Panasonic LP-410TU Installation Manual

6

6

Preface

R

Thank you for purchasing Laser Marker "LP-400 Series".

For full use of this laser marker safely and properly, please read this manual carefully.

This system has been strictly checked and tested prior to its delivery, however, please make sure that this

system operates properly before using it.

In case that the system becomes damaged or does not operate as specified in this manual, contact the shop

Before Use/Contents

Preparation

you bought it or our sales agency.

Symbol Indications

This manual uses a variety of symbols to explain safety precautions, instructions, and references for operating

personnel.

Before reading this manual, fully understand the contents of these indications.

DANGE

"DANGER" denotes hazards that could result in serious personnel injury or death

when handling error occurs, and emergency precautions (urgency level) when any

dangerous situation causes.

Procedure

Basic Operation

Description of

Operation Screen

REFERENCE

TroubleshootingMaintenanceSpecificationAppendixIndex

WARNING

CAUTION

CHECK

"WARNING" denotes hazards that could result in serious personnel injury or death

when handling error occurs.

"CAUTION" denotes that any damages on personnels or objects could result in when

handling error occurs.

"CHECK" denotes any instructions or precautions for using this system.

"REFERENCE" denotes any hints for operation, detail explanations, or references.

This symbol denotes that the contents gives notice of the above "DANGER" and

"CAUTION" to operators. Read and keep the contents carefully.

This symbol denotes the possibility of fire.

This symbol denotes a general prohibition notice.

This symbol denotes the prohibition of disassembling the product.

This symbol denotes the prohibition of touching the specified place.

This symbol denotes a general action which operators must take.

Note

1. This manual is subject to LP-400 Series. This manual uses illustrations and screens of LP-400 Series

standard model type. Be careful that the illustrations shown in these manuals might be different.

2. Before using this product, or before every starting operation, please confirm the correct functioning and

performance of this product.

3. Contents of this manual will be changed without notice. This manual and software must not be partially or

totally copied or revised.

4. If there are any questions, mistakes, or comments in this manual, please notify us.

5. Please remind that we have not responsibility of any results of operations in regardless of the above 4

clause.

2 Preface

Before Use

Trademarks

Window XP is a registered trademark or trademark of U.S.A. Microsoft Corporation in U.S.A and other

countries.

All other product names and companies provided in this manual are trademarks or registered trademarks

of their respective companies.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Warranty of Product

1. Warranty Period

The warranty period is one year after delivery of the system to the ordered place by a purchaser.

2. Warranty Limitation

When a failure is produced by a supplier, exchange of the failure parts of the system, or repair of it is

performed in the responsibility of the supplier.

However, if failure of the system has resulted from the following reasons, the warranty is void.

1) Any fault or defect caused by inadequate handling or abnormal use.

2) Any fault or defect caused by the other reasons than the supplier's fault.

3) Any fault or defect caused by modification or repair of the system by any others than the suppliers.

4) Any fault or defect caused by acts of God or force majeure.

Note that the warranties set forth herein cover faults of defects of delivered products alone and do not

cover any damage induced by faults or defects of delivered products.

Before Use/Contents

Preparation

Procedure

Basic Operation

Adaptation Model

LP-400 series has various models shown in the below list. Please confirm their adaptation types.

Model Standard (JIS Standard compliant) -A (FDA standard compliant)

LP-430U

LP-430TU

LP-431U

LP-431TU

LP-435U

LP-435TU

LP-420S9U

LP-420S9TU

LP-421S9U

LP-421S9TU

LP-425S9U

LP-425S9TU

LP-410U

LP-410TU

LP-411U

LP-411TU

Note:

1. " △ " marked models will be available in the near future. Please call your nearest agent for the details.

2. In this manual, “-A” just after the model number of laser marker indicates that the model is FDA-compliant.

○○

○○

○○

○○

△△

○○

○○

○○

○○

○○

△△

△△

○○

○○

○○

○○

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Preface 3

License Agreement

• You have acquired a device (“DEVICE”) that includes software licensed by “SUNX Limited” from an affiliate of Microsoft Corporation (“MS”). Those installed software

products of MS origin, as well as associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual

property laws and treaties. Manufacturer, MS and its suppliers (including Microsoft Corporation) own the title, copyright, and other intellectual property rights in the

SOFTWARE. The SOFTWARE is licensed, not sold. All rights reserved.

• This EULA is valid and grants the end-user rights ONLY if the SOFTWARE is genuine and a genuine Certificate of Authenticity for the SOFTWARE is included. For more

information on identifying whether your software is genuine, please see http://www.microsoft.com/piracy/howtotell.

• IF YOU DO NOT AGREE TO THIS END USER LICENSE AGREEMENT (“EULA”), DO NOT USE THE DEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLY

Before Use/Contents

CONTACT “SUNX Limited” FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND. ANY USE OF THE SOFTWARE, INCLUDING BUT

NOT LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TO THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

1 You may use the SOFTWARE only on the DEVICE.

2 RESTRICTED FUNCTIONALITY. You are licensed to use the SOFTWARE to provide only the limited functionality (specific tasks or processes) for which

the DEVICE has been designed and marketed by “SUNX Limited”. This license specifically prohibits any other use of the SOFTWARE programs or

functions, or inclusion of additional software programs or functions that do not directly support the limited functionality on the DEVICE. Notwithstanding the

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

foregoing, you may install or enable on the DEVICE systems utilities, resource management or similar software solely for the purpose of administration,

performance enhancement and/or preventive maintenance of the DEVICE.

3 If you use the DEVICE to access or utilize the services or functionality of Microsoft Windows Server products (such as Microsoft Windows Server 2003), or

use the DEVICE to permit workstation or computing devices to access or utilize the services or functionality of Microsoft Windows Server products, you may

be required to obtain a Client Access License for the DEVICE and/or each such workstation or computing device. Please refer to the end user license

agreement for your Microsoft Windows Server product for additional information.

4 NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. “SUNX Limited” HAS INDEPENDENTLY DETERMINED HOW TO USE THE

SOFTWARE IN THE DEVICE, AND MS HAS RELIED UPON “SUNX Limited” TO CONDUCT SUFFICIENT TESTING TO DETERMINE THAT THE

SOFTWARE IS SUITABLE FOR SUCH USE.

5 NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS” and with all faults. THE ENTIRE RISK AS TO SATISFACTORY

QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU. ALSO, THERE IS NO WARRANTY

AGAINST INTERFERENCE WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINST INFRINGEMENT. IF YOU HAVE RECEIVED ANY

WARRANTIES REGARDING THE DEVICE OR THE SOFTWARE, THOSE WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT BINDING ON,

MS.

6 No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE.

THIS LIMITATION SHALL APPLY EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN NO EVENT SHALL MS BE LIABLE FOR ANY

AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

7 Restricted Uses. The SOFTWARE is not designed or intended for use or resale in hazardous environments requiring fail-safe performance, such as in the

operation of nuclear facilities, aircraft navigation or communication systems, air traffic control, or other devices or systems in which a malfunction of the

SOFTWARE would result in foreseeable risk of injury or death to the operator of the device or system, or to others.

