Page 1

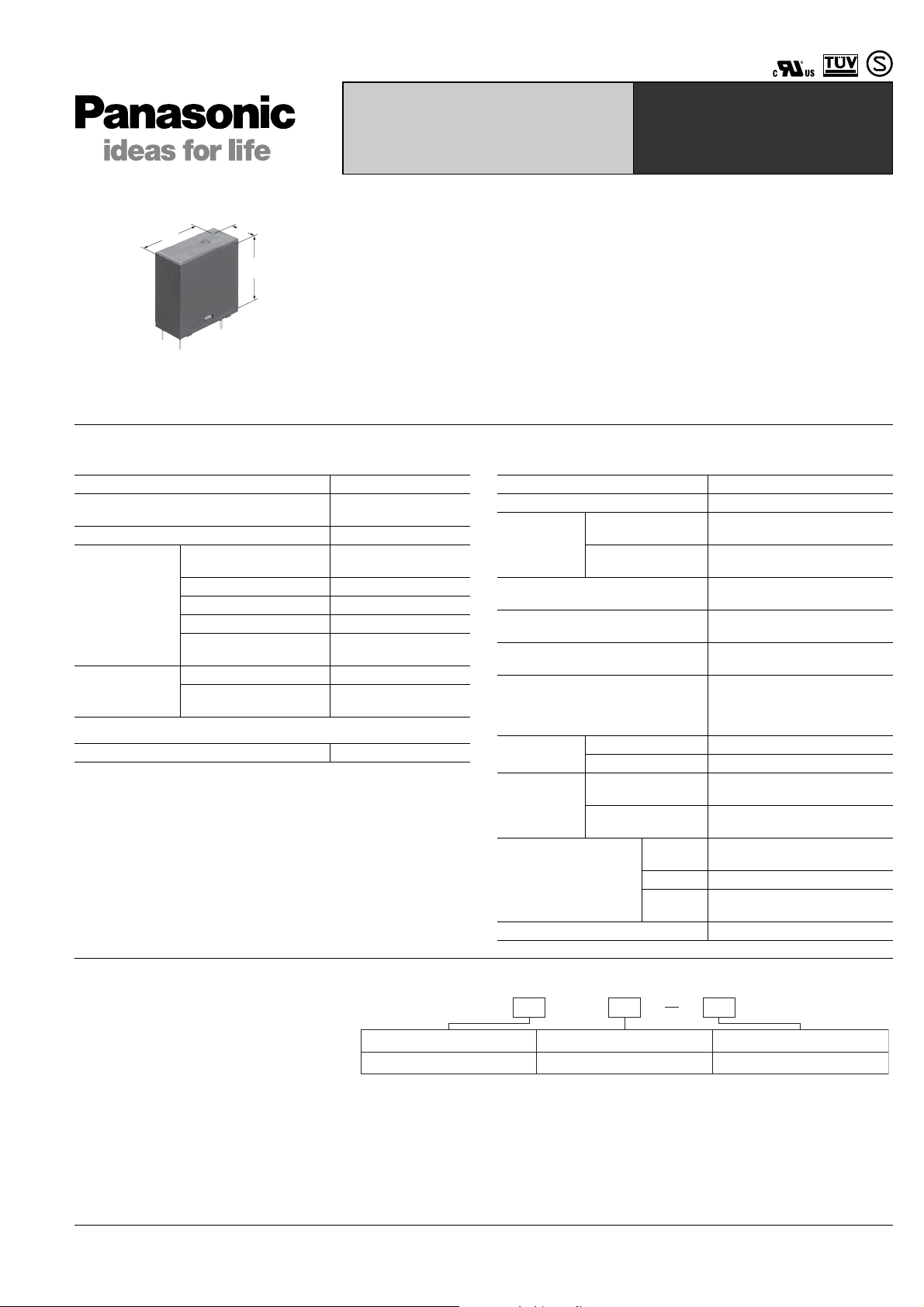

SLIM POWER RELAY

WITH HIGH INRUSH

CURRENT CAPABILITY

TV-8 CERTIFIED

LK-T

LK-T RELAYS

24.0

.945

11.0

.433

25.0

.984

FEATURES

1. High inrush current capability

1) Operating load capability:

inrush 118 A, steady 8 A

2) UL/C-UL TV-8 approved

2. High insulation resistance

1) Creepage distance and clearances

between contact and coil: Min. 6 mm .236

inch (In compliance with IEC65)

