Panasonic MDF-DU702VH, MDF-DU502VH Service Manual

Service Manual

Ultra-Low Temperature Freezer

MDF-DU502VH

MDF-DU702VH

Panasonic Healthcare Co., Ltd.

Biomedical Div.

SM0000002-03

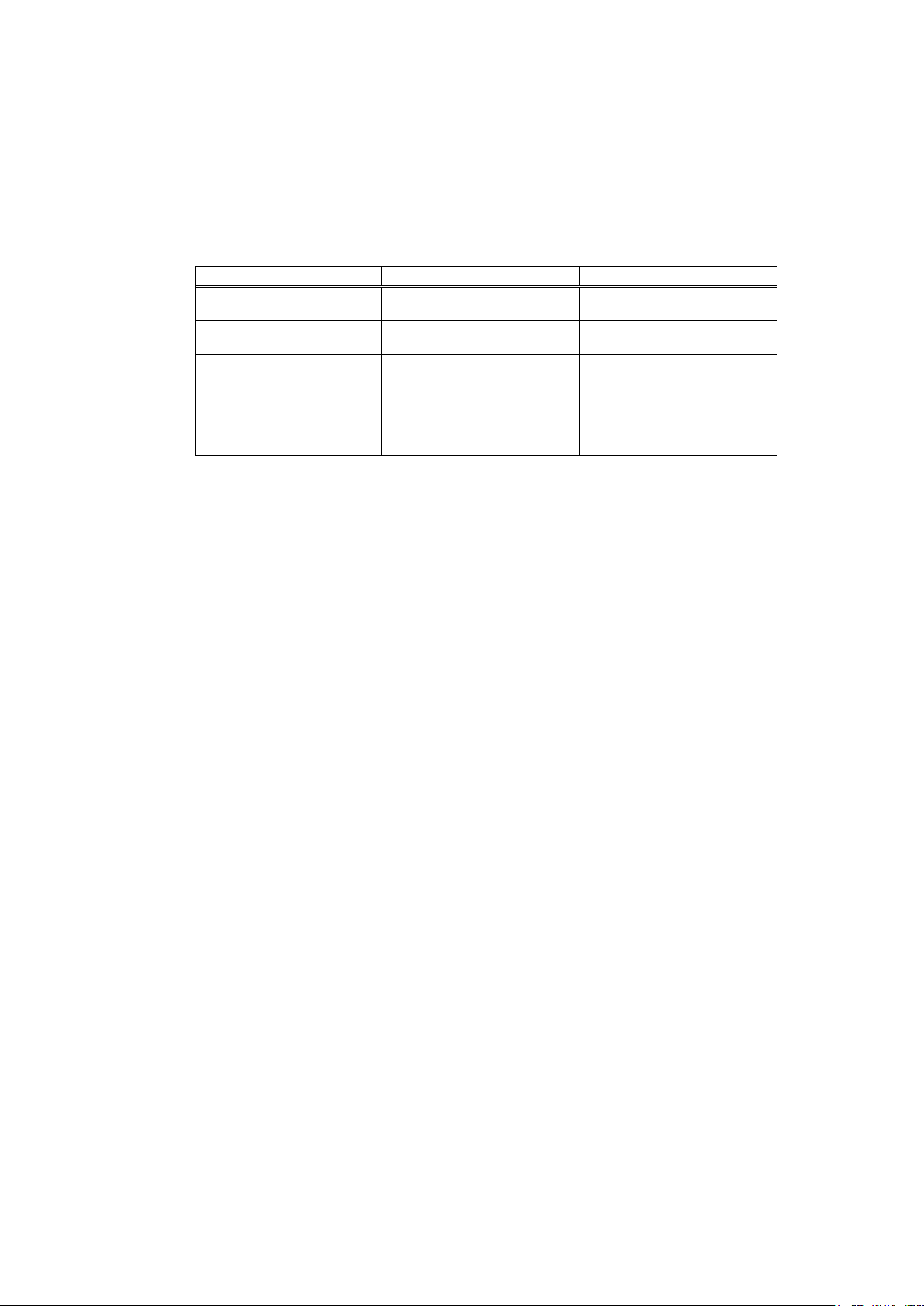

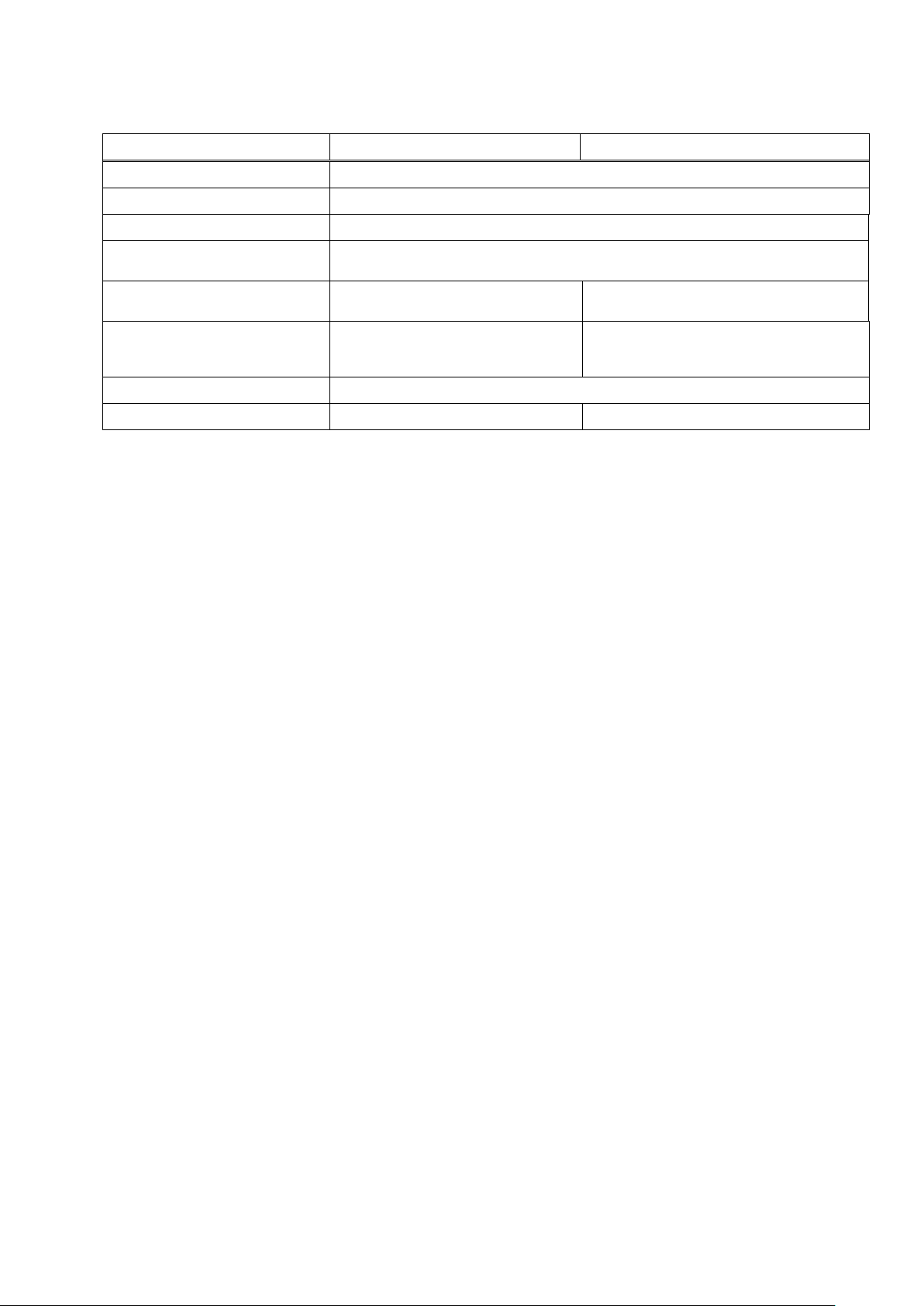

Effective model

This service manual is effective for following models.

