Page 1

FX-301

08/2005

Digital Fiber Sensor

http://www.fiber-sensor.com

* UL 61010C-1 compatible, Passed the UL 991 Environment Test based on SEMI S2-0200.

[Category applicable for semiconductor manufacturing: TWW2, Process Equipment]

[Applicable standards: UL 61010C-1]

[Additional test / evaluation standards as per intended use: UL 991, SEMI S2-0200]

SERIES

Superior performance and

advanced user-friendly

multi-functionality

enables expert usage on

the very first day

* Passed the UL 991 Environment Test

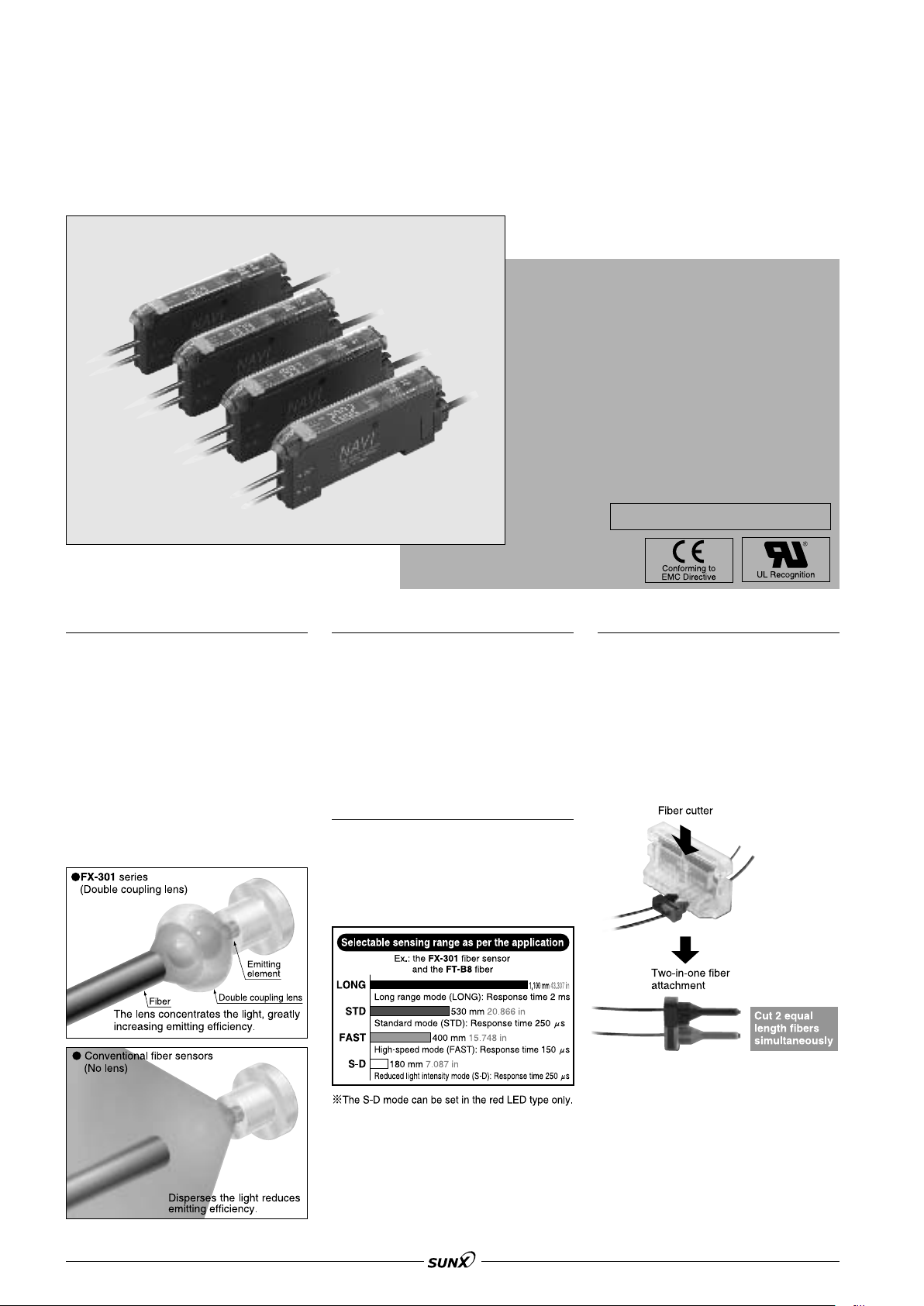

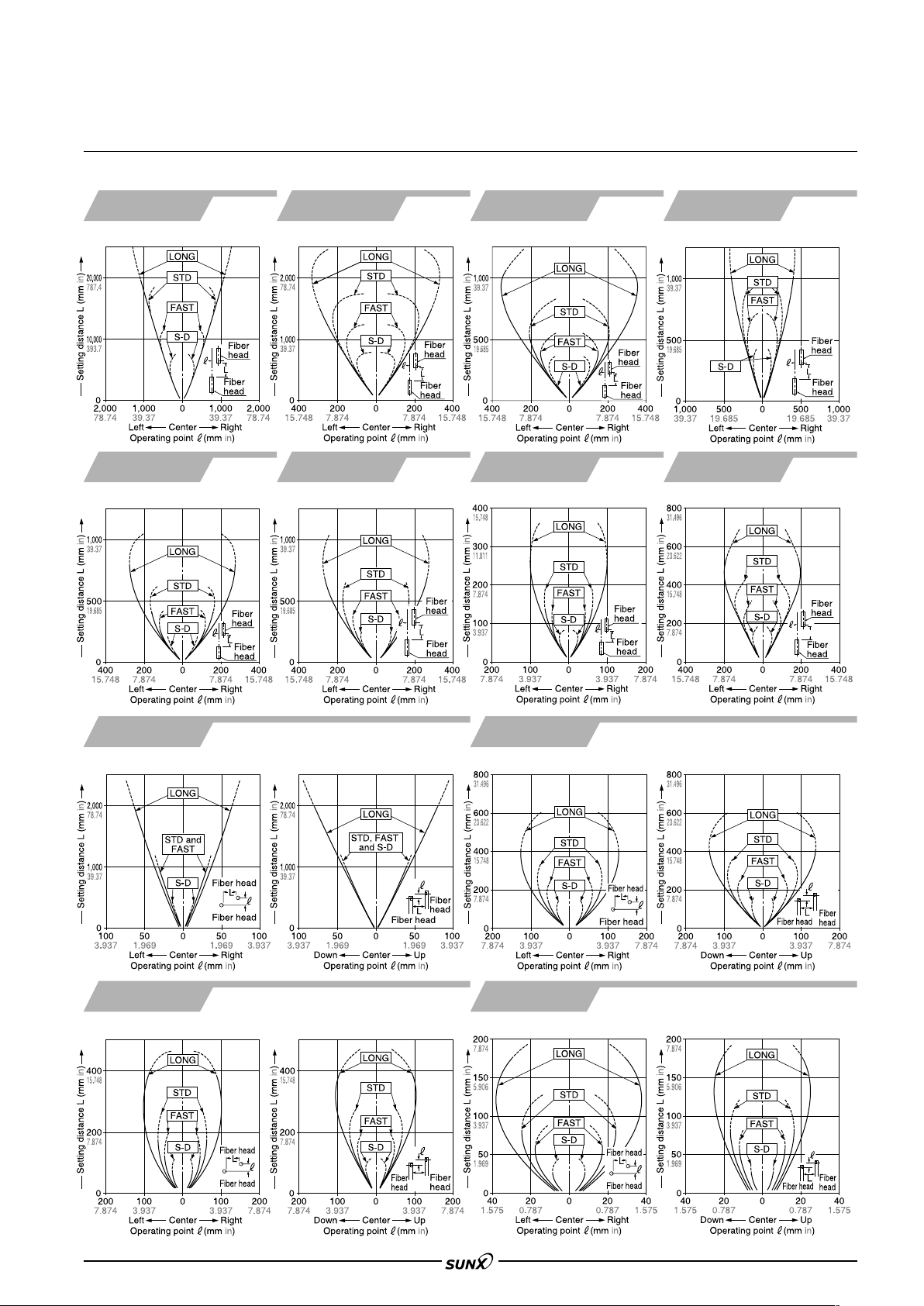

Long-range sensing made possible with built-in optical lens

For the first time in the industry, an

optical ‘double coupling lens’ has been

incorporated directly into the fiber

sensor itself. This lens maximizes the

light emission efficiency, resulting in a

tremendous improvement in the

sensing range. Sensing ranges with

small diameter fibers and ultra-small

diameter fibers, which have become

very popular in recent years due to the

miniaturization of chip components,

have been increased by 50 % over

previous values achieved with other

amplifiers.

Stable long-term sensing

The newly developed four-chemical

emitting element that uses the FX-301

(red LED type) suppresses changes

over long periods of time as much as

possible, so that a stable light emitting

level is maintained. There is very little

element deterioration so that stable

and accurate sensing can be

maintained over long periods.

Selectable response time

We offer 4 selectable levels to

correspond with various applications:

the response time 150 !s FAST mode,

the LONG mode, perfect for adverse

environments, and the S-D mode,

especially made for minute detection.

Enhanced worksite-friendly installability

Our new fiber cutter utilizes a specially

developed two-in-one fiber attachment

that now makes it possible to cut two

fibers simultaneously to exactly the

same length. Also, since the fibers can

be attached to the amplifier while

being fixed in position in the two-in-one

fiber attachment, sensitivity changes

due to variation in the amount of fiber

insertion do not occur.

68

Page 2

FX-301

08/2005

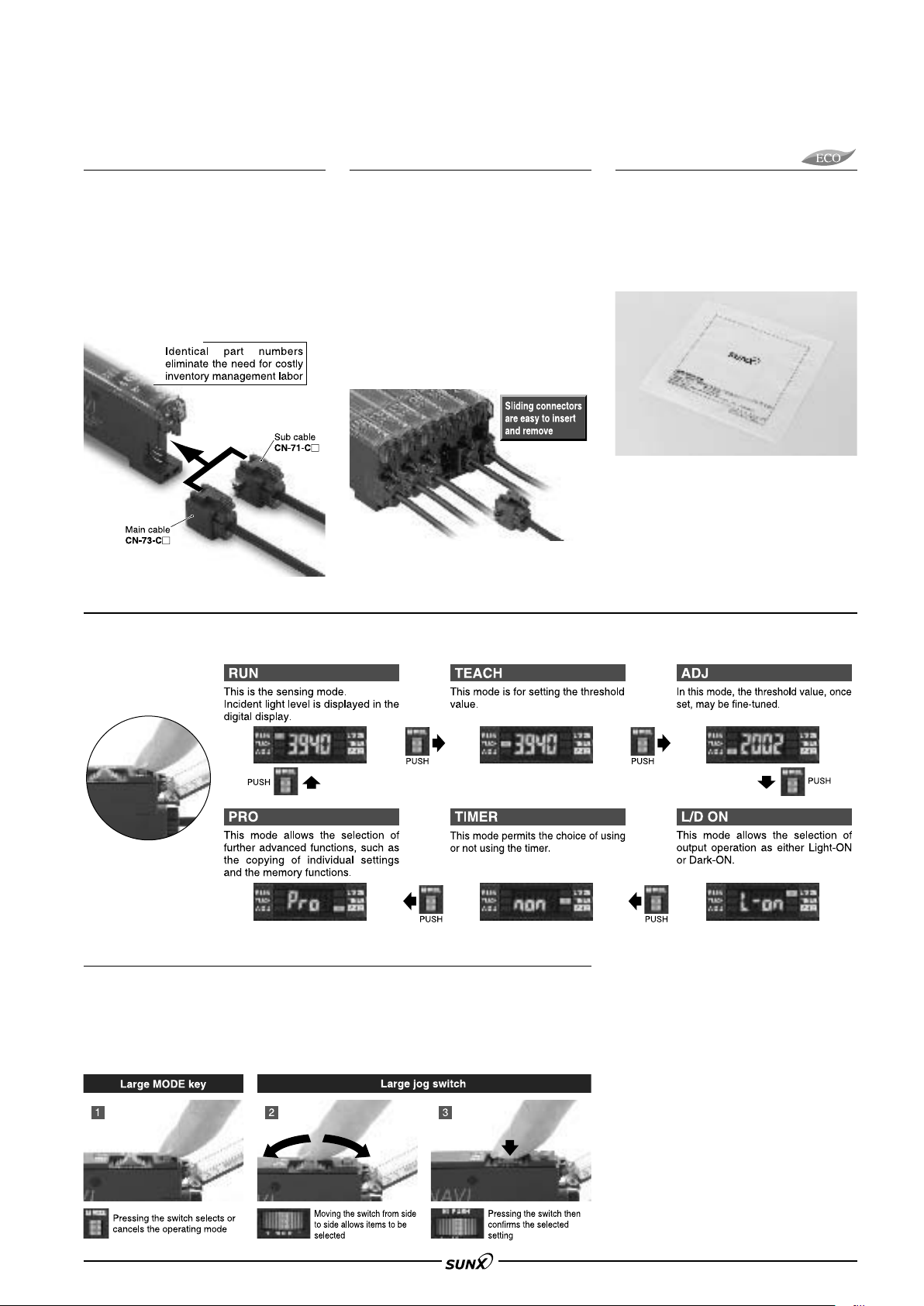

Easy maintenance, as main

and sub units are identical

Both main and sub units utilize the same

amplifier body. This feature allows for

easy mounting in the side-by-side

configuration. The main and sub unit

functions are distinguished only by the

proper use of 3-core main cable and the

1-core sub cable. Moreover, by utilizing

the same body for both main and sub

units, inventory management and

maintenance is simplified.

Wiring- and labor-saving design allows sideby-side configuration for up to sixteen units

Up to sixteen amplifiers can be

connected in a side-by-side configuration.

As the sub cable contains only one output

line, a great amount of wiring and space

can be saved. Also, special ‘sliding’

connectors have been provided for all

main and sub cables, which can be

detached merely by releasing the lock

and pulling directly back, without having

to slide the amplifier body to the side.

Using this connector system, only a

minimal amount of space is required for

regular maintenance.

Environmentally friendly packaging

With regard to effects on the environment,

we only utilize the simplest of packaging

methods greatly contributing to the reduction

in wastes generated by your worksite.

Also, the bags are made of polyethylene, a

substance that doesn’t give off polluting

gases when burned.

Polyethylene packaging

Even beginners can quickly learn how to use the MODE NAVI

MODE NAVI uses six indicators to display the amplifier’s basic operations. The current operating mode can be confirmed at a

glance, so even a first time user can easily operate the amplifier without becoming confused.

The use of only two switches makes for very simple operations

Only two switches, the large jog switch and the large MODE key, are required for

operation. Depressing the large MODE key sets the ‘mode selection’ and ‘mode

cancel’ functions. The large jog switch is used to select from the detailed functions

available within each mode, as well as to change numerical values after the mode

has been chosen.

69

Page 3

FX-301

08/2005

4 types of light sources available

In addition to our red LED (four-chemical

emitting element) type, the blue, green,

and infrared LED types are also provided

to correspond to your specific application.

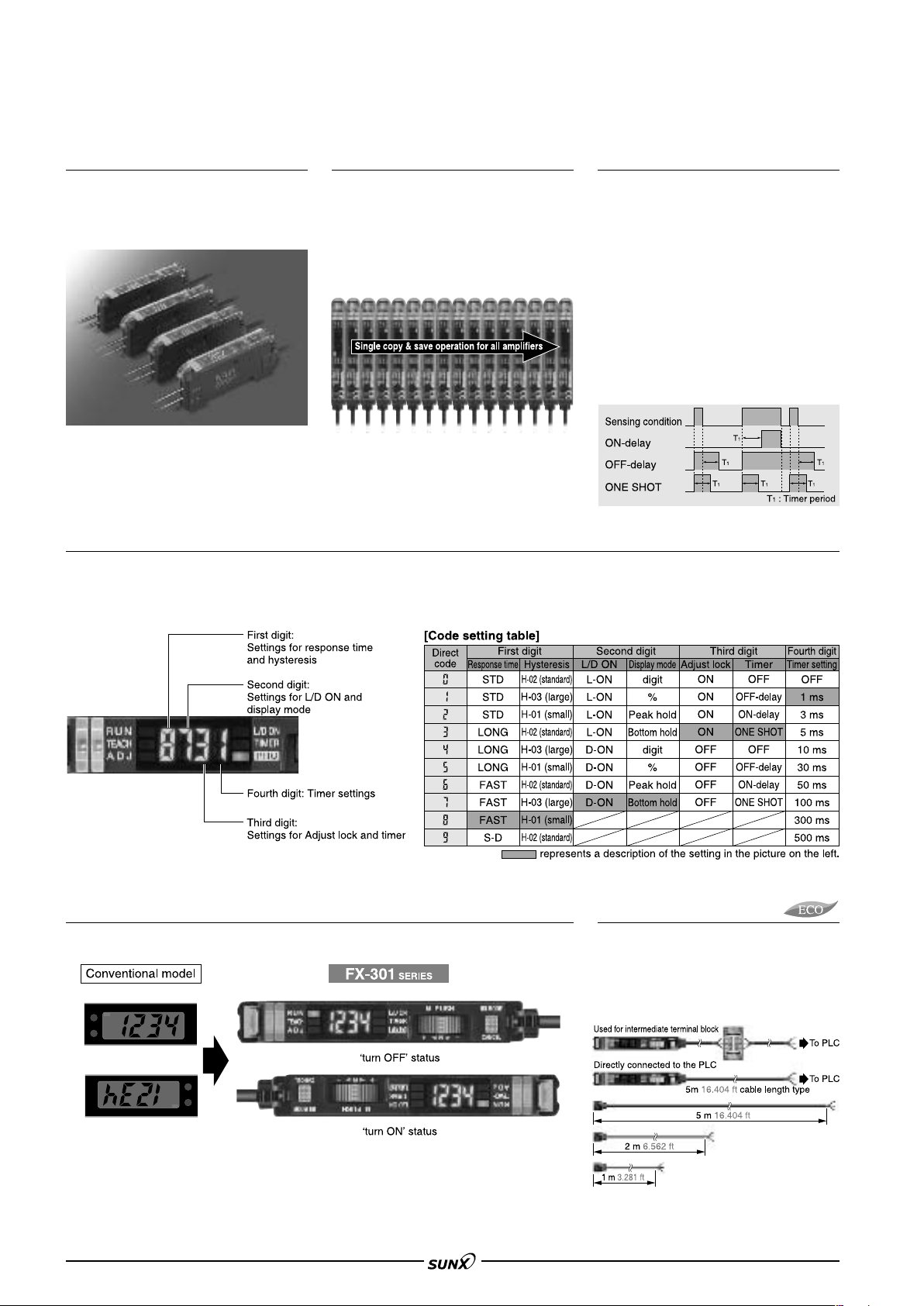

Optical communication function lets

multiple sensors be adjusted all at once

The optical communication function

allows the data that is currently set to

be copied and saved all at once for all

amplifiers connected together from the

right side. This greatly reduces

troublesome setup tasks and makes

setup much smoother.

