Page 1

Instruction Manual

AC Servo Motor & Driver

MINAS E-series

Thank you very much for buying Panasonic AC Servo Motor & Driver, MINAS E-series.

Before using this driver, please read this manual especially refer the safty precautions (page 8 to 11) to ensure

proper use.

Then, keep this manual for your future use.

Page 2

Contents

[Before Use] Page

Safety Precautions ................................................................................................ 8

Maintenance/Inspections .................................................................................... 12

Introduction ......................................................................................................... 14

General ....................................................................................................................................................14

After Opening the Package......................................................................................................................14

Model of Driver ........................................................................................................................................ 14

Model of Motor ......................................................................................................................................... 15

Check the Combination of Driver and Motor............................................................................................15

Parts Description ................................................................................................. 16

Driver ....................................................................................................................................................... 16

Motor........................................................................................................................................................16

Console....................................................................................................................................................17

Installation ........................................................................................................... 18

Driver ....................................................................................................................................................... 18

Motor........................................................................................................................................................20

Console....................................................................................................................................................22

[Preparations] Page

System Configuration and Wiring......................................................................24

General Wiring Diagram .......................................................................................................................... 24

List of Driver and Compatible Peripheral Equipment ............................................................................... 26

Wiring of Connectors CN X1 and X3 (Wiring of Main Circuits) ................................................................ 27

Wiring of Connector CN X4 (Connection with Encoder) .......................................................................... 29

Wiring of Connector CN X5 (Connection with Host Controller) ............................................................... 30

Wiring of Connector CN X6 (Connection with Personal Computer/Console) .......................................... 31

Timing Chart ........................................................................................................ 32

Holding Brake ...................................................................................................... 35

Dynamic Brake (DB) ............................................................................................ 36

Homing Operation (Precautions) ....................................................................... 38

Setting the Parameters ....................................................................................... 39

Overview of Parameters .......................................................................................................................... 39

How to Set ............................................................................................................................................... 39

Overview of Console................................................................................................................................39

Overview of PANATERM® ........................................................................................................................ 39

How to Connect ....................................................................................................................................... 40

Parameter Groups and Listing ................................................................................................................. 41

Using the Console ............................................................................................... 47

Using the Console ................................................................................................................................... 47

The initial State of the Display (7-segment LED) ..................................................................................... 47

Structure of Each Mode ...........................................................................................................................48

Monitoring Mode ......................................................................................................................................51

2

Page 3

Parameter Setting Mode .......................................................................................................................... 57

Before Use

Preparations

Connections and

Settings in Position

Control Mode

Connections and

Settings in Internal

Velocity Control Mode

Adjustment

Trouble Case

Reference

Normal Auto Gain Tuning Mode............................................................................................................... 58

Alarm Clear .............................................................................................................................................. 59

Test Run (JOG) ........................................................................................................................................ 60

Test Run Procedures ...............................................................................................................................61

Copy Function..........................................................................................................................................62

[Connections and Settings in Position Control Mode]

Page

Control Block Diagram in Position Control Mode ............................................ 66

Wiring to Connector CN X5 ................................................................................ 67

Example of Wiring in Position Control Mode ........................................................................................... 67

Interface Circuit........................................................................................................................................68

Input Signal and Pin No. of Connector CN X5 ......................................................................................... 70

Output Signal and Pin No. of Connector CN X5 ...................................................................................... 72

Example of Connection to a Host Controller............................................................................................73

Test Run in Position Control Mode .................................................................... 82

Inspection prior to Test Run ..................................................................................................................... 82

Test Run with Connector CN X5 Connected............................................................................................ 82

Real time Auto Gain Tuning................................................................................86

Outline ..................................................................................................................................................... 86

Scope.......................................................................................................................................................86

Operating Instruction ............................................................................................................................... 86

Adaptive Filter .......................................................................................................................................... 87

Parameters to be Set Automatically......................................................................................................... 87

Cautions...................................................................................................................................................87

[Connections and Settings in Internal Velocity Control Mode]

Parameter Setting ................................................................................................ 88

Parameter for Selection of Functions ...................................................................................................... 88

Parameters for Adjustment of Time Constants of Gains/Filters ............................................................... 91

Parameters for Auto Gain Tuning ............................................................................................................ 92

Parameters for Adjustment (Related to Second Gain Switching Function) ............................................. 94

Parameters for Position Control...............................................................................................................95

Parameters for Internal Velocity Control .................................................................................................. 98

Parameters for Torque Limits................................................................................................................... 99

Parameters for Sequences ...................................................................................................................... 99

Page

Control Block Diagram in Internal Velocity Control Mode ............................ 104

Wiring to Connector CN X5 .............................................................................. 105

Example of Wiring to Connector CN X5 ................................................................................................ 105

Interface Circuit...................................................................................................................................... 106

Input Signal and Pin No. of Connector CN X5 ....................................................................................... 107

Output Signal and Pin No. of Connector CN X5 .................................................................................... 109

Test Run in Internal Velocity Control Mode .................................................... 110

3

Page 4

Inspection prior to Test Run ................................................................................................................... 110

Test Run with Connector CN X5 Connected ......................................................................................... . 111

Real time Auto Gain Tuning.............................................................................. 114

Outline ................................................................................................................................................... 114

Scope..................................................................................................................................................... 114

Operating Instruction ............................................................................................................................. 114

Parameters to be Set Automatically....................................................................................................... 115

Cautions................................................................................................................................................. 115

Parameter Setting .............................................................................................. 116

Parameter for Selection of Functions .................................................................................................... 116

Parameters for Adjustment of Time Constants of Gains/Filters ............................................................. 119

Parameters for Auto Gain Tuning .......................................................................................................... 120

Parameters for Position Control............................................................................................................. 121

Parameters for Internal Velocity Control ................................................................................................ 122

Parameters for Torque Limits ................................................................................................................. 123

Parameters for Sequences .................................................................................................................... 123

[Adjustment] Page

Gain Adjustment ................................................................................................ 128

Objective of Gain Adjustment ................................................................................................................ 128

Types of Gain Adjustment ...................................................................................................................... 128

Procedures of Gain Adjustment ............................................................................................................. 129

Real time Auto Gain Tuning.............................................................................. 130

Normal Auto Gain Tuning ................................................................................. 132

Cancellation of the Automatic Gain Tuning .................................................... 135

Manual Gain Tuning (Basic) ............................................................................. 136

Manual Gain Tuning (Application) ................................................................... 138

Gain Switching Function ........................................................................................................................138

To Reduce Mechanical Resonance ....................................................................................................... 140

Anti-Vibration Control............................................................................................................................. 142

4

Page 5

Before Use

Preparations

Connections and

Settings in Position

Control Mode

Connections and

Settings in Internal

Velocity Control Mode

Adjustment

[Trouble Case] Page

Reference

Trouble Case

Protective Functions ......................................................................................... 144

What are Protective Functions?............................................................................................................. 144

Details of Protective Functions .............................................................................................................. 145

Software limit function............................................................................................................................ 148

Troubleshooting ................................................................................................ 150

[Reference] Page

Outline of “PANATERM®”, Setup Support Software ............................................................................... 156

Communications ....................................................................................................................................158

Description on Dividing/Multiplier Ratio ................................................................................................. 178

Conformance to EC Directives/UL Standards ....................................................................................... 180

Optional Parts ........................................................................................................................................184

Recommended Parts .............................................................................................................................192

Dimensional Outline Drawing (Driver) ................................................................................................... 193

Dimensional Outline Drawing (Motor) .................................................................................................... 194

Allowable Load of Output Shaft ............................................................................................................. 196

Motor Characteristics (S-T Characteristics) ........................................................................................... 197

Servo Motor with Gear ........................................................................................................................... 198

Dimensional Outline Drawing of Motor with Gear .................................................................................. 200

Allowable Load of Output Shaft of Servo Motor with Gear .................................................................... 202

Characteristics of Servo Motor with Gear (S-T Characteristics) ............................................................203

Driver Internal Block Diagram ................................................................................................................ 204

Control Block Diagram ........................................................................................................................... 205

Specifications (Driver/Motor) ................................................................................................................. 206

Hit-and-stop Initialization and Load Pressing Control ............................................................................ 207

Index ......................................................................................................................................................209

Reference .............................................................................................................................................. 214

After-Sale Service (Repair) ........................................................................................................ Back cover

5

Page 6

MEMO

6

Page 7

Before Use

Before Use

Page

Safety Precautions .......................................................... 8

Maintenance/Inspections ............................................. 12

Introduction ................................................................... 14

General ...................................................................................................14

After Opening the Package ..................................................................... 14

Model of Driver ........................................................................................ 14

Model of Motor ........................................................................................15

Check the Combination of Driver and Motor ........................................... 15

Parts Description .......................................................... 16

Driver ......................................................................................................16

Motor ....................................................................................................... 16

Console ................................................................................................... 17

Installation ..................................................................... 18

Driver ......................................................................................................18

Motor ....................................................................................................... 20

Console ................................................................................................... 22

7

Page 8

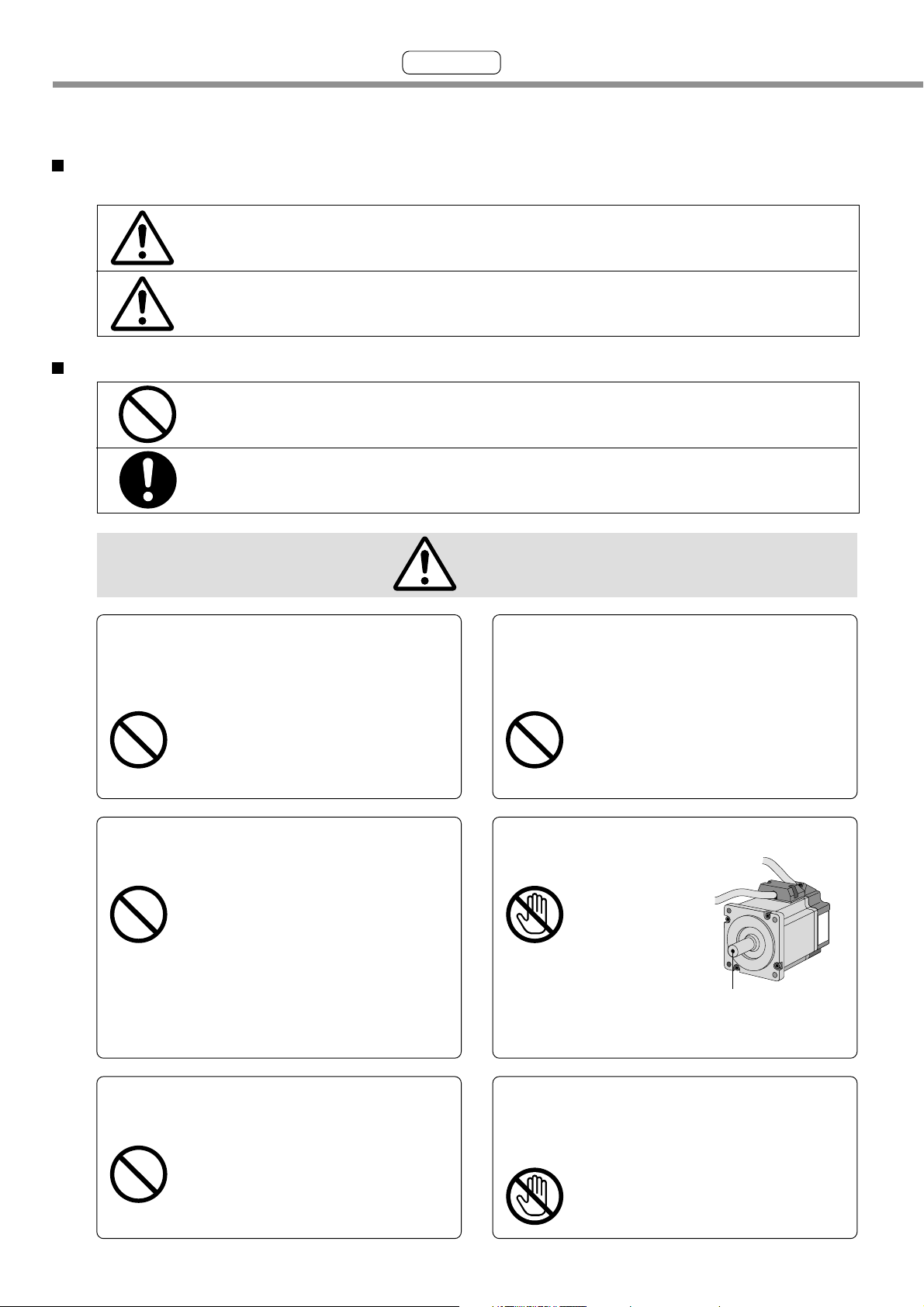

Safety Precautions

See the following precautions in order to avoid damages on machinery and injuries among the

operators and other people during the operation.

The following symbols are used to indicate the degrees of hazard seriousness possibly occurred when

you fail to comply with the safety precautions.

Indicates a potentially hazardous situation, which if not avoided, will result in

DANGER

CAUTION

The following symbols indicate what you must do.

Indicates that the operation is prohibited to do.

Indicates that the operation must be done.

death or serious injury.

Indicates a potentially hazardous situation, which if not avoided, will result in

minor injury or physical damage.

Important

DANGER

Do not subject the product to water,

corrosive or flammable gases, and

combustibles.

The failure could result in

fire.

Do not put your hands in the servo

driver.

The failure could result in

burns, or electric shocks.

Do not expose the cables to sharp

objects, excessive pressing or

pinching forces, and heavy loads.

The failure could result in

electric shocks, damages, or

malfunction.

Do not touch the rotating part of the

motor while operating.

Rotating Part

Do not drive the motor from the

external power.

The failure could result in

fire.

The failure could result in injuries.

Do not touch the motor, driver, and

external regenerative resistor, since

they become hot.

The failure could result in

burns.

8

Page 9

Before Use

DANGER

[Before Use]

Do not place inflammable matter

near the motor, driver, and

regenerative resistor.

The failure could result in

fire.

Ground the earth of the servo motor

and servo driver.

The failure could result

in electric shocks.

Install an external emergency stop

device to shut down the main power

source in any emergency.

The failure could result in

electric shocks, injuries, fire,

damages or malfunction.

Do not install the console near

sources of heat like the heater, the

resistor, or etc.

The failure could result in

fire or damages.

An over-current protection, earth leakage

breaker, over temperature protecter and

emergency stop device must be installed.

The failure could result in

electric shocks, injuries, or

fire.

Wait at least the time described on the

driver after switching off the power to

allow the capacitors to discharge before

beginning to conduct the transportation,

wiring, and inspection of the driver.

The failure could result in

electric shocks.

Install the product properly to avoid

personal accidents or fire in case of

an earthquake.

The failure could result in

electric shocks, injuries, or

fire.

Make sure to secure the safety after

the earthquake.

The failure could result in

electric shocks, injuries, or

fire.

Attach the motor, driver,

regenerative resistor to

incombustible matter such as metal.

The failure could result in

fire.

Confirm that there is no danger of an

electric shock before beginning to

conduct the transportation, wiring,

and inspection of the motor.

The failure could result in

electric shocks.

Only persons who are trained and qualified to work with or on electrical equipment are permitted to operate or maintain this equipment.

The failure could result in

electric shocks.

