Panasonic HDC-TM700PU, HDC-TM700EE, HDC-TM700P, HDC-TM700EF, HDC-TM700EG Service Manual

...

© Panasonic Corporation 2010 Unauthorized copying and distribution is a violation of law.

ORDER NO. VM1002003CE

B27

High Definition Video Camera

Model No. HDC-TM700P

HDC-TM700PC

HDC-TM700PU

HDC-TM700EB

HDC-TM700EC

HDC-TM700EE

HDC-TM700EF

HDC-TM700EG

HDC-TM700EP

HDC-TM700GC

HDC-TM700GD

HDC-TM700GK

HDC-TM700GT

HDC-SD700EB

HDC-SD700EC

HDC-SD700EE

HDC-SD700EF

HDC-SD700EG

HDC-SD700EP

HDC-SD700GC

HDC-SD700GN

HDC-SD707EG

Vol. 1

2

Colour

[ HDC-TM700/SD700 ]

(K)...........Black Type

[ HDC-SD707 ]

(S)...........Silver Type

(K)...........Black Type

4

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1.)--------3

1.4. How to Discharge the Capacitor on Flash

P.C.B.----------------------------------------------------------4

2Warning--------------------------------------------------------------5

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------5

2.2. How to Recycle the Lithium Ion Battery (U.S.

Only)-----------------------------------------------------------5

2.3. Caution for AC Cord (For EB/GC) ---------------------6

2.4. How to Replace the Lithium Battery-------------------7

3 Service Navigation------------------------------------------------8

3.1. Introduction --------------------------------------------------8

3.2. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------8

3.3. Important Notice 1:(Other than U.S.A. and

Canadian Market)------------------------------------------8

3.4. How to Define the Model Suffix (NTSC or PAL

model)---------------------------------------------------------9

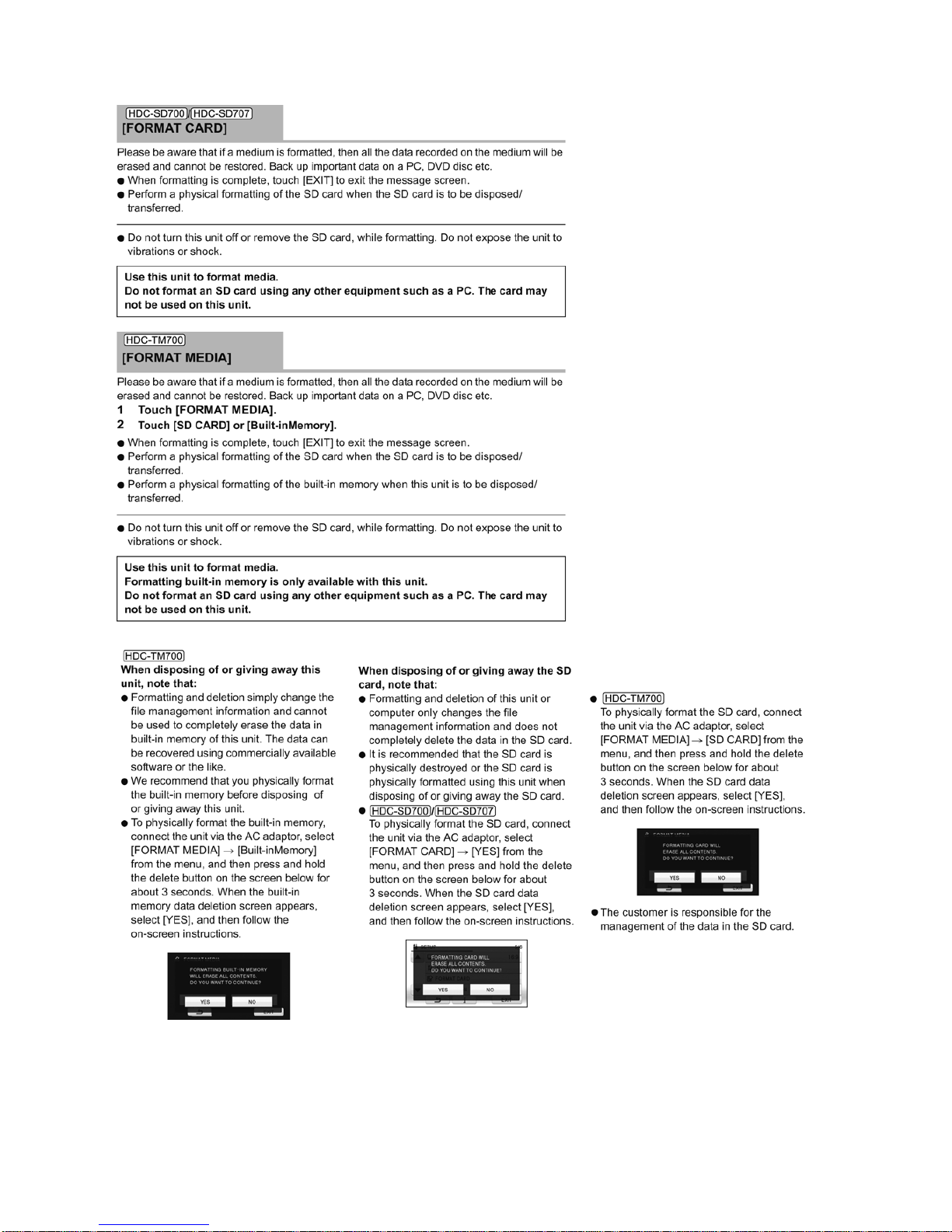

3.5. Formatting--------------------------------------------------10

4 Specifications---------------------------------------------------- 11

5 Location of Controls and Components------------------14

6 Service Mode-----------------------------------------------------17

6.1. Built-in Memory Self Check Execution (HDCTM700 only) -----------------------------------------------18

6.2. Lock Search History Indication -----------------------18

6.3. Power ON Self Check Result Display--------------- 19

7 Service Fixture & Tools---------------------------------------20

7.1. When Replacing the Main P.C.B. --------------------20

7.2. Service Position ------------------------------------------20

8 Disassembly and Assembly Instructions--------------- 22

8.1. Disassembly Flow Chart--------------------------------22

8.2. PCB Location----------------------------------------------22

8.3. Disassembly Procedure--------------------------------23

9 Measurements and Adjustments --------------------------42

9.1. Electric Adjustment --------------------------------------42

10 Factory Setting---------------------------------------------------44

10.1. How To Turn On The Factory Settings?------------4 4

10.2. What Is The Factory Settings? -----------------------45

3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These part s are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

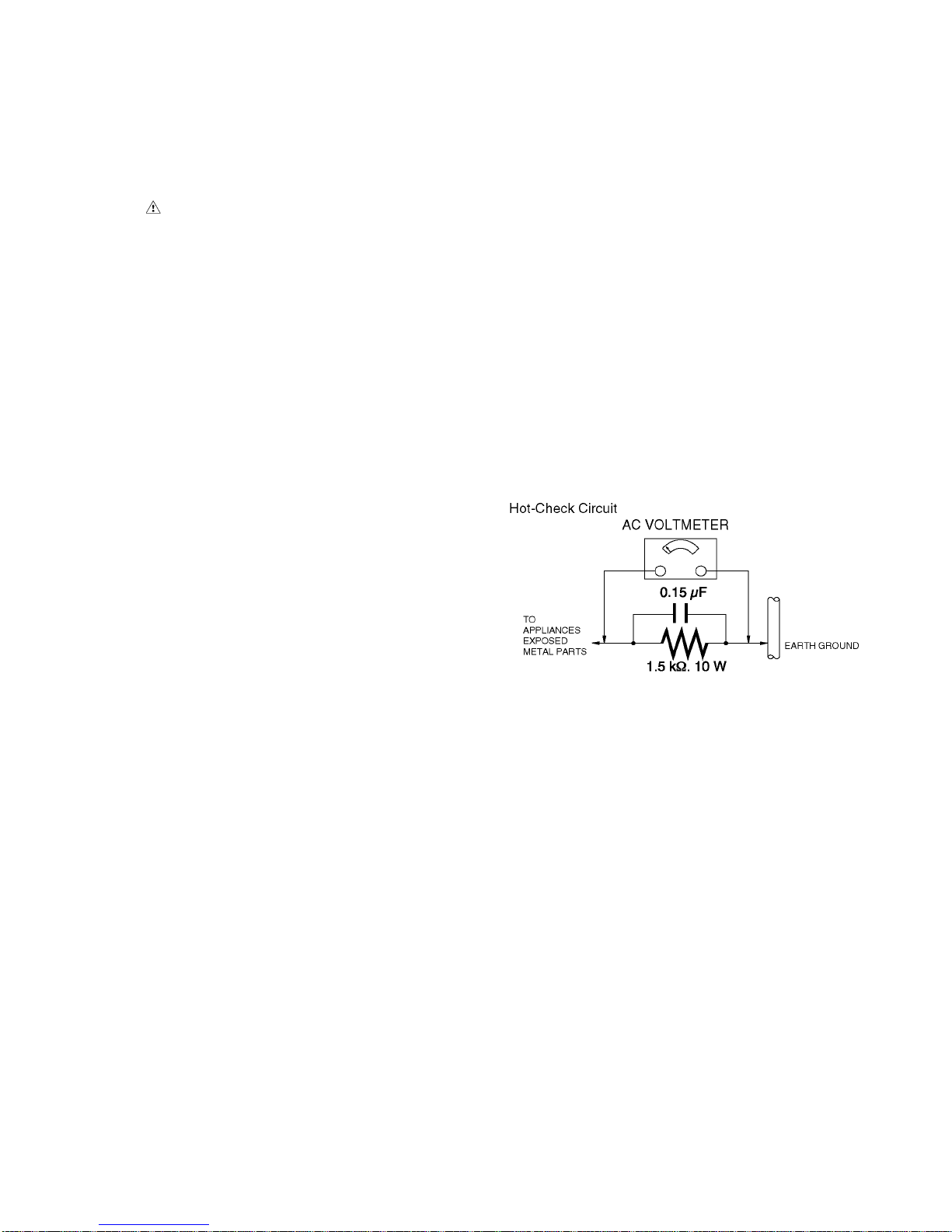

1.3. Leakage Current Hot Check

(See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

Figure. 1

4

1.4. How to Discharge the Capacitor on Flash P.C.B.

CAUTION:

1. Be sure to discharge the capacitor on FLASH P.C.B..

2. Be careful of the high voltage circuit on FLASH P.C.B. when servicing.

[Discharging Procedure]

1. Refer to the disassemble procedure and Remove the necessary parts/unit.

2. Put the insulation tube onto the lead part of Resistor (ERG5SJ102:1kΩ /5W).

(an equivalent type of resistor may be used.)

