Page 1

M2X Series Inverter

for

3-phase Induction Motor Speed Control

INSTRUCTION MANUAL

Be sure to hand over this instruction manual to customers.

● Thank you for purchasing Panasonic Inverter.

● To ensure proper use of this product, read this instruction manual

thoroughly.

Keep this manual in place, and read it whenever required.

Page 2

Contents

Before startup

Preparation and

adjustment

Safety Precautions

Introduction

• Unpacking and inspection

• Checking the inverter model

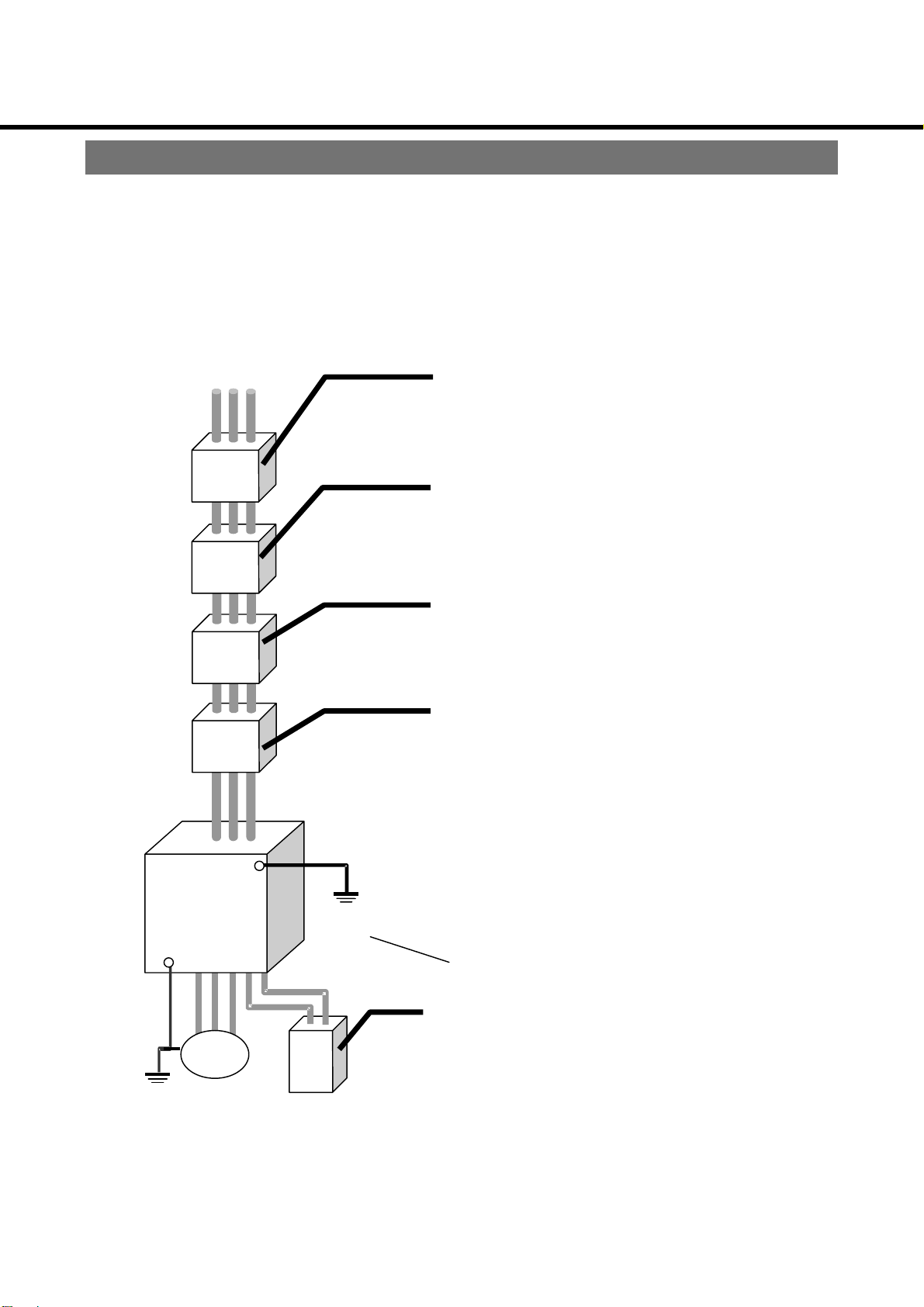

System Configuration and Wiring

• Wiring general view

• Inverter and applicable

• Wiring

• Changing the input signal logic

• Terminal function

・・・・・・・・・・・・・・・・・・・・・・・

peripheral equipment

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・

4

8

8

8

12

12

13

14

16

17

If necessary

Application

Specifications

Protective Function

• Protective functions

• Canceling trip

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

Parameter Description

Detailed Parameter Description

• Function of parameter

(Parameter initialization

Specifications

Dimensions

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・

33

33

36

39

45

45

59)

67

68

Conformity to EC Directive /

UL Standard

- 2 -

・・・・・・・・・・・・・・・・・・・・・・

69

Page 3

Parts Description

• Outline and Part Names

CAUTION

• Instructions for safe and

correct operation

• Precautions when wiring

Parameter Setting

• Setting

Test Operation

• Pre-operation inspections

• Tes t ru n

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

9

9

10

10

20

21

21 • Selection of the run command

23

23 • Acceleration/deceleration time

23

Installation

Operation Function

• Frequency command selection

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・

changing procedure

changing procedure

・・・・・・・・・・

・・・・・・・・・・

11

24

24

24

25

Before startup

• Operation function

• Run mode

Maintenance/Inspsection

Troubleshooting

• Inspection to determine cause

of problem

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・

37

Servicing (Repair)

38

38

・・・・・・・・・・・・・・・・・・・・・・・・・・・

• Copying parameter

• Extracting and locking parameters

• Structure of peripheral equipment

・・・・・・・・・・・・・・・・・・・

・・・・・・

・・・・・・・

62

65

70

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・

Back cover

26

28

Preparation and adjustment

If necessary

Application

• List of Inverters and Applicable Peripheral

Equipment

- 3 -

・・・・・・・・・・・・・・・・・・・

Optional Accessories

71

Recommended Equipment

Warranty

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・

72

74

75

Spec.

Page 4

Safety Precautions

Precautions that must be heeded in order to protect the user and others from harm and

prevent property loss or damage are as follows:

■ The extent of injury or damage that could be suffered by

improper use contrary to directions is ranked as follows:

!

!

!!

!

!

!!

Items labeled as CAUTION could be connected with core serious

consequences, depending upon the circumstances. These instructions are extremely

important and should be observed in all cases.

DANGER

CAUTION

Situation involving danger which could result in death or serious

injury if equipment is handled incorrectly.

Situation involving danger which could result in medium to light injury,

or property damage if equipment is handled incorrectly.

!!!!

Safety precautions should always be followed.

■ Installation

!

!

!!

● Install on non-combustible material such as metal.

Failure to do so could result in fire.

● Do not use this product in a place where it may be splashed with water, in corrosive

gas or inflammable gas atmosphere, or near a combustible object. Neglecting this

instruction may result in fire.

● Do not carry by the front case when moving the inverter.

Doing so is dangerous and could result in injury if dropped.

● Do not allow foreign material such as metal chips to get inside the inverter.

Doing so could result in fire.

● Be sure to install on a base capable of supporting the inverter’s weight in

accordance with the directions given in the instruction manual.

Failure to do so could result in the inverter dropping or falling.

CAUTION

- 4 -

Page 5

■ Wiring

!

!

!!

DANGER

● Make sure the power is cut off before handling wiring.

Failure to do so could result in electrical shock or fire.

● Be sure to install a no-fuse breaker (NFB) or an earth leakage breaker.

Failure to do so could result in fire.

● Be sure to ground the GND terminal.

Failure to do so could result in electrical shock or fire.

● Have wiring work done a licensed electrician.

Failure to do so could result in electrical shock or fire.

● Be sure to install the inverter before wiring.

Failure to do so could result in electrical shock or fire.

CAUTION

!

!

!!

● Do not ground the AC power source with the output terminals (U/T1, V/T2,

W/T3).

Doing so could result in injury or fire.

● Make sure the voltage of the AC power source agrees with the rated voltage of the

inverter.

If not, it could result in injury or fire.

- 5 -

Page 6

Safety Precautions

Safety precautions should always be followed.

■■■■ Operation

!

!

!!

