Panasonic MGSDB2, MGSDB1, MGSDA1, MGSD Instruction Manual

Instruction Manual

Speed Controller for Small Geared Motors

MGSD Series

• Thank you for purchasing the Panasonic speed controller

MGSD for small geared motor.

• Carefully read this manual thoroughly before installing and

operating the product.

Section "Safety Precautions" (pp. 3-9) contains very

important information concerning safety and reliable

operation.

Keep this manual in a safe location where it can be easily

accessed for reference.

The user and operator should always refer to this manual.

This product is for industrial equipment.Don't use this product

at general household.

Safety Precautions

Please observe safety precautions fully.

• Contents

page

Safety Precautions .......................................................... 3

1. Introduction ................................................................10

Unpacking .............................................................................. 10

General description of the speed controller ........................... 10

2. Names and functions ................................................ 14

3. Installation..................................................................15

4. Wiring diagram ..........................................................17

Considerations for wiring ....................................................... 17

Wiring diagram .......................................................................18

Standard electrical wiring diagram .........................................20

Speed change only ............................................................ 20

Unidirectional rotation and electric brake...........................22

Normal/reverse rotation and electric brake ........................ 24

Peripheral wiring .................................................................... 26

Motor wiring with cooling fan motor (F) or thermal protector (TP)

Wiring to electromagnetic brake ........................................ 27

5. Options ....................................................................... 28

6. References ................................................................. 32

7. Compatible with international standards ................ 38

8. Specication .............................................................. 42

9. Inspection and maintenance .................................... 44

Inspection ..............................................................................44

Troubleshooting .....................................................................45

10. After-Sale Service (Repair) .....................................46

....26

Please strictly observe safety precautions described below

to prevent personal injury and property damage.

■ The below explains what will happen if someone fails to

heed a particular precaution statement.

Indicates hazards or unsafe

Danger

practices which could result in

severe personal injury or death.

Indicates hazards or unsafe

practices which could result in

Caution

minor personal injury or product

or property damage.

■ The following symbols are used to describe the type of

Do and Don't.

This symbol is used to indicate

a practice that shall not be

attempted.

This symbol is used to indicate

a practice that shall be done.

– 3 –– 2 –

Don't move the product by

holding leadwires or motor shaft.

Don't put the machine into

unstable operation.

Don't apply excessive shock to

the motor shaft.

Don't apply excessive shock to

the product.

Don't get on the product. Don't

place heavy object on the

product.

Once power failure occurs, don't

come close to the machine that

will unexpectedly start upon

recovery of the power.

Provide secure mechanism so

that the restarting of the machine

will not cause personal injury.

Failure to heed

these precautions

will cause bodily

injury.

Excessive shock will

cause failure.

Failure to heed this

instruction will result in

electric shock, personal

injury, fire, malfunction

or damage.

After correctly connecting

leadwires, insulate the live parts

with insulator.

Incorrect wiring will

result in short circuit,

electric shock, fire or

malfunction.

Install the equipment in the

control board and keep the

terminal block and protect it from

inadvertent contact.

Failure to heed this

precaution will result in

electric shock, personal

injury, fire, malfunction

or damage.

Ground the motor ground to the

earth.

Floating ground

circuit will cause

electric shock.

Caution

Danger

Safety Precautions

Don't use the speed controller in

or near environment containing

water, corrosive gas, flammable

gas or flammable material.

Don't place flammable materials

near the motor (including the

controller).

Don't make soldering joint on a

round pin of the speed controller.

Don't damage leadwires or

subject leadwires to excessive

stress such as strong pressure,

heavy object and clamping load.

Don't use leadwires soaked in

water or oil.

Don't use the controller in a place

subject to excessive vibration or

shock.

Don't remove the speed controller

setting knob.

Don't touch rotating member of

the motor.

Don't touch potentially hot motor

casing.

Don't attempt to carry out wiring or

manual operation with wet hand.

Wiring work should be done by a

qualified electrician.

Please observe safety precautions fully.

To prevent possibility

of fire.

Will cause electric

shock, malfunction

or damage.

Will cause electric

shock, personal

injury or fire.

Will cause burn

injury or electric

shock.

Will cause personal

injury.

