Panasonic KX-TG2820, KX-TG2822 Service Manual

ORDER NO. KM40506787CE

Telephone Equipment

KX-TG2820LAB

KX-TG2822LAB

KX-TGA243LAB

KX-TGA246LAB

2.4 GHz Digital Cordless Phone

Black Version

(for Latin America)

© 2005 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

Note:

Because CONTENTS 4 is the extract from the Operating Instructions of this model, it is subject to change without notice. You can

download and refer to the original Operating Instructions on TSN Server for further information.

CONTENTS

Page Page

1 ABOUT LEAD FREE SOLDER (PbF: Pb free) 4

1.1. Suggested PbF Solder

1.2. How to Recognize that Pb Free Solder is Used

2 FOR SERVICE TECHNICIANS

3 CAUTION

4 OPERATING INSTRUCTIONS

4.1. Battery

4.2. Location of Controls

4.3. Displays

4.4. Settings

4.5. Troubleshooting

5 DISASSEMBLY INSTRUCTIONS

5.1. Base Unit

5.2. Handset

5.3. Charger Unit

6 HOW TO REPLACE THE HANDSET LCD

7 TROUBLESHOOTING GUIDE

7.1. Check Power

7.2. Check Battery Charge

7.3. Check Link

7.4. Check the RF part

7.5. Check Handset Transmission

7.6. Check Handset Reception

7.7. Check Caller ID

8 ADJUSTMENT AND TEST MODE

8.1. Test Mode Flow Chart for Base Unit

8.2. Test Mode Flow Chart for Handset

8.3. X501 (Base Unit), X201 (Handset) Check

8.4. Adjust Battery Low Detector Voltage (Handset)

8.5. Base Unit Reference Drawing

8.6. Handset Reference Drawing

8.7. Frequency Table

8.8. How to Clear User Setting (Handset Only)

9 DESCRIPTION

9.1. Frequency

9.2. FHSS (Frequency Hopping Spread Spectrum)

10

11

15

18

18

19

20

21

22

23

24

25

26

33

33

33

34

34

38

42

42

43

44

45

46

47

47

47

4

5

5

5

6

6

8

9.3. Signal Flowchart in the Whole System

10 EXPLANATION OF LINK DATA COMMUNICATION

10.1. Calling

10.2. To Terminate Communication

10.3. Ringing

11 BLOCK DIAGRAM (BASE UNIT_MAIN)

12 BLOCK DIAGRAM (BASE UNIT_RF PART)

13 CIRCUIT OPERATION (BASE UNIT_MAIN)

13.1. DSP (Digital Speech/Signal Processing: IC501)

13.2. EEPROM (IC611)

13.3. Power Supply Circuit

13.4. Reset Circuit

13.5. Telephone Line Interface

13.6. Parallel Connection Detect Circuit

13.7. Calling Line Identification (Caller ID)

13.8. 2.4GHz Mod/Demod Circuit (Base Unit RF Part)

14 BLOCK DIAGRAM (HANDSET_MAIN)

15 BLOCK DIAGRAM (HANDSET_RF PART)

16 CIRCUIT OPERATION (HANDSET)

16.1. Construction

16.2. Power Supply Circuit

16.3. Charge Circuit

16.4. Ringer and Handset SP-Phone

16.5. Sending Signal

16.6. Reception Signal

16.7. 2.4GHz Mod/Demod Circuit (Handset RF Part)