DANGER

● Be sure to mount the case and cover before turning the power on. Never remove

the case or cover while the inverter is receiving power.

Failure to mount or removing the case/cover could result in electric shock.

● Never operate the switches with wet hands.

Doing so could result in electric shock.

● Provide an emergency stop device externally, so that you can immediately stop

operation and turn OFF the power supply in case of emergency.

Neglecting this instruction may result in injury, electric shock, fire or damage to

equipment.

● Do not turn ON/OFF the electromagnetic contactor of the power supply frequently. Do

not start or stop the motor with this magnetic contactor.

Neglecting this instruction may result in breakdown or fire.

● If the retry function is selected, the inverter could unexpectedly start operating

again if tripped. Do not approach the inverter in the condition.

Doing so could result in injury.

● If trip reset is carried out with the operate signal ON, the inverter could

unexpectedly start operating again. Do not approach the inverter in the condition.

Doing so could result in injury.

● To copy parameters by using the operation panel, be sure to use the inverters of the

same model.

Neglecting this instruction may result in injury.

CAUTION

!

!

!!

● The radiator and regenerative resistor become very hot.

Touching these parts could result in skin burning injury.

● The inverter can be easily set to operate at speeds ranging from low to high. Set the

operating speed so that the motor and machine tolerance is not exceeded.

Failure to do so could result in injury.

- 6 -

Page 7

■■■■ Maintenance/Inspection

!

!

!!

DANGER

● Wait for at least 15 minutes after turning off the power to perform inspections.

Failure to do so could result in electric shock.

● Except for qualified personnel, anyone must not perform maintenance or inspection.

Neglecting this instruction may result in electric shock or injury.

■■■■ Other

!

!

!!

DANGER

● Never attempt to modify, disassemble or repair this product by yourself.

Neglecting this instruction may result in electric shock, injury or fire.

● Install this product securely to prevent a fire or accident resulting in injury or death in case

of earthquake.

Neglecting this instruction may result in fire, electric shock or injury.

● After occurrence of an earthquake, be sure to perform safety inspections.

Neglecting this instruction may result in fire, electric shock or injury.

GENERAL PRECAUTIONS

The diagrams given in this instruction manual may show the cases, covers or safety

breakers removed in order to show details.

When operating, be sure to return the cases, covers or safety breakers and operate as

specified in the manual.

When disposing of the inverter, handle it as an industrial waste.

- 7 -

Page 8

Introduction

Unpacking and inspection

• Is the model correct?

• Was the equipment damaged in transport?

If there is anything wrong with the equipment,

contact your Panasonic dealer.

Checking the inverter model

Legend on the nameplate

M1SO83CSA

M1SO83CSA

Rated input

Rated output

M1SO83CSAM1SO83CSA

Model No M2X374BSA

Power 3.7kW

Input 3PH AC 380~460V 50/60Hz

Output 3PH AC 380~460V 0~400Hz

Ser.No. 01110001

Matsushita Electric Industrial Co., Ltd Made in Japan

10.5A

9.0A

Model number

Production number

(serial number)

Model number

M

Series

Code

04

08

15

22

37

55

75

Code

4 3-phase 400V

2X

Applicable motor capacity

0.4 kW

0.75 kW

1.5 kW

2.2 kW

3.7 kW

5.5 kW

7.5 kW

Supply voltage

3

7

4

B S A

Code

B C With regenerative braking circuit and resistor

With regenerative braking circuit

Code Communication (RS485) specification

A

C

Code

S

V

N

Regenerative braking

Without communication interface

With communication interface

Operation panel specification

Without control dial (standard)

With control dial

Blank cover

- 8 -

Page 9

Parts Description

Outline and Part Names

0.4

0.4 - 7.5kW

0.40.4

Outline

7.5kW

7.5kW7.5kW

Example (0.4 to 3.7 kW)

Ventilation cover

Rubber bush for wiring

Case

Operation panel cover removed

Mounted at four places

Operation panel mounting screws

Operation panel

A control dial is equipped

on the control dial model.

Cover mounting screws

Cover

Cooling fan

Not provided for the inverter

with 0.4 to 1.5 kW capacity.

For terminal assignment, refer to P17, 18.

Operation panel connector

Control terminal

Output signal terminal

Power supply and motor terminals

Ground terminal

* The inverter is shipped with the ventilation cover mounted. If the inverter is

used at +40°C or higher temperatures, be sure to remove the ventilation cover

and the rubber bushes for wiring.

- 9 -

Page 10

CAUTION

Instructions for safe and correct operation

1. The capacity of the power source must be in the range 1.5 times the inverter capacity to 500

kVA. If the power source has 500 kVA or higher capacity and the length of the cable

between it and the inverter is 100 m or less, or if the power source has a phase advancing

capacitor selector, excessive peak current will flow into the power source input circuit and

may damage the converter. If this is the case, install power factor improvement AC reactor

at the input of each inverter.

2. Do not connect the phase advancing capacitor to the inverter output. Otherwise, the

capacitor may be damaged.

3. Do not install an electromagnetic contactor between the inverter and motor. Run/stop the

motor from inverter operation panel using the RUN switch or control input terminal. Do not

operate the electromagnetic contactor installed on the power source more often than

actually required.

In particular, never attempt to start or stop the motor with this electromagnetic contactor.

4. Operating the motor through the inverter increases leakage current that may trip the leakage

breaker. If this is the case, use leakage breaker of high frequency proof type (designed for

use with inverter) on both the system causing the problem and system affected.

5. The total cable length of the inverter and motor must be shorter than 30 m. To use a cable

longer than 30 m, provide a reactor between the inverter and the motor, or reduce the

inverter’s carrier frequency.

Inverter ↔ motor cable length

[ Carrier frequency]

Up to 30 m Up to 50 m Up to 100 m

0 to 7

(14.9 kHz or less)

0 to 5

(10.1 kHz or less)

0 to 2

(3.9 kHz or less)

6. To use the electronic thermal trip function incorporated in the inverter, observe the following

instructions.

• Check the rated current of your 3-phase induction motor to define the electric thermal

value.

• Use one motor for each inverter.

7. To control several motors with an inverter (parallel operation), select the inverter’s capacity

so that the total of the motors’ rated currents does not exceed the inverter’s rated current.

Note that, if you select the inverter’s capacity based on the total of the motors’ capacity, the

inverter’s rated current may be exceeded depending on the motor type.

- 10 -

Page 11

Installation

Install the inverter properly to prevent equipment failure or accidents.

Installation location

① Install the inverter indoors in a place not exposed to rain or direct sunlight. The

inverter is not waterproof.

② Install in a place not exposed to corrosive/flammable gases, grinding fluid, oil mist,

metal powder or chips.

③ Place with adequate ventilation, which is not exposed to excessive humidity, dirt

or dust.

④ Place not subject to vibration.

Environmental conditions

Item Conditions

-10 to 50°C (no freezing)

Ambient temperature

Ambient humidity

Storage temperature

Storage humidity

Protective construction

Vibration Max. 5.9 m/s2(10 to 60Hz)

Elevation Max. 1000 m

∗1 For a shorter period in transit.

If the ambient temperature exceeds 40°C, remove the

ventilation cover and rubber bushes.

Max. 90%RH(no dewing)

-20℃ to 65℃ (no freezing) ∗1

Max. 90 %RH(no dewing)

IP40 (Fully enclosed) (With ventilation cover)

Mounting direction and clearance

• Provide sufficient clearance for effective cooling.

30 mm

Min.

50 mm

Upper

Inverter Inverter

Min.

Lower

10 mm

Upper

Lower

Min.

10 mm

30 mm

Make sure ambient temperature doesn’t exceed allowable temperature at position indicated by

● in the figure above.

Upper

Inverter

Lower

Min.

100 mm

Min. 100 mm

30 mm

Min.

50 mm

- 11 -

Page 12

System Configuration and Wiring

Wiring general view

● Wiring must be performed by a qualified electrician.

● To avoid electric shock, do not connect the power supply to the unit.

Inverter

GND

Motor

No-fuse breaker (NFB)

or earth leakage breaker

Used to protect the power line.

Interrupts the circuit in the case of excessive

current.

Note: Use a high frequency proof earth leakage

breaker for the inverter.

Noise filter (NF)

Blocks noise from the power line.

Also reduces effect of noise from the inverter.

Magnetic contactor (MC)

Turn main power to inverter on/off.

Used with surge absorber mounted.

