................................................................................................................49

6-1 Torque Limit Switching ...................................................................................................................49

6-2 Motor Movement Range Setting ......................................................................................................50

6-3 Electronic Gear Switching ...............................................................................................................52

6-4 Setting of Sequence Movements ......................................................................................................53

6-4-1 Drive prohibition input (POT , NOT ) sequence......................................................................53

6-4-2 Sequence at Servo Off..............................................................................................................54

6-4-3 Emergency Stop at Alarm ........................................................................................................55

6-4-4 Emergency Stop at Alarm ........................................................................................................56

7. Protective/Warning Functions.............................................................................................................57

7-1 List of Protective Functions .............................................................................................................57

7-2 Details of Protective Functions ........................................................................................................59

7-3 Warning Functions ...........................................................................................................................64

7-4 Protection Function Setting before Gain Adjustment ......................................................................65

8. Others..................................................................................................................................................67

8-1 List of parameters.............................................................................................................................67

8-2 Timing Chart....................................................................................................................................73

8-2-1 Timing Chart of Operations After Turning Power On .............................................................73

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039

8-2-2 Timing Chart of Servo On/Off When Monitor is Turned Off ..................................................74

8-2-3 Timing Chart of Servo On/Off When Motor is Operating .......................................................74

8-2-4 Timing Chart of Operations When Alarm is Issued (Servo-On Command Status)..................75

8-2-5 Timing Chart of Operations When Alarm is Cleared (Servo-On Command Status) ...............76

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 1 -

B and

Maximum command

time and automatically setting gain that meets set stiffness

1.Specification Overview

Control method IGBT PWM method sine wave drive

Control mode Position Control

Encoder feedback

Input

Control signal

output

Input

Pulse signal

output

Basic Specification

Communication function(USB)

Front panel

Regeneration

Dynamic brake Provided

Control input

Control output In-position, etc.

2500p/r(resolution: 10,000) 5-wire serial incremental encoder

6 multi-function inputs

Functions of multi-function inputs: parameter-selectable

3 multi-function outputs

Functions of multi-function outputs: parameter-selectable

1 inputs each

Both line driver interface and open collector interface supported using optocouple

r input

4 outputs each

Encoder pulses (phase A, B and Z signals) or external scale pulses (phase EXA, EX

EXZ signals) output by line driver. Open collector output is also available for phase Z

and EXZ signals.

Personal computer, etc. can be connected for parameter setting configuration and status

monitoring.

①7 seg LED 2pcs ②RSW 1pcs

External resistor

Deviation counter clear, command pulse input inhibition, electronic gear switching,

damping control switching, etc.

pulse frequency

Input pulse train

Input pulse

Position control

Function

Damping control

Auto tuning

Dividing encoder pulse Pulse count can be arbitrarily specified (up to encoder pulse count).

Common

Protective function

Alarm data trace back function Alarm data history can be viewed.

Command scaling

(electric gear ratio

setting)

Smoothing filter Selectable between first order filter and FIR filter for command input.

Differential input; parameter-selectable (1) Positive/Negative 2) Phase A/Phase B 3)

Command/Direction)

Encoder resolution (numerator) and command pulse count per motor revolution (denominator) can be arbitrarily specified between 1-220 for numerator and 1-220 for denominator but use within the range above.

Identifying load inertia real-

when the motor is driving by a operation command from the host or drive

Overvoltage, undervoltage, overspeed, overload, overheat, overcurrent,

Position deviation fault, Command pulse division, EEPROM error, etc.

500 kpps

1/1000 - thousandfold

Available

encoder abnormalities

Motor Business Unit, Appliances Company, Panasonic Corporation

he edges with the default setting.

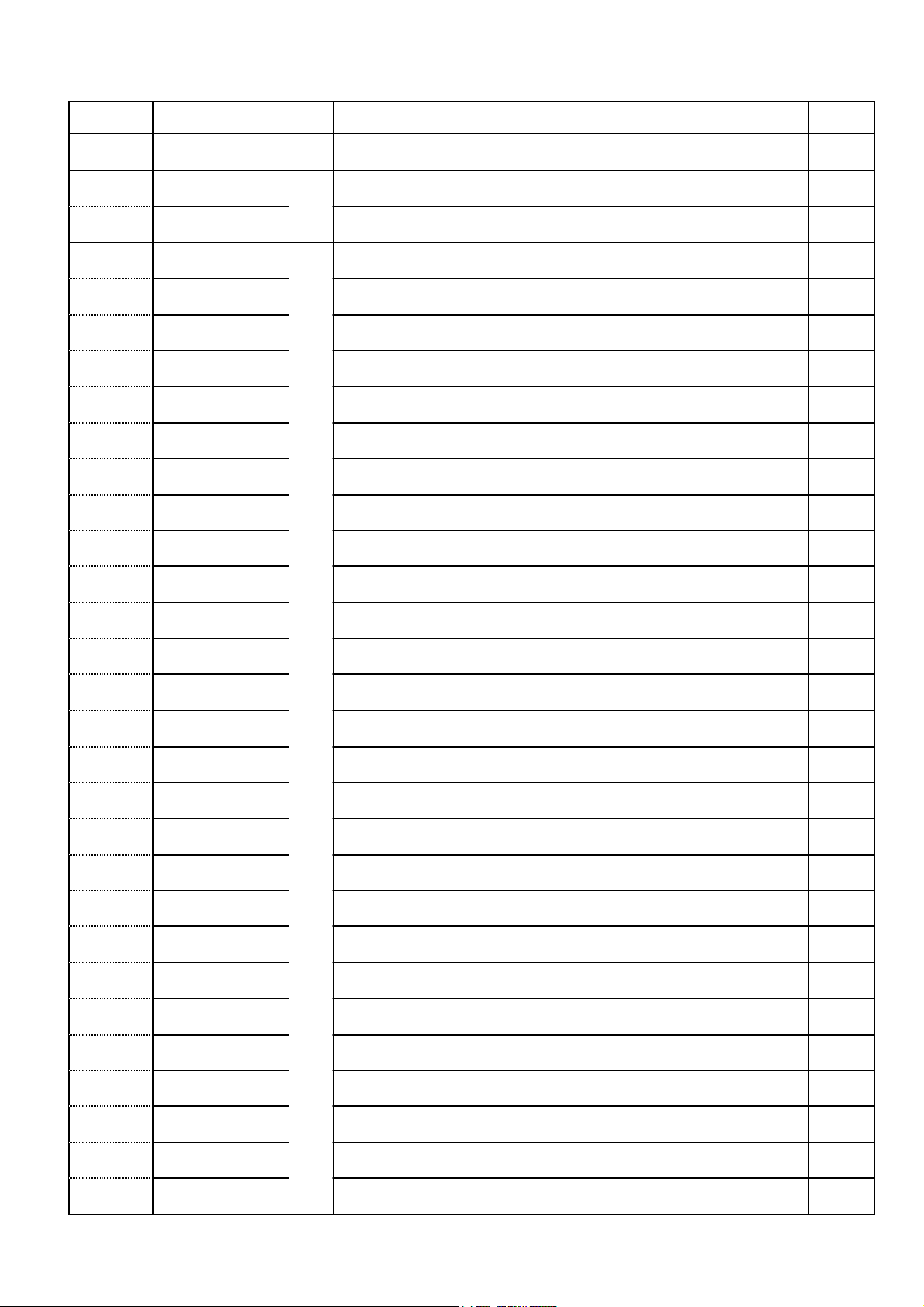

2.Specifications of Interface

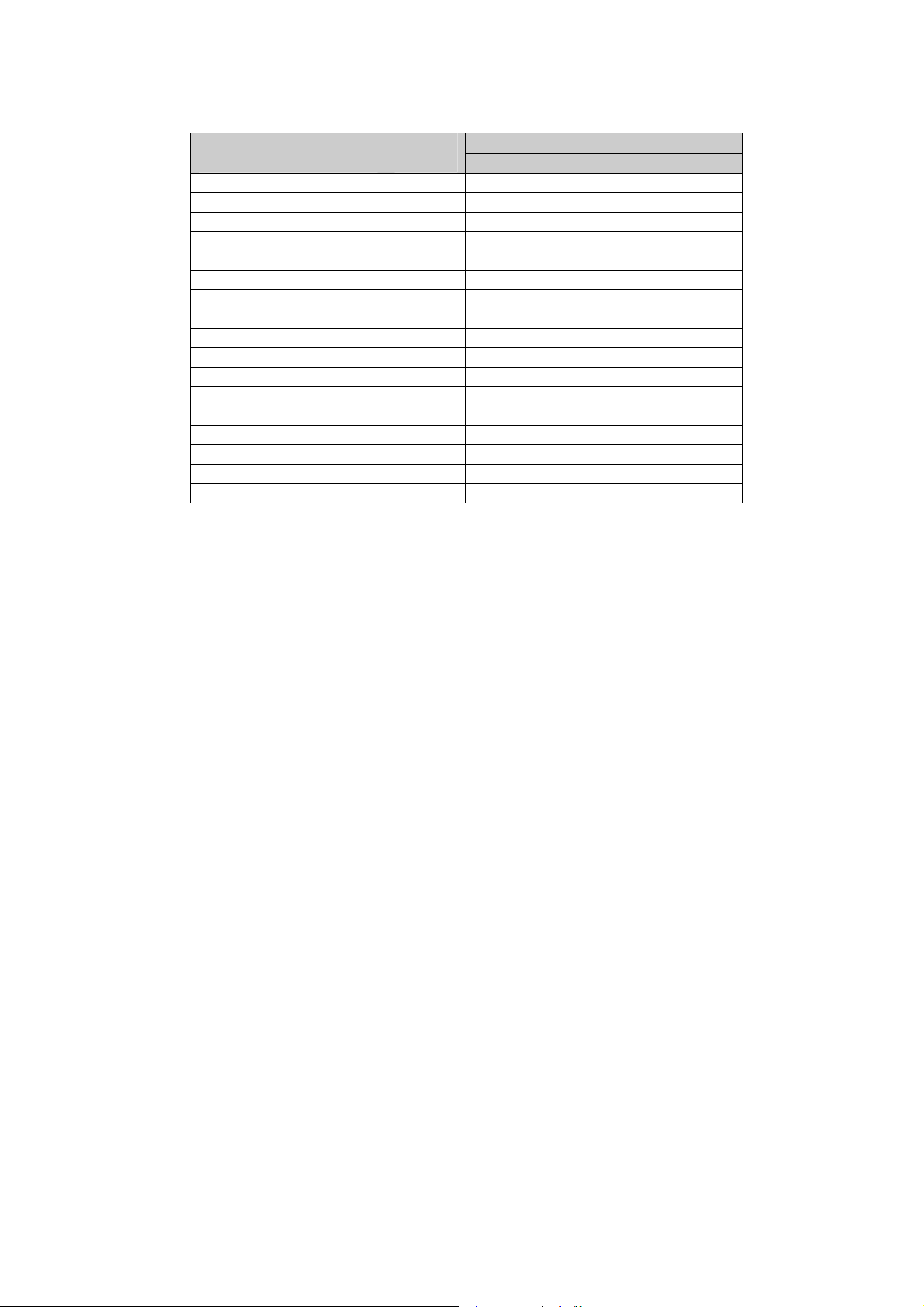

2-1 Specifications of Input Signal of I/F Connector

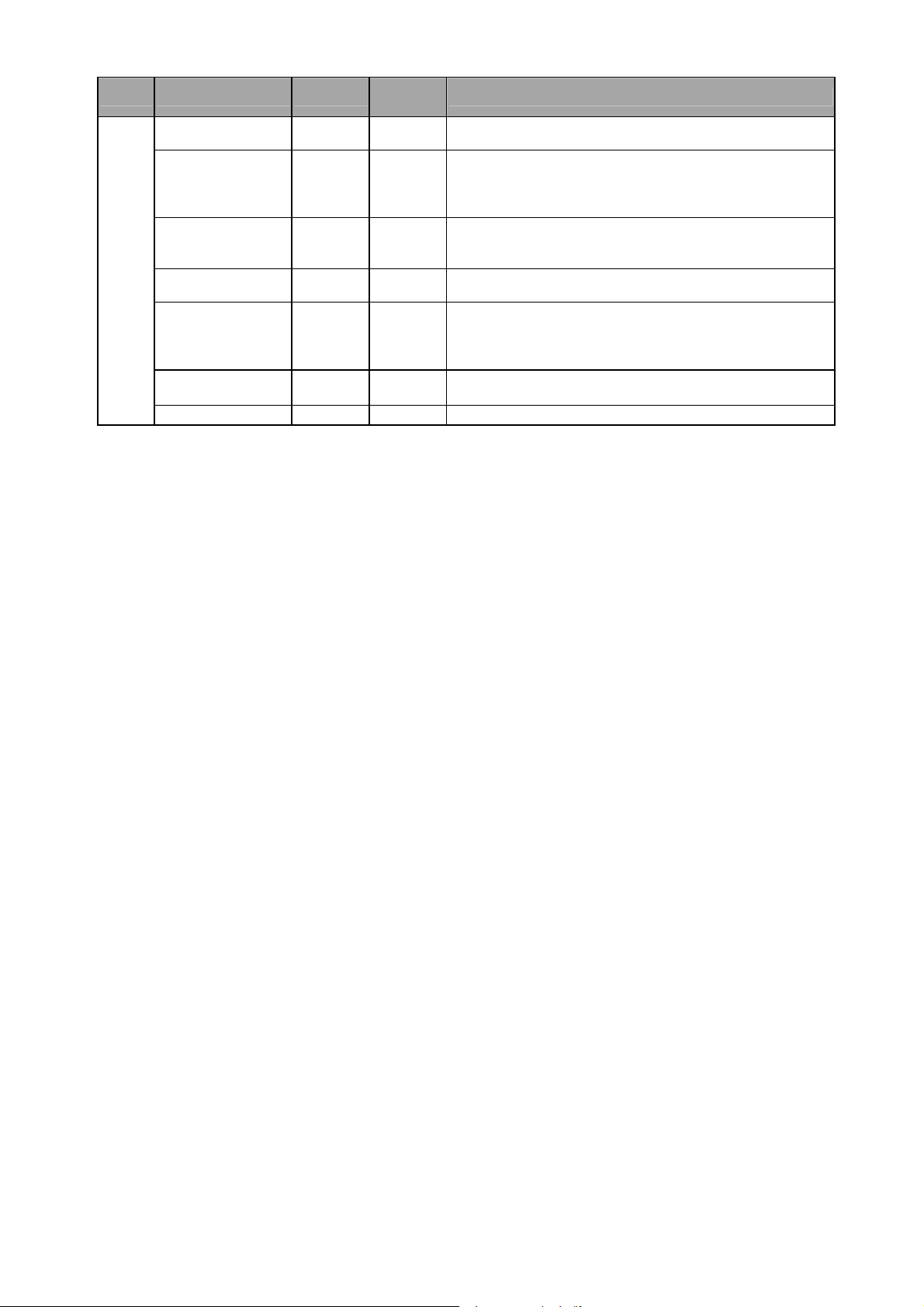

Input signals and their functions

Category

Signal Code

Connector

pin No.

