Panasonic MCO-5M Installation Manual

INSTRUCTION MANUAL

MCO-5M

Multi-gas Incubator

1

Note:

1. No part of this manual may be reproduced in any form without the expressed written

permission of SANYO.

2. The contents of this manual are subject to change without notice.

3. Please contact SANYO if any point in this manual is unclear or if there are any

inaccuracies.

SANYO Electric Biomedical Co., Ltd. All rights reserved. Printed in Japan.

CONTENT

PRECAUTIONS FOR SAFE OPERATION P. 2

CAUTIONS FOR USAGE P. 7

Labels on the unit P. 9

INCUBATOR COMPONENTS P.11

Control panel and keypad P.13

Remote alarm terminal P.15

INSTALLATION

Installation site P.16

Prevent contamination P.17

Installation P.17

BEFORE COMMENCING OPERATION

Sterilizing of chamber and attachments P.18

Connection of N

Connection of gas injection nozzle P.20

Connection of CO

OPERATING INSTRUCTIONS

Set of chamber temperature and CO

UV lamp P.23

Change of setting of UV lamp ON period P.24

Automatic gas cylinder changeover P.25

Key lock function P.27

Water level sensor P.28

ALARMS & SAFETY FUNCTIONS P.29

Operation after power failure P.30

SETTING OF ALARM RESUME TIME P.31

ROUTINE MAINTENANCE

Sterilizing of chamber and attachments P.32

Removal of attachments P.33

Filling the humidifying pan P.35

CALIBRATION

Temperature calibration P.36

CO

O

TROUBLESHOOTING P.39

ENVIRONMENTAL CONDITIONS P.40

DISPOSAL OF UNIT P.40

STACKED MODULE P.41

SPECIFICATIONS P.43

PERFORMANCE P.44

SAFETY CHECK SHEET P.45

calibration P.37

2

calibration P.38

2

( or O2 ) gas cylinder P.19

2

gas cylinder P.21

2

density P.22

2

2

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with this manual as it contains

important safety advice.

Items and procedures are described so that you can use this unit correctly and safely.

If the precautions advised are followed, this will prevent possible injury to the user and

any other person.

Precautions are illustrated in the following way:

WARNING

Failure to observe WARNING signs could result in a hazard to personnel

possibly resulting in serious injury or death.

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and

damage to the unit and associated property.

Symbol shows;

this symbol means caution or warning.

this symbol means an action is prohibited.

this symbol means an instruction must be followed.

Be sure to keep this manual in a place accessible to users of this unit.