17 CIRCUIT OPERATION (CHARGER UNIT)

18 SIGNAL ROUTE

19 CPU DATA (BASE UNIT)

19.1. IC501

20 CPU DATA (HANDSET)

20.1. IC201

21 EXPLANATION OF IC TERMINALS (RF PART)

21.1. IC901

22 HOW TO REPLACE A FLAT PACKAGE IC

22.1. PREPARATION

49

50

50

50

50

51

52

53

53

53

54

56

57

58

59

60

61

62

63

63

64

65

65

66

66

67

68

69

70

70

71

71

72

72

73

73

2

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

22.2. FLAT PACKAGE IC REMOVAL PROCEDURE 73

22.3. FLAT PACKAGE IC INSTALLATION PROCEDURE

22.4. BRIDGE MODIFICATION PROCEDURE

23 CABINET AND ELECTRICAL PARTS (BASE UNIT)

23.1. KX-TG2820LAB

23.2. KX-TG2822LAB

24 CABINET AND ELECTRICAL PARTS (HANDSET)

25 CABINET AND ELECTRICAL PARTS (CHARGER UNIT)

26 ACCESSORIES AND PACKING MATERIALS

26.1. KX-TG2820LAB

26.2. KX-TG2822LAB

27 TERMINAL GUIDE OF THE ICs, TRANSISTORS AND DIODES

27.1. Base Unit

27.2. Handset

27.3. Charger Unit

28 REPLACEMENT PARTS LIST

28.1. Base Unit

28.2. Handset

28.3. Charger Unit

28.4. Accessories and Packing Materials

28.5. Fixtures and Tools

29 FOR SCHEMATIC DIAGRAM

74

74

75

75

76

77

78

79

79

80

29.1. Base Unit (SCHEMATIC DIAGRAM (BASE UNIT_MAIN))

29.2. Handset (SCHEMATIC DIAGRAM (HANDSET_MAIN))

29.3. Charger Unit (SCHEMATIC DIAGRAM (CHARGER UNIT))

30 SCHEMATIC DIAGRAM (BASE UNIT_MAIN)

31 SCHEMATIC DIAGRAM (BASE UNIT_RF PART)

32 SCHEMATIC DIAGRAM (HANDSET_MAIN)

