Page 1

[Connections and Settings

in Torque Control Mode]

page

Torque control block diagram..............................132

CN X5 Connector...................................................133

CN X5 Connector ...................................................................... 133

Interface Circuit ......................................................................... 134

Input signal (common) assignment to CN X5 connector pins... 136

Input signal assignment to CN X5 connector pins - designation(logic)

Output signal assignment to CN X5 connector pins - designation(logic)

Trial run at Torque Control Mode.........................140

Operation with CN X5 Connected ............................................. 140

Real time auto gain tuning ...................................142

Outline ....................................................................................... 142

Application range....................................................................... 142

How to use ................................................................................ 142

Parameters, which are set up automatically ............................. 143

Caution ...................................................................................... 143

Parameter Setting .................................................144

Parameters for Function Selection............................................ 144

Parameters for Time Constants of Gains and Filters: Related to Real Time Auto Tuning .....

Parameters for real time auto gain tuning................................. 148

Parameters for Switching to 2nd Gains..................................... 150

Parameters for Position Control ................................................ 150

Parameters for Speed Control .................................................. 151

Parameters for Torque Control.................................................. 152

Parameters for various sequences ........................................... 152

.......... 138

....... 138

147

Page 2

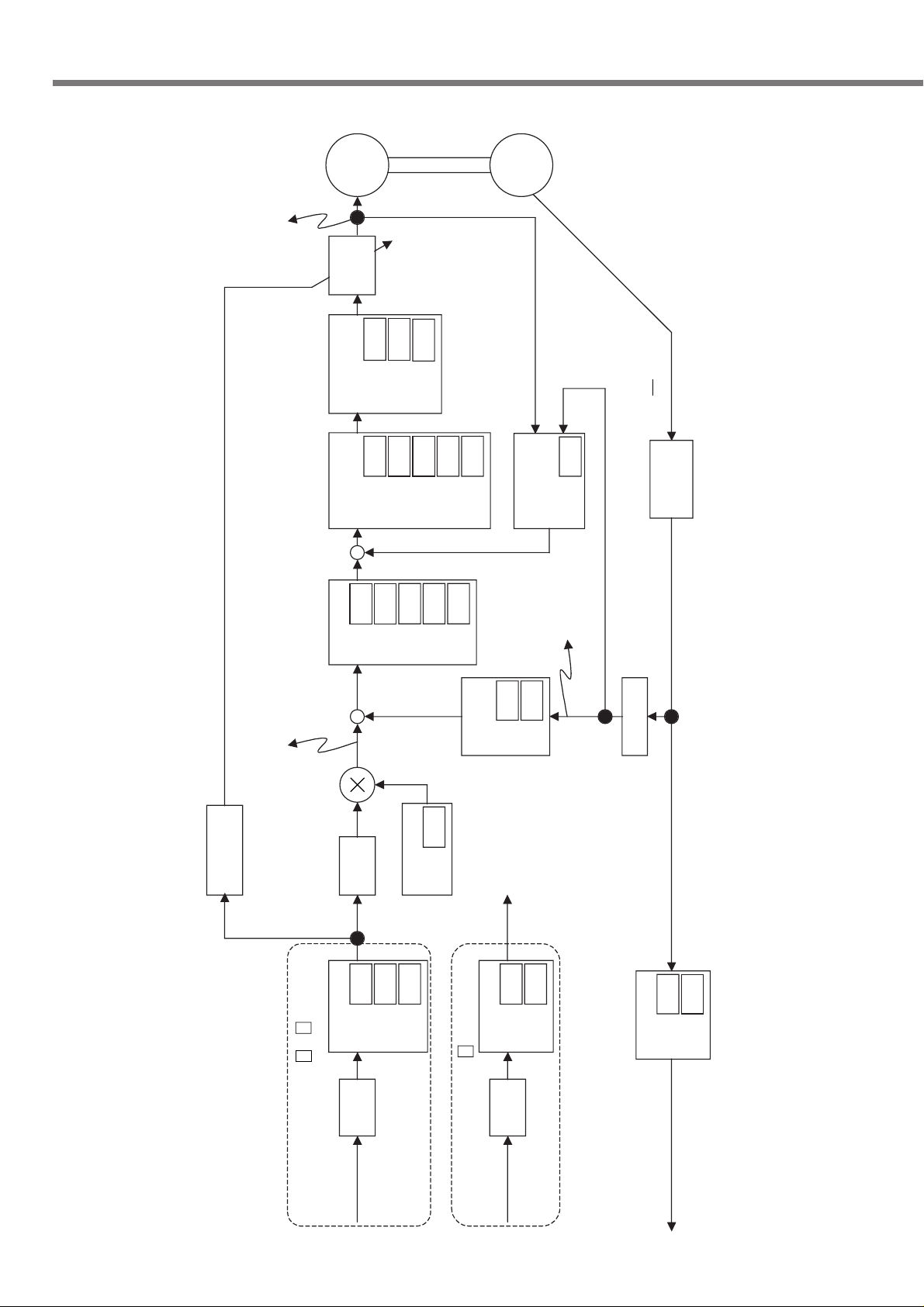

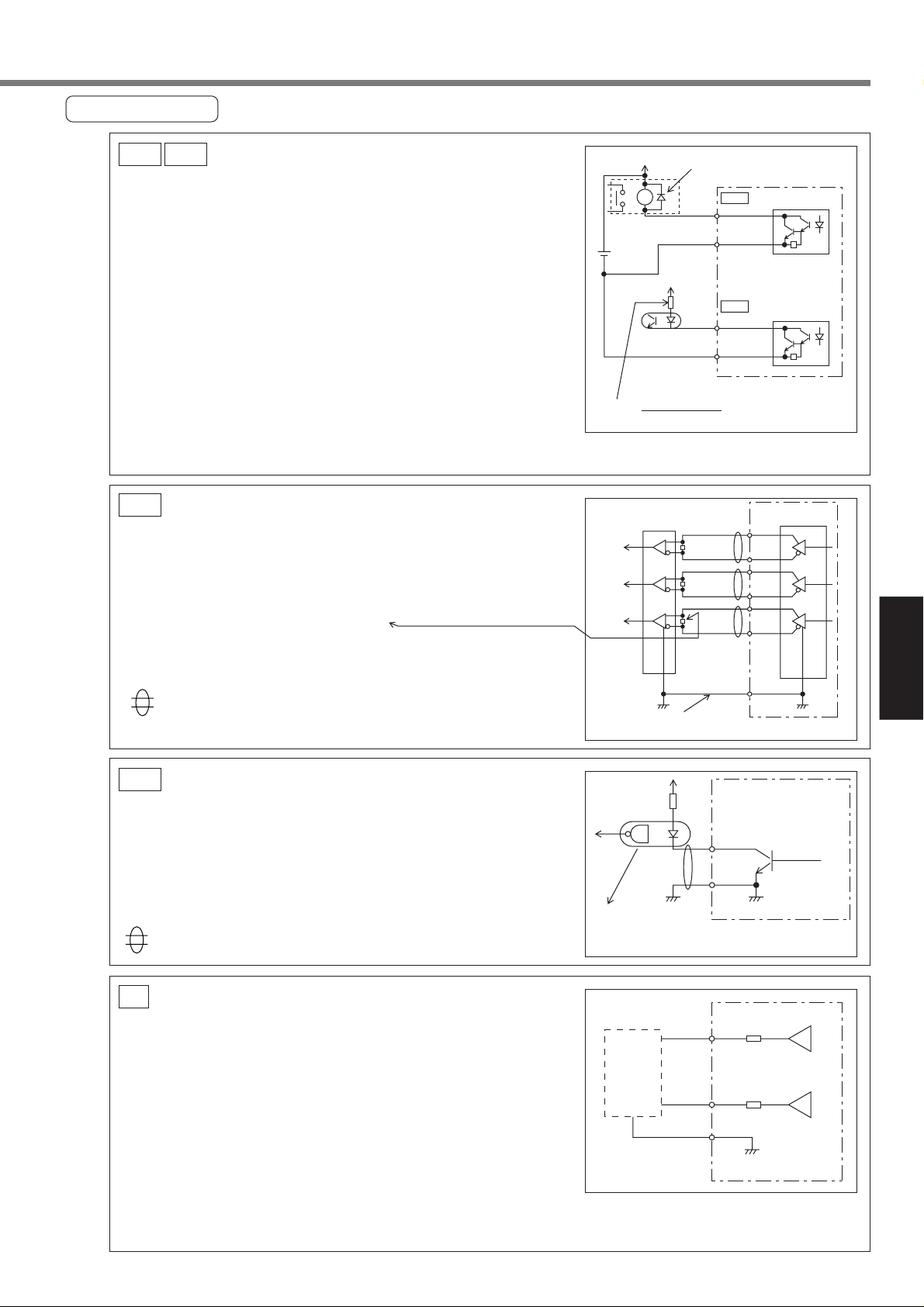

Pr 11

Pr 1

2

Pr 1

3

Pr 14

Pr 1

9

Pr 1

A

Pr 1

B

Pr 1

C

Pr 1

D

Pr 1

E

Pr 2

0

Pr 2

8

Pr 2

9

Pr 2

A

Pr 5

C

Pr 5

D

Pr 5

2

Pr 4

4

Pr 4

5

Inverse

Offset

Gain

Inverse

Gain

1st ratio

1st

differential

2nd

differential

2nd ratio

Inertia

ratio

1st

frequency

1st width

2nd

frequency

2nd

width

2nd

depth

1st time

constant

2nd time

constant

2nd

1st

Inverse

Division

Limit

Pr 5

E

Pr 2

7

Pr 5

6

16bitA/

D

Pr 5

C

Pr 5

D

10bitA/

D

Sign( )

Analog torque

command

Analog torque

command

SPR /

TRQR

When pr 02 = 2 or 4

Input setting

Input setting

When pr 02 = 5

Absolute

(magnitude)

