Panasonic FA-MA301 Service manual

FA-MA301 Back to Model List

(FA-MA301) LCC

Contents

WARNING

I. Introduction

1.1 Specifications.......................................................................................... 1-1

1.2 Features.................................................................................................. 1-1

1.3 Exterior ................................................................................................... 1-2

1.4 Component Location............................................................................... 1-2

II. Mechanical components

2.1 Operation of LCC elevating drive............................................................ 2-1

2.2 Operation of the LCC.............................................................................. 2-2

III. Maintenance

3.1 Maintenance components....................................................................... 3-1

3.2 Disassembly and Assembly.................................................................... 3-2

Mechanical

components

Maintenance Introduction

Electrical

IV. Electrical

4.1 Electrical components operation............................................................. 4-1

4.2 Signal information ................................................................................... 4-3

V. Troubleshooting

5.1 Self-diagnosis / Machine malfunction ..........

5.2 Service mode...............................................

Refer to System console service manual

Refer to System console service manual

VI. Installation procedure

6.1 Unpacking............................................................................................... 6-1

6.2 Installation procedure ............................................................................. 6-2

6.3 Adjustment.............................................................................................. 6-3

Schematic diagram (LCC)

Trouble

Shooting

Installation

WARNING

This service information is designed for experienced repair technicians only and

is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of

potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced

professional technicians. Any attempt to service or repair the product or products

dealt with in this service information by anyone else could result serious injury or

death.

(For USA)

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Communications & Systems Co. for the sole purpose of providing

information necessary for the equipment's proper support. It is intended that this

information be confidential and may not be reproduced without prior written consent

from Panasonic Communications & Systems Co. Panasonic Communications &

Systems Co. reserves the right to change any information enclosed herein without

prior notification.

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Co. for the sole purpose of providing information necessary for the

equipment's proper support. It is intended that this information be confidential

and may not be reproduced without prior written consent from Panasonic Co.

Panasonic Co. reserves the right to change any information enclosed herein without

prior notification.

© February, 1999

Section I Introduction

1.1 Specifications

Type Large capacity paper feed cassette

Paper capacity 3000 sheets (20 lb / 80g/m

Paper weight Standard : 20 lb / 80 g/m

Range : 16 to 24 lb / 60 g/m2 to 90 g/m

Paper size Letter / A4 size width

Power source DC 24V ( Power source is supplied by copier main body)

Power consumption 20W

Dimensions 11.4" (W) x 17.5" (D) x 20.4" (H)

290 (W) x 445 (D) x 517 (H) mm

Weight 30.8 lb / 14 kg

Ambient conditions Temperature : 50 ~ 86 F / 10 ~ 30 degree

Relative humidity : 30 ~80 % RH

Applicable models FP-7728 / 7735 / 7742 / 7750

FP-D250/D350/D450/D600 Series

2

)

2

2

1.2 Features

• Large capacity design holds 3000 sheets.

• Easy to install using an outside connector directly to the copy machine.