Note: Never attempt to start or stop the motor with

the electromagnetic contactor.

AC reactor (AC-L)

Reduces harmonic current of the power source.

Be sure to connect GND wire to the earth

to avoid electric shock.

Regenerative resistor

Improves regenerative braking capability.

Only for the inverter incorporating the

regenerative braking circuit and resistor

- 12 -

Page 13

)

)

)

)

)

)

)

Inverter and applicable peripheral equipment

Wiring apparatus selection

(1) Selection of no-fuse breaker, magnetic contactor, thermal relay, and wiring

Inverter No.

M2X044***

M2X084***

M2X154***

M2X224***

M2X374***

M2X554***

M2X754***

The cables connected to the ground terminal must be the same size as the power

supply cable and the motor cable, respectively.

(2) Relay selection

For relays used in control circuits such as the control input terminal, you should use a

small signal relay (min. guaranteed current of 1mA or less) in order to prevent poor

contact.

Applicable

motor

(kW)

0.4

0.75

1.5

2.2

3.7

5.5

7.5

No-fuse breaker

(Rated current)

Matsushita Electric Works

BBC35N

(5A)

BBC35N

(5A)

BBC310N

(10A)

BBC315N

(15A)

BBC320N

(20A)

BBC320N

(20A)

BBC330N

(30A)

Magnetic

contactor

(Contact configuration)

Matsushita Electric Works

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

BMFT61044N

(3P+1a)

Thermal

∗

relay

(Current adjustment range)

Matsushita Electric Works

BMF903E

(1.4 - 2.2A)

BMF904E

(1.7 - 2.6A)

BMF907E

(2.8 - 4.2A)

BMF911E

(4.0 - 6.0A)

BMF915E

(5.0 - 8.0A)

BMF927E

(9.0 - 13.0A)

BMF937E

(12 - 18A)

∗

2

Output

Control

circuit

0.75

(AWG18)

0.75

(AWG18)

0.75

(AWG18)

0.75

(AWG18)

0.75

(AWG18)

0.75

(AWG18)

0.75

(AWG18)

1

Input

(for power

supply)

2.0

(AWG14)

2.0

(AWG14)

2.0

(AWG14)

2.0

(AWG14)

2.0

(AWG14)

3.5

(AWG12)

3.5

(AWG12)

Wiring (mm2)

(for motor)

2.0

(AWG14

2.0

(AWG14

2.0

(AWG14

2.0

(AWG14

2.0

(AWG14

2.0

(AWG14

3.5

(

AWG12

<Examples> Matsushita Electric Works: DS type, NK type, HC type

Omron: G2A type

(3) Control circuit switch selection

If using a switch instead of a relay, use a switch for extremely small current in order to

prevent poor contact.

<Example> Nihon Kaiheiki: M-2012J-G

∗1 To use the inverter for parallel operation, select the thermal relay according to the motor used.

∗2 The above motor cable sizes apply to the case where the distance between the motor and the inverter is

20 m or less. If the distance between the motor and the inverter exceeds 20 m, select a cable size of

the next higher rank.

- 13 -

Page 14

System Configuration and Wiring

Wiring

Standard wiring diagram

・・・・0000.4kW,0

3-phase power supply

AC380~460V

50/60Hz

External frequency setting

potentiometer

1/4 W, 5 kΩ, B curve

CCW/stop switch

CW/stop switch

Frequency setting selection (1)

Frequency setting selection (2)

Free-run

Trip reset

Control ground

Note 1) When the “PLC” and “12 V” terminals are short-circuited, sink input is available.

4kW,0.75kW,1

4kW,04kW,0

Frequency meter

1 mA (full scale)

Terminate the shielded cables

properly.

75kW,1.5kW,2

75kW,175kW,1

NFB

③

①

Note 1) Short-circuit bar

5kW,2.2kW,3

5kW,25kW,2

R/L1

S/L2

T/L3

5V

②

FIN1

G

FOUT

FIN2

12V

PLC

I1

I2

I3

I4

I5

I6

G

3.3kΩ

2kW,3.7kW

2kW,32kW,3

Main circuit

Control circuit

▽

▽

▽

△

▽

△

▽

△

▽

△

▽

△

▽

△

(Frame ground)

E E

Be sure to connect the ground terminal. (Ground resistance:

10Ω or less, φ1.6 mm or more)

7kW

7kW7kW

U/T1

V/T2

W/T3

O1

(Collector) Trip output

(Collector) Arrival signal

O2

(Emitter)

COM1

NC

COM2

NO

CE

V

C

max.=50mA

I

Trip signal contact

capacity

DC30V 2A

AC30V 2A

Motor

IM

Ground terminal

max.=DC24V

When the “PLC” and “G” terminals are short-circuited, source input is available.

For details on sink input and source input, see P16.

- 14 -

Page 15

Wiring

・5

・5.5kW,7

5kW,7.5kW

・5・5

5kW,75kW,7

5kW

5kW5kW

3-phase power supply

AC380~460V

50/60Hz

External frequency setting

potentiometer

1/4 W, 5 kΩ, B curve

Frequency meter

1 mA (full scale)

Run/stop switch

CCW/CW switch

Frequency setting selection (1)

Frequency setting selection (2)

Free-run

Trip reset

Control ground

Note 2)

Regenerative

braking resistor

NFB

③

①

Note 1) Short-circuit bar

connection terminal

②

R/L1

S/L2

T/L3

5V

FIN1

G

FOUT

FIN2

12V

PLC

I1

I2

I3

I4

I5

I6

G

P PB

3.3kΩ

R

Main circuit

Control circuit

▽

△

▽

△

▽

△

▽

△

▽

△

▽

△

U/T1

V/T2

W/T3

O1

▽

▽

(Collector) Trip output

O2

(Collector) Arrival signal

COM1

(Emitter)

V

CE

max.=DC24V

I

C

max.=50mA

NC

Trip signal contact

capacity

COM2

DC30V 2A

AC30V 2A

NO

Motor

IM

Ground terminal

Terminate the shielded cables

properly.

(Frame ground)

E E

Be sure to connect the ground terminal. (Ground resistance:

10Ω or less, φ 1.6 mm or more)

Note 1) When the “PLC” and “12 V” terminals are short-circuited, sink input is available.

When the “PLC” and “G” terminals are short-circuited, source input is available.

For details on sink input and source input, see P16.

Note 2) If you intend to connect an external regenerative braking resistor, specification

check is required. Contact Motor Co., Matsushita Electric Industrial Co., Ltd.

- 15 -

Page 16

o

System Configuration and Wiring

Changing the input signal logic

The inverter provides two types of input signal logics: sink input and source input.

When the “PLC” and “12 V” terminals are short-circuited, sink input is available. When the “PLC”

and “G” terminals are short-circuited, source input is available.

The inverter has been set for sink input before shipment.

The following description is provided on the assumption that the inverter has been set for

sink input.

1) Sink input

This logic indicates that a signal turns ON when a current flows out of an input terminal.

“G” is the common terminal for input signals.

Short-circuit bar

12V

PLC

* The same logic applies to

“I2” through “I6”.

2) Source input

This logic indicates that a signal turns ON when a current flows into an input terminal.

“12 V” is the common terminal for input signals.

Short-circuit bar

G

I 1

G

12V

PLC

G

* The same logic applies t

“I2” through “I6”.

I1

- 16 -

Page 17

2

3

Terminal function

(1) Main circuit terminal

0.4kW - 3.7kW 5.5kW - 7.5kW

E R/L1 S/L2 T/L3 U/T1 V/T2 W/T3 E E R/L1 S/L

T/L3 P

U/T1V/T2

PB

/T

E

Capacity Terminal

screw

0.4kW - 7.5kW M4 1.0 - 1.2 All terminals (including “E” terminal)

Tightening torque

N・m

Location

Terminal code Terminal name Function

R, S, T/

L1, L2, L3

U, V, W/

T1, T2, T3

E

P

PB PB terminal

∗1: Only for 5.5 kW and 7.5 kW.

Power supply

terminal

Motor terminal Connected to a 3-phase induction motor.

Ground

terminal

P terminal Converter’s + terminal

Connected to a commercial power supply (3-phase 380 to 460 V,

50/60 Hz).

Inverter’s frame ground (FG) terminal. Ground resistance: 10 Ω or

less

Regenerative resistor connection terminal

Connect a regenerative resistor between the P and PB terminals.