Command speed

monitor

Multiplication

Internal speed limit

4th

speed

Speed control

Notch filter Torque f ilter

Torque

limit

Disturbance

observer

Filter

Actual speed

monitor

Speed

detection filter

Speed detection

Encored

receive

processing

PS / PS signal

Division

Feedback pulse

OA / OB / OZ

Torque command

monitor

Encoder

Motor

CCWTL /

TRQR

+

–

+

–

±

Torque contr ol block diagram

132

Page 3

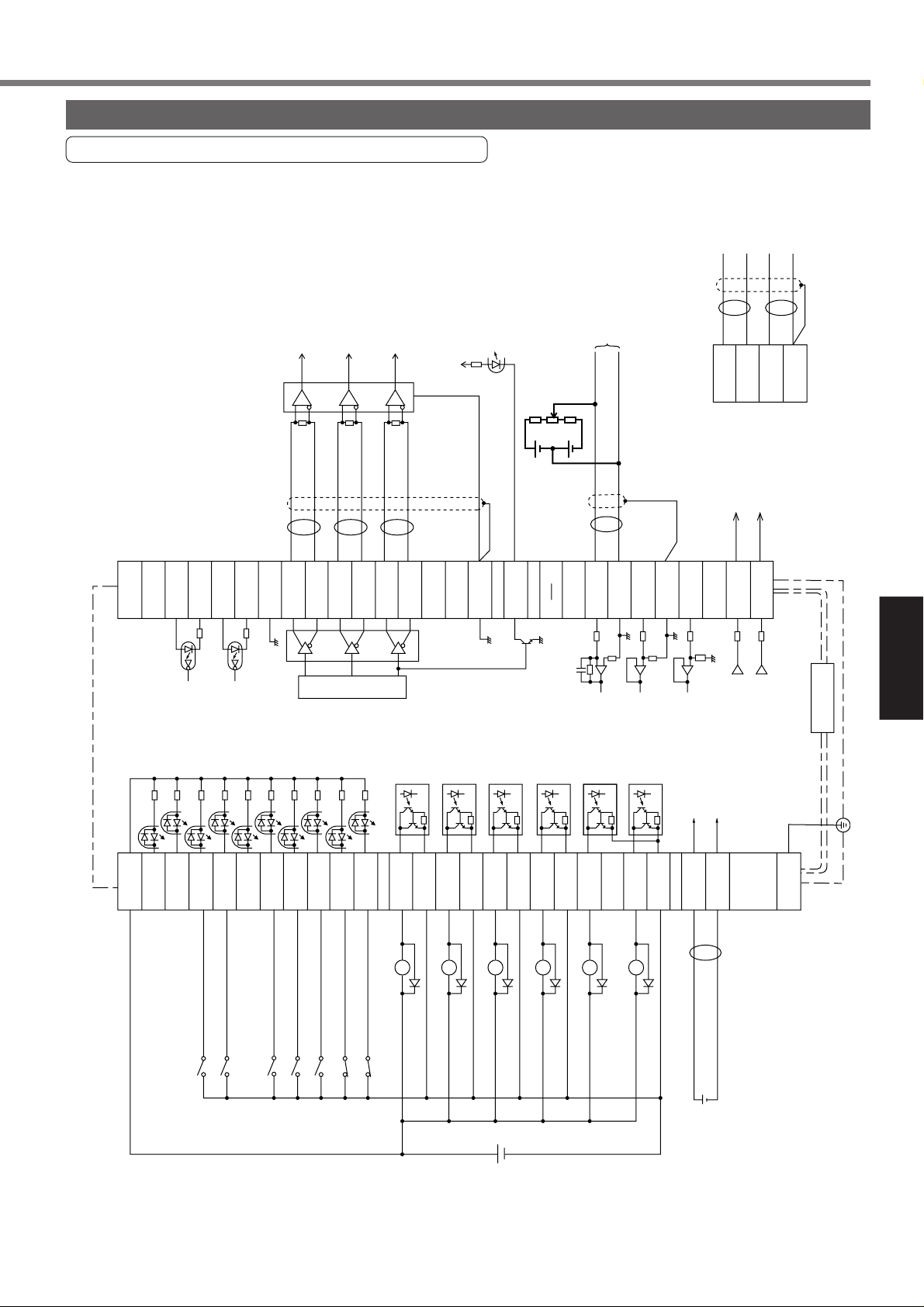

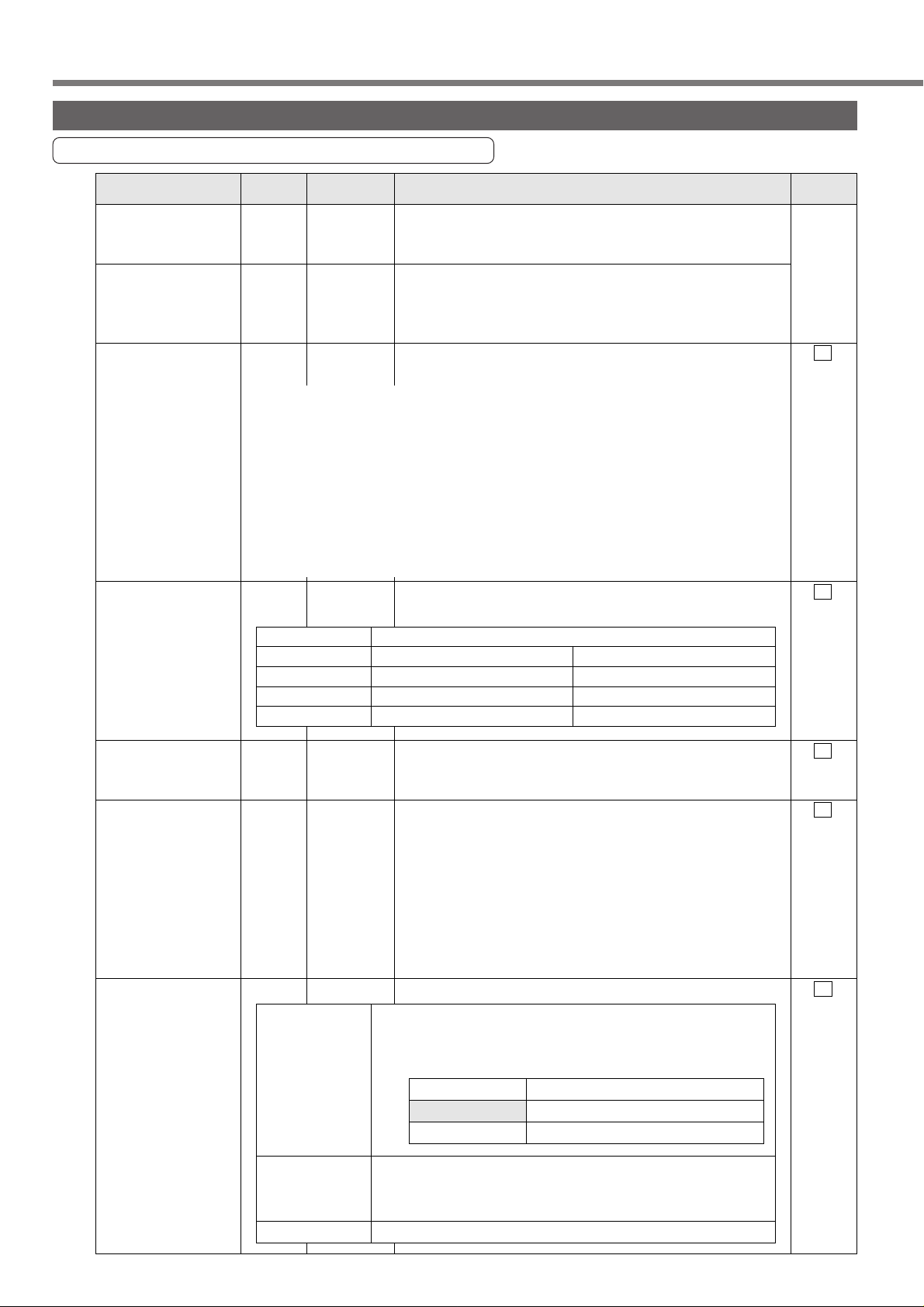

Connections and Settings in

Torque Control Mode

Battery for absolute encoder

7

4.7k

Ω

COM+

PULS2

SIGN1

SIGN2

GND

OA+

OA

OB+

OB

OZ+

OZ

GND

CZ

SPR/TRQR

GND

CCWTL/TRQR

GND

CWTL

SP

IM

1

2

3

4

5

6

13

21

22

48

24

46

47

25

19

20

14

15

16

17

43

18

42

49

23

10k

Ω

10k

Ω

20k

Ω

220

Ω

220

Ω

10k

Ω

10k

Ω

1k

Ω

1k

Ω

PULS1

INH

CL

SRV-ON

GAIN

DIV

ZEROSPD

C-MODE

A-CLR

CCWL

CWL

S-RDY+

S-RDY

-

ALM+

COIN+

BRKOFF

+

BRKOFF

TLC

V

DC

12

-

24V

ZSP

COM

BATT+

to CN X4 (5th pin)

to CN X4 (6th pin)

BATT

-

CN X5

FG

COIN

-

ALM

-

33

30

29

27

28

26

32

31

9

8

35

34

37

36

39

38

11

10

40

12

41

44

45

50

Servo-ON

P-operation/2nd gain

switching

Control mode switching

Scaler

Alarm clear

CCW overtravel inhibit

A-phase

output

B-phase

output

Z

Z-phase

output

Speed monitor

Torque monitor

Z-phase output (Open collector)

CW overtravel inhibit

Servo ready

Servo alarm

At-speed

Mechanical brake release

· In case the battery for absolute encoder

is installed at the controller side

Torque limited

(Pr09)

Zero speed detected

(Pr0A)

<Note> Specify the speed limit value using

4th speed set-up (Pr56) parameter.