3. Put the resistor between both terminals of capacitor on FLASH P.C.B. for approx. 5 seconds.

4. After discharging confirm that the capacitor voltage is lower than 10V using a voltmeter.

Fig. F1

5

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help re duce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as al uminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

2.2. How to Recycle the Lithium Ion Battery (U.S. Only)

6

2.3. Caution for AC Cord

(For EB/GC)

2.3.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To redu ce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

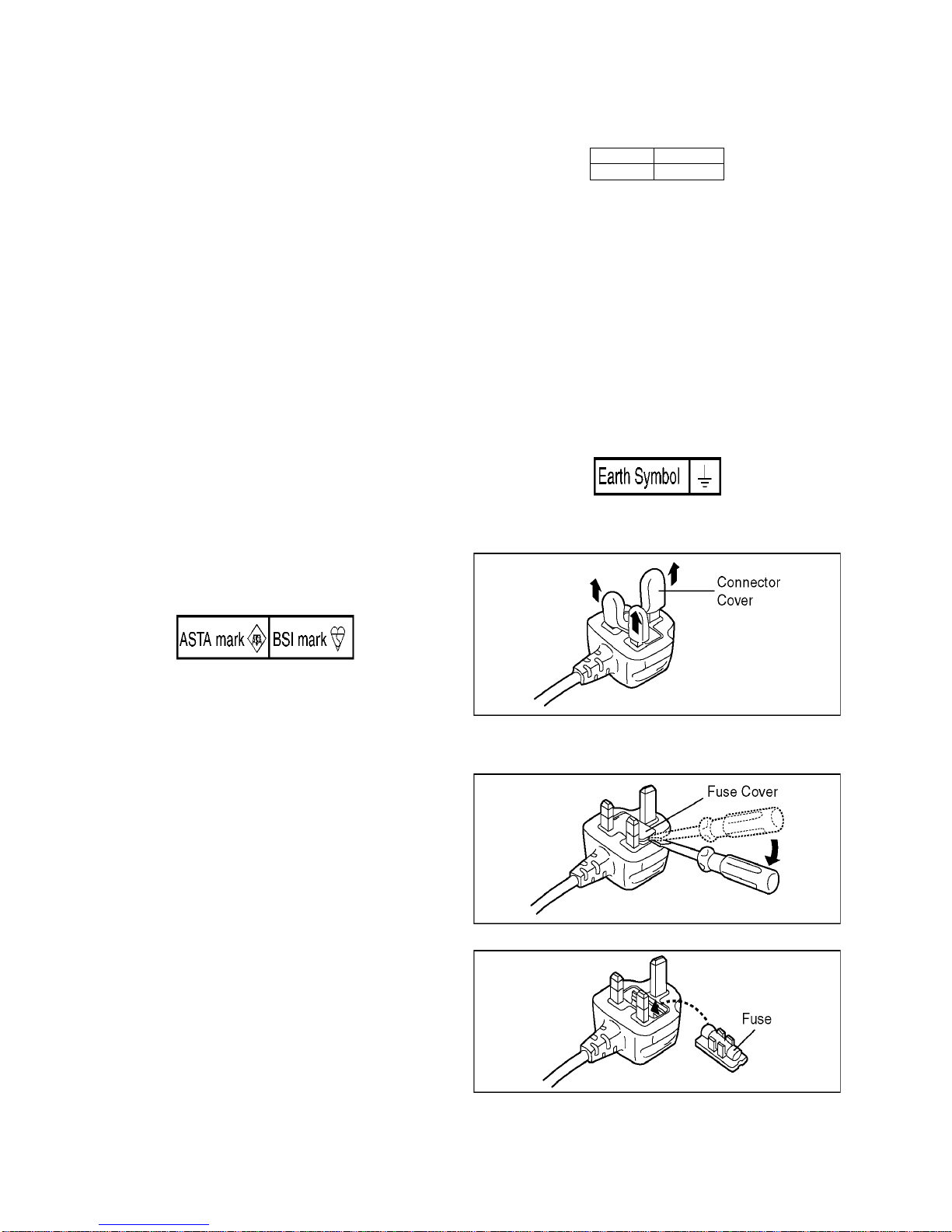

2.3.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.3.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings i dentifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with the le tter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.3.2.2. Before Use

Remove the Connector Cover as follows.

2.3.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

Blue Neutral

Brown Live

7

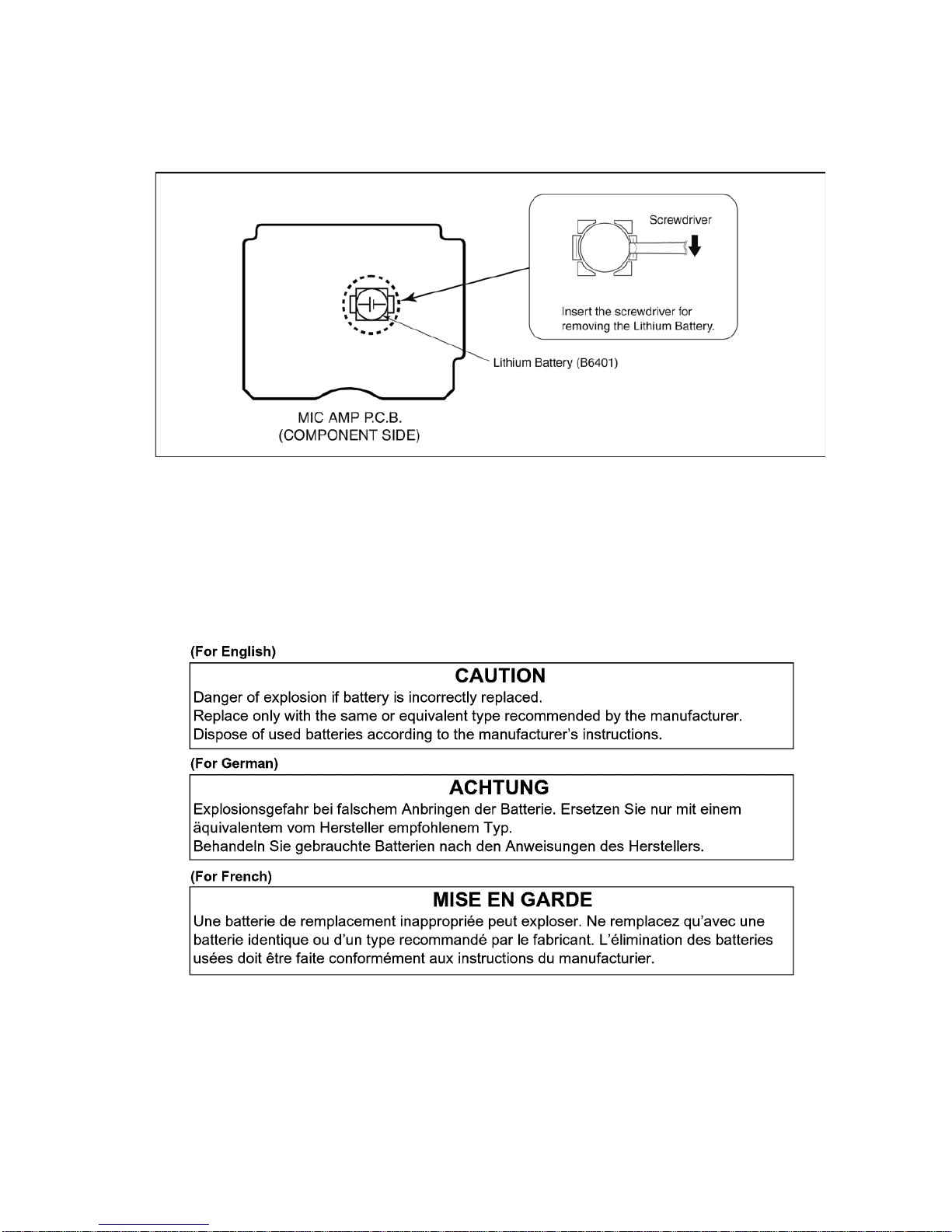

2.4. How to Replace the Lithium Battery

2.4.1. Replacement Procedure

1. Remove the MIC AMP P.C.B.. (Refer to Disassembly Procedures.)

2. Remove the Lithium battery (Ref. No. “B6401” at component side of MIC AMP P.C.B.) and then replace it into new one.

NOTE:

This Lithium battery is a critical component.

(Type No.: ML-614S/ZTK Manufactured by Energy Company, Panasonic Corporation)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in requirement designed specifically for its use.

Replacement batteries must be of same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for HDC-TM700/SD700/SD707 series, as well.

1. Battery Pack for this model.

2. Button-type battery for Remote controller (CR2025: Being supplied from Energy Company, Panasonic Corporation).

8

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical compone nts on the printed circuit bo ards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) mo re than th at of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is high er than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

3.3. Important Notice 1:(Other than U.S.A. and Canadian Market)

1. The service manual does not contain the following information, because of the impossibility of servi cing at component level

without concerned equipment/facilities.

a. Schematic diagram, Block Diagram and P.C.B. layout of MAIN P.C.B..

b. Parts list for individual parts for MAIN P.C.B..

When a part replacement is required for repairing MAIN P.C.B., replace as an assembled parts. (Main P.C.B.)

2. The following category is /are recycle module part. Please send it/them to Central Repair Center.

• MAIN P.C.B. (VEP03H98CN: HDC-TM700P/PC/PU/GD)

• MAIN P.C.B. (VEP03H98CQ: HDC-TM700EE/GC/GK)

• MAIN P.C.B. (VEP03H98CP: HDC-TM700EB/EC/EF/EG/EP)

• MAIN P.C.B. (VEP03H98DP: HDC-SD700EB/EC/EF/EG/EP, SD707EG)

• MAIN P.C.B. (VEP03H98DQ: HDC-SD700EE/GC/GN)

9

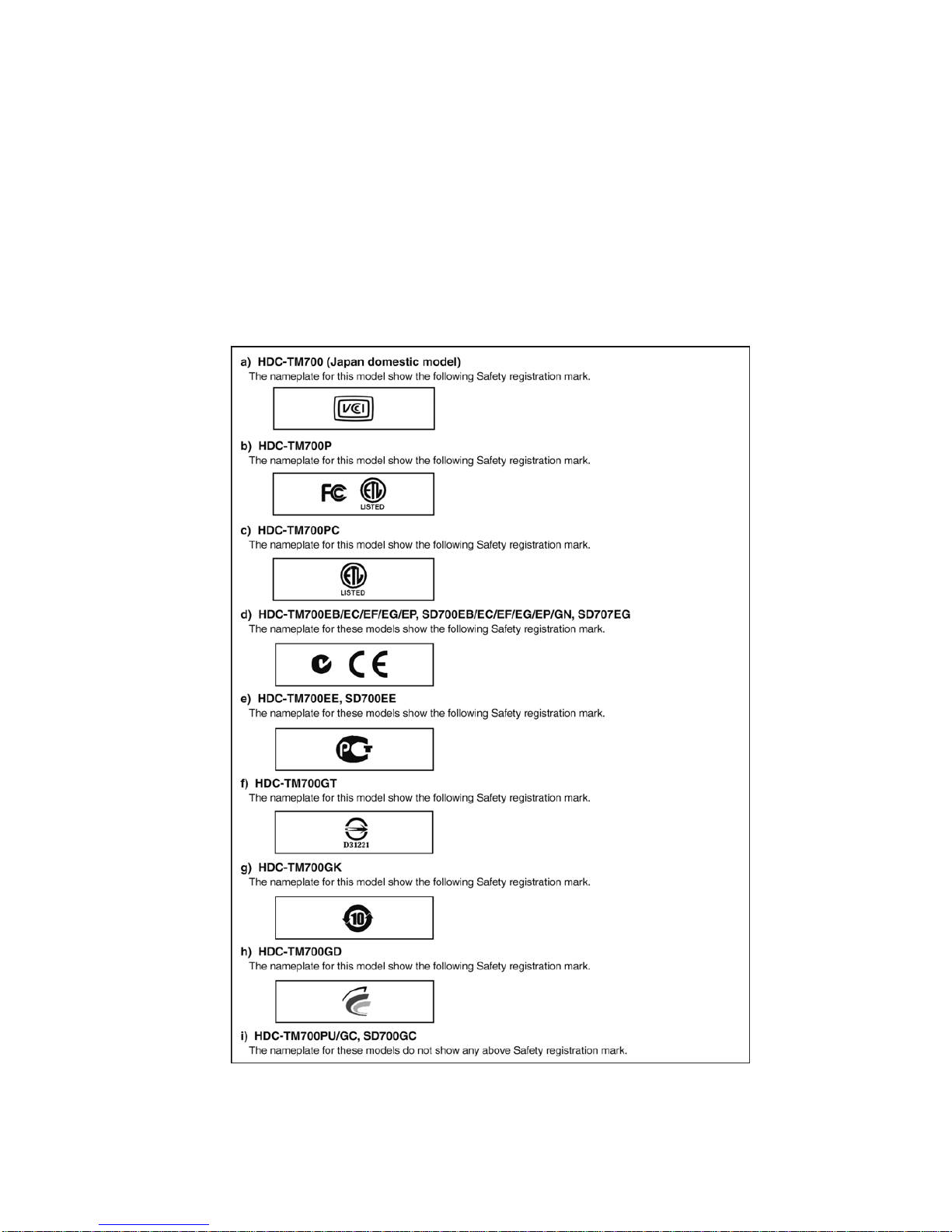

3.4. How to Define the Model Suffix (NTSC or PAL model)

There are nine kinds of HDC-TM700/SD700/SD707.