Model

Voltage

Frequency

MDF-DU502VH-PA

220V

60Hz

MDF-DU502VH-PE

220V/230V/240V

50Hz

MDF-DU702VH-PA

220V

60Hz

MDF-DU702VH-PE

220V/230V/240V

50Hz

Contents

Page

Features, Caution

----------------------------------------------------------

1

S p e c i f i c a t i o n s

----------------------------------------------------------

2

-Structural s p e c ifications

-Control spec if i c ations

-Performance s p ecificat i ons

D i m e n s i o n s

----------------------------------------------------------

5

Cooling unit parts

----------------------------------------------------------

7

R e f i r i g e r a t i o n c i r c u i t s

--------------------------------------------------

9

C o m p o n e n t s o n P C B

--------------------------------------------------

10

C o n n e c t i o n s o n P C B

--------------------------------------------------

11

E l e c t r i c p a r t s

-------------------------------------------------------

12

Sp e c i f i c a t i o n of s en s or

--------------------------------------------------

13

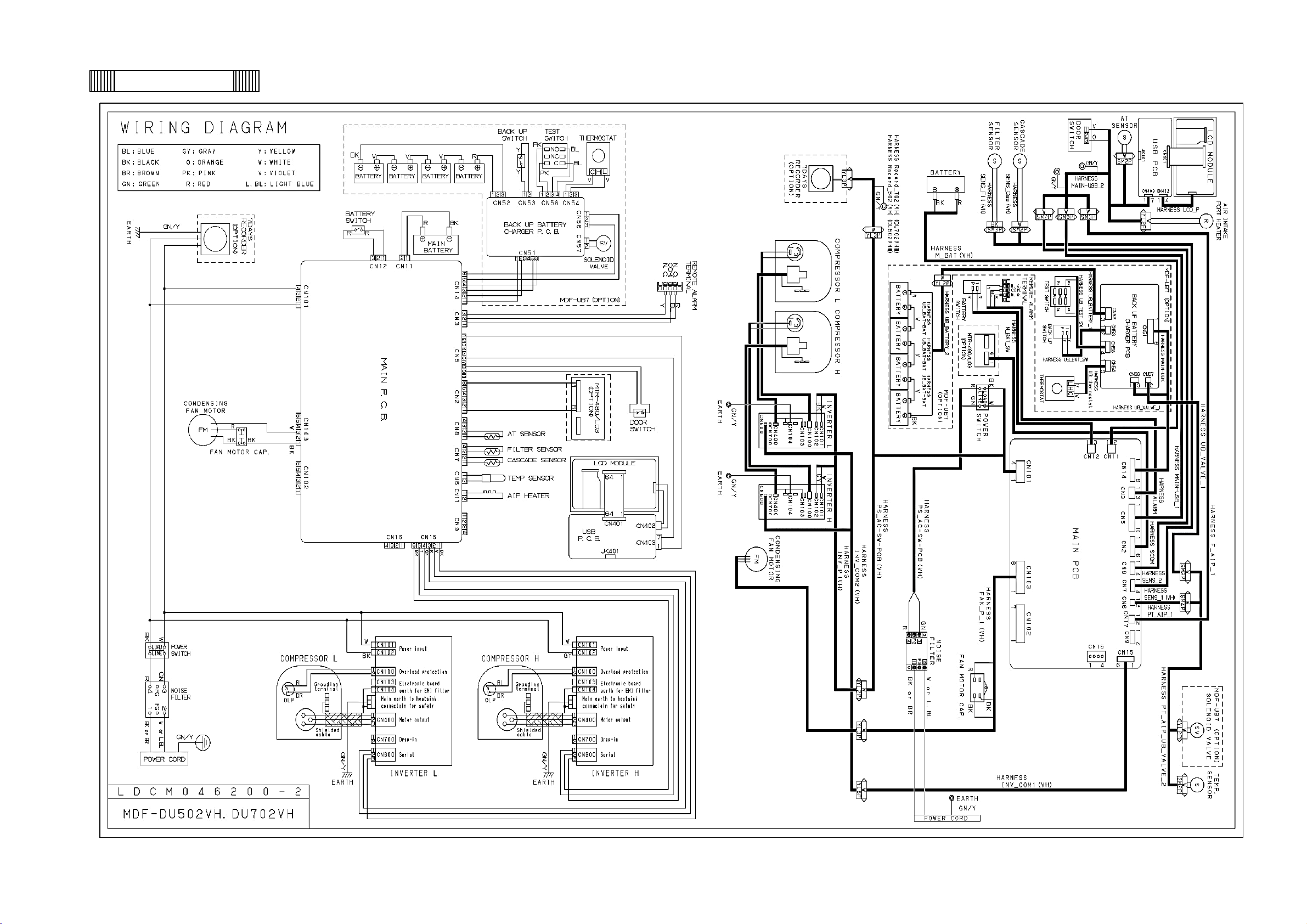

W i r i n g d i a g r a m

-------------------------------------------------------

14

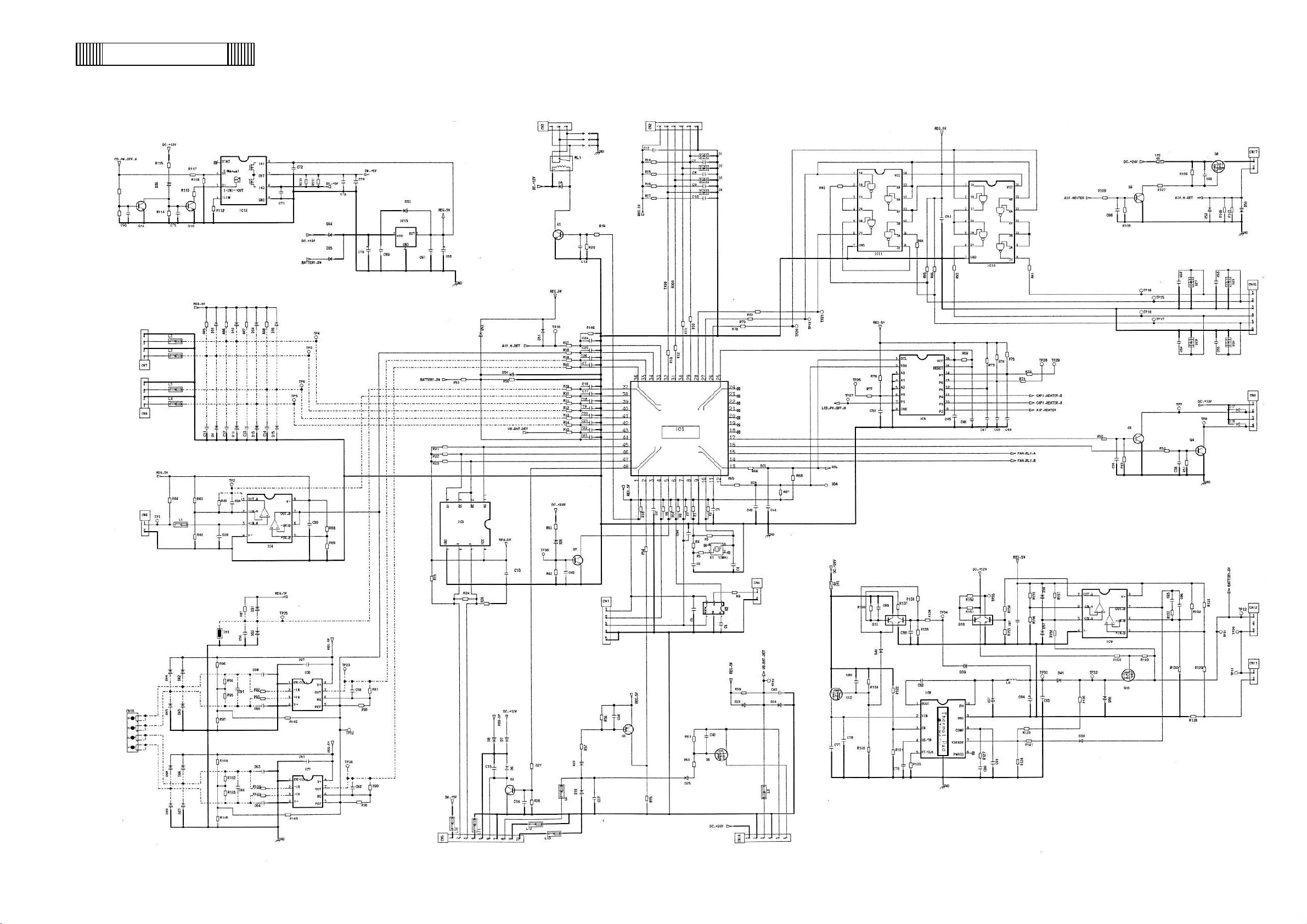

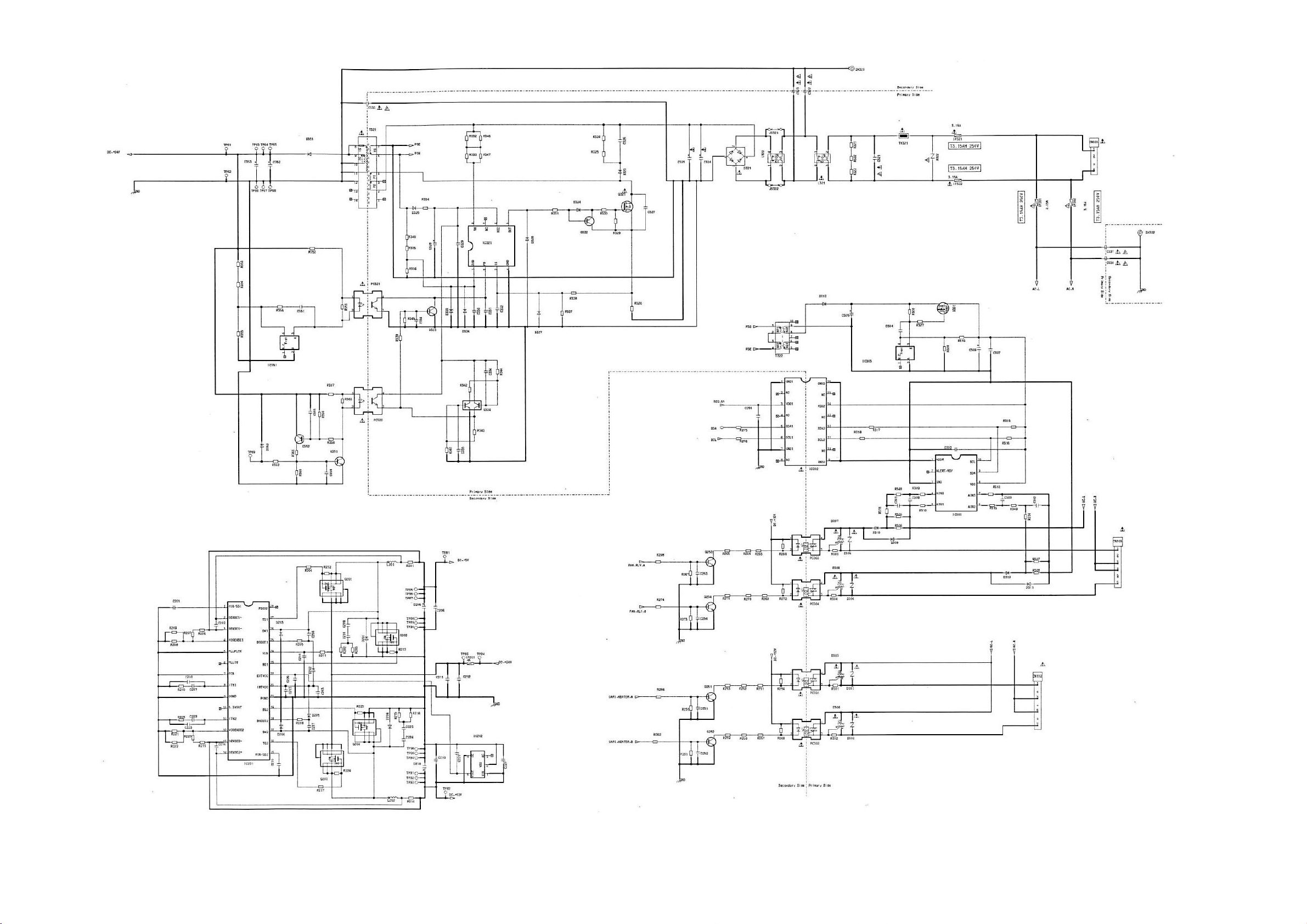

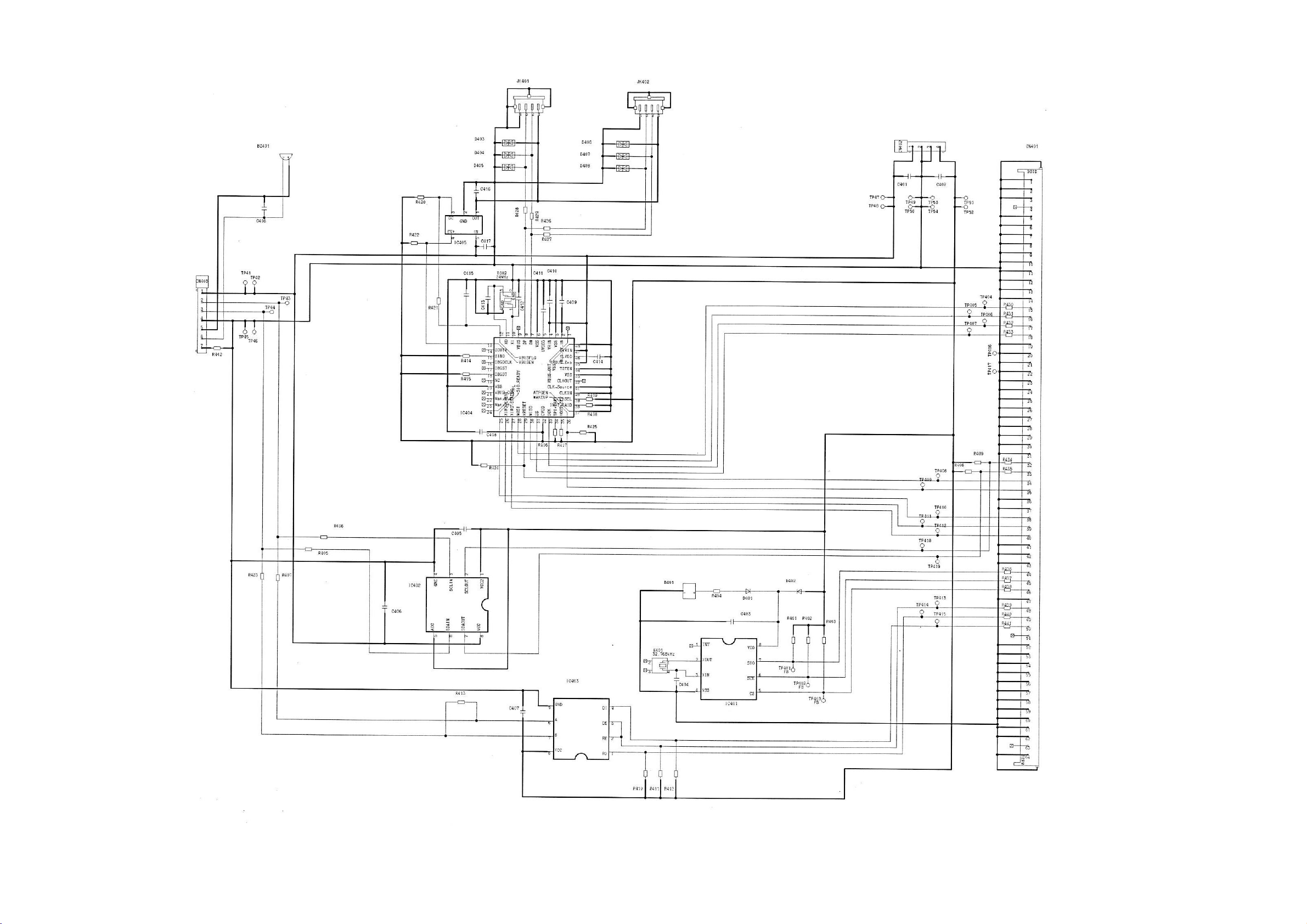

C i r c u i t d i a g r a m

-------------------------------------------------------

15

O p e r a t i o n

------------------------------------------------------- - - ----------

18

C o n tr o l s p e c if i c a t i o n s

---------------------------------------------------

25

I n v e t e r s i g n a l

----------------------------------------------------------

33

P a r t s l a y o u t

----------------------------------------------------------

34

R e p a i r i n g u n i t / G a s c h a r g e

------------------------------------------

36

T e s t d a t a

----------------------------------------------------------

52

MDF-DU502VH, MDF-DU702V H

-Pull-down & P ull-up tem p e r ature

-Pull-down t e m perature

-Pull-down p r e s sure

-Pull-down c urrent-inp u t

-Temperature u n iformit y ( 1 7points meas u r e d)

-Amount of po w e r consumpti o n

-Cycle runni ng

Bac kup cooli n g kit instal la t ion and sett i n g procedure