SPR/TRQR

GND

CCWTL/TRQR

GND

14

15

16

17

330

Ω

330

Ω

330

Ω

Zero speed clamp (Pr06)

Torque command

(0 to ±10V)

Wiring when Pr02

(Control Mode) = 5

Speed

command

(0 to ±10V)

Torque

command

(0 to ±10V)

CN X5 Connector

[Connections and Settings in Torque Control Mode]

CN X5 Connector

Circuits Available for Torque control mode

133

Page 4

+

CN X5 Connector

1

1

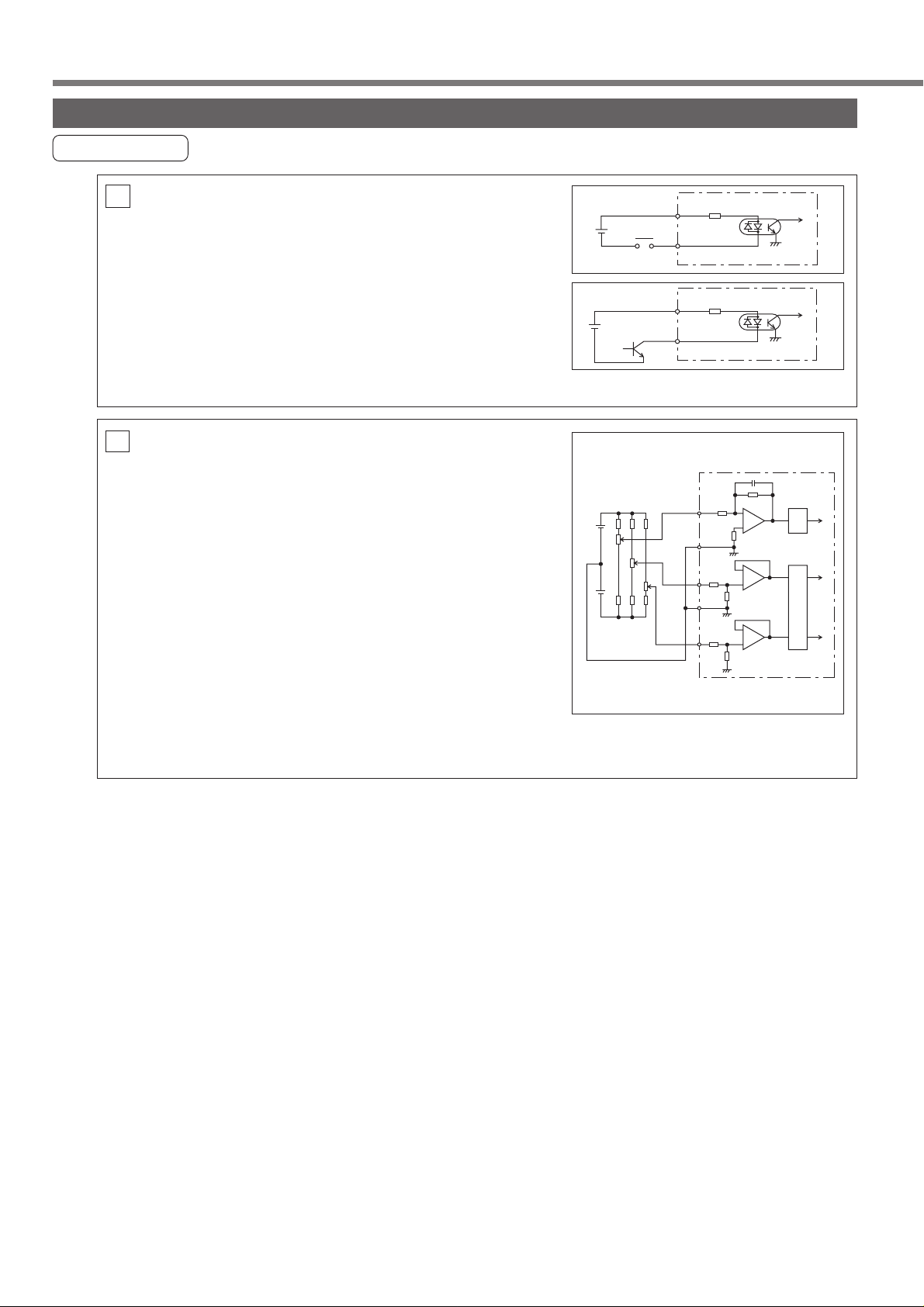

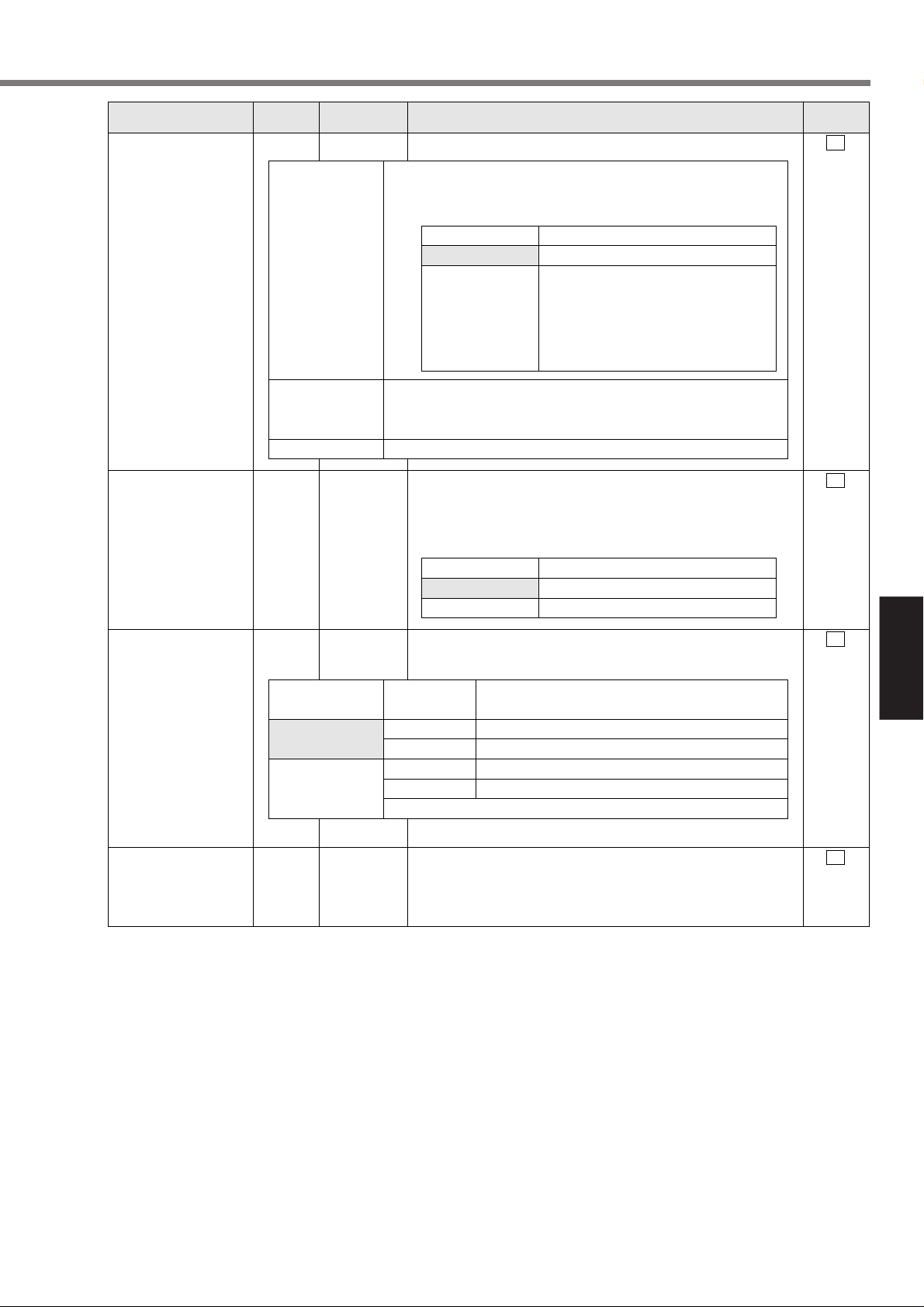

Interface Circuit

Input Circuit

SI Connecting to

SI

sequence input signals

• Connect to a contact of switch and relay, or a transistor

of an open collector output.

• Use a s witch or relay for micro current so that insufficient

contact can be avoided.

• Lower limit of the power supply (12 to 24V) should not be

less than 11.4V in order to secure the appropriate level

of primary current of the photo coupler.

AI

AI Analogue Command Input

• There are three analogue command inputs of SPR/RTQR

(14 pins), CCWTL (16 pins) and CWTL (18 pins).

• The maximum permissible input voltage is ±10V. F or the

input impedance of these inputs, see the right figure.

• If you make a simplified circuit comprising a variable resistor (VR) and resistor (R), refer to the right figure.

When the variable range of each input is -10V to +10V,

the VR should be a B type resistor of 2kΩ (min.1/2W).

The R should be 200Ω (min.1/2W).

• The A/D converters for these inputs should have the following resolution.

12V

2–24V

2–24V

R

VR

-12V

R

Relay

SPR/TRQR

CWTL

7

COM+4.7kΩ

Servo-ON or

other input

7 COM+4.7kΩ

Servo-ON or

other input

20kΩ

14

GND

15

10kΩ

16

CCWTL

GND

17

10kΩ

18

10kΩ

10kΩ

-

ADC

ADC

1

2

+

+

+

1) ADC1 (SPR and TRQR) : 16 bits (including one bit for sign)

2) ADC2 (CCWTL and CWTL) : 10 bits (including one bit for sign)

