Page 1

AC Servo Motor Driver

MINAS S-series

Operating Manual

Be sure give this instruction manual to the user.

• Thank you very much for your buying Panasonic AC Servo Motor Driver,A-series.

• Before use, read through this manual to ensure proper use. Keep this manual at an easily

accessible place so as to be referred anytime as necessary.

Page 2

Table of Contents

Before Use

Safety Precautions

•••••4

Introduction •••••••••••••8

After Opening the Package•••••••••••••••• 8

Check the Model Number of Amplifier ••••••••••••••••••

Check the Model Number of Motor •••••••••••••••••••

Check the Combination of Amplifier and Motor •••••••••••••••••••••

8

9

10

Preparations

and Adjustments

System Configuration and Wiring •••••

General Wiring Diagram

List of Available Components

Main Circuits ••••••••••••••••••••••••••••••• 22

CN SIG Connector

For Encoder ••••••••••••••••••••••••••••• 23

CN SER Connector ••••••••••••••••••••••• 24

CN I/F Connector

For Controller •••••••••••••••••••••••••••• 25

CN MON Connector ••••••••••••••••••• 35

Parameter Setting

Overview •••••••••••••••••••••••••••••••••••• 36

Parameter Groups and Listing

Setting the Parameters ••••••••••••••••••• 41

Overview of PANATERM

How to Connect•••••••••••••••••••••••••••• 41

••••••••••••••••••••••• 18

•••••••••••••••••• 20

•••••••••••36

••••••••••••••• 36

••••••••••••••• 41

“

18

Parts Description

Amplifier ••••••••••••••••••••••••••••••••••••• 12

Motor ••••••••••••••••••••••••••••••••••••••••• 13

•••••••••••12

Installation •••••••••••••••••14

Amplifier ••••••••••••••••••••••••••••••••••••• 14

Motor ••••••••••••••••••••••••••••••••••••••••• 16

Trial Run •••••••••••••••••••44

Inspections before Trial Run

Operation with

CN I/F Connected •••••••••••••••••• 45

••••••••••••••••••• 44

Adjustments•••••••••••••••50

Purposes of Gain Adjustments

Types of Gain Adjustments •••••••••••••• 50

How to Adjust Gain •••••••••••••••••••••••• 52

How to Use

"Normal Auto-Gain" Tuning

How to Use "Real Time

Auto-Gain" Tuning •••••••••••••••• 54

How to Adjust Gain Manually

Gain Tuning Using

Gain Adjustment Rotary Switch

To reduce the mechanincal

resonance

••••••••••••••••••••••••••• 59

••••••••••••••• 50

•••••••••• 53

••••••••••••••• 55

••••••••• 58

- 2 -

Page 3

Important Information

Protective Functions •••••••••••

60

Maintenance and

Inspections ••••••••••• 6 6

Appendixes

Conformance to EC Directives and UL Standards

Holding Brake ••••••••••••••••••••••••• App. 6

Dynamic Brake•••••••••••••••••••••••• App. 8

Timing Chart ••••••••••••••••••••••••• App. 10

Acceptable Loads on Output Shaft •••••••••••••••

Homing Operation (Precautions) ••••••••••••••

••••••••••• App. 2

App. 14

App. 15

Troubleshooting

••••••••••••••••••••••••••••••68

After-Sale Service

•••••••••••••••••••••• Back cover

Details of Parameters ••••••••••••• App. 16

Optional Parts ••••••••••••••••••••••• App. 38

Recommended Parts •••••••••••••• App. 47

Dimensions •••••••••••••••••••••••••• App. 48

Characteristics •••••••••••••••••••••• App. 53

Specifications ••••••••••••••••••••••• App. 54

- 3 -

Page 4

Safety Precautions

Observe the following precautions in order to avoid injuries of operators and other persons, and mechanical damages.

The following DANGER and CAUTION symbols are used according to the level of dangers possibly occur-

ring if you fail to observe the instructions or precautions indicated.

(Important)

DANGER

CAUTION

The following symbols indicate what you are not allowed to do, or what you

must observe.

Indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury and physical damage.

This symbol indicates that the operation is prohibited.

This symbol indicates that the operation must

be performed without fail.

DANGER

An over-current protection, earth leakage

breaker, over-temperature protection and

emergency stop should be installed.

Failure to observe this

instruction could result in electric

shocks, injuries and/or fire.

Don't insert your hands in

the amplifier.

Failure to observe this

instruction could result in

burns and/or electric shocks.

Install the amplifier securely to prevent fire hazard and personal injury

resulting from earthquake.

Failure to observe this

instruction could result in electric

shocks, injuries and/or fire.

Be sure to check safety

after occurrence of earthquake.

Failure to observe this

instruction could result in electric

shocks, injuries and/or fire.

-4-

Page 5

DANGER

Before Use

Don't touch the rotating

part of the motor in motion.

Rotating part

Failure to observe this instruction could

result in injuries.

Do not expose the cables to

sharp edges, excessive

pressing forces, heavy

loads or pinching forces.

Failure to observe this

instruction could result in

electric shocks,

malfunction and/or

damages.

Don't subject the product to

water splash, corrosive

gases, flammable gases and

combustible things.

Failure to observe this instruction could result in

fire.

Perform the transportation,

wiring and inspection at

least 10 minutes after the

power off.

Failure to observe this instruction could result in

electric shocks.

Always ask to an electrical engineer for wiring.

Ground the earth terminal

of the amplifier.

Failure to observe this

instruction could result in

electric shocks.

Install an external

emergency stop device so

that you can shut off the

power in any emergency

cases.

Failure to observe this

instruction could result in

injuries, electric shocks, fire,

malfunction and/or mechanical

damages.

-5-

Page 6

Safety Precautions

Caution

(Important)

Use the motor and

amplifier in the specified

combination.

Failure to observe this instruction could result in fire.

If an error occurs,

remove the causes for

the error and secure the

safety before restarting

the operation.

Failure to observe this

instruction could result in

injuries.

Execute the trial operations

with the motor fixed but

without motor load connected.

Connecting a load to the

motor is possible only after

successful trial operation.

Failure to observe this instruction could result in injuries.

Don't touch the motor,

amplifier or its

regenerative discharge

resistor, since they

become hot.

Failure to observe this

instruction could result in

burns.

Avoid extreme

adjustment or change.

Avoid an operation

which causes unstable

action.

Failure to observe this

instruction could result in

injuries.

Don't modify, dismantle

or repair the amplifier.

Failure to observe this instruction could result in fire,

electric shocks and/or injuries.

-6-

Page 7

Caution

Before Use

Don't hold the cables or

motor shaft when

transporting the motor.

Failure to observe this

instruction could result

in injuries.

Don't block the heat

dissipation hole or insert

foreign matters in it.

Failure to observe this

instruction could result

in electric shocks,

injuries and/or fire.

After recovery from the

power failure, the

equipment may restart

suddenly. Don't approach

the equipment

Failure to observe this

instruction could result in

injuries.

*Provide appropriate settings as a preparedness against

the accidental restart of the machine in order to ensure

the safety of personnel.

Observe the voltage

specified.

Failure to observe this

instruction could result in

electric shocks,

injuries and/or fire.

Make sure that the

wirings are made

correctly.

Failure to observe this

instruction could result in

electric shocks, injuries.

This equipment should be

treated as an industrial

waste when it is disposed of.

Do not turn on/off the

main power frequently.

Failure to observe this

instruction could result

in malfunctions.

-7-

Page 8

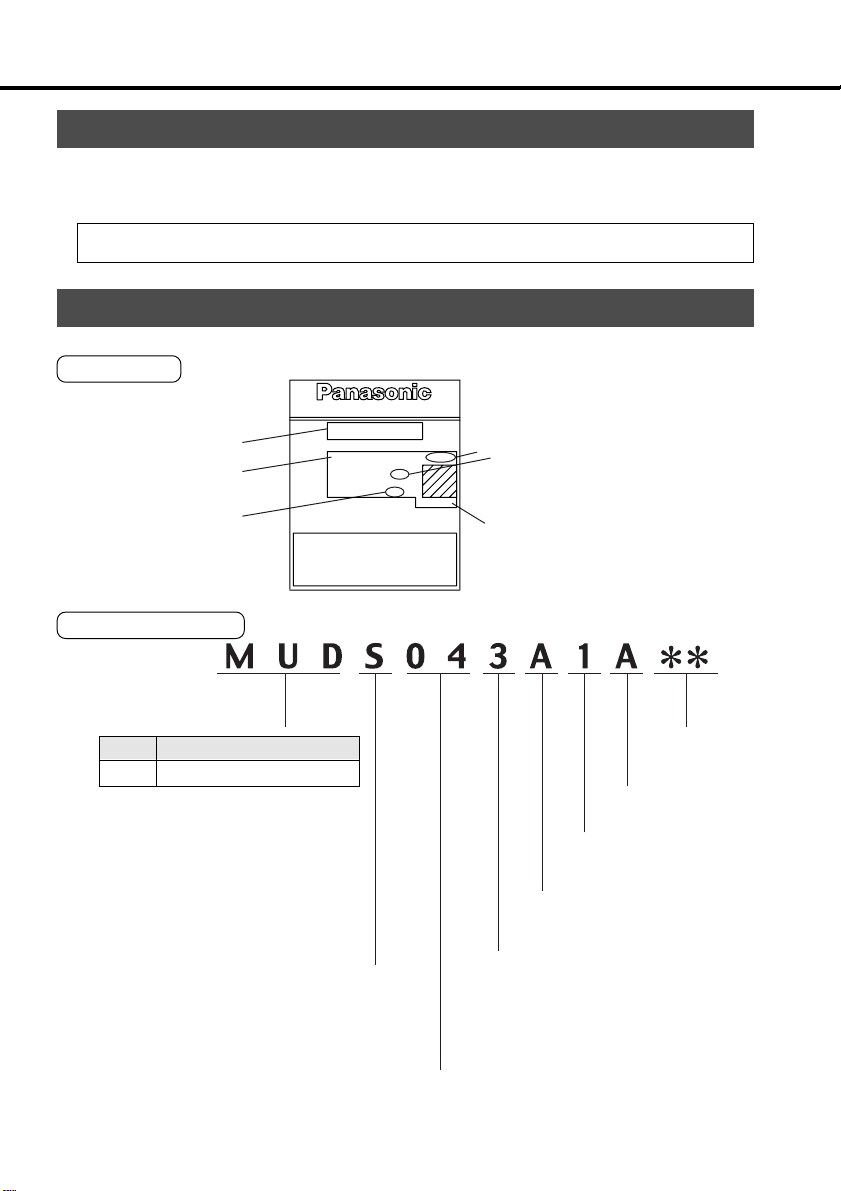

Introduction

After Opening the Package

• Make sure that the product is what you have ordered.

Check whether the product has been damaged or not during transportation.

•

If the product is not correct, or it has been damaged, contact dealer or sales agent.

Check the Model of Amplifier

Name plate

Model

Rated input voltage

Rated motor output

Model Designation

Symbol

Applicable motors

MUD

MUMÅi

Extra low inertia

AC SERVO DRIVER

MUDS3A1A1A

Model No.

INPUT OUTPUT ENCODER

Voltage

100-115V 32V

1ø 3ø

Phase

1.0A 1.0A

F.L .C

Freq.

50/60Hz 0~333.3Hz

Power

60/75 Wire Only

Use Copper Conductors Only

Refer to Manual for Wiring and Wire Size

Refer to Manual for Over Load Protection

1~3 5~6

30W

00010001

SER.NO.

478910

Åj

Series symbol

S: S-series

Rated motor output (see

Table 1-a)

Number of pulses of the

encoder(resolution)

2500P/R

Rated output current

Serial Number

Custom specification 1 (1,

2, 3...)

1: Standard

Rotary encoder

(see Table 1-b)

Power supply

1: Single-phase, 100V

2: Single-phase, 200V

3: Three-phase, 200V

5: Three-phase/Single-phase, 200V

(common phase)

11~12

Custom

specification

Custom specification 2

(A, B, C...)

A: Standard

-8-

Page 9

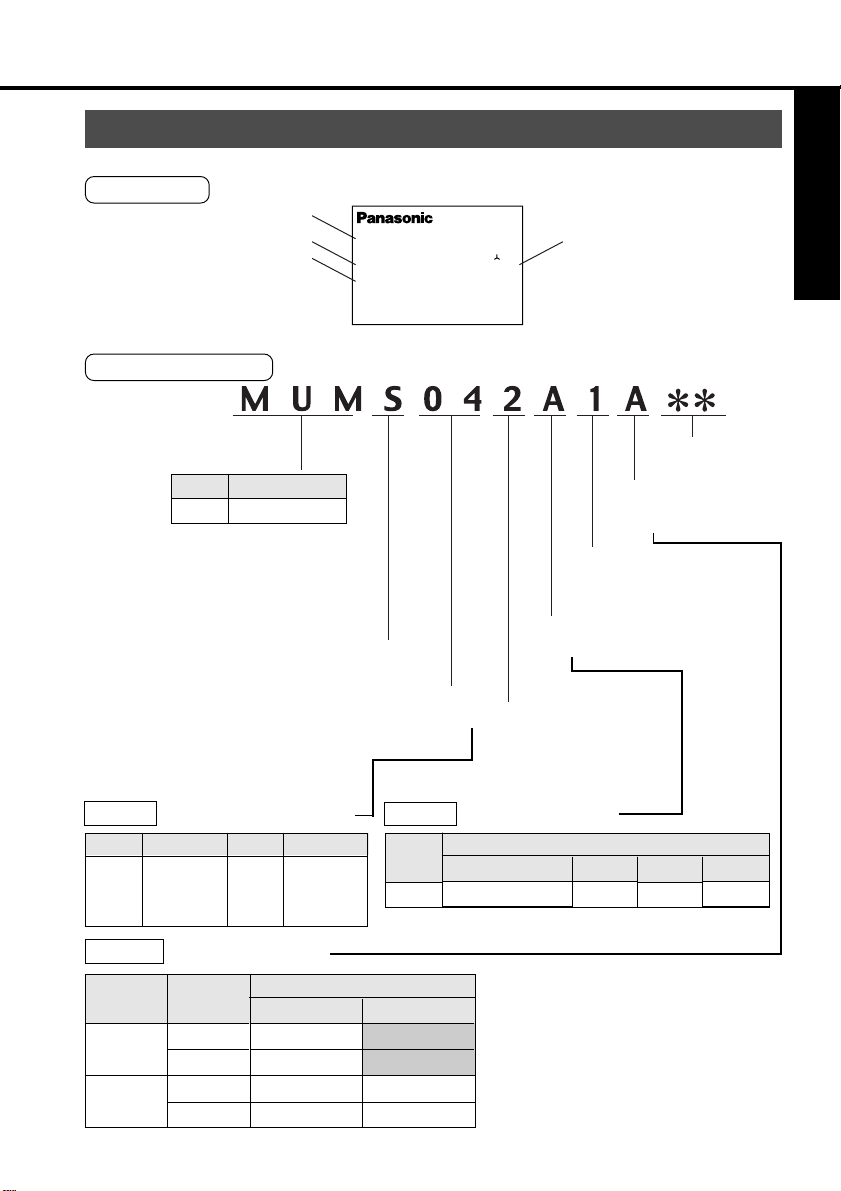

Check the Model of Motor

Name plate

Type

Rated output

Revolution rating

Model Designation

AC SERVO MOTOR

Model No.

MUMS042A1A

INPUT 3ØAC

RATED OUTPUT

200

RATED FREQ.

RATED REV.

3000

92

V

A1.6

kW

0.2

Hz

r/min

CONT. TORQUE

0.64

RATING S1

INS. CLASS B (TÜV) A (UL)

IP65

CONNECTION

SER No.

00010001

MatsushitaElectric Industrial Co..Ltd.