Will cause burn

injury.

Will cause electric

shock, personal

injury or fire.

Wiring work done by

an inexperienced

person will cause

electric shock.

Use overcurrent protection device,

ground-fault circuit interrupter,

overtemperature protecting device,

and emergency stop device.

After an earthquake, first verify

safety.

Before transferring, wiring or

checking product, disconnect the

power source for safe isolation.

Securely install the equipment to

prevent bodily injury or fire in

case of earthquake.

Provide emergency stop circuit

externally for instantaneous

interruption of operation and

power supply.

Install the unit to a nonflammable

construction (e.g. metal).

Installation area should be free

from excessive dust, and from

splashing water and oil.

Correctly run wirings to the

tacho-generator.

Turn off power upon power

interruption or activation of

overtemperature protecting device.

– 5 –– 4 –

Failure to heed

these requirements

will result in electric

shock, personal

injury or fire.

Incomplete power

disconnection will

cause electric shock.

Failure to heed

these requirements

will result in electric

shock, personal

injury, fire,

malfunction or

damage.

Installation on a

flammable material

may cause fire.

Failure to heed this

precaution will result

in electric shock,

personal injury, fire,

malfunction or

damage.

Incorrect wiring will

result in short circuit,

electric shock,

personal injury, etc.

Unpredictable

restarting will cause

personal injury.

Perform installation by taking into

consideration the mass of the

body and rated output of the

product.

Exactly follow the installing

method and direction specified.

Adjust ambient environmental

condition of motor and speed

controller to match the motor

operating temperature and

humidity.

Connect the motor

electromagnetic brake control

relay in series with a ground-fault

interrupter, circuit breaker and

relay so that they turn off the

circuit upon emergency stop.

Test-run the securely fixed motor

without loading to verify normal

operation, and then connect it to

the mechanical system.

Level of input voltage to the

speed controller should

correspond to the motor rated

voltage.

Operation using a

wrong model or

wrong wiring

connection will result

in personal injury.

Use the speed controller in

combination with the specified

motor.

Failure to heed this

instruction

will result

in fire.

Failure to heed these

instructions will result

in personal injury or

malfunction.

Operation from a

voltage outside the

rated voltage will

cause electric shock,

personal injury or fire.

Provide protection device against

idling of electro-magnetic brake

or gear head, or grease leakage

from gear head.

Lack of protection

will cause personal

injury, damage,

pollution or fire.

Lack of connection

will cause

malfunction.

Locked motor will

Safety Precautions

Please observe safety precautions fully.

Install the equipment in the

control board and keep the

terminal block and protect it from

inadvertent contact.

After correctly connecting

leadwires, insulate the live parts

with insulator.

Ground the motor ground to the

earth.

Caution

Don't move the product by

holding leadwires or motor shaft.

Don't put the machine into

unstable operation.

Once power failure occurs, don't

come close to the machine that

will unexpectedly start upon

recovery of the power.

Provide secure mechanism so

that the restarting of the machine

will not cause personal injury.

Don't apply excessive shock to

the motor shaft.

Don't apply excessive shock to

the product.

Don't get on the product. Don't

place heavy object on the

product.

Failure to heed this

precaution will result in

electric shock, personal

injury, fire, malfunction

or damage.

Incorrect wiring will

result in short circuit,

electric shock, fire or

malfunction.

Floating ground

circuit will cause

electric shock.

Failure to heed

these precautions

will cause bodily

injury.

Excessive shock will

cause failure.

Failure to heed this

instruction will result in

electric shock, personal

injury, fire, malfunction

or damage.

Don't lock the motor shaft while

the motor is running.

Don't clog or put an object into

the radiating hole of the motor.

Don't turn off and on power so

frequently.

Don't pull leadwires with an

excessive force.

Don't use the equipment in highly

intensive electric field.

Don't use the equipment under

direct sunshine.

Don't use the equipment in an

environment where electrostatic

voltage potentials may be

produced.

Don't drop or cause topple over

of something during

transportation or installation.

Don't use a variable transformer

or transformer having capacity

insufficient to feed the load.

Don't use the equipment outside

the limits described on the

nameplate and user's manual.