134

Page 5

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

A

R

H

p

(

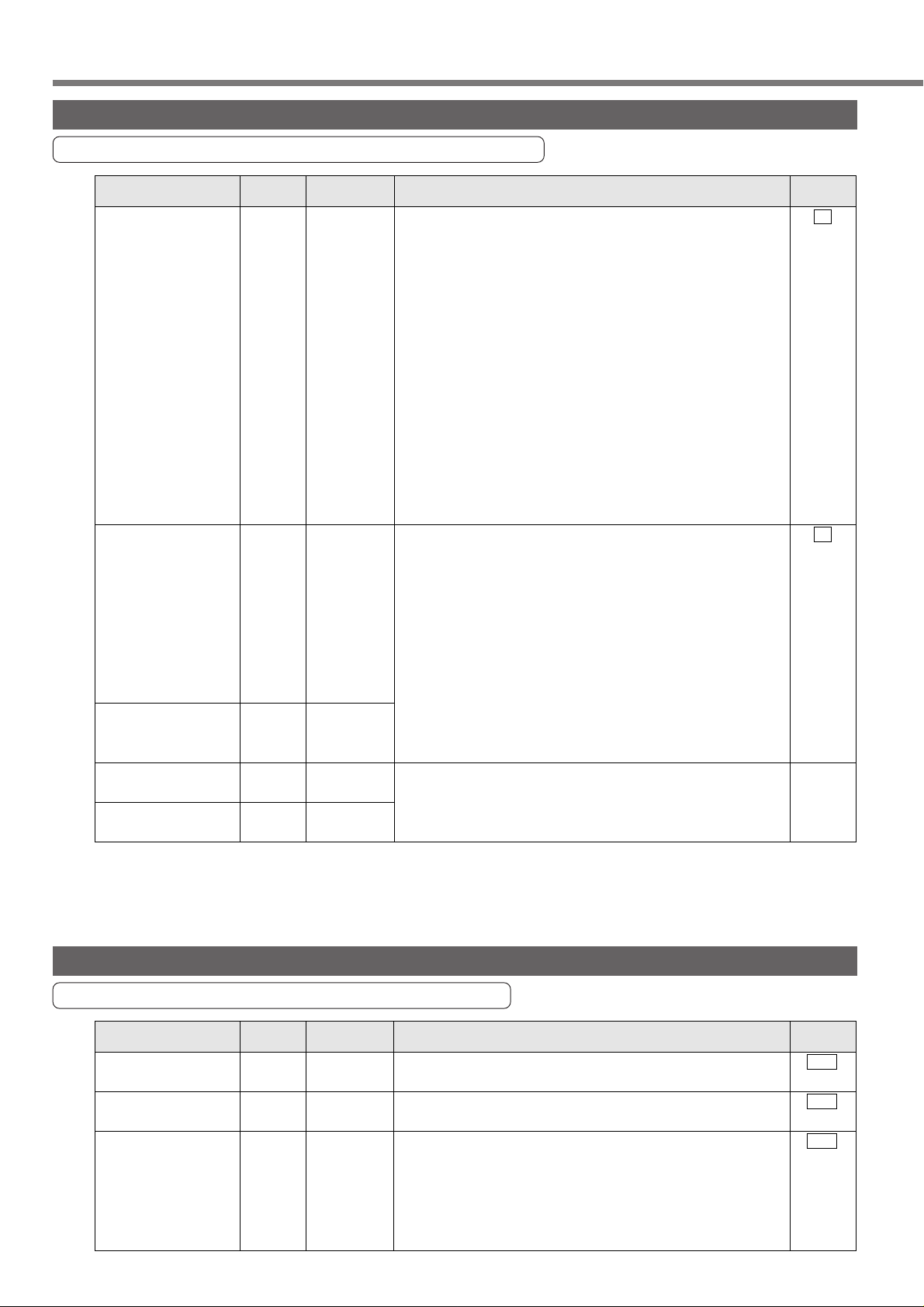

Output Circuit

Sequence output circuit

SO1 SO2

• This comprises a Darlington driver with an open collector.

This is connected to a relay or photo coupler.

• There exists a collector-to-emitter voltage V

approx. 1V at transistor ON, because of Darlington con-

CE(SAT) of

12–24V

nection of the out put transistor. Note that normal TTLIC

can't be directly connected since this does not meet VIL

requirement.

• This circuit has an independent emitter connection, or an

emitter connection that is commonly used as the minus

(–) terminal (COM–) of the control power.

• Calculate the value of R using the formula below so as the

primary current of the photo coupler become approx. 10mA.

[kΩ] =

VDC[V] — 2.5[V]

For the recommended primary current value, check the data sheet on the equipment and photocoupler used.

Install as per the fig. Shows

without fail

SO1

ALM+

or other signal

ALM–

or other signal

V

DC

SO2

ZSP, TLC

COM–41

Maximum rating: 30V, 50m

10

PO1

Line Driver (Differential Output) Output

• Provides differential outputs of encoder signals (A, B and

Z phases) that come from the scalar.

• Receive these signals with a line receivers. In this case,

install a resistor of approx. 330Ω between the inputs.

• These outputs are non-insulated signals.

shows a pair of twisted wires.

Open Collector Output

PO2

• Outputs Z-phase signals among those from the encoder.

The outputs are non-insulated.

• Receive these signal with high-speed photo coupler at

controller side, since these Z-phase signal width is normally narrow.

shows a pair of twisted wires.

AM26LS32

or equivalent

OA+

OA-

OB+

OB-

OZ+

OZ-

Connect the signal

grounds between the controller and driver.

1925CZ

igh-speed

hoto coupler

Equivalent to T oshiba TLP554)

AM26LS31

or equivalent

21

22

48

49

23

24

25GND

Maximum rating:

30V, 50mA

GND

A

B

Z

Analogue Monitor Output

AO

• This output is the speed monitor signal (SP) or torque moni-

• The signal range is approx. 0 to ± 9V.

• The output impedance is 1kΩ. Pay attention to the input

<Resolution>

1) Speed monitor signal (SP): 8r/min./LSB calculated from

2) Torque monitor signal (IM): 0.4%/LSB calculated from 3V/rated value (100%)

tor signal (IM).

impedance of your measuring instruments and external

circuits connected.

6V/3000r/min (Pr07 = 3)

Measuring

instrument

or external

circuit

43

42

17

SP

IM

GND

1kΩ

1kΩ

135

Page 6

CN X5 Connector

it

4

4

4

4

4

Input signal (common) assignment to CN X5 connector pins

Input Signals (Common) and their Functions

Signal Pin No. Symbol Function I/F circu

Control signal

power (+)

Control signal

power (–)

Servo-ON

Control mode

switching

7

41

29

<Notes>

This signal becomes effective about two seconds after power on (see the Timing Chart).

1.

2. Don't use this Servo-ON or Servo-OFF signal to turn on or off the motor. See page

46 "Dynamic Brake" in Preparations.

• Allow at least 50ms delay after the driver is enabled before any command input is

entered.

• By opening the connection to COM– , the driver will be disabled(Servo-OFF) and

the current flow to the motor will be inhibited.

• Operation of the dynamic brake and clearing action of the position error counter can

be selected using Pr69 (Sequence under Servo-OFF).

32

Pr02 value

COM +

COM –

SRV-ON

C-MODE

3

4

5

• Connect to (+) of an external power supply (12VDC to

24VDC).

• Use source voltage of 12V±10% – 24V±10%.

• Connect to (–) of an external power supply (12VDC to

24VDC).

• The required capacity depends on the I/O circuit

configuration. 0.5A or larger is recommended.

• When this signal is connected to COM-, the dynamic brake

will be released and the driver is enabled. (Servo-ON).

• When Pr02 (Control Mode Selection) = 3, 4 or 5, the control

mode is selected per the table below.

Connection with COM–

open (1st)

Position control mode

Position control mode

Speed control mode

closed (2nd)

Speed control mode

Torque control mode

Torque control mode

–

SI

page 13

SI

page 13

CW overtravel

inhibit

CCW overtravel

inhibit

Counter clear

8

9

30

Position control

Speed control

Torque control

CWL

CCWL

CL

• If COM– is opened when the movable part of the machine

has moved to CW exceeding the limit, the motor does not

generate torque.

• If COM– is opened when the movable part of the machine

has moved CCW exceeding the limit, the motor does not

generate torque.

•

If you set 1 to Pr04 (Overtravel input inhibited invalid), CWL/CCWL

input will be disabled. A factory setting is Disable (1).

• With Pr66 (DB deactivate when driving is inhibited), you can

activate dynamic brake when CWL/CCWL input is enabled.

According to a factory setting, dynamic brake operates

(Pr66 is set to 0).

The function differs depending on the control mode.

• Clears the position error counter.

Connect to COM– to clear the counter.

• Use Pr4D to select the clear mode.

Pr4D value

0(Factory-setting)

1

• With speed setting of the 2nd selection input, you can set 4

speeds in combination with INH.

• For details, see Pr05 (Speed Set-Up Switching) description.

• Invalid

Meaning

LEVEL

EDGE

SI

page 13

SI

page 13

SI

page 13

136

Page 7

Connections and Settings in

Torque Control Mode

Signal Pin No. Symbol Function I/F circu

it

4

4

4

4

Command pulse

input inhibit

33

Position control

INH

[Connections and Settings in Torque Control Mode]

The function differs depending on the control mode.

• Enter command pulse input inhibit.

• You can disable this input with Pr43

(disable command pulse input inhibit).

Pr43 value

1(Factory-setting)

0

The INH signal (input) is disabled.

• With COM– closed, the pulse

command signal (PULSE SIGN) is

enabled.

• With COM– open, the pulse

command signal (PULSE SIGN) is

inhibited.

Meaning

SI

page 13

Speed zero clamp

Gain switching

Alarm clear

Speed control

Torque control

26

27

(Factory-setting)

31

ZEROSPD

GAIN

Pr30 value

0

1

A-CLR

• With speed setting of the 1st selection input, you can set 4

speeds in combination with CL input.

• For details, see Pr05 (Speed Set-Up Switching) description.

• Invalid

• With COM– open, the speed command is considered zero.

• This input can be made disabled using Pr06.

• With factory setting, disconnecting this pin from COM– sets

the speed to zero.

Pr06 value

0 (Factory-setting)

1

• This is setting of Pr30 (2nd gain setting) and has the

following 2 types of functions:

Connection

to COM-

Open

Close

Open

Close

To use the second gain, set Pr31 to “2”.

No.2 Gain change Funcutions, see page 202 "Adjustments ".

•

• If the COM- connection is kept closed for more than 120

ms, the alarm status will be cleared.

• For details about not cleared alarm, see page 216

"Protective Functions".

Speed loop: PI (Proportional / Integral) action

Speed loop: P (Proportional) action

• 1st gain selected (Pr10, 11, 12, 13 and 14)

• 2nd gain selected (Pr18, 19, 1A, 1B, 1C)

ZEROSPD is disabled.

ZEROSPD is enabled.

Meaning

Function

SI

page 13

SI

page 13

SI

page 13

137

Page 8

CN X5 Connector

it

4

4

it

5

5

5

Input signal assignment to CN X5 connector pins - designation(logic)

Input Signals (Speed Control) and their Functions

Signal Pin No. Symbol Function I/F circu

Speed (torque)

command

CCW torque limit

CW torque limit

Battery +

Battery -

14

(15)

16

(17)

18

(17)

44

45

SPR/TRQR

(GND)

CCWTL/

TRQR*

(GND)

CWTL

(GND)

BATT +

BATT -

* When the torque control mode is selected at the speed/torque switching mode (Pr02 = 5), the

No.16 pin (CCWTL/TRQR) becomes the torque command input (analogue). You can set-up the

relationship between the command voltage level and the motor torque with Pr5C (Torque Command Input Gain).

