Page 1

MICROCOMPUTER MN101C

MN101C77C/F77G

LSI User ’s Manual

Pub.No.21477-011E

Page 2

Page 3

PanaXSeries is a trademark of Matsushita Electric Industrial Co., Ltd.

The other corporation names, logotype and product names written in this book are trademarks or registered trademarks of their

corresponding corporations.

Request for your special attention and precautions in using the technical information

and semiconductors described in this book

(1) An export permit needs to be obtained from the competent authorities of the Japanese Government if any of

the products or technologies described in this book and controlled under the "Foreign Exchange and Foreign

Trade Law" is to be exported or taken out of Japan.

(2) The technical information described in this book is limited to showing representative characteristics and

applied circuits examples of the products. It neither warrants non-infringement of intellectual property right

or any other rights owned by our company or a third party, nor grants any license.

(3) W e are not liable for the infringement of rights owned by a third party arising out of the use of the product or

technologies as described in this book.

(4) The products described in this book are intended to be used for standard applications or general electronic

equipment (such as office equipment, communications equipment, measuring instrument s and household

appliances).

Consult our sales staff in advance for information on the following applications:

• Special applications (such as for airplanes, aerospace, automobiles, traffic control equipment, combustion

equipment, life support systems and safety devices) in which exceptional quality and reliability are required,

or if the failure or malfunction of the products may directly jeopardize life or harm the human body.

• Any applications other than the standard applications intended.

(5) The products and product specifications described in this book are subject to change without notice for

modification and/or improvement. At the final stage of your design, purchasing, or use of the prod ucts,

therefore, ask for the most up-to-date Product Standards in advance to make sure that the latest specifications

satisfy your requirements.

(6) When designing your equipment, comply with the guaranteed values, in particular those of maximum rating,

the range of operating power supply volta ge, and heat radiation characteristics. Otherwise, we will not be

liable for any defect which may arise later in your equipment.

Even when the products are used within the guaranteed values, take into the consideration of incidence of

break down and failure mode, possible to occur to semiconductor products. Measures on the systems such as

redundant design, arresting the spread of fire or preventing glitch are recommended in order to prevent

physical injury, fire, social damages, for example, by using the products.

(7) When using products for which damp-proof packing is required, observe the conditions (including shelf life

and amount of time let standing of unsealed items) agreed upon when specification sheets are individually

exchanged.

(8) This book may be not reprinted or reproduced whether wholly or partially, without the prior written

permission of Matsushita Electric Industrial Co., Ltd.

If you have any inquiries or questions about this book or our semiconductors, please contact one of our sales

offices listed at the back of this book.

Page 4

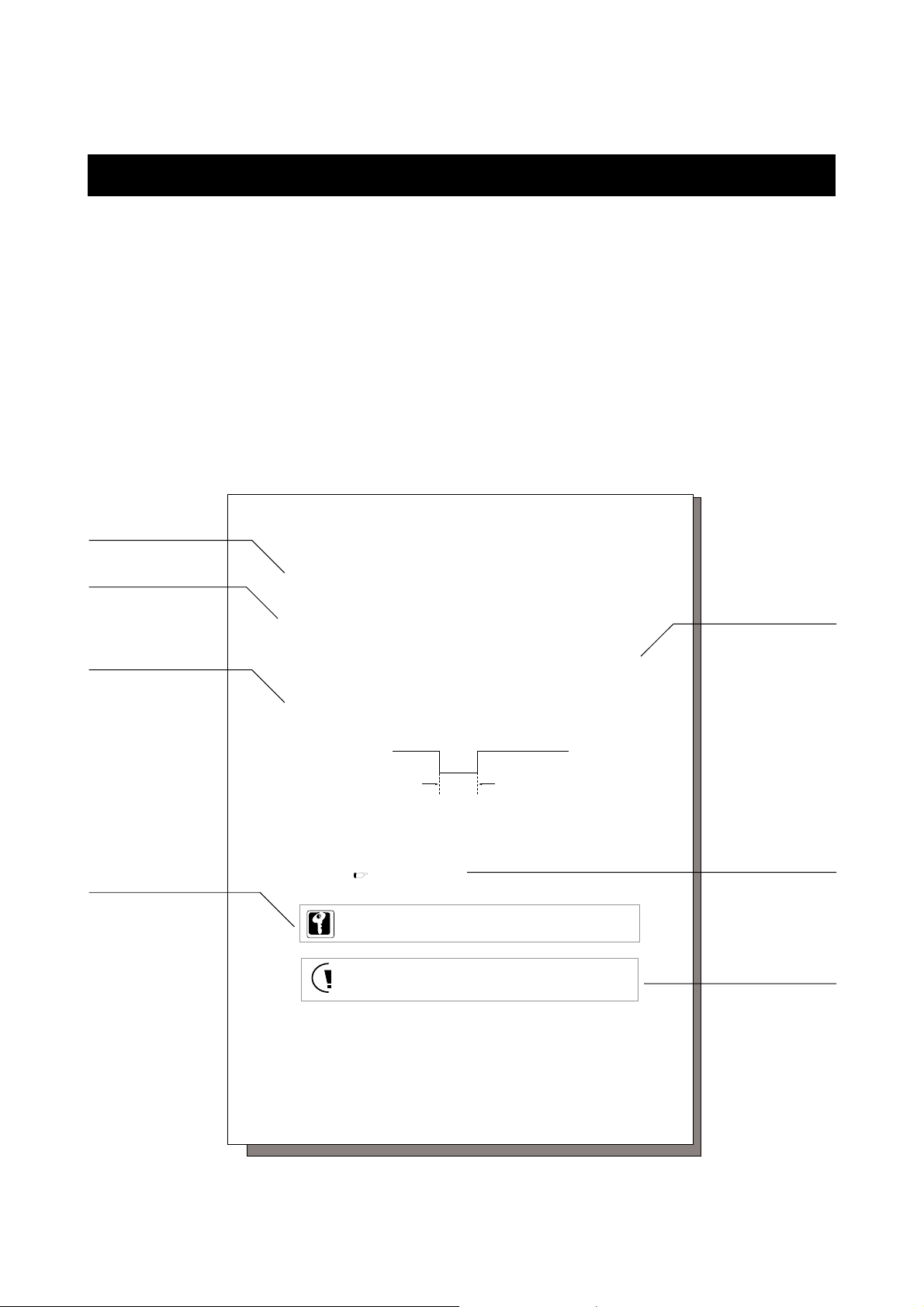

About This Manual

Organization

In this LSI manual, this LSI functions are presented in the following order : overview, basic CPU functions, interrupt

functions, port functions, timer functions, serial functions, and other peripheral hardware functions.

Each section contains overview of function, block diagram, control register, operation, and setting example.