Introduction

1-1

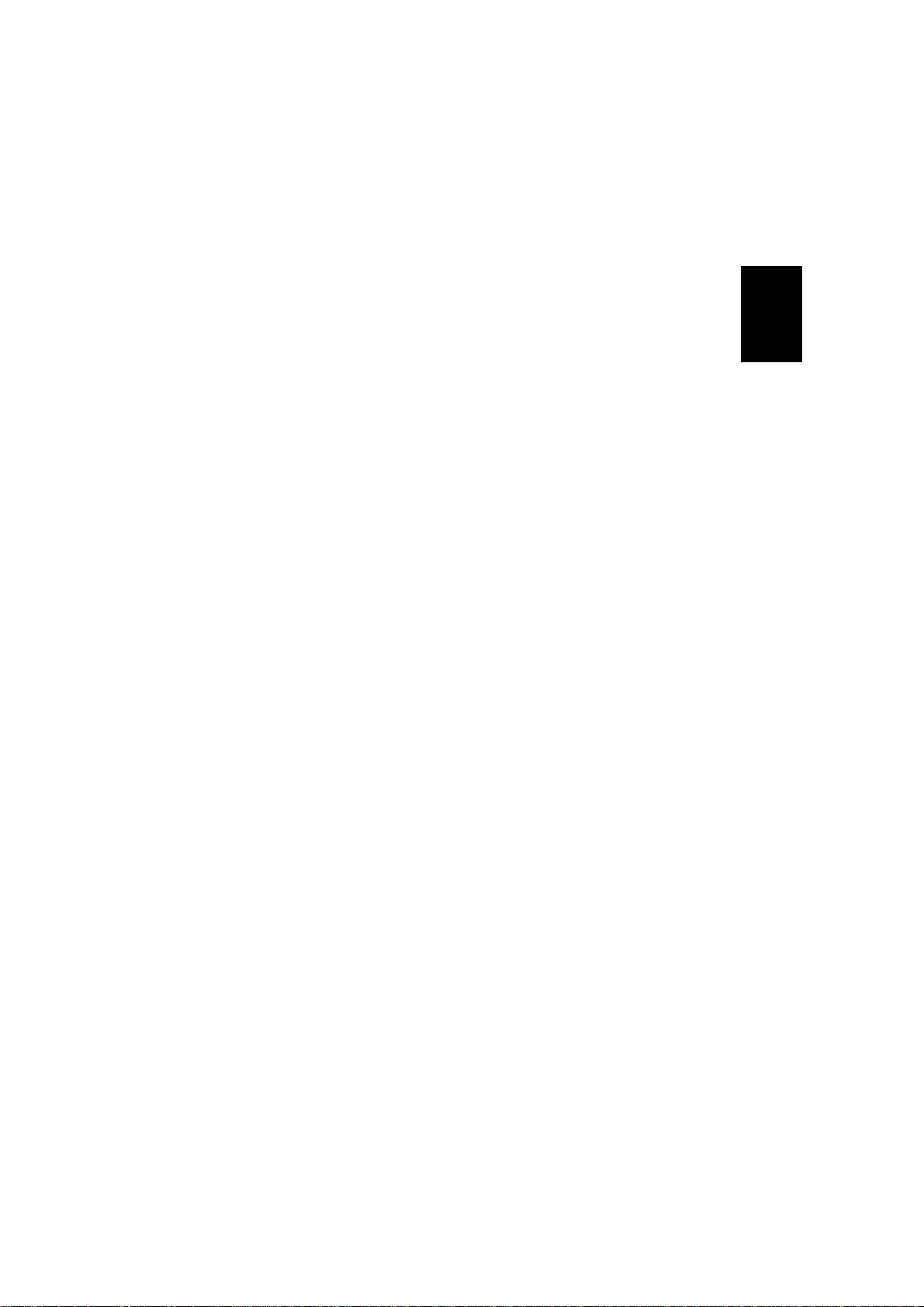

1.3 Exterior

Door

Paper feed table

Upper cover

Rear cover

Connecting cord

to the copy

machine frame

Junction

cord

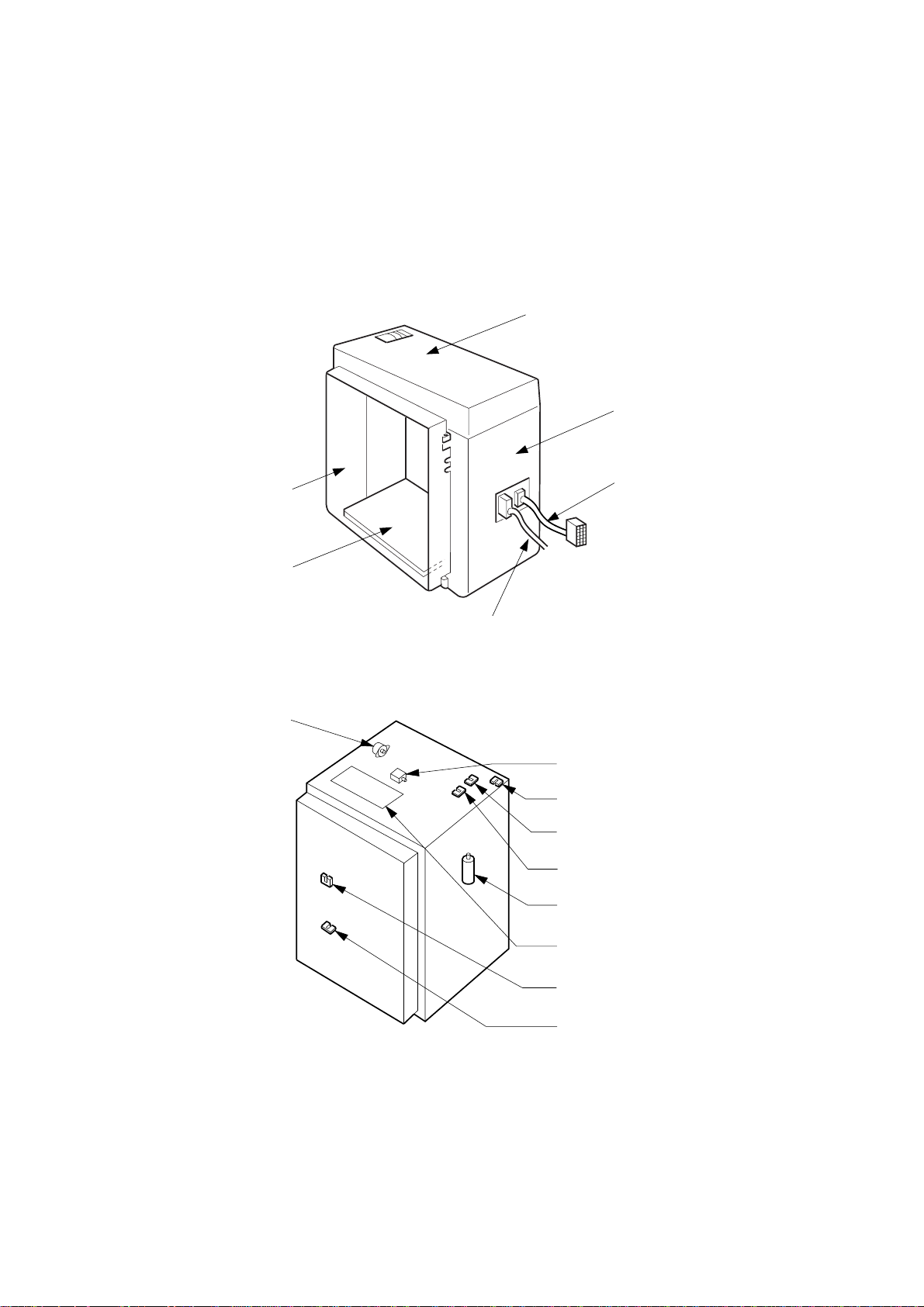

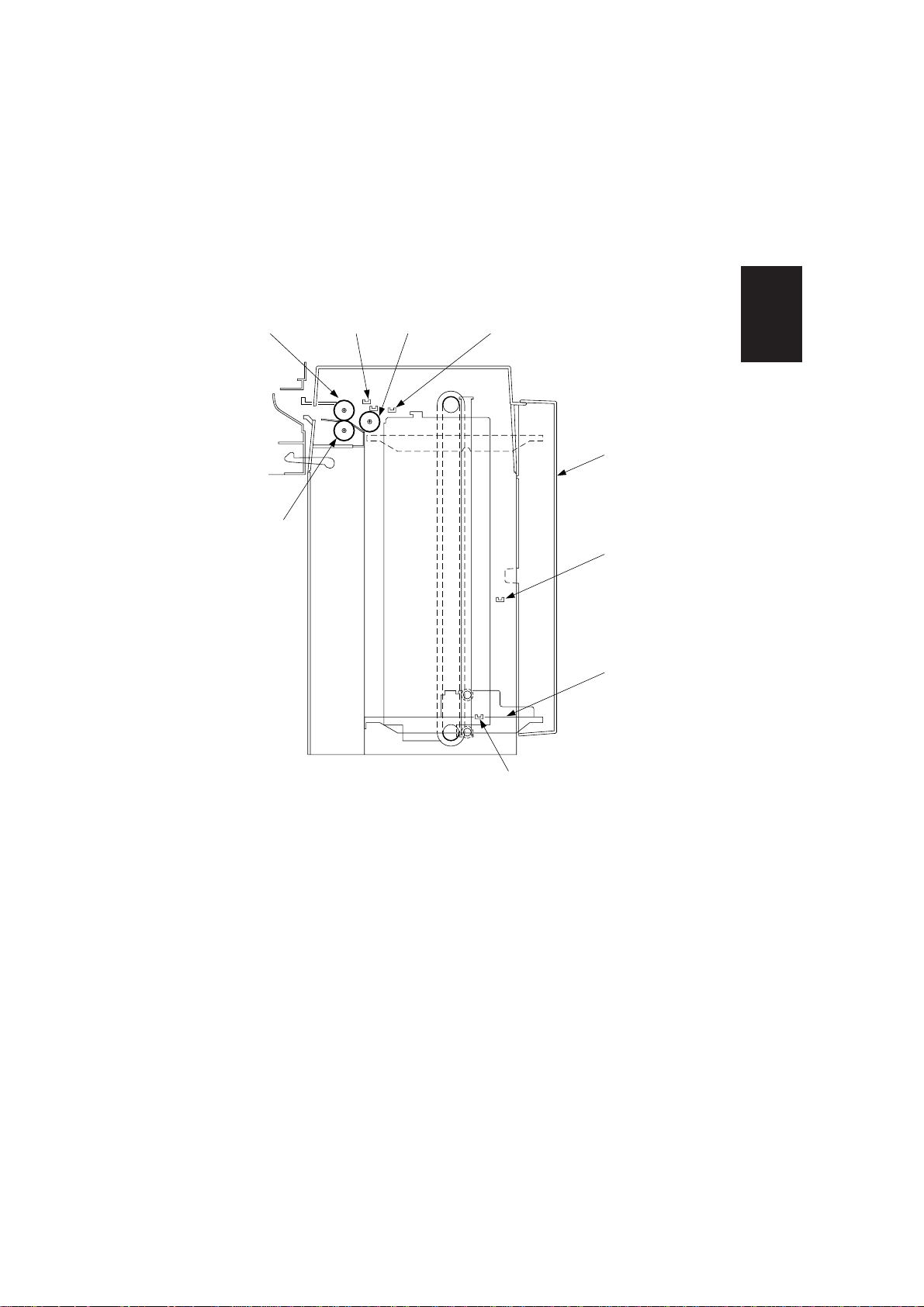

1.4 Component location

Paper feed motor

SV006

Paper feed solenoid

LCC sensor

Upper limit sensor

Paper detecting sensor

Elevator motor

Driver PCB

Door open /close sensor

Lower limit sensor

SV005

1-2

DFP roller

Upper limit

sensor

Pick up rollerPaper feed roller

Paper detecting sensor

Introduction

Door

Door open /

close sensor