---------------

64

F e a t u re s

Energy saving

Inverter control of compressor

Improvement of storage efficiency

Auto air intake port

Enhancement of safety functions

New control panel with LCD touch panel

Caution

*Parts replacement and option unit installation must be done by trained service engineer.

*Service engineer must refer to the section “Electric parts” and “Cooling unit parts”

about the parts for those operations.

-1-

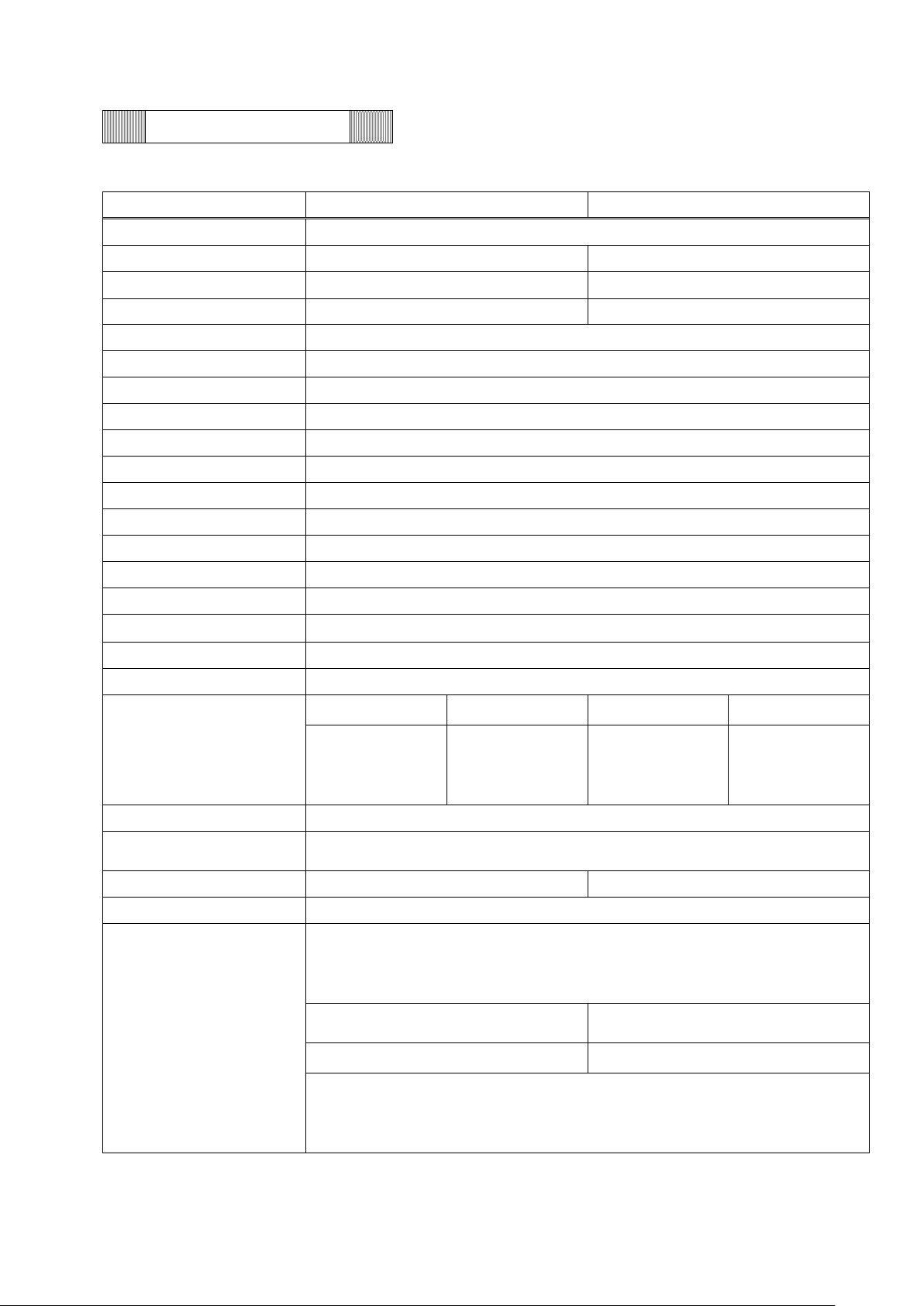

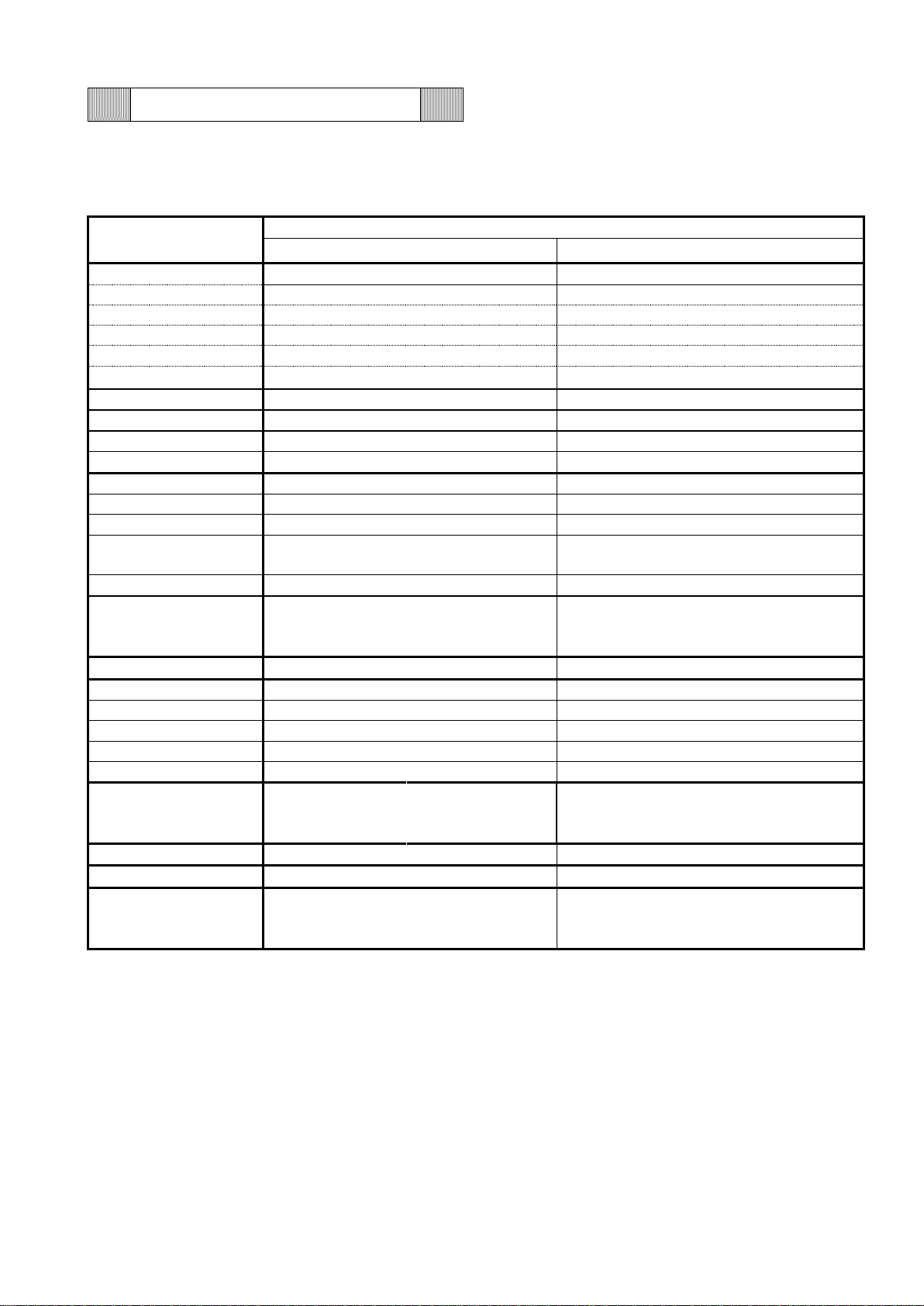

Specifications

Structural specifications

Item

MDF-DU502VH

MDF-DU702VH

Name

Ultra-Low Temperature Freezer

Exterior dimensions

W 790 × D 882 × H 1993 mm

W 1030 × D 882 × H 1993 mm

Interior dimensions

W 630 × D 600 × H 1400 mm

W 870 × D 600 × H 1400 mm

Effective capacity

528 liters

729 liters

Exterior

Painted steel

Interior

Painted steel

Outer door

Painted steel

Inner door

2

Shelf

3

Outer door latch

1

Outer door lock

1

Insulation

Rigid polyurethane foam+VIP PLUS

Access port

3 (back x 1, bottom x 2)

Auto air intake port

Inside of control panel (built-in anti freezing heater)

Manual air intake port

Product left side lower part

Compressor

VNEU213U (single-phase 220-240V 50/60Hz)x 2

Evaporator

High: Cascade, Low: Tube on sheet

Condenser

High: Fin and tube, Low: Cascade

Refrigerant

High Temp. side

Low Temp. side

High Temp. side

Low Temp. side

R290 135 g ±5 g

R170 70 g ±3 g

n-pentane 10 g

(16cc) 0+3 g

(12.5%wt)

R290 135 g ±5 g

R170 85 g ±3 g

n-pentane 12 g

(19cc) 0+3 g

(12.5%wt)

Refrigerant oil

Ze-NIUSL22SA

Battery

For power failure alarm, Lead storage battery, DC6 V 7200 mAh,

Auto-recharge

Weight

246 kg

278 kg

Accessories

1 key, 1 scraper, 1 stick for air intake port cleaning

Optional components

Temperature recorder: (MTR-85H MTR-G85C),

Recorder fixing (MDF-S3085, MTR-85H)

Recorder sensor Cover:(MTR-DU700SF)

Backup cooling kit:(MDF-UB7);For Liquid CO2

Small inner door

(MDF-5ID4, MDF-5ID5)

Small inner door

(MDF-7ID4, MDF-7ID5)

Drawers (MDF-50R)

-

Storage rack (MDF-70SC)

Inventory rack (IR-224U, IR-316U)

Interface board (MTR-L03)*; For LAN

Interface board (MTR-480)*; For RS-232C/RS-485

* For the data acquisition system MTR-5000 user only.

