Panasonic FA-A355 User Manual

FA-A355

Contents/Index

WARNING

I. Introduction

1.1 Specifications.......................................................................................... 1-1

1.2 Features.................................................................................................. 1-1

1.3 Exterior ................................................................................................... 1-2

1.4 Interior..................................................................................................... 1-2

II. Operation

2.1 Normal feeding (copy) ............................................................................ 2-1

III. Maintenance

3.1 Maintenance chart .................................................................................. 3-1

3.2 Cleaning.................................................................................................. 3-1

3.3 Disassembly/Assembly........................................................................... 3-2

IV. Electrical

4.1 Signal information by connector ............................................................. 4-1

4.2 Explanation of circuit............................................................................... 4-6

V. Troubleshooting

5.1 Error detection by self-diagnostics.......................................................... 5-1

5.2 Service mode.......................................................................................... 5-3

VI. Installation

6.1 Installation requirements......................................................................... 6-1

6.2 Unpacking............................................................................................... 6-2

6.3 Installation procedure ............................................................................. 6-3

6.4 Adjustment.............................................................................................. 6-6

ADF Driver PCB

Electrical Maintenance Operation Introduction

Installation

Troubleshooting

FA-A355 Back to Model List

WARNING

This service information is designed for experienced repair technicians only and

is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of

potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced

professional technicians. Any attempt to service or repair the product or products

dealt with in this service information by anyone else could result serious injury or

death.

(For USA)

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Communications & Systems Co. for the sole purpose of providing

information necessary for the equipment's proper support. It is intended that this

information be confidential and may not be reproduced without prior written consent

from Panasonic Communications & Systems Co. Panasonic Communications &

Systems Co. reserves the right to change any information enclosed herein without

prior notification.

© February, 1999

This manual was developed and is supplied to authorized servicing dealers by

Panasonic Co. for the sole purpose of providing information necessary for the

equipment's proper support. It is intended that this information be confidential

and may not be reproduced without prior written consent from Panasonic Co.

Panasonic Co. reserves the right to change any information enclosed herein without

prior notification.

1-1

Introduction

1. For use with: FP-D250/D350 Series

2. Original paper capacity: 50 sheets (20 lb/80 g/m

2

)

30 sheets (20 lb/80 g/m2) Ledger, Legal/A3,B4

3. Original size: Ledger to Invoice/A3 to A5

4. Original paper weight: 14 to 28 lb/50 to 110 g/m

2

5. Original feed speed: 35 sheets/min.

6. Power source: DC +24V (Supplied from copier)

7. Dimensions (W x H x D): 24.5" x 21.5" x 4.6"/622 x 546 x 117 mm

(without tray)

8. Weight: 24.2 lb/11 kg

9. Ambient conditions: Temperature 50˚F to 86˚F/10˚C to 30˚C

Relative humidity 30 to 80%

1.2 Features

• Original size feeding system

• Originals of different size but with the same width (Ledger/Letter, A3/A4) can be

combined for feeding.

• Original size detection system

• By placing the originals onto the tray, original size can be detected automatically.

• Realization of space saving

• Power unit is installed in the copier, so the document feeder is physically smaller.

• Capable of feeding originals up to Ledger/A3 size.

Section I Introduction

1.1 Specifications

1-2

1.3 Exterior

1.4 Interior

Original guides

Original exit cover

Original exit tray

ADF driver PCB

Door open/close sensor

Original pick up solenoid

Transport motor

ADF open/close sensor

Original feed motor

Paper exit deceleration

clutch

Original exit sensor 2

Original exit

sensor 1

Paper exit

switching solenoid

Registration

sensor

Original detecting

sensor

Original size detecting sensor

2-1

Operation

1

Section II Operation

2.1 Normal feeding (copy)

• Original feeding begins with the last page.

(1) When the start button is pressed, the paper feed motor and pick-up solenoid

are energized. The pick-up roller moves down towards the stack of originals

and transports the original on the top of the stack to the paper feed roller. The

entrance gate is opened and the paper feed roller rotates to feed the original to

the registration roller. Double feed prevention is provided by the lower paper

feed/double feed prevention roller.

The paper feed motor stops a predetermined time after the lead edge of the

original passes by the registration sensor. The original is held in place by the

resistration roller.

(2) The transport motor is energized and the registration roller begins to rotate.

The original is then transported to the original holding roller.

The original is scanned as it passes between the original holding roller and the

platen glass.

The paper exit switching solenoid is then energized and the paper exit-switching

claw is switched to the upper paper discharge position.

After the trail edge of the original passes by the original holding roller, the

transport motor stops.

Normal feeding (copy)

Fed from the last page of originals

3 (STOP)

4

5

Pick-up roller

Paper feed roller

Double feed prevention roller

Paper exit roller C

Paper exit roller F

Transport roller

Optical

Registration roller

2

2

3

4

5

1

2-2

(3) The paper feed motor and pick-up solenoid are energized again. The pick-up

roller moves down towards the stack of originals and the next original is fed.

The paper exit rollers rotate to discharge the original. During paper discharge

the deceleration clutch is released to ensure that the paper is neatly stacked in

the exit tray.

Paper exit roller C

Paper exit roller F

Transport roller

Paper feed roller

Double feed prevention roller

Registration roller

Pick-up roller

Optical

2

3

4

5

3-1

Maintenance

Cleaning

Replacement

Section III Maintenance

3.1 Maintenance chart

• In addition to the following maintenance table, the platen mat must be cleaned as

part of regular service calls.