• a) HDC-TM700 (Japan domestic model)

• b) HDC-TM700P

• c) HDC-TM700PC

• d) HDC-TM700EB/EC/EF/EG/EP, SD700EB/EC/EF/EG/EP/GN, SD707EG

• e) HDC-TM700EE, SD700EE

• f) HDC-TM700GT

• g) HDC-TM700GK

• h) HDC-TM700GD

• i) HDC-TM700PU/GC, SD700GC

What is the difference is that the “INITIAL SETTING” data which is stored in Flash ROM mounted on Main P .C.B..

3.4.1. Defining methods:

To define the model suffix to be serviced, refer to the rating label which is putted on the Unit.

NOTE:

After replacing the MAIN P.C.B., be sure to achieve adjustment.

The adjustment instruction is available at “software download” on the “Support Information from NWBG/VDBG-A VC” web-site in

“TSN system”, together with Maintenance software.

10

3.5. Formatting

11

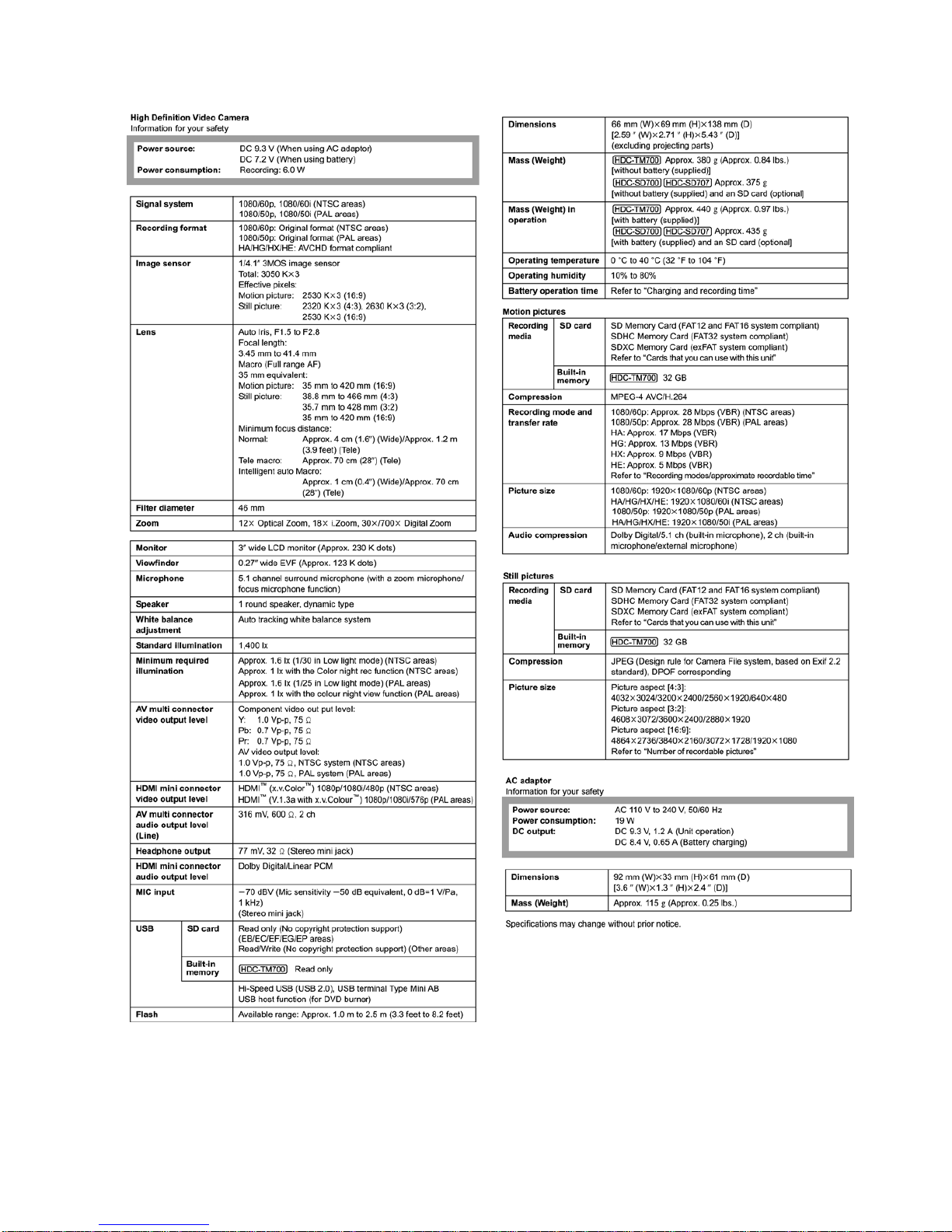

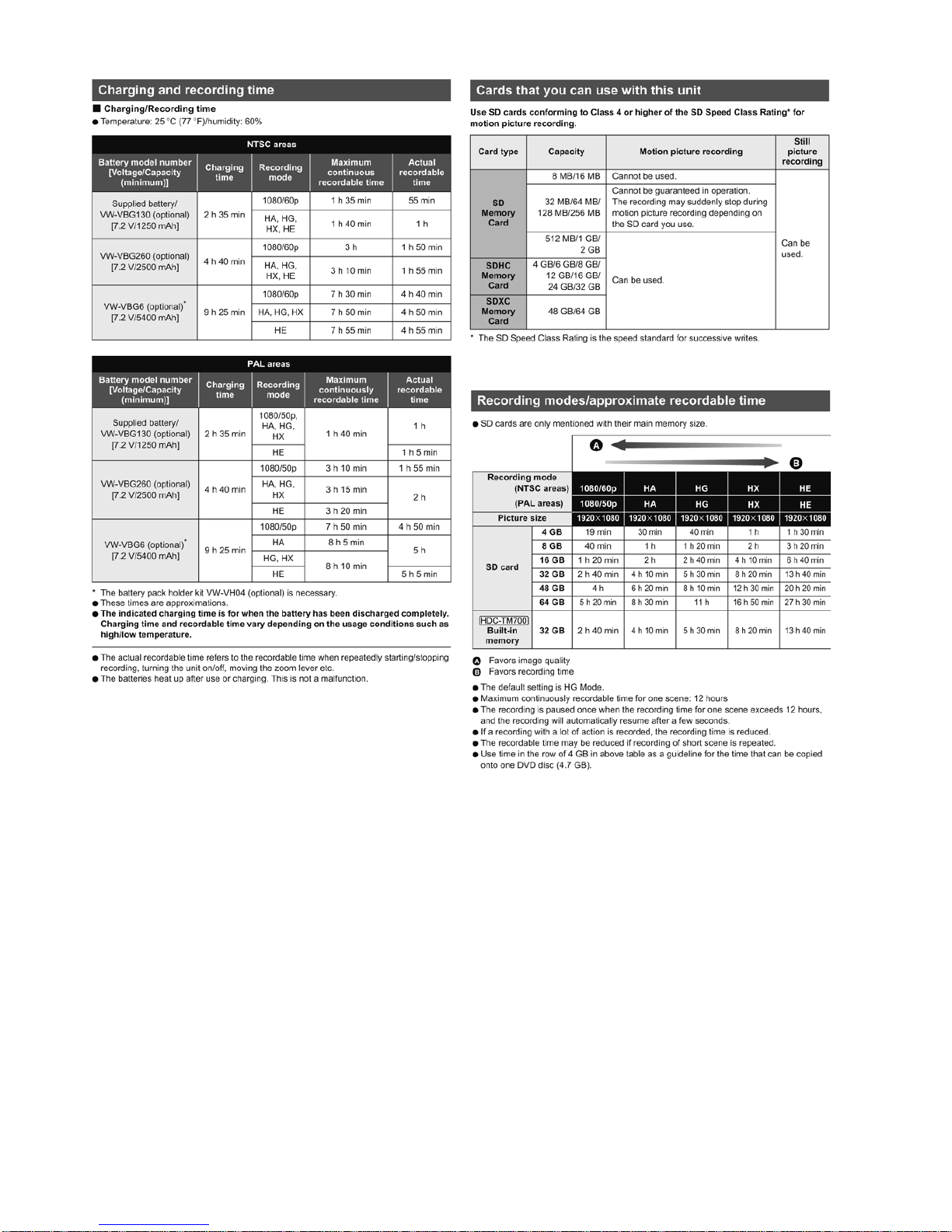

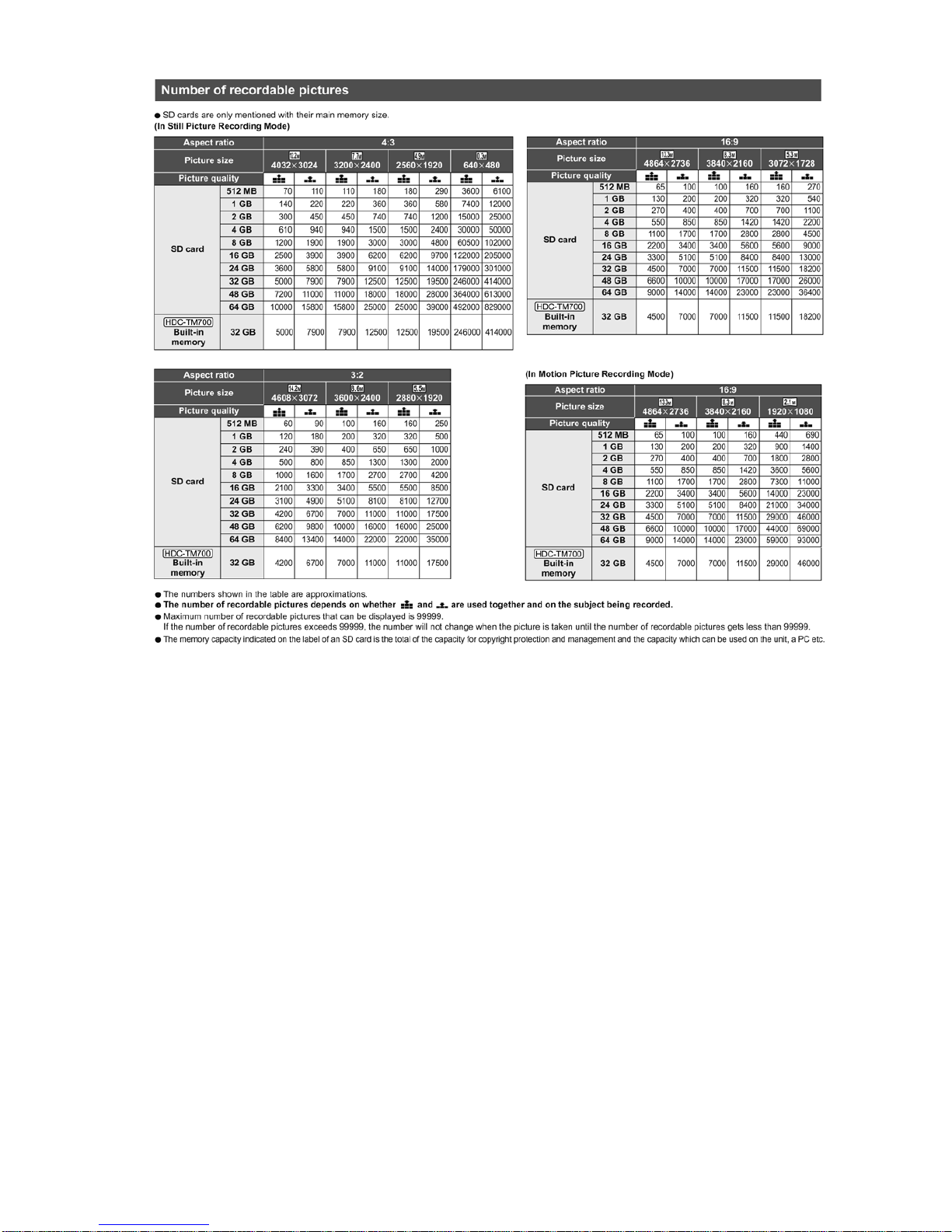

4 Specifications

12

13

14

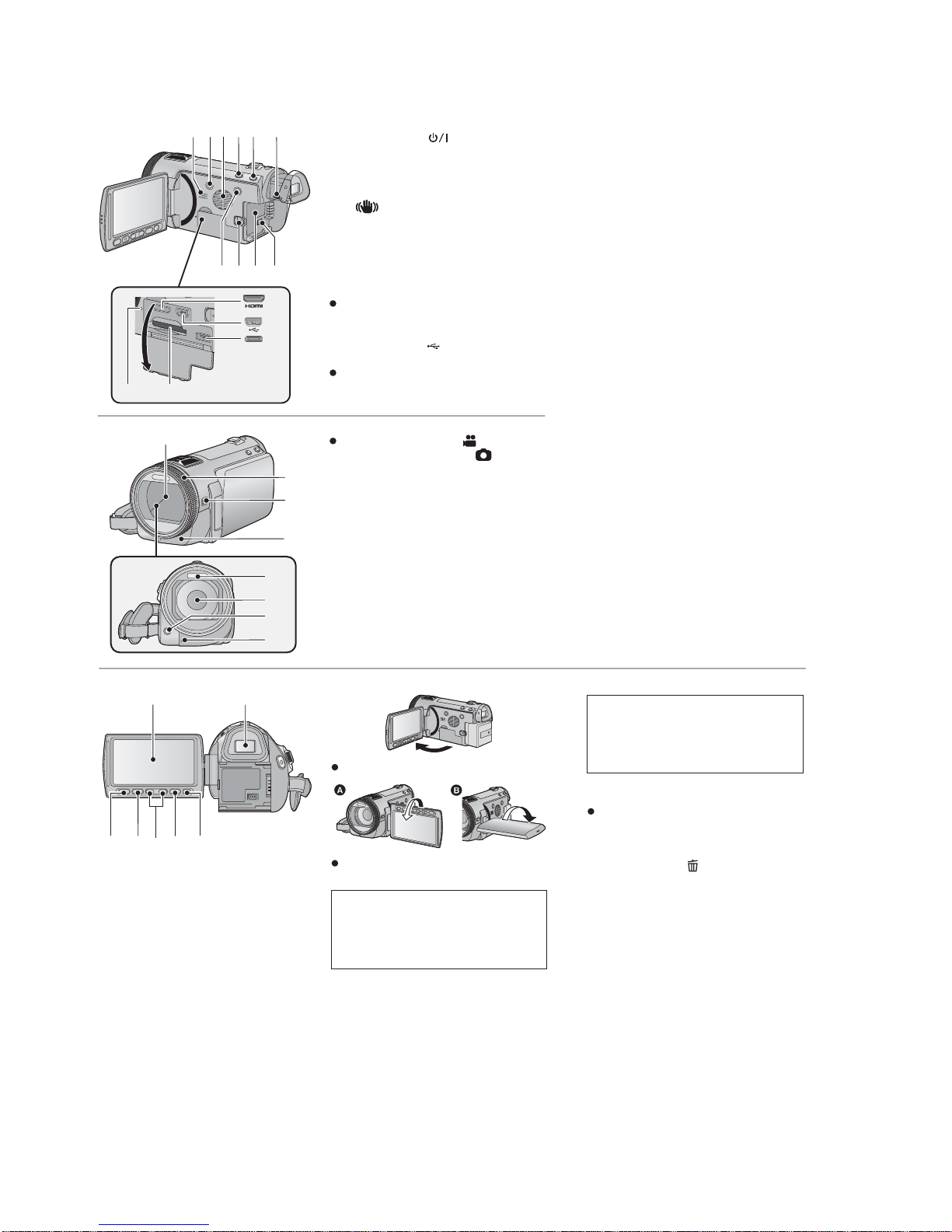

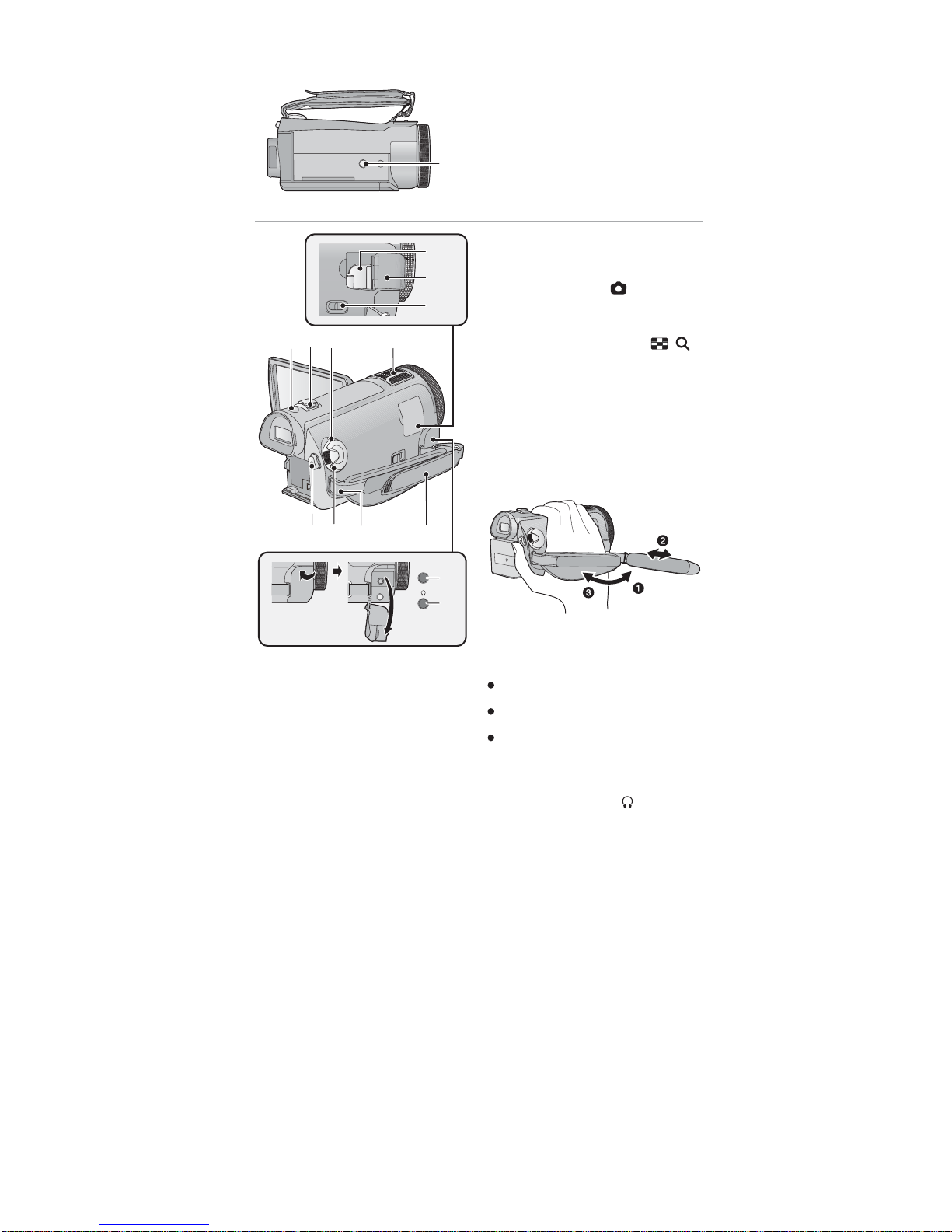

5 Location of Controls and Components

1 Speaker

2 Power button [ ]

3 Inlet (cooling fan)

4 Intelligent auto/Manual button

[iA/MANUAL]

5 Optical image stabilizer button

[ /O.I.S.]

6 Eyepiece corrector dial

7 1080/60p button [1080/60p] (NTSC areas)

8 Battery release lever [BATT]

9 Battery holder

10 DC input terminal [DC IN]

Always use the supplied AC adaptor or a

genuine Panasonic AC adaptor.

11 HDMI mini connector [HDMI]

12 USB terminal [ ]

13 AV multi connector

Use the AV multi cable (only the supplied cable).

14 Card slot

15 Access lamp [ACCESS]

16 Lens cover

The lens cover opens in Motion

Picture Recording Mode or Still

