Panasonic FC-SF2BH-20 Installation Manual

INSTRUCTION MANUAL

Type 2Light Curtain

SF2B

Series

SUNX Limited MJE-SF2B No.6095-00

- 1 -

MEMO

- 2 -

SUNX Limited MJE-SF2B No.6095-00

Thank you for purchasing SUNX’s Light Curtain,

SF2B

series (hereinafter called ‘this

device’).

Please read this instruction manual carefully and thoroughly for the correct and optimum use

of this product.

Kindly keep this manual in a convenient place for quick reference.

This device is a light curtain for protecting a person from dangerous parts of a machine which

can cause injury or accident.

This manual has been written for the following personnel who have undergone suitable

training and have knowledge of light curtains, as well as, safety systems and standards.

who are responsible for the introduction of this device

who design the system using this device

who install and connect this device

who manage and operate a plant using this device

Note

1) All the contents of this instruction manual are the copyright of the publishers, and may

not be reproduced (even extracts) in any form by any electronic or mechanical means

(including photocopying, recording, or information storage and retrieval) without

permission in writing from the publisher.

2) The contents of this instruction manual may be changed without prior notice for

further improvement of the product.

3) Though we have carefully drawn up the contents of this instruction manual, if there

are any aspects that are not clear, or any error that you may notice, please contact

our local SUNX office of the nearest distributor.

SUNX Limited MJE-SF2B No.6095-00

- 3 -

Contents

Introduction········································································· 6

Attention Marks············································································· 6

Safety Precautions········································································ 6

Applicable Standards / Regulations ·············································· 9

Confirmation of Packed Contents ················································· 9

Chapter 1 Before Using This Device·······························10

1-1 Features··············································································· 10

1-2 Part Description ··································································· 11

1-3 Protection Area ···································································· 13

1-3-1 Sensing Area ··························································· 13

1-3-2 Safety Distance························································ 14

1-3-3 Influence of Reflective Surfaces ······························ 18

1-3-4 Sensor Placement ··················································· 19

1-4 Mounting ·············································································· 20

1-4-1 Mounting of the Mounting Bracket ·········································· 20

1-4-2 Mounting of the Bottom Cap Cable (Optional) ······················ 24

1-4-3 Extension and Dismantling of Sensor (Series Connection)···· 25

1-5 Wiring··················································································· 27

1-5-1 Power Supply Unit ···································································27

1-5-2

I/O Circuit Diagrams and Wiring·············································· 27

1-5-3

Cable Specification·································································· 38

1-5-4

Series Connection and Parallel Connection ··························· 40

1-6 Adjustment··········································································· 44

1-6-1 Beam-axis Alignment······························································· 44

1-6-2 Operation Test ········································································· 45

1-6-3 Operation················································································· 46

Chapter 2 Functions·························································55

2-1 Self-diagnosis Function························································ 55

2-2 Test Input (Emission Halt Function) ····································· 55

2-3Auxiliary Output···································································· 56

2-4Interference Prevention Function ········································· 57

2-5External Device Monitor Function ········································ 58

2-6Compatibility ········································································ 59

Chapter 3 Maintenance ····················································60

3-1 Daily Inspection···································································· 60

3-2 Periodic Inspection (Every Six Months)································ 61

3-3 Inspection after Maintenance ··············································· 61

SUNX Limited MJE-SF2B No.6095-00

- 4 -

Chapter 4 Troubleshooting ············································· 62

4-1 Troubleshooting of Emitter ··················································· 62

4-2 Troubleshooting of Receiver················································· 63

Chapter 5 SpecificationsDimensions·························· 64

5-1 Specifications ······································································· 64

5-2 Options················································································· 68

5-3 Dimensions···········································································71

5-3-1 Rear Mounting

with Standard Mounting Bracket (

5-3-2 Side Mounting

with Standard Mounting Bracket (

5-3-3 Mounting Bracket ···································································73

MS-SF2B-1

MS-SF2B-1

) ······················71

) ······················72

Chapter 6 Others······························································ 80

6-1 Glossary ··············································································· 80

SUNX Limited MJE-SF2B No.6095-00

- 5 -

Introduction

Attention Marks

This instruction manual employs the following attentions marks ,

depending on the degree of the danger to call operator’s attention to each particular action.

Read the following explanation of these marks thoroughly and observe these notices without

fail.

If you ignore the advice with this mark, death or serious injury could result.

If you ignore the advice with this mark, injury or material damage could

result.

<Reference>

It gives useful information for better use of this device.

Safety Precautions

ع

Use this device as per its specifications. Do not modify this device since its functions and

capabilities may not be maintained and it may malfunction.

ع

Use of this device under the following conditions or environment is not presupposed.

Please consult us if there is no other choice but to use this device in such an environment.

1) Operating this device under conditions and environment not described in this manual.

2) Using this device in the following fields: nuclear power control, railroad, aircraft,

automobiles, combustion facilities, medical systems, aerospace development, etc.

ع

When this device is to be used for enforcing protection of a person from any danger

occurring around an operating machine, the user should satisfy the regulations

established by national or regional security committees (Occupational Safety and Health

Administration: OSHA, the European Standardization Committee, etc.). Contact the

relative organization(s) for details.

ع

In case of applying this device to particular equipment, follow the safety regulations in

regard to appropriate usage, mounting (installation), operation and maintenance. The

users including the installation operator are responsible for the introduction of this device.

ع

Use this device by installing suitable protection equipment as a countermeasure for failure,

damage, or malfunction of this device.

ع

Before using this device, check whether the device performs properly with the functions

and capabilities as per the design specifications.

ع

In case of disposal, dispose this device as industrial waste.

٧

Machine designer, installer, employer and operator

The machine designer, installer, employer and operator are solely responsible to

ensure that all applicable legal requirements relating to the installation and the use in

any application are satisfied and all instructions for installation and maintenance

contained in the instruction manual are followed.

Whether this product functions as intended to and systems including this product

comply with safety regulations depends on the appropriateness of the application,

installation, maintenance and operation. The machine designer, installer, employer

and operator are solely responsible for these items.

٧

Engineer

The engineer would be a person who is appropriately educated, has widespread

knowledge and experience, and can solve various problems which may arise during

work, such as a machine designer, or a person in charge of installation or operation

etc.

- 6 -

SUNX Limited MJE-SF2B No.6095-00

٧

Operator

The operator should read this instruction manual thoroughly, understand its contents,

and perform operations following the procedures described in this manual for the

correct operation of this device.

In case this device does not perform properly, the operator should report this to the

person in charge and stop the machine operation immediately. The machine must

not be operated until correct performance of this device has been confirmed.

٧

Environment

Do not use a mobile phone or a radio phone near this device.

Install the sensor by considering the effect of nearby reflective surfaces, and take

countermeasures, such as painting, masking, roughening, or changing the material

of the reflective surfaces, etc. Failure to do so may cause the sensor not to detect,

resulting in death or serious body injury.

Do not install this device in the following environments.

1) Areas exposed to intense interference (extraneous) light such as direct sunlight

2) Areas with high humidity where condensation is likely to occur

3) Areas exposed to corrosive or explosive gases

4) Areas exposed to vibration or shock of levels higher than that specified

5) Areas exposed to contact with water

6) Areas exposed to too much steam or dust

7) Areas where the beam-receiving part of this device is directly exposed to light

from high-frequency fluorescent lamp (inverter type) or rapid starter fluorescent

lamp.

٧

Installation

Always keep the correctly calculated safety distance between this device and the

dangerous parts of the machine.

Install extra protection structure around the machine so that the operator must pass

through the sensing area of this device to reach the dangerous parts of the machine.

Install this device such that some part of the operator’s body always remains in the

sensing area when operator is done with the dangerous parts of the machine.

Do not install this device at a location where it can be affected by wall reflection.

When installing multiple sets of this device, connect the sets and, if necessary, install

some barriers such that mutual interference does not occur.

Do not use this device in a reflective configuration.

٧

Equipment in which this device is installed

Do not use this device as safety equipment for a press machine.

Do not install this device with a machine whose operation cannot be stopped

immediately in the middle of an operation cycle by an emergency stop equipment.

This device starts the performance after 2 seconds from the power ON. Have the

control system started to function with this timing.

SUNX Limited MJE-SF2B No.6095-00

- 7 -

٧

Wiring

Be sure to carry out the wiring in the power supply off condition.

Do not use this device under a transitional condition at power-on (approx.2 seconds).

All electrical wiring should conform to the regional electrical regulations and laws.

The wiring should be done by engineer(s) having the special electrical knowledge.

Do not run the sensor cable together with high-voltage lines or power lines or put

them together in the same raceway.

In case of extending the cable of the emitter or the receiver, each can be extended

up to 30.5m by using the exclusive cable.

٧

Maintenance

When replacement parts are required, always use only genuine supplied

replacement parts. If substitute parts from another manufacturer are used, the

sensor may not come to detect, result in death or serious body injury.

The periodical inspection of this device must be performed by an engineer having the

special knowledge.

After maintenance or adjustment, and before starting operation, test this device

following the procedure specified in ‘

Clean this device with a clean cloth. Do not use any volatile chemicals.

٧

Others

Never modify this device. Modification may cause the sensor not to detect, resulting

in death or serious body injury.

Do not use this device to detect objects flying over the sensing area.

Do not use this device to detect transparent objects, translucent objects or objects

smaller than the specified minimum sensing objects.

Chapter 3 Maintenance

’.

- 8 -

SUNX Limited MJE-SF2B No.6095-00

Applicable Standards/Regulations

This device complies with the following standards/regulations.

<EU Directives>

EU Machinery Directive 98/37/EC, EMC Directive 89/336/EEC

<European Standards>

EN 61496-1 (Type 2), EN55011

<International Standards>

IEC 61496-1/2 (Type 2)

<Japanese Industrial Standard(JIS)>

JIS B 9704-1/2 (Type 2), JIS B 9705-1 (ISO 13849-1) (Category 2)

<Standards in U.S./Canada)>

UL 61496-1/2 (Type 2), UL 1998, CSA22.2 No.14, CSA22.2 No.08

<Regulations in U.S.>

OSHA 1910.212, OSHA 1910.217(C), ANSI B11.1 - B11.19, ANSI/RIA 15.06

Regarding EU Machinery Directive, a Notified Body, UL International Demko A/S, has

certified with the type examination certificate.

With regard to the standards in US / Canada, a NRTL, UL (Underwriters Laboratories Inc.)

has certified for Canada-U.S. Listing.

<Reference>

The conformity to JIS, OSHA and ANSI for this device has been evaluated by ourselves.