8 Limitations on Reverse Engineering, Decompilation, and Disassembly. You may not reverse engineer, decompile, or disassemble the SOFTWARE,

except and only to the extent that such activity is expressly permitted by applicable law notwithstanding this limitation.

9 SOFTWARE as a Component of the DEVICE - Transfer. This license may not be shared, transferred to or used concurrently on different computers. The

SOFTWARE is licensed with the DEVICE as a single integrated product and may only be used with the DEVICE. If the SOFTWARE is not accompanied by

a DEVICE, you may not use the SOFTWARE. You may permanently transfer all of your rights under this EULA only as part of a permanent sale or transfer

of the DEVICE, provided you retain no copies of the SOFTWARE. If the SOFTWARE is an upgrade, any transfer must also include all prior versions of the

SOFTWARE. This transfer must also include the Certificate of Authenticity label. The transfer may not be an indirect transfer, such as a consignment. Prior

to the transfer, the end user receiving the SOFTWARE must agree to all the EULA terms.

10 Consent to Use of Data. You agree that MS, Microsoft Corporation and their affiliates may collect and use technical information gathered in any manner

as part of product support services related to the SOFTWARE. MS, Microsoft Corporation and their affiliates may use this information solely to improve

their products or to provide customized services or technologies to you. MS, Microsoft Corporation and their affiliates may disclose this information to

others, but not in a form that personally identifies you.

11 Internet Gaming/Update Features. If the SOFTWARE provides, and you choose to utilize, the Internet gaming or update features within the SOFTWARE,

it is necessary to use certain computer system, hardware, and software information to implement the features. By using these features, you explicitly

authorize MS, Microsoft Corporation and/or their designated agent to use this information solely to improve their products or to provide customized services

or technologies to you. MS or Microsoft Corporation may disclose this information to others, but not in a form that personally identifies you.

12 Internet-Based Services Components. The SOFTWARE may contain components that enable and facilitate the use of certain Internet-based services.

You acknowledge and agree that MS, Microsoft Corporation or their affiliates may automatically check the version of the SOFTWARE and/or its

components that you are utilizing and may provide upgrades or supplements to the SOFTWARE that may be automatically downloaded to your DEVICE.

Microsoft Corporation or their affiliates do not use these features to collect any information that will be used to identify you or contact you. For more

information about these features, please see the privacy statement at http://go.microsoft.com/fwlink/?LinkId=25243.

13 Links to Third Party Sites. You may link to third party sites through the use of the SOFTWARE. The third party sites are not under the control of MS or

Microsoft Corporation, and MS or Microsoft are not responsible for the contents of any third party sites, any links contained in third party sites, or any

changes or updates to third party sites. MS or Microsoft Corporation is not responsible for webcasting or any other form of transmission received from any

third party sites. MS or Microsoft Corporation are providing these links to third party sites to you only as a convenience, and the inclusion of any link does

not imply an endorsement by MS or Microsoft Corporation of the third party site.

14 Notice Regarding Security. To help protect against breaches of security and malicious software, periodically back up your data and system information,

use security features such as firewalls, and install and use security updates.

15 No Rental/Commercial Hosting. You may not rent, lease, lend or provide commercial hosting services with the SOFTWARE to others.

16 Separation of Components. The SOFTWARE is licensed as a single product. Its component parts may not be separated for use on more than one

computer.

17 Additional Software/Services. This EULA applies to updates, supplements, add-on components, product support services, or Internet-based services

components (“Supplemental Components”), of the SOFTWARE that you may obtain from “SUNX Limited”, MS, Microsoft Corporation or their subsidiaries

after the date you obtain your initial copy of the SOFTWARE, unless you accept updated terms or another agreement governs. If

provided along with such Supplemental Components and the Supplemental Components are provided to you by MS, Microsoft Corporation or their

subsidiaries then you will be licensed by such entity under the same terms and conditions of this EULA, except that (i) MS, Microsoft Corporation or their

subsidiaries providing the Supplemental Components will be the licensor with respect to such Supplemental Components in lieu of the "COMPANY" for the

purposes of the EULA, and (ii) TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THE SUPPLEMENTAL COMPONENTS AND ANY (IF

ANY) SUPPORT SERVICES RELATED TO THE SUPPLEMENTAL COMPONENTS ARE PROVIDED AS IS AND WITH ALL FAULTS. ALL OTHER

DISCLAIMERS, LIMITATION OF DAMAGES, AND SPECIAL PROVISIONS PROVIDED BELOW AND/OR OTHERWISE WITH THE SOFTWARE SHALL

APPLY TO SUCH SUPPLEMENTAL COMPONENTS. MS, Microsoft Corporation or their subsidiaries reserve the right to discontinue any Internet-based

services provided to you or made available to you through the use of the SOFTWARE.

18 Recovery Media. If SOFTWARE is provided by “SUNX Limited” on separate media and labeled “Recovery Media” you may use the Recovery Media solely

to restore or reinstall the SOFTWARE originally installed on the DEVICE.

19 Backup Copy. You may make one (1) backup copy of the SOFTWARE. You may use this backup copy solely for your archival purposes and to reinstall

the SOFTWARE on the DEVICE. Except as expressly provided in this EULA or by local law, you may not otherwise make copies of the SOFTWARE,

including the printed materials accompanying the SOFTWARE. You may not loan, rent, lend or otherwise transfer the backup copy to another user.

20 End User Proof of License. If you acquired the SOFTWARE on a DEVICE, or on a compact disc or other media, a genuine Microsoft “Proof of License”/

Certificate of Authenticity label with a genuine copy of the SOFTWARE identifies a licensed copy of the SOFTWARE. To be valid, the label must be affixed

to the DEVICE, or appear on “SUNX Limited’s” software packaging. If you receive the label separately other than from “SUNX Limited”, it is invalid. You

should keep the label on the DEVICE or packaging to prove that you are licensed to use the SOFTWARE.

21 Product Support. Product support for the SOFTWARE is not provided by MS, Microsoft Corporation, or their affiliates or subsidiaries. For product

support, please refer to “SUNX Limited” support number provided in the documentation for the DEVICE. Should you have any questions concerning this

EULA, or if you desire to contact “SUNX Limited” for any other reason, please refer to the address provided in the documentation for the DEVICE.

22 Termination. Without prejudice to any other rights, “SUNX Limited” may terminate this EULA if you fail to comply with the terms and conditions of this

EULA. In such event, you must destroy all copies of the SOFTWARE and all of its component parts.

EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is subject to U.S. and European Union export jurisdiction. You agree to comply with all appli-

cable international and national laws that apply to the SOFTWARE, including the U.S. Export Administration Regulations, as well as end-user, end-use

and destination restrictions issued by U.S. and other governments. For additional information see http://www.microsoft.com/exporting/.

other terms are not

4 Preface

MEMO

Before Use

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Preface 5

Caution in Handling Laser Beam

The system uses invisible CO2 laser beam with maximum output of 75W or 40W whose wave length is either

10.6µm or 9.3µm. Refer to the following table for each specificaion cross-checking the adaptive model.