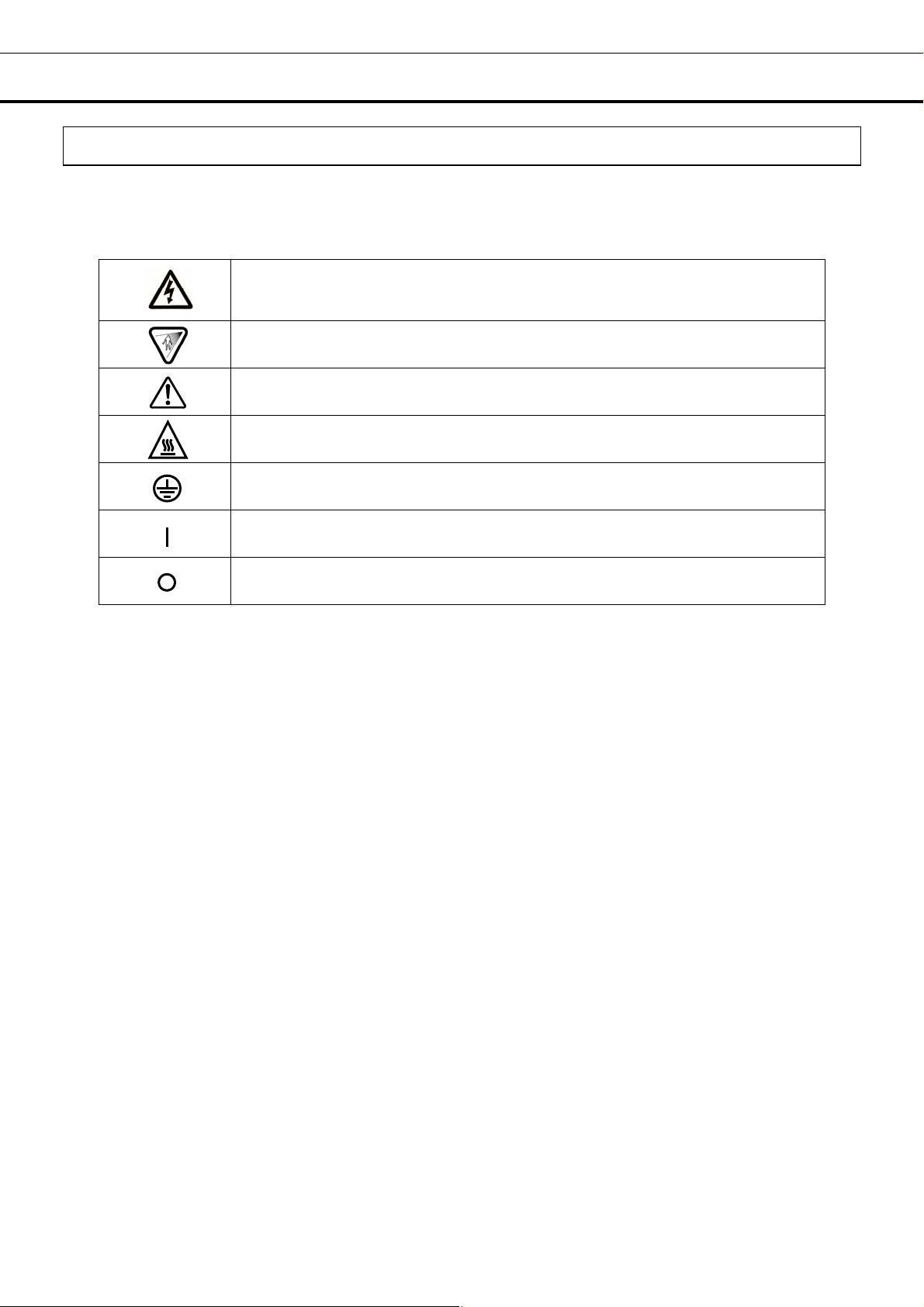

< Label on the unit >

This mark is labeled on the cover in which the electrical components of high voltage are

enclosed to prevent the electric shock.

The cover should be removed by a qualified engineer or a service personnel only.

WARNING

As with any equipment that uses CO

of the equipment. It is important that you assess the work site to ensure there is suitable and sufficient

ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe environment

must be considered. These may include atmosphere monitoring and warning devices.

O

gas increases the susceptibility of substances to burn. Take care of the handling of flame in a room

2

where the incubator is installed.

/ O2 / N2 gas, there is a likelihood of oxygen depletion in the vicinity

2

3

PRECAUTIONS FOR SAFE OPERATION

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to

rain water.

Only qualified engineers or service personnel should install the unit. The installation by

unqualified personnel may cause electric shock or fire.

Install the unit on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, this may result in injury from the unit falling or tipping over.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Use a dedicated power source as indicated on the rating label attached to the unit.

Remove dust from the power supply plug before inserting in a power source. A dusty plug or

improper insertion may cause a hazard.

Use a power supply outlet with ground (earth) to prevent electric shock. If the power supply

outlet is not grounded (earthed), it will be necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

Check the gas type and ensure that it is fit for the purpose. Make sure that all pipes are

connected correctly and are not liable to become disconnected. Ensure that the gas pressure

is set at the specified value. Improper connection of the gas pipe or use of incorrect gas

pressure may result in leakage of CO

health and may lead to asphyxiation and risk of death.

Never store volatile or flammable substances in this unit. This may cause explosion or fire.

Ventilate a room air occasionally when using CO

in an enclosed small room and high level of gas density can be hazardous to health. In addition,

avoid inhaling the chamber air directly when opening the door if CO

Si l’appareil est utilisé dans un evdroit restreint, le niveau de la densité CO2 de l’air peut s’élever

et peut être nocif aux humains. Évitez d’aspirer l’air provenant de l’intérieur de l’appareil quand

vous ouverz la porte.

Do not insert metal objects such as a pin or a wire into any vent, gap or any outlet for inner air

circulation. This may cause electric shock or injury by accidental contact with moving parts.

WARNING

gas. Elevated level of CO2 gas can be hazardous to

2

gas for control. The gas density will increase

2

gas is used.