The C-CL US Listing Mark

This device conforms to the EMC directive and the Machinery directive. The

body indicates that this product conforms to the EMC directive.

In Japan, never use this device as a safety equipment for any press machine or shearing

machine.

When this device is used in a place other than the places shown in the table above, be sure

to confirm the standards or regulations applicable in each region or country before use.

indicates compliance with both Canadian and U.S. requirements.

Confirmation of Packed Contents

غ

Sensor: Emitter, Receiver each 1pc.

غ

Test Rod 1 pc.

For

SF2B-Hغ:

غ

Intermediate Supporting Bracket (

Note: The intermediate support bracket (

differs depending on the product as shown below:

SF2B-TR27 (Ǿ27

1 set:

SF2B-H

SF2B-A

2 sets:

SF2B-H

SF2B-A

3 sets:

SF2B-H

SF2B-A

220mm)

MS-SF2B-2

MS-SF2B-2

غ㨯㨯㨯

Sensor with 40 to 56 beam channels

غ㨯㨯㨯

Sensor with 20 to 28 beam channels

غ㨯㨯㨯

Sensor with 64 to 80 beam channels

غ㨯㨯㨯

Sensor with 32 to 40 beam channels

غ㨯㨯㨯

Sensor with 88 to 96 beam channels

غ㨯㨯㨯

Sensor with 44 to 48 beam channels

) is enclosed with the following products. The quantity

) 0 to 3 sets

mark on the sensor main

غ

Instruction Manual (this manual) 1 pc.

SUNX Limited MJE-SF2B No.6095-00

- 9 -

Chapter 1 Before Using This Device

1-1 Features

This device is the light curtain with the following features.

No special controller is required.

Beam-axis alignment indicators which make beam-axis alignment easy are incorporated.

IP65 is used as the protective construction.

Synchronization system is different depending on the type bottom cap cable to be

used.

Wiring synchronization using 8-core cable (sensing range: 0.2 to 13m)

Beam synchronization using 4-core cable (sensing range: 0.2 to 5m)

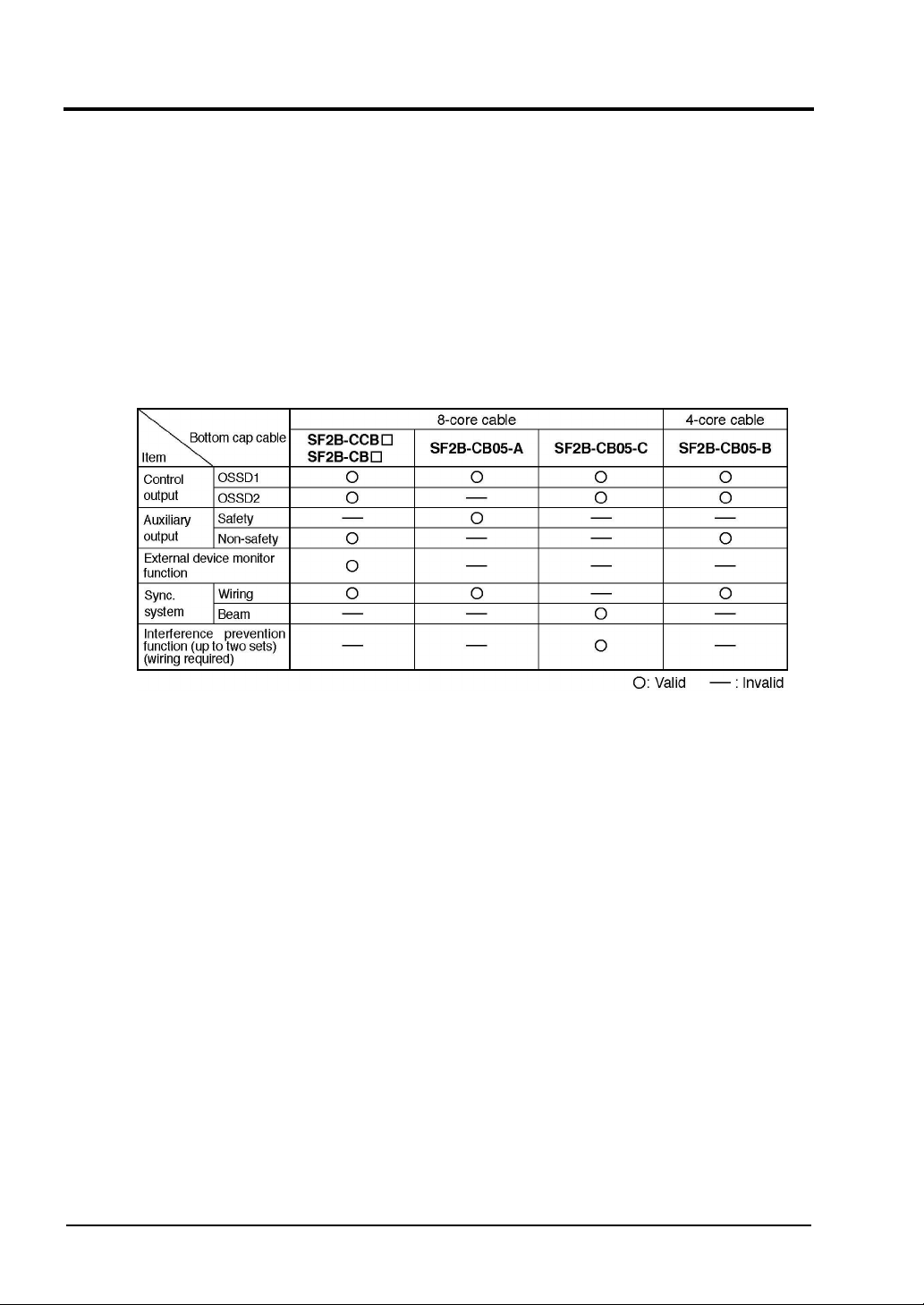

Output and functions are different depending on the type of bottom cap cable (op-

tional) to be used.

㧨

Function list available by bottom cap cable

㧪

Refer to ‘

5-2 Options

’ for details of options.

