Panasonic MDF-237 Operating Instructions Manual

Please read these instructions carefully before using this product, and save this operating instructions

for future use.

See page 32 for all Model numbers.

MDF-237

MDF-237

Biomedical Freezer

Operating Instructions

1

CONTENTS

INTRODUCTION P. 2

PRECAUTIONS FOR SAFE OPERATION P. 3

ENVIRONMENTAL CONDITIONS P. 7

FREEZER COMPONENTS P. 8

Control panel P.10

INSTALLATION SITE P.11

INSTALLATION P.12

START-UP OF UNIT P.13

REMOTE ALARM TERMINAL P.13

CHAMBER TEMPERATURE SETTING P.14

Key lock function P.14

ALARM TEMPERATURE SETTING P.15

SETTING OF ALARM RESUME TIME P.16

CHANGE OF COMPRESSOR DELAY TIME P.17

ALARMS & SAFETY FUNCTIONS P.18

ROUTINE MAINTENANCE P.19

Cleaning of cabinet P.19

Defrosting P.19

TROUBLESHOOTING P.20

DISPOSAL OF UNIT P.21

Recycle of battery P.21

Decontamination of unit P.21

DISPOSAL OF BATTERY P.26

TEMPERATURE RECORDER (OPTION) P.27

Setting of MTR-4015LH P.27

Setting of MTR-G85C P.29

SPECIFICATIONS P.31

PERFORMANCE P.32

SAFETY CHECK SHEET P.33

2

INTRODUCTION

Read this operating instructions carefully before using the appliance and follow the instructions for

safety operation.

Our company never guarantee any safety if the appliance is used for any objects other than intended

use or used by any procedures other than those mentioned in this operating instructions.

Keep this operating instructions in an adequate place to refer to it as necessary.

The contents of the operating instructions will be subjected to change without notice due to the

improvement of performance or functions.

Contact our sales representative or agent if any page of the operating instructions is lost or page order

is incorrect.

Contact our sales representative or agent if any point in this operating instructions is unclear or if there

are any inaccuracies.

No part of this operating instructions may be reproduced in any form without the expressed written

permission of our company.

CAUTION

Our company guarantees the product under certain warranty conditions. Our company in no

way shall be responsible for any loss of content or damage of content.

3

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with this operating instructions

as it contains important safety advice.

Items and procedures are described so that you can use this unit correctly and safely.

If the precautions advised are followed, this will prevent possible injury to the user and

any other person.

Precautions are illustrated in the following way:

WARNING

Failure to observe WARNING signs could result in a hazard to personnel

possibly resulting in serious injury or death.

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and

damage to the unit and associated property.

Symbol shows;

this symbol means caution.

this symbol means an action is prohibited.

this symbol means an instruction must be followed.

Be sure to keep this operating instructions in a place accessible to users of this unit.

4

PRECAUTIONS FOR SAFE OPERATION

Do not use the unit outdoors.

Current leakage or electric shock may result if the unit is exposed to

rain water.

Only qualified engineers or service personnel should install the unit.

The installation by

unqualified personnel may cause electric shock or fire.

Install the unit on a sturdy floor and take an adequate precaution to prevent the unit from

turning over.

If the floor is not strong enough or the installation site is not adequate, this may result

in injury from the unit falling or tipping over.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

Never install the unit in a flammable or volatile location.

This may cause explosion or fire.

Never install the unit where acid or corrosive gases are present

as current leakage or electric

shock may result due to corrosion.

Always ground (earth) the unit to prevent electric shock.

If the power supply outlet is not

grounded, it will be necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod.

Such

grounding may cause electric shock in the case of an incomplete circuit.

Connect the unit to a power source as indicated on the rating label attached to the unit.

Use of

any other voltage or frequency other than that on the rating label may cause fire or electric shock.

Never store volatile or flammable substances

in this unit if the container cannot be sealed. These

may cause explosion or fire.

Do not insert metal objects such as a pin or a wire into any vent, gap or any outlet on the unit.

This may cause electric shock or injury by accidental contact with moving parts.

Use this unit in safe area when treating the poison, harmful or radiate articles.

Improper use

may cause bad effect on your health or environment.

Turn off the power switch (if provided) and disconnect the power supply to the unit prior to any

repair or maintenance

of the unit in order to prevent electric shock or injury.

Do not touch any electrical parts (such as power supply plug) or operate switches with a wet

hand.

This may cause electric shock.

WARNING

5

PRECAUTIONS FOR SAFE OPERATION

Ensure you do not inhale or consume medication or aerosols

from around the unit at the time of

maintenance. These may be harmful to your health.