Equipped with each type of timer

These sensors are equipped with 3

types of timers, ON-delay, OFF-delay,

and ONE SHOT, for compatibility to

variegated environments.

ON-delay timer

This function is useful for sensing only

objects taking a long time travel.

OFF-delay timer

This function is useful when the

connected device has a slow response

time.

ONE SHOT timer

This function is useful when the input

specifications of the connected device

require a signal of fixed width.

Easy code input setting

Every function can be directly set merely by the input of a four digit code (numbers) from the code table. This convenient

feature is easy to set up.

In the event that settings are accidentally changed at the operating site, merely entering the correct code can restore the

original settings. This results in easy and quick maintenance.

Invertible digital display

The digital display can be inverted as per its orientation once mounted onto the amplifier.

Selectable cable length

Made available are 3 lengths, 1 m 3.281 ft,

2 m 6.562 ft, and 5 m 16.404 ft, to suit

your application requirements. This helps

reduce the waste caused by cutting cables

and lightens the installation workload.

70

Page 4

FX-301

08/2005

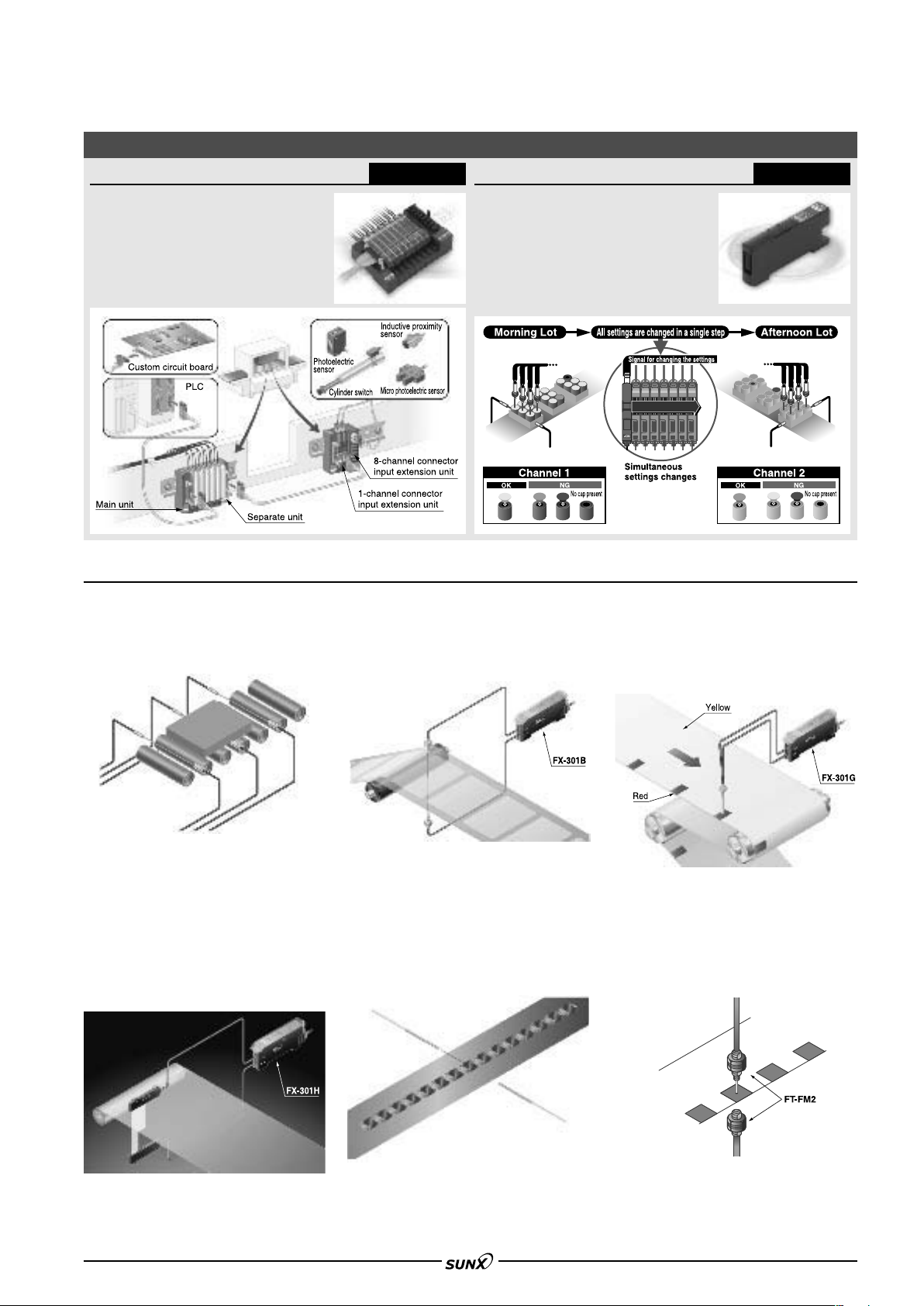

Optional units for greater freedom and control when installing

Sensor-PLC connection system

This wire-saving system enables the

collective connection of up to 16 I/O

devices with an MIL connector.

Scattered installation is also possible

with the help of a sensor separate

unit.

APPLICATIONS

Workpieces detection

This standard type of FX-301 using red light

has a four-chemical emitting element for

stable sensing over long periods.

SC

SERIES

Bank selection unit

Without directly manipulating the

sensor itself, you can simultaneously

switch up to 16 fiber sensors’ settings

using an external emitted signal.

(Load and save)

mAlso possible with the FX-301 series’ databank

function

Sensing semi-transparent stickers

The blue LED type greatly reduces the

dampening rate, making it ideal for delicate

sensing.

FX-CH

SERIES

Sensing register marks

The green LED type can accurately

discriminate between red and yellow, that

cannot be easily detected using red LED

type.

Sensing film meandering

Infrared LED type is ideal for sensing

environments with light restrictions, such as

places where light-sensitive film is being

handled. (The emission peak wavelength:

940 nm 0.037 mil.) It includes full-auto

teaching function which allows sensitivity to

be set without stopping the workpiece line.

Detecting chip component

Because of low light intensity fluctuations

when detecting minute moving objects,

decrease the hysteresis in PRO mode and

accurate sensing will be possible in highspeed mode. This method is optimal for chip

component verification in taping equipment.

Detecting register marks on a

transparent sheet

When detecting registration marks on

transparent film with a thru-beam type, the

S-D (reduced light intensity) mode will

enable minute light intensity fluctuation

sensing.

71

Page 5

FX-301

08/2005

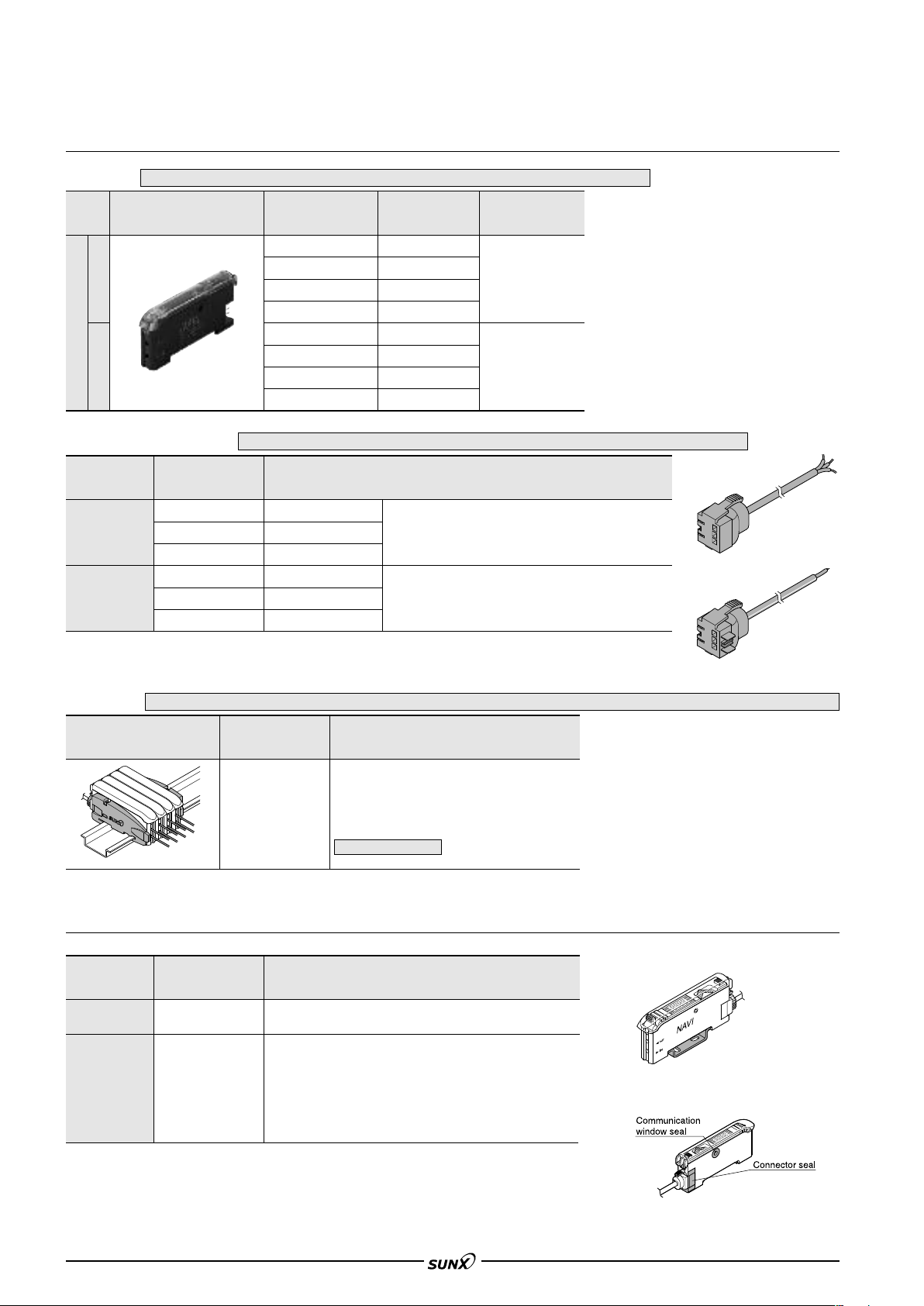

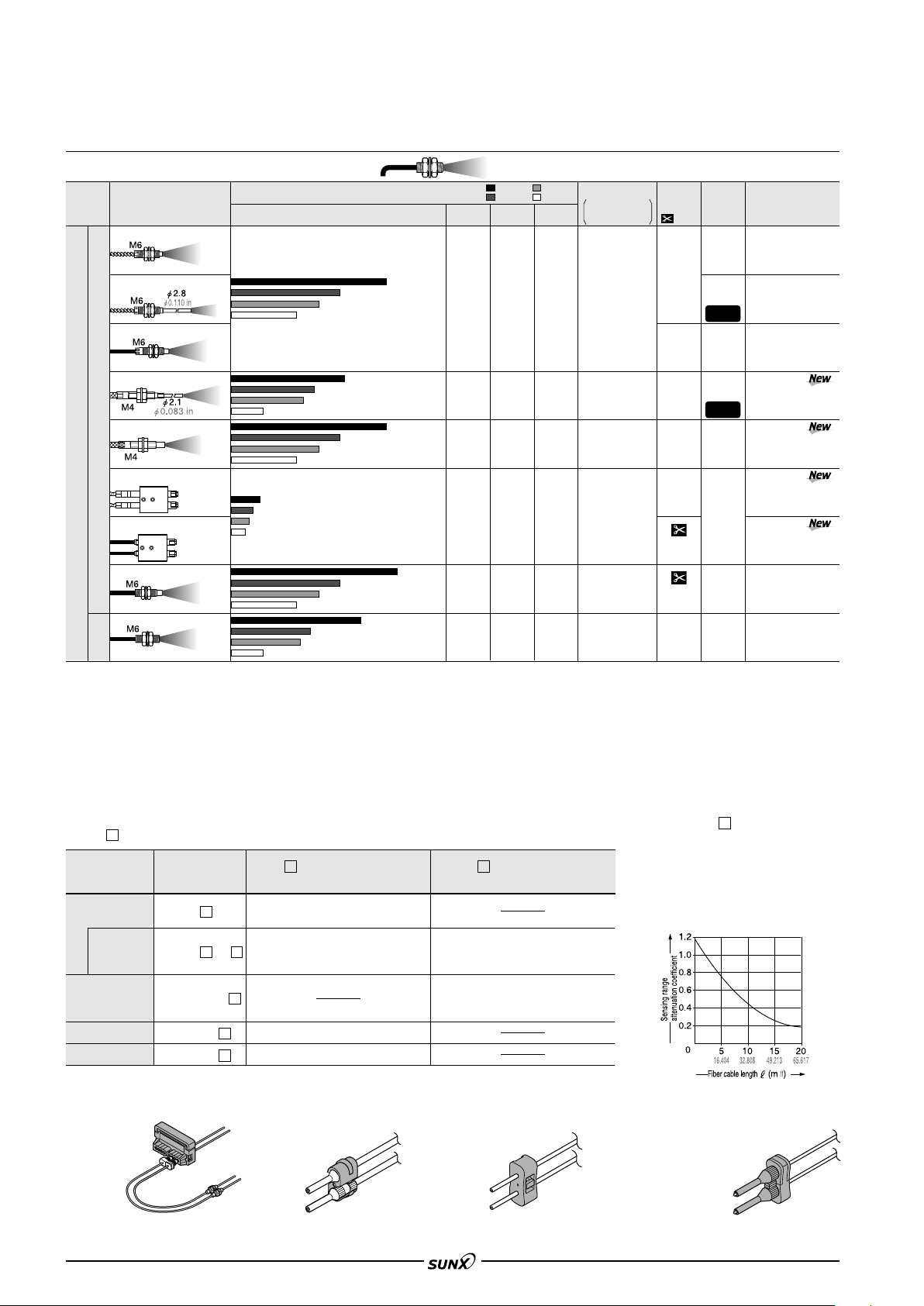

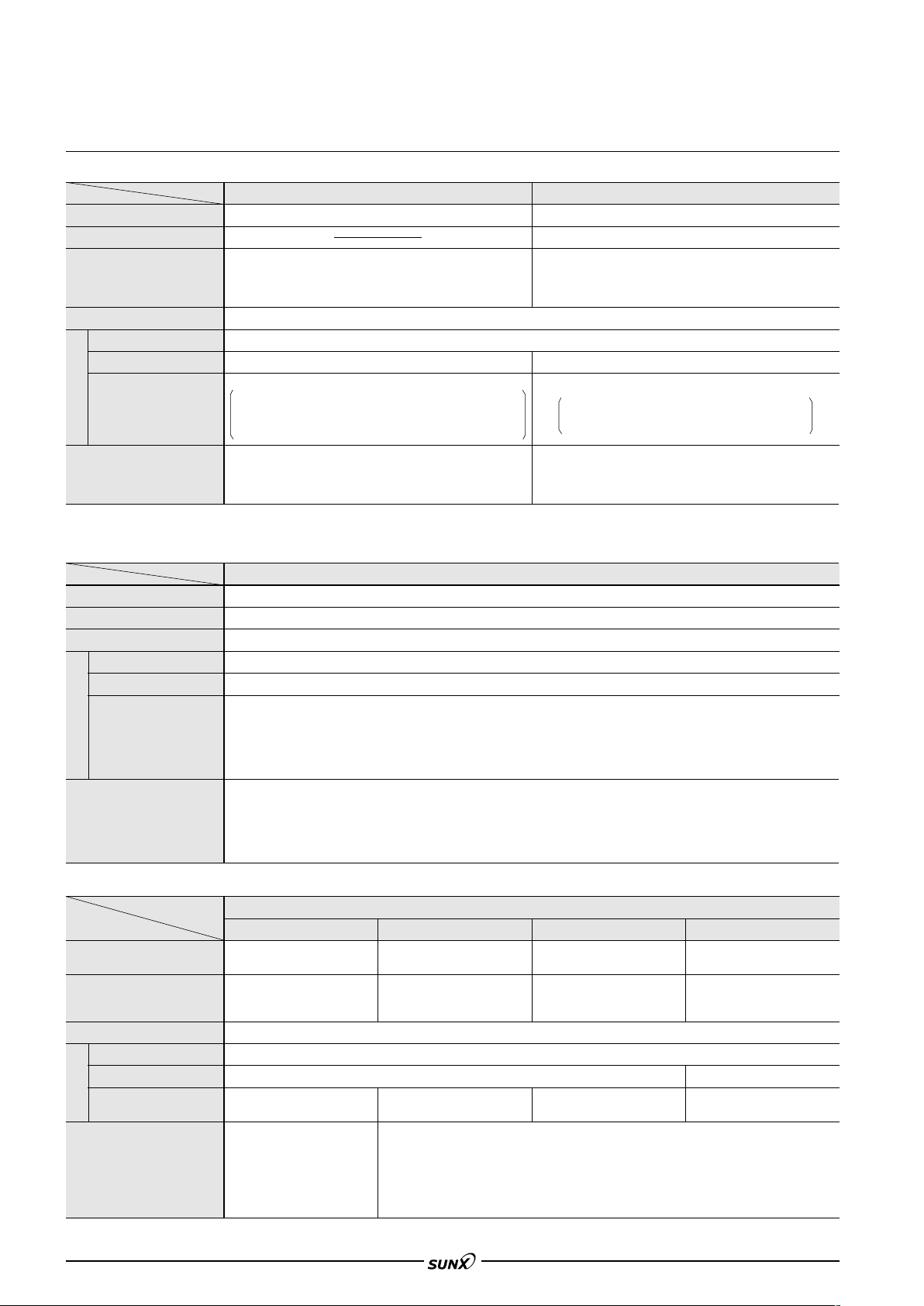

ORDER GUIDE

Amplifiers

Quick-connection cable is not supplied with the amplifier. Please order it separately.

