Page 1

MCO-80IC

Reach-In CO2

Incubator

Features:

• The industry’s most complete cell culture

solution for large volume applications.

• Exceptionally low CO

recovery following door openings.

CO

2

Panasonic… the new name for SANYO

www.panasonic.com/biomedical

consumption with fast

2

Page 2

MCO-80IC

CO2 recovery after a 60 second door opening

for the Panasonic MCO-80IC

Temperature Recovery

5%

4%

3%

2%

1%

10 min. 20 min.

10 min. 20 min.

CO2 recovery after a 60 second door opening

for the Panasonic MCO-80IC

Temperature Recovery

5%

4%

3%

2%

1%

37°C

36°C

35°C

34°C

33°C

10 min. 20 min.

10 min. 20 min.

Reach-In CO2 Incubator

Panasonic’s large capacity, reach-in CO2 incubator has the capacity and flexibility to grow with your

culturing needs while providing a precise and repeatable temperature, humidity and CO

environment.

2

The MCO-80IC is ideal for culturing

large volumes of biological samples,

performing short-term studies, and

working with large volume cell culture

apparatus. It includes Panasonic’s

exclusive incubator technologies such as

inCu-saFe

®

interiors, UV decontamination option, infrared (IR) CO

P.I.D. control, and features exceptionally

low CO

gas consumption.

2

Superior CO2 and

Temperature Control

• IR CO2 sensor with P.I.D. microproces-

sor control and forced air circulation

system delivers fast CO

characteristics.

• Exceptionally low CO

tion rates, less than half of similar

competitive units.

• P.I.D. temperature control with

deviation of ±0.1°C.

