Page 1

ARCT1F409E-3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

'07・04

Page 2

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User

Make sure that you fully understand the product and information on safe.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cau

battery or other electronic parts.

CAUTION

If critical situations that could lead to user’s injury or only property damage is assumed

by mishandling of the product.

-To prevent abnormal exothermic heat or smoke generation, use thi

than the maximum of the characteristics and performance that are assure in these specifications.

-Do not dismantle or remodel the product. It could lead to abnormal exothermi

smoke generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock..

-Use the external devices to function the

-Connect the wires or connectors securely.

The loose connection might cause abnormal exothermic heat or smoke generation

-Ground the protective earth (PE) terminal (Class

an electric shock.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the

inside of the prod

-Do not undertake construction (such as connection and disconnection) while the power

supply is on.

uct. It might cause exothermic heat or smoke generation.

emerge

ncy stop and interlock circuit.

D groundi

’s Manual thoroughly before use.

se damage to the lithium

s product at the values less

c heat or

ng). Failure to do so could lead to

Copyright / Trademarks

-This manual and its contents are copylighted.

-You may not copy this manual,in whole or part,without written consent of Matsushita Electric

Works,Lt

-Windows and Windows NT are registered trademarks of Microsof

United States and/o r othe r countries.

-All other company names and product name

trademarks of their respective owners.

-Matsushita Electric Works,Ltd. pursues a policy of co

Design and performan e of its products, therefore,we re

product without notice.

d.

t Corporation in the

s are tradem

arks or registered

ntinuous imp

serve the right to change the manual/ c

rovement of the

Page 3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Table of Contents

Before You Start

Differences in Functions Between Versions of Controller

Programming Tool Restrictions

1. Features, Functions and Restrictions................................................. 1-1

1.1 Features and Functions of the Unit...............................................................................1-2

1.2 Unit Types ........................................................................................................................1-6

1.2.1 FP-X Control Units......................................................................................................1-6

1.2.2 FP-X Expansion Unit...................................................................................................1-7

1.2.3 FP-X Expansion FP0 Adapter.....................................................................................1-7

1.2.4 Add-on Cassettes

1.2.5 Related Parts ..............................................................................................................1-9

(Communication cassettes/Application cassettes)........................1-8

1.3 Restrictions on Unit Combinations .............................................................................1-10

1.3.1 Restrictions on FP-X Expansion Unit

1.4 Programming Tools.......................................................................................................1-14

1.4.1 Tools Needed for Programm

1.4.2 Software Environment and Suitable Cable...............................................................1-1

ing................................................................................1-14

........................................................................1-10

4

2. Specifications and Functions of Control Unit....................................2-1

2.1 Parts and Functions........................................................................................................2-2

2.1.1 Parts and Functions....................................................................................................2-2

2.2 Powe

2.2.1 AC Power Supply........................................................................................................2-5

2.2.2 Service Power Supply for Input (Output) (A

2.2.3 DC Power Supply........................................................................................................2-5

2.3 Input Specifications ........................................................................................................2-6

2.3.1 Relay (Ry) Type..........................................................................................................2-6

2.3.2 Transi

2.4 Output Specifications .....................................................................................................2-8

2.4.1 Relay (Ry) Type..........................................................................................................2-8

2.4.2 Transis

2.4.3 Transis

r Supply Specifications .........................................................................................2-5

C Power Supply Type Only)...................2-5

s

tor (Tr) Type (Common to NPN and PNP)......................................................2-7

tor (Tr) Type (NPN).........................................................................................2-9

tor (Tr) Type (PNP) .......................................................................................2-10

2.5 Terminal Layout

2.5.1 Relay Type................................................................................................................2-14

2.5.2 Transistor type

.............................................................................................................2-14

..........................................................................................................2-16

Page 4

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3. Expansion Cassette and Expansion FP0 Adapter Specifications ....3-1

3.1 Expansion Method...........................................................................................................3-2

3.1.1 Expansion Using the Expansion Cable.......................................................................3-2

3.2 FP-X Expansion Unit .......................................................................................................3-4

3.2.1 Parts and Functions

3.2.2 Power Supply Specifications.......................................................................................3-5

3.2.3 Input and output specifications ...................................................................................3-6

3.2.4 Terminal layout............................................................................................................3-9

....................................................................................................3-4

3.3 FP-X Expansion FP0 Adapter

3.3.1 Overview ...................................................................................................................3-12

3.3.2 Parts and Functions

..................................................................................................3-13

.......................................................................................3-1

2

4. I/O Allocation.........................................................................................4-1

4.1 I/O Allocation....................................................................................................................4-2

4.2 Allocation of FP-X Control Unit......................................................................................4-3

4.3 FP0 Expansion Unit Allocation

4.4 Allocation of FP0 Expansion Unit..................................................................................4-4

4.4.1 I/O A

4.4.2 Number of Expansion Units and I/O Allocation...........................................................4-4

4.4.3 I/O Allocation of FP0 Expansion Unit..........................................................................4-5

4.5 I/O Allocation of FP-X Add-on Cassette........................................................................4-6

llocation

...............................................................................................................4-4

......................................................................................4-3

5. Installation and Wiring..........................................................................5-1

5.1 Installation........................................................................................................................5-2

5.1.1 Installation Environment and Space ...........................................................................5-2

5.2 Installation Using Expansion Cable...............................................................................5-5

5.3 Expansion Method of FP0 Expansion Unit ...................................................................5-8

5.4 How

5.5 Powe

to Install Add-on Cassette......................................................................................5-9

r Supply.................................................................................................................5-11

ii

Page 5

5.6 Wiring of Input and Output...........................................................................................5-15

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

5.7 Wiring of Terminal Block ..............................................................................................5-18

5.8 Wiring of Add-on Cassette Terminal Block ................................................................5-20

5.9 Installation and Setting of Backup Battery

5.9.1 Installat

5.9.2 System R

5.9.3 Time for Replacement of Back

5.9.4 Lifetime of Backu

5.10 Safety Measu

5.10.1 Safety Measures.....................................................................................................5-27

5.10.2 Momentary Power Failures.....................................................................................5-27

5.10.3 Protection of Output Sections.................................................................................5-2

ion of Backup Battery ...................................................................................5-24

egister Setting ...........................................................................................5-25

up Battery.................................................................5-25

p Battery........................................................................................5-26

res ..........................................................................................................5-27

.................................................................5-23

7

6. Tool Port and USB Port........................................................................ 6-1

6.1 Tool Port and USB Port...................................................................................................6-2

6.2 Functions of Tool Port ....................................................................................................6-3

6.2.1 Tool Port......................................................................................................................6-3

6.2.2 Tool Port Setting .........................................................................................................6-4

6.3 USB Port...........................................................................................................................6-6

6.3.1 Functions of USB Port

6.3.2 USB Port Setting.........................................................................................................6-7

6.3.3 USB Connection

6.3.4 USB Connection Procedure........................................................................................6-9

6.3.5 Installat

6.3.6 Installat

6.3.7 Confirming COM Ports..............................................................................................6-1

6.3.8 Communication with FPWIN GR

6.3.9 Reinstallation of USB Driver

6.3.10 Restric

ion of FPWIN GR............................................................................................6-9

ion of USB Driver..........................................................................................6-10

tions on USB Communication......................................................................6-22

................................................................................................6-6

.........................................................................................................6-8

8

...............................................................................6-20

.....................................................................................6-21

7. Communication Cassette..................................................................... 7-1

7.1 Functions and Types.......................................................................................................7-2

7.1.1 Overview of Communication Cassette........................................................................7-2

7.1.2 Functions of Communic

7.1.3 Communication Cassettes..........................................................................................7-7

7.1.4 Examples of Connection

7.1.5 Names and Principl

7.1.6 About USB Port (For C30/C60 Only

7.2 Communication Specifications....................................................................................7-15

ation Cassette.......................................................................7-3

...........................................................................................7-12

e Applications of the Ports.........................................................7-13

)........................................................................7-14

iii

Page 6

7.2.1 Precaution When Using RS485 Port.........................................................................7-18

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

7.3 Communication Function 1: Computer Link...............................................................7-19

7.3.1 Computer Link...........................................................................................................7-19

7.3.2 1:1 Communicati

7.3.3 1:N Communication (Computer Link)

7.3.4 MEWTOCOL Master (Sample Program)

7.4 Communication Function 2: General-purpose Serial Communication....................7-3

7.4.1 General-purpose Serial Communication...................................................................7-3

7.4.2 Communication with External Devic

7.4.3 Connection with 1:1 Communication (General-purpos

7.4.4 1:N Communication

7.5 Communication Function 3: PC(PLC) Link.................................................................7-59

7.5.1 PC(PLC) Link............................................................................................................7-59

7.5.2 Setting Communication Parameters

7.5.3 Monitoring .................................................................................................................7-70

7.5.4 Connection Example of PC(PLC) Link......................................................................7-71

7.5.5 PC(PLC) Link Response

7.6 Communication Function 4: MODBUS RTU Communication...................................7-78

7.6.1 MODBUS RTU Communica

7.6.2 MEWTOCOL Master (Sample Program)

on (Computer link) .........................................................................7-27

........................................................................7-30

..................................................................7-33

5

5

es......................................................................7-37

e serial communication).......7-47

(General-purpose Serial Communication)................................7-58

.........................................................................7-61

Time..................................................................................7-74

tion................................................................................7-78

..................................................................7-82

8. Application Cassette.............................................................................8-1

8.1 Expansion of Application Cassette ...............................................................................8-2

8.2 Application Cassettes.....................................................................................................8-3

8.3 Specifications ..................................................................................................................8-5

8.3.1 FP-X Analog Input Cassette........................................................................................8-5

8.3.2 FP-X Input Cassette....................................................................................................8-8

8.3.3 FP-X Output Cass

8.3.4 FP-X Pulse I/O Cassette...........................................................................................8-23

8.3.5 FP-X Master Memory Cass

ette

...............................................................................................8-21

ette.................................................................................8-26

9. High-speed Counter, Pulse Output and PWM Output Functions (For

Tr Type) .................................................................................................9-1

9.1 Overview of Each Functions...........................................................................................9-2

9.1.1 Usable Units and Cassettes........................................................................................9-2

9.1.2 Three Pulse I/O Functions ..........................................................................................9-2

tion

9.1.3 Performance of Pulse I/O Func

9.2.1 Specifications..............................................................................................................9-4

9.2.2 Functions Used and Restrictions................................................................................9-6

9.2.3 Booting Time.............................................................................................................9-10

.............................................................................9-3

iv

Page 7

9.3 High-speed Counter Function......................................................................................9-11

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

9.3.1 Overview of High-speed Counter Function

9.3.2 Input Modes and Count.............................................................................................9-11

9.3.3 Minimum Input Pulse Width......................................................................................9-12

9.3.4 I/O Allocation

9.3.5 Instruc

9.3.6 Sample program (Control Unit and Main Unit I/O)....................................................9-16

.............................................................................................................9-13

tions used with High-speed Counter Function...............................................9-13