Picture Recording Mode.

17 Multi manual ring

18 Camera function button

[CAMERA FUNCTION]

19 Remote control sensor

20 Built-in flash

21 Lens (LEICA DICOMAR)

22 AF assist lamp

23 Recording lamp

1089

2

3

4

5

6

7

11

12

13

1

1415

16

17

18

19

20

21

22

23

1080/50p button [1080/50p] (PAL areas)

24 LCD monitor (Touch screen)

It can open up to 90Q.

It can rotate up to 180Q towards the lens

or 90Qtowards the viewfinder.

25 Viewfinder

26 Quick menu button [Q.MENU]

27 Sub recording start/stop button

This button functions in the same manner

as the recording start/stop button.

28 Adjust zoom buttons

29 Menu button [MENU]

30 Delete button [ ]

24 25

27

26 28 29 30

Due to limitations in LCD production

technology, there may be some tiny bright

or dark spots on the LCD monitor screen.

However, this is not a malfunction and

does not affect the recorded picture.

Due to limitations in LCD production

technology, there may be some tiny bright

or dark spots on the viewfinder screen.

However, this is not a malfunction and

does not affect the recorded picture.

15

31 Tripod receptacle

31

32 Shoe adaptor mount

33 Shoe adaptor cover

34 Shoe adaptor release lever

[SHOE ADAPTOR RELEASE]

35 Photoshot button [ ]

36 Zoom lever [W/T] (In Motion Picture

Recording Mode or Still Picture

Recording Mode)

Thumbnail display switch [ / ]/

Volume lever [UVOLT] (In Playback

Mode)

37 Status indicator

38 Internal microphones

39 Recording start/stop button

40 Mode dial

41 Shoulder strap fixture

42 Grip belt

Adjust the length of the grip belt so that it fits

your hand.