∗1

- 17 -

Page 18

System Configuration and Wiring

(2) Control terminal

Relay contact output terminal

<

COM2 NC NO

Terminal code

5V

12V

FIN1

FIN2

G

FOUT

Terminal name Function

terminal for frequency

External power

supply terminal

Input terminal for

frequency setting

Control ground

Frequency meter

Power supply

setting

terminal

O1 O2 FIN2 FIN1 FOUT IIII2 IIII4 IIII6 12V

>

COM1 12V PLC G IIII1 IIII3 IIII5 G 5V

Short-circuit bar

Only fossr the inverter with

*

communication interface.

Terminal screw size: M2.5, Tightening torque: 0.3 to 0.5 N•m

+5 VDC is applied. Imax = 20 mA

+12 VDC is applied. Imax = 20 mA

Serves as a common terminal for contact inputs when the source input

logic is selected.

When the source input logic is selected (the PLC and G terminals are

short-circuited), short-circuiting each input terminal and this terminal turns

ON the input signal. Opening these terminals turns it OFF.

Frequency setting is enabled by applying 0 to +5 VDC (or 0 to +10 VDC)

between the FIN1 and G terminals, or by applying 4 to 20 mA between

the FIN2 and G terminals.

If both the FIN1 and FIN2 inputs are activated, a larger frequency setting

is enabled.

To use these terminals, change [ Frequency command selection] to

-

“

Input impedance FIN1: 100 kΩ

FIN2: 250 Ω

Common ground terminal for contact inputs.

Serves as a common terminal for contact inputs when the sink input logic is

selected.

When the sink input logic is selected (the PLC and 12V terminals are

short-circuited), short-circuiting each input terminal and this terminal turns

ON the input signal. Opening these terminals turns it OFF.

Outputs a voltage proportional to the output frequency between the

FOUT and G terminals. Connect a DC ammeter with 1 mA full-scale.

By changing [ FOUT switching], a pulse output synchronized with the

output frequency is enabled.

” or “

-

”.

DSW1*

CN4*

- 18 -

Page 19

Terminal code

IIII1

IIII2

IIII3

IIII4

Input terminals

IIII5

IIII6

G

O1

O2

COM1

Output terminals

NC

NO

COM2

*

CN4

*

DSW1

Terminal name Function

CCW/stop

command terminal

CW/stop command

terminal

Frequency setting

selection terminal

Control ground Common ground terminal for contact inputs.

Output signal

terminal

Output signal

terminal

RS485

communication

connector

Terminating

resistance

Short-circuiting the “I1” and “G” terminals activates the CCW command.

Opening these terminals activates the stop command.

Short-circuiting the “I2” and “G” terminals activates the CW command.

Opening these terminals activates the stop command.

When [ I1・I2 function selection] is changed, “I1” serves as run/stop

command, and “I2” serves as CCW/CW command.

By using [ Operation mode selection], [ I5 function selection] and

[ I6 function selection], you can select the following functions:

Operation mode

2-speed operation mode

4-speed operation mode

8-speed operation mode

16-speed operation mode

Open-collector output terminals. (Signal is not retained when power is OFF.)

By using [ Output signal ① selection] and [ Output signal ②

selection], you can select the signal type. The default settings of “O1” and

“O2” are trip signal (transistor turns ON at trip), and arrival signal (transistor

turns ON at arrival), respectively.

“O1” “O2” (collector) Ic max. = 50 mA

“COM1” (emitter) Vce max. = 24 VDC

Relay contact output terminals. (Signal is not retained when power is OFF.)

By using [ Relay output signal selection], you can select the signal

type.

When inactivated: NO - COM2 open, NC - COM2 closed

When activated: NO - COM2 closed, NC - COM2 open

Contact capacity: 30 VAC 2 A, 30 VDC 2A

Contact rating: Contact resistance 50 mΩ or less (via 5 VDC 1A voltage drop

method)

RS485 communication connector

(6-pin modular jack RJ11)

Terminating resistance selection switch

The 390Ω resistance ON/OFF can be selected.

OFF: ON:

Pin No.

1 Unused

2 +5V

3 RS485+

4 RS485-

5 G (Control ground)

6 Unused

IIII3

CCW jogging CW jogging

IIII4

Frequency setting selection

Function

IIII5

Selectable from Free-run stop, External

forced trip, No. 2 acceleration/ deceleration

time and Trip reset commands.

Pin 6

IIII6

Pin 1

* Only for the inverter with communication interface

- 19 -

Page 20

System Configuration and Wiring

Precautions when wiring

Internal circuits retain high voltage for a certain period time after power is off. Wait at least for

15 minutes after power off before starting any wiring.

Main circuit

(1) If the power supply terminals (R/L1, S/L2 and T/L3) and motor terminals (U/T1,

V/T2 and W/T3) are connected in reverse, the inverter will be damaged. Be

sure not to connect these terminals in reverse.

(2) Do not ground the main circuit terminal.

(3) Do not short-circuit the motor terminals (U/T1, V/T2 and W/T3).

(4) The ground (E) terminal is the inverter’s frame ground terminal.

(5) To connect the main circuit terminal, be sure to use a crimp terminal with

insulation sheath.

(6) To run the inverter, use the no-fuse breaker (NFB) according to the standard

connection diagram.

Select a no-fuse breaker according to the motor ratings.

(7) Be sure to remove the phase advancing capacitor from an existing motor.

Control circuit

(1) When connecting a control circuit conductor, strip off a suitable length of insulation: too

long bare conductor will touch with another conductor; too short bare conductor will

easily pull off the connection. When connecting two more conductors together, twist

them before wiring or connecting.

(2) When using a bar terminal or solid conductor, select one having a diameter equal to 0.9

mm or less. Fastening screw may be damaged.

(3) Do not apply more than 24 VDC, 50 mA to the output terminals (COM1, O1, O2), or

apply voltage to terminal in reverse.

Do not apply 30 VAC, 2 A (or 30 VDC, 2 A) to the output terminals (COM2, NO and NC).

(4) Do not apply an external voltage to the input terminals (I1 to I6).

(5) Do not short-circuit the frequency setting power supply terminal (5 V) and the external

power supply terminal (12 V) with the control ground (G) terminal.

(6) To directly drive the relay by the output terminals (COM1, O1, O2), mount a flywheel diode

(FD).

5.5㎜±1㎜

COM1

01/02

FD(100V

1A)

R Y

<Examples> Fuji Electric ERA15-01

Pay attention to polarity of diode.

(7) For connections to the control circuit, use twisted cables or shielded cables.

(8) The cable connected to the control circuit must be placed apart from a power cable.

(9) To tighten a cable, put a screwdriver on the terminal perpendicularly.

ERB12-01

- 20 -

Page 21

y

asonic

asonic

Parameter Setting

Setting

Operation Panel

2-digit LED

Pan

Pan

r/min

Hz

A

V

*

5-digit LED

DATA

SET

RUN

MODE

^

^

STOP

* Normally in the monitor mode, the operation panel displays frequency (Hz).

* The indicated value is just for reference. Do not use this device as a measuring instrument.

Also, the operation panel can display the magnification factor specified by [ Display scale

factor].

5-digit LED

2-digit LED

MODE switch

DATA SET switch

Displays an output frequency, set frequency, value magnified by the scale factor,

cause of error and parameter value.

Display a parameter number. In the monitor mode, the direction of motor rotation

is displa

Used to change the monitor mode. Pressing this switch changes the monitor as

follows:

Used to switch between the parameter No. mode and the parameter value mode,

and to register a parameter value.

ed.

Output frequency Converter voltage Motor current

Description on each mode

●

Monitor mode

Parameter No.

mode

Parameter

value mode

Displays an output frequency, converter voltage and motor current.

At power-ON, the operation panel is set to this mode.

If the MODE switch is pressed in the parameter No. mode or

parameter value mode, the display will be changed to this mode.

A parameter number (

is pressed in the monitor mode, the display will be changed to this

mode.

A parameter set value blinks. The set value can be changed with

the △ or ▽ button.

Pressing the DATA SET switch after changing a set value

registers the updated value. Even if the MODE switch is

pressed, the data will not be registered.

- )) blinks. If the DATA SET switch

△ ▽ switch

RUN switch

STOP switch

Use to select, set and modify a parameter.

Can be held down for continuous changing.

Issues the run command.

Issues the stop command.