№SR-ZSV00039 - 2 -

Item

Power supply

Common

Command pulse inp

ut 1

Command direction i

Input pulse

nput 1

Servo On

Positive overtravel

limit

Negative overtravel

limit

Control input

Deviation counter

clear

COM+

COM-

PULS1 20

PULS2 21

SIGN1 22

SIGN2 23

SRV-ON 2 (SI1)

POT

NOT

CL

1

11

*

7

(SI6)

*

6

(SI5)

*

4

(SI3)

*

Plus terminal of an external 12 - 24 V DC power

Minus terminal of an external 12 - 24 V DC power

Position command pulse input terminal dedicated for the line

driver output.

This input is invalid with the default setting.

For details, see Section 4-2-1.

Digital input to enable/disable the drive (with and without p

ower to the motor).

This is an overtravel limit to the positive direction.

The operation when this input is turned on is set by Pr5.04

"Over-travel inhibit input setup".

Before use, set "Over-travel inhibit input setup" to any value other

than 1, and connect pins so that the input is turned on when the

signal input exceeds the moving range in the positive direction of

the moving part of the machine.

An overtravel limit to the negative direction.

The operation when this input is turned on is set by Pr5.04

"Over-travel inhibit input setup".

Before use, set "Over-travel inhibit input setup" to any value other

than 1, and connect pins so that the input is turned on when the

signal input exceeds the moving range in the negative direction of

the moving part of the machine.

Digital input to clear the deviation counter.

This input clears the counter at t

To change the setting, use Pr5.17 "Counter clear input mode".

For details, see Section 4-2-5.

Alarm clear

Command pulse

inhibition input

A-CLR 3 (SI2)

*

INH

(SI4)

*

This input clears the alarm state.

Note some alarms cannot be cleared with this input.

Digital input to inhibit the position command pulse input

5

Before use, set Pr5.18 "Invalidation of command pulse inhibit

input" to 0.

For details, see Section 4-2-7.

*1 "-" in the table means that operations do not depend on "on/off" of the input signal.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 3 -

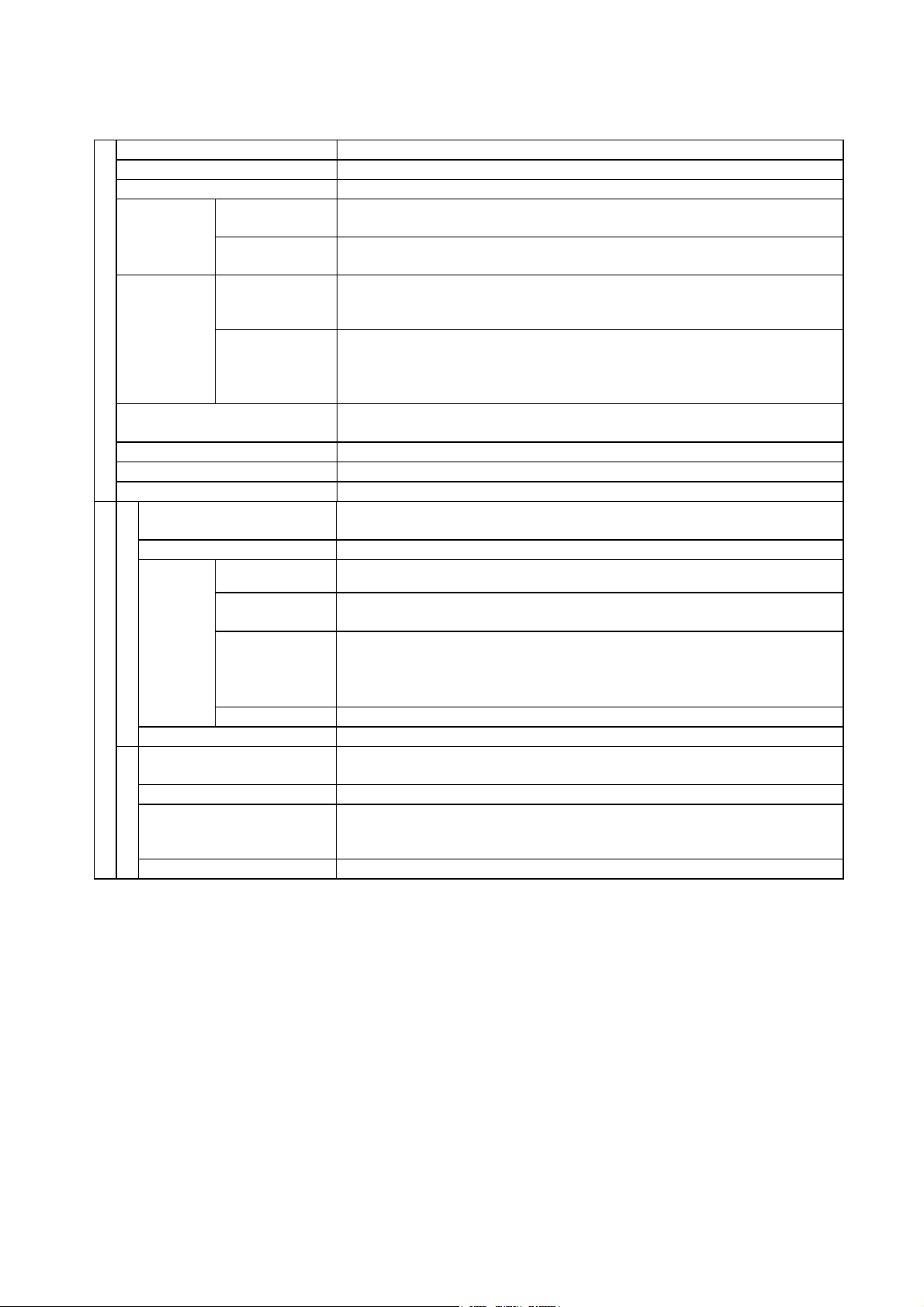

Category

Control input

Signal Code

Command scaling

switch 1

Damping switch 1

Gain switch

Torque limit switch

Damping switch 2

Command scaling

switch 2

Forced Alarm Input

DIV1 -

VS-SEL1 -

GAIN -

TL-SEL -

VS-SEL2 -

DIV2

E-STOP

Connector

pin No.

Item

This input switches the command scaling numerator.

For details, see Section 6-4.

This input switches frequencies applied for the damping control.

Together with the damping switch 2 (VS-SEL2), it is possible to

switch between four frequencies at the maximum.

For details, see Section 5-2-4.

Digital input to switch the gains between the 1st and 2nd in the

servo loop.

For details, see Section 5-2-2.

Digital input to switch between the 1st and 2nd torque limits.

For details, see Section 6-1.

This input switches frequencies applied for the damping control.

Together with the damping switch 1 (VS-SEL1), it is possible to

switch between four frequencies at the maximum.

For details, see Section 5-2-4.

This input switches the command scaling.

For details, see Section 6-3.

Generates Err87.0 "Compulsory alarm input protection".

The "*" mark attached to pin numbers displays that functions of signals and logics can be altered among pins with number

Pr4.00 - Pr4.05 (SI* input selection). Note that pin numbers assignable to the following functions cannot be changed.

Deviation Counter Clear Input (CL): SI3; Command Pulse Inhibition Input (INH): SI4

No function is allocated to the connector pins marked with "-" in the default setting.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 4 -

when the main DC power after

2-2 Specifications of Output Signal of I/F Connector

Output signals and their functions

Category

Common

Pulse output

Control output

Control output

Signal Code

Frame ground

Signal ground

Phase A signal output

Phase B signal output

Phase Z signal output

Phase Z signal output

Servo alarm output

Servo ready output

Motor holding brake

release

In-position

Torque limited

Zero speed

In-position 2

Warning 1

Warning 2

Output for

presence/absence of

position command

Alarm clear attribute

output

Main Power output

FG

GND 12

OA+ 13

OA- 14

OB+ 15

OB- 16

OZ+ 17

OZ- 18

CZ 19

ALM

S-RDY

BRK-OFF -

INP

TLC

ZSP

INP2 -

WARN1 -

WARN2 -

P-CMD -

ALM-ATB -

P-ON -

Connector

pin No.

Shell

26

8

(SO1)

*

10

(SO3)

*

9

(SO2)

*

-

-

Item

Internally connected with the earth terminal.

Signal ground

The signal ground is internally isolated from the control signal

power supply (COM-).

Differential outputs after the parameterized scaling of either an

encoder signal or an external scale signal (A, B, and Z phases)

(RS422 equivalent).

The ground terminal of the line driver in the output circuit is

connected to the signal ground (GND) and thus not isolated.

The maximum frequency of the pulse output is 4 Mpps after

quadrature.

Open collector output of phase Z signal

The emitter terminal of the transistor in the output circuit is

connected to the signal ground (GND) and thus not isolated.

Digital output to display the alarm state.

Turns on the output transistor in a normal state, and turns off the

output transistor when an alarm is issued.

Digital output to display the driver is ready to be enabled.

The output transistor turns on when both the main and control

power supplies are properly provided and no alarm is shown.

Turns on the output transistor after absolute data are transferred,

when the absolute I/F function is valid in the absolute mode.

Outputs a timing signal that activates the electromagnetic brake of

the motor.

Turns on the output transistor at the time the electromagnetic

brake is released.

Digital output to give an in-position signal.

Turns on the output transistor in the in-position state.

For details, see Section 4-2-6.

Digital output to display the torque is limited.

Turns on the output transistor while torque is limited.

Digital output to display the zero speed state.

Turns on the output transistor while zero-speed is detected.

Outputs the in-position 2 signal.

Turns on the output transistor in the state of in-position.

For details, see Section 4-2-6.

Outputs a warning output signal that has been set by Pr4.40

"Selection of alarm output 1".

Turns on the output transistor while a warning is issued.

Outputs a warning output signal that has been set by Pr4.41

"Selection of alarm output 2".

Turns on the output transistor while a warning is issued.

Turns on the output transistor when a position command is

present.

・Turns on the output transistor when an alarm that can be cleared

is issued.

・Turns on the output transistor

commuting is in low level.

·The "*" mark attached to pin numbers displays that signal functions can be altered among pins with number Pr4.10 - Pr4.10 (which

can be selected by SO* output).

·No function is allocated to the connector pins marked with "-" in the default setting.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 5 -

2-3 Input/Output Signal Allocation

The assignment of the input/output signals can be changed from the default setting.

2-3-1 Allocation of Input Signal

An input signal that you wish can be assigned to an input pin of the I/F connectors. It is also possible to change the

logic.

Note that for some signals, assignment is limited. For details, see (2) "Change the default assignment for input

signals."

(1) Use the default signal assignment

The following table shows the default setting for the signal assignment.

Input signals*2

SI1 input Pr4.00

SI2 input Pr4.01

SI3 input Pr4.02

SI4 input Pr4.03

SI5 input Pr4.04

SI6 input Pr4.05

Corresponding

parameter

Default value

(): Decimal

number

00000003h

(3)

00000004h

(4)

00000007h

(7)

00000088h

(136)

00000082h

(130)

00000081h

(129)

Default status

Signal Logic *1

SRV-ON a connect

A-CLR a connect

CL a connect

INH b connect

NOT b connect

POT b connect

*1 "a connect" and "b connect" represent the following respectively:

a connect : A signal input is open with COM-, and thus the function is invalid (OFF state).

A signal input is connected with COM-, and thus the function is valid (ON state).

b connect : A signal input is open with COM-, and thus the function is valid (ON state).

A signal input is connected with COM-, and thus the function is invalid (OFF state).

In this specification, a signal input is defined ON when its function is valid; OFF when the function is invalid.

*2 For pin numbers assigned as input signals SI1 – SI10, see Specifications.

*3 The mark "-" displays that there is no function assigned.

