Page 1

FA-A888 Back to Model List

Contents

WARNING

I. Introduction

1.1 Specifications.......................................................................................... 1-1

1.2 Features.................................................................................................. 1-2

1.3 Exterior ................................................................................................... 1-3

1.4 Interior..................................................................................................... 1-3

II. Sequence

2.1 Original paper feed system..................................................................... 2-1

2.2 Original paper exit system ...................................................................... 2-5

2.3 Original count system ............................................................................. 2-8

III. Maintenance

3.1 Maintenance chart .................................................................................. 3-1

3.2 Disassembly and Assembly.................................................................... 3-2

3.3 Adjustment.............................................................................................. 3-9

IV. Electrical

4.1 Function of electrical parts...................................................................... 4-1

4.2 Signal information by connectors............................................................ 4-9

4.3 Explanation of circuit............................................................................... 4-13

IntroductionStructureMaintenanceElectrical

Troubleshooting

V. Troubleshooting

5.1 Error detection by self-diagnosis ............................................................ 5-1

(1) User Error ........................................................................................ 5-1

(2) Paper jam......................................................................................... 5-2

(3) ADF function error............................................................................ 5-3

VI. Installation

6.1 Unpacking............................................................................................... 6-1

6.2 Installation procedure ............................................................................. 6-2

Installation

Page 2

WARNING

This service information is designed for experienced repair technicians only and

is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of

potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced

professional technicians. Any attempt to service or repair the product or products

dealt with in this service information by anyone else could result serious injury or

death.

(For USA)

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Communications & Systems Co. for the sole purpose of providing

information necessary for the equipment's proper support. It is intended that this

information be confidential and may not be reproduced without prior written consent

from Panasonic Communications & Systems Co. Panasonic Communications &

Systems Co. reserves the right to change any information enclosed herein without

prior notification.

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Co. for the sole purpose of providing information necessary for the

equipment's proper support. It is intended that this information be confidential

and may not be reproduced without prior written consent from Panasonic Co.

Panasonic Co. reserves the right to change any information enclosed herein without

prior notification.

© February, 1999

Page 3

Section I Introduction

1.1 Specification

1. For use with: FP-7718/7722/7728/7735/7742/7750

FP-D250/D350/D450/D600 Series

2. Original paper capacity: 50 sheets (20 lb/80 g/m

30 sheets (20 lb/80 g/m2) Ledger, Legal/A3, B4

3. Original size: Ledger to Invoice/A3 to A5

4. Original paper weight: 14 to 28 lb/50 to 110 g/m

5. Original feed speed: 55 sheets/min.

6. Power source: DC +24V (Supplied from copier)

7. Dimensions (W x H x D): 23.6" x 20.2" x 4.7"/600 x 518.5 x 120mm

(without tray)

8. Weight: 26.4 lb/12kg

9. Ambient conditions: Temperature 50°F to 86°F/10°C to 35°C

Relative humidity 20 to 85%

2

)

2

Introduction

1-1

Page 4

1.2 Features

• Auto two-sided original feeding system

• When two-sided originals are loaded, the originals are automatically turned over

to copy both sides according to the copy mode selected at the copier.

• Function to count originals

• In auto two-sided copy mode, if the counted number of originals is an odd number,

the first copy will be a one-sided copy then the subsequent copies will be twosided.

• Original size feeding system

• Originals of different size but with the same width (Ledger/Letter, A3/A4) can

be combined for feeding.

• Realization of space saving

• Power unit is installed in the copier, so the former bump is removed.

• Capable of feeding originals up to Ledger/A3 size.

1-2

Page 5

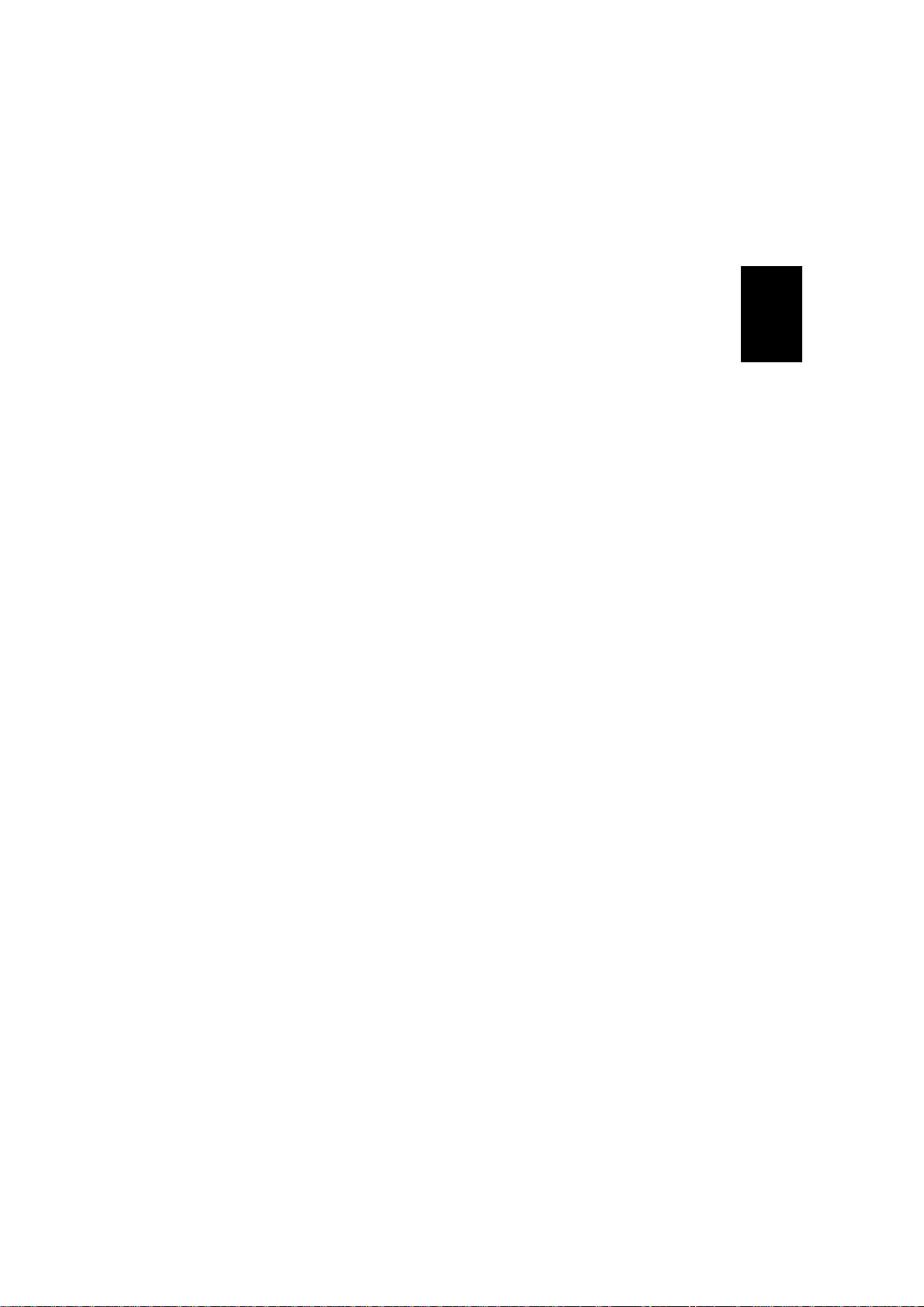

1.3 Exterior

Original feed

cover

1.4 Interior

Original guide

Original feed tray

Introduction

Original size

indicator

Original exit cover

SV027

Reverse motor

CPU

Transfer belt

motor

Clock sensor

Original feed

motor

Registration

sensor

Timing sensor

Original

detecting sensor

Exit/Reverse

sensor

Original exit cover

open/close sensor

Reverse solenoid

Original size

sensor

Original size

switch

Original feed cover

open/close switch

SV012

1-3

Page 6

Section II Sequence

2.1 Original paper feed system

(1) The original is transported from the original feed tray to the original

registration roller.

Originals

SV028

1) When the wait/stopper solenoid is ON and the stopper and weight have

lowered, movement of the originals from the original feed tray becomes

possible.

2) After the original feed motor stops for 50msec (300msec to 1st paper) it starts

to rotate normally and transfers the original in the direction of the registration

roller.

3) The original arrives at the registration sensor within 2200msec for the JAM

timer (1) , when the pulse count reaches 100, the original feed motor stops.

(If the original is not detected by the registration sensor within 2200msec, a

paper jam will be indicated.)

4) After the original feed motor stops for 50msec, it starts to rotate in reverse

moving the original in the direction of the platen glass.

5) When the original feed motor reaches a predetermined count, it stops and

lead edge of the original is stopped approximately 42mm into the registration

roller.

Structure

2-1

Page 7

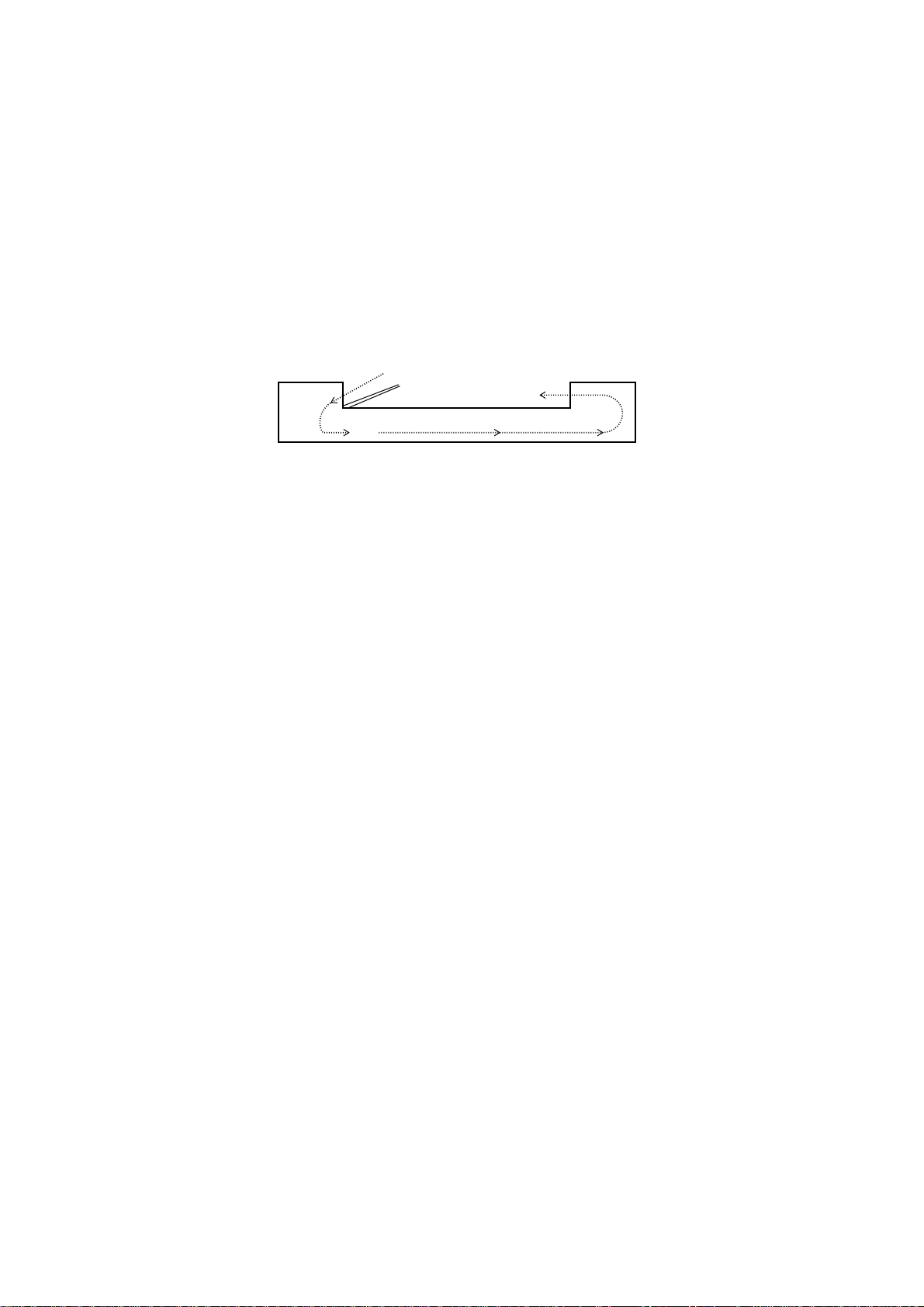

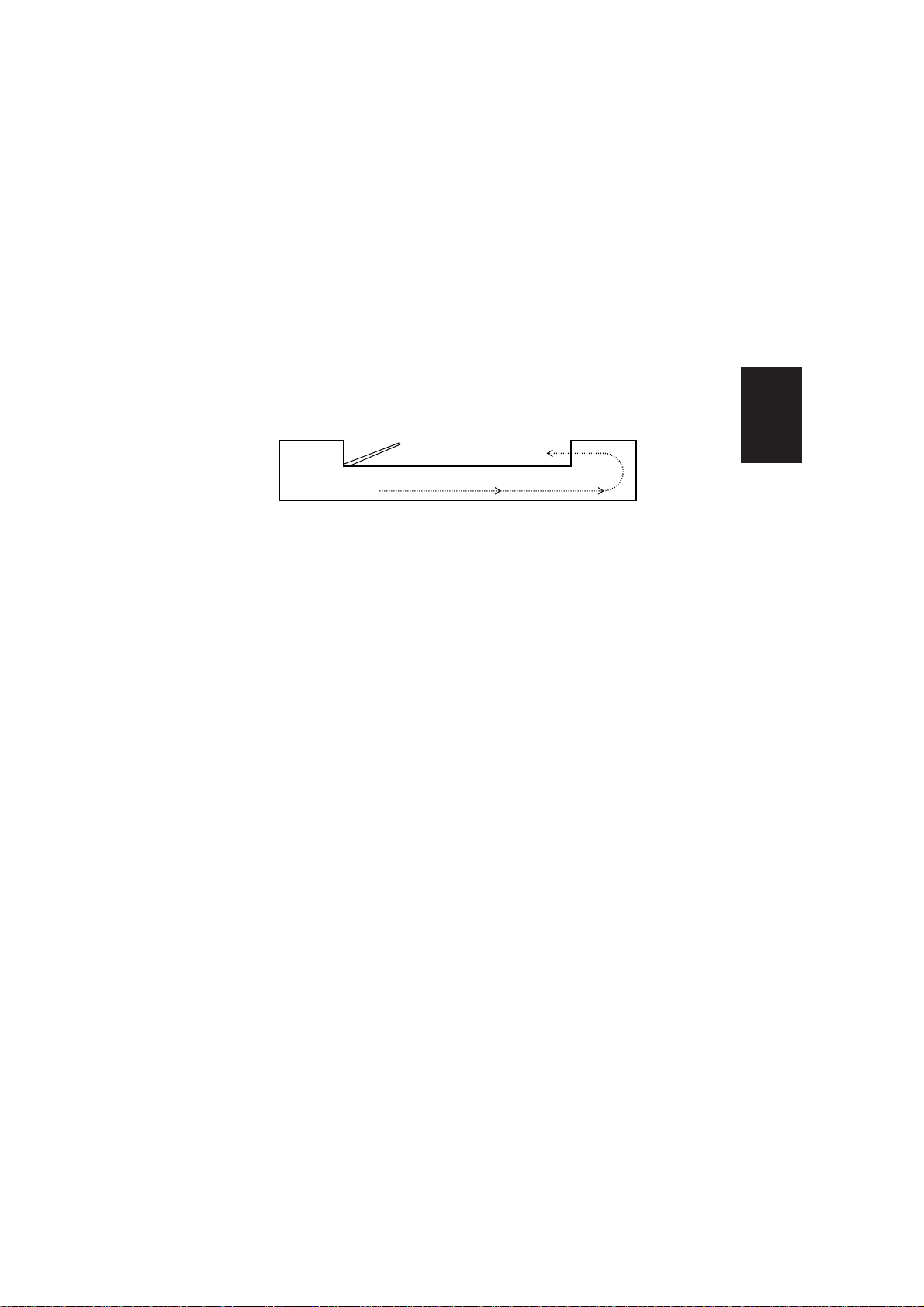

(2) One-sided original feed

• This operation feeds the original from the original feed tray onto the platen glass.