-2-

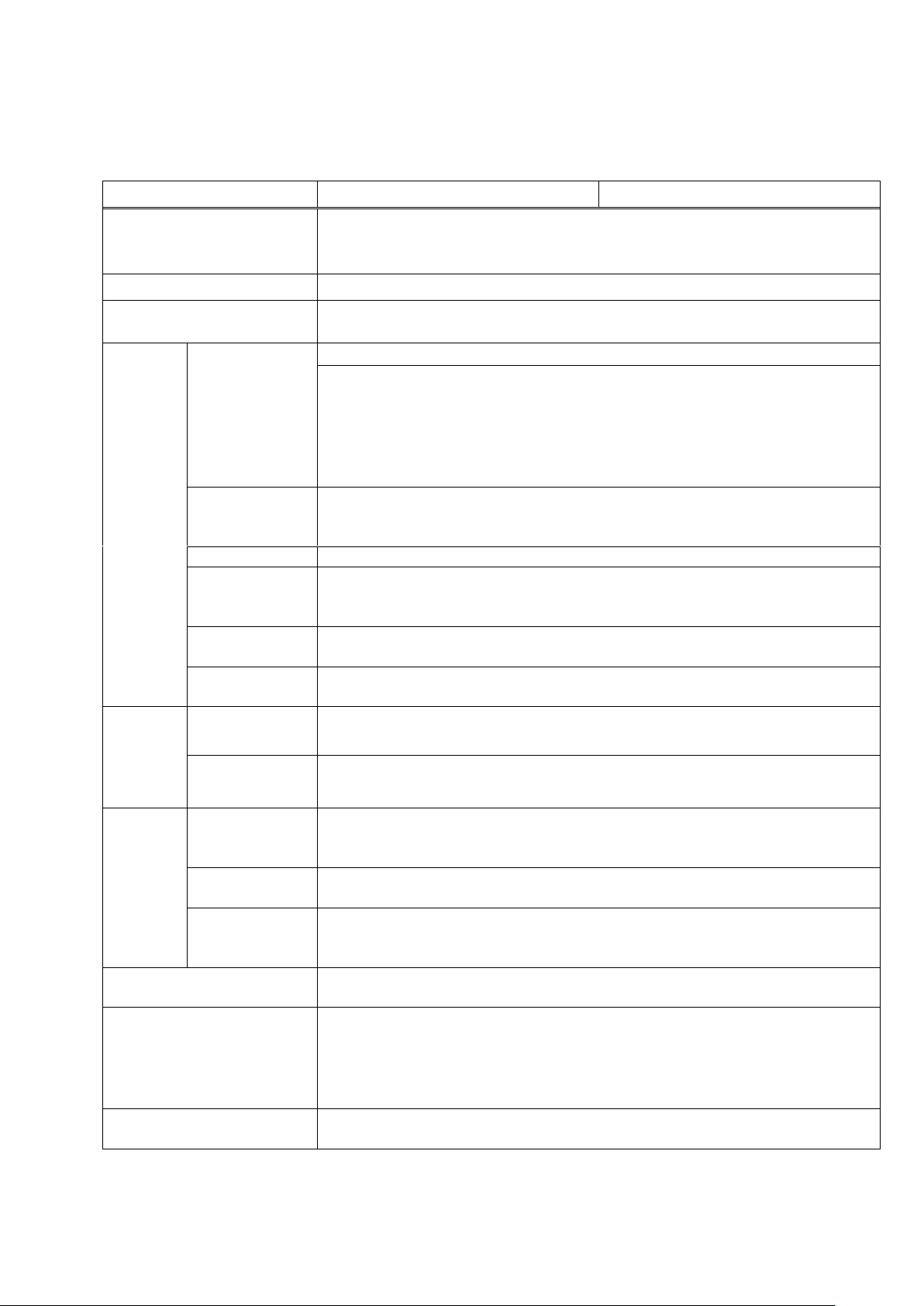

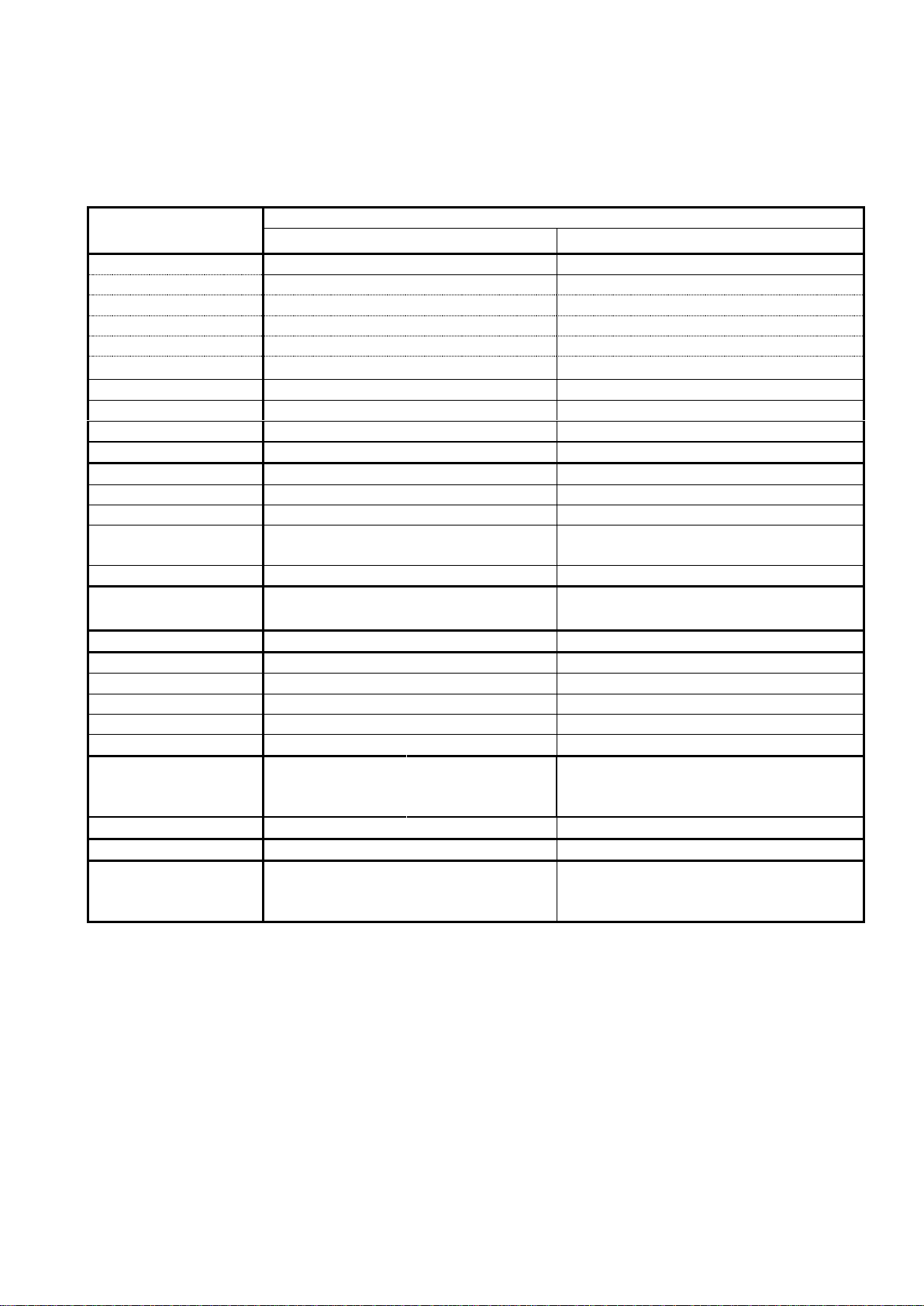

Control specifications

Item

MDF-DU502VH

MDF-DU702VH

Temperature controller

Microprocessor control system: LCD touch panel input

Settable range : -90 ℃~-50 ℃ (unit:1 ℃)

Memorized by Non-volatile memory

Temperature sensor

Platinum resistance (Type: PT 1000 Ω)

Temperature display

WVGA full color LCD

Digital display (Unit: 1 ℃)

Alarms

High / Low

temp. alarm

SV±5 ℃~±40 ℃, changeable (default:±10 ℃)

When the chamber temperature exceeds the alarm set temperature,

"Alarm" is displayed alternately in normal characters and reverse video

in the alarm display field and chamber temperature blinks. After 15 min.

(0-15 min. changeable, default: 15℃), "Warning" is displayed in the

message display field, buzzer beeps and remote alarm activates and

chamber temperature blinks.

Door alarm

When the door opens, "Open" is displayed alternately in normal

characters and reverse video in the alarm display field. After 2 min.

(0-15 min. changeable), buzzer beeps, no remote alarm activates.

Fan lock alarm

No detection function.

Power failure

"Warning" is displayed alternately in normal characters and reverse

video in the alarm display field. And the notification is displayed in the

message display field. Buzzer beeps and the remote alarm activates.

Filter alarm

Filter alarm indicator is lit when the excessive dust is accumulated on

the condenser filter. When this indicator is lit, clean the condenser filter.

Remote alarm

Remote alarm terminal 3P; contact capacity DC 30 V, 2 A (Max)

Remote alarm activates when temp. alarm or power failure occur.

Parts

replacement

notification

Battery age

Two type of battery accumulation time display in service mode. At

replacement time, it is informed in the message display field.

Fan motor age

Fan motor accumulation time display in service mode. Replacement

notification is not performed.

Status

Ambient

temperature

abnormality

When the sensor is out of the range of 35 ℃ from 0 ℃ , the

notification display in the message display field.

Supply voltage

drop

No detection function.

High-load

operation

display

When low side compressor operation rate is over 95 %, the notification

display in the message display field.

Self-diagnosis function

When a sensor is failed, the notification display in the message display

field. Buzzer beeps and remote alarm activates.

Compressor protection

Overload relay (internal)

Detected value of filter sensor is 50 ℃ or more.

"Warning" is displayed alternately in normal characters and reverse

video in the alarm display field and the notification is displayed in the

message display field. Buzzer beeps and remote alarm activates.

Key lock

Selection of ON or OFF by slide in Key Lock mode.