Paper feed

table

Lower limit

sensor

SV001

1-3

Section II Mechanical components

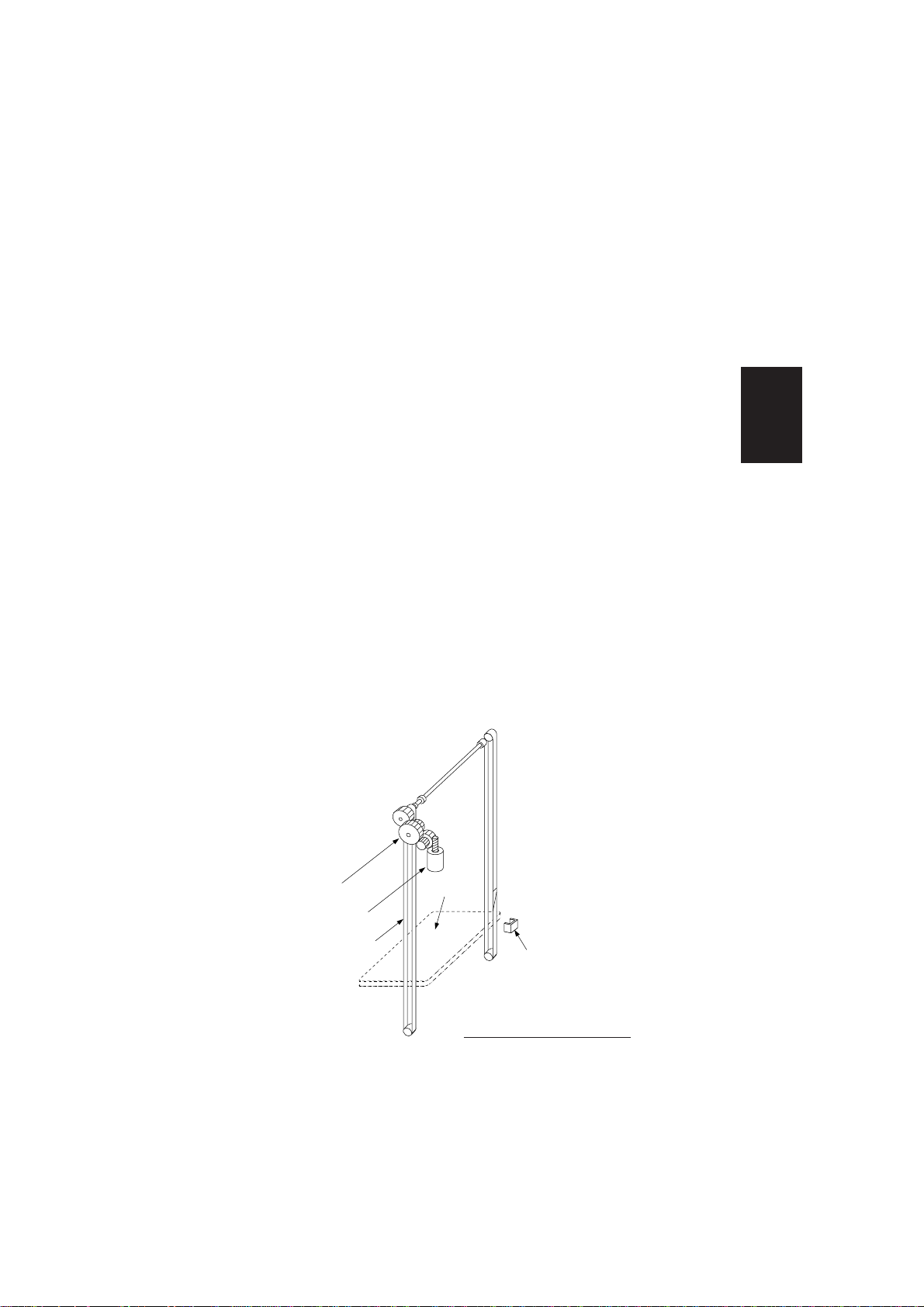

2.1 Operation of LCC elevating drive

The LCC system enables 3,000 sheets of paper to be put on the paper feed table.

Elevating operation of the table is as follows.

• When the elevator motor of the paper feed table rotates, the drive gear of the

elevator chain is driven by the middle gear and the elevator chain begins to

drive. The paper feed table, which is connected to the elevator chain, begins to

rise or to fall according to the direction the chain is driving.

• When the door closes, the paper feed table is lifted. When the lower limit sensor

detects the paper feed table, the sensor stops the elevator drive.

• When the door opens, the paper feed table is driven down. When the lower limit

sensor detects the paper feed table, the sensor stops elevator drive.

• When the paper is fed, and the sheets of paper on the paper feed table are

removed, the upper limit sensor turns OFF. The elevator motor rotates, and by

the rotation, the paper feed table is elevated.

When the upper limit sensor detects the paper, the elevator motor stops and the

upper limit of paper on the table is compensated.