Arrange the phase sequense of the

motor and wiring of the encoder.

The failure could result in

injuries, damages, or

malfunction.

9

Page 10

Safety Precautions

CAUTION

Important

Do not hold the cables or motor

shaft when transporting the motor.

The failure could result in

injuries.

Never start and stop the motor by

magnet contactor which is provide on

the main line.

The failure could result in

damages.

Do not give hard

pressure to the shaft.

The failure

could result

in damages.

Do not block the heat dissipation

hole.

The failure could result in

electric shocks, or fire.

Do not climb or stand on the servo

equipment.

The failure could result in

electric shocks, injuries,

damages, or malfunction.

Do not turn on or off the power

frequently.

The failure could result in

damages.

Do not shock the driver and the motor.

The failure could result in

damages.

Do not use the motor internal brake

for the purpose of controlling speed

of load.

The failure could result in

injuries, or damages.

Do not modify, dismantle or repair

the product.

The failure could result in

Avoid excessive gain adjustments, changes,

or unstable operation of the product.

The failure could result in

injuries.

Do not approach to the equipment

after recovery from the power failure

because they may restart suddenly.

Execute the personal safety setting

on the Equipment after the restart.

The failure could result in

injuries.

Do not pull the motor cable by too

much power.

electric shocks, injuries, or

fire.

The failure could result in

damages.

10

Page 11

Before Use

CAUTION

[Before Use]

Use the motor and driver with the

specified combination.

The failure could result in

fire.

Use the eye-bolt of the motor only

when you carry the motor.

Do not use it when you carry the machine.

The failure could result in

injuries, or damages.

Conduct proper installation according

to product weight or rated output.

Make sure that the wirings are

correctly connected.

The failure could result in

electric shocks, or injuries.

Install the driver and the motor in the

specified direction.

The failure could result in

damages.

Use the specified voltage on the

product.

The failure could result in

The failure could result in

injuries, or damages.

Ambient temperature of installed

motor and driver should be under

permittable one.

The failure could result in

damages.

Connect a relay that stops at

emergency stop in series with the

brake control relay.

The failure could result in

injuries, or damages.

electric shocks, injuries, or

fire.

Execute the trial-operations with the

motor fixed and a load unconnected.

Connect a load to the motor after the

successful trial-operations.

The failure could result in

injuries.

If an error occurs, remove the causes

of the error and secure the safety

before restarting the operation.

The failure could result in

injuries.

This product should be treated as an

industrial waste when it is disposed.

11

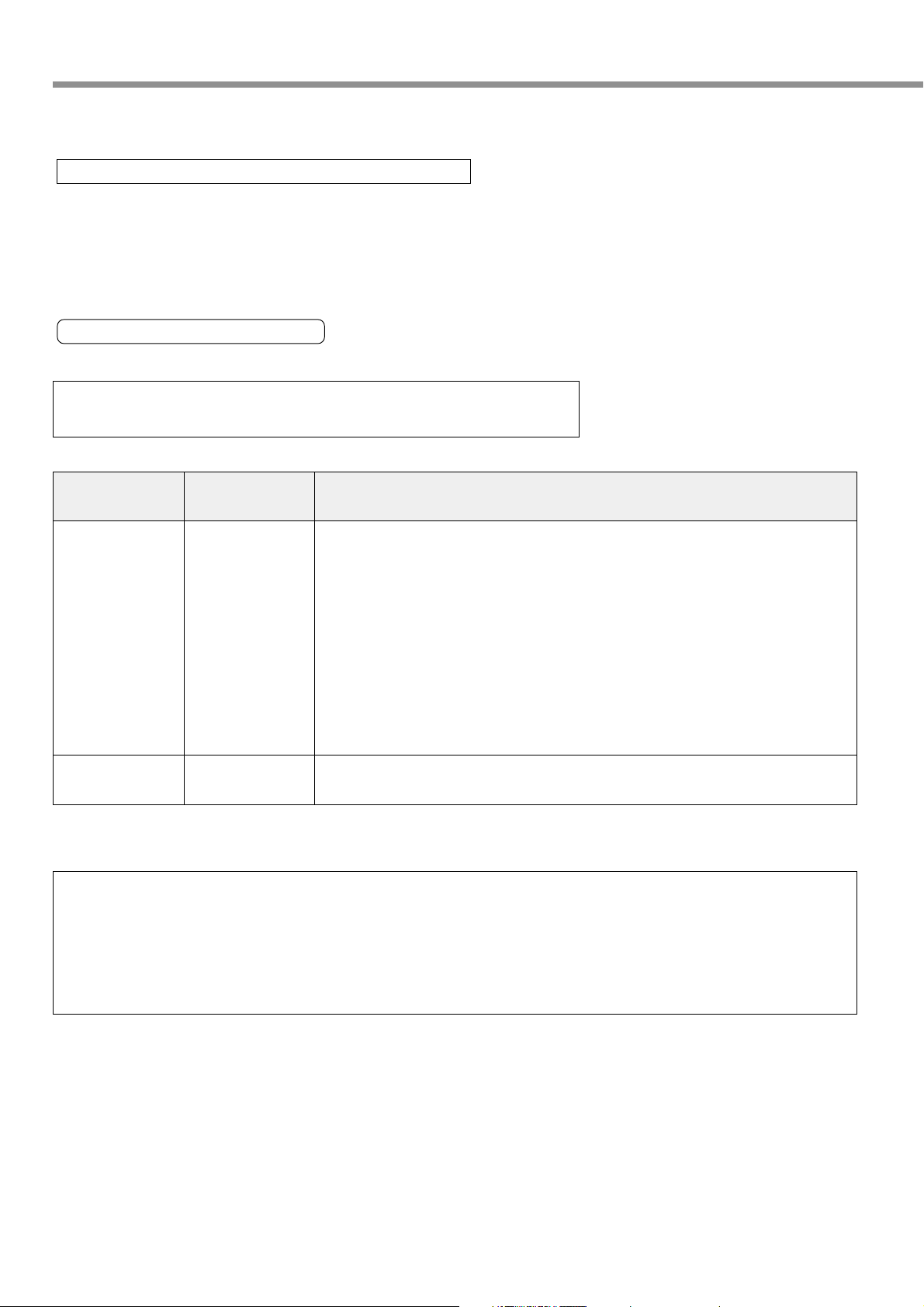

Page 12

Maintenance/Inspection

• Routine maintenance and inspections are essential for proper and satisfactory operation of the driver

and motor.

Notes to Maintenance/Inspections Personnel

(1) Power-on/off operations should be done by the operators themselves.

(2) For a while after power off, the internal circuits is kept charged at higher voltage. Inspections should be done a

while (about 10 minutes), after the power is turned off and the LED lamp on the panel is extinguished.

(3) When conducting meager test (to measure insulation resistance) on the servo driver, disconnect all the connec-

tions from the driver. Conducting the test as connected would cause trouble of the driver.

Inspection Items and Cycles

Normal (correct) operating conditions:

Ambient temperature: 30˚C (annual average) Load factor: max. 80%

Operating hours: max. 20 hours per day

Daily and periodical inspections should be done per the following instructions.

Type

Daily inspection

Periodical

inspection

<Notes>

If the operating conditions (as stated above) differ, this periodic inspection interval is subject to change.

Cycles

Daily

Every year

Inspection items

• Ambient temperature, humidity, dust, particles, foreign matters, etc.

• Abnormal sound and vibration

• Main circuit voltage

• Odor

• No yarn piece, etc. adhered to the air hole?

• How the driver front and connector are cleaned?

• Each wired cable is damage-free?

• The portions connected with the motors of equipment/plant are free

from loose and center deviation?

• No inclusion of foreign matter at the load side?

• Loosened screws

• Signs of overheat

We make the utmost effort to ensure the quality of our product. However, the product may

operate differently from your settings, due to unexpectedly high exogenous noise/applied

static electricity, or an unforeseen failure in the input power supply, wiring, components, etc.

Hence, we would like to request you to give adequate consideration to the fail-safe design and

assurance of safety within the operable range at the place of operation in your company.

12

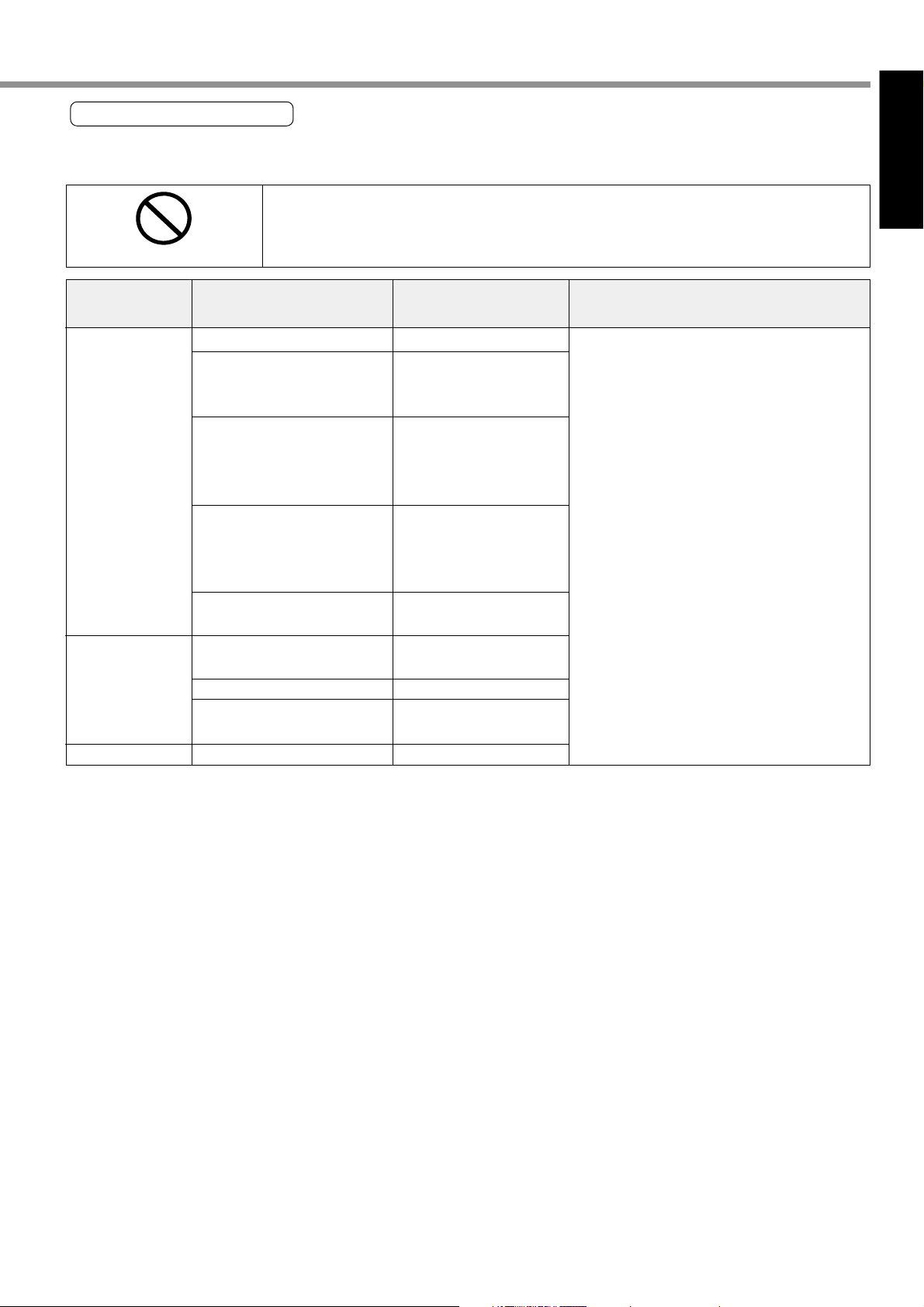

Page 13

[Before Use]

Before Use

Replacement Guidance

Parts replacement cycles depend on the actual operating conditions and how the equipment has been used.

Defective parts should be replaced or repaired immediately.

Dismantling for inspections or repairs should be done by our

company (or our sales agents).

Prohibited

Equipment

Driver

Motor

Motor with Gear

Part

Smoothing condenser

Aluminum electrolytic

capacitor on the print

board

Rush current

preventive relay

Rush current

preventive resistor

Cooling fan

Bearing

Oil seal

Encoder

Speed reducer

Standard replacement

cycles (hour)

about 5 years

about 5 years

Approx. 100,000 cycles

(The life depends on the

actual operating

conditions.)

Approx. 20,000 cycles

(The life depends on the

actual operating

conditions.)

2 to 3 years

(10,000 to 30,000 hours)

3 to 5 years

(20,000 to 30,000 hours)

5000 hours

3 to 5 years

(20,000 to 30,000 hours)

10,000 hours

Remarks

The replacement cycles shown here

are just only for reference if any part

is found defective regardless of the

standard replacement cycles,

immediately replace it with a new

one.

13

Page 14

Introduction

General

MINAS-E series is a unit of an AC servo motor and driver with downsized capability and performance that are useful

for positioning of a motor whose capacity is small from 50W to 400W.

By adopting 2500 P/r incremental encoder with velocity response frequency of approximately 400 Hz and 5 wires,

we could omit wiring.

The equipment includes real-time auto tuning and enables automatic setting of complicated gain tuning. In addition,

it has a damping control function that provides for stable stop performance and contributes to miniaturization of the

equipment and reduction of tact time.

It supports a console (available as an option) capable of monitoring such as display of rotation speed, parameter

setting, test run (JOG operation), parameter copying, etc., and pursues maximum ease for use.

This document is designed for you to properly and sufficiently use functions of MINAS-E series with such excellent

features.

Cautions

(1) No part or whole of this document may be reproduced in any form or by any means.

(2) Contents of this document are subject to change without notice.

After Opening the Package

• Make sure that the product is what you ordered.

• Check whether the product is damaged.

•

The instruction manual (Safety edition and Extracted edition) is included in a carton box.

If the product is not what you purchase, or it is, or damaged, contact dealer or sales agent.