33 SCHEMATIC DIAGRAM (HANDSET_RF PART)

34 SCHEMATIC DIAGRAM (CHARGER UNIT)

35 CIRCUIT BOARD (BASE UNIT_MAIN)

81

81

81

82

83

83

85

87

87

87

35.1. Component View

35.2. Flow Solder Side View

36 CIRCUIT BOARD (BASE UNIT_RF PART)

37 CIRCUIT BOARD (HANDSET_MAIN)

37.1. Component View

37.2. Flow Solder Side View

38 CIRCUIT BOARD (HANDSET_RF PART)

39 CIRCUIT BOARD (CHARGER UNIT)

39.1. Component View

39.2. Flow Solder Side View

89

89

89

89

90

92

94

96

97

99

99

100

101

103

103

104

105

106

106

106

3

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

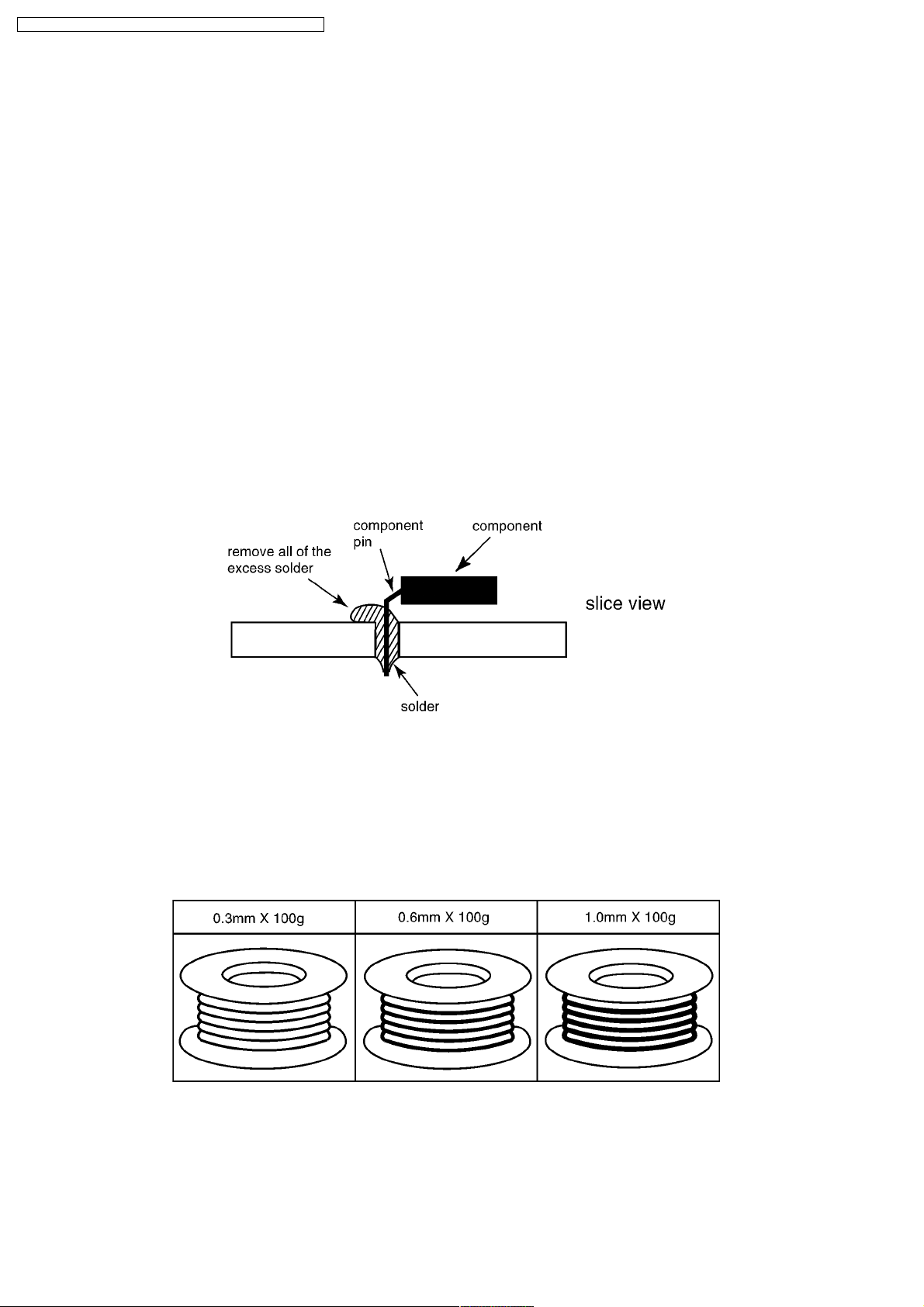

1 ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

•

• PbF solder has a melting point that is 50°F ~ 70° F (30°C ~ 40°C) higher than Pb solder. Please use a soldering iron with

• •

temperature control and adjust it to 700°F ± 20° F (370°C ± 10°C). In case of using high temperature soldering iron, please

be careful not to heat too long.

•

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F (600°C).

• •

•

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

• •

and be sure that any remaining is melted prior to applying the Pb solder.

•

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

• •

opposite side (See the figure below).

1.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu), or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the