Made in Japan

Before Use

Nm

Serial No

Table 1-a

Symbol

3A

5A

01

Table 1-c

Oil seal

None

Yes

1~3 5~6

Symbol

MUM

Rated Motor Output

Rated output

30W

50W

100W

Motor Structure

Brake

None

Yes

None

Yes

Type

Super low inertia

Symbol

Rated output

02

04

08

Straight

200W

400W

750W

A

B

C

D

478910

11~1 2

Custom specification 2

Motor structure

(see Table 1-c)

Custom specification 1

1: Standard

Rotary encoder

Series symbol

(see Table 1-b)

S: S-series

Rated output

(see Table 1-a)

Voltage

1: 100V

2: 200V

Z: 100/200V

Table 1-b

Symbol

A

Shaft

Key way

Rotary Encoder

Specifications

Type

Incremental

No. of pulses

2500P/r

Resolution

10000

∑ Specifications with the shaft

provided with key way are standard.

E

F

G

H

-9-

Lead wire

11- wire

Page 10

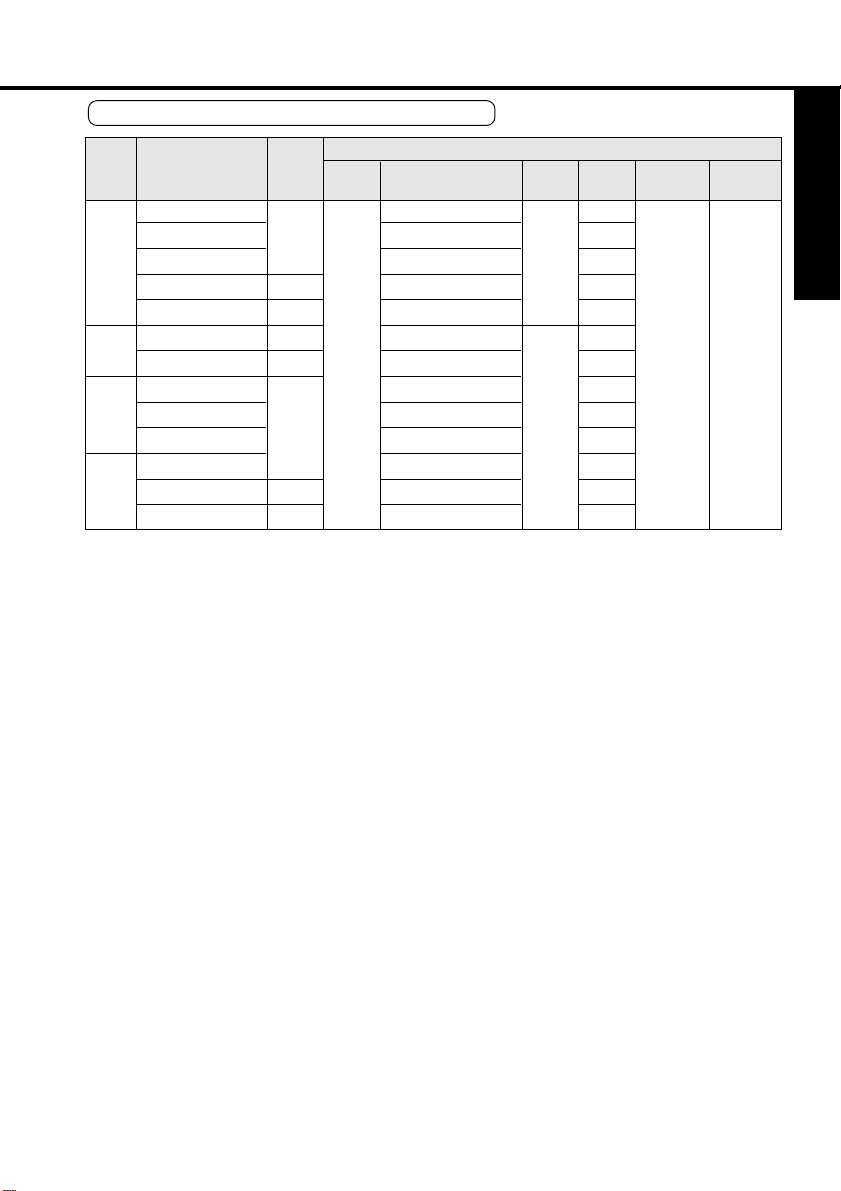

Introduction

Check the Combination of Amplifier and Motor

The amplifier has been designed for use in combination with the specified motors only.

Check the specifications (Series symbol, output rating, voltage rating and encoder type) of

the motor you want to use.