Mechanical

components

Middle gear

Elevator motor

Elevator chain

Paper

feed

table

Lower limit sensor

Tray elevating mechanism

SV008

2-1

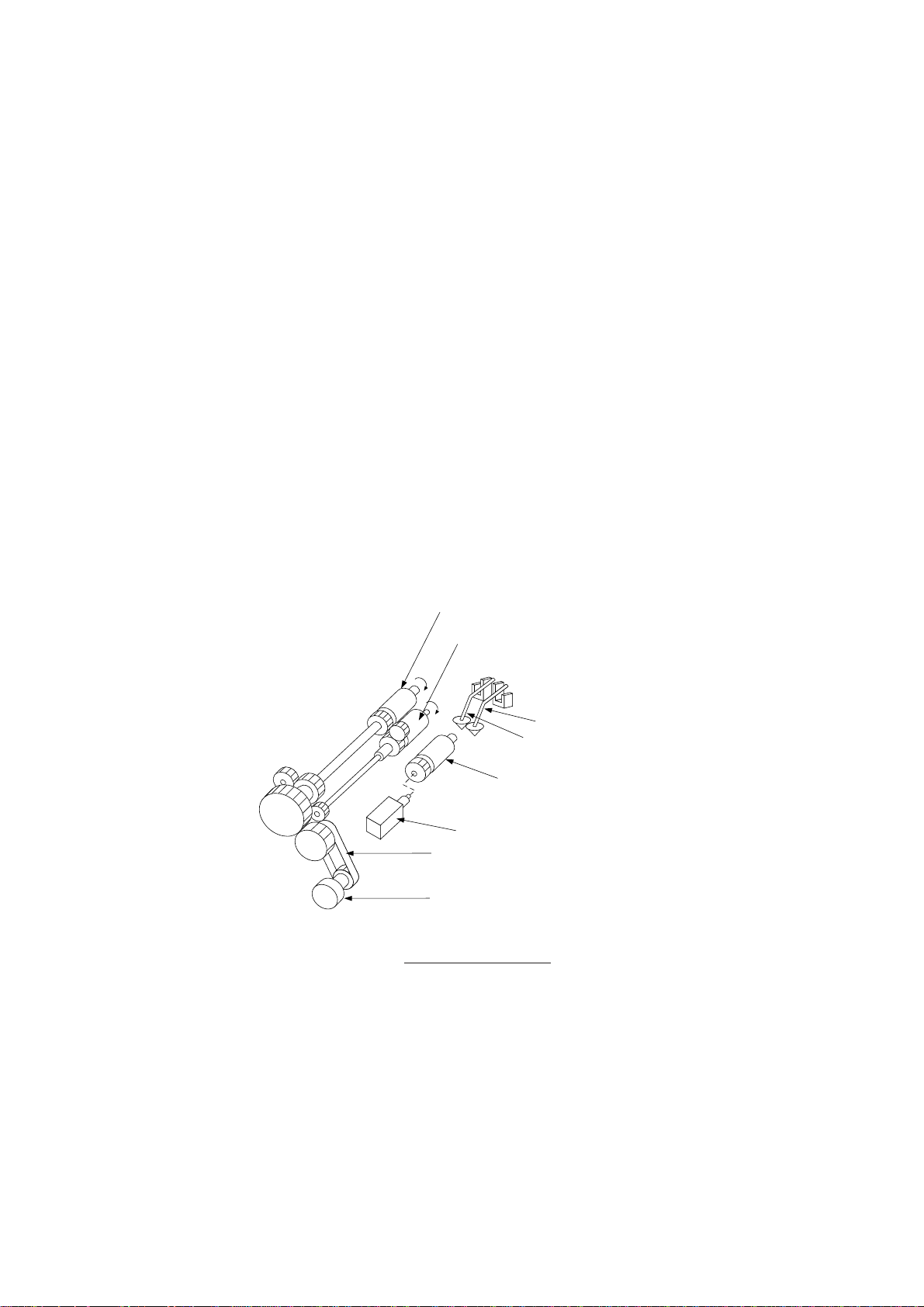

2.2 Operation of the LCC

As for the structure of LCC paper feed unit, please refer to the paper feed section in

the basic version of main body Service Manual of the copy machine.

• When the copy-start-key is pressed, and the paper feed motor rotates, the paper

feed roller and pick up roller are driven by the drive belt and gear.

• When the paper feed solenoid turns on, the pick up roller contacts the paper.

The paper on the paper feed table is fed to the main body of the copy machine

by the pick up roller and paper feed roller.

If paper is double fed, the lower sheet is returned by the DFP roller.

• When there is no paper on the paper feed table, the sensor lever enters a slot on

the table. In this way the paper detecting sensor detects a paper empty condition.