OFF: Unlocked ON: Locked

-3-

Performance specifications

Item

MDF-DU502VH

MDF-DU702VH

Cooling performance

-86 ℃ (AT;30 ℃, no load)

Temperature control range

-86 ℃~-50 ℃ (ambient temperature; 30 ℃, no load)*

Rated voltage

AC 220/230/240 V

Rated frequency

50 Hz (PE)

60 Hz (PA)

Rated power consumption

430 W (Max. 820 W)(PA)

420 W (Max. 840 W)(PE)

545 W (MAX 930W/ 945 W/ 960 W) (PE)

550 W (MAX 930 W) (PA)

Rated heat radiation

1548 kJ/h (Max. 2952 kJ/h)

1512 kJ/h (Max. 3024 kJ/h)

1962 kJ/h

(Max.3348 kJ/h /3402 kJ/h /3456 kJ/h) (PE)

1980 kJ/h (Max. 3348 kJ/h))(PA)

Noise level

52 dB [A] (background noise; 20 dB)

Maximum pressure

2200 kPa

2200 kPa

*Maximum cooling performance.

The chamber temperature can be reached at -86 ℃ at ambient temperature 30 ℃ with no load.

-4-

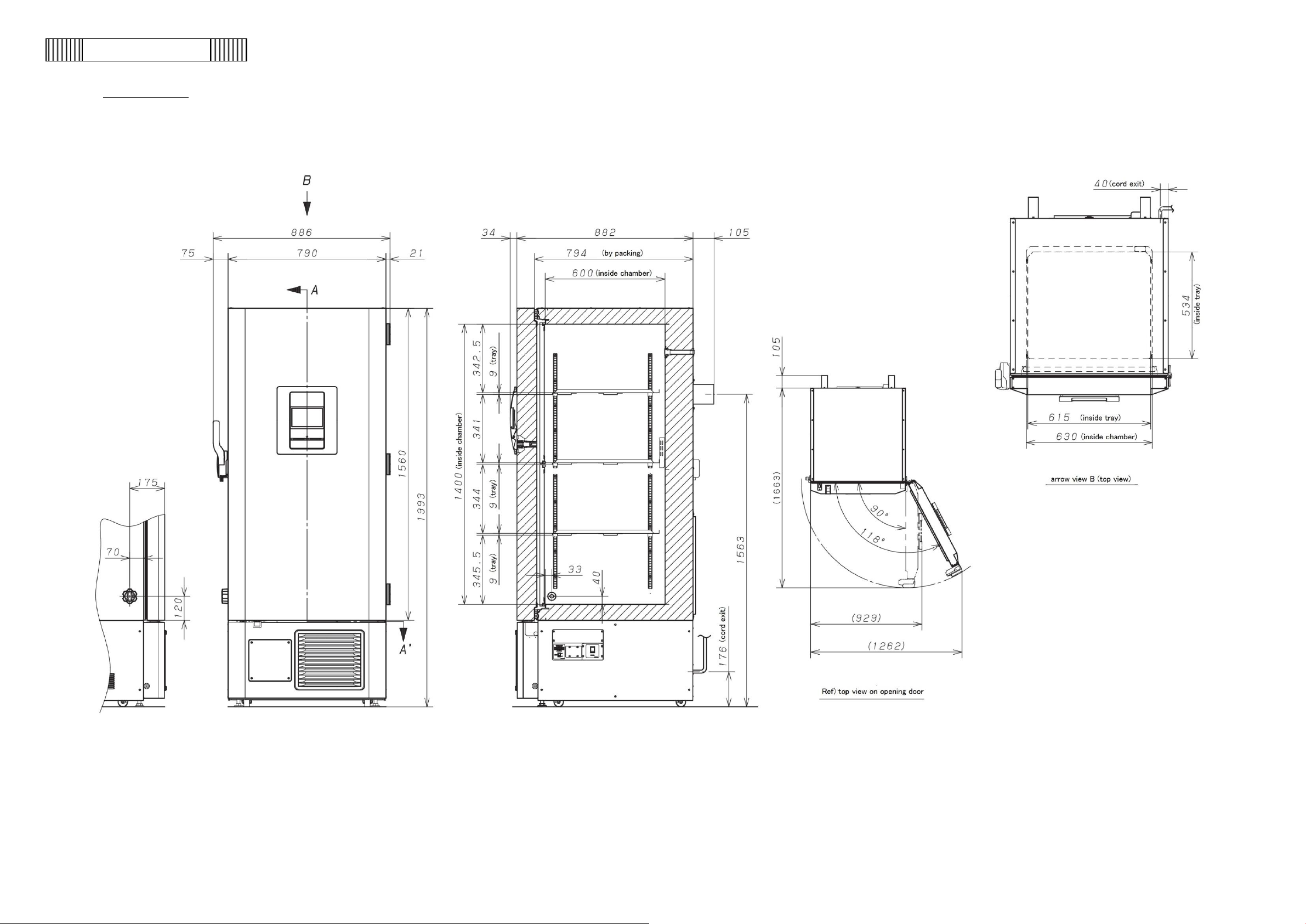

Dimension

MDF-DU502VH

-5-

MDF-DU702VH

-6-

Cooling unit parts

MDF-DU502VH

1Φ220-240V 50/60Hz

Parts description

Specification

Circuit H(Left side at rear view)

Circuit L(Right side at rear view)

Compressor

Type

VNEU213U

VNEU213U

Compressor cord

LDDG000200

LDDG000200

Rated power supply

Single phase, 220-240 V, 50/60 Hz

Single phase, 220-240 V, 50/60 Hz

Refrigeration oil

Ze-NIUSL22SA Q’ty:500 cc

Ze-NIUSL22SA Q’ty:500 cc

Cooling method

Forcible air circulation(partially)

Forcible air circulation(partially)

Inverter

Type

VENEU213U

VENEU213U

Inverter code

LDLB041800

LDLB041800

power supply

220-240 V, 50/60 Hz

220-240 V, 50/60 Hz

Condenser

Type

Finless tube

Finless tube

Condenser

12 columns x 2 lines 5pitch Fin 50spc

Coil pipe Φ6.35 mm

Pre-condenser

W250 mm

(within 1column x6lines pre-con)

Frame pipe

Φ6.35mm

Evaporator

Type

Accumulator

Cascade condenser, Shell & Tube

Φ80 mm

Φ38 mm

Tube on sheet, Φ7.94mm

(Sharing with interior)

Accumulator

Φ38mm

Capillary tube

Resistance

78 PSI

4.0 kg/cm2

Length

3000 mm

2000 mm

Outer diameter

Φ2.4 mm

Φ1.8 mm

Inner diameter

Φ1.2 mm

Φ0.9 mm

Refrigerant

TYPE

R-290

Amount

135g ±5 g

TYPE

R-170

n-pentane

Amount

70g ±3 g

10g (16cc)-0+3g

Dryer

4AXH-9 18 g

4AXH-9 55 g

Condensing fan

Material: ABS Blade: 4 pcs. 230 mm

Material: ABS Blade: 4 pcs. Φ230 mm

Condensing fan

motor

Type

SV4-11AB5P

(440VAC,1.0μF running condenser)

SV4-11AB5P

(440VAC,1.0μF running condenser)

-7-

MDF-DU702VH

1Φ220-240V 50/60Hz

Parts description

Specification

Circuit H(Left side at rear view)

Circuit L(Right side at rear view)

Compressor

Type

VNEU213U

VNEU213U

Compressor cord

LDDG000200

LDDG000200

Rated power supply

Single phase, 220-240 V, 50/60 Hz

Single phase, 220-240 V, 50/60 Hz

Refrigeration oil

Ze-NIUSL22SA Q’ty:500 cc

Ze-NIUSL22SA Q’ty:500 cc

Cooling method

Forcible air circulation(partially)

Forcible air circulation(partially)

Inverter

Type

VENEU213U

VENEU213U

Inverter code

LDLB041800

LDLB041800

power supply

220-240 V, 50/60 Hz

220-240 V, 50/60 Hz

Condenser

Type

Finless tube

Finless tube

Condenser

12 columns x 2 lines 5pitch Fin 50spc

Coil pipe Φ6.35mm

Pre-condenser

W250 mm

(within 1column x6lines pre-con)

Frame pipe

Φ6.35mm

Evaporator

Type

Cascade condenser, Shell & Tube

Φ80mm

Tube on sheet, Φ7.94mm

(Sharing with interior)

Accumulator

Φ38mm

Capillary tube

Resistance

78PSI

4.0 kg/cm2

Length

3000mm

2000mm

Outer diameter

Φ2.4mm

Φ1.8mm

Inner diameter

Φ1.2mm

Φ0.9mm

Refrigerant

TYPE

R-290

Amount

135g ±5 g

TYPE

R-170

n-pentane

Amount

85g ±3 g

12g (19cc)-0+3g

Dryer

4AXH-9 18 g

4AXH-9 55 g

Condensing fan

Material: ABS Blade: 4 pcs. 230mm

Material: ABS Blade: 4 pcs. Φ230mm

Condensing fan

motor

Type

SV4-11AB5P

(440VAC,1.0μF running condenser)

SV4-11AB5P

(440VAC,1.0μF running condenser)

-8-

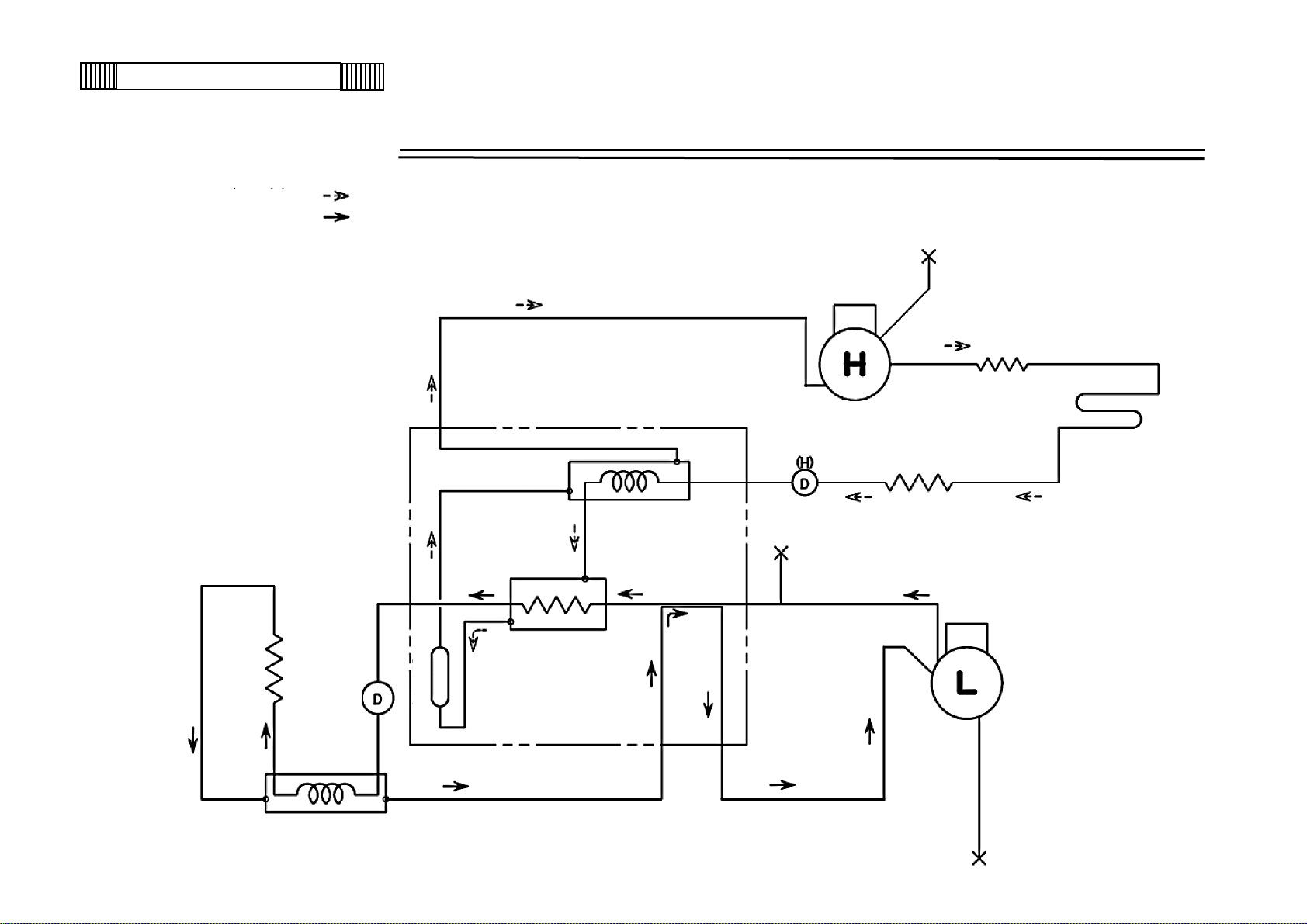

Refrigeration circuit

High temp.