Flip the belt.

Adjust the length.

Replace the belt.

43 Microphone terminal [MIC]

A compatible plug-in powered microphone

can be used as an external microphone.

Audio will be stereo (2 ch) with the

external microphone input.

When the unit is connected with the AC

adaptor, sometimes noise may be heard

depending on the microphone type. In this

case, please switch to the battery for the

power supply and the noise will stop.

44 Headphone terminal [ ]

MIC

32

33

34

383635

39 40 41 42

43

44

37

16

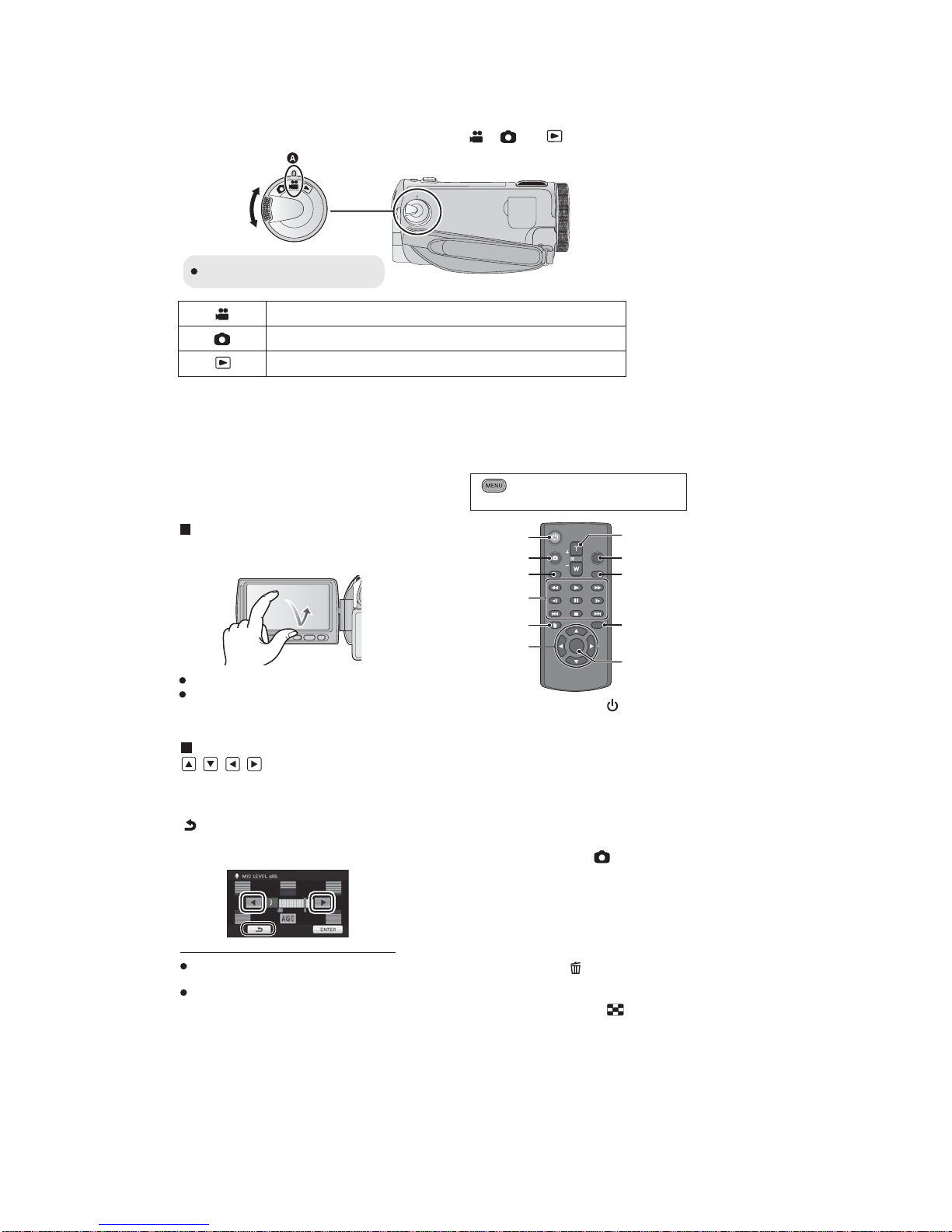

Selecting a mode

Change the mode to recording or playback.

Operate the mode dial to change the mode to , or .

Motion Picture Recording Mode

Still Picture Recording Mode

Playback Mode

Align with the status indicator .

How to use the touch

screen

You can operate by directly touching the

LCD monitor (touch screen) with your finger.

It is easier to use the stylus pen (supplied)

for detailed operation or if it is hard to

operate with your fingers.

Touch

Touch and release the touch screen to select

icon or picture.

Touch the center of the icon.

Touching the touch screen will not operate

while you are touching another part of the

touch screen.

About the operation icons

///:

These icons are used to switch the menu

and thumbnail display page, for item

selection and setting etc.

:

Touch to return to the previous screen

such as when setting menus.

Do not touch on the LCD monitor with

hard pointed tips, such as ball point pens.

Perform the touch screen calibration when

the touch is not recognized or wrong

location is recognized.

Using with the remote

control

Select the menu.

1 Power on/off button [ ]

Power can be turned on/off when the LCD

monitor is opened or the viewfinder is

extended.

●

Power cannot be turned on by the power

on/off button when 36 hours have passed

after the power is turned off. Press the

power button on the unit and turn the

power back on.

●

Power cannot be turned off when it is

connected to the PC or the DVD burner.

2 Photoshot button [ ]

*

3 On-screen display button

[EXT DISPLAY]

4 Playback operation buttons

These buttons function in the same manner

as the

corresponding playback operation

icon being displayed on screen.

[Excluding skip playback.]

5 Delete button [ ]

*

6 Direction buttons [,,,]

7 Zoom/volume/thumbnail display

switch buttons [T, W, /VOL]*

8 Recording start/stop button [START/STOP]

*

9 Date/time button [DATE/TIME]

:

[SETUP]

[REMOTE CONTROL]

[ON]

SEARCH

STILL ADV STILL ADV

SEARCH

/VOL

DATE/TIME

START/

STOP

EXT DISPLAY

PLAY

STOP

OK

SKIP SKIP

MENU

PAUSE

2

3

4

6

5

8

7

9

10

11

1

10 Menu button [MENU]

*

11 OK button [OK]

* means that these buttons function in the

same manner as the corresponding

buttons on the unit.

17

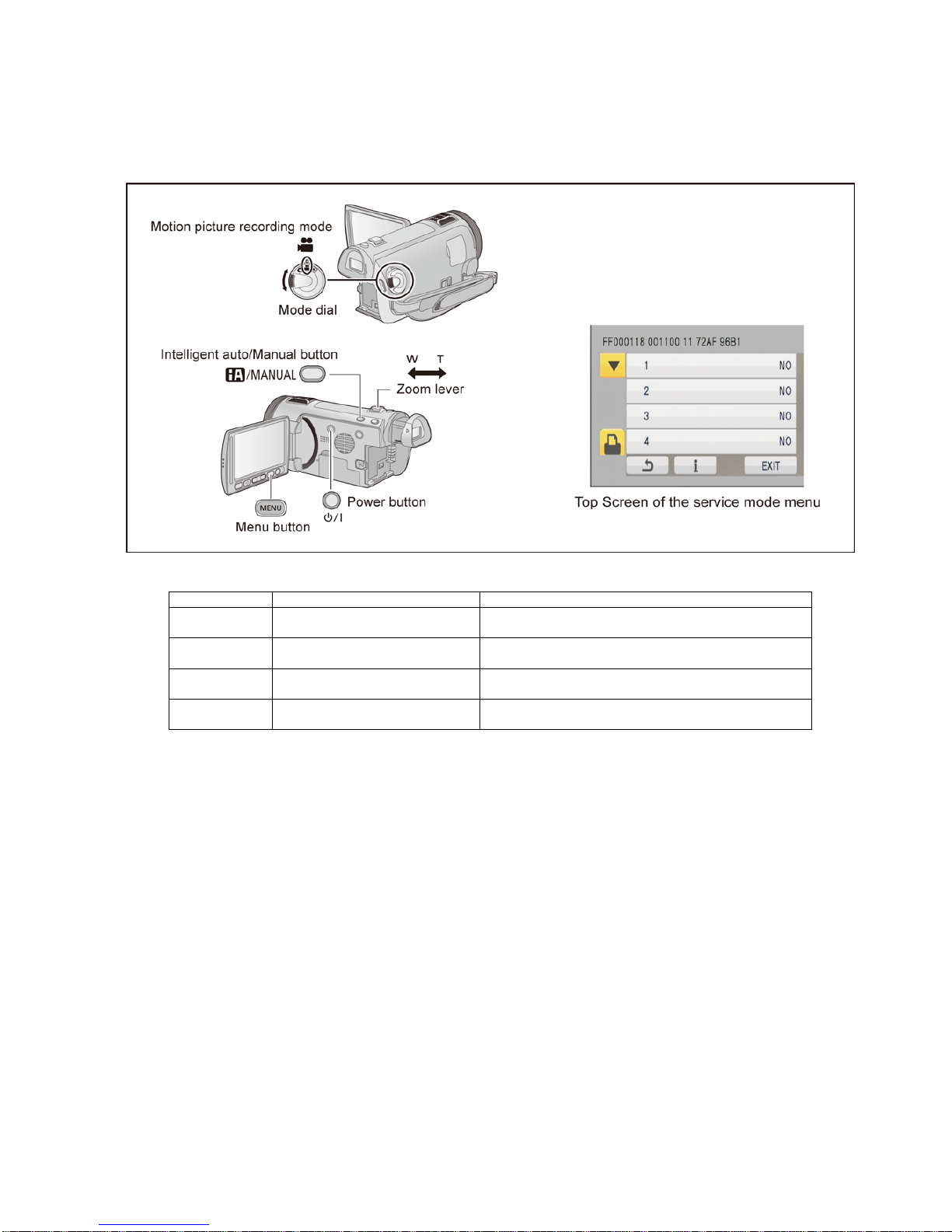

6 Service Mode

1. Indication method of the service menu

Set the mode dial “Motion Picture Recording” mode.

2. Turn the power on, and then while keep pressing the “Zoom lever” to W side, “Intelligent auto/Manual” button and “Menu” button for more than 3 seconds until the top screen of the Service Mode Menu being displayed.

Service mode menu

NOTE:

Do not using service mode except above table of Service mode menu.

3. End method of the top screen of the service mode menu

Push the “Menu” button to end the service mode, and then POWER OFF.