...............................................................9-11

9.4 Pulse Output Function..................................................................................................9-19

9.4.1 Overview of Pulse Output Function

9.4.2 Types of Pulse Output Method and Operation Modes .............................................9-2

9.4.3 I/O Allocation

9.4.4 Pulse output cont

9.4.5 Wiring for Pulse Output Sample Program (F171 to F174)

9.4.6 Positioning Control Instruc

9.4.7 Positioning Control In

9.4.8 Pulse Output Inst

9.4.9 Positioning Control Inst

9.4.10 Pulse Output Instruc

9.5 PWM Output Function (Pulse I/O Cassette)................................................................9-51

9.5.1 Overview of PWM Output Function...........................................................................9-51

9.5.2 Instruc

.............................................................................................................9-23

rol instructions (F0) (F1)................................................................9-25

tion F171 - Trapezoidal...................................................9-28

struction F171 – Home Return (Common to Transistor type) 9-33

ruction F172 – JOG operation.......................................................9-38

ruction F174 – Data Table Control ......................................9-42

tion F175 – Linear Interpolation.............................................9-44

tion to be Used for PWM Output Function.....................................................9-51

..........................................................................9-19

0

........................................9-27

10. High-speed counter, Pulse Output and PWM Output functions (For Ry

Type)....................................................................................................10-1

10.1 Overview of Each Functions ......................................................................................10-2

10.1.1 Usable Units and Cassettes....................................................................................10-2

10.1.2 Three Pulse I/O Func

10.1.3 Performance of Pulse I/O Func

10.2.1 Specifications

10.2.2 Functions

10.2.3 Booting Time...........................................................................................................10-8

..........................................................................................................10-4

Used and Restrictions............................................................................10-7

tions......................................................................................10-2

tion.........................................................................10-3

10.3 High-speed Counter Function....................................................................................10-9

10.3.1 Overview of High-speed Counter Function.............................................................10-9

10.3.2 Input Modes and Count...........................................................................................10-9

10.3.3 Minimu

10.3.4 I/O Allocation

10.3.5 Instructions used with High-speed Counter Function

10.3.6 Sample program (Control Unit and Main Unit I/O)................................................10-14

10.3.7 Sample program (Pulse

10.4 Pulse Output Function (Pulse I/O Cassette)...........................................................10-20

10.4.1 Overview of Pulse Output Function ......................................................................10-20

10.4.2 Types of Pulse Output Method and Operation Modes .........................................10-21

10.4.3 I/O Allocation

10.4.4 Pulse output control ins

10.4.5 Wiring for Pulse Output Sample P

m Input Pulse Width

.........................................................................................................10-11

.........................................................................................................10-24

..................................................................................10-10

...........................................10-11

I/O Cassette)..................................................................10-17

tructions (F0) (F1)............................................................10-25

rogram (F171 to F174)....................................10-27

v

Page 8

10.4.6 Positioning Control Instruction F171 - Trapezoidal...............................................10-28

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

10.4.7 Positioning Control Instructio

33

10.4.8 Pulse Output Instruc

10.4.9 Positioning Control Inst

10.4.10 Pulse Output Inst

10.5 PWM Output Function (Pulse I/O Cassette)............................................................10-51

10.5.1 Overview of PWM Output Function

10.5.2 Instruction to be Used

tion F172 – JOG operation...................................................

ruction F175 – Linear Interpolation .........................................10-44

n F171 – Home Return (Common to Transistor type) 10-

10-38

ruction F174 – Data Table Control...................................10-42

.......................................................................10-51

for PWM Output Function.................................................10-51

11. Security Functions.............................................................................. 11-1

11.1 Type of Security Functions.........................................................................................11-2

11.2 Password Protect Function........................................................................................11-2

11.2.1 Password Setting....................................................................................................11-3

11.3 Upload Protection........................................................................................................11-7

11.3.1 Upload Protection Setting .......................................................................................11-7

11.4 Table of Security Set

tings/Cancel..............................................................................11-9

12. Other Functions ..................................................................................12-1

12.1 Transfer Function between Memories.......................................................................12-2

12.2 Function of Master Memory Cassette........................................................................12-3

12.2.1 Realtime Clock Function

12.2.2 Master Memory Func

12.2.3 Relation between S

12.2.4 Handling of Master Memories Created with

12.3 P13 (ICWT) Instruction

12.4 Analog Potentiometer .................................................................................................12-9

12.4.1 Overview of Analog Potentiometer .........................................................................12-9

12.4.2 Example Showing How to Use Analog Potentiometer

12.5 Sampling Trace Function..........................................................................................12-10

12.5.1 Overview...............................................................................................................12-10

12.5.2 Details of Sampling Trace Function

12.5.3 How to Use Sampling Trace.................................................................................12-11

.........................................................................................12-3

tion ........................................................................................12-5

ecurity Setting and Transmission ............................................12-6

Different Models ................................12-7

................................................................................................12-8

............................................12-9

......................................................................12-10

12.6 Time Constant Processing .......................................................................................12-13

vi

Page 9

13. Self-Diagnostic and Troubleshooting............................................... 13-1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

13.1 Self-Diagnostic function.............................................................................................13-2

13.1.1 LED Display for Status Condition............................................................................13-2

13.1.2 Operation Mode When an Error Oc

13.2 Troubleshooting ..........................................................................................................13-4

13.2.1 If ERROR LED is Flashing

13.2.2 If ERROR LED is ON

13.2.3 ALL LEDs are OFF .................................................................................................13-6

13.2.4 Diagnosing Output Malfunc

13.2.5 A Protect Error Message Appears

13.2.6 PROG Mode does not Change to RUN..................................................................13-8

13.2.7 A Communica

13.2.8 A Communication Error has

13.2.9 A Communication Error has

13.2.10 Expansion Unit does not Operate

tion Error has

......................................................................................13-4

..............................................................................................13-5

tion

Occurred through RS485 ..........................................13-9

Occurred through RS232C........................................13-9

Occurred through RS422 ........................................13-10

curs.................................................................13-3

...............................................................................13-7

..........................................................................13-8

.......................................................................13-10

14. Precautions During Programming..................................................... 14-1

14.1 Use of Duplicated Output ...........................................................................................14-2

14.1.1 Duplicated Output...................................................................................................14-2

14.1.2 When Output is Repeated with an OT, KP,

SET or RST Instruction......................14-2

14.2 Handling BCD Data......................................................................................................14-4

14.2.1 BCD Data................................................................................................................14-4

14.2.2 Handling BCD Data in the PLC...............................................................................14-4

14.3 Handling Index Registers

14.3.1 Index Registers.......................................................................................................14-5

14.3.2 Memory Areas Which can be Modified with Index Regis

14.3.3 Example of Using an Index Register

14.4 Operation Errors..........................................................................................................14-7

14.4.1 Outline of Operation Errors.....................................................................................14-7

14.4.2 Operation Mode When an Operation Error Oc

14.4.3 Dealing with Operation Errors.................................................................................14-7

14.4.4 Points to Chec

14.5 Instruction of Leading Edge Detection Method........................................................14-9

14.5.1 Instructions of Leading Edge Detection Method

14.5.2 Operation and Precautions When RUN Starts .....................................................14-10

14.5.3 Precautions

14.6 Precautions for Programming..................................................................................14-13

14.7 Rewr

14.7.1 Operation of Rewrite During RUN.........................................................................14-14

14.7.2 Cases Where Rewriting

ite Function During RUN..................................................................................14-14

k in Program....................................................................................14-8

When Using a Control Instruction.....................................................14-11

...........................................................................................14-5

ters .................................14-5

......................................................................14-6

curs ................................................14-7

.....................................................14-9

During Run is not Possible.............................................14-15

vii

Page 10

14.7.3 Procedures and Operation of Rewrite During RUN..............................................14-17

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

14.8 Processing During Forced Input and Output..........................................................14-19

14.8.1 Processing when forced input/output is initiated during RUN...............................14-19

15. Specifications......................................................................................15-1

15.1 Table of Specifications................................................................................................15-2

15.1.1 General Specifications............................................................................................15-2

15.1.2 Performance Specific

15.1.3 Communication Specifications

15.2 Table of I/O Number Allocation................................................................................15-13

15.2.1 I/O Allocation of FP-X Control Unit

15.2.2 FP0 Expansion Unit Allocation..............................................................................15-13

15.2.3 FP0 Expansion Unit Allocation..............................................................................15-13

15.2.4 I/O Allocation of FP-X Add-on Cas

ations ....................................................................................15-7

..............................................................................15-10

.......................................................................15-13

sette................................................................15-15

15.3 Relays, Memor

y Areas and Constants....................................................................15-16

16. Dimensions..........................................................................................16-1

16.1 Dimensions...................................................................................................................16-2

16.1.1 Control Unit.............................................................................................................16-2

16.1.2 Expansion Unit

16.1.3 Expansion FP0 Adapter..........................................................................................16-3

16.1.4 Dimension Diagram for Ins

........................................................................................................16-2

tallation.........................................................................16-3

17 Appendix....................................................................................………17-1

17.1 System Registers / Special Internal Relays / Special Data Registers.…………….17-3

17.1.1 Table of System Registers for FP-X........................................………………………..............17-5

17.1.2 Table of Special Internal Relays for FP-X.....................................………………………......17-17

17.1.3 Table of Special Data Registers for FP-X..........................……………………….................17-28

17.2 Table of Basic Instructions................................................................……………….17-50

17.3 Table of High-level Instructions.........................................................………………17-84

17.4 Table of Error codes........................................................................……………….17-144

17.5 MEWTOCOL-COM Communication Commands......................………………......17-158

17.6 Hexadecimal/Binary/BCD....................................................……………….............17-159

17.7 ASCII Codes....................................................................………………...................17-160

viii

Page 11

Before You Start

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Installation environment

Do not use the unit where it will be exposed to the following:

• Direct sunlight and ambient temperatures outside the range of 0°C to 55°C /32°F to 131°F.

• Ambient humidity outside the range of 10 to 95% RH (at 25°C, non-condensing) and sudden

temperature changes causing condensation.

• Inflammable or corrosive gas.

• Excessive vibration or shock.

• Excessive airborne dust, metal particles or salts.

• Water, oil or chemicals in any from including spray or mist.

• Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as ammonia

or caustic soda.

• Influence from power transmission lines, high voltage equipment, power cables, power equipment,

radio transmitters, or any other equipment that would generate high switching surges.

Static electricity

• Before touching the unit, always touch a grounded piece of metal in order to discharge static electricity.

• In dry locations, excessive static electricity can cause problems.

Cleaning

• Do not use thinner based cleaners because they deform the unit case and fade colors.

Power supplies

• It is recommended to use an insulated power supply with an internal protective circuit for resistance to

noise.

• If using a power supply without a protective circuit, power should be supplied through a protective

element such as a fuse.

Power supply sequence

• Have the power supply sequence such that the power supply of the control unit turns off before the

power supply for input and output.