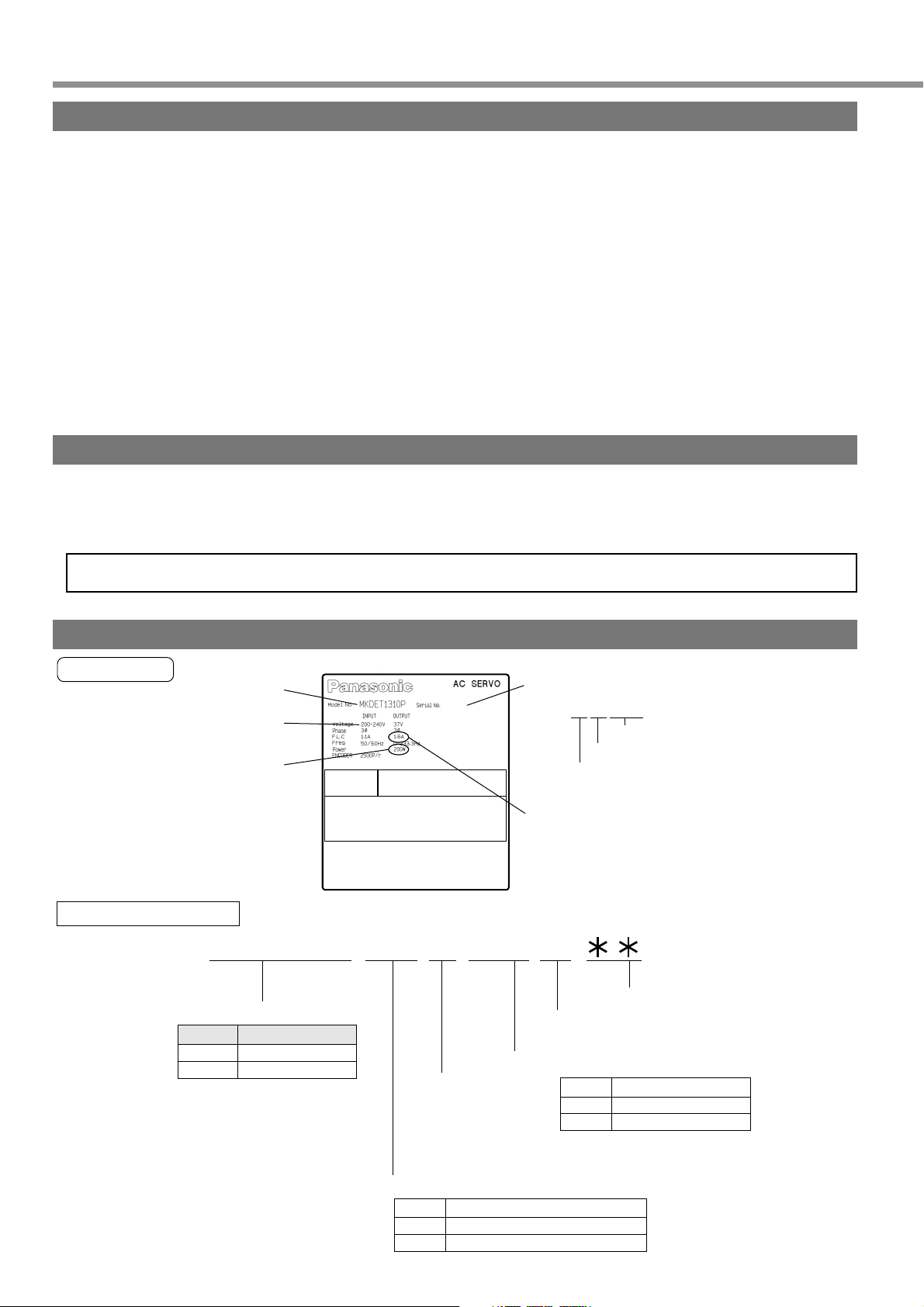

Model of Driver

Name plate

Rated input voltage

Rated motor output

Model Designation

Outer frame symbolic characters

Symbol

MKDE

MLDE

Model

03010001

Serial Number

Ex.:

03010001

Rated output current

MKDET1310 P

1~4 5~6

Frame name

E-Series K frame

E-Series L frame

7 10

Control Mode

P: Position Control

Current rating of current detector

Power supply

1: Single-phase 100 V

2: Single-phase 200 V

3: Three-phase, 200 V

5: Single-phase/Three-phase, 200 V

Symbol

Lot Number

Month of production

Year of production

(Lower 2 digits of AD year)

11~128~9

Special specifications

Current rating of current detector

05

10

5A

10A

Maximum current rating of power element

Symbol

Maximum current rating of power element

T1

T2

14

10A

15A

Page 15

Before Use

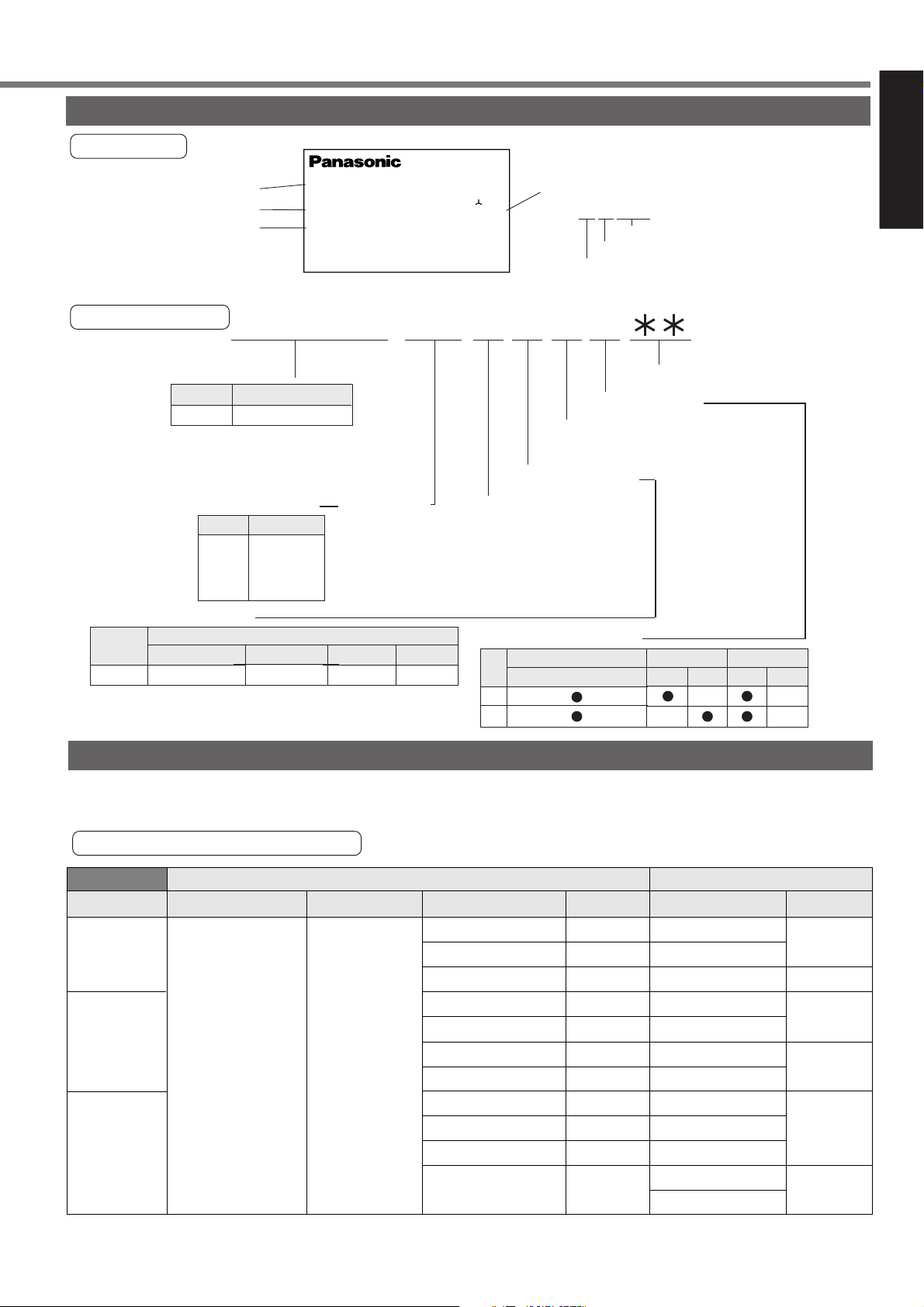

Model of Motor

)

Name plate

Rated output

Rated speed

Type

AC SERVO MOTOR

MODEL No.

MUMA022PIS

INPUT 3flAC

RATED OUTPUT

RATED FREQ.

RATED REV.

200

3000

102

CONT. TORQUE

RATING S1

INS. CLASS B (T V) A (UL)

IP65

V

A1.6

CONNECTION

kW

0.2

SER No.

Hz

r/min

0.64

03010001

Nm

Serial Number

Ex.:

03010001

Lot Number

Month of production

Year of production

(Lower 2 digits of AD year

[Before Use]

Model Designation

MUMA5AZP1S

1~4 5~6

Symbol

MUMA

Table 1a:

Motor rated output

Symbol

5A

01

02

04

Table 1-b: Rotary encoder

Symbol

P

Type

Incremental

Type

Ultra low inertia

Rated output

50W

100W

200W

400W

Specifications

No. of pulses

2500P/r

Rated output

Resolution

10000

Lead wire

5-wire

Check the Combination of Driver and Motor

78910

11~12

Motor structure

Design order

1: Standard

Type of encoder

Power supply

1: 100 V

2: 200 V

Z: 100/200 V common-used

(Limited to 50W only)

Table 1c: Motor structure

Shaft

Center tap on key-wayed shaft end

S

T

Custom specifications

Holding brake

Without

With

Oil seal

Without

With

This driver is designed for use in combination with a motor to be specified by us.

Check a name of series, rated output, voltage specifications and encoder specifications of a motor you wish to use.

Incremental specification 2500 P/r

Power Supply Motor Series Driver Type

Single-phase

100V

Single-phase

200V

MUMA

Ultra low inertia

Three-phase

200V

Rated Speed

3000r/min

<Note> You must not use any other combinations than those listed below:

Applicable Motor Applicable Driver

Motor Type

MUMA5AZP1*

MUMA011P1*

MUMA021P1*

MUMA5AZP1*

MUMA012P1*

MUMA022P1*

MUMA042P1*

MUMA5AZP1*

MUMA012P1*

MUMA022P1*

MUMA042P1*

Rated Output

50W

100W

200W

50W

100W

200W

400W

50W

100W

200W

400W

MKDET1105P

MKDET1110P

MLDET2110P

MKDET1505P

MKDET1505P

MLDET2210P

MLDET2510P

MKDET1505P

MKDET1505P

MKDET1310P

MLDET2310P

MLDET2510P

Driver

Frame

Frame K

Frame L

Frame K

Frame L

Frame K

Frame L

<Remarks>

The marking " * " in Motor Type column of Applicable Motor represents a motor specifications.

