Panasonic MEW01 351, EBL512 G3 Planning Manual

Planning Instructions

MEW01351

Revision -

Fire Alarm System EBL512 G3

V1.1.x

Author: Jan Pettersson

Date of issue: 2011-02-11

Date of rev:

This page has deliberately been left blank.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

1

Table of contents

1 Introduction________________________________ 8

2 Definitions / Explanations ___________________ 10

2.1 PEWN AB _______________________________________ 10

2.2 Alarm points _____________________________________ 10

2.2.1 Smoke detector _______________________________ 10

2.2.2 Sensor ______________________________________ 10

2.2.3 Analog detector _______________________________ 10

2.2.4 Analog (Sensor) Base (ASB) ____________________ 10

2.2.5 Conventional detector __________________________ 10

2.2.6 (Conventional Detector) Base (CDB) ______________ 10

2.2.7 Addressable __________________________________ 10

2.2.8 Conventional zone line input / External line _________ 11

2.3 Output unit ______________________________________ 11

2.4 Output / Control output _____________________________ 11

2.5 Short circuit isolator (ISO) __________________________ 11

2.6 Display unit (D.U.) ________________________________ 11

2.7 COM loop _______________________________________ 11

2.8 Control Unit / C.U. / C.I.E. __________________________ 11

2.9 Fire Brigade Panel (FBP) ___________________________ 11

2.10 Control panel (CP) ________________________________ 11

2.11 System __________________________________________ 11

2.12 Network / TLON® / LonWorks® / Echelon / Node / TLON

Conn. board / Channel / Backbone net / Router / Repeater _______ 12

2.13 LED ____________________________________________ 12

2.14 External Indicator (Ext. LED) ________________________ 12

2.15 Display / LCD ____________________________________ 12

2.16 Door open (Door / Key switch) _______________________ 12

2.17 Site Specific Data (SSD) ____________________________ 13

2.18 Software (S/W) / System program ____________________ 13

3 Overview _________________________________ 14

3.1 The EBL512 G3 system ____________________________ 14

3.1.1 Printer ______________________________________ 14

3.1.2 Expansion boards _____________________________ 14

3.1.3 Power supply _________________________________ 14

3.2 S/W versions _____________________________________ 15

3.3 Documents ______________________________________ 15

3.4 Applications _____________________________________ 15

3.5 PC software (S/W) ________________________________ 15

3.5.1 WinG3 ______________________________________ 15

3.5.2 TLON Manager _______________________________ 16

3.5.3 WebG3 IConfig tool ___________________________ 16

4 Control Unit / TLON Network _______________ 17

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

2

4.1 The TLON network ________________________________ 17

4.2 Single TLON Network / redundant TLON Network ______ 17

5 Control Units 5000 and 5001 _________________ 19

5.1 Mounting plates ___________________________________ 21

5.1.1 Mounting plate for 19" mounting rack, 5020 ________ 21

5.1.2 Mounting plate for inflammable wall, 5021 _________ 21

5.2 COM loops ______________________________________ 22

5.3 Programmable voltage outputs (S0-S3) ________________ 24

5.4 Programmable relay outputs (R0-R1) __________________ 24

5.5 Programmable inputs (I0-I3) _________________________ 24

5.6 Relay outputs for routing equipment (tx) _______________ 25

5.6.1 Fire alarm output ______________________________ 25

5.6.2 Fault condition output __________________________ 25

6 Expansion boards 458x _____________________ 26

6.1 Expansion board no. (address) setting __________________ 27

6.2 8 zones expansion board 4580 _______________________ 27

6.2.1 Type of zone line input _________________________ 28

6.2.2 Input states __________________________________ 28

6.3 8 relays expansion board 4581 _______________________ 29

6.4 Inputs and outputs expansion board 4583 _______________ 30

6.5 I/O Matrix board 4582 _____________________________ 31

6.5.1 Generic _____________________________________ 33

6.5.2 Fan control __________________________________ 33

6.5.3 Zone control _________________________________ 34

7 Printer ___________________________________ 35

8 TLON connection board 1590 ________________ 36

8.1 Single TLON Network _____________________________ 36

8.2 Redundant TLON network __________________________ 36

8.3 Network programming _____________________________ 36

9 Peripheral devices __________________________ 37

9.1 COM loop units ___________________________________ 37

9.1.1 Input units ___________________________________ 39

9.1.2 Addressable I/O units __________________________ 46

9.1.3 Alarm devices (addressable sounders) _____________ 48

9.1.4 Short circuit isolators (addressable) _______________ 49

9.1.5 Units for Hazardous (Ex) areas ___________________ 50

9.1.6 Other COM loop units __________________________ 51

9.1.7 COM loop addresses for Base station and Wireless

detectors 54

9.2 Units connected to the RS485 interface ________________ 54

9.2.1 External Fire Brigade Panels _____________________ 55

9.2.2 Alert Annunciation Units _______________________ 56

9.2.3 External Presentation Units ______________________ 57

9.2.4 German Fire Brigade Panels _____________________ 58

9.3 Units connected to the RS232 interface J7 ______________ 59

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

3

9.3.1 Web-servers __________________________________ 59

9.4 Other units _______________________________________ 59

9.4.1 Alert Annunciation Controllers ___________________ 59

9.4.2 External LED ________________________________ 60

9.4.3 Alarm devices (sounders, etc.) ___________________ 60

9.4.4 Door release magnets __________________________ 60

9.4.5 Boxes _______________________________________ 61

9.4.6 Duct detector chambers _________________________ 61

10 Programmable inputs _______________________ 62

10.1 Control unit Inputs I0 - I3 & Inputs 0 -4 on exp. board 4583 63

10.1.1 Not supervised ________________________________ 63

10.1.2 Supervised ___________________________________ 63

10.2 The 3361 unit's Inputs In0 / Z & In1 ___________________ 63

11 Input programming ________________________ 64

11.1 Trigger conditions _________________________________ 64

11.2 Logic ___________________________________________ 67

11.2.1 Supervised ___________________________________ 67

12 Programmable outputs ______________________ 68

12.1 Control unit outputs S0 – S3 _________________________ 69

12.2 Control unit outputs R0 & R1 ________________________ 70

12.3 8 relays expansion board 4581 Output 0 – Output 7 _______ 70

12.4 Inputs and Outputs expansion board 4583 Output 0 & Output 170

12.5 The 3361 unit's Outputs Re0 & Re1 ___________________ 70

12.6 The 3364 unit's VO0 – VO2 _________________________ 71

12.7 The 3377 unit's Output (siren) ________________________ 71

12.8 The 3379 unit's Output (sounder) _____________________ 71

12.9 The 4380 unit's Output (beacon) ______________________ 71

13 Output programming _______________________ 72

13.1 Type of output ____________________________________ 72

13.2 Logic ___________________________________________ 73

13.3 Supervised / Not supervised _________________________ 73

13.4 Output signal period _______________________________ 73

13.5 Control expression ________________________________ 76

13.5.1 Trigger conditions _____________________________ 76

13.5.2 Logical operators ______________________________ 80

13.5.3 Control expression examples ____________________ 80

14 Interlocking function _______________________ 84

14.1 Programming of interlocking function _________________ 84

14.1.1 Interlocking output ____________________________ 84

14.1.2 Interlocking input _____________________________ 84

14.1.3 Interlocking combination _______________________ 84

14.2 Interlocking indications _____________________________ 86

14.3 Information of interlocking combinations (H9) __________ 86

14.3.1 Display interlocking information (H9/C1) __________ 86

14.3.2 Activate interlocking output (H9/C2) ______________ 87

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

4

14.3.3 Reset interlocking output (H9/C3) ________________ 87

14.3.4 Disable interlocking output (H9/C4) _______________ 87

14.3.5 Re-enable interlocking output (H9/C5) _____________ 87