manufacturer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

4

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

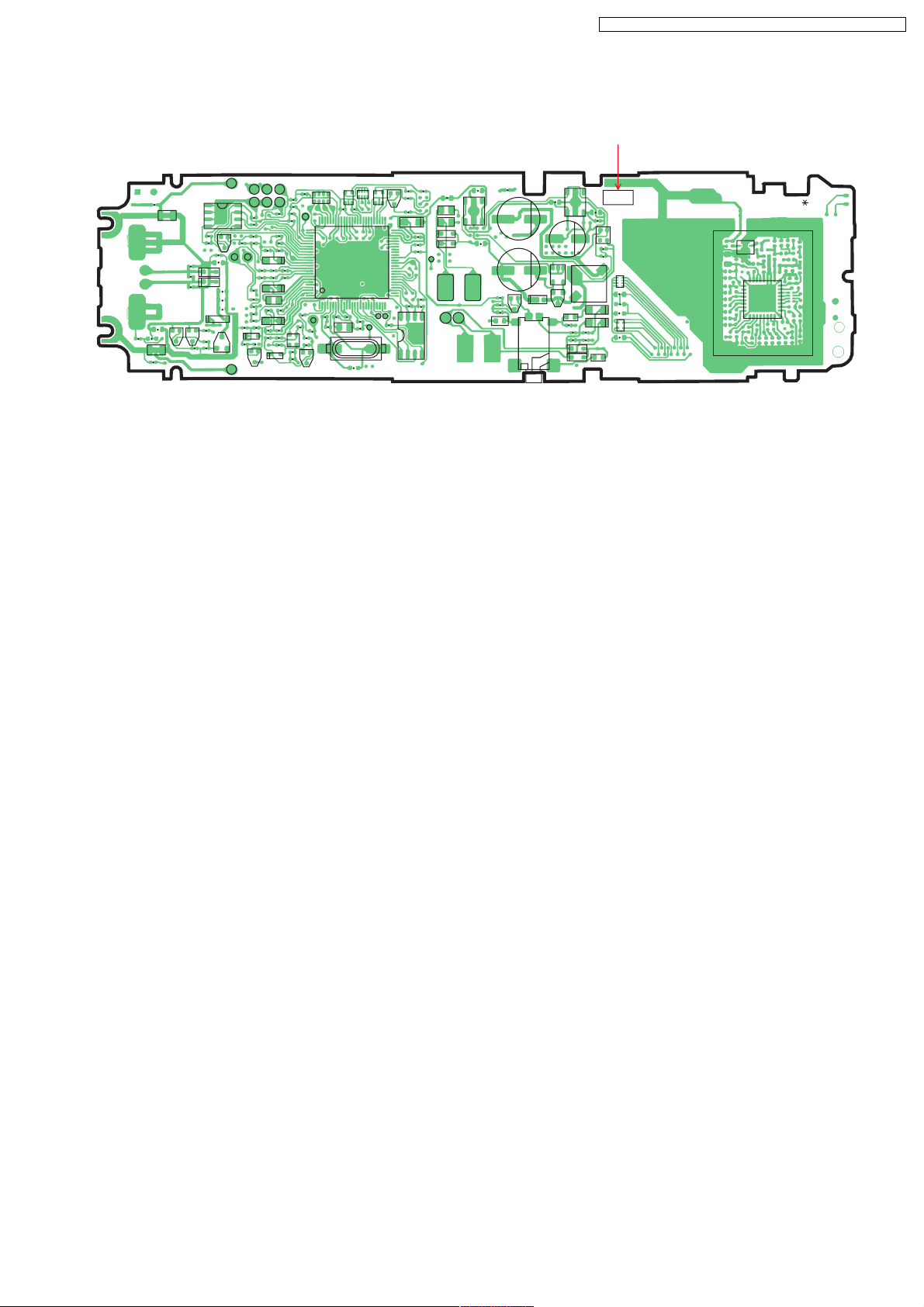

1.2. How to Recognize that Pb Free Solder is Used

(Example: Handset P.C.B.)

Marked

VBATT

R376

R352

C353

L351

R377

R351

JTAG

R243

R231

TX

C209

RX

R207

R206

VSSVSS

C241

R209

R205

R241

5

R226

C244

C226

C243

C377

C303

C304

C315

R315

C316

R317

R314

C314

C317

R312

R318

C208

R334

C336

C305

C333

R333

C307

R228

C231

C306

R208

C222

R222

D231

IC221

R232

Q231

C221

R223

D223

C223

CHG2

1

L352

C313

C311

C312

Q362

R242

C242

Q363

R362

R361R363

R354

C354

D313

D312

R368

R367

R366

R364

IC241

D361

Q361

Q243

R230

CHG1

C206

R340

100

Q221

76

C340

TEST

R224

C224

RA201

75

C202

Q251 Q252 Q253

RA251

R251 R252

IC201

TXO

C212C215C201

R225

C219

C214

RESET

C225

X201

R201

51

251

MOE

R258 R261

R257

R256

C205

50

26

C246

1

C204

R204

R203

RSSI

R234

R249

5

IC249

L211

L326

L327

D326

D327

(Component View)

Note:

The location of the “PbF” mark is subject to change without notice.

C371

IC371

C372

SP_PHONE

RECEIVER

C361

1

R331

R332

C332

L332

C211

C373

Q331

CN331

D373

C384

IC373

Q373

C334

C381

R324

C322

IC381

L334

D324

D323

L373

C335

C321

R325

R323

L331

C382

1

C383

PbF

IC374

C227

R227

CA274

C273

R273

R272

C272

CA271

ANT

SHIELD

PQUP11285Z

FL901

IC901

A

2 FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

3 CAUTION

1. Danger of explosion if battery is incorrectly replaced.

2. Replace only with the same or equivalent type recommended by the manufacturer.

3. Dispose of used batteries according to the manufacturer´s Instructions.

5

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

4 OPERATING INSTRUCTIONS

4.1. Battery

4.1.1. Battery Installation

4.1.2. Battery Charge

4.1.3. Recharging the Battery

Note for service:

The battery strength may not be indicated correctly if the battery is disconnected and connected again, even after it is fully

charged. In that case, by recharging the battery as mentioned above, you will get a correct indication of the battery strength.