• The timing of regular maintenance is determined on the basis of the number of

ADF original feed count. (F7-06)

Original feed roller/DFP roller

Original pick-up roller

Original detecting sensor

Registration sensor

Original exit sensor

Original support roller

Transport roller

Registration roller (upper)

Registration roller (lower)

Original exit roller (left)

(right)

Torque limiter spring

FFPMA0604

FFPMA0605

GP1A73A

FFPMA0609

FFPMA0607

FFPMA0606

FFPMA0608

FFPMA0602

FFPMA0603

FFPLR0287

Brush, air blower,

isopropyl alcohol (IPA)

Note: •Rollers should be

cleaned with water

and cloth.

•Use of IPA

(Isopropyl alcohol)

should be used

sparingly.

Part name

Part number

Remarks

3.2 Cleaning

Clean each rollers.

Maintenance interval

120,000

120,000

–––

–––

–––

–––

–––

–––

(Lubrication)

Exit roller Original feed roller

Pick-up roller

Registration roller

Transport roller

Original support roller

60,000

60,000

120,000

60,000

60,000

60,000

60,000

60,000

120,000

DFP roller (lower)

3-2

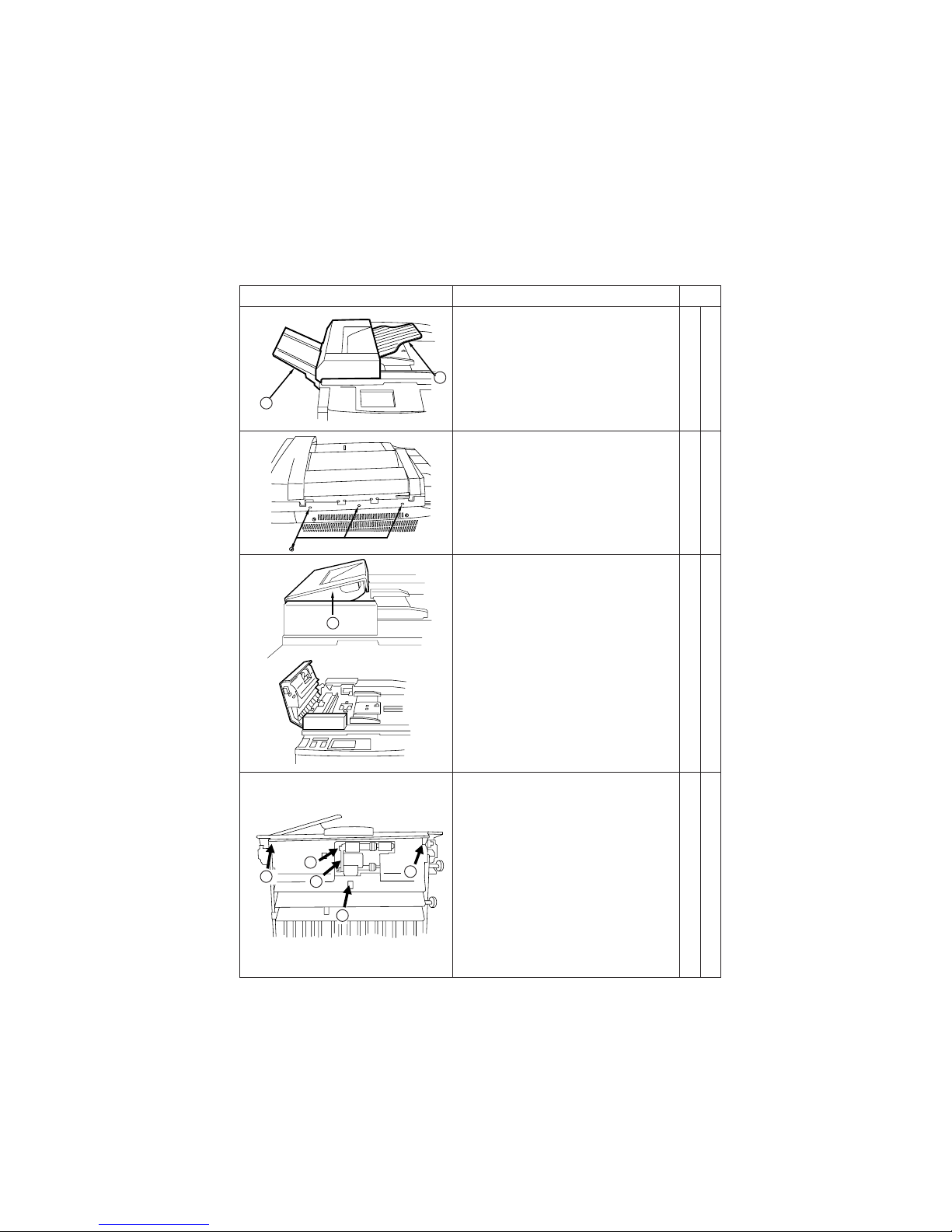

3.3 Disassembly/Assembly

Location Procedure

Check

1

2

(1) Remove the original catch tray 1.

(2) Remove the original catch tray 2.

(FA-F350)

(1) Remove the left side cover (3

screws).

3

(1) Open up the paper feed section.

(2) Remove the stopper (1 shoulder

screw).

Note: Removing the stopper allows

paper feed section to open

completely allowing easy

access to the feed rollers.

4

Removal of upper pick up roller

and paper feed/DFP roller

(1) Remove the original feed cover

(upper) (3 screws).

(2) Remove touch rings (x2).

(3) Remove the link.

(4) Slide the upper pick up roller and

paper feed roller off of their shafts.

(5) Replace rollers and reassemble

in reverse order.

2

1

1

2

3

1

1

2

Loading...

Loading...