15

Page 16

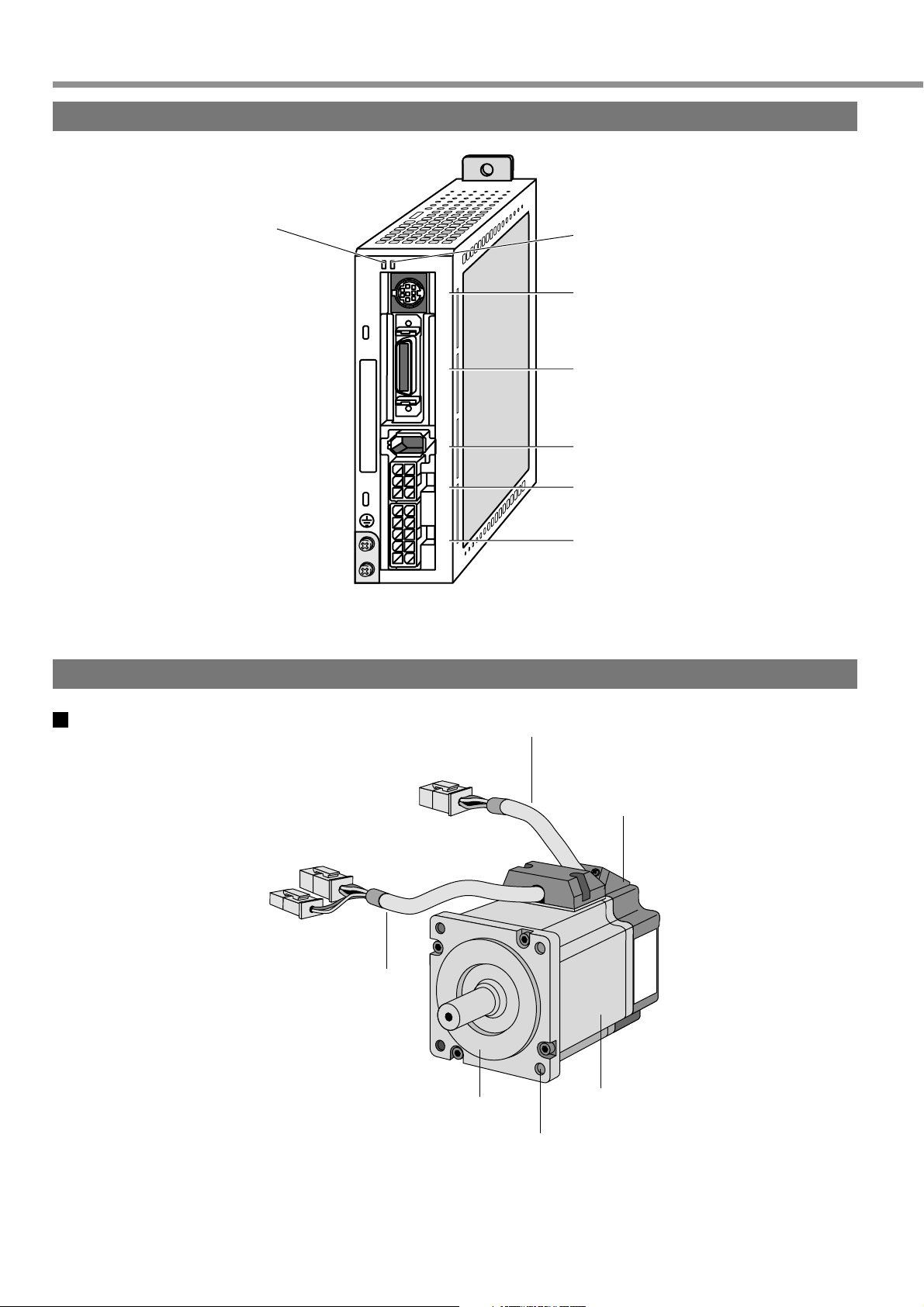

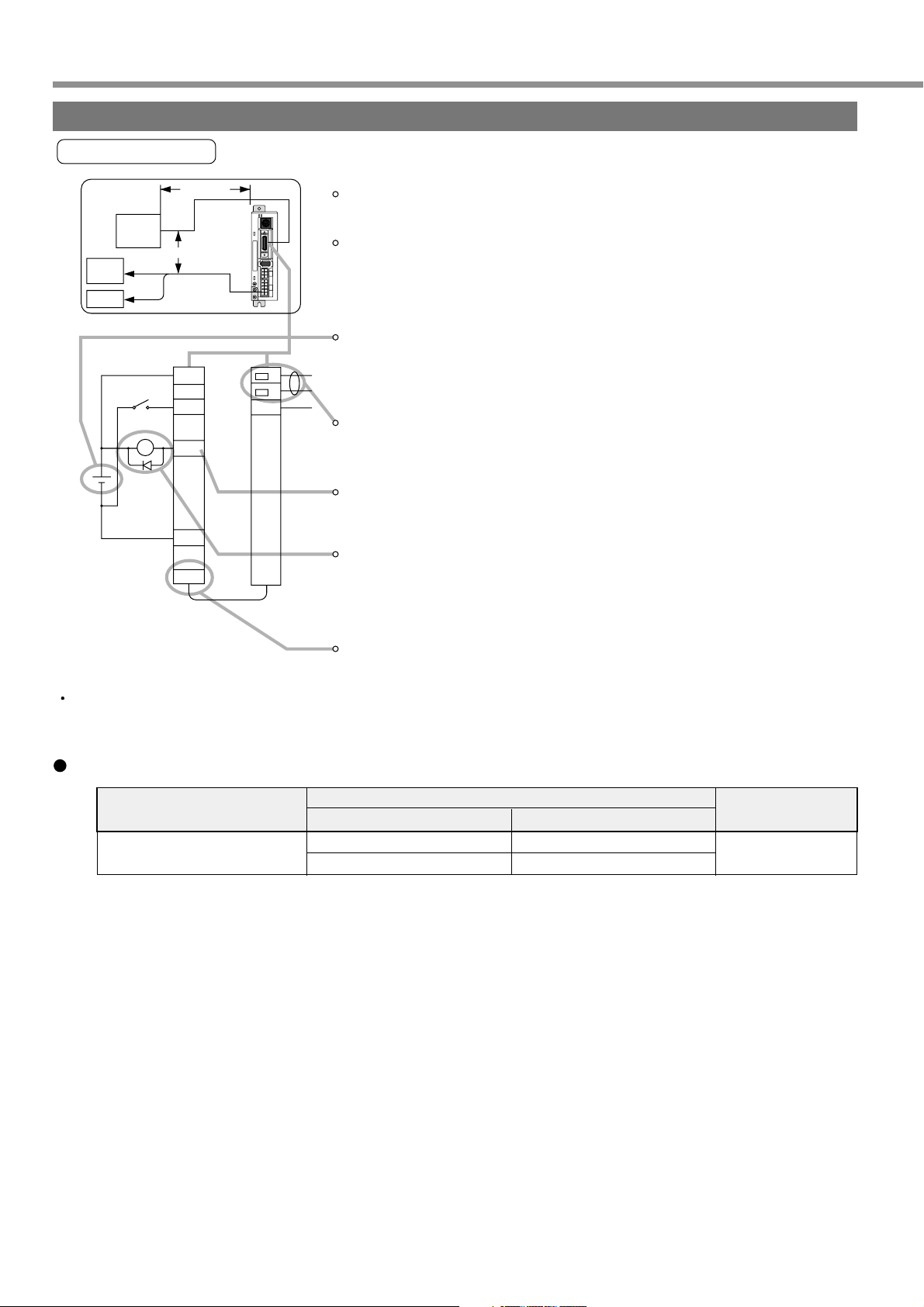

Parts Description

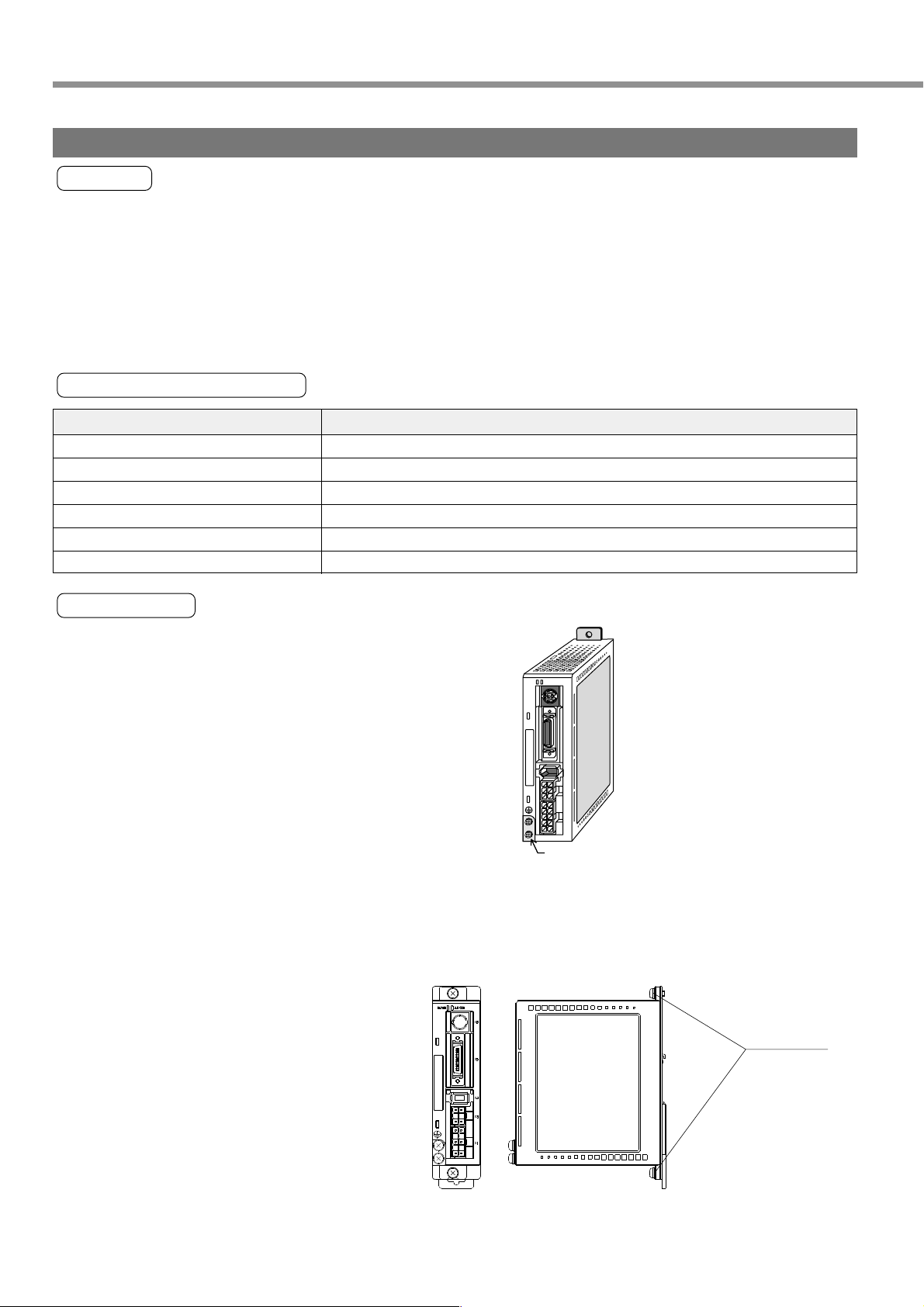

Driver

Motor

Status LED

STATUS

ALM CODE

Alarm Code LED

x

6

Connector for Serial Communications

(X6)

x

5

x

4

x

3

x

1

Interface Connector (X5)

Encoder Connector (X4)

Motor Connector (X3)

Main Power Supply Connector (X1)

MUMA 50W - 400W

Motor Cable

Encoder Cable

Encoder

Flange

Frame

Mounting Holes (in 4 locations)

Example: Super Low Inertia Type (MUMA Series 50W)

<Remarks>

For detailed information on each type, refer to a dimensional outline drawing (Pages 194 to 195) of

Reference edition.

16

Page 17

Before Use

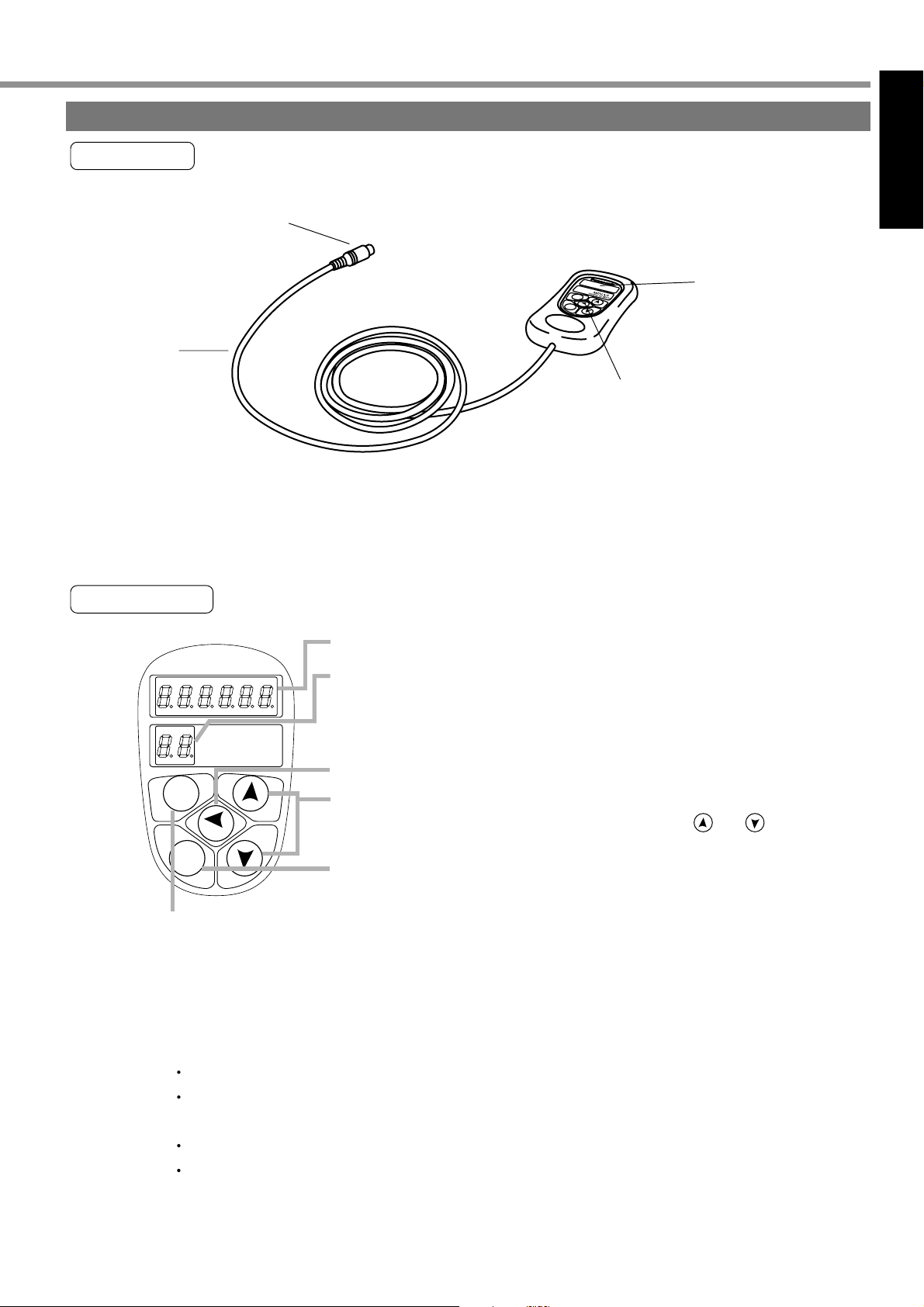

Console

Main body

[Before Use]

Connector

Console main unit

Cable

<Remarks>

The console is optionally available. (Part No.: DV0P3690)

Touch panel

Display, LED (display in 6 digits)

Display of selected Driver ID No. (2 digits)

The value set up on Pr00 (shaft name) is ID No.

Parameter No. (2 digits) is displayed under Parameter Setting

mode.

This is used to shift the digits of data.

This is used to change the data and to execute parameter selection.

The numerical value goes up and down by pressing and .

M

MODE

MINAS

DIGITAL AC SERVO

SHIFT

M

M

O

D

E

S

H

I

F

T

S

S

E

T

Touch panel

Display

(7-segment LED)

S

SET

Setting Button: This is to shift each mode, which was selected by

the mode selector button, to EXECUTE display.

Mode Selector Buttons: These buttons are used to select 6 different modes.

(1) MONITOR mode

(2) PARAMETER SETTING mode

(3) EEPROM WRITE mode

(4) NORMAL AUTO GAIN TUNING mode

(5) AUXI FUNCTION mode

Test run (JOG mode)

Alarm clear

(6) COPING FUNCTION mode

To copy parameters to the console from the servo driver.

To copy parameters to the servo driver from the console.

17

Page 18

Installation

The driver and motor should be properly installed to avoid failures, mechanical damages and injuries.

Driver

Location

(1) Indoors, where the driver is not subjected to rain water and direct sun beams. Note that the driver is not a

waterproof structure.

(2) The place where the driver is not exposed to corrosive atmospheres such as hydrogen sulfide, sulfurous acid,

chlorine, ammonia, sulfur, chlorine gas, sulfuric gas, acid, alkali, salt, etc. and is free from splash of flammable

gas, grinding coolant, oil mist, iron powder, chips, etc.

(3) Place in a well-ventilated, and humid-and dust-free space.

(4) Place in a vibration-free space.

Environmental Conditions

Item

Ambient temperature

Ambient humidity

Lower than 90%RH (free from condensation)

Storage temperature

Storage humidity

Vibration

Lower than 90%RH (free from condensation)

Lower than 5.9 m/s2 (0.6G) at 10 to 60 Hz

Altitude

How to Install

(1) Parallel type. Install in vertical position. Reserve a drafting

space around the driver for ventilation.

(2) For the mounting dimensions onto the wall face in the board,

refer to Page 193 of the dimensional outline drawing.

Conditions

0 to 55°C (free from freezing)

-20 to 80°C (free from freezing)

Lower than 1000 m

Base mount type

STATUS

ALM CODE

x

6

x

5

x

4

x

3

x

1

Earth connection (M4 screw) tightening

torque shall not exceed 0.39 - 0.59 N•m

(3) Installing to DIN Rail

Install the main body of the driver by using optionally available DV0P3811 (see an “optional” DIN rail mounting unit

on page 190 of Reference edition) and screws (M4 x length 8, pan-head machine screws) supplied with the

option.

Ancillary Screws

(M4 x Length 8 )

DIN rail mounting unit attached to the driver

18

Page 19

Before Use

Part where DIN

rail is mounted

DIN rail

With rail stop

pushed in

Press lightly.

Ensure that the rail stop

has been pushed in.

[Before Use]

Driver mounted to DIN rail

Hook the upper side of DIN rail

mounting part on the DIN rail.

Press lightly the lower part of

the main body of driver.

(4) Removing from DIN Rail

By lifting the driver, you can remove it

from the DIN rail.

Pull out the lower part

of the driver to the

near side.

With the rail stop released, pull out the

lower part of the driver to the near side.