2

4

PRECAUTIONS FOR SAFE OPERATION

As with any equipment that uses CO

vicinity of the equipment. It is important that you assess the work site to ensure there is

suitable and sufficient ventilation. If restricted ventilation is suspected, then other methods

of ensuring a safe environment must be considered. These may include atmosphere

monitoring and warning devices. Keep proper gas pressure to avoid gas leak.

Use this unit in a safe area if using poisonous, harmful or radioactive substances. Improper

use may be harmful to your health or the environment.

Disconnect the power supply to the unit prior to any repair or maintenance in order to prevent

electric shock or injury.

Never expose the eyes directly to UV light as UV light can cause permanent damage to eyes.

Never remove cover when UV light is ON (when an optional UV system kit MCO-18UVS2 is installed).

Hazardous UV light. Do not press door switch.

Never disassemble, repair, or modify the unit yourself. Any such work carried out by an

unauthorized person may result in fire or injury due to a malfunction.

Disconnect the power supply plug if there is anything wrong with the unit. Continued

abnormal operation may cause electric shock or fire.

If the unit is to be stored unused in an unsupervised area for an extended period, ensure that

children do not have access and that doors cannot be closed completely.

The disposal of the unit should be undertaken by appropriate personnel. Remove doors to

prevent accidents such as suffocation.

Prepare a safety check sheet when you request any repair or maintenance for the safety of service

personnel.

WARNING

gas, there is a likelihood of oxygen depletion in the

2

5

PRECAUTIONS FOR SAFE OPERATION

Select a level and sturdy floor for installation. This precaution will prevent the unit from tipping.

Improper installation may result in water spillage or injury from the unit tipping over.

Connect the unit to a power source as indicated on the rating label attached to the unit. Use

of any other voltage or frequency other than that on the rating label may cause fire or electric shock.

When removing the plug from the power supply outlet, grip the power supply plug, not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Never damage or break the power supply plug or cord. Do not use the supply plug if its cord

is loose. This may cause fire or electric shock.

Do not touch any electrical parts such as the power supply plug or any switches with a wet

hand. This may cause electric shock.

Do not put a container with water or heavy articles on the unit. It may cause injury if the articles

fall. Current leakage or electric shock may result form deterioration of insulation by spilled water.

Do not climb onto the unit and do not put articles on the unit. This may cause injury by tipping

or damage to the unit. When stacking the unit, follow the procedure shown on page 35.

Always hold the handle when closing the door. This will reduce the likelihood of a trapped finger.

Do not damage the power supply cord. Stepping on the cord, or processing, pulling, twisting, or

binding of cord may cause fire or electric shock by damaged cord.

Never lean or press on the glass or never hit the glass with sharp edge. Intentional force may

cause injury if the glass breaks.

Do not lean on the door. This may cause injury, current leakage, or electric shock if the unit tips

over or door becomes detached.

Always put on gloves at the time of maintenance. The corners of fixtures may cause injury.

Disconnect the power supply plug before moving the unit. Take care not to damage the power

cord. A damaged cord may cause electric shock or fire.

Empty the humidifying pan completely before moving the unit. Spilled or splashed water may

cause current leakage or electric shock.

CAUTION

6

PRECAUTIONS FOR SAFE OPERATION

Be careful not to tip over the unit during movement to prevent damage or injury.

Disconnect the power plug when the unit is not used for long periods. The deteriorated insulation

may cause electric shock, current leakage or fire.

Do not put the packing plastic bag within reach of children as suffocation may result

Take care of the inside of the outer door. It may get hot.

Use the power supply cord enclosed with the unit. Use of an inferior power supply cord may cause

electric shock or fire.

CAUTION

7

CAUTIONS FOR USAGE

1. Install on a sturdy and level floor

Install the unit on a sturdy and level floor and take precaution for preventing tipping over. Inadequate

installation may result in water leakage or injury from the unit falling or tipping over.

2. Install in a place not subject to direct sunlight and far from heat sources

Never install the unit outdoor, near windows, or in direct sunlight. And install the unit far from heat

sources such as exhausted heat from other equipment. The installation in improper location may result

in insufficient performance.

3. Ventilate a room air

Ventilate a room air occasionally when using CO

enclosed small room and high level of gas density can be hazardous to health. In addition, avoid

inhaling the chamber air directly when opening the door if CO

4. Setting of 5

o

C higher than the ambient temperature

The chamber temperature must be at least 5

chamber temperature is set to 37

o

C, the ambient temperature must be less than 32oC. Ensure the

ambient temperature is within the desired range.