Type Appearance Model No. Emitting element Output

Red LED

Blue LED

Green LED

Infrared LED

Red LED

Blue LED

Green LED

Infrared LED

NPN open-collector

transistor

PNP open-collector

transistor

NPN output

Digital

PNP output

Quick-connection cables

FX-301

FX-301B

FX-301G

FX-301H

FX-301P

FX-301BP

FX-301GP

FX-301HP

Quick-connection cable is not supplied with the amplifier. Please order it separately.

Type Model No. Description

Length: 1 m 3.281 ft

Length: 2 m 6.562 ft

Length: 5 m 16.404 ft

Length: 1 m 3.281 ft

Length: 2 m 6.562 ft

Length: 5 m 16.404 ft

2

0.15 mm

Cable outer diameter: "3.0 mm "0.118 in

0.15 mm

Cable outer diameter: "3.0 mm "0.118 in

3-core cabtyre cable, with connector on one end

2

1-core cabtyre cable, with connector on one end

Main cable

Sub cable

CN-73-C1

CN-73-C2

CN-73-C5

CN-71-C1

CN-71-C2

CN-71-C5

Main cable

• CN-73-C

Sub cable

• CN-71-C

End plates

End plates are not supplied with the amplifier. Please order separately when the amplifiers are mounted in cascade.

Appearance Model No. Description

When cascading multiple amplifiers, or when it

moves depending on the way it is installed on a

MS-DIN-E

DIN rail, these end plates ensure that all

amplifiers are mounted together in a secure and

fully connected manner.

Two pcs. per set

OPTIONS

Designation Model No. Description

Amplifier mounting

bracket

Fiber amplifier

protective seal

MS-DIN-2

FX-MB1

Mounting bracket for amplifier

10 sets of 2 communication window seals and 1 connector seal

Communication window seal:

It prevents malfunction due to transmission signal from another

amplifier, as well as, prevents effect on another amplifier.

Connector seal:

It prevents contact of any metal, etc., with the pins of the quickconnection cable.

Amplifier mounting bracket

• MS-DIN-2

Fiber amplifier protective seal

• FX-MB1

72

Page 6

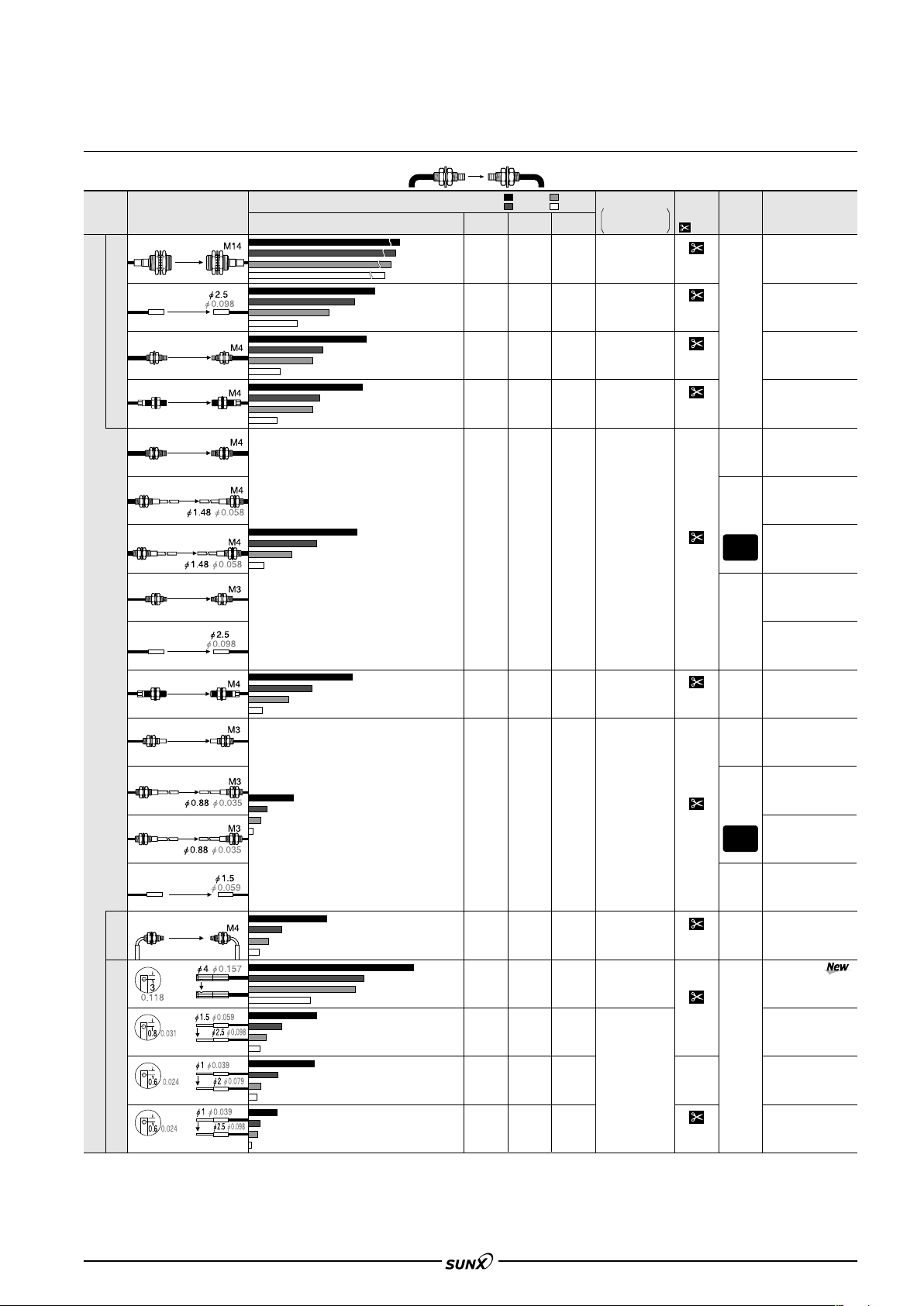

LIST OF FIBERS

08/2005

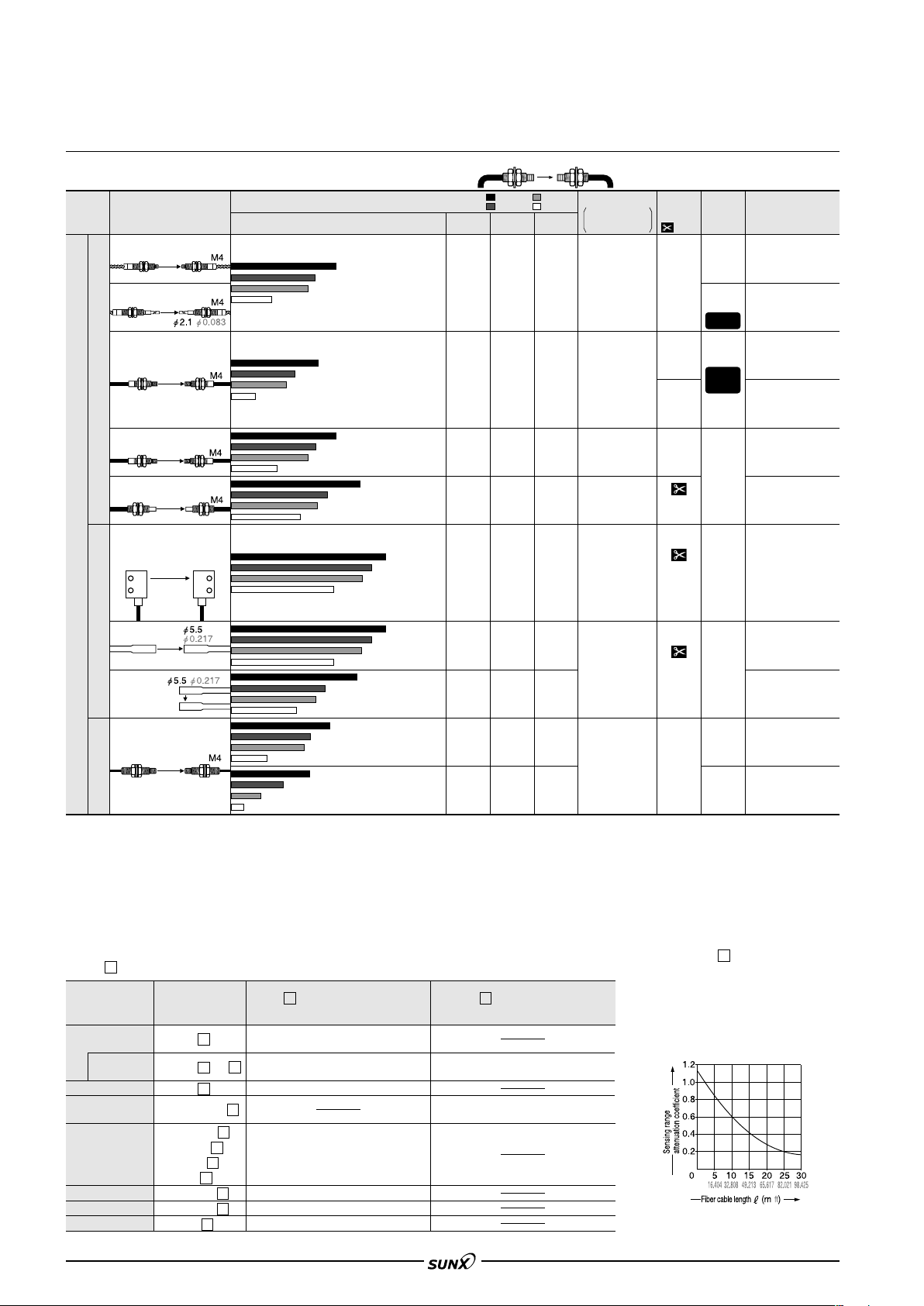

Standard fibers [Thru-beam type (one pair set)]

Shape of fiber head

Type

With lens

With lens

Lens mountable

Long sensing range

Lens mountable

Sleeve 90 mm 3.543 in

Sleeve 40 mm 1.575 in

Lens mountable

(mm in)

Sensing range (mm in ) (Note 1)

Red LED

1,600 62.992

800 31.496

580 22.835

280 11.024

180 7.087

168 6.614

280 11.024

130 5.118

400 15.748

360 14.173

400 15.748

530 20.866

480 18.898

780 30.709

1,100 43.307

1,000 39.370

19,500 767,715

14,000 551.180

10,000 393.700

3,800 149.606

Blue LED

5,400

212.598

2,700

106.299

1,900 74.803

400 15.748

200 7.874

130 5.118

220 8.661

110 4.331

75 2.953

200 7.874

100 3.937

70 2.756

150 5.906

75 2.953

40 1.575

:LONG

:STD

Green LED

Infrared LED

2.400

2,800

110.236

1,200 47.244

1,400 55.118

1,000 39.370

200 7.874

100 3.937

65 2.559

110 4.331

55 2.165

40 1.575

100 3.937

50 1.969

35 1.378

70 2.756

35 1.378

24 0.945

900 35.433

(Note 3)

155 6.102

100 3.937

:FAST

Min. sensing object

:S-D

under the optimum

condition (Note 2)

94.488

"0.4 mm

"0.016 in

opaque object

"0.02 mm

77 3.031

"0.0008 in

55 2.165

opaque object

"0.04 mm

50 1.969

"0.0016 in

30 1.181

opaque object

90 3.543

"0.03 mm

45 1.772

"0.0012 in

28 1.102

opaque object

50 1.969

"0.03 mm

25 0.984

"0.0012 in

18 0.709

opaque object

FX-301

Allowable

Fiber cable

bending

length

:

Free-cut

10 m

32.808 ft

2 m

6.562 ft

2 m

6.562 ft

2 m 6.562 ft

(Note 4)

2 m

6.562 ft

radius

R25 mm

R0.984 in

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R25 mm

R0.984 in

Model No.

FT-FM10L

FT-SFM2L

FT-B8

FT-NB8

FT-FM2

FT-FM2S

FT-FM2S4

FT-T80

FT-SFM2

700 27.559

360 14.173

250 9.843

Standard

Sleeve 90 mm 3.543 in

Sleeve 40 mm 1.575 in

Lens mountable

Elbow

Sleeve part cannot be bent.

Side-view

Sleeve part cannot be bent.

Sleeve part cannot be bent.

Notes: 1)

Notes: 2) The minimum sensing object size is the value for red LED type. Please contact our office for information on the minimum sensing object size if using

Notes: 3) Sensing range for a 2 m 6.562 ft long fiber. A 10 m 32.808 ft long fiber will cause damping of the beam and cannot be used.

Notes: 4) The fiber cutter is not supplied as an accessor y with FT-NB8 and FT-N8. Please order it separately.

Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the infrared

type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can fluctuate.

amplifiers other than red LED type.

The optimum condition is the condition when the sensitivity is set so that the sensing output just changes to light incident operation in the object absent

condition.

126 4.961

140 5.512

100 3.937

49 1.929

150 5.906

80 3.150

140 5.512

70 2.756

180 7.087

125 4.921

63 2.480

175 6.890

80 3.150

60 2.362

27 1.063

270 10.630

230 9.055

350 13.780

400 15.748

200 7.874

390 15.354

530 20.866

1,000 39.370

800 31.496

2,000 78.740

140 5.512

70 2.756

40 1.575

50 1.969

25 0.984

16 0.630

85 3.346

42 1.654

28 1.102

400 15.748

200 7.874

130 5.118

80 3.150

40 1.575

28 1.102

50 1.969

25 0.984

16 0.630

28 1.102

14 0.551

10 0.394

200 7.874

100 3.937

66 2.598

33 1.299

22 0.866

24 0.945

12 0.472

8 0.315

44 1.732

22 0.866

16 0.630

65 2.559

40 1.575

20 0.787

14 0.551

26 1.024

13 0.512

8 0.315

14 0.551

7 0.276

5 0.197

45 1.772

22 0.866

17 0.669

16 0.630

8 0.315

5 0.197

32 1.260

16 0.630

12 0.472

150 5.906

75 2.953

40 1.575

30 1.181

15 0.591

12 0.472

44 1.732

22 0.866

15 0.591

10 0.394

5 0.197

3 0.118

"0.03 mm

"0.0012 in

opaque object

"0.025 mm

"0.0010 in

opaque object

"0.04 mm

"0.0016 in

opaque object

"0.05 mm

"0.0019 in

opaque object

"0.02 mm

"0.0008 in

opaque object

2 m 6.562 ft

(Note 4)