14.4 Interlocking control expressions ______________________ 87

15 Fire Door Closing __________________________ 88

16 Functions / Services / Features _______________ 89

16.1 Sensor value _____________________________________ 89

16.2 Week average sensor value __________________________ 89

16.3 Decision value ____________________________________ 90

16.4 Alarm algorithms for smoke detectors / Detection levels /

Offsets 90

16.4.1 Alarm algorithm / Alternative alarm algorithm ______ 91

16.4.2 Filtering algorithm ____________________________ 92

16.4.3 Smouldering smoke algorithm ___________________ 94

16.5 Performance factor ________________________________ 95

16.6 Algorithms for analog heat detectors __________________ 96

16.6.1 Class A1 algorithm ____________________________ 97

16.6.2 Class A2 S algorithm __________________________ 97

16.6.3 Class B S algorithm ____________________________ 97

16.7 Self verification ___________________________________ 98

16.8 Minimum / Maximum sensor values ___________________ 98

16.9 2-zone / 2-address dependence (Co-incidence alarm) ______ 99

16.9.1 2-zone dependence ____________________________ 99

16.9.2 2-address (-unit) dependence ___________________ 100

16.9.3 Reset of 2-zone / 2-address dependence (co-incidence

alarm 100

16.10 Delayed alarm _________________________________ 101

16.11 Alert Annunciation _____________________________ 102

16.12 Alarm Acknowledgement Facility (AAF) ____________ 104

16.13 Quiet alarm ___________________________________ 106

16.14 Fire alarm type A and Fire alarm type B _____________ 106

16.14.1 Fire alarm type B ___________________________ 107

16.14.2 Fire alarm type A __________________________ 107

16.15 Disable alarm points and outputs __________________ 107

16.15.1 Disable zone ______________________________ 108

16.15.2 Disable zone / address _______________________ 108

16.15.3 Disable control output _______________________ 108

16.15.4 Disable / Re-enable output type _______________ 108

16.15.5 Disable / Re-enable alarm devices _____________ 108

16.16 Disable interlocking output _______________________ 108

16.17 Disable outputs for routing equipment ______________ 108

16.18 Disconnect & Re-connect loop / zone line input _______ 109

16.19 External time channels 15-63 _____________________ 109

16.20 Test mode ____________________________________ 109

16.21 Test alarm devices ______________________________ 109

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

5

16.22 Test of routing equipment ________________________ 110

16.23 Calibration of supervised outputs __________________ 110

16.24 Service signal _________________________________ 110

16.25 Fault signal (fault condition) ______________________ 111

16.26 Alarm texts ___________________________________ 111

16.26.1 Creating the alarm texts via WinG3 ____________ 111

16.26.2 Downloading alarm texts to the DU:s 1728 / 1735 /

1736 and ext. FBP:s 1826 / 1828 ________________________ 113

16.27 Real time clock (RTC) __________________________ 113

16.27.1 Daylight saving time ________________________ 114

16.28 Loss of main power source _______________________ 114

16.29 Evacuate _____________________________________ 114

16.30 WinG3 menu Tools _____________________________ 115

17 Special New Zealand functions ______________ 117

17.1 Alarm devices ___________________________________ 117

17.1.1 Silence alarm devices (inside switch) _____________ 117

17.1.2 New Zealand FB Silence switch (outside switch) ____ 117

17.2 Battery faults ____________________________________ 119

17.2.1 FAULT: Battery _____________________________ 119

17.2.2 FAULT: Low battery capacity __________________ 119

17.3 Watchdog reset __________________________________ 119

17.4 Routing equipment isolate (disable) __________________ 119

17.5 Acknowledged alarm _____________________________ 119

18 Cyber sensor functions _____________________ 121

18.1 Pulse up – down counter ___________________________ 122

18.1.1 Pulse up – down counter for smoke ______________ 122

18.1.2 Pulse up – down counter for temperature __________ 122

18.1.3 Pulse up – down counter for smoke & temperature __ 122

18.2 Fire judgement __________________________________ 122

18.3 Alarm threshold levels ____________________________ 123

18.4 Learning function / Learning conditions _______________ 123

18.4.1 Learning conditions ___________________________ 123

18.5 Alarm delay time _________________________________ 125

18.6 Analog data output _______________________________ 126

18.7 Sensitivity compensation __________________________ 126

18.8 Self diagnosis of internal devices ____________________ 127

18.9 Address setting check _____________________________ 127

19 Control unit properties ____________________ 128

19.1 Control unit properties dialog box ___________________ 128

19.1.1 General Information __________________________ 128

19.1.2 Peripherals __________________________________ 128

19.1.3 Misc. ______________________________________ 128

19.2 WinG3 Control unit pop-up menu ___________________ 129

19.2.1 Reset alarm counter ___________________________ 129

19.2.2 Software version _____________________________ 129

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

6

19.2.3 Upgrade number of alarm points _________________ 129

19.2.4 Restart _____________________________________ 130

19.2.5 Delete _____________________________________ 130

19.2.6 Properties___________________________________ 130

20 System properties (settings) _________________ 131

20.1 System properties dialog box _______________________ 131

20.1.1 Name ______________________________________ 131

20.1.2 User definable text ___________________________ 131

20.1.3 System properties, Page 1 ______________________ 131

20.1.4 System properties, Page 2 ______________________ 133

20.2 Menu System ____________________________________ 134

20.2.1 Properties___________________________________ 134

20.2.2 Time channels _______________________________ 134

20.2.3 Alarm algorithms ____________________________ 136

20.2.4 Output Signal Periods _________________________ 138

20.2.5 National holidays ____________________________ 139

20.2.6 Two zone dependence _________________________ 140

20.2.7 Statistics (System information) __________________ 141

20.2.8 Edit Alarm texts _____________________________ 141

21 Compatibility_____________________________ 142

22 Cable types ______________________________ 143

22.1 TLON Network cables ____________________________ 143

22.2 COM loop cables_________________________________ 143

22.3 Ext. FBP / Display Units cables _____________________ 143

22.4 Conventional zone line cables _______________________ 143

22.5 Alarm device cables ______________________________ 144

22.6 Other cables _____________________________________ 144

23 COM loop cable length _____________________ 145

24 Current consumption ______________________ 148

25 Power supply _____________________________ 152

25.1 Charger functions ________________________________ 153

25.1.1 Charging ___________________________________ 153

25.1.2 Battery charging functions: _____________________ 153

25.1.3 Security functions ____________________________ 153

25.2 Current consumption calculations ____________________ 154

25.3 Rectifier (main power source) _______________________ 155

25.4 Battery (second power source) ______________________ 155

25.5 Fuses __________________________________________ 156

25.6 Form / Table of current consumption _________________ 156

26 S/W versions _____________________________ 158

27 Technical data ____________________________ 159

28 Limitations_______________________________ 160

28.1 User definable texts _______________________________ 160

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

7

28.2 C.i.e. / System ___________________________________ 160

29 National regulations _______________________ 162

30 Drawings / connection diagrams _____________ 163

31 Revision history ___________________________ 164

Drawings according to the valid table of drawings.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

8

1 Introduction

EBL512 G3 Planning Instructions is a document1 intended to be used

by planning engineers as well as service / commissioning engineers.

This document should be read in conjunction with the drawings

according to the valid Table of drawings and the EBL512 G3

Operating Instructions MEW01163.