Also, do not place the unit in the direct air flow from an air conditioning system. Cool air from an air

conditioning system may cause condensation and lead to possible contamination.

5. Always keep the chamber clean

The condensation may be caused on the inside of the door by spilled water form humidifying pan or

opening of outer door for long period. Wipe off the condensation completely with a sterile dry gauze.

Especially when the culture medium is spilled, clean and disinfect the chamber immediately. Refer to

page 27 “Routine maintenance” for details.

6. Fill the humidifying pan with sterile distilled water

Always use sterile distilled water to fill the pan. The RH PAN lamp on the control panel flashes when the

water level is low. Refill the sterile distilled water to the pan when the RH PAN lamp blinks. Note that

when low temperature water is poured, the chamber temperature drops significantly. Clean the pan

once a month.

7. Always shut the inner door

Shut the inner door completely, and then shut the outer door. If the inner door is not closed completely,

even if the outer door is closed, the unit will fail to exhibit its maximum performance.

8. Open/close the doors gently

Ensure you close the doors gently. Robust closing may cause spillage of medium, incomplete closing,

or damage of gasket. Also, before opening the inner door, check that the UV light is OFF (when an

optional UV system kit MCO-18UVS2 is installed).

gas for control. The gas density will increase in an

2

o

C higher than the ambient temperature. For example, the

gas is used.

2

8

CAUTIONS FOR USAGE

9. Use clean containers

The Petri dishes or bottles for culturing may cause contamination in the chamber. Clean the containers

before storing them in the chamber.

10. Allow adequate space between the cultures

When storing cultures in the chamber, keep the Petri dishes or bottles containing the cultures sufficiently

apart from each other to allow adequate air circulation. Inadequate space may result in uneven

temperature distribution and CO

11. Stored materials

Never place acid or alkaline materials or materials that release corrosive gas in the chamber. Such

materials can cause failure resulting from discoloration or corrosion.

12. Alarm

Always investigate the cause and fix the alarm condition immediately when the alarm is activated. Refer

to page 25 for alarm details.

13. Do not use CAL key

Do not use CAL key on the control panel in normal use. Pressing this key leads the calibration mode.

Wrong key operation affects the basic performance. Never touch any other keys on the control panel in

the event of pressing CAL key accidentally. After about 90 seconds, the unit returns to chamber

temperature display mode automatically.

14. If not used

When the unit is not used, dispose of the water in the humidifying pan and completely remove any

moisture in the chamber completely. Check that the chamber is completely dry before closing the doors.

15.Thermal conductivity CO

It is not abnormal that the thermal conductivity CO

density when the chamber humidity temporarily goes down. And take care of the level of humidifying

water because the lack of water affects the CO

concentration in the chamber.

2

sensor

2

sensor displays CO2 density higher than the actual

2

density.

2

9

CAUTIONS FOR USAGE

Labels on the unit

Some warning and/or caution labels are attached on the unit. Following shows the description of such

labels.

This label is on the cover in which the electrical components of high voltage are

enclosed to prevent the electric shock. The cover should be removed by a

qualified engineer or a service personnel only.

This symbol means UV caution.

This symbol means attention or refer to document.

This symbol means hot surface.

This symbol means earth.

This symbol means power switch “ON”.

This symbol means power switch “OFF”.

10

CAUTIONS FOR USAGE

The cautions below are applicable when an optional UV system kit MCO-18UVS2 is installed.

1. Always use humidifying pan and pan cover

The humidifying pan and pan cover prevent the UV light from escaping. Make sure they are installed

even if you do not need humidity.

2. Notice of recommended replacement of UV lamp

This unit is provided with a function to notify the recommendation of UV lamp replacement when the

accumulated ON time of UV lamp is over about 1,000 hours. The blink of the UV indicator on the control

panel recommends the replacement of UV lamp. For the replacement, contact Sanyo sales

representative or agent.

E18 will be displayed on the temperature indicator when the UV lamp is burned out. Contact Sanyo

sales representative or agent for the replacement.

3. Location of UV lamp

The UV lamp is located in the duct. Take care not to damage the lamp at the time of installation/removal

of attachments or humidifying pan.

