Panasonic MEW00098 User Manual

Panasonic Electric Works Nordic AB

Jungmansgatan 12, SE-211 19 Malmö, Sweden

Tel: +46 (0)40 697 70 00 • Fax: +46 (0)40 697 70 99

info-fste@eu.pewg.panasonic.com • www.panasonic-fire-security.com

Fire alarm systems

Enclosed

addressable manual

call point

3339

Attractive design compliant with EN54-11. IP rating IP56

Test key for routine testing without breaking the glass element

Protection against accidental operation

General

The call point has an attractive design

compliant with EN54-11, and is surface

mounted in the supplied red back box. It has

a clip retained front cover that makes it easy

to replace the glass element and adds

security since the clips are concealed. The

frangible element is a glass element with a

protective plastic film. To operate the call

point, the glass element is pressed until it is

broken. This will activate the built-in micro

switch, which will generate a fire alarm in

the c.i.e.

Test / cover removal key

Routine testing is made with a supplied test

key, without breaking the glass element.

Inserting the test key simulates the breaking

of the glass element. The call point will be

reset when the test key is pulled out. The

test key is also used to release the security

clips for the front cover removal.

Protective cover

To protect the call point against accidental

operation, a transparent polycarbonate flap

has to be lifted to get access to the glass

element.

Encapsulated circuit

All electronics are encapsulated. Only the

terminal block is accessible from the rear.

Mounted in the supplied red back box with

the tightening gasket on place (see the

opposite page), the IP rating is IP56.

LED indicator

An LED on the front cover indicates fire

alarm generated by the call point.

Furthermore it can via Win512 / Win128 be

set to be flashing or non-flashing:

Flashing LED: Is indicating that the c.i.e. is

communicating with the call point. When

the call point is operated the LED will be

turned on continuously.

Non-flashing LED: The LED is turned off

until the call point is operated and the LED

will be turned on continuously.

Connections / Settings

The COM loop is connected directly to the

call point via a 4-way terminal block. For

COM loop address setting is the address

setting tool 3314 used. 3314 is also used to

set the call point type and the LED mode:

NORMAL mode: (EBL512 SW

version >2.0 / EBL128). M.c.p. type

3339. (Flashing or non-flashing LED is

set via Win512 / Win128.)

2330 mode: M.c.p. type 2339, flashing

LED. NOTE! This mode is only used

for backwards compatibility.

2312 mode: M.c.p. type 2339, non-

flashing LED. NOTE! This mode is

only used for backwards compatibility.

Two flying leads (wires) are connected to

the terminal block and shall be used for the

address setting tool's connection cable. The

wires shall be disconnected before the COM

loop wires are connected.

Product applications

Used in the systems EBL512 / 128 / 1000 /

2000 and is intended for indoor use in

premises where IP56 rating is required.

All technical features and data are subject to changes without notice, resulting from continuous development and improvement.

Product Leaflet

Date of issue

Revision / Date of revision

MEW00098

2005-04-14

3 / 2010-03-03

Type numbers

3339

Enclosed addressable manual call point

2347

Replacement glass (10 pcs.)

2348

Replacement polycarbonate flap (10 pcs.)