(During this operation, if an original is already on the platen glass, that original

will exit.)

SV029

1) When an original is not on the original timing feed position, original timing

feed operation begins.

2) After 50msec, the transport belt motor begins to rotate normally. (At this time,

JAM timer (3) starts its count to 1225msec.)

3) After 105msec, the original feed motor reverse rotation commences. (At this

time, JAM timer (2) starts its count to 840msec.)

4) When the original arrives at the original exit/reverse sensor within 1225msec

for JAM timer(3), the count is started for JAM timer (5) to 1080msec and the

original reverse motor deceleration pulse.

5) When the count of the original reverse motor deceleration pulse is increased,

the original reverse motor switches from high gear to low gear.

6) When the original passes the original exit/reverse sensor within 1080msec for

JAM timer(5), the original exit motor stop pulse starts its count to 30.

7) When the original reverse motor stop pulse count increases, the original reverse

motor stops.

8) When the original passes the registration sensor within 840msec for JAM

timer(2), the original feed stop pulse of the transport belt motor starts the

count to 187.

9) At the same time, the original feed motor stops.

10) When the rotational pulse of the transport belt motor increases to a

predetermined pulse count, the transport belt motor stops.

11) After 50msec, the transport belt motor reverse rotation begins at a low speed.

12) When the rotational pulse of the transport belt motor increases to 63 pulse

count, the transport belt motor stops. (Only in switch back)

2-2

Page 8

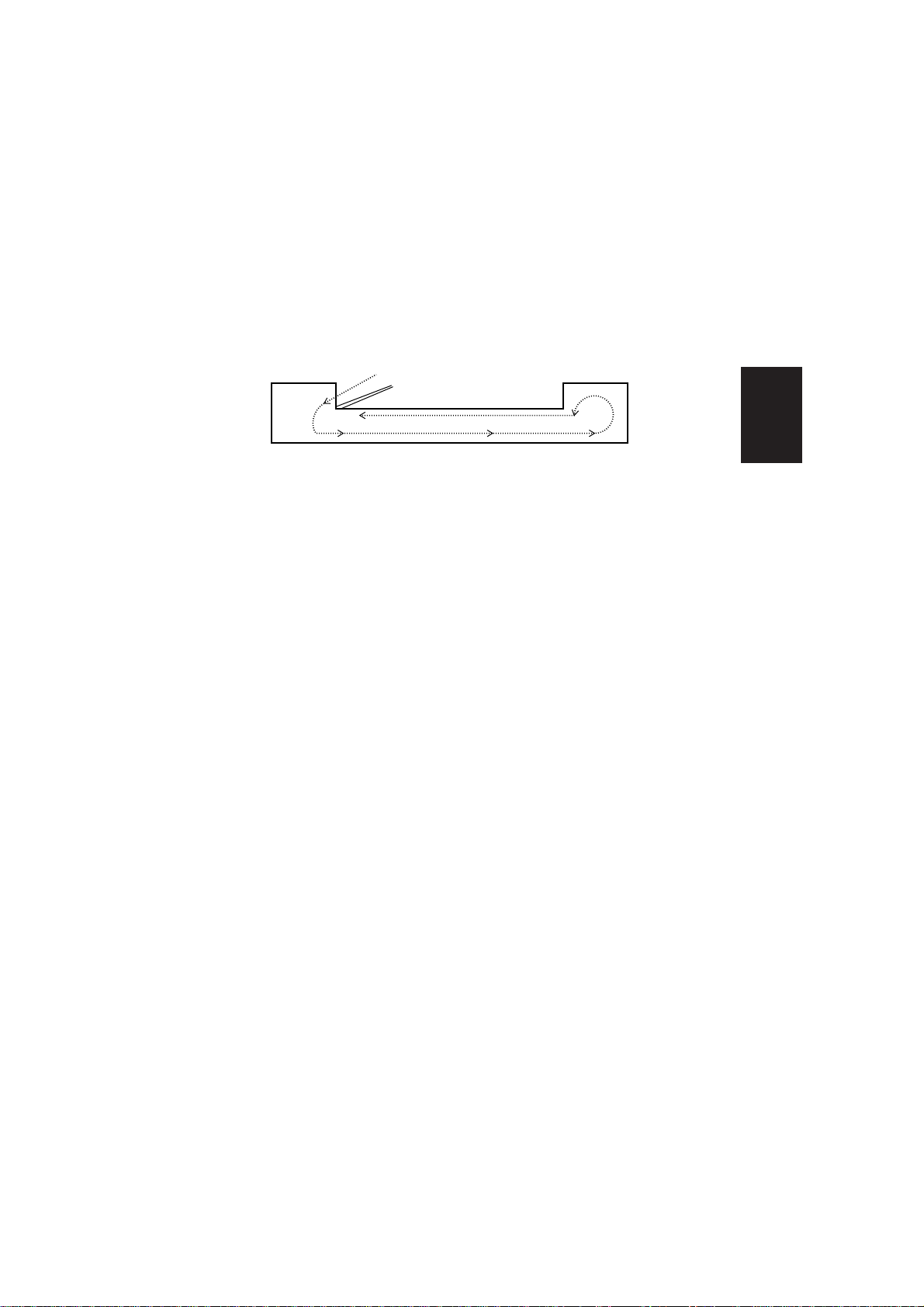

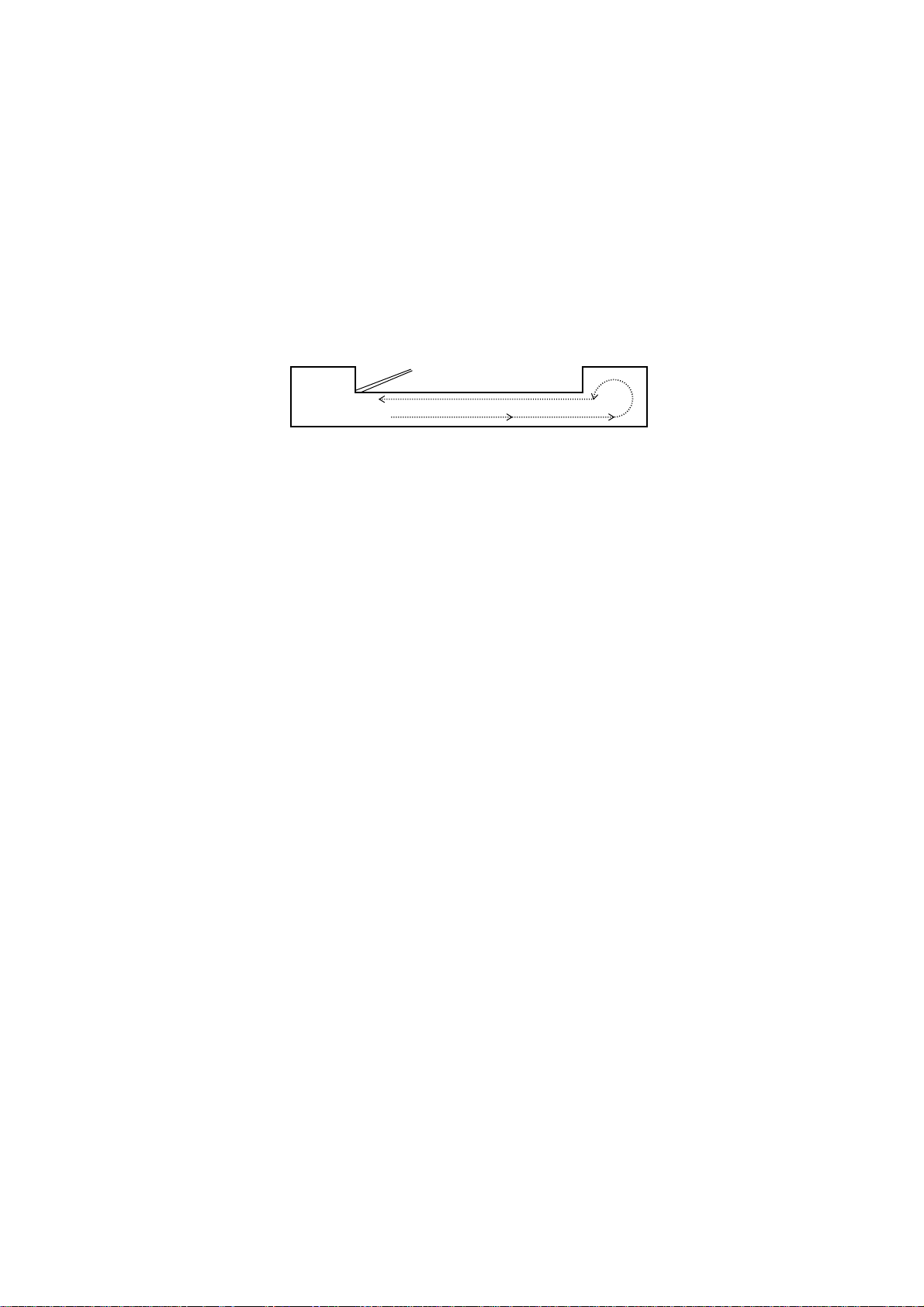

(3) Two-sided original feed

• This operation turns over the original at the reverse section then feeds it to the

platen glass. (During this operation, if an original is already on the platen glass,

that original will exit.)

SV030

1) When the original is not in the original timing feed position, the original timing

feed operation begins.

2) After 50msec, the original reverse and exit motor begins to rotate

simultaneously. (At this time, JAM timer (3) starts it count to 1225msec.)

3) After 100msec of the original feed motor reverse start timer, the original feed

motor reverse rotation begins. (At this time, JAM timer starts its count to

840msec, and JAM timer starts it count to 1585msec.)

4) When an original is on the platen glass, JAM timer(6) within 1585msec, and

the original timing feed position original JAM timer(3) within 1225msec have

arrived at the original exit/reverse sensor, and have passed the registration

sensor within 840msec of JAM timer(2), the original on the platen glass is

exited, and the original timing feed position original is reversed.

Structure

2-3

Page 9

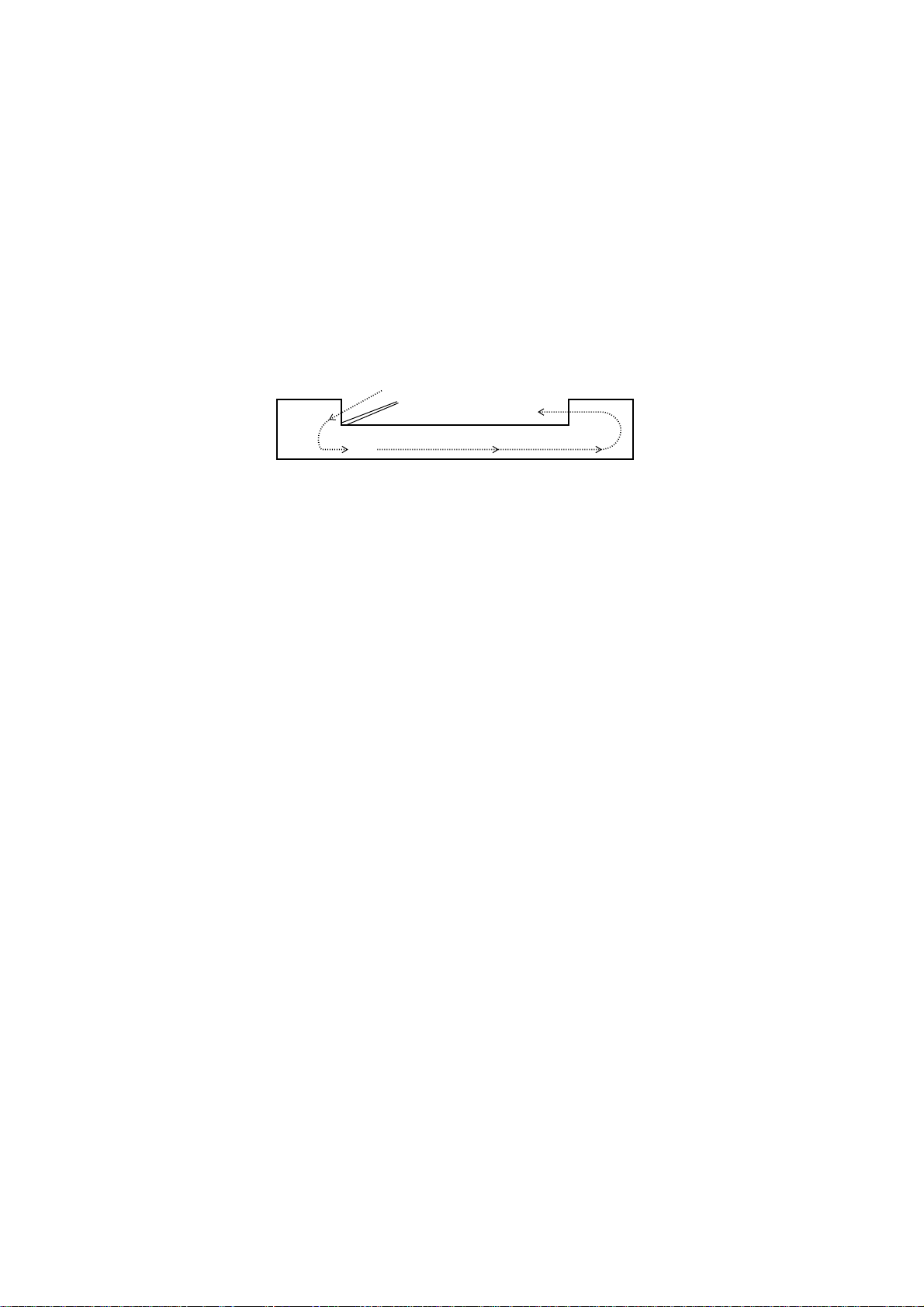

(4) 2 in 1 feed

• This operation feeds two originals in one pair from the original feed tray onto the

platen glass.

(During this operation, if an original is already on the platen glass, that original

will exit.)

7) ~ 12)

1) ~ 6)

SV033

1) When the original is not on the original timing feed position, the original timing

feed operation begins.

2) After the original timing feed operation, the transport motor begins to rotate

normally.

3) After 105msec, the original feed motor reverse rotation commences.

(At this time, JAM timer stopped by the timing sensor starts its count to

955msec.)

4) When the original passes the timing sensor within 955msec, the original feed

stop pulse of the transport belt motor starts its count to 103. And at the same

time the original feed motor stops.

5) When the rotational pulse of the transport motor increases to a predetermined

pulse count, the transport motor stops. (If an odd number, the original is not

flipped over.)

6) The original timing feed operation begins. (In an even number, the original is

fed.)

7) When the original of an even number arrives at the registration sensor, and

the count increases to 100, the original feed motor stops.

8) The original feed motor reverse rotation begins. <Start of 2 in 1 original feed >

9) After timing sensor is turned ON, the transport motor begins to rotate normally

by 7 pulses.

10) When the transport motor begins to rotate normally by, two originals in one

pair are transported to the platen glass.

When the original passes the timing sensor, pulse count to stop original feed by the

11)

transport belt motor starts to 135. At the same time the original feed motor stops.

12)

The rotational pulse of the transport motor reaches pre-fixed number, the

transport motor stops. (Completion of original set on the glass surface)

2-4

Page 10

2.2 Original paper exit system

(1) Original Exiting

• This operation exits the originals. When a page with the lower page number of

original is not facing downward, the original will be turned over before being

exited. (The originals are always exited so that the page with lower page number

is on top.)

SV031

1) Only when the original is in the original timing feed position, one-sided original

feeding is done. The original on the platen glass is exited, and the original on

the timing feed position is moved to the platen glass. (When exiting both, the

original on the platen glass and the original on the timing feed position is

done, only when it is necessary is a reversal done.)

2) After completion of the transfer in 1) above, the reverse transport belt motor

begins to rotate normally. (At this time, JAM timer (3) starts its count to

1225msec.)

3) When the original arrives at the original exit/reverse sensor within 1225msec

of JAM timer (3), the original reverse motor begins the deceleration pulse

count. (At this time, JAM timer (5) starts its count to 1080msec.)