11

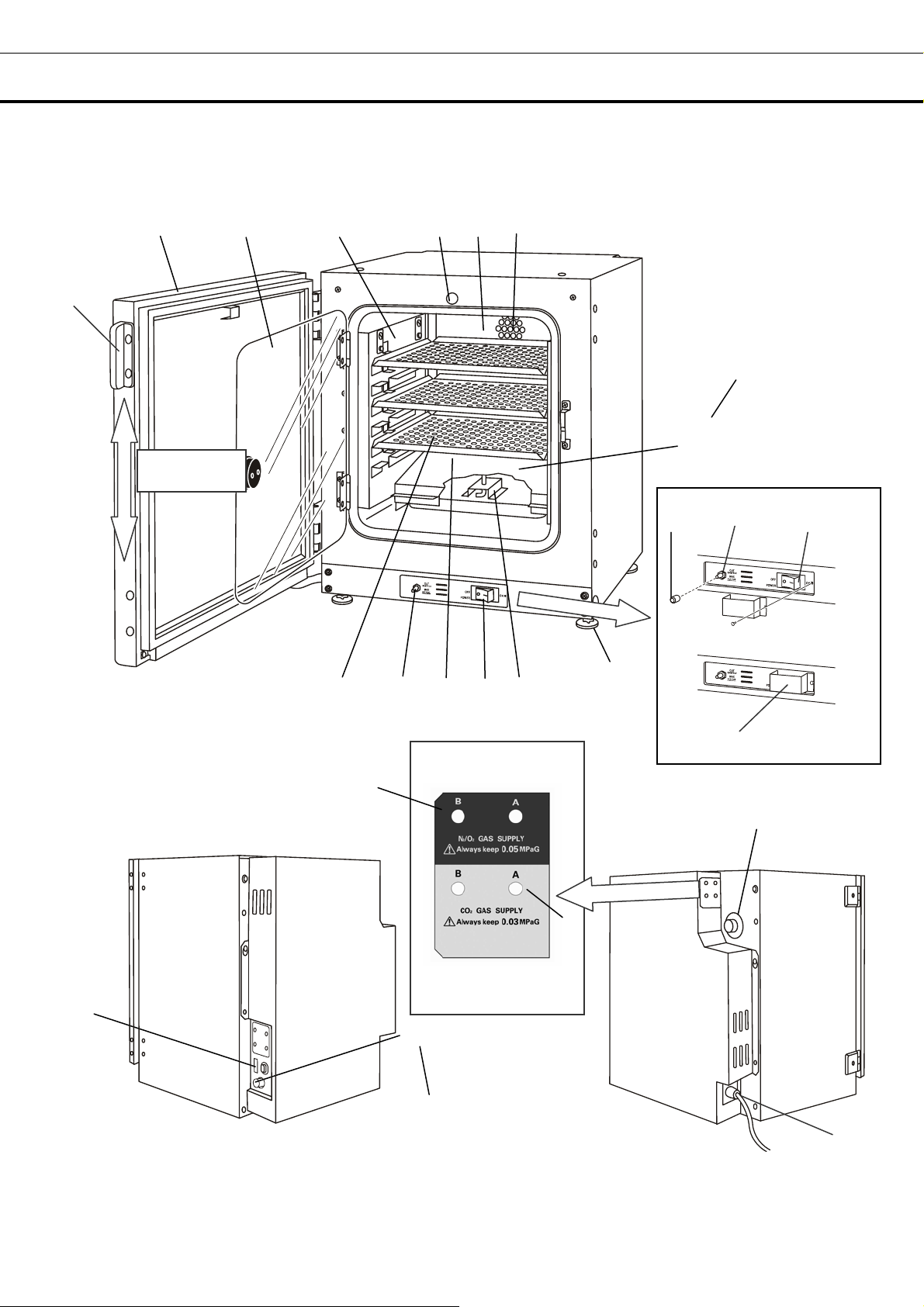

INCUBATOR COMPONENTS

g

g

22

17

1

Chageable

Rear right side

2

5

4

8

11

When MCO-18UVS2

is installed

6 7 (inside)

12

14

Connecting port for N2/O2 gas

Connectin

23

19

port for CO

20

10

as

2

When MCO-18UVS2

is installed

13 ,15 ,16(inside)

9

8

19

3

Switch cover

18

21

Rear left side

12

INCUBATOR COMPONENTS

1. Outer door: Sticks to frame with magnetic seal. Door heater is installed in the door panel. The

door opening is reversible. Contact Sanyo representative or agent to change the door hinge from left to

right or vice versa.