-10-

Page 11

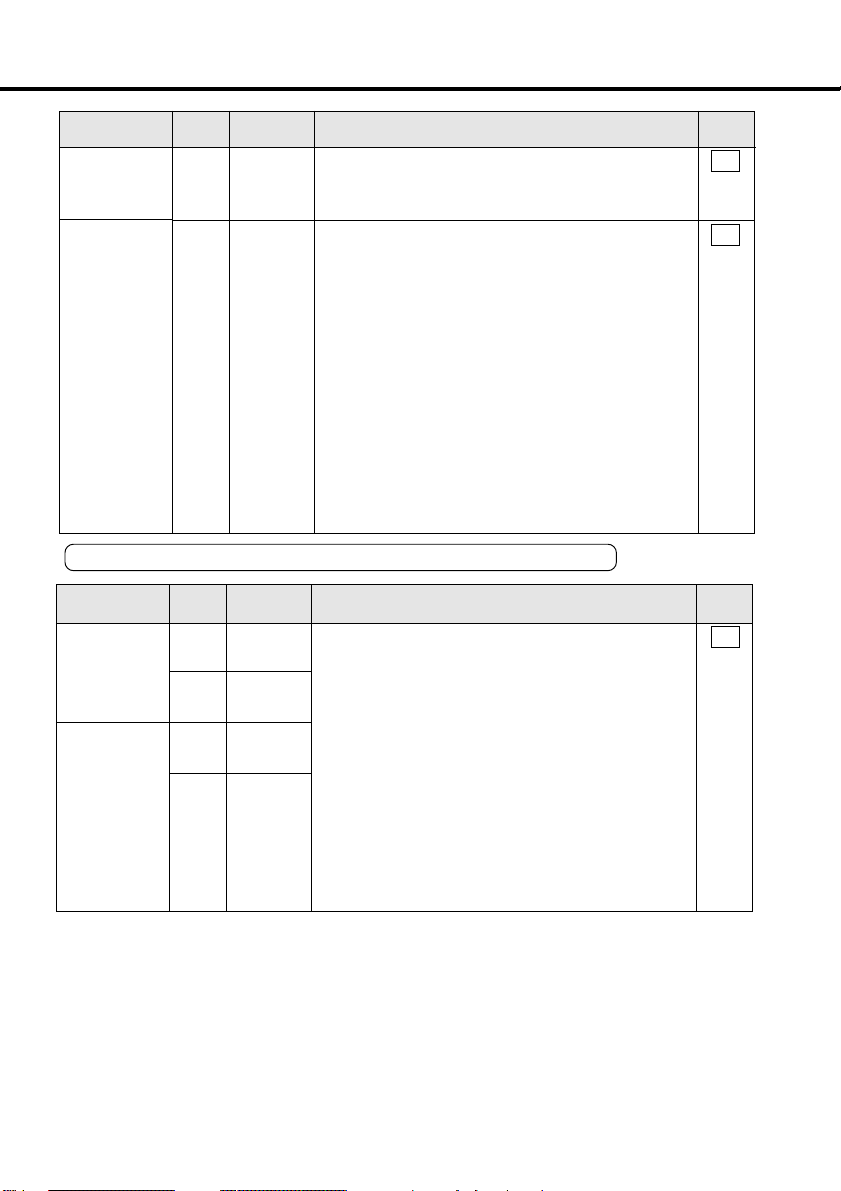

With the incremental type encoder: 2500P/r

Power

supply for

amplifier

MUDS3A1A1A

1-phase,

MUDS5A1A1A

100V

MUDS011A1A

MUDS021A1A

MUDS041A1A

MUDS022A1A

1-phase,

MUDS042A1A

200V

MUDS3A5A1A

3-phase/

1-

MUDS5A5A1A

phase,

MUDS015A1A

200V

MUDS023A1A

3-phase,

MUDS043A1A

200V

MUDS083A1A

Amplifier

Amplifier

Series

type

symbol

Type1

MUMS

Super

Type2

Type3

Type2

Type3

Type1

Type2

Type3

Low

inertia

Motor type

MUMS3AZ

MUMS5AZ

MUMS011A

MUMS021A

MUMS041A

MUMS022A

MUMS042A

MUMS3AZA

MUMS5AZA

MUMS012A

MUMS022A

MUMS042A

MUMS082A

****

****

****

****

****

****

****

****

****

****

****

****

****

Motor

Voltage

100V

200V

Output

rating

30W

50W

100W

200W

400W

200W

400W

30W

50W

100W

200W

400W

750W

Revolution

rating

3000r/min

Encoder

Incremental

2500P/r, 11

wires

Before Use

type

-11-

Page 12

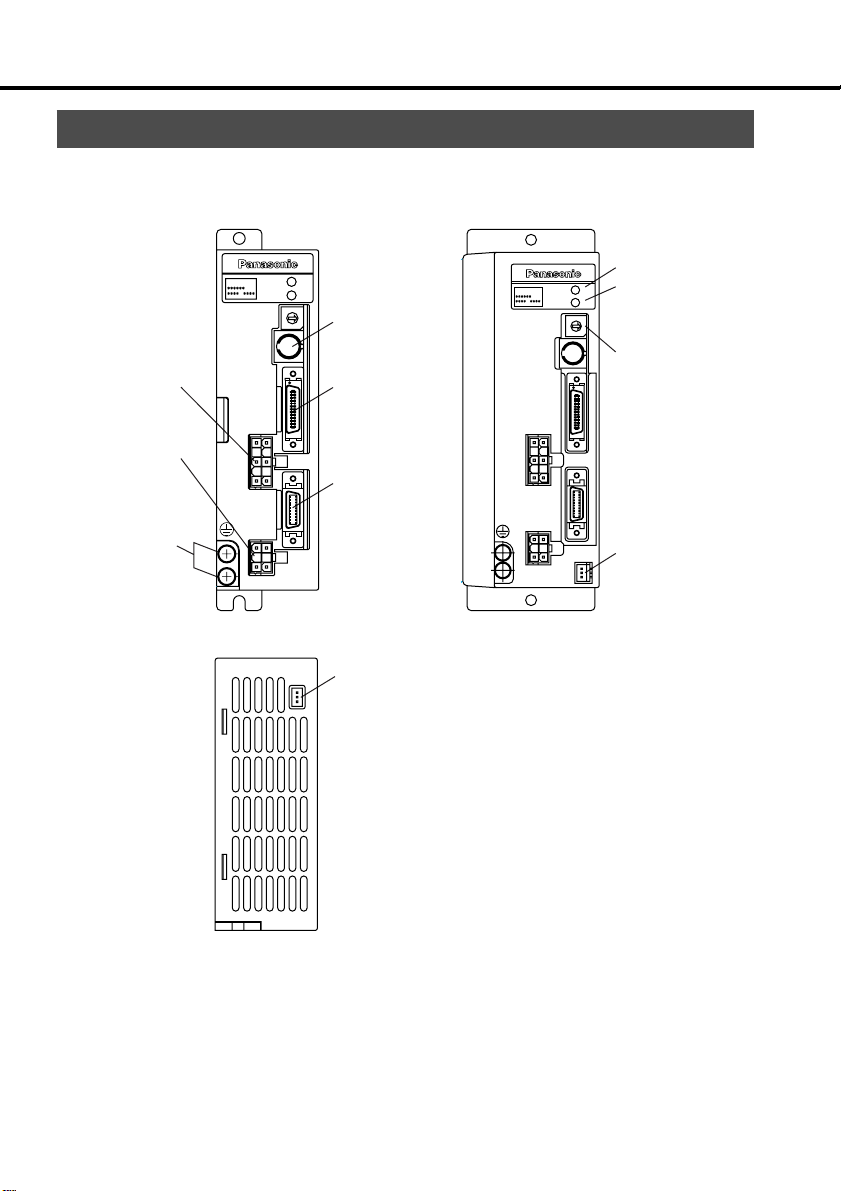

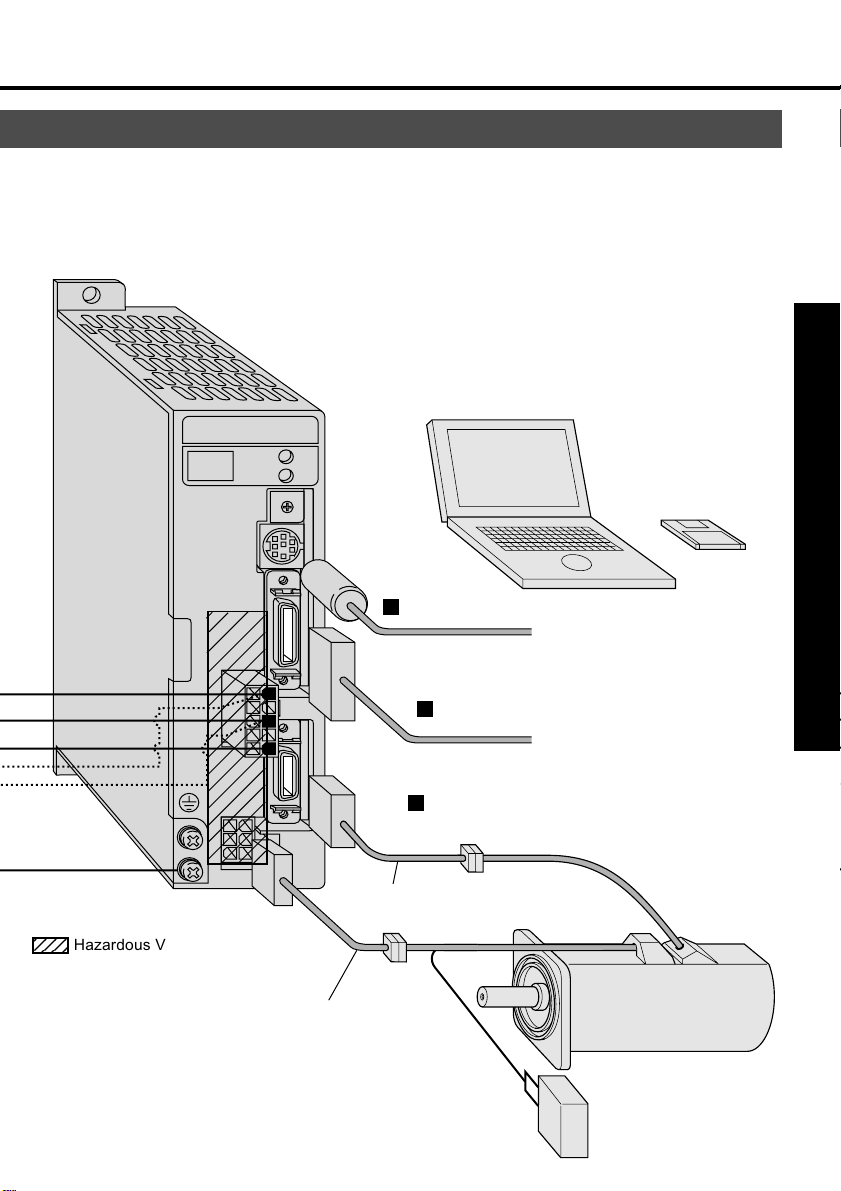

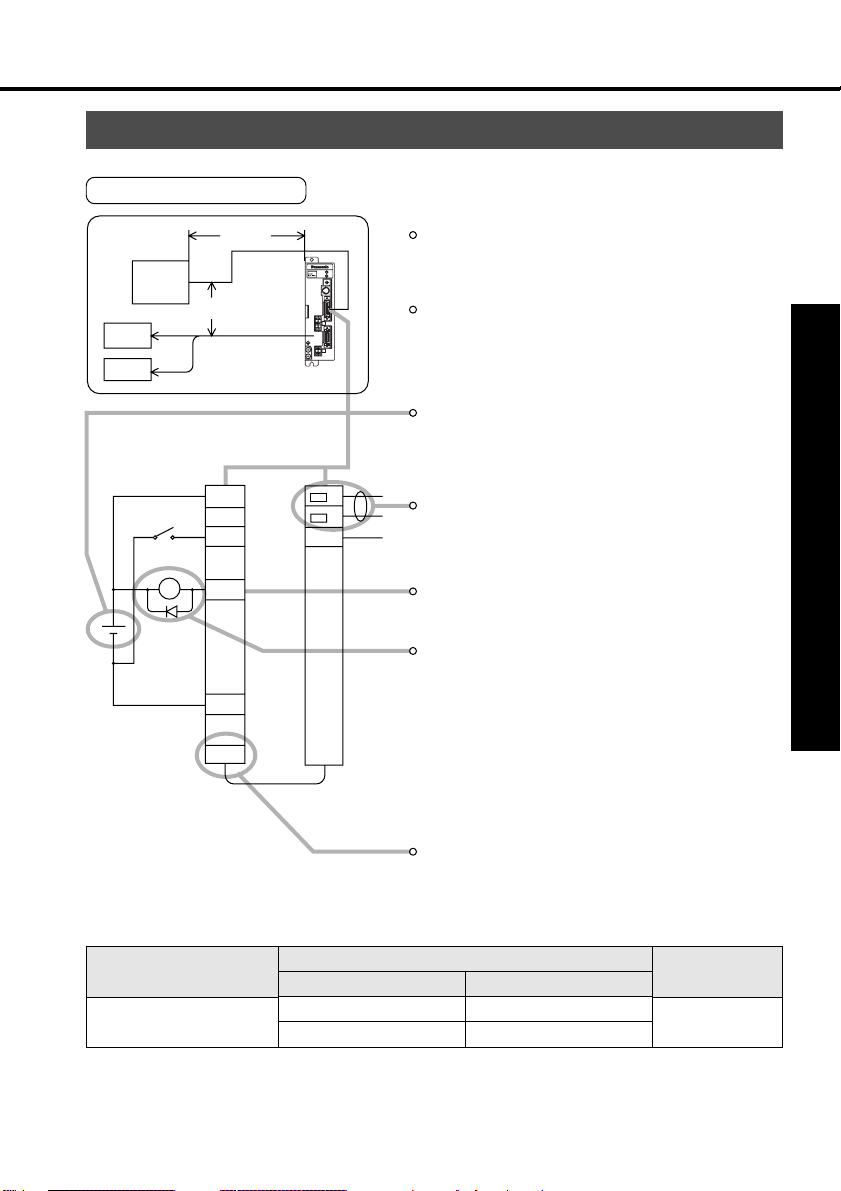

Parts Description

Amplifier

Example: MUDS023A1A

(3-phase, 200V 200W: Type 1)

STATUS

MSDS

ALM CODE

GAIN

CN

SER

Main power

input connector

(L1, L2, L3,P, B)

Motor

connection

(U, V, W, E)

Earth

connections

CN

POWER

CN

MOTOR

CN

I/F

CN

SIG

MON

CN

Communication

connector

CN SER

Controller

connection

(CN I/F)

Encoder

connection

(CN SIG)

Check pins

(CN MON)

Example: MUDS042A1A

(1-phase, 200V 400W: Type 3)

Status LED

CN

MON

Alarm code LED

Rotary switch

for gain (GAIN)

tuning

Check pins

(CN MON)

MSDS

CN

POWER

CN

MOTOR

STATUS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

SIG

<Notes>

For detailed information for each of motor types, see the drawings in the Appendix

(App.50 to 52).

-12-

Page 13

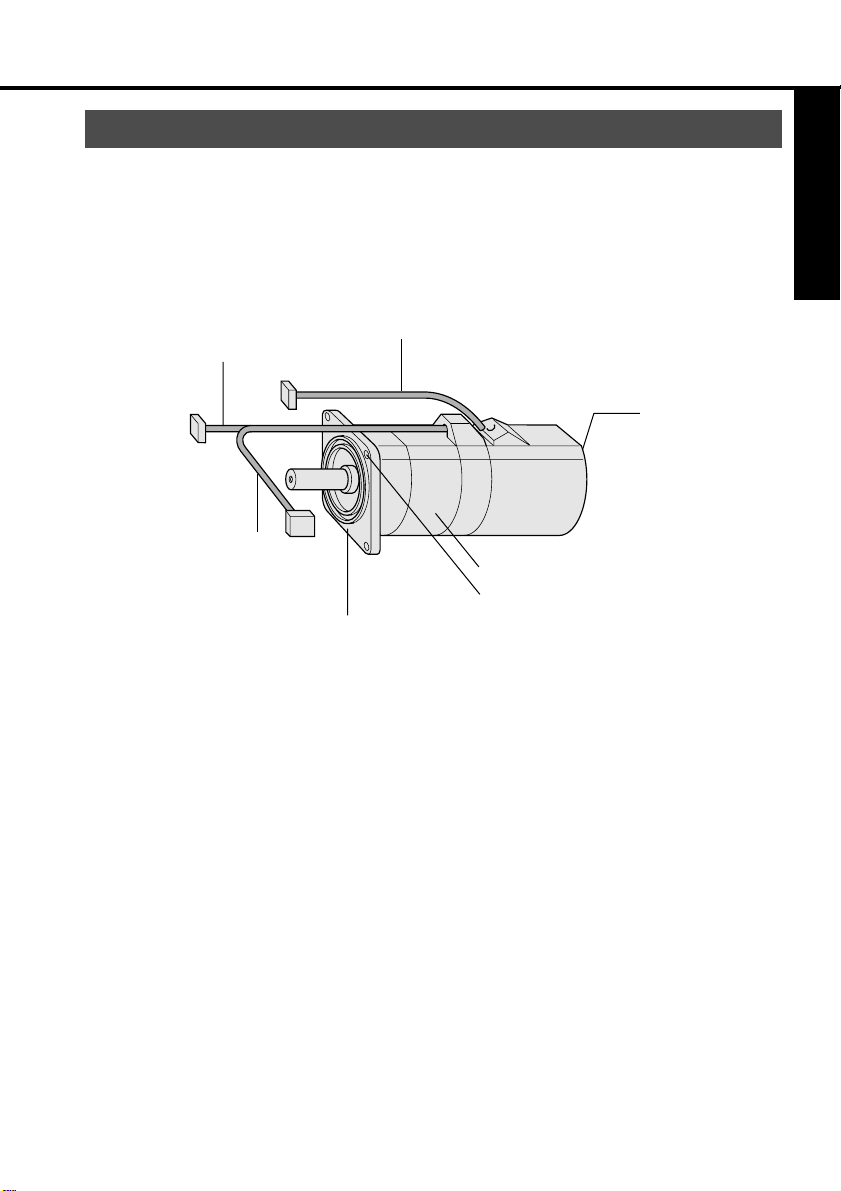

Motor

Example: Super Low-Inertia Motor (MUMS Series, 400W)

Encoder cable

Motor cable

Encoder

Brake cable

(Motor with electromagnetic brake only )

Flange

Frame

Mounting bolt holes (4)

Before Use

<Notes>

For detailed information for each of motor types, see the drawings in the Appendix

(App.48 & 49).

-13-

Page 14

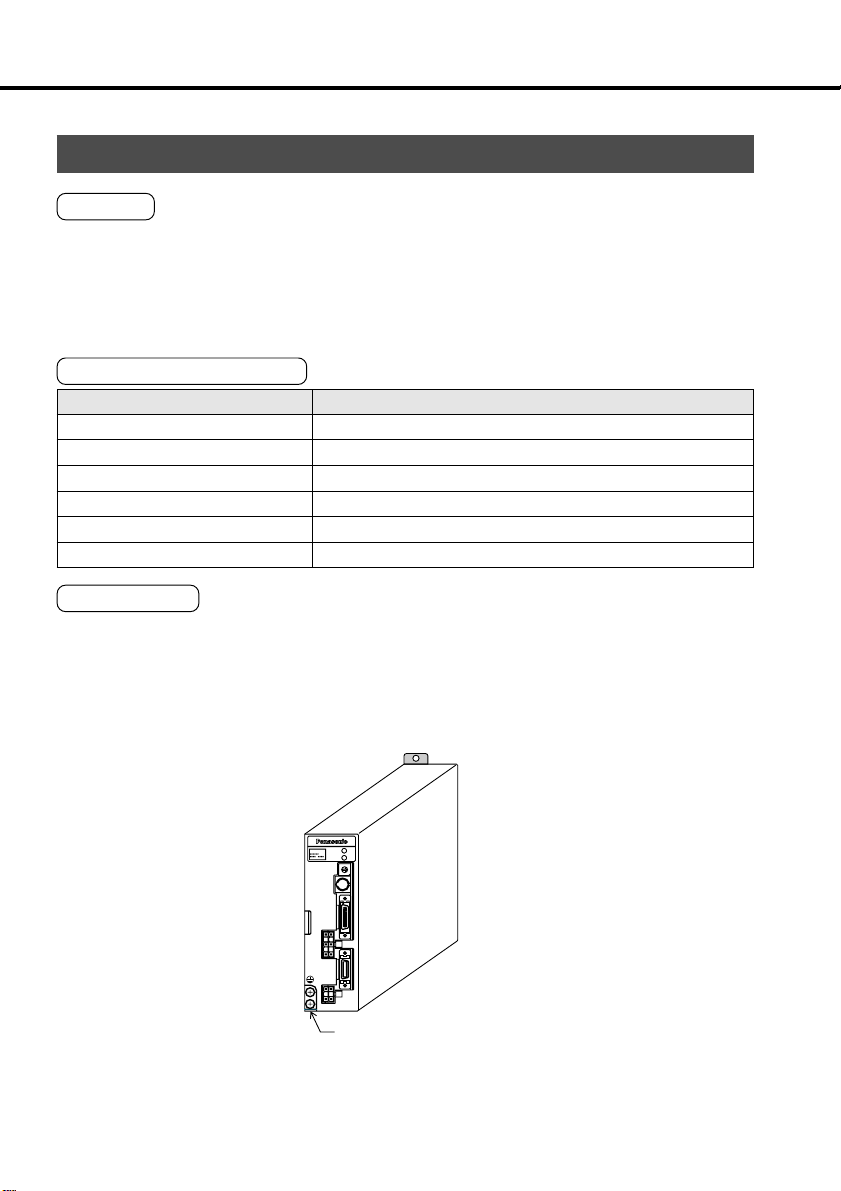

Installation

The amplifier and motor should be properly installed to avoid failures, mechanical damages and injuries.

Amplifier

Location

• Indoors, where the amplifier is not subjected to rain water and direct sun beams. Note

that the amplifier is not a waterproof structure.

• Avoid the place where the amplifier is subjected to corrosive gases, flammable gases,

grinding liquids, oil mists, iron powders and cutting particles.

• Place in a well-ventilated, and humid- and dust-free space.

• Place in a vibration-free space.

Environmental Conditions

Item

Ambient temperature

Ambient humidity

Storage temperature

Storage humidity

Vibration

Not greater than 90%RH (free from condensation)

0 to 55˚C (free from freezing)

-20 to 80˚C (free from condensation)

Not greater than 90%RH (free from condensation)

Not greater than 5.9m/s2 (0.6G) at 10 to 60 Hz

Altitude

How to Install

•

This is a rack-mount type.

Place the amplifier vertically. Allow enough space surrounding for ventilation.

Front panel mount type (recessed)

Conditions

Not greater than 1000 m

STATUS

MSDS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

Earth connection (M4 screw) tightening torque

shall not exceed 0.39 ~ 0.59 N·m.

-14-

Page 15

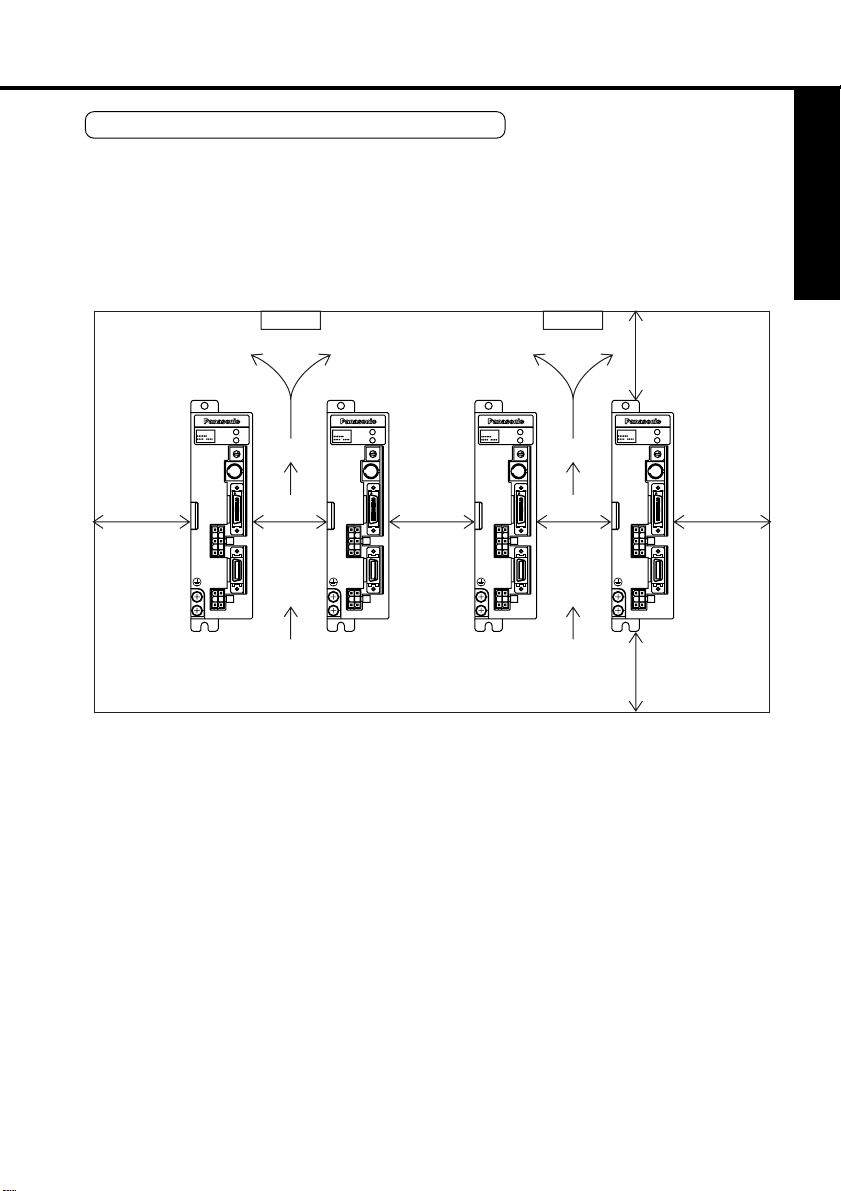

Mounting Direction and Space Requirements

• Allow enough space to ensure enough cooling.

• Install fans to provide a uniform distribution of temperature in the control box.

The airflow of fan is more than 0.43m

amplifier.

• Observe the environmental requirements for the control box, mentioned in the previous

page.

3

/min. And it should be located 10 cm away from the

Before Use

min.

40mm

Fan Fan

min.

100mm

STATUS

MSDS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

min.

10mm

CN

SIG

CN

MOTOR

STATUS

MSDS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

min.

10mm

CN

SIG

CN

MOTOR

STATUS

MSDS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

min.

10mm

CN

SIG

CN

MOTOR

STATUS

MSDS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

min.

CN

SIG

CN

MOTOR

40mm

min.

100mm

-15-

Page 16

Installation

Motor

Location

•

Indoors, where the amplifier is not subjected to rain water and direct sun beams.

• Avoid the place where the amplifier is subjected to corrosive gases, flammable gases,

grinding liquids, oil mists, iron powders and cutting particles.

• Place in a well-ventilated, and humid- and dust-free space.

• Easy maintenance, inspections and cleaning is also important.