4) When the count of the original reverse motor deceleration pulse increases,

the original reverse motor switches from high gear to low gear.

5) When the original passes the original exit/reverse sensor within 1080msec of

JAM timer (5), the transport motor stops. Simultaneously, the original reverse

motor stop pulse begins its count to 307.

6) When the original reverse motor stop pulse increases to 307, the original

reverse motor stops.

Structure

2-5

Page 11

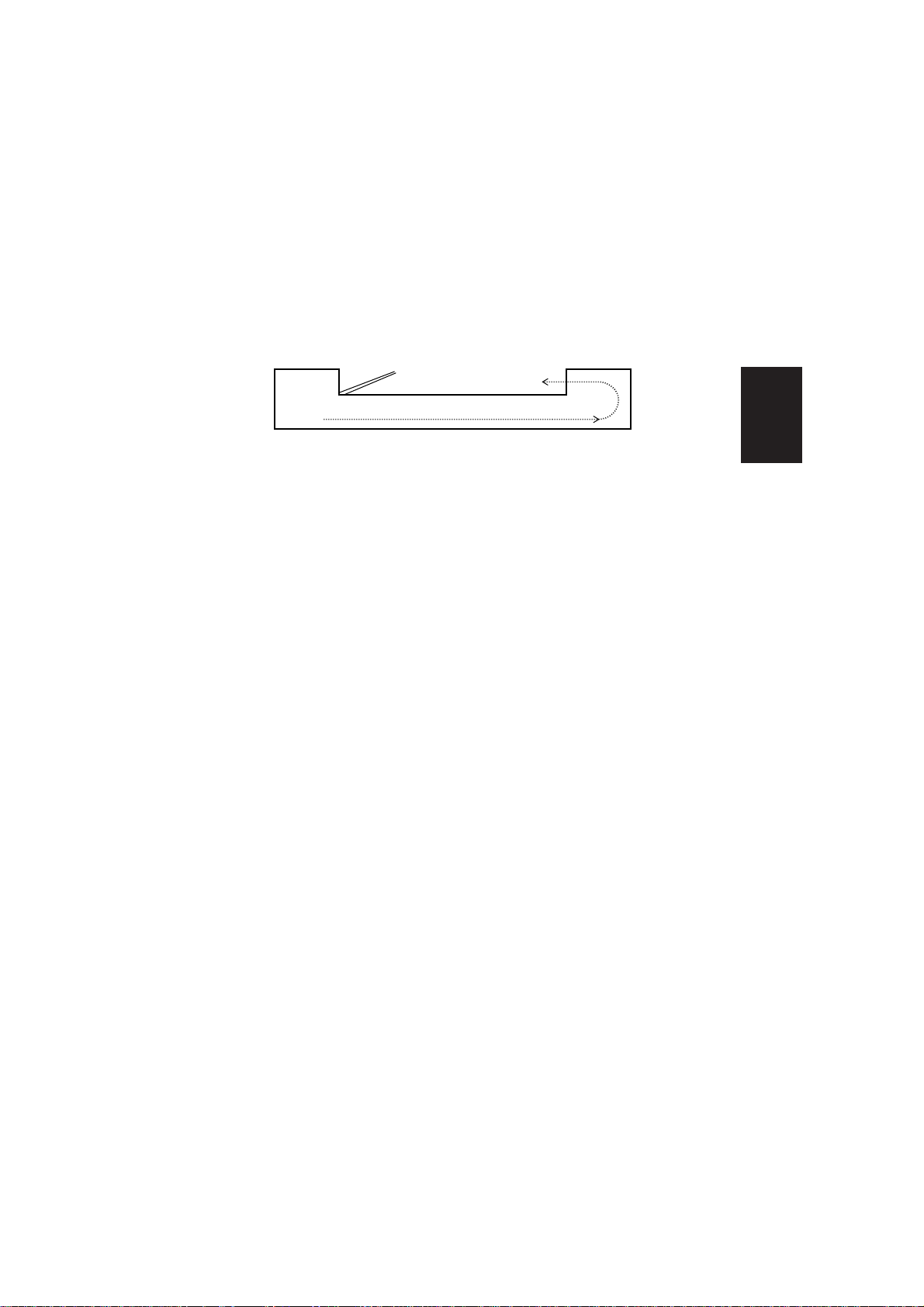

(2) Original reverse feeding

• This operation takes the original on the platen glass turns it over then places it

on the platen glass.

SV032

1) After 50msec, the transport belt motor begins to rotate normally. At this time,

the original reverse solenoid is turned ON, and the original is now in a position

where it can be reversed.

2) Simultaneously, JAM timer (3) starts its count to 1225msec.

3) The original reverse motor starts.

4) When the original arrives at the original exit/reverse sensor within 1225msec

of JAM timer (3), both the transport belt motor and the reverse motor stop and

the rotational pulse of the original reverse motor is started to count.

5) After 50msec, the transport belt motor begins to rotate in reverse. And after

40msec, the original reverse motor starts. At this time JAM timer (4) begins

its count to 1000 msec.

6) When the original has passed the original exit/reverse sensor within 1000msec

of JAM timer (4), the rotational pulse that is counted is switched from the

original reverse motor to the transport belt motor.

7) When the rotational pulse of the transport belt motor is increased to 2476,

both the transport belt motor and the original reverse motor stop.

2-6

Page 12

(3) 2 in 1 Original exit operation

1) ~ 6)

7) ~ 8)

SV034

1) The original reverse motor and the transport motor begin to rotate normally.

At this time, when the original does not arrive at the original reverse/exit sensor

within 1395msec of JAM timer, the original stop pulse of the transport motor

begins its count to 732.

2) When the original arrives at the reverse/exit sensor within 1395msec, the the

deceleration pulse of the original reverse motor begins to count.

At this time JAM timer stopped at the reverse/exit sensor begins its count to

2600msec.

3) When the original stop pulse of the transport motor increases its count, the

transport motor stops.

4) When the deceleration pulse of the original reverse motor increases, the

reverse motor is switched from high gear to low gear.

5) When the reverse/exit sensor is turned OFF, the timer delayed the second

original exit starts its count to 60msec.

6) When the delayed timer increases, the transport motor begins to rotate

normally.

7) When the original has passed the original reverse/exit sensor, the transport

motor stops. Simultaneously the original reverse motor stop pulse starts its

count to 424.

8) When the original reverse motor stop pulse is increased to 424, the reverse

motor stops.

Structure

2-7

Page 13

2.3 Original count system

(1) Original count

• This operation counts the originals. It consists of 2 operations, one is the original

feed count, and the other is the original exit count, and each operates

simultaneously.

SV029

1) When the wait solenoid is turned ON, the stopper and the weight are moved

downward and the originals on the original feed tray can move.

2) After 100msec, the reverse motor stops.

3) After 30msec, the transport belt motor begins to rotate normally.

4) After 170msec, the original feed motor begins to rotate normally and the original

is moved in the direction of the registration roller. (At this time JAM timer (1)

starts to count to 220msec.)

5) When the original arrives at the registration sensor within 2200msec of JAM

timer (1) and 100 pulse count is started, the original feed motor stops. The

original waits until it is pressed against the registration roller.

6) After the original feed motor stops and 50msec has elapsed, the original feed

motor begins to rotate in reverse, and the original is moved in the direction of

the platen glass. (At this time, the counts of JAM timer (2) to 840msec and

JAM timer (7) to 1595msec are started.)

7)

When the original has passed the timing sensor within 840msec of JAM timer

(2), the original feed motor stops. (At this time, when an original is in the original

feed tray, and 50msec has elapsed, the original feed operation is repeated.)

8) When the original has passed the original exit/reverse sensor within 1080msec

of JAM timer (7), the count of the original reverse motor deceleration pulse is

started. (At this time, the count of JAM timer (5) starts to 1080msec.)

9) When the count of the original reverse motor deceleration pulse is increased,

the original reverse motor is switched from high to low speed.

10) When the original passes the original exit/reverse sensor within a

predetermined time of JAM timer (5), the transport belt motor stops and the

original reverse motor stop pulse starts to count to 307.

11) When the count of the original reverse motor stop pulse is increased to307,

the original reverse motor stops. (At this time, when all of the originals have

2-8

not yet exited, it will switch from low gear to high speed without stopping.)

Page 14

Section III Maintenance

3.1 Maintenance chart

• In addition to the following maintenance table, the transport belt must be cleaned

as part of regular service calls.

• The timing of regular maintenance is determined on the basis of the number of

ADF original feed count.

Part name

Original feed roller

PF2217P316A

Original pick-up roller

PF2214P471A

DFP roller

PF2217K050A

Registration roller

PF2214P301A

Registration sensor

PF2214K224A

Timing sensor

PF2214K224A

Original reverse roller

PF2217P317A

Original exit roller

PF2214P323B

Original exit/

reverse sensor

PF2214K222A

Maintenance interval

Cleaning Replacement

Every

120,000

copies

Every

40,000

copies

—

Remarks

Brush, waste, air

blower, isopropyl

alcohol

NOTE: Minimum

quantity of

isopropyl

alcohol should

be used and be

wiped

immediately

after its use.

Maintenance

Transport belt

PF2214P353A

Every

120,000

copies

3-1

Page 15

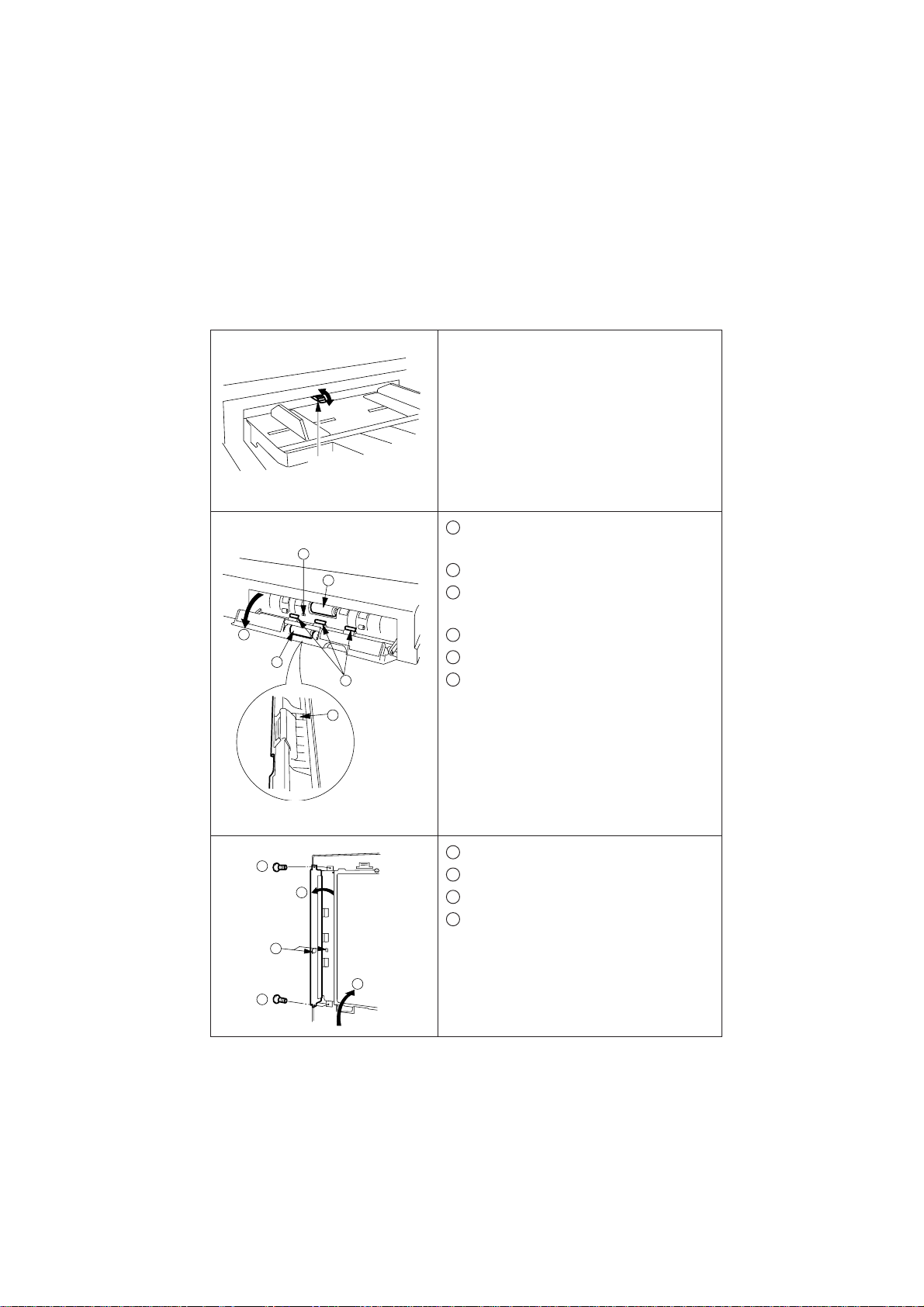

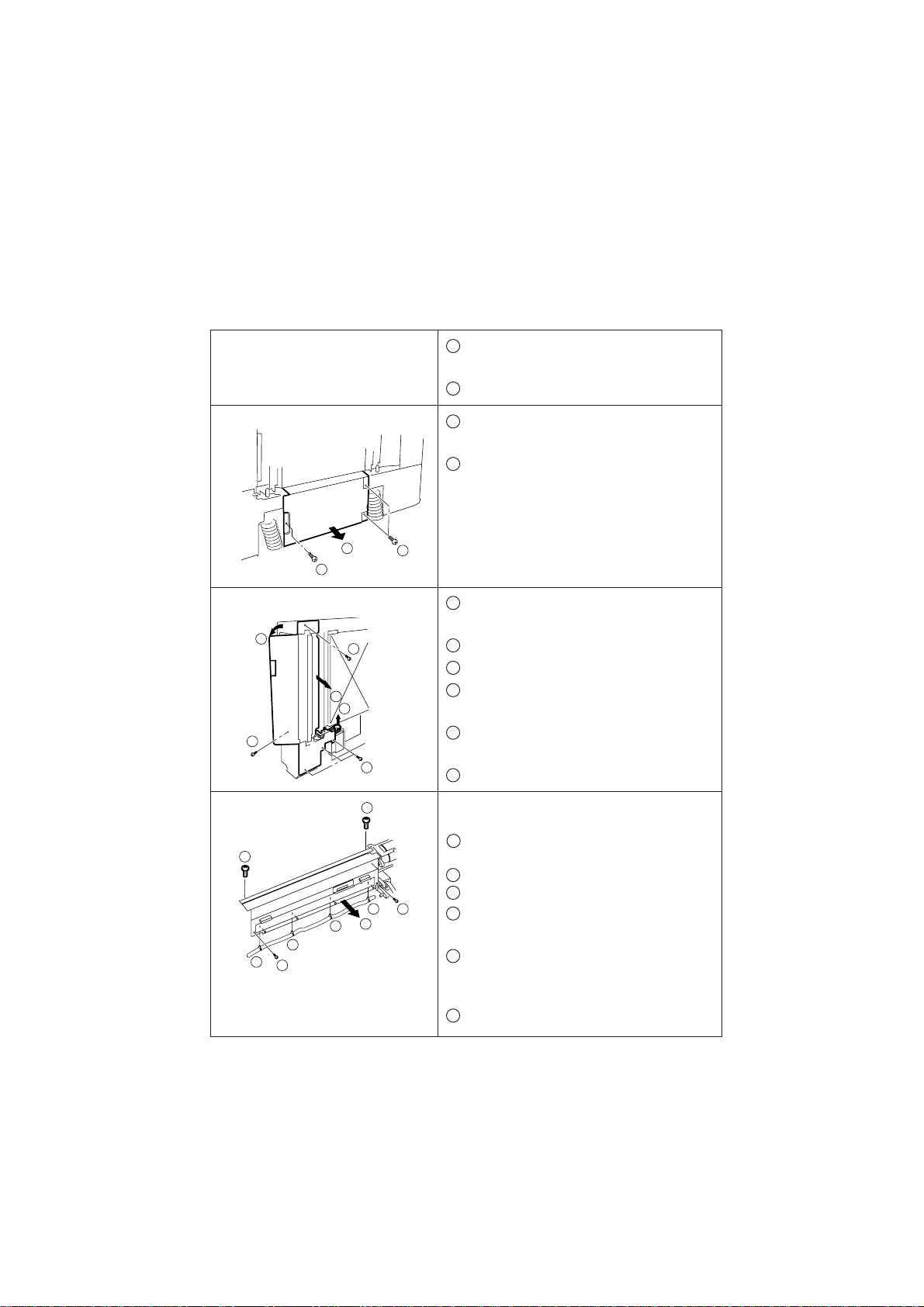

3.2 Disassembly and Assembly

(1) Cleaning

1

Pick-up roller

SV001

2

5

2

Clean the pick-up roller by rotating it.

