Panasonic Limux DMC-CM1P, Limux DMC-CM1GC, Limux DMC-CM1GN, Limux DMC-CM1GT, Limux DMC-CM1GH Service Manual

© Panasonic Corporation 2015 Unauthorized copying and distribution is a violation of law.

ORDER NO. DSC1504014CE

B26

Digital Camera

Model No. DMC-CM1P

DMC-CM1GC

DMC-CM1GH

DMC-CM1GN

DMC-CM1GT

Colour

(S)...........Silver Type

2

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure. 1) --------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. How to Replace the Lithium Ion Battery --------------5

3 Service Navigation------------------------------------------------6

3.1. Introduction --------------------------------------------------6

3.2. Important Notice -------------------------------------------6

3.3. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------8

3.4. How to Define the Model Suffix-------------------------9

4 Specifications ---------------------------------------------------- 10

5 Location of Controls and Components ------------------ 12

6 Service Fixture & Tools --------------------------------------- 13

6.1. Service Fixture and Tools ------------------------------ 13

6.2. When Replacing the Main P.C.B. Unit -------------- 13

7 Disassembly and Assembly Instructions--------------- 14

7.1. Disassembly Flow Chart-------------------------------- 14

7.2. P.C.B. Location ------------------------------------------- 14

7.3. Disassembly Procedure --------------------------------15

7.4. Removal of the MOS Unit ------------------------------ 20

7.5. How to Use Servicing Tool for Assembling -------- 20

8 Measurements and Adjustments -------------------------- 23

8.1. Matrix Chart for Replaced Part and Necessary

Adjustment------------------------------------------------- 23

9 Maintenance ------------------------------------------------------ 24

9.1. Cleaning Lens and LCD Panel ----------------------- 24

3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 M and 5.2 M. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

1.3. Leakage Current Hot Check

(See Figure. 1)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 k, 10 W resistor, in parallel with a 0.15 F

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure. 1.

3. Use an AC voltmeter, with 1 k/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

Figure. 1

4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as “antistatic (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

5

2.2. How to Replace the Lithium Ion Battery

Please refer to the disassembly procedure for replacement method.

NOTE:

This Lithium Ion battery is a critical component.

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in requirement designed specifically for its use.

Replacement batteries must be of same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for DMC-CM1 series, as well.

6

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2. Important Notice

3.2.1. P.C.B.:

P.C.B. module is unit exchange.

3.2.2. Lens Unit:

The minimum replacement part size of the Lens part is as shown below.

When servicing, replace the following numbered replacement part size as the smallest size.

3.2.3. Notes on repairing of disassembly

When disassemble for repair, please replace the new cover glass tape every time.

3.2.4. Notice of Front Cover Unit replacement

When replace the Front Cover Unit, replace the Nameplate from the original Front Cover Unit.

For more information, see the 7.3.1. Removal of the LCD Module Unit and Front Cover Unit.