sensor with

2

recovery

2

gas consump-

2

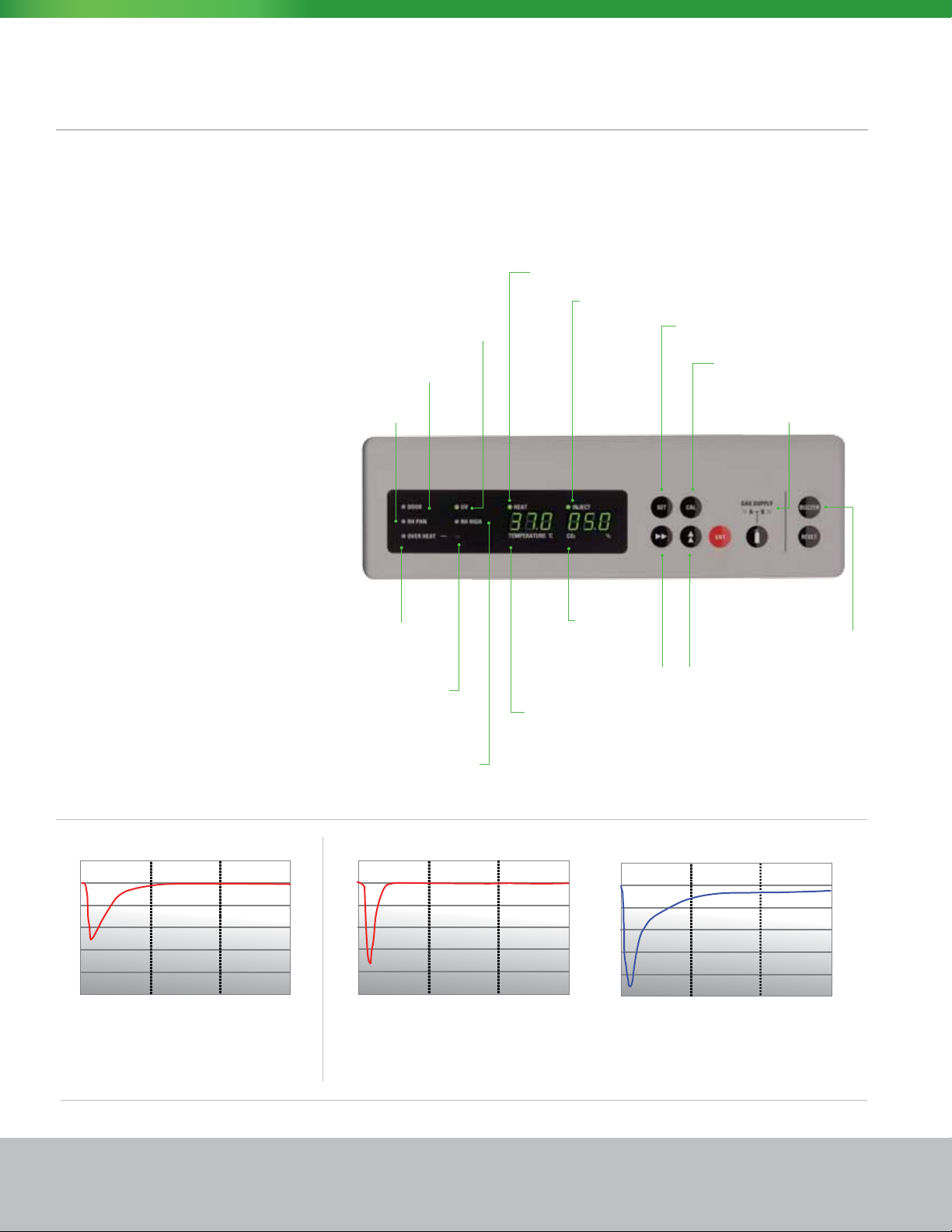

UV Decontamination –

Light Indicator

Open Door Indicator

Water Reservoir

Level Indicator

Secondary Over

Temp. Indicator

Over Temp. Safety

Shut off Adjustment

High Humidity Mode Indicator

Heater On

Indicator

CO

Inject Indicator

2

CO

Display

2

Scroll Programming Buttons

Temperature Display

Setpoint – Set Temperature and CO

Calibration - Calibrate chamber

temperature and CO

2

Optional Built-in CO

Tank Switchover System

Alarm, Buzzer

Silence

2

2

Panasonic MCO-80IC

Recovery after a 30 second door opening for the

Panasonic MCO-80IC.

2 MCO-80IC Reach-In Incubator www.panasonic.com/biomedical

CO2 recovery after a 60 second door opening

for the Panasonic MCO-80IC

5%

4%

3%

2%

1%

10 min. 20 min.

CO2 recovery after a 60 second door opening

for the competitor

5%

4%

3%

2%

1%

10 min. 20 min.

Panasonic MCO-80IC Competitor

Faster CO2 Recovery and lower CO2 Consumption after 60 second door opening.

Page 3

Anti-Contamination Measures

• Interior, plenums and shelving

constructed of Panasonic’s exclusive

inCu-saFe

enriched stainless steel.

• Optional UV decontamination system

for humidity reservoir.

• Extra heaters positioned around

the outer glass door to eliminate

condensation.

®

, germicidal, copper-

Horizontal Laminar

Airow System

Panasonic’s reach-in incubator’s crossshelf directed air ow system promotes

optimum temperature uniformity

throughout the chamber and contributes

to quick temperature recovery after door

openings. Utilizing Panasonic’s exclusive inCu-saFe

perforated side plenums helps minimize

contamination concerns and direct positive and negative pressure air ow.

Humidied air minimizes potential for cell culture

media desiccation.

Perforated sidewall panels right (pressure) and left

(negative pressure) assure a positive, gentle airow

from right to left.

Access ports (each side, 40mm).

®

chamber material in the

Optional UV Decontamination

and Humidity Selection

Panasonic’s patented Safe Cell UV

decontamination system is employed to

decontaminate the humidifying water

reservoir and help eliminate contamination concerns. The unit can be set to both

nominal (above 80% RH) and high humidity setpoints (above 90% RH).

Humidity reservoir heaters are located

on the outside walls of the reservoir

and are not as susceptible to corrosion

and scaling from water as competitive

systems are. An optional autofill secondary tank (Model MCO-80AS) system is

also available to ensure continuous

water supply to the humidity reservoir.

This system employs a large tank

(4.8 gal./18 L), with electronic water level

sensor and autofill solenoid valve.

Optional Shaker shelves with additional support

available in 2 or 3 shelf congurations.

Horizontal airow maintains accurate temperature

and CO2 control and uniformity at all shelf levels,

top-to-bottom, front-to-back.

Optional SafeCell UV decontamination system provides

decontamination of the humidity reservoir.