SV001

1 Open the original feed cover and clean

the parts below.

2 Original feed roller.

3 Original double feed prevention roller

(mounted on the feed cover).

1

3

4

4 Registration rollers.

5 Registration sensor.

6 Reflection seal for the sensor (mounted

on the feed cover).

6

SV002

3-2

SV002

3

2

3

4

2

1

SV003

SV003

1 Open the ADF.

2 Remove the screws (x 2).

3 Open the registration roller guide.

4 Clean the timing sensor and the reflection

seal.

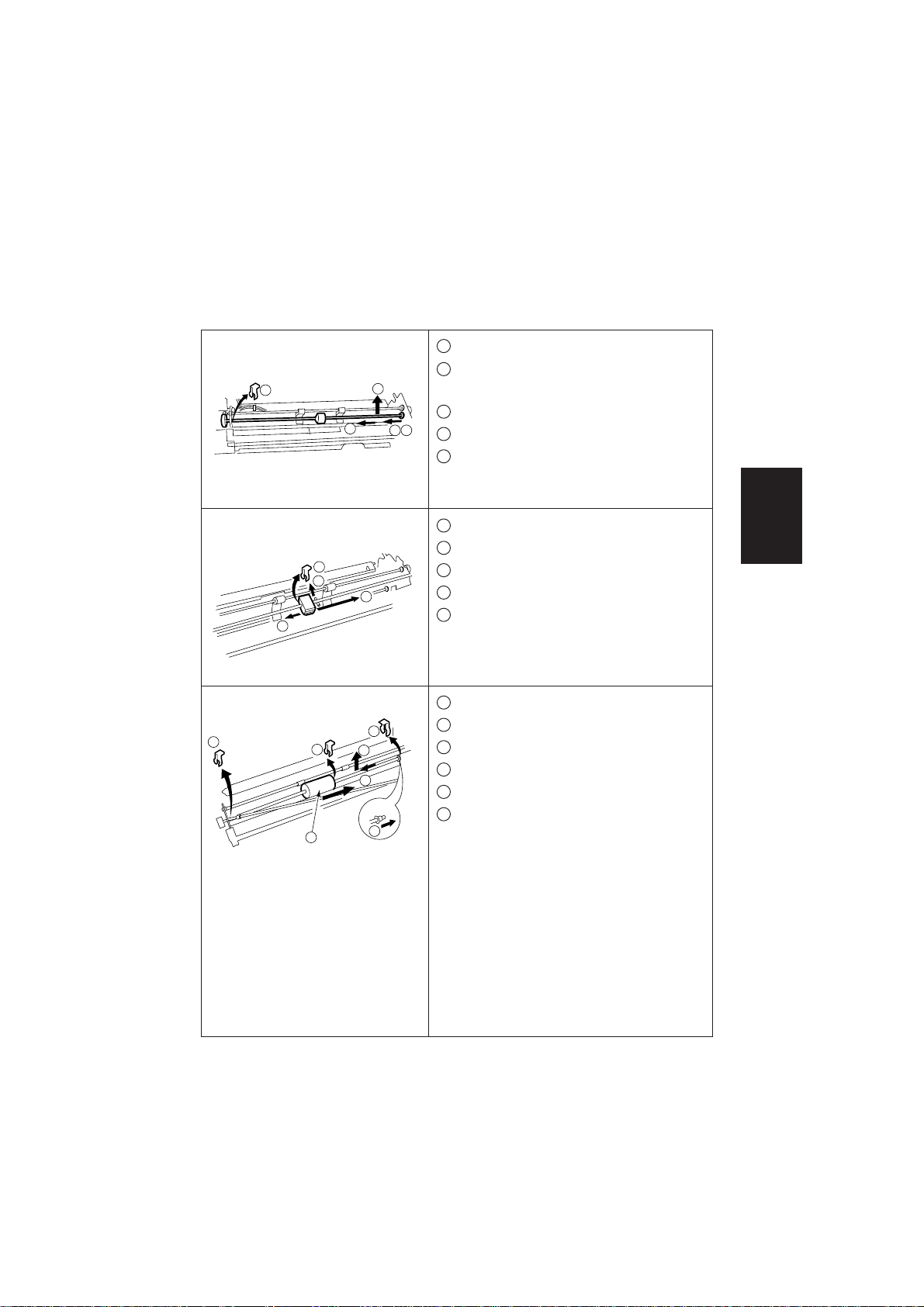

Page 16

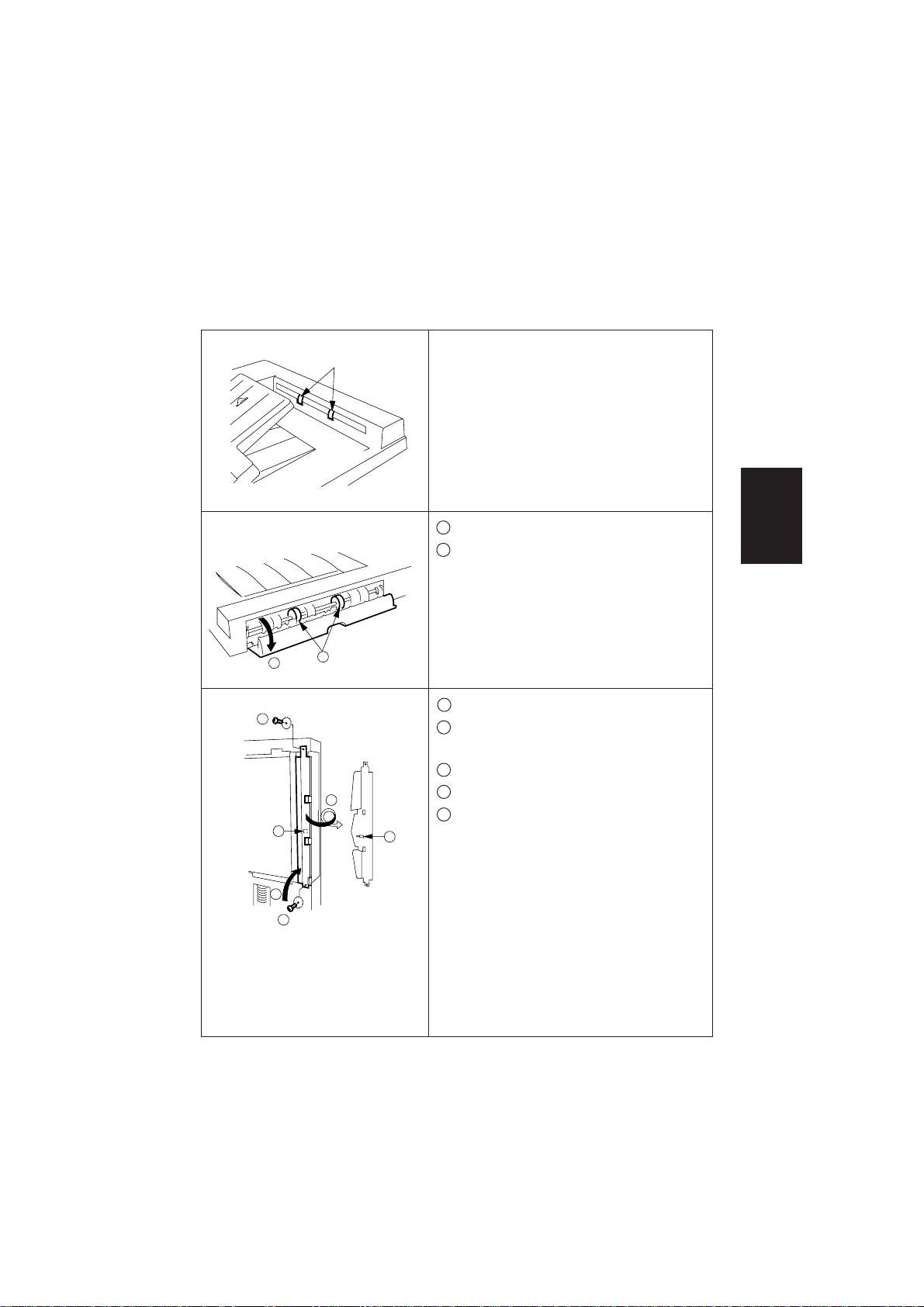

(1) Cleaning (continued)

4

Original exit roller

SV004

5

1

6

2

2

SV005

Clean the original exit rollers.

SV004

1 Open the original exit cover.

2 Clean the reverse rollers.

SV005

1 Open the ADF.

2 Remove the screws and star-washers

Maintenance

(x 2).

3 Remove the exit guide.

3

5

4

4 Clean the reflection seal for the sensor.

5 Clean the original exit sensor.

Note: Check the condition of the guide mylar

and replace as required.

1

2

SV006

SV006

3-3

Page 17

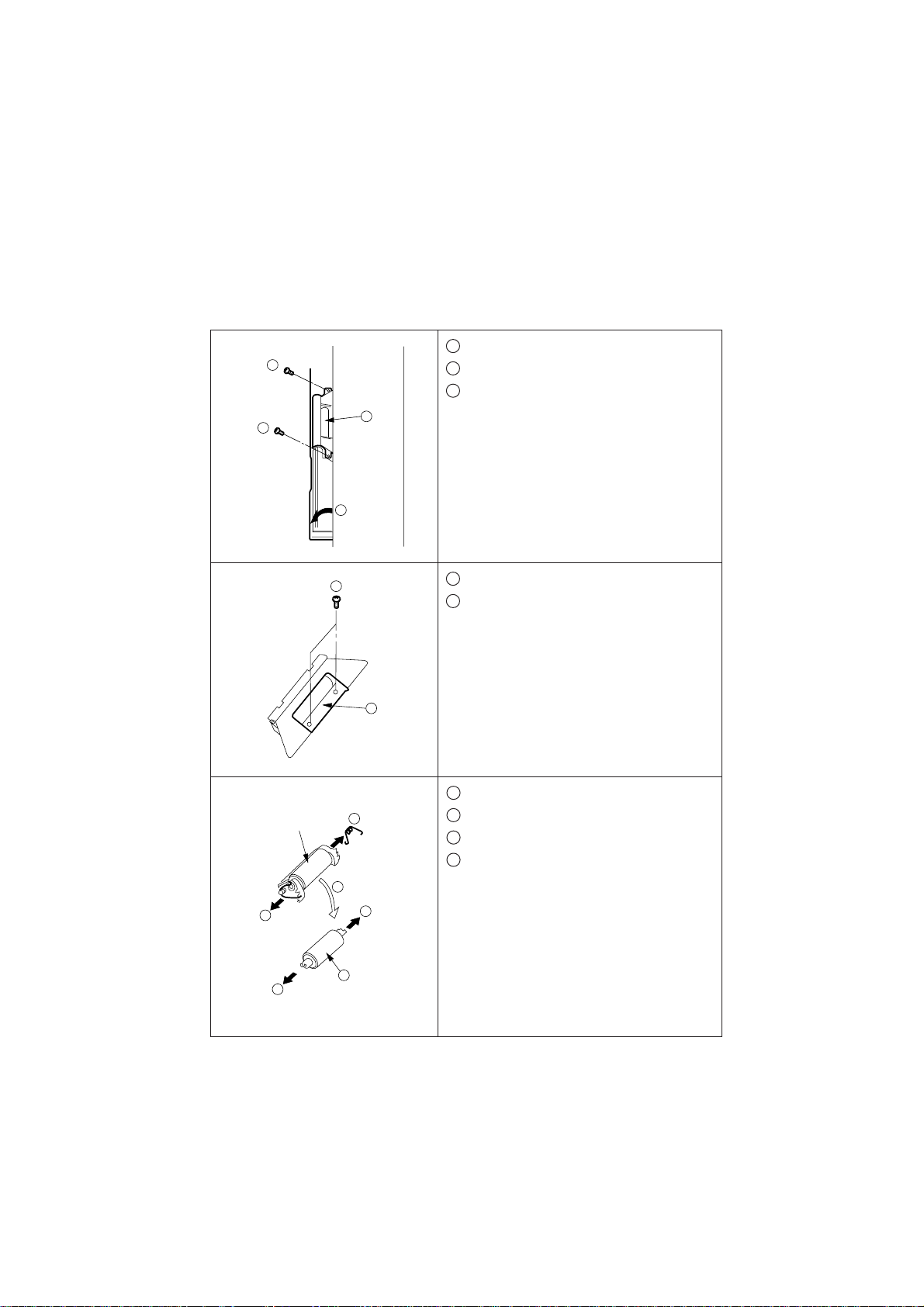

(2) To replace the DFP roller

1

2

3

2

2

DFP roller ass'y

1

3

1

SV007

1

SV008

1

2

4

3

2

3

SV009

1 Open the original feed cover.

2 Remove the screws (x 2).

3 Remove the DFP roller unit.

Note: This procedure is performed easier

with the ADF down, or closed.

Be careful to avoid damaging the guide

mylar.

SV007

1 Remove the screws (x 2).

2 Remove the DFP roller ass'y.

Note: Be careful to avoid damaging the

mylars.

SV008

1 Remove the springs (x 2).

2 Remove the DFP roller (ass'y).

3 Remove the bearings (x 2).

4 Remove the DFP roller.

Note: (1) Note the position of the spring for

use in re-assembly.

(2) Do not lose the bearings.

(3) Clean the roller after re-assembly.

(4) Re-assemble in reverse order.