< At speed control >

• This becomes speed command input (analogue) 0–±10V

• You can set-up the relationship between the command

voltage level and the motor speed, with Pr50 (Speed

Command Input Gain) .

• Use Pr51 to inverse the polarity of the command input.

< At torque control >*

• This becomes torque command input (analogue) 0–±10V

• You can set-up the relationship between the command

voltage level and the motor torque, with Pr5C (Torque

Command Input Gain) .

• Use Pr5D to inverse the polarity of input signals.

• Use Pr56 (4th Speed Set-up) to adjust the speed limit in

torque control.

< Note >

SPR/TRQR are invalid in position control mode.

< At speed and position control >

• You can limit the motor torque in the CCW direction by

entering positive voltage (0 to +10V) to CCWTL.

• You can limit the motor torque in the CW direction by

entering negative voltage (-10 to 0V) to CWTL.

• The torque limit value is proportional to the voltage with a

factor of 100%/3V.

• CCWTL and CWTL are valid when Pr03 (Torque Limit Input

Inhibit) = 0. They are invalid when Pr03 = 1.

< At torque control >*

• Both of CCWTL and CWTL are invalid.

• Use the 4th speed set-up(Pr56) to limit the speed.

• Connect a backup battery for absolute encoder (polesensitive !).

• If the battery is connected directly to the driver, it is not

necessary to connect a battery to this terminal.

AI

page 13

AI

page 13

–

Output signal assignment to CN X5 connector pins - designation(logic)

Output Signals (Common) and their Functions

Signal Pin No. Symbol Function I/F circu

• This output(transistor) turns OFF, when the driver detects

and error(trip).

• This output(transistor) turns ON, when the main power is

on(for both the driver and the motor) and no alarm is active.

•

This is used to release the electromagnetic brake of the motor.

• Turn the output transistor ON when releasing brake.

• Refer to “Timing Chart” on page 40, on Preparations.

• This output(transistor) turns ON , when the brake is re-

leased.

• See page 40 "Timing Chart".

138

Servo alarm output

Servo-ready output

Mechanical brake

release output

37

36

35

34

11

10

ALM +

ALM –

S-RDY +

S-RDY BRK-OFF +

BRK-OFF –

SO1

page 13

SO1

page 13

SO1

page 13

Page 9

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

it

5

5

5

5

5

5

5

it

Signal Pin No. Symbol Function I/F circu

Zero speed

detection

Torque in-limit

In-position/

At-speed

12

Pr0A value

(Factory-setting)

* When the setting is a value between 2 and 5, the output transistor will be turned on

for at least 1 second upon detecting an alarm condition.

40

39

38

Position

Speed and

torque

ZSP

0

1

2*

3*

4*

5*

TLC

COIN +

COIN –

• Signal which is selected at Pr0A (ZSP Output Selection) will

be turned on.

Function

Output(transistor) turns ON during the In-toque limiting.

Output(transistor) turns ON when the motor speed becomes

lower than that of the preset speed with Pr61(Zero speed).

Output(transistor) turns ON when either one of overregeneration, overload or battery warning is activated.

Output(transistor) turns ON when the over-regeneration (more

than 85% of permissible power of the internal regenerative

discharge resistor) warning is activated.

Output(transistor) turns ON when the overload (the effective torque is

more than 85% of the overload trip level) warning is activated.

Output(transistor) turns ON when the battery (the voltage of the

backup battery becomes lower than approx. 3.2V at the

encoder side) warning is activated.

• Signal which is selected by Pr09 (TLC Output Selection) will

be turned ON. Factory-setting: 0

See the above ZSP signal for the set-up of Pr09 and functions.

•

• Function changes at control mode.

• In-position output

• Output(transistor) turns ON when the position error is below

the preset value by Pr60 (In-Position Range).

• At-speed output

• Output(transistor) turns ON when the motor speed reaches

the preset value by Pr62 (At-Speed ).

SO2

page 13

SO2

page 13

SO1

page 13

A-phase output

B-phase output

Z-phase output

Z-phase output

Speed monitor

output

Torque monitor

output

21

22

48

49

23

24

19

43

(17)

42

(17)

OA +

OA –

OB +

OB –

OZ +

OZ –

CZ

SP

(GND)

IM

(GND)

• Provides differential outputs of the encoder signals (A, B

and Z phases) that come from the driver (equivalent to

RS422 signals).

• The logical relation between A and B phases can be

selected by Pr45 (Output Pulse Logic Inversion).

• Not insulated

• Z-phase signal output in an open collector (not insulated)

• Not insulated

• Outputs the motor speed, or voltage in proportion to the

commanded speed with polarity.

+ : CCW rotation

– : CW rotation

• Use Pr07 (Speed Monitor Selection) to switch between

actual and commanded speed, and to define the relation

between speed and output voltage.

• Outputs the output torque, or voltage in proportion to the

position error with polarity.

+ : Fgenerating CCW-torque

– : Fgenerating CW-torque

• Use Pr08 (Torque Monitor Selection) to switch between

torque and positional error, and to define the relation

between torque/positional error and output voltage.

Output Signals (Others) and their Functions

PO1

page 13

PO2

page 13

AO

page 13

AO

page 13

Signal ground

Frame ground

(Not in use)

Signal Pin No. Symbol Function I/F circu

13, 15

17, 25

50

1, 2, 20

46, 47

GND

FG

–

• Signal ground in the driver

• Internally isolated from the control power (COM -).

• Internally connected to the earth terminal.

• No connections should be made.

–

–

–

139

Page 10

Trial run at Torque Control Mode

D

1

h

n

d

•

Operation with CN X5 Connected

1) Connect CN X5.

2) Connect the control signal (COM+/COM–) to the power supply (12 to 24 VDC) .

3) Turn the main power (driver) ON.

4) Check the defaults of the parameters.

5) Connect between SR V-ON (CN X5 pin 29) and COM- (CN X5 pin 41) to make Servo-On active. The motor

will be kept excited.

6) Apply an appropriate DC voltage between Torque command input TRQR (CN X5 pin 14) and GND (CN X5

pin 15) and verify the motor rotating direction (CW/CCW) and then reverse the voltage polarity and then

verify reversed motor rotation. Also check the speed set by Pr56.

7) To change torque Pr5C, direction Pr5D and speed limit Pr56 in response to the command voltage,

modify the following parameter.

Pr56: 4th speed

Pr5C: torque command input gain

Pr5D: torque command input inversion

See page 144 "Parameter setting" in Torgue control mode.

Wiring Diagram Parameters

7

COM+

29

C

2V–24V

DC

10V

SRV-ON

26

ZEROSPD

41

COM–

14

SPR/TRQR

15

GND

ZEROSPD switc

Close: Run

Open: Stop

One way

operation

For multi directio

(CW and CCW)

operation, use a

bipolar power

source.

PrNo.

Pr02

Control mode set-up

Pr04

Overtravel input inhibit

Pr06

ZEROSPD input selection

Pr56

4th internal speed

Pr5C

Torque command input gain

Pr5D

Torque command input inversion

Use the controller to send command pulses.

Input Signals Status

No. Input signal

Servo-ON

0

CW overtravel inhibit

2

CCW overtravel inhibit

3

Speed zero clamp

5

ValueParameter description

2

1

0

Set as

require

Monitor

display

+ A

–

–

–

140

Page 11

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

MEMO

141

Page 12

Real time auto gain tuning

r

Outline

Load inertia of the machine is estimated

at real time, and the optimum gain is set

up automatically based on the estimated

result. A load, which has a resonance, also

can be handled owing to the adaptive filter.

Position/speed

command

Operation command under

actual operation conditions

Gain auto

setting

Position/speed

control

Filter auto

tuning

Applied

filter

Resonant frequency estimate

Load inertia estimate

Real time auto

gain tuning

Servo driver

Torque

command

Current

control

Motor

current

Motor

speed

Motor

Encoder

Application range

Under the following conditions, the real time auto gain tuning may not function properly.

In such case, use the normal mode auto gain tuning (see page 193 "Adjustments") or manual gain tuning

(see page 197 "Adjustments").

Conditions under which the real time auto gain tuning is prevented from functioning

• When the load inertia is smaller/larger than the rotor inertia

Load inertia

Load

Operation pattern

(3 times or less; or 20 times or more)

• When the load inertia fluctuates

• When the machine stiffness is extremely low

• When any unsecured part resides in such as backlash, etc.

• In case of a continuous low speed operation under 100 [r/min].

• In case of soft acceleration/deceleration under 2000 [r/min] per 1 [s].

•

When acceleration/deceleration torque is smaller than unbalanced load/viscous friction torque.

How to use

[1] Stop the motor (Servo-OFF).

[2] Set up Pr21 (Real-time auto tuning set-up) to 1 – 6.

Set up value before shipment is1.

Setting value

0

Real-time auto tuning

Not used

[1]

2

3

Used

4

5

6

7

Not used

When the changing degree of the load inertia is too large, set Pr21 to 3 or 6.

When the influence of resonance is conceivable, select “adaptive filter YES”.

[3] Set 0 – 2 to Pr22 (real-time auto tuning machine stiffness).

[4] Tur n the servo ON to operate the machine ordinarily.

[5] To increase the response performance, gradually increase Pr22 (Machine stiffness at real-time

auto tuning). When any noise or vibration is found, decrease the Pr22 to a lower value soon.

Changing degree of load inertia during operation

–

Adaptive filte

No

Little change

Change slowly

Yes

Change s haply

Little change

Change slowly

No

Change s haply

–

Yes

[6] To store the result, wr ite the data into the EEPROM.

142

Page 13

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

e

Parameters, which are set up automatically

The following parameters

are tuned automatically.

Parameter No.

11

12

13

14

19

1A

1B

1C

20

Name

1st speed loop gain

1st

speed loop integration time constant

1st speed detection filter

1st torque filter time constant

2nd speed loop gain

2nd

speed loop integration time constant

2nd speed detection filter

2nd torque filter time constant

Inertia ratio

Parameter No.

The following parameters are also set up

to the following fixed values automatically.