Environmental Conditions

Item

Ambient temperature

Ambient humidity

Storage temperature

Storage humidity

Vibration

Shock

Motor only

With gear

(At rotation)

Motor only

With gear

0 to 40˚C (free from freezing)

Not greater than 85%RH (free from condensation)

-20 to 80˚C (free from freezing)

Not greater than 85%RH (free from condensation)

49 m/s2 (5G) or less at rotation, 24.5 m/s2 (2.5G) or less at rest

High precision and normal type: 24 m/s2 (2G) or less

Standard type: 49 m/s2 (5G) or less

98 m/s2 (10G) or less

High precision and normal type: 98 m/s2 (10G) or less

Standard type: 24 m/s2 (2G) or less

Conditions

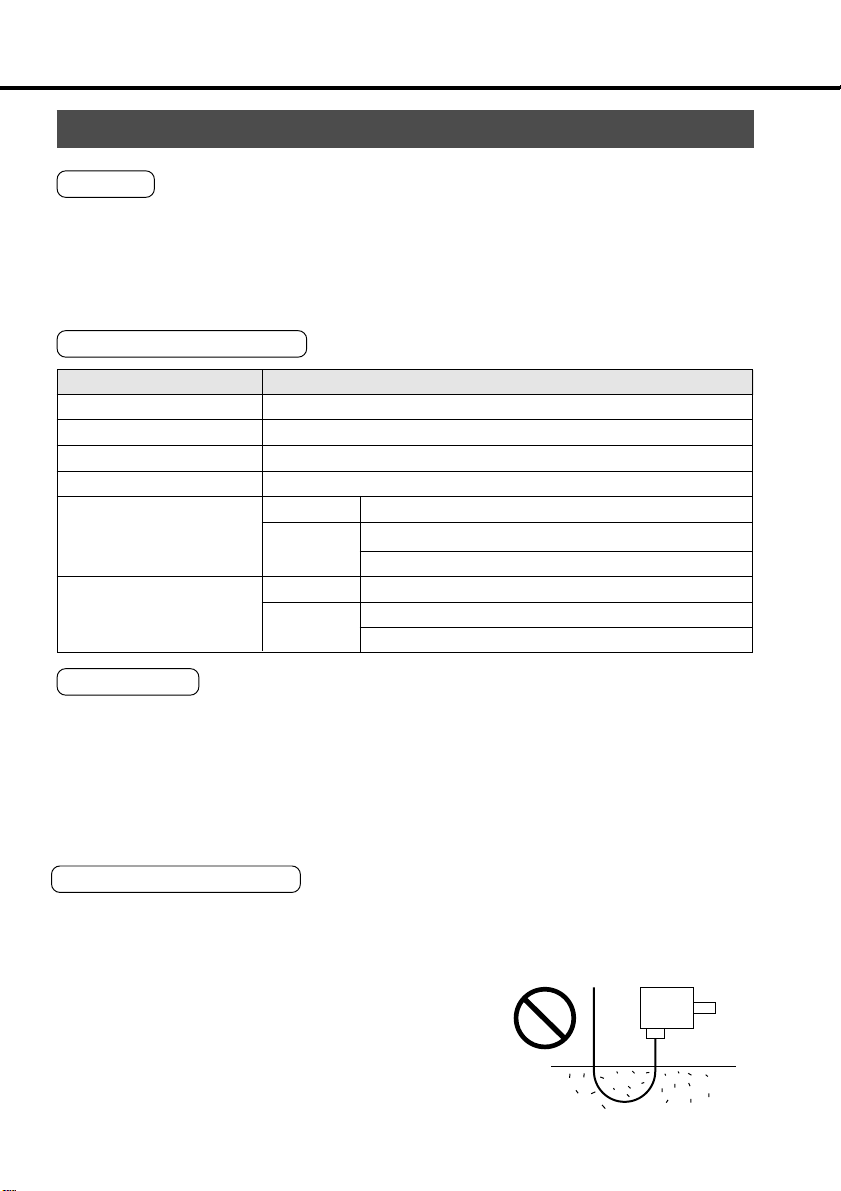

How to Install

The motor can be installed either vertically or horizontally. Observe the following notes.

• Horizontal mounting

Place the motor with the cable outlet facing down to prevent the entry of oil and water.

•

• Vertical mounting

• If a motor is coupled with a reduction gear, use a motor equipped with oil seal so that oil

in the reduction gear may not enter into the motor.

Oil and Water Protections

• This motor(IP65 rating) can be used where it is subjected

to water and/or oil drops, but is not water - or oil - proof.

Therefore, the motors should not be placed or used in

such environment.

•

If the motor is coupled with a reduction gear, use the motor

with oil seals to prevent the reduction gear oil from

entering into the motor.

•

Don't use the motor with the cables being immersed in oil

or water.

-16-

Cable

Motor

Oil and water

Page 17

Cable: Stress Relieving

•

Make sure that the cables are not subjected to moments or vertical loads due to external

bending forces or self-weight at the cable outlets or connections.

• In case the motor is movable, secure the cable (proper one supplied together with the

motor) to a stationery part (e.g. floor), and it should be extended with an additional cable

which should be housed in a cable bearer so that bending stresses can be minimized.

• Make the bending radius of cables as large as possible.

(Minimum bend radius: 20 mm)

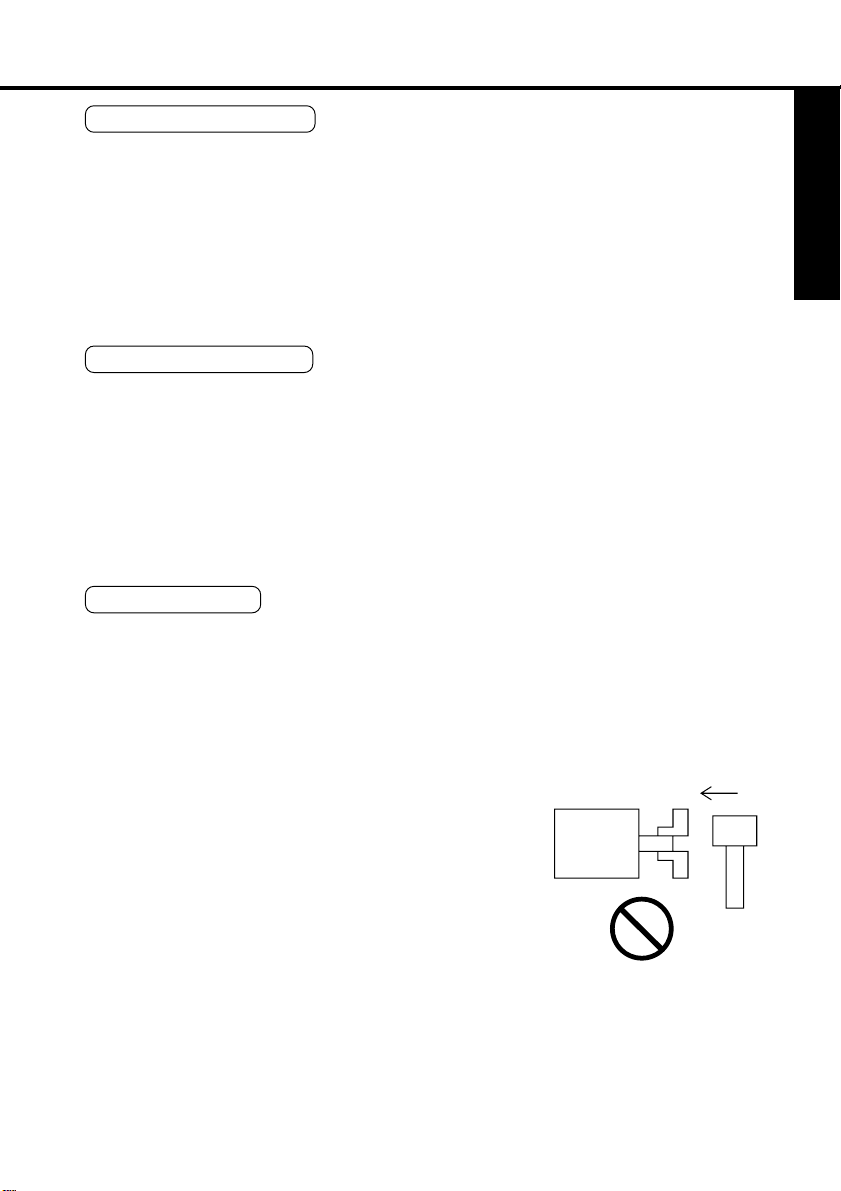

Permissible Shaft Load

• Make sure that both of radial and thrust load to be applied to the motor shaft during installation and running, are within the specified value of each model.

•

Pay extra attention to installing a rigid coupling (especially an excess bending load which may

cause the damages and/or wear of the shaft and bearings).

• Flexible coupling is recommended in order to keep the radial load smaller than the permissible value, which is designed exclusively for servo motors with high mechanical stiffness.

•

For the permissible shaft load, see "Allowable Shaft Loads Listing" in Appendix.

Installation Notes

•

Don't hit the shaft with a hammer directly while

attaching/detaching the coupling to the motor

shaft.(otherwise the encoder at the opposite

end of the shaft will be damaged).

• Try perfect alignment between shafts (misalignment may cause vibration, and damages of

the bearings).