4.1.4. Battery Strength

6

4.1.5. Battery Replacement

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

4.1.6. Battery Performance

7

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

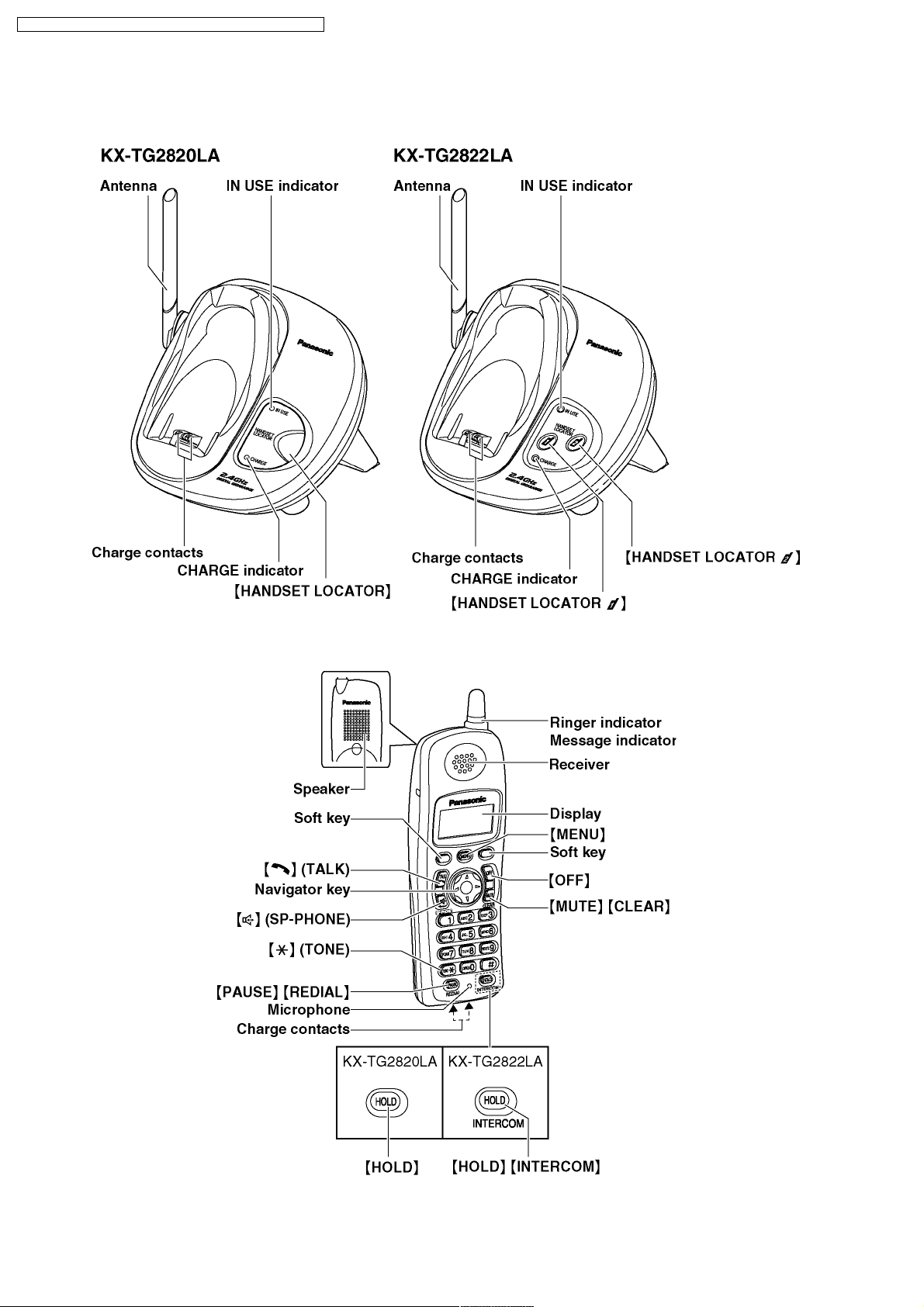

4.2. Location of Controls

4.2.1. Base Unit

4.2.2. Handset

8

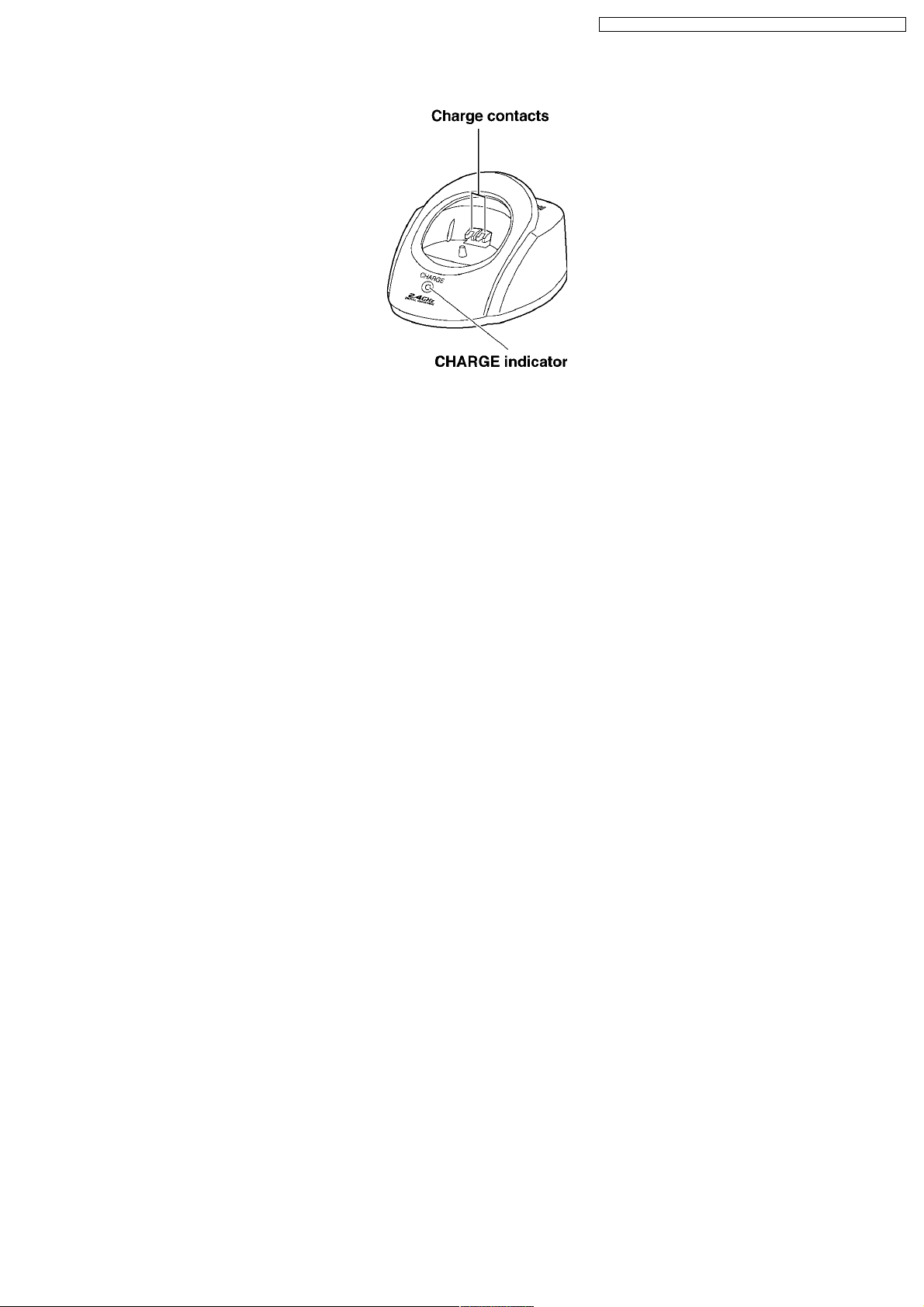

4.2.3. Charger Unit (KX-TG2822LA only)

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

9

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

4.3. Displays

4.3.1. Display Items

4.3.2. Troubleshooting (Handset LCD)

10

4.4. Settings

4.4.1. Connections

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

11

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

12

4.4.2. Guide to Handset Programming

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

13

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

4.4.3. Direct Commands

14

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

4.5. Troubleshooting

If the handset display shows error messages, see “Troubleshooting (Handset LCD) (P.10)” for the Cause & Solution.