The laser used here corresponds to the Class 4 according to "Safety of laser products" in JIS C 6802, IEC60825-1.

Before Use/Contents

Preparation

Procedure

Basic Operation

Item

Wave length 10.6µm9.3µm10.6µm9.3µm10.6µm9.3µm

Laser Medium

Max. Output

Oscillation

Frequency

Class 4

NOHD

NHZ

Refer to "Laser Radiation Information" (also refer to the attachment of this manual "Radiation Information"

( P.320) for more details).

Specification

LP-430U

LP-430U-A

LP-430TU

LP-430TU-A

75W 40W 75W 40W 75W

Approx.

4.5m

NHZ represents the area where the amount of beam irradiance or radiant

expposure exceeds the maximum permissible exposure to eyes. It is equal to the

value of NOHD at a maximum.

NHZ varies depending on the reflectance or surface condition of works. Please

calculate it based on the actual working environment.

LP-410U

LP-410U-A

LP-410TU

LP-410TU-A

Approx.

3.5m

LP-420S9U

LP-420S9U-A

LP-420S9TU

LP-420S9TU-A

Approx.

4.5m

LP-431U

LP-431U-A

LP-431TU

LP-431TU-A

5 kHz, 10kHz, 20kHz

Approx.

2.5m

LP-411U

LP-411U-A

LP-411TU

LP-411TU-A

CO

Approx.

2

2.0m

LP-421S9U

LP-421S9U-A

LP-421S9TU

LP-421S9TU-A

Approx.

2.5m

LP-435U

LP-435U-A

LP-435TU

LP-435TU-A

Approx. 6.0m

LP-425S9U

LP-425S9U-A

LP-425S9TU

LP-425S9TU-A

Remarks

Invisible beam

-

-

-

-

Nominal optical

hazard distance

Nominal

hazard area

Description of

Operation Screen

The “CLASS 4 LASER PRODUCT” refers to

Perform the safety prevention measure before using the system. Refer to "Safety Protection Measures" (

P.8) for details.

TroubleshootingMaintenanceSpecificationAppendixIndex

Never look at laser beam directly or

through lens. Diffused reflected beam is

also harmful.

CO

however, if it exposed to the eyes, it can

inflict severe corneal injuries.

Avoid human skin exposure directly to laser

"a product which may cause injury to a human if exposed to its directly radiated light, even

it is reflecting light and diffused reflecting light, or which may produce a risk of a fire.

DANGER

laser does not enter into eye's retina,

2

beam. Burning into deep skin might result.

6 Caution in Handling Laser Beam

WARNING

Wear laser protective goggles for operator's

eyes. The goggles should be used against

scattered beam, so avoid to direct beam or

reflection beam. (Do not look laser beam during guide indication even when laser pumping

switch is turned off.)

In order to prevent unexpected exposures from

object to be marked or its peripherals, set protective enclosure which is made of acrylic resin,

glass, or metal to enclose the laser radiation

.

area

Before Use

Before Use/Contents

Preparation

Procedure

Basic Operation

Never touch laser beam.

Be careful not to touch laser beam with

clothing as well.

When using the system, do not touch laser beam with human

body, papers, or clothing, etc.

Never disassemble the product.

Exposure of laser beam or electric shock by high-voltage area

might occur.

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Read this manual thoroughly, and do not operate any other methods except

the instructions provided in this manual.

Exposure of laser beam might occur.

Caution in Handling Laser Beam 7

Safety Protection Measures

In the "PART1040 PERFORMANCE STANDARDS FOR LIGHT-EMITTING PRODUCTS" of FDA, safety

prevention measures to be taken by any user of laser products are stipulated. In order for you to use the

system safety, working environment is shown below for your references.

1. Wearing protective goggles

Before Use/Contents

For protection of eyes of an operator, make it mandatory to wear goggles against laser beam.

(Recommendation)

Manufacturer: Yamamoto Optics Co., Ltd. (Japan)

Model : YL-120H CO

Preparation

2. Protective enclosure

In order to prevent exposure to laser beam accidentally reflected from the substrate to be marked or from its

circumferential areas, place a protective enclosure using the following materials so that it can enclose the

area in the range of laser radiation.

Procedure

Basic Operation

i.e., please made from acrylic resins, glass, metals, etc.

It is, however, recommended that the thickness of an acrylic or glass plate is more than 3mm and that the

plate has a color to prevent secondary radiation beam.

2

3. Interlock system

Description of

Operation Screen

Construct an interlock mechanism in the system.

Provide doors used for taking out products or for maintenance attached to the protection enclosure with functions

of stopping laser radiation whenever a door is opened.

4. Power failure recovery

When power failure occurs on the laser marker, construct a laser re-pumping system by manual operation for

TroubleshootingMaintenanceSpecificationAppendixIndex

safety.

5. Radiation direction of laser beam

To assure safety, be sure to place the protective enclosure. Measures should be taken so that the direction of

laser radiation can be seen and checked by others as well as an operator. (Labels of cautions, instructions,

and open indication are adhered to the system at delivery from the plant. Do not peel them off.)

6. Termination of laser beam

High output laser is used for marking taking into consideration a case where there is no substrate in a laser

path, terminate a laser beam path within the marking range by using a flame-resistant object.

7. Path of laser beam

It is recommended that laser beam passes through the position being either lower than eye-level at the time of

human's sitting or being higher than eye-level at the time of human's standing.

8. Illumination

Make the area surrounding the laser marker well-lighted as much as possible. Because the peoples are contracted

in the well-lit place, your eyes can be well protected.

9. Protective clothing

Exposure of the skin to the laser beam may cause a skin burn. Exposure of the clothing to the laser beam

may cause burning as well. Wear the clothing which can minimize the exposure of the skin to the laser and

which is flame-resistant.

8 Safety Protection Measures

10. Appointment of laser safety manager

By appointing a laser safety manager, ensure that the laser product is handled safely.

Items that the laser safety manager has to manage and execute are as follows:

A. Storage of laser system

B. Designation of users for the laser product and execution of education and training

C. Designation of controlled zone

D. Maintenance of facilities and fixtures installed within controlled zone

E. Establishment of procedures for operations of the laser system

Establishment of procedures for safety management and installation of warning markings and their execution

F.

G. Keeping and management of key switch

H. Execution of periodical inspection

Refer to the laser safety precautions in ANSI Z136.1-1993, "American National Standard for Safe

Use of Lasers". Procedures listed under the Standard include the appointment of a Laser Safety

Manager, operation of the product in an area of limited access by trained personnel, servicing of

REFERENCE

REFERENCE

equipment only by trained and authorized personnel, and posting of signs warning of the potential

hazards.