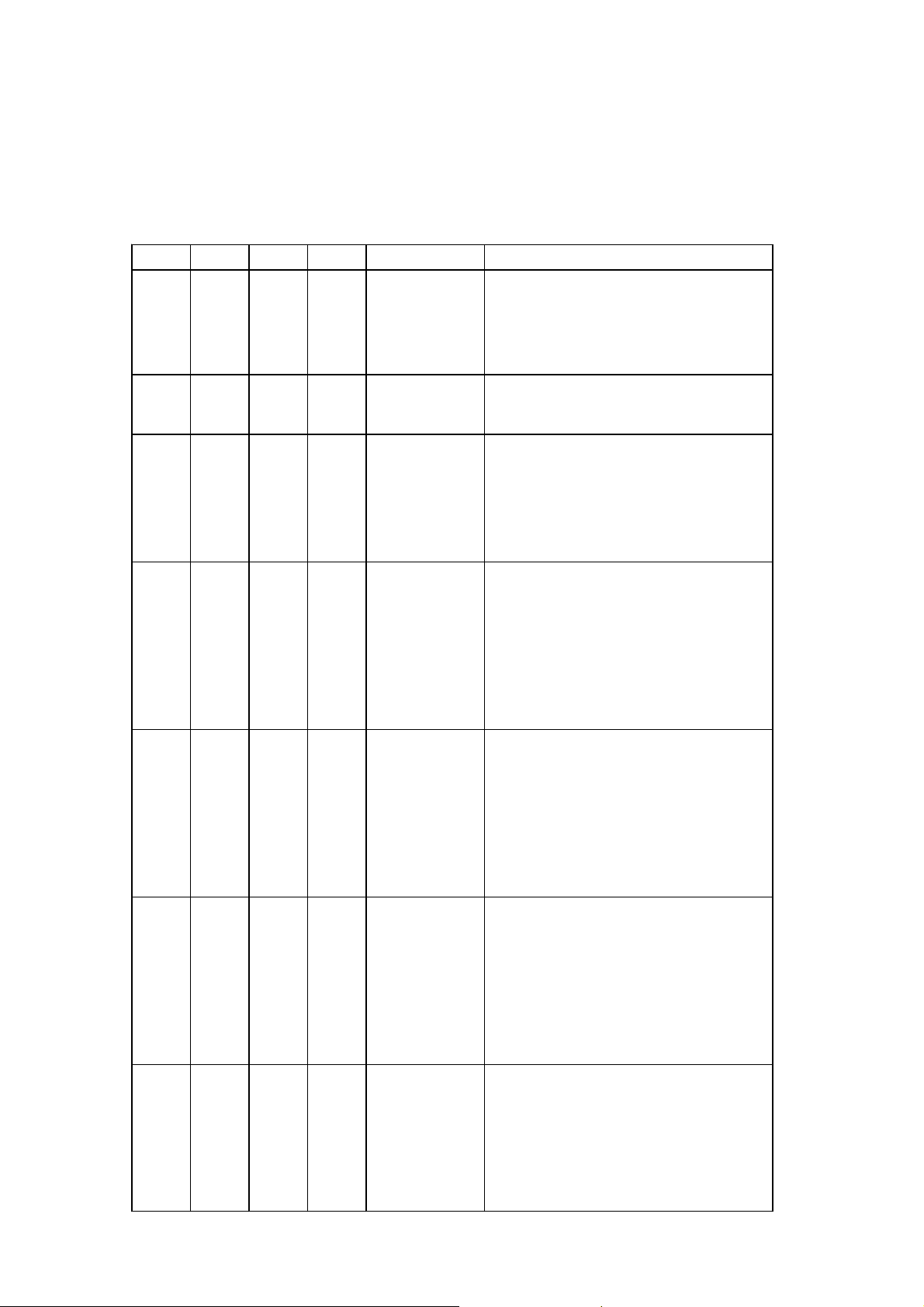

Manual Configuration

Each section of this manual consists of a title, summary, main text, key information, precautions and warnings, and

references.

The layout and definition of each section are shown below.

Subtitle

Sub-subtitle

The smallest block

in this manual.

Main text

Key information

Important information

from the text.

Chapter 2 Basic CPU

2-8 Reset

2-8-1 Reset operation

The CPU contents are reset and registers are initialized when the NRST pin (P.27) is pulled to low.

Initiating a Reset

There are two methods to initiate a reset.

(1) Drive the NRST pin low for at least four clock cycles.

NRST pin should be holded "low" for more than 4 clock cycles (200 nS at a 20 MHz).

NRST pin

4 clock cycles

(200 nS at a 20 MHz)

Figure 2-8-1 Minimum Reset Pulse Width

(2) Setting the P2OUT7 flag of the P2OUT register to "0" outputs low level at P27 (NRST) pin. And

transfering to reset by program (software reset) can be executed. If the internal LSI is reset and

register is initiated, the P2OUT7 flag becomes "1" and reset is released.

[ Chapter 4. 4-4-2 Registers ]

On this LSI, the starting mode is NORMAL mode that high oscillation is the base clock.

When the power voltage low circuit is connected to NRST pin, circuit that gives pulse for

enough low level time at sudeen unconnected. And reset can be generated even if its pulse

is low level as the oscillation clock is under 4 clocks, take notice of noise.

Summary

Introduction to the

section.

References

References for the

main text.

Precautions and

warnings

Precautions are listed

in case.

Be sure to read these

of lost functionality or

damage.

About This Manual 1

II - 44

Reset

Page 5

Finding Desired Information

This manual provides three methods for finding desired information quickly and easily.

(1) Consult the index at the front of the manual to locate the beginning of each section.

(2) Consult the table of contents at the front of the manual to locate desired titles.

(3) Chapter names are located at the top outer corner of each page, and section titles are located

at the bottom outer corner of each page.

Related Manuals

Note that the following related documents are available.

"MN101C Series LSI user's Manual"

<Describes the device hardware>

"MN101C Series Instruction Manual"

<Describes the instruction set.>

"MN101C Series C Compiler User's Manual: Usage Guide"

<Describes the installation, the commands, and options of the C Compiler.>

"MN101C Series C Compiler User's Manual: Language Description"

<Describes the syntax of the C Compiler.>

"MN101C Series C Compiler User's Manual: Library Reference"

<Describes the standard library of the C Compiler.>

"MN101C Series Cross-assembler User's Manual"

<Describes the assembler syntax and notation.>

"MN101C Series C Source Code Debugger User's Manual"

<Describes the use of C source code debugger.>

"MN101C Series PanaX Series Installation Manual"

<Describes the installation of C compiler, cross-assembler and C source code debugger

and the procedure for bringing up the in-circuit emulator.>

About This Manual 2

Page 6

Page 7

Chapter 1 Overview

1

Chapter 2 CPU Basics

Chapter 3 Interrupts

2

3

3

Chapter 4 I/O Ports

Chapter 5 Prescaler 5

Chapter 6 8-bit Timers

Chapter 7 16-bit Timer

Chapter 8 Time Base Timer /

8-bit Free-running Timer

4

6

7

8

11

2

Chapter 9 Watchdog Timer

Chapter 10 Buzzer

Chapter 11 Serial Interface 0,1

Chapter 12 Serial Interface 3

Chapter 13 Serial Interface 4

Chapter 14 Automatic Transfer

Controller

Chapter 15 A/D Converter

9

10

11

12

13

14

15

Chapter 16 D/A Converter

Chapter 17 Appendices

Chapter 18 Flash EEPROM

16

17

18

Page 8

Contents

Chapter 1 Overview

1-1 Overview ..................................................................................................................... I - 2

1-1-1 Overview .................................................................................................... I - 2

1-1-2 Product Summary ....................................................................................... I - 2

1-2 Hardware Functions .................................................................................................... I - 3

1-3 Pin Description............................................................................................................ I - 9

1-3-1 Pin Configuration ....................................................................................... I - 9

1-3-2 Pin Specification....................................................................................... I - 10

1-3-3 Pin Functions ........................................................................................... I - 1 1

1- 4 Block Diagram ........................................................................................................... I - 17

1-4-1 Block Diagram .......................................................................................... I - 1 7

1- 5 Electrical Characteristics ........................................................................................... I - 18

1-5-1 Absolute Maximum Ratings ..................................................................... I - 18

1-5-2 Operating Conditions ............................................................................... I - 19

1-5-3 DC Characteristics .................................................................................... I - 22

1-5-4 A/D Converter Characteristics ................................................................. I - 26