• If the power supply for input and output is turned off before the power supply of the control unit, the

control unit will detect the input fluctuations and may begin an unscheduled operation.

Before turning on the power

When turning on the power for the first time, be sure to take the precautions given below.

• When performing installation, check to make sure that there are no scraps of wiring, particularly

conductive fragments, adhering to the unit.

• Verify that the power supply wiring, I/O wiring, and power supply voltage are all correct.

• Sufficiently tighten the installation screws and terminal screws.

• Set the mode selector to PROG. Mode.

ix

Page 12

Before entering a program

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Be sure to perform a program clear operation before entering a program.

Operation procedure when using FPWIN GR Ver.2

Select “Online Edit Mode” on the FPWIN GR “On line” menu.

Select “Clear Program” on the “Edit” menu.

When the confirmation dialog box is displaye d, click on “Yes” to clear the program.

Request concerning program storage

To prevent the accidental loss of programs, the user should consider the following measures.

• Drafting of documents

To avoid accidentally losing programs, destroying files, or overwriting the contents of a file, documents

should be printed out and then saved.

• Specifying the password carefully

The password setting is designed to avoid programs being accidentally overwritten. If the password is

forgotten, however, it will be impossible to overwrite the program even if you want to. Also, if a

possword is forcibly bypassed, the program is deleted. When specifying the password, note it in the

specifications manual or in another safe location in case it is forgotten at some point.

• Upload protection

When the upload protection setting is specified, programs will be disalbed to be read out. If the setting

is cancelled forcibly, all programs and system registers will be deleted. Therefore, note that programs

and system registers should be managed on your own responsibility.

Backup battery

Do not install the battery when it is not used.

There is a possibility of leak if the battery remains discharged.

x

Page 13

Differences in Functions Between Versions of Controller

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

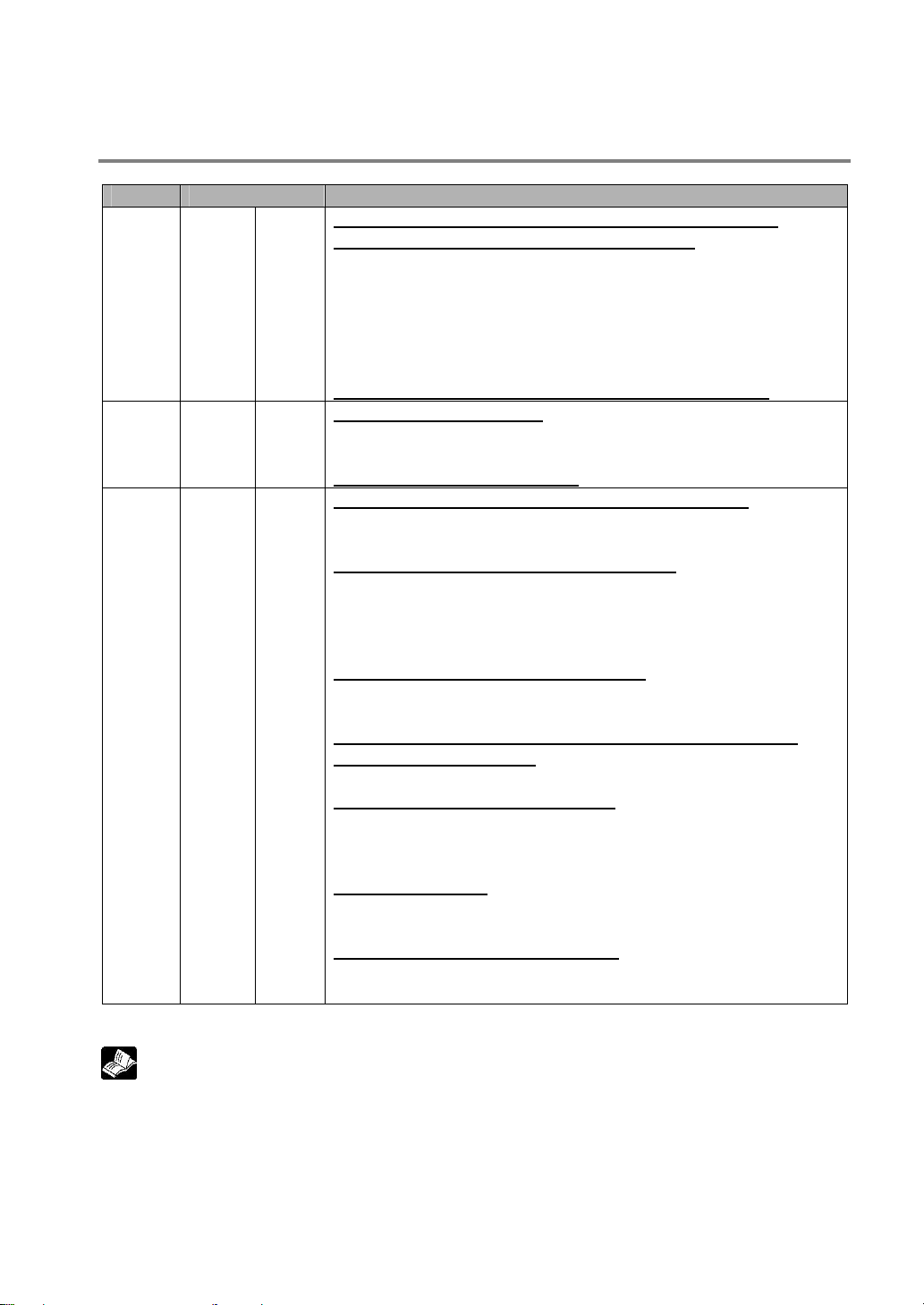

Version Usable model Usable functions

UP/DOWN switching of high-speed counter by SYS instruction

Real number basic compare instructions 18 types

STF=S1, S2 ANF=S1, S2 ORF=S1, S2

STF<>S1, S2 ANF<>S1, S2 ORF<>S1, S2

V1.10 Ry type -

V1.20 Ry type -

V2.00 Ry type Tr type

Note) The Ry and Tr types with the same specifications have the same version name

STF>S1, S2 ANF>S1, S2 ORF>S1, S2

STF>=S1, S2 ANF>=S1, S2 ORF>=S1, S2

STF<S1, S2 ANF<S1, S2 ORF<S1, S2

STF<=S1, S2 ANF<=S1, S2 ORF<=S1, S2

System register 36 for setting expansion unit recognition time

MEWTOCOL master function

F145(SEND) Data send

F146(RECV) Data receive

E356(EZPID) Easy PID instruction

Time constant processing of input (Refer to Chapter 12.6.)

CPU input: System register setting

Other input: F182(FILTR) Time constant processing

Sampling trace function (Refer to Chapter 12.5.)

Sampling by instrucitons

F155(SMPL) Sampling

F156(STRG) Sampling trigger

Sampling by specifying time

Leading contact, trailing contact instructions

ST↑ AN↑ OR↑

ST↓ AN↓ OR↓

An arbitrary device can be specified for the setting value of

Timer/counter instruction.

e.g.) TML 0, DT0

Other additional convenient instructions

F252(ACHK) ASCII data check

F284(RAMP) Inclination output

Baud rate setting (300, 600, 1200 bps) by SYS instruction

High-speed operaiton

F0(MV) and F1(DMV) instructions Execution time: Approx. 1us

Only when every operands are without index modifier.

Function addition to exsiting instructions

F70(BCC) Block check code calculation

F356(EZPID) Easy PID instruction

Reference: <Programming Manual ARCT1F313E>

xi

Page 14

Programming Tool Restrictions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Restrictions on usable programming tools depending on the units (as of August, 2006)

Type of unit

Type of programming tool

Windows software

Windows software

Conforms to

IEC61131-3

MS-DOS software

Handy programming

unit

FP memory loader

AFPX-C14R

AFPX-C30R

AFPX-C60R

FPWIN GR Ver.2

FPWIN GR Ver.1 Not used Not used

FPWIN Pro

Ver.5

NPST-GR Ver.4 Not used Not used

NPST-GR Ver.3 Not used Not used

AFP1113V2

AFP1114V2

AFP1113

AFP1114

AFP1111A

AFP1112A

AFP1111

AFP1112

AFP8670

AFP8671

Used

(Ver. 2.5 or later)

Used

(Ver. 5.1 or later)

Not used Not used

Not used Not used

Not used Not used

(Only porgrams and system registers can be transmitted.)

AFPX-C14T, C14TD, C14P, C14PD

AFPX-C30T, C30TD, C30P, C30PD

AFPX-C60T, C60TD, C60P, C60PD

Used

(Ver. 2.70 or later)

Used

(Ver. 5.22 or later)

Used

Note: Precautions concerning version upgrade

• In case of using FPWIN GR Ver.1, please purchase upgrade model FPWIN GR Ver.2.

• FPWIN GR Ver. 2.0 can be upgraded to Ver. 2.5 or later free of charge at our web site

(

http://www.nais-e.com/plc/).

• In case of using FPW

• FPWIN Pro Ver. 5.0 can be free of charge at our web site (

• The handy

Do not download any programs for other units such as FP1 to the FP-X using the handy programming

unit .

programmign unit cannot be used.

IN Pro Ver.4, please purchase upgrade model FPWIN Pro Ver.5.

http://www.nais-e.com/plc/).

xii

Page 15

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 1

Features, Functions and Restrictions

Page 16

1.1 Features and Functions of the Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Features

• Compact size general-purpose PLC that is suitable for the small-scale facility control.

• Can be directly connected to a personal computer using USB communication port.

• High demensional security functions to deal with copying programs.

• Supports analog control.

• Following items are provided as options,

- Application cassettes, such as the positioning control function by the high-speed counter and

pulse output.

- Fulfilling communication cassettes.

- Realtime clock function.

Basic functions as compact size general-purpose PLC suitable for the small-scale facility control

Basic functions including the followings are equipped even though it is a general-pur pose sytle such as

AC power supply, screw terminal block and relay output.

1. 32k-step program capacity

2. 0.32 μs command processing speed

3. Max. 382-points I/O control

Single-phase 8-channel and 2-phase 4 channel high-speed counter functions are equipped for

the control unit.

Fulfilling function enhancement

Various add-on cassettes are available as options (such as 10 types of application cassettes and

6 types of communication cassette).

• Application cassettes

DC 8-point input type, transistor 8-point NPN output type, transistor 6-point PNP output type, DC 4-point

input + transistor 3-point NPN output type, analog 2-ch output type, analog 2-ch input + analog 1-ch

output type, thermocouple 2-ch type, analog 2-ch input type, high-speed counter input + pulse output

type, master memory type with realtime clock (32k-step program can be copied and stored.)

• Communication cassettes

1-ch RS232C type, 2-ch RS232C type, 1-ch RS485/RS422 changeover type, 1-ch RS232C + 1-ch

RS485 type, Ethernet + 1-ch RS232C type, 2-ch RS485 type

FP0 expansion units can be connected as well as the exclusive expansio n unit.