- 10 -

SUNX Limited MJE-SF2B No.6095-00

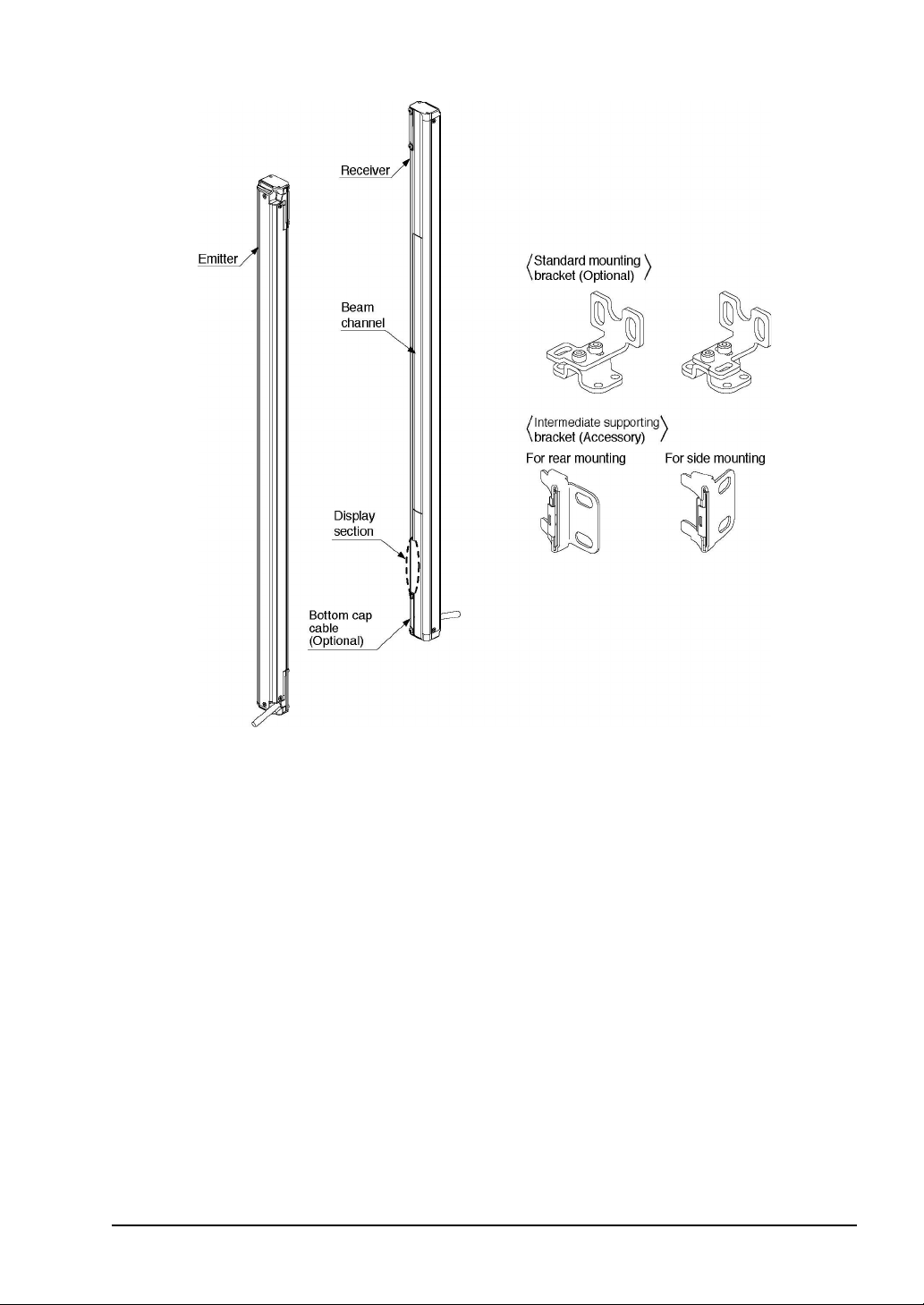

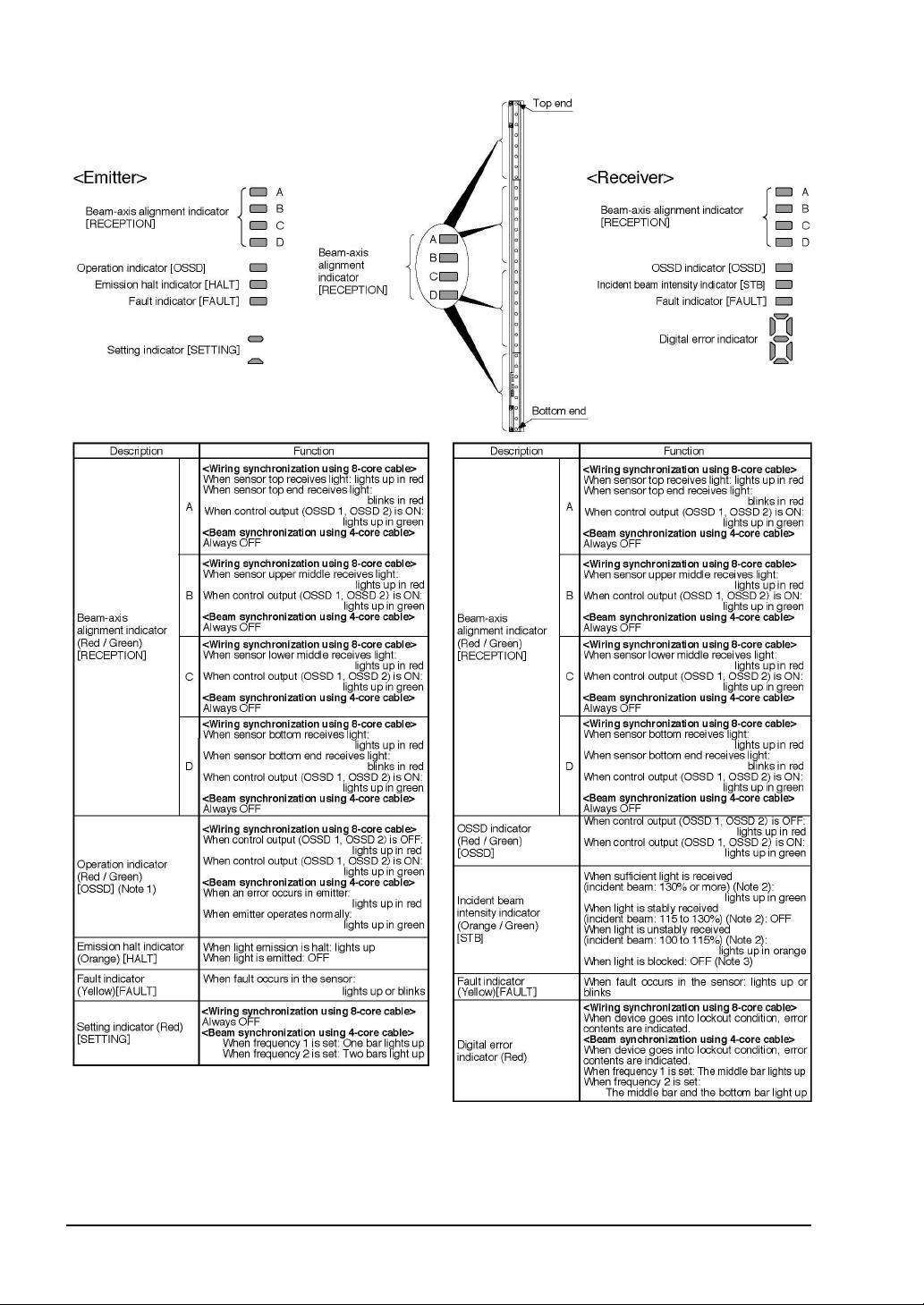

1-2 Part Description

<Emitter>

It emits light to the receiver facing it. Furthermore, the status of the emitter and the receiver is indicated on its display section.

<Receiver>

It receives light from the emitter facing it. Simultaneously, it turns ON the control output (OSSD 1,

OSSD 2) when the all beam channels receive light from emitter, and it turns OFF the control output

(OSSD1, OSSD2) when one or more beam channels are blocked light. Besides, the receiver displays

its status on the display section.

<Beam channel>

The light emitting elements of the emitter and the light receiving elements of the receiver are placed at

the following intervals, 20mm (

<Standard mounting bracket (optional)>

This bracket is to be used for mounting the emitter / receiver. It enables to adjust the horizontal mounting angle using the standard mounting bracket.

<Intermediate supporting bracket (For rear mounting) (For side mounting)>

This bracket is to be used for mounting the sensor.

nels or more,

SUNX Limited MJE-SF2B No.6095-00

SF2B-Aغ is for 20 beam channels or more.

SF2B-Hغ) and 40mm (

SF2B-Hغ is for the sensor having 40 beam chan-

SF2B-Aغ).

- 11 -

Display section:

Notes: 1) Since the color of the operation indicator changes according to ON/OFF status of the control output (OSSD

2) The threshold where the control output (OSSD 1, OSSD 2) changes from OFF to ON is applied as ‘100%

3) The status ‘when light is blocked’ refers to the status that the some obstacle is existed in the sensing area.

1, OSSD 2), the operation indicator is marked as ‘OSSD’ on the sensor.

incident beam intensity’.

4) The description given in [ ] is marked on the sensor.

SUNX Limited MJE-SF2B No.6095-00

- 12 -

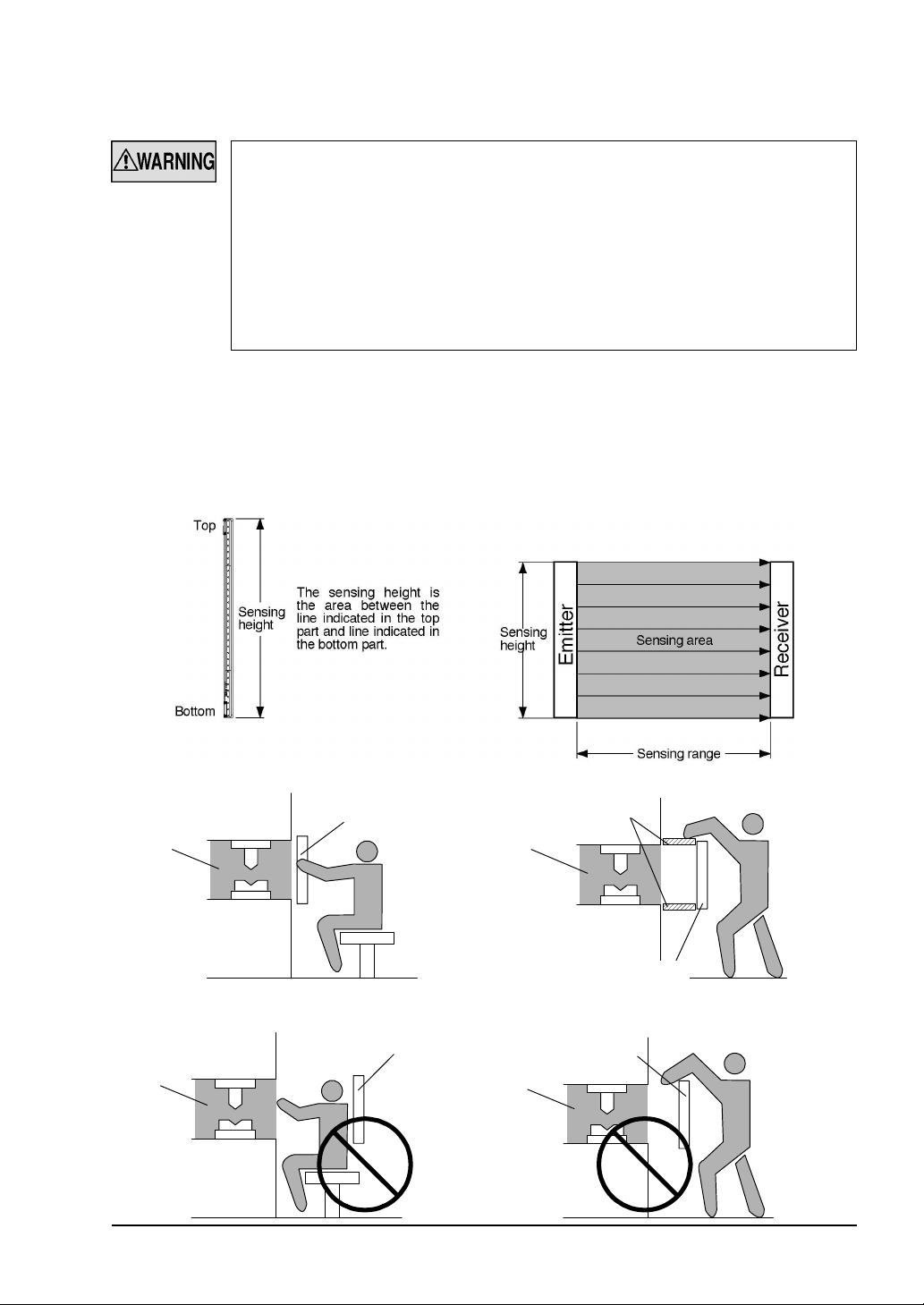

1-3 Protection Area

1-3-1 Sensing Area

Be sure to install protection structure around the machine so that the operator must pass

through the sensing area of this device to reach the dangerous parts of the machine.

Furthermore, ensure that some part of the operator’s body always remains in the sensing

area when operation is done with the dangerous parts of the machine. Failure to do so can

result in serious injury or death.

Do not use any reflection type or recursive reflection type arrangement.

When connecting the sensor, use the correct combination of emitter and receiver (same

beam pitch and number of beam channels) and match their top-bottom orientation. Combining different types of emitter and receiver could produce a non-sensing area, which may

result in serious injury or death.

Furthermore, facing several receivers towards one emitter, or vice versa, could produce a

non-sensing area or cause mutual interference, which may result in serious injury or death.

The sensing area is the zone formed by the sensing height of the sensor and the sensing

range between the emitter and the receiver. The sensing height is determined by the number

of beam channels. The sensing range can be 0.2 to 13m for the wiring synchronization using

8-core cable and 0.2 to 5m for the beam synchronization using 4-core cable. Take care that

the sensing range becomes short after mounting either protection cover (

(optional). Take care that if the sensing range is less than 0.2m, malfunction may occur due

to the optical structure.