15

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

16

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

17

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

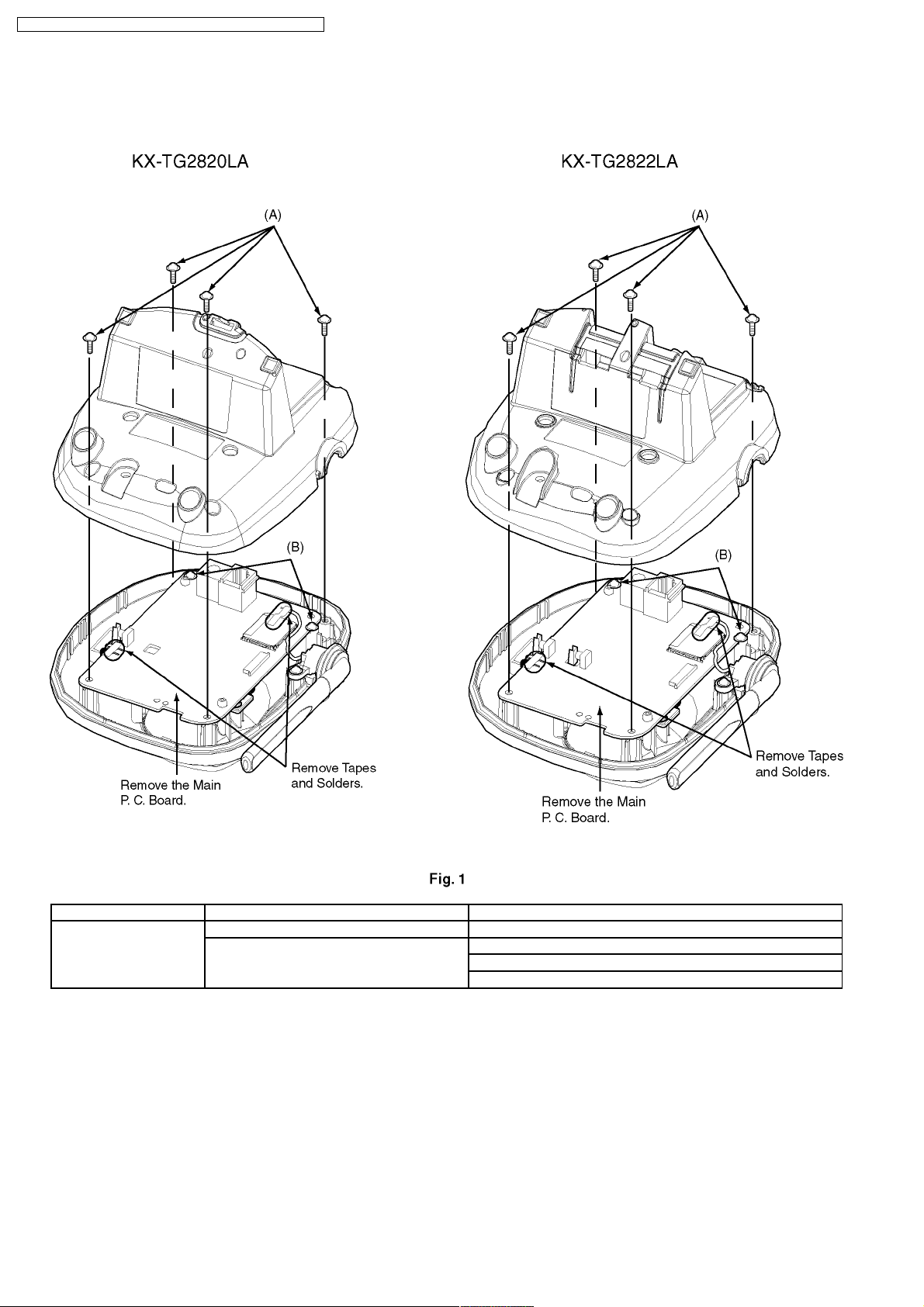

5 DISASSEMBLY INSTRUCTIONS

5.1. Base Unit

Shown in Fig.- To Remove - Remove -

1 Cabinet Cover Screws (2.6 × 12).....(A) × 4

Main P. C. Board Screws (2.6 × 8).......(B) × 2

Tapes and Solders

Main P. C. Board

18

5.2. Handset

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

Shown in Fig.- To Remove - Remove -

2 Cabinet Cover Screws (2 × 10).............(C) × 2

3 Follow the procedure.

4 Main P. C. Board Tape and Solders

Screws (2 × 10).............(D) × 3

Charge Terminals

Main P. C. Board

19

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

5.3. Charger Unit

Shown in Fig.- To Remove - Remove -

5 Cabinet Cover Screws (2.6 × 12).............( E) × 2

Main P. C. Board Solders

Main P. C. Board

20

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

6 HOW TO REPLACE THE HANDSET LCD

21

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7 TROUBLESHOOTING GUIDE

Cross Reference:

Check Power (P.23)

Check Battery Charge (P.24)

Check Link (P.25)

Check the RF part (P.26)

Check Handset Transmission (P.33)

Check Handset Reception (P.33)

Check Caller ID (P.33)

22

7.1. Check Power

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

Cross Reference:

Power Supply Circuit (P.54)

Reset Circuit (P.56)

Note:

DSP is IC501.

23

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7.2. Check Battery Charge

Note:

DSP is IC501.

24

7.3. Check Link

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

Note:

DSP is IC501.

(*1) Refer to Finding out the Defective part (P.26).

Cross Reference:

Check the RF part (P.26)

25

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7.4. Check the RF part

7.4.1. Finding out the Defective part

After All the Checkings or Repairing

1. Re-register the checked Handset to the checked Base Unit, and Regular HS to Regular BU.

Note:

(*1) HS: Handset

(*2) BU: Base Unit

26

7.4.1.1. Re-registering the Handset

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

27

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7.4.2. RF Check Flowchart

Each item (1 ~ 6) of RF Check Flowchart corresponds to Check Table for RF part (P.29).

Please refer to the each item.

28

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7.4.3. Check Table for RF part

No. Item BU (Base Unit) Check HS (HandSet) Check

1 Link Confirmation Normal

HS, BU Mode [Normal Mode]

2 Control signal confirmation

HS, BU Mode: [Test Burst Mode] (*1)

3 X’tal Frequency confirmation (*7)

HS, BU Mode: [Adjustment] (*3)

4 TX Power confirmation

Regular HS, BU Mode:

[RX-CW Mode.] (*4)

HS, BU (to be checked) Mode:

[Test Burst Mode.] (*1)

5 RX Sensitivity confirmation

Regular HS, BU Mode:

[Test Burst Mode.] (*1)

HS, BU (to be checked) Mode:

[RX-CW Mode.] (*4)

6 Range Confirmation Normal

HS, BU Mode: [Normal Mode]

1. Register Regular HS to BU (to be checked).

2. Press [Talk] key of the Regular HS to

establish link.