A maximum of 3 FP0 expansion units can be connected using the expansion FP0 adapter.

A personal computer can be directly connected with the USB communication port.

A personal computer can be directly connected with the USB cable (excluding C14).

The USB⇔RS232C conversion adapter/cable is not necessary.

(A tool port (RS232C) is also equipped.)

1-2

Page 17

High demensional security functions to deal with copying programs.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The uploading disabling function prohibits uploading (readin g) programs in the PLC main unit and

prevent illegal copying.

(It also enables to transfer the programs to the FP-X master memory cassette, when the uploading

disabling function is specified).

The protection for programs can be selected from

3 security methods.

• 4-digit password

• 8-digit password

• Uploading disabling

A full range of communication functions

Using the Tool port (RS232C) provided as a standard feature on the main unit, communication can be

carried out with a display panel or computer. Additionally, communication cassettes with RS232C,

RS485 and Ethernet interfaces are available as an option. Installing a 2-channel RS232C type

communication cassette in the FP-X makes it possible to connect two devices with RS232C port. A full

lineup of communication functions means you can also work with 1:N communication (up to 99 units)

and PC(PLC) link function (up to 16 units).

Controlling two devices with RS232C port with one FP-X

When using the 2-channel RS232C type communication cassette

1:N communication possible with up to 99 stations (units)

When using the 1-channel RS485/RS422 type communication cassette

When using the 1-channel RS485 and 1-channel RS232C in combination

Link with FP2 and FPΣ is possible

Data sharing between small size and medium size PLCs is easily achievable in one network.

The FP-X supports MEWNET-W0, and the programless PLC link with the FP2 or FP Σ is possible.

1-3

Page 18

Supports Modbus RTU

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

It can be used as a master unit/slave units (F145 and F146 instructions).

It can be easily communicated with a temperature control device, inverter, FP-e or overseas PLCs.

It is possible to communicate with up to 99 units

MEWTOCOL communication

It can be used as a master unit/slave units (F145 and F146 instructions).

It can be easily communicated with a PLC, image processor, temperature control device, message

runner or eco-power meter.

It is possible to communicate with up to 99 units

1-4

Page 19

Positioning control supported through high-speed counter and pulse output

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

With the FP-X Tr type, a high-speed counter function can be used by using the CPU I/O.

With the FP-X Ry type, a high-speed counter and pulse output functions can be used by using the pulse

I/O cassette. The pulse output function supports frequencies of up to 100kHz, enabling positioning

control using a stepping motor or servo motor.

Note) The pulse I/O cassette cannot be used for the FP-X Tr type.

Measurement using high-speed counter supported

Increment input mode, decrement input mode, 2-phase input mode, individual input mode, and direction

discrimination mode are supported.

Note) Differs depending on combinations.

Positioning control based on pulse output supported

Pulse/direction and clockwise/counter –clockwise output are supporte d.

Heater control based on PWM output function supported

The pulse output at any duty ratio can be picked up with special instruction.

Analog potentionmeter (volume dial)

An analog potentionmeter (volume dial) is provided as a standard feature. This can be used in

applications such as analog timers, without using the programming tools.

Realtime clock function can be added

Optional FP-X master memory cassette (AFPX-MRTC) and backup battery enables the realtime clock

function.

1-5

Page 20

1.2 Unit Types

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2.1 FP-X Control Units

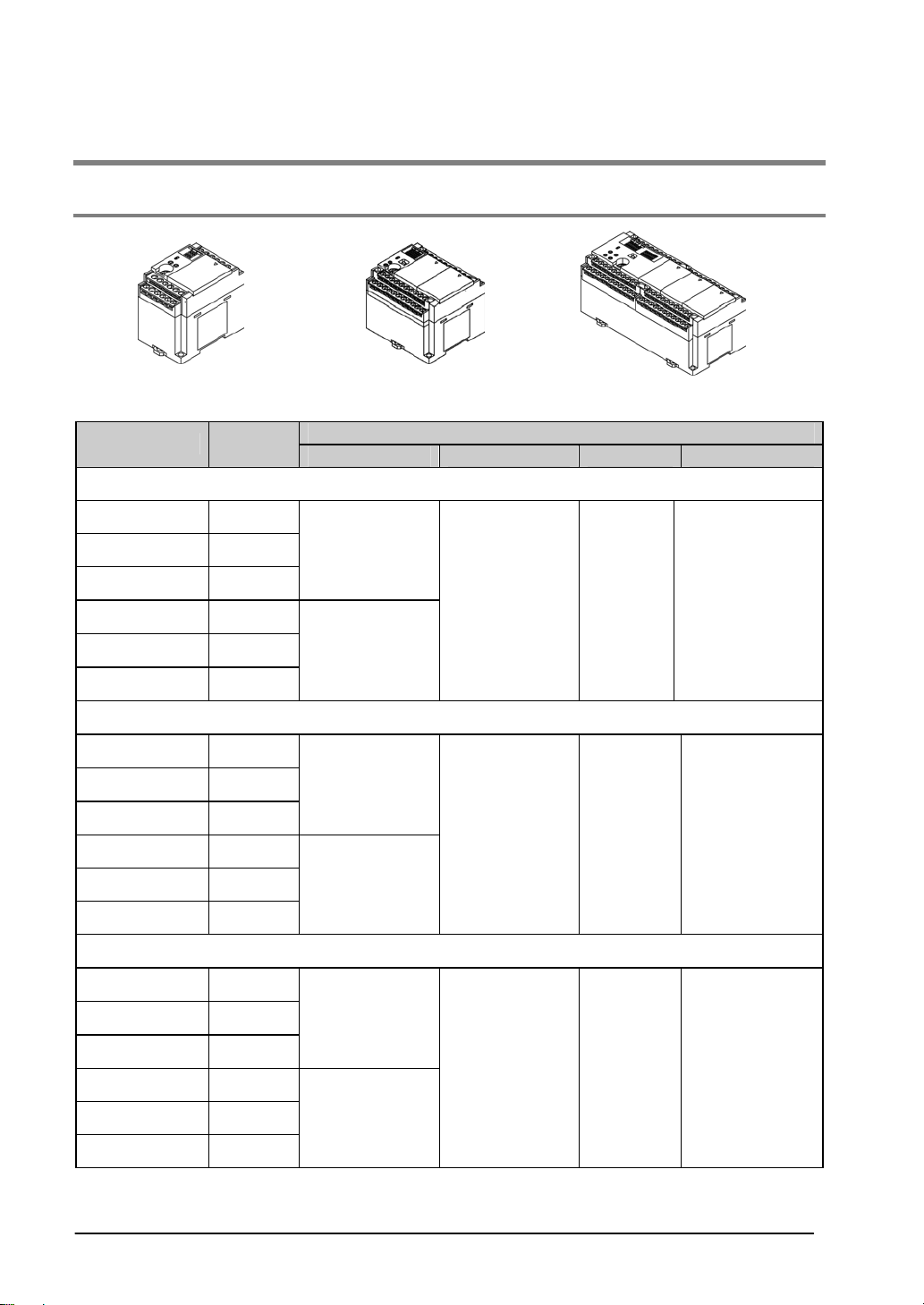

C14 C30 C60

Product No.

Relay type (Ry type)

AFPX-C14R 8/6

AFPX-C30R 16/14

AFPX-C60R 32/28

AFPX-C14RD 8/6

AFPX-C30RD 16/14

AFPX-C60RD 32/28

Transistor type (NPN) (Tr type)

AFPX-C14T 8/6

AFPX-C30T 16/14

AFPX-C60T 32/28

AFPX-C14TD 8/6

AFPX-C30TD 16/14

No. of I/O

points

Specifications

Power supply Input Output Connection

100 to 240 V AC

24 V DC

(Common

polarities

+ & - common)

24 V DC

100 to 240 V AC

24 V DC

(Common

polarities

+ & - common)

24V DC

Relay Terminal block

Transistor

(NPN)

Terminal block

AFPX-C60TD 32/28

Transistor type (PNP) (Tr type)

AFPX-C14P 8/6

AFPX-C30P 16/14

AFPX-C60P 32/28

AFPX-C14PD 8/6

AFPX-C30PD 16/14

AFPX-C60PD 32/28

100 to 240 V AC

24V DC

24 V DC

(Common

polarities

+ & - common)

Transistor

(PNP)

Terminal block

1-6

Page 21

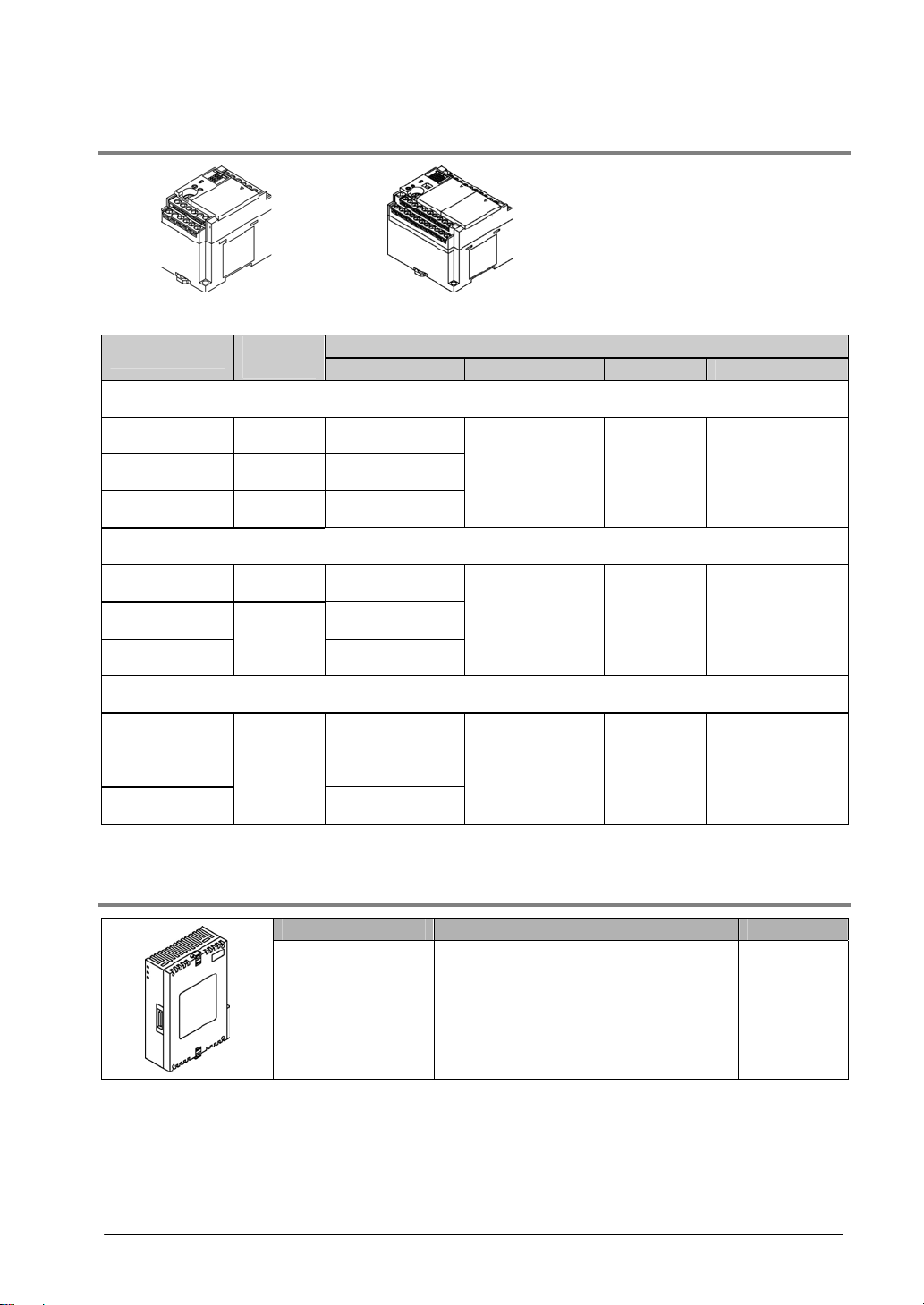

1.2.2 FP-X Expansion Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

E16 E30

Product No.