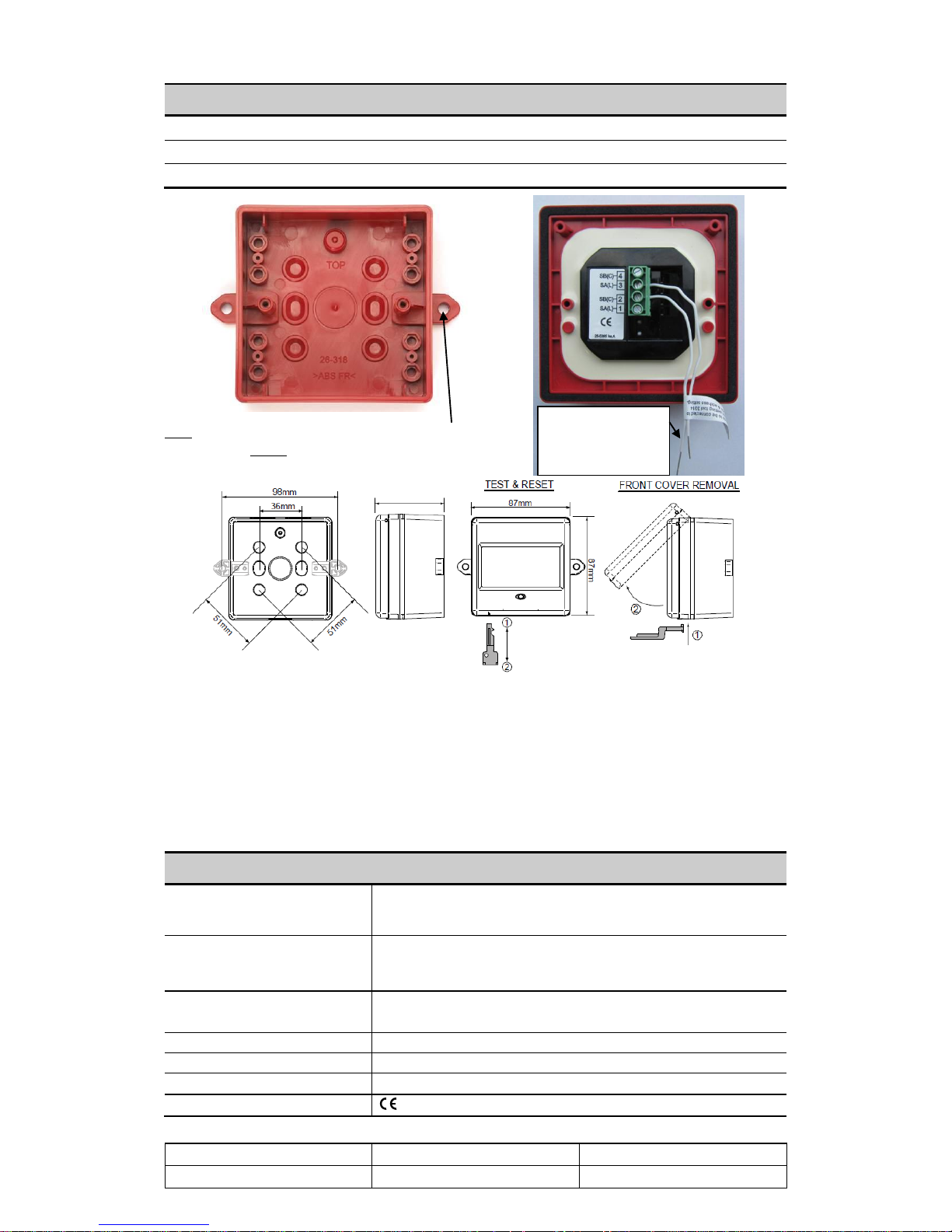

Left: The supplied back box. Mounting lug hole

Ø = 5 mm. Right: The call point backside view

(note the black tightening gasket).

Technical data

Voltage (V DC)

allowed

nominal

12-30

24

Current consumption at nom. volt.

from COM loop (mA)

quiescent / active

2 / 5

Ambient temperature (C)

operating / storage

-10 to +55 / -40 to +85

Ingress Protection rating

IP56

Weight (g)

242

Construction / Colour

ABS / Red (ISO 3864)

Approvals

10 EC Certificate no. 0786-CPD-20918, EN54-11

Flying leads to be

connected to the

Address setting tool

3314 during mode and

address setting

59mm

1)

1)

66mm with the

polycarbonate flap.

How to perform routine testing

Insert the test key into the hole in the front cover.

The glass position will change, indicating

that the call point is operated.

Wait until the LED is turned on, i.e. fire alarm

is activated in the c.i.e.

Pull out the test key and the glass position will

return to normal.

The LED will be turned off when the fire alarm

is reset in the c.i.e.

How to replace the glass element

Lift the polycarbonate flap.

Release the front cover security clips with the test key.

Lift and remove the front cover.

Remove the broken glass element.

Place the top edge of the replacement glass element

against the micro switch plunger and push it upwards

until the glass element is in correct position.

Put back the front cover and lower the polycarbonate flap.

Perform a routine test (see left).

Loading...

Loading...