Name Set valu

27

30

3A

Disturbance torque observer filter selection

2nd gain action set-up

Torque control switching mode

0

1

0

Caution

[1] Immediately after the first servo ON at startup or when Pr22 (machine stiffness at real-time auto tuning)

is increased, abnormal noise or oscillation may be generated before load inertia is determined. This is

not anomaly if it is stabilized shortly. However when such problems as oscillation or noise that continues

for 3 reciprocal operations or longer is encountered frequently, take the following measures:

1) Write the parameter of normal operation into the EEPROM.

2) Decrease the Pr22 (Machine stiffness at real-time auto tuning).

3) Once set up Pr21 (Real-time auto tuning set-up) to 0 to disable the adaptive filter. Then, enable the

real time auto tuning again. (resetting of inertia estimate adaptive operation)

[2] After abnormal noise or oscillation, Pr20 (inertial ratio) may be changed to an extreme value. In such a

case, also take the above measures.

[3] Among results of real-time auto gain tuning, Pr20 (inertia ratio) is programmed into EEPROM every 30 min-

utes. When you turn on the power again, auto tuning will be executed using the data as initial value.

143

Page 14

Parameter Setting

]

Parameters for Function Selection

Parameter

No.

00 0 – 15

Parameter Name Function/Description

Axis address In communications with a host device such as a personal computer that uses

• At power on, settings of the rotary switch ID on the front panel (0 – F) will be

programmed into parameters of the driver.

• Settings of Pr00 can be changed only by means of the rotary switch ID.

Setting

range

[1]

RS232C/485 with multiple axes, you should identify to which axis the host accesses

and use this parameter to confirm axis address in terms of numerals.

Default setting is shown by [

01 0 – 15LED display at

power up

Power ON

Setting of Pr01

See page 56 "Front Panel Key Operations and Display".

02 0 – 14Control mode Select the control mode of the servo driver.

In the initial condition after turning ON the control power, the following data displayed

on the 7-segment LED can be selected.

Setting

value

0

Positional deviation

[1]

Flashing during initialization

(about 2 seconds)

10

11

12

13

14

15

Motor revolving speed

2

Torque output

3

Control mode

4

I/O signal status

5

Error cause/record

6

Software version

7

Alarm

8

Regenerative load ratio

9

Overload load ratio

Inertia ratio

Feedback pulse sum

Command pulse sum

External scale deviation

External scale feedback pulse sum

Motor auto recognition

Description

144

Setting

value

0

[1]

2

3

4

5

6

7

8

9

10

11

12

13

14

Control mode

The 1st Mode The 2nd Mode*1

Position control

Speed control

Torque control

Position

Position

Speed

Semi-closed control

Full-closed control

Hybrid control

Speed

Speed

High-stiff equipment

position control

Low-stiff equipment

position control

Low-stiff equipment

speed control

Second full-closed control

–

–

–

Speed control

Torque control

Torque control

–

–

–

External encoder control

Semi-closed control

–

–

–

–

*1 A special control mode focused on the full-closed

specification. For details, refer to “Full-Closed

Control” volume on Page 000.

*2 When composite mode (Pr02 = 3,4,5,9,10) is set,

you can switch the 1st and 2nd modes with the

control mode switch input (C-MODE).

C-MODE

<Caution>

Enter a command after 10ms or longer have passed

since C-MODE was entered.

Do not enter any command on position, speed or

torque.

Open

The 1st The 2nd

10 ms or longer 10 ms or longer

Closed

Open

The 1st

Page 15

Connections and Settings in

Torque Control Mode

-

l

r

Parameter

]

,

No.

Parameter Name Function/Description

04 0 – 1Overtravel input

inhibit

Setting

range

[Connections and Settings in Torque Control Mode]

Default setting is shown by [

In the case of linear driving, in particular, to prevent mechanical damage due to

overtraveling of work, you should provide limit switches on both ends of the axis, as

shown below, whereby driving in a direction of switch action is required to be

inhibited.

CW direction CCW direction

Work

Setting

value

0

[1]

06 0 – 1ZEROSPD input

selection

CCWL/CWL

Input

Enable

Disable

Servo Motor

Limit

Switch

Limit

Switch

Driver

CCWL

CWL

Input

CCWL

(CN X5-9 pin)

CWL

(CN X5-8 pin)

Connection with COM-

Connected

Open

Connected

Open

Normal condition in which the limit switch on

CCW side is not operating.

CCW direction inhibited, CW direction allowed

Normal condition in which the limit switch on

CW side is not operating.

CW direction inhibited, CCW direction allowed

Action

Both CCWL and CWL inputs are ignored and they normally operate as no

overtravel inhibit being set.

<Cautions>

1. When you set 0 to Pr04 and do not connect both CCWL and CWL inputs to COM

(off), abnormal condition in which limits are exceeded in both CCW and CW

directions is detected, and the driver will then trip due to “abnormal overtrave

input inhibit“.

2. You can set whether or not to activate the dynamic brake when slowdown occurs

because CCW or CW overtravel input inhibit has been enabled. For details, refe

to descriptions on Pr66 (DB deactivation at overtravel input inhibit).

This sets switching of enable and disable of speed zero clamp input (ZEROSPD

CNX5 26-pin).

Setting value

[0]

1

Function of ZEROSPD Input (26-pin)

ZEROSPD input being ignored, it is determined that it is not speed

zero clamp state at all times.

ZEROSPD input has been enabled. If connection with COM- is

opened, speed command will be regarded as zero.

07 0 – 9Speed monitor

(SP) selection

The parameter selects/sets a relationship between voltage output to the speed

monitor signal output (SP: CN X5 43-pin) and the actual motor speed or command

speed.

Setting value

0

1

2

[3]

4

5

6

7

8

9

SP Signals

Motor Actual

Speed

Command

Speed

Relationship between Output Voltage Level and Speed

6V / 47 r/min

6V / 187 r/min

6V / 750 r/min

6V / 3000 r/min

1.5V / 3000 r/min

6V / 47 r/min

6V / 187 r/min

6V / 750 r/min

6V / 3000 r/min

1.5V / 3000 r/min

145

Page 16

Parameter Setting

r

]

Parameter

No.

08 0 – 12Torque monitor

Parameter Name Function/Description

(IM) selection

Setting

range

The parameter selects/sets a relationship between voltage output to the torque

monitor signal output (IM: CN X5 42-pin) and generated torque of the motor o

number of deviation pulses.

Default setting is shown by [

09 0 – 5TLC output

selection

0A 0 – 5ZSP output

selection

1

2

3

4

5

1

2

3

4

5

0

2

3

4

5

IM Signals

Torque

No. of

Deviation

Pulses

Torque

Output in torque limit

Output of zero-speed detection

Output of an alarm due to either of overregeneration/overload/absolute battery

Output of over-regeneration alarm

Output of overload alarm

Output of absolute battery alarm

Output in torque limit

Output of zero-speed detection

Output of an alarm due to either of overregeneration/overload/absolute battery

Output of over-regeneration alarm

Output of overload alarm

Output of absolute battery alarm

Relationship between output level and torque or number of deviation pulses

3V / rated (100%) torque

3V / 31Pulse

3V / 125Pulse

3V / 500Pulse

3V / 2000Pulse

3V / 8000Pulse

Enabled under full-closed control (See P156 –.)

3V / 200% torque

3V / 400% torque

Functions

Functions

Remarks

For functional details of respective

outputs listed left,

refer to "Wiring to

Connector CN X5"

on page 78.

Remarks

For functional details of respective

outputs listed left,

refer to "Wiring to

Connector CN X5"

on page 78.

Setting value

[0]

6 – 10

11

12

The parameter allocates functions of output in torque limits (TLC: CN X5 40-pin).

Setting value

[0]

The parameter allocates functions of zero speed detection output (ZSP: CN X5 12-pin).

Setting value

[1]

0B 0 – 2Absolute encoder

set up

0C 0 – 2Baud rate of

RS232C

0D 0 – 2Baud rate of

RS485

Listed below are settings when you use the absolute encoder:

Setting value

0

[1]

2

Setting value

0

1

[2]

Setting value

0

1

[2]

To use the absolute encoder as absolute.

To use the absolute encoder as incremental.

To use the absolute encode as absolute. In this case, multi-rotation

excess counter is ignored.

Description

Baud Rate

2400bps

4800bps

9600bps

Baud Rate

2400bps

4800bps

9600bps

146

Page 17

[Connections and Settings in Torque Control Mode]

Connections and Settings in

Torque Control Mode

r

]

Parameters for Time Constants of Gains and Filters: Related to Real Time Auto Tuning

Default setting is shown by [

Parameter

No.

11 1 – 3500

12 1 – 1000

13 0 – 6

14 0 – 2500

19

1A

1B

1C

1D

1E 0 – 4

Parameter Name Unit Function/Description

gain

integration time

constant

detection

filter

time constant

2nd Velocity loop

gain

2nd Velocity loop integration time constant

2nd speed

detection filter

2nd torque filter

time constant

frequency

selection

Setting

range

[35]*

[16]*

[0]*

[65]*

1 – 3500

[35]*

1 – 1000

[1000]*

0 – 6

[0]*

0 – 2500

[65]*

100 – 1500

[1500]

[2]

Hz1st Velocity loop

ms1st Velocity loop

–1st speed

0.01ms1st torque filter

Hz

ms

–

0.01ms

Hz1st notch

–1st notch width

• The parameter defines responsiveness of the speed loop. You need to

set this speed loop gain high so as to improve responsiveness of the

entire servo system by increasing position loop gain.

• This parameter is an integration element of a speed loop and acts to

drive quickly the subtle speed deviation into zero. The smaller the

setting is, the faster deviation will be zeroed.

• Setting of “1000” will remove effects of integration.

• The parameter sets in 6 phases (0 to 5) a time constant of the low-pass

filter inserted after the block of converting an encoder signal into a

speed signal.

•

Setting this parameter high would increase a time constant, thereby

reducing noise of the motor. However, usually use the factory setting (0).

• The parameter sets a time constant of the primary delay filter inserted

into the torque command unit.

• It effects the control of vibration because of the torsion resonance.

• A position loop, speed loop, speed detection filter, and torque command

filter, respectively, has 2 pairs of gains or time constants (the 1st and

2nd).