2) Surge withstand voltage between

contact and coil: 10,000 V or more

SPECIFICATIONS

Contact

Arrangement 1 Form A

Initial contact resistance

(By voltage drop 6 V DC 1 A)

Contact material AgSnO2 type

Nominal switching

capacity

Rating

(resistive load)

Expected life

(min. operations)

Max. switching power 1,385 V A

Max. switching voltage 277 V AC

Max. switching current 8 A (120V AC)

Min. switching capacity

(Reference value)

Mechanical (at 180 cpm) 10

Electrical (at 20 cpm)

(at rated load)

#1

Coil

Nominal operating power 250 mW

#1 This value can change due to the switching frequency , environment al conditions,

and desired reliability level, therefore it is recommended to check this with the

actual load.

Remarks

*1Measurement at same location as “Initial breakdown voltage” section.

2

Detection current: 10mA

*

3

Wave is standard shock voltage of ±1.2 × 50μs according to JEC-212-1981

*

4

Excluding contact bounce time.

*

5

Half-wave pulse of sine wave: 11 ms; detection time: 10 μs

*

6

Half-wave pulse of sine wave: 6 ms

*

7

Detection time: 10 μs

*

8

The upper operation ambient temperature limit is the ma ximum t emperature t hat

*

can satisfy the coil temperature rise value. Refer to 1. Usage, transport and

storage conditions in NOTES on page 3.

Max. 100 mΩ

5 A 277 V AC

100 mA, 5 V DC

6

5

10

3. High noise immunity realized by the

card separation structure between

contact and coil

4. Conforms to the various safety

standards

UL, C-UL, TÜV, and SEMKO approved

Characteristics

Max. operating speed 20 cpm (at rated load)

Initial insulation resistance*

Initial *2

breakdown

voltage

Initial surge voltage between contact

and coil*

Operate time*

(at nominal voltage)

Release time (without diode)*

(at nominal voltage)

Temperature rise (at 70°C)

Shock

resistance

Vibration

resistance

Conditions for operation,

transport and storage*

(Not freezing and

condensing at low

temperature)

Unit weight Approx. 12 g .42 oz

Between open

contacts

Between contact

and coil

3

4

Functional*

Destructive*

Functional*

Destructive

1

4

5

6

7

Ambient

temp.

8

Humidity 5 to 85% R.H.

Air

pressure

Min. 1,000 MΩ (at 500 V DC)

1,000 Vrms for 1 min.

4,000 Vrms for 1 min.

10,000 V

Max. 15ms (at 20°C 68°F)

Max. 5ms (at 20°C 68°F)

Max. 35°C with nominal coil

voltage and at 5 A contact

carrying current

(resistance method)

200 m/s2{approx. 20 G}

1,000 m/s2{approx. 100 G}

10 to 55Hz

at double amplitude of 1.5mm

10 to 55Hz

at double amplitude of 1.5mm

–40°C to +70°C

–40°F to +158°F

86 to 106 kPa

TYPICAL

APPLICATIONS

• Audio visual equipment

• Flat TVs and audio equipment, etc.

• Office equipment

• Home appliances

ds_61113_0004_en_lkt: 091008J

ORDERING INFORMATION

Ex. LKT 1a F 12V

Contact arrangement Protective construction Coil voltage(DC)

1a: 1 Form A F: Flux-resistant type 5, 9, 12, 24V

UL/C-UL, TÜV, SEMKO, TV-8 approved type is standard.

Notes: 1. Standard packing Carton: 100 pcs. Case: 500 pcs.