Never attempt to perform

modification, dismantle or repair.

cause fire, electric

shock, or malfunction.

Failure to heed this

instruction will result

in fire.

Failure to heed this

instruction will result in

fire, personal injury,

malfunction or damage.

Failure to heed this

instruction will cause

fire, electric shock or

personal injury.

Failure to heed

these instructions

will cause personal

injury or fire.

Induced malfunction

will cause

malfunction or

personal injury.

Failure to heed this

instruction will result

in personal injury or

malfunction.

Failure to heed this

instruction will cause

fire, electric shock or

malfunction.

Failure to heed this

instruction will result in

electric shock, personal

injury, fire, malfunction

or damage.

Failure to heed this

instruction will cause

fire, electric shock or

personal injury.

– 7 –– 6 –

Safety Precautions

Perform installation by taking into

consideration the mass of the

body and rated output of the

product.

Adjust ambient environmental

condition of motor and speed

controller to match the motor

operating temperature and

humidity.

Exactly follow the installing

method and direction specified.

Use the speed controller in

combination with the specified

motor.

Connect the motor

electromagnetic brake control

relay in series with a ground-fault

interrupter, circuit breaker and

relay so that they turn off the

circuit upon emergency stop.

Test-run the securely fixed motor

without loading to verify normal

operation, and then connect it to

the mechanical system.

Level of input voltage to the

speed controller should

correspond to the motor rated

voltage.

Please observe safety precautions fully.

Failure to heed these

instructions will result

in personal injury or

malfunction.

Failure to heed this

instruction

in fire.

Lack of connection

will cause

malfunction.

Operation using a

wrong model or

wrong wiring

connection will result

in personal injury.

Operation from a

voltage outside the

rated voltage will

cause electric shock,

personal injury or fire.

will result

Don't place any obstacle object

around the motor and peripheral,

which blocks air passage.

Correctly run and arrange wiring.

Maintenance must be performed

by an experienced personnel.

Always keep power disconnected

when the power is not necessary

for a long time.

Scraps must be treated as

industrial waste.

Temperature rise will

cause burn injury or

fire.

Wrong wiring will

cause personal injury

or electric shock.

Improper operation

will cause personal

injury.

Provide protection device against

idling of electro-magnetic brake

or gear head, or grease leakage

from gear head.

Lack of protection

will cause personal

injury, damage,

pollution or fire.