Relay type (Ry type)

AFPX-E16R 8/8 AFPX-E30R 16/14 100 to 240 V AC

AFPX-E30RD 16/14 24 V DC

Transistor type (NPN) (Tr type)

AFPX-E16T 8/8 AFPX-E30T 100 to 240 V AC

AFPX-E30TD

Transistor type (PNP) (Tr type)

AFPX-E16P 8/8 AFPX-E30P 100 to 240 V AC

AFPX-E30PD

No. of I/O

points

16/14

16/14

Power supply Input Output Connection

24V DC

24V DC

24 V DC

(Common

polarities

+ & - common)

24 V DC

(Common

polarities

+ & - common)

24 V DC

(Common

polarities

+ & - common)

Specifications

An 8-cm expansion cable is provided with anxpansion unit

Relay Terminal block

Transistor

(NPN)

Transistor

(PNP)

Terminal block

Terminal block

1.2.3 FP-X Expansion FP0 Adapter

Name Specifications Product No.

FP-X Expansion

FP0 adapter (with 8

cm expansion

cable, power supply

cable)

1-7

For connecting FP0 expansion unit AFPX-EFP0

Page 22

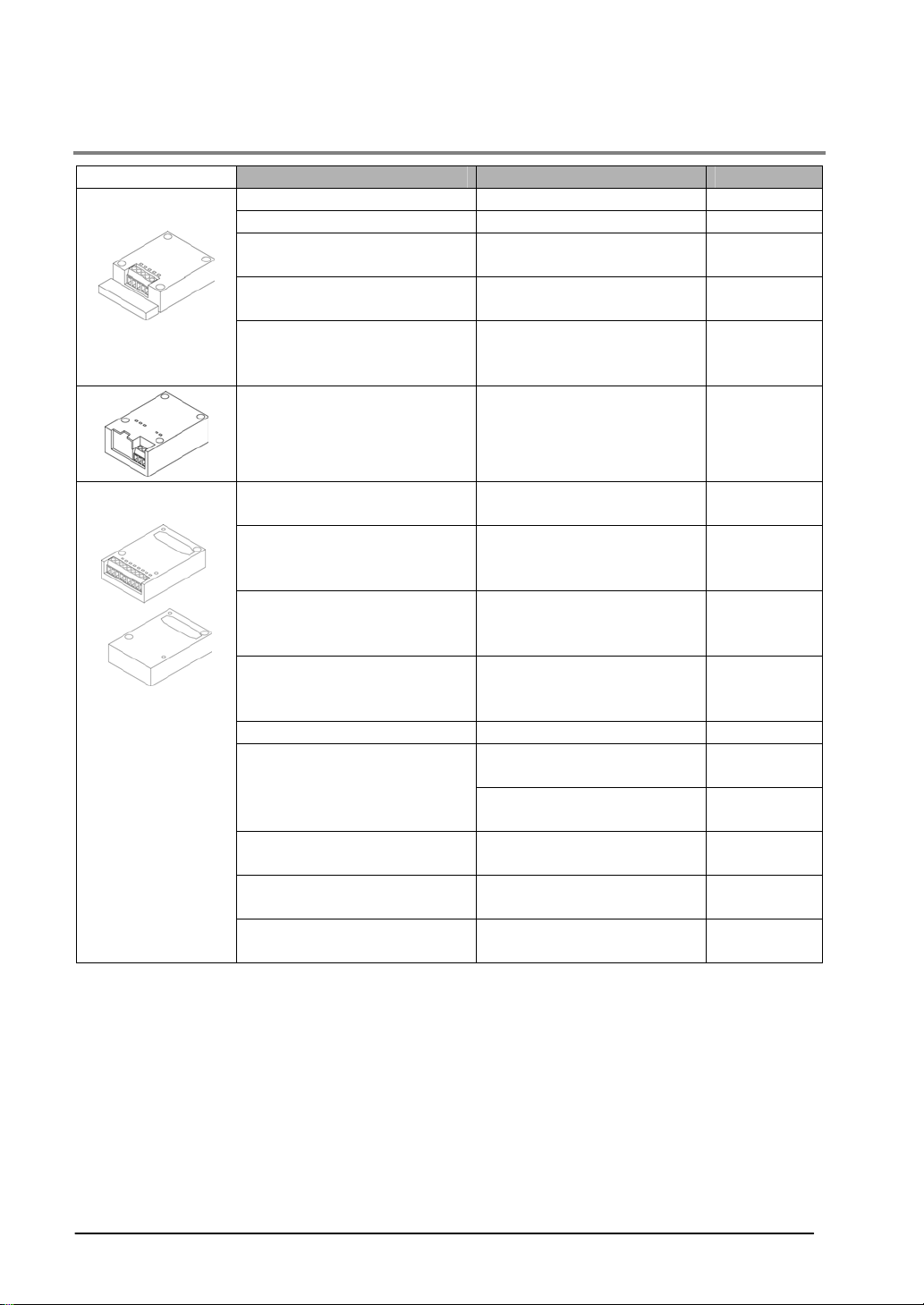

1.2.4 Add-on Cassettes (Communication cassettes/Application cassettes)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Communication

cassette

Application

cassette

Name Specifications Product No.

FP-X Communication cassette 5-wire 1-channel RS232C AFPX-COM1

FP-X Communication cassette 3-wire 2-channel RS232C AFPX-COM2

FP-X Communication cassette

FP-X Communication cassette

FP-X Communication cassette

FP-X Communication cassette

FP-X Analog input cassette

FP-X Analog output cassette

FP-X Analog I/O cassette

FP-X Thermocouple cassette

FP-X Input cassette 8-point DC input AFPX-IN8

FP-X Output cassette

FP-X I/O cassette

FP-X Pulse I/O cassette

FP-X Master memory cassette

1-channel RS485/RS422

(insulated)

1-channel RS485 (insulated)

3-wire 1-channel RS232C

2-channel RS485

(non-insulated between

channels)

Ethernet,

3-wire 1-channel RS232C

2-channel analog input

(non-insulated)

2-channel analog output

(insulated) (non-insulated

between channels)

2-channel analog input

(insulated) + 1-channel

analog output (insulated)

2-channel thermocouple input

(insulated) (non-insulated

between channels)

8-point transistor output

(NPN)

6-point transistor output

(PNP)

4-point DC input + 3-point

transistor output (NPN)

2-ch high-speed counter +

1-ch pulse output

Master memory + realtime

clock

AFPX-COM3

AFPX-COM4

AFPX-COM6

AFPX-COM5

AFPX-AD2

AFPX-DA2

AFPX-A21

AFPX-TC2

AFPX-TR8

AFPX-TR6P

AFPX-IN4T3

AFPX-PLS

AFPX-MRTC

1-8

Page 23

1.2.5 Related Parts

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

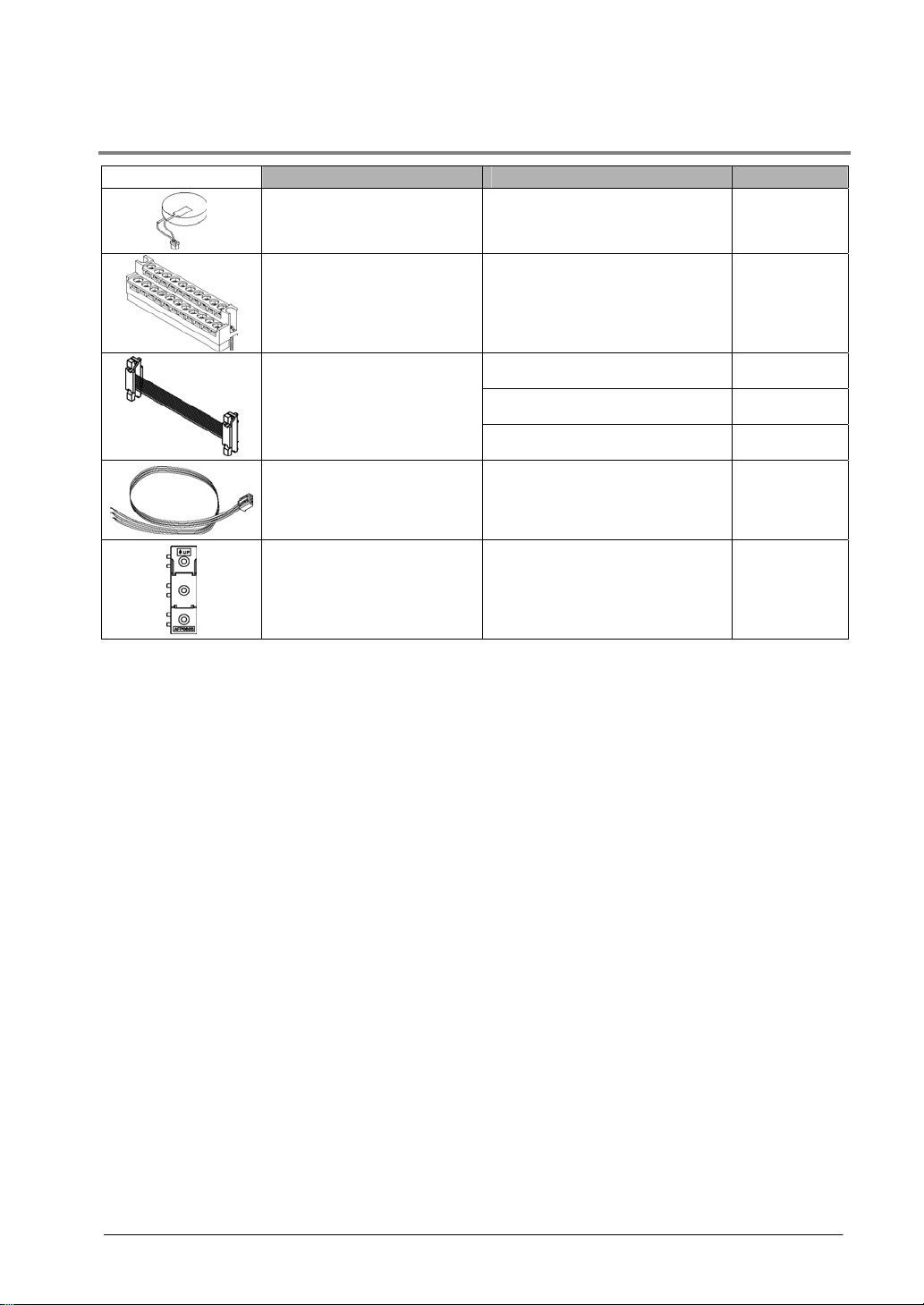

Name Description Product No.