When planning a fire alarm installation the national regulations have

to be obeyed. A lot of detector types can be used. Detector coverage

area and detector placing in the room / building, etc. are matters for

the planning engineers and are not described in this document.

Due to continual development and improvement, different S/W

versions might be found. This document is valid for S/W version

1.1.x. On the date / revision date of the document x = 0.

Since the EBL512 G3 control unit (c.i.e.) is produced for many

countries the look, the texts, the functions, etc. might vary.

Products

Consists of one or more parts (HW) according to a Product Parts

List. A product has:

a type number

5000 EBL512 G3 c.i.e. Configured for 128, 256 or 512 alarm

points and with or without printer depending on article number.

5001 EBL512 G3 c.i.e. No front panel and no Plexiglas in the

door. Configured for 128, 256 or 512 alarm points depending

on the article number.

an article number is often the same as the type no. but a country

code can be added (e.g. SE for Sweden). If the letters PRT also

are added in the article number the product comes with a printer.

If digits are added to the article number they are showing the

number of alarm points configured (e.g. 5000PRTSE-128).

a product name (e.g. EBL512 G3 CU, 128 alarm points, with

printer)

HW

A HW (e.g. a printed circuit board) has:

a type number (e.g. 5010)

an article number, often the same as the type no. but sometimes a

country code is added (e.g. 5010SE)

1

File name: L:\Retailers\Panasonic Russia\Training 110223_25\EBL512

G3\Documents\MEW01351(Rev -).doc

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

9

a product name (e.g. Main Board 128 alarm points)

a p.c.b. number (e.g. 9290-2B) and can also have a configuration

(e.g. CFG: 2) and a revision (e.g. REV: 1)

sometimes a S/W

S/W

A S/W has:

a version number (e.g. V1.1.x)

sometimes additional information, such as Convention (different

functions / facilities), Language, Number of addresses, etc.

PC S/W

A PC S/W is a program used for programming, commissioning, etc.

(e.g. WinG3). It has a version number (e.g. V1.1.x).

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

10

2 Definitions / Explanations

Definitions / explanations / abbreviations / etc. frequently used or not

explained elsewhere in the document.

2.1 PEWN AB

Panasonic Electric Works Nordic AB

2.2 Alarm points

Units, which can generate a fire alarm (in the control unit), i.e. analog

detectors (sensors), conventional detectors, manual call points, etc.

2.2.1 Smoke detector

Analog and conventional photoelectric (optical) smoke detectors are

available.

2.2.2 Sensor

Sensor = Analog detector

2.2.3 Analog detector

Contains an A/D-converter. The Control Unit pick up the digital

values ("sensor values") for each detector individually. All

evaluations and "decisions" are then made in the c.i.e. Analog

detectors are addressable – an address setting tool is used for detector

types 430x.

An analog detector has to be plugged in an analog sensor base (ASB).

2.2.4 Analog (Sensor) Base (ASB)

An analog detector is plugged in an ASB, which is connected to a

COM loop (see below).

2.2.5 Conventional detector

Detector with only two statuses, i.e. normal and fire alarm. The

detector has a closing contact and a series alarm resistor. Normally

plugged in a conventional detector base CDB (see below) connected

to a conventional zone line input, with an end-of-line device. Some

types (e.g. water proof types) are connected directly on zone line.

2.2.6 (Conventional Detector) Base (CDB)

A conventional detector is plugged in a CDB, connected to a

conventional zone line input.

2.2.7 Addressable

A unit with a built-in address device, i.e. each unit is individually

identified, handled and indicated in the c.i.e.

(The unit can be an I/O unit with a zone line input, to which one or

more conventional "alarm points" can be connected.)

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

11

2.2.8 Conventional zone line input / External line

Input intended for one or more conventional alarm points. End-of-line

device in the last alarm point on the line.

2.3 Output unit

Addressable unit with programmable control outputs. Connected to a

COM loop (see below).

2.4 Output / Control output

Defined or programmable function. Relay output or voltage output

(supervised / monitored or not), in the c.i.e. or an output unit

connected on a COM loop.

2.5 Short circuit isolator (ISO)

Addressable unit for automatic disconnection of a part (segment) of a

COM loop (see below) in case of short circuit on the loop.

(According to EN54-2, one ISO is required per 32 alarm points.)

2.6 Display unit (D.U.)

Addressable unit for fire alarm presentation (incl. user definable alarm

text messages, if programmed).

2.7 COM loop

Loop = a cable, with two wires, to which all the addressable units can

be connected. Starts in the c.i.e. and it returns back to the c.i.e.

2.8 Control Unit / C.U. / C.I.E.

Control Unit = Control and Indicating Equipment = Unit to which the

alarm points are connected (via e.g. a COM loop). Indicates fire

alarm, fault condition, etc. Fire Brigade Panel & Control Panel, i.e.

the front, included or not included. Printer included or not included.

2.9 Fire Brigade Panel (FBP)

Unit intended for fire alarm presentation, etc. for the fire brigade

personnel. Can be a part of the control unit (a part of the front) or a

separate unit (external FBP).

In the ext. FBP, a printer can be included or not included.

2.10 Control panel (CP)

A part of the control unit (a part of the front), intended for the building

occupier, service personnel, etc., to "communicate" with the control

unit / system.

2.11 System

One control unit or several control units connected via a TLON

network (co-operating control units).

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

12

2.12 Network / TLON® / LonWorks® / Echelon /

Node / TLON Conn. board / Channel /

Backbone net / Router / Repeater

Brief explanations to the words/expressions to be found in connection

with a "network". See also separate TLON Technical description.

TLON® = TeleLarm Local Operating Network = a LonWorks®- based

network2 for communication between several units/nodes. The

protocol is called LonTalk and the transmission works with doublyterminated bus topology (Echelon FTT-10). To connect a control unit

to the network, a TLON connection board has to be plugged in the

control unit. EBL512 G3 also supports redundant TLON system

communication. In this case two TLON connection boards have to be

plugged in each control unit.

A network can be one channel (FTT-10) or several channels,

connected via routers. (In the TLON Network a sub net = a channel.)

Routers are also used to increase the maximum cable length, node to

node, in a network.

Router or Repeater is the same type of unit (different configuration).

All network programming (configuration) are made with the PC

program "TLON Manager".

2.13 LED

LED (Light Emitting Diode) = Yellow, green or red optical indicator

("lamp").

2.14 External Indicator (Ext. LED)

A unit with an LED. Connected to an ASB, CDB or any detector with

an output for an ext. LED. (In old installations also an ADB.)

Lit when the built-in LED in the detector / base is lit.

2.15 Display / LCD

LCD (Liquid Crystal Display) = Display (in the c.i.e. or Display unit)

for presentation of fire alarms, fault messages, etc. In EBL512 G3 it

is a graphical monochrome LCD (320 x 240 dots) with backlight.

2.16 Door open (Door / Key switch)

In EBL512 G3 there is a door switch, which is activated when the

control unit's door is open. In the ext. FBP 1828 this door switch is

replaced with a key switch.

An open door is indicated in the LCD (i.e. an "open door" icon).

2

LonWorks® = A "summing-up-name" for the market of Echelon

Corporation Inc. technology.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

13

2.17 Site Specific Data (SSD)

The SSD is unique for each installation. All alarm points,

presentation numbers, user definable alarm text messages,

programmable outputs, etc. are created in the PC program WinG3 and

also downloaded in EBL512 G3 with WinG3.