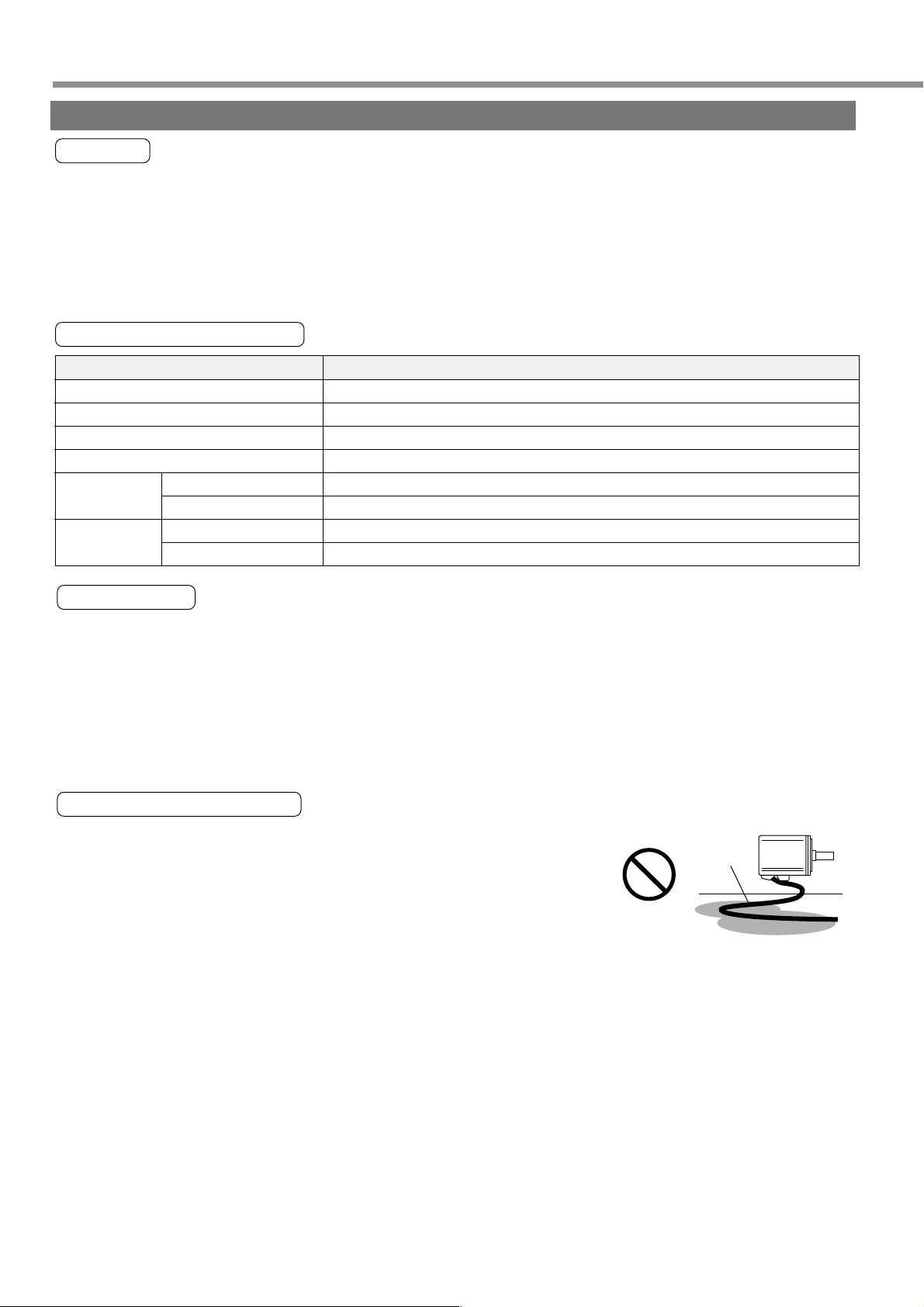

Mounting Direction and Space Requirements

• Allow enough space to ensure enough cooling.

• Install fans to provide a uniform distribution of temperature in the control box.

• Observe the environmental requirements for the control box, mentioned in the previous page.

min.

40 mm

Fan

Driver Exhaust

Direction

STATUS

ALM CODE

x

6

x

5

x

4

x

3

x

1

Driver Intake

Direction

min.

10 mm

Driver Exhaust

Direction

STATUS

ALM CODE

x

6

x

5

x

4

x

3

x

1

Driver Intake

Direction

min.

10 mm

Fan

Driver Exhaust

Direction

STATUS

ALM CODE

x

6

x

5

x

4

x

3

x

1

Driver Intake

Direction

min.

10 mm

Driver Exhaust

Direction

STATUS

ALM CODE

Driver Intake

Direction

min.

100 mm

x

6

x

5

x

4

min.

40 mm

x

3

x

1

min.

100 mm

This driver has a cooling fan in its bottom and a mounting face.

To install the driver, ensure that there is enough space around the inlet and outlet ports so as not to prevent

intake and exhaust of the fans.

19

Page 20

Installation

Motor

Location

(1) Indoors, where the driver is not subjected to rain water and direct sun beams.

(2) The place where the motor is not exposed to corrosive atmospheres such as hydrogen sulfide, sulfurous acid,

chlorine, ammonia, sulfur, chlorine gas, sulfuric gas, acid, alkali, salt, etc. and is free from splash of flammable

gas, grinding coolant, oil mist, iron powder, chips, etc.

(3) Place in a well-ventilated, and humid- and dust-free space.

(4) The place where the motor can be checked and cleaned easily.

Environmental Conditions

Vibration

Shock

Item

Ambient temperature

Ambient humidity

Storage temperature

Storage humidity

Motor only

With gear (At rotation)

Motor only

With gear

0 to 40°C (free from freezing)

Lower than 85%RH (free from condensation)

-20 to 80°C (free from freezing)

Lower than 85%RH (free from condensation)

49 m/s2 (5G) or less at rotation, 24 5 m/s2 (2.5G) or less

High precision: 24.5 m/s2 (2.5G) max.

98 m/s2 (10G) max.

High precision: 98 m/s2 (10G) max.

Conditions

How to Install

The motor can be installed either vertically or horizontally. Observe the following notes.

(1) When installing in horizontal direction

• Mount the motor with its cable lead-out port faced downward as the countermeasure for oil and water.

(2) When installing in vertical direction

• When installing the motor with speed reducer with its output shaft upside, use the oil-sealed motor to prevent oil

inflow to the motor from the speed reducer. In this case, the oil-sealed motor is a special product.

(3) For the mounting dimensions, refer to a dimensional outline drawing (Pages 194 to 195).

Oil and Water Protections

(1) Don’t use the motor under an environment where oil and water splash over

the motor body.

(2) In combining with the speed reducer, use the oil-sealed motor to prevent oil

inflow to the motor internal through its shaft through-penetration hole. In this

case, the oil-sealed motor used is a special product.

(3) Don’t use the motor with its cable dipped in oil/water.

20

Oil and water

Cable

Motor

Page 21

[Before Use]

Before Use

Cable: Stress relieving

(1) Don’t apply stress to the cable lead-out port and connections by bending and self-weight.

(2) Particularly in the case of application in which the servo motor must be movable, fix the accessory cable of the

motor and house the extension junction cable, which is connected to the terminal end of the said cable, in the

cable bearer to thereby minimize stress acting on the cable by bending.

(3) Make the cable bending radius as large as possible. (Minimum bending radius: to be 20 mm and over.)

Permissible Shaft Load

(1) Do mechanical design so both of radial load and thrust load being applied to the motor shaft during installation

and running are maintained within the permissible value specified for each model.

(2) In using the rigid coupling, take good care of mounting. (Over-bending load on it, if any, would cause damage/

wear of the shaft and shorter life of the bearings.)

(3) Use the flexible coupling of possibly high stiffness to control radial load arising from minor center deviation at the

permissible value or less.

(4) For information on allowable load of an output shaft of each type, refer to Allowable Load of Output Shafts on

Page 196 of Reference.

Installation Notes

(1) When connecting /disconnecting the coupling to/from the motor shaft end, don’t apply

direct impact to the shaft by hammering, etc. (Failure to observe this instruction would

cause damage of the encoder mounted on the counter-load side shaft end.)

(2) Do perfect centering. (Imperfect centering would result in vibration, which would cause

damage of the bearings.)

Motor

21

Page 22

Installation

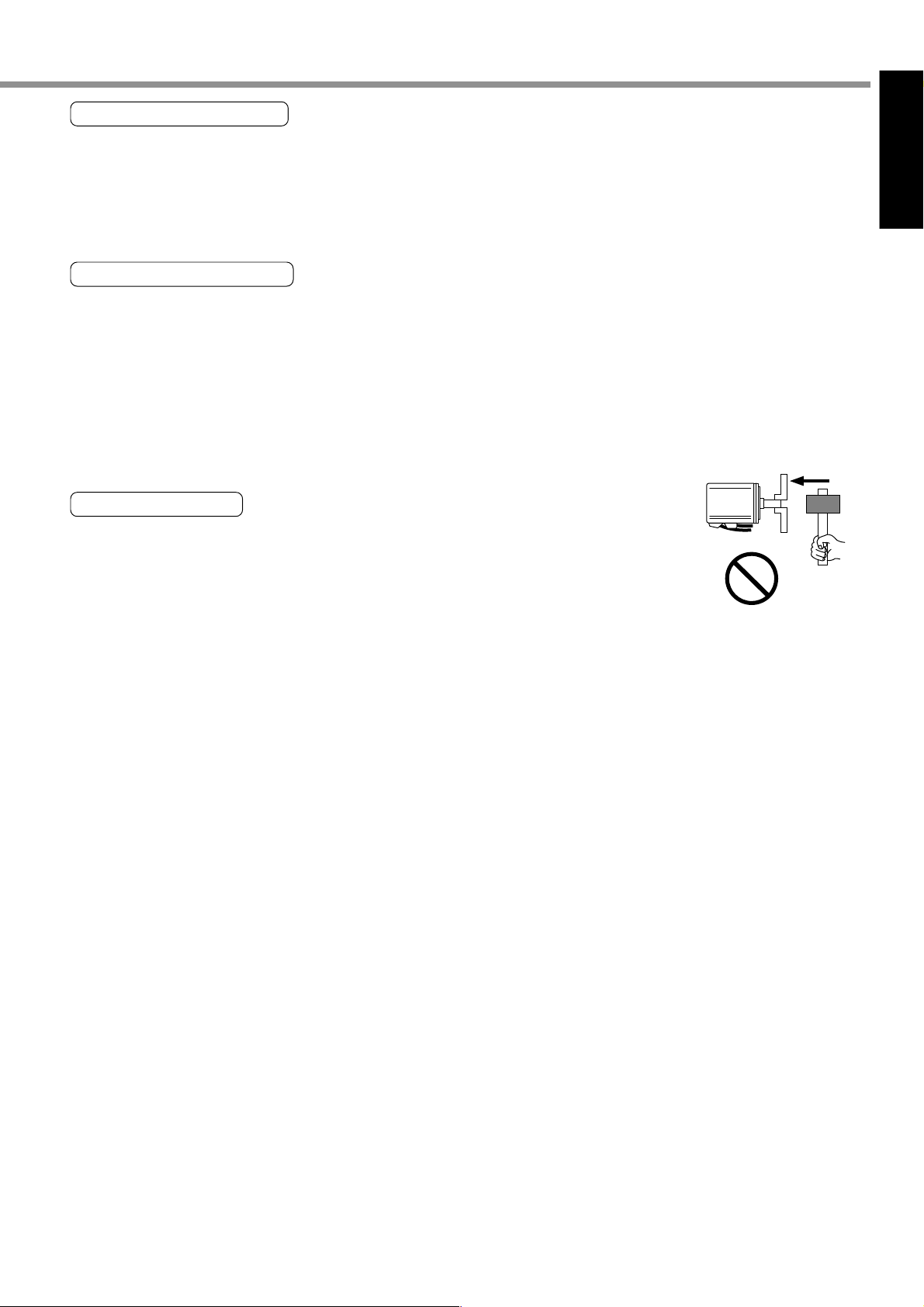

Console

Location

(1) Indoors, where the driver is not subjected to rain water and direct sun beams. The console is not water-

resistant.

(2) The place where the driver is not exposed to corrosive atmospheres such as hydrogen sulfide, sulfurous acid,

chlorine, ammonia, sulfur, chlorine gas, sulfuric gas, acid, alkali, salt, etc. and is free from splash of flammable

gas, grinding coolant, oil mist, iron powder, chips, etc.

(3) Place in a well-ventilated, and humid-and dust-free space.

(4) Place in a space to be easily accessed for inspection and cleaning.

Environmental Conditions

Item

Ambient temperature

Ambient humidity

Storage temperature

Storage humidity

Vibration

Shock

Altitude

0 to 55°C (free from freezing)

Lower than 90%RH (free from condensation)

-20 to 70°C (free from freezing)

Lower than 90%RH (free from condensation)

Lower than 5.9 m/s2 (0.6G) at 10 to 60 Hz

Compliant with free-fall test JIS C 0044 (1-m fall with a fall guide, twice in each direction)

Conditions

Lower than 1000 m

<Note>

• Avoid strong physical shock to the product.

• Do not drop the product.

• Do not pull the cable with an excessive force.

• Do not set the product near a heat generating device such as heater and large wire wound resistor.

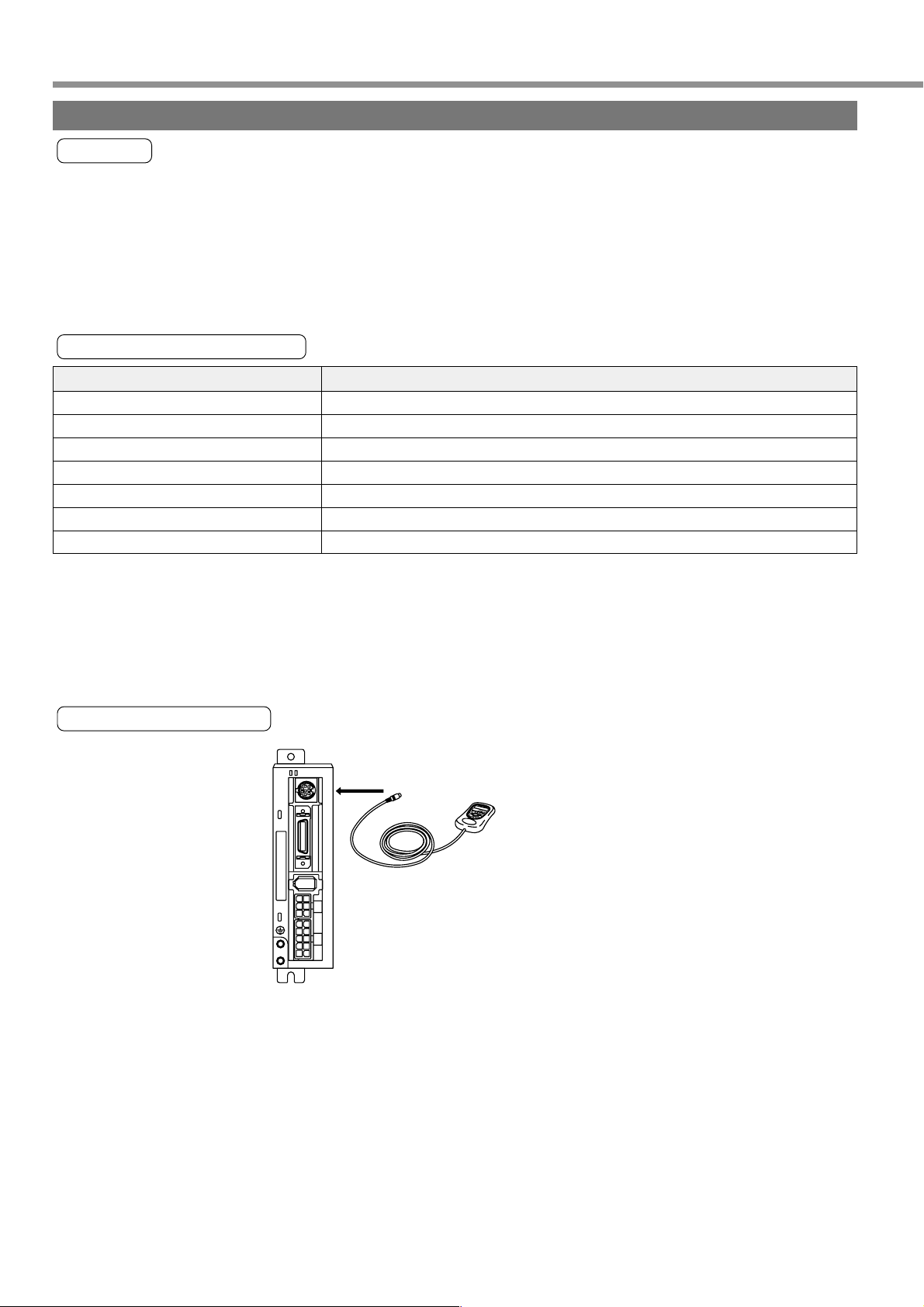

Method of Connection

STATUS

Connect to CN X6.