Motor Business Unit, Appliances Company, Panasonic Corporation

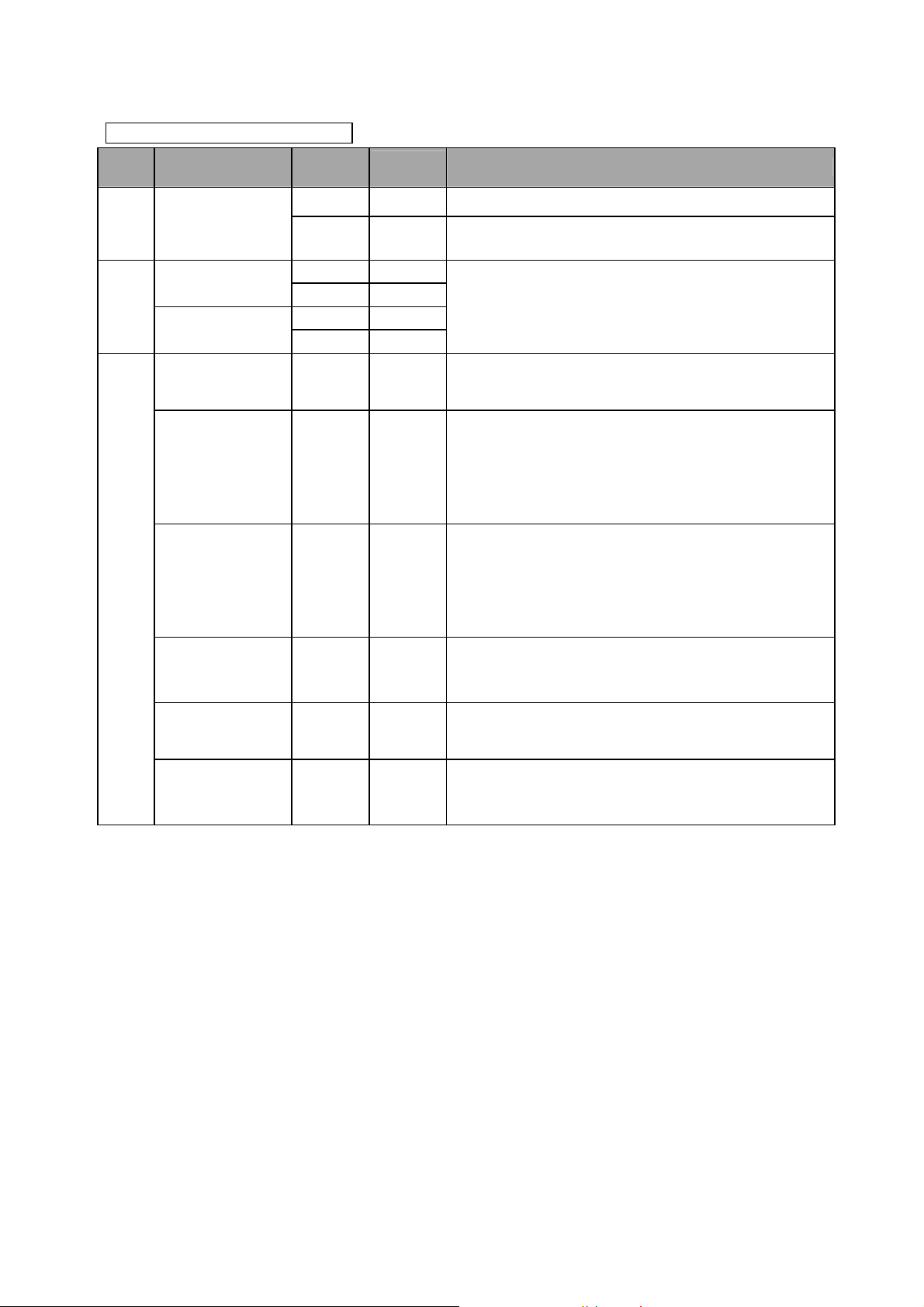

Category

4 00

4 01

4 02

4 03

4 04

4 05

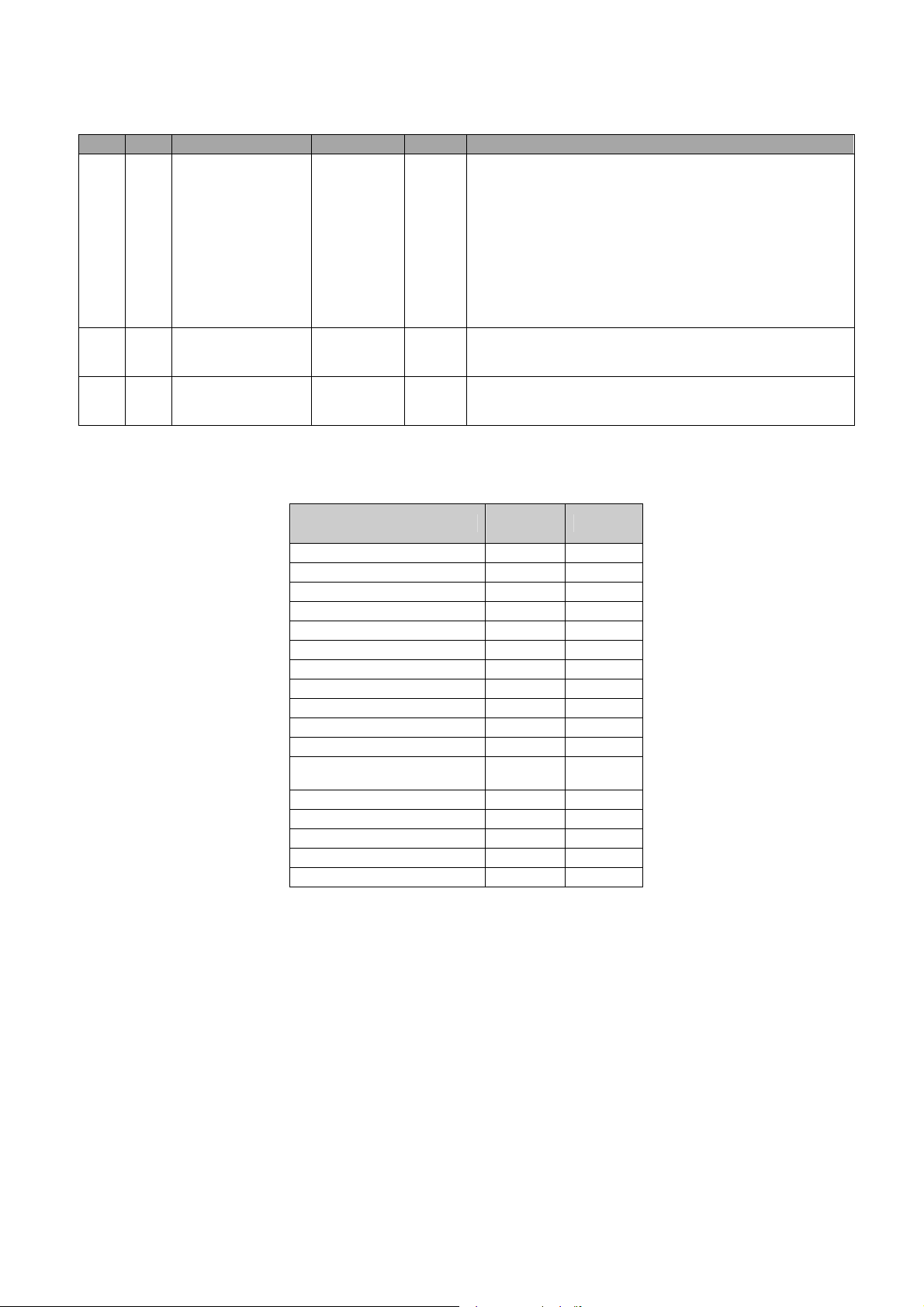

(2) Change the default assignment for input signals

To reassign an input signal, change the following parameter.

No.

Parameter Setup range

SI1 input selection

SI2 input selection

SI3 input selection

SI4 input selection

SI5 input selection

SI6 input selection

00FFFFFFh

00FFFFFFh

00FFFFFFh

00FFFFFFh

00FFFFFFh

00FFFFFFh

0~

0~

0~

0~

0~

0~

Unit Function

To assign a function to the input SI1.

Set this parameter with the hexadecimal system. *1

Following the hexadecimal form, set each control mode as follows:

000000**h

Enter a function number in the place marked with "**."

-

Please refer to the function number table shown later in this section.

The setting of logics is also included in the function numbers.

If you wish to assign to a pin DIV1_a connect,

the setting will be0000000Ch.

To assign a function to the input SI2.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.00.

To assign a function to the input SI3.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.00.

To assign a function to the input SI4.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.00.

To assign a function to the input SI5.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.00.

To assign a function to the input SI6.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.00.

№SR-ZSV00039 - 6 -

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 7 -

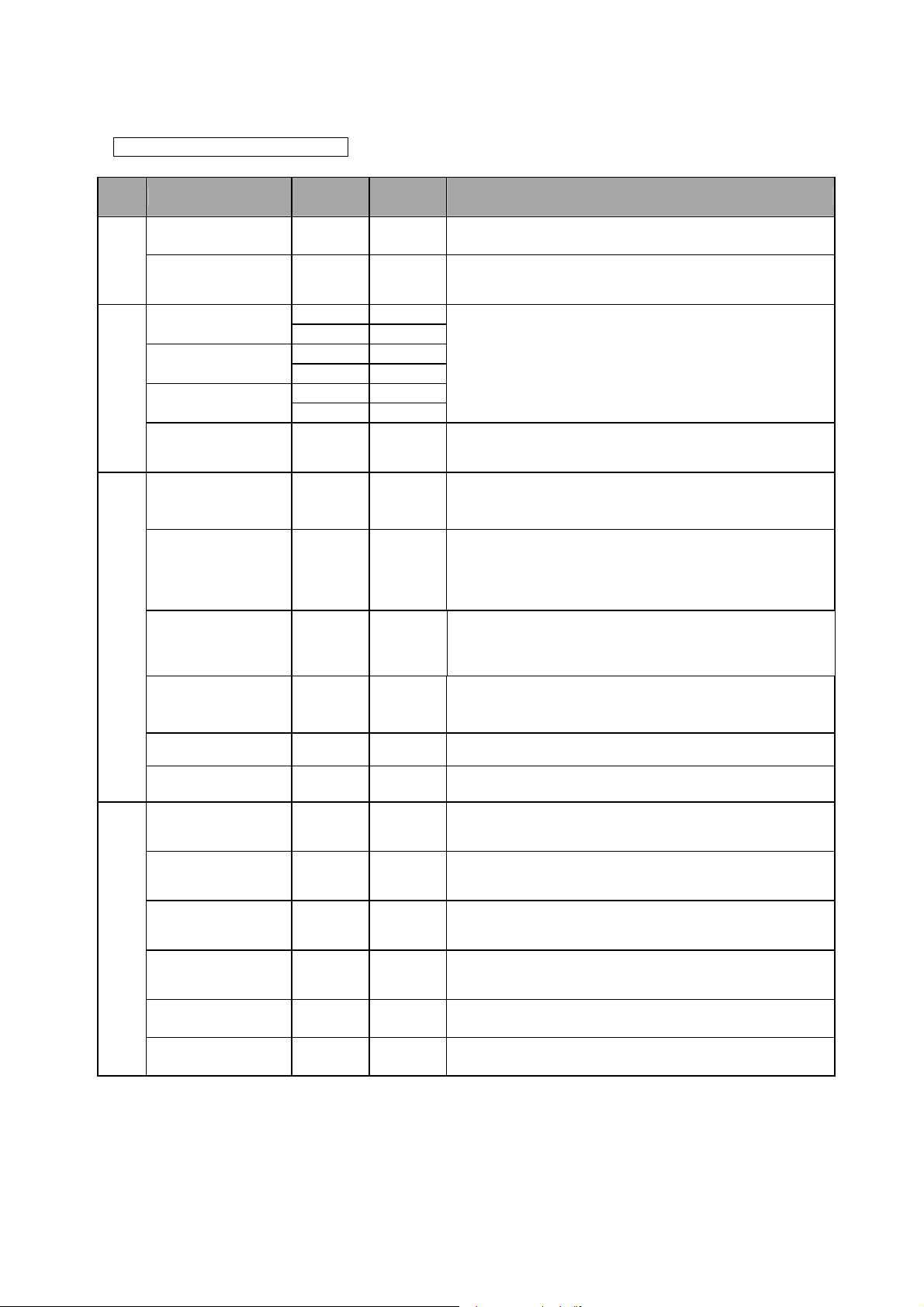

Function number table

Code

Invalid

Positive overtravel limit

Negative overtravel limit

Servo on

Alarm clear

(No setting) - 05h 85h

Gain switch

Deviation counter clear

Command pulse inhibition

Torque limit switch

Damping switch 1

Damping switch 2

Command scaling switch

Command scaling switch 2

(No setting) - 0Eh~13h 8Eh~93h

Forced alarm input

(No setting) - 15h 95h

a connect b connect

- 00h

POT 01h 81h

NOT 02h 82h

SRV-ON 03h 83h

A-CLR 04h

GAIN 06h 86h

CL 07h

INH 08h 88h

TL-SEL 09h 89h

VS-SEL1 0Ah 8Ah

VS-SEL2 0Bh 8Bh

DIV1 0Ch 8Ch

DIV2 0Dh 8Dh

E-STOP 14h 94h

Setting Signal

Not available

Not available

Not available

Precautions:

・Do not set any value other than set values specified in the table.。If it is set other than values specified in the

table,Err33.2 "IF input function number error 1 protection" or Err33.3 "IF input function number error 2 protection" will occur.

And the (No setting) in the table is set to protection function. Because input do not operate, please set it to invalid(00h).

・A function can not be assigned to more than one signal. If any function is assigned to more than one signal, Err33.0 "IF overlaps

allocation error 1 protection" and Err33.1 "IF overlaps allocation error 2 protection" will occur.

・Deviation Counter Clear (CL) can be assigned only to SI7 Input. If it is assigned to the other signals, Err33.6 "CL fitting error

protection" will occur.

・Command Pulse Inhibition (INH) can be assigned only to SI10 Input. If it is assigned to the others, Err33.7 "INH fitting error

protection" will occur.

・Control input pins set as invalid do not affect operations.