– 9 –– 8 –

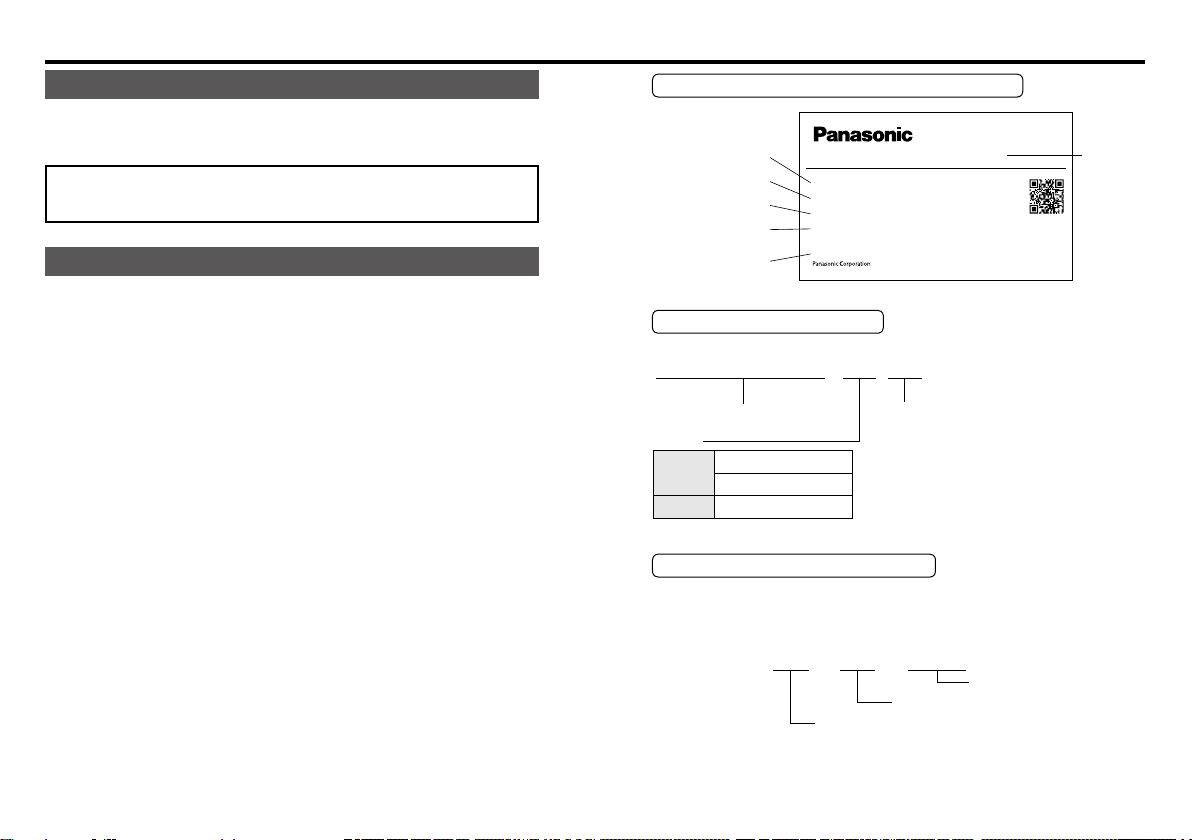

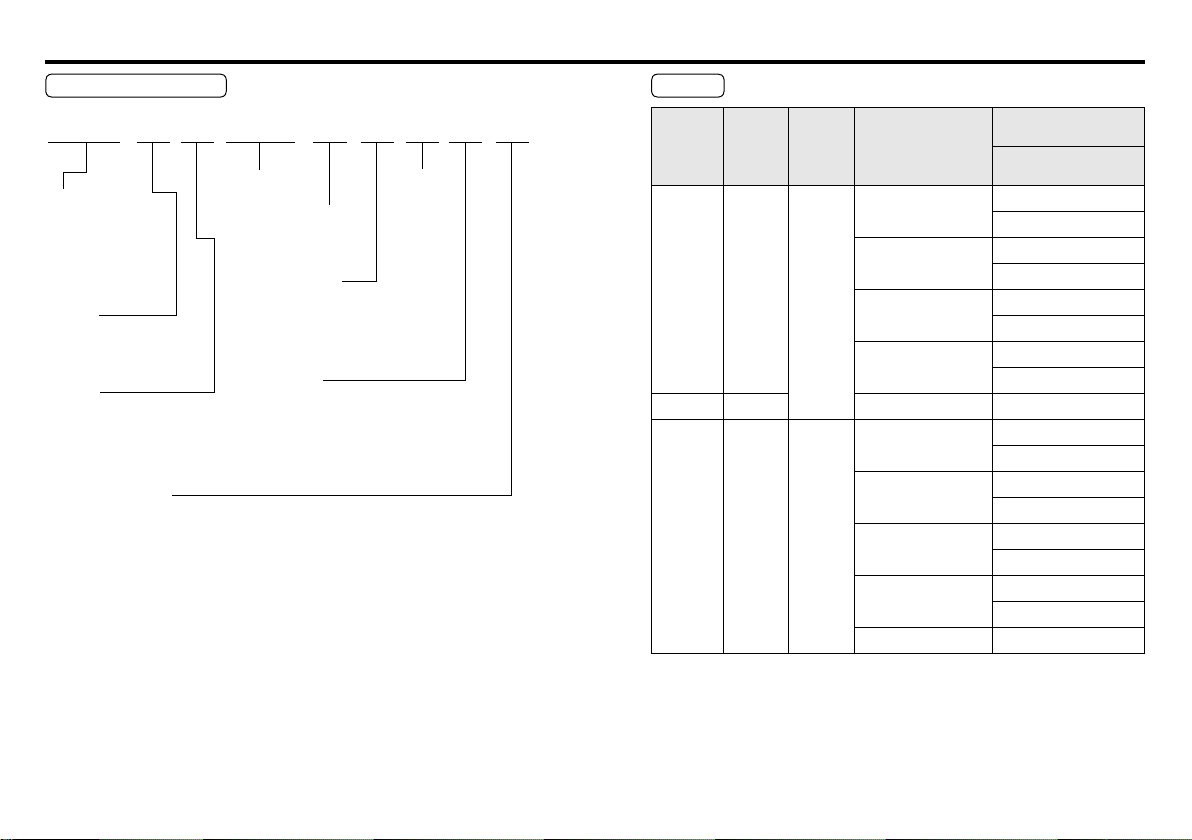

MGSDB2

120 VAC

240 VAC

Example

1. Introduction

Unpacking

· Verify that the model No. matches your order sheet.