ALM CODE

x

6

x

5

M

M

O

D

E

S

H

I

F

T

S

S

E

T

x

4

x

3

x

1

<Remarks>

• Securely connect the console connector to the connector CN X6 of the driver.

• Never connect or disconnect the connector by grabbing the connector cable.

22

Page 23

Preparations

Preparations

Page

System Configuration and Wiring ............................... 24

General Wiring Diagram ......................................................................... 24

List of Driver and Compatible Peripheral Equipment ..............................26

Wiring of Connectors CN X1 and X3 (Wiring of Main Circuits) ...............27

Wiring of Connector CN X4 (Connection with Encoder) ......................... 29

Wiring of Connector CN X5 (Connection with Host Controller)............... 30

Wiring of Connector CN X6 (Connection with Personal Computer/Console) ......

Timing Chart .................................................................. 32

Holding Brake ................................................................ 35

Dynamic Brake (DB)...................................................... 36

Homing Operation (Precautions) ................................. 38

Setting the Parameters ................................................. 39

Overview of Parameters .........................................................................39

How to Set ..............................................................................................39

Overview of Console ............................................................................... 39

Overview of PANATERM® ....................................................................... 39

How to Connect ......................................................................................40

Parameter Groups and Listing ................................................................41

31

Using the Console......................................................... 47

Using the Console ................................................................................... 47

The initial State of the Display (7-segment LED) ....................................47

Structure of Each Mode ..........................................................................48

Monitoring Mode .....................................................................................51

Parameter Setting Mode .........................................................................57

Normal Auto Gain Tuning Mode .............................................................. 58

Alarm Clear .............................................................................................59

Test Run (JOG) .......................................................................................60

Test Run Procedures .............................................................................. 61

Copy Function ......................................................................................... 62

23

Page 24

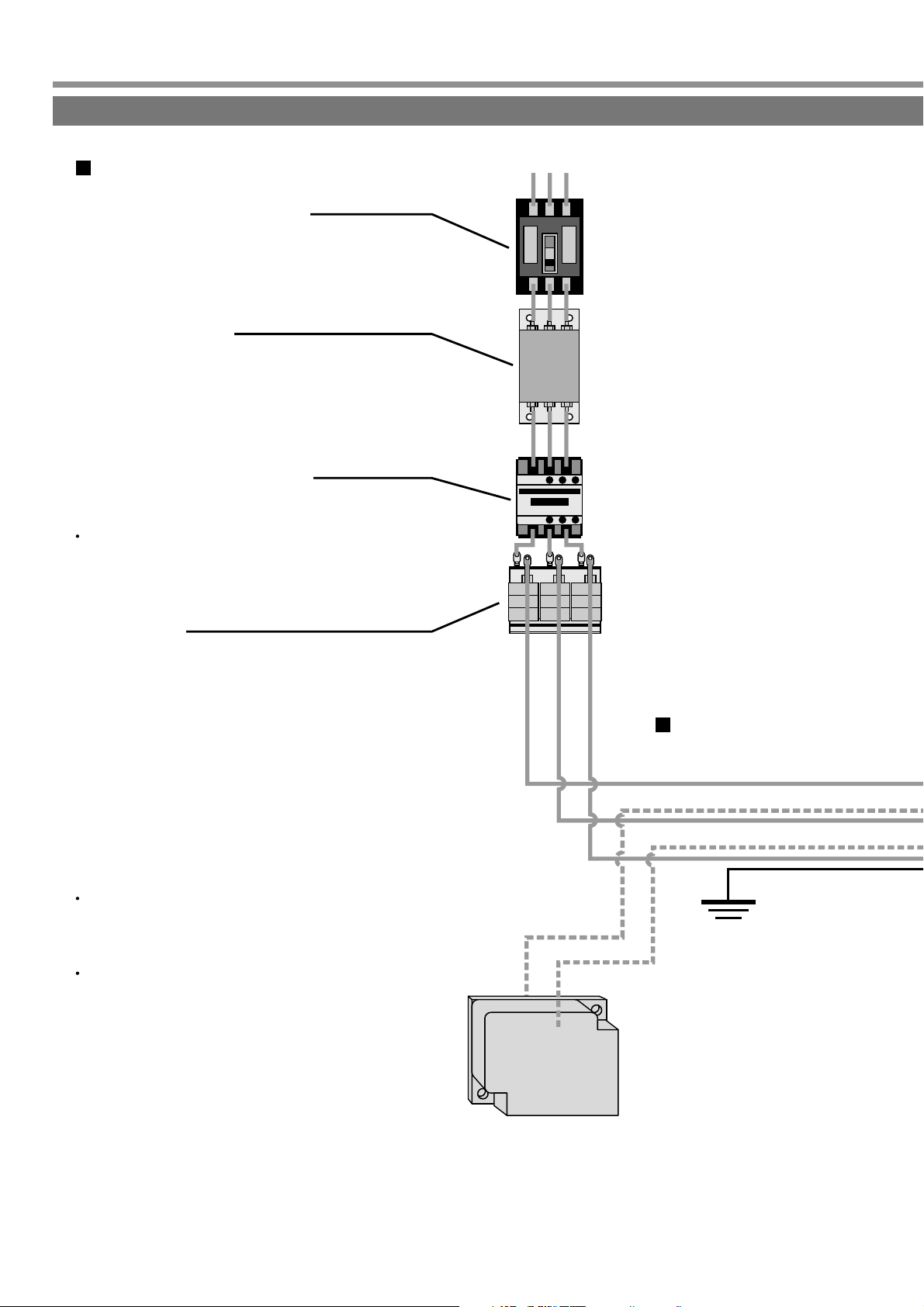

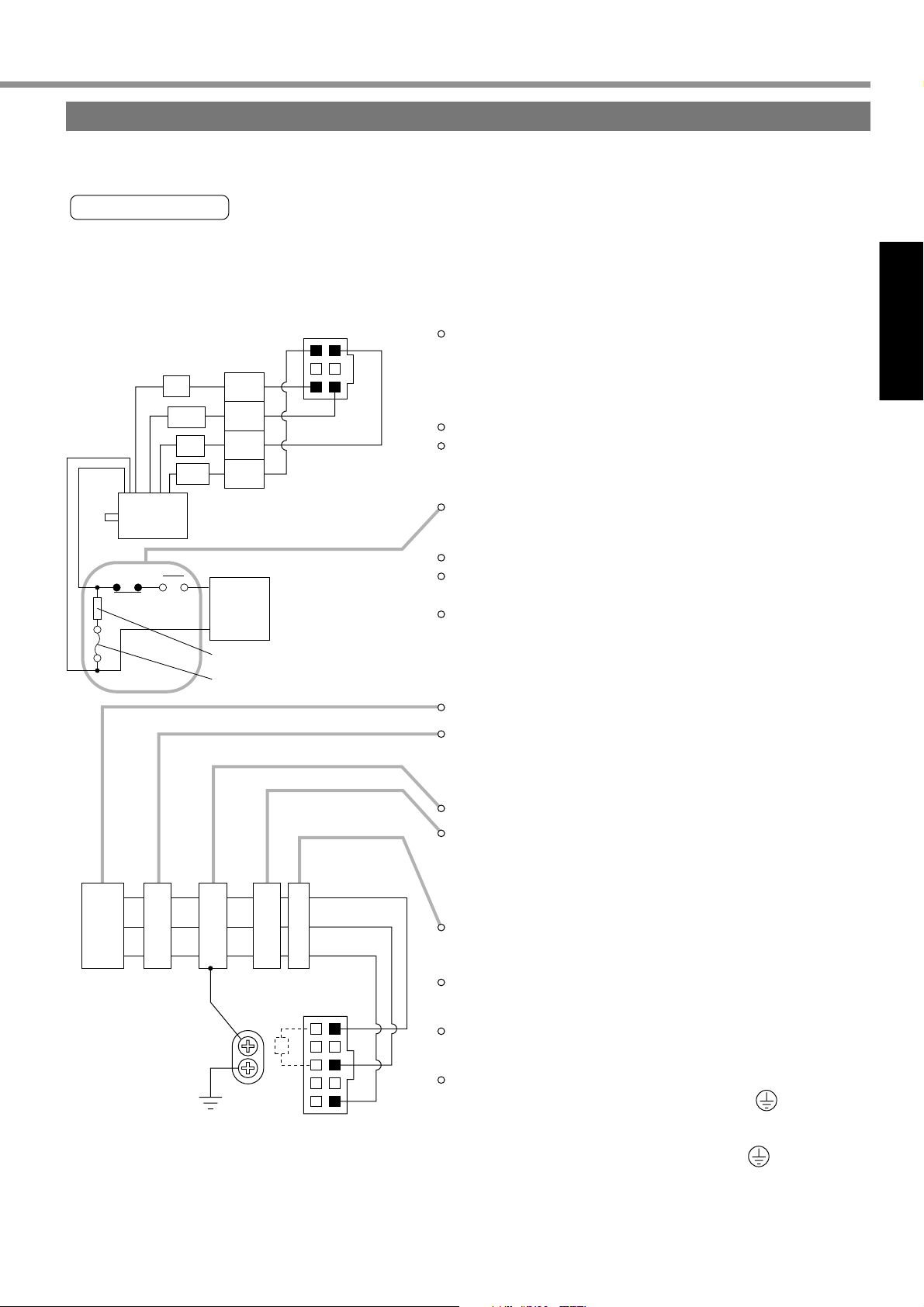

System Configuration and Wiring

p

L1

L2

L3

General Wiring Diagram

Main Circuits

Circuit Breaker (NFB)

(Refer to Page 26)

Used to protect the power lines:

overcurrent will shut off the circuit.

(Refer to Page 26, 182)

Noise Filter (NF)

Prevents the external noise from the power line,

and reduces the effect of the noises generated

by the servo motor.

(Refer to Page 26)

Magnetic Contactor (MC)

Turns on/off the main power of the servo motor.

Used together with a surge absorber.

Never start or stop the motor with the

magnetic contactor.

(Refer to Page 191)

Reactor (L)

Reduces the harmonic current in the main

power.

5 Pins - 3 Pins of CN X1 ---

When using the driver for an application of large

regenerative energy, connect an external

regenerative resistor between P (5 pins) and B

(3 pins) of connector CN X1.

Install an external regenerative resistor on

incombustible material, such as metal, and

provide the regenerative resistor with a

protective device such as temperature fuse, etc,

to prevent the resistor from being overheated.

Regenerative discharge resistor

(Optional)

Wiring connection to

Connector CN X1

(Connection with the input power su

P

B

Ground

24

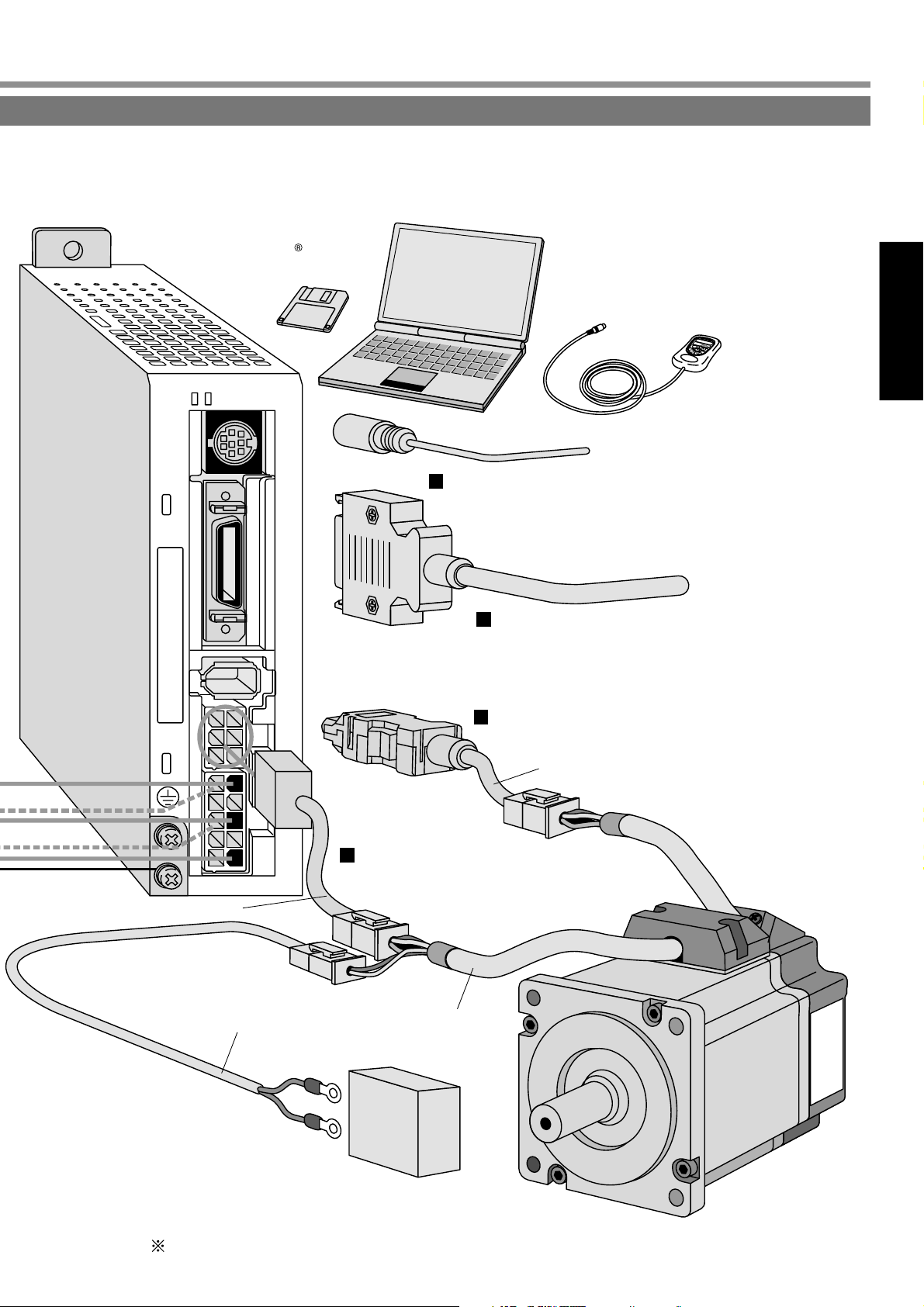

Page 25

[Preparations]

Preparations

L1

L2

Setup support software

"PANATERM "

STATUS

ALM CODE

x6

x5

Personal computer

Console

M

M

O

D

E

S

H

I

F

T

S

S

E

T

Wiring to Connector CN X6

(Connection with personal computers and consoles)

Wiring to Connector CN X5

(Connection with host controllers such as PLC, etc.)

ply)

MKDET1310P 200V

L1

L1

L2

L2

L3L3L3

Junction cable for motor

Junction cable for brake

x4

x3

x1

Wiring to Connector CN X4

(Connection with encoder)

Junction cable for encoder

Wiring to Connector CN X3

(Connection with each phase of motor

windings)

Motor cable

Power supply for motor brake

(24 V DC)

For connections, refer to Points in Wiring (Page 27).