2. 3 V, 6 V, and 18 V DC types are also available. Please consult us for details.

1

Page 2

LK-T

2-0.9 dia. 2-1.3 dia.

2

a.

A

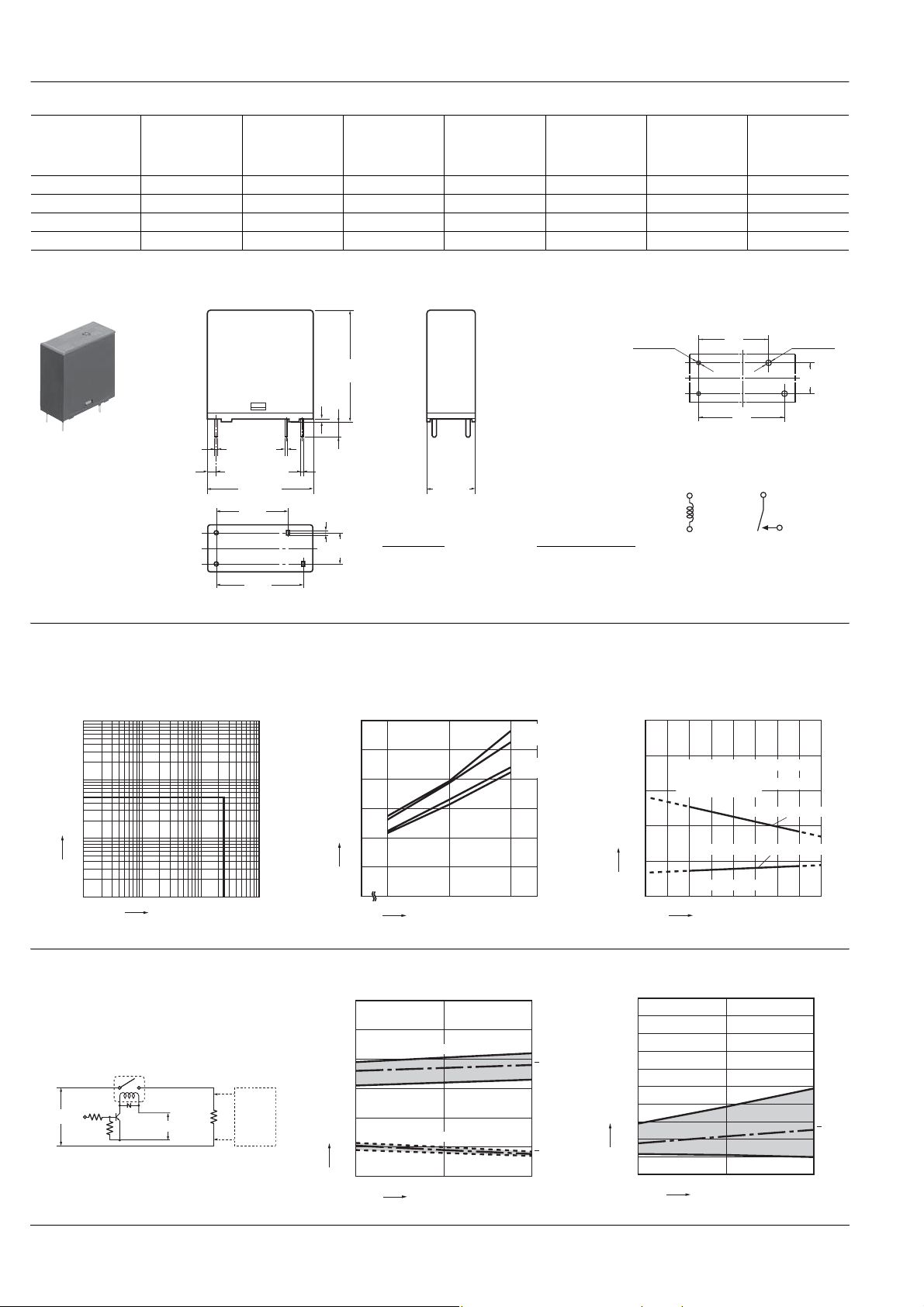

TYPES AND COIL DATA (at 20°C 68°F)

Drop-out

voltage,

V DC (min.)