• Each function/content is similar to the 1st gain/time constraint, described

earlier.

• For details on switching of the 1st and 2nd gains or time constants, refe

to Adjustment volume on page 186.

* Pr11 and Pr19 will be set in terms of (Hz) when Pr20 inertia ratio has

been set correctly.

• The parameter sets frequency of the resonance suppression notch filter.

• You should set it about 10% lower than the resonance frequency of the

mechanical system that has been found by the frequency characteristics

analysis facility of the setup assisted software “PANATERMR®”.

• Setting this parameter ”1500” would disable the function of notch filter.

• The parameter sets width of the resonance suppression notch filter in 5

steps. The higher the setting is, the greater the width is.

• Normally, use a factory setting.

Note) Standard default setting in [ ] under "Setting range" and marked with * is automatically set during the

real time auto gain tuning. T o man ually change the value, first disable the auto gain tuning feature be

seeing page 196 "Disabling of auto tuning function" in Adjustments, and then enter the desired v alue .

147

Page 18

Parameter Setting

t

r

]

t

,

Parameters for real time auto gain tuning

Parameter

No.

20

21 0 – 7 –Real time auto

22 0 – 15

Parameter Name Unit Function/Description

Inertia ratio • Defines the ratio of load inertia to the motor's rotor inertia.

tuning set up

at auto tuning

Setting

range

0 – 10000

[100]*

Setting value

[4]

[1]

%

Pr20 = (rotor inertia / load inertia) x 100[%]

• When you execute auto gain tuning, load inertia will be estimated and

the result will be reflected in this parameter.

Pr11 and Pr19 will be set in terms of (Hz) when iner tia ratio has been se

correctly. When Pr20 inertia ratio is greater than the actual ratio, setting

of the speed loop gain will increase. When Pr20 inertia ratio is smalle

than the actual ratio, setting of speed loop gain will decrease.

• Defines the operation mode of real-time auto tuning. Increasing the se

value (3, 6,...) provides higher response to the inertia change during

operation. However, operation may become unstable depending on the

operation pattern. Normally, set this parameter to "1" or "4".

• If you set this parameter to any value other than 0, Pr27 disturbance

observer filter selection will be disabled (0). In addition, if you set the

adaptive filter to disabled, Pr2F adaptive filter frequency will be reset to 0.

• When Pr20 is "0", Pr2F (Adaptive notch frequency) is reset to "0".

In the torque control mode, the adaptive notch filter is always invalid.

Real-time Auto Gain

0

2

3

4

5

6

7

• Note that any change in this parameter will be enabled when Servo OFF

changes to Servo ON.

–Machine stiffness

• Defines the machine stiffness during execution of real-time auto tuning.

Tuning

Not used

Used

Not used

Default setting is shown by [

Degree of Changes

in Load Inertia

–

Hardly changes.

Changes moderately.

Changes sharply.

Hardly changes.

Changes moderately.

Changes sharply.

–

Low Machine stiffness High

Low Servo gain High

Pr22 0 , 1- - - - - - - - - - - - 14, 15

Low Responsiveness High

Adaptive Filter

Absent

Present

Absent

Present

25 0 – 7 –Normal auto

tuning motion

set up

148

• If the parameter value is rapidly changed, the gain significantly changes

applying a shock to the machine. Be sure to set a small value first, and

increase it gradually, while monitoring the operating condition.

• Defines the operation pattern of the normal mode auto tuning.

Set value

[0]

Example) Setting this parameter to "0" provides two CCW revolutions and

two CW revolutions.

Number of revolutions

1

2

3

4

5

6

7

2[revolution]

1[revolution]

Revolving direction

CCW –› CW

CW –› CCW

CCW –› CCW

CW –› CW

CCW –› CW

CW –› CCW

CCW –› CCW

CW –› CW

Page 19

Connections and Settings in

Torque Control Mode

-

Parameter

]

-

t

-

-

-

l

-

No.

27 0 –255 –Disturbance

Parameter Name Unit Function/Description

torque observer

filter selection

A larger value provides stronger disturbance suppression; but a larger operation noise is emitted. When using this

function, it is necessary to set Pr20 inertia ratio correctly. When Pr.21 real time auto tuning mode setting is altered,

Pr27 changes to 0(disabled). Also, while the real time auto tuning is enabled (Pr21 is not 0 or 7), Pr27 is fixed to 0

and the disturbance observer is disabled.

Setting

range

[Connections and Settings in Torque Control Mode]

Default setting is shown by [

• Cut-off frequency of the filter for disturbance torque observer is set.

Set value

[0]*

1 – 255

Enabled, filter cutoff frequency [Hz] = 3.7 x setting

Cutoff Frequency

Disturbance Observer Disabled

28

frequency

29 0 – 4

selection

2A 0 – 99

selection

2F

frequency

100 – 1500

[1500]

[2]

[0]

0 – 64

[0]*

Hz2nd notch

• Defines the notch frequency of the second resonance suppression notch

filter.

• The unit is [Hz]. Match the notch frequency with the machine's reso

nance frequency.

100 to 1499: Filter enabled 1500: Filter disabled

–2nd notch width

• Select the notch width of the second resonance suppression notch filter.

• Increasing the set value enlarges the notch width.

–2nd notch depth

• Select the notch depth of the second resonance suppression notch filter.

• Increasing the set value reduces the notch depth and the phase delay.

–Adaptive filter

• Table No. corresponding to the frequency of the applied filter is dis

played. (See page 196)

• When the applied filter is enabled (when Pr21 (real time auto tuning

mode setting) is 1-3,7), this parameter is set automatically and can no

be altered.

0: Filter disabled 1 - 64: Filter enabled

Before using this function, see page 196 “Disabling of auto tuning func

tion” in adjustments.

• When the applied filter is enabled, the parameter is stored in the EE

PROM every 30 minutes. And when the applied filter is enabled at turn

ing ON the power next time, the data stored in the EEPROM is used as

the initial value to adapt the operation.

• When clearing the parameter to reset the adapted operation due to un

satisfactory operation, once set the applied filter disabled (set Pr21 (rea

time auto tuning mode setting) to other than 1 - 3, 7), and make it en

abled again.

•

Refer to “Control of Vibration Damping” of Adjustment volume on page 211.

Note) Standard default setting in [ ] under "Setting range" and marked with * is automatically set during the

real time auto gain tuning. T o man ually change the value, first disable the auto gain tuning feature be

seeing page 196 "Disabling of auto tuning function" in Adjustments, and then enter the desired v alue .

149

Page 20

Parameter Setting

t

]

-

]

Parameters for Switching to 2nd Gains

Parameter

No.

30 0 – 1 –2nd gain action

3A 0 – 3 –Torque control

3B

3C

3D

Parameter Name Unit Function/Description

set up

switching mode

Torque control

switching delay time

Torque control

switching level

Torque control

switching hysteresis

Setting

range

0 – 10000

[0]

0 – 20000

[0]

0 – 20000

[0]

x 166µs

–

–

• The parameter selects switching of PI/P operation and the 1st/2nd gain

Setting value

*1 Switching of 1 PI/P operation is done through gain switching inpu

*2 For conditions of switching between the 1st and 2nd gains, refer to

• The parameter selects conditions for switching between the 1st and 2nd

• This is same as Pr31 except parts related to position and speed control.

Setting value

*1 For details on levels to be switched, refer to “Adjustment upon switching

• This is same as content of:

Pr32: Switching delay time

Pr33: Switching level

Pr34: Hysteresis at switching”

in position control mode.

Default setting is shown by [

switching.

Gain Selection/Switching

0

[1]*

(GAIN CN X5 27-pin).

Connect to COM–.

“Adjustment upon switching gain” of Adjustment volume on page 202.

gains in torque control mode.

[0]*

1

2

*1

3

gain” of Adjustment volume on page 202.

The 1st Gain (Possible to switch PI/P) *1

Possible to switch the 1st/2nd gain *2

GAIN input

Open with COM–

Conditions for Switching Gains

Fixed to the 1st gain.

Fixed to the 2nd gain.

With the gain switching input (GAIN) turned ON, 2nd gain is

selected. (Pr30 should be set to 1.)

With much variation of torque command, the 2nd gain is

selected.

Operation of speed loop

PI operation

P operation

Parameters for Position Control

Parameter

No.

44

45 0 – 1Pulse output

150

Parameter Name Function/Description

Output pulses per

single turn

logic inversion

Setting

range

1 – 16384

[2500]

The parameter sets number of pulses per one revolution of encoder pulse to be out

put to the host device. The pulse will be set in dividing.

You should directly set in this parameter the number of pulses per revolution needed

for your device/system in terms of [Pulse/rev].

In a relationship of phases of output pulse from the rotary encoder, Phase B pulse is

behind pulse A when the motor rotates in CW direction. (Phase B pulse advances

ahead of phase A pulse, when the motor rotates in CCW direction.)

Inversion of logic of phase B pulse with this parameter could invert a phase

relation of phase B pulse to phase A pulse.

Setting value

[0]

1

A pulse(OA)

B pulse(OB)

Non-inverting

B pulse(OB)

Inverting

IWhen Motor is Rotating

in CCW direction

Default setting is shown by [

IWhen Motor is Rotating

in CW direction

Page 21

Connections and Settings in

Torque Control Mode

Parameters for Speed Control

-

]

,

-

l

t

-

Parameter

No.

Parameter Name Unit Function/Description

52 –2047

command

offset

Setting

range

– 2047

[0]

[Connections and Settings in Torque Control Mode]

Default setting is shown by [

0.3mVVelocity

• This parameter adjusts offset of external analog speed command system

including the host device.

• Offset volume will be approximately 0.3mV per a set value “1”.

• To adjust offset, there are 2 ways of (1) manual adjustment and (2) auto

matic adjustment.

1) Manual adjustment

• When you make offset adjustment with the driver only:

Using this parameter, set a value that prevents the motor from rotat-

ing, after you have correctly input 0V in torque command input

(SPR/TRQR) (or connected to signal ground).

• When the host device establishes a position loop:

With servo locked, using this parameter, set a value so that deviation

pulse will be zero.

2) Automatic Adjustment

• For details on operating instructions in automatic offset adjustment

mode, refer to “Details of Execution Display of Auxiliary Function

Mode” of Preparations volume on page 66.