FC-SF2BH-غ)

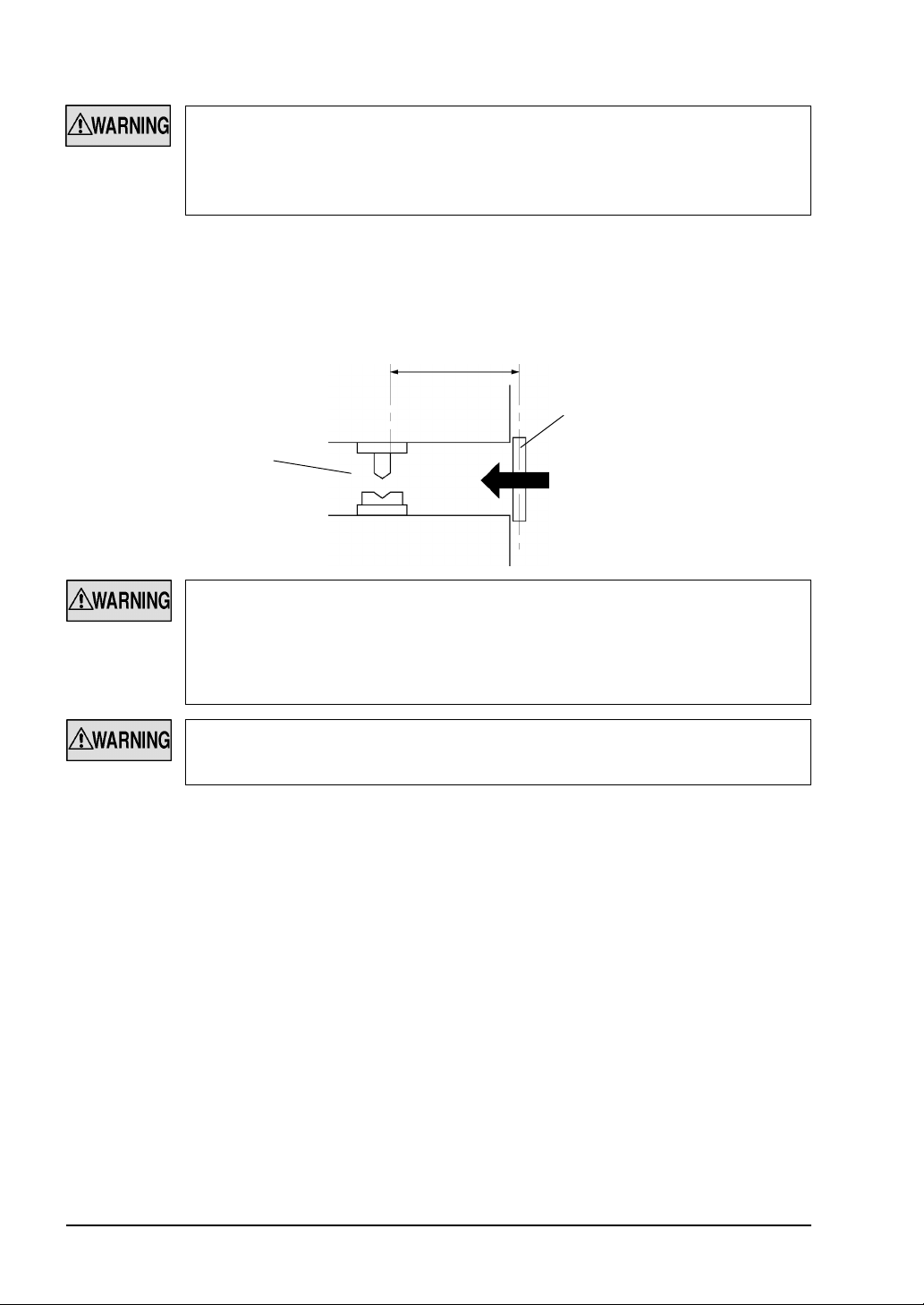

<Example of Correct Installation>

Dangerous

part

<Example of Incorrect Installation>

Dangerous

part

SUNX Limited MJE-SF2B No.6095-00

Sensing

area

Protective structure

Dangerous

part

Sensing

area

Sensing area

Dangerous

part

Sensing area

- 13 -

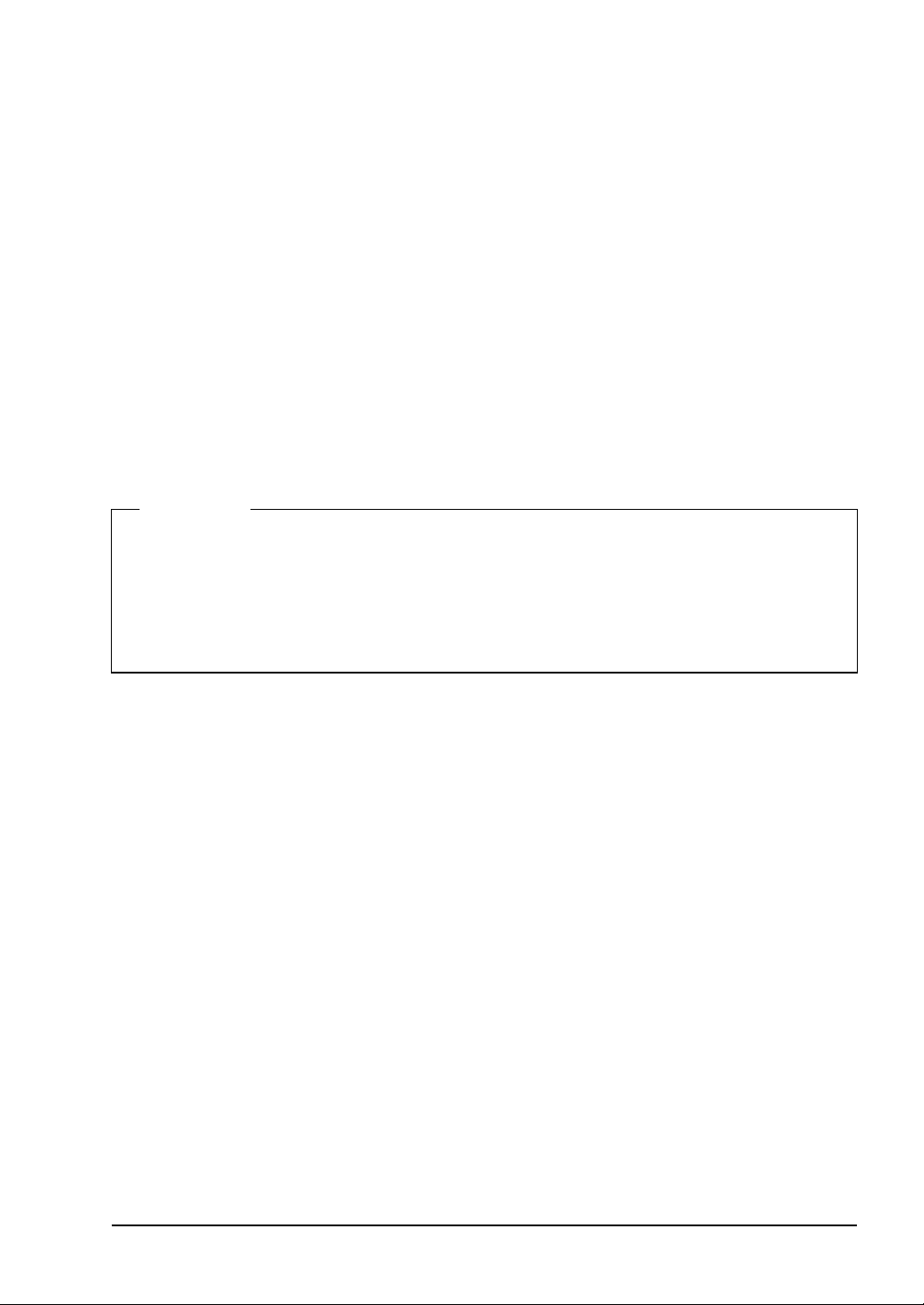

1-3-2 Safety Distance

r

t

r

f

Calculate the safety distance correctly, and always maintain the distance which is equal to o

greater than the safety distance, between the sensing area of this device and the dangerous

parts of the machine. If the safety distance is miscalculated or if sufficient distance is not maintained, the machine will not stop quickly before reaching to the dangerous parts, which can

result in serious injury or death.

The safety distance is the minimum distance that must be maintained between the light cur-

tain and the dangerous parts of the machine so that the machine can be stopped before a

human body or an object can reach the dangerous parts.

The safety distance is calculated based on the equation described in the next page when a

person moves perpendicular (normal intrusion) to the sensing area of the area sensor.

Safety distance S

Sensing area

Dangerous

part

Before designing the system, refer to the relevant standards of the region where this device is to

be used, and then install this device.

Furthermore, the equation described in the next pages is to be used only in case the intrusion

direction is perpendicular to the sensing area. In case the intrusion direction is not perpendicula

to the sensing area, be sure to refer to the relevant standard (regional standard, specification o

the machine, etc.) for details of the calculation.

Intrusion direction

- 14 -

The max. response time of the machine is from the point that the machine receives the hal

signal from this device to the point that the dangerous part of the machine stops. The max.

response time of the machine should be timed with the machine to be actually used.

SUNX Limited MJE-SF2B No.6095-00

[For use in Europe (EU) (as EN 999)] (Also applicable to ISO 13855)

(For intrusion direction perpendicular to the sensing area)

<In case that the minimum sensing object is

Equation Ԙ S=(KT)+C

Ǿ

40mm or less (SF2B-Hغ)>

S: Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of the

machine

K: Intrusion velocity of operator’s body or object (mm/s)

Taken as 2,000 (mm/s) for calculation

T: Response time of total equipment (s)

T=Tm+T

SF2B

Tm: Maximum halting time of device (s)

SF2B

: Response time of this device (s)

T

C: Additional distance calculated from the size of the minimum sensing object of the

sensor (mm)

However, the value of C cannot be 0 or less.

C=8

(d-14)

C:

SF2B-Hغ104 (mm)

d:

SF2B-Hغ27 (mm)

<Reference>

For calculating the safety distance S, there are the following five cases.

First calculate by substituting the value K=2,000 (mm/s) in the equation above. Then, classify the obtained value

of S into three cases, 1) S<100, 2) 100

the value K=1,600 (mm/s). After that, classify the calculation result into two cases, 4) S

details, refer to ‘

For calculating T

When this device is used in the ‘PSDI Mode’, an appropriate safety distance S must be calculated. For details,

be sure to refer to the standards or regulations applicable in each region or country.

Calculation Example Ԙ For use in Europe

m

(maximum halt time of the device), use a special device called a ‘brake monitor’.

҇S҇

500, and 3) S>500. For Case 3) S>500, recalculate by substituting

҇

’.

500 and 5) S>500. For

<In case the minimum sensing object is Ǿ40mm or more (SF2B-Aغ)>

Equation S=(KT)+C

S: Safety distance (mm)

K: Intrusion velocity of operator’s body or object (mm/s)

Taken as 1,600 (mm/s) for calculation

T: Response time of total equipment (s)

T=Tm+T

SF2B

Tm: Maximum halting time of device (s)

SF2B

: Response time of this device (s)

T

C: Additional distance calculated from the minimum sensing object of the sensor

(mm)

C=850 (mm)

SUNX Limited MJE-SF2B No.6095-00

- 15 -

<Calculation Example>

Calculation Example Ԙ For use in Europe

(OFF response time: 15ms or less, minimum sensing object diameter: 27mm)

First, calculate with K=2,000.