1-5-5 D/A Converter Characteristics ................................................................. I - 27

1-6 Precautions................................................................................................................ I - 28

1-6-1 General Usage .......................................................................................... I - 28

1-6-2 Unused Pins ............................................................................................. I - 2 9

1-6-3 Power Supply ........................................................................................... I - 31

1-6-4 Power Supply Circuit................................................................................ I - 32

1-7 Package Dimension ................................................................................................... I - 33

Chapter 2 CPU Basics

2-1 Overview.................................................................................................................. II - 2

2-1-1 Block Diagram ....................................................................................... II - 3

2-1-2 CPU Control Registers ........................................................................... II - 4

2-1-3 Instruction Execution Controller ........................................................... II - 5

2-1-4 Pipeline Process...................................................................................... II - 6

2-1-5 Registers for Address.............................................................................. II - 6

2-1-6 Registers for Data ................................................................................... II - 7

2-1-7 Processor Status Word ............................................................................ II - 8

2-1-8 Addressing Modes ............................................................................... II - 10

2-2 Memory Space....................................................................................................... II - 12

2-2-1 Memory Mode ...................................................................................... II - 12

2-2-2 Single-chip Mode ................................................................................. II - 13

2-2-3 Special Function Registers...................................................................... II - 14

2-3 Bus Interface ............................................................................................................ II - 15

ii

contents

Page 9

2-3-1 Bus Controller ......................................................................................... II - 15

2-3-2 Control Registers..................................................................................... II - 16

2-4 Standby Function..................................................................................................... II - 19

2-4-1 Overview ................................................................................................. II - 19

2-4-2 CPU Mode Control Register.................................................................... II - 2 1

2-4-3 Transition between SLOW and NORMAL.............................................. II - 22

2-4-4 Transition to ST ANDBY Modes ............................................................. II - 23

2- 5 Clock Switching........................................................................................................ II - 25

2-6 Bank Function .......................................................................................................... II - 27

2-6-1 Overview ................................................................................................. II - 27

2-6-2 Bank Setting ............................................................................................ II - 27

2-6-3 Bank Memory Space ............................................................................... II - 29

2- 7 ROM Correction ....................................................................................................... II - 30

2-7-1 Overview ................................................................................................. II - 30

2-7-2 Correction Sequence ............................................................................... II - 30

2-7-3 ROM Correction Control Register ........................................................... II - 32

2-7-4 ROM Correction Setup Example .............................................................. II - 35

2-8 Reset ........................................................................................................................ II - 38

2-8-1 Reset Operation....................................................................................... II - 38

2-8-2 Oscillation Stabilization W ait T ime.......................................................... II - 40

2-9 Register Protection................................................................................................... II - 42

2-9-1 Overview ................................................................................................. II - 42

2-9-2 Setting of the Register Protection Function ............................................ II - 4 2

2-9-3 Rewrite Procedure ................................................................................... II - 42

Chapter 3 Interrupts

3-1 Overview................................................................................................................. III - 2

3-1-1 Functions ............................................................................................... III - 3

3-1-2 Block Diagram ...................................................................................... III - 4

3-1-3 Operation ............................................................................................... III - 5

3-1-4 Interrupt Flag Setup............................................................................... III - 14

3-2 Control Registers.................................................................................................. III - 15

3-2-1 Registers List ....................................................................................... III - 15

3-2-2 Interrupt Control Registers.................................................................. III - 16

3-3 External Interrupts ................................................................................................... III - 38

3-3-1 Overview ................................................................................................ III - 38

3-3-2 Block Diagram ........................................................................................ III - 39

3-3-3 Control Registers.................................................................................... III - 42

3-3-4 Programmable Active Edge Interrupt ..................................................... III - 47

3-3-5 Both Edges Interrupt.............................................................................. III - 48

3-3-6 Key Input Interrupt ................................................................................ III - 19

3-3-7 Noise Filter ............................................................................................. III - 51

iii

contents

Page 10

3-3-8 AC Zero-Cross Detector ........................................................................ III - 54

Chapter 4 I/O Ports

4-1 Overview .................................................................................................................. IV - 2

4-1-1 I/O Port Diagram...................................................................................... IV - 2

4-1-2 I/O Port Status at Reset ........................................................................... IV - 3

4-1-3 Control Registers..................................................................................... IV - 4

4-2 Port 0 ........................................................................................................................ IV - 6

4-2-1 Description.............................................................................................. IV - 6

4-2-2 Registers ................................................................................................. IV - 7

4-2-3 Block Diagram ......................................................................................... IV - 8

4-3 Port 1 ....................................................................................................................... IV - 12

4-3-1 Description............................................................................................. IV - 12

4-3-2 Registers ................................................................................................ IV - 13

4-3-3 Block Diagram ........................................................................................ IV - 16

4-4 Port 2 ....................................................................................................................... IV - 17

4-4-1 Description............................................................................................. IV - 17

4-4-2 Registers ................................................................................................ IV - 18

4-4-3 Block Diagram ........................................................................................ IV - 19

4-5 Port 5 ....................................................................................................................... IV - 21

4-5-1 Description............................................................................................. IV - 21

4-5-2 Registers ................................................................................................ IV - 22

4-5-3 Block Diagram ........................................................................................ IV - 23

4-6 Port 6 ....................................................................................................................... IV - 26

4-6-1 Description............................................................................................. IV - 26

4-6-2 Registers ................................................................................................ IV - 27

4-6-3 Block Diagram ........................................................................................ IV - 29

4-7 Port 7 ....................................................................................................................... IV - 30

4-7-1 Description............................................................................................. IV - 30

4-7-2 Registers ................................................................................................ IV - 31

4-7-3 Block Diagram ........................................................................................ IV - 33

4-8 Port 8 ....................................................................................................................... IV - 37

4-8-1 Description............................................................................................. IV - 37

4-8-2 Registers ................................................................................................ IV - 38

4-8-3 Block Diagram ........................................................................................ IV - 40

4-9 Port A ...................................................................................................................... IV - 41

4-9-1 Description............................................................................................. IV - 41

4-9-2 Registers ................................................................................................ IV - 42

4-9-3 Block Diagram ........................................................................................ IV - 44

4-10 Real Time Output Control (Port 1) ........................................................................... IV - 45

iv

contents

Page 11

4-10-1 Registers ................................................................................................ IV - 45

4-10-2 Operation................................................................................................ IV - 46

4-11 Synchronous Output (Port 7) .................................................................................. IV - 4 8

4-11-1 Block Diagram ........................................................................................ IV - 48

4-11-2 Registers ................................................................................................ IV - 49

4-11-3 Operation................................................................................................ IV - 50

4-11-4 Setup Example ........................................................................................ IV - 52

Chapter 5 Prescaler

5-1 Overview .................................................................................................................... V - 2

5-1-1 Peripheral Functions ................................................................................. V - 3

5-1-2 Block Diagram ........................................................................................... V - 4

5-2 Control Registers........................................................................................................ V - 5

5-2-1 Registers List............................................................................................. V - 5

5-2-2 Control Registers....................................................................................... V - 6

5-3 Operation.................................................................................................................. V - 11

5-3-1 Operation................................................................................................. V - 11

5-3-2 Setup Example ......................................................................................... V - 12

Chapter 6 8-bit T imers

6-1 Overview................................................................................................................. VI - 2

6-1-1 Functions .................................................................................................VI - 2

6-1-2 Block Diagram ........................................................................................VI - 3

6-2 Control Registers...................................................................................................... VI - 6

6-2-1 Registers ................................................................................................. VI - 6

6-2-2 Programmable Timer Registers ................................................................ VI - 8