Never splash water directly onto the unit

as this may cause electric shock or short circuit.

Never put containers with liquid on the unit

as this may cause electric shock or short circuit when

the liquid is spilled.

Never bind, process, or step on the power supply cord, or never damage or break the power

supply plug.

A broken supply cord or plug may cause fire or electric shock.

Do not use the supply cord if its plug is loose.

Such supply cord may cause fire or electric shock.

Never disassemble, repair, or modify the unit yourself.

Any such work carried out by an

unauthorized person may result in fire, or electric shock or injury due to a malfunction.

Disconnect the power supply plug if there is something wrong with the unit.

Continued

abnormal operation may cause electric shock or fire.

When removing the plug from the power supply outlet, grip the power supply plug,

not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Disconnect the power supply plug

before moving the unit. Take care not to damage the power

cord. A damaged cord may cause electric shock or fire.

Disconnect the power plug when the unit is not used for long periods.

Keeping the connection

may cause electric shock, current leakage, or fire due to the deterioration of insulation.

If the unit is to be stored unused in an unsupervised area for an extended period,

ensure that

children do not have access and that doors cannot be closed completely.

The disposal of the unit should be accomplished by appropriate personnel.

Remove doors to

prevent accidents such as suffocation.

Do not put the packing plastic bag within reach of children

as suffocation may result.

WARNING

6

PRECAUTIONS FOR SAFE OPERATION

Use a dedicated power source

(a dedicated circuit with a breaker) as indicated on the rating label

attached to the unit. A branched circuit may cause fire resulting from abnormal heating.

Connect the power supply plug to the power source firmly after removing the dust on the plug.

A dusty plug or improper insertion may cause a heat or ignition.

Never store corrosive substances such as acid or alkali

in this unit if the container cannot be

sealed. These may cause corrosion of inner components or electric parts.

Check the setting when starting up of operation after power failure or turning off of power

switch.

The stored items may be damaged due to the change of setting.

Be careful not to tip over the unit

during movement to prevent damage or injury.

Prepare a safety check sheet

when you request any repair or maintenance for the safety of service

personnel.

CAUTION

7

ENVIRONMENTAL CONDITIONS

This equipment is designed to be safe at least under the following conditions (based on the IEC 61010-1):

Indoor use;

Altitude up to 2000 m;

Ambient temperature 5oC to 40oC;

Maximum relative humidity 80% for temperature up to 31oC decreasing linearly to 50% relative humidity

at 40

o

C;

Mains supply voltage fluctuations up to ±10% of the nominal voltage;

Transient overvoltages up to the levels of OVERVOLTAGE CATEGORY II;

Temporary OVERVOLTAGES occurring on the mains supply;

Applicable pollution degree of the intended environment (POLUTION DEGREE 2 in most cases);