・Servo-on Input Signal (SRV-ON) must always be assigned. When it is not assigned, Servo-on cannot be activated

Motor Business Unit, Appliances Company, Panasonic Corporation

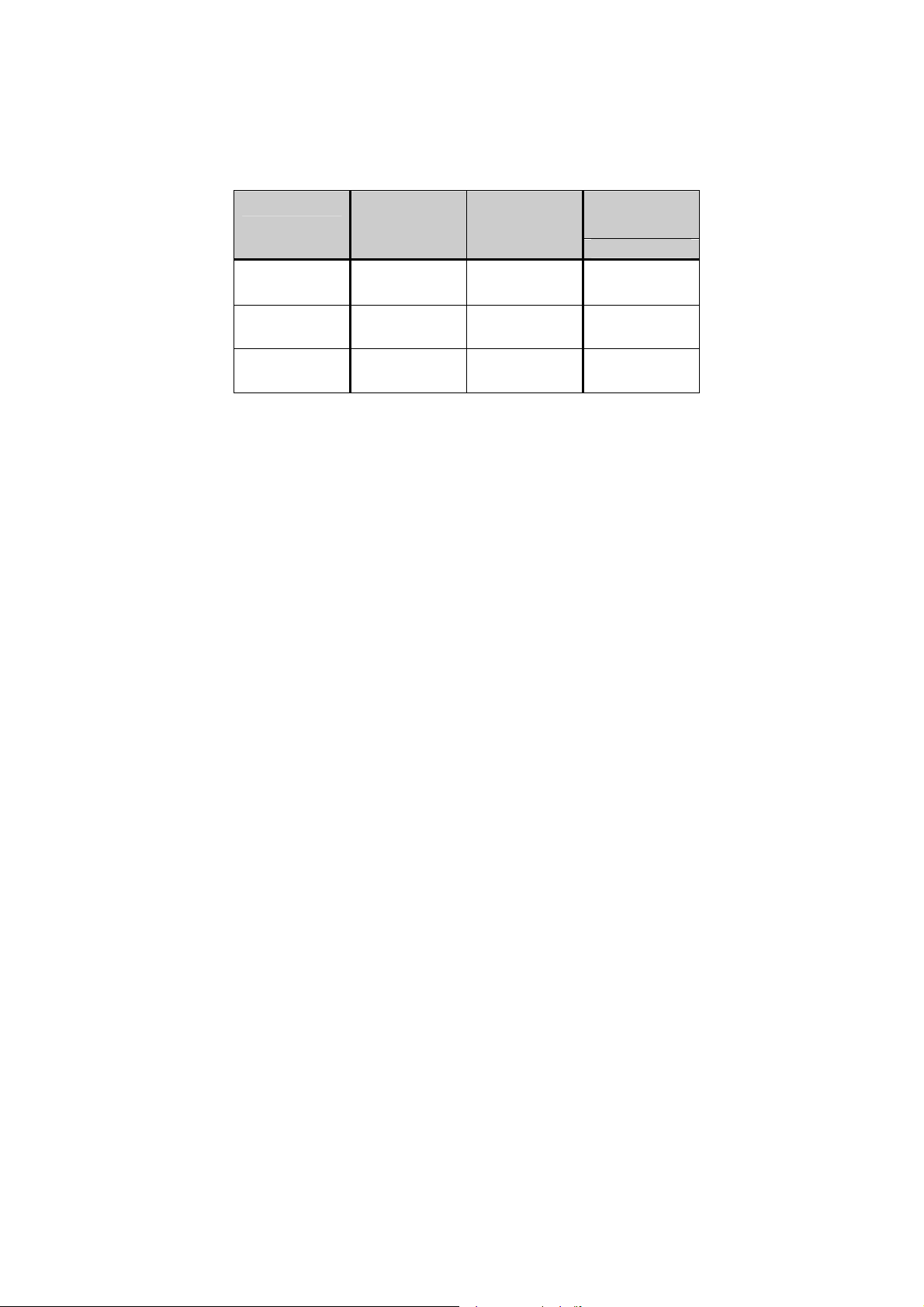

2-3-2 Allocation of Output Signal

Output signals can assign any function except Servo Alarm Output (ALM) to output pins of the I/F connector.

The logic cannot be changed for the output pins.

(1) Use the default signal assignment

The following table shows the default setting for the signal assignment.

Output signals *1

SO1 output

SO2 output

SO3 output

*1 For pin numbers assigned as output signals SO1 – SO3, see Specifications.

Corresponding

parameter

Pr4.10

Pr4.11

Pr4.12

Default value

(): Decimal

number

00000001h

(1)

00000004h

(4)

00000002h

(2)

№SR-ZSV00039 - 8 -

Default status

Signal

ALM

INP

S-RDY

Motor Business Unit, Appliances Company, Panasonic Corporation

(2) Change the default assignment for output signals

Category

No.

4 10

4 11

4 12

SO1 output selection

SO2 output selection

SO3 output selection

Function number table

To reassign an output signal, change the following parameter.

Parameter Setup range

0~

00FFFFFFh

0~

00FFFFFFh

0~

00FFFFFFh

Unit Function

To assign a function to the output SO1.

Set this parameter with the hexadecimal system.*1

Following the hexadecimal form, set each control mode as follows:

000000**h

Enter a function number in the place marked with "**."

Please refer to the function number table shown later in this section.

To assign a function to the output SO2.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.10.

To assign a function to the output SO3.

Set this parameter with the hexadecimal system.

-

Settings can be made in the same way for Pr4.10.

№SR-ZSV00039 - 9 -

Signal Code Setting

Invalid - 00h

Servo alarm output ALM 01h

Servo ready output

Motor holding brake release

In-position

(No setting) - 05h

Torque limited

Zero speed

(No setting) - 08h

Warning 1

Warning 2

Output for presence/absence of

position command

In-position 2

(No setting) - 0Dh

Alarm attribute output

(No setting) - 0Fh

Main power on output P-ON 10h

S-RDY 02h

BRK-OFF 03h

INP 04h

TLC 06h

ZSP 07h

WARN1 09h

WARN2 0Ah

P-CMD 0Bh

INP2 0Ch

ALM-ATB 0Eh

Precautions:

The same function can be assigned to multiple output signals.

A control output pin set as invalid normally keeps the output transistor turned off.

Do not set any value other than set values specified in the table.

If it is set to other than set values specified in the table, Err33.4「I/F output function code error

will occur. And the (No setting) in the table is set to protection function..If it is set to any values ,output will get unstable.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 10 -

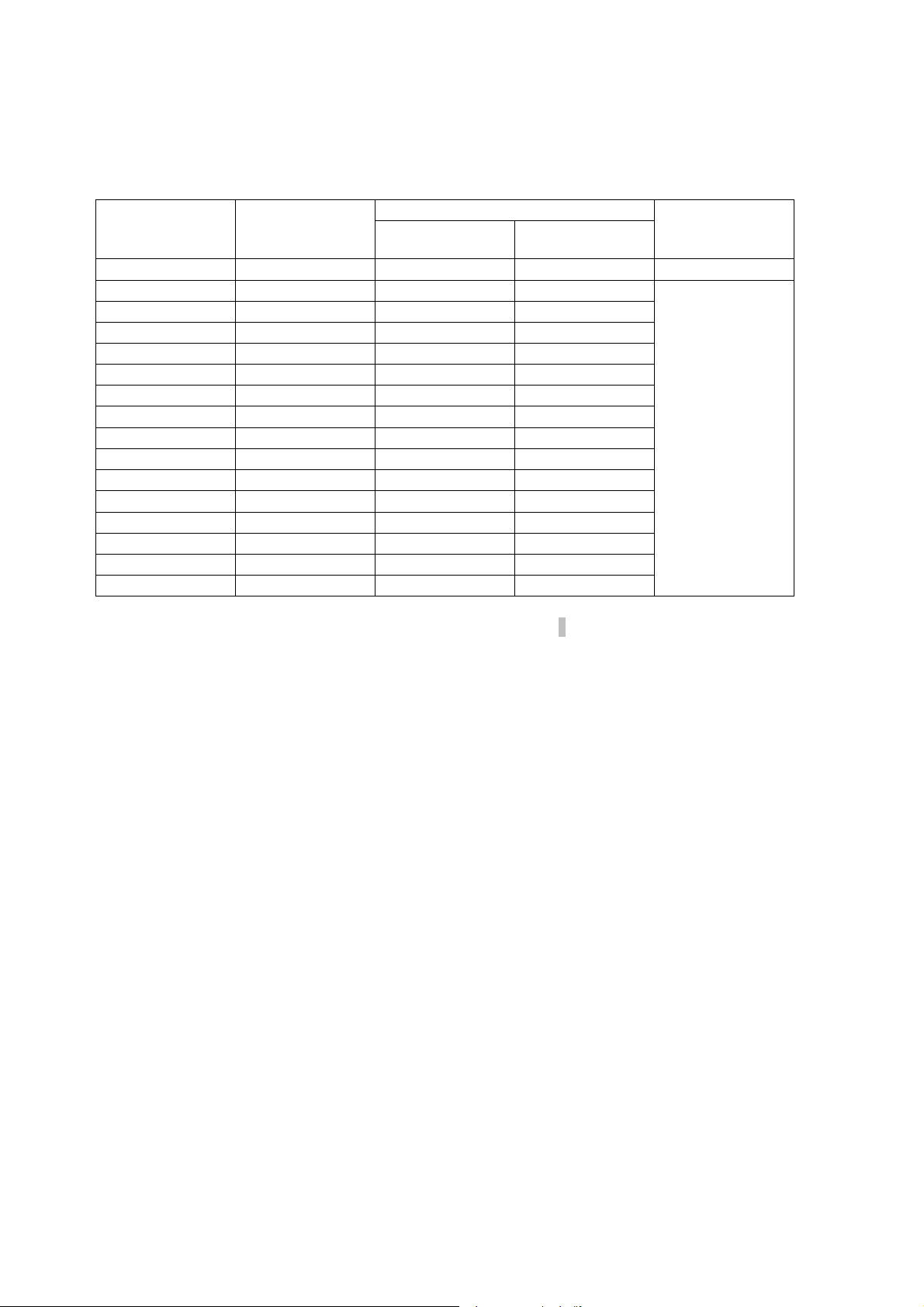

3.Specifications of Front Panel

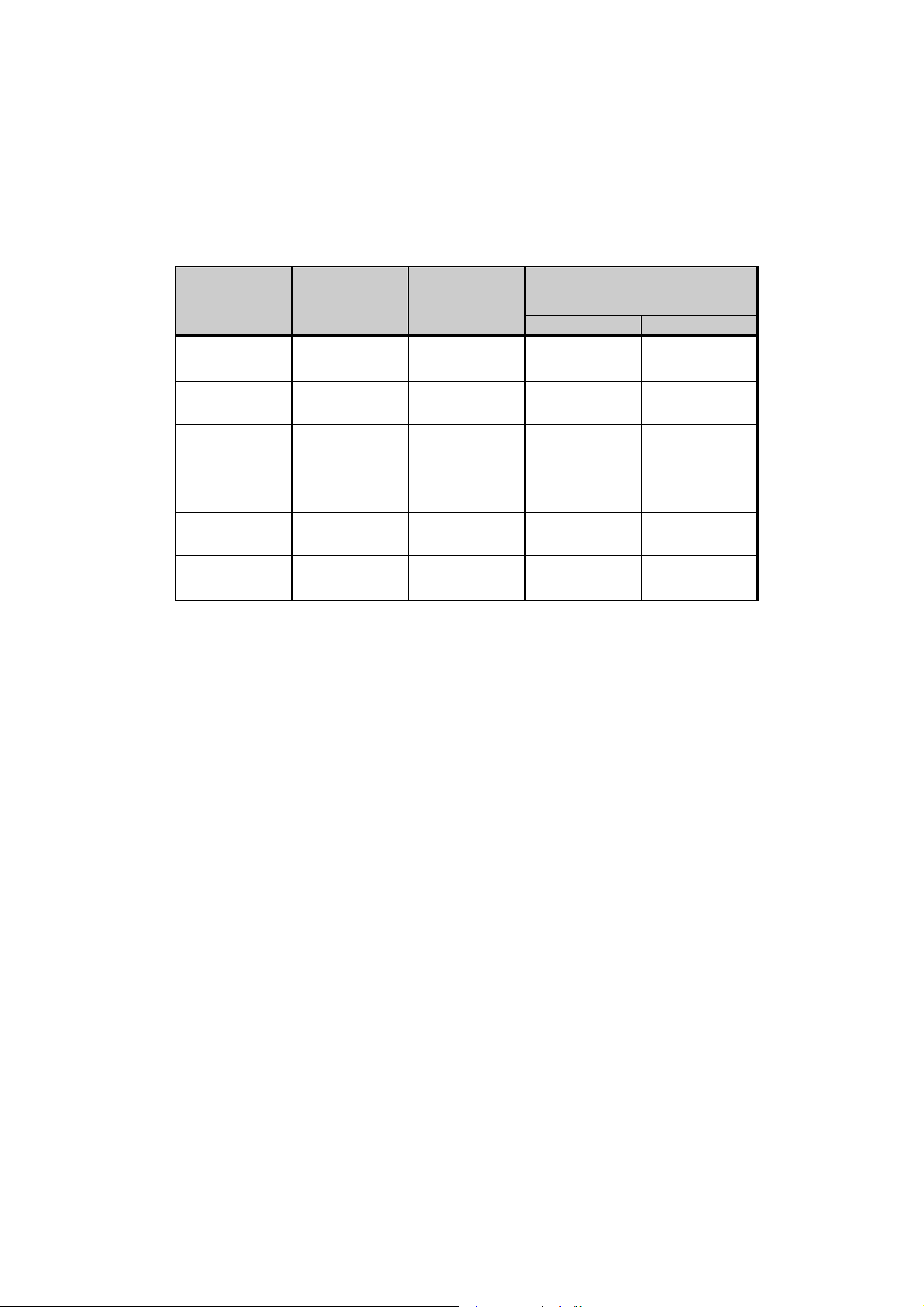

3-1 Rotary switch(RSW)

By manipulating the RSW、Pr.0.03(selection of stiffness at real-time auto-gain tuning) was corrected by setting the RSW, and can be changed from the front panel gain control.

RSW setting

PC ±0 8 Pc

+1 +1 9 9

+2 +2 10 10

+3 +3 11 11

+4 +4 12 12

+5 +5 13 13

+6 +6 14 14

+7 +7 15 15

- ±0 8 8

-7 -7 1 1

-6 -6 2 2

-5 -5 3 3

-4 -4 4 4

-3 -3 5 5

-2 -2 6 6

-1 -1 7 7

The stiffness cor-

rection

Stiffness after

*1 The setting value is 0 that the arrow of rotary switch upward direction. The value is increased

while the arrow is turned by clockwise direction.