Screen display Contents Function

1 Factory settings Function to throw a product up in a factory shipment state

(When recorded data in Built-in memory, “error display” is done)

3 Built-in memory self check execution

(HDC-TM700 only)

Function to check self as for the state of Built-in memory

4 Lock search history indication Display the camera system error cord for three histories saved

in EEPROM

5 Power ON self check result display Power ON self check (function to diagnose correct function of

the device and interface between devices) result display

18

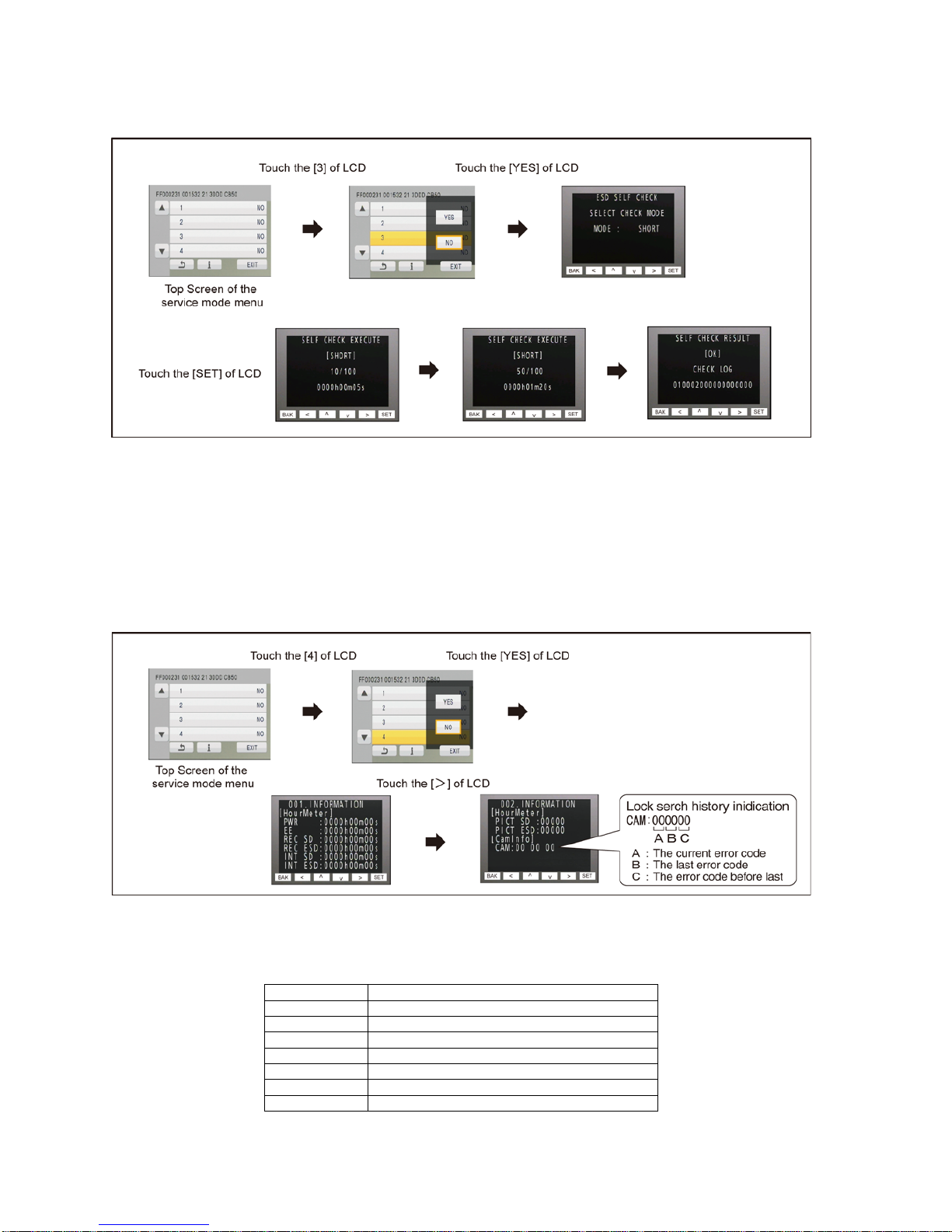

6.1. Built-in Memory Self Check Execution (HDC-TM700 only)

Touch the [ 3 ] of LCD, select Built-in memory self check execution.

Operation specifications

Indication contents

• Built-in memory self check result display

Display the Built-in memory self check execution.

Displays other than “OK” are abnormalities of Built-in memory.

Push the “Menu” button to end the service mode, and then POWER OFF.

6.2. Lock Search History Indication

Touc h the [ 4 ] of LCD, select Lock search history indication.

Operation specifications

Indication contents

• Lock search history indication

Display the camera system error cord for three histories saved in EEPROM.

• The error cord contents which are displayed

Push the “Menu” button to end the service mode, and then POWER OFF.

Error code Function

51 Focus control is abnormal

52 Zoom control is abnormal

53 OIS lens control is abnormal

71 Lens cover open/close is abnormal

72 Cooling fan is abnormal

73 High temperature is abnormal

33 Communication between camera to ARM is abnormal

19

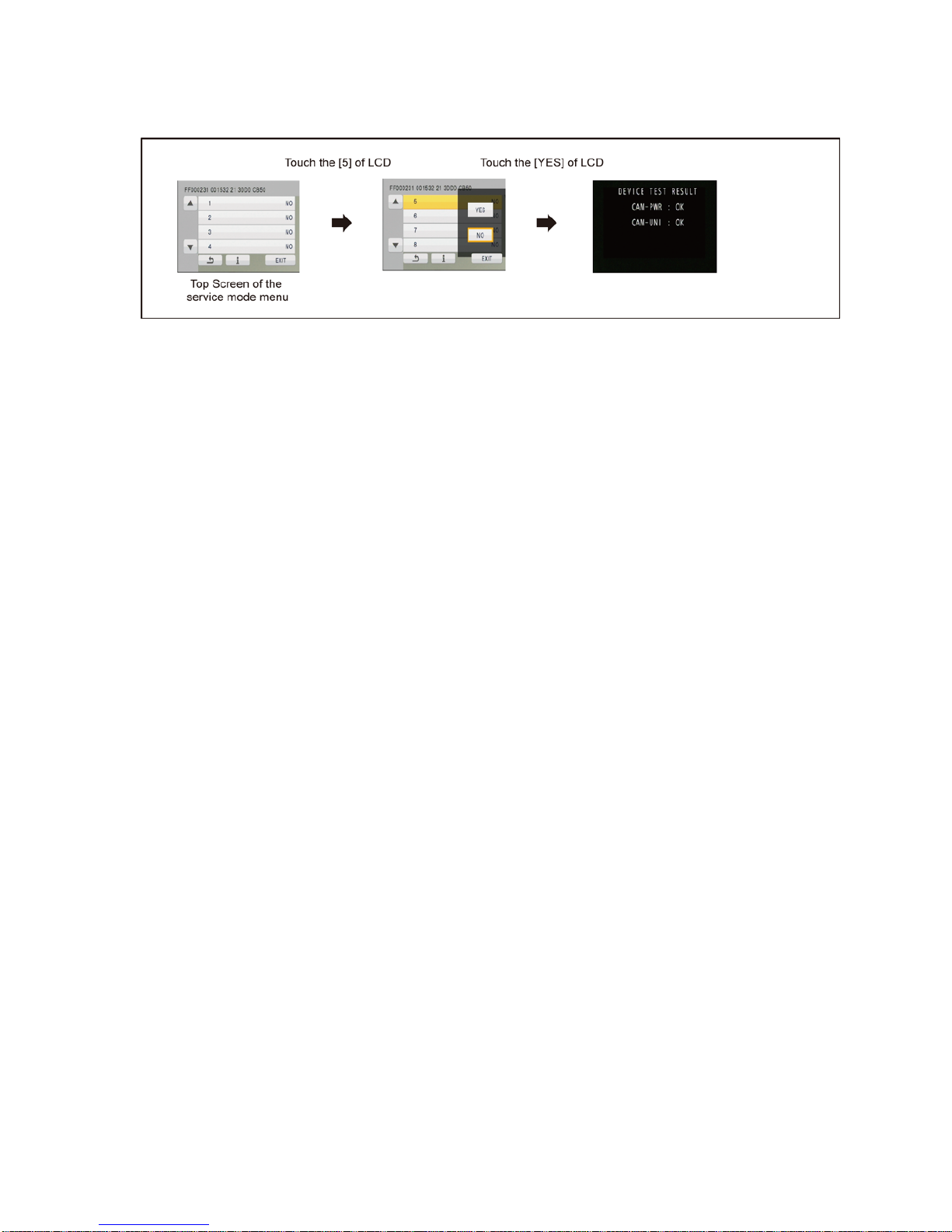

6.3. Power ON Self Check Result Display

Touch the [ 5 ] of LCD, select Power ON self check result display.

Operation specifications

Indication contents

• Power ON self check result display

Function to diagnose correct function of the device and interface between devices result display.

Display the following commnucation test result.

- CAM-PWR : Commnucation test between IC2006 to IC301

- CAM-UNI : Commnucation test between IC3401 to IC301

Display other than “OK” are abnomalities of each lines.

Cutting of battery connection or AC power supply connection to end the service mode.

20

7 Service Fixture & Tools

7.1. When Replacing the Main P.C.B.

After replacing the MAIN P.C.B., be sure to achieve adjustment.

The adjustment instruction is available at “software download” on th e “Support Information from NWBG/VDBG-AVC” web-site in

“TSN system”, together with Maintenance software.

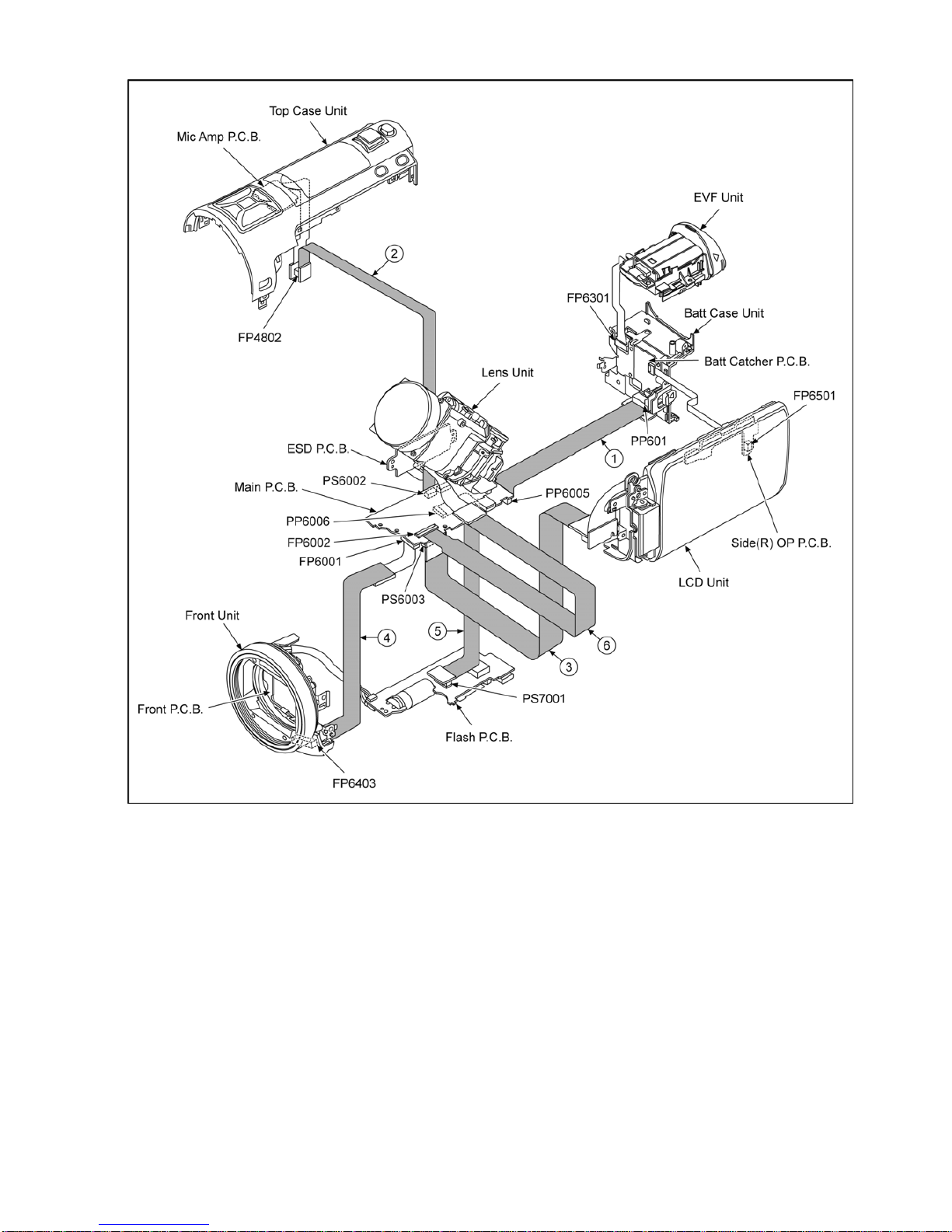

7.2. Service Position

This Service Position is used for checking and replacing parts. Use the following Extension cables for servicing.