Check DSP interface. (*2) Check DSP interface. (*2)

Check X’tal Frequency.

(13.824000MHz ±100Hz)

1. Place the Regular HS about 15cm away

from the BU.

2. Confirm that RSSI of the Regular HS is

approximately 2V by Oscilloscope. (*5)

1. Place the Regular HS about 15cm away

from the BU.

2. Confirm that RSSI of the BU is

approximately 2V by Oscilloscope. (*5)

1. Register Regular HS to BU (to be checked).

2. Press [Talk] key of the Regular HS to

establish link.

3. Compare the range of the BU (being

checked) with that of the Regular BU.

1. Register HS (to be checked) to Regular BU.

2. Press [Talk] key of the HS to establish link.

Check X’tal Frequency.

(13.824000MHz ±100Hz)

1. Place the HS about 15cm away from the

Regular BU.

2. Confirm that RSSI of the Regular BU is

approximately 2V by Oscilloscope. (*6)

1. Place the HS about 15cm away from the

Regular BU.

2. Confirm that RSSI of the HS is

approximately 2V by Oscilloscope. (*6)

1. Register HS (to be checked) to Regular BU.

2. Press [Talk] key of the HS to establish link.

3. Compare the range of the HS (being

checked) with that of the Regular HS.

Note:

(*1)(*3)(*4) ADJUSTMENT AND TEST MODE (P.34)

(*2) RF-DSP Interface Signal Wave Form (P.31)

(*5) Base Unit Reference Drawing (P.43)

(*6) Handset Reference Drawing (P.44)

(*7) X501 (Base Unit), X201 (Handset) Check (P.42)

29

KX-TG282 0LAB / KX-TG2822L AB / KX-TGA243L AB / KX-TGA2 46LAB

7.4.4. TEST RANGE Check

Circuit block which range is defective can be found by the following check.

Item BU (Base Unit) Check HS (HandSet) Check

Range Confirmation TX

TEST

(TX Power check)

HS, BU Mode:

[Test Link Mode] (*1)

1. Register Regular HS to BU (to be checked).

2. Set BU to “Test Link mode”.

3. Set Regular HS to “Test Link mode”.

*Set TX Power and RX Sensitivity of the BU and the

Regular HS by CHART1.

1. Register HS (to be checked) to Regular BU.

2. Set Regular BU to “Test Link mode”.

3. Set HS to “Test Link mode”.

*Set TX Power and RX Sensitivity of the HS and the

Regular BU by CHART1.

Range Confirmation RX

TEST

(RX sensitivity check)

HS, BU Mode:

[Test Link Mode] (*1)

* At distance of about 20m between HS and BU,

Link OK = TX Power of the BU is OK.

No Link = TX Power of the BU is NG.

1. Register Regular HS to BU (to be checked).

2. Set BU to “Test Link mode”.

3. Set Regular HS to “Test Link mode”.

*Set TX Power and RX Sensitivity of the BU and

Regular HS by CHART1.

* At distance of about 20m between HS and BU,

Link OK= RX Sensitivity of the BU is OK.

No Link = RX Sensitivity of the BU is NG.

* At distance of about 20m between HS and BU,

Link OK = TX Power of the HS is OK.

No Link = TX Power of the HS is NG.

1. Register HS (to be checked) to Regular BU.

2. Set Regular BU to “Test Link mode”.

3. Set HS to “Test Link mode”.

* Set TX Power and RX Sensitivity of Checking_HS

and Regular_BU by CHART1.

* At distance of about 20m between HS and BU,

Link OK= RX Sensitivity of the HS is OK.

No Link = RX Sensitivity of the HS is NG

CHART1: Setting of TX Power and RX Sensitivity in Range Confirmation TX TEST, RX TEST

BU (to be checked) Regular_HS

TX Power RX Sens. TX Power RX Sens.

BU (Base Unit) TX Power Check High High High Low

BU (Base Unit) RX Sensitivity Check High High Low High

HS (to be checked) Regular_BU

TX Power RX Sens. TX Power RX Sens.

HS (Handset) TX Power Check High High High Low

HS (Handset) RX Sensitivity Check High High Low High

Note:

(*1) ADJUSTMENT AND TEST MODE (P.34)

30

Loading...

Loading...