Paper feed roller

DFP roller

Paper detecting sensor

Upper limit sensor

2-2

Pick-up roller

Paper feed solenoid

Drive belt

Paper feed motor

Operation of LCC drive

SV009

Section III Maintenance

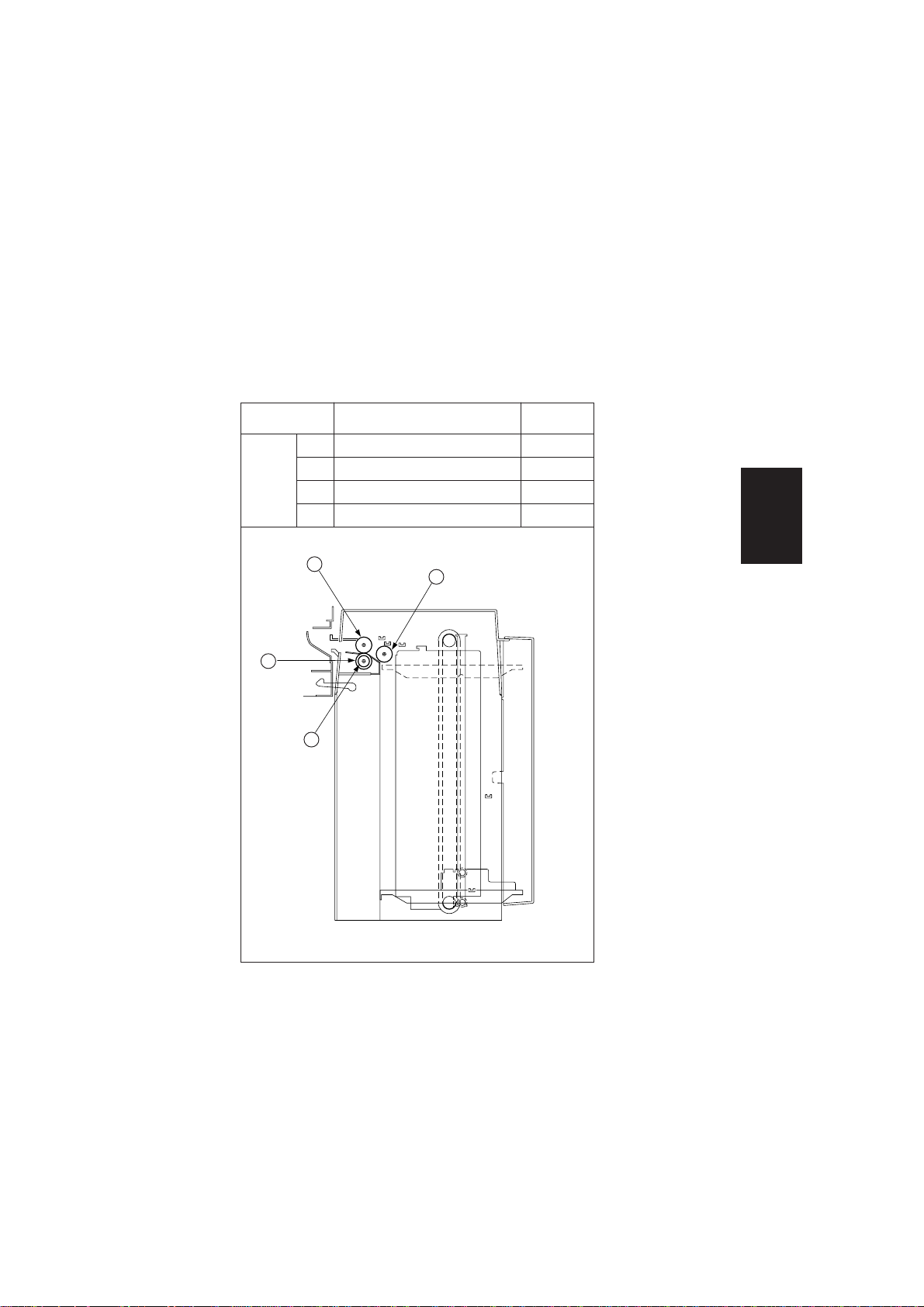

3.1 Maintenance components

The following is the replacement parts of LCC maintenance.