7

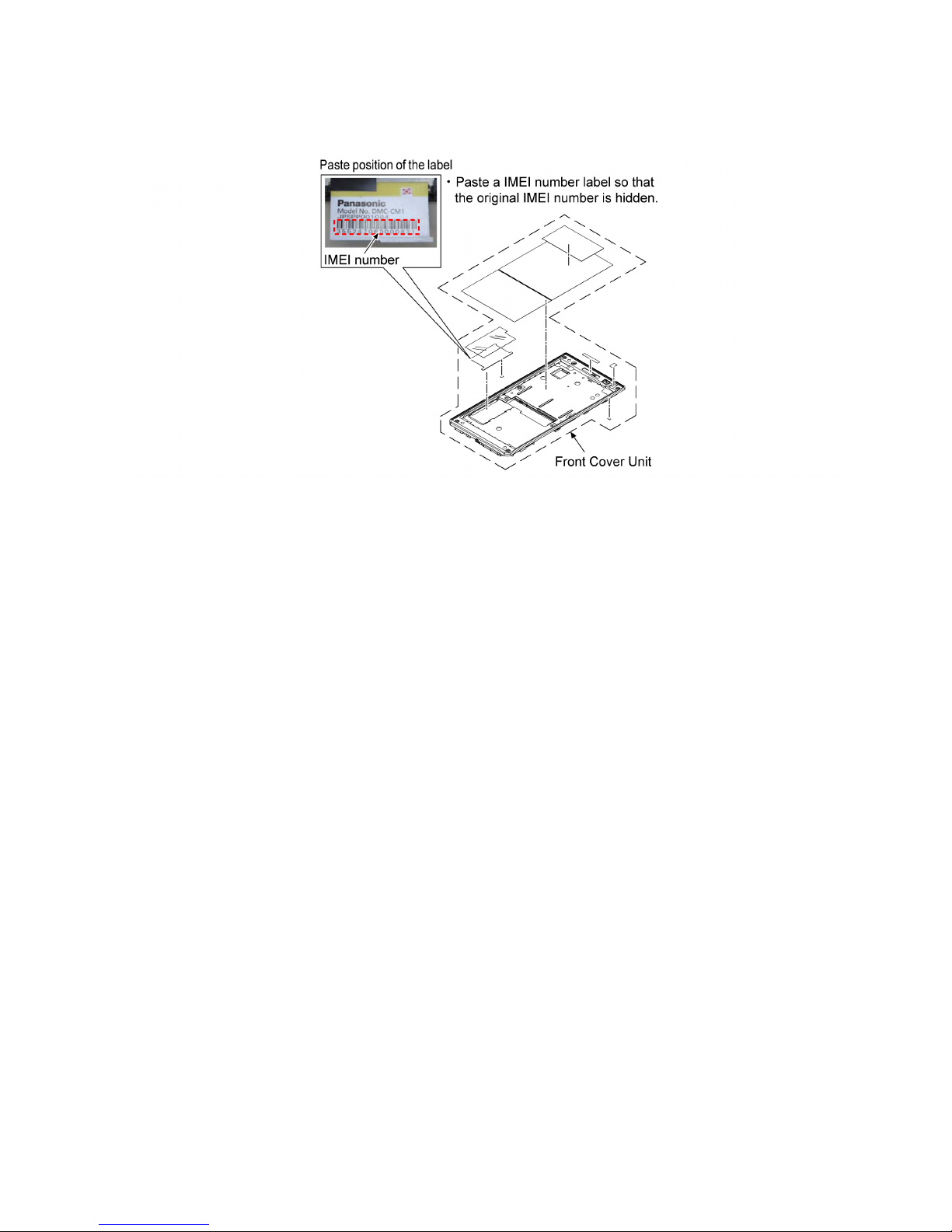

3.2.5. Notice of Main P.C.B. Unit replacement

IMEI number is different for each Main P.C.B. Unit. Therefore, IMEI number label is shipped with the repair Main P.C.B. Unit.

When replace the Main P.C.B. Unit, paste new IMEI number label on the paste position of the label of the Front Cover Unit.

For more information, see the 7.3.2. Removal of the Lens Unit and Main P.C.B. Unit.

3.2.6. About adjustment condition/procedure and firmware update

As for Adjustment condition/procedure, see the “Adjustment method” which is available in Adjustment software.

3.2.7. About servicing SIM card

SIM card is required to use the call function/communication function.

When check the call function/communication function, prepare a SIM card.

3.2.8. About personal information

Because of call function/communication function, this camera unit has the personal information of wireless LAN connection the customer has registered.

In operating instructions, enlightening to customers that deleting personal information in advance when repairing.

Take care in the handling of personal information.

After repairing, execute from the home screen: [Settings] [Backup & reset] [Factory data reset] [Reset phone].

3.2.9. About Flexible Cable and Connector

Do not touch carelessly so that the foreign body should not adhere to the terminal part of flexible cable and connector.

Wipe off with a clean cloth and the cotton bud, etc. when the terminal part is dirty.

8

3.3. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

SVKZ000001-----------(0.3mm 100g Reel)

SVKZ000002-----------(0.6mm 100g Reel)

SVKZ000003-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn) 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%. (Flux cored)

Loading...

Loading...