2.18 Software (S/W) / System program

The S/W (firmware) makes the control unit (the microprocessor)

work. It is factory downloaded but a new version can, via the PC

program WinG3, be downloaded in EBL512 G3 on site.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

14

3 Overview

3.1 The EBL512 G3 system

EBL512 G3 is a microprocessor controlled intelligent fire alarm

system, intended for analog addressable smoke detectors, as well as

conventional detectors and manual call points. Programmable control

outputs and output units are available. Up to 1020 addresses (of

which up to 512 can be alarm points) can be connected to each control

unit (c.i.e.) - according to EN54-2.

EBL512 G3 is available in several types, versions and configurations.

It can be connected to a TLON network, i.e. in a "system" with up to

30 control units. Each control unit has access to all information.

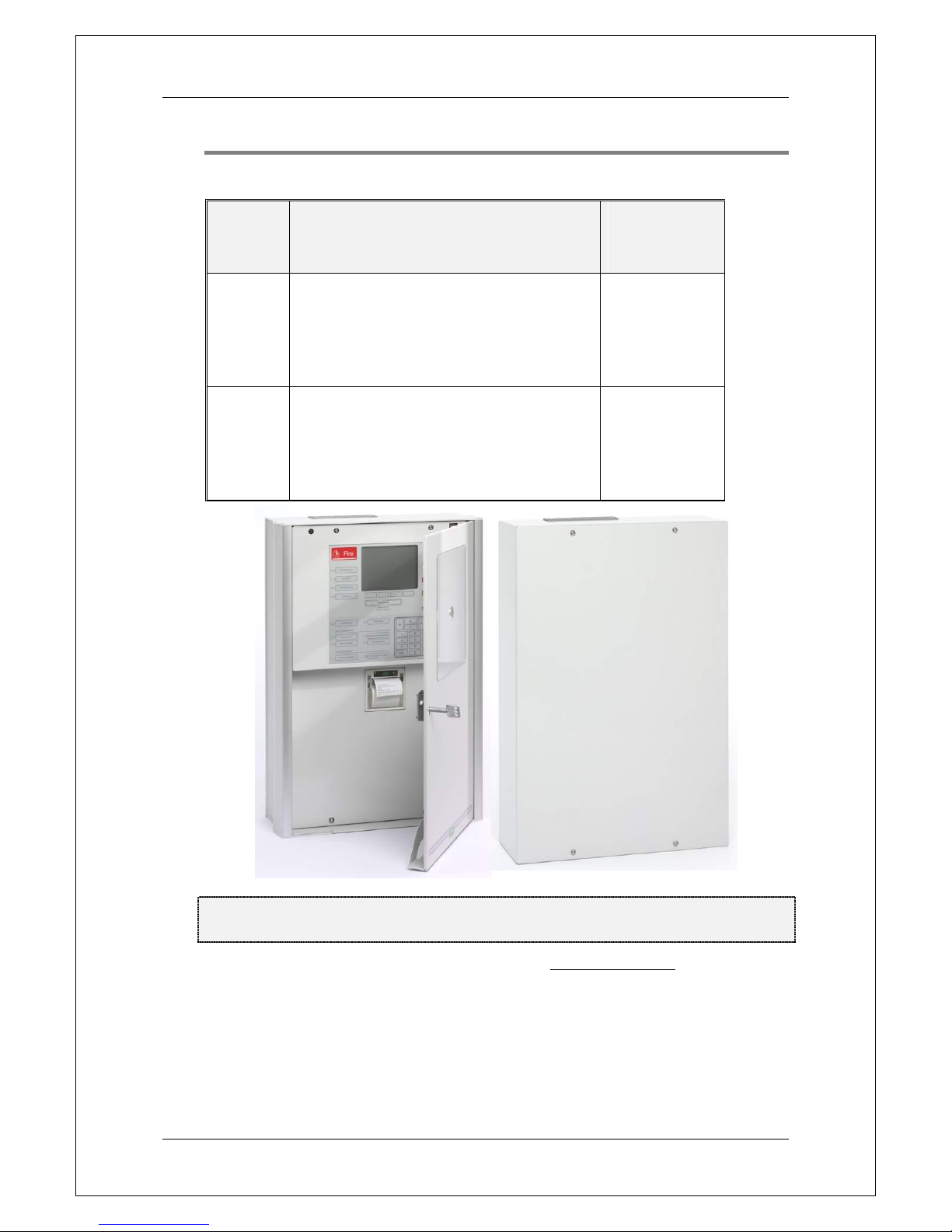

Product type no.

Product name

5000

EBL512 G3 c.i.e. With or without a printer.

With front and display.

5001

EBL512 G3 c.i.e.

Without front, display and printer. No door.

EBL512 G3 is designed according to the European standard EN54,

part 2 and 4. The Swedish front conforms to SS3654.

3.1.1 Printer

The control unit EBL512 G3 type 5000 can be delivered with a printer

("PRN" included in the article number) or without a printer.3

In Ext. Fire Brigade Panel 1826 it is possible to mount an optional

Printer 1535.

3.1.2 Expansion boards

In the control unit (c.i.e.) it is possible to mount up to six expansion

boards. The following types are available:

Product type no.

Product name

Note

4580

8 zones expansion board

4581

8 relay outputs expansion board

4583

In- and outputs expansion board

Regarding the expansion boards, see also chapter "Expansion boards

458x, page 26 and EBL512 G3 drawings.

3.1.3 Power supply

The main power source is a built-in switched power supply (rectifier)

5037. 230 V AC, 1.6 A / 24 V DC, 6.5 A.

The second power source is a backup battery (2 x 12 V). In the c.i.e.

3

Printer 5058 is a spare part for the c.i.e. type 5000 with a printer, i.e. it

comes without a mounting frame etc.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

15

is space for two 28 Ah batteries. Larger batteries (up to 65 Ah) have

to be placed outside the c.i.e.

The batteries and the power supply are connected to the Main board

(5010), which handles the charging of the batteries, etc. See chapter

"Power supply", page 152 for more information.

3.2 S/W versions

Due to continual development and improvement, different S/W

versions can be found. When installing a new control unit in a system

with "older" control units, you might have to update the S/W in the

old control units (or download an older version in the new control

unit). The same S/W version is required in all control units in a

TLON network.

3.3 Documents

The following documents are available:

Planning Instructions

Operating Instructions MEW01163

Drawings

Normally, information found in one of the documents is not found in

another document, i.e. the documents complement each other.

3.4 Applications

The EBL512 G3 system is intended for small, medium and large

installations. The intelligent control units offer the system designer

and end user a technically sophisticated range of facilities and

functions. Programming (PC software WinG3 and TLON Manager)

and commissioning of the control units / system is very easy.

Start with one control unit and then later when it is required, add more

units. The TLON network makes it possible to install the control units

in one building or in many buildings.

3.5 PC software (S/W)

The following PC software is used together with the EBL512 G3

system.

3.5.1 WinG3

WinG3 is used for programming and commissioning of one or more

control units, i.e. to:

create and download / make a backup of site specific data (SSD)

download new software / settings / conventions / configurations /

control unit & system properties / etc.

create and download the user definable alarm text messages

shown in the display in the control units / ext. FBPs and other

Display Units.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

16

WinG3 shall have the same version number as the EBL512 G3

software version number, e.g. 1.1.x and 1.1.x respectively. (x

indicates only a small correction and is not required to be the same.)

Old SSD files can be opened in a newer (higher) version of WinG3,

saved, edited and thereafter downloaded to an EBL512 G3 with the

corresponding version.

3.5.2 TLON Manager

TLON Manager is used for the TLON Network programming, i.e

data / addresses / etc.