Example)Pr0.03=8

correction

LED Display

Parameter Pr0.03

is changed

Possible

Impossible

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 11 -

All di

s

play

time stiffness in

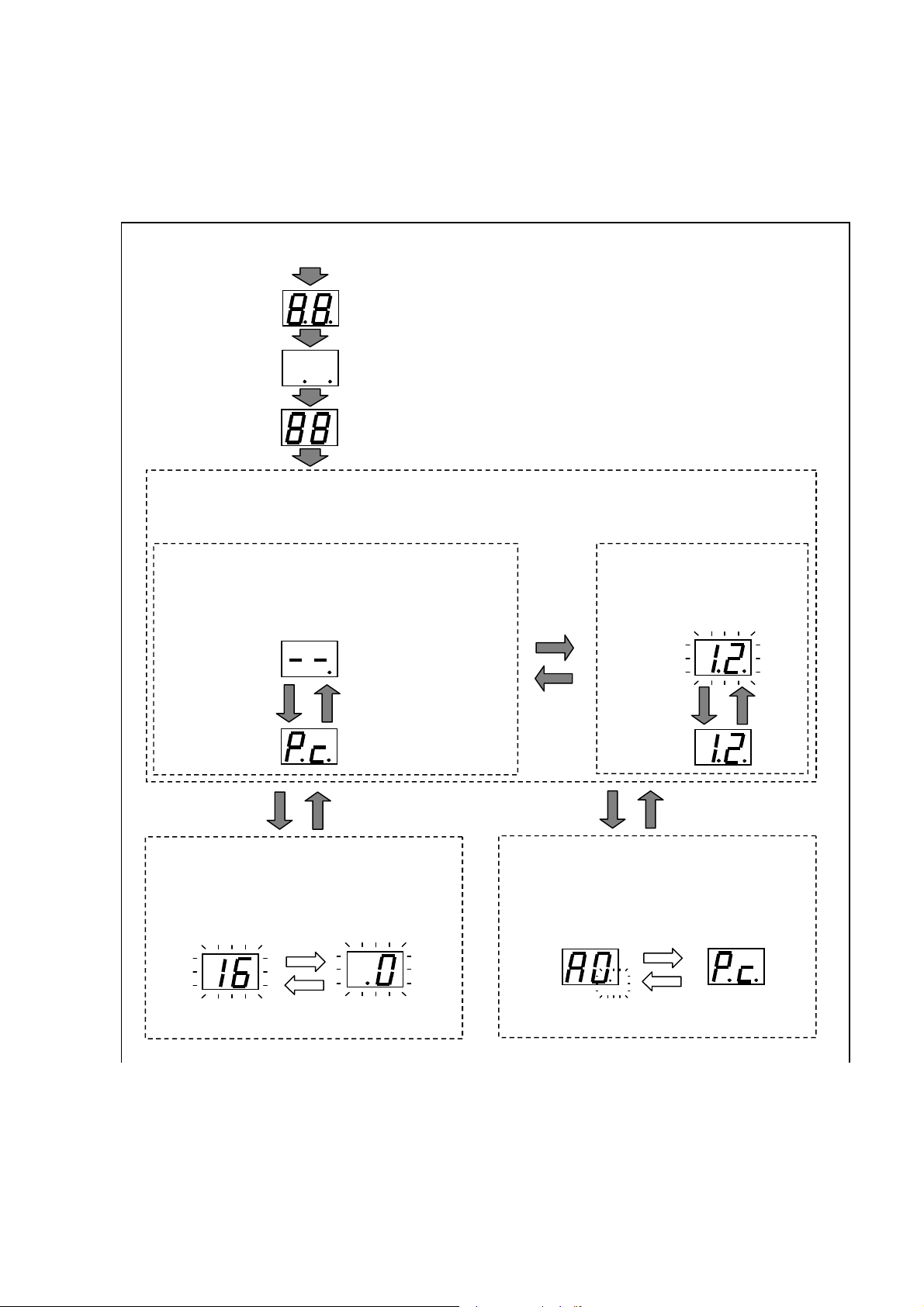

3-2 7 segment LED

At power-up after displaying the check pattern, perform the following normal display.

If you operate the front RSW will show the real-time stiffness value of RSW after adjustment for the front.

However, when an alarm occurs when an alert will display a warning code, the alarm code (main + sub)。

Control power ON

Dot display

[88] display

<Normal >

Priority display of PANATERM and panel RSW is decided by the vaule of RSW.

The display of right dot means main power OK. The diplay of left dot means motor electrified.

<PANATERM priority indicate(RSW=0)>

Servo on/off state is displayed by character。

Set the stiffness by using computer(PANATERM).

Panel RSW

operate

Panel RSW priority indicate (RSW≠0)

LED displays a real-

algorism after adjustment for the

RSW. It can not be set by computer.

Servo-off state

[--]

Servo-on command

Servo-on state

[Pc]

Alarm occur

Decimal indicate:

(right dot:main power OK)

Servo-off command

(riht dot:main power OK)

(left dot:motor electrified)

Alarm clear

< Alarm>

The main code and sub-code(+left dot) of alarm

code(algorism) display alternantly.

(For example:overload)

Main code

Sub-code

(+left dot)

RSW operating

RSW=0

confirm(2s)

Warning occur

RSW except 0

confirm(2s)

RSW confirm

latch:settle problem+alarm clear

No latch:settle problem

Panel RSW

operate

< Warning >

Warning code(hex) and normal state display

alternantly. Left dot flash while warning occur.

(For example:overload)

Warning code(about 2s)

Left dot flash

Normal(about 4s)

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 12 -

4.Basic function

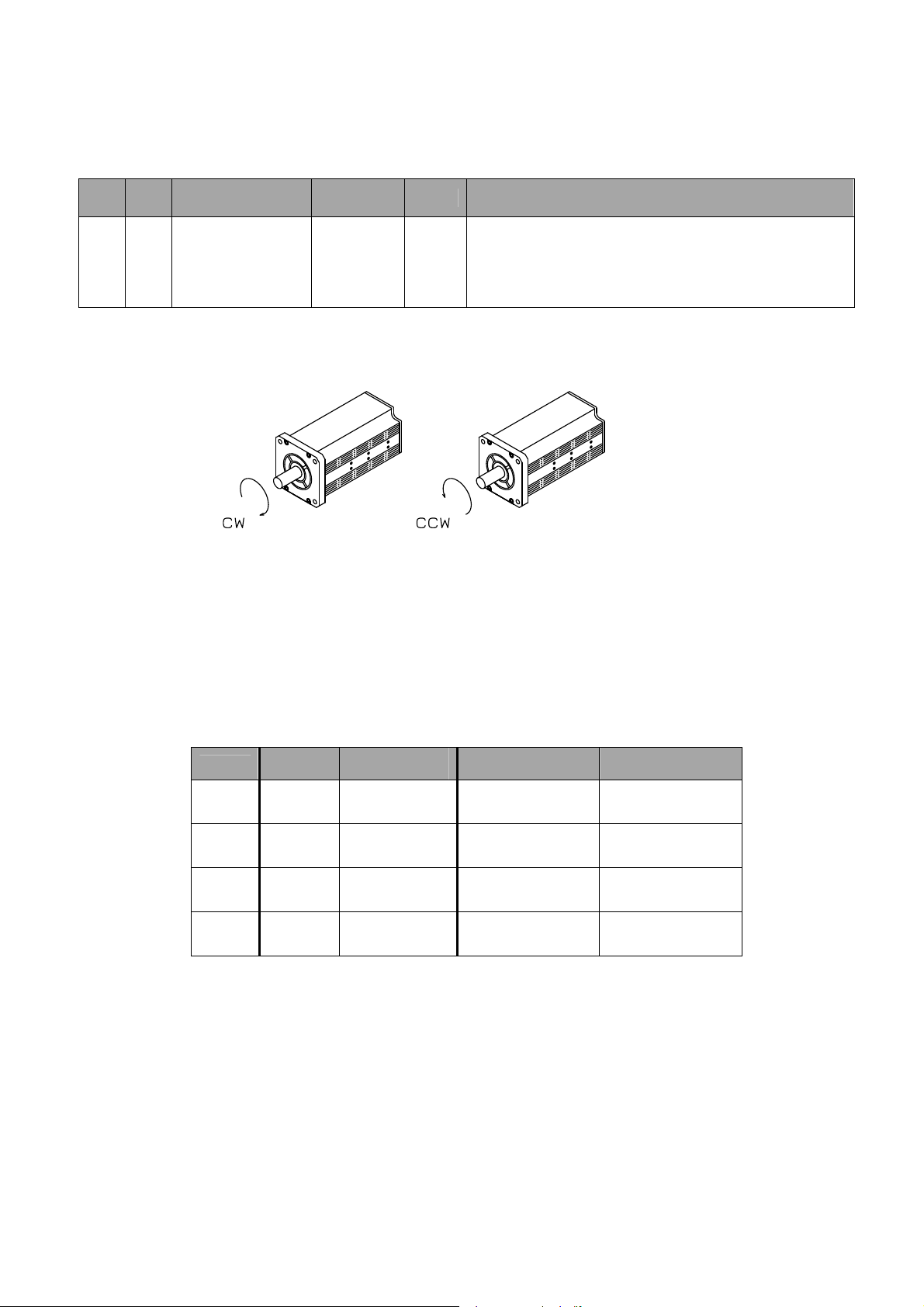

4-1 Setting Rotational Direction

The rotation direction of the motor to the directions of position command can be switched.

■Related parameters

Cate-

gory

0 0

No.

Parameter

Rotational

direction setup

As the direction of motor rotation, clockwise as seen from the shaft end to the load is defined as CW and

counterclockwise as CCW

The positive or negative direction referred to in this document displays the direction as specified with this parameter.

The table below shows the relationships with positive overtravel limit and negative overtravel limit as examples.

Pr0.00

0 Positive CW Enabled

0 Negative CCW

1 Positive CCW Enabled

1 Negative CW

Command

direction

Setup range

0~1

Direction of

motor rotation

Unit Function

Specifies the relationship between the commanded direction and the

-

direction of rotation of the motor.

0 : CW motor rotation for positive direction command

1 : CCW motor rotation for positive direction command

Positive overtravel

limit

Negative overtravel

limit

Enabled

Enabled

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 13 -

Pulse output

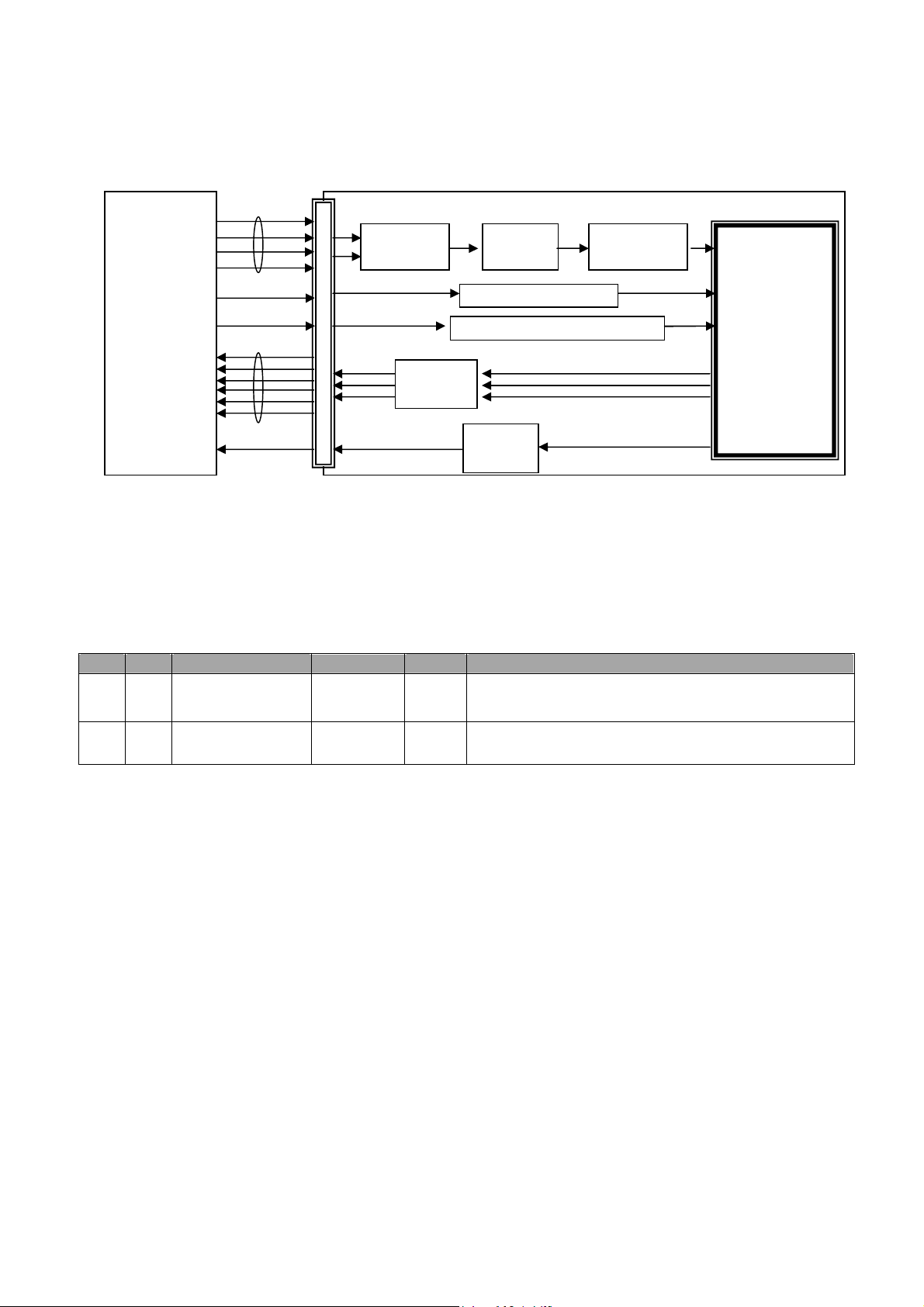

4-2 Position control

Position control is performed based on a position command (pulse train) input from the controller. This sec-

tion describes basic settings for position control.

Controller Servo drive

Position

command

(pulse train)

CL input

INH input

Command

pulse input

section

Command

scaling

function

Counter clear function

Command pulse inhibition function

Position command filter

function

Position con-

trol section

Pulse regeneration function

INP

Output

INP output function

4-2-1 Command Pulse Input

The input of position command (pulse train) use PULS1,PULS2,SIGN1,SIGN2.

Three command pulse formats are supported: 2-phase pulse, positive pulse train/negative pulse train and pulse

train + sign. The pulse format must be selected out of the three and the pulse counting direction must be specified

according to the specifications of the controller and equipment installation condition.