Before Use

-17-

Motor

Page 18

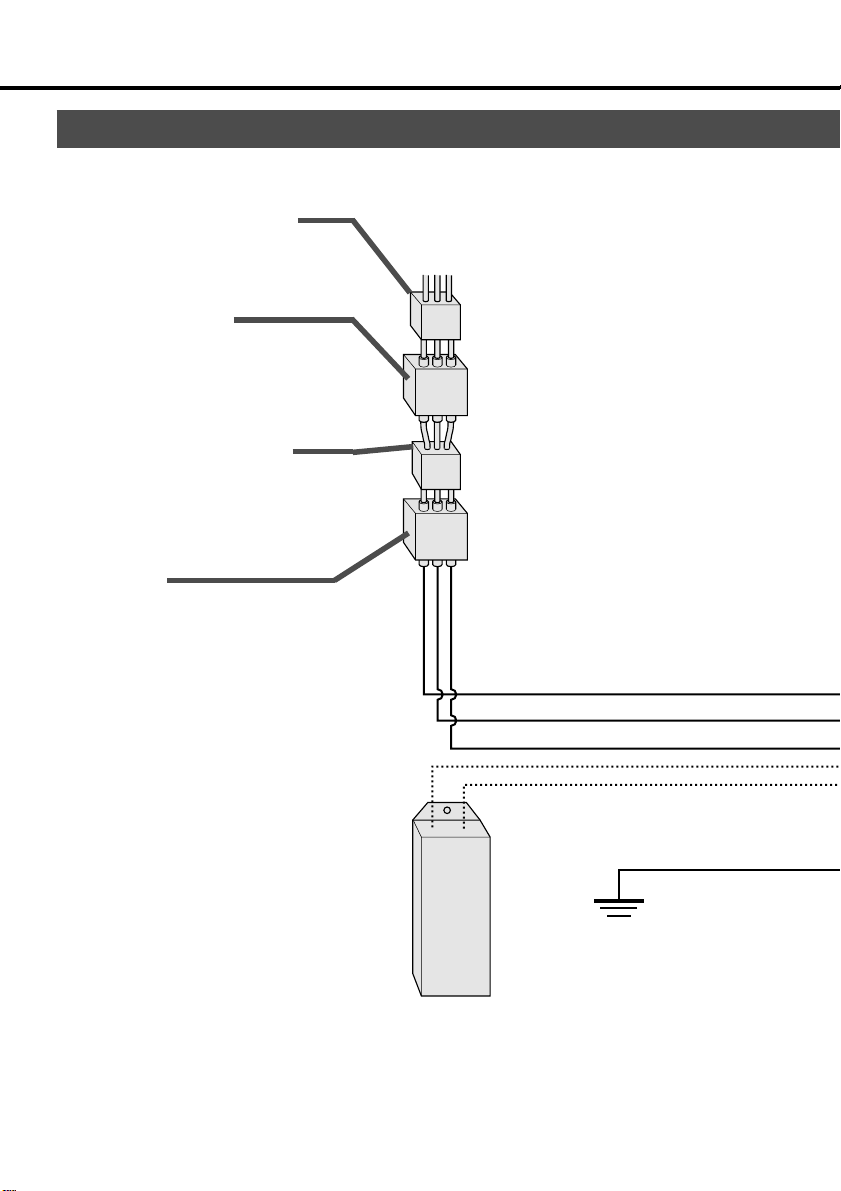

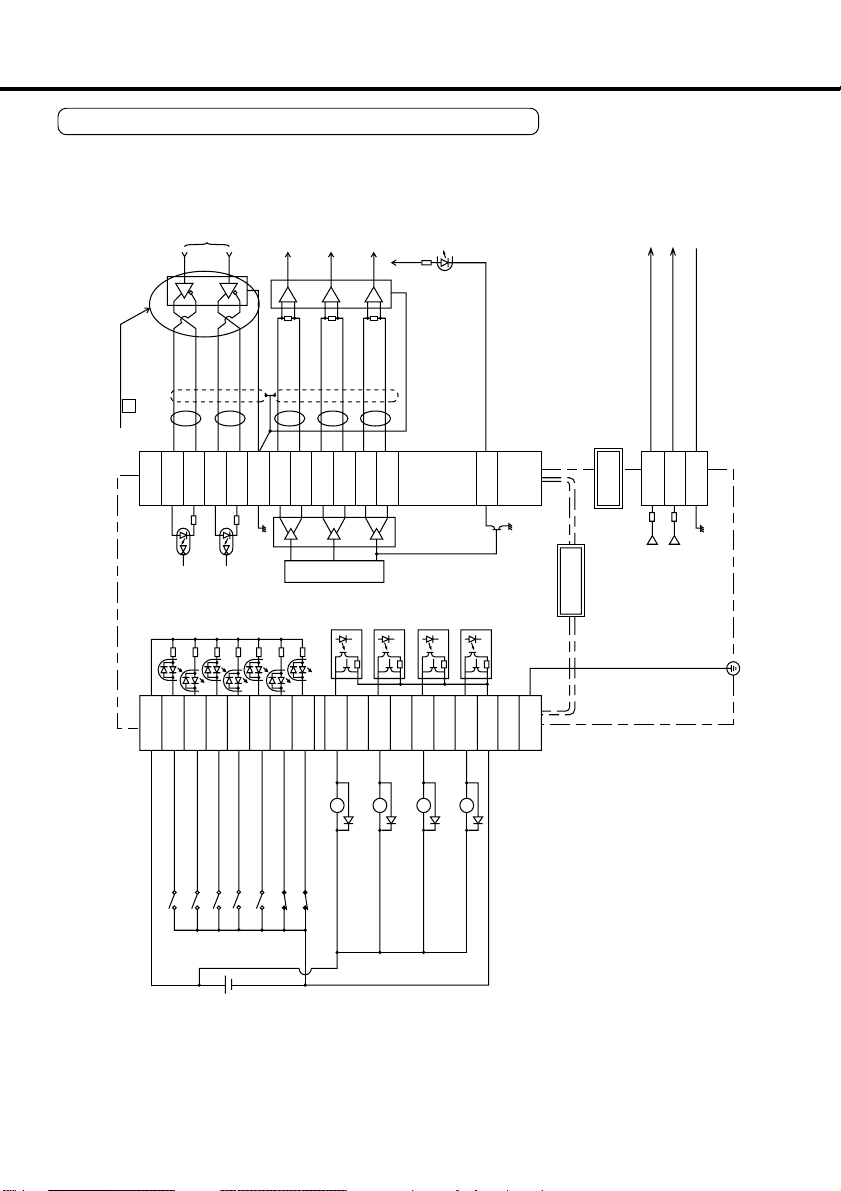

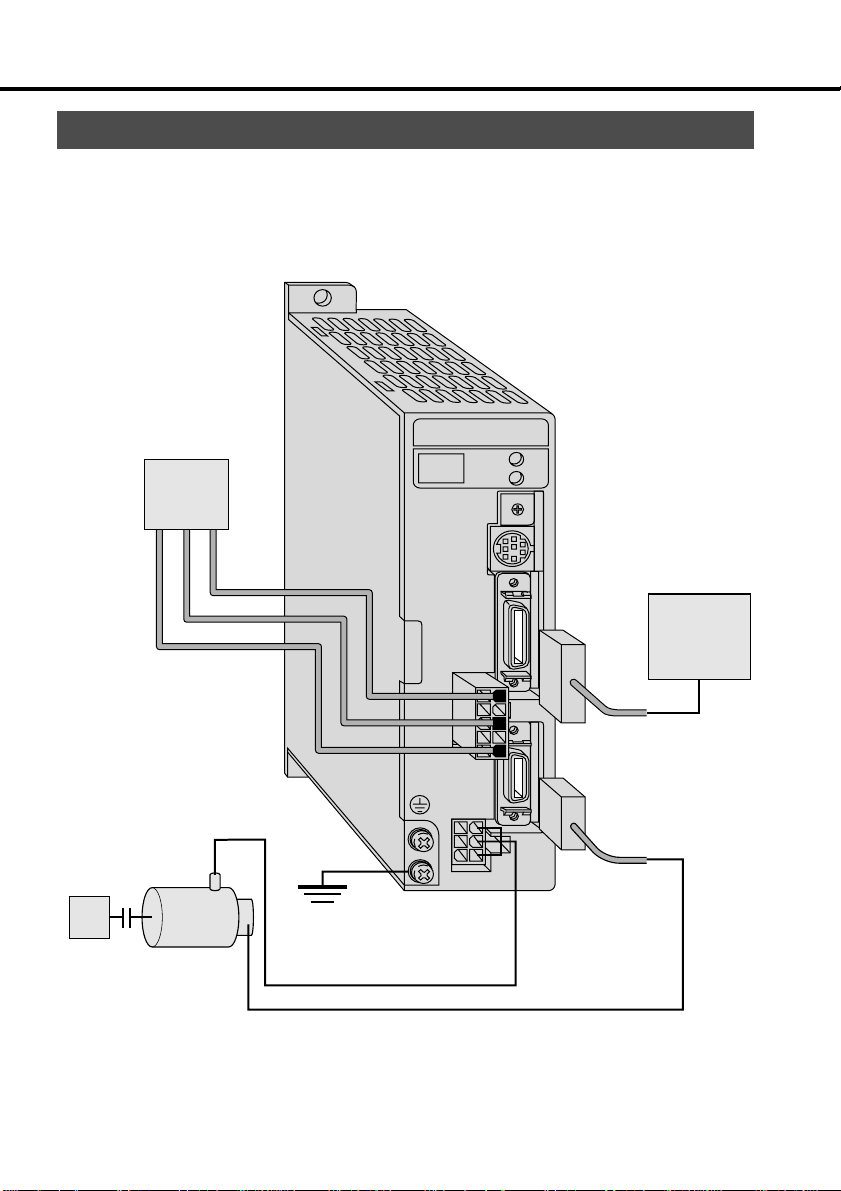

System Configuration and Wiring

General Wiring Diagram

• Main Circuits

Non-Fuse Breaker (NFB)

Used to protect the power lines:

overcurrent will shut off the circuit.

Noise Filter (NF)

Prevents the external noise from the power

line, and reduces the effect of the noises generated by the servo motor.

Magnetic Contactor (MC)

Turns on/off the main power of the servo

motor.

Used together with a surge absorber.

Reactor (L)

Reduces the harmonic current in the

main power.

Terminals P and B

• In case of use under large regenerative

energy, connect an external

regenerative discharge resistor to P

and B terminals.

<Notes>

Where residual-current-operated

protective device (RCD) is used for

protection in case of direct or indirect

contact. Only RCD of Type B is allowed

on supply side of this Electronic

Equipment (EE).

Ground

Regenerative

discharge resistor

-18-

Page 19

Personal computer

4

Preparations and Adjustments

CN

MOTOR

23

Hazardous Voltage

Others; Low Voltage circuit

CN

POWER

STATUS

ALM CODE

6

GAIN

5

CN

SER

CN

I/F

CN

SIG

Motor cable

Communication

control software

9

8

0

7

1

2

4

3

PANATERM

“

CN SER

(to connect a PC or

controller)

CN I/F

(to connect a controller)

CN SIG

(to connect an encoder)

Encoder cable

Power supply for motor

brake

(24VDC)

-19-

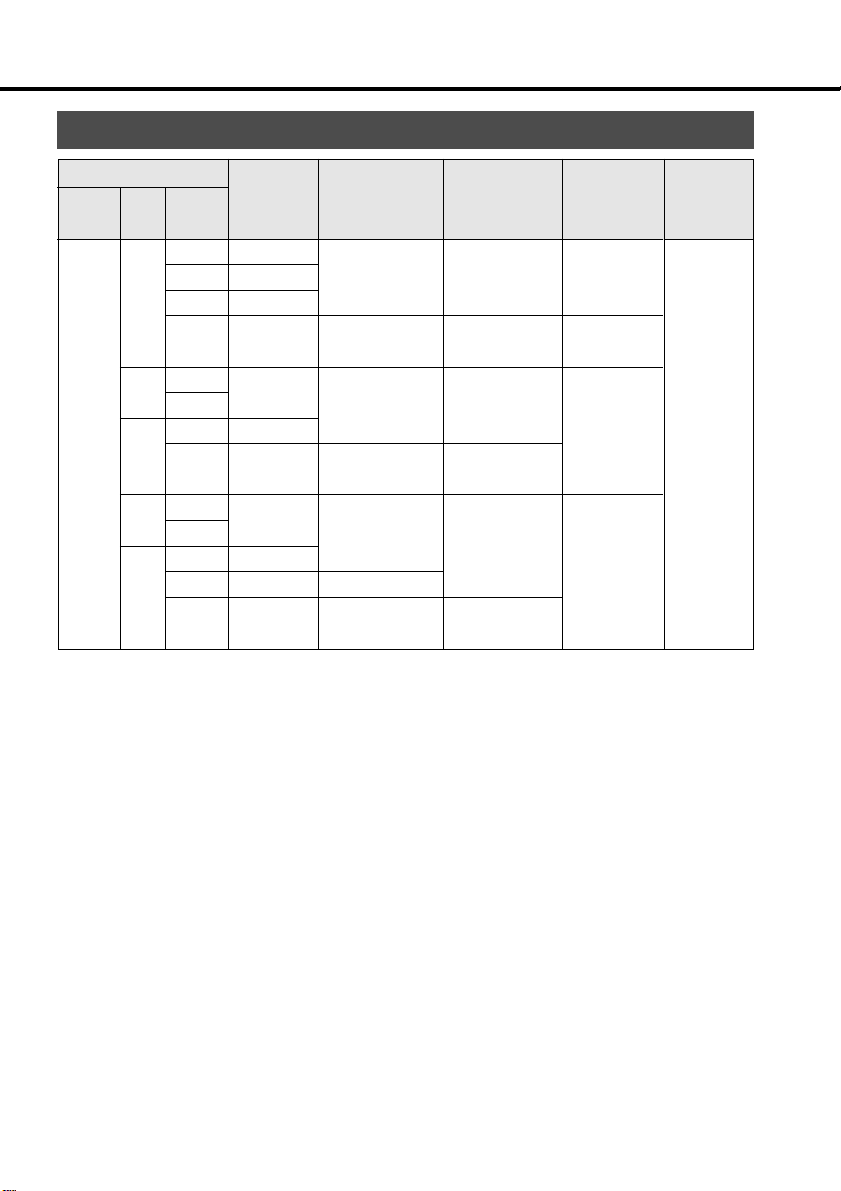

Page 20

System Configuration and Wiring

List of Available Components

Amplifier

Series

MUDS

Output

Voltage

30 ~ 50W

100W

1-phase,

200W

100V

400W

30 ~ 50W

*1-phase,

100W

200V

200W

1-phase,

400W

200V

30 ~ 50W

*3-phase,

100W

200V

200W

400W

3-phase,

750W

200V

Required Power

(at the rated load)

Approx. 0.3kVA

Approx.

0.4kVA

Approx.

0.5kVA

Approx.

1.0kVA

Approx.

0.3kVA

Approx.

0.5kVA

Approx.

0.9kVA

Approx.

0.3kVA

Approx.

0.5kVA

Approx. 0.9kVA

1.3kVA

Approx.

Circuit

breaker

(rated current)

BK251

(5A)

BK2101

(10A)

BK351

(5A)

BK3101

(10A)

BK351

(5A)

BK3101(10A)

BK3151

Noise

filter

DVOP1441

DVOP1442

DVOP1441

DVOP1442

DVOP1441

DVOP1442

Magnetic contactor

(contacts)

BMFT61041N

(3P+1a)

BMFT61541N

(3P+1a)

BMFT61541N

(3P+1a)

MMFT61042N

(3P+1a)

0.75mm

~ 0.85mm

AWG 18

Main circuit wire diameter

(L1 , L2, L3,

U, V, W, E)

2

2

(15A)

As these models with * are used for both 1-phase 200V and 3-phase 200V, make a choice

according to the power source.

•

When these wires are used, wire length between circuit breaker and amplifier should be less than 3 m.

•

The model numbers of circuit breaker and magnetic contactors shown in the above list are manufactured by

Matsushita Electric Works, Ltd.

• Use the circuit breaker as shown in App.3 to meet relevant EC Directives.

•

The model number of noise filters (options) shown in the above are manufactured by Okaya Electric Industries

Co., Ltd.

<Notes>

• CN POWER, CN MOTOR and earth terminals

Wires should be copper conductors of a temperature rating of 60˚C or above.

•

Earth wire diameter should be 2.0 mm2 (AWG14) or larger.

•

Please also consider the electrochemical potentials between metal conductor including closed loop terminals.

The electrochemical potentials shall be less than 0.6V.

- 20 -

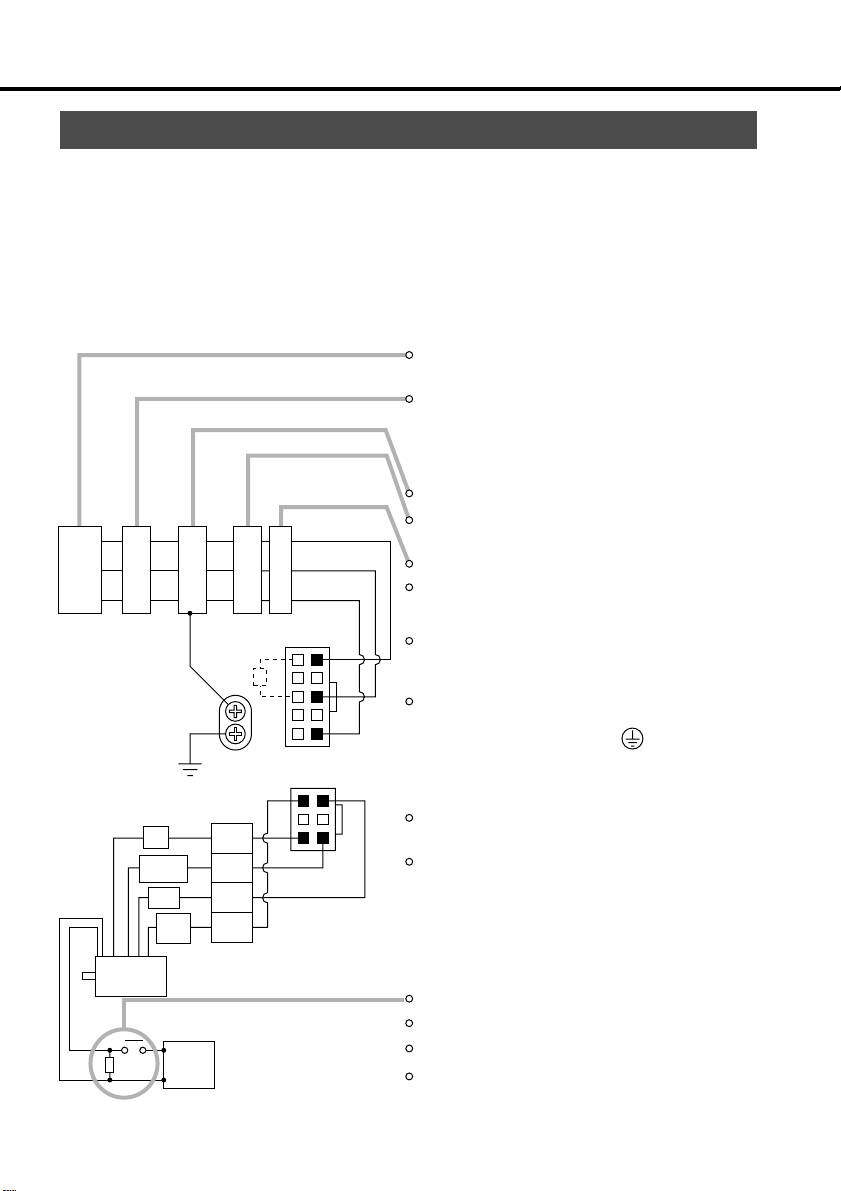

Page 21

For 3-phase 200VAC

3-phase

200V

172167-1

White or yellow

Motor

Red

Black

Green/yellow

1

2

3

4

NFB

172159-1

tyco Electronics AMPtyco Electronics AMP

Noise filter

12~24V

MC

MC

5557-10R-210

5557-06R-210

V

DC

ON

ALM

For 1-phase 100V/200V

Single-phase 100V or

Single-phase 200V

NFB

172167-1 172159-1

tyco Electronics AMP tyco Electronics AMP

Red

1

White or yellow

2

Black

3

Green/yellow

4

Noise filter

ON

MC

MC

5557-10R-210

5557-06R-210

MC

OFF

L

10

L1

8

L2

6

L3

5

3

1

4

6

W

3

9

ALM

13

COM –

OFF

L

10

L1

L2

6

L3

5

3

1

4

6

3

P

N

P

P

N

B

U

V

E

MC

P

N

P

P

N

B

U

V

W

E

Preparations and Adjustments

Motor

9

ALM

ALM

V

DC

12~24V

13

COM –

<Note>

In case that alarm occurs, construct the circuits so that the main power is switched off.

•

- 21 -

Page 22

System Configuration and Wiring

Main Circuits

Always ask to an electric engineer for wiring.

Don't turn on the main power until the wiring and connectings are completed, to avoid electric shocks.

Wiring Instructions

•

Make necessary connections.

For wire diameter, see List of Available Components (page 20).

•

Securely insert connectors.

See the nameplate of the amplifier to check

the power specification.

Install a non-fuse breaker or leakage breaker.

The latter should be a special one intended for

inverters, i.e. with a countermeasure against

higher harmonics.

Install a noise filter without fail.

Install a surge absorber to the magnetic

contactor coil.

Power

supply

NFB

NF MC L

D class ground: 100Ω max.

For wire diameter, see page 20.

U

Red

White or

yellow

Black

Green

yellow

1

V

2

W

3

E

4

CN

POWER

5

P

B

1

10

L1

L2

L3

6

CN

MOTOR

3

14

6

Install an AC reactor.

For three-phase 200V,connect L1(10pin), L2(8pin),

and L3(6pin).

For single-phase 100V and 200V, connect

L1(10pin) and L3(6pin).

Connect to the grounding system of the facility.

Never fail to connect between the amplifier's

protective earth terminal ( ) and control

board's protective earth terminal (ground plate)

in order to avoid electric shocks.

Ensure to connect matching in color between

the motor wires and terminals (U, V, W and E).

Don't short circuit or ground. Don't connect to

the main power.

Motor

Power supply for

DC

elector magnetic brake

24V

(Min, 0.5A)

The electromagnetic brake is not polar-sensitive.

For power capacities, see the App. 7.

For use of the brake, see "Holding Brake" in App. 6.

Install a surge absorber.

- 22 -

Page 23

CN SIG Connector (For Encoder)

Wiring Instructions

The cable length between the amplifier and motor should be max. 20 m. If you use a longer

cable, contact the dealer or sales agent.

Separate these wiring min. 30 cm from the

main circuit wires. Don't lay these wires in

the same duct of the mains or bundle with

them.