3.5.3 WebG3 IConfig tool

A PC tool, WebG3 Config tool is used for configuration of the Webserver II (1598).

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

17

4 Control Unit / TLON Network

4.1 The TLON network

An installation (a system) can be one control unit (c.i.e.) or up to 30

control units connected in a TLON Network.

In a TLON Network each control unit works independent but has

nevertheless total access to all information in the system.

NOTE!

In a system with two or more control units in a TLON Network, pay

attention to the following:

A zone must not be distributed over the system, i.e. all alarm

points in a zone have to be connected to one c.i.e.

When the "Fire door closing" function is used, the alarm points

and their "belonging" output must be connected to the same c.i.e.

When the interlocking function is used, the input, the output and

the Interlocking Combination (area-point) must be in / connected

to one c.i.e. An input and an output can only be used in one

Interlocking combination.

When the AAF function is used, all devices within the same AAF

zone must be connected to the same c.i.e.

4.2 Single TLON Network / redundant TLON

Network

The EBL512 G3 system can be build up as a single TLON Network or

a redundant TLON Network.

In the single TLON Network, one TLON connection board (1590) has

to be plugged in each control unit whereas in the redundant TLON

Network, two TLON connection boards have to be plugged in each

control unit.

In the single TLON Network, only one network is available (Network

no. 0) but in the redundant TLON Network, two networks are

available (Network no. 0 and Network no. 1).

The redundant TLON Network supports full functionality also in case

of a network fault (i.e. open circuit or short circuit) in one of the

TLON networks. A fault in one of the TLON Networks generates the

following fault:

FAULT: Control unit xx has no contact

with control unit xx, network x

Where network x = Network no. 0 or Network no. 1.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

18

NOTE!

In a system where each control unit is independent of the other (i.e.

each control unit works like a "standalone" control unit) a single

TLON Network may be sufficient. To maintain security, in this case:

All control units shall be of type 5000, i.e. including front panel.

The alarm points and their "belonging" outputs shall be connected

to the same control unit.

If fire alarm routing equipment (Fire brigade tx) shall be used,

each control unit in the system shall be able to activate a fire

alarm routing equipment independent of the other control units.

In all other cases and for highest security, a redundant TLON Network

shall be used.

(According to EN54-13, 4.3.1.2: A single fault on a transmission

path connecting one CIE to another CIE, shall not adversely affect the

correct functioning of any part of the networked system.)

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

19

5 Control Units 5000 and 5001

Two types of control units are available:

Type no.

Product

Front

(FBP with

display & CP)

5000

EBL512 G3 c.i.e.

Expansion boards can be mounted (option).

Configured for 128, 256 or 512 alarm points

and with or without printer is depending on

the article number.

Yes

5001

EBL512 G3 c.i.e.

Expansion boards can be mounted (option).

Configured for 128, 256 or 512 alarm points

depending on the article number.

Printer cannot be mounted.

No

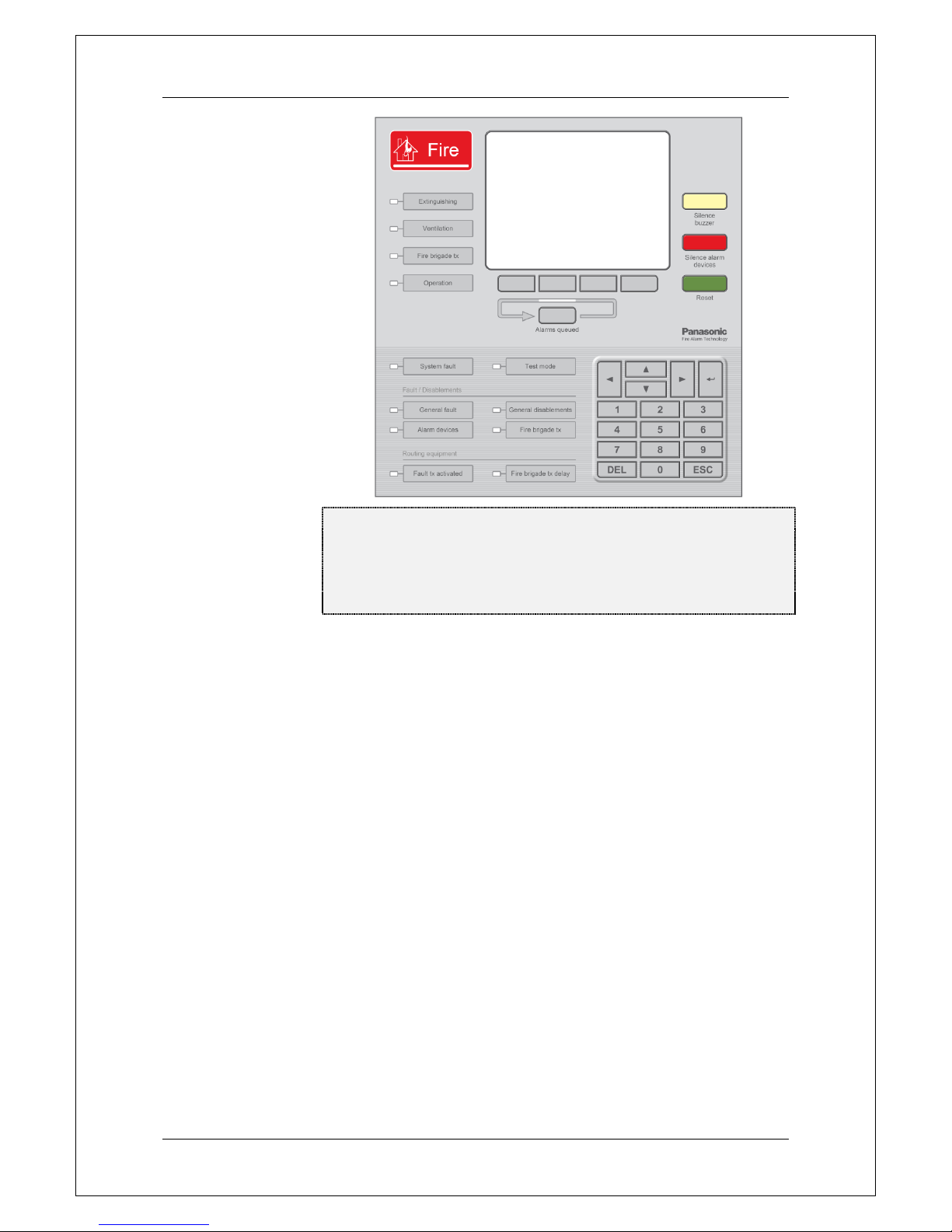

Figure 1. Left: The EBL512 G3 Control Unit 5000, with printer. The look might

vary according to configuration, etc. Right: The EBL512 G3 Control Unit 5001.

The control unit is housed in a grey metal cabinet. Depending on

country, convention, configuration, etc. the look, language and

functions might vary, as well as the max. number of alarm points

(128, 256 or 512). In total, 1020 COM loop units (addresses) can

always be used.

The door in type 5000 has a Plexiglas ahead of the front, see Figure 1

and Figure 2 respectively.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

20

Figure 2. The EBL512 G3 front with display ("Man-Machine-

Interface"); The Fire Brigade Panel (FBP) is the upper part and

the Control Panel (CP) is the lower part. The look might vary

depending on the language, country, etc. (A front with texts in

English is shown in the figure).

The FBP is used by the fire brigade personnel to see which alarm

point(s) / zone(s) having activated fire alarm and to take required

operational control of the system. In the graphical display, the

information displayed in the upper part is depending on how many

alarm points / zones having activated fire alarm. In the middle part

will the fire alarms be shown, i.e. one alarm point or one zone together

with a user definable alarm text (if programmed) plus some other

information.