Block Section Part name

Pick-up roller

1

Paper feed roller

2

LCC

3

DFP roller

3

Torque limiter

4

2

4

1

Replacement

interval

120K

120K

120K

1200K

Maintenance

SV010

3-1

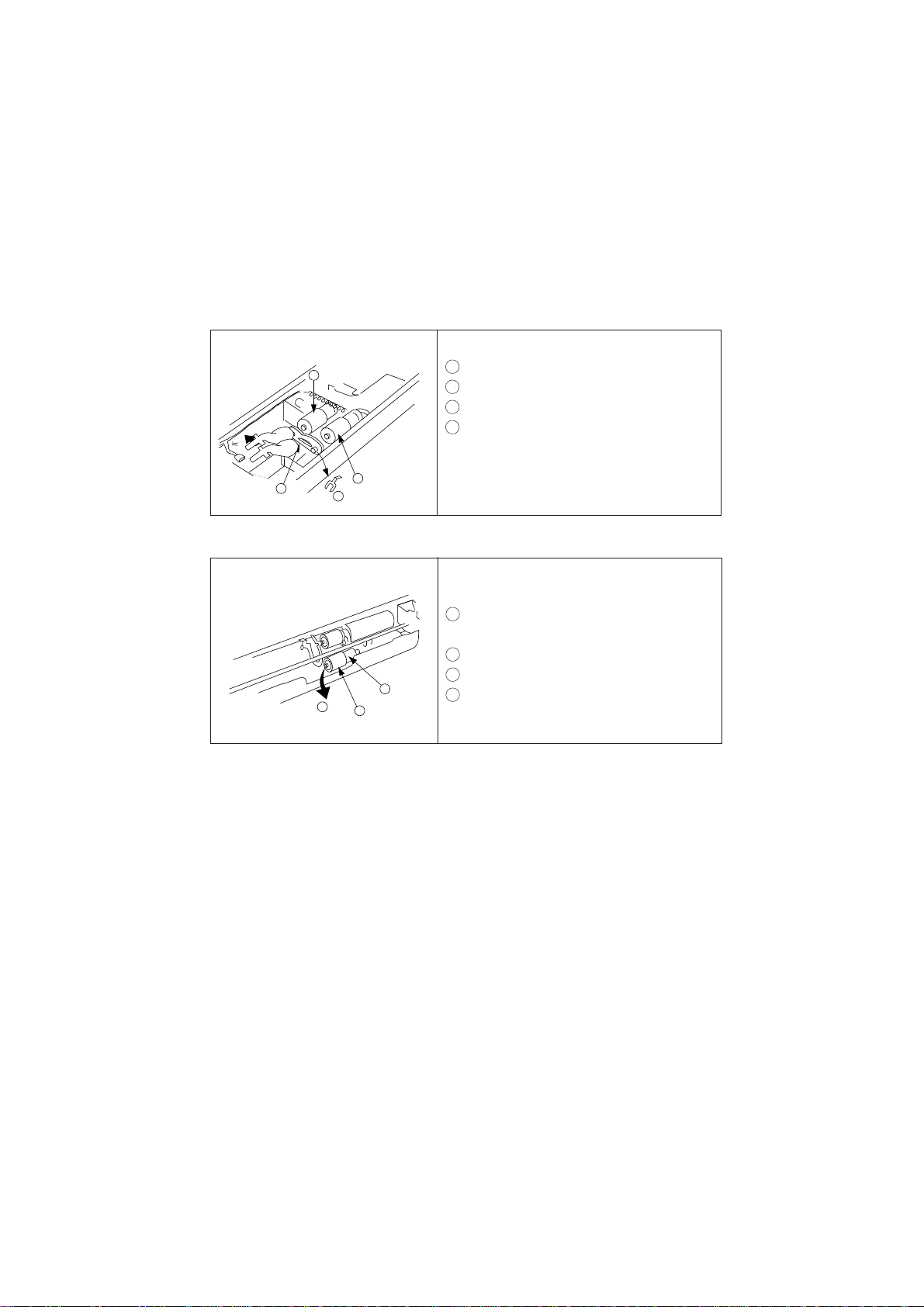

3.2 Disassembly / Assembly

1) Replacement of the pick-up roller / paper feed roller

1

Pick up roller

3

• Remove the upper cover.

1 Remove the touch ring.

2 Remove the bracket guide.

3 Remove and replace the pick-up roller.

4 Remove and replace the paper feed roller.

4

2

1

Paper feed roller

SV011

2) Replacement of the paper drawer double feed prevention roller/torque limiter

2

• Remove the front guide from the paper

feed side. ( 2 screws )

1 Remove the touch ring lowering the DFP

roller downward.