Motor

Power

Encoder

min.30cm

max.20m

POWER

MSDS

ALARM

GAIN

RS232C

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

Preparations and Adjustment

Wiring Diagrams

172171-1

tyco Electronics AMP

Yellow

Orange

Yellow

Green

Blue

Red

Pink

Light

Blue

Purple

White

Black

Moter side

tyco Electronics AMP

5

Z

6

Z

3

B

4

B

1

A

2

A

11

RX

12

RX

13

+5V

14

0V

15

FG

172163-1

Connecting cable

11

12

9

10

7

8

17

18

3

1

4

2

20

CN SIG

Z

Z

B

B

A

A

RX

RX

+5V

0V

+5V

0V

FG

Driver side

When you prepare your own connecting cables see the "Optional Parts"

for connectors, and

1) Follow the wiring diagram and use the

2) Wire material: 0.18 mm

2

(AWG24) or more,

shielded twist-paired wire Å@with an

enough bending durability,

3) Signal/power paired wires should be of a

twist-paired type.

4) Shield:

• The shield at the amplifier side should be

connected to Pin 20 (FG) of CN SIG Connector.

• The shield at the motor side should be connected to: connector of 15 pins type

5) If the cable is longer than 10 m, the encoder power line (+5V and 0V) should be

dual per the figure shown left.

6) Other terminals should be left

unconnected.

- 23 -

Page 24

System Configuration and Wiring

MSDS

CN

I/F

ALM CODE

STATUS

GAIN

CN

SER

CN SER Connector

For RC232C communications

Connect a personal computer to the amplifier with RS232C at 1:1, and use the

communication control software "PANATERM“" (Option). Operate "PANATERM“"

on the personal computer. Convenient functions of high operability can be

obtained such as monitor and parameter setting and setting change and

waveform graphic display.

Connection

Exclusive

connection cable

(Option)

Personal

computer

See App. 44.

CN SER RS232C connector

Insert and pull out connector

after cutting power to both

personal computer and

amplifier

Securely tighten the fixing

screw

- 24 -

Page 25

List of Available Components

CN I/F Connector (For Controller)

Wiring Instructions

Controller

Power

supply

Motor

max. 3 m

min. 30 cm

POWER

MSDS

ALARM

GAIN

RS232C

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

Place the peripheral devices such as the

controller max. 3 m away from the amplifier.

Separate these wiring min. 30 cm from the main

circuit wires. Don't lay these wires in the same

duct of the mains or bundle with them.

T

he control power (VDC) between COM+ and COM- should

Preparations and Adjustments

be supplied by the customer (recommended voltage:

+12VDC to +24VDC).

COM+

GND

1

2

Use a shielded twist-paired type for the wiring

of pulse input, encoder signal output, etc.

Do not apply power higher than 24V or 50mA to control

DC

V

signal output terminal.

If you directly activate a relay using the control

signal,install a diode in parallel to the relay as

COM-

shown in the left figure. Without a diode or with

it but placed in the opposite direction, the

amplifier will be damaged.

FG

CN I/F

• CN I/F Connector Specifications

Receptacle on the

amplifier side

10226-52A2JL

Part description

Solder type plug (Soldering type)

Connector cover

• The CN I/F pins assignment is shown in "Optional Parts" in Appendix.

The Frame Ground (FG) is connected to

an earth terminal in the amplifier.

Connector to controller side

Part No.

10126-3000VE

10326-52A0-008

- 25 -

Manufacturer

Sumitomo

three M

Page 26

System configutration and wiring

1

4.7k

Ω

220

Ω

220

Ω

COM+

PULS2

SIGN1

SIGN2

GND

OA+

OA

OB+

OB

OZ+

OZ

CZ

SPM

IM

22

23

24

25

14

15

16

17

20

330Ω

330Ω

330Ω

1

2

3

21

18

19

1K

1K

PULS1

SRV-ON

A-CLR

CL

GAIN

DIV

CWL

CCWL

ALM

COIN

BRKOFF

COM-

WARN

CN I/F

FG

2

3

4

5

6

7

8

9

10

11

13

12

26

V

DC

12~24V

CN MON

GND

Monitor pin

Monitor pin

If this is an open collector I/F,

see P1 in page 33.

Velocity monitor

output

Torque monitor

output

Command

pulse input

A-phase

output

B-phase

output

Z-phase

output

Z-phase output (open collector)

2nd gain switching

Servo-ON

Alarm clear

Position error counter clear

Command pulse scaler switch

CW overtravel inhibit

CCW overtravel inhibit

Servo alarm

In-position

Mechanical brake release

Alarm

(Pr09)

Scaler

Circuits Available for Typical Control Modes

• CN I/F Wiring for Position Control

- 26 -

Page 27

1

4.7k

Ω

COM+

PULS2

SIGN1

SIGN2

OA+

OA

OB+

OB

OZ+

OZ

CZ

SPM

IM

22

23

24

25

15

GND

14

16

17

20

21

1

2

3

18

19

1K

1K

PULS1

SRV-ON

A-CLR

INTSPD2

ZEROSPD

INTSPD1

CWL

CCWL

ALM

COIN

BRKOFF

WARN

COM

-

CN I/F

FG

3

4

2

5

6

7

8

9

10

11

12

13

26

V

DC

12~24V

220

Ω

220

Ω

CN MON

GND

330Ω

330Ω

330Ω

Servo-ON

Alarm clear

CCW overtravel inhibit

A-phase

output

B-phase

output

Z-phase

output

CW overtravel inhibit

Servo alarm

At-speed

Mechanical brake release

Alarm

(Pr09)

Internal vel .cmnd.select 1

Internal vel .cmnd.select 2

Speed zero clamp

Scaler

Z-phase output (open collector)

Monitor pin

Monitor pin

Velocity monitor

output

Torque monitor

output

Preparations and Adjustments

• CN I/F Wiring for Internal Velocity Control

- 27 -

Page 28

System configuration and wiring

CN I/F Connector

Input Signals (Common) and their Functions

Signal

Control signal

power

(+)

Control signal

power

(-)

Servo-ON

Alarm

clear

Position error

counter

clear/Internal

command

velocity

selection 2

Pin

Symbol Function

No.

COMÅ{

1

13

COMÅ|

2

SRV-ON

<Notes>

1. This signal becomes effective about two seconds after power on

(see the Timing chart).

2. Don't use this Servo-ON or Servo-OFF signal to turn on or off the

motor. (See App.8)

•

Allow at least 100ms delay after the amplifier is enabled before any

command input is entered.

•

By opening the connection to COM- , the amplifier will be disabled(Servo-OFF) and

the current flow to the motor will be inhibited.

•

Operation of the dynamic brake and clearing action of the position error counter can be

selected using Pr69 (Sequence under Servo-OFF).

3

A-CLR

4

CL/

INTSPD2

Position

control

Internal

velocity

control

•

Connect to (+) of an external power supply(12VDC to 24VDC).

•

Use power supply of 12V±10%Å`24V±10%

•

Connect to (-) of an external power supply(12VDC to 24VDC).

•

The required capacity depends on the I/O circuit configuration.

0.5A or larger is recommended.

•

When this signal is connected to COM-, the dynamic brake will be

released and the amplifier is enabled. (Servo-ON).

•

If the COM- connection is kept closed for more than 120 ms,

the alarm status will be cleared.

•

Some alarms cannot be cleared by this input.

For details, see Protective Functions on page 60.

The function differs depending on the control mode.

• Clears the position error counter. Connect to COMto clear the counter.

•

Use Pr4D to select the clear mode (0 Default: level 1: Edge)

•

The internal velocity selection 2 (input) is valid. 4 kinds of

velocity settings are available by combination with DIV/

INTSPD1 input. See control mode setting Pr02 (APP. 16).

I/F

circuit

Å\Å\

SI

page 33

SI

page 33

SI

page 33

- 28 -

Page 29

Signal

Gain

switching/

Speed zero

clamp

Pin

Symbol Function

No.

GAIN/

5

ZEROSPD

Position

control

Internal

velocity

control

The function differs depending on the control mode.

•

The functions depend on the value of Pr30.

•

Gain switching input results. Input for switching PI/P

operation and No. 1/No. 2 gains.

Connection

Pr30

to COM-

value

0

Open

(Default)

Close

1

Open

Close

At Pr31 value of 2

•

For No.2 Gain change Funcution, see Protective Adjustments on page 57.

•

Speed zero clamp input results. With COM- open, the

velocity command is considered zero.

• This input can be made disabled using Pr06.

• Default: Contact is set. With COM- open, the velocity

command is considered zero.

Pr06 value

0

1

[Default]

Speed loop:PI(ProportionalÅEIntegration) operation

Speed loop: P (Proportion) operation

#1 gain selection (Pr10, 11, 12, 13, 14)

#2 gain selection (Pr 18, 19, 1A, 1B, 1C)

ZEROSPD is disabled.

ZEROSPD is enabled

Function

Meaning

I/F

circuit

SI

page 33

Preparations and Adjustments

Command

pulse scaler

switch/

Internal

command

velocity

selection 1

6

INTSPD1

Position

control

Internal

velocity

control

DIV/

The function differs depending on the control mode.

This is the input to switch command pulse scaler.

•

•

With COM- closed, the numerator of the command scaler is changed

from the value stored in Pr46 (Numerator of 1st Command Scaler) to

the value stored in Pr47 (Numerator of 2nd Command Scaler).

<Note>

Don't enter command pulses 10 ms after or before switching.

•

The internal velocity selection 1 (input) is valid. 4 kinds of velocity

settings are available by the combination with CL/INTSPD2 input.

• See control mode setting Pr02 (APP. 16).

- 29 -

SI

page 33

Page 30

System configuration and wiring

Signal

CW overtravel

inhibit

CCW overtravel

inhibit

Pin

Symbol Function

No.

7

CWL

8

CCWL

•

If COM- is opened when the movable part of the

machine has moved to CW exceeding the limit, the

motor does not generate torque.

•

If the COM- is opened when the movable part of the

machine has moved CCW exceeding the limit, the

motor does not generate torque.

•

When Pr04 (Overtravel Limit Input Disabled) = 1, CWL

and CCWL inputs are disabled. The default is

"Disabled" (1).

•

The dynamic brake can be made operable during CWL/

CCWL inputs valid. Use Pr66 (Dynamic Brake

Inactivation at Overtravel Limit) to make the dynamic

brake operable. The default is to allow the dynamic

brake to operate. (Pr66 value is 0.)

Input Signals (Position Control) and their Functions

Signal

Command

pulse

Command

sign

Pin

Symbol Function

No.

22

23

24

25

PULS1

PULS2

SIGN1

SIGN2

This is the input terminal for command pulses. The maximum allowable

•

input frequency is 500 kpps for line amplifier input and 200 kpps for

open collector input. The amplifier is the high-speed photocoupler

of TOSHIBA TLP554 or equivalent.

• The input impedance of PULSE and SIGN signals is 220Ω.

•

Command pulses can be input in three different ways. Use Pr42 to

select one of the following. (See App.26.)

1) Quadrature (A and B) input

2) CW (PULSE)/CCW (SIGN) pulse input

Command pulse (PULS)/Sign (SIGN) input

3)

I/F

circuit

SI

page 33

SI

page 33

I/F

circuit

PI

page 33

- 30 -

Page 31

Output Signals (Common) and their Functions

Signal

Servo alarm

In-position/

At-speed

Mechanical

brake release

Warning

Pin

Symbol Function

No.

9

ALM

10

COIN

Position

control

Internal

velocity

control

11

BRK-OFF

12

WARN

Pr0A value

0

1

2

[Default]

3

4

5

• This output (transistor) turns off, when the

detector detects an alarm.

• The function differs depending on the control

mode.

• In-position output

•

Output(transistor) turns ON when the position error is below the

preset value by Pr60 (In-Position Range).

• At-speed.

•

This output (transistor) turns ON, when the motor speed exceeds

the preset value by Pr62 (At-Speed).

•

Used to release the motor electromagnetic brake.

•

Use "Output (transistor) ON" to release the electromagnetic brake.

• See Timing Charts (App. 10 -13).

•

Signal which is selected at Pr09 (warning output selection)

will be turned on. This output (transistor) turns ON at least

for one second after warning indication signals are output.

"In-torque limiting" output

Output(transistor) turns ON during the In-toque limiting.

Zero speed output

Output(transistor) turns ON when the motor speed becomes

lower than that of the preset speed with Pr61(Zero speed).

Output of both over-regeneration and overload warnings

Output(transistor) turns ON when either one of overregeneration or overload is activated.

Over-regeneration warning output

Output(transistor) turns ON when the over-regeneration

(more than 85% of permissible power of the internal

regenerative discharge resistor) warning is activated.

Overload warning output

Output(transistor) turns ON when the overload (the

effective torque is more than 85% of the overload trip

level) warning is activated.

Does not function, although displayed.

I/F

circuit

SO1

page 34

SO1

page 34

Preparations and Adjustments

SO1

page 34

SO1

page 34

Function

- 31 -

Page 32

System configuration and wiring

Signal

A-phase output

B-phase output

Z-phase output

Z-phase output

Signal

ground

Pin

Symbol Function

No.

•

15

16

17

18

19

20

21

14

OA +

OA OB +

OB OZ +

OZ -

CZ

GND

Provides differential outputs of the encoder signals

(A, B and Z phases) that come from the divider

(equivalent to RS422 signals).

•

The logical relation between A and B phases can be selected by

Pr45 (Output Pulse Logic Inversion).

• Not insulated

• Z-phase signal output in an open collector

• Not insulated

• Signal ground for pulse output

Internally isolated from the control power (COM-).

•

Others

Signal

Frame

ground

Pin

Symbol Function

No.

• Internally connected to the earth terminal.2 6 FG ------

Output Signals (Others) and their Functions

Signal

Speed

monitor

signal

output

Torque

monitor

output

Signal

ground

Pin

Symbol Function

No.

1

2

3

SP

IM

GND

Outputs the motor speed, or voltage in proportion to the

•

commanded speed with polarity.

+ : CCW rotation

– : CW rotation

Use Pr07 (Velocity Monitor Selection) to switch between actual

•

and commanded speed, and to define the relation between

speed and output voltage.

•

Outputs the output torque, or voltage in proportion to the position

error with polarity.

+ : generating CCW-torque

– : Fgenerating CW-torque

Use Pr08 (Torque Monitor Selection) to switch between torque

•

and positional error, and to define the relation

between torque/positional error and output voltage.

• Signal ground for monitor signal

• Internally isolated from the control power (COM-

).

I/F

circuit

PO1

page 34

PO2

page 35

------

I/F

circuit

I/F

circuit

AO

page 35

AO

page 35

-----

- 32 -

Page 33

CN I/F Connector

Interface Circuit (Input Circuit)

Connecting to

SI

sequence input signals

•

Connect to a contact of switch and relay, or a tran-

sistor of an open collector output.

•

Use a switch or relay for micro current so that in-

sufficient contact can be avoided.

•

Can be used with COM- instead of COM+

PI Command pulse

input circuit

1) Line Amplifier I/F

•

This is a good signal transmission method that is

less sensitive to noises. We recommend you to

use this to maintain the reliability of signals.

2) Open Collector I/F

This uses an external control power supply(VDC).

•

•

This requires a current-limiting resistor correspond-

ing to the capacity of the VDC value.

VDC R value

12V 1kΩ1/4W

24V 2kΩ1/4W

V

DC

V

DC

Available at reverse polarity

1)

2)

12~24V

12~24V

AM26LS31or equivalent

Relay

Relay

R

R

1

V

DC

COM+ 4.7k

Servo-ON or

other input

Servo-ON or

other input

COM+ 4.7k

1

PULS1

22

23

PULS2

SIGN1

24

25

SIGN2

14

GND

22

23

24

25

14

220Ω

220Ω

PULS1

PULS2

SIGN1

SIGN2

GND

Ω

Preparations and Adjustments

Ω

220Ω

220Ω

V

DC - 1.5

R + 220

10mA

shows a pair of twisted wires.

- 33 -

Page 34

System configuration and wiring

Interface Circuit (Output Circuit)

SO1

Sequence output circuit

•

This comprises a Darlington amplifier with

an open collector. This is connected to a

relay or photo coupler.

• There exists a collector-to-emitter

voltage V

transistor ON, because of Darlington

connection of the output transistor.

Note that normal TTL IC can't be

directly connected since this

does not meet V

•

If the recommended current value of the actual

photocoupler is 10mA, calculate the resistance

using the formula below.