■Related parameters

Category

0

0

No.

6

*

7

*

Command pulse

rotational direction

Command pulse input

mode setup

Parameter

setup

Setup range

01

03

Unit Function

Specifies the counting direction for command pulse input.

See the table on the following page for the details.

Specifies the counting mode for command pulse input.

See the table on the following page for the details.

Motor Business Unit, Appliances Company, Panasonic Corporation

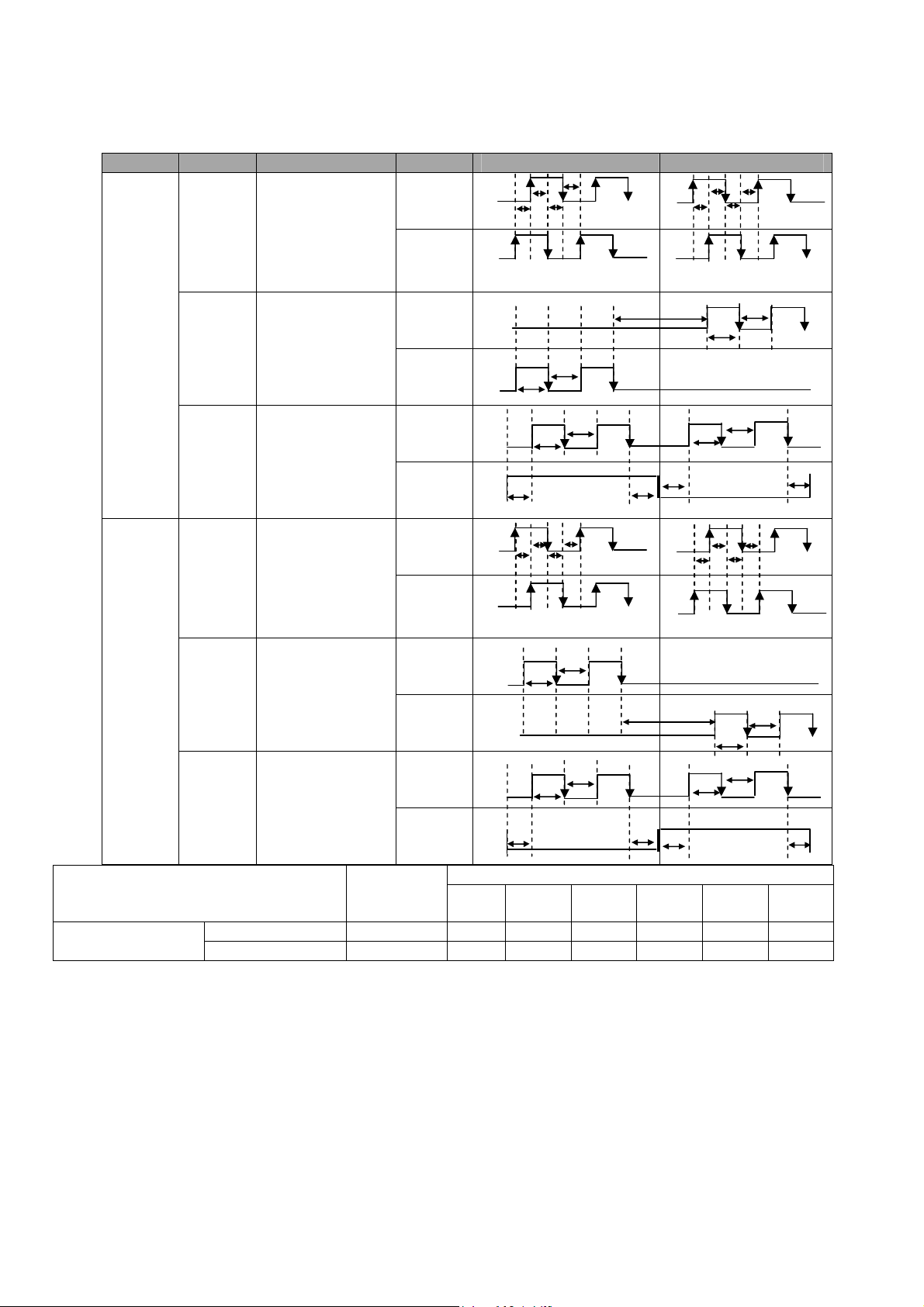

№SR-ZSV00039 - 14 -

t1

t1

t1 t1 t1 t1 t1

t1

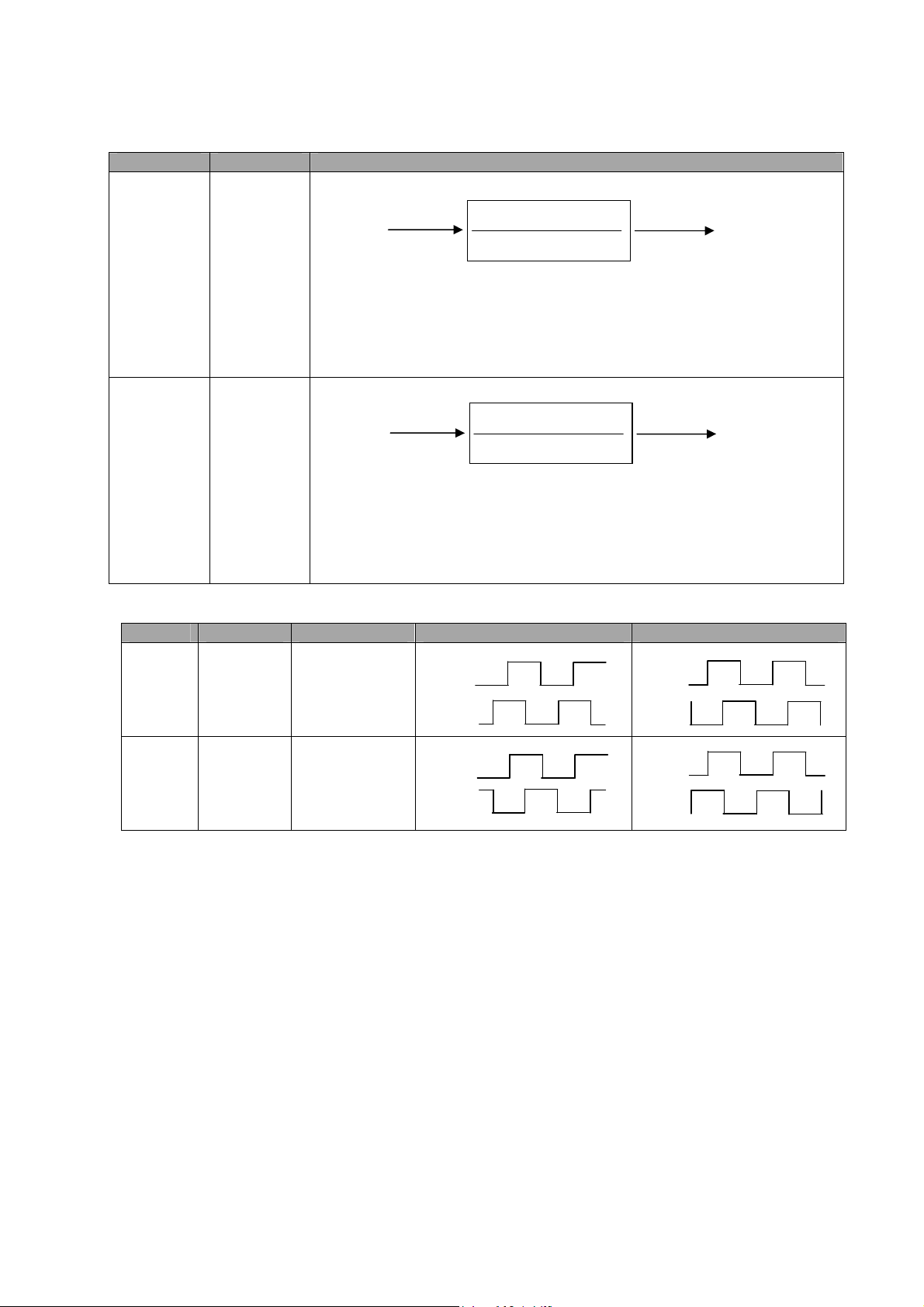

The following table shows the combinations of Pr0.06 "Command pulse rotational direction setup" and Pr0.07

"Command pulse input mode setup"

Pulses are counted at the edges with arrows in the table.

Pr0.06 Pr0.07 Command pulse Signal Positive command Negative command

t1

t1

Phase B delayed by 90 deg from

t2

T4

Phase B advanced by 90 deg from

t2

t4

t6

0

1

PULS/SIGN signal

PULS1, 2, SIGN1, 2

t2

t1

phase A

t2

t3

0

or

2

1

2-phase pulse with

90 difference

(Phase A + Phase B)

Positive pulse train +

Negative pulse train

PULS

SIGN

PULS

SIGN

Phase A

t1

Phase B

Phase B advanced by 90 deg from

T5

T4

H

t6

t6

3 Pulse train + Sign

PULS

SIGN

t6

t2

t1

A

t2

t3

0

or

2

1

2-phase pulse with

90 difference

(Phase A + Phase B)

Positive pulse train +

Negative pulse train

PULS

SIGN

Phase A

t1

Phase B

Phase B delayed by 90 deg from phase

PULS

SIGN

t5

PULS

3 Pulse train + Sign

SIGN

t4

L

t6 t6

Max. allow-

able input

frequency

t1

Minimum required time width [μs]

t2 t3 t4 t5 t6

Line driver 500 kpps 2 1 1 1 1 1

Open collector 200 kpps 5 2.5 2.5 2.5 2.5 2.5

t1

t1

phase A

t2

T5

L

phase A

t5

H

t6

t2

t6

Motor Business Unit, Appliances Company, Panasonic Corporation

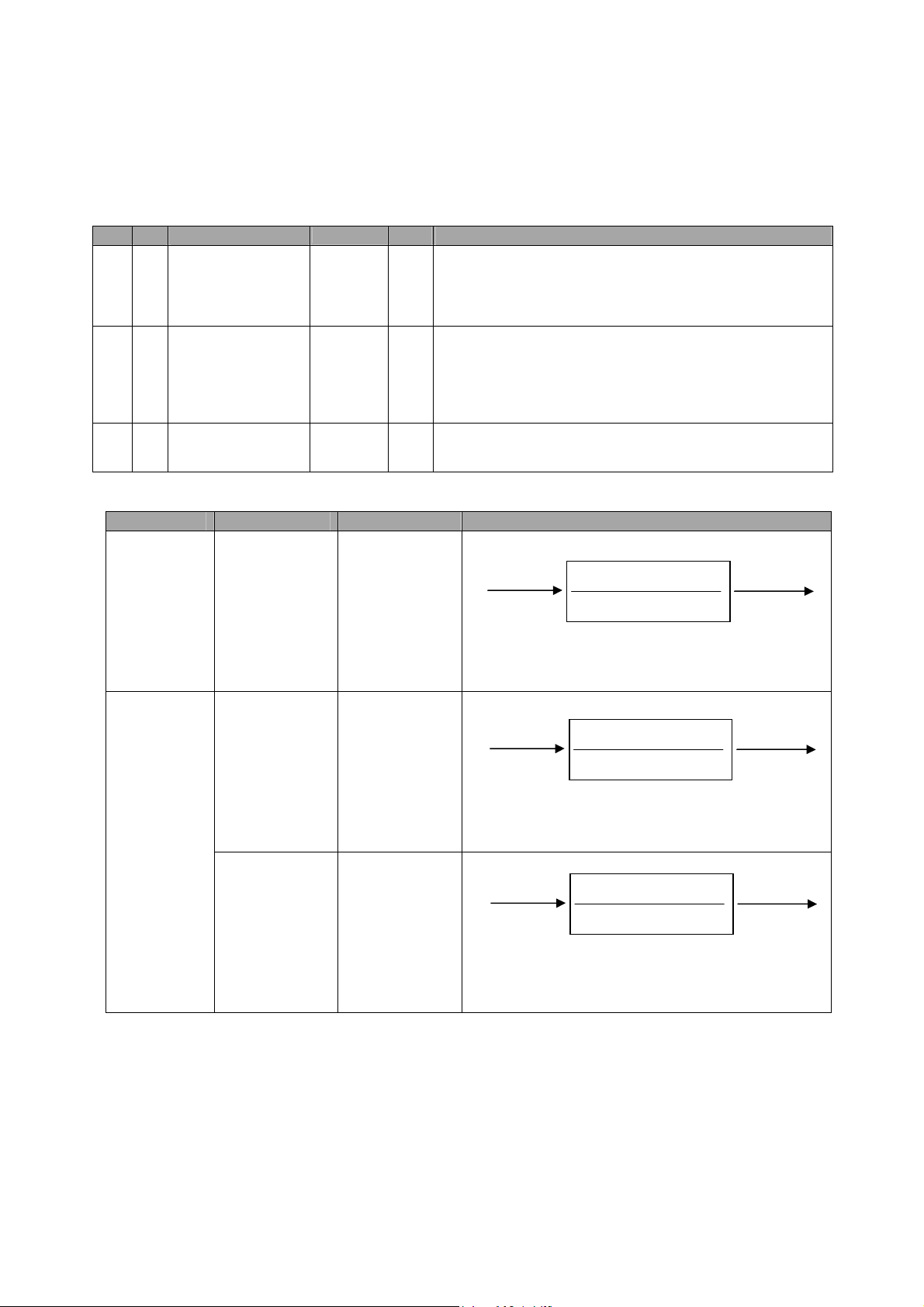

4-2-2 Command Scaling (Electronic Gear)

This function multiplies a pulse command value input from the controller by the specified scaling factor to use as a posi-

tion command to the position control section. Using this function allows arbitrary setting of the motor revolution and distance per unit input command pulse and increase of a command pulse frequency when the required motor speed cannot be

obtained due to the limit to the controller pulse output capability.

Related parameters

Category

0 08

0 09

0 10

No.