S=(K

T)+C

=K

=2,000

=2,000

=2,000

(Tm+T

)+8(d㧙14)

SF2B

(Tm+0.015)+8(27㧙14)

Tm+2,0000.015+104

Tm+134

If the result is:

1) In case S<100 (mm)

Safety distance S is taken as 100 (mm)

҇S҇

2) In case 100

Safety distance S is taken as 2,000

500 (mm)

Tm+28 (mm)

3) In case S>500 (mm)

S=K’

=1,600

=1,600

=1,600

(Tm+T

)+8(d㧙14)

SF2B

(Tm+0.015)+8(27㧙14)

Tm+1,6000.015+104

Tm+128

then, calculate again.

If the result is:

҇

4) In case S

500 (mm)

Safety distance S is taken as 500 (mm)

5) In case S>500 (mm)

Safety distance S is taken as 1,600

Tm+128 (mm)

In case this device is installed in a system with a maximum halting time of 0.1 (s)

S=2,000

=2,000

Tm+134

0.1+134

=334

Since this value matches with Case 2) above, S is 334 (mm).

In case this device is installed in a system with a maximum halting time of 0.4 (s)

S=2,000

=2,000

Tm+134

0.4+134

=934

Since this value matches with Case 3) above,

S=1,600

=1,600

Tm+128

0.4+128

=768

Since this value matches with Case 5) above, S is 768 (mm).

- 16 -

SUNX Limited MJE-SF2B No.6095-00

[For use in the United States of America (as per ANSI B11.19)]

Equation ԙ S=K(Ts+Tc+T

SF2B+Tbm

)+Dpf

S : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of the

machine

K : Intrusion speed {Recommended value in OSHA is 63 (inch/s) [ѳ1,600 (mm/s)] }

ANSI B11.19 does not define the intrusion speed ‘K’. When determining K, consider possible

factors including physical ability of operators.

Ts: Halting time calculated from the operation time of the control element (air valve,

etc.) (s)

T

: Maximum response time of the control circuit required for functioning the brake (s)

c

T

: Response time of this device (s)

SF2B

: Additional halting time tolerance for the brake monitor (s)

T

bm

The following equation holds when the machine is equipped with a brake monitor.

Tbm=Ta㧙

T

a

When the machine is not equipped with a brake monitor, it is recommended that 20% or more of

(T

s+Tc

pf

D

: Additional distance calculated from the size of the minimum sensing of the sen-

(Ts+Tc)

: Setting time of brake monitor (s)

) is taken as additional halting time.

sor (mm)

SF2B-Hغ Dpf=2.676 (inch)ѳ68mm

SF2B-Aغ Dpf=5.355 (inch)ѳ136mm

Dpf = 3.4

(d㧙

ѳ

3.4(d㧙7) (mm)

d: Minimum sensing object diameter 1.063 (inch)

Minimum sensing object diameter 1.851 (inch)ѳ47 (mm)

Note that the value of Dpf cannot be 0 or less.

0.276) (inch)

ѳ

27 (mm)

SF2B-H

SF2B-A

غ

غ

<Reference>

Since the calculation above is performed by taking 1 (inch)=25.4 (mm), there is a slight difference between the

representation in (mm) and that in (inch).

<Calculation Example>

Calculation Example ԙ For use in the United States of America

ѳ

[OFF response time: 15ms or less, minimum sensing object diameter: 1.063 inch

S=K

(Ts+Tc㧗

(Ta+0.015)+3.4(d㧙0.276) (inch)

=63

(Ta+0.015)+3.4(1.063㧙0.276)

=63

Ta+630.015+3.40.787

=63

Ta+3.6208

=63

ѳ63

T

㧗

SF2B

Ta+3.62 (inch)

Tbm)+Dpf

27 (mm)]

In case this device is installed in a system with a maximum halting time 0.1 (s)

S=63

Ta+3.62

0.1+3.62

=63

=9.92 (inch)

=251.968 (mm)

ѳ

252 (mm)

Hence, as per the calculations S is 252 (mm).

SUNX Limited MJE-SF2B No.6095-00

- 17 -

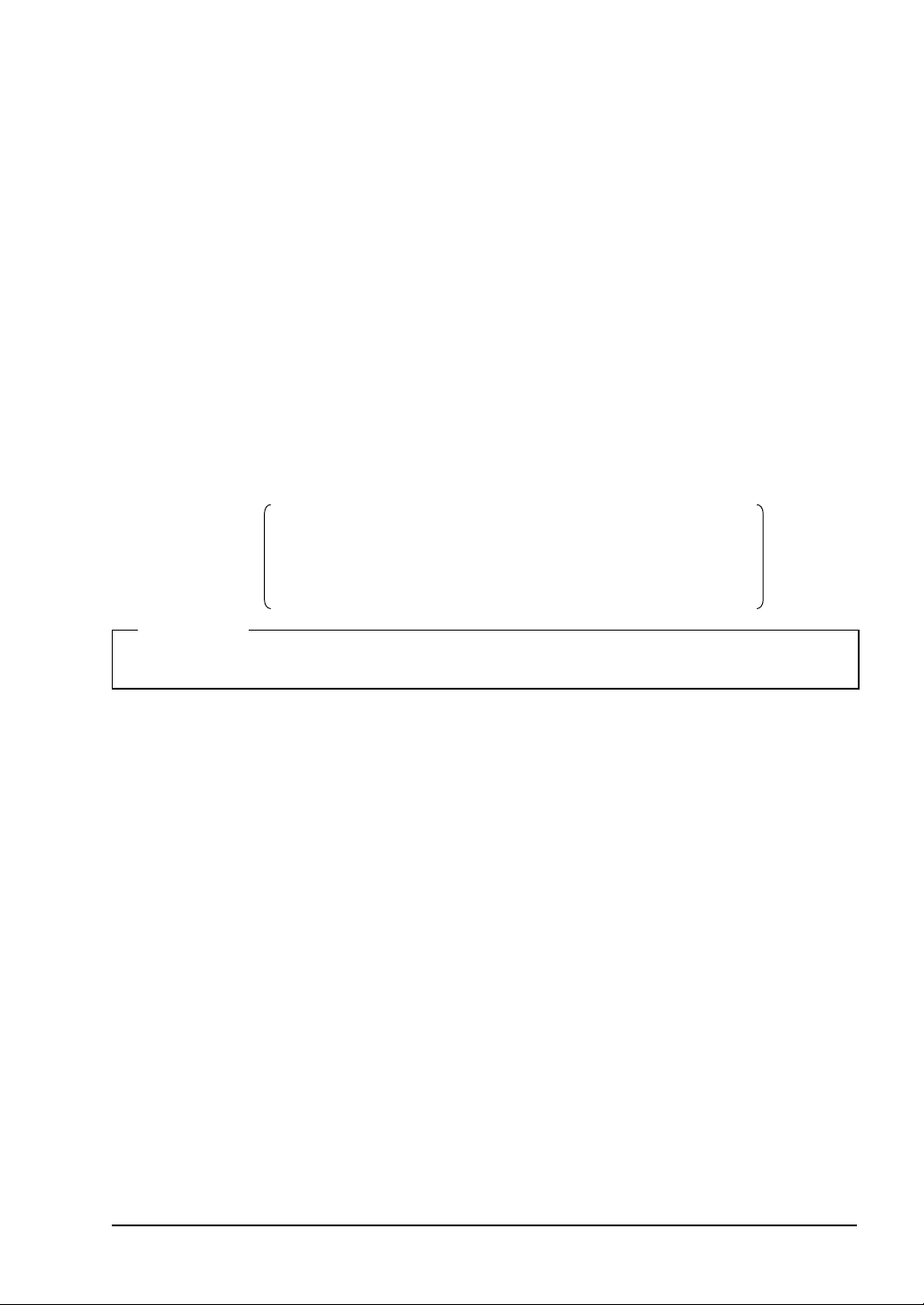

1-3-3 Influence of Reflective Surfaces

Install the sensor by considering the effect of nearby reflective surfaces, and take countermeasures such as painting, masking, or changing the material of the reflective surface, etc. Failure

to do so may cause the sensor not to detect, resulting in death or serious body injury.

Install this device at a distance of at least A (m) (given below) away from reflective surfaces

such as metal walls, floors, ceilings, workpieces, covers, panels or glass surfaces.

<SideView>

<Top View>

<Top View>

Distance between emitter and

receiver (Sensing range L)

0.2 to 3m 0.32m

3 to 13m (Note 1)

Notes: 1) The sensing range L is applicable to the wiring synchronization using 8-core cable. For the beam

synchronization using the 4-core cable, the distance between emitter and receiver is 0.2 to 5m.

2) The effective aperture angle for this device is

61496-2. However, install this device away from reflective surfaces considering an effective aperture

angle of

r6ࠑ

to take care of beam misalignment, etc. during installation.