The safety measures are described above based on the "Safety of laser products" (JIS C 6802,

IEC60825-1). In addition to these measures, Ministry of Health, Labor and Welfare issued the

aviso ("Protection Measures against Affection by Laser Beam" (No. 39 Aviso by Ministry of Labor

dated January 27, 1986), and defines the detail cautions for using laser beam aiming for

publicizing the cautions as best one can. Besides, the many relative articles for the protection

from operators from the laser beam are dealt with in various regulations such as Industrial Safety

and Health Law, Ordinance on Labor Safety and Hygiene, Air Pollution Control Law. etc.

Before Use

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Safety Protection Measures 9

Functions for Safety Measures

This laser marker has the functions shown below for safety measures.

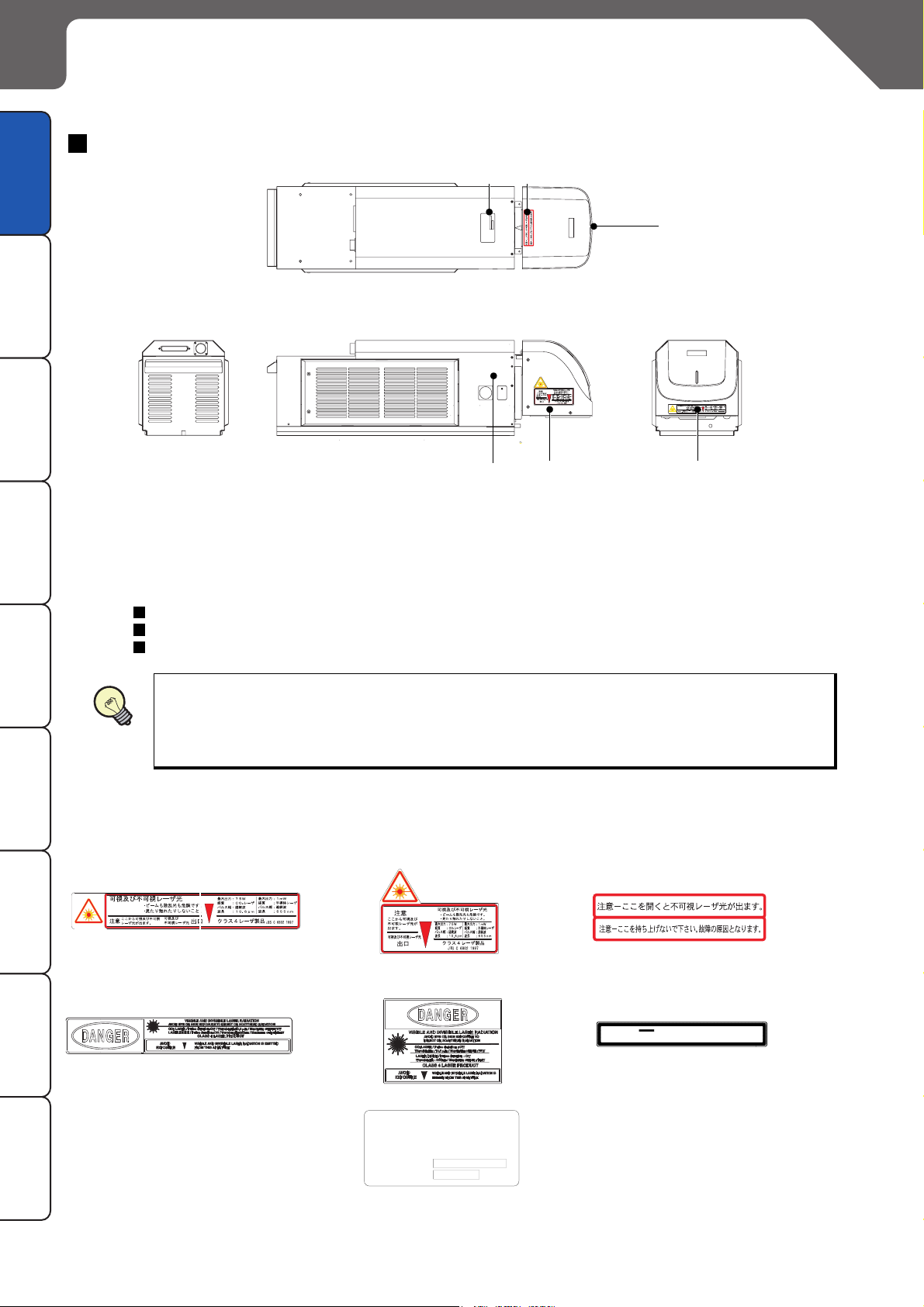

Head Section (Standard model (LP-430U)

Before Use/Contents

Preparation

Procedure

Basic Operation

6

570:.KOKVGF

7UJK[COC-CUWICK#KEJK,CRCP

5'4+#.01

%.#55.#5'4241&7%6

/#07(#%674'&

%QORNKGUYKVJ%(4CPF

1

5

2

4

3

1. Automatic Shutter

Automatic shutter locates inside the head and protects laser beam by closing the inside shutter.

2. Laser Radiation Indicator

Description of

Operation Screen

The operations of the laser radiation indicator are as follows:

Blue lighted-up : Being in laser pumped state and automatic shutter being closed

Purple lighted-up

Red lighted-up

During pumping of laser (approx. 15sec), the laser radiation indicator flashes in blue or purple

TroubleshootingMaintenanceSpecificationAppendixIndex

REFERENCE

accoridng to the automatic shutter state (open or close).

When the system is in the starting state, if a laser is not in the pumped state, the laser radiation

indicator goes off.

3, 4, 5, 6. Labels

A variety of labels shown below are affixed to the head part of the laser marker.

LP-430U/431U/435U/420S9U/421S9U/425S9U/410U/411U

3. Warning Logotype, Aperture Label

(Front)

: Being in laser pumped state and automatic shutter being opened

: Being in laser emitting

(Contents vary in each model.)

4. Warning Logotype, Aperture Label (Sides)

5. Label for Non-Interlocked Protective

Housing

LP-430U-A/431U-A/435U-A/420S9U-A/421S9U-A/425S9U-A/410U-A/411U-A

3. Warning Logotype, Aperture Label

(Front)

10 Functions for Safety Measures

4. Warning Logotype, Aperture Label (Sides)

6. Certification and Identification Label

%.#55.#5'4241&7%6

%QORNKGUYKVJ%(4CPF

570:.KOKVGF

7UJK[COC-CUWICK#KEJK,CRCP

/#07(#%674'&

5'4+#.01

(Contents vary in each model.)

5. Label for Non-Interlocked Protective

Housing

DANGER

INVISIBLE LASER RADIATION WHEN OPEN

AVOID EYE OR SKIN EXPOSURE TO DIRECT OR SCATTERED RADIATION

Head Section (Tower head model (LP-430U))

1

4

5

Before Use

Before Use/Contents

Preparation

%.#55.#5'4241&7%6

%QORNKGUYKVJ%(4CPF

570:.KOKVGF

7UJK[COC-CUWICK#KEJK,CRCP

/#07(#%674'&

5'4+#.01

2

6

Procedure

Basic Operation

4

5

3

1. Automatic Shutter

Automatic shutter locates inside the head and protects laser beam by closing the inside shutter.