Cascade Condenser

Dehydrator (L)

Evaporator

Pre-Condenser

Cascade

Dehydrator

Frame Pipe

Compressor (L)

Suction heat

exchanger

Capillary Tube (L)

Capillary Tube (H)

Low temp.

Condenser

Compressor (H)

Binary refrigerating cuircuit 〈cascade system〉 〈MDF-DU502VH/DU702VH)

-9-

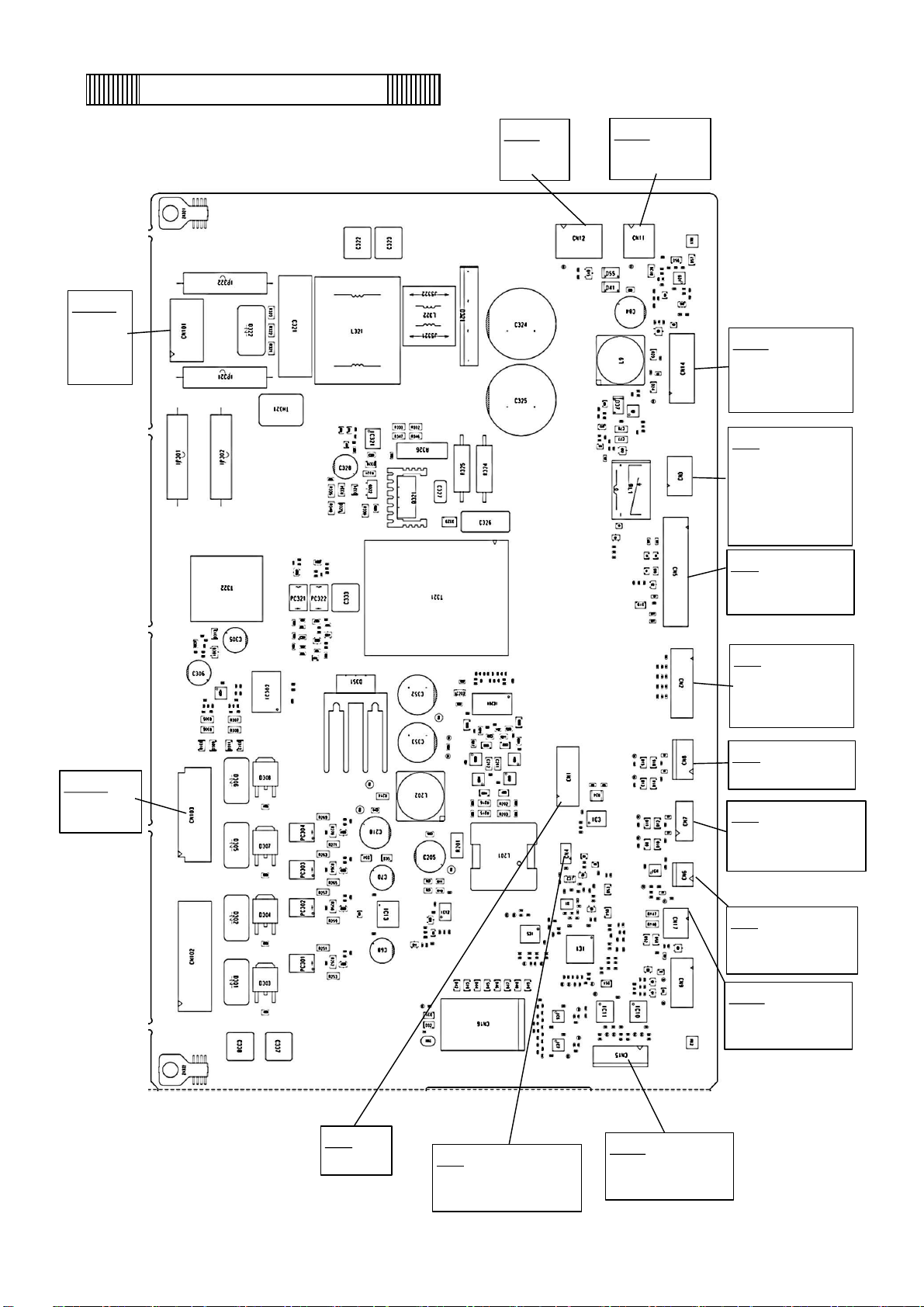

Components on PCB

CN8

#1-#2 AT sensor

CN101

#1,#4

Power SW

Recorder

(option)

CN2

#1-#6

MTR-480,MTR-L03

(option)

CN6

#1-#2

Temp. sensor

CN103

#1,#3:

FM cond.

CN12

#1,#3

Battery SW

CN14

#1-#6

Backup Battery

PCB

CN5

#1,#7:USB PCB

#8,#9:Door SW

CN11

#1,#2

Main Battery SW

CN3

Remote alarm

terminal

#1: COM

#2: N.O.

#3: N.C.

CN7

#1-#2 Cascade sensor

#3-#4 Filter sensor

CN17

#1-#2

AIP heater

CN15

#1-#3 Inverter L

#4-#6 Inverter H

CN4

#1-#2

Jumper for emulator

CN1

Emulator

-10-

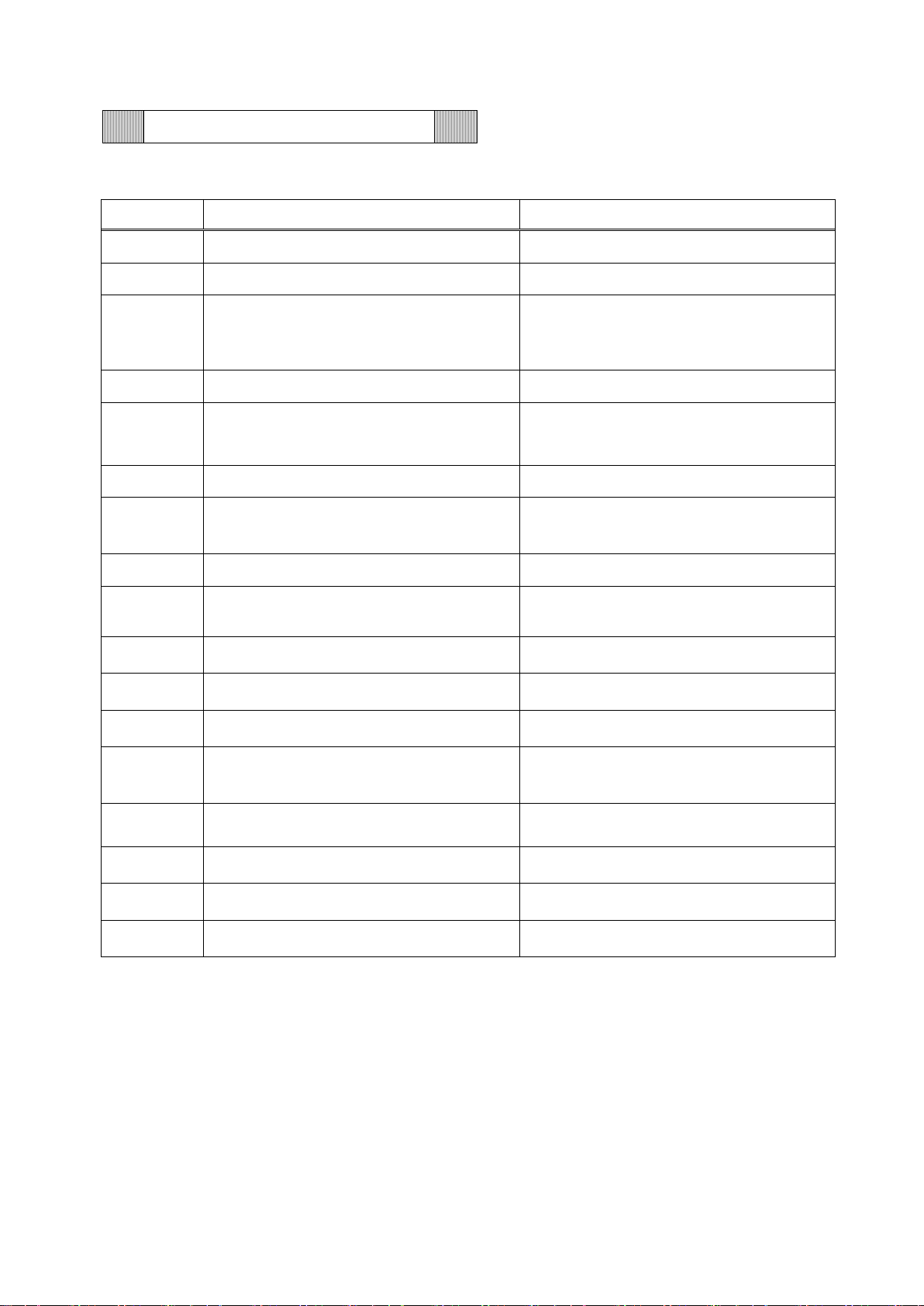

Connections on PCB

The following shows connections of connector on Main PCB.

Connector

Connects to

Usage

CN1

Emulator

To version up firmware

CN2

#1~#6: MTR-480/MTR-L03 (Option)

To connect with MTR-480/MTR-L03.

CN3

Remote alarm terminal

#1: COM

#2: N.O.

#3: N.C.

Remote alarm contact outputs.