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

1 m

3.281 ft

2 m

6.562 ft

R25 mm

R0.984 in

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R25 mm

R0.984 in

R25 mm

R0.984

in

R25 mm

R0.984 in

FT-N8

FT-NFM2

FT-NFM2S

FT-NFM2S4

FT-SNFM2

FT-R80

FT-V10

FT-SFM2SV2

FT-V22

FT-V41

73

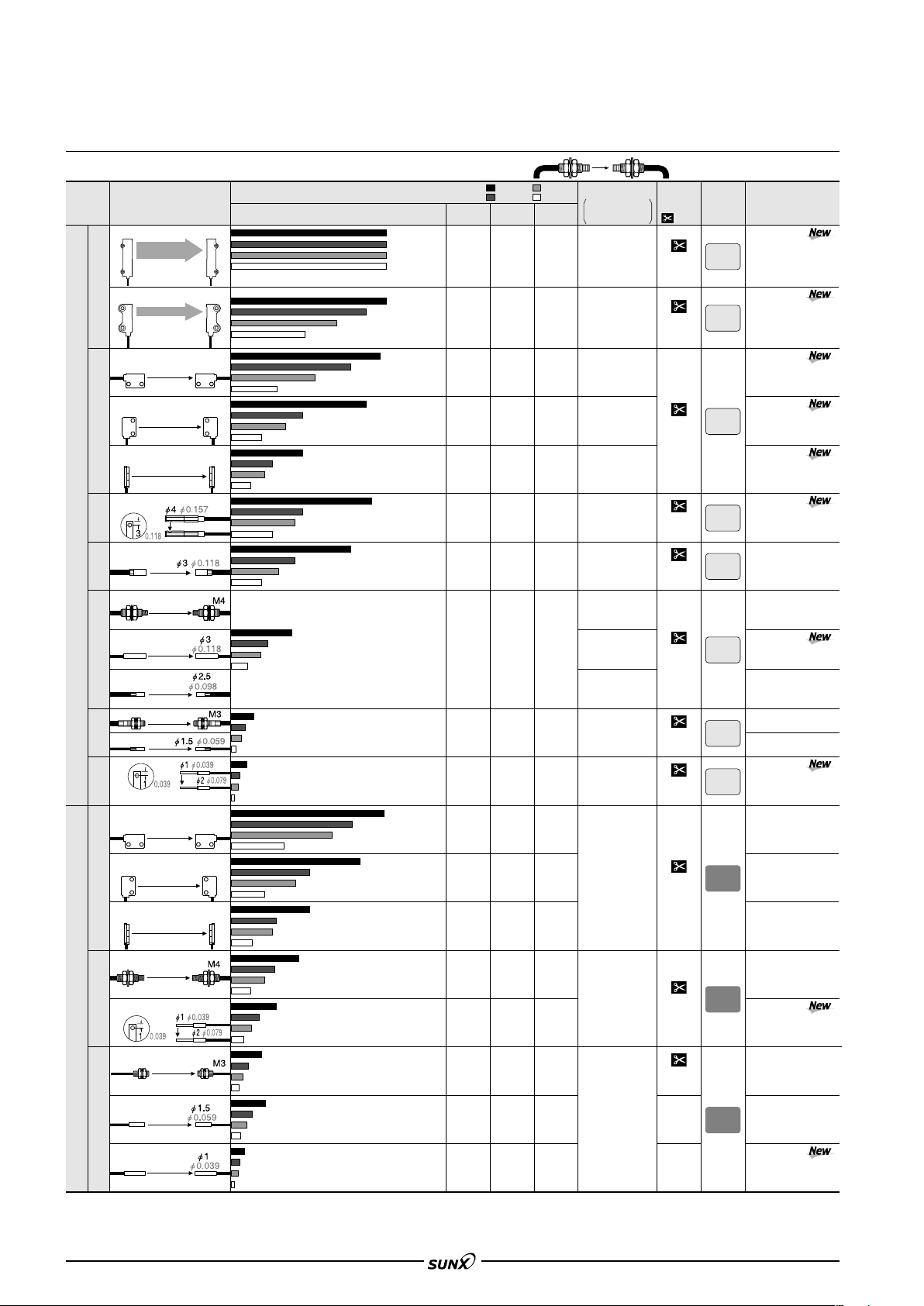

Page 7

FX-301

08/2005

LIST OF FIBERS

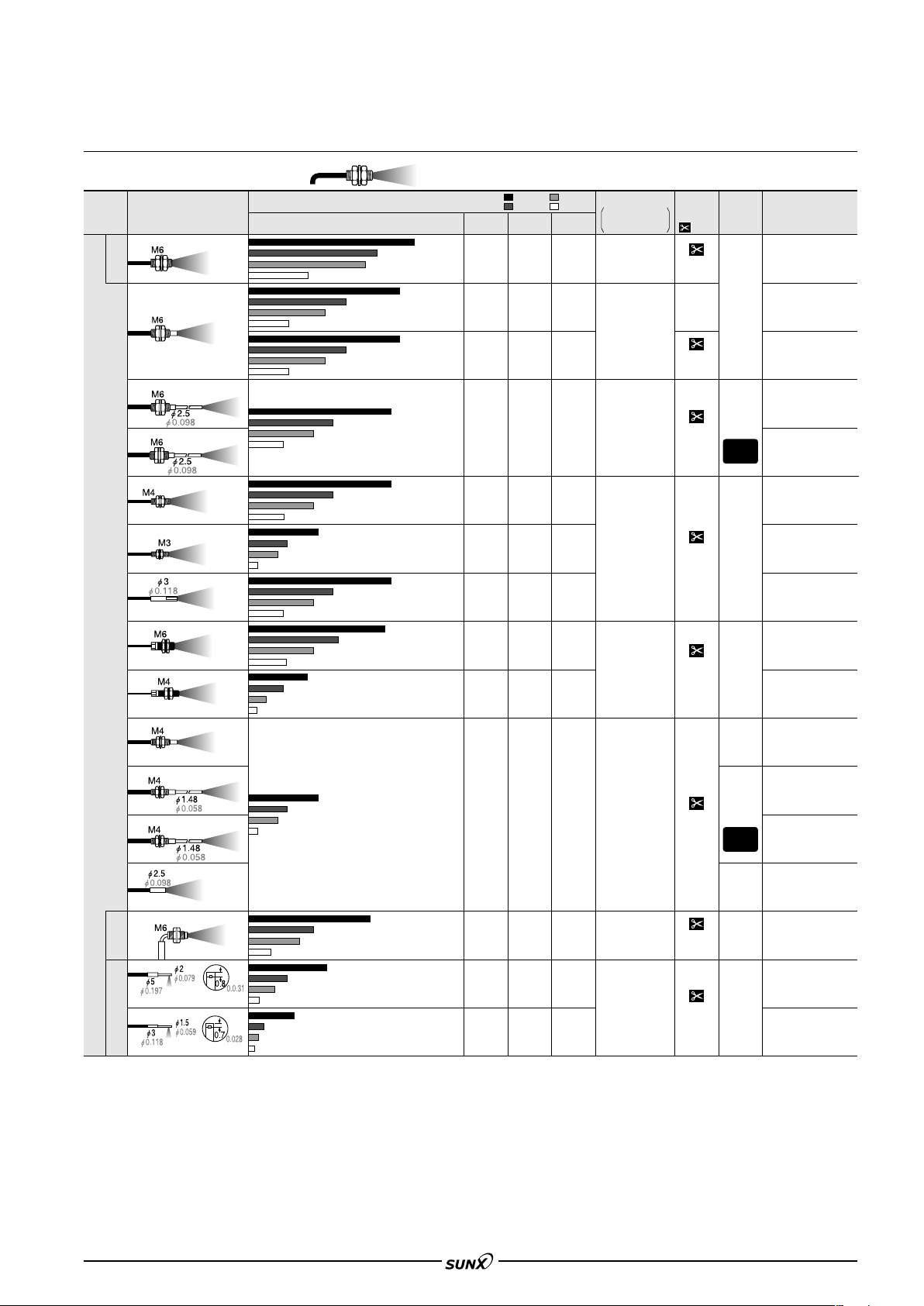

Sharp bending fibers / Flexible fibers [Thru-beam type (one pair set)]

700 27.559

600 23.622

300 11.811

220 8.661

400 15.748

200 7.874

140 5.512

240 9.449

120 4.724

80 3.150

80 3.150

40 1.575

25 0.984

300 11.811

150 5.906

100 3.937

240 9.449

120 4.724

90 3.543

90 3.543

45 1.772

30 1.181

16 0.630

8 0.315

5 0.197

560 22.047

280 11.024

200 7.874

400 15.748

200 7.874

140 5.512

120 4.724

60 2.362

40 1.575

130 5.118

65 2.559

45 1.772

50 1.969

25 0.984

18 0.709

32 1.260

16 0.630

12 0.472

36 1.417

18 0.709

14 0.551

14 0.551

7 0.276

4 0.157

:LONG

:STD

Green LED

1,200 47.244

600 23.622

350 13.780

300 11.811

150 5.906

110 4.331

200 7.874

100 3.937

70 2.756

120 4.724

60 2.362

40 1.575

40 1.575

20 0.787

13 0.512

160 6.299

80 3.150

60 2.362

120 4.724

60 2.362

40 1.575

56 2.205

28 1.102

20 0.787

10 0.394

5 0.197

3 0.118

200 7.874

100 3.937

65 2.559

200 7.874

100 3.937

65 2.559

60 2.362

30 1.181

22 0.866

70 2.756

35 1.378

25 0.984

26 1.024

13 0.512

8 0.315

18 0.709

9 0.354

7 0.276

20 0.787

10 0.394

8 0.315

6 0.236

3 0.118

2 0.079

Shape of fiber head

Type

Wide beam

Rectangular head

Narrow beam

Sharp bending

Long sensing range

Standard

Small diameter

Side-view

Rectangular head

Flexible

Standard

Small diameter

Notes: 1)

Notes: 2)

Notes: 3) The fiber cable length practically limits the sensing range to 3,500 mm 137.795 in long.

(mm in)

Wide area sensing

Sensing width

32 mm

1.260 in

W5H69D20

W0.197H2.717D0.787

Wide area sensing

Sensing width

11 mm

0.433 in

W4.2H31D13.5

W0.165H1.220D0.531

Easy mounting Top sensing

W3H8D12 W0.118H0.315D0.472

Easy mounting Side sensing

W3H12D8 W0.118H0.472D0.315

Easy mounting Front sensing

W8.5H12D3 W0.335H0.472D0.118

Side-view type with small light

dispersion

With lens Long sensing range

Lens mountable

Sleeve part cannot be bent.

Easy mounting

W3H8D12 W0.118H0.315D0.472

Easy mounting Side sensing

W3H12D8 W0.118H0.472D0.315

Easy mounting

W8.5H12D3 W0.335H0.472D0.118

Lens mountable

Lens mountable

Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the infrared

type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can fluctuate.

The minimum sensing object size is the value for red LED type. Please contact our office for information on the minimum sensing object size if using amplifiers other than red LED

type. The optimum condition is the condition when the sensitivity is set so that the sensing output just changes to light incident operation in the object absent co

Top sensing

Front sensing

Sensing range (mm in) (Note 1)

Red LED

1,100 43.307

750 29.528

1,200 47.244

850 33.465

410 16.142

700 27.559

500 19.685

210 8.268

700 27.559

330 12.992

240 9.449

120 4.724

700 27.559

600 23.622

210 8.268

200 7.874

100 3.937

160 6.299

80 3.150

55 2.165

28 1.102

90 3.543

40 1.575

30 1.181

15 0.591

280 11.024

140 5.512

230 9.055

110 4.331

190 7.480

140 5.512

80 3.150

250 9.843

100 3.937

75 2.953

35 1.378

280 11.024

120 4.724

90 3.543

42 1.654

80 3.150

40 1.575

30 1.181

17 0.669

300 11.811

600 23.622

420 16.535

570 22.441

290 11.417

490 19.291

600 23.622

400 15.748

300 11.811

650 25.591

320 12.598

400 15.748

1,000 39.370

800 31.496

800 31.496

1,200 47.244

1,400 55.118

1,600 62.992

3,500 137.795

3,500 137.795

3,500 137.795

3,500 137.795

(Note 3)

3,500 137.795

1,500 59.055

2,500 98.425

1,500 59.055

1,700 66.929

2,700 106.299

Blue LED

2,400 94.488

1,200 47.244

:FAST

:S-D

Infrared LED

800 31.496

400 15.748

240 9.449

220 8.661

110 4.331

80 3.150

180 7.087

90 3.543

65 2.559

100 3.937

50 1.969

30 1.181

36 1.417

18 0.709

12 0.472

150 5.906

75 2.953

45 1.772

110 4.331

55 2.165

35 1.378

42 1.654

21 0.827

15 0.591

8 0.315

4 0.157

2.5 0.098

180 7.087

90 3.543

65 2.559

140 5.512

70 2.756

50 1.969

46 1.811

23 0.906

16 0.630

56 2.205

28 1.102

20 0.787

20 0.787

10 0.394

7 0.276

14 0.551

7 0.276

5 0.197

18 0.709

9 0.354

7 0.276

14 0.551

7 0.276

4 0.157

Min. sensing object

under the optimum

condition (Note 2)

"0.3 mm

"0.012 in

opaque object

"0.25 mm

"0.010 in

opaque object

"0.08 mm

"0.003 in

opaque object

"0.05 mm

"0.0020 in

opaque object

"0.04 mm

"0.0016 in

opaque object

"0.06 mm

"0.0024 in

opaque object

"0.02 mm

"0.0008 in

opaque object

"0.03 mm

"0.0012 in

opaque object

"0.05 mm

"0.0020 in

opaque object

"0.03 mm

"0.0012 in

opaque object

"0.02 mm

"0.0008 in

opaque object

"0.02 mm

"0.0008 in

opaque object

"0.03 mm

"0.0012 in

opaque object

"0.04 mm

"0.0016 in

opaque object

"0.02 mm

"0.0008 in

opaque object

Fiber cable

length

:

Free-cut

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

1 m

3.281 ft

500 mm

19.685 in

Allowable

bending

radius

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R1 mm

R0.039 in

R4 mm

R0.157 in

R4 mm

R0.157 in

R4 mm

R0.157 in

Model No.

FT-WA30

FT-WA8

FT-WZ8H

FT-WZ8E

FT-WZ8

FT-WKV8

FT-WS8L

FT-W8

FT-WS3

FT-WS8

FT-W4

FT-WS4

FT-WV42

FT-Z8H

FT-Z8E

FT-Z8

FT-P80

FT-P60

FT-P40

FT-P2

FT-PS1

ndition.

74

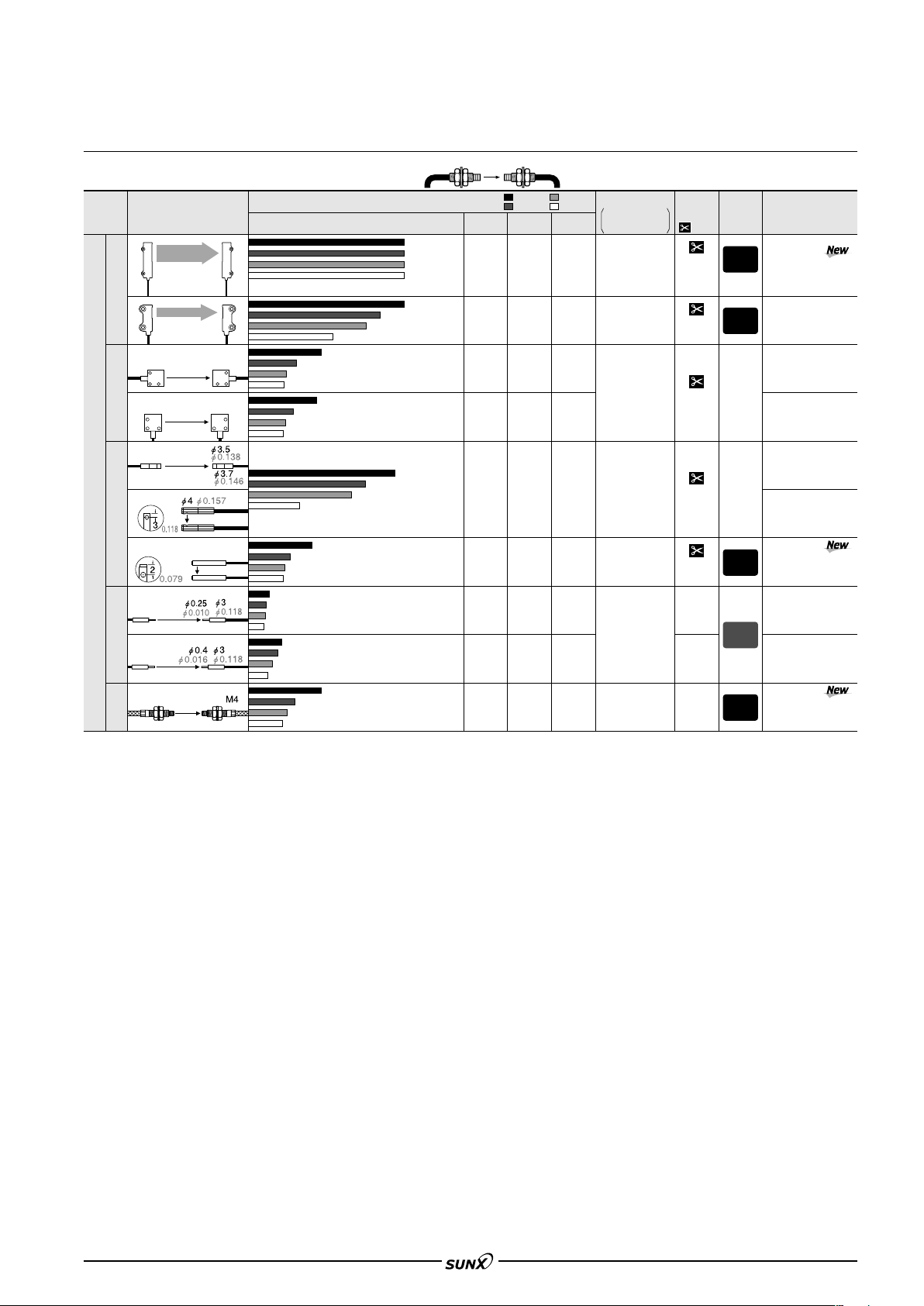

Page 8

LIST OF FIBERS

08/2005

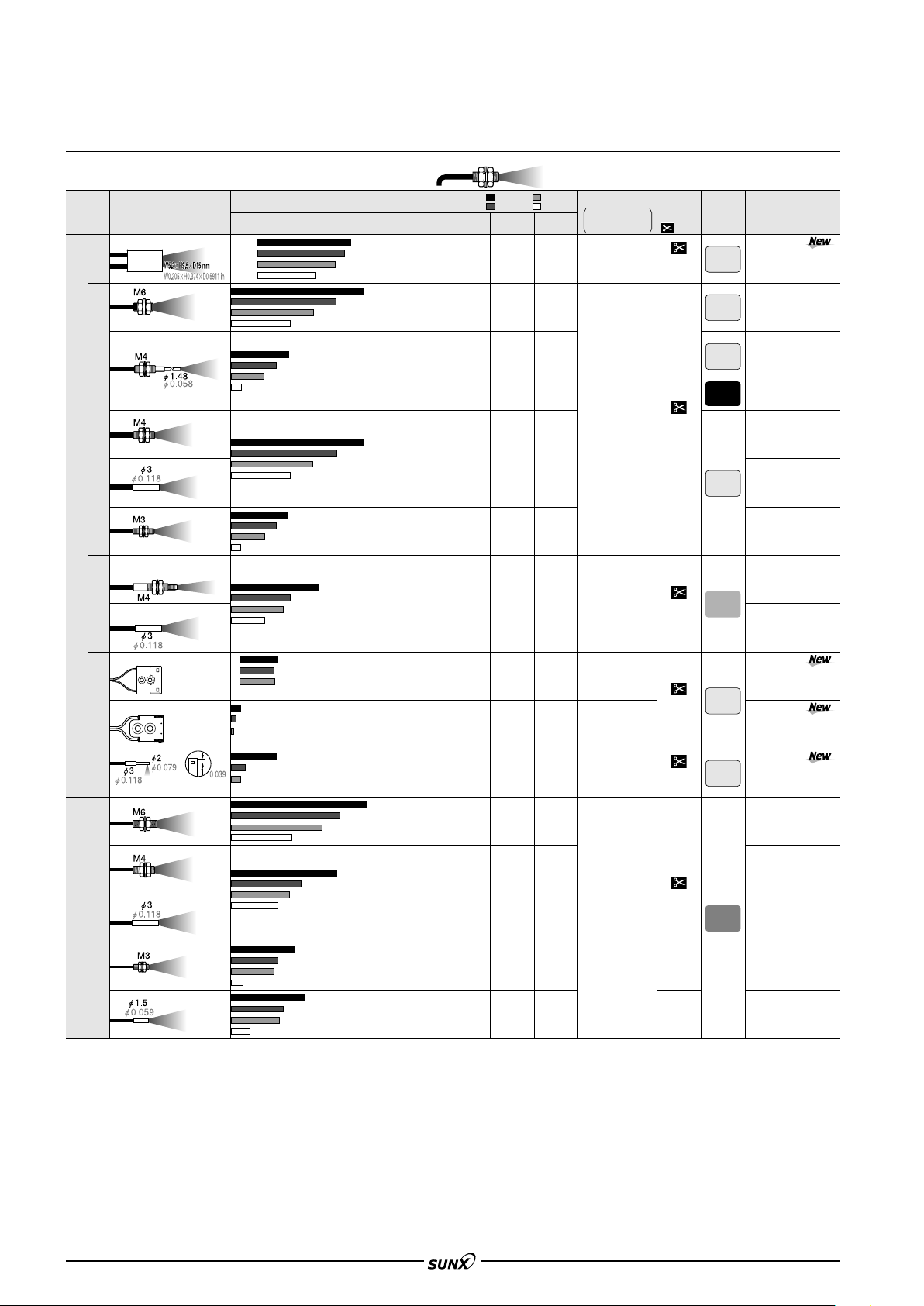

Special use fibers [Thru-beam type (one pair set)]