· Damage in transit is not found.

Should you nd any discrepancy in the product,

consult your local dealer.

General description of the speed controller

The MGSD type speed controller is designed to operate with a small

geared motor to adjust and vary its speed. The speed is adjusted

from the speed setting knob. The input voltage can be single-phase

100-120 VAC, or single-phase 200 – 240 VAC. The speed controller

is compatible with EC directive and UL standard.

Compatible with DIN terminal block which is convenient to install on

the distribution board, and small timer common option available from

Panasonic Corporation (pp. 32 – 37).

Read this manual thoroughly so that you will become gradually acquainted with the excellent features of your speed controller for small

geared motor and understand how to fully utilize these functions. The

speed controller is designed to be integrated into a general control

board.

The product must be handled by experienced personnel familiar with

the product.

Designation and rating on the nameplate

Rated

input voltage

Input current

Rated speed

Rated output

Serial No.

(production No.)

Model No.

Input

Input Current

Rated Speed

Rated Output

Ser.No. 06110001G

Made in China

50/60Hz 1Ph 200–240V

1.0A

1400/1700min

6–90W

SPEED CONTROLLER

MGSDB2

–

1

C58401

Description of model No.

651 – 4

Input power supply

1. Single phase 100 –

2. Single phase 200 –

Output

100 V

200 V

Series

A : 3 – 40 W

B : 60 – 90 W

B : 6 – 90 W

Serial number (production No.)

The Ser. No. on the nameplate contains the following codes.

Ser.No. * 06 11 0001 *

Sequential number

Manufacturing month

Manufacturing year

This product was manufactured in November 2006

and assigned a sequential number 0001.

Model

name

– 11 –– 10 –

1. Introduction

M91Z90GV4LG

Motor Part Number

3

Size

M6: Sq.60 mm

M7: Sq.70 mm

80 mm

M8: Sq.

M9: Sq.

90 mm

Series

1 : Induction motor

R : Reversible motor

Series

X : 40 W or lower

Z : 60 W or higher

Version

Blank : Pinion shaft motor (Japanese standard)

S : Round shaft motor (Japanese standard)

G : International standard approved motor (CE, UL, CCC)

5,61,2

Output

7 8 9 10 114

No. of

poles

Shape of shaft

G : Pinion

S : Round

Variable speed

V : Variable (without brake)

Variable with electromagnetic

BV :