- 21 -

Page 22

r

r

Parameter Setting

Power ON

Monitor mode

Output frequency

MODE

Output current

r/min

Hz

A

MODE

△

▽

Direct speed setting of No.0.

MODE

DATA SET

MODE

Converter voltage

V

Use △ and ▽ .

Note: When [ Speed

setting selection] is

● Parameter LED will blink

Parameter

No. mode

△

▽

△

▽

MODE

mode

DATA SET

Storage To monitor

DATA SET

Parameter value

mode

Pressing DATA SET switch in the

parameter value mode stores the data.

If MODE switch, the data will be

saved upon power off.

Select the desired paramete

No. using △ and ▽ .

● Parameter LED will blink

△

▽

Select the desired paramete

No. using △ and ▽ .

△

▽

- 22 -

Page 23

Test Operation

Pre-operation inspections

After installing and wiring, inspect the following before running the inverter.

(1) Check if wiring is correct. (In particular, check improper connections of the power

supply terminals (R/L1, S/L2 and T/L3) and motor terminals (U/T1, V/T2 and W/T3),

short-circuited load and ground fault.)

(2) Does input power comply with the rating?

(3) Are there any places that could be shorted by wire cuttings, etc?

(4) Are any screws or terminals loose?

Test run

(1) Preparation for safety operation

① Set the motor so that it can be independently operated.

② Turn off all the inputs on the control terminal block.

(2) Follow the test procedure:

Step

①

Power ON

Operation panel

Switch Display on LED

Remarks

•

Monitor mode upon power-up

(Output frequency display)

②

Frequency

setting

(See Note)

③

Return back

to the monitor

mode

④

Run (forward)

command

⑤

Stop

command

Press △ .

Press △ to

specify frequency.

Press

register data.

MODE

Press RUN .

to

Press STOP .

•

The 0th speed frequency is

displayed. (The set value is “0.00”

Hz.)

•

Set the 0th speed frequency to

“60” Hz.

•

Frequency gradually changes.

•

The direction of motor rotation is

displayed.

•

Frequency gradually changes to

“0” Hz.

<Operation check>

① Smooth motor rotation. No unusual sound. No excessive vibration.

② Smooth acceleration and deceleration.

③ Motor direction and speed.

Note) To specify frequency with the inverter’s control dial, set [ Frequency command selection] to

(Inverter’s control dial).

- 23 -

Page 24

(

)

(

)

(

)

y

Operation Function

Selection of the run command

The M2X series inverter provides the following six types of operations depending on

whether frequency commands and run commands are entered through the operation panel

or the terminal block.

Speed command

From

operation

panel, or

control dial

Terminal block

FIN1 or FIN2 on

terminal block

∗

2

Run command Parameter

Operation

panel

Terminal

block

Frequency command

selection

1 ○ ○ ∗1 ○ ∗1 or

2 ○ ○ ∗1 ○ ∗1 or

3 ○ ○ or

4 ○ ○ or

5 ○ ○ or

6 ○ ○ or

Run command

selection

both)

(both

panel

panel

(terminal block)

(terminal block)

Default settings of [ Frequency command selection] and [ Run command selection] are and

, respectively.

Frequency command selection changing procedure

Example) Change [ Frequency command selection] from to .

Step

① Power ON

② Parameter

number mode

③ Parameter set

value mode

Switch LED displa

Press DATA SET

Using △ , select the

parameter No.

Press DATA SET

Using △ , select the

parameter value

Press DATA SET to

save the value

Operation panel

∗1 The run command from the terminal block overrides the command from the operation panel, if both

are enabled.

The RUN switch on the operation panel is active only when both the CCW/stop switch (I1) and the

CW/stop switch (I2) on the terminal block are OFF. If both or one of [I1] and [I2] are turned on while

the RUN switch is active, the operation mode set from RUN switch is cancelled.

∗2 The “FIN1” and “FIN2” terminals are intended for voltage command (0 to 5 VDC or 0 to 10 VDC) and

current command (4 to 20 mADC), respectively. For details, refer to “Terminal function: “(2) Control

Terminal” on P18.

- 24 -

Page 25

y

Acceleration/deceleration time changing procedure

Example) Change [ Acceleration time] from

.

to

.

Step

①

Power ON

②

Parameter

number mode

③

Parameter set

value mode

Switch

Press DATA SET .

Using △ , select the

parameter No.

Press DATA SET .

Using △ , select the

parameter value.

Press DATA SET to

save the value.

Operation panel

.

.

LED displa

∗1

∗

1

∗1 To change deceleration time, use [ Deceleration time].

- 25 -

Page 26

Operation Function

Operation function

The inverter has the following control functions that are made active from the operation

panel and terminal block.

Operation control

Jogging

Free-run stop

DC brake

Positioning DC

brake

Acceleration/deceleration time is set to “0”. This function is optimum for

positioning. By setting [ Operation mode selection] to “2-speed mode”,

jogging operation is enabled.

When the “I3” and “G” control input terminals are short-circuited, CCW

jogging is enabled. When “I4” and “G” are short-circuited, CW jogging is

enabled, and the jogging frequency is output.

You can switch over between the normal operation mode and the jogging

mode.

The jogging frequency can be specified in the range of 0 to 30 Hz. If the

jogging frequency is too high, the inverter may trip due to overcurrent.

Turns off the output voltage applied to the motor, allowing the motor to coast.

This function is useful to brake the motor mechanically. Remember that

touching the motor output terminals (U/T1, V/T2 and W/T3) may cause

electric shock even if the free-run stop function is activated.

Activates the brake by applying a direct current to the motor at the time

when the inverter shifts from the running status to the stop status. If the

CCW, CW or jogging command is issued while the DC brake function is

activated, the DC brake is disabled, and the motor starts running as

specified by the command.

When a stop command is issued during normal operation, the motor

soft-stops, and the DC brake is activated when the output frequency is

reduced to 3 Hz. (The frequency at which the brake is activated can be

changed with the parameter).

Description

DC brake for

full-range stop

When the frequency is set to “0”, the DC brake is activated when the output

frequency falls below 1 Hz.

The DC brake intensity (torque) and time can be specified with the

parameters.

When a stop command is issued during normal operation, the DC brake is

immediately activated without soft-stop.

The DC brake intensity (torque) and time can be specified with the

parameters.

The DC brake time is twice as long as the time specified for “Positioning DC

brake”.

- 26 -

Page 27

<Examples of DC Brake Operation Patterns>

Run

command

Positioning DC brake

Preset deceleration time

Time specified by [ DC brake time]

Frequency specified by [ Brake start frequency]

Output

frequency

Time determined by GD2 and

torque of the load, and [

DC brake intensity]

Motor speed

vs brake

Regenerative

braking

DC brake

DC brake for full-range stop

Run

command

Time specified by [ DC brake time]

Output

frequency

Motor speed

vs brake

DC brake

Time determined by GD2 and

torque of the load, and

[ DC brake intensity]

- 27 -

Page 28

Operation Function

Run mode

The inverter operates in the following two run modes.

Select the desired mode in the parameter [ Run mode selection].

Function of terminal block

Mode

IIII1 IIII2 IIII3 IIII4 IIII5

2-speed

4-speed CCW CW

CCW CW

CCW

jogging

Frequency setting

CW

jogging

selection

Free-run stop

External forced trip

command

No.2 acceleration/

deceleration time

selection

Trip reset command

Free-run stop

External forced trip

command

No.2 acceleration/

deceleration time

selection

Trip reset command

∗

1

IIII6∗1

Free-run stop

External forced trip

command

No.2 acceleration/

deceleration time

selection

Trip reset command

Free-run stop

External forced trip

command

No.2 acceleration/

deceleration time

selection

Trip reset command

Setting in

[ Run

mode

selection].

[Default setting]

Free-run stop

8-speed

CCW CW Frequency setting selection

External forced trip

command

No.2 acceleration/

deceleration time

selection

Trip reset command

16-speed

CCW CW Frequency setting selection

In the 4-, 8- or 16-speed mode, the following multi-speed operation is enabled by short-circuiting or

opening the frequency setting selection terminals. When all the terminals are opened, the 0th speed

frequency is selected, allowing you to specify frequency with the [ Set frequency (0th speed)]

parameter, external frequency setting control dial, or the inverter’s control dial.

With [ Frequency command selection], select whether to use the 0th speed frequency, external

frequency setting control dial or the inverter’s control dial.

■ Input terminal description

(1) Input terminals are given the following priority.