Shape of fiber head

Type

Wide beam

Array

(mm in)

Sensing width

32 mm

1.260 in

W5H69D20

W0.197H2.717D0.787

Sensing width

11 mm

0.433 in

W4.2H31D13.5

W0.165H1.220D0.531

Top sensing

W5H15D15 W0.197H0.591D0.591

Side sensing

W5H15D15 W0.197H0.591D0.591

Sensing range (mm in) (Note 1)

Red LED

1,500 59.055

1,100 43.307

750 29.528

650 25.591

330 12.992

220 8.661

115 4.528

590 23.228

290 11.417

200 7.874

100 3.937

3,500 137.795

3,500 137.795

3,500 137.795

3,500 137.795

(Note 3)

3,500 137.795

Blue LED

2,400 94.488

1,200 47.244

700 27.559

600 23.622

300 11.811

220 8.661

120 4.724

60 2.362

40 1.575

120 4.724

60 2.362

40 1.575

:LONG

:STD

Green LED

Infrared LED

1,200 47.244

600 23.622

350 13.780

300 11.811

150 5.906

110 4.331

60 2.362

30 1.181

20 0.787

60 2.362

30 1.181

20 0.787

800 31.496

400 15.748

240 9.449

220 8.661

110 4.331

:FAST

Min. sensing object

:S-D

under the optimum

condition (Note 2)

"0.3 mm

"0.012 in

opaque object

"0.25 mm

"0.010 in

80 3.150

opaque object

Horizontal:

48 1.890

"0.025 mm

24 0.945

"0.0010 in

18 0.709

opaque object

Vertical:

48 1.890

"0.45 mm

24 0.945

"0.018 in

18 0.709

opaque object

FX-301

Allowable

Fiber cable

bending

length

:

Free-cut

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

radius

R10 mm

R0.394 in

R10 mm

R0.394 in

R25 mm

R0.984 in

Model No.

FT-A30

FT-A8

FT-AFM2

FT-AFM2E

2,000 78.740

1,000 39.370

Side-view

Special use

Narrow beam

Side-view

W2H1.5D20

Beam diameter:"0.125 mm "0.005 in

Sleeve part cannot be bent.

Beam diameter:"0.25 mm "0.010 in

Ultra-small diameter

Sleeve part cannot be bent.

Lens mountable

Tough flexible

Notes: 1) Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the

Notes: 2) The minimum sensing object size is the value for red LED type. Please contact our office for information on the minimum sensing object size if using

Notes: 3) The fiber cable length practically limits the sensing range to 3,500 mm 137.795 in long.

infrared type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can

fluctuate.

amplifiers other than red LED type.

The optimum condition is the condition when the sensitivity is set so that the sensing output just changes to light incident operation in the object absent

condition.

W0.079H0.059D0.787

250 9.843

180 7.087

100 3.937

18 0.709

10 0.394

8 0.315

3 0.118

80 3.150

50 1.969

36 1.417

15 0.591

230 9.055

110 4.331

350 13.780

320 12.598

800 31.496

500 19.685

650 25.591

400 15.748

200 7.874

130 5.118

80 3.150

35 1.378

10 0.394

3 0.118

2 0.079

1 0.039

14 0.551

7 0.276

4 0.157

130 5.118

64 2.520

45 1.772

200 7.874

100 3.937

65 2.559

1 0.039

6 0.236

3 0.118

2 0.079

64 2.520

32 1.260

22 0.866

150 5.906

75 2.953

40 1.575

4 0.157

2 0.079

1.5 0.059

10 0.394

5 0.197

3 0.118

130 5.118

64 2.520

45 1.772

"0.06 mm

"0.0024 in

opaque object

"0.02 mm

"0.0008 in

opaque object

"0.02 mm

"0.0008 in

opaque object

"0.05 mm

"0.0020 in

opaque object

2 m

6.562 ft

2 m

6.562 ft

500 mm

19.685 in

1 m

3.281 ft

1 m

3.281 ft

R25 mm

R0.984 in

R10 mm

R0.394 in

R5 mm

R0.197 in

R10 mm

R0.394 in

FT-K8

FT-KV8

FT-KV1

FT-E12

FT-E22

FT-P81X

75

Page 9

FX-301

08/2005

LIST OF FIBERS

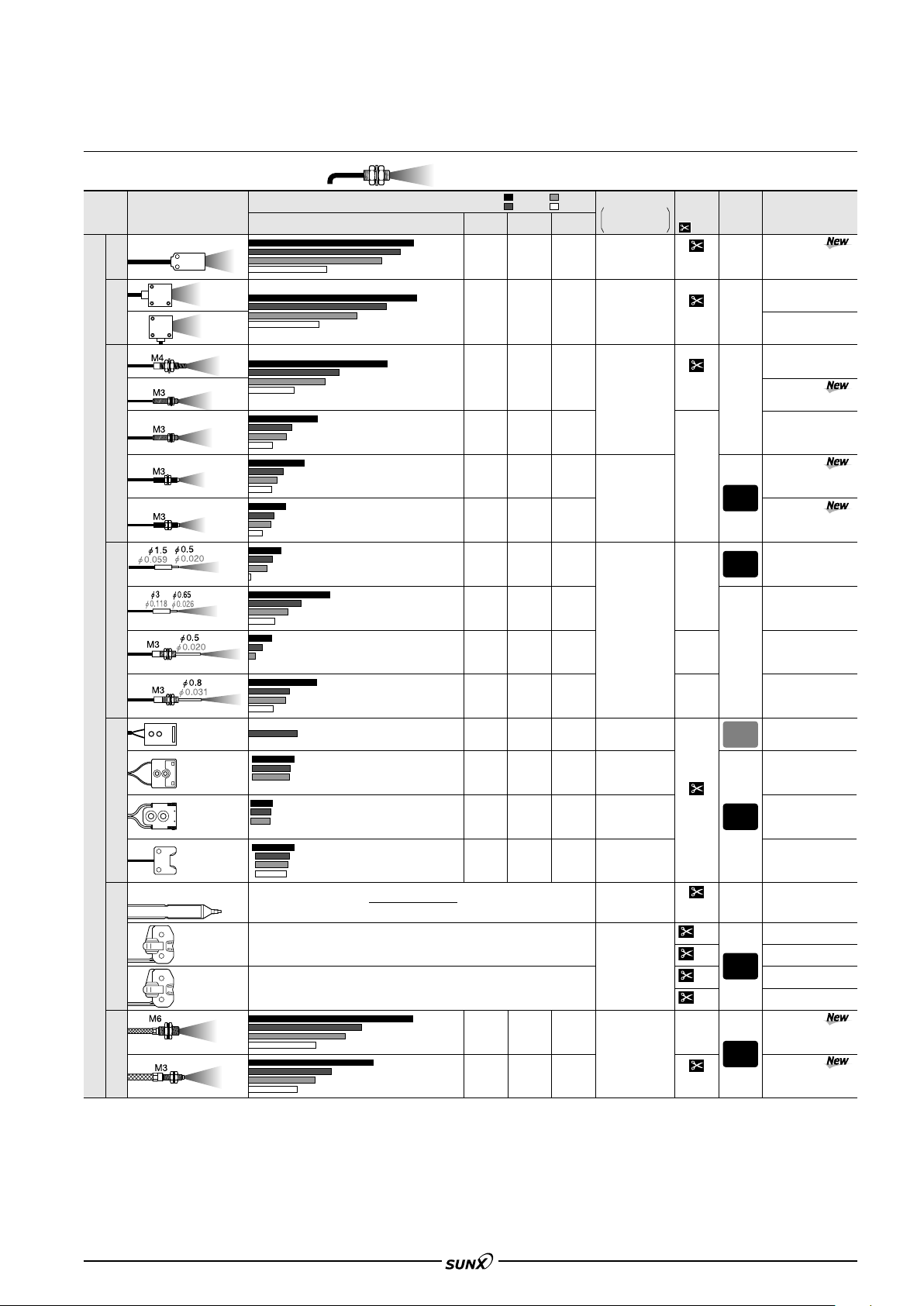

Environment resistant fibers [Thru-beam type (one pair set)]

Shape of fiber head

Type

Heat-resistant

Environment resistant

(mm in)

350 C 662 F

Lens mountable

350 C 662 F

Sleeve 60 mm 2.362 in

Allows flexible wiring

200 C 392 F

Lens mountable

200 C 392 F

Lens mountable

130 C 266 F

Lens mountable

Easy mounting Rectangular head

SEMI S2 compliant

W7H15D13

W0.276

H0.591D0.512

Sensing range (mm in) (Note 1)

Red LED

550 21.654

280 11.024

200 7.874

90 3.543

310 12.205

140 5.512

100 3.937

50 1.969

550 21.654

280 11.024

200 7.874

90 3.543

155 6.102

440 17.323

300 11.811

530 20.866

880 34.646

3,500 137.795

1,500 59.055

1,000 39.370

Blue LED

100 3.937

50 1.969

35 1.378

44 1.732

22 0.866

14 0.551

100 3.937

50 1.969

35 1.378

72 2.835

36 1.417

26 1.024

320 12.598

160 6.299

120 4.724

:LONG

:STD

Green LED

Infrared LED

50 1.969

420 16.535

25 0.984

210 8.268

18 0.709

160 6.299

22 0.866

220 8.661

11 0.433

110 4.331

7 0.276

50 1.969

420 16.535

25 0.984

210 8.268

18 0.709

160 6.299

32 1.260

16 0.630

10 0.394

160 6.299

320 12.598

80 3.150

160 6.299

60 2.362

120 4.724

:FAST

Min. sensing object

:S-D

under the optimum

condition (Note 2)

"0.04 mm

"0.0016 in

opaque object

"0.02 mm

"0.0008 in

70 2.756

opaque object

"0.04 mm

"0.0016 in

opaque object

70 2.756

"0.06 mm

35 1.378

"0.0024 in

25 0.984

opaque object

"4 mm

"0.157 in

opaque object

Fiber cable

length

:

Free-cut

2 m

6.562 ft

1 m

3.281 ft

2 m

6.562 ft

1 m

3.281 ft

2 m

6.562 ft

2 m

6.562 ft

Allowable

bending

radius

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R10 mm

R0.394 in

R25 mm

R0

.984 in

R25 mm

R

0.984 in

Model No.

FT-H35-M2

FT-H35-M2S6

FT-H20W-M1

FT-H20W-M2

FT-H20-M1

FT-H13-FM2

FT-Z802Y

160 6.299

160 6.299

3,500 137.795

1,500 59.055

1,000 39.370

400 15.748

280 11.024

140 5.512

470 18.504

230 9.055

165 6.496

220 8.661

530 20.866

800 31.496

Chemical-resistant

Side-view

Lens mountable

80 3.150

Vacuum

Notes: 1)

Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the infrared

type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can fluctuate.

Notes: 2)

The minimum sensing object size is the value for red LED type. Please contact our office for information on the minimum sensing object size if using amplifiers other than red

LED type. The optimum condition is the condition when the sensitivity is set so that the sensing output just changes to light incident operation in the object absent

Notes: 3) The allowable cutting range is 500 mm 19.685 in from the end that the amplifier inserted.

75 2.953

35 1.378

100 3.937

80 3.150

50 1.969

120 4.724

60 2.362

35 1.378

100 3.937

50 1.969

30 1.181

36 1.417

18 0.709

12 0.472

80 3.150

50 1.969

80 3.150

40 1.575

25 0.984

46 1.811

23 0.906

16 0.630

18 0.709

9 0.354

6 0.236

400 15.748

200 7.874

150 5.906

75 2.953

38 1.496

24 0.945

70 2.756

35 1.378

22 0.866

28 1.102

14 0.551

10 0.394

"0.08 mm

"0.003 in

opaque object

"0.02 mm

"0.0008 in

opaque object

2 m

6.562 ft

(Note 3)

1 m

3.281 ft

R30 mm

R1.181 in

R200 mm

R7.874 in

R30 mm

R1.181 in

FT-L8Y

FT-V8Y

FT-6V

FT-60V

condition.

The vacuum type fiber must be used with the following products as a set.

FT-J6: Fiber at atmospheric side (one pair set) FV-BR1: Photo-terminal (one pair set)

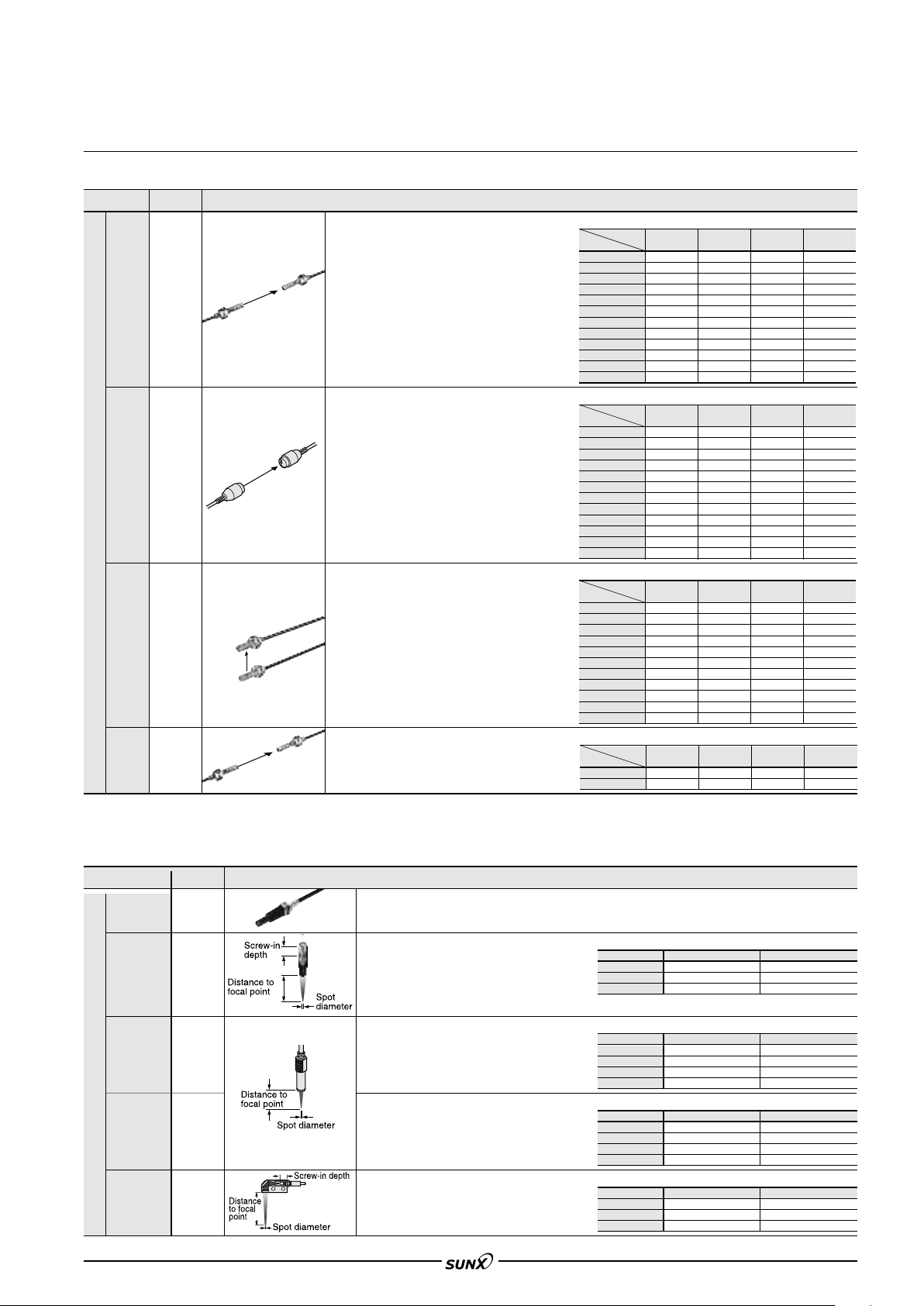

Semi-standard fibers (Custom made per order)

The fiber cable length or sleeve length of the standard fibers can be modified at your request. Select the fiber cable length (symbol ) or the sleeve length

(symbol f ) from the table below.

Type

Standard threaded

head (free-cut)

With sleeve

With large diameter lens

Small diameter threaded

head with sleeve (free-cut)

Basic model No.