2. Laser Radiation Indicator

The operations of the laser radiation indicator are as follows:

Blue lighted-up : Being in laser pumped state and automatic shutter being closed

Purple lighted-up

Red lighted-up

: Being in laser pumped state and automatic shutter being opened

: Being in laser emitting

During pumping of laser (approx. 15sec), the laser radiation indicator flashes in blue or purple

accoridng to the automatic shutter state (open or close).

When the system is in the starting state, if a laser is not in the pumped state, the laser radiation

REFERENCE

indicator goes off.

3, 4, 5, 6. Labels

A variety of labels shown below are affixed to the head part of the laser marker.

LP-430TU/431TU/435TU/420S9TU/421S9TU/425S9TU/410TU/411TU

3. Warning Logotype, Aperture Label

(Front)

4. Warning Logotype, Aperture Label (Sides)

(Contents vary in each model.)

5. Label for Non-Interlocked Protective

Housing

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

LP-430TU-A/431TU-A/435TU-A/420S9TU-A/421S9TU-A/425S9TU-A/410TU-A/411TU-A

3. Warning Logotype, Aperture Label

(Front)

4. Warning Logotype, Aperture Label (Sides)

6. Certification and Identification Label

%.#55.#5'4241&7%6

%QORNKGUYKVJ%(4CPF

570:.KOKVGF

7UJK[COC-CUWICK#KEJK,CRCP

/#07(#%674'&

5'4+#.01

5. Label for Non-Interlocked Protective

Housing

DANGER

AVOID EYE OR SKIN EXPOSURE TO DIRECT OR SCAT TERED RADIATION

(Contents vary in each model.)

INVISIBLE LASER RADIATION WHEN OPEN

Functions for Safety Measures 11

Controller

Before Use/Contents

1

2

7

3

Preparation

5

6

4

Procedure

Basic Operation

Description of

Operation Screen

1. Key Switch: POWER

This key switch is used to start the laser marker system. Turn On ( l ) the switch to start-up the system, and

turn Off (O) the switch to shutdown the system.

While the switch is ON, the key cannot be removed, however, while it is OFF, the key can be removed.

When the laser marker is not used, remove the key, and the safety controller must keep it.

Since the ON/OFF operation of the key switch makes a load to the laser marker, leave an interval for at least 5

TroubleshootingMaintenanceSpecificationAppendixIndex

seconds from turning OFF the power to turning ON the power again. Do not turn off the power supply while

the system starts (during the system start indicator is flashing).

2. Emergency Stop Switch: EMERGENCY STOP

This switch is used to forcibly stop the laser pumping.

Push this switch at emergency or to stop the laser radiation. Turn the switch to the direction of the arrow to

release it.

8

3. Main Power Indicator (Green): MAIN

This indicator flashes when key switch is turned on, and it switches to light-up state when the system

starts.

4. Laser Radiation Indicator (Red): MARKING

This indicator lights up while laser radiation is under operation.

5. Laser Pumping Switch (with White LED): LASER

This switch starts laser pumping.

LED flashes (approx. 15sec) in white when the switch is pressed, and it lights up when the laser irradiation

becomes enabled.

6. Remote Switch (with White LED): REMOTE

This switch enables remote mode. LED lights up in white when this remote switch is pressed.

7. File No./Error Code Indicator: FILE No./ERROR CODE

Selected file number is displayed. When an error occurs, its error code is displayed as well.

For the action when an error code is displayed, refer to "4-2 Error Indication" ( P.298).

8. Alarm Reset Switch (with Blue LED): ALARM RESET

This switch is used to reset the system when an alarm generates. LED lights up in blue when an alarm

generates. Release the cause of alarm and press this switch. Alarm reset can also be performed from terminal block, console (option), or monitor screen.

12 Functions for Safety Measures

Terminal Block

The system has an emergency stop input and laser stop input on the terminal block.

2

Before Use

Before Use/Contents

1

1. Emergency Stop Input

Power supply is turned off by opening the emergency stop input (B12) and the emergency stop 0V (B11).

Connect of B12 and of B11 for starting marking.

EMER. + EMER. -

(B12 and B11 are short-circuited by a short bar at delivery.)

2. Laser Stop Input

Automatic shutter in the head is closed and laser radiation is shut-off by opening the laser stop input (A12)

and the laser stop 0V (A11).

Connect

LASER STOP

of A12 and

+

(A12 and A11 are short-circuited by a short bar at delivery.)

Connection Sample (In case of operating only laser marker)

LP-430U/430TU/431U/431TU/435U/435TU/420S9U/420S9TU/421S9U/421S9TU/425S9U/425S9TU/

410U/410TU/411U/411TU/430U-A/430TU-A/431U-A/431TU-A/435U-A/435TU-A/420S9U-A/

420S9TU-A/421S9U-A/421S9TU-A/425S9U-A/425S9TU-A/410U-A/410TU-A/411U-A/411TU-A

LASER STOP

A12: LASER STOP +

A11: LASER STOP -

B12: EMER.+

-

of A11 for starting marking.

To Manual Door

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Connect power supply (internal power and outside power) to A2 and B2

CHECK

B11: EMER.-

A4 : TRIG.IN

A2 : IN COM.

A1 : +12V OUT

B2 : OUT COM.

B1 : 0V OUT

To Emergency Stop Switch

To Sensor

IN COM.

.

OUT COM

+12V OUT

A1 and A2

to operates the laser marker.

0V OUT OUT COM

IN COM.

, B1 and B2 are short-circuited by a

.

short bar at delivery.

When using outside power supply, make sure to perform wiring after removing the short bar.

Functions for Safety Measures 13

Construction of Interlock System

For operating this product, construct the protective enclosure enclosing the range of the laser radiation for protecting the exposure caused by the reflection of the laser radiation from the object being marked or the surrounding

objects, and also construct the interlock system at the same time. The following figure shows the construction

Before Use/Contents

Preparation

Procedure

Basic Operation

sample of the interlock system

Emergency Stop Button

.

Controller Terminal Block

To Emergency Stop Input

Emergency Stop

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Emergency Stop Input/Laser Stop Input Operation

When the emergency stop input or the laser stop input is opened, the automatic shutter operates as follows:

Automatic Shutter

Laser Power

Supply

When primary AC power supply of the system is performed as a safety measure, process AC

power cable to set the switch as follows.

Manual Door

Controller Terminal Block

To Laser Stop Input

Marking Status

In marking

In not marking ON (Keeps pumping)

In marking

In not marking

Emergency Stop Input

OPEN

OFF

Closed Closed

Laser Stop Input

OPEN

OFF

AC Power Cable

REFERENCE

Emergency Stop

Switch

14 Functions for Safety Measures

Relay

MEMO

Before Use

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Functions for Safety Measures 15

Cautions in Handling

Handling the System

Before Use/Contents

This product is developed and manufactured for the purpose of using in

industrial environment.