Allowable installation distance A

L/2

tan2

ǰ

=L0.106 (m) (ǰ=6㫦)

r5ࠑ

(when L>3m) as required by IEC 61496-2 / UL

Allowable Distance from Sensor Beam Channel to Reflective Surface

- 18 -

SUNX Limited MJE-SF2B No.6095-00

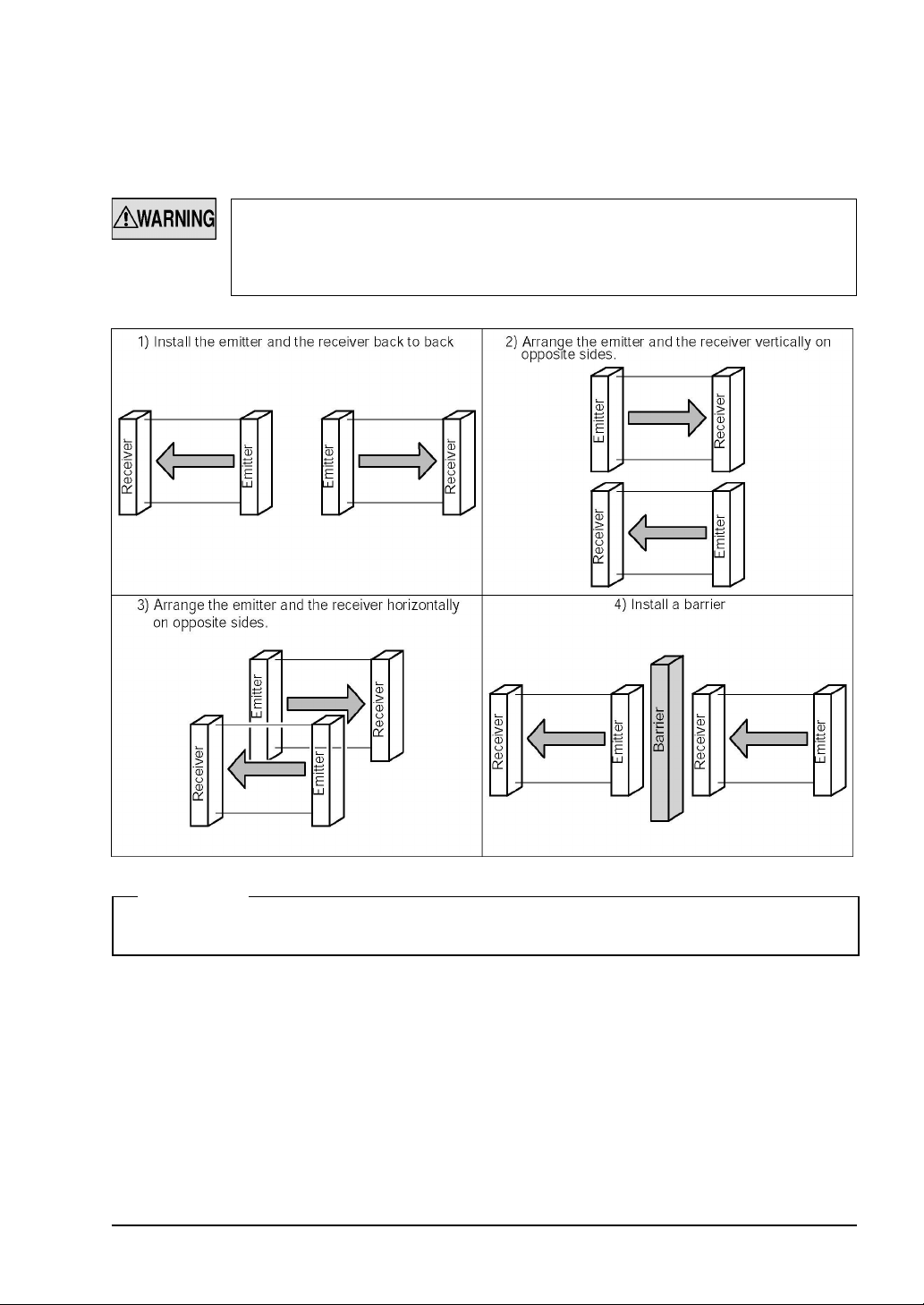

1-3-4 Sensor Placement

This is the configuration when two or more sets of emitter and receiver facing each other are

placed without series or parallel connection between them. It is used for the case that there is

a problem in wiring or for system evaluation in case of addition of equipment. Perform an

operation test by referring to ‘

Refer to the examples of sensor placement given below and understand them thoroughly

before installing the sensors. Improper sensor placement could cause sensor malfunction,

which can result in serious injury or death.

If this device is used in multiple sets, arrange them to avoid mutual interference. If mutual

interference occurs, it can result in serious injury or death.

<Example of sensor placement>

1-6-2 Operation Test

’.

<Reference>

The above figures are just examples of sensor placement. If there are any questions or problems, please contact our office.

SUNX Limited MJE-SF2B No.6095-00

- 19 -

1-4 Mounting

r

1-4-1 Mounting of the Mounting Bracket

For selecting the appropriate mounting bracket matched to the installation environment, the

mounting bracket is not incorporated in this device. Please purchase the optional mounting

bracket to fit on the mounting environment.

Do not apply the load such as forced bending to the cable of this device. Applying imprope

load could cause the wire breakage.

The minimum bending radius of the cable is R6mm. Mount the sensor considering the cable

bending radius.

<Reference>

Mount the emitter and the receiver at the same level and parallel to each other. The effective aperture angle

of this device is

Unless otherwise specified, the following mounting procedure is common for both emitter and receiver. For

the mounting, prepare the mounting holes on the mounting surface by referring to

5-3 Dimensions

‘

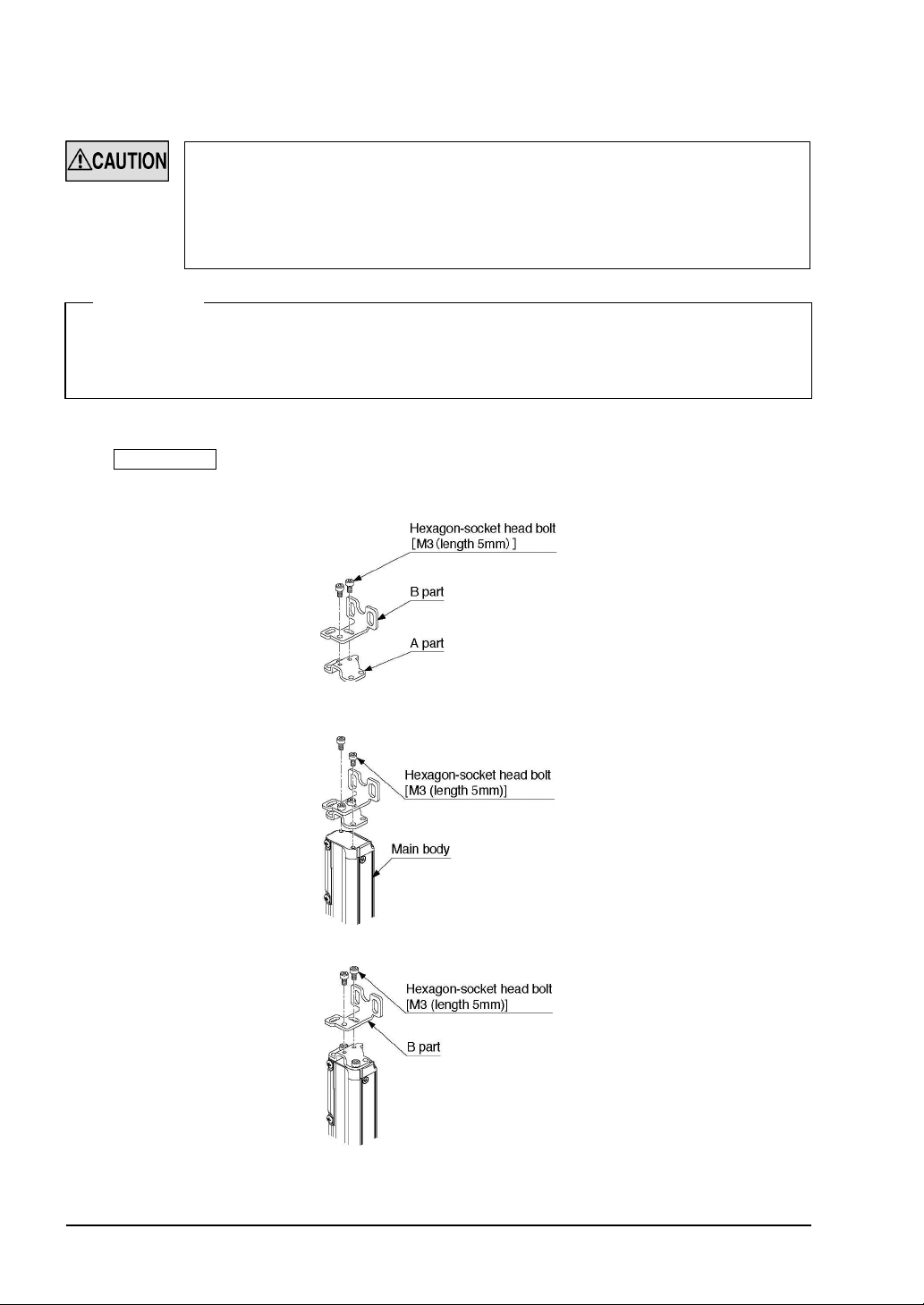

<When the standard mounting bracket (MS-SF2B-1) (Optional) is used>

Configuration

r5ࠑ

or less for a sensing distance exceeding 3m.

’.

The standard mounting bracket (

MS-SF2B-1

) configures as follows.

1. Fix the standard mounting bracket with two hexagon-socket head bolts [M3 (length: 5mm)].

㨯

The tightening torque should be 0.6N

m or less.