External FBPs are also available.

The CP is to "communicate" with the system, i.e. for commissioning,

monthly tests, maintenance, etc. Access codes for different access

levels are required. A keypad is used to get access to the system (a

menu tree with main and sub menus) and for operational control of the

system. The CP has several system status LEDs.

NOTE! Regarding LED indicators, keypad / push buttons / soft keys,

access levels and for more information, see EBL512 G3 Operating

Instructions MEW01163.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

21

Each control unit 5000-5001 has the following basic configuration:

Grey metal cabinet

MMI board (5011) (not in 5001)

EBL512 G3 front with display (not in 5001)

Main board (5010)

Space & connectors for two TLON connection boards (1590).

Four COM loops (0-3) to which the loop units are connected.

Four programmable supervised voltage outputs (S0-S3).

Two programmable relay outputs (R0-R1).

Four programmable inputs (I0-I3).

Six 24 V DC outputs (power supply outputs for Web-server II

(1598), routing equipment and external equipment).

Connections and more information, see dwg. 512 G3 - 22.

Two not programmable relay outputs for routing equipment

(Fire alarm output for Fire brigade tx and Fault condition

output for Fault tx). Connections and more information, see

dwg. 512 G3 - 24.

Battery charger.

Built-in power supply. See chapter "Power supply", page 152.

Connections and more information, see dwg. 512 G3 - 21.

Switched power supply (rectifier), 230 V AC / 24 V DC

(5037).

Space and connection cables for two Sealed Lead-Acid backup

batteries (12 V, 28 Ah).

Space for up to six expansion boards (458x).

See following chapters for more and detailed information.

5.1 Mounting plates

The 5000 and 5001 units are delivered with a mounting plate

approved for mounting on an incombustible wall (e.g. concrete).

5.1.1 Mounting plate for 19" mounting rack, 5020

When the 5000 and 5001 units shall be mounted in a 19" mounting

rack, the standard mounting plate can be replaced with a Mounting

plate for 19" mounting rack 5020.

5.1.2 Mounting plate for inflammable wall, 5021

When the 5000 and 5001 units shall be mounted on an inflammable

wall (e.g. wood), the standard mounting plate should be replaced with

a Mounting plate for inflammable wall 5021, which can be provided

with cable glands.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

22

5.2 COM loops

Each control unit has four COM loops (0-3) to which the loop units

are connected. Connections according to dwg 512 G3 – 25, - 31, - 36,

- 37 & - 38.

On each COM loop can up to 255 COM loop units be connected

(COM loop address 001 – 255). Regarding type and number of COM

loop units in relation to the cable length / type, see dwg 512 G3 – 41

and chapters "COM loop cable length", page 145 and "Current

consumption", page 148.

NOTE! In total, up to 1020 (4 x 255) COM loop units can be used

but only 512 can be alarm points, according to EN54-2.

Each COM loop unit has a COM loop address (e.g. 123) and

depending on the loop number (e.g. 0) and the control unit number

(e.g. 04) each COM loop unit gets a technical number (04 0 123).

Each alarm point and zone line input has a fire alarm presentation

number (Zone-Address), e.g. 001-01. See EBL512 G3 Operating

Instructions MEW01163 for more information.

Break or short circuit on a COM loop

Normally the control unit communicates with the COM loop units in

the A-direction only. In the B-direction is only the COM loop voltage

checked, in order to find a break on the loop.

A break or short circuit on a COM loop will generate a fault in the

control unit within 60-100 seconds (EN54-2 requirement).

A single break (cut-off) on a COM loop (open circuit).

The following will happen:

Since not all COM loop units are found by the control unit, the

communication starts in the B-direction also.

Since it is a single break, all units will now be found by the

control unit. A fault will be generated and a fault message will be

shown in the display:

FAULT: Cut-off loop x, control unit xxSCI nn

<-> SCI nn

NOTE! nn = A, 00, 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11, 12,

13, 14, 15 or B.

Each 10th minute a new attempt is made to communicate in the

A-direction only, i.e. when the break is repaired / corrected, the

communication starts again in the A-direction only, within 10

minutes.

Regarding Fault acknowledge, see the EBL512 G3 Operating

Instructions MEW01163.

Two or more breaks on a COM loop.

The following will happen:

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

23

Since not all COM loop units are found by the control unit, the

communication starts in the B-direction also.

Since it is not a single break, all units will not be found by the

control unit. A fault will be generated for each unit not found and

one or more fault messages will be shown in the display:

FAULT: No reply xxx-xx

Technical number xxxxxx

Each 10th minute a new attempt is made to communicate in the A-

direction only. When the breaks are repaired / corrected, the

communication starts again in the A- direction only, within 10

minutes.

Regarding Fault acknowledge, see the EBL512 G3 Operating

Instructions MEW01163.

Short circuit on a COM loop

The following will happen:

Since the COM loop current will be too high, the communication

will be stopped and the COM loop will be disabled.

A fault will be generated and a fault message shown in the

display:

FAULT: Short-circuit SCI nn <-> SCI nn,loop

x, control unit xx

NOTE! nn = A, 00, 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11, 12,

13, 14, 15 or B.

Each 10th minute a new attempt is made to re-enable the COM

loop. When the short circuit is repaired / corrected, the

communication starts again in the A-direction only, within 10

minutes.

Regarding Fault acknowledge, see the EBL512 G3 Operating

Instructions MEW01163.

NOTE! If one or more Addressable short circuit isolators (4313) are

used4, the loop will be divided into "segments" (i.e. the part between

two short circuit isolators or between the control unit and one short

circuit isolator). Only the affected segment will be isolated, which

will minimise the number of units disabled by a short circuit.

The fault messages will also show between which isolators the short

circuit or the double breaks are situated, e.g.:

FAULT: Short-circuit SCI 02 <-> SCI 03, loop

0, control unit 00

If no addressable short circuit isolator (4313) is used, the whole COM

loop will be disabled and the fault message will be (e.g.):

FAULT: Short-circuit SCI A <-> SCI B, loop 0,

control unit 00

4

One short circuit isolator per 32 alarm points is required according to

EN54-2.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

24

5.3 Programmable voltage outputs (S0-S3)

The 24 V DC outputs S0-S3 are supervised (monitored)5.

Connections according to dwg 512 G3 – 23. When all connections are

done a calibration has to be performed, see chapter "Calibration of

supervised outputs", page 110 and the EBL512 G3 Operating

Instructions MEW01163, chapter "Calibration of supervised outputs

(menu H5/A1)".

Each output has to be programmed (via WinG3) regarding:

Type of output, i.e. output for Control, Alarm devices, etc.

Logic, i.e. normally low (default) or normally high (24 V DC)6.

Activation time and type (steady, pulse, delay, etc.).

Control expression (one or more trigger conditions).

See also the WinG3 help and chapter "Programmable outputs", page

68.

5.4 Programmable relay outputs (R0-R1)

Connections according to dwg 512 G3 – 23.

Each output has to be programmed (via WinG3) regarding:

Type of output, i.e. output for Control, Alarm devices, etc.

Logic, i.e. normally open (NO) or normally closed (NC) contacts.

Activation time and type (steady, pulse, delay, etc.).

Control expression (one or more trigger conditions).

See also the WinG3 help and chapter "Programmable outputs", page

68.

5.5 Programmable inputs (I0-I3)

Connections according to dwg 512 G3 – 23.

Each input has to be programmed (via WinG3) regarding:

Trigger condition (Triggered by).