SV009

3-4

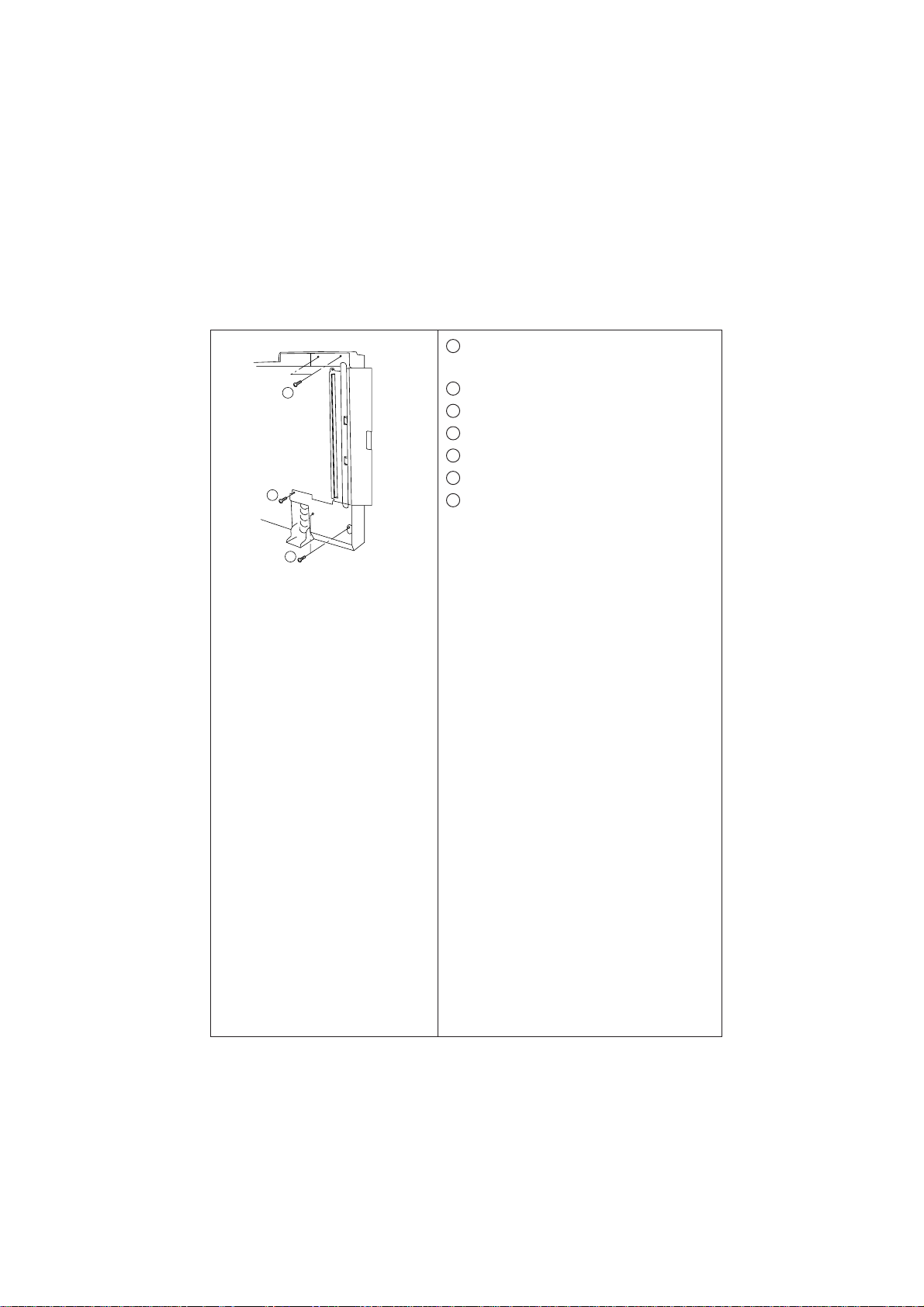

Page 18

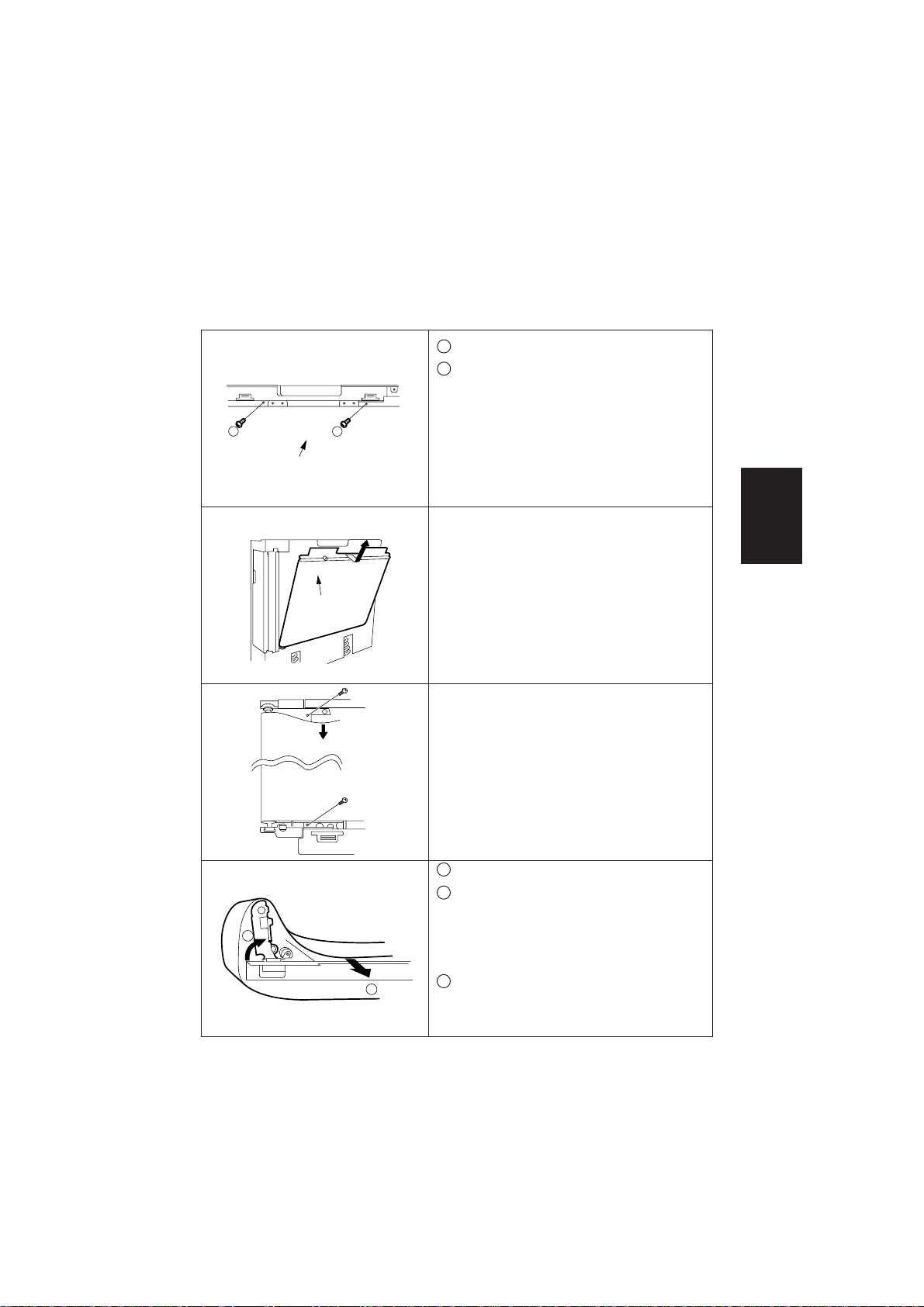

(3) Replacement of the transport belt

SV014

1

1 Open the ADF to the service position.

2 Remove the screws (with star-washers)

on the upper frame (x 2).

2

Transfer belt

2

3

Transfer belt

assembly

2

SV010

Remove the transport belt assembly.

Maintenance

SV011

Remove the screws (with star-washers)

(x 2).

SV014

4

1 Pull up the frame of the transport.

2 Remove the belt.

Note: During re-assembly, be careful to avoid

1

pinching the belt in the frame. (Belt

must be inside the frame flange.)

2

3 Re-assemble in reverse order.

Note: Confirm that the drive belt is correctly

SV015

SV015

aligned on the belt drive pulley.

3-5

Page 19

(4) Replacement of the pick-up and the original feed rollers

1

1 Remove the original feed tray (2 screws,

1 connector).

2 Open the ADF to the service position.

1 Remove the screws (with star-washers)

2

(x 3).

2 Remove the bottom cover.

2

1

3

2

3

1

SV017

SV017

1 Remove the original feed drive belt ass'y

(2 screws).

2 Open the original feed cover.

3 Remove the screws (x 5).

5

4

3

4 Slide the drive belt OFF of the drive motor

pulley.

5 Lower the original feed unit onto the copier

top left cover.

3

SV018

SV018

6 Disconnect the four(4) connectors.

3-6

4

3

Turn the feed unit over and rest it on the

original feed cover.

1 Remove (or detach the harness from) four

3

1

2

6

1

1

1

2

SV019

SV019

mini-clamps.

2 Remove the screws (x 2).

3 Loosen two screws.

4 Rotate the pick-up roller so it is below the

tray guide.

5 Remove the original feed tray connector

(2 screws) push the connector back

through the hole.

6 Remove the original feed tray guide.

Page 20

(4) Replacement of the pick-up and the original feed rollers (continued)

5

1 Remove the rear touch ring.

2 Slide the shaft of the pick-up roller toward

1

4

the motor.

3 Slide the bearing toward the left.

2

3 5

4 Pull the shaft upward.

5 Remove the bearing.

SV020

SV020

6

2

4

5

3

1 Remove the front touch ring.

2 Remove the center touch ring.

3 Slide the pick-up roller toward the left.

4 Pull the pin out.

5 Slide the pick-up roller toward the front

and remove it.

Maintenance

SV021

SV021

7

1

5

3

4

2

1 Remove the touch rings on both sides.

2 Slide the roller shaft toward the motor.

3 Pull the shaft up.

4 Remove the bearing on the front side.

5 Remove the touch ring.

6 Slide the original feed roller to the front

6

4

side and remove it.

SV022

SV022

Note: During re-installation, the roller should

rotate freely counter-clockwise and

lock if turned clockwise.

3-7

Page 21

(5) Exit assembly removal procedure

5

5

5

SV047

1 Conduct the procedure 1 and 2 of page

3-5.

2 Conduct the procedure 2 of page 3-6.

3 Disconnect ADF CPU CN6 and CN7.

4 Cover the platen glass with clean copier paper.

5

Remove the exit ass'y mounting screws (x 5).

6 Lower the exit ass'y onto the platen glass.

7 Remove CN6 and CN7 harness from the LWS.

3-8

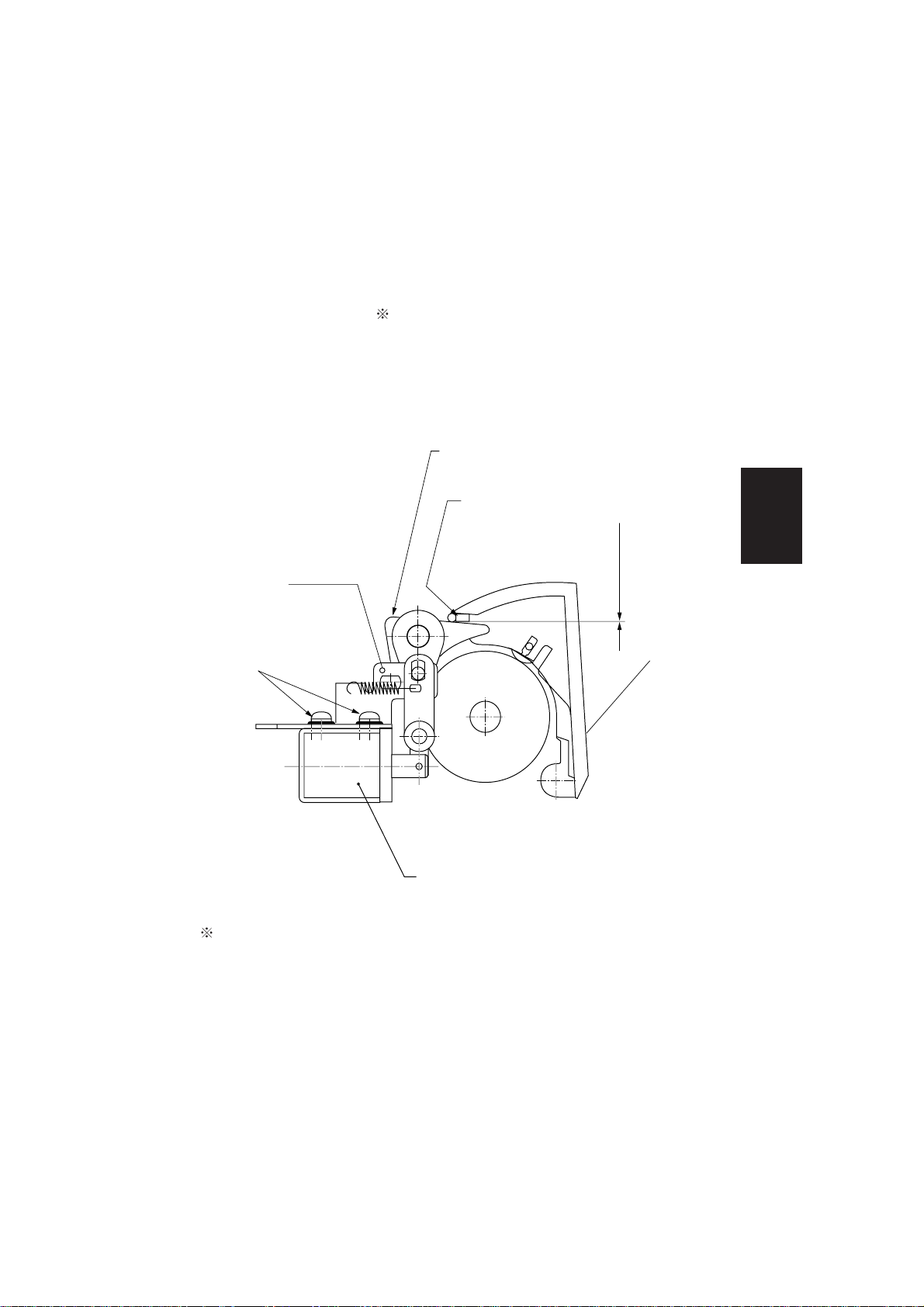

Page 22

3.3 Adjustment

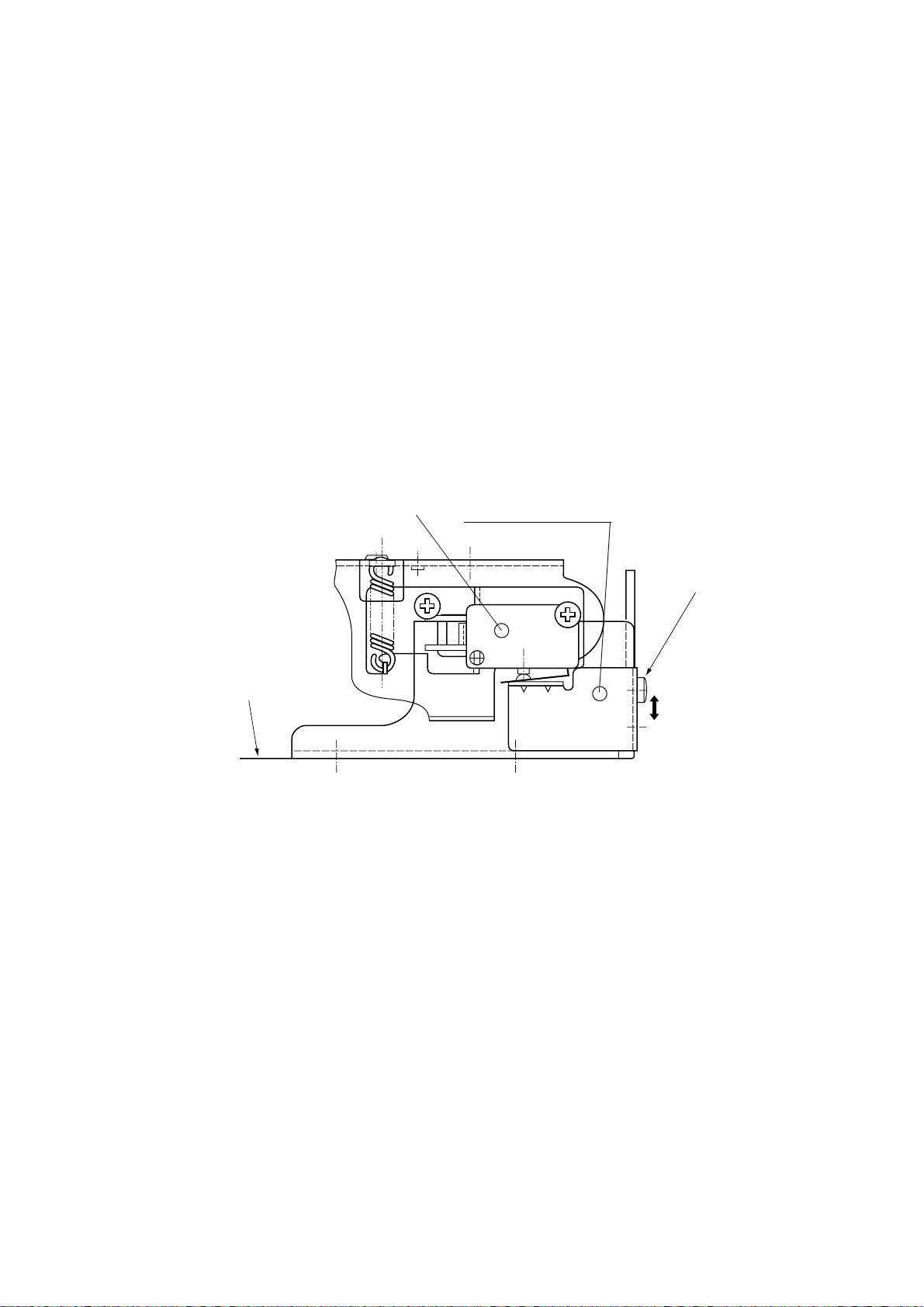

(1) Switching original exit

• With the solenoid screws loose, manually engage the plunger into the solenoid.