DC brake < Normal operation < Jogging < Free-run stop < External forced trip

Example)

① If the run command is issued while the DC brake is activated, the motor

will immediately start running.

② If the free-run stop command is issued during jogging operation, the

motor will coast to stop.

③ Even if the run command is issued while the free-run command is

activated, the motor will not start running.

(2) If both the CCW and CW commands are issued during trip, the trip can be

canceled. Before canceling the trip, remove the cause of the trip.

∗1 [ I5 function selection], [ I6 function selection]

- 28 -

Page 29

■ Frequency setting selection method for multi-speed operation

(1) When [ Multi-speed input selection] is set to (1 BIT): 1-bit

input

One type of multi-speed frequency can be assigned to one of the [Frequency

setting selection] terminals. When the 4-speed, 8-speed and 16-speed

operation modes are selected, up to 3-stepped, 4-stepped and 5-stepped

speed operations are enabled, respectively.

Example: 16-speed mode

Control terminal number

IIII3 IIII4 IIII5 IIII6

OFF OFF OFF OFF

ON × × ×

OFF ON × ×

OFF OFF ON ×

OFF OFF OFF ON

• “ON” and “OFF” indicate the connection between each frequency setting selection

terminal and the “G” terminal.

• “x” indicates that either “ON” or “OFF” is acceptable.

(2) When [ Multi-speed input selection] is set to

input [Default setting]

You can select frequency by setting a binary number for the frequency setting

selection terminals.

< 4-speed mode >

IIII3 IIII4

OFF OFF

ON OFF

OFF ON

ON ON

Frequency setting

0th speed frequency

1st speed frequency

2nd speed frequency

3rd speed frequency

Frequency setting

0th speed frequency

1st speed frequency

2nd speed frequency

3rd speed frequency

4th speed frequency

(Binary): Binary

<

8-speed mode

IIII3 IIII4 IIII5

OFF OFF OFF

ON OFF OFF

OFF ON OFF

ON ON OFF

OFF OFF ON

ON OFF ON

OFF ON ON

ON ON ON

>

Frequency setting

0th speed frequency

1st speed frequency

2nd speed frequency

3rd speed frequency

4th speed frequency

5th speed frequency

6th speed frequency

7th speed frequency

- 29 -

Page 30

Operation Function

< 16-speed mode >

Control terminal number

IIII3 IIII4 IIII5 IIII6

OFF OFF OFF OFF

ON OFF OFF OFF

OFF ON OFF OFF

ON ON OFF OFF

OFF OFF ON OFF

ON OFF ON OFF

OFF ON ON OFF

ON ON ON OFF

OFF OFF OFF ON

ON OFF OFF ON

OFF ON OFF ON

ON ON OFF ON

OFF OFF ON ON

ON OFF ON ON

OFF ON ON ON

ON ON ON ON

Frequency setting

0th speed frequency

1st speed frequency

2nd speed frequency

3rd speed frequency

4th speed frequency

5th speed frequency

6th speed frequency

7th speed frequency

8th speed frequency

9th speed frequency

10th speed frequency

11th speed frequency

12th speed frequency

13th speed frequency

14th speed frequency

15th speed frequency

• “ON” and “OFF” indicate the connection between each frequency setting

selection terminal and the “G” terminal.

- 30 -

Page 31

p

p

p

■ Operation pattern in 2-speed mode - Example:

When [ I5 function selection] is set to - (No. 2 acceleration/deceleration

time)

When [ I6 function selection] is set to (External forced trip)

CCW

CW

CCW/stop switch

(I1)

CW/stop switch

(I2)

CCW jogging

(I3)

CW jogging

(I4)

No. 2 acceleration/deceleration time

(I5)

External forced trip

(I6)

Acceleration time

0th speed

Deceleration

time

Positioning DC brake

0th

No. 2

eed

s

deceleration time

Jogging frequency

Positioning DC brake

■ Operation pattern in 4-speed mode - Example:

Acceleration time

Free-run stop

(trip)

0th speed

When [ I5 function selection] is set to (Free-run command)

When [ I6 function selection] is set to - (No. 2 acceleration/deceleration

time)

Acceleration time

2nd speed

CCW/stop switch

Frequency setting selection (1)

Frequency setting selection (2)

No. 2 acceleration/deceleration time

(I1)

CW/stop switch

(I2)

(I3)

(I4)

Free-run

(I5)

(I6)

CCW

CW

0th speed

Deceleration

time

Positioning DC brake

0th

s

eed

No. 2

deceleration

time

1st speed

Deceleration time

No. 2 acceleration time

3rd

s

eed

Free-run stop

- 31 -

Page 32

p

Operation Function

■ Operation pattern in 4-speed mode - Example:

When both [ I5 function selection] and [ I6 function selection] are set to

-

(No. 2 acceleration/deceleration time)

CCW

CW

CCW/stop switch

(I1)

CW/stop switch

(I2)

Frequency setting selection (1)

(I3)

Frequency setting selection (2)

(I4)

No. 2 acceleration/deceleration time

(I5)

No. 2 acceleration/deceleration time

(I6)

Acceleration time

0th speed

Positioning DC brake

Deceleration

time

No. 2 acceleration time

0th

eed

s

No. 4 acceleration time

1st speed

No. 3

acceleration

time

No. 2

deceleration

time

No. 4 deceleration time

2nd speed

- 32 -

Page 33

Protective Function

Protective functions

Your inverter is equipped with the following protective function that:

① displays warning message, or

② avoids trip without displaying warning message.

③ displays warning message and turns off inverter output, or

④ trips the inverter (the trip signal will be removed upon power off)

Display on

Type

①

②

③

5-digit LED

Electronic

thermal trip

Monitor

(

Flashes

Overcurrent stall

prevention

(Not displayed)

Overvoltage

stall prevention

(Not displayed)

Undervoltage

Instantaneous

power failure

protection

)

CW rotation

prevention

Monitor display flashes when the

∗

3

output current reaches the

electronic thermal trip level and

the timer operates.

If the output current exceeds [

Current limit operating point] during

acceleration or constant-speed

operation, the output frequency is

reduced for trip prevention.

(The operation level can be

adjusted with [ Current limit

operating point].)

If the converter’s DC voltage

exceeds approx. 775 V during

deceleration, the deceleration time

is prolonged for trip prevention.

(The deceleration time can be

adjusted with [ Deceleration

factor at stall].)

When the converter’s DC voltage

falls below approx. 360 V, it is

judged as “instantaneous power

failure”, and the inverter’s output is

turned off.

DC voltage falls below approx.

300 V, the control circuit is reset.

If the voltage is restored by the

time the control circuit is reset, the

operation can be continued.

When the CW rotation prevention

function is selected, CW rotation is

prevented when the CW signal is

issued.

Protective function

∗1

When the converter’s

Check for overloading and reduce

the load as necessary.

Increase the acceleration time, or

reduce the inertial load.

Prolong the deceleration time, or

reduce the inertial load.

Check the power source, cabling,

wiring, etc.

∗2

Check if the CW command is not

issued.

Corrective action

∗1 The inverter can continue normal operation with approx. 15 ms power interruption.

∗2 Enabled when [

∗3 This function is enabled only when [

- -

Restart prevention upon power recovery] is set to .

CW rotation prevention] is set to .

33

Page 34

Protective Function

Type

③

④

Display on

5-digit LED

Restart

prevention

when

power is

restored

Overcurrent trip

(at constant speed)

-

Protection by CT

detection

(During acceleration)

-

(During deceleration)

Regenerative

overvoltage trip

Overvoltage trip

retry at

power-ON

Overload trip

(electronic

thermal)

∗2

-

Protective function Corrective action

Prevents the inverter from

restarting automatically if already

given the run command before

power is recovered or turned up or

it is reset.

When the inverter’s output current

exceeds approx. 200% of its rated

current, the inverter trips. (The

displayed message varies

depending on the inverter’s

operating condition.)

When the converter’s DC voltage

exceeds approx. 800 V, the inverter

trips.

When overvoltage trip occurs

because of too large inductance of

the power factor improving AC

reactor in the inverter’s input circuit,

output is turned off.

When the converter’s DC voltage

falls below approx. 800 V, the trip

is automatically canceled,

enabling normal operation.

If the motor current continues to

exceed the level set in [Electronic

thermal], the inverter will be

tripped because it may be

overloaded.

is displayed, and the

∗1

Issue the stop command once,

and then issue the run command.