brake

Voltage

L : 100 V

D : 110 – 115 V

Y : 200 V

G : 220 – 230 V

Rating

Model No. Output

MGSDA1

MGSDB1

MGSDB2

3-40 W

60-90

6

-

90 W

W

Power

supply

AC100 V

to

AC120 V

AC200 V

to

AC240 V

Compatible

induction motor

M61X***V4**

M71X***V4**

M81X***V4**

M91X***V4**

M91Z***V4**

M61X***V4**

M71X***V4**

M81X***V4**

M91X***V4**

M91Z***V4**

Compatible

reversible motor

Compatible reversible motor

with electromagnetic brake

M6RX***V4**

M6RX**GBV4**

M7RX***V4**

M7RX**GBV4**

M8RX***V4**

M8RX**GBV4**

M9RX***V4**

M9RX**GBV4**

M9RZ***V4**

M6RX***V4**

M6RX**GBV4**

M7RX***V4**

M7RX**GBV4**

M8RX***V4**

M8RX**GBV4**

M9RX***V4**

M9RX**GBV4**

M9RZ***V4**

– 13 –– 12 –

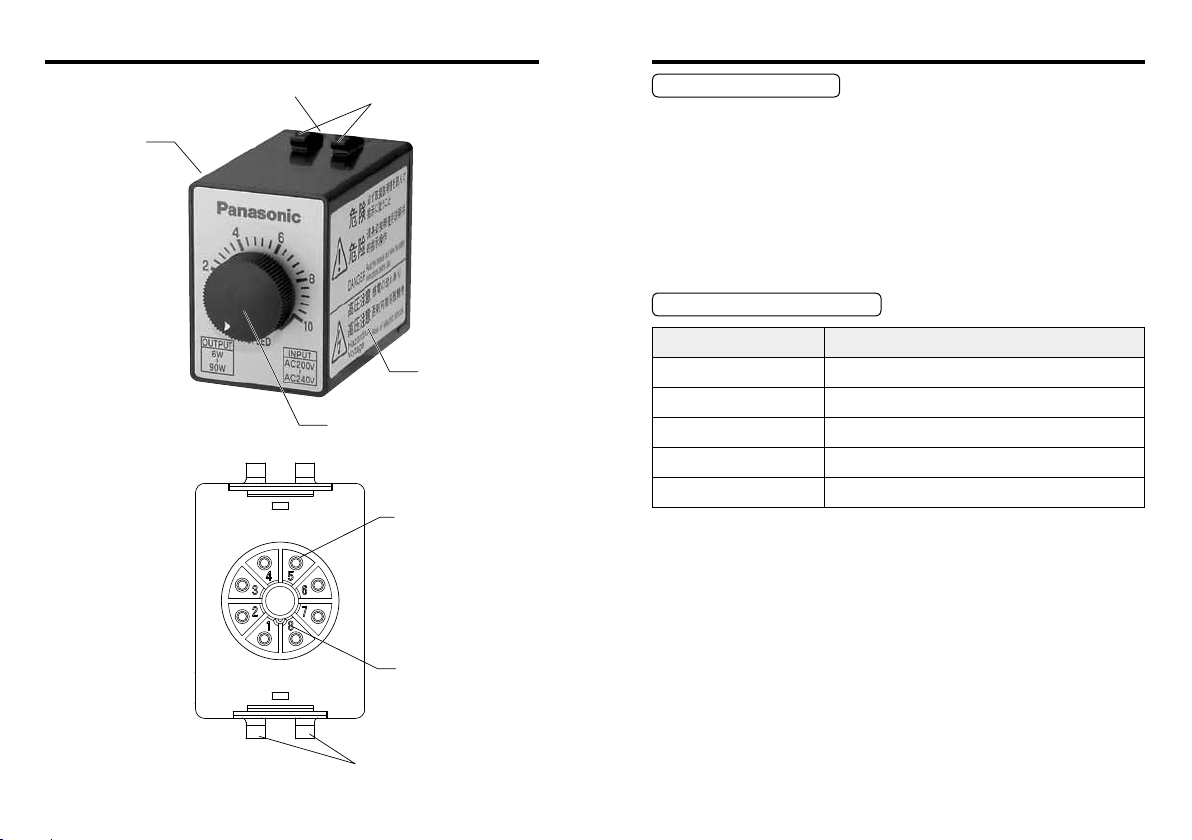

2. Names and functions

Terminal block

Terminal block locking

hook mounting hole

Nameplate

locking claw

3. Installation

Installation location

(1) Indoors free from rain and direct sunlight: the product is not of a

waterproof construction.

(2) Free from vibration 4.9 m/s2 or more; shock, dust, iron powder

or oil mist; splash of water, oil and grinding uid; and away from

ammable materials, corrosive gas (H2S, SO2, NO2, Cl2, etc.) or

ammable gas.

(3) Well ventilated dry and clean location containing negligible amount

of oil or dust.

Environmental condition

<Rear panel>

Caution plate

Speed control knob

Pin

Pin number

Terminal block

locking claw

Item

Operating temperature

Storage temperature

Operating humidity

Allowable vibration

Altitude

Condition

–10 °C – 50 °C

–20 ˚C – 60 ˚C

90 % RH or below (no dewing)

2

or below (10 Hz – 60 Hz)

4.9 m/s

1000 m max.

– 15 –– 14 –

Loading...

Loading...