While holding the plunger engaged, slide the solenoid side to side to obtain a

0 - 5mm gap between the flapper and flapper rubber.

Flapper

Flapper rubber

Flapper

solenoid

bracket

Screws

SV035

Reverse

solenoid

To perform this adjustment, the exit assembly must be removed.

Maintenance

0 ~0.5mm

Exit cover

3-9

Page 23

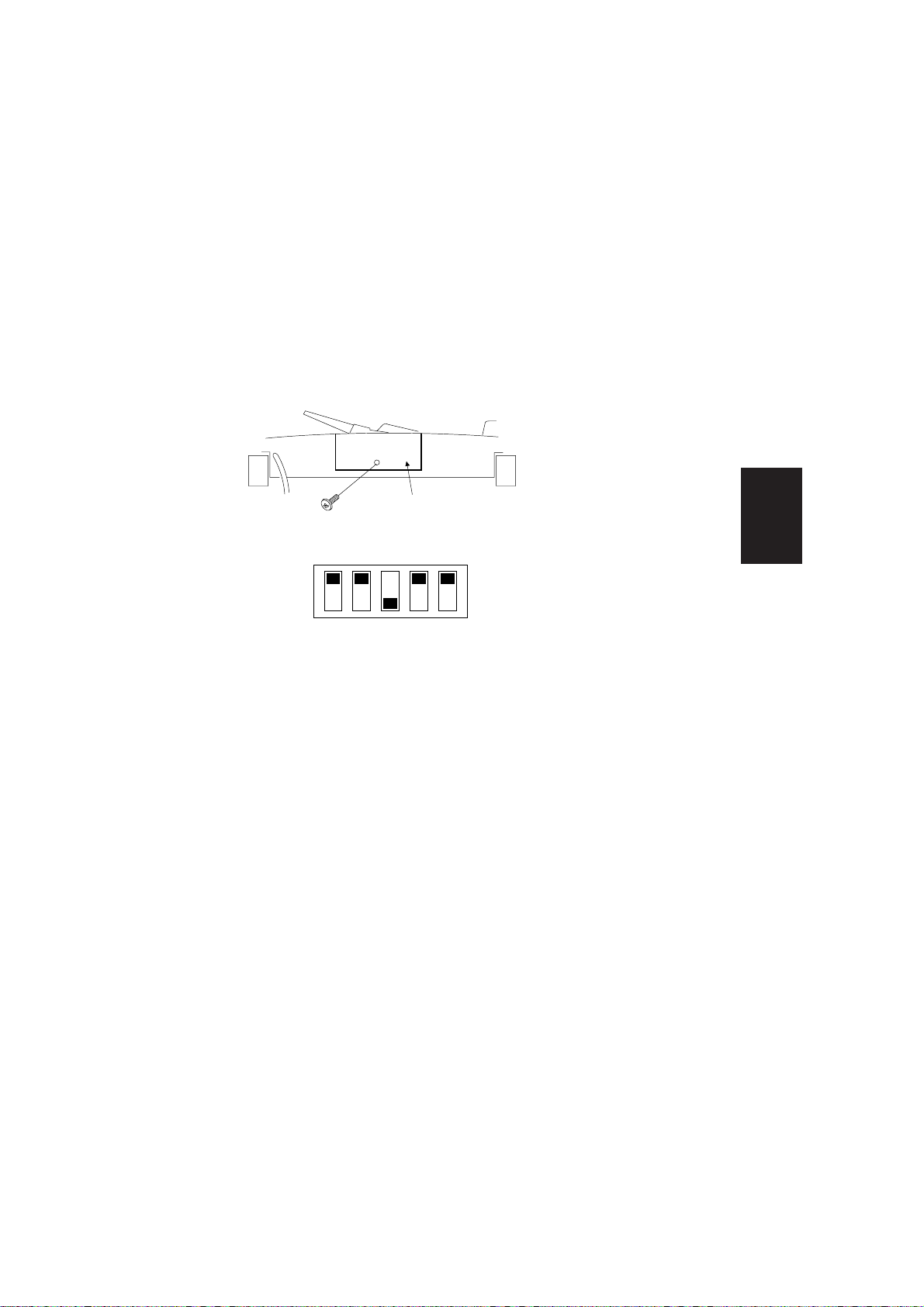

(2) ADF open/close detecting switch adjustment

• Perform this adjustment when the ADF open/close action is not detected.

1) Open the ADF.

2) Remove the ADF CPU cover (3 screws with star washers).

3) Loosen the screw retaining the switch lever.

4) Turn the switch lever in the direction of the arrow. Open the ADF 10 to 70mm

from the copier, and close the ADF 10 to 30mm from the copier, while checking

the display of copier.

ADF open/close

switch

Switch lever

Copier upper

cover (Rear)

Screw

5) Slide the switch lever so the ADF open/close switch is actuated when the

ADF is opened 10 to 30mm from the platen glass. Confirm by placing an

original in the infeed guide and opening/closing the ADF while watching the

copier display.

3-10

SV036

Page 24

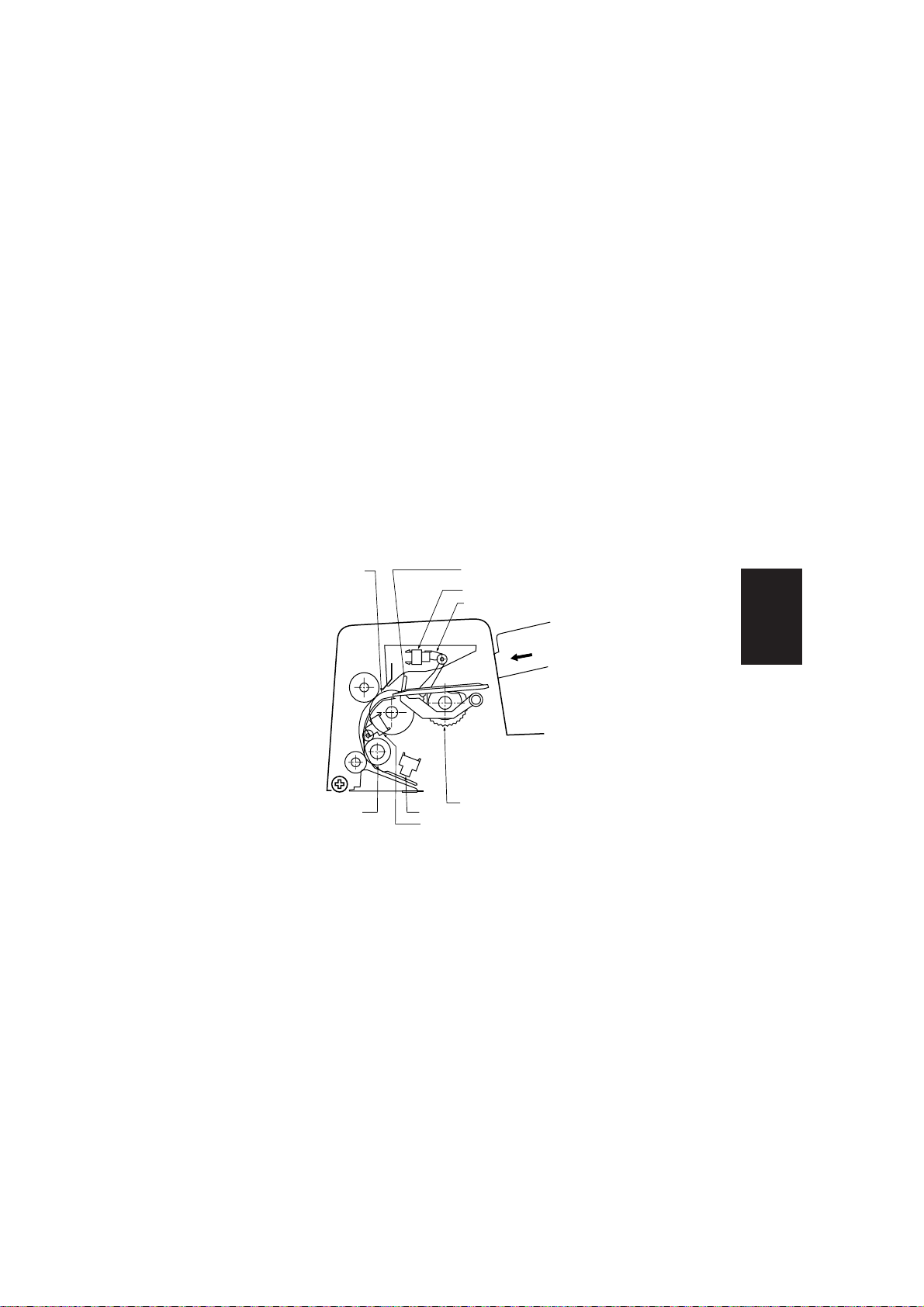

(3) Registration sensor and original exit/reverse sensor adjustment

• Perform this adjustment after replacing ADF CPU P.C.B. , registration sensor or

original exit/reverse sensor.

NOTE: Make sure no originals are in the ADF.

1) Turn the copier power switch OFF.

2) Remove the ADF service cover (1 screw).

Service cover

SV043

SV043

3) Set the ADF CPU PCB dip switches as follows:

ON

OFF

12345

4) Turn the copier power switch ON. The LED of ADF CPU PCB will flash.

(This is normal before pressing PSW1.)

5) The sensor adjustment and E2PROM initialization will be automatically

performed when the push switch (PSW1) is pressed on the ADF CPU PCB.

6) When the sensor adjustments are completed, the LED will turn OFF.

If an adjustment error is detected, the LED will be illuminated as follows:

a) Registration roller sensor: Lights up

b) Timing sensor: Flashes slowly (100msec interval)

c) Exit/Reverse sensor: Flashes quickly (500msec interval)

Repeat steps 1 to 5. If an error still remains, replace the indicated defective

sensor and repeat the procedure.

7) Turn OFF the all DIP switches (SW1) on the ADF CPU PCB after the adjustment

and turn the copier power switch OFF and ON.

8) Re-install the ADF service cover.

Maintenance

3-11

Page 25

Section IV Electrical

4. 1 Function of electrical parts

(1) Original detecting sensor / Registration roller sensor

( Original detecting sensor )

•Detects originals in the original feed tray.

1) When an original is loaded in the original feed tray, it will contact the original

stopper. The original detecting sensor lever, which is positioned in front of the

original stopper, is raised and detects the presence of an original.

2) As soon as the original is detected, the ADF indicator in the copier's display

lights up and ADF operation is enabled.

Original

feed roller

Regist roller

( Registration roller sensor )

•Detects the original feed status and counts the number of originals.

1) When the paper feed roller is rotated, an original is fed to the registration roller,

then registration roller rotates to feed the original. The registration roller sensor

counts the number of originals which pass and informs the copier.

Original stopper

Original detecting sensor

Original detecting sensor lever

Pick up roller

Timing sensor

Regist roller sensor

SV037

Electrical

4-1

Page 26

( Timing sensor )

•Detects the tail edge of original

1) During registration roller operation, an original is fed to the transport belt. At the

same time, the timing sensor detects the tail edge of the original to control

original feed operation.

(2)Weight / Stopper solenoid

1) When the weight/stopper solenoid turns ON( 1 ), weight shaft rotates in the

direction indicated by arrow( 2 ) and the weight plate contacts ( 3 ) the original.

The pressure is determined by the weight of the weight plate and tension of the

spring.

2) At the same time, the original stopper is moved below the paper guide(

4 ).

Weight shaft

Original stopper

2

1

Stopper shaft

Paper guideWeight plate

Stopper shaft

4

3

SV038

4-2

Page 27

(3) Original feed drive

•In order to feed an original, the motor rotates the paper feed and pick-up rollers.

1) When the original feed motor rotates ( forward rotation / A direction ), pully 56

is driven by timing belt 82, and one way pully 18 (which is mounted on the

same shaft) also rotates.

2) At the same time, pully 50 is driven by timing belt 72, and gear 21 (which is

mounted on the same shaft) also rotates.

3) Then gear 30, 32, 32OW also rotate as well as the pick-up roller and paper feed

roller .

•In order to feed the original from the original feed area to the transport belt, the

registration roller also rotates.

1) When the original feed roller is driven ( reverse rotation / B direction ), pully 56

is driven by pully 20 and timing belt 82, and one way gear 30OW (which is

mounted on the same shaft) also rotates.

2) At the same time, gear 21 is also driven so the registration roller turns.

Pully 56

Gear 30 ow

Timing belt

72

Registration

roller

Pully

18 ow

Original

feed

Gear

roller

32

Gear 21

Timing belt 82

A

Gear 21

B

Pully 50

Pully 20

Original feed roller

Pick up

roller

Gear

Gear

30 ow

32 ow

Electrical

SV024

4-3

Page 28

(4) Transport belt motor

•Rotates the transport belt to feed the original

1) When belt motor pully 37 is driven ( forward rotation), pully 24 is driven by

timing belt 136, and pully 24 (which is mounted on the same shaft) also rotates.

2) At the same time, pully 30 is driven by timing belt 60 and the belt roller (L) is

driven ( forward rotation ) rotating the transfer belt.

Pully 24

Belt roller (L)

Pully 37

Transport belt

Transport belt motor

Pully 30

Timing belt 136

Timing belt 60

SV023

(5) Reverse motor

• In order to reverse and exit the original, the original exit roller and original reverse

roller are driven.

1) When the reverse motor drives ( Forward rotation), the original reverse roller is

driven by Pully 28/31 and timing belt 56.

2) At same time, timing belt 44 and pully 17 are driven then original exit roller

rotates.

Original reverse motor

Timing belt 44

Pully 17

Link 1 Link 2

Original exit roller

Pully 28/31

Timing belt 56

Original reverse roller

Reverse claw

SV025

Reverse

solenoid

4-4

Page 29

(6) Original reverse solenoid

• This solenoid engages the reverse claw which switches driven direction of the

original.

( refer to figure page 4-4 )

1) When the reverse solenoid turns ON, link 2 moves in the direction indicated by

arrow.

2) The reverse claw is raised to turn the original over and feed it to the platen

glass.

3) When the original reverse solenoid turns OFF, the reverse claw lowers to exit

the original.

4) Consequently, switching between reversing and exiting the original is determined

by ON/OFF status of the original reverse solenoid.

(7) Original exit/reverse sensor

• Detects the feeding status of an original which was turned over at the reverse

section. Also, detects an original that has exited the ADF.

1) The original exit/reverse sensor is mounted near the reverse roller to detect the

feeding and exit status of original.

Original exit/reverse

sensor

Original reverse

roller

Reverse

claw

Electrical

Link 1

Link 2

Reverse solenoid

SV039

4-5

Page 30

(8)ADF open/close detecting switch

•Detects the open/close status of the ADF and activates the reset operation for

recovery from original Jams.

1)This switch constantly monitors the open/close status of the ADF by going OFF

when the ADF is opened or ON when it is closed. While the ADF is open, ADF

operation is disabled.

2) This sensor also activates reset after the ADF has been opened and closed as

a result of a original jam.

ADF open/close detecting switch

4-6

SV036

Page 31

(9) Original feed motor clock sensor

•Detects original feed motor speed and machine error by rotation pulses.

1) A timing disc has been installed on the original feed motor shaft. Depending on

the movement of the slits on the timing disc, the clock sensor switches ON/

OFF and outputs a timing pulse.

Original feed cover open/close

Original feed motor timing disk

detecting switch

SV040

(10) Original feed cover open / close detecting switch

•Detects the open/close status of the original feed cover and activates reset.

1) This sensor detects the open/close status of the original feed cover by going

OFF when the original feed cover is opened or going ON when the original

feed cover is closed. When the original feed cover is opened and closed, this

switch also activates reset for recovery from an original jam.

(11) Original exit cover open / close detecting switch

•Detects the open/close status of the original exit cover and activates the reset

operation.

1) This sensor detects the open/close status of the original exit cover by going

OFF when the original exit cover is opened or going ON when it is closed.

While the original exit cover is open, ADF operation is disabled.

2) When the original exit cover is opened and closed, this switch also activates

the reset operation for recovery from an original jam.