2. Inner door: Made of tempered glass, however avoid excessive impact on the glass.

3. Leveling foot: Screw type for adjusting the height. Adjust the foot so that the unit can be level.

4. Tray: Can be pulled toward you.

5. Side support: Right and left side supports can be removed for disinfection. See page 33 and 34.

6. Rear duct: Flow path for circulating air. Removable.

7. Fan (inside the rear duct): Made from polypropylene resin. Can be sterilized by an autoclave.

8. Sample air outlet: This also functions as an internal gas outlet. Use only a supplied cap(9).

9. Sample air outlet cap: Always attach this cap except at the time of using of sample air outlet.

10. Connecting port for CO

gas pipe (rear side): When an optional component MCO-5GC (gas

2

cylinder changeover accessory) is installed, both A and B are available. If MCO-5GC is not used, only A

is available. Refer to page 21 for gas cylinder connection. Ensure that the gas pressure is set at

0.03MPaG (0.3kgf/cm

11. Connecting port (A/B) for N

2

G, 4.3psiG). Refer to page 25 for automatic cylinder changeover.

gas pipe (rear side): Refer to page 19 for gas cylinder connection.

2/O2

Ensure that gas pressure is set at 0.05MPaG (0.5kgf/cm2G, 7.1psiG). Refer to page25 for automatic

cylinder changeover.

12. Door switch: Detects the door opening/closing and stops the circulating fan and electromagnetic

valve for CO

and N2/O2 when door is open. UV lamp is also deactivated by door opening (When an

2

optional UV system kit MCO-18UVS2 is installed).

13. Humidifying pan: Use sterile distilled water to fill the pan.

14. Humidifying pan cover: Prevents UV light being exposed to the chamber. When filling the pan,

lift the front side and take out the pan. See page 35 for details.

15. UV lamp (When an optional UV system kit MCO-18UVS2 is installed):

Sanyo UV lamp does not generate ozone. Never look at the UV light directly. For replacement, contact

Sanyo representative or agent.

16. Water level sensor for humidifying pan: Detects the water level in the humidifying pan. See

page 28 for details.

17. Remote alarm terminal: Refer to page 15.

18. Access port: When not in use, cap with the rubber cap on both outside and inside.

19. Power switch: Main switch of the unit. Also functions as an over-current breaker. The switch is

covered by a switch cover to prevent the accidental push. To turn on or off the switch, remove the

switch cover by loosening the screw. See figure on the right.

20. Glow starter (When an optional UV system kit MCO-18UVS2 is installed): For UV lamp (model; FG-7P)

21. Removal Power supply cord

22. Handle: Outer door handle. When moving the handle from upper to a lower position remove it from

original position first, then remove two cups and screws at the lower position and attach the handle there.