6-2-3 Timer Mode Registers ............................................................................ VI - 10

6- 3 8-bit Timer Count..................................................................................................... VI - 15

6-3-1 Operation................................................................................................ VI - 15

6-3-2 Setup Example ........................................................................................ VI - 17

6-4 8-bit Event Count .................................................................................................... VI - 19

6-4-1 Operation................................................................................................ VI - 19

6-4-2 Setup Example ........................................................................................ VI - 21

6-5 8-bit Timer Pulse Output ......................................................................................... VI - 23

6-5-1 Operation................................................................................................ VI - 23

6-5-2 Setup Example ........................................................................................ VI - 24

6-6 8-bit PWM Output .................................................................................................. VI - 26

6-6-1 Operation................................................................................................ VI - 26

6-6-2 Setup Example ........................................................................................ VI - 28

6-7 8-bit Timer Synchronous Output............................................................................. VI - 3 0

v

contents

Page 12

6-7-1 Operation................................................................................................ VI - 30

6-7-2 Setup Example ........................................................................................ VI - 31

6-8 Serial Interface Transfer Clock Output .................................................................... VI - 33

6-8-1 Operation................................................................................................ VI - 33

6-8-2 Setup Example ........................................................................................ VI - 34

6-9 Simple Pulse W idth Measurement........................................................................... VI - 36

6-9-1 Operation................................................................................................ VI - 36

6-9-2 Setup Example ........................................................................................ VI - 37

6-10 Cascade Connection ............................................................................................... VI - 3 9

6-10-1 Operation................................................................................................ VI - 39

6-10-2 Setup Example ........................................................................................ VI - 41

6-11 Remote Control Carrier Output ................................................................................ VI - 43

6-11-1 Operation................................................................................................ VI - 43

6-11-2 Setup Example ........................................................................................ VI - 44

Chapter 7 16-bit T imer

7-1 Overview................................................................................................................ VII - 2

7-1-1 Functions .............................................................................................. VII - 2

7-1-2 Block Diagram ..................................................................................... VII - 3

7-2 Control Registers................................................................................................... VII - 4

7-2-1 Registers ............................................................................................... VII - 4

7-2-2 Programmable Timer Registers............................................................ VII - 5

7-2-3 Timer Mode Registers.......................................................................... VII - 8

7-3 16-bit Timer Count .............................................................................................. VII - 10

7-3-1 Operation ............................................................................................ VII - 10

7-3-2 Setup Example.................................................................................... VII - 13

7-4 16-bit Event Count .............................................................................................. VII - 15

7-4-1 Operation ............................................................................................ VII - 15

7-4-2 Setup Example.................................................................................... VII - 17

7-5 16-bit Timer Pulse Output................................................................................... VII - 19

7-5-1 Operation ............................................................................................ VII - 19

7-5-2 Setup Example.................................................................................... VII - 21

7-6 16-bit Standard PWM Output

(Only duty can be changed consecutively) .................................... VII - 23

7-6-1 Operation ............................................................................................ VII - 23

7-6-2 Setup Example.................................................................................... VII - 25

7-7 16-bit High Precision PWM Output

(Cycle/Duty can be changed consecutively)...................................... VII - 27

7-7-1 Operation ............................................................................................ VII - 27

7-7-2 Setup Example.................................................................................... VII - 29

7-8 16-bit Timer Synchronous Output ...................................................................... VII - 31

vi

contents

Page 13

7-8-1 Operation ............................................................................................ VII - 31

7-8-2 Setup Example.................................................................................... VII - 32

7-9 16-bit Timer Capture ........................................................................................... VII - 34

7-9-1 Operation ............................................................................................ VII - 34

7-9-2 Setup Example.................................................................................... VII - 37

Chapter 8 Time Base Timer / 8-bit Free-running Timer

8-1 Overview ................................................................................................................ VIII - 2

8-1-1 Functions .............................................................................................. VIII - 2

8-1-2 Block Diagram ....................................................................................... VIII - 3

8-2 Control Registers.................................................................................................... VIII - 4

8-2-1 Control Registers................................................................................... VIII - 4

8-2-2 Programmable Timer Registers .............................................................. VIII - 5

8-2-3 Timer Mode Registers ........................................................................... VIII - 6

8- 3 8-bit Free-running Timer......................................................................................... VIII - 7

8-3-1 Operation............................................................................................... VIII - 7

8-3-2 Setup Example ..................................................................................... VIII - 10

8- 4 Time Base Timer ................................................................................................... VIII - 12

8-4-1 Operation............................................................................................. VIII - 12

8-4-2 Setup Example ..................................................................................... VIII - 14

Chapter 9 Watchdog Timer

9-1 Overview................................................................................................................. IX - 2

9-1-1 Block Diagram ...................................................................................... IX - 2

9-2 Control Registers.................................................................................................... IX - 3

9-3 Operation ................................................................................................................ IX - 4

9-3-1 Operation ............................................................................................... IX - 4

9-3-2 Setup Example....................................................................................... IX - 7

Chapter 10 Buzzer

10-1 Overview ................................................................................................................... X - 2

10-1-1 Block Diagram .......................................................................................... X - 2

10-2 Control Register ........................................................................................................ X - 3

10-3 Operation................................................................................................................... X - 4

10-3-1 Operation.................................................................................................. X - 4

10-3-2 Setup Example .......................................................................................... X - 5

Chapter 11 Serial Interface 0,1

vii

contents

Page 14

11-1 Overview .................................................................................................................. XI - 2

11-1-1 Functions ................................................................................................ XI - 2

11-1-2 Block Diagram ......................................................................................... XI - 4

11-2 Control Registers...................................................................................................... XI - 6

11-2-1 Registers ................................................................................................. XI - 6

11-2-2 Serial Interface 0 Data Buffer Registers ................................................... XI - 7

11-2-3 Serial Interface 0 Mode Registers............................................................ XI - 8

11-2-4 Serial Interface 1 Data Buffer Registers ................................................. XI - 14

11-2-5 Serial Interface 1 Mode Registers.......................................................... XI - 15

11-3 Operation................................................................................................................ XI - 21

11-3-1 Clock Synchronous Serial Interface ...................................................... XI - 21

11-3-2 Serial interface 0 Synchronous Serial Interface Pin Setup ..................... XI - 33

11-3-3 Serial interface 1 Synchronous Serial Interface Pin Setup ..................... XI - 36

11-3-4 Setup Example ....................................................................................... XI - 39

11-3-5 UART Serial Interface............................................................................ XI - 4 2

11-3-6 Serial interface 0 UART Serial Interface Pin Setup ................................ XI - 5 4

11-3-7 Serial interface 1 UART Serial Interface Pin Setup ................................ XI - 5 6

11-3-8 Setup Example ....................................................................................... XI - 58

Chapter 12 Serial Interface 3

12-1 Overview............................................................................................................... XII - 2

12-1-1 Functions ............................................................................................. XII - 2

12-1-2 Block Diagram .................................................................................... XII - 3

12-2 Control Registers .................................................................................................. XII - 4

12-2-1 Registers .............................................................................................. XII - 4

12-2-2 Data Buffer Registers .......................................................................... XII - 5

12-2-3 Mode Registers ...................................................................................... XII - 6

12-3 Operation............................................................................................................... XII - 10

12-3-1 Clock Synchronous Serial Interface ..................................................... XII - 10

12-3-2 Setup Example ...................................................................................... XII - 24

12-3-3 Single Master IIC Interface................................................................... XII - 27

12-3-4 Setup Example ...................................................................................... XII - 36

Chapter 13 Serial Interface 4

13-1 Overview ................................................................................................................ XIII - 2