FT-FM

FT-FM -S f

FT-FM L

FT-NFM2-S f

FT-WA30-

Wide beam

FT-WA8-

FT-A30-

(Unit: m ft)

3 9.843, 4 13.123, 5 16.404, 10 32.808,

15 49.213, 20 65.617,25 82.021, 30 98.425

2 6.562 (Note), 3 9.843, 4 13.123, 5 16.404,

10 32.808, 15 49.213, 20 65.617, 25 82.021, 30 98.425

20 65.617, 30 98.425

5 16.404

1 0.394, 2 0.787, 3 1.181, 4 1.575, 5 1.969, 6 2.362,

7 2.756, 8 3.150, 9 3.543, 10 3.937, 11 4.331, 12

4.724

1 0.394, 2 0.787, 3 1.181, 4 1.575, 5 1.969, 6 2.362,

7 2.756, 8 3.150, 9 3.543, 10 3.937, 11 4.331, 12

4.724

Sleeve length

f

(Unit: cm in)

Fiber cable length

FT-A8-

200C 392F heat-resistant

350C 662F heat-resistant

Chemical-resistant

Note:

The standard fiber has a 2 m 6.562 ft fiber cable length and a 4 cm 1.575 in or 9 cm 3.543 in sleeve length.

FT-H20-M

FT-H35-M

FT-Z80 Y

2 6.562, 3 9.843

3 9.843

5 16.404, 7 22.966

Correlation between sensing

range attenuation coefficient and

fiber cable length

The longer the fiber cable, the shorter the

sensing range.

76

Page 10

LIST OF FIBERS

08/2005

Standard fibers (Reflective type)

Shape of fiber head

Type

Long sensing range

Coaxial

Sleeve 90 mm 3.543 in

Sleeve 40 mm 1.575 in

Small diameter

Standard

Sleeve 90 mm 3.543 in

Sleeve 40 mm 1.575 in

(mm in)

Sensing range (mm in ) (Note 1, 2)

35 1.378

16 0.630

28 1.102

13 0.512

35 1.378

16 0.630

75 2.953

47 1.850

47 1.850

85 3.346

39 1.535

85 3.346

39 1.535

45 1.772

85 3.346

39 1.535

85 3.346

42 1.654

75 2.953

38 1.496

45 1.772

Red LED

140 5.512

100 3.937

140 5.512

100 3.937

110 4.331

110 4.331

90 3.543

110 4.331

120 4.724

90 3.543

220 8.661

160 6.299

310 12.205

310 12.205

270 10.630

270 10.630

270 10.630

260 10.236

480 18.898

Blue LED

80 3.150

40 1.575

26 1.024

46 1.811

23 0.906

15 0.591

46 1.811

23 0.906

15 0.591

46 1.811

23 0.906

15 0.591

46 1.811

23 0.906

15 0.591

16 0.630

8 0.315

5 0.197

46 1.811

23 0.906

15 0.591

46 1.811

23 0.906

15 0.591

16 0.630

8 0.315

5 0.197

16 0.630

8 0.315

5 0.197

:LONG

:STD

Green LED

Infrared LED

42 1.654

21 0.827

14 0.551

24 0.945

12 0.472

8 0.315

24 0.945

12 0.472

8 0.315

24 0.945

12 0.472

8 0.315

24 0.945

12 0.472

8 0.315

8 0.315

4 0.157

2 0.079

24 0.945

12 0.472

8 0.315

24 0.945

12 0.472

8 0.315

8 0.315

4 0.157

2 0.079

8 0.315

4 0.157

2 0.079

:FAST

Min. sensing object

:S-D

at the maximum

sensitivity (Note 3)

26 1.654

13 0.827

9 0.551

90 3.543

45 1.772

30 1.181

20 0.787

10 0.394

7 0.276

20 0.787

10 0.394

7 0.276

20 0.787

10 0.394

7 0.276

6 0.236

3 0.118

2 0.079

20 0.787

10 0.394

7 0.276

20 0.787

10 0.394

7 0.276

4 0.157

2 0.079

1.5 0.059

6 0.236

3 0.118

2 0.079

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

FX-301

Allowable

Fiber cable

bending

length

:

Free-cut

2 m

6.562 ft

500 mm

19.685 in

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

(Note 4)

2 m

6.562 ft

radius

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R25 mm

R0.984 in

R25 mm

R

0.984 in

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

Model No.

FD-B8

FD-5

FD-FM2

FD-FM2S

FD-FM2S4

FD-T80

FD-T40

FD-S80

FD-N8

FD-N4

FD-NFM2

FD-NFM2S

FD-NFM2S4

R25 mm

R0.984 in

32 1.260

16 0.630

85 3.346

60 2.362

30 1.181

45 1.772

32 1.260

Sleeve part cannot be bent.

Small diameter

Side-view Elbow

Sleeve part cannot be bent.

Notes: 1) The sensing range is specified for white non-glossy paper (FD-B8, FD-5, FD-FM2, FD-FM2S, FD-FM2S4, FD-N8, FD-T80, FD-S80 and FD-R80:

Notes: 2) Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the

Notes: 3) The minimum sensing object size is the value for red LED type at maximum sensitivity. Please contact our office for information on the minimum sensing

Notes: 4) The fiber cutter is not supplied as an accessor y with FD-N8 and FD-N4. Please order it separately.

400 mm 15.74815.748 in, FD-T40, FD-N4, FD-NFM2, FD-NFM2S, FD-NFM2S4, FD-SNFM2, FD-SFM2SV2 and FD-V41: 200200 mm

400

7.874 in) as the object.

7.874

infrared type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can

fluctuate.

object size if using amplifiers other than red LED type.

Also, note that the corresponding setting distance is different from the rated sensing distance.

16 0.630

25 0.984

17 0.669

9 0.354

55 2.165

185 7.283

100 3.937

16 0.630

10 0.394

14 0.551

7 0.276

4 0.157

6 0.236

3 0.118

8 0.315

5 0.197

7 0.276

3.5 0.138

3 0.118

10 0.472

5 0.197

3 0.118

4 0.157

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

2 m

6.562 ft

2 m

6.562 ft

R25 mm

R0.984 in

R25 mm

R0.984

FD-SNFM2

FD-R80

FD-SFM2SV2

in

FD-V41

77

Page 11

FX-301

08/2005

LIST OF FIBERS

Sharp bending fibers / Flexible fibers (Reflective type)

Shape of fiber head

Type

Long sensing range

Standard

Sharp bending

High precision

Fixed-focus reflective

Side-view

(mm in)

Long sensing range Rectangular head

Sleeve 40 mm 1.575 in

Small spot for sensing minute objects

Coaxial Lens mountable

For sensing minute objects Coaxial

Glass substrate detection

Specular object detection

Sleeve part cannot be bent.

W24H21D4

W0.945H0.8270.157

W15H19D3

W0.591H0.7480.118

Sensing range (mm in) (Note 1, 2)

Red LED

20 to 480 0.787 to 18.898

20 to 230 0.787 to 9.055

20 to 170 0.787 to 6.693

25 to 100 0.984 to 3.937

60 2.362

32 1.260

30 1.181

15 0.591

12 0.472

5 0.197

60 2.362

32 1.260

30 1.181

15 0.591

12 0.472

5 0.197

32 1.260

25 0.984

11 0.433

6.5 to 14 0.256 to 0.551 (Convergent point 8 0.315)

7 to 12 0.276 to 0.472 (Convergent point 8 0.315)

7.5 to 12 0.295 to 0.472 (Convergent point 8 0.315)

Cannot use

0.6 to 3.5 0.024 to 0.138 (Convergent point 2 0.079)

0.9 to 2.7 0.035 to 0.106 (Convergent point 2 0.079)

1 to 2.5 0.039 to 0.098 (Convergent point 2 0.079)

Cannot use

15 0.591

7 0.276

5 0.197

Cannot use

35 1.378

90 3.543

90 3.543

65 2.559

100 3.937

70 2.756

190 7.480

190 7.480

220 8.661

Blue LED

23 0.906

11 0.433

8 0.315

5 0.197

2.5 0.098

1.5 0.059

23 0.906

11 0.433

8 0.315

5 0.197

2.5 0.098

1.5 0.059

11 0.433

5 0.197

3 0.118

40 1.575

20 0.787

13 0.512

:LONG

:STD

Green LED

Infrared LED

14 0.551

7 0.276

4 0.157

3 0.118

1.5 0.059

1 0.039

14 0.551

7 0.276

4 0.157

3 0.118

1.5 0.059

1 0.039

6 0.236

3 0.118

2 0.079

20 0.787

10 0.394

7 0.276

:FAST

Min. sensing object

:S-D

at the maximum

sensitivity (Note 3)

"0.3 mm

"0.012 in

copper wire

11 0.433

5.5 0.217

3 0.118

2 0.079

1 0.039

11 0.433

5.5 0.217

3 0.118

2 0.079

1 0.039

5 0.197

2.5 0.098

1.5 0.059

"1.9 mm

"0.075 in

metal pipe (gray)

18 0.709

9 0.354

6 0.236

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.08 mm

"0.003 in

gold wire

"0.02 mm

"0.0008 in

gold wire

Fiber cable

length

:

Free-cut

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

Allowable

bending

radius

R1 mm

R0.039 in

R1 mm

R0.039 in

Fiber

R1 mm

R0.039 in

Sleeve

R10 mm

R0.394 in

R1 mm

R0.039 in

R2 mm

R0.079 in

R1 mm

R0.039 in

R1 mm

R0.039 in

Model No.

FD-WKZ1

FD-W8

FD-W44

FD-WT8

FD-WS8

FD-WT4

FD-WG4

FD-WSG4

FD-WL41

FD-WL42

FD-WV42

FD-P80

20 0.787

90 3.543

Standard

Flexible

6 0.236

Small diameter

Notes: 1) The sensing range is specified for white non-glossy paper [100100 mm 3.9373.937 in (FD-WKZ1, FD-W8, FD-WT8, FD-WS8 and FD-P80:

Notes: 2) Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the

Notes: 3) The minimum sensing object size is the value for red LED type at maximum sensitivity. Please contact our office for information on the minimum sensing

78

400 mm 15.748 15.748 in, FD-WG4, FD-WSG4, FD-P60 and FD-P50: 200 200 mm 7.8747.874 in, FD-WL41: glass substrate

400

100t 2 mm 3.9373.937t 0.472 in)] as the object.

100

infrared type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can

fluctuate.

object size if using amplifiers other than red LED type.

Also, note that the corresponding setting distance is different from the rated sensing distance. However, with the fixed-focus reflective type, when the

sensitivity is at MAX., it is only possible to detect the minimum size of the sensing object at a distance corresponding to the convergent point.

9 0.354

45 1.772

30 1.181

16 0.630

36 1.417

18 0.709

14 0.551

25 0.984

19 0.748

50 1.969

10 0.394

6 0.236

5 0.197

2.5 0.098

1.5 0.059

8 0.315

4 0.157

2.5 0.098

10 0.394

1.5 0.059

1.5 0.059

5 0.197

3 0.118

3 0.118

1 0.039

4 0.157

2 0.079

8 0.315

4 0.157

2.5 0.098

2 0.079

1 0.039

7 0.276

3.5 0.138

2 0.079

"0.02 mm

"0.0008 in

gold wire

2 m

6.562 ft

1 m

3.281 ft

R4 mm

R0.157 in

FD-P60

FD-P50

FD-P40

FD-P2

Page 12

FX-301

08/2005

LIST OF FIBERS

Special use fibers (Reflective type)

:LONG

:FAST

Shape of fiber head

Type

(mm in)

W7H15D30 W0.276H0.591D1.181

Wide beam

Top sensing

W5H20D20

W0.197H0.787D0.787

Array

Side sensing

W5H20D20

W0.197H0.787D0.787

Coaxial Lens mountable

Coaxial Lens mountable

Coaxial Lens mountable

Coaxial Lens mountable

High precision

Coaxial Lens mountable

Sleeve part cannot be bent.

Coaxial

Sleeve part cannot be bent.

Sleeve part cannot be bent.

Ultra-small diameter

Coaxial

Special use

Sleeve part cannot be bent.

Fixed-focus reflective

Contact type

Liquid level sensing

Small spot for sensing minute objects

Glass substrate detection

SEMI S2 compliant

W17H29D3.8

W0.669H1.142D0.150

Glass substrate detection

W24H21D4

W0.945H0.827D0.157

Specular object detection

W15H19D3

W0.591H0.748D0.118

W6H18D14

W0.236H0.709D0.551

"6 "0.236

Mountable on pipe

Standard

W25H13D20

W0.984H0.512D0.787

Mountable on pipe For PFA, wall

thickness 1 mm 0.039 in pipe

W25H13D20

W0.984H0.512D0.787

Tough flexible

Coaxial High precision

Notes: 1)

Notes: 2) Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the

The sensing range is specified for white non-glossy paper [100100 mm 3.9373.937 in (FD-A15, FD-G4, FD-G6X:200200 mm 7.8747.874 in,

FD-AFM2, FD-AFM2E, FD-P81X: 400

glass substrate 100

100t 2 mm 3.9373.937t 0.079 in)] as the object.

Sensing range (mm in) (Note 1, 2)

Red LED

78 3.071

55 2.165

100 3.937

110 4.331

110 4.331

50 1.969

39 1.535

42 1.654

19 0.748

38 1.496

18 0.709

14 0.551

6 0.236

25 0.984

12 0.472

9 0.354

5 0.197

15 0.591

8 0.315

5 0.197

3 0.118

11 0.433

6 0.236

4 0.157

1 0.039

45 1.772

23 0.906

17 0.669

7 0.276

5 0.197

3 0.118

2 0.079

Cannot use

38 1.496

18 0.709

14 0.551

6 0.236

0 to 20 0 to 0.787

2.5 to 18 0.098 to 0.709 (Convergent point 8 0.315)

3 to 16 0.118 to 0.630 (Convergent point 8 0.315)

3.5 to 15 0.138 to 0.591 (Convergent point 8 0.315)

Cannot use

0.5 to 4 0.020 to 0.157 (Convergent point 2 0.079)

1 to 3.8 0.039 to 0.150 (Convergent point 2 0.079)

1.3 to 3.5 0.051 to 0.138 (Convergent point 2 0.079)

Cannot use

2.5 to 18 0.098 to 0.709 (Convergent point 6 0.236)

4 to 12 0.157 to 0.472 (Convergent point 6 0.236)

4.5 to 11 0.177 to 0.433 (Convergent point 6 0.236)

4.8 to 9.5 0.189 to 0.374 (Convergent point 6 0.236)

200 7.874

150 5.906

220 8.661

Blue LED

4.5 to 9.5 0.177 to 0.374

:STD

Green LED

25 0.984

15 0.591

40 1.575

20 0.787

13 0.512

22 0.866

11 0.433

8 0.315

6 0.236

3 0.118

2 0.079

5 0.197

2 0.079

1 0.039

2 0.079

1 0.039

2 0.079

1 0.039

6 0.236

3 0.118

2 0.079

6 0.236

3 0.118

2 0.079

5 to 9 0.197 to 0.354

5.5 to 8 0.217 to 0.315

18 0.709

9 0.354

5 0.197

12 0.472

6 0.236

4 0.157

3 0.118

1.5 0.059

1 0.039

2 0.079

1 0.039

1 0.039

1 0.039

3 0.118

1.5 0.059

1 0.039

3 0.118

1.5 0.059

1 0.039

5 to 9 0.197 to 0.354

5.5 to 8 0.217 to 0.315

Applicable pipe diameter:

Outer dia. "6 to "26 mm "0.236 to "1.024 in transparent pipe

[

PVC, fluorine resin, polycarbonate, acrylic, glass, wall thickness 1 to 3 mm 0.039 to 0.118 in

Applicable pipe diameter:

Outer dia. "6 to "26 mm "0.236 to "1.024 in transparent pipe

[PFA (fluorine resin) or equivalently transparent pipe, wall thickness 1 mm 0.039 in]

80 3.150

60 2.362

35 1.378

45 1.772

35 1.378

20 0.787

400 mm 15.74815.748 in, FD-L43: glass substrate 7652t 1.1 mm 2.9922.047t 0.043 in, FD-L41:

185 7.283

90 3.543

32 1.260

16 0.630

10 0.394

22 0.866

11 0.433

6 0.236

16 0.630

8 0.315

5 0.197

12 0.472

6 0.236

4 0.157

Min. sensing object

:S-D

12 0.472

6 0.236

4 0.157

7 0.276

3.5 0.138

2 0.079

10 0.394

5 0.197

3 0.118

6 0.236

3 0.118

2 0.079

3 0.118

1.5 0.059

1 0.039

1 0.039

6 0.236

3 0.118

2 0.079

4 0.157

2 0.079

1.5 0.059

at the maximum

sensitivity (Note 3)

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.04 mm

"0.0016 in

gold wire

"0.02 mm

"0.0008 in

gold wire

(LCD glass)

"0.06 mm

"0.0024 in

gold wire

"0.03 mm

"0.0012 in

gold wire

"0.02 mm

"0.0008 in

gold wire

Infrared LED

4.5 to 9.5 0.177 to 0.374

(Liquid)

]

(Liquid)

30 1.181

15 0.591

10 0.394

18 0.709

9 0.354

5 0.197

"0.02 mm

"0.0008 in

gold wire

infrared type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can

fluctuate.

Notes: 3) The minimum sensing object size is the value for red LED type at maximum sensitivity. Please contact our office for information on the minimum sensing

object size if using amplifiers other than red LED type.

Also, note that the corresponding setting distance is different from the rated sensing distance. However, with the fixed-focus reflective type, when the

sensitivity is at MAX., it is only possible to detect the minimum size of the sensing object at a distance corresponding to the convergent point.

Notes: 4) Following is the allowable cutting range from the end that the amplifier is inserted FD-F8Y: 1,000 mm 39.370 in, FD-G6X: 700 mm 27.559 in.