23. N

or O2 gas injection nozzle

2

13

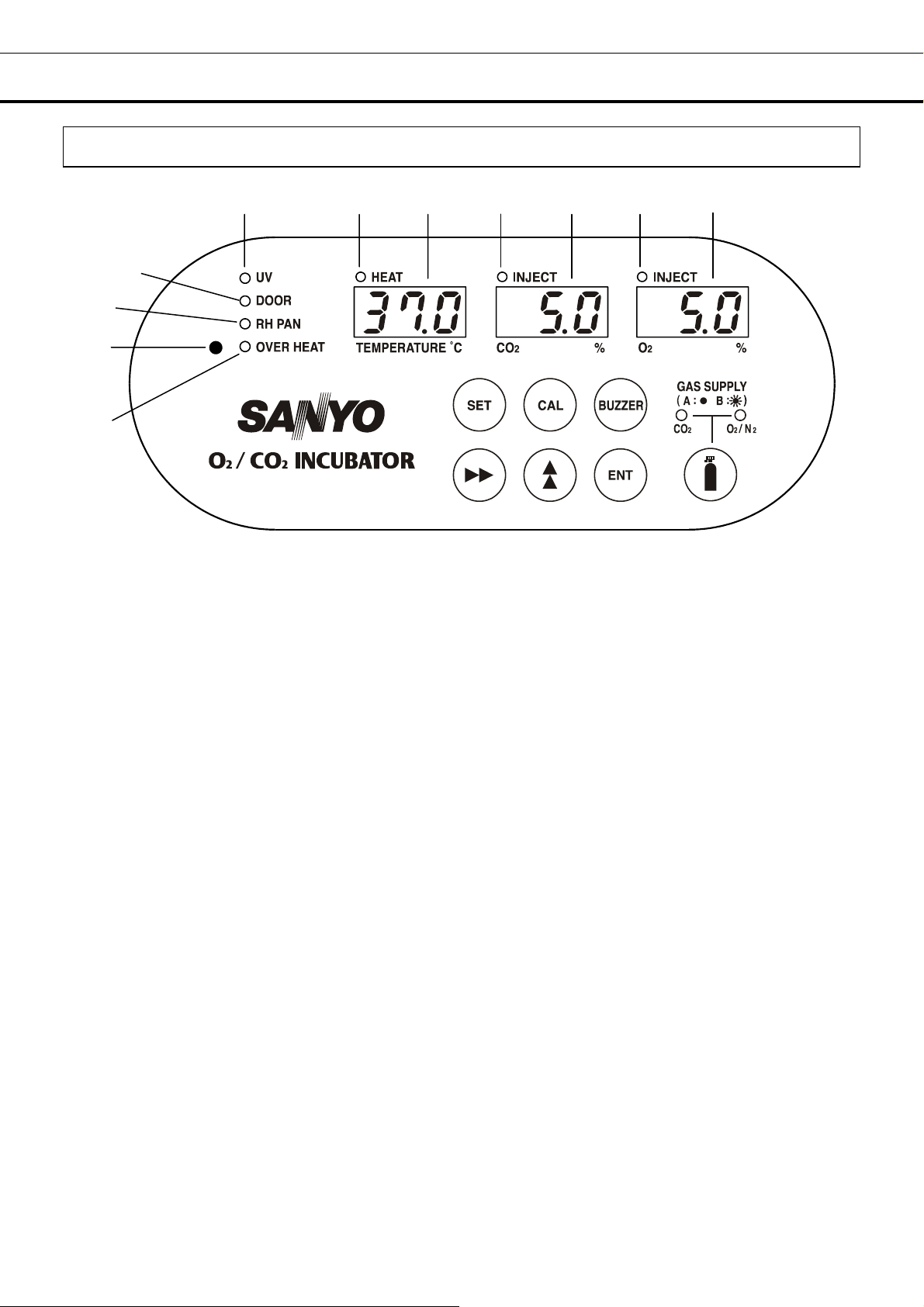

INCUBATOR COMPONENTS

Control panel and keypad

2 3

4

5

6

7

1. Digital temperature indicator (TEMPERATURE

temperature. In the setting mode, it shows the set value of the chamber temperature. If the self

diagnostic function detects any abnormality, an error code will be displayed.

2. Heater lamp (HEAT): This lamp lights when the heater is energized.

3. UV indicator (UV): This lamp lights when the UV lamp is ON. The blink of this indicator

recommends the replacement of UV lamp. See page 23 for the details.

4. Door lamp (DOOR): This lamp lights when the outer door is open.

5. Water level alarm lamp (RH PAN): This lamp flashes when the water in the humidifying pan is less

than approximately 0.8 liter.

6. Upper limit regulator: This regulator is used to set the upper temperature limit.

7. Over heat lamp (OVER HEAT): This lamp lights when the chamber temperature reaches the upper

limit set value.

8. CO

inject lamp (INJECT): This lamp lights when CO2 gas is being injected.

2

9. Digital CO

density indicator (CO2 %): Normally, this indicator shows the CO2 concentration in the

2

chamber. In the setting mode, it indicates the set value of the CO

supply line is displayed when CO

gas cylinder becomes empty (only when MCO-5GC is installed). See

2

page 25 for details.

10. O

inject lamp (INJECT): This lamp lights when N2 or O2 gas is being injected.

2

11. Digital O

density indicator (O2 %): Normally, this indicator shows the O2 concentration in the

2

chamber. In the setting mode, it indicates the set value of the CO

supply line is displayed when N

or O2 gas cylinder becomes empty (only when MCO-5GC is installed).

2

See page 25 for details.

1

8 9 10 11

o

C): Normally, this indicator shows the chamber

concentration. The empty gas

2

concentration. The empty gas

2

14

Loading...

Loading...