Table S1 Extension Cable List

No. Parts No. Connection Form

1 RFKZ0444 PP6005(MAIN) - PP601(BATT CATCHER) 50PIN 0.5 B to B

2 RFKZ0342 PS6002(MAIN) - FP4802(MIC AMP) 20PIN 0.5 B to B

3 VFK1933 PS6003(MAIN) - MONITOR FPC 34PIN 0.5 B to B

4 VFK1950 FP6001(MAIN) - FP6403(FRONT) 33PIN 0.3 FFC

5 RFKZ0343 PP6006(MAIN) - PS7001(FLASH) 30PIN 0.5 B to B

6 RFKZ0416 FP6002(MAIN) - LENS UNIT 41PIN 0.3 FFC

21

CAUTION-1. (When servicing FLASH P.C.B.)

1. Be sure to discharge the capacitor on FLASH P.C.B..

Refer to “HOW TO DISCHARGE THE CAPACITOR ON FLASH P.C.B.”.

The capacitor voltage is not lowered soon even if the AC Cord is unplugged or the battery is removed.

2. Be careful of the high voltage circuit on FLASH P.C.B..

3. DO NOT allow other parts to touch the high voltage circuit on FLASH P.C.B..

22

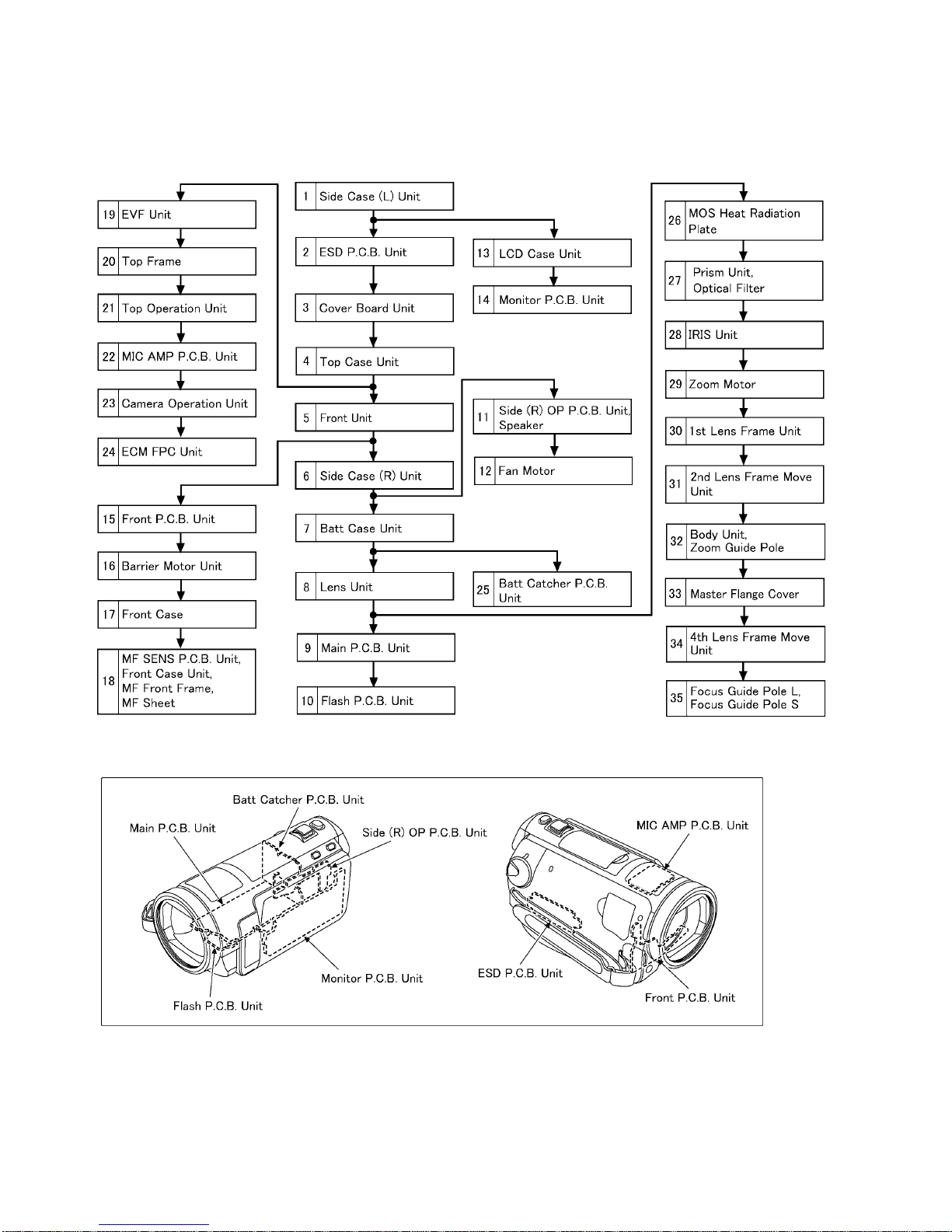

8 Disassembly and Assembly Instructions

8.1. Disassembly Flow Chart

This is a disassembling chart.

When assembling, perform this chart conversely.