Logic, i.e. normally open (NO) or normally closed (NC) contacts.

Additional information, depending on the selected trigger

condition (Fault no., Zone, Address, Fault message (Error text),

etc.)

Open = R > 2K. Closed 0 R < 2K.

An input has to be activated > 0.5 sec.

See also the WinG3 help and chapter "Programmable inputs", page

62.

5

The outputs are in WinG3 default set as supervised but via WinG3 it is

possible to set each output (S0-S3) individually to be not supervised.

6

A normally high output is not supervised.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

25

5.6 Relay outputs for routing equipment (tx)

Not programmable outputs. The outputs can be tested via menu H1,

see the EBL512 G3 Operating Instructions MEW01163. Connections

according to dwg 512 G3 – 24.

5.6.1 Fire alarm output

This output is normally used for fire alarm routing equipment (Fire

brigade tx). It is a change-over relay contact that will be activated

when a fire alarm is generated in the system7. Activated output is

(normally) indicated by the LED "Fire brigade tx".8

5.6.2 Fault condition output

This output is normally used for fault warning routing equipment

(Fault tx). It is a change-over relay contact that is normally activated

and will be de-activated in case of a fault9 in the control unit (c.i.e.)10.

De-activated output (i.e. fault condition) is indicated by the LED

Routing equipment "Fault tx activated".

7

The output can be disabled via "door open" or via menu H2/B9. See also

chapter "Alert Annunciation", page 100.

8

This output and programmable outputs with type of output = Fire brigade

tx, will normally turn on the LED but a programmable input with trigger

condition = Activated routing equipment, can turn on the LED instead.

9

Also when the control unit is out of power (i.e. power supply and battery

out of work) or Watch-dog fault.

10

The output can be disabled via "door open" or via menu H2/B9.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

26

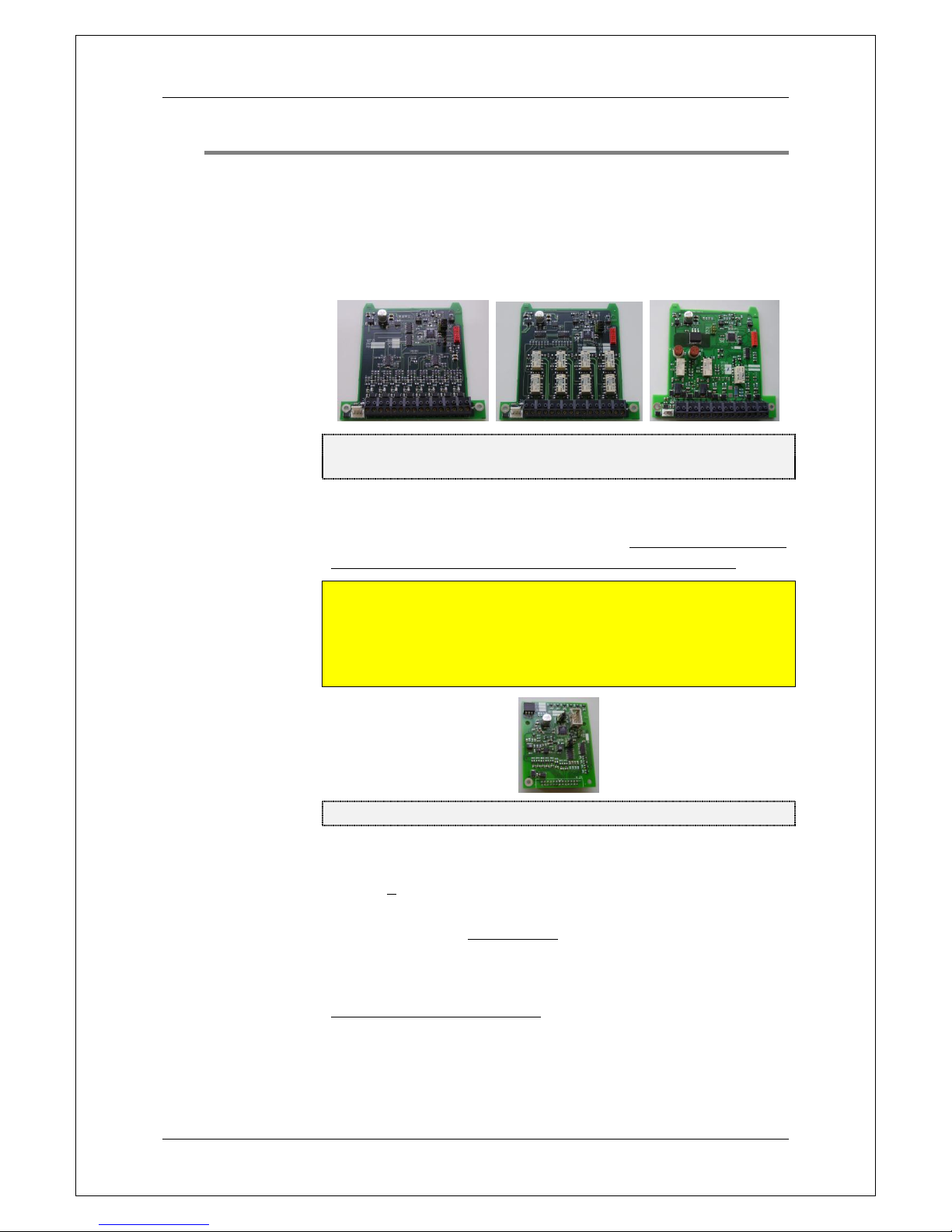

6 Expansion boards 458x

Inside EBL512 G3 (5000 and 5001) there are space and holders for up

to six optional expansion boards of the types 4580, 4581 and 4583 to

be mounted, see drawing 512 G3 - 01. A ribbon cable 5089 shall be

used for connection of up to six expansion board(s) to the main board.

(Connector "J2" on the expansion board respectively and "J9" on the

main board 5010.) See drawing 512 G3 - 26.

Figure 3. 8 zones expansion board 4580, 8 relays expansion

board 4581 and In- and outputs expansion board 4583.

I/O Matrix board 458211 is a special type of "expansion board",

plugged as a "piggy back" to an Application board11, which is

connected to a COM loop and to 24 V DC. On each COM loop 0-3

can up to six 4582 boards be used (i.e. up to 24 boards in total).

NOTE! COM loop 0 is however a special loop, since the exp. boards

4580, 4581 and 4583 actually are internally connected on this loop,

i.e. on COM loop 0 can in total up to six 4580, 4581, 4583 and 4582

boards be used. This means that for each exp. board 4580, 4581 and

4583 used, the number of 4582 boards is reduced with one.

Figure 4. I/O Matrix board 4582.

Max. six of the I/O Matrix boards 4582 can be programmed as type

Generic and/or Zone control.

NOTE! < 200 programmable outputs per c.i.e. can be used.

Each expansion board 4580, 4581 & 4583 and the I/O Matrix board

4582 have to have a board address (board no. 0-5) set via jumpers on

the board respectively. On boards of type 4580, 4581 and 4583

jumpers "JP2-JP4" and on board type 4582 jumpers "JP1-JP3", see

Figure 5, page 27. All the board programming is done via WinG3.

11

The 4582 board can be programmed as type Fan, Generic or Zone control.

It is mostly used with Australian Application boards but the General I/O

application board 4596 and Fan control application board 4594 (used with the

Fan control panel 4593) are available on all markets, see page 51.