Preparation

When using the system, do not touch laser

beam with any part of body, papers, or clothing,

.

etc

Procedure

Basic Operation

This product contains ZnSe (zinc selenide) in the lens mounted on

the laser radiation window. If the lens is damaged, care should be

taken of the following.

Description of

TroubleshootingMaintenanceSpecificationAppendixIndex

In order to prevent from swallowing of flakes or particles, inhaling them, or adhering them

Operation Screen

to skin, be sure to wear glove, mask and protective goggles.

When disposing of the lens, be sure to overve the disposing method prescribed in the reg-

ulations of user’s region/countryfully. Do not dispose of he lens with general industrial

waste.

Do not throw the lens into the fire.

Do not soak the lens in acid and alkali.

Never disassemble the product. It can result

WARNING

in exposure to laser radiation or an electric

shock due to high voltage.

In the event a failure occurs in the system, contact us.

After the power supply of laser marker is turned off, laser safety

manager must remove key and keep it.

16 Cautions in Handling

CAUTION

Before Use

Use this product neither in inflammable

gas, a dusty place nor the place of fire

strict prohibition. It might cause a fire.

Never put the object which is easy to burn

Gasoline

on near. It might causes a fire.

Construct an interlock systems such as a

function to stop laser radiation for the maintenance door of the protective enclosure.

Use the product with the below environmental condition:

Ambient temperature :

0 to +40 C (no condensation and icing)

Ambient humidity : 35 to 85%

°

(no condensation and icing)

The air cooling system is used for this product

as a laser cooling system. Please install not

to bar the flow of air cooling. Moreover,

please do not install a heat source in near,

either.

Thinner

Emergency Stop

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Since this product includes precision parts,

please avoid vibration and use in a place

with any shocks. Marking quality may

deteriorate or the optical system may be

affected. Moreover, please do not drop this

product.

Cautions in Handling 17

Before Use/Contents

Never let water, oil, fingerprints, dust

garbage, etc. adhere to the lens part

of the head. It might result in

deterioration of marking quality, and

Preparation

failure. When cleaning, wipe with the

dry soft cloth etc. lightly.

Refer to “5-2 Contamination of fθ Lens” ( P.306).

Be sure to connect the head to the exclusive controller. It will

Procedure

Basic Operation

cause a failure if it connects with any equipment other than the

exclusive controller. Moreover, it may be exposed to dangerous

laser radiation.

When re-switching on the power supply, after turning OFF key

Description of

Operation Screen

switch of the power supply BOX supply and 5 seconds or more

pass, turn ON key switch of the power supply BOX again.

CAUTION

Soft Cloth

TroubleshootingMaintenanceSpecificationAppendixIndex

When carrying the head part, carry

the head part as shown in the right

figure.

Clean air filter when it is dirty with dust etc. If the air filter is dirty,

the air-flow might become bad and might stop marking operation.

Exchange air filter periodically.

Refer to "5-1 Cleaning of Air Filter" ( P.304).

While marking is carried out, dust and/

or gas may be produced from the place

to be marked. Always ventilate and

remove them using a dust collector,

etc.

They may affect the marking quality badly.

Dust

Collector

18 Cautions in Handling

Before Use

Applicable Standards

This product is applied the following standards. When the system is exported as a single unit or a part

mounted on other machines or equipment, prior to exporting, make sure that the system may meet the

requirement of the standards in countries or regions where the system is to be exported.

LP-430U/430TU/431U/431TU/435U/435TU/420S9U/420S9TU/421S9U/421S9TU/425S9U/425S9TU/

410U/410TU/411U/411TU: JIS (Japanese Industrial Standards)

This product is compliant to the "Safety of laser products" (JIS C 6802).

LP-430U-A/430TU-A/431U-A/431TU-A/435U-A/435TU-A/420S9U-A/420S9TU-A/421S9U-A/421S9TU-A/

425S9U-A/425S9TU-A/410U-A/410TU-A/411U-A/411TU-A: FDA

T

he "Radiation Control for Health and Safety" gives the restriction to the manufacturer of the laser prod-

ucts to be marketed in the U.S.A., and obliges to adapt the laser product to the reference.

The FDA

(Food and Drug Administration) constitutes the “PART 1040 PERFORMANCE STANDARDS

FOR LIGHT-EMITTING PRODUCTS” in accordance with the performance standards of the laser

products, regulates this performacen standards in FDA Standard (21 CFR 1040.10 and 1040.11),

and is compliant with this standard.

Other Cautions

1. Prior to wiring and/or cable connecting work, ensure that all the power has been turned off.

2. USB cable should not be connected in parallel with AC power or the power cable of monitor.

3. Use the accessory cables attached to the system for connecting cables without fail.

4. Be sure that the supplied power does not exceed the rating. Prior to turning the power on, check any change

in voltage.

5. If a surge occurs in the power supplied, connect a surge absorber to a source of the surge to absorb it.

6. Make sure to ground a terminal of a frame ground (F.G.) of the system.

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

7. Install such that the controller housing and the head housing are at the same electric potential.Install such that

the controller housing and the head housing are at the same electric potential.

8. Laser Marker which can be controlled by Laser Marker NAVI is controller version 2.2X and after of LP-400

series Laser Marker.

9. When using the optional console (LP-ADP40), take care the items below.

The console is formed with a resin case. If it is dropped, it may be cracked. Care must be taken not to

damage it.

The indicator section is composed of a touch panel. Do not use a sharp-pointed object to operate the

touch panel, which may break the touch panel. Operate it with a round-pointed object.

Equipment harnessed high frequency wave

SUNX CO2 laser marker harnesses the high frequency wave internally. Because the device has the

mechanism generating laser, it is classified into "various equipment" in the equipment harnessed high

frequency wave in Japan. Before using the system, please check whether the system is required to apply the

similar law and regulation described above or not in user's region/country, and if required, go through the

required procedure(s) by the user.

TroubleshootingMaintenanceSpecificationAppendixIndex

Cautions in Handling 19

Contents

Before Use

Preface •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2

Caution in Handling Laser Beam•••••••••••••••••••••••••••••••••••••••••••••••••••••• 6

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

1

Safety Protection Measures•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 8

Functions for Safety Measures •••••••••••••••••••••••••••••••••••••••••••••••••••••••10

Cautions in Handling••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••16

Contents •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 20

Whole Manual Construction••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 24

Construction of Manual ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••25

"Let's Try" Contents••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 26

Preparation

1-1 Package Check ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 30

1-2 Name of Each Part••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 32

1-2-1 Head••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 32

1-2-2 Controller ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 34

1-3 Installation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••36

1-3-1 Installation Method•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 36

1-3-2 Center of Marking ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 39

1-3-3 Rotation of Head Scanner••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 40

1-3-4 Useful Function for Installation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 41

TroubleshootingMaintenanceSpecificationAppendixIndex

2

1-4 Connecting Laser Marker••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 44