For the recommended current value, see the data sheets

of actual equipment and photocoupler.

CE(SAT) of approx. 1.2V at

IL requirement.

DC - 2.5

V

R =

10

[KΩ]

12~24V

Install as per the fig. shows

without fail

SO1

ALM

V

DC

R [kΩ]

SO1

WARN

or other

signal

COM–13

Maximum rating:

30V, 50mA

PO1

Line Driver (Differential Output)

Output

• Provides differential outputs of encoder

signals (A, B and Z phases) that come

from the scaler.

• Receive these signals with a line receivers. In this case, install a resistor of

approx. 330Ω between the inputs.

shows a pair of twisted

wires.

AM26LS32

or equivalent

OA+

OA-

OB+

OB-

OZ+

OZ-

Connect the amplifier signal grounds to the

controller.

- 34 -

AM26LS31

or equivalent

15

16

17

18

19

20

GND

14

A

B

Z

Page 35

PO2

Open Collector Output

• Outputs Z-phase signals among those

from the encoder. The outputs are noninsulated.

• Receive these signal with high-speed

photo coupler at controller side, since

these Z-phase signal width is normally

narrow.

shows a pair of twisted wires.

CN MON Connector

Monitor Circuit (Output Circuit)

AO

Analogue Monitor Output

• Output from CN MON Connector

• This output is the velocity monitor signal

(SP) or torque monitor signal (IM).

The signal range is approx. 0 to 9V.

•

• The output impedance is 1kΩ. Pay attention to the input impedance of your measuring instruments and

external circuits connected.

Maximum rating:

1914CZ

GND

High-speed

photo coupler

TOSHIBA TLP554 or equivalent

CN MON

1k

SP1

Measuring

instrument

or external

circuit

1k

2

IM

GND

3

30V, 50mA

Preparations and Adjustments

Ω

Ω

<Resolution>

1) Velocity monitor signal (SP): 8r/min./

LSB calculated from 6V/3000r/min

(Pr07 = 3)

2) Torque monitor signal (IM): 0.4%/LSB

calculated from 3V/rated value (100%)

- 35 -

Page 36

Parameter Setting

Overview

The servo amplifier has various parameters that are used for adjusting or setting the features or functions of the amplifier. This section describes the purpose and functions of these parameters. Understanding these parameters is

essential for obtaining the best, application-specific operation of the amplifier.

You can view, set and adjust these parameters using your personal computer

with the communication software PANATERM“.

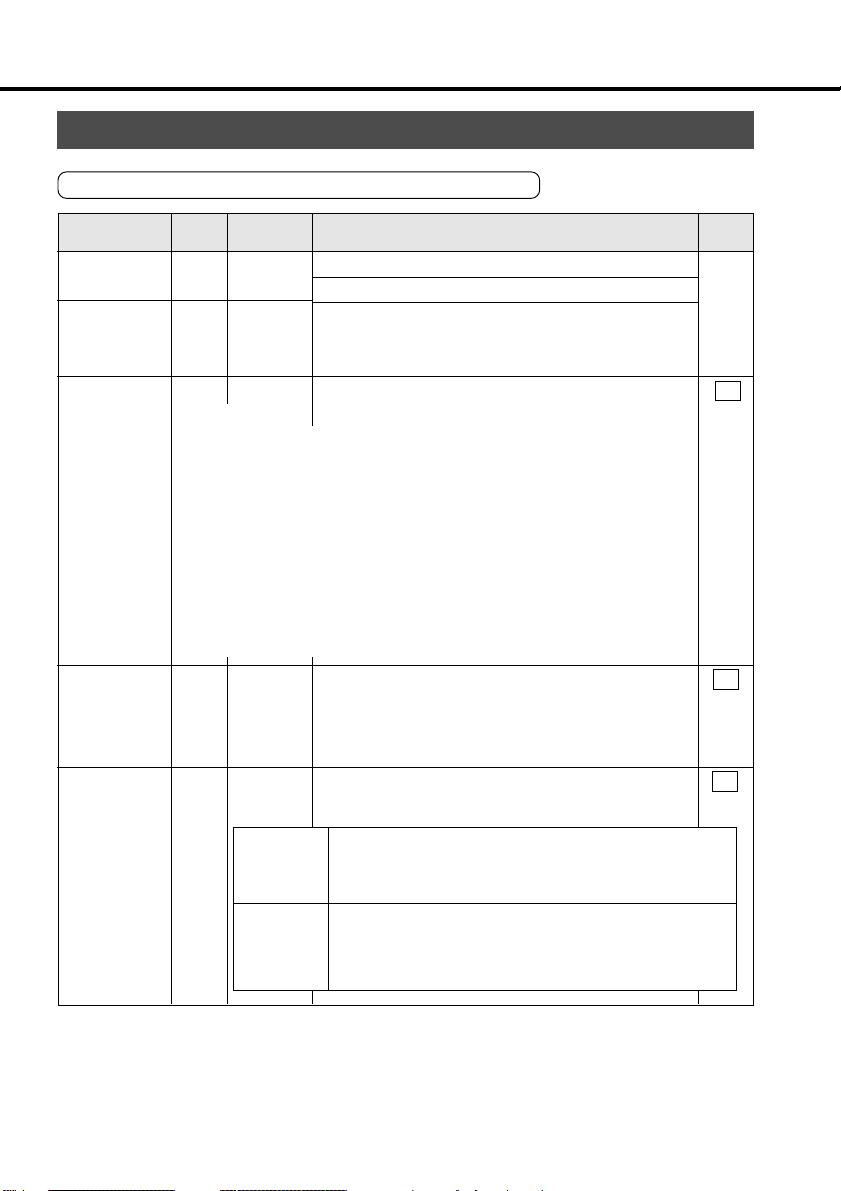

Parameter Groups and Listing

Group

Function selection

Adjustment

Position control

Internal velocity and

torque control

Sequence

For details, see "Details of Parameters" in Appendix.

ParameterNo.

Pr**

00 ~ 0F

10 ~ 1F

20 ~ 22

30 ~ 35

40 ~ 4D

53 ~ 5A

5E

60 ~ 6C

You can select the control mode, allocate I/O signals,

and set the baud rate and etc.

You can set various factors and constants such as

the servo gains (1st and 2nd) for position, velocity

and integration, and time constants of filters.

Real time auto-tuning parameters. You can set the

real time auto-tuning mode, select the machine

stiffness, etc.

You can set the parameters relating to the switching between 1st and 2nd gains.

You can set the input format of command pulses,

logical selection, encoder pulse rate and pulse scaler.

You can set the internal speed (1st to 4th), and it's

acceleration and deceleration time.

You can set the torque limit.

You can set the conditions for detecting the output such as inposition and zero-speed, and set the processing conditions at

excess position error, etc.

You can also set the conditions for stopping at the main poweroff, in-alarm and servo-off, or conditions for the error counter

clearance, etc.

Brief explanation

<Notes>

Parameters marked with * are enabled, when set data are written to EEPROM,

main power is once turned OFF and then turned ON again.

- 36 -

Page 37

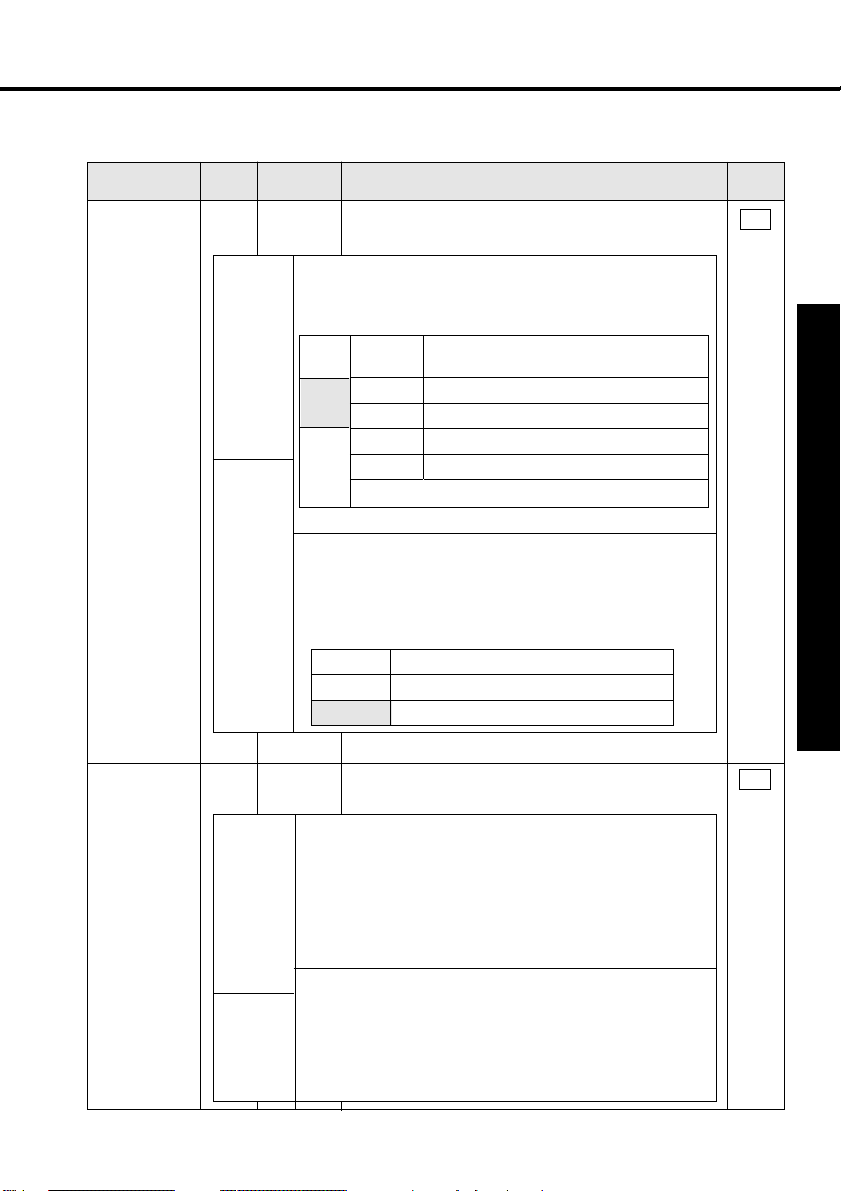

Parameters for Selecting Function

Parameter

NO.

(

Pr**

)

Åñ0 0

Åñ0 1

Åñ0 2

Åñ0 3

Åñ0 4

Åñ0 5

Åñ0 6

Åñ0 7

Åñ0 8

Åñ0 9

Åñ0 A

Åñ0 B

Åñ0 C

Åñ0 D

0 E, 0 F

For values marked with *, see page 36.

Axis address

(Internal use)

Control mode set-up

(Internal use)

Overtravel Input inhibit

(Internal use)

ZEROSPD input selection

Speed monitor(SP) selection

Torque monitor (IM) selection

Warning output selection

(Internal use)

(Internal use)

Baud rate set-up of RS232C

(Internal use)

(Internal use)

Parameter description

Range Default Unit

0 ~ 15

-----

0 ~ 1

------

0 ~ 1

----0 ~ 1

0 ~ 9

0 ~ 5

0 ~ 5

------

------

0 ~ 2

------

------

1

0

0

1

1

1

1

3

0

2

1

1

2

2

0

Parameters for Adjusting Time Constants of Gain Filters, etc.

Parameter

NO.

(

Pr**

)

Åñ1 0

Åñ1 1

Åñ1 2

Åñ1 3

Åñ1 4

Åñ1 5

Åñ1 6

Åñ1 7

Åñ1 8

Åñ1 9

Åñ1 A

Åñ1 B

Åñ1 C

Åñ1 D

Åñ1 E

Åñ1 F

1st position loop gain

1st velocity loop gain

1st velocity loop integration time constant

1st speed detection filter

1st torque filter time constant

Velocity feed forward

Feed forward filter time constant

(Internal use)

2nd position loop gain

2nd velocity loop gain

2nd velocity loop integration time constant

2nd speed detection filter

2nd torque filter time constant

Notch frequency

Notch width selection

Disturbance torque obserber

Parameter description Range Default Unit

0

~

1

1

0

0

0

0

1

1

0

100

~

~

0

~

~

~

~

----- ~

~

~

0

~

~

~

0

~

0 ~ 8

2000

3500

1000

5

2500

100

6400

2000

3500

1000

5

2500

1500

4

100

100

50

4

50

0

0

0

100

100

50

4

50

1500

2

8

------

------

------

------

------

------

-----

------

------

------

------

------

------

------

------

1/s

Hz

ms

------

0.01ms

%

0.01ms

-----1/s

Hz

ms

------

0.01ms

Hz

------

------

Preparations and Adjustments

- 37 -

Page 38

Parameter Setting

Parameters for Defining the Real Time Auto Gain Tuning

Parameter No.

(Pr**)

Åñ2 0

Åñ2 1

Åñ2 2

Åñ2 3

2 4 ~ 2 F

Inertia ratio

Real time auto tuning set-up

Machine stiffness at auto tuning

(Not available)

(Internal use)

Parameter description Range Default Unit

0 ~ 10000

Parameters for Adjustments (for 2nd Gain)

Parameter No.

(Pr**)

Åñ3 0

Åñ3 1

Åñ3 2

Åñ3 3

Åñ3 4

Åñ3 5

Åñ3 6

3 7 ~ 3 9

3 E ~ 3 F

2nd gain action set-up

Position control switching mode

Position control switching delay time

Position control switching level

Position control swiching hysteresis

Position loop gain switching time

(Not available)

(Not available)

(Internal use)

Parameter description Range Default Unit

0 ~ 10000

0 ~ 10000

0 ~ 10000

0 ~ 10000

0 ~ 3

0 ~ 9

-----

-----

0 ~ 1

0 ~ 8

-----

-----

-----

100

0

2

100

0

0

0

0

0

0

0

0

0

0

%

-----

-----

-----

-----

-----

-----

166µs

-----

-----

(1 + Setting value)

x166µs

-----

-----

-----

- 38 -

Page 39

Parameters for Position Control

Parameter No.

(Pr**)

*4 0

*4 1

*4 2

4 3

*4 4

*4 5

Åñ4 6

Åñ4 7

Åñ4 8

Åñ4 9

Åñ4 A

Åñ4 B

Åñ4 C

Åñ4 D

4 E, 4 F

For values marked with *, see <Note> in page 36.

Command pulse multiplier set-up

Command pulse logic inversion

Command pulse input mode set-up

(Internal use)

Output pulses per single turn

Pulse output logic Inversion

Numerator of 1st command pulse ratio

Numerator of 2nd command pulse ratio

(Internal use)

(Internal use)

Multiplier of numerator of command pulse ratio

Denominator of command pulse ratio

Smoothing filter set-up

Counter clear input

(Internal use)

Parameter description Range Default Unit

1 ~ 16384

1 ~ 10000

1 ~ 10000

0 ~ 17

1 ~ 10000

Parameters for Velocity and Torque Control

Parameter No.

(Pr**)

Åñ5 0

Åñ5 1

Åñ5 2

Åñ5 3

Åñ5 4

Åñ5 5

Åñ5 6

Åñ5 7

Åñ5 8

Åñ5 9

Åñ5 A

Åñ5 B

Åñ5 C

Åñ5 D

Åñ5 E

Åñ5 F

(Internal use)

(Internal use)

(Internal use)

1st internal speed

2nd internal speed

3rd internal speed

4th internal speed

(Internal use)

Acceleration time set-up

Deceleration time set-up

S-shaped Accel./Decel. time set-up

(Internal use)

(Internal use)

(Internal use)

Torque limit set-up

(Internal use)

Parameter description Range Default Unit

- 10000 ~ 10000

- 10000 ~ 10000

- 10000 ~ 10000

- 10000 ~ 0000

0 ~ 5000

0 ~ 5000

0 ~ 500

0 ~ 500

1 ~ 4

0 ~ 3

0 ~ 3

1

0 ~ 1

-----

-----

0 ~ 7

0 ~ 1

-----

-----

-----

-----

-----

-----

-----

-----

-----

4

0

1

1

2500

0

10000

10000

10000

10000

0

10000

1

0

0

500

1

0

0

0

0

0

300

0

0

0

0

30

0

300

0

-----

-----

-----

-----

-----

-----

-----

-----

-----

-----

n

2

-----

-----

-----

-----

-----

----r/min

r/min

r/min

r/min

-----

2ms/kr/min

2ms/kr/min

2ms

-----

-----

-----

%

-----

Preparations and Adjustments

- 39 -

Page 40

Setting the Parameters

Parameters for Sequence

Parameter No

(Pr )

Åñ6 0

Åñ6 1

Åñ6 2

Åñ6 3

Åñ6 4

Åñ6 5

Åñ6 6

Åñ6 7

Åñ6 8

Åñ6 9

Åñ6 A

Åñ6 B

* 6 C

6 D ~ F

For values marked with *, see <Note> in page 36.