Necessary fro the backup of

FP-X Backup battery

data registers, etc. or for using

the realtime clock function.

For C30/C60 control unit

FP-X terminal block

(C30/C60)

for E30 expansion I/O unit

with 21-pin cover (no printing)

4 pcs/pack

8 cm AFPX-EC08

FP-X expansion cable

FP0 power supply cable

FP0 mounting plate

(slim type)

Note)

30 cm AFPX-EC30

80 cm AFPX-EC80

For Expansion FP0 adapter,

Length: 1 m

Used for expansion FP0

adapter and FP0 Expansion

unit, 10 pcs/pack

Note) The total length of the exapansion cable should be within 160 cm.

AFPX-BATT

AFPX-TAN1

AFP0581

AFP0803

1-9

Page 24

1.3 Restrictions on Unit Combinations

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.3.1 Restrictions on FP-X Expansion Unit

Controllable I/O points

Type of control unit

FP-X C14 Control unit 14 points Max. 254 points

FP-X C30 Control unit 30 points Max. 270 points

FP-X C60 Control unit 60 points Max. 300 points

Number of I/O points when

using control unit

Number of I/O points when

using 8 units of E30

expansion I/O unit

Note:

- Up to eight units of FP-X can be connected, however, the restrictions on each expansion unit vary.

- For AFPX-E16: Two units cannot be connected consecutively since the power should be supplied from

the unit with the power supply (as no power supply is built in AFPX-E16).

E16 expansion I/O unit cannot be connected on the right side of the control unit or AFPX-E30.

- For AFPX-E30: There is no restriction on AFPX-E30 so that up to 8 units can be connected

consecutively.

- The total length of the expansion cable should be within 160 cm.

1-10

Page 25

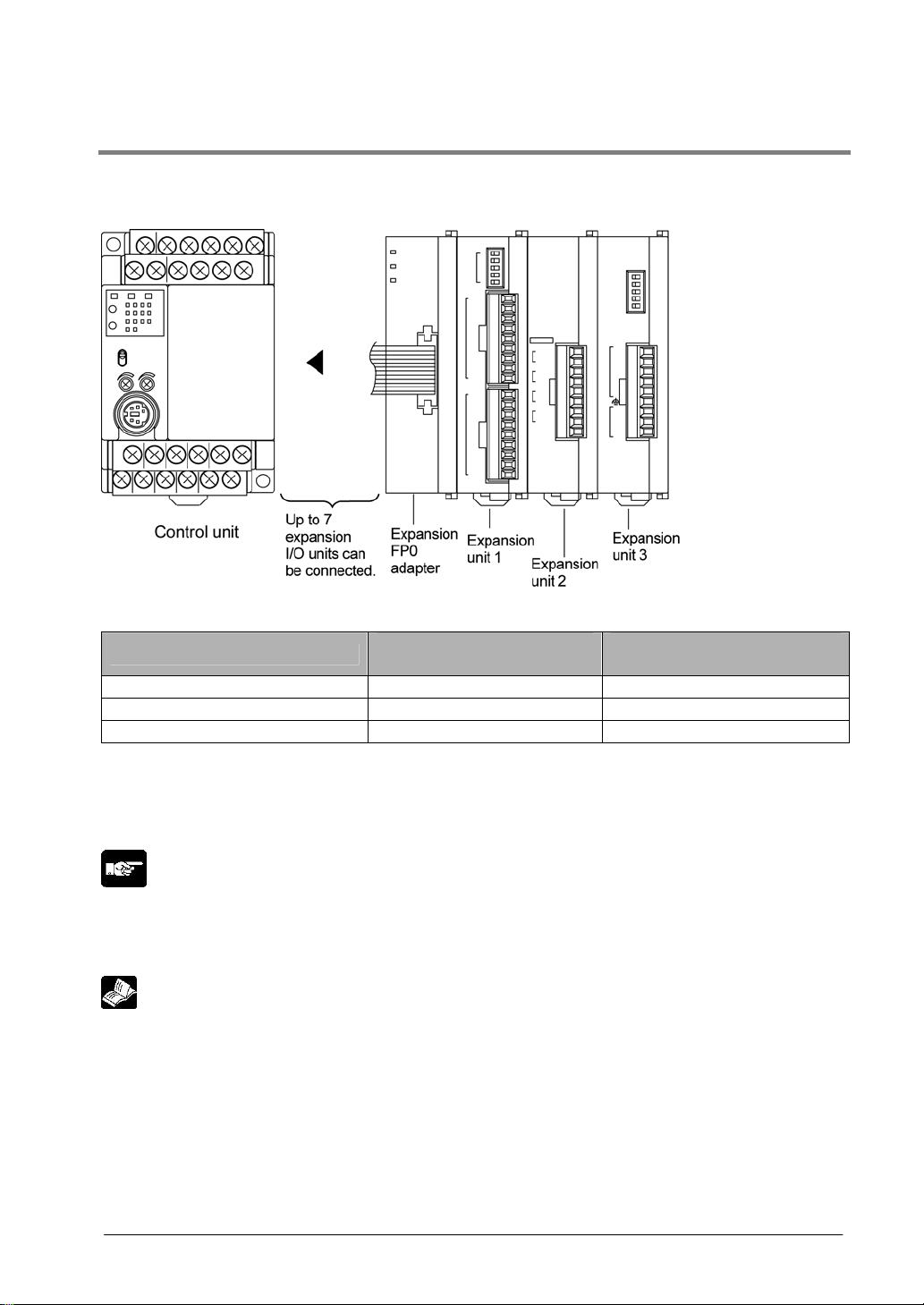

1.3.2 Restrictions on FP0 Expansion Unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Up to three dedicated FP0 expansion units can be added using the FP- X and the expansion FP0 adapter.

The relay output type and the transistor output type can be used in combination.

Controllable I/O points

Type of control unit

FP-X C14 Control unit 14 points Max. 110 points

FP-X C30 Control unit 30 points Max. 126 points

FP-X C60 Control unit 60 points Max. 156 points

Note1) Up to seven FP-X expansion I/O units can be also installed between the control unit and the

expansion FP0 adapter.

Note2) Only one expansion FP0 adapter can be installed at the last position of the FP-X expansion bus.

(It should be installed at the right hand side of the AFPX-E16 and E30.)

Note:

• Install the FP0 thermocouple unit on the right side of other expansion units. If it is installed on the left

side, the total precision will deteriorate.

• Install the FP0 CC-Link slave unit on the right side of the other expansion units. There is no expansion

connector on the right side.

Reference: For the details, <FP0 Thermocouple Unit Manual ARCT1F366E>

<FP0 CC-Link Slave Unit Manual ARCT1F380E>

Number of I/O points when

using control unit

Number of I/O points when

using FP0 expansion unit

1-11

Page 26

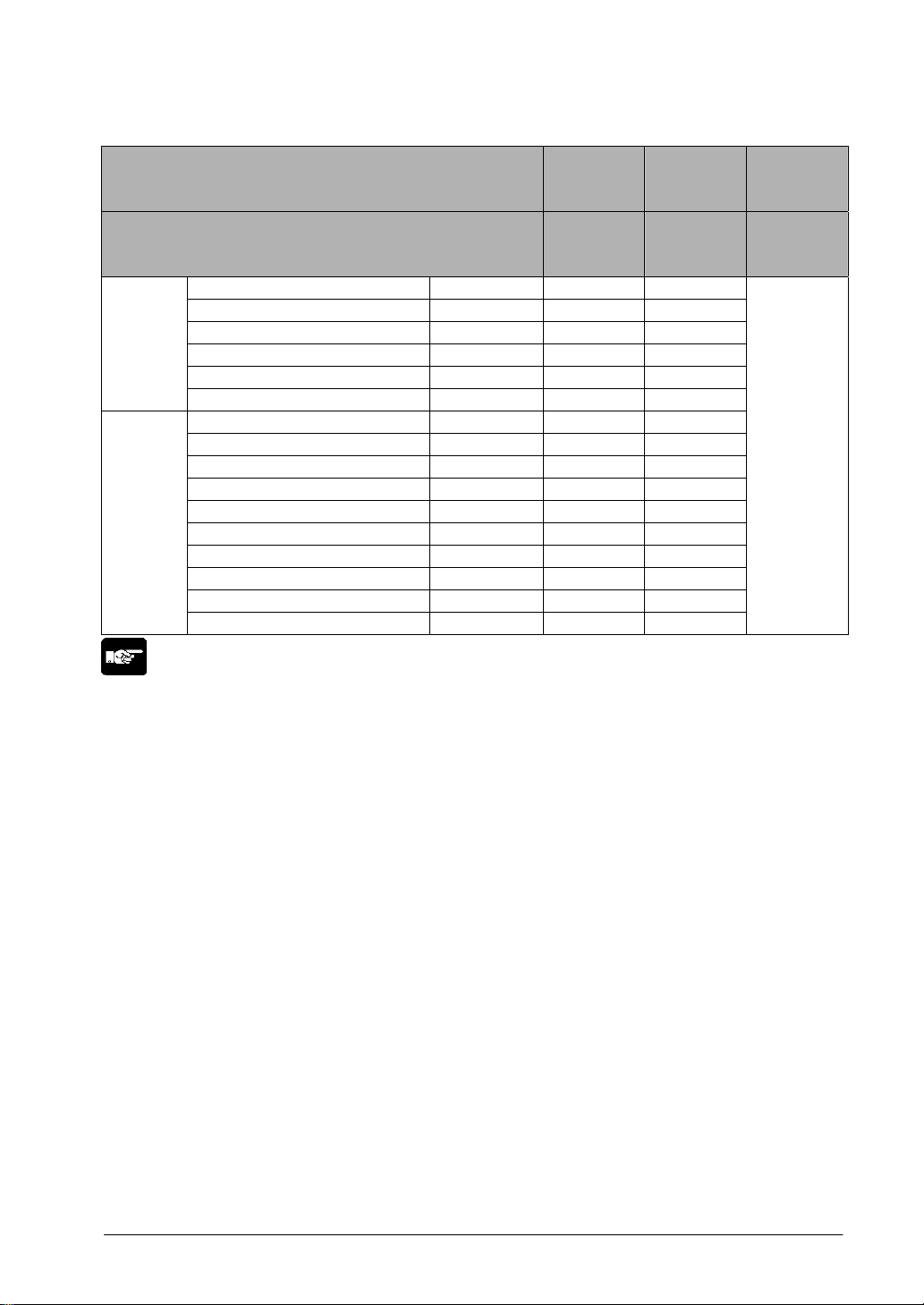

1.3.3 Restrictions on FP-X Add-on Cassette

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The add-on cassette is installed in the cassette mounting part 1 and 2 (only the cassette mounting part 1

is available for C14) of the control unit.