Power supply voltage drop,

excessive GD

acceleration/deceleration time,

short-circuited load or ground fault

may be considered as the cause

of the trip. Examine the cause of

trip thoroughly.

If trip occurs while the inverter is

running, the deceleration time may

be too short and should be

extended. In some cases, an

external regenerative resistor may

be required. If the trip occurs

upon power-up, the inductance of

the power factor improving AC

reactor at the input of inverter may

be too large, use an AC reactor

compatible with the capacity of the

inverter.

The power factor improving AC

reactor’ capacity may be too large.

Select a proper rector according to

the inverter’s capacity.

Reduce the load, change

operating pattern or use larger

size inverter.

2

of load, insufficient

∗1 This function is enabled only when [

∗2 When [

inverter from restarting automatically.

Restart prevention when power is restored] is set to , this function prevents the

- -

Overvoltage trip retry at power-ON] is set to .

34

Page 35

Type

Display on

5-digit LED

Radiator fin

overheat

protection

CPU error

When the temperature of the

radiator fin exceeds approx.

100℃, the temperature sensor is

activated to trip the inverter.

Trips the inverter if the

micro-computer causes an error.

Protective function

Examine the cooling fan and the

ambient temperature.

The microcomputer operation may

be interfered by external noise.

Locate and remove the noise

source or reduce the noise level.

Corrective action

④

Self-diagnosis

trip

Communication

error

External forced

trip

Trips upon changing in certain

parameter, e.g. [ Operation

mode selection].

If communication is interrupted for

a period of, or longer than [

Protocol timeout] as many times

as, or more frequently than [

Communication retry frequency], it

is judged as communication error.

Trips the inverter when [ I5

function selection] or [ I6

function selection] is set to

external forced trip and I5/I6 is not

connected to [G].

After short-circuiting “I5/I6” and

“G”, reset the trip.

This is not an error. After trip is

canceled, the updated result will

become effective.

Check the communication host for

abnormal condition.

After short-circuiting the “I5” or “I6”

terminal and the “G” terminal,

cancel the trip.

When a thermal protector is

connected, examine the cause of

overload.

Note) If the LED display shows a cause of trip and “ ” alternately after

the trip is reset, the cuase of trip has not been removed yet. Remove the

cause of trip first, and then reset the trip again.

Note) The cooling fan driving sequence is shown below.

Power supply

Run command

Fan

2 min. 2 min.

ON

OFF

Running

Halted

Driven

Halted

While the inverter trips, the fan is driven only for two minutes.

- -

35

Page 36

Protective Function

Canceling trip

First remove the cause and then reset the system by following one of the following steps.

[1] Turn off the inverter. Wait until the trip message disappears and then power

on again.

[2] Leaving the trip message displayed, connect both [I1] and [I2] to [G] for at

least 0.1 seconds. ∗1

[3] Leaving the trip message displayed, press both △ and ▽ switches

on the operation panel for at least 1 second.

[4] Leaving the trip message displayed, issue the trip reset command.∗2

* If the CPU error

procedure. The trip cannot be canceled with the above [2], [3] and [4] methods.

occurs, cancel the trip according to the above

∗1

When [

canceled.

∗2

This method is effective only when [ I5 function selection] or [ I6 function selection] are set

to

- -

I1/I2 function selection] is set to “I1: Run/stop” and “I2: CCW/CW”, the trip cannot be

.

36

Page 37

Maintenance/Inspection

You should perform maintenance/inspection on a regular basis in order to ensure safety

and keep the inverter in good running order.

Precautions when performing maintenance/inspections

(1) The power should be turned on/off only by the person performing the task.

(2) The internal circuits of the inverter remain charged with high voltage for a short

while after power is turned off. To perform inspection, first turn off the power and

then wait for the LED display on the operation panel to go off (min. 15 minutes).

(3) Do not use a megger for the purpose of measuring insulation resistance.

Otherwise, the inverter is damaged.

Inspection items and environment

●

Ordinary/normal usage conditions

Ambient conditions: Annual mean temperature 30°C, max. 20 hrs/day at max. load rate 80%

●

Perform daily and periodic inspections in accordance with the following items:

Classification Inspection cycle Inspection items

・Ambient temperature, humidity, dirt, dust, foreign objects, etc.

・Is there abnormal vibration/noise?

・Is main circuit voltage normal?

・Is there strange odor?

Daily inspection Daily

Periodic

inspections

Caution>

<

1 year

・Is there lint in the air holes?

・Cleanliness of control unit

・Is wiring damaged?

・Are equipment connections loose or off center?

・Are foreign objects lodged in at the load side?

・Are fastened sections loose?

・Is there evidence of overheating?

・Are terminal blocks damaged?

Inspection cycle for periodic inspections may vary if usage conditions differ from those

given above.

Approximate period for part replacement

Period for part replacement varies depending on how the inverter is used. Parts must

be replaced or repaired when something is wrong with them.

Product

name

Inverter

Part name

Smoothing capacitor Approx. 5 years

Cooling fan

Aluminum electrolytic

capacitor on PCB

Standard

replacement period

(hrs)

2 - 3 years (10 - 30

thousand hours)

Approx. 5 years

Remarks

Standard replacement period

gives a number of years for

reference only. If a part becomes

faulty it must be replaced even if

the standard replacement period

has not yet been reached.

- -

37

Page 38

Troubleshooting

Inspection to determine cause of problem

When a problem occurs, perform the inspections and take the measures prescribed in the

following table. If you cannot determine the cause of the problem, if you suspect that the

inverter is not working properly, if a part is damaged, or there are any other problems you

cannot solve, contact your Panasonic dealer.

Problem Possible cause Corrective action

Motor won't run

Motor runs in

wrong direction

Motor runs but

cannot change

speed

Motor runs at

incorrect speed

Unstable motor

speed

Improper wiring

Power is not fed to power input

terminals.

LED on the operation panel is

unlit.

Not a rated voltage on the supply

input terminals.

Error is displayed.

Free-run command is issued.

Both CCW and CW switches are

on.

Check if the frequency setting is

correct.

Motor is locked or overloaded.

One phase is missing.

Check the output terminals (U/T1,

V/T2 and W/T3) for incorrect

phase order.

Motor is overloaded.

No. of phases and voltage of the

motor do not match those of

power source.

Voltage on power input terminal

(R/L1, S/L2 or T/L3) is out of spec.

Check if the frequency setting

range is correct.

Check if the motor’s terminal

voltage is extremely low.

Motor is overloaded.

Load varies excessively.

Correct wiring.

Turn on power.

Turn off and then on power.

Check power supply.

Check the voltage.

See Section [Protective function].

Cancel the command.

Turn off unnecessary one.

Check the frequency setting.

Release the lock or reduce the

load.

Check wiring between the inverter

and motor.

Match the phase order of the output

terminals (U/T1, V/T2 and W/T3)

with those of the motor terminals.

Reduce the load.

Check the specifications and the

identification plate.

Check the voltage.

Check [ Lower limit frequency]

and [ Upper limit frequency].

Check [ Base frequency],

[

Maximum output voltage adjustment]

and [ V/F reduction

characteristic].

Reduce the load.

Keep fluctuations in the load at

minimum. Replace with larger

inverter and motor set.

- -

38

Page 39

,

Parameter Description

No. Parameter name

Set frequency (0th speed)0, 0.5

1st speed frequency 0, 0.5

2nd speed frequency 0, 0.5

3rd speed frequency 0, 0.5

4th speed frequency 0, 0.5

5th speed frequency 0, 0.5

6th speed frequency 0, 0.5

7th speed frequency 0, 0.5

8th speed frequency 0, 0.5

9th speed frequency 0, 0.5

10th speed frequency 0, 0.5

11th speed frequency 0, 0.5

12th speed frequency 0, 0.5

13th speed frequency 0, 0.5

14th speed frequency 0, 0.5

15th speed frequency 0, 0.5

Run command selection

Parameter setting

Adjustment range Min. unit

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

2

∗

- Upper limit frequency

Operation panel

Factory setting

0.01Hz∗3 0Hz

0.01Hz∗3 50Hz

0.01Hz∗3 30Hz

0.01Hz∗3 15Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

0.01Hz∗3 0Hz

Check

∗1

Terminal block

Both

Frequency command

selection

RS485 communication

Operation panel

Control dial

- 0 - 5V(4-20mA)

Operation mode

selection

Torque control

- 0 - 10V(4-20mA)

2, 4, 8, 16 speed operation mode

0 - 100 2

Automatic boost

Slip frequency vector control

Jogging frequency

∗

1 Parameters marked by

memorized.