• When you execute automatic offset adjustment, result will be reflected in this parameter Pr52.

56

speed

–20000

– 20000

[0]

57 JOG speed set up

0 – 500

[300]

5C 10 – 100

Torque command

input gain

[30]

r/min4th internal

r/min

0.1V/

100%

The parameter directly sets the 1st to 4th speed of internal command

speed of when setting of internal speed has been enabled with the para

meter “speed setting internal/external switching” (Pr05), to Pr53 to Pr56

respectively, in the unit of [r/min].

<Caution>

Polarity of settings shows that of internal command speed.

CCW direction viewed from the edge of axis for (+) command

+

CW direction viewed from the edge of axis for (-) command

–

Pr56 is a value of speed limits in torque control mode.

You should set this parameter in a range of rotational speeds of the

motor to be used.

The parameter directly sets JOG speed in JOG run in “motor trial run

mode” in terms of [r/min].

For details on JOG function, refer to “Trial Run (JOG)” of Preparations vol

ume on page 68.

The parameter sets a relationship between voltage applied to the torque

command input (TRQR: CN X5 14-pin) in torque control mode and gener

ated torque of the motor.

• Setting is in the unit of [0.1V/100%]

and used to set a value of input voltage necessary for calculating rated

torque.

• At a factory setting of 30, the relationship will be 3V/100%.

Setting of

Shipment

Time

Torque

Rated

Torque

300[%]

CW

200

100

CCW

-2-4-6-8-10V

2

46810V

Command

100

Input Voltage

200

300[%]

5D 0 – 1 –Torque command

input inversion

The parameter inverts polarity of the torque command input signa

(TRQR: CN X5 14-pin).

In speed/torque switching mode (when Pr02 is 5), torque command inpu

under torque control will be 16-pin of the connector CN X5.

Setting value

[0]

1

CCW direction viewed from the edge of axis for (+) command

CW direction viewed from the edge of axis for (+) command

Direction of Generation of Motor Torque

151

Page 22

Parameter Setting

f

-

r

t

f

]

-

l

]

Parameters for Torque Control

Default setting is shown by [

Parameter

No.

Parameter Name Unit Function/Description

5E 0 – 500 %Torque limit • This function limits maximum torque of the motor through setting o

Setting

range

parameters within the driver.

• In normal specifications, torque about 3 times higher than the rated is al

lowed for an instant. This parameter limits the maximum torque, how

ever, if the triple torque may cause a trouble in the strength of moto

load (machine).

• Setting should be given as a %

value to rated torque.

• The right figure shows a case

in which the maximum torque

is limited to 150%.

• Pr5E limits maximum torque in

both CW and CCW directions

simultaneously.

Torque [%]

300 (Max.)

When Pr5E=150

(Rated)

CW

200

100

100

200

300

CCW

(Rated)

<Caution>

You cannot set this parameter to a value above a factory setting of the

system parameter (i.e., a factory set parameter that cannot be changed

through of PANATERM® and panel manipulation) “Maximum Outpu

Torque Setting”. A factory setting may vary depending on a combination

of an driver and motor. For further information, refer to “Pr5E Setting o

Torque Limit” of Preparations volume on page 55.

Speed

(Max.)

Parameters for various sequences

Parameter

No.

61

62

Parameter Name Unit Function/Description

Zero speed • The parameter directly sets timing to an output zero speed detection out

At-speed • The parameter sets timing to output a at-speed signal (COIN;CN X5 39

Setting

range

0 – 20000

[50]

0 – 20000

[1000]

r/min

r/min

Default setting is shown by [

put signal (ZSP: CN X5 12-pin) in terms of [r/min].

• A zero speed detection signal (ZSP) is output when motor speed falls

below the speed set with this parameter Pr61.

• Setting of Pr61 acts on both

CW and CCW directions, ir-

Speed

Pr61

CCW

respective of the rotating direction of the motor.

ZSP

CW

ON

Pr61

pin) in speed control and torque control modes in terms of rotationa

speed [r/min].

• When the motor speed exceeds setting of this parameter Pr62, at-speed

signal (COIN) will be output.

• Setting of Pr61 acts on both

CW and CCW directions, ir-

Speed

Pr62

CCW

respective of the rotating direction of the motor.

152

COIN

CW

Pr62

OFF ON

Page 23

Connections and Settings in

Torque Control Mode

r

f

-

Parameter

]

”

t

No.

65 0 – 1 –Undervoltage

66 0 – 1 –Dynamic breke

Parameter Name Unit Function/Description

error response

at main power-off

inhibition at

overtravel limit

Setting

range

[Connections and Settings in Torque Control Mode]

Default setting is shown by [

The parameter sets whether to enable the “protection against main powe

source under-voltage” function when you shut down the main power o

main and control power supplies.

Setting value

0

[1]

Refer to the timing chart “At Power ON” of Preparations volume on page 40.

The parameter sets driving conditions at decelerated operation after over

travel input inhibit (CCWL: connector CN X5 9-pin or CWL: connector CN

X5 8-pin) has been activated and enabled.

Setting value

[0]

1

Main Power Source Under-voltage Protection Action

In this case, if you shut off the main power during Servo ON, it

will be SERVO-OFF without a trip. Then, when the main power supply turns ON again, it will be recovered to Servo ON.

Shutting off main power during Servo ON will activate abnormal main power supply under-voltage (alarm code

No.13) and cause a trip.

Driving Conditions from Deceleration to Stop

T

he motor decelerates and stops as the dynamic brake (DB) is

operated. The motor will be in free condition after it stops.

Free running, the motor decelerates and stops. The motor

will be in free condition after it stops.

67 0 – 7 –Error response

at main power-off

68 0 – 3 –Error response

action

69 0 – 7

Servo-OFF

[0]

The parameter sets:

(1) Driving conditions during deceleration and after stopping; and

(2) Processing to clear content of the deviation counter

after the main power source is shut off.

Setting

value

[0]

DB: Activation of dynamic brake

The parameter sets driving conditions during deceleration or following

stop, after any of protective functions of the driver has been activated and

alarm has been generated.

Setting

value

[0]

(DB: Activation of dynamic brake)

See also “When Abnormality (Alarm) Occurs (Serve ON Command State)

of the timing chart, Preparations volume on page 41.

• The parameter sets:

–Sequence at

1) Driving conditions during deceleration or after stop

2) Processing to clear the deviation counter

following Servo off (SRV-ON signal: CN X5 29-pin turns On ‡ Off).

• A relationship between setting of Pr69 and driving conditions/deviation

counter processing conditions is similar to that of Pr67 (Sequence a

Main Power Off).

• See also “Serve On/Off Operation When the Motor Stops” of the timing

chart of Preparations volume on page 42.

During Deceleration

1

2

3

4

5

6

7

During Deceleration

1

2

3

Driving Conditions

DB

Free Run

DB

Free Run

DB

Free Run

DB

Free Run

Driving Conditions

DB

Free Run

DB

Free Run

Content of Deviation

After Stopped

DB

DB

Free

Free

DB

DB

Free

Free

Content of Deviation

After Stopped

DB

DB

Free

Free

Counter

Clear

Clear

Clear

Clear

Retention

Retention

Retention

Retention

Counter

Clear

Clear

Clear

Clear

153

Page 24

Parameter Setting

]

r

)

-

r

-

-

-

Parameter

No.

Parameter Name Unit Function/Description

6A 0 – 100

delay at

motor standstill

6B 0 – 100

delay at

motor in motion

6C 0 – 3 –External

regenerative

resister set up

6D

detection time

Setting

range

[0]

[0]

0 – 32767

[35]

2msMechanical brake

2msMechanical brake

2msMain power-off

Default setting is shown by [

The parameter sets time till non-energization of motor (servo free) afte

the brake release signal (BRK-OFF) turns off (brake retained), at Serve

Off while the motor stops.

• In order to prevent minor

movement/drop of the motor

(work) due to operation delay time of the brake (tb):

Setting of Pr6A

>

tb.

=

• See “Serve On/Off Operation

When the Motor Stops” of

the timing chart on page 42.

SRV-ON

BRK-OFF

Actual Brake

Motor Energized

ON

Release

Release

Energization

tb

Pr6A

OFF

Retention

Retention

Non-

energization

See also “Serve On/Off Operation When the Motor Stops” of the timing

chart of Preparations volume on page 43.

Unlike Pr6A, the parameter sets time till brake release signal (BRK-OFF

turns off (brake retained) after motor non-energization (servo-free), at Ser

vo off while the motor is rotating.

• This should be set to prevent deterioration of the brake due to

revolutions of the motor.

• At Servo off while the motor is rotating, time tb in the right figure

will be either set time of Pr6B or

time till the motor rotational

speed falls below approximately

SRV-ON

BRK-OFF

Motor Energized

Energization

Motor Speed

ON

Release

tb

OFF

Retention

Non-

energization

30 r/min

30r/min, whichever is smaller.

• See “Serve On/Off Operation When the Motor is

Rotating” of the timing chart of on page 43.

See also “Serve On/Off Operation When the Motor Stops” of the timing

chart of Preparations volume on page 42.

This parameter is set depending on whether to use regeneration resis

tance built in the driver, or to provide a regeneration resistance in the ex

ternal (connect between RB1 and RB2 of connector CN X 2 in types A to

D, and between terminal blocks P and B2 in types E - G).

Setting

value

Regeneration

Resistance to Use

Protection against Regeneration

Resistance Overload

According to built-in resistance, (about

[0]

Built-in resistance

1% duty) protection against regeneration resistance overload works.

External resistance

1

2

Built-in resistance

This is activated with operating limits of

the external resistance at 10% duty.

This is activated with operating limits of

the external resistance at 100% duty.

Regeneration resistance does not

External resistance

3

work, and a built-in condenser accommodates all regenerated power.

<Request>

When you use an external regeneration, you must install external safe

guards such as a temperature fuse, etc.

Otherwise, as protection of regeneration resistance would be lost, causing

abnormal heat generation and burnout.

<Caution>

Be careful not to touch an external regeneration resistance.

While you are using an external resistance, it may become hot and scald

you. For type A, only external regeneration resistance is used.

The parameter sets time to detect shut-off when shut-off of main powe

supply continues.

154

Loading...

Loading...