Original exit cover open/close

detecting switch

Electrical

SV041

4-7

Page 32

(12) Original size detecting sensor

•Detects the size of original loaded in the original feed tray

1) When an original is loaded and the original guides are adjusted to fit the size of

original, the size of original is detected by the ON/OFF status of three original

size detecting sensors which are mounted on the original feed tray.

2)Original size detecting sensor (2) and (3) consist of a micro switch, where as

original size detecting sensor (1) consists of photointerruptor.

Original size

detecting sensor

(1)

Original size

detecting sensor

(2), (3)

SV042

4-8

Page 33

4.2 Signal information by connector

(1) CPU P.C.B.

(CN1)

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

10

11

12

Signal

name

GND

STL

VL

SWH1

GND

SWH2

GND

Signal

name

VL

GND

EMP

GND

KMCLK

VL

VL

TIMS

TIMS DA

VL

REGS

REGS DA

Destination

Original size detecting

sensor (1) CN13-3

Original size detecting

sensor (1) CN13-2

Original size detecting

sensor (1) CN13-1

Original size detecting

switch (2) CN31-1

Original size detecting

switch (2) CN31-2

Original size detecting

switch (3) CN31-3

Original size detecting

switch (3) CN31-4

Destination

Original detecting

sensor CN16-3

Original detecting

sensor CN16-2

Original detecting

sensor CN16-1

Paper feed motor clock

sensor CN17-3

Paper feed motor clock

sensor CN17-2

Paper feed motor clock

sensor CN17-1

Timing sensor

CN18-3

Timing sensor

CN18-2

Timing sensor

CN18-1

Registration roller

sensor CN19-3

Registration roller

sensor CN19-2

Registration roller

sensor CN19-1

ON/OFF

5V

5V

5V

OFF

0

ON

5V

OFF

0

ON

OFF

0

ON

ON/OFF

5V

0

No detecting detecting

Pulse signal

5V

0

No detecting detecting

5V

LED ON

OFF

No detecting detecting

OFF

LED ON

5V

3.8V

0

5V

3.8V

Pin

No.

(CN2)

Pin

No.

Function

Ground

Original size detecting

signal

DC +5V

0

Original size detecting

signal

Ground

Original size detecting

signal

Ground

Function

DC+5V

Ground

5V

Original detecting

0

signal

Ground

Paper feed motor clock

sensor signal

DC+5V

DC+5V

3V

Timing sensor output

1V

singal

Timing sensor control

signal

DC+5V

3V

Registration roller

1V

sensor output signal

Registration roller

sensor control signal

Electrical

4-9

Page 34

(CN3)

Pin

No.

1

2

3

4

5

6

(CN4)

Pin

No.

1

2

3

4

5

6

7

8

9

Signal

name

*B

B

*A

A

Vp

Vp

Signal

name

DFM1

DFM2

DFSO

Vp

FGOD

ADF Vp

AUOD

Vp

–

Destination

ON/OFF

Transfer belt motor

CN33-11

Transfer belt motor

CN33-7

Transfer belt motor

CN33-5

Transfer belt motor

CN33-1

Transfer belt motor

CN33-9

Transfer belt motor

CN33-3

Destination

ON/OFF

Original feed motor

CN21-1

Original feed motor

CN21-2

Original feed solenoid

CN35-1

Original feed solenoid

CN35-2

Original feed cover open/close

detecting switch CN23-1

Open Close

Original feed cover open/close

detecting switch CN23-2

ADFopen/close

detecting switch CN24-1

Open Close

ADF open/close

detecting switch CN24-2

–

Function

Transfer belt motor

OFF24V

signal

ON0

DC+24V

24V

0

DC+24V

Function

Original feed motor

drive signal

OFF24V

ON0

Solenoid control signal

24V

DC+24V

0

24V

Original feed cover open/

0

close detecting signal

24V

DC+24V

0

ADFOpen/close

24V

detecting signal

0

24V

DC+24V

–

4-10

(CN5)

Pin

No.

1

2

Signal

name

Vp

PGND

Destination

Connecting harness for

copier CN34-1

Connecting harness for

copier CN34-2

ON/OFF

24V

0

Function

DC+24V

Ground

Page 35

(CN6)

Pin

No.

1

2

3

4

5

6

7

8

(CN7)

Pin

No.

1

2

3

4

5

Signal

name

FD Vp

TGOD

Vp

Vp

*B

B

*A

A

Signal

name

AN Vp

HANS

RDDLED

Vp

DRSOL

Destination

Exit cover open/close

detecting switch CN25-1

Exit cover open/close

detecting switch CN25-2

Original reverse/exit

motor CN26-1

Original reverse/exit

motor CN26-2

Original reverse/exit

motor CN26-3

Original reverse/exit

motor CN26-4

Original reverse/exit

motor CN26-5

Original reverse/exit

motor CN26-6

Destination

Original reverse/exit

sensor CN28-3

Original reverse/exit

sensor CN28-2

Original reverse/exit

sensor CN28-1

Original reverse/exit

solenoid CN29-1

Original reverse/exit

solenoid CN29-2

ON/OFF

closeopen

ON/OFF

No detecting detecting

LED ON

OFF

24V

0

Function

24V

DC+24V

0

24V

Exit cover open/close

detecting signal

0

DC+24V

24V

0

DC+24V

Original reverse/exit

motor drive signal

OFF24V

ON0

Function

24V

DC+24V

0

13~3V

Original reverse/exit

1.6

sensor output signal

~0.4V

Sensor LED control

5V

3.8V

signal

24V

DC+24V

0

Original reverse/exit

OFF

sensor drive signal

ON

Electrical

4-11

Page 36

(CN8)

Pin

No.

1

2

3

4

5

6

7

Signal

name

IADFRX

ADFRX

GND

IADFTX

ADFTX

ADFCHGES

ADFFSFD

Destination

Connecting harness for

copier CN34-8

Connecting harness for

copier CN34-9

Connecting harness for

copier CN34-10

Connecting harness for

copier CN34-11

Connecting harness for

copier CN34-12

Connecting harness for

copier CN34-7

Connecting harness for

copier CN34-2

ON/OFF

Pulse signal

Pulse signal

No detecting detecting

5V

0

Function

ADF reverse receiving

signal

ADF receiving signal

Ground

ADF reverse

transmission signal

ADF transmission signal

Original change

subscription signal

One sided original feed

operation request signal

4-12

Page 37

4.3 Explanation of circuit

1.ADF CPU P.C.B.

(1) Comunication circuit

This circuit allows both serial and parallel communication between the copier

and the ADF. IC10 is used for serial communication. Data is transferred as

both a normal and inverse signal, so that any line noise will be cancelled out by

adding the two signals together inside IC10. The ADF also communicates with

the copier using 2 parallel data lines. One line for output using IC4 and Q3

(buffer) and the other for data input using pull up resistor.

CN8

1

IADFRX

2

ADFRX

3

GND

4

IADFTX

5

ADFTX

6

ADFCHGS

ADFFSFD

7

R92

100

+5V

2

R70

1.0k

+5V

R39

4.7k

R40

DA1

4.7k

DT

1

11

3

R43

4.7k

DA2

13

IC4

12

ADFFSFD

ADF

CHGES

+5V

IC10

RI1

RI1

DO1

*

DO1

*

RI2

R12

DO2

*

DO2

RO1

DI1

*RE

DE

RO2

DI2

3

15

4

12

5

9

SD003

1

*

2

14

13

6

7

10

11

(2)Sensor input circuit

1) Original size detecting switch ( SWH1/SWH2 )

Original size detecting switch (2) and (3) are micro switches for detecting original

width, and output of these switches are input to gatearray ( IC14 ) via a noise

filter which consists of resistors and capacitors, then input to the CPU through

data bus.

CN1

SWH1

4

5

GND

CN1

6

SWH2

7

GND

R42

4.7k

R41

4.7k

+5V

+5V

R23

10k

R22

10k

C24

0.1

C25

0.1

58

59

IC14

P5

P6

IC13

79

RxD

80

TxD

24

TXEN

Electrical

SD004

4-13

Page 38

2) Original size detecting sensor (1) (STL)

The original size detecting sensor (1) consists of a photointerruptor for detecting

original length, and output of this sensor is input to gatearray ( IC14 ) via noise

filter which consists of resistors and capacitors, then input to the CPU through

a data bus.

54

IC14

P1

SD005

CN1

3

2

1

VL

STL

GND

+5V

R37

+5V

4.7k

R10

10k

C26

0.1

3) Original detecting sensor (EMP)

The original detecting sensor consists of a photointerruptor, and output of this

sensor is input to gatearray ( IC14 ) via noise filter which consists of resistors,

capacitors, and Q14, then input to the CPU through a data bus.

IC14

1B

R36

10k

C2

GND

+5V

E3

DT

TP3

53

P0

SD006

CN2

1

3

2

VL

EMP

GND

GND

R1

180

15k

+5V

R75

R9

10k

GND

C26

0.1

4-14

Page 39

4) Original feed motor clock sensor ( KM CLK )

The original feed motor clock sensor consists of a photointerruptor and timing

plate (for monitoring motor rotation) and output of this sensor is input to the

CPU via a noise filter which consists of resistors and capacitors.

CN2

6

VL

5

KM CLK

4

GND

+5V

GND

R38

4.7k

R14

10k

GND

C33

1000p

TP12

74

IC13

INTP2

SD020

5) Registration sensor ( REGS ) / Timing sensor ( TIMS )

The registration sensor and timing sensor is a reflection type of photointerruptor

which consists of an LED and phototransistor. The phototransistor detects the

reflection of infrared light from the LED for detecting the original.

The cathode terminal of the LED is connected to a voltage-current converting

circuit and D-A output ( Analog voltage output ) from the CPU controls the input

current for the LED. In addition, the photocurrent of the phototransistor is

converted to a voltage value by resistors. They are connected to the input

terminal of the sensor, to the input comparator circuit via a noise filter for

comparing to the reference voltage ( Aprrox. +2V ). When the output voltage

from the sensor is higher than reference voltage, the output signal from the

comparator circuit becomes Low, and transfers to the CPU as no original

detection.

The CPU controls the input current for the LED ( brightness of LED ) to maintain

proper sensor output voltage.

VL

REGS DA

REGS

+5V

R34

9.1k

PGND

R15

10k

AN+24V

C8

0.1

R18

PGND

Q8

2SC2712

2

1

3

22k

R28

2k

R66

10k

R48

100k

9

8

IC1.2

27

14

IC3.3

5

6

TP8

R24

100

GND

TP13

C34

100pF

+5V

R17

10k

68

56

73

IC13

ANO1

INPT1

ANI0

SD007

CN2

7

9

CN2

8

Electrical

4-15

Page 40

6) Original exit / reverse sensor ( HANS )

The original exit/reverse sensor is a reflection type of photointerruptor which

consists of an LED and phototransistor. The phototransistor detects the reflection

of infrared light from the LED for detecting the original.

The sensor input voltage is divided 1/3 by R87 and R88 and inputs to the A-D

converter. Then PWM signal which is a corresponding output from the A-D

converter, is output from the gatearray ( IC14 ). This PWM signal is converted

to analog voltage by an integrating circuit ( R2, C12 ) and is amplified 2 times

by a non-inverting amplifier to be a reference voltage for the comparator.

The reference voltage for the comparater is 2/3 of the high level of each sensor

output.

Also,during a no original detecting condition, the input voltage to the CPU is

less than 1V, pin 49 of CPU becomes high to increase brightness of the LED.

RDDPWM

(IC14-18)

R2

10k

CN7

1

AN+24V

HANS

2

3

RDDLED

C12

0.1

R51

PGND

R89

3.3k

C11 0.1

22k

2

3

IC1.1

R52

22k

PGND

1

R90

2.2k

AN+24V

2

3

PGND

R35

10k

TP1

DT

PGND

1

C9

0.1

R4

10k

R87

3k

R88

1.5k

4

5

R47

IC3.1

100k

PGND

+5V

R24

10k

2

+5V

R3

10k

C29

0.1

D1

TPS

IC13

INTP3

75

58

ANI2

49

P12

4-16

SD008

Page 41

7) ADF open/close detecting switch,original feed cover open/close detecting switch,

original exit cover open/close switch( AUOD,FGOD,TGOD )input circuit.

This circuit is the input circuit for the ADF open/close detecting switch, original

feed cover open/close detecting switch, and exit cover open/close detecting

switch. When one of these switches are in the OFF condition, the power ( DC

24V ) to all motors and solenoids is cut. The 24V ON/OFF signal is input to a

zener diode which reduces the voltage to DC 17.2V, and this lower voltage is

input to the base terminal of the transistor to convert a DC5V signal. The DC

5V signal is, then input to the CPU.

CN6

2

TGOD

FD+24V

1

CN4

3

NC

Vp

8

7

AUOD

ADF+24V

6

5

FGOD

DC+24V

ZD2

R25

2

1

DT

ZD9

+5V

10k

3

ZD10

+5V

R33

10k

DT

1

+5V

R13

10k

1

DT

IC14

55

P2

2

3

56

P3

57

P4

2

3

SD009

(3)Reset circuit

This circuit resets the CPU and output reset signal for the gate array.

When the DC 5V line drops to less than 4.3V (or immediately after the power is

turns ON) the output of IC6 is set to a low level. ( After power is turned ON and

the DC 5V line is higher than 4.3V, the reset is maintained for a while.) Also,

this circuit is a timer which is monitoring the CPU status to avoid abnormal

operation.

+5V

GND

7

36

37

39

IC13

RESET

IC14

RES1

WDT

RES2

SD010

C6

0.1

5

C42

0.33

+5V

IC6

GND

R95

10k

DT

C19

0.1

1

C3

0.1

GND

+5V

R53

7

22k

6

4

D4

2

3

GND

Electrical

4-17

Page 42

(4) Drive circuit

1) Original feed motor( DFM ) drive circuit

This circuit controls the forward and reverse movement of the original motor

which is a gatearray ( IC14 ), hybrid IC ( IC15 )and other components.

The CPU outputs the control signal ( 2 bits control signal ) to the gatearray

through a data bus for operating the original feed motor. The gatearray outputs

the original feed motor control signal from pin 65~68. Pin 65 and 66 of the

gatearray output the PWM signal for controlling the original feed motor speed.

( Forward rotation : pin 65 / Reverse rotation : pin 66 )

IC15 is a hybrid IC which is 4 elements of power MOSFET, and input control

signals from pin 65~68 from the gatearray is output for driving the original feed

motor. The original feed motor is driven the combination of control signals

which are output from pin 65~68 of gatearray ( IC14 ).

Pin No.

OFF

Rotate registration roller

Rotate pick-up/original

feed roller

Brake

IC14

67

M1H1

65

M1L1

68

M1H2

66

M1L2

CHGCLK

72

C18

Pulse control

14

12

15

+5V

13

16

0.1

GND

65

signal

IC15

INA

INB

INC

3

IND

1

CLK

VCC2

SG

0.1

0

1

0

1

CN4

68

0

0

1

1

1

2

66

0

0

0

Pulse control

signal

67

0

0

OUT1-1

OUT1-2

OUT2-1

OUT2-2

VCC1-1

VCC1-2

VZ

10

11

7

0

DFM1

L2

6

2

9

8

L1

C47

1

DFM2

+24V

C5

0.1

PGND

SD011

4-18

Page 43

2) Transport belt motor ( DTM )/ Original reverse motor( DRM ) drive circuit

This circuit controls the forward and reverse movement of the transport belt

motor and original reverse motor.