Fiber cable

length

:

Free-cut

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

500 mm

19.685 in

1 m

3.281 ft

500 mm

19.685 in

1 m

3.281 ft

2 m

6.562 ft

2 m 6.562 ft

(Note 4)

2 m

6.562 ft

5 m

16.404 ft

2 m

6.562 ft

5 m

16.404 ft

1 m

3.281 ft

1 m 3.281 ft

(Note 4)

Allowable

bending

radius

R25 mm

R0.984 in

R25 mm

R0.984 in

R25 mm

R0.984 in

R10 mm

R0.394 in

R10 mm

R0.394 in

R25 mm

R0.984 in

R4

R0.157

R10 mm

R0.394 in

Protective tube

R40 mm R1.575 in

Fiber

R15 mm R0.591 in

R10 mm

R0.394 in

R10 mm

R0.394 in

Model No.

FD-A15

FD-AFM2

FD-AFM2E

FD-G4

FD-G6

FD-EG1

FD-EG2

FD-EG3

FD-E12

FD-E22

FD-EN500S1

FD-ENM1S1

FD-L43

FD-L41

FD-L42

FD-L4

FD-F8Y

FD-F41

FD-F91

FD-F4

FD-F9

FD-P81X

FD-G6X

79

Page 13

FX-301

08/2005

LIST OF FIBERS

Environment resistant fibers (Reflective type)

:LONG

:FAST

Shape of fiber head

Type

Heat-resistant

Environment resistant

Vacuum

Notes: 1)

Notes: 2)

Notes: 3) The minimum sensing object size is the value for red LED type at maximum sensitivity. Please contact our office for information on the minimum sensing

(mm in)

350 C 662 F Coaxial

350 C 662 F Sleeve 60 mm 2.362 in

200 C 392 F Coaxial

350 C 662 F Sleeve 90 mm 3.543 in

200 C 392 F Coaxial

300 C 572 F Glass substrate detection

Fixed-focus reflective type

180 C 356 F Glass substrate detection

Fixed-focus reflective type

130 C 266 F

The sensing range is specified for white non-glossy paper [400400 mm 15.74815.748 in (FD-H30-L32, FD-H18-L31: glass substrate 5050 mm 1.9691.969 in)] as the object.

Please take care that the sensing range of the free-cut type fiber may be reduced by 20 % max. depending upon how the fiber is cut. In addition, the infrared

type is easily affected by humidity, so contact our office if using these sensors in environments with high humidity or where humidity levels can fluctuate.

object size if using amplifiers other than red LED type. Also, note that the corresponding setting distance is different from the rated sensing distance.

W19H27D5

H1.063

W0.748

D0.197

W19H27D5

W0.748H1.063

D0.197

Sensing range (mm in) (Note 1, 2)

Red LED

270 10.630

140 5.512

100 3.937

47 1.850

160 6.299

80 3.150

57 2.244

26 1.024

100 3.937

47 1.850

0 to 15 0 to 0.591

0 to 10 0 to 0.394

1 to 8 0.039 to 0.315

2 to 6 0.079 to 0.236

100 3.937

47 1.850

75 2.953

52 2.047

26 1.024

140 5.512

140 5.512

165 6.496

270 10.630

310 12.205

Blue LED

36 1.417

18 0.709

12 0.472

22 0.866

11 0.433

7 0.276

36 1.417

18 0.709

12 0.472

20 0.787

11 0.433

7 0.276

26 1.024

13 0.512

9 0.354

:STD

Green LED

20 0.787

10 0.394

7 0.276

12 0.472

6 0.236

4 0.157

20 0.787

10 0.394

7 0.276

20 0.787

11 0.433

7 0.276

14 0.551

7 0.276

4 0.157

Min. sensing object

:S-D

140 5.512

70 2.756

45 1.772

80 3.150

40 1.575

28 1.102

140 5.512

70 2.756

45 1.772

25 0.984

12 0.472

8 0.315

21 0.827

10 0.394

6 0.236

at the maximum

sensitivity (Note 3)

Infrared LED

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

"0.02 mm

"0.0008 in

gold wire

Fiber cable

length

:

Free-cut

2 m

6.562 ft

1 m

3,281 ft

1 m

3,281 ft

1 m

3,281 ft

2 m

6.562 ft

2 m

6.562 ft

2 m

6.562 ft

1 m

3,281 ft

Allowable

bending

radius

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R25 mm

R0.984 in

Fiber

R25 mm

R0.984 in

Sleeve

R10 mm

R0.394 in

R25 mm

R0.984 in

R25 mm

R0

.984 in

R25 mm

R0.984 in

R200 mm

R7.874 in

Model No.

FD-H35-M2

FD-H35-M2S6

FD-H20-M1

FD-H35-20S

FD-H20-21

FD-H30-L32

FD-H18-L31

FD-H13-FM2

FD-6V

The vacuum type fiber must be used with the following products as a set.

FT-J6: Fiber at atmospheric side (one pair set)

FV-BR1: Photo-terminal (one pair set)

Semi-standard fibers (Custom made per order)

The fiber cable length or sleeve length of the standard fibers can be modified at your request. Select the fiber cable length (symbol ) or the sleeve length

(symbol f ) from the table below.

Fiber cable length

Type

Standard threaded

head (free-cut)

With sleeve

Small diameter

threaded head with

sleeve (free-cut)

200C 392F heat-resistant

350C 662F heat-resistant

Note:

The standard fiber has a 2 m 6.562 ft fiber cable length and a 4 cm 1.575 in or 9 cm 3.543 in sleeve length.

Basic model No.

FD-FM

FD-FM -S f

FD-NFM2-S f

FD-H20-M

FD-H35-M

(Unit: m ft)

3 9.843, 4 13.123, 5 16.404,

10 32.808, 15 49.213, 20 65.617

2 6.562 (Note), 3 9.843, 4 13.123,

5 16.404, 10 32.808, 15 49.213,

20 65.617

2 6.562, 3 9.843

3 9.843

1 0.394, 2 0.787, 3 1.181, 4 1.575,

5 1.969, 6 2.362, 7 2.756, 8 3.150,

9 3.543, 10 3.937, 11 4.331, 12 4.724

1 0.394, 2 0.787, 3 1.181, 4 1.575,

5 1.969, 6 2.362, 7 2.756, 8 3.150,

9 3.543, 10 3.937, 11 4.331, 12 4.724

Sleeve length

f

(Unit: cm in)

Correlation between sensing

range attenuation coefficient and

fiber cable length

The longer the fiber cable, the

shorter the sensing range.

Accessories (attached with fibers)

Fiber cutter

• FX-CT2

Notes: 1)

Fiber cutter is not supplied as accessory along with FT-NB8, FT-N8, FD-N8 and FD-N4. Please order it separately.

The fiber attachment is not attached with FT-N8/NB8/P80 and FD-N8/P80. The previous FX-AT10 attachment is attached with FD-N4.

Notes: 2)

Fiber attachment

• FX-AT2

(for fixed-length fiber)

• FX-AT3

for "2.2 mm

()

"0.087 in fiber

• FX-AT4

(for "1 mm "0.039 in fiber)

• FX-AT5

(for "1.3 mm "0.051 in fiber)

• FX-AT6

for "1 mm "0.039 in and "1.3 mm

(

"0.051 in mixed fiber

)

80

Page 14

FX-301

08/2005

FIBER OPTIONS

Lens (For thru-beam type fiber)

Designation

Model No.

Increases the sensing range by 5 times or

more.

• Ambient temperature:

60 to 350 C

Expansion

lens

(Note 1)

FX-LE1

76 to 662 F

Tremendously increases the sensing

range with large diameter lenses.

• Ambient temperature:

60 to 350 C

Superexpansion

lens

FX-LE2

76 to 662 F

(Note 1)

For thru-beam type fiber

Beam axis is bent by 90 .

• Ambient temperature:

60 to 300 C

76 to 572 F

Sideview

FX-SV1

lens

Expansion

lens for

vacuum

FV-LE1

fiber

(Note 1)

Notes: 1)

Notes: 2) The sensing ranges are the values for red LED type amplifier. Please contact our office for details on sensing ranges for other types of amplifiers.

Be careful when installing the thru-beam type fiber equipped with the expansion lens, as the beam envelope becomes narrow and alignment is difficult.

Especially when installing a fiber with many cores (sharp bending fibers and heat-resistant glass fiber) please be sure to use it only after you have adjusted it sufficiently.

Sensing range increases by 15 times or

more.

• Ambient temperature:

40 to 120 C

40 to 248 F

Notes: 3) The fiber cable length practically limits the sensing range to 3.500 mm 137.795 in long (FT-H20W-M1 and FT-H20-M1: 1,600 mm 62.992 in).

Lens (For reflective type fiber)

Designation

Pinpoint

spot lens

Zoom lens

Finest spot

lens

For reflective type fiber

Finest spot

lens

Zoom lens

Side-view

type

()

Note:

The sensing ranges are the values when used in combination with red LED type amplifier. Please contact our office for details on sensing distances for other types of amplifier.

Model No.

FX-MR1

FX-MR2

FX-MR3

FX-MR6

FX-MR5

Pinpoint spot of "0.5 mm "0.020 in. Enables detection of minute objects or small marks.

• Applicable fibers: FD-WG4, FD-G4 • Distance to focal point: 6

• Ambient temperature:

The spot diameter is adjustable from "0.7 mm

"0.028 in to "2 mm "0.079 in according to

how much the fiber is screwed in.

• Applicable fibers: FD-WG4, FD-G4

Ambient temperature:40 to70 C 40 to 158 F

•

• Accessory: MS-EX-3 (mounting bracket)

Extremely fine spot of "0.3 mm "0.012 in approx.

achieved.

•

Applicable fibers:

•

Ambient temperature:40 to 70 C 40 to 158 F

Extremely fine spot of "0.1 mm "0.004 in

achieved.

•

Applicable fibers:

•

Ambient temperature:20 to 60 C 4 to 140 F

FX-MR2 is converted into a side-view type and

can be mounted in a very small space.

• Applicable fibers: FD-WG4, FD-G4

Ambient temperature:40 to 70 C 40 to 158 F

•

Description

Sensing range (mm) [Lens on both sides]

Sensing range (mm) [Lens on both sides]

Sensing range (mm) [Lens on both sides]

Sensing range (mm) [Lens on both sides] (Note 2)

Description

40 to 70 C 40 to 158 F

FD-WG4, FD-G4, FD-EG1,

FD-EG3, FD-G6X, FD-G6

FD-WG4, FD-G4, FD-EG1

FD-EG3, FD-G6X, FD-G6

FD-EG2,

approx.

,FD-EG2,

Mode

Fiber

FT-B8

FT-FM2

FT-T80

FT-R80

FT-W8

FT-P80

FT-P60

FT-P81X

FT-H35-M2

FT-H20W-M1

FT-H20W-M2

FT-H20-M1

Fiber

FT-B8

FT-FM2

FT-R80

FT-W8

FT-P80

FT-P60

FT-P81X

FT-H35-M2

FT-H20W-M1

FT-H20W-M2

FT-H20-M1

FT-H13-FM2

Fiber

FT-B8

FT-FM2

FT-T80

FT-W8

FT-P80

FT-P60

FT-P81X

FT-H35-M2

FT-H20W-M1

FT-H20W-M2

FT-H20-M1

Fiber

FT-6V

FT-60V

LONG STD FAST S-D

(

)

Note 3

3,500

3,500

3,500

3,500

3,500

3,500

3,500

3,500

3,500

1,600

2,600

1,600

Mode

LONG STD FAST S-D

3,500

3,500

3,500

3,500

3,500

3,500

3,500

3,500

1,600

3,500

1,600

3,500

Mode

LONG STD FAST S-D

Mode

LONG STD FAST S-D

3,500

2,800

1,100

1,200

1,200

900

1,200

650

1,200

550

310

310

550

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

2,500

3,500

3,500

2,300

2,900

3,500

3,500

3,500

2,000

1,300

1,300

1,600

3,500

3,500

3,500

3,500

3,500

3,500

3,500

3,500

1,600

3,500

1,600

3,500

530

600

600

450

600

300

600

280

140

140

280

2,700

1,450

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

3,500

3,500

3,500

3,500

3,500

3,500

3,500

3,500

1,600

3,000

1,600

3,500

2,000

2,500

2,500

1,600

2,000

2,500

1,500

2,500

1,500

900

900

1,100

400

440

440

330

440

200

440

200

100

100

200

1,800

1,000

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

1 mm 0.236 0.039 in

Sensing range (Note 1)

Screw-in depth Distance to focal point Spot diameter

7 mm

12 mm

14 mm

Sensing range (Note 1)

Fiber Distance to focal point Spot diameter

FD-EG3

FD-EG2

FD-EG1

FD-WG4/G4/G6X/G6

Sensing range (Note 1)

Fiber Distance to focal point Spot diameter

FD-EG3

FD-EG2

FD-EG1

FD-WG4/G4/G6X/G6

Sensing range (Note 1)

Screw-in depth Distance to focal point Spot diameter

8 mm

10 mm

14 mm

"18.5 mm approx.

"27 mm approx.

"43 mm approx.

7.5 0.5 mm

7.5

0.5 mm

7.5

0.5 mm

7.5

0.5 mm

7 0.5 mm

7

0.5 mm

7

0.5 mm

7

0.5 mm

13 mm approx.

15 mm approx.

30 mm approx.

"

"

"

"0.15 mm approx.

"0.2 mm approx.

"0.3 mm approx.

"0.5 mm approx.

"0.1 mm approx.

"0.15 mm approx.

"0.2 mm approx.

"0.4 mm approx.

"0.5 mm

"0.8 mm

"3.0 mm

)

3,500

)

3,500

)

3,500

)

3,500

)

3,500

)

3,500

)

3,500

)

3,500

)

1,500

1,500

)

1,600

)

3,500

0.7 mm

1.2 mm

2.0 mm

(Note 2)

1,000

1,300

1,300

800

1,000

1,100

900

1,100

750

500

500

900

(Note 2)

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(

Note 3

(Note 2)

186

210

210

160

210

130

200

90

50

50

90

940

490

)

)

)

)

)

)

)

)

)

)

81

Page 15

FX-301

08/2005

FIBER OPTIONS

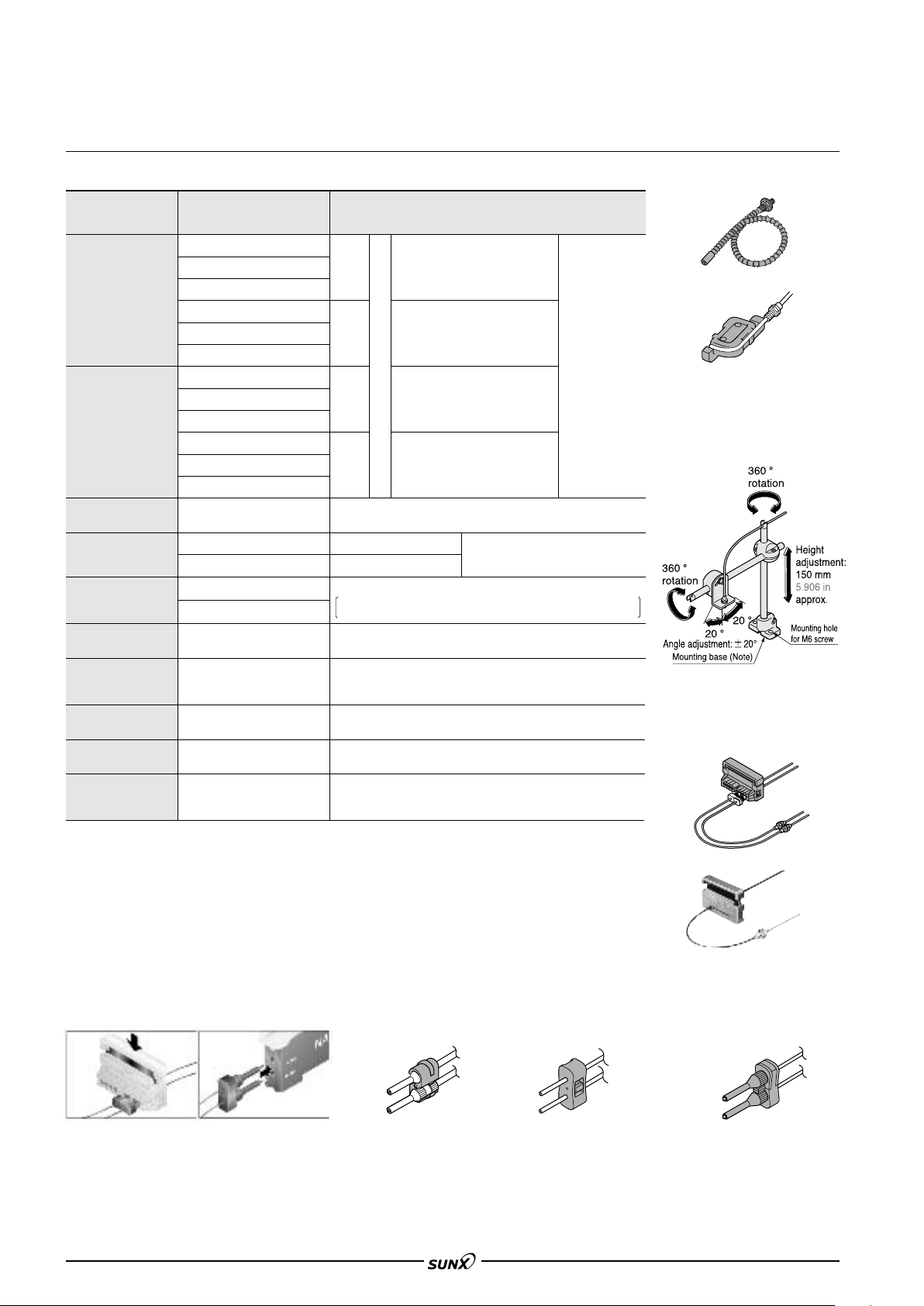

Others

Designation

Protective tube

For thru-beam

(

type fiber

Protective tube

For reflective

(

type fiber

Fiber bender

Universal sensor

mounting stand

(Note 2)

Fiber cutter

Attachment for fixedlength fiber

)

)

Model No. Description

FTP-500 (0.5 m 1.640 ft)

FTP-1000 (1 m 3.281 ft)

FTP-1500 (1.5 m 4.921 ft)

FTP-N500 (0.5 m 1.640 ft)

FTP-N1000 (1 m 3.281 ft)

FTP-N1500 (1.5 m

4.921 ft

FDP-500 (0.5 m 1.640 ft)

FDP-1000 (1 m 3.281 ft)

FDP-1500 (1.5 m 4.921 ft)

FDP-N500 (0.5 m 1.640 ft)

FDP-N1000 (1 m 3.281 ft)

FDP-N1500 (1.5 m

4.921 ft

FB-1

MS-AJ1-F

MS-AJ2-F

FX-CT2

FX-CT1

FX-AT2

For

M4

thread

For

M3

thread

)

For

M6

thread

For

M4

thread

)

The fiber bender bends the sleeve part of the fiber head at the

proper radius. (Note 1)

Horizontal mounting type

Vertical mounting type

The free-cut type fiber can be easily cut.