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

27

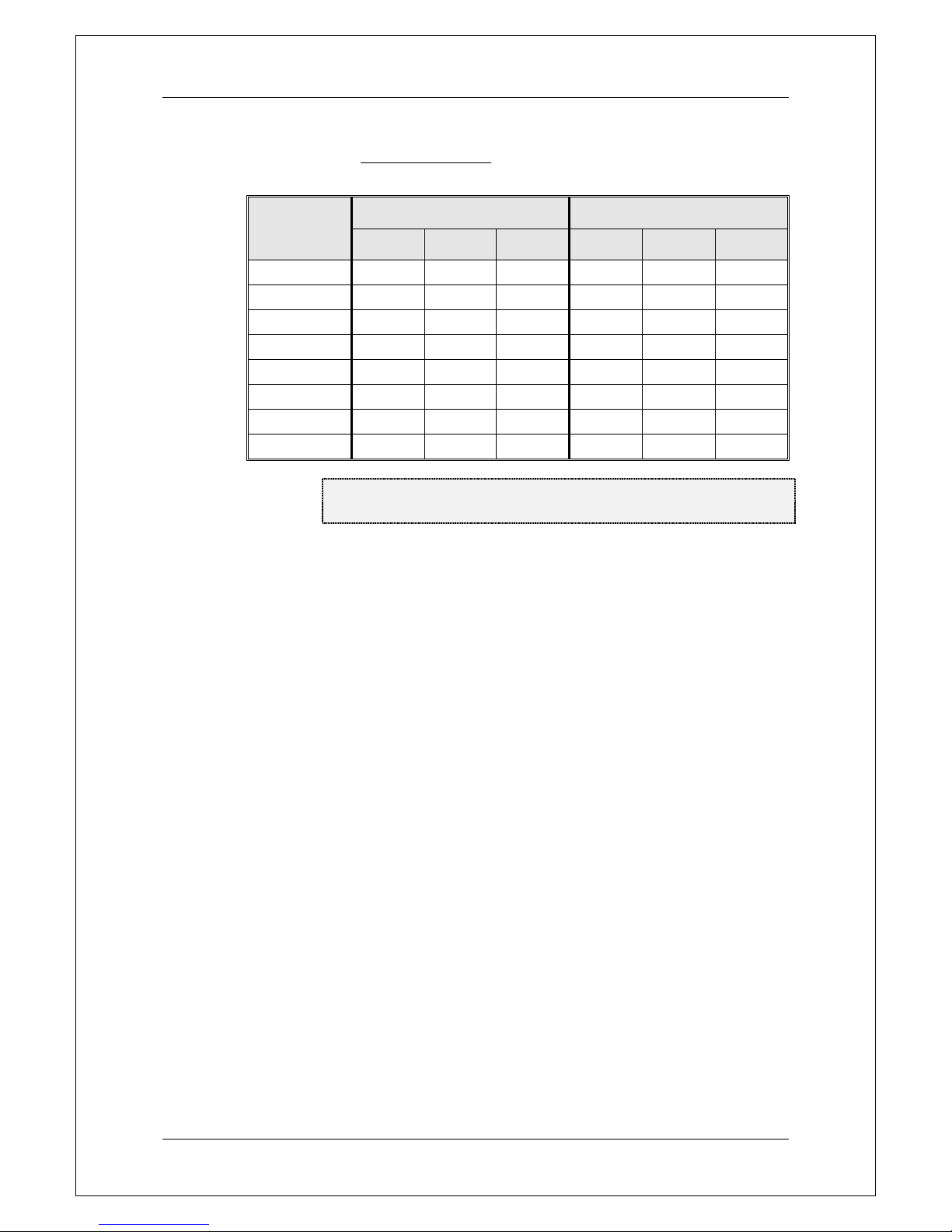

6.1 Expansion board no. (address) setting

The expansion board no. (address) is set via jumpers on the expansion

board respectively.

Board no.

(address)

4580, 4581 and 4583

4582

JP2

JP3

JP4

JP1

JP2

JP3

0

Open

Open

Open

Open

Open

Open

1

Shunted

Open

Open

Shunted

Open

Open

2

Open

Shunted

Open

Open

Shunted

Open

3

Shunted

Shunted

Open

Shunted

Shunted

Open

4

Open

Open

Shunted

Open

Open

Shunted

5

Shunted

Open

Shunted

Shunted

Open

Shunted

Figure 5. Expansion boards 4580 - 4583. Jumpers for

expansion board no. (address) setting.

6.2 8 zones expansion board 4580

Each board has to be programmed via WinG3 regarding:

Address / Board no. (set via the jumpers "JP2-JP4", see Figure 5

above.)

The 4580 board has eight conventional zone line inputs (0-7) intended

for conventional detectors. In the last alarm point on each zone line,

has to be connected an end-of-line device, depending on the selected

"Type of zone line input", see below.

Connections to "J1:1-16" and "J2" according to drawing 512 G3 - 33.

Each zone line input has to be programmed via WinG3 regarding:

Type of zone line input (see below), depending on detectors / end-

of-line device (capacitor or resistor), i.e. different threshold levels

etc.

Alarm at short circuit / No alarm at short circuit (i.e. if short-

circuit on the zone line shall generate a fire alarm or a fault)

Zone number (no address)

Fire alarm delay / No fire alarm delay

Text (Alarm text – if you wish)

Alert annunciation & time channel

Disablement & time channel

For more information, see the WinG3 help.

The terminals support a wire size up to 1.13 mm2 (1.2 mm).

Panasonic Electric Works Nordic AB

MEW01351 Rev: - Planning Instructions Fire alarm system EBL512 G3, V1.1.x

28

6.2.1 Type of zone line input

Each input shall be selected as Not used or one of the following types

/ modes.

6.2.1.1 Zone line input (EOL capacitor)

This type is normally used. It has the lowest zone line current

consumption since the end-of-line device is a capacitor, 470 nF (±10

%). Max. allowed cable resistance is 50 ohm. Max. allowed cable

capacitance is 50 nF. Total detector current consumption < 1.5 mA.

6.2.1.2 EX zone line input (EOL resistor)

This type shall be used only when units for Hazardous (Ex) areas shall

be connected, i.e. via the Galvanic isolator MTL5061 (2820). The

end-of-line device has to be a resistor, 10K (±5 %) with a body

surface area > 230 mm2 (supplied with the Galvanic isolator). Max.

allowed cable resistance is 40 ohm. Max. allowed cable capacitance is

70 nF. Total detector current consumption < 1.5 mA.

6.2.1.3 Zone line input (EOL resistor)

NOTE! Valid for the Australian and New Zealand conventions only.

This type shall be used only when any of the other types cannot be

used (e.g. for some older type of detectors and not Panasonic

detectors). It has the highest zone line current consumption since the

end-of-line device is a resistor, 4K7 (±5 %). Max. allowed cable

resistance is 50 ohm. Total detector current consumption < 2.0 mA.

6.2.2 Input states

Each input will be in one of six different states.

6.2.2.1 Normal state

The normal zone line input state, i.e. no alarm, no fault, etc. and the

nominal voltage is 24 V DC12. From this state any other state can be

reached / activated.

6.2.2.2 High current state

The max. current consumption limit13 for the zone line input is

exceeded, which is indicating that e.g. too many detectors are

connected. This generates a fault condition in EBL512 G3. From this

state any other state can be reached / activated except the open circuit

state.

6.2.2.3 Alarm state

One alarm point (or more) on the zone line is in alarm state and the

alarm limit13 for the zone line is exceeded. This activates a fire alarm

in EBL512 G3. In this state short-circuit, open circuit, high current

12

Allowed voltage 15-28 V DC.

13

This limit is depending on the selected input mode.

Loading...

Loading...