(Initial)

Coil resistance,

Ω (±10%)

Part No.

Nominal voltage,

V DC

Pick-up voltage,

V DC (max.)

(Initial)

LKT1aF-5V 5 (Initial) 3.5 (Initial) 0.5 100 50 250 6.5

LKT1aF-9V 9 (Initial) 6.3 (Initial) 0.9 324 27.8 250 11.7

LKT1aF-12V 12 (Initial) 8.4 (Initial) 1.2 576 20.8 250 15.6

LKT1aF-24V 24 (Initial) 16.8 (Initial) 2.4 2,304 10.4 250 31.2

DIMENSIONS

Max. 25.0

.984

0.5

.020

4

0.4

.016

1.0

.039

7.5

.295

.157

Max. 11.0

.433

Dimension: General tolerance

Max. 1mm .039 inch: ±0.1 ±.004

1 to 3mm .039 to .118 inch: ±0.2 ±.008

Min. 3mm .118 inch: ±0.3 ±.012

0.5 dia.

.020 dia.

1.65

.065

0.3

.012

Max. 24.0

.945

16.5

.650

20.0

.787

Nominal

operating

current, mA

(±10%)

Nominal

operating power,

mW

PC board pattern (Bottom view)

-.035 dia. 2-.051 di

16.5

.650

20.0

.787

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

Maximum

allowable

voltage, V DC

(at 20°C 68°F)

mm inch

7.5

.295

REFERENCE DATA

1. Max. switching power (AC resistive load) 2. Coil temperature rise

100

10

5

Contact current, A

1

0 10 100

Contact voltage, V

4-(1). Electrical life test

(5 A 277 V AC, resistive load)

Sample: LKT1aF-12V, 6 pcs.

Operation frequency: 20 times/min.

(ON/OFF = 1.5s: 1.5s)

Ambient temperature: 20°C 68°F

Circuit:

Contact

welding

detection

277V AC

12V DC

and Miscontacting

detection

circuit

2

Sample: LKT1aF-12V, 6 pcs.

Point measured: coil inside

Contact current: 0 A, 5A

30

25

20

15

Temperature rise, °C

10

5

0

Change of pick-up and drop-out voltage Change of contact resistance

12

10

8

6

4

Pick-up and drop-out voltage, V

2

0

0

800

100 120

Coil applied voltage, %V

Pick-up voltage

Drop-out voltage

510

No. of operations, ×10

4

20°C 5A

20°C 0A

70°C 5A

70°C 0A

Max.

x

Min.

Max.

x

Min.

3. Ambient temperature characteristics and coil

applied voltage

500

400

300

200

Coil applied voltage, %V

100

50

45

40

35

30

25

20

Contact resistance, mΩ

15

10

5

0

Allowable ambient temperatures

against % coil voltages

(max. inside the coil temperature

set as 115°C

0

0 1020304050607080

0

239°F)

Carrying current: 5

Coil & contact no carrying current

Pick-up voltage

Ambient temperature, °C

105

No. of operations, ×10

4

Max.

x

Min.

ds_61113_0004_en_lkt: 091008J

Page 3

4-(2). Electrical life test

(UL508 TV-8 rating test)

Sample: LKT1aF-12V, 6 pcs.

• Overload test

Load: 12 A 120 V AC (60 Hz),

Inductive load (cosφ = 0.75)

Operation frequency: 6 times/min

(ON : OFF = 1 s : 9 s)

No. of operations: 50 ope.

• Endurance test

Load: 8A 120 V AC (960 W lamp load),

(Inrush: 118 A)

Operation frequency: 1 times/min

(ON: OFF = 1 s: 59 s)

No. of operations: 25,000 ope.

NOTES

1. Usage, transport and storage

conditions

1) Temperature:

–40 to +70°C –40 to +158°F

2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the

temperature. Use within the range

indicated in the graph below.