13-1-1 Functions .............................................................................................. XIII - 2

viii

contents

Page 15

13-1-2 Block Diagram ....................................................................................... XIII - 3

13-2 Control Registers.................................................................................................... XIII - 4

13-2-1 Registers List......................................................................................... XIII - 4

13-2-2 Data Register......................................................................................... XIII - 5

13-2-3 Mode Registers ..................................................................................... XIII - 6

13-3 Operation................................................................................................................ XIII - 9

13-3-1 Setup Example of the Slave IIC Serial Interface ................................... XIII - 11

Chapter 14 Automatic Transfer Controller

14-1 Overview ................................................................................................................ XIV - 2

14-1-1 A TC1 ..................................................................................................... XIV - 2

14-1-2 Functions .............................................................................................. XIV - 3

14-1-3 Block Diagram ....................................................................................... XIV - 4

14-2 Control Registers.................................................................................................... XIV - 5

14-2-1 Registers ............................................................................................... XIV - 5

14-3 Operation................................................................................................................ XIV - 9

14-3-1 Basic Operations and Timing ................................................................ XIV - 9

14-3-2 Setting the Memory Address .............................................................. XIV - 11

14-3-3 Setting the Data Transfer Count ......................................................... XIV - 12

14-3-4 Setting the Data Transfer Modes ........................................................ XIV - 13

14-3-5 Transfer Mode 0.................................................................................. XIV - 14

14-3-6 Transfer Mode 1.................................................................................. XIV - 15

14-3-7 Transfer Mode 2.................................................................................. XIV - 16

14-3-8 Transfer Mode 3.................................................................................. XIV - 17

14-3-9 Transfer Mode 4.................................................................................. XIV - 18

14-3-10 Transfer Mode 5.................................................................................. XIV - 19

14-3-11 Transfer Mode 6.................................................................................. XIV - 20

14-3-12 Transfer Mode 7.................................................................................. XIV - 22

14-3-13 Transfer Mode 8.................................................................................. XIV - 24

14-3-14 Transfer Mode 9.................................................................................. XIV - 26

14-3-15 Transfer Mode A................................................................................. XIV - 28

14-3-16 Transfer Mode B ................................................................................. XIV - 29

14-3-17 Transfer Mode C ................................................................................. XIV - 30

14-3-18 Transfer Mode D ................................................................................. XIV - 31

14-3-19 Transfer Mode E ................................................................................. XIV - 32

14-3-20 Transfer Mode F ................................................................................. XIV - 33

14-4 Setup Example ...................................................................................................... XIV - 34

Chapter 15 A/D Converter

15-1 Overview ................................................................................................................. XV - 2

15-1-1 Functions ............................................................................................... XV - 2

ix

contents

Page 16

15-1-2 Block Diagram ........................................................................................ XV - 3

15-2 Control Registers..................................................................................................... XV - 4

15-2-1 Registers ................................................................................................ XV - 4

15-2-2 Control Registers.................................................................................... XV - 5

15-2-3 Data Buffers ........................................................................................... XV - 7

15-3 Operation................................................................................................................. XV - 8

15-3-1 Setup .................................................................................................... XV - 1 0

15-3-2 Setup Example ...................................................................................... XV - 12

15-3-3 Cautions ............................................................................................... XV - 16

Chapter 16 D/A Converter

16-1 Overview ................................................................................................................ XVI - 2

16-1-1 Functions .............................................................................................. XVI - 2

16-2 Operation................................................................................................................ XVI - 3

16-3 Control Registers.................................................................................................... XVI - 4

16-3-1 Overview ............................................................................................... XVI - 4

16-3-2 Control Registers................................................................................... XVI - 5

16-3-3 Input Data Register ............................................................................... XVI - 6

16-4 Setup Example ........................................................................................................ XVI - 7

Chapter 17 Appendices

17-1 Probe Switches ..................................................................................................... XVII - 2

17-1-1 PRB-MBB101C77-M.............................................................................. XVII - 2

17-1-2 PX-CN101-M ......................................................................................... XVII - 3

17-1-3 PX-ADP101-64-M.................................................................................. XVII - 4

17-1-4 PRB-DMY101C77-M ............................................................................. XVII - 5

17-2 Special Function Registers List ............................................................................ XVII - 6

17-3

Instruction Set..................................................................................................... XVII - 15

17-4

Instruction Map .................................................................................................. XVII - 21

Chapter 18 Flash EEPROM

18-1 Overview ............................................................................................................. XVIII - 2

18-1-1 Overview .............................................................................................. XVIII - 2

18-1-2 Differences between Mask ROM version and EPROM version........... XVIII - 4

18-2 Pin Descriptions .................................................................................................. XVIII - 5

18-3 Electrical Characteristics ..................................................................................... XVIII - 6

18-3-1 Absolute Maximum Ratings ................................................................. XVIII - 6

18-3-2 Operating Conditions ........................................................................... XVIII - 7

18-3-3 DC Characteristics ................................................................................ XVIII - 8

x

contents

Page 17

18-4 Reprogramming Flow........................................................................................... XVIII - 9

18-5 PROM writer mode ............................................................................................ XV III - 10

18-6 Onboard Serial Programming Mode .................................................................. XVII I - 1 2

18-6-1 Overview ............................................................................................ XVIII - 12

18-6-2 Circuit Requirements for the T arget Board (in Clock Synchronous

Communication using the YDC Serial Writer)..................................... XVIII - 13

18-6-3 Circuit Requirements for the T arget Board (in Clock Synchronous

Communication using the PanaX Serial Writer).................................. XVIII - 16

xi

contents

Page 18

Page 19

Chapter 1 Overview

1

Page 20

Chapter 1 Overview

1-1 Overview

1-1-1 Overview

The MN101C series of 8-bit single-chip microcontroller incorporates multiple types of peripheral functions.

This chip series is well suited for camera, VCR, MD, TV, CD, LD, printer, telephone, home automation

products, pager, air conditioner, PPC remote control, fax machine, musical instrument, and other applications.

The MN101C77 series brings to embedded microcontroller applications flexible, optimized hardware

configurations and a simple efficient instruction set. The MN101C77C has an internal 48 KB of ROM and

3 KB of RAM. Peripheral functions include 5 external interrupts, 17 internal interrupts including NMI,

independent 6 timer counters, 4 sets of serial interfaces, A/D converter, D/A converter, watchdog timer,

automatic data transfer, synchronous output, buzzer output, and remote control output. The configuration of this microcontroller is well suited for application such as a system controller in a camera, VCR

selection timer, CD player, or MD.

With two oscillation systems (max.20 MHz/32 kHz) contained on the chip, the system clock can be

switched to high speed oscillation (NORMAL mode), or to low speed oscillation (SLOW mode). The

system clock is generated by dividing the oscillation clock. The best operation clock for the system can

be selected by switching its frequency by software. There are 2 choices for high speed oscillation : the

normal mode, which has a system clock based on the clock (fosc/2) divided by 2, and the 2x-speed

mode, which has a system clock based on the same cycle clock (fosc).

On the normal mode, when the oscillation source(fosc) is 8 MHz, minimum instructions execution

time is for 250 ns, and when fosc is 20 MHz, it is 100 ns. On the 2x-speed mode, CPU is operated with

the same cycle to the external clock, when fosc is 8 MHz, minimum instructions execution time is 125 ns.

The packages are 64-pin LQFP and 64-pin TQFP (under development).

1-1-2 Product Summary

This manual describes the following models of the MN101C77 series. These products have same peripheral functions. (Refer to chapter 18 Flash EEPROM for Flash version.)