Parameter

Command pulse counts

per one motor

revolution

1st numerator of

electronic gear

Denominator of

electronic gear

Setup range

0

1048576

0

1073741824

1

1073741824

Unit

pulse

The relationships between Pr0.08, 0.09, and 0.10 in position control

Pr0.08 Pr0.09 Pr0.10 Command scaling

11048576

(No effect)

0

(No effect)

11073741824

0

11073741824 11073741824

№SR-ZSV00039 - 15 -

Function

Specifies the command pulse count corresponding to one revolution

of the motor.

When this setting is 0, Pr0.09 "1st numerator of electronic gear" and

Pr0.10 "Denominator of electronic gear" are valid.

This setting is invalid in full-closed control.

Specifies the numerator for scaling for a command pulse input.

Valid when Pr0.08 "Command pulse counts per one motor revolution"

is 0 or in full-closed control.

When this parameter is set to 0, the encoder resolution is set to the

numerator for position control, and for full-closed control, the

command scaling ratio becomes 1:1.

Specifies the denominator for scaling for a command pulse input.

Valid when Pr0.08 "Command pulse counts per one motor revolution"

is 0 or in full-closed control.

Command

pulse input

Encoder resolution *1

[Set value of Pr0.08]

Position

command

* The process shown in the above diagram is executed in

accordance with the set value of Pr0.08, regardless of settings of Pr0.09 and Pr0.10.

Command

pulse input

Encoder resolution *1

[Set value of Pr0.10]

Position

command

* When the set value of both Pr0.08 and Pr0.09 is 0, the

process shown in the above diagram is executed in accordance with the set value of Pr0.10.

Command

pulse input

* When the set value of Pr0.08 is 0 and that of Pr0.09 is not 0,

the process shown in the above diagram is executed in accordance with the set values of Pr0.09 and Pr0.10.

[Set value of Pr0.09]

[Set value of Pr0.10]

Position

command

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 16 -

Velocity

Vc0.632

Vc0.368

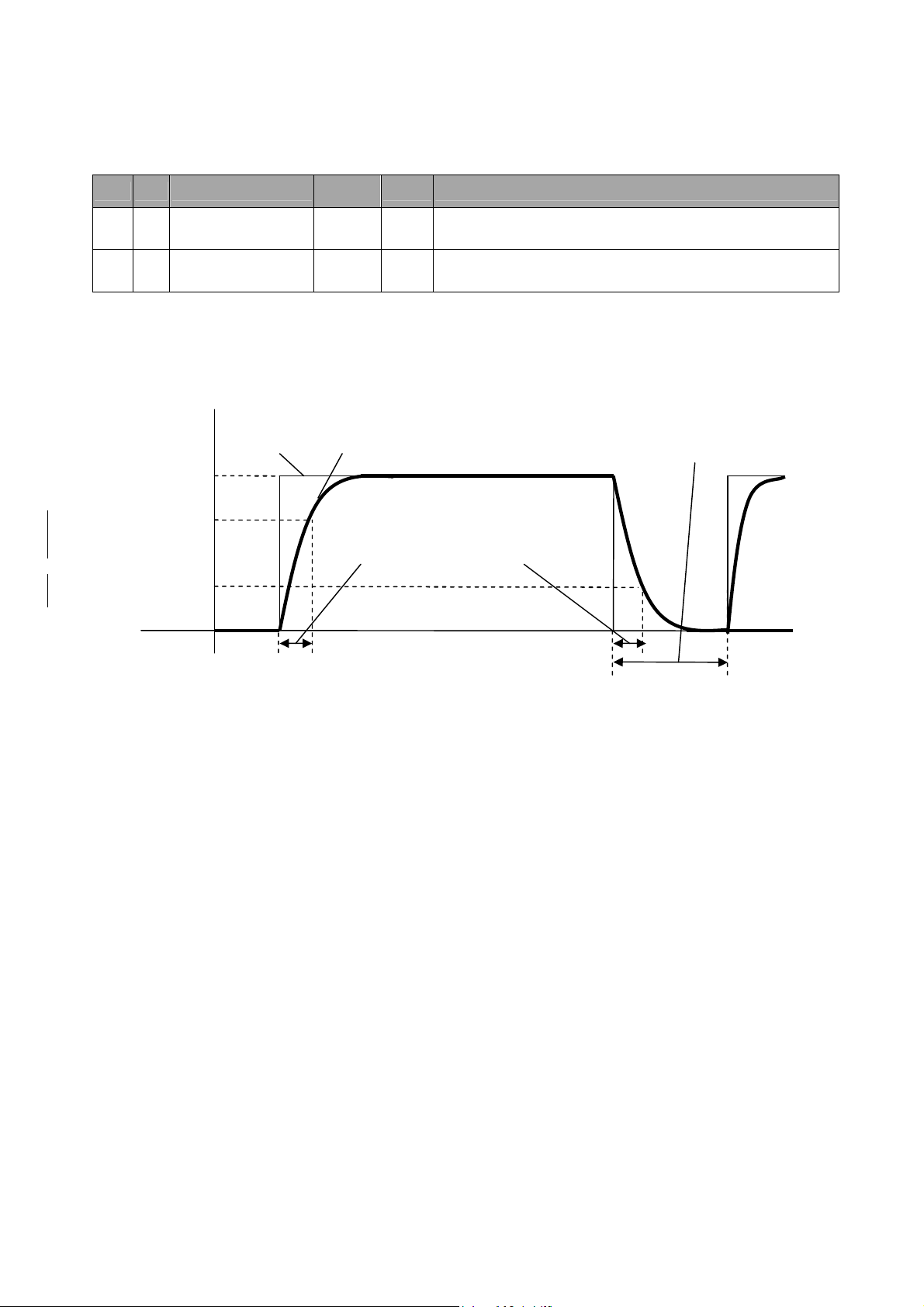

4-2-3 Position Command Filter

A command filter can be specified to smooth a position command after scaling (electric gear).

Related parameters

Category

2 22

2 23

No.

Parameter

Position command

smoothing filter

Position command FIR

filter

Setup

range

010000 0.1 ms

010000 0.1 ms

Unit

Function

Specifies the first order filter time constant for a position command.

Specifies the FIR filter time constant for a position command.

Pr2.22 "Position command smoothing filter"

Specifies the first order filter time constant for a square wave command with a target velocity of Vc as shown in the

figure below.

[r/min]

Position command before

filtering

Position command after filtering

Waiting time for swiching filter *2

Vc

Positional command smoothing

*1

filter Position command

smoothing filter setting time

[ms]

(Pn2Pr2.22×0.1 ms)

*1

Time

*1 Actual filter time constant contains absolute error of 0.4 ms maximum when the set value multiplied by 0.1 ms is less than

100 ms and relative error of 0.2% maximum when the set value multiplied by 0.1 ms is 20 ms or greater.

*2 Pr2.22 " Positional command smoothing filter " is switched when "in-position" is being output and when a command whose

command pulse per time (0.166 ms) changes from 0 to any state except 0 is rising.

Specifically when filter time constant is decreased and the in-position range is increased, the motor may temporarily rotates at

a faster speed than the command speed if accumulated pulses—an area acquired by integrating the difference between the position command before filtering and the position command after filtering by time—are left in the filter at the point above. This

is because accumulated pulses are rapidly cleared immediately after the switching and the motor goes back to the initial position. Use caution.

*3 There is a delay until the change in Pr2.22 " Positional command smoothing filter " is applied to internal calculation. If the switching

timing described in *2 comes during the delay, the change may be suspen

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 17 -

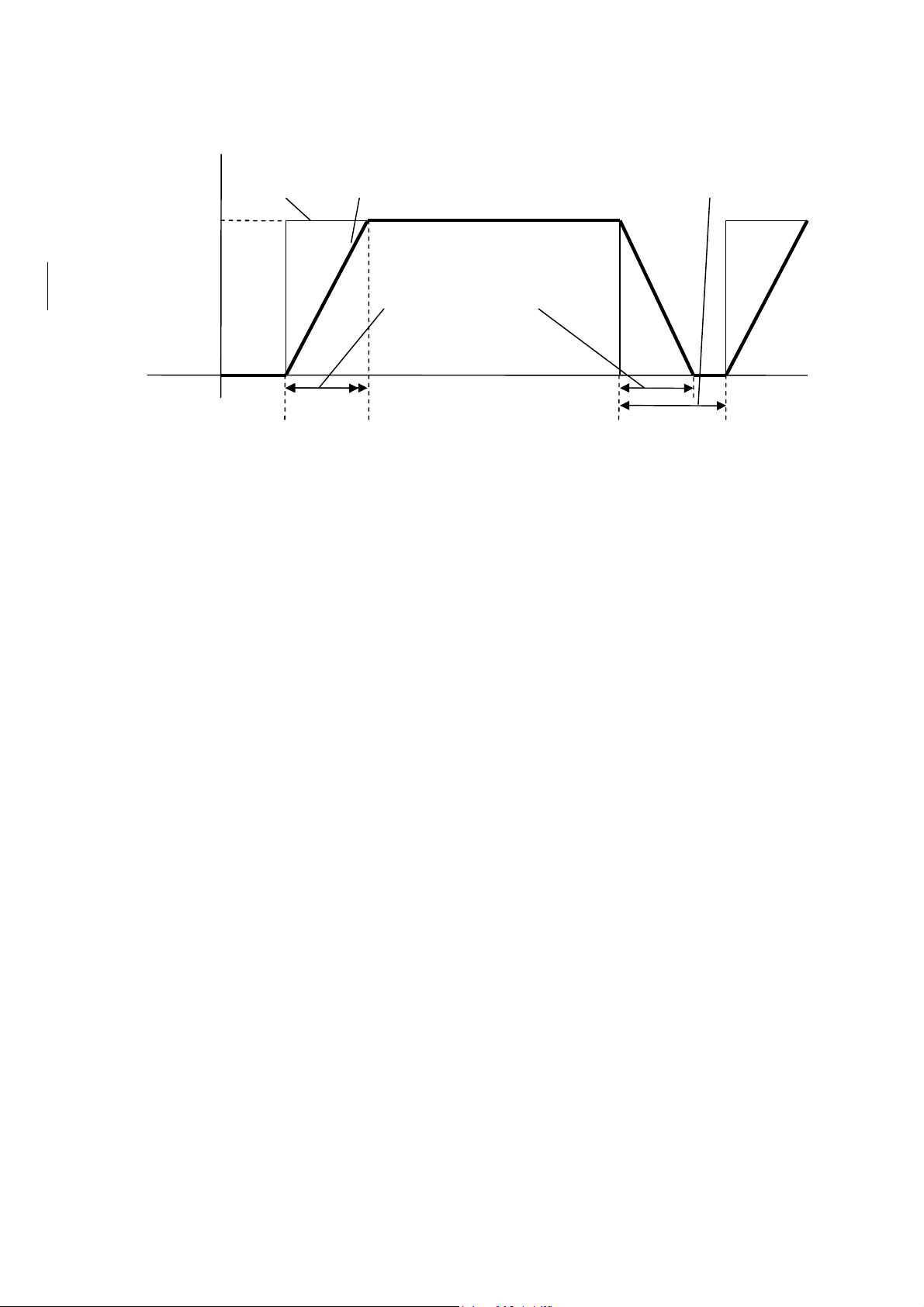

Pr2.23 "Position command FIR filter"

Specifies the time required to reach Vc for a square wave command with a target velocity of Vc as shown in the figure

below.

Velocity

[r/min]

Position command before filtering

Position command after filtering

Waiting time for swiching filter *2

Vc

Position command FIR filter

setting time [ms]

(Pn2Pr2.230.1 ms) *1

Time

*1 Actual average travel times contains absolute error of 0.2 ms maximum when the set value multiplied by 0.1 ms is less than

10 ms and relative error of 1.6% maximum when the set value multiplied by 0.1 ms is 10 ms or greater.

*2 Before changing Pr2.23 "Position command FIR filter," stop the command pulse, and wait until the time for filter switching

passes. The time for filter switching is as follows: the set value 0.1 ms + 0.25 ms in the range of 10 ms or smaller, and the

set value 0.1 ms 1.05 ms in the range of 10 ms or greater. When changing Pr2.23 "Position command FIR filter" during

inputting a command pulse, the change is not updated immediately. It is updated when no command pulse is present during

the time for filter switching.