1-4-1 Connecting Head, Controller, Terminal Block ••••••••••••••••••••••••••••••••••••••••• 44

1-4-2 When Using Console (Option)•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 45

1-4-3 When Using Monitor and Mouse••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 45

1-5 Connection with External Devices •••••••••••••••••••••••••••••••••••••••••••••• 46

1-5-1 Operation Sample Using External Control ••••••••••••••••••••••••••••••••••••••••••••• 46

1-5-2 Operation Procedures Using External Control •••••••••••••••••••••••••••••••••••••••• 47

1-5-3 Shift to Remote Mode •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 48

1-5-4 Shift to RUN Mode•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 49

1-5-5 Terminal Block and I/O Connector••••••••••••••••••••••••••••••••••••••••••••••••••••••• 50

1-5-6 RS-232C•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 54

1-5-7 DIP Switch•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 56

Basic Operation Procedure

2-1 When Using Laser Marker for the First Time ••••••••••••••••••••••••••••••••• 58

2-1-1

Preparation of Laser Marker Operation

2-1-2 Startup of Laser Marker•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 60

2-1-3 Procedure from Laser Marker Setting to Marking •••••••••••••••••••••••••••••••••••• 61

2-1-4 Turn OFF Power of Laser Marker ••••••••••••••••••••••••••••••••••••••••••••••••••••••• 71

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 59

20 Contents

3

2-2 Setting Procedure for Basic Function •••••••••••••••••••••••••••••••••••••••••• 72

2-2-1 Mark Counter •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 72

2-2-2 Mark Lot No. ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 78

2-2-3 Mark Expiry Date•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 84

2-2-4 Mark Logo •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 90

2-2-5 Mark Date •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 94

2-2-6 Mark Flying Object•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 98

2-2-7 Mark Step and Repeat Character•••••••••••••••••••••••••••••••••••••••••••••••••••••••102

2-2-8 QR Code Setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••108

Description of Operation Screen

3-1 Description of Control Screen ••••••••••••••••••••••••••••••••••••••••••••••••••116

3-2 Operation Screen •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••118

3-2-1 Character Display••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••118

3-2-2 Image Display ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••119

3-2-3 Password Function ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••120

3-3 Operator Adjustment Screen •••••••••••••••••••••••••••••••••••••••••••••••••••122

3-3-1 Outline •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••122

3-3-2 Setting Method •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••123

3-4 Maintenance & Inspection•••••••••••••••••••••••••••••••••••••••••••••••••••••••128

3-4-1 I/O Check Monitor •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••128

3-4-2 Error Log•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••129

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

3-5 Selecting Marking Mode •••••••••••••••••••••••••••••••••••••••••••••••••••••••••130

3-5-1 Outline •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••130

3-5-2 Dual Pointer•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••131

3-5-3 Guide Laser •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••132

3-5-4 Test Marking ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••134

3-5-5 RUN Mode ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••135

3-6 File •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••136

3-6-1 Comment ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••136

3-6-2 Change File No. ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••137

3-6-3 Save ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••138

3-6-4 Save to Different No. ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••139

3-6-5 New Creation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••140

3-7 Character Setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••142

3-7-1 Character Type•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••142

3-7-2 Input and Edit Character••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••145

3-7-3 Function Character ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••151

3-8 Function Setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••170

3-8-1 Expiry Date••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••170

3-8-2 Counter ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••172

3-8-3 Lot•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••174

3-8-4 Rank••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••176

3-8-5 External Offset••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••178

TroubleshootingMaintenanceSpecificationAppendixIndex

Contents 21

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

3-9 Marking Condition •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 180

3-9-1 Overall Condition•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••180

3-9-2 Character Condition •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••187

3-9-3 Logo Condition •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••193

3-9-4 Bar Code Condition••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••196

3-9-5 Processing Condition••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••226

3-10 Laser Setting••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 234

3-10-1 Setting Parameters•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••234

3-10-2 Line Width and Marking Pitch••••••••••••••••••••••••••••••••••••••••••••••••••••••••••237

3-10-3 Adjustment of Marking Quality •••••••••••••••••••••••••••••••••••••••••••••••••••••••••238

3-11 Trigger Setting••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 240

3-11-1 Marking to Static Work ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••240

3-11-2 Marking to Flying Object ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••241

3-12 Common Setting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 252

3-12-1 Comment•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••252

3-12-2 Common Character Setting ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••253

3-12-3 Common Expiry Date••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••254

3-12-4 Common Counter ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••255

3-12-5 Common Lot•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••257

3-13 Image Display ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 258

3-13-1 Image Display Screen •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••258

3-13-2 Work Image Display •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••259

TroubleshootingMaintenanceSpecificationAppendixIndex

4

3-14 USB Media ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 260

3-14-1 Registration File ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••260

3-14-2 Common File ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••264

3-14-3 Logo File •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••267

3-14-4 Font File••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••270

3-14-5 Others ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••276

3-15 Environment Setting•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 280

3-15-1 Environment 1•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••280

3-15-2 Environment 2•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••285

3-15-3 Communication I/O•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••288

3-15-4 Output Simulation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••290

3-15-5 Adjustment of Touch Panel/Switching Language, etc. ••••••••••••••••••••••••••••291

Troubleshooting

4-1 Troubleshooting •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 296

4-2 Error Indication•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 298

4-2-1 Alarm •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••298

4-2-2 Warning ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••300

22 Contents

5

Maintenance

5-1 Cleaning of Air Filter••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••304

5-1-1 Cleaning of Air Filter•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••304

5-1-2 Replacement of Air Filter •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••305

5-2 Contamination of fθ Lens••••••••••••••••••••••••••••••••••••••••••••••••••••••••306

5-3 Replacement of Fuse ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••307

Before Use/Contents

6

5-4 Maintenance Parts and Procurement •••••••••••••••••••••••••••••••••••••••••308

Specification

6-1 Specification •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••310

6-2 Outer Dimensional Drawing•••••••••••••••••••••••••••••••••••••••••••••••••••••312

6-2-1 Head••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••312

6-2-2 Controller ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••317

6-2-3 Console (Option) •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••318

Appendix

Radiation Information •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••320

Safety Standard of Laser Product ••••••••••••••••••••••••••••••••••••••••••••••••••326

Safety Measures Operation••••••••••••••••••••••••••••••••••••••••••••••••••••••••••328

Description of Code Symbols••••••••••••••••••••••••••••••••••••••••••••••••••••••••330

Readable DXF File ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••346

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Character Code Table•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••348

Index

Index••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••370

Contents 23

Whole Manual Construction

This laser marker is prepared for the following manuals. Read the corresponding manual for the target, and operate

this laser marker fully. Also, store these manuals after reading them.

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

This Manual

This manual describes the items required for the introduction,

installation, and operation of the laser marker.

The following contents, cautions, preparation for introducing,

installing, and wiring the laser marker after unpacking, basic

active operation, screen operation for setting marking contents,

measurement and maintenance for error and maintenance

inspection, and specifications are described in this manual.