3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for

usage, transport, and storage

Humidity, %RH

85

Tolerance range

(Avoid freezing

when used at

temperatures lower

than 0°C

4) Condensation

Condensation forms when there is a

sudden change in temperature under

high temperature and high humidity

conditions. Condensation will cause

deterioration of the relay insulation.

5) Freezing

Condensation or other moisture may

freeze on the relay when the

temperatures is lower than 0°C 32°F.

This causes problems such as sticking of

movable parts or operational time lags.

6) Low temperature, low humidity

environments

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

(Avoid

condensation

when used at

temperatures higher

32°F)

than 0°C 32°F)

5

070-40

+32 +158-40

Temperature, °C °F

Change of pick-up and drop-out voltage Change of contact resistance

12

10

8

6

4

Pick-up and drop-out voltage, V

2

0

025

Pick-up voltage

Drop-out voltage

No. of operations, ×10

Max.

x

Min.

Max.

x

Min.

3

2. Solder and cleaning conditions

1) Please obey the following conditions

when soldering automatically.

(1) Preheating: Within 120°C 248°F

(solder surface terminal portion) and

within 120 seconds

(2) Soldering iron: 260°C±5°C

500°F±41°F (solder temperature) and

within 6 seconds (soldering time)

2) Since this is not a sealed type relay, do

not clean it as is. Also, be careful not to

allow flux to overflow above the PC board

or enter the inside of the relay.

3. Certification

1) This relay is UL and C-UL certified

(File No. E43149).

UL, C-UL rating: TV-8

2) This relay is certified by TUV as an

electromagnetic relay that complies with

VDE0435 (File No. B040413461035).

(1) TUV rating: 8A, 250 V to COSφ = 1.0

(2) The terminals of this relay can only be

connected with solder.

(3) This relay is certified by SEMKO (File

No. 400968).

SEMKO rating: 3/100A 250 V AC, 5/40A

250 V AC

4. Others

1) For precautions regarding use and

explanations of technical terminology,

please refer to “Relay Technical

Information”.

2) T o ensure good operation, please keep

the voltage on the coil ends to ±5% (at

20°C 68°F) of the rated coil operation

voltage. Also, please be aware that the

pick-up voltage and drop-out voltage may

change depending on the temperature

and conditions of use.

3) Keep the ripple rate of the nominal coil

50

45

40

35

30

25

20

Contact resistance, mΩ

15

10

5

0

0

No. of operations,

4) The cycle lifetime is defined under the

standard test condition specified in the

JIS* C 5442 standard (temperature 15 to

°C 59 to 95°F, humidity 2 5 to 75%).

35

Check this with the real device as it is

affected by coil driving circuit, load type,

activation frequency, activation

phase,ambient conditions and other

factors.

Also, be especially careful of loads such

as those listed below.

(1) When used for AC load-operating and

the operating phase is synchronous.

Rocking and fusing can easily occur due

to contact shifting.

(2) High-frequency load-operating

When high-frequency opening and

closing of the relay is performed with a

load that causes arcs at the contacts,

nitrogen and oxygen in the air is fused by

the arc energy and HNO

can corrode metal materials.

Three countermeasures for these are

listed here.

• Incorporate an arc-extinguishing circuit.

• Lower the operating frequency

• Lower the ambient humidity

5) Heat, smoke, and even a fire may

occur if the relay is used in conditions

outside of the allowable ranges for the

coil ratings, contact ratings, operating

cycle lifetime, and other specifications.

Therefore, do not use the relay if these

ratings are exceeded.

6) If the relay has been dropped, the

appearance and characteristics should

always be checked before use.

7) Incorrect wiring may cause

unexpected events or the generation of

heat or flames.

voltage below 5%.

LK-T

Max.

x

Min.

25

3

×10

3 is formed. This

For Cautions for Use, see Relay Technical Information.

ds_61113_0004_en_lkt: 091008J

3

Loading...

Loading...