Accessory. Does not attach with the FT-N8/NB8 or the

FD-N8/N4. (Note 3)

This is the attachment for the fixed length fiber. (

FT-B8

FT-NB8

FT-FM2

FT-FM2S

FT-FM2S4

FT-T80

FT-NFM2

FT-NFM2S

FT-NFM2S4

FD-B8

FD-FM2

FD-FM2S

Applicable fibers

FD-FM2S4

FD-N8

FD-T80

FD-N4

FD-NFM2

FD-NFM2S

FD-NFM2S4

FT-N8

FT-P80

FT-P60

FT-H13-FM2

FT-P40

FD-T40

FD-P40

FD-P80

FD-H13-FM2

Mounting stand assembly for fiber

(For M3, M4 or M6 threaded head fiber)

The protective

tube, made of

non-corrosive

stainless steel,

protects the

inner fiber cable

from any

external forces.

Accessory

)

Protective tube

• FTP-

• FDP-

Fiber bender

• FB-1

Universal sensor mounting stand

• MS-AJ1-F

• MS-AJ2-F

Using the arm which enables adjustment

in the horizontal direction, sensing can

also be done from above an assembly line.

Attachment for "2.2 mm

"0.087 in fiber

Attachment for "1 mm

"0.039 in fiber

Attachment for "1.3 mm

"0.051 in fiber

Attachment for "1 mm

"0.039 in / "1.3 mm

"0.051 in mixed fiber

Notes: 1) Do not bend the sleeve part of any side-view type fiber or ultra-small diameter head type fiber.

Notes: 2) Refer to p.332l for details of the universal sensor mounting stand.

Notes: 3) A conventional FX-CT1 fiber cutter is attached with the FT-P80 and the FD-P80.

Notes: 4) The conventional FX-AT10 fiber attachment is attached with the FD-N4.

FX-AT3

FX-AT4

FX-AT5

FX-AT6

This is the attachment for the "2.2 mm "0.087 in fiber.

Accessory. Does not attach with the FT-N8/NB8/P80 or the FD-N8/P80

(

This is the attachment for the "1 mm "0.039 in fiber

(Accessory. Does not attach with the FD-N4.) (Note 4)

This is the attachment for the "1.3 mm "0.051 in fiber (Accessory)

This is the attachment for the "1 mm"0.039 in / "1.3 mm

"0.051 in mixed fiber. (Accessory)

Note:

.)

Fiber cutter

• FX-CT2

• FX-CT1

The above figure is MS-AJ1-F.

The mounting base of MS-AJ2-F

has a different shape.

Fiber attachment

It’s possible to simultaneously cut two fibers to the same length

Each fiber (with some exceptions) has a newly developed two-in-one fiber attachment (FX-AT3/AT4/AT5/AT6) which enables two fibers to be cut simultaneously

to the same length with the new fiber cutter (FX-CT2). Also, since the fibers can be attached to the amplifier while being fixed in position in the two-in-one fiber

attachment, sensitivity changes resulting from variation in the amount of fiber insertion do not occur.

FX-AT2 FX-AT3

FX-AT4/AT5/AT6

82

Page 16

FX-301

08/2005

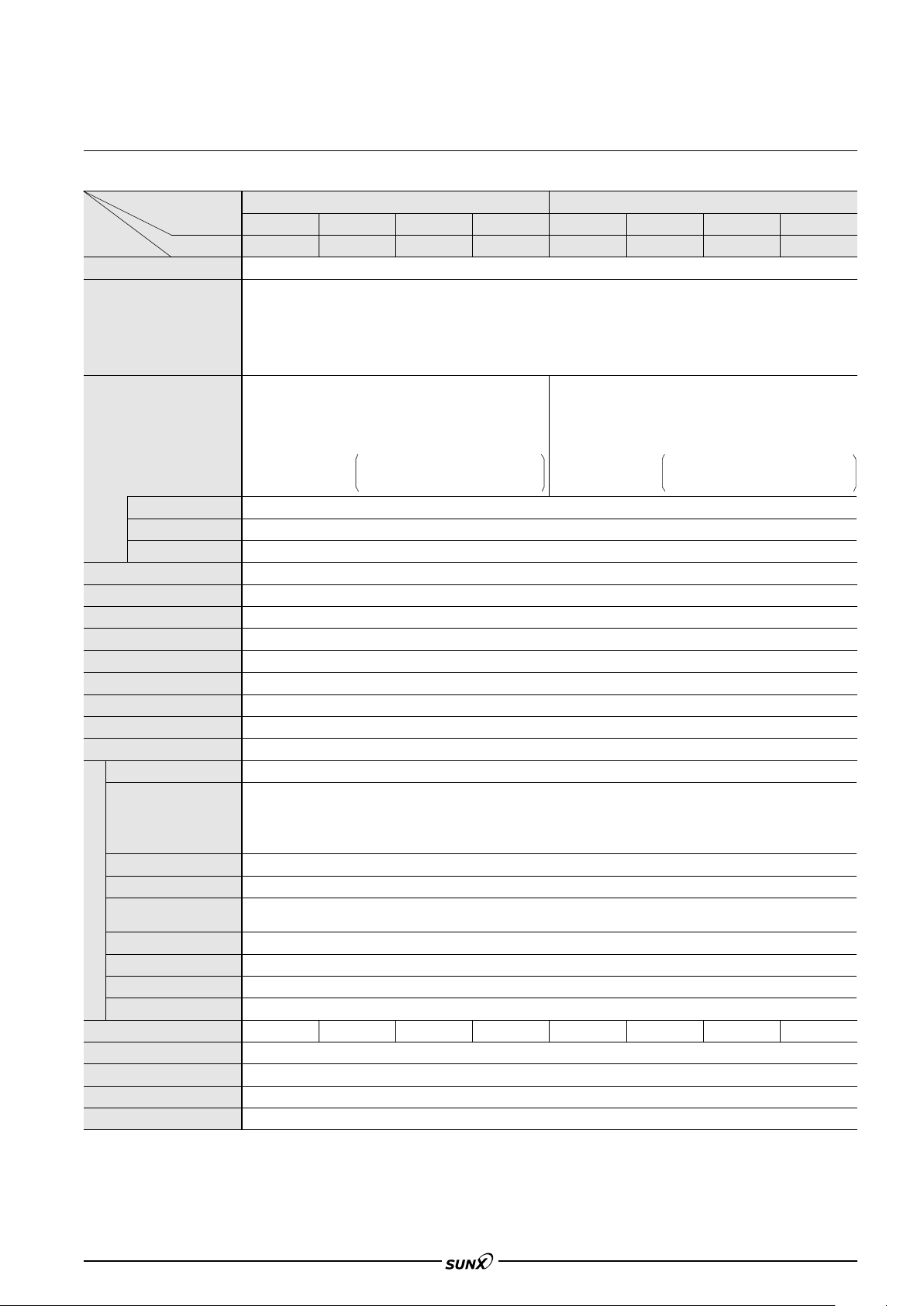

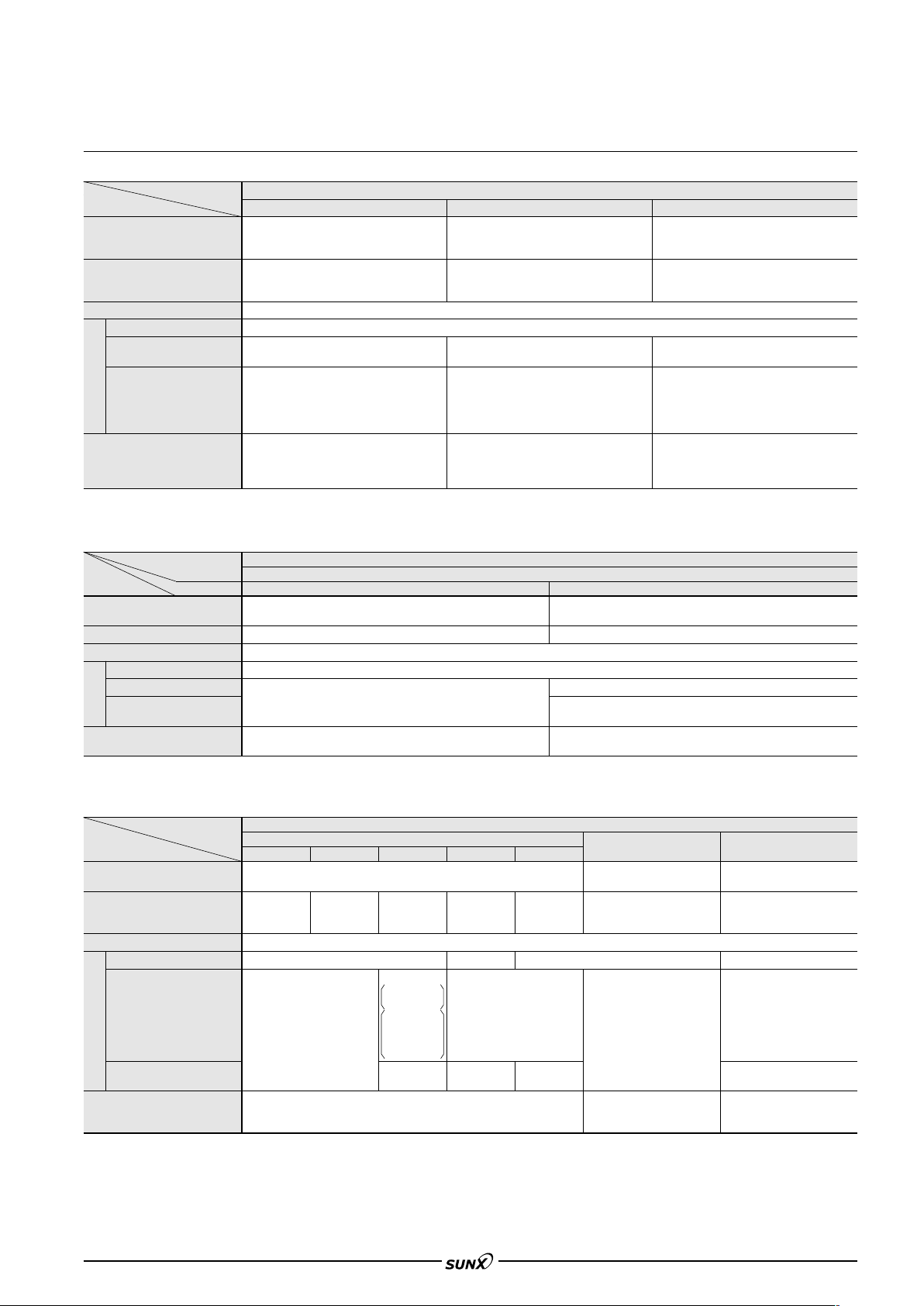

SPECIFICATIONS

Amplifiers

Type

Red LED Blue LED Green LED Infrared LED Red LED Blue LED Green LED

Item

Supply voltage

Model No.

FX-301 FX-301B FX-301G FX-301H FX-301P FX-301BP FX-301GP FX-301HP

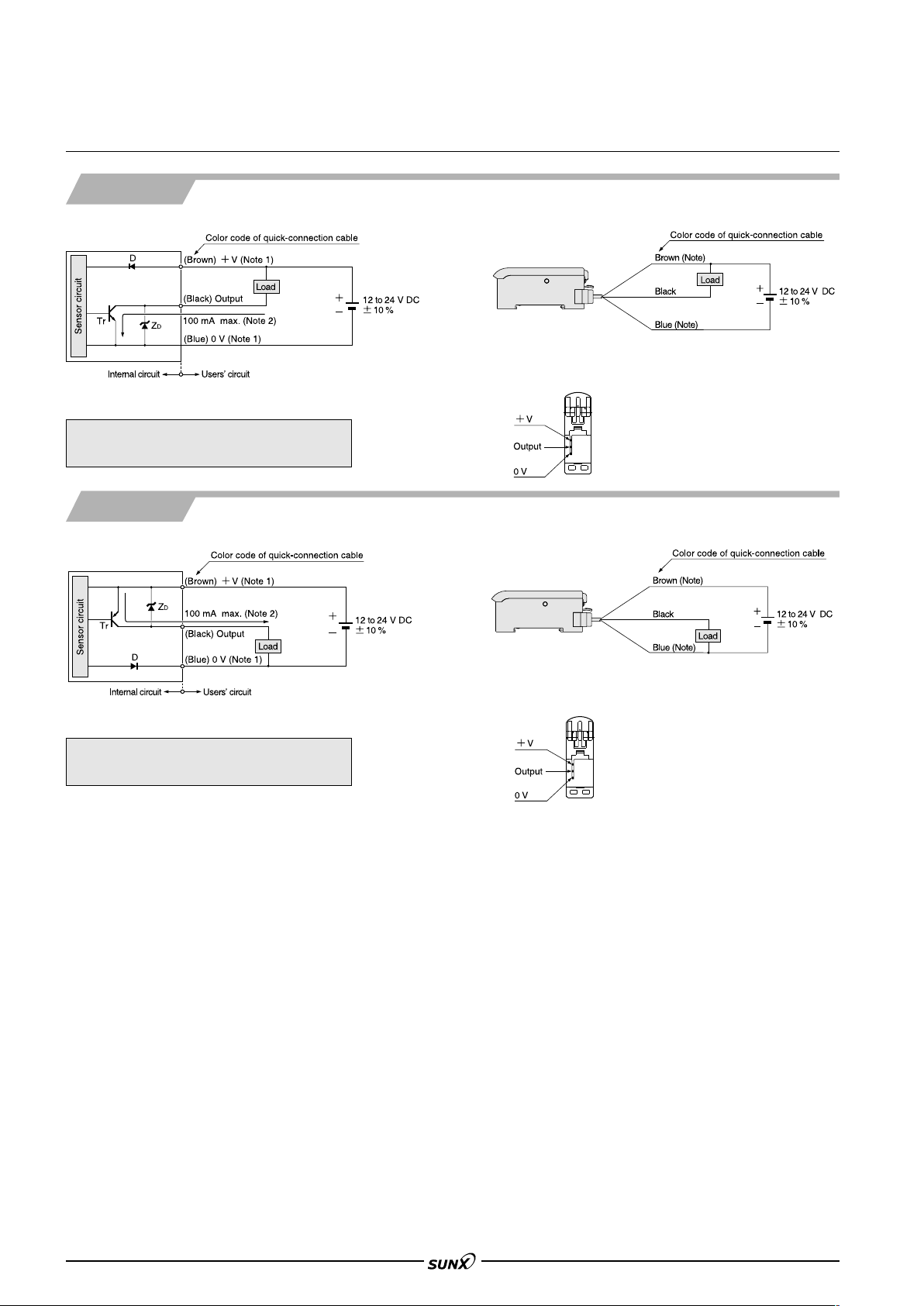

<Red LED / Infrared LED type>

Normal operation: 960 mW or less

Power consumption

Output

Utilization category

Output operation

Short-circuit

protection

Response time

Sensitivity setting

Operation indicator

Stability indicator

MODE indicator

Digital display

Fine sensitivity adjustment function

Timer function

Automatic interference prevention function

Pollution degree

Ambient temperature

Ambient humidity

Ambient illuminance

EMC

Voltage withstandability

Environmental resistance

Insulation resistance

Vibration resistance

Shock resistance

Emitting element (modulated)

Material

Connecting method

Cable extension

Weight

Notes: 1) When the power supply is switched on, the emission timing are automatically set for interference prevention.

Notes: 2) The voltage withstandability and the insulation resistance values given in the above table are for the amplifier only.

Notes: 3) The cable for amplifier connection is not supplied as an accessory. Make sure to use the optional quick-connection cable given below.

Main cable (3-core): CN-73-C1 (cable length 1 m 3.281 ft), CN-73-C2 (cable length 2 m 6.562 ft), CN-73-C5 (cable length 5 m 16.404 ft)

Sub cable (1-core): CN-71-C1 (cable length 1 m 3.281 ft), CN-71-C2 (cable length 2 m 6.562 ft), CN-71-C5 (cable length 5 m 16.404 ft)

ECO mode: 600 mW or less

NPN open-collector transistor

65 !s or less (ultra high speed), 150 !s or less (FAST), 250 !s or less [STD / S-D (Red LED type only)], 2 ms or less (LONG) selectable with jog switch

Incorporated with variable ON-delay / OFF-delay / ONE SHOT timer, switchable either effective or ineffective. (timer period: 0.5 to 500 ms approx.)

Red LED Blue LED Green LED Infrared LED Red LED Blue LED Green LED

Current consumption 25 mA or less at 24 V

()( )

supply voltage

Maximum sink current:100 mA

•

Applied voltage:

•

Residual voltage: 1.5 V or less

•

Sunlight: 10,000?x at the light-receiving face, Incandescent light: 3,000?x at the light-receiving face

20 MΩ, or more, with 250 V DC megger between all supply terminals connected together and enclosure (Note 2)

NPN output PNP output

12 to 24 V DC10 % Ripple P-P 10 % or less

<Blue LED / Green LED type>

Current consumption 40 mA or less at

()

24 V supply voltage

50 mA, if five, or more, amplifiers

()()

are connected in cascade.

30 V DC or less (between output and 0 V)

at 100 mA (at 50 mA, if five, or more,

amplifiers are connected in cascade)

sink current.