*3 There is a delay until the change in Pr2.23 "Position command FIR filter" is applied to internal calculation. If the switching

timing described in *2 comes during the delay, the change may be suspended.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 18 -

Output pulse counts per

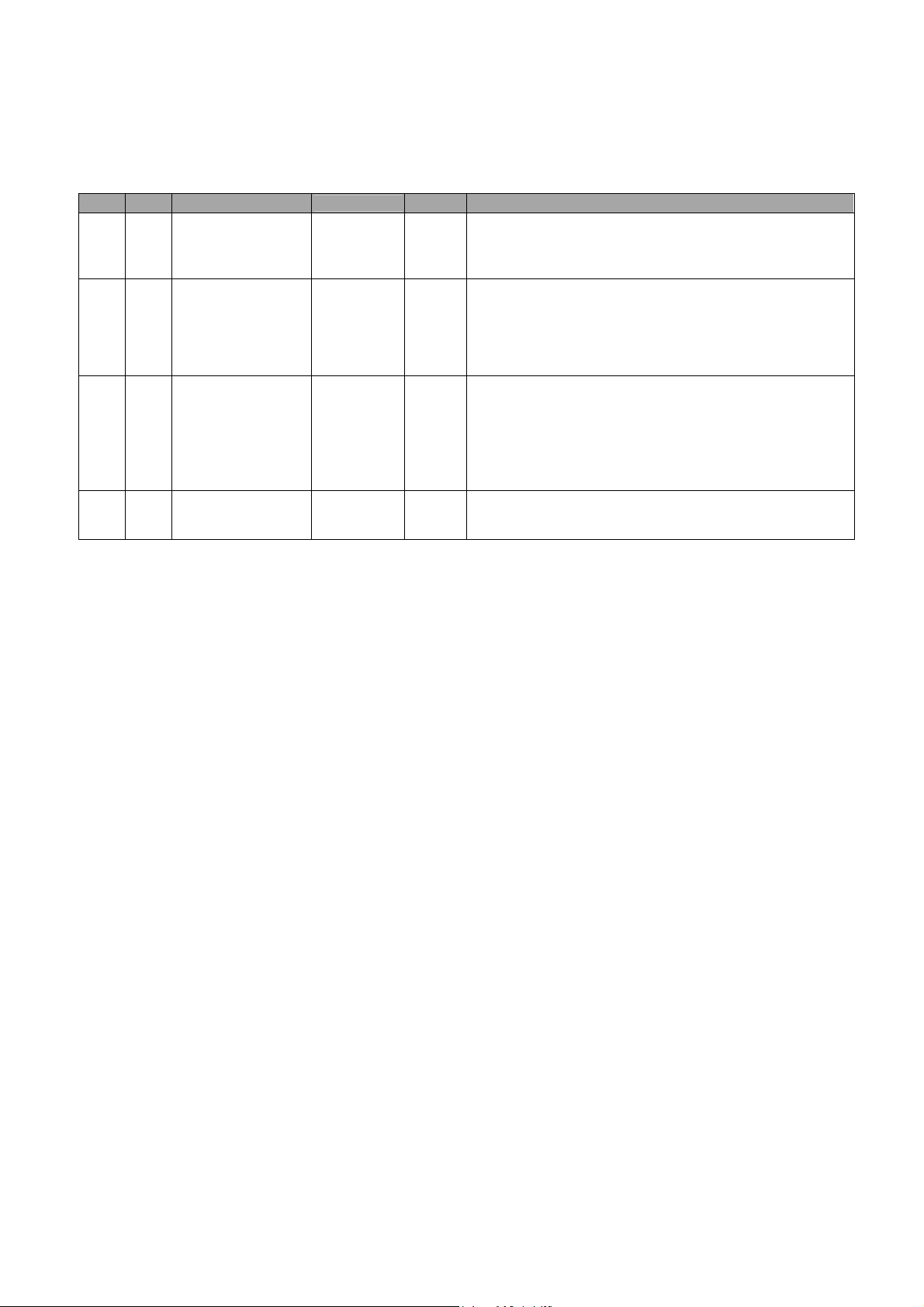

4-2-4 Pulse Regeneration

A distance can be transmitted from the servo drive as phase A and phase B pulses signal to the controller. If the

output source is an encoder, the phase Z signal is output one time per rotation of the motor.

■Related parameters

Category

0 11

0 12

5 03

5 33

No.

one motor revolution

Reversal of pulse

output logic

Denominator of pulse

output division

Pulse regenerative

output limit setup

Parameter

Setup range

1262144 P/r

03

0262144

01

Unit Function

Specifies the output pulse resolution as the output pulse count per

rotation for OA and OB. Accordingly, if the pulse count has been

multiplied by 4, the equation below applies.

Output pulse resolution per rotation = Set value of Pr0.11 4

Specifies the logic of the pulse output phase B signal and the output

source. Reversing the phase B pulse logic allows the phase

relation of phase B pulse with reference to phase A pulse. In the

full-closed control mode, an encoder or external scale can be chosen

as the output source. The output source must be an encoder in

other than full-closed control modes.

If the output pulse counts per one motor revolution is not an integer,

set "Denominator of pulse output division" to any value except 0.

It is also set using a divider ratio with Pr0.11 as the numerator and

Pr5.03 as the denominator. Accordingly, if the pulse count has

been multiplied by 4, the equation below applies.

Output pulse resolution per rotation

= (Set value of Pr0.11 / Set value of Pr5.03) Encoder resolution

Set the error detection function (Err28.0 "Limit of pulse replay error

protection") as valid or invalid.

0: Invalid 1: Valid

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 19 -

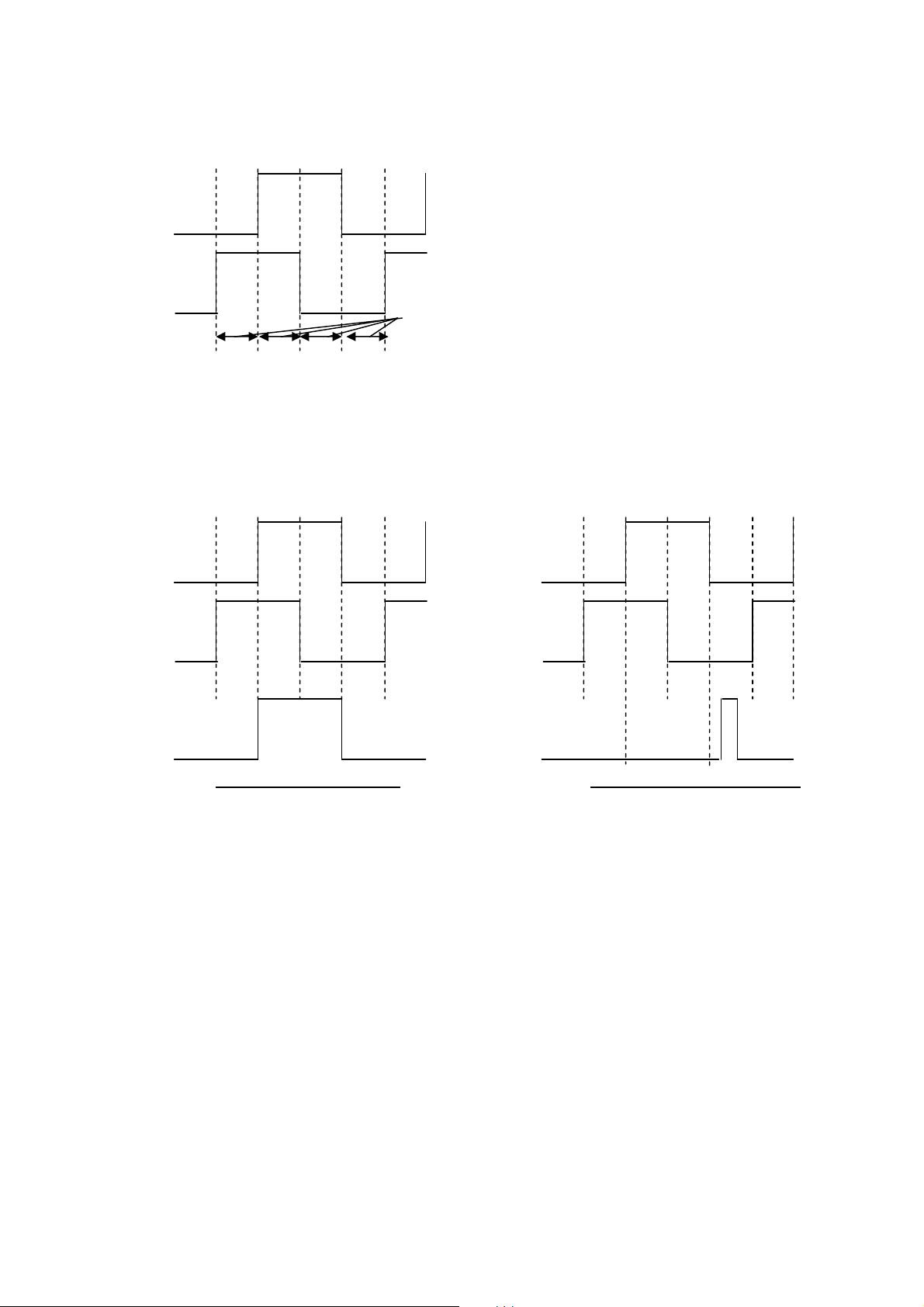

PH A PH B

PH A PH A PH A PH B

PH B

PH B

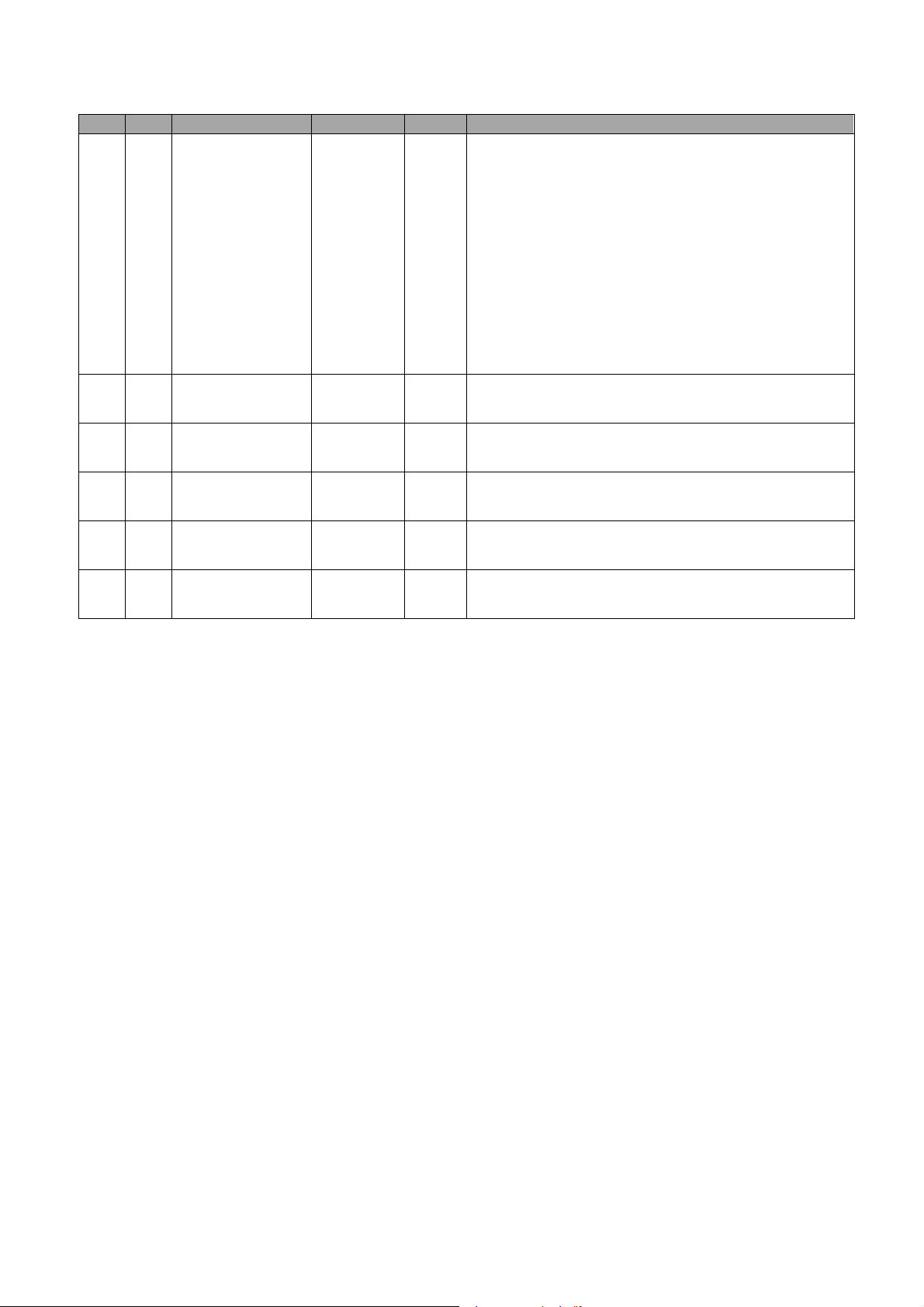

The following table shows combinations of Pr0.11 "Output pulse counts per one motor revolution" and Pr5.03 "Denomi-

nator of pulse output division".

Pr0.11 Pr5.03

1~262144 0

Encoder pulse

[pulse]

* When Pr5.03 is set as 0, the process shown above is executed in accordance with the set

value of Pr0.11. Accordingly, each of OA and OB of pulse regeneration output will be

identical to the number of pulses set in Pr0.11. The output pulse resolution will not be

identical to the encoder pulse resolution or greater.

Pulse regeneration output processing

[When the output source is the encoder]

[Set value of Pr0.11] 4

Encoder resolution

Output pulse

[pulse]

Encoder FB pulse

[pulse]

[Set value of Pr0.11]

[Set value of Pr5.03]

Output pulse

[pulse]

1~262144 1~262144

* When Pr5.03 ≠ 0, the process above takes place based on the Pr0.11 and Pr5.03

settings, which allows applications where the pulse count per rotation of the pulse regeneration output OA and OB is not an integer.

Note that when the pulse output resolution per rotation is not a multiple of 4, output of

phase Z may not be synchronous with phase A, resulting in a smaller pulse width. The

output pulse resolution will not be identical to the encoder pulse resolution or greater.

Details of Pr0.12 "Reversal of pulse output logic" are shown below.

Pr0.12 Ph B logic Output source For positive direction For negative direction

0

1

Non-reversed

Encoder

Reverse Encoder

*Please do not set setting 2 and 3.

Motor Business Unit, Appliances Company, Panasonic Corporation

№SR-ZSV00039 - 20 -

0.25

■Notes on pulse regeneration function

The maximum output frequency of pulse regeneration output is 4 Mpps (after multiplying by 4). Operation at a

speed exceeding this may cause faulty functioning of regeneration leading to displacement.

PH A

PH B

By Pr5.33 "Pulse regenerative output limit setup", Err28.0 "Limit of pulse replay error protection" can be issued

when reaching the limit of pulse regeneration. Note that this error message is issued by detecting the output limit

of pulse regeneration, not using the maximum output frequency. The error message may be issued when frequency jumps instantaneously, depending on the rotational state of the motor such as rotational fluctuation.

・When the output source is an encoder and the pulse output resolution per rotation is not a multiple of 4, phase Z

may not be synchronous with phase A, leading to a smaller pulse width.

PH A

PH B

PH Z

・When an incremental encoder is used, the first phase Z signal after power-up may not agree with the pulse width as

shown above. When using a phase Z signal, operate the motor by at least one rotation after power-up, make sure

that the phase Z signal has been regenerated once and use the second or later phase Z signal.

Scaling factor: multiple of 4

* If Pr5.03 = 0 and output resolution is specified with Pr0.11, factor is always a multiple of 4.

μs min

PH A

PH B

PH Z

* Not in sync with ph A

Scaling factor: not multiple of 4

Motor Business Unit, Appliances Company, Panasonic Corporation

Loading...

Loading...