Table 1-1-1 Product Summary

Model ROM Size RAM Size Classification

MN101C77C 48 KB 3 KB Mask ROM version

MN101CF77G 128 KB 6 KB Flash EEPROM version

I - 2

Overview

Page 21

1-2 Hardware Functions

CPU Core MN101C Core

- LOAD-STORE architecture (3-stage pipeline)

- Half-byte instruction set / Handy addressing

- Memory addressing space is 256 KB

- Minimum instructions execution time (3.0 V to 3.6 V for Flash version)

High speed oscillation

[normal] 0.10 µs / 20 MHz (2.5 V to 3.6 V)

0.50 µs / 4 MHz (1.8 V to 3.6 V)

[2x-speed] 0.119 µs / 8.39 MHz (2.5 V to 3.6 V)

Low speed oscillation 61.04 µs / 32.768 kHz (1.8 V to 3.6 V)

- Operation modes

NORMAL mode ( High speed oscillation )

SLOW mode ( Low speed oscillation )

HALT mode

STOP mode

(The operation clock can be switched in each mode.)

Chapter 1 Overview

0.20 µs / 10 MHz (2.1 V to 3.6 V)

Memory bank Data memory space expansion by bank form (4 banks unit : 64 KB / 1 bank)

- Bank for source address / Bank for destination address

ROM correction Max.3 parts in program can be corrected

Internal memory ROM 48 KB (Flash version 128 KB)

RAM 3 KB (Flash version 6 KB)

Interrupts 17 Internal interrupts

<Non-maskable interrupt (NMI)>

- Incorrect code execution interrupt and Watchdog timer interrupt

< Timer interrupts >

- Timer 0 interrupt (8-bit timer)

- Timer 1 interrupt (8-bit timer)

- Timer 4 interrupt (8-bit timer)

- Timer 5 interrupt (8-bit timer)

- Timer 6 interrupt (8-bit timer)

- Time base interrupt (8-bit timer)

- Timer 7 interrupt (16-bit timer)

- Match interrupt for Timer 7 compare register 2

Hardware Functions

I - 3

Page 22

Chapter 1 Overview

< Serial interface interrupts >

- Serial interface 0 reception interrupt (Full-Duplex UART)

- Serial interface 0 transmission interrupt (synchronous + Full-Duplex UART)

- Serial interface 1 reception interrupt (Full-Duplex UART)

- Serial interface 1 transmission interrupt (synchronous + Full-Duplex UART)

- Serial interface 3 interrupt (synchronous + single master IIC)

- Serial interface 4 interrupt (slave IIC)

< A/D interrupt >

- A/D converter interrupt

< Automatic transfer controller(ATC) interrupt >

- ATC 1 interrupt

5 External interrupts (with/without noise filter)

- IRQ0 : Edge selectable. Both edges interrupt.

- IRQ1 : Edge selectable. Both edges interrupt. AC zero cross detector.

- IRQ2 : Edge selectable. Both edges interrupt.

- IRQ3 : Edge selectable. Both edges interrupt.

- IRQ4 : Edge selectable. Both edges interrupt. Key interrupt function.

Timers

7 timers ( 6 can operate independently )

- 8-Bit timer for general use 2 sets

- 8-Bit timer for general use (UART baud rate timer) 2 sets

- 8-Bit free-running timer 1 set

Time base timer 1 set

- 16-Bit timer for general use 1 set

Timer 0 ( 8-Bit timer for general use )

- Square wave output ( Timer pulse output ), PWM output,

Event count, Remote control carrier output, Simple pulse width measurement

- Clock source

fosc, fosc/4, fosc/16, fosc/32, fosc/64, fs/2, fs/4, fx, external clock

Timer 1 ( 8-Bit timer for general use )

- Square wave output ( Timer pulse output ), Event count,

16-Bit cascade connection function ( connected to timer 0 ), Timer

synchronous output

- Clock source

fosc, fosc/4, fosc/16, fosc/64, fosc/128, fs/2, fs/8, fx, external clock

I - 4

Hardware Functions

Page 23

Timer 4 ( 8-Bit timer for general use or UART baud rate timer )

- Square wave output ( Timer pulse output ), PWM output, Event count

Simple pulse width measurement, Serial interface transfer clock

- Clock source

fosc, fosc/4, fosc/16, fosc/32, fosc/64, fs/2, fs/4, fx, external clock

Timer 5 ( 8-Bit timer for general use or UART baud rate timer )

- Square wave output ( Timer pulse output ), PWM output, Event count,

Remote control carrier output, Simple pulse width measurement,

Serial interface transfer clock

- Clock source

fosc, fosc/4, fosc/16, fosc/32, fosc/64, fs/2, fs/4, fx, external clock

Timer 6 ( 8-Bit free-running timer, Time base timer )

8-Bit free-running timer

- Clock source

fosc, fosc/212, fosc/213, fs, fx, fx/212, fx/2

13

Time base timer

- Interrupt generation cycle

fosc/27, fosc/28, fosc/29, fosc/210, fosc/213, fosc/215,

fx/27, fx/28, fx/29, fx/210, fx/213, fx/2

15

Chapter 1 Overview

Timer 7 ( 16-Bit timer for general use )

- Clock source

fosc, fosc/2, fosc/4, fosc/16, fs, fs/2, fs/4, fs/16,

1/1, 1/2, 1/4, 1/16 of the external clock

- Hardware organization

Compare register with double buffer 2 sets

Input capture register 1 set

Timer interrupt 2 vectors

- Timer functions

Square wave output ( Timer pulse output ), Event count,

High precision PWM output ( Cycle/Duty variable continuously ),

Timer synchronous output, Input capture function ( Both edges

can be operated )

- Real time output control

PWM output is controlled in real time by the external interrupt 0 (IRQ0).

At the interrupt enable edge of the external interrupt 0 (IRQ0), PWM output

( Timer output ) is controlled in 3 values ; "fixed high", "fixed low",

"Hi-z".

Hardware Functions

I - 5

Page 24

Chapter 1 Overview

Watchdog timer

- Watchdog timer frequency can be selected from fs/216, fs/2

18

or fs/220.

Remote control output

Based on the timer 0, and timer 3 output, a remote control carrier with duty

cycle of 1/2 or 1/3 can be output.

Synchronous output

Timer synchronous output, Interrupt synchronous output

- Port 6 outputs the latched data, on the event timing of the synchronous

output signal of timer 1, 5, or 7, or of the external interrupt 2 (IRQ 2).

Buzzer output Output frequency can be selected from fosc/29, fosc/210, fosc/211,

fosc/212, fosc/213, fosc/214, fx/23, fx/24.

Automatic transfer controller (ATC)

Data in the whole memory space (256 KB) can be transferred.

- External interrupt start / internal event start / software start

- Max. 255 bytes continuous transfer

- Support serial interface sequence transmission / reception

- Burst transfer ( interrupt shutdown is built-in )

A/D converter 10 bits X 7 channels input

D/A converter 8 bits X 2 channels input

Serial interface 4 types

Serial interface 0 (Full-Duplex UART / Synchronous serial interface )

❑ Synchronous serial interface

- Transfer clock source

fosc/2, fosc/4, fosx/16, fosc/64, fs/2, fs/4

1/2 of UART baud rate timer ( timer 5 ) output

- MSB/LSB can be selected as the first bit to be transferred. Any

transfer size from 1 to 8 bits can be selected.

- Sequence transmission, sequence reception or both are available.

❑ Full-Duplex UART ( Baud rate timer : Timer 5 )

- Parity check, Overrun error, Framing error detection

- Transfer size 7 to 8 bits can be selected.

[Note : When Matsushita standard serial writer is used for flash memory

version, serial interface 0 is used for program transfer.]