CN4

#1~#2 Jumper

To upgrade firmware version

CN5

#1,#7:USB PCB

#8,#9:Door switch

To connect with LCD PCB

To detect door open and shut

CN6

#1~#2:Temp. sensor

To control chamber temperature

CN7

#1~#2:Cascade sensor

#3~#4:Filter sensor

To detect temperature of cascade

To detect temperature of filter

CN8

#1~#2:AT sensor

To detect ambient temperature

CN9

#1~#4:Unused

CN11

#1,#2:Main battery switch

To supply power during power failure

CN12

#1,#3:Battery switch

To supply power during power failure

CN14

#1~#6:Back-up battery charging PCB

To control battery charging

CN15

#1~#3:Inverter L

#3~#6:Inverter H

To control inverter L

To control inverter H

CN16

#1~#4:Unused

CN17

#1,#2: Auto air intake port (AIP) heater

To control AIP heater

CN101

#1,#4:Recorder, Power switch

To supply power to PCB

CN103

#1、#3:Fan motor condenser

To control condensing fan motor

-11-

Compressor(A)(B) Type VNEU213U VNEU213U

Rating

220-240 V, 50/60 Hz 220-240 V, 50/60 Hz

Inverter Type VCCHP2456 VCCHP2456

Rating

220-240 V, 50/60 Hz 220-240 V, 50/60 Hz

Condensing fan motor Type SV4-11AB5P SV4-11AB5P

Rating 230 V,10 W 230 V,10 W

Capi. Tube Heater(A),(B) Rating 230V,12W 230V,12W

MDF-DU702VH Resistance(25℃) 4700Ω 4700Ω

S/N:~18010001 only

Temp. sensoor Type Pt (THC-663) Pt (THC-663)

Rating 1000Ω 1000Ω

Cascade sensor Type 502AT-11 502AT-11

Rating 5 kΩ,25 ℃ 5 kΩ,25 ℃

Filter sensor Type 502AT-11 502AT-11

Rating 5 kΩ,25 ℃ 5 kΩ,25 ℃

Door Switch Type SDKNA20700 SDKNA20700

Rating 5 V 5 mA 5 V 5 mA

Battery Type LC-P067R2J LC-P067R2J

Rating 6 V 7.2 AH 6 V 7.2 AH

Battery Switch

Type SLE6A2-5 SLE6A2-5

Rating 4 A 250 VAC 4 A 250 VAC

Power Switch Type JW-L21RRK-P4G JW-L21RRK-P4G

Rating 16A, 250VAC 16A, 250VAC

Power Cord Plug U3 250VAC 15A K3 250VAC 16A

Length 3.8m 3.5m

ーPA

MDF-DU502VH

MDF-DU702VH

ーPE

Electric parts

-12-

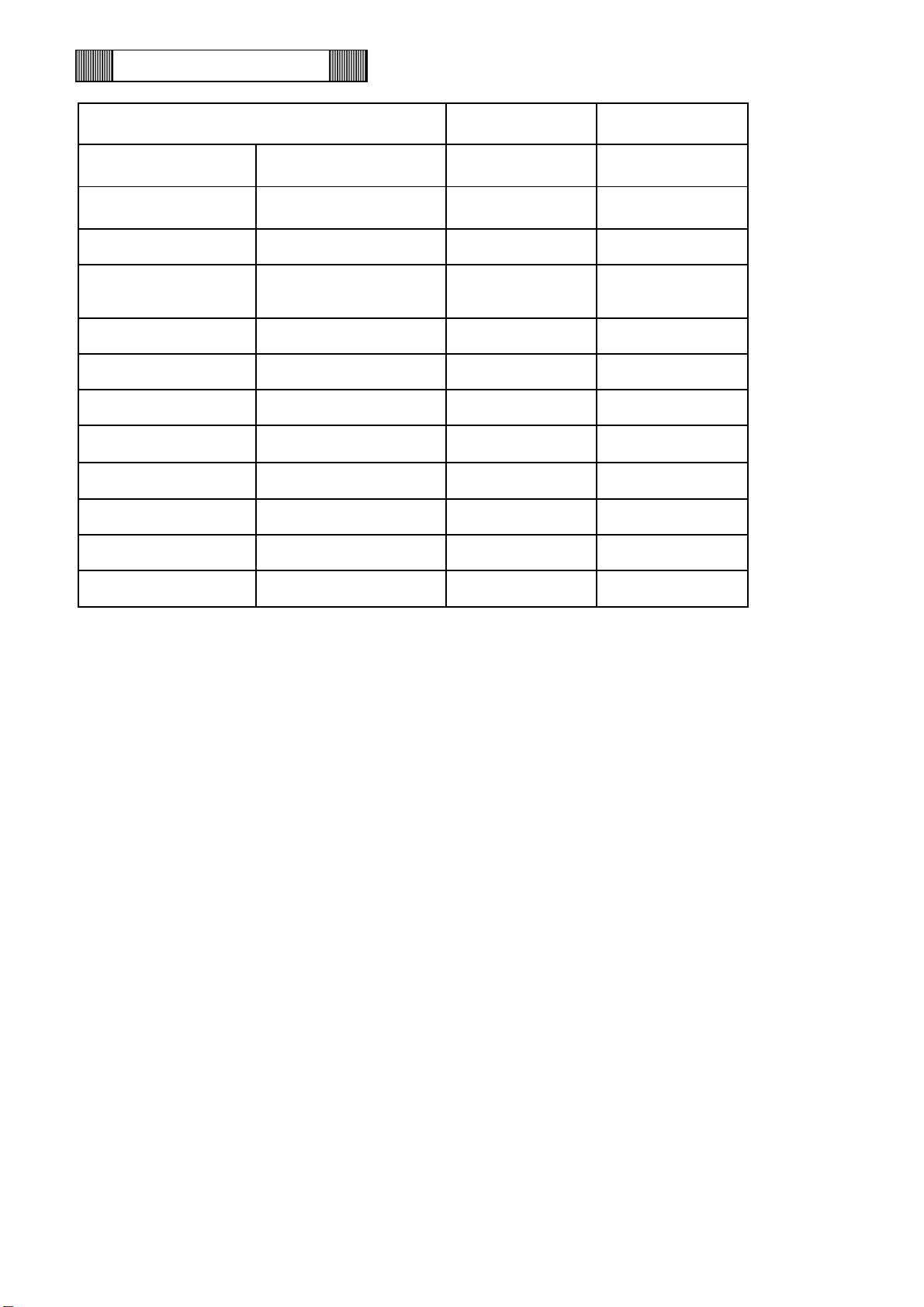

Specifications of sensor

The following shows the temperature in thermal sensor (502AT-11) and its resistance value.

Temp.

(℃)

Resistance

Value (kΩ)

Temp.

(℃)

Resistance

Value (kΩ)

Temp.

(℃)

Resistance

Value (kΩ)

-50

154.6

-7

17.93

12

8.167

-45

116.5

-6

17.16

13

7.853

-40

88.91

-5

16.43

14

7.553

-35

68.19

-4

15.74

15

7.267

-30

52.87

-3

15.08

16

6.993

-25

41.21

-2

14.46

17

6.731

-20

32.44

-1

13.86

18

6.481

-19

30.93

0

13.29

19

6.242

-18

29.51

1

12.74

20

6.013

-17

28.16

2

12.22

25

5.000

-16

26.88

3

11.73

30

4.179

-15

25.66

4

11.25

35

3.508

-14

24.52

5

10.80

40

2.961

-13

23.43

6

10.37

45

2.509

-12

22.39

7

9.960

50

2.137

-11

21.41

8

9.569

55

1.826

-10

20.48

9

9.196

60

1.567

-9

19.59

10

8.840

-8

18.74

11

8.496

The following shows the temperature in thermal control sensor (PT1000Ω) and its resistance value.

Temp.

(℃)

Resistance

Value (Ω)

Temp.

(℃)

Resistance

Value (Ω)

Temp.

(℃)

Resistance

Value (Ω)

-140

452.8

-70

730.3

0

1000.0

-130

493.0

-60

769.3

10

1038.0

-120

533.1

-50

808.1

20

1076.0

-110

572.9

-40

846.7

30

1113.8

-100

612.6

-30

885.2

40

1151.4

-90

652.0

-20

923.6

50

1189.0

-80

691.3

-10

961.9

60

1226.4

-13-

Wiring Diagram

-14-

main

Circuit Diagram

-15-

power

-16-

USB

-17-

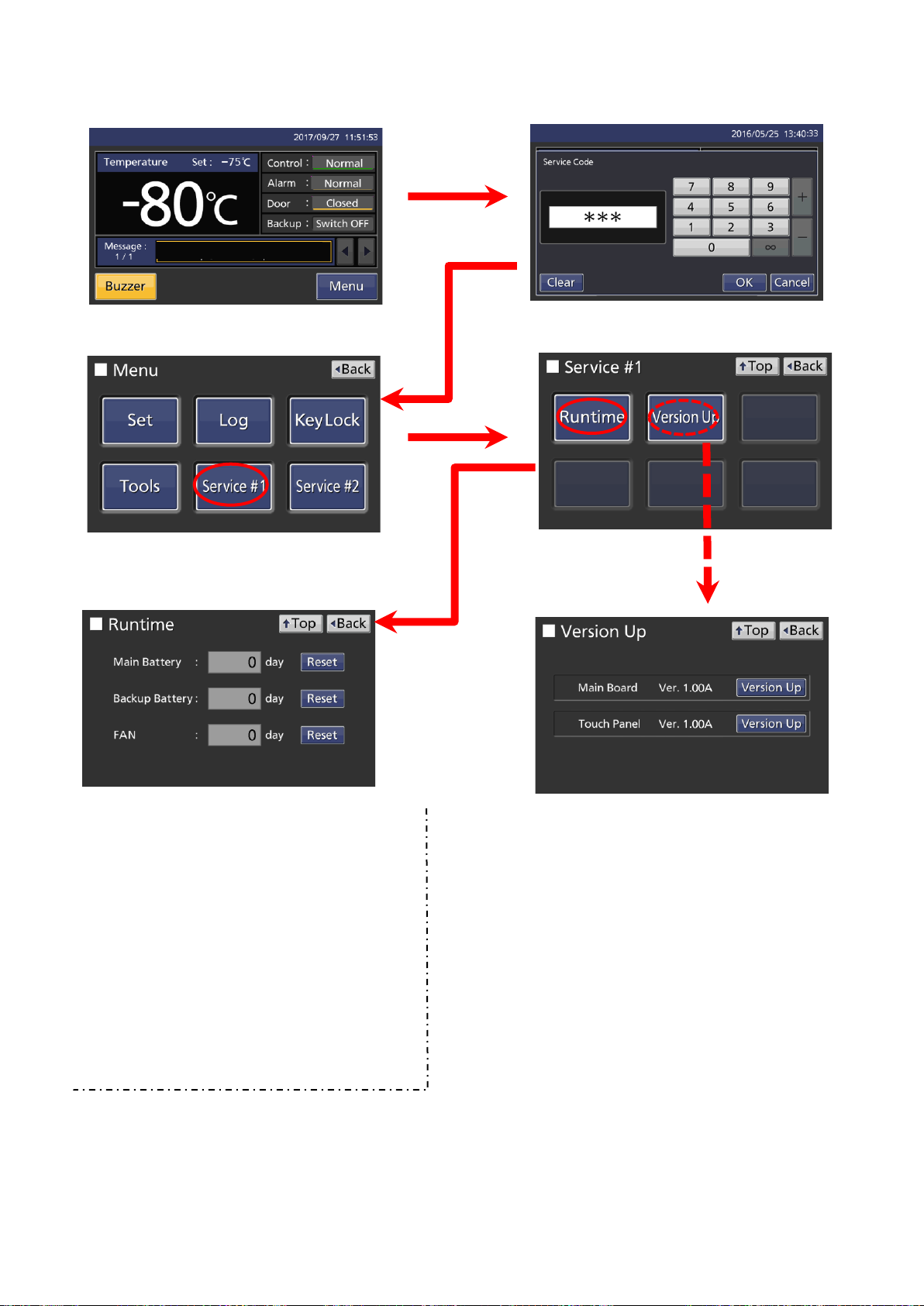

Operation

How to operate Service # 1 and Service # 2 on the service menu is described below. For other operations on the LCD, refer

to the instruction manual.