8

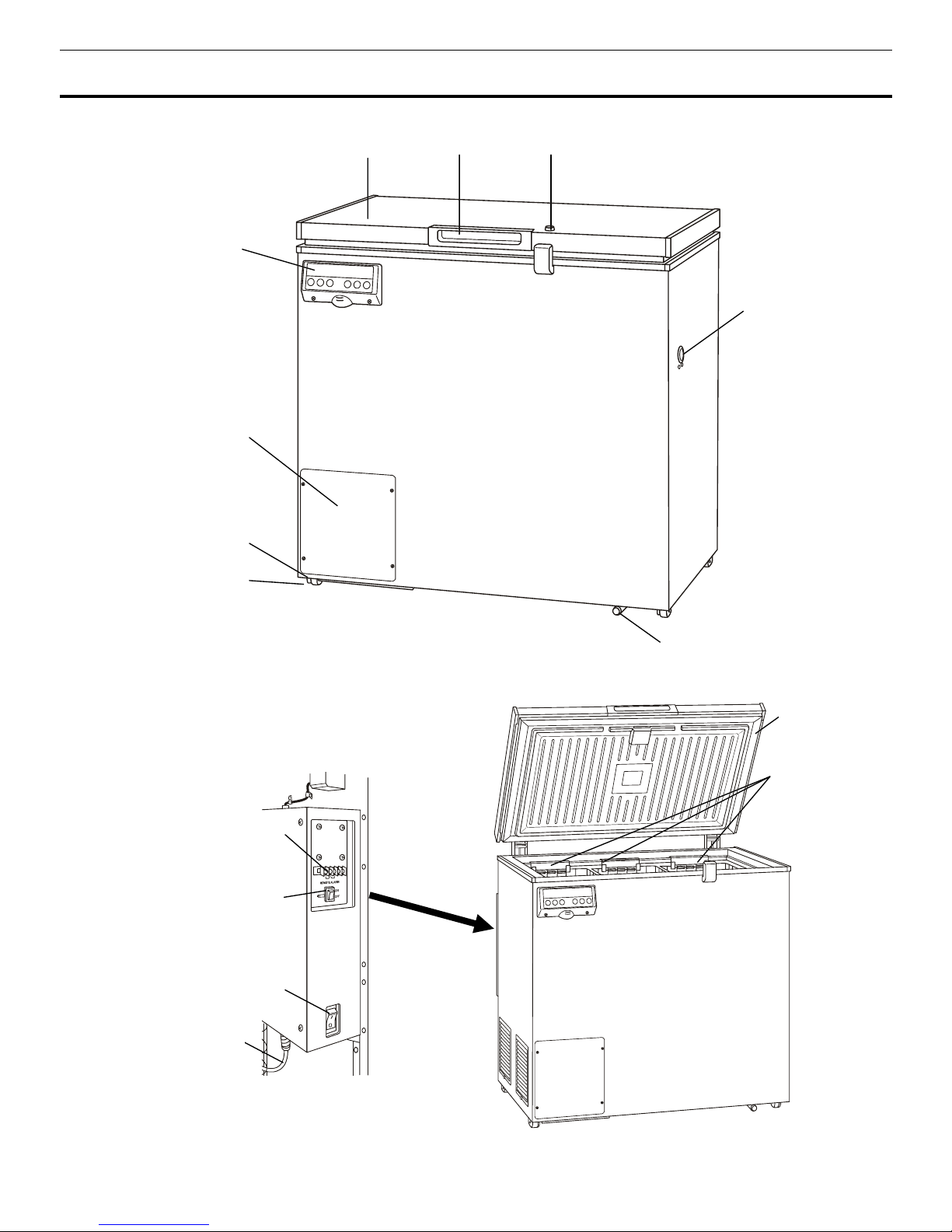

FREEZER COMPONENTS

MDF-13

2

1

4

3

9

7

6

8

5

12

13

14

11

Power cord

10

9

FREEZER COMPONENTS

1. Door:

To open the door, grip the handle.

2. Handle:

Always grip this handle to open and close the door.

3. Lock:

Turn counterclockwise to 180o with a key and the door is securely locked.

4. Access port:

This is used for leading the measuring cable from the chamber to the outside.

5. Drain port:

The water accumulated on the bottom of the chamber can be drained through this port.

6. Caster:

4 casters are provided to facilitate moving of the cabinet. At the time of installation, make

sure that the front 2 casters are not contact with the floor, by adjusting the leveling feet.

7. Leveling foot:

2 feet are provided on the front side (right and left). Keep the unit in level by

adjusting these feet at the installation.

8. Space for temperature recorder:

A temperature recorder (optional part) can be attached here. See

page 27 “Temperature recorder (OPTION)”.

9. Control panel:

To display the temperature setting and running condition. See page 10 for the

details.

10. Door gasket:

This provides a tight door seal and prevents cold air leak. Keep clean.

11. Basket:

Used for storing the materials in the chamber.

12. Remote alarm terminal (on back side):

This is used to notice an alarm condition of the unit to

remote location. Refer to page 13 “Remote alarm terminal”.

13. Battery switch:

This is a switch for power failure. Always set the switch in ON position. Be sure

to turn off this switch to save the battery if the freezer is not in operating for the long period (more than 1

month).

14. Power switch:

This is for turning ON/OFF the power to the unit. ON – “I” OFF – “○”. This has

a function as an over-current protection breaker (15 A).