CPU output pin

Gatearray output pin

Driver IC

Signal flow

Convert analog

signal for motor

Operation

Control motor

speed and

Control rotation

torque

rotation direction

Transport belt

motor

Original

reverse motor

12~15

16~19

17

16

IC5

IC2

• DTM drive circuit

IC13

IC14

PO0

PO1

PO2

PO3

PWM4

12

13

14

15

17

TP19

• DRM drive circuit

IC13

IC14

PO4

PO5

PO6

PO7

PWM3

16

17

18

19

16

TP15

R45

68k

R91

12k

R46

68k

R94

6.2k

TP18

GND

TP16

GND

TP20

C14

0.1

C39

100p

TP17

C13

0.1

C38

100p

13

A1

15

A2

14

B1

16

B2

9

Vref

11

Vref

8

Td1

10

Td2

5

4

PGND

13

A1

15

A2

14

B1

16

B2

9

Vref

11

Vref

8

Td1

10

Td2

5

4

PGND

IC5

SG

PG

IC2

SG

PG

+5V

+5V

A10

A20

B10

B20

NC

A10

A20

B10

B20

NC

C41

10

2

GND

3

6

7

+24V

PGND

C40

10

2

GND

3

6

7

+24V

PGND

C49

100

C48

100

A

*A

B

*B

Vp

Vp

SD012

A

*A

B

*B

Vp

Vp

SD013

CN3

CN6

4

3

2

1

5

6

Electrical

8

7

6

5

3

4

4-19

Page 44

3) Original feed solenoid ( DFSOL ),original reverse solenoid ( DRSOL ) drive

circuit

This circuit controls the original feed solenoid and the original reverse solenoid.

Operation of both the original feed solenoid and the original reverse solenoid

drive circuit is the same. When the drive signal from the gatearray becomes

HIGH, FET ( Q10,Q11 ) turns ON and the solenoid is activated.

Vp

DRSOL

Vp

DFSOL

SD014

CN7

CN4

4

5

4

3

IC14

PWM2

PWM1

15

14

R68

1k

R64

1k

Q11

1

PGND

Q10

1

2

3

2

3

PGND

D7

D6

+24V

+24V

(5) Original feed motor ( DFM ) current control circuit

This circuit controls the motor starting current within a limited current level.

IC14

M1CUR

63

TP4

+5V

IC3.2

TP2

R63

2

1

3

R12

10k

C32

1000p

0.2

R62

0.2

IC15

4

PG1

5

PG2

4-20

IC3 input

More than 0.32V

( 3.2A )

Less than 0.32V

( 3.2A )

IC3 output

Low

High

R44

R89

R72

+24V

22k 1k

PGND

3k

+24V

OFF

ON

PGND

ZD6

SD015

Motor current

Controling

No controling

Page 45

(6)Rush current control circuit

This circuit controls the rush current for the capacitors ( C48, C49 ) in the

transport belt motor and original belt motor drive circuits and is a limiting resistor

and FET.

This circuit limits the current by R93 until so the voltage of the cathode terminal

of ZD7 reaches the reference level ( 16V ). When all of the ADF open/close

detecting switch, original feed cover open/close switch, and original exit cover

switch are closed, or power is turned ON to the ADF. After the voltage of

cathode terminal of ZD7 reaches reference level, this control is cancelled. R30

is a discharge resistor for C48 and C49, when either ADF open/close detecting

switch, original feed cover open/close switch, or original exit cover switch is

opened.

32

C3

100p

R65

3k

To CN6-2

R93

15

1

R61

6.2k

Q12

3

PGND

+24V

PGND

2

Q4

R58

R30

1.8k

1

D5

22k

C30

2.2

GND

ZD7

SD016

(7) EEPROM ( IC7 ) circuit

This circuits memorizes the adjustment values of the ADF and original count

data. The data is not erased when the power switch turns OFF.

+5V

D3

R81

C43

E2ROM+5V

10

100

GND

6

7

100k

IC7

ORG

TEST

R50

D0

CS

SK

DI

4

1

2

3

(22k x 4)

R54

R55

R56

R57

+5V

D2

R19

R20

(10k x 3)

R8

10k

R21

IC13

59

AN13

51

P14

52

P15

50

P13

Electrical

GND

SD017

4-21

Page 46

(8) +5V power supply circuit

This circuit converts +24V which is supplied from the copier to +5V by a switching

regulator ( IC11 ). This circuit supplies +5V input voltage ( +24V ) is dropped

+9V.

D8

+24V

CN5

Vp

1

2 PGND

SW2

TP1

R84

9.1

C43

1500

IC11

5

Vin

GND

1

Vo

3

C44

470

+5V

ZD5

PGND

PGND

GND

SD018

(9) DC+24V Detecting circuit

This circuit is ZD4 and Q7 for monitoring +24V supplied from the copier. In

case power supplied from copier drops below +24V, this circuit detects and

inputs to the CPU ( IC13 ).

+24V

ZD4

C36 0.1

GND

+5V

R29

10k

Q7

2

1

3

GND

77

IC13

INTP5

SD019

4-22

Page 47

Section V Troubleshooting

5. 1 Error detection by self-diagnosis

The self-diagnosis function detects troubles in important areas of the ADF. When

any trouble occurs, the machine is stopped. The error indication appears in the

"digit" display of the copier ( except J70 ) and the "Wait" indicator on the copier turns

ON.

(1)User error

Code

U10

Problem

a. ADF is not closed

securely.

b. Original feed cover is not

closed securely.

c. Original exit cover is not

closed securely.

Note : When the original is

placed in the original

feed tray, the user error

is detected.

1. The ADF is not installed correctly

2. The ADF is open.

3. CN4-7, 8 of ADF CPU P.C.B. is

broken.

4. ADF open/close detection switch is

defective.

5. Original feed cover is open.

6. CN4-5,6 of ADF CPU P.C.B. is broken.

7. Original feed cover open/close

detection switch is defective.

8. Original exit cover is open.

9. CN6-1,2 of ADF CPU P.C.B. is broken.

10.Original exit cover open/close

detection switch is defective.

11.ADF CPU P.C.B. is defective.

Cause / Check

Troubleshooting

5-1

Page 48

(2) Paper Jam

Code

J70

Original feed section

a. When the registration

b. When the registration

c. The ADF entry paper

J71

Original transport/reverse/exit section.

a. When the original exit/

b.

J72

Original transport/reverse/exit section.

a. When the original exit/

b. When the trail edge of the

Cause

roller sensor does not

detect an original within

the original feed motor

has started in forward

rotation.

roller sensor detects an

original within a

predetermind time after

original feed motor has

started in reverse

rotation.

pass sensor is detecting

paper before using ADF.

reverse sensor does not

detect an original within a

predetermind time after

transport belt motor has

started in forward rotation.

When the trail edge of the

original is not detected

within a predetermind time

after the original exit/

reverse sensor detects the

lead edge of the original.

(exit operation)

reverse sensor does not

detect an original within a

predetermind time after

transport belt motor has

started in reverse rotation.

original is not detected

within a predetermind time

after the original exit/

reverse sensor detects the

lead edge of the original.

(reverse operation)

Check

1. Original feed roller is worn or dirty.

Foreign material is inside original feed section.

2.

3. Drive mechanism of original feed

section is defective.

4. Original feed motor is defective.

CN4-1,2 of ADF CPU P.C.B is shorted or broken.

5.

6. Original feed solenoid is defective.

CN4-3,4 of ADF CPU P.C.B is shorted or broken.

7.

8. Original detecting sensor is defective.

9. CN2-1,2, of ADF CPU P.C.B is

shorted or broken.

10. Registration roller sensor is defective.

11. CN2-10,11,12,7 of ADF CPU P.C.B is

shorted or broken.

12. Timing sensor is defective.

13. CN2-7,8,9 of ADF CPU P.C.B is

shorted or broken.

14. ADF CPU P.C.B.is defective.

1. Transfer belt is worn or dirty.

2. Each roller is worn or dirty.

3. Foreign material is inside original

transport / reverse / exit section.

4. Drive mechanism of original exit

section is defective.

5. Transport belt motor is defective.

6. CN3-1~6 of ADF CPU P.C.B is

shorted or broken.

7. Original reverse motor is defective.

8. CN6-3~8 of ADF CPU P.C.B is

shorted or broken.

9. Original reverse solenoid is defective.

10. CN7-4,5 of ADF CPU P.C.B is shorted

or broken.

11. Original exit/reverse sensor is

defective.

12. CN7-1,2,3,6 of ADF CPU P.C.B is

shorted or broken.

13. ADF CPU P.C.B.is defective.

5-2

Page 49

(3) ADF function error ( E7 indication )

Code

10

ADF transport belt motor

Cause

rotation

10

ADF original feed motor

rotation

10

ADF original reverse motor

rotation

11

ADF registration roller or

timing sensor output

abnormal

ADF original exit / reverse

11

sensor output abnormal

Check

1. ADF transport belt motor is defective.

2. CN3-1~6 of ADF CPU P.C.B is

shorted or broken.

3. Drive mechanism of transport belt

motor is defective.

4. ADF CPU P.C.B.is defective.

1. Original feed motor is defective.

2. CN4-1,2 of ADF CPU P.C.B is shorted

or broken.

3. Drive mechanism of original feed

motor is defective.

4. ADF CPU P.C.B.is defective.

1. Original reverse motor is defective.

2. CN6-3~8 of ADF CPU P.C.B is

shorted or broken.

3. Drive mechanism of the original

reverse motor is defective.

4. ADF CPU P.C.B.is defective.

1. Sensor is defective.

2. Sensor output is detected without a

predetermined output.

3. ADF CPU P.C.B.is defective.

Troubleshooting

5-3

Page 50

Section VI Installation

6.1 Unpacking

Check the condition and contents of the box for any shipping damage and

completeness before installation. (Visual check)

*Check the contents of the box.

Original feed tray (x1) Magnet catch plate (x2)

Hinge positioning screws (x2)

Original tray mounting screws (x2)

Anti-electrostatic liquid

(Not packaged with machine)

Hinge mounting screws (x2)

Installation

SV046

6-1

Page 51

6.2 Installation procedure

Please keep this procedure (It is not printed in the Service Manual).

Remove all shipping materials before installation.

Caution: Make sure the copier is unplugged before the installation.

Location Shipping material / Procedure

1

2

3

(For FP-7718/7722/7728/7735/7742/7750)

Upper Rear Cover

Check

Remove the original guide plate

of the copier.

Application of the anti-electrostatic liquid

(1)Clean the Plate glass before

application.

(2)

Apply (10cc) to a soft pad folded in half.

(3) Uniformly wipe the platen glass in

a lateral direction.

(4) Leave the platen glass for 10

minutes or longer, before handling.

Install the hinge positioning

screw.

(2 shoulder screws)

6-2

Upper Rear Cover

(For FP-D250/D350 Series)

SU001

Page 52

Location Shipping material / Procedure

4

3

8

6

7

2

1

(For FP-7718/7722/7728/7735/7742/7750)

3

4

6

6

6

5

Check

Installation of magenet catch plate.

(For FP-7718/7722/7728/7735/7742/7750)

(1) Remove right cover (upper).

(2) Remove the platen glass.

(3) Install the magnet catch plate to the

notches in the control panel.

(4) Reassemble in the reverse order.

Note:Use shorter screws to fix the

original guide plate.

(For FP-D250/D350 Series)

(1) Remove the top right cover.

(2 screws)

(2) Remove the original guide plate and

platen glass (2 screws)

(3) Install the magnet catch plates onto

the notches on the control panel.

(4) Reassemble in reverse order.

(For FP-D250/D350 Series)

5

Installation of ADF

(1) Place the ADF on the copier.

(2) Slide the hinges forward.

3

(The screws mentioned above fit

Installation

into the holes of both hinges.)

(3) Fix both hinges of the ADF by

2

1

1

Hinge

positioning

screw

SU002

tightening the hinge mounting

screws.

* Install the hinge positioning

screws at the center of the

hinge holes.

6-3

Page 53

Location Shipping material / Procedure

6

2

Installation of Original Feed Tray.

(1) Connect the connector.

Check

(2)Install the original feed tray. (2

screws)

2

* Do not pinch the harness

when installing the original

1

SU003

feed tray.

7

Copier ADF Connector

8

Connect the ADF harness to the

copier ADF connector.

SU007

Change the position of the signal

harness of the CPU PCB.

Note: For the FP-D250/D350 series

(Digital copier), the following.

additional procedure must be

performed.

1

(1)Remove the blind plate from the

rear cover of the copier.

(2)Disconnect the harness from the

connector CN25 on the CPU PCB

and reconnect it to CN19 on the

CPU PCB.

2

(3) Reinstall rear cover.

6-4

Page 54

6.3 Adjustment

Location Shipping material /Procedure Check

1

2

Transport belt unit

Fixing screw

(Left side)

Platen Glass

Fixing screw

2

Rubber

spacer

Magnet

Magnet cartch

(Right side)

Rubber spacer

Height adjustment

Only required if the gap between the

platen glass and rubber spacer is over

0.5mm.

SV010

(See bottom figure)

a) Remove the top right cover of the

copier. (2 screws)

b) Remove the top left cover of the

copier. (2 screws)

c) Remove the original guide plate

of the copier. (3 screws)

(1) Remove the transport belt unit.

SV011

a)

Open the ADF to the service

position.

(90 degrees)

b) Remove the 2 screws on the

upper frame. (See top figure)

c) Remove the transport belt unit.

(2) Place the transport belt unit on the

platen glass. (See the figure on the

left)

Note:Make sure to align the

magnet with the magnet

catches.

(3) Loosen the fixing screws. (4 screws)

(4) Adjust the position of the magnets

so the gap between the platen glass

and the rubber spacer is less than

0.5mm.

(Right and left side)

(5) Reassemble in the reverse order.

(Left and right)

Installation

Magnet

Magnet cartch

SU009

6-5

Page 55

Location Shipping material / Procedure

2

11

2 2

SU005

Check

Original side to side adjustment

Note:Make sure the copier is

adjusted correctly before

making this adjustment.

(1) Loosen the original feed tray

adjusting screws (2 screws), and

move the tray front or rear as

required, then tighten the screws.

3

Hinge fixing screw

ADF hinge (Right)

A

B

Copy A

Copy B

Original skew adjustment

Note:Make sure the copier is

adjusted correctly before

making this adjustment.

(1) Open the ADF.

(2)Loosen the ADF hinge mounting

screw.

(Right side)

(3) Move the ADF in "A" or "B" direction

as required, then tighten the screw.

Copy A: Move the ADF in "A" direction.

Copy B: Move the ADF in "B" direction.

6-6

SU010

Page 56

Location Shipping material /Procedure Check

4

Original registration adjustment

(1)Press the "User Preset", "Ledger/

A3 of Original Size" and "3" keys

simultaneously to enter the F mode.

(2)Press the "6" key to enter the F6

mode.

(3)Press the "Print" key then "3" and

"6" key or "3" and "7" to enter the

required F6 code.

F6-36: Non-inverted original

F6-37: Inverted original

(4) Press the "Print" key.

(5) Enter the new content.

Note: The "Reset" key is used to

enter the "-" content.

(6) Press the "Print" key.

(7) Press the "User Preset" and "Clear/

Stop" keys simultaneously to

escape from the F mode.

(8)Place an original on the platen

glass.

(9)

Make a copy to confirm the adjustment.

5

1

1

ADF Open/Close position change

(1)Loosen the 4 screws securing the

stopper plate.

(2) Change the position of the screws

Installation

to upper position.

Upper: 65 degrees (In use)

2

2

65°

90°

SU006

Lower: 90 degrees (In service)

6-7

Page 57

Back to Model List

FA-A888 Parts Manual [Revised]

Contents/Index

1. Frame ................................................................................... AF1

2. Original Feed Section -1....................................................... AF2

3. Original Feed Section -2....................................................... AF3

4. Original Feed Section -3....................................................... AF4

5. Original Exit Section ............................................................. AF5

6. Transport Belt Section .......................................................... AF6

7. Numerical Parts Index .......................................................... AF7

Frame

Section -1

Original Feed

Section -2

Original Feed

Section -3

Original Feed

NOTE: For optimum machine performance, use recommended

Panasonic Parts.

Section

Original Exit

Section

Transport Belt

Numerical

Parts Index

Page 58

Use and Ordering Information

For USA

1. Information contained in this Parts manual is subject to change.

Change notices and supplementary pages will be issued on a timely basis.

2. Electrical parts supplied may include previously used components.

3. A Numerical Part Number List is located at the rear of this manual.

4. This manual was developed and is supplied to authorized servicing dealers by

Panasonic Document Imaging Company. for the sole purpose of providing

information necessary for the equipment's proper support. It is intended that this

information be confidential and may not be reproduced without prior written

consent from Panasonic Document Imaging Company.

5. Panasonic Document Imaging Company. reserves the right to change any

information enclosed herein without prior notification.

(This includes, but is not limited to, parts pricing and availability, and text.)