CAUTION) Firmware update, compressor, FAN, and cap heater settings affect basic performance.

Be careful when operating.

Term

Function

Runtime

Display the accumulate time of Main battery, Backup battery FAN A and FAN B, Reset

them.

Version UP

Update the firmware of main board and touch panel.

Temp. Calibration

Chamber adjustment method.

System Configuration #1

Setting Capi. Heater and its timer, compressors, Fan A/B .

Status

Monitoring of chamber temp. , ambient temp, comp. evaporator and fan.

System Configuration #2

Turning On/Off of AIP heater, and Backup. Setting overload alarm delay..

Reset Data

Initialization of data, and flash memory. Setting model code.

Error Log

Output of error log data.

Setup Data

Input and output the data.

Other Setting

Turning On/Off Screen Capture, Demo Mode, Self-diagnosis Function and FAN Alarm.

-18-

(Runtime,Version Up)

Main Battery

Main Battery accumulated time

Backup Battery

Backup Battery accumulated time

FAN

FAN accumulated time

When each part replace, reset corresponding

data.

・Confirm the existence of file in predefined folder of USB

memory.

・If file is not existence, message “File not found.” is displayed

in “Notice” screen and the process end.

・If file is a existence, if it is not compatible model, "Confirm

firmware" is displayed and the process is terminated. If it is a

compatible model, "Confirm firmware rewrite · · ·" is displayed

and when “Yes” is selected, version upgrade of the touch

panel embedded software is started, and when “No” is

selected, the process is ended.

・During version up, wheel appear in the screen.

・ When version upgrade is completed, "Firmware rewrite

complete. ..." is displayed.

・If an error (other than Verify check) occurs during version

upgrade, "Firmware rewrite failure ... ..." is displayed

・If a Verify error occurs in the Verify check, "Verify check

NG. ..." is displayed.

Service code “384”

※When some version up files are plurality, the first found file is used for version up

※During appearance “wheel”, all operations are not able to receive.

※“OK” button in “Result” screen is disable, and all operations are not able to receive.(unless user turn off power)

※“OK” button in “Error” screen is disable, and all operations are not able to received. (unless user turn off power)

※During version up , no communication is not carried out and no log.is not output.

※If you cancel after or during upgrade, restart the main power supply.

Keep touching MENU KEY (5 sec)

Move to Service Code input display, so

input “384” or “335232”

Move to Menu display, touch service #1

key.

Move to Service #1

display, touch Runtime

or Version Up key

Service code “335232”

Input “384”,

only can check

the firmware

version.

-19-

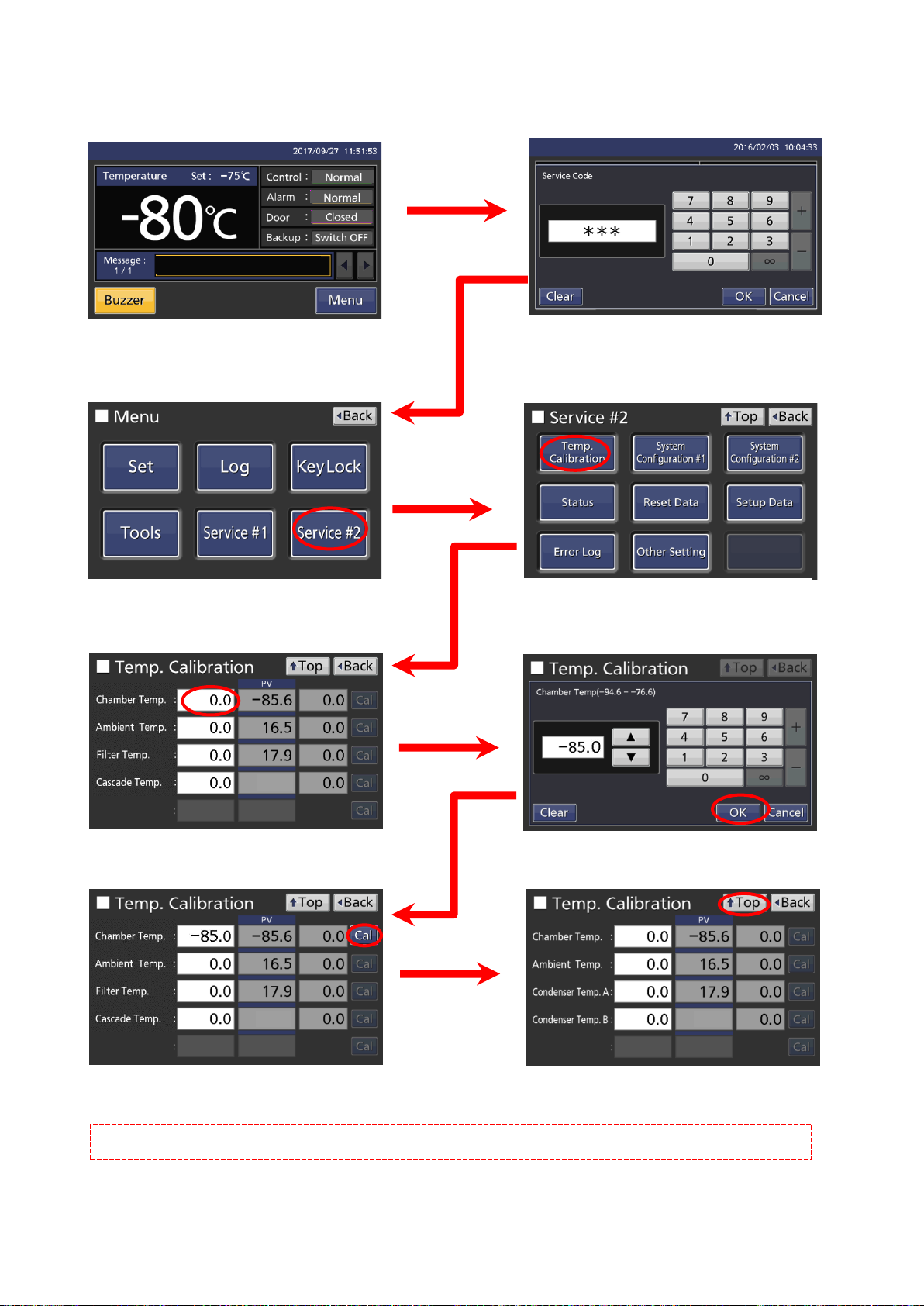

(Temperature calibration procedure:chamber sensor)

Cal key is vialed within setting range, touch

Cal key.

Move to Menu display, touch Service #2

key.

Move to Service display, touch Temp.

Calibration key

Move to input value display.

Input measured value by thermometer

Touch mark area.

Touch TOP key, so return to Menu display.

Input value area return to zero.

NOTE:: Ambient Temp. sensor and condenser A&B sensor can calibrate in the same procedure.

Keep touching MENU KEY (5 sec)

Move to Service Code input display,

so input “335232”

-43.3

-43.3

-43.3

-20-

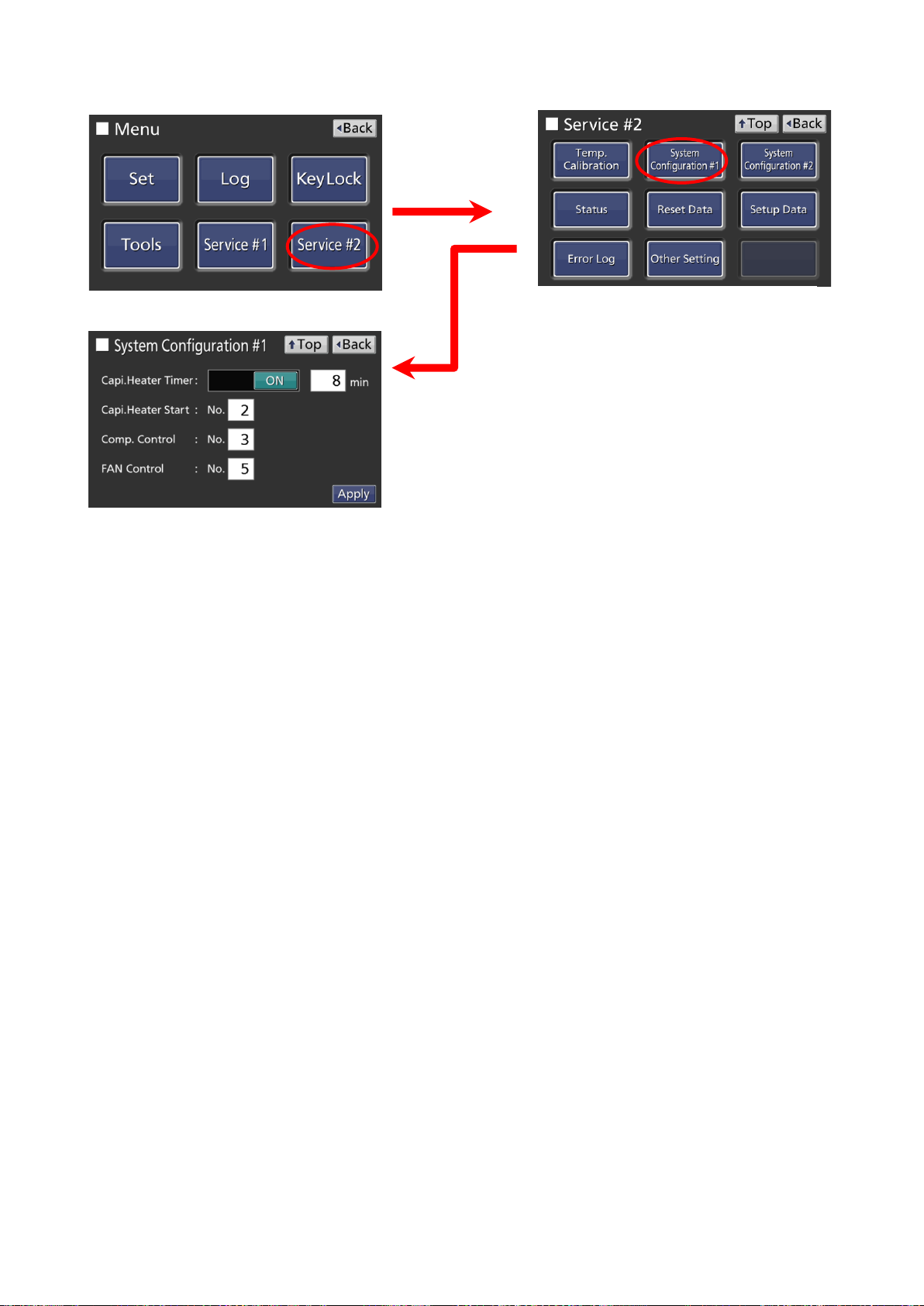

(Operation System Configuration #1)

■

Capi. Heater Timer

Slide key ON(enable),

setting time(Default 8 min).

Capi. Heater Start

Capi. heater control setting

(0) Heater on once in 18 hours

(1) Force on now

(2) Force off now(default)

Comp. Control

Compressor control setting

(0)Off

(1)On

(2)Auto(default)

(3)Manual

FAN control setting

(0) Off

(1) On

(2) Auto(default)

Refer to Control Specification for Capi. Heater Start,

Comp. Control, FAN Control.

Move to Menu display, touch Service #2 key.

Move to Service display, touch System

Configuration #1 key

-21-

Loading...

Loading...