Parameter description Range Default Unit

In-position range

Zero speed

At-speed

Position error set-up

0 ~ 32767

0 ~ 10000

0 ~ 10000

0 ~ 32767

Position error invalidation

(Internal use)

Dynamic Brake inhibition at overtravel limit

(Internal use)

Sequence at alarm

Sequence at Servo-OFF

Mech. break action set-up at motor stadstill

Mech. break action set-up at motor in motion

External regenerative discharge resistor selection

(Internal use)

0 ~ 1

------

0 ~ 1

-----0 ~ 3

0 ~ 7

0 ~ 100

0 ~ 100

0 ~ 2

------

10

50

1000

1875

0

1

0

0

0

0

0

0

2

0

Pulse

r/min

r/min

256Pulse

------

------

------

------

------

-----2ms

2ms

------

------

Set-up range of excessive positional deviation of Pr63 is "Set-up value x 256 pulses".

Set-up is made before shipment so that the excessive positional deviation error takes

place at value in excess of 1875 x 256 pulses.

Pr5E Torque limit set-up

Power supply

for amplifier

Single-phase

100V

Single-phase

200V

3-phase /

Single-phase

200V

3-phase

200V

Amplifier

MUDS3A1A1A

MUDS5A1A1A

MUDS011A1A

MUDS021A1A

MUDS041A1A

MUDS022A1A

MUDS042A1A

MUDS3A5A1A

MUDS5A5A1A

MUDS015A1A

MUDS023A1A

MUDS043A1A

MUDS083A1A

Amplifier

type

Type 1

Type 2

Type 3

Type 2

Type 3

Type 1

Type 2

Type 3

Default

300

330

350

330

300

330

300

• Pr5E "Torque limit set-up"

disables set-up in excess of

the values set up for the

system parameter "Max. torque

set-up".

Values for "Max. torque set-up"

are same as defaults.

• The system parameters are

fault parameters that cannot

be changed with PANATERM

or on the operation panel.

“

- 40 -

Page 41

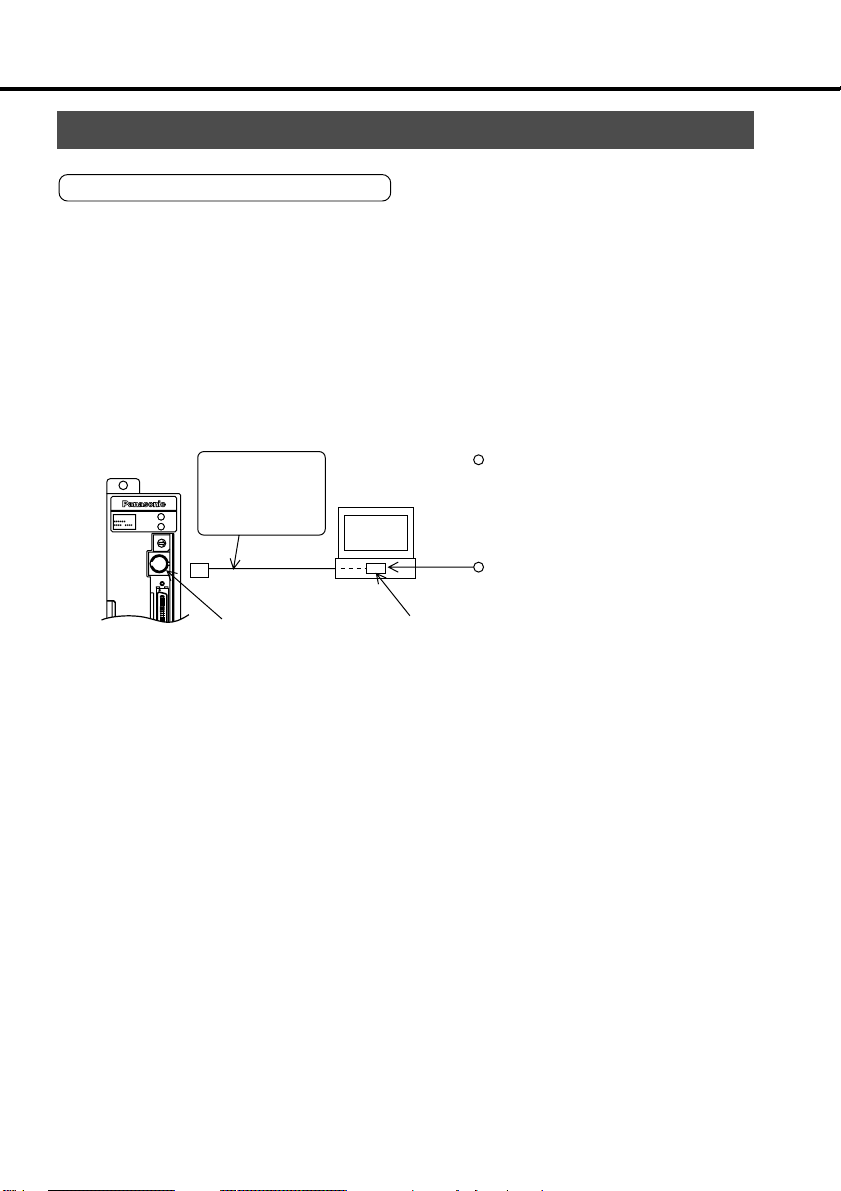

Setting the Parameters

• You can set the Parameters with

your personal computer with the S-series communication software PANATERM“.

<Notes>

For the use of PANATERM“ for parameter handling, see the instruction manual of the software.

Preparations and Adjustments

Overview of PANATERM

“

You can conduct the following operations using PANATERM“:

1)

Setting the Parameters for amplifier, storing them, and writing in the memory (EEPROM)

2)

Monitoring input/output status, monitoring pulse input, monitoring load ratio.

3)

Checking current error status and error history

4)

Measurement of wave form graphic data, and storage and reading of the data

5)

Automatic tuning

6)

Measurement of frequency characteristics

How to Connect

POWER

MSDS

ALARM

GAIN

CN

SER

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

RS232C cable

Connect to

CN SER.

DVOP1960

DVOP1160

Setup disc of DVOP2820

communication software

PANATERM

(DOS/V)

(For PC-98 series)

“

- 41 -

Page 42

Setting the Parameters

Installing PANATERM“ on a hard disc

<Notes>

1. The memory capacity of the hard disc should be 15MB or more. Prepare OS of Windows

or Windows

2. Install PANATERM

98.

“

with setup discs, otherwise the software does not work.

“

Procedure

1)

Turn on your personal computer. Start Windows“95 (or 98).

(If there is any application program on, close all of them.)

2) Insert the PANATERM

3) Start Explorer, and switch (select) to the floppy disk drive. (For the procedure for starting the Explorer program,

see the instructions for Windows

4) Double click on the setup program (Setup. exe) in the floppy disk. (PANATERM

5) Click on to start the setup program.

6) Keep the operation according to the guide of the setup program.

(When indication to replace the setup disk appears, follow this instruction.)

7) Click on Start installing? to start the setup routine.

8) Confirm an message "Setup completed". Then click on .

9) Close all the applications. Then restart Windows

restarted.

OK

setup floppy disk in the floppy disk drive.

“

.)

“

OK

. PANATERM“ will be added to the program menu when

“

setup program will start.)

“

95

“

- 42 -

Page 43

Starting PANATERM

<Notes>

1. Once you install PANATERM

next use.

2. Before using PANATERM

connected. For the procedure for starting PANATERM

“

on your hard disc, you do not have to install it again for

“

, the amplifier, power supply, motor and encoder should be

“

, see the Windows“ manual

“

Procedure

1)

Turn on your personal computer. Start Windows“95 (or 98).

2) Turn on the amplifier.

3) Click on the start button of Windows

4) Select (click on) PANATERM

5) An opening splash will be displayed for two seconds, and then PANATERM

(see the Windows“ manual).

“

from the program menu.

“

screen will appear.

“

.

Preparations and Adjustments

For the operation, functions and other details about PANATERM

PANATERM

program.

“

, see the Instructions for the

“

- 43 -

Page 44

Trial Run

Inspections before Trial Run

1) Inspecting the wiring

• Make sure that all wire connections (especially main power and motor output ) are correct.

• Make sure that there is no short, and earth wires are properly connected.

• Make sure that there is no poor connections.

2) Inspecting the

power specifications

• Make sure that the voltage is

correct.

STATUS

ALM CODE

Power

GAIN

CN

SER

8

7

9

6

0

5

1

4

2

3

3)

Securing the servo motor

• Make sure that the servo

motor is firmly secured.

4)

Disconnecting the motor load

Trial run without load

5)

Releasing the brake

Motor

Machine

(motor load)

Ground

- 44 -

CN

POWER

CN

MOTOR

CN

I/F

Controller

CN I/F

CN

SIG

CN SIG

Page 45

Operation with CN I/F Connected

1) Connect CN I/F.

2) Connect the control signal (COM+/-) to the power supply (12 to 24V DC).

3) Turn the main power (amplifier) ON.

4) Check the defaults of the parameters. Control mode setting (Pr2 value: 0).

5) Connect between SRV-ON (CN I/F pin 2) and COM- (CN I/F pin 13) to make Servo-On active. The

motor will be kept excited.

Run at Position Control Mode

1) Set Pr42 (Command Pulse Input Mode Set-Up) according to the output form of the controller. Then

write it down to EEPROM. Then turn the power OFF and then ON again.

2) Send a low-frequency pulse signal from the controller to the amplifier to run the motor at low

speed.

3) Check the motor speed at monitor mode with PANATERM“.

• Make sure that the speed is per the set-up.

• Check if the motor stops when the command (pulse) is stopped.

Preparations and Adjustments

DC

12V~24V

DC

5V

Wiring Diagram

1

COM+

2

SRV-ON

13

COM–

22

120Ω

120Ω

PULS1

23

PULS2

24

SIGN1

25

SIGN2

21

CZ

14

GND

Parameters

Parameter description

PrNo.

Control mode set-up

Pr02

Overtravel input inhibit

Pr04

Command pulse input mode set-up

Pr42

Use the controller to send command pulses.

In case of op

collector for

CW/CCW

pulse inputs

Z-phase

output

for homing

- 45 -

Input Signals Status

No.

Input signal

0

Servo-ON

A

Counter clear

Monitor display

+ A

---

Value

0

1

1

with PANATERM

“

Page 46

Trial Run

Set-up of motor speed and input pulse frequency

Pr 4B

10000

5000

2000

10000

Pr 4A

0

0

0

0

Gear

Pulley ratio: 18/60

60°

Gear ratio: 12/73

Overall reduction: 18/365

Input pulse

frequency

(pps)

500k

250k

100k

500k

* You can set any value by setting any value for the numerator and denominator. However, the motor action will not

follow the extreme setting of the ratio. It is recommended to set within a range from 1/50 to 20.

Motor

speed

(r/min)

3000

3000

3000

1500

Pr 46 x 2

2500P/r

10000 x 2

10000 x 2

10000 x 2

5000 x 2

Relationship between motor speed

and input pulse frequency

(Example) Rotate the motor by 60 degrees with an overall reduction ratio of 18/365

Encoder pulse

2500P/r

108

10000

108

0

60Åã

360Åã

0

Pr46 x 2

Pr4A

Pr4B

Theory

Determining

the

parameter

365 x 2

Set the parameter so that motor

turns 60Åãwith 10000 pulses when

a command is entered from the

controller to the amplifier.

3651810000

x x

365 x 2

=

<Notes>

Default: The motor output shaft turns one revolution with 10000 pulses.

- 46 -

Page 47

Test Run at Internal Velocity Control Mode

1) Select the internal velocity control mode (Pr02: 1) for the control mode.

2) Run with zero speed clamp input (ZEROSPD) (5 pin) switch close, and rotate the motor with the

combination of the internal command speed selection INTSPD 1 (6 pin) and INTSPD 2 (4 pin).

3) Check the motor speed on the PANATERM

ÅE

Speed and direction

4) Make sure that the motor stops by making zero speed clamp input (ZEROSPD) open.

5) To change the speed or direction, adjust the following parameters again.

Pr53 - Pr56: Velocity set-up for 1st speed through 4th speed See "Details of Parameters"

in Appendix 31.

monitor.

“

Preparations and Adjustments

Wiring Diagram

DC

12V~24V

1

COM+

2

SRV-ON

4

INTSPD2

5

ZEROSPD

6

INTSPD1

COM

-

ZEROSPD

switch

Close: Run

Open: Stop

Internal speed

1st speed (Pr53)

2nd speed (Pr54)

3rd speed (Pr55)

4th speed (Pr56)

Parameters

PrNo.

Pr02

Pr04

Pr06

Pr53

Pr56

Pr58

Pr59

Pr5A

Parameter description

Control mode set-up

Overtravel input inhibit

ZEROSPD input selection

Velocity

~

set-up

Acceleration time set-up

Deceleration time set-up

S-shaped accel/decel time set-up

DIV/INTSPD1

(6 pin)

OPEN

CLOSE

OPEN

CLOSE

1st speed

4th speed

Input Signal Status

No.

Input signal

0

Servo-ON

5

Speed zero clamp

through

Value

Set as required

Default

1

1

1

0

1

1

0

0

0

0

CL/INTSPD2

(4 pin)

OPEN

OPEN

CLOSE

CLOSE

Monitor display

+ A

----

Stop with +A

- 47 -

Page 48

Trial Run

1

2

3

4

5

6

7

8

9

0

STATUS

ALM CODE

GAIN

CN

SER

CN

I/F

CN

SIG

CN

POWER

CN

MOTOR

Motor

Power

supply

CN POWER

1. Turn on

the power.

Fundamental Operations and LED Indications

- 48 -

Page 49

2.Check LED status.

LED color

Green

Orange

Red

Main power is on. Amplifier power is on.

Flashing when warning occurs. (Overload, excessive regenerative energy)

Alarm

Meaning

Set the rotary switch to

default "0" position

for GAIN adjustment.

CN I/F

CN SIG

Make sure that the alarm code LED is not flashing.

(Under the normal operation, the alarm indicator is OFF.)

This indicator will start flashing when an alarm occurs.

Alarm codes (see page 60-65) are indicated by the number of flash

(in orange and red)

Orange: Tens digits, Red: Unit digits

(Example)

When an overload (alarm code No.16) occurs:

The alarm indicator will flash in orange once and in red six times.

0.5 sec.1 sec.

0.5 sec. 0.5 sec. 0.5 sec. 0.5 sec.

orange

1 sec.

red

0.5 sec.

red

0.5 sec.

red

0.5 sec.

red

0.5 sec.

red

0.5 sec.

red

0.5 sec.

After

2

seconds

3. Set Parameters.

Prepare a personal computer and PANATERM®.

4. Input commands relevant to

the desirable control mode.

Preparations and Adjustments

CN MOTOR

- 49 -

Page 50

Adjustments

Purposes of Gain Adjustment

In case of the servo motor, the motor is required to act per any command without any

time delay, or without missing any commands. To ensure this, gain adjustment is

necessary.

<Example: ball screw>

Gain set-up: low

+2000

+2000

0

0

-2000

-2000

0.0 375250125 0.0 375250125 0.0 375250125

{r/min}

{r/min}

Position loop gain

Velocity loop gain

Velocity loop integration time constant

Velocity feed forward

Inertia ratio

Command Speed

Actual velocity

: 20

: 100

: 50

: 0