Cancel the trip before use.

∗

2 The lower limit of the adjustment range varies depending on the [

∗

3 When the set value exceeds 160 Hz, the minimum unit of setting is 0.05 Hz.

0

∗2

0.5

in the Check column are tripped for safety if modified or

~30Hz 0.01Hz 7Hz

40

20

4 speed

operation mode

400W -

1.5kW

2.2kW -

7.5kW

Starting frequency] setting.

- -

39

Page 40

(

)

Parameter Description

No.

Acceleration time

No.2 acceleration time

No.3 acceleration time

No.4 acceleration time

DC brake intensity

DC brake time

DC brake selection

Start-up brake time

Brake starting

Carrier frequency

Deceleration time

No.2 deceleration time

No.3 deceleration time

No.4 deceleration time

Base frequency

Maximum output

V/F reduction

characteristic

Parameter name

Adjustment range Min. unit

- 3 sec

0 - 3600 sec

3 sec - 10 sec

10 sec -

0 - 100 2 70

Case of :

0 - 3 sec

Case of - :

0 - 6 sec

Positioning

- Full-range stop

0 - 3 sec 0.05 sec 0

0.5 - 400Hz 0.01Hz∗3 3 Hz

0, 1, 2, 3, 4, 5, 6, 7 5

- 3 sec

0 - 3600 sec

3 sec - 10 sec

10 sec -

30 - 400Hz

0 - 100%

1.0 - 2.0 squared 0.1 1.0

Parameter setting

: in steps of 0.01 sec

: in steps of 0.1 sec

: in steps of 1 sec

: in steps of 0.01 sec

: in steps of 0.1 sec

: in steps of 1 sec

0.05 sec

0.1 sec

1Hz

1%

Factory setting

5 sec

5 sec

5 sec

5 sec

0.5 sec

1.0 sec

Disabled

5 sec

5 sec

5 sec

5 sec

50Hz

100%

Check

∗1

2nd V/F selection

No selection

(Ordinary V/F pattern)

Upper pattern

Lower pattern

2nd V/F base frequency

2nd V/F boost

Jump frequency width

Jump frequency ①

Jump frequency ②

Jump frequency ③

Jump frequency ④

∗

1 Parameters marked by

memorized.

Cancel the trip before use.

∗2 The lower limit of the adjustment range varies depending on the [

∗3 When the set value exceeds 160 Hz, the minimum unit of setting is 0.05 Hz.

in the Check column are tripped for safety if modified or

30 - 400Hz 1Hz 50Hz

0 - 100 2 0

0 - 400Hz 0.01Hz∗3 0Hz

∗2

0, 0.5

0, 0.5

0, 0.5

0, 0.5

- 400Hz 0.01Hz∗3 0Hz

∗2

- 400Hz 0.01Hz∗3 0Hz

∗2

- 400Hz 0.01Hz∗3 0Hz

∗2

- 400Hz 0.01Hz∗3 0Hz

Starting frequency] setting.

- -

40

Page 41

No. Parameter name

I1/I2 function selection

I5 function selection

I6 function selection

Multi-speed input

selection

Parameter setting

Adjustment range Min. unit

I2: Reverse (cw) /stop

I2: Forward (ccw) /Reverse (cw)

External forced trip

Trip reset

Binary

I1: Forward (ccw) /stop

I1: Run/stop

Free-run

- 2nd acceleration/deceleration

1 bit

Factory setting

Check

∗1

Unused

Output signal ①

selection

Output signal ②

selection

Relay output signal

selection

Enabled only when the

relay output terminals

(NC, COM2 and NO)

are used.

Motor current detection

level

Output signal polarity ①

selection

Current limit operating

point

Deceleration factor at

stall

Acceleration mode

selection

Deceleration mode

selection

Running

Free-run

CCW, CW

- Output frequency detection

- Motor current detection

Cause of trip

- DC braking

Running

Free-run

CCW, CW

- Output frequency detection

- Motor current detection

Trip,

Trip, Arrival

50 - 150% 5% 100%

Normal, Reverse

50 - 150% 10% 150%

x1, x2, x4, x8, x16 x8

Linear

Arrival

S curve ①

-

S curve ②

-

∗1 Parameters marked by in the Check column are tripped for safety if modified or

memorized.

Cancel the trip before use.

- -

41

Page 42

Parameter Description

No. Parameter name

Monitor mode

selection

Adjustment range Min. unit

- Set frequency

- Output frequency

Parameter setting

Factory setting

Check

∗1

Display scale factor

Frequency meter adjustment

Frequency meter full-scale

FOUT switching

Comparative frequency A

Comparative frequency B

Agreement detection width

Drop frequency at

instantaneous power failure

Free-run time at instantaneous

power failure

Restart prevention

upon power recovery

- DC voltage

Output current

- Feedback frequency

0.1 - 60.0 0.1 1.0

Current analog output

Digital

Analog

-

0 - 400Hz 1Hz 60Hz

0, 0.5∗2 - 400Hz

0, 0.5∗2 - 400Hz 0.01

0 - 400Hz 0.01

0 - 400Hz 0.01

1, 2, 3, 4, 5 1

Restart

No restart

-

0.01

-

-

∗3

0Hz

Hz

∗3

0Hz

Hz

∗3

3Hz

Hz

∗3

3Hz

Hz

Retry selection

Retry start time

Frequency setting bias

Lower limit frequency

Upper limit frequency

Input filter time constant

Overvoltage trip retry at

power-ON

Trip retry

CW rotation

prevention

No retry

-

Retry up to No. of times set

0 - 120 sec 2 sec 4 sec

0, 0.5

(Lower limit frequency + 0.01) to 400 Hz

0 - − 60Hz 0.01

2

∗

(Upper limit frequency – 0.01) Hz

to

1, 2, 3, 4, 5

No retry

Retry

Enables CW rotation

0.01

0.01

Hz

Hz

Hz

∗3

∗3

∗3

Prevents CW rotation

Electronic thermal

∗

1 Parameters marked by

memorized.

Cancel the trip before use.

∗

2 The lower limit of the adjustment range varies depending on the [

∗

3 When the set value exceeds 160 Hz, the minimum unit of setting is 0.05 Hz.

30 - 150% 5%

in the Check column are tripped for safety if modified or

0Hz

0Hz

60Hz

3

115%

Starting frequency] setting.

- -

42

Page 43

No. Parameter name

Parameter setting

Adjustment range Min. unit

Factory setting

Check

∗1

Trip cause clear

Trip cause①

Trip cause②

Trip cause③

Trip cause④

Trip cause⑤

Parameter initialization

Motor selection

Starting frequency

Automatic voltage

adjustment reference

voltage

Automatic voltage

adjustment selection

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0.5 - 10Hz 0.01Hz

∗2

Motor capacity

Number of motor poles

4-pole inverter

capacity

1Hz

∗3

380, 400, 440, 460V 400V

-

-

Enables automatic voltage adjustment

Disables automatic voltage adjustment

Disables automatic voltage adjustment

during deceleration only

Parameter lock

Copy parameter

Motor rated current

Motor no-load current

Motor primary resistance

Slip correction gain

Slip correction response time

∗1 Parameters marked by in the Check column are tripped for safety if modified or memorized.

Cancel the trip before use.

∗2 The motor capacity is defined as follows:

: 3.7 kW, : 5.5 kW, : 7.5 kW.

∗3 The 4-pole motor with the same capacity as the inverter’s rating has been specified as the default

setting.

∗4 The parameter settings marked with asterisk (※) vary depending on the capacity. They will be restored

to the default settings through initialization.

Parameters are not locked

All parameters are locked

Locks unnecessary parameter

Parameters not copied

Parameters are read out to panel

Parameters are written into inverter

Panel data is initialized

0 - 100A 0.01

0 - 100A 0.01

0 – 100Ω 0.01

0, 1, 2, 3, 4, 5, 6, 7

0, 1, 2, 3, 4, 5, 6, 7

: 0.4 kW, : 0.75 kW, : 1.5 kW, : 2.2 kW,

∗4

※

※

※

∗4

∗4

4

0

- -

43

Page 44

Parameter Description

Parameter setting

No. Parameter name

Adjustment range Min. unit

∗1

Factory setting

Check

PID function selection

Proportional (P) gain setting

Integral ( I ) time constant setting