I - 6

Hardware Functions

Page 25

Chapter 1 Overview

Serial interface 1 ( Full-Duplex UART / Synchronous serial interface )

❑ Synchronous serial interface

- Transfer clock source

fosc/2, fosc/4, fosx/16, fosc/64, fs/2, fs/4

1/2 of UART baud rate timer ( timer 4 ) output

- MSB/LSB can be selected as the first bit to be transferred. Any

transfer size 1 to 8 bits can be selected.

- Sequence transmission, sequence reception or both are available.

❑ Full-Duplex UART ( Baud rate timer : Timer 4 )

- Parity check, Overrun error, Framing error detection

- Transfer size 7 to 8 bits can be selected.

Serial interface 3 ( Single master IIC / Synchronous serial interface )

Synchronous serial interface

- Transfer clock source

fosc/2, fosc/4, fosc/16, fosc/32, fs/2, fs/4, 1/2 of timer 5 output

- MSB/LSB can be selected as the first bit to be transferred. Any

transfer size 1 to 8 bits can be selected.

- Sequence transmission, sequence reception or both are available.

Single master IIC

- IIC communication for single master ( 9-bit transfer )

Serial interface 4 ( Slave IIC )

IIC slave serial interface

- IIC high-speed transfer mode (400 kbps) is available.

- 7 bits or 10 bits slave address setting is available.

- Compatible with general call communication mode

LED driver 8 pins

Port I/O ports 53 pins

- LED ( large current ) driver pin 8 pins

- Serves as external interrupt 5 pins

Special pins 10 pins

- Analog reference voltage input pin 2 pins

- Operation mode input pin 1 pin

- Reset input pin 1 pin

- Power pin 2 pins

- Oscillation pin 4 pins

Package 64-pin LQFP ( 14 mm square / 0.8 mm pitch )

64-pin TQFP ( 10 mm square / 0.5 mm pitch )

Hardware Functions

I - 7

Page 26

Chapter 1 Overview

On Flash version MN101CF77G, NC pin cannot be used as user pin as it is used as VPP pin.

Refer to chapter 18 Flash EEPROM when designing your board for compatibility with Flash

version.

Set VREF+ to VDD, VREF- to VSS even when A/D converter is not used.

I - 8

Hardware Functions

Page 27

1-3 Pin Description

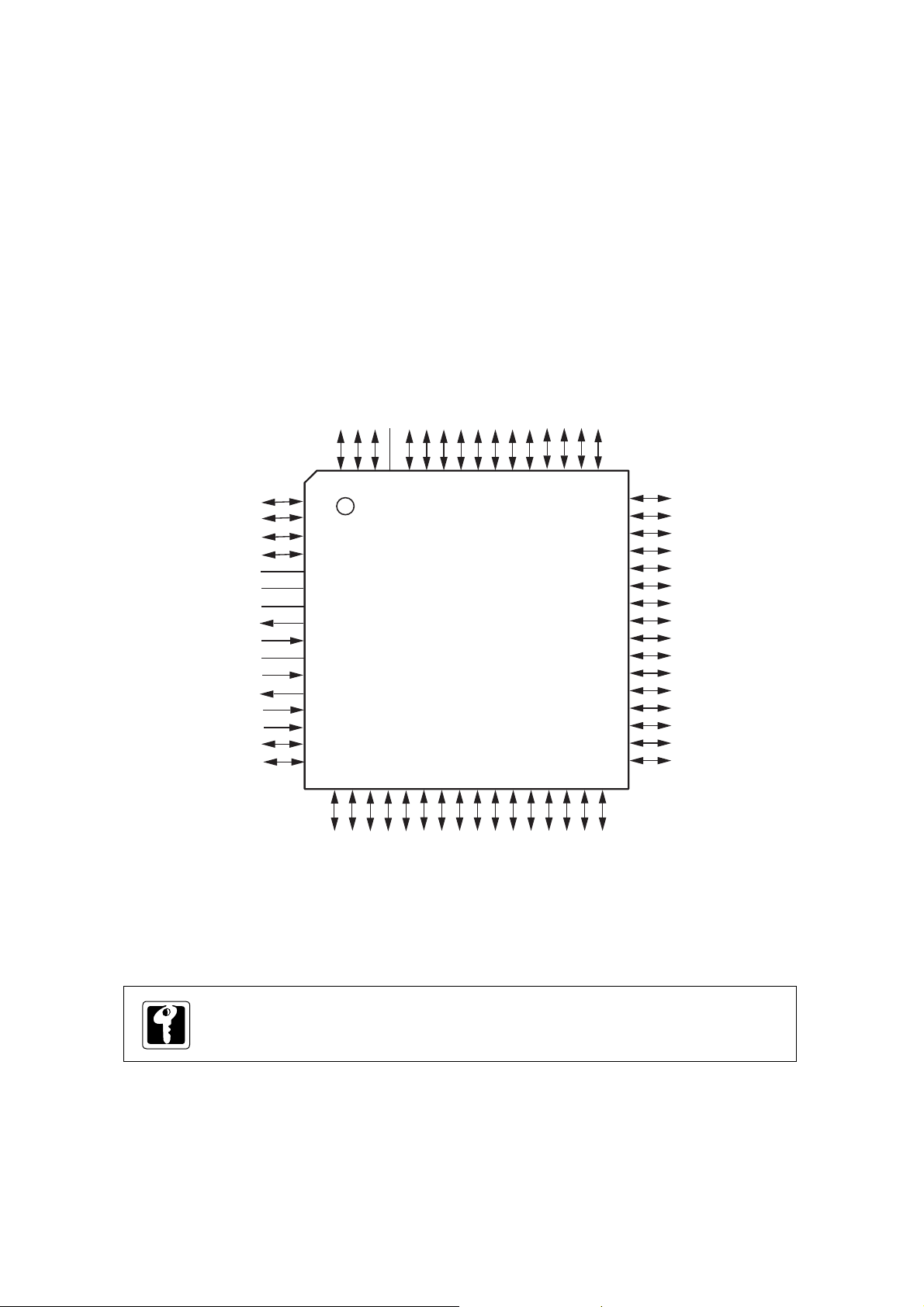

1-3-1 Pin Configuration

Chapter 1 Overview

AN3/PA3

AN4/PA4

AN5/PA5

AN6/PA6

NC(VPP)

VREF+

VDD

OSC2

OSC1

VSS

XI

XO

MMOD

NRST/P27

TXD1A/SBO1A/P00

SDA4B/RXD1A/SBI1A/P01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PA2/AN2

PA1/AN1/DA1

636261

64

171819

PA0/AN0/DA0

VREF-

P80/LED0

P81/LED1

P82/LED2

P83/LED3

P84/LED4

P85/LED5

P86/LED6

6059585756555453525150

MN101C77C

- 64 pin for general use -

20

2122232425262728293031

P87/LED7

P77/TCIO5

P76/TCIO1

P75/SBT1B

P74/SBI1B/RXD1B

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

P73/SBO1B/TXD1B

P72/SBT0B

P71/SBI0B/RXD0B

P70/SBO0B/TXD0B

P67/SDO7/KEY7

P66/SDO6/KEY6

P65/SDO5/KEY5

P64/SDO4/KEY4

P63/SDO3/KEY3

P62/SDO2/KEY2

P61/SDO1/KEY1

P60/SDO0/KEY0

P54/SCL4A

P53/SDA4A

P52/SBT3/SCL3

P51/SB03/SDA3

SBT0A/P05

BUZZER/P06

RXD0A/SBI0A/P04

SCL4B/SBT1A/P02

TXD0A/SBO0A/P03

RMOUTA/TCO0A/P10

IRQ0/P20

TCIO7/P14

TCO4A/P12

TCIO4B/P13

RMOUTB/TCIO0B/P11

IRQ2/P22

ACZ/IRQ1/P21

SBI3/P50

IRQ3/P23

IRQ4/P24

On Flash version of MN101CF77G, NC pin is VPP.