Laser Maker

Laser Maker

Mainly the users that operate this laser marker for actual marking procedure shall be required for reading this manual.

Operation Manual

This manual describes the items required for the introduction

and installation of the laser marker, and for the external control of the laser marker.

•Control from Terminal Block, I/O Connector:

Describes the signal layout of the terminal block and I/O connector, I/O rating, timing chart, example of control, etc.

•Control from RS-232C connector:

Describes the signal layout of the connector, communication

data format, communication command, example of control,

etc.

"Let's Try" Contents

The "Let's Try" conten

prepraed in P.22 of this manual.

Refer to corresponding page

that the user wants to try

"Let's Try" Contents

The "Let's Try" contents is

prepraed in P.26 of this manual.

Refer to corresponding page

that the user w

ants to try

5th Edition

ts is

.

E

.

E

4th Edition

Please use the laser marker properly.

Laser Beam

The laser beam emitted from this laser marker is

equivalent to the Class 4 laser. Take care of not

to look at or touch the direct laser beam and its

reflected beam.

Be sure to take safety measures that is in

accordance with the contents of warning labels.

External Control Manual

Please use the laser marker properly.

Laser Beam

The laser beam emitted from this laser marker is

equivalent to the Class 4 laser. Take care of not

to look at or touch the direct laser beam and its

reflected beam.

Be sure to take safety measures that is in

accordance with the contents of warning labels.

Laser Marker

Operation Manual

Laser Marker

Mainly the provider and system designer shall be required for reading

this manual.

External Control Manual

For marking logo data and image data using the laser marker, it

needs to convert the data. This manual desctibes how to install the

logo data conversion software up to convert/output data.

Besides, the operation for the font maker that enables to create

character to be marked freely.

Mainly the provider and system designer shall be required for reading

this manual.

Operation Manual

Logo Data Convert/Font Maker

* The PDF data of the Logo Data Conversion/Font Maker Software Operation Manual are stored in attached

CD-ROM of this manual.

The published manual is not prepared for the Logo Data Conversion/Font Maker Software Operation Manual.

*

24 Whole Manual Construction

Construction of Manual

Maintenance

The important items for safety laser

marker operation are described in

Before Use

this section.

Be sure to read this section before

using the laser marker.

)P. 2

Before Use/Contents

Chapter

1

Chapter

2

Chapter

3

Chapter

4

This chapter describes the items

Preparation

Basic Operation

Procedure

Description of Operation Screen

Troubleshooting

required for using the laser marker.

Be sure to read this chapter at preparation.

This chapter describes the basic

operation targetting for the first user

briefly. Since the control sample is

also involved, refer to them together.

Read this chapter for operating the

laser marker such as the setting

character to be marked and the

function for marking.

This chapter describes the error

messages and measures. Read this

chapter when error message is

appeared or marking is not performed

properly.

)P. 2 9

)P. 5 7

)P. 11 5

)P. 2 95

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Chapter

Maintenance

5

Chapter

Specification

6

Appendix

Index

This chapter describes the maintenance,

replacement of filter and cleaning of lens,

etc.

Please read this chapter when performing

maintenance.

This chapter describes the specification

and outer dimension of laser marker.

This appendix describes the character

code table.

With this table, the code of character

and symbols to be marked can be

checked.

With this index, the corresponding

page describing details for desired

contents using the terms.

)P. 3 03

)P. 3 09

)P. 3 19

)P. 3 69

Whole Manual Construction 25

"Let's Try" Contents

The user can refer to the corresponding pages in which the contents of what user "tries to do" are described

using this "Let's Try" Contents.

Before Use/Contents

Preparation

"Connecting Laser Marker"

Procedure

Basic Operation

Description of

Operation Screen

Setup Laser Marker

Install and Connect

Marking

Mark Counter

0001000200030004

"Installation"

P. 3 6

"Mark Counter"

P. 4 4

"Counter"

Mark Lot Symbol Mark Expiry Date

January

February

December

Expiry DateExpiry Date

2006

.11.20.

…

P. 7 2

P.172

TroubleshootingMaintenanceSpecificationAppendixIndex

"Mark Lot No."

"Lot"

P. 7 8

P. 1 74

"Mark Expiry Date"

"Expiry Date"

Mark Logo Mark Date

"Mark Logo"

P. 9 0

"Mark Date"

Mark Flying Object Mark Step and Repeat

P. 8 4

P.170

P. 9 4

"Mark Flying Object"

26 "Let's Try" Contents

P. 9 8

"Mark Step and Repeat"

P.102

Make and Edit LogoData Convert and Font

Before Use

Description of Software

Logo Data Convert Software

Font Maker

Logo Data Conversion

Font Maker Software

Operation Manual

Logo Data Conversion

Font Maker Software

Operation Manual

/

P. 1 0

/

P. 1 0

Control Laser Marker from External

Check Item before Controlling from External

Convert Logo Data

"Convert Logo Data"

Logo Data Conversion

Font Maker Software

Operation Manual

/

P. 2 0

Make Font

"Make Font"

Logo Data Conversion

Font Maker Software

Operation Manual

/

P. 4 0

Control by Terminal Block and I/O

Before Use/Contents

Preparation

Procedure

Basic Operation

Description of

Operation Screen

"Check DIP Switch"

"Check Basic Operation Procedure"

"Set Remote Mode"

Control by RS-232C

Personal Computer

"Control by RS-232C"

External

Control

Manual

External

Control

Manual

External

Control

Manual

External

Control

Manual

P. 5 2

P. 4 9

P. 5 0

P. 7 9

"Control by Terminal Block·I/O"

When in Trouble...

P.295

External

Control

Manual

PLC

TroubleshootingMaintenanceSpecificationAppendixIndex

P. 5 3

"Look Through Communication

Command"

"Read Description of Each

Command"

External

Control

Manual

External

Control

Manual

P. 9 7

P. 9 8

External

Control

Manual

Logo Data Conversion

Font Maker Software

Operation Manual

P.149

/

P. 6 7

"Let's Try" Contents 27

Before Use/Contents

Preparation

Procedure

Basic Operation

MEMO

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

28 "Let's Try" Contents

1

Preparation

Before Use/Contents

1-1 Package Check••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 30

1-2 Name of Each Part •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 32

1-3 Installation ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 36

1-4 Connecting Laser Marker •••••••••••••••••••••••••••••••••••••••••••••••••••••••• 44

1-5 Connection with External Devices •••••••••••••••••••••••••••••••••••••••••••••• 46

Preparation

Procedure

Basic Operation

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

29

1-1

Before using this product, be sure to check the packed objects shown below.

Before Use/Contents

Preparation

Procedure

Basic Operation

CHECK

Package Check

Be sure to store the packing material.

Since this product is delicate one, apply the packing material that is used for this product for preventing from the failure caused by transferring.

Description of

Operation Screen

TroubleshootingMaintenanceSpecificationAppendixIndex

Standard model

Tower head model

Head

1 pc

30 1-1 Package Check

Loading...

Loading...