2 Remove the DFP roller.

3

1

2

SV012

3 Remove the torque limiter.

4 Check the direction of the torque limiter

3-2

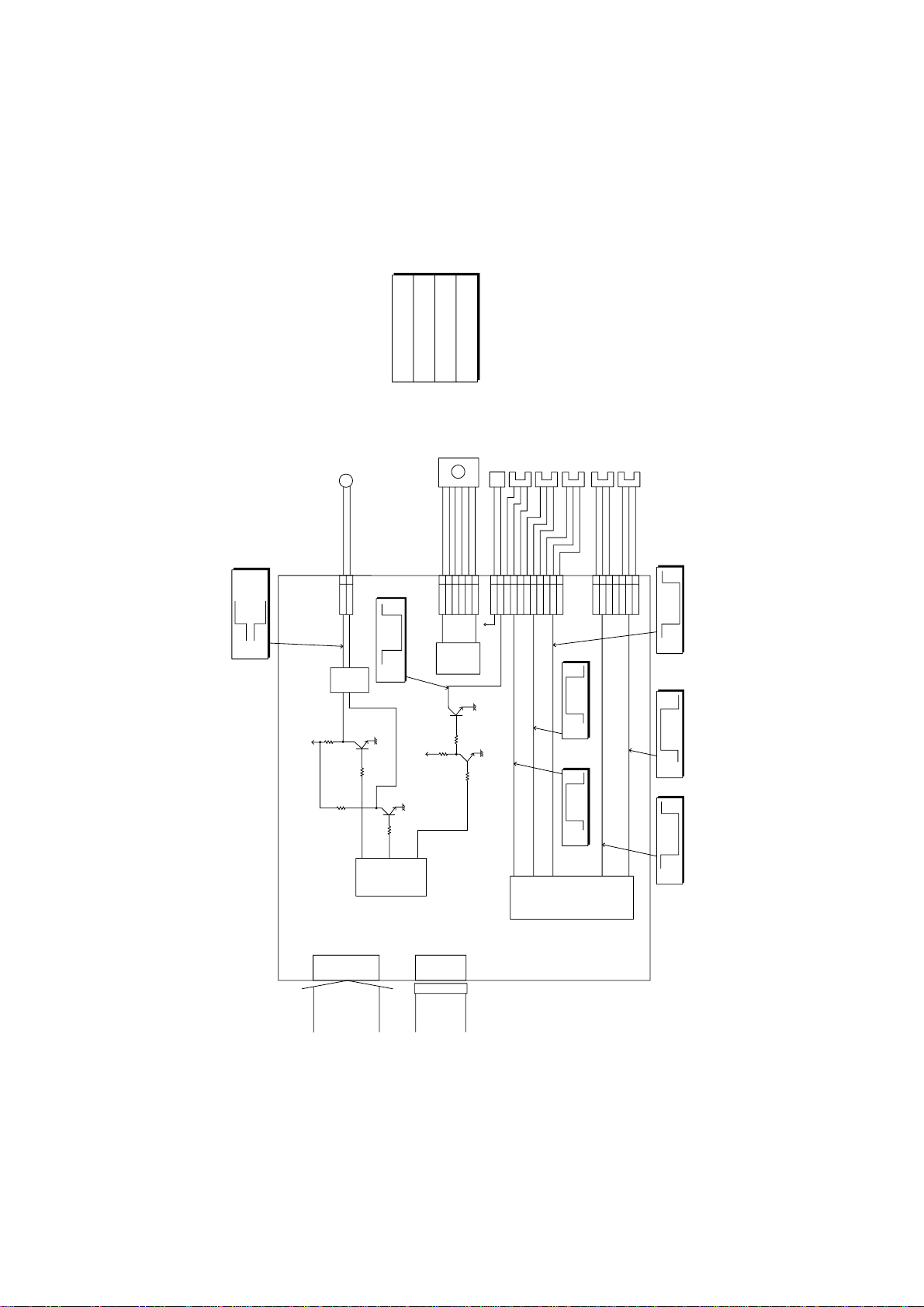

Section IV Electrical

4.1 Electrical Components Operation

The circuit construction of the electrical components in LCC three thousand sheet

cassette is shown in the figure below.

• When the LCC door is opened, the door open/close detecting sensor detects

open/close and the signal from it is inputted into IC563. Then, the up/down signal

of the paper feed tray is transmitted from IC562 to transistor DT563 and IC564,

which sends an electric current to the up/down motor and rotates it downward.

The combination of transistor DT563 and DT564 signals controls the up and

down motion of the tray. It is transmitted to IC565 and starts the up/down motor.

• When the paper tray reaches the lower limit sensor, the sensor is actuated, and

the signal from it (LCLDSN is high) is inputted into IC563 to stop the downward

movement of the tray.

• When the door is closed after paper is installed on the paper tray, the signal from

the door open/close detecting sensor is inputted into IC563 and the tray goes

up.

• When the upper surface of paper reaches the upper limit, the sensor lever

attached to the paper limit sensor is lifted up. At this time, the paper upper limit

sensor signal (LCLBSN) becomes high. This signal is inputted into IC563 to stop

the elevator motor.

• When copying starts, the paper feed motor starts rotation and the paper feed

solenoid is turned on. Then the paper transfer roller is pushed against paper on

the paper tray, and the paper is sent to copier by the paper transfer roller and the

paper feed roller.

• When the amount of paper on the tray decreases, the upper limit sensor is turned

off. (Intercepted: 5V) In this condition, the elevator motor goes up and the

upper limit sensor is turned on (Unintercepted: 0V), the motor stops and the

upper surface position of paper in the tray is maintained.

• When there is no paper in the tray, the sensor lever falls into the slit hole on the

bottom plate. Then paper detecting sensor is turned off (Intercepted: 5V) and

detects no paper.

• The photosensors such as paper detecting sensor show high (5V) when the

sensor levers intercept the sensors and low (0V) when they do not. The voltage

is read by IC563 as the input signals.

Electrical

4-1

CN564

123456789

10

11

V

P

LCSOL

V

L

LCLBSN

GND

V

L

LCPESN

CN566

1234567

GND

LCDOSN

V

L

–

GND

LCLDSN

CN565

12345

6

LCMBB

COMB

LCMB

LCMAB

COMA

LCMA

V

L

GND

VLLCDSN

GND

CN563

1

2

LCLUM1

LCLUM2

24V0V24V

0V

LCLUM1

LCLUM2

IN1

IN2

ST

+5V

R585

Q561

R586

DT565

IC564

+24V

IC565

1

2

R582

+5V

R583

DT563

DT564

1

2

24

IC562

11

12

14

3

13

IC563

4

8

24V

0V

5V

0V

5V

0V

5V

0V

5V

0V

5V

0V

UP

DOWN

UP

DOWN

F4 MODE OUTPUT CHECK

ELEVATOR MOTOR

PAPER FEED

SOLENOID ON

PAPER FEED SOLENOID ON

F4-65:

F4-66: TRAY GOING UP

F4-67: TRAY GOING DOWN

PAPER FEED

MOTOR

PAPER FEED SOLONOID

UPPER LIMIT SENSOR

PAPER DETECTING SENSOR

LCC INSTALLATION SENSOR

NO PAPER

(INTERCEPTED)

DOOR OPEN/CLOSE DETECTING SENSOR

LOWER LIMIT SENSOR

LCC INSTALLED

(INTERCEPTED)

TRAY LOWER

LIMIT

(INTERCEPTED)

PAPER UPPER

LIMIT

(INTERCEPTED)

DOOR

CLOSED

(INTERCEPTED)

LCC DRIVER CIRCUIT

CONNECTING

CABLE

(TO COPIER)

CONNECTOR

(TO SYSTEM

CONSOLE

PAPER FEED)

4-2

Loading...

Loading...