25

Page 26

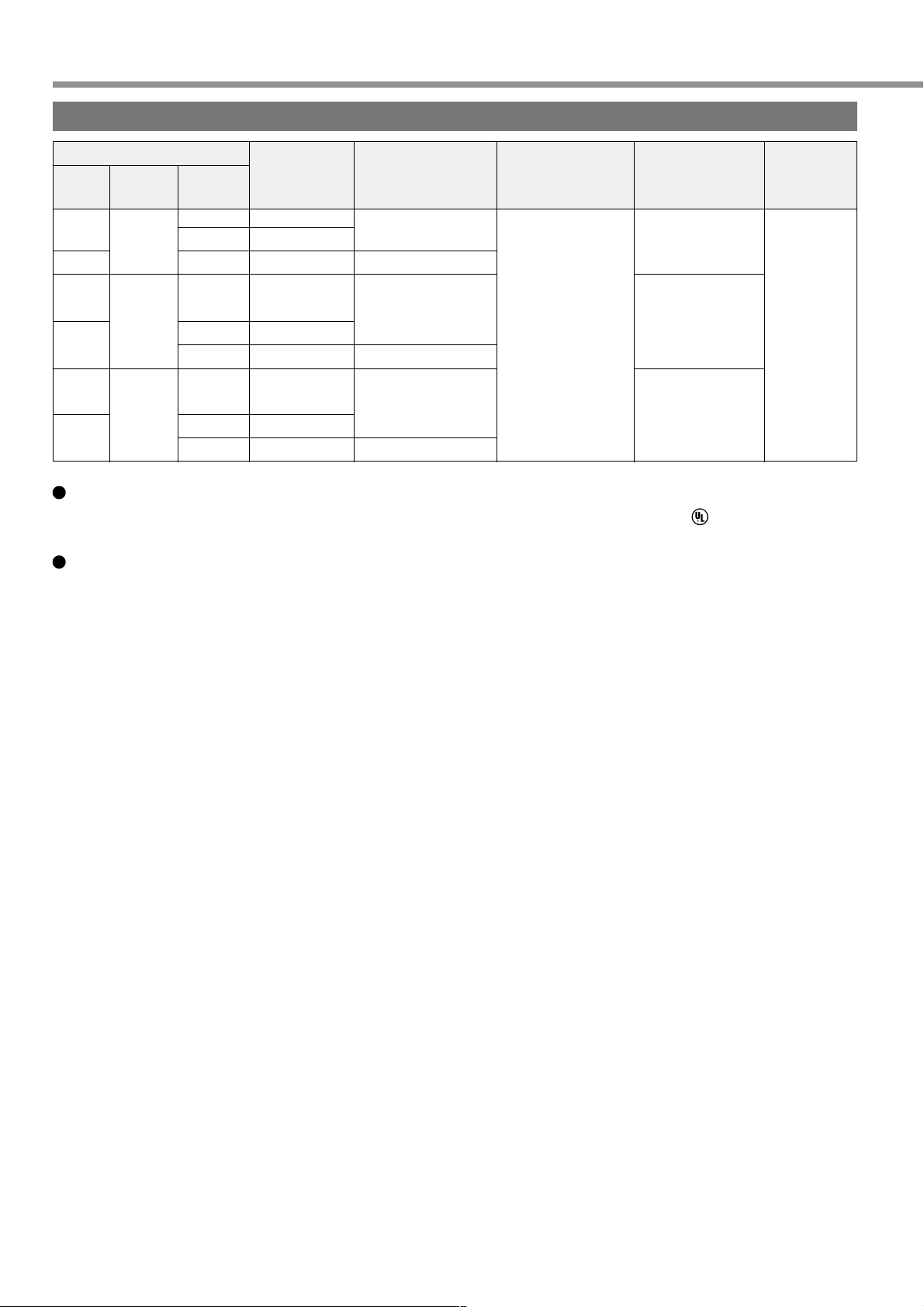

System Configuration and Wiring

List of Driver and Compatible Peripheral Equipment

Series

MKDE

MLDE

MKDE

MLDE

MKDE

MLDE

Driver

Power

voltage

1-phase,

100V

1-phase,

200V

3-phase,

200V

Output

50W

100W

200W

50W

100W

200W

400W

50W

100W

200W

400W

Required

Power

(rated load)

0.3kVA

0.4kVA

0.5kVA

0.3kVA

0.5kVA

0.9kVA

0.3kVA

0.5kVA

0.9kVA

Circuit breaker

(rated current)

BBC25N

(5A)

BBC2101N(10A)

BBC25N

(5A)

BBC2101N(10A)

BBC35N

(5A)

BBC3101N(10A)

Noise filter

DV0P4160

Magnetic contactor

(composition of

contacts)

BMFT61041N

(3P+1a)

BMFT61542N

(3P+1a)

BMFT61042N

(3P+1a)

0.75mm

AWG18

Circuit breaker, magnetic contactor: manufactured by Matsushita Electric Industrial Co., Ltd.

For compliance with EC Directives, don’t fail to connect the circuit breaker (with LISTED, Mark), which is

authorized and certified under IEC and UL Standards, between the power supply and the noise filter.

Noise filter

For DV0P4160, refer to Page 182.

Cable

diameter

(L1, L2, L3,

U, V, W, E)

2

-

0.85mm

2

< Remarks >

• For wiring to the power connector, motor connector and earth terminal, use the copper conductors of 60°C and

over in the temperature rating.

• For the connector-side earth cable, use the cable of 0.75 mm2 - 0.85 mm2 (AWG18) in diameter.

• For the mounting screw-side earth cable, use the cable of 2.0 mm2 (AWG14) or more in diameter.

• Where two or more drivers are used and the noise filters for the drivers are mounted in set in the power unit, feel

free to consult with the noise filter manufacturer.

26

Page 27

[Preparations]

Preparations

Wiring of Connectors CNX1, X3 (Wiring of Main Circuits)

• Don’t fail to request an electric wiring specialist for wiring.

• Don’t switch ON the electric power until completion of the wiring, to prevent electric shock.

Points in Wiring

(1) For the cable diameter used, refer to “List of Driver and Compatible Peripheral Equipment” (page 26).

(2) Insert securely the connectors.

CN X3

(Driver side)

Do wiring in perfect color matching between the

identification colors of the motor lead-out cable and

corresponding motor output terminal (U, V, W).

Connect U (1 pin), V (4 pins), W (6 pins) and E (3 pins)

respectively.

Avoid shorting and ground fault.

At this stage, don't connect the power supply cable.

Adopt a duplex circuit as the brake control circuit so it can

actuate even with emergency stop signal from external

device.

The magnetic brake has no polarity.

For the power capacity and operation detail of the magnetic

brake, refer to the "Holding Brake" (page 35).

Install the surge absorber (C-5A2 or Z15D151 made by

Ishizuka Electronic).

Read the driver nameplate to check the power specification.

Provide circuit breaker or leakage breaker without fail. In this

case, use a leakage breaker to which countermeasure for high

frequency is applied for "inverter application".

Motor

Red

White or

yellow

Black

Green/

yellow

36

U

1

V

W

E

DC

2

3

4

24V

14

DC power for brake use

Surge absorber

Fuse (5A)

NFB

NF MC L

Power

(Driver side)

Ground resistance: 100Ω max.

For applicable wire, see page 26.

CN X1

5

P

B

16

10

L1

L2

L3

Don't fail to provide noise filter.

Provide the magnetic contactor coil with surge absorber.

Never start/stop the motor by magnetic contactor.

Install AC reactor.

For three-phase 200V, connect L1 (10 pints), L2 (8 pins) and

L3 (6 pins).

For single-phase 100V and 200V, connect L1 (10 pins) and

L3 (6 pins).

Connect to the grounding system of the facility.

Connect the driver protective earth terminal ( ) and the

protective earth (earth plate) of the control panel for

preventing of electric shock. In this case, don't co-clamp the

earth wires to the protective earth terminal ( ). Two

protective earth terminals are provided.

27

Page 28

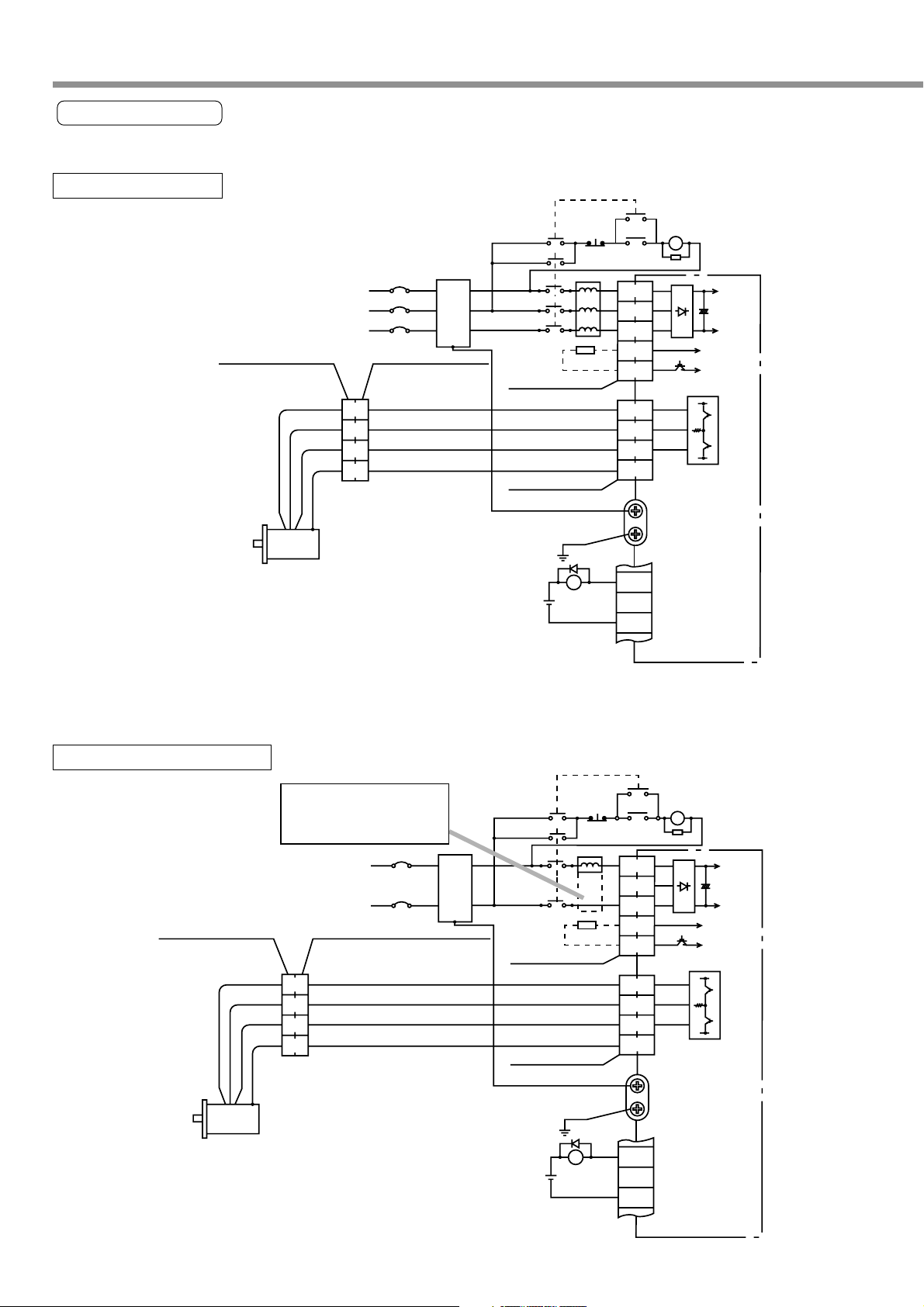

System Configuration and Wiring

Wiring Diagrams

Compose such a power supply as to switch OFF the power against alarm output.

For three-phase 200V

Power supply

172167-1

(Tyco Electronics

AMP K.K.)

Motor

Red

White or

yellow

Black

Green

yellow

NFB

172159-1

(Tyco Electronics

AMP K.K.)

1

2

3

4

Noise

filter

ON

MC

MC

OFF

L

5557-10R-210

(Molex Incorporated)

5557-06R-210

(Molex Incorporated)

V

ALM

DC

12~24V

10

13

8

6

5

3

1

4

6

3

9

ALM

L1

L2

L3

P

B

U

V

W

E

ALM

COM —

MC

P

N

P

N

CN X1

CN X3

CN X5

For Single-phase 100V/200V

172167-1

(Tyco Electronics

AMP K.K.)

Motor

Red

White or

yellow

Black

Green

yellow

For single-phase 200V,

use the reactor for

three-phase.

NFB

Power supply

172159-1

(Tyco Electronics

AMP K.K.)

1

2

3

4

Noise

filter

ON

MC

MC

OFF

L

5557-10R-210

(Molex Incorporated)

5557-06R-210

(Molex Incorporated)

V

ALM

DC

12~24V

10

6

5

3

1

4

6

3

9

13

ALM

L1

L2

L3

P

B

U

V

W

E

ALM

COM —

MC

P

N

P

N

CN X1

CN X3

28

CN X5

Page 29

Preparations

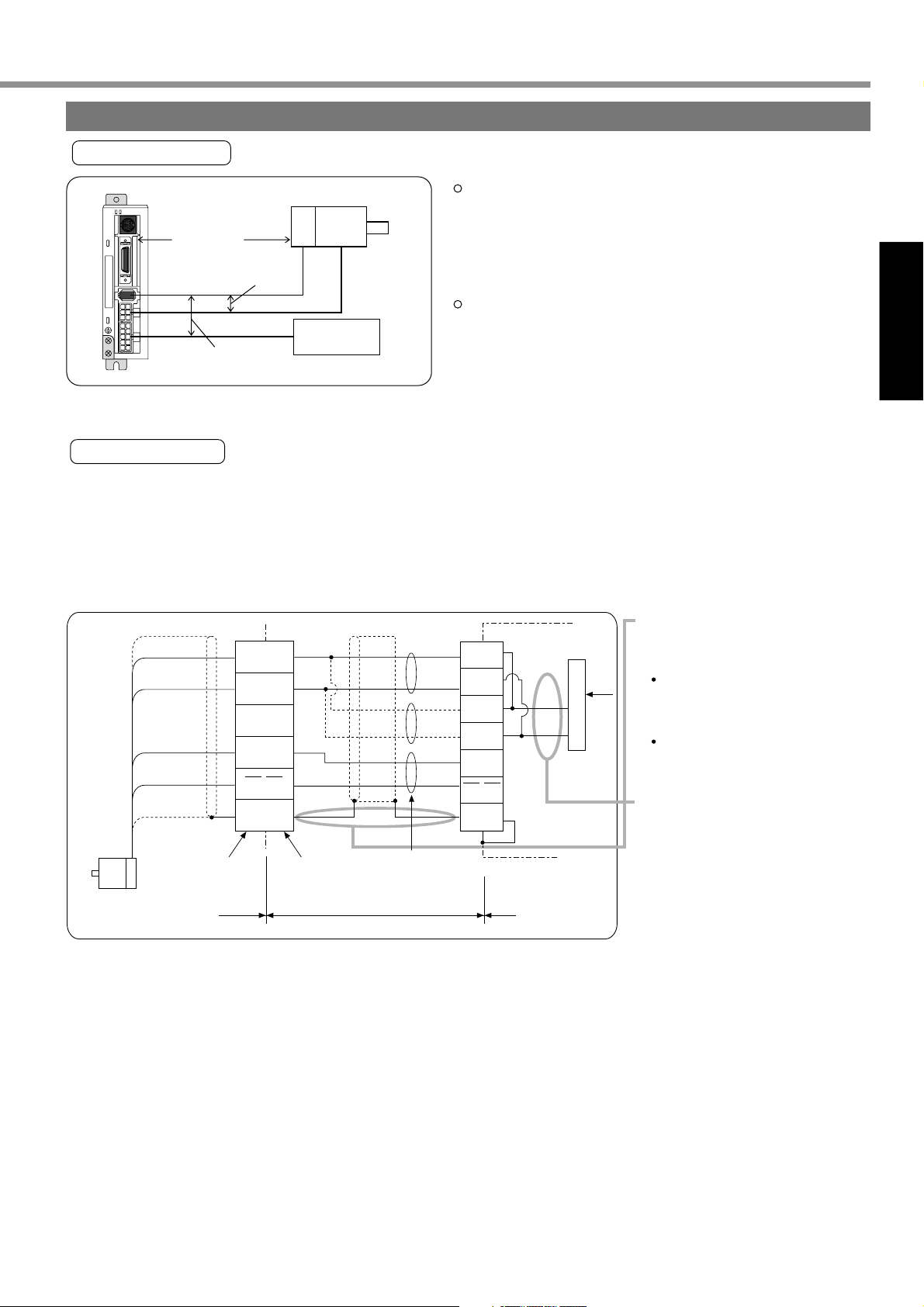

Wiring to Connector CN X4 (Connection with Encoder)

Points in Wiring

[Preparations]

STATUS

ALM CODE

x

6

20 m max.

x

Encoder

5

x

4

x

3

x

1

30 cm min.