8.2. PCB Location

23

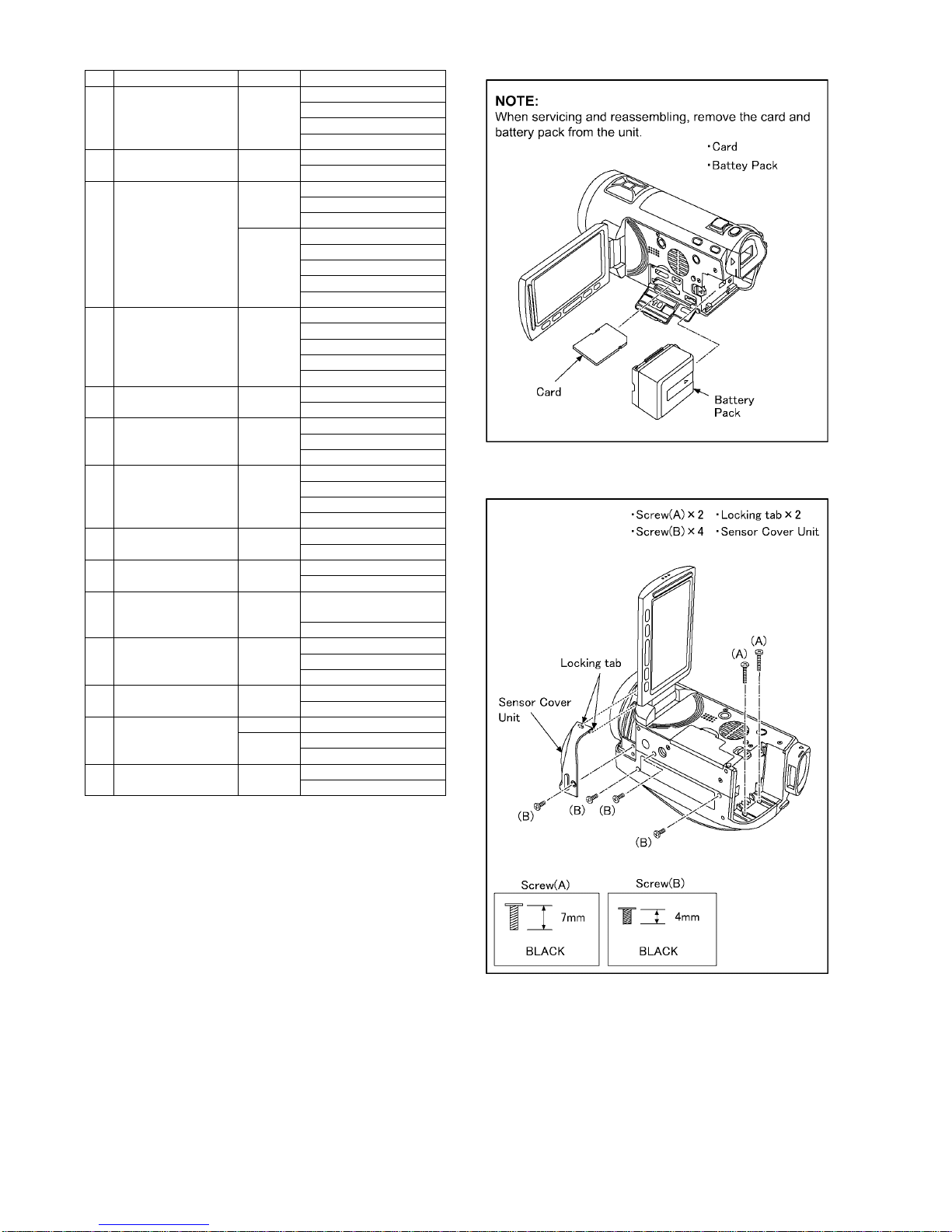

8.3. Disassembly Procedure

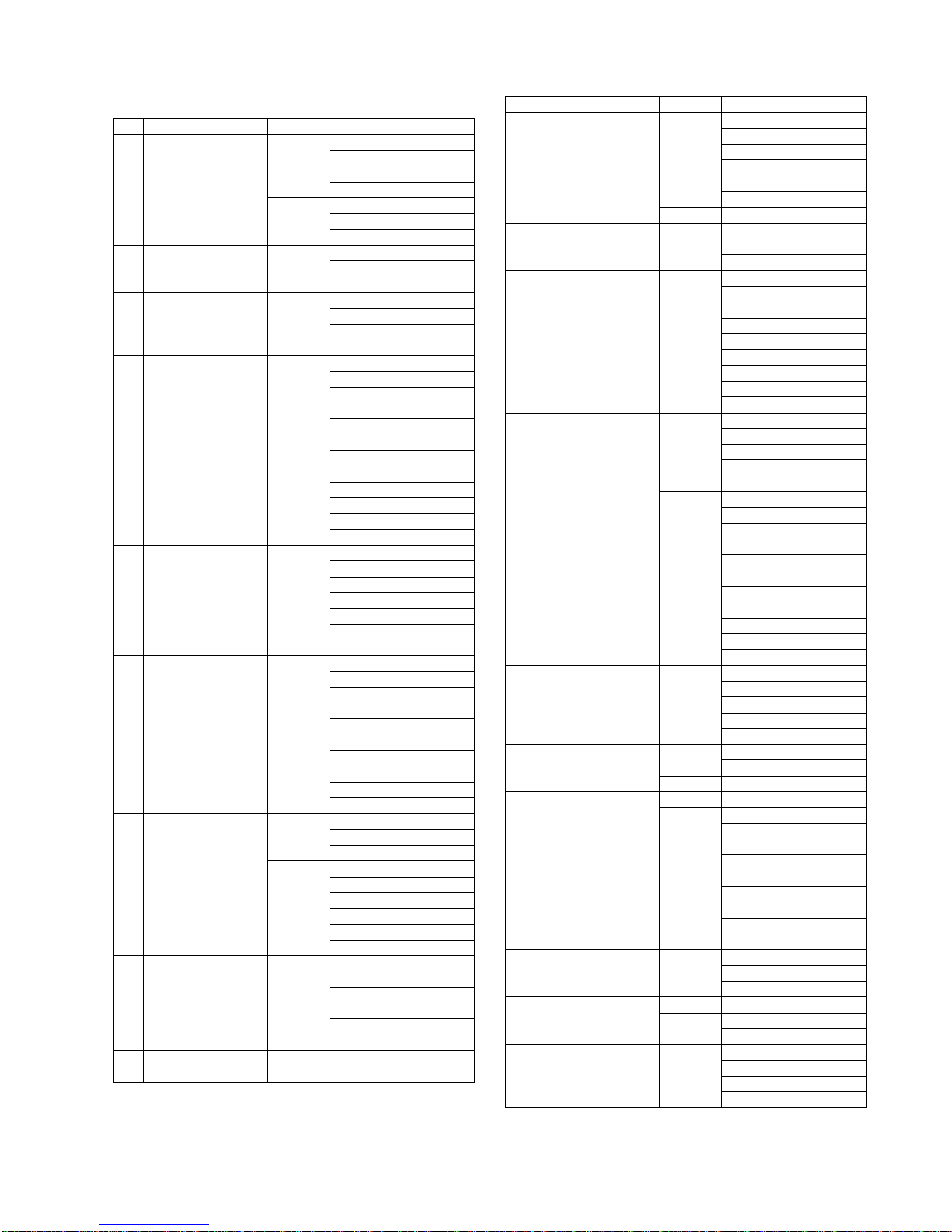

No. Item Fig Removal

1 Side Case (L) Unit Fig.D1 2 Screws (A)

4 Screws (B)

2 Locking tabs

Sensor Cover Unit

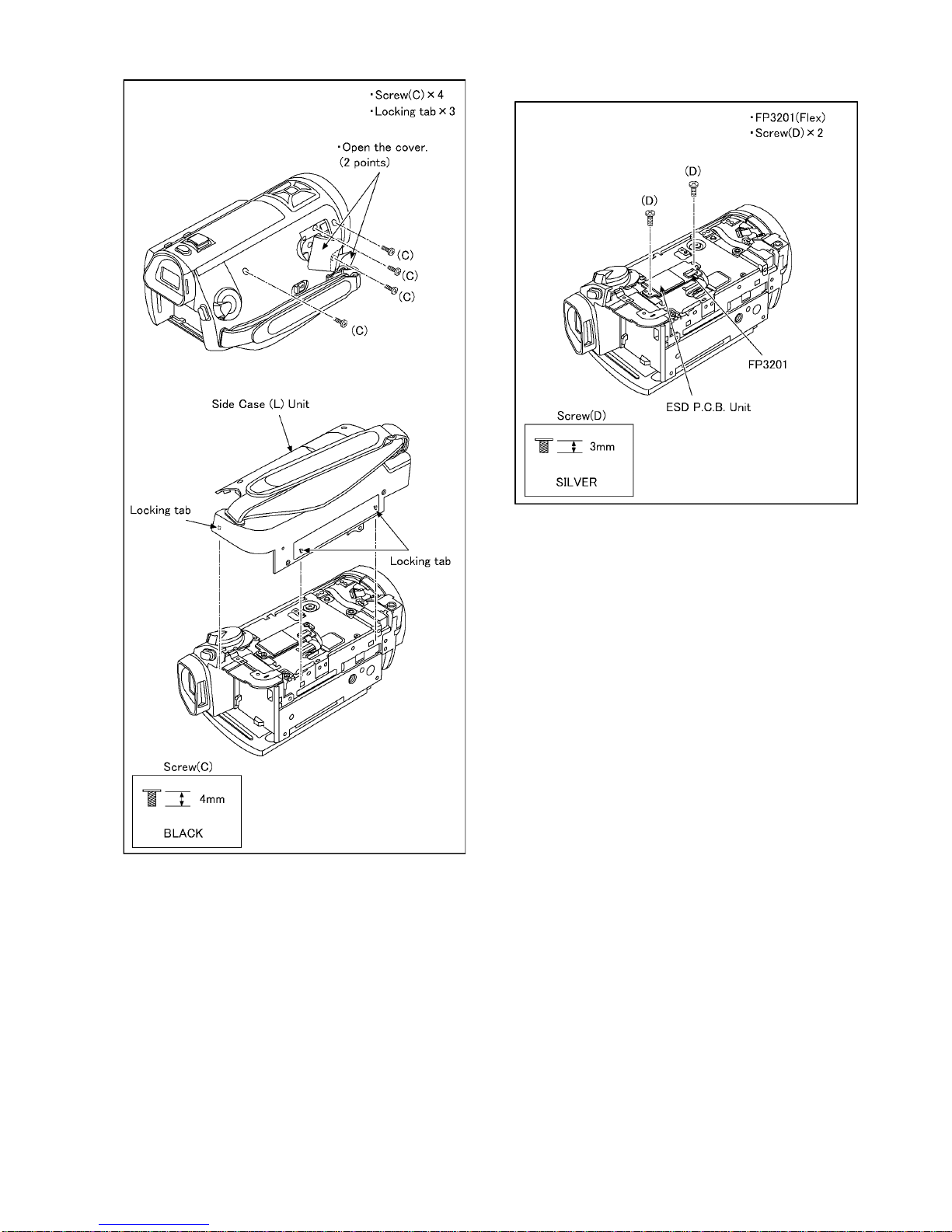

Fig.D2 4 Screws (C)

3 Locking tabs

Side Case (L) Unit

2 ESD P.C.B. Unit Fig.D3 FP3201 (Flex)

2 Screws (D)

ESD P.C.B. Unit

3 Cover Board Unit Fig.D4 1 Screw (E)

2 Screws (F)

1 Rib

Cover Board Unit

4 Top Case Unit Fig.D5 2 Screws (G)

1 Screw (H)

1 Screw (I)

1 Screw (J)

2 Locking tabs

1 Rib

SR Cover

Fig.D6 PS6002 (Connector)

1 Rib

1 Locking tab

FP6301 (Flex)

Top Case Unit

5 Front Unit Fig.D7 P7001 (Connector)

P7002 (Connector)

1 Screw (K)

1 Rib

1 Locking tab

FP6403 (Flex)

Front Unit

6 Side Case (R) Unit Fig.D8 4 Screws (L)

1 Screw (M)

PS6005 (Connector)

FP6501 (Flex)

Side Case (R) Unit

7 Batt Case Unit Fig.D9 1 Screw (N)

1 Screw (O)

2 Ribs

PP6005 (Connector)

Batt Case Unit

8 Lens Unit Fig.D10 2 Screws (P)

1 Rib

2 Projection parts

Fig.D11 PP6004 (Connector)

PP6007 (Connector)

FP6002 (Flex)

1 Screw (Q)

Lens Frame Unit

Lens Unit

9 Main P.C.B. Unit Fig.D12 3 Screws (R)

2 Ribs

Main Heat Radiation Plate

Fig.D13 PP6006 (Connector)

1 Projection part

Main P.C.B. Unit

10 Flash P.C.B. Unit Fig.D14 2 Screws (S)

1 Projection part

11 Side (R) OP P.C.B.

Unit

Speaker

Fig.D15 2 Screws (T)

SP Angle

PS6501 (Connector)

P6501 (Connector)

Speaker

Side (R) OP P.C.B. Unit

Fig.D16 NOTE: (When Installing)

12 Fan Motor Fig.D17 3 Convexes

Fan Damper

Fan Motor

13 LCD Case Unit Fig.D18 2 Screws (U)

Holder

Switch Unit

3 Locking tabs

Earth Plate

Sheet

Light Guide Plate

3 Ribs

LCD Case Unit

14 Monitor P.C.B. Unit Fig.D19 FP904 (Flex)

FP905 (Flex)

2 Ribs

2 Convexes

LCD Frame

Fig.D20 FP903 (Flex)

4 Locking tabs

Monitor P.C.B. Unit

Fig.D21 1 Locking tab

Reflection Sheet

Light Guide Plate

Diffusion Sheet

Prism Sheet B

Prism Sheet A

Lighting Plate Holder

Monitor P.C.B. Unit

15 Front P.C.B. Unit Fig.D22 1 Screw (V)

1 Screw (W)

FP6400 (Flex)

FP6402 (Flex)

Front P.C.B. Unit

16 Barrier Motor Unit Fig.D23 1 Screw (X)

Barrier Motor Unit

Fig.D24 NOTE: (When Installing)

17 Front Case Fig.D25 Lens Ornament Sheet

Fig.D26 4 Screws (Y)

Front Case

18 MF SENS P.C.B. Unit

Front Case Unit

MF Front Frame

MF Sheet

Fig.D27 1 Screw (Z)

MF P.C.B. Holder

MF SENS P.C.B. Unit

Front Case Unit

MF Front Frame

MF Sheet

Fig.D28 NOTE: (When Replacing)

19 EVF Unit Fig.D29 2 Screws (a)

1 Screw (b)

EVF Unit

20 Top Frame Fig.D30 4 Screws (c)

Fig.D31 1 Locking tab

Top Frame

21 Top Operation Unit Fig.D32 4 Screws (e)

FP4803 (Flex)

2 Ribs

Top Operation Unit

No. Item Fig Removal

24

8.3.1. Removal of the Side Case (L) Unit

Fig.D1

22 MIC AMP P.C.B. Unit Fig.D33 FP4801 (Flex)

FP4804 (Flex)

2 Hooks

MIC AMP P.C.B. Unit

23 Camera Operation Unit Fig.D34 2 Locking tabs

Camera Operation Unit

24 ECM FPC Unit Fig.D35 4 Locking tabs

MIC Sheet

MIC Unit

Fig.D36 MIC Cushion (A)

MIC Cushion (B)

MIC Cushion (C)

MIC Case

ECM FPC Unit

25 Batt Catcher P.C.B.

Unit

Fig.D37 2 Screws (f)

2 Locking tabs

Rear Frame

2 Locking tabs

Batt Catcher P.C.B. Unit

26 MOS Heat Radiation

Plate

Fig.D38 1 Screw (g)

MOS Heat Radiation Plate

27 Prism Unit

Optical Filter

Fig.D39 2 Screws (h)

Prism Unit

Optical Filter

28 IRIS Unit Fig.D40 18 Solders

3 Screws (i)

3 Ribs

IRIS Unit

29 Zoom Motor Fig.D41 2 Screws (j)

Zoom Motor

30 1st Lens Frame Unit Fig.D42 3 Screws (k)

1st Lens Frame Unit

31 2nd Lens Frame Move

Unit

Fig.D43 2nd Lens Frame Move Unit

Spring

2nd Lens Frame Move Unit

32 Body Unit

Zoom Guide Pole

Fig.D44 3 Screws (l)

Body Unit

2 Zoom Guide Poles

33 Master Flange Cover Fig.D45 2 Screws (m)

Master Flange Cover

34 4th Lens Frame Move

Unit

Fig.D46 2 Side Yorks

Fig.D47 3 Ribs

4th Lens Frame Move Unit

35 Focus Guide Pole L

Focus Guide Pole S

Fig.D48 Focus Guide Pole L

Focus Guide Pole S

No. Item Fig Removal

25

Fig.D2

8.3.2. Removal of the ESD P.C.B. Unit

Fig.D3

Loading...

Loading...