1-12

Page 27

Commu-

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

nication

cassette

Application

cassette

A: Available, N/A: Not available

Restrictions on control unit

Type of add-on cassette

FP-X C14

FP-X C30

FP-X C60

Cassette

mounting

part 1

FP-X C30

FP-X C60

Cassette

mounting

part 2

FP-X C60

Expansion

connector

part

FP-X Communication cassette AFPX-COM1 A N/A

FP-X Communication cassette AFPX-COM2 A N/A

FP-X Communication cassette AFPX-COM3 A N/A

FP-X Communication cassette AFPX-COM4 A N/A

FP-X Communication cassette AFPX-COM5 A N/A

FP-X Communication cassette AFPX-COM6 A N/A

FP-X Analog input cassette AFPX-AD2 A A

FP-X Input cassette AFPX-IN8 A A

FP-X Analog output cassette AFPX-DA2 A A

FP-X Analog I/O cassette AFPX-A21 A A

The add-on

cassette

cannot be

installed.

FP-X Thermocouple cassette AFPX-TC2 A A

FP-X Output cassette AFPX-TR8 A A

FP-X Output cassette AFPX-TR6P A A

FP-X I/O cassette AFPX-IN4T3 A A

FP-X Pulse I/O cassette AFPX-PLS A

FP-X Master memory cassette AFPX-MTRC A

Note5)

A

Note1)

A

Note5)

Note1)

Note:

1. Only one FP-X master memory cassette AFPX-MRTC can be installed. If 2 units are installed, E26

(user ROM error) will occur.

2. One application cassette can be installed in either cassette mounting part 1 or 2 of C30/C60.

3. As only one communication cassette can be installed in the cassette mounting part 1, it should be

installed on on the application cassette if the application cassette is installed. (It cannot be installed in

the cassette mounting part 2.)

4. The add-on cassette cannot be installed in the expansion connector part of C60 (it does not work).

5. The pulse I/O cassette cannot be installed on the FP-X Tr type.

1-13

Page 28

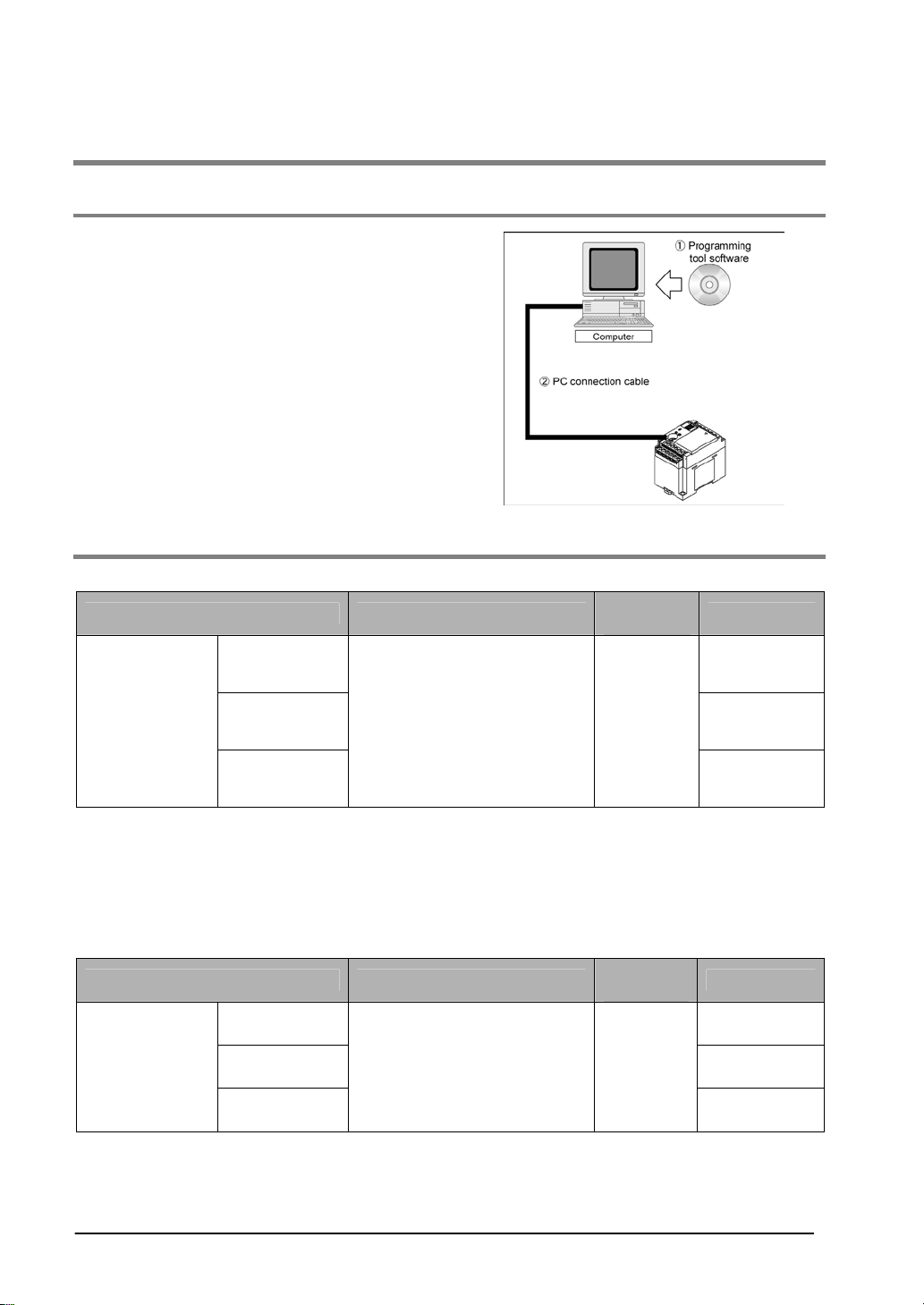

1.4 Programming Tools

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.4.1 Tools Needed for Programming

1. Programming tool software

• The tool software can also be used with the FP

series.

• “FPWIN Pro Ver.5” or “FPWIN GR Ver.2”

Windows sorware is used with FP-X.

FPWIN GR Ver.1x, NPST-GR and FP

Programmer cannot be used.

2. PC connection cable

• The connection cable for DOS/V machine is

available.

• A commercial USB cable can be used for the

connection for C30/C60 control unit.

1.4.2 Software Environment and Suitable Cable

Standard ladder diagram tool software FPWIN-GR Ver.2

Type of software OS (Operating system)

Hard disk

capacity

Product No.

Full type AFPS10520

FPWIN GR Ver.2

English-

Small type AFPS11520

language menu

Upgrade

version

Note1) Ver.1.1 must be installed to install the upgrade version.

Note2) Ver.2.0 can be upgraded to the latest version after Ver. 2.1 free of charge at our web site

(http://www.mew.co.jp/ac/e/). Use the latest version.

Note3) The small type can be used only for each series of FP-e, FPΣ, FP0, FP-X, FP1 and FP-M.

Note4) A USB cable cannot be used when using Windows®95.

Conforms to IEC61131-3 programming tool software FPWIN-Pro Ver.5

Type of software OS (Operating system)

FPWIN Pro

Ver.5

Englishlanguage menu

Note1) The small type can be used only for each series of FP-e, FPΣ, FP0, FP-X, FP1 and FP-M.

Note2) Ver.4 must be installed to install the upgrade version.

Note3) Ver.5.0 can be upgraded to the latest version after Ver. 5.1 free of charge at our web site

(

http://www.mew.co.jp/ac/e/). Use the latest version.

Full type AFPS50550

Small type AFPS51550

Upgrade

version

Windows®95 (OSR 2 or later)

Windows®98

Windows®Me

WindowsNT® (Ver. 4 or later)

Windows®2000

Windows®XP

Windows®95 (OSR 2 or later)

Windows®98

Windows®Me

WindowsNT® (Ver. 4 or later)

Windows®2000

Windows®XP

40MB or

more

Hard disk

capacity

100MB or

more

AFPS10520R

Product No.

AFPS50550R

1-14

Page 29

Type of computer and suitable cable

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

For the connection between a personal computer (RS232C) and the control unit (RS232C)

PC side connector PLC side connector Specifications Product No.

D-sub 9-pin

Note) A USB/RS232C conversion cable is necessary to connect with a personal computer without a

serial port using a PC connection cable.

female-Mini DIN round 5-pin L type (3 m) AFC8503

female-Mini DIN round 5-pin Straight type (3 m) AFC8503S

For the connection between a personal computer (USB) and the control unit (USB)

USB cable (For C30 and C60 only)

Use a commercial cable.

Cable type Length

USB 2.0 (or 1.1) AB type Max. 5 m

Reference: <Chapter 6 Tool Port and USB Port>

1-15

Page 30

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1-16

Page 31

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 2

Specifications and Functions of Control

Unit

Page 32

2.1 Parts and Functions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.1.1 Parts and Functions

2-2

Page 33

Status indicator LEDs

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

These LEDs display the current mode of operation or the occurrence of an error.

LED LED and operation status

Lights when in the RUN mode and indicates that the program is

RUN Green

PROG. Green

ERROR/

ALARM

Input/output indicator LEDs

Indicates the on/off status of the input and output.

RUN/PROG. mode switch

This switch is used to change the operation mode of the PLC.

Switch position Operation mode

RUN (upward)

PROG. (downword) This sets the PROG. mode. The operation stops.

• The remote switching operation from the programming tool is operable.

• When performing remote switching from the programming tool, the setting of the mode switch and the

actual mode of operation may differ. Verify the mode with the status indicator LED.

• Restart FPΣ to operate in the mode set with the RUN/PROG. mode switch.

USB connector (B type)

Red

This sets the RUN mode. The program is executed is executed and operation

begins.

being executed.

It flashes during forced input/output. (The RUN and PROG. LEDs

flash alternately.)

Lights when in the PROG. Mode and indicates that operation has

stopped.

Lights when in the PROG. Mode during forced input/output.

It flashes during forced input/output. (The RUN and PROG. LEDs

flash alternately.)

Flashes when an error is detected during the self-diagnostic

function. (ERROR)

Lights if a hardware error occurs, or if oepration slows because of

the program, and the watchdog timer is activated. (ALARM)

This is a connector to connect the programming tool.

Commercial USB cables (AB type) can be used.

• The baud rate with the USB is 115.2 kbps (fixed).