30 cm min.

Power

section

Motor

Cable length between the driver and the motor - 20 m max.

If this cable length exceeds 20 m, consult with the

dealer/distributor from which you have purchased the

driver.

Keep 30 cm or more spacing from the main circuit wiring.

Neither guide this wiring through the same duct, together

with the main circuit nor bundle these two together.

Wiring Diagram

¥ When you plan to make an encoder junction cable by yourself, refer to Requests on a self-made encoder junction

cable (For connectors, refer to Optional Parts (Connector Kits for Connection of Motor and Encoder) on Page

186 of Reference edition).

(1) Refer to the wiring diagram below.

(2) Cable used: Shielded twist pair cable of 0.18 mm

bending resistance.

5

0V

4

+5V

1

2

3

6

FG

172160-1172168-1

(made by Tyco Electronics AMP K.K.)

Junction cable

Servo motor

Black

White

(NC)

Light blue

Purple

Shielded

cable

(made by Tyco

Electronics AMP K.K.)

Motor side Servo driver side

TX/RX

TX/RX

2

(AWG 24) minimum in conductor diameter that is excellent in

(3) For signal/power wiring in pair,

Case

2

1

4

3

5

6

0V

+5V

0V

+5V

TX/RX

TX/RX

FG

X4CN

0V

Regulator

+5V

use twist pair cable.

(4) Shielding treatment

Driver-side shield sheath:

Connect to CNX4 connector

case (FG).

Motor-side shield sheath:

Connect to 6 pins.

(5) Where the cable length

exceeds 10 m, do double-

wiring for the encoder power

Twist pair

(+5V, 0V), as illustrated left.

(6) Connect nothing to the empty

terminal (NC) of the

connector.

(7) Don’t use a cable pair composed of the motor cable and encoder cable which were shielded in batch.

29

Page 30

System Configuration and Wiring

Wiring of Connector CN X5 (Connection with Host Controller)

Points in Wiring

V

Power

Supply

Motor

DC

Unit

Controller

Within 3 m

30 cm or More

COM+

COM-

FG

CN X5

STATUS

GND

Place any peripheral equipment such as a host controller within 3 meters

ALM CODE

x

6

x

5

x

4

x

3

x

1

from the driver.

Separate the wiring at least 30 cm or more from the main circuit wires.

The wiring should neither run through a same duct as the main circuit

wires nor be bundled together with them.

A customer is requested to prepare for power supply for control signals

(V

DC

1

2

) between COM+ and —COM.

Voltage: DC +12 to 24V

For such wiring as command pulse input or encoder signal output, etc.,

use shielded twist pair cable.

Neither apply 24V or more to a control signal output terminal, nor run

50mA or higher.

If you directly activate a relay using the control signal output, install a

diode in parallel with a relay in the direction shown in the left figure.

Without a diode or with it but placed in the opposite direction, the driver

will be damaged.

The Frame Ground (FG) is connected to an earth terminal in the driver.

For detailed information on wiring of respective pins, refer to Page 65 (position control mode) and Page

103 (internal velocity control mode) of connections for each control mode.

CN X5 Connector Specifications

Connectors on Driver Side

10226-52A2JL

Connector (solder type)

Connector cover

Compatible Connectors on User Side

Part Name

10126-3000VE

10326-52A0-008

Part No.

Manufacturer

Sumitomo 3M Ltd.

<Remarks>

• For details, refer to “Optional Parts” on Page 188 of Reference edition.

30

Page 31

[Preparations]

Preparations

x

5

x

6

STATUS

ALM CODE

x

5

x

6

STATUS

ALM CODE

Wiring of Connector CN X6 (Connection with Personal Computer/Console)

• It is capable of RS232C communications.

For RS232C communications only

1) Connect the personal computer and driver 1:1 through RS-232C, and use “PANATERM®” (optional component),

the setup supporting software. Running “PANATERM®” on your personal computer, you can have convenient

functions with excellent operability, such as various types of monitors, parameter settings/changes, waveform

graphic displays, etc.

2) You can connect a host (personal computer, or host controller) and driver through RS 232C for communications.

For detailed information, refer to “Communications” on Page 158 of Reference edition.

Connection

Refer to "Optional

Parts" of dedicated

connecting cables.

Insert or pull out a connector

only after cutting power off

both personal computer and driver.

Tighten stop screws firmly.

Connection with Console

CN X6

Connect to CN X6.

Back Plane of Connector for RS232C

M

M

O

D

E

S

H

I

F

T

S

S

E

T

31

Page 32

Timing Chart

Power Supply

Internal Control

Power Supply

Initialization of

Driver

Servo-ON Input

(SRV-ON)

(X5 2 pins)

Dynamic Brake

Motor Energized

Brake Release

Output

(BRK-OFF)

(X5 11 pins)

Position/Velocity

Command

ON

ON

Normal Operation

OFF

* 1

OFF (Braking Operation)

ON

(Brake Release)

OFF

ON

Not Energized

Energized

Not input

Input

100ms or Longer

Approx.

700 ms

Established

Initialize Approx. 2 seconds

Approx. 40 ms

Approx. 1 - 5 ms

Approx. 10 ms

Approx. 2 seconds

OFF

-After Power-ON (Receiving Servo-ON Signal)

<Cautions>

• The above chart shows timing from AC power-ON to command input.

• Enter Servo-ON signal and external command according to the above timing chart.

*1: During this period, the SRV-ON signal has not been accepted although it was mechanically input.

32

Page 33

Preparations

After an Alarm event (during Servo-ON)

[Preparations]

Alarm

Dynamic Brake

Motor Energized

Servo Alarm

(ALM)

Brake Release

(BRK-OFF)

Normal

Energized

Not Alarm

Release (ON)

A

1 - 5 ms

Setting of Pr6B

Operation (OFF)

t1 *1

Error

Operation *2

Not Energized

Alarm

Approx. 30r/min

Setting of Pr6B

Release (ON)

B

t1 *1

Operation (OFF)

Approx. 30r/min

<Cautions>

*1. A value of t1 is a value of Pr6B or time needed for decreasing the motor speed to approx. 30 r/min,

whichever is shorter.

*2. For operation of the dynamic brake following an alarm event, also refer to the description in “Sequence at

Alarm” (“Parameter Setting” for every control mode) on Pr68.

After an Alarm is Cleared (during Servo-ON Command)

120ms or Longer

Alarm Clear

Input (A-CLR)

Dynamic Brake

Motor Energized

Brake Release

Output

Servo Alarm

Output (ALM)

Position/Velocity

Command

(BRK-OFF)

Operation

Not Energized

Operation (OFF)

Alarm

Cleared

Approx. 40 ms

100ms or Longer

Release

Energized

Release (ON)

Approx. 10 ms

Not Alarm

No Input

Input Enabled

33

Page 34

Timing Chart

Servo-ON/OFF Operation When the Motor is Stopped

(During normal operation, perform the Servo-ON/OFF operation after the motor stops.)

Servo-ON Input

(SRV-ON)

Dynamic Brake

Motor Energized

Brake Release

Output (BRK-OFF)

When you turn off the power of the electromagnetic brake, the motor brake will run. When you turn on the

power of the electromagnetic brake, the motor brake will be released.

OFF

Approx. 1 - 5 ms

Operation *3

Not Energized

Approx. 40 ms

Operation (OFF)

ON

Release

Energized

Approx. 10 ms

Release (ON)

OFF

Approx. 1 - 5 ms

Operation *2

t1 *1

Not Energized

Operation (OFF)

<Cautions>

*1. A value of t1 depends on a setting of Pr6A.

*2. For the operation of the dynamic brake during Servo-OFF, also refer to the description of “Sequence

during Servo-OFF” (“Parameter Settings” of every control mode) on Pr69.

*3. Servo-ON input will not be active until the motor rotation speed falls below approx. 30r/min.

Servo-ON/OFF Operation When the Motor is Rotating

(The following chart shows timing in the case of emergency stop or trip. You cannot use Servo-ON/OFF

repeatedly.)

Servo-ON Input

(SRV-ON)

Dynamic Brake

OFF

ON

* 4

Operation Release

OFF

Approx. 1 - 5 ms

Operation *3

Motor Energized

Not Energized

Brake Release

Output

(BRK-OFF)

Operation

(OFF)

Number of Motor Rotations

Motor Rotation

Speed

Servo-ON input will not be active

until the motor rotation speed

falls below approx. 30r/min.

Approx.

Approx. 30 r/min

Servo enabled

40 ms

Energized

Approx. 10 ms

Release

(ON)

Motor Rotation Speed A

Approx. 30 r/min

Setting of Pr.6B

Release

(ON)

Motor Rotation Speed B

Approx. 30 r/min

Not Energized

Setting of Pr.6B

Operation

t1 * 1

Operation

t1 * 1

(OFF)

When the motor rotation speed

falls below 30r/min earlier.

(OFF)

When the time defined by

Pr.6B is reached earlier.

<Cautions>

*1. A value of t1 is a value of Pr6B or time needed for decreasing motor speed to approx. 30 r/min,

whichever is shorter.

*2. Even if SRV-ON signal turns on again during deceleration of the motor, SRV-ON input does not become

active until it stops.

*3. For operation of the dynamic brake during Servo-OFF, also refer to the description of “Sequence at

Servo-OFF” (“Parameter Settings” of every control mode) on Pr69.

*4. Servo-ON input will not be active until the motor rotation speed falls below approx. 30r/min.

34

Page 35

Preparations

Holding Brake

[Preparations]

The brake is to hold a work (movable part) and prevent it from dropping by gravity when power to the servo is shut

off for the purpose of driving a vertical shaft in the servo motor.

<Caution>

The brake built in the servo motor is only for holding, namely, maintaining,

stopped condition. Thus, you must not use it for “braking” to stop moving load.

Wiring (Example)

This circut shows an example

in which a brake release (BRK-OFF)

signal from the driver is used to

control the brake.

<Remarks and Cautions>

1. A brake coil has no polarity.

2. A customer is requested to provide for power supply for the brake. In addition, do not use power supply for

control signals (VDC) for driving the brake.

3. In order to suppress surge voltage due to ON/OFF operation of the relay (RY), install a surge absorber. When

you’re using a diode in place of a surge absorber, note that start of the servo motor is delayed in comparison with

when the latter is used.

4. For a surge absorber for the brake, refer to “Recommended Parts” on Page 192 of Reference edition.

5. The recommended parts are those specified for measuring brake release time. In some cases, reactance of

electric wires may vary depending on wire length, causing sporadic rise of voltage. Select a surge absorber so

that the relay coil voltage (maximum rating: 30V, 50 mA) and voltage between brake terminals do not exceed a

rated value.

Driver

BRK-OFF

11

COM-

13

CN X5

RY

12~24V

DC

V

Cut off upon emergency stop

Surge absober

RY

Power for brake

DC24V

Motor

Brake coil

Fuse

(5A)

• For timing of brake release upon power-on or that of brake operations in case of servo-off/alarm while the motor

• In case of Servo-OFF or alarm while the motor is rotating, you can set with the parameter (i.e., Pr6B: Mech.

<Remarks>

1. The servo motor with built-in brake could result in brake lining sound (Chattering, etc.) while it is running. But this

2. When the current is fed into the brake coil (with the brake kept released), it could result in leak magnetic flux from

• Excitation voltage should be DC24V ± 10%.

• The values in the above table are representative characteristics (except static friction torque, releasing voltage,

• A backlash of the brake is ± 1˚ of a setup value.

• Allowable angular acceleration of MUMA series: …..10000 rad/s

• Service life of the number of accelerations/decelerations with the allowable angular acceleration is 10 million

BRK-OFF Signal Output Timing

is rotating, refer to “Timing Chart” on Page 32.

break action set-up at motor in motion) time till BRK-OFF signal turns off (i.e., the brake is actuated) after the

motor is freed from energized state. For details, refer to “Parameter Settings” of every control mode.

is not a problem.

the shaft, etc. Be careful when a magnetic sensor, etc. are used around the motor.

Specifications of Holding Brake

Motor

Series

MUMA

Motor Output

50W, 100W

200W, 400W

Static Friction

Torque (N/m)

0.29 or higher

1.27 or higher

Inertia

-4

x 10

kg•m

0.003

0.03

Intake Time

2

25 or shorter

50 or shorter

(ms)

Release Time

(ms)

20 or

shorter(30)

15 or shorter

(100)

*1 A value when the surge absorber is used.

Values given in ( ) are actual values measured with diodes (V03C manufactured by HITACHI Semiconductor

and Devices Sales Co., Ltd.).

and excitation current).

2

times or greater. (The number of accelerations/decelerations till backlash of the brake changes drastically.)

Excitation

Current DC A

*1

(during cooling)

0.26

0.36

Release

Voltage

DC1V or

higher

Allowable

Workload per

Braking J

39.2

137

Allowable

Workload

Total

x 103J

4.9

44.1

35

Page 36

Dynamic Brake

Dynamic Brake

Dynamic brake is built in this driver for emergency stop.

For this dynamic brake observe the precautions given below.

<Notes>

1. This dynamic brake functions for emergency stop of the driver.

Don’t start and stop by ON/OFF of the Servo-ON signal (SRV-ON signal).

Doing so could result in rupture of the dynamic brake circuit built in the driver.