2. For side mounting, remove the B part.

- 20 -

SUNX Limited MJE-SF2B No.6095-00

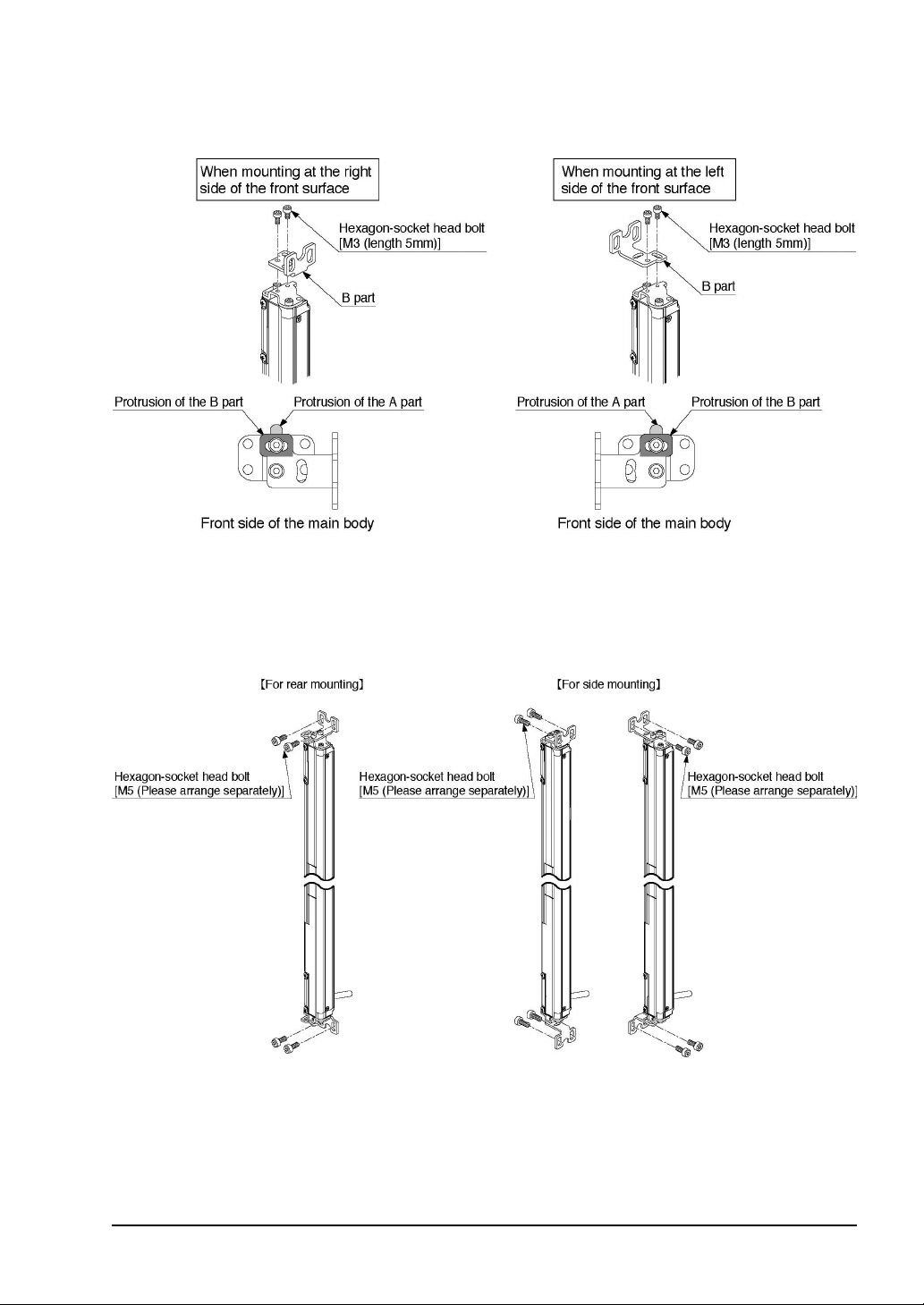

3. Mount the brackets so that the protrusion of the A part and the B part are overlapped.

B part to be attached to the top or bottom side of this product differs depending on the

direction of mounting described as the following chart.

4. Mount the mounting bracket on to the mounting surface with two hexagon-socket head

bolts [M5 (please arrange separately)] temporarily.

5. Adjust the height of the emitter and the receiver to level with the elongate holes and then

tighten the hexagon-socket head bolts.

Note: For the models that the intermediate supporting bracket (

intermediate supporting bracket (

bracket (MS-SF2B-2) (Accessory) is used>

MS-SF2B-2

). For details, refer to

MS-SF2B-2

) is enclosed with, be sure to use the

<When the intermediate supporting

SUNX Limited MJE-SF2B No.6095-00

- 21 -

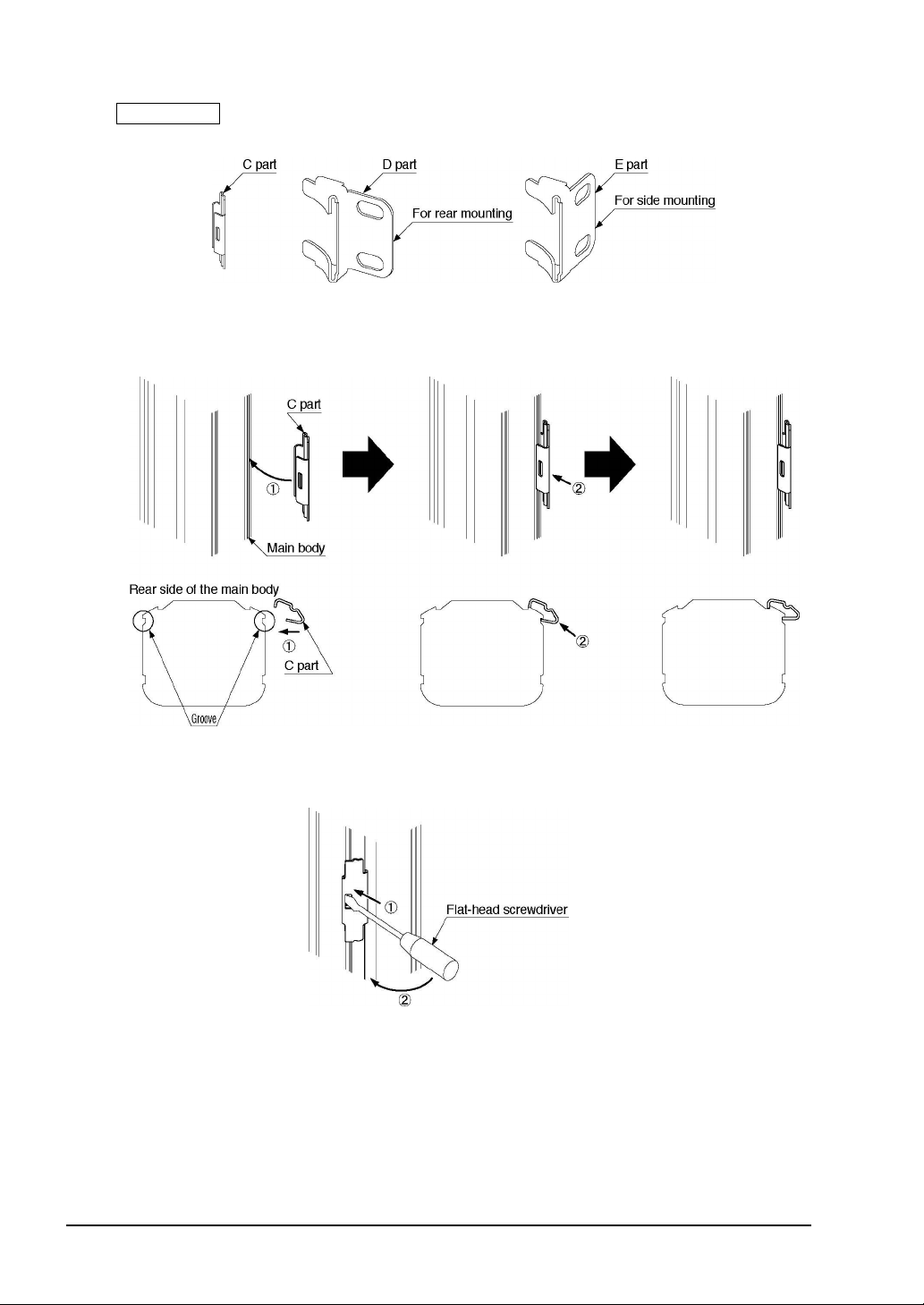

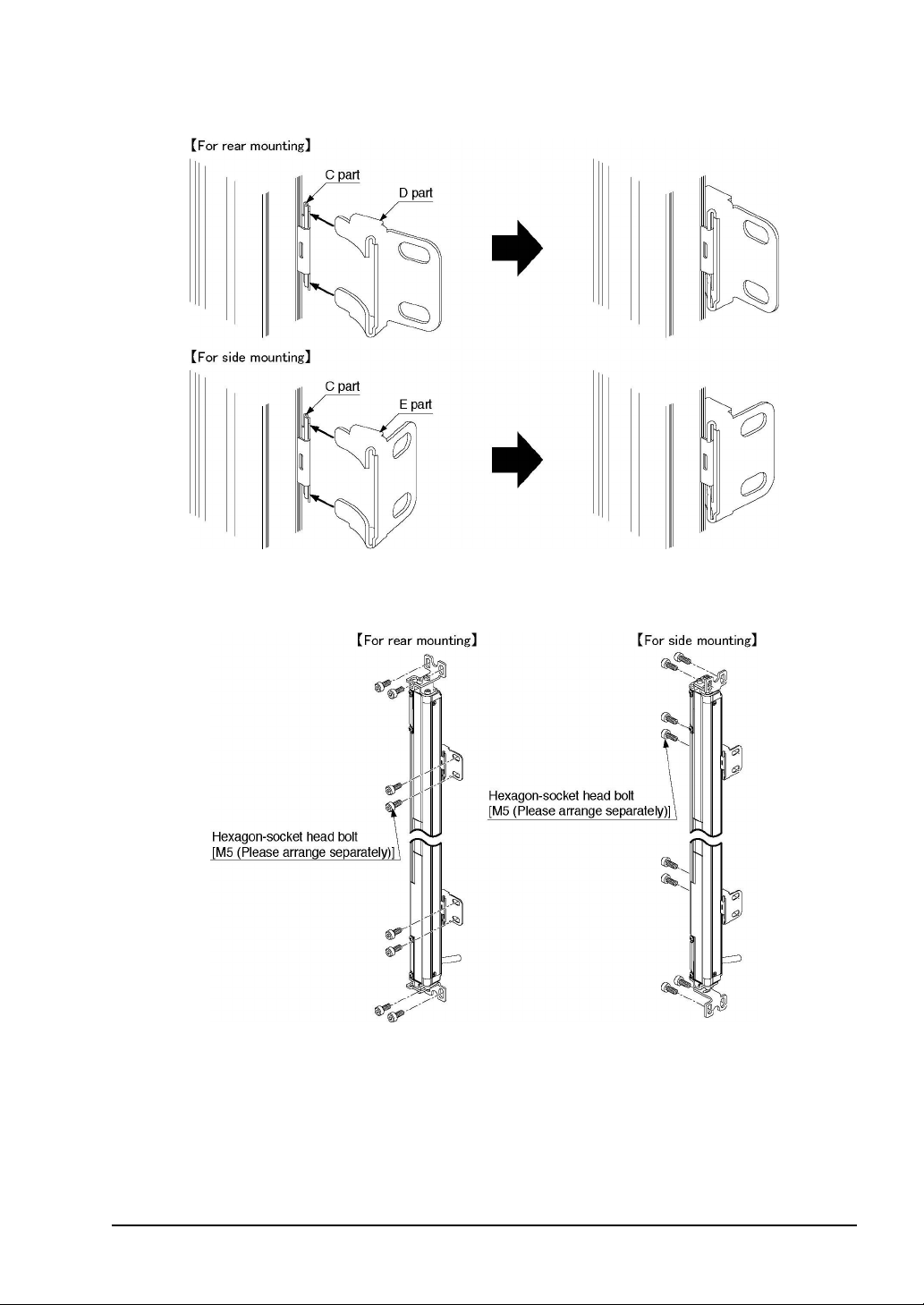

<When the intermediate mounting bracket (MS-SF2B-2) (Accessory) is used>

Configuration

The intermediate mounting bracket (accessory) configures as follows.

1. Hook the C part into the groove on the side of the body and press it.

Note that the position to fit the C part onto the main body differs from the surface where the

intermediate mounting bracket is fit.

<How to remove the bracket>

Insert a flat-head screwdriver into the hole located on the rear side of the C part and tilt it to

remove the C part.