Optional Accessories

Option Code

MCO-80GC-P W Built in gas automatic switcher kit

MCO-80RBS-PW Roller bot tle apparatus mounting ramp kit

MCO-80ID-PW Inner Door Kit 5 partition doors, made with acrylic resin

MCO - 80 UV S- PA UV sterilization of humidifying water reservoir only

MCO-80AS-PW

MCO -80S T-P W Additional shelf

MCO-420MA-PW 4 to 20 mA analog output module

MCO-10 0L CO

MCO-80IC3RSLF Reinforced shelves for shaker use

Automatic water supply system: Includes control box,

water tank, water supply hose, 18L (4.8 gallon) tank

tank regulator

2

3

Page 4

Specications

MCO-80IC-PA

Dimensions

Overall Exterior Dimensions (w x f- b x h) 33.8” × 33.6” × 8 0.3” / 986 × 853 × 2040 mm

Interior Dimensions (w x f- b x h) 31.7” × 27.3 " × 60.0” / 806 × 693 × 1524 mm

Interior Volume 30.1 cu.ft / 851 L

Shelving (w x f-b x h)

Construction

Exterior Cabinet Electrogalvanized Steel (Acr ylic resin baking painted nish)

Interior Cabinet Copper Alloy Stainless Steel (expect humidif ying reser voir)

External Door Double Paned Glass Door with out door latch

Shelving Copper alloy Stainless Steel (5 standard)

Net Unit weight 605 lbs. / 275 kg.

Access Ports 40 mm(1.57”), 2 locations (right and left sides) with silicone rubber stopper)

Environmental Performance

Temperature Control Range

Temperature Uniformity Deviation ±0. 5°C (in 25°C ambient, setting 37° C, 5% CO

Temperature Fluctuation Margin

Control Range 0 to 20% ± 0.15%, no load

CO

2

Chamber Humidity Over 80% RH (High humidit y mode: over 90% RH)

30.5” x 25. 9” x 0.4” / 776 x 659 x 10 mm

Load Capacity: 66 lbs. / 30 kg

+5°C above ambient to 50°C (in a 20 °C to 35°C ambient )

, no load 9 point measurement)

2

±0.1% (in 25°C ambient, setting 37°C, 5% CO

, no load )

2

Environmental Controls

Humidifying Reservoir Integrated with an inner chamber (Stainless Steel, SUS30 4)

Humidif ying Method Heated vaporization with water in humidity pan (High humidit y mode available)

High Humidity Mode Selectable by function mode (for over 90%RH)

Humidif ying Water Retention Days (Reference)

(Under a condition of 25°C ambient, setting 37°C, 5% CO

15 days (Reference)

, no load, no door opening, 80 %RH )

2

Heating Method Heater with fan air circulation, cross shelf laminar air ow

Temperature Control System

Temperature Display

Water Drainage

Microprocessor P.I.D. with thermistor sensor, temperature uctuation of + 0 .1° C

Digital display (0.1°C increments)

Drainage valve (lower side of front frame)

Drainage into a tray/bottle (provided)

Water Fill Water ll located at the front side of interior bottom (optional autoll)

CO

Gas Control

2

Gas Inlet Pressure

CO

2

Microprocessor P.I.D. with infrared sensor (0.1% increments)

15 psi (0.1 MPa)

Electrical

Power Requirements 115V, 20 Amps, 60 Hz, NEMA 5-20P Plug

Interior/Exterior Convenience Receptacle Interior Duplex: Vapor Proof. 115V, 3 Amps Max. Rating - Ex terior Duplex:115V, 1 Amp. Max Rating

Alarms

High/ Low Temperature Alarm. CO

Upper limit temperature Alarm. Door Ajar Alarm, Self Diagnostics

density alarm.

2

Remote Alarm Contacts N.O. (normally open) and N.C. (normally closed) contacts included, rating DC 30 v, 2A

Panasonic Healthcare Company of North America

1300 Michael Drive, Suite A, Wood Dale, IL 60191

Toll Free USA (800) 858-8442, Fax (630) 238-0074

www.panasonic.com/biomedical

© Panasonic Printed in USA 2012.02 JB

JB201202V1

Loading...

Loading...