• Either USB port or COM2 port of 2-channnel type communication

cassette is selected.

The USB port cannot be used when the COM2 port is used.

Reference: <Chapter 6 Tool Port and USB Port>

<7.1.6 About USB Port>

Analog potentiometer (analog dial)

Turning this dial chanes the values of special data registers DT90040 to DT90043 within the range of K0

to K1000. It can be used for analog timers and other applications.

C14R and C30R equips 2 points and C60R equips 4 points.

Expample: <12.4 Analog potentiometer>

2-3

Page 34

Tool port (RS232C)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This port is used to connect a programming tool.

A commercial mini-DIN 5-pin connector is used for the Tool port on the control unit.

Pin No. Signal name Abbreviation Signal direction

1 Signal Ground SG −

2 Send Data SD Unit → External device

3 Receive Data RD Unit ← External device

4 (Not used) − −

The followings are the default settings set when the unit is shipped from the factory. The system register

“Tool port setting” should be used to change these.

- Baud rate …….. 9600 bps

- Character bit …. 8 bit

- Parity check ….. Odd parity

- Stop bit length .. 1 bit

Note) The unit numbers (station numbers) of the tool port should be specified using the system register

“Tool port setting”.

5 +5V +5V Unit → External device

Power supply and input terminal block

This is the power supply and input wiring terminal. A solderless terminal for M3 can be used.

Service power supply for input and output terminal block

This is the service power supply for input and output wiring terminal. A solderless terminal for M3 can be

used.

Reference: <5.7 Wiring of Terminal Block>

Expansion cover

It is used after the expansion cable and the battery has been installed.

Add-on cassette connector

Reference: <5.4 How to Install Add-on Cassette>

Connector For connecting expansion I/O unit and expansion FP0 adapter

An exclusive expansion cable is inserted.

Reference: <5.2 Installation Using Expansion Cable>

Battery cover

This battery cover is removed when the optional backup battery is installed.

Installing the backup battery enables the backup of the realtime clock or data registers.

Reference: <5.9 Installation and Setting of Backup Battery >

<12.2.1 Realtime Clock Function>

DIN rail attachment lever

This lever enables the units to attach to a DIN rail at a touch.

2-4

Page 35

2.2 Power Supply Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.2.1 AC Power Supply

Item

Rated voltage 100 to 240 V AC

Voltage regulation range 85 to 264 V AC

Surge current 40 A or less (at 240 V AC, 25 °C) 45 A or less (at 240 V AC, 25 °C)

Momentary power off time 10 ms (when using 100 V AC)

Frequency 50/60 Hz (47 to 63 Hz)

Leakage current 0.75 mA or less between input and protective earth terminals

Internal power supply part

Guaranteed life

Fuse Built-in (Cannot be replaced)

Insulation system Transformer insulation

Terminal screw M3

20,000 hours (at 55 °C)

C14 C30R/C60

Specifications

2.2.2 Service Power Supply for Input (Output) (AC Power Supply Type Only)

Item

Rated output voltage 24 V DC

Voltage regulation range 21.6 to 26.4 V DC

Rated output current 0.15 A 0.4 A

Overcurrent protection

function

Terminal screw M3

Note) This is a function to protect overcurernt temporarily, which protects the output short-circuit. If the

Note)

short-circuit is detected, all the power supply for the PLC will be turned off. If a current load that is

out of the specifications is connected and the overloaded status continues, it may lead to damages.

Available

C14 C30/C60

Specifications

2.2.3 DC Power Supply

Item

Rated voltage 24 V DC

Voltage regulation range 20.4 to 28.8 V DC

Inrush current 12 A or less (at 25 °C)

Momentary power off time 10 ms

Internal power supply part

Guaranteed life

Fuse Built-in (Cannot be replaced)

Insulation system Transformer insulation

Terminal screw M3

20,000 h (at 55 °C)

C14 C30/C60

2-5

Specifications

Page 36

2.3 Input Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.3.1 Relay (Ry) Type

Input Specifications (For C14R/C30R/C60R control units)

Item Description

Insulation method Optical coupler

Rated input voltage 24V DC

Operating voltage range 21.6 to 26.4V DC

Rated inptu current

Input points per common

Min. on voltage/Min. on current 19.2 V DC/3 mA

Max. off voltage/Max. off current 2.4V DC/1 mA

Input impedance

Response time

Operating mode indicator LED display

EN61131-2 Applicable type TYPE3 (however, according to the above specifications)

Note) this specification is applied when the rated input voltage is 24 V DC and the temperature is 25 °C.

Circuit diagram

off→on

on→off Same as above

Approx. 4.7 mA (for control units X0 to X7)

Approx. 4.3 mA (from control unit X8 )

8 points/common (C14R)

16 points/common (C30R/C60R)

(Either the positive or negative of the input power supply can be

connected to common terminal.)

Approx. 5.1 kΩ (for control units X0 to X7)

Approx. 5.6 kΩ (from control unit X8 )

For control units X0 to X7:

0.6 ms or less: normal input

50 μs or less: high-speed counter, pulse catch, interrupt

input settings

From control unit X8 :

0.6 ms or less

Note)

For X0 to X7: R1=5.1 kΩ R2=3 kΩ

From X8: R1=5.6 kΩ R2=1 kΩ

Limitations on number of simultaneous input on points

Reference: <2.5 Limitations on Number of Simultaneous Input/Output On Points>

2-6

Page 37

2.3.2 Transistor (Tr) Type (Common to NPN and PNP)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Transistor type (common to NPN and PNP)

Item

C14 C30/C60

Insulation method Optical coupler

Rated input voltage 24V DC

Operating voltage range 21.6 to 26.4V DC

Approx. 8 mA (for control units X0 to X3)

Rated input current

Approx. 4.7 mA (for control units X4 to X7)

Approx. 4.3 mA (from control unit X8)

8 points/common 16 points/common

Input points per common

(Either the positive or negative of the input power supply can be

connected to common terminal.)

Min. on voltage/Min. on current

Max. off voltage/Max. off current

19.2 V DC/6 mA (for control units X0 to X3)

19.2 V DC/3 mA (from control unit X4)

2.4V DC/1.3 mA (for control units X0 to X3)

2.4V DC/1 mA (from control unit X4)

Approx. 3 kΩ (for control units X0 to X3)

Input impedance

Approx. 5.1 kΩ (for control units X4 to X7)

Approx. 5.6 kΩ (from control unit X8 )

For control units X0 to X3:

135 μs or less: normal input

5 μs or less

Note)

: high-speed counter, pulse catch,

interrupt input settings

For control units X4 to X7:

135 μs or less: normal input

50 μs or less

Note)

Response time

off→on

From control unit X8 (C30/C60 only) :

0.6 ms or less

on→off Same as above

Operating mode indicator LED display

EN61131-2 Applicable type TYPE3 (however, according to the above specifications)

Note) this specification is applied when the rated input voltage is 24 V DC and the temperature is 25 °C.

Circuit diagram

[X0 to X3] [From X4]

Description

: high-speed counter, pulse catch,

interrupt input settings

X4 to X7 :R1=5.1kΩ R2=3kΩ

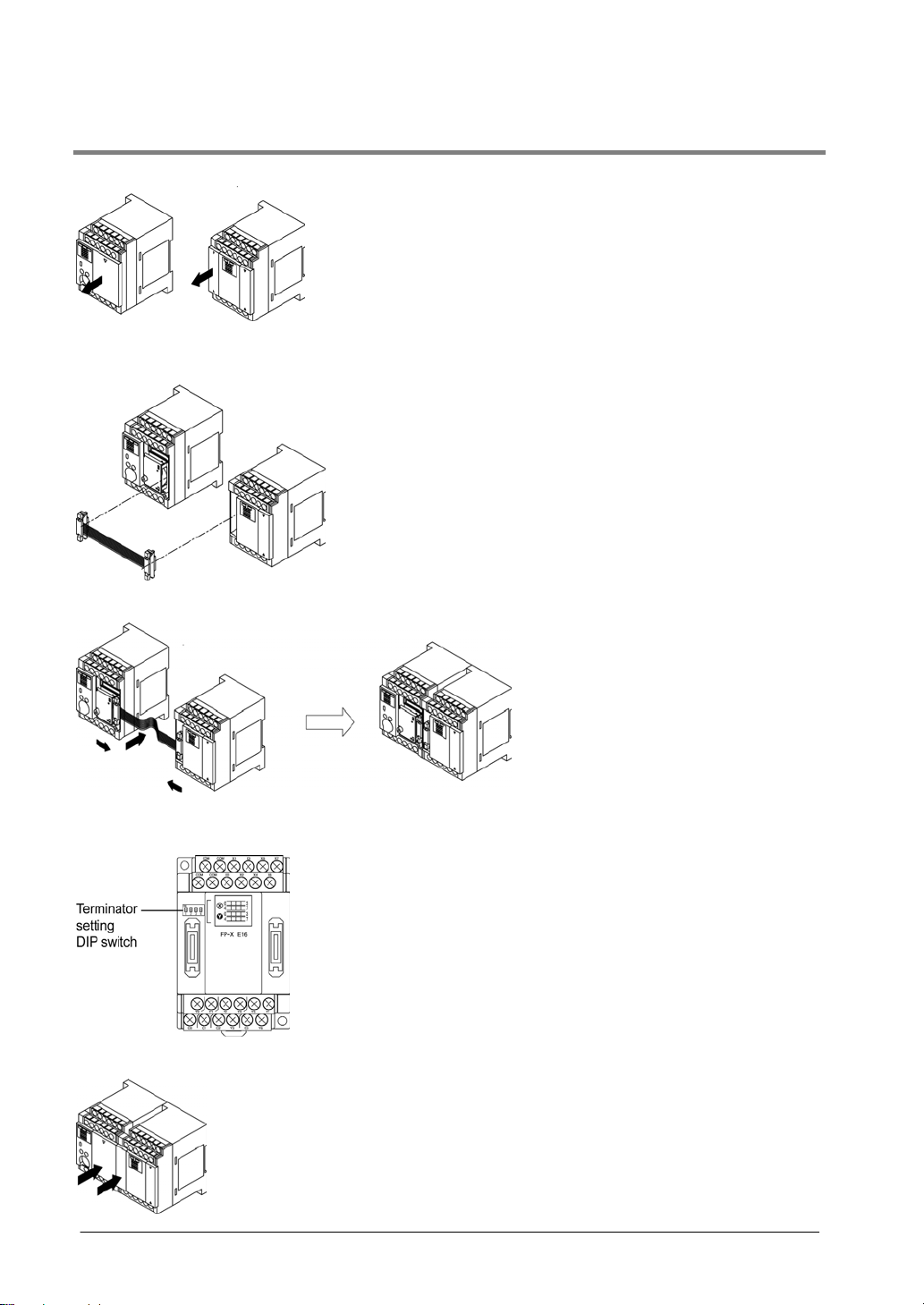

From X8 :R1=5.6kΩ R2=1kΩ