- 22 -

SUNX Limited MJE-SF2B No.6095-00

2. Insert the D part or E part into the C part in the step 1 condition.

3. Mount the D part on to the mounting surface with the two hexagon-socket head bolts [M5

(Please arrange separately)].

SUNX Limited MJE-SF2B No.6095-00

- 23 -

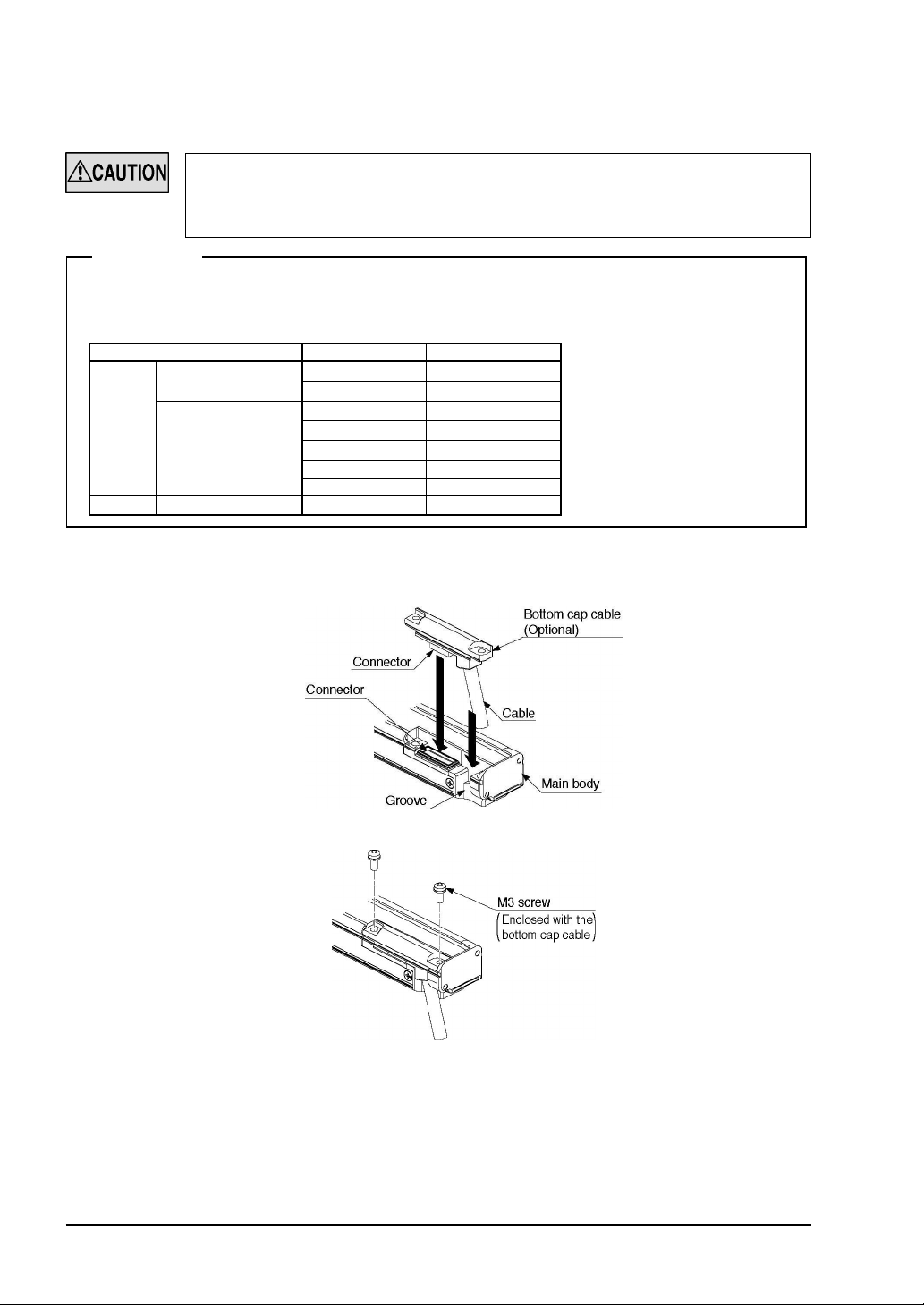

1-4-2 Mounting of the Bottom Cap Cable (Optional)

r

The cable is not enclosed with this device.

Mount the bottom cap cable (optional) in accordance with the following procedure.

Do not lose any screws during extension / dismantling.

The bottom cap cables are distinguished with the color of the connectors, the color of the

connector for emitter is gray and that of the receiver is black. Connect the cable to emitte

and receiver without fail using their colors as the guide.

<Reference>

There are two types of the bottom cap cable, 8-core type and 4-core type, and in addition to these types, two

more types are available for the bottom cap cable, discrete wire type and connector type. Select the bottom cap

cable as usage.

The length of the bottom cap cable differs depending on the model No.

Type Model No. Cable length (m)

Discrete wire type

8-core

Connector type

4-core Connector type

SF2B-CCB3

SF2B-CCB7

SF2B-CB05

SF2B-CB5

SF2B-CB10

SF2B-CB05-A

SF2B-CB05-C

SF2B-CB05-B

<Mounting method>

1. Insert the connector of the bottom cap cable (optional) into the connector of this device.

When inserting the connector, fit the cable to the groove of this device.

3

7

0.5

5

10

0.5

0.5

0.5

2. Tighten the two M3 screws. The tightening torque should be 0.3N

- 24 -

㨯

m or less.

SUNX Limited MJE-SF2B No.6095-00

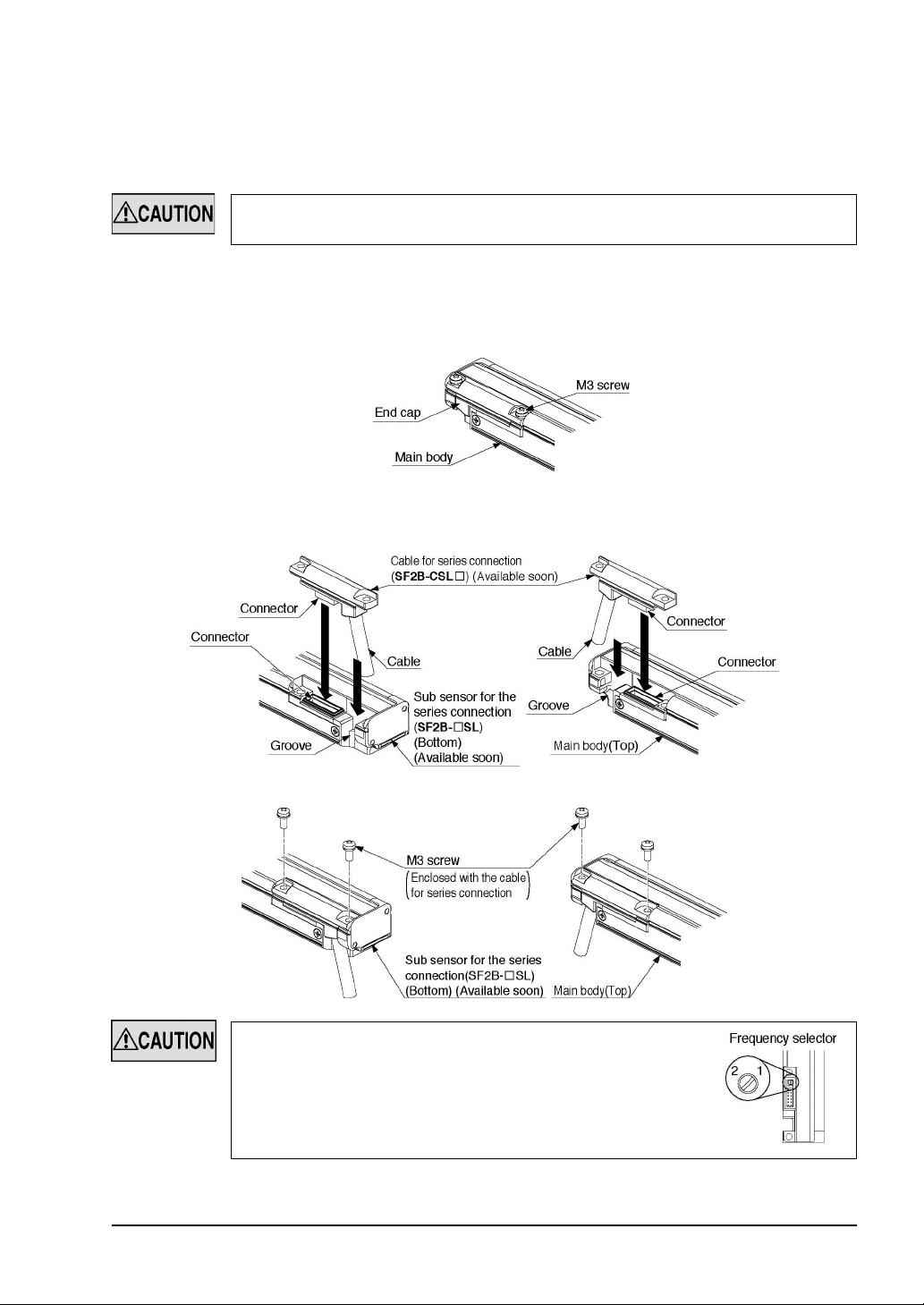

1-4-3 Extension and Dismantling of Sensor (Series Connection)

For constructing the series connection, optional sub sensor for the series connection (

(available soon) and the cable for the series connection (

SF2B-CSLغ) (available soon) are

required.

For constructing the series connection, the following procedure is required.

Do not lose any screws during extension / dismantling work.

Furthermore, do not mix emitters and receivers to mount in series connection.

<Constructing method for the series connection>

1. Loosen the two M3 screws of the end cap on the main side sensor (emitter and receiver to

which the synchronization wire has been connected), and then remove the end cap from

the sensor.

SF2B-غSL

)

2. Insert the cable for the series connection (

connector of the main body and the sub sensor for the series connection (

SF2B-CSLغ) (available soon) into the

SF2B-غSL

(available soon). When inserting the connector, fit the cable into the groove of this device.

3. Tighten each two M3 screws. The tightening torque should be 0.3N㨯m or less.

)

When using the bottom cap cable (

that the frequency selector at the insertion slot of bottom cap cable on

this device is set to ‘1’ position (on both emitter and receiver). If they are

in the position other than the above, the device may not operate properly.

SUNX Limited MJE-SF2B No.6095-00

SF2B-CB05-B

) (optional), make sure

- 25 -

Loading...

Loading...