10

FREEZER COMPONENTS

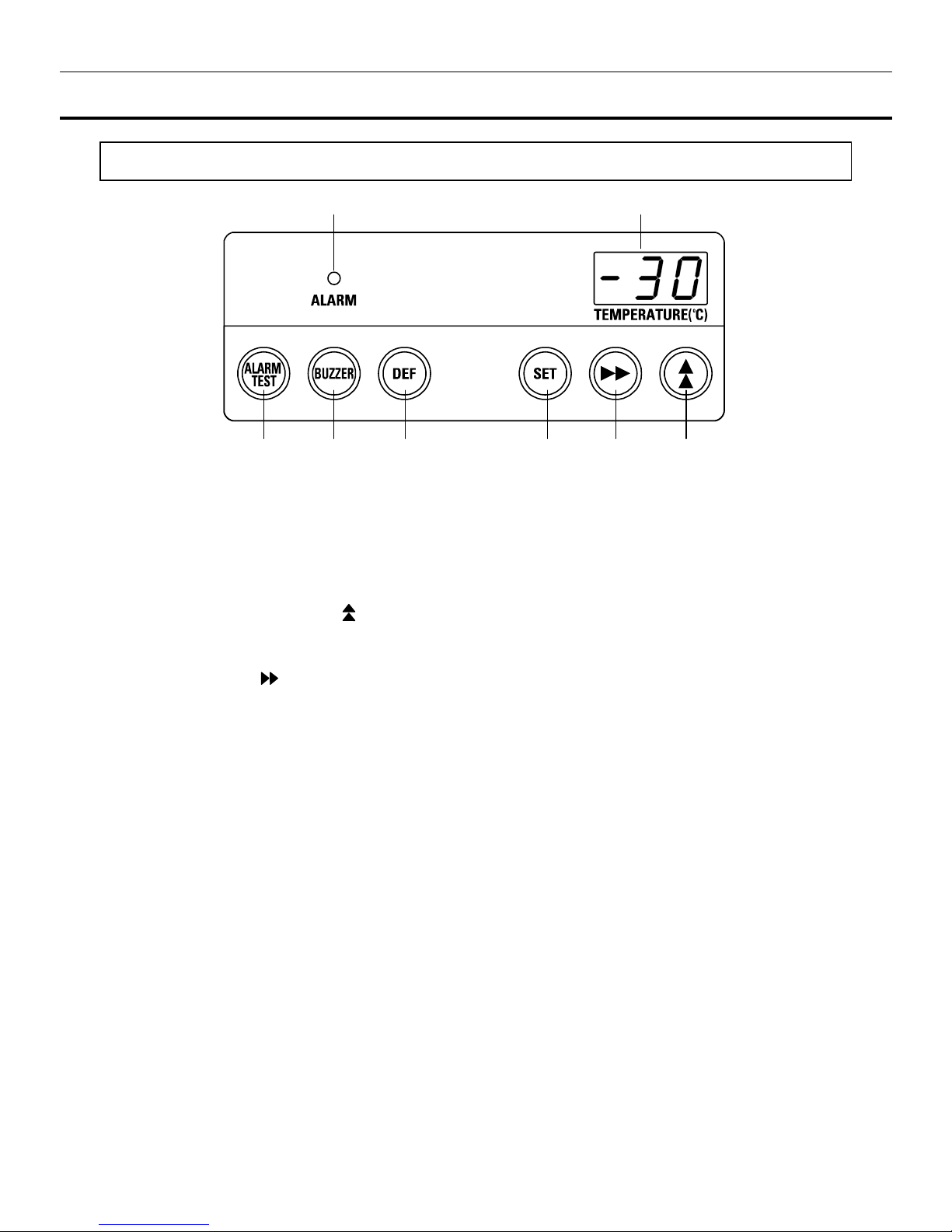

Control panel

1. Alarm lamp (ALARM):

This lamp will flash when the unit is in alarm condition.

2. Digital temperature indicator:

This indicator shows the current chamber temperature or set

temperature.

3. Numerical value shift key ( ):

Pressing this key in the setting mode causes the numerical value to

shift. ON-OFF of key lock can be selected by pressing this key in the key lock mode.

4. Digit shift key ( ):

Pressing this key in the setting mode causes the changeable digit to shift. Key

lock mode is led by pressing this key for more than 5 seconds in the temperature display mode.

5. Set key (SET):

Temperature setting mode is led by pressing this key. Once the key is pressed, the

changeable digit is flashed. Pressing this key again after setting desired temperature, the setting is

stored into computer memory. If there is no key operation for 90 seconds during the setting mode, the

setting mode is invalid automatically. See page 14 for the details..

6. Defrost key (DEF):

By pressing this key for 5 seconds, the refrigerating operation is stopped.

Pressing this key again after defrosting leads resumption of the refrigerating operation. See page 19.

Note:

The refrigerating operation never resumes automatically after defrosting.

7. Buzzer stop key (BUZZER):

Buzzer stop key. Should a further abnormality occur, the buzzer will

sound automatically.

8. Alarm test key (ALARM TEST):

Test key for alarm device. By pressing this key, the alarm lamp is

flashed, remote alarm is activated and buzzer sounds. This means all alarm function operate correctly.

This key is available only during normal running.

8 7 6 5 4 3

1 2

Loading...

Loading...