Figure 1-3-1 Pin Configuration ( 64 LQFP/64TQFP : Top view )

Pin Description

I - 9

Page 28

Chapter 1 Overview

1-3-2 Pin Specification

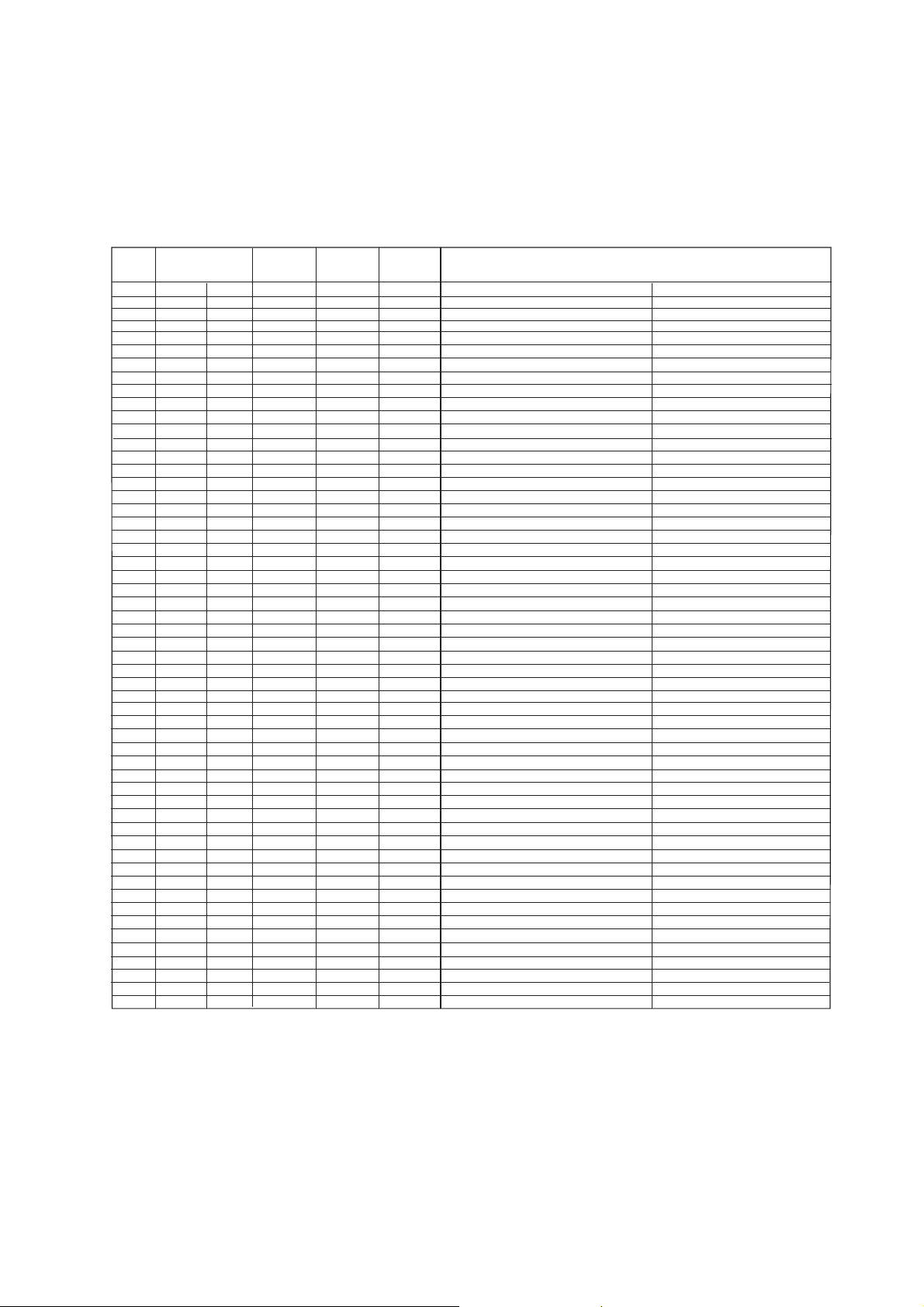

Table 1-3-2 Pin Specification

Pin

P00 SBO1A TXD1A in/out P0DIR0 P0PLU0 SBO1A : Serial Interface 1 transmission data output TXD1A : UART 1 transmission data output

P01 SBI1A RXD1A in/out P0DIR1 P0PLU1 SBI1A : Serial Interface 1 reception data input

P02 SBT1A in/out P0DIR2 P0PLU2 SBT1A : Serial 1 clock I/O

P03 SBO0A in/out P0DIR3 P0PLU3 SBO0A : Serial 0 transmission data output

P04 SBI0A in/out P0DIR4 P0PLU4 SBI0A : Serial 0 reception data input

P05 SBT0A in/out P0DIR5 P0PLU5 SBT0A : Serial 0 clock I/O

P06 BUZZER in/out P0DIR6 P0PLU6 BUZZER : Buzzer output

P10 TCO0A RMOUTA in/out P1DIR0

P11 TCIO0B in/out P1DIR1 P1PLU1 TCIOOB : Timer 0 I/O

P12 TCO4A in/out P1DIR2 P1PLU2 TCIO4A : Timer 4 I/O

P13 TCIO4B in/out P1DIR3 P1PLU3 TCIO4B : Timer 4 I/O

P14 TCIO7 in/out

P20 IRQ0 P2PLU0 IRQ0 : External interrupt 0

P21 IRQ1 P2PLU1 IRQ1 : External interrupt 1

P22 IRQ2 P2PLU2 IRQ2 : External interrupt 2

P23 IRQ3 P2PLU3 IRQ3 : External interrupt 3

P24 IRQ4 P2PLU4 IRQ4 : External interrupt 4

P27 NRST in/out - - NRST : Reset

P50

P51

P52 SBT3 in/out P5DIR2 P5PLU2 SBT3 : Serial interface 3 clock I/O

P53 in/out P5DIR3 P5PLU3

P54 in/out P5DIR4 P5PLU4

P60 SDO0 in/out P6DIR0 P6PLU0 KEY0 : KEY interrupt input 0

P61 SDO1 in/out P6DIR1 P6PLU1 KEY1 : KEY interrupt input 1

P62 in/out P6DIR2 P6PLU2

P63 SDO3

P64

P65

P66

P67

P70 in/out P7DIR0 P7PLUD0

P71 in/out P7DIR1 P7PLUD1

P72 in/out P7DIR2 P7PLUD2

P73 in/out P7DIR3 P7PLUD3

P74 in/out P7DIR4 P7PLUD4

P75 in/out P7DIR5 P7PLUD5

P76 in/out P7DIR6 P7PLUD6

P77 in/out P7DIR7 P7PLUD7

P80 LED0 in/out P8DIR0 P8PLU0 LED0 : LED driving pin 0

P81 LED1 in/out P8DIR1 P8PLU1 LED1 : LED driving pin 1

P82 LED2 in/out P8DIR2 P8PLU2 LED2 : LED driving pin 2

P83 LED3 in/out P8DIR3 P8PLU3 LED3 : LED driving pin 3

P84 LED4 in/out P8DIR4 P8PLU4 LED4 : LED driving pin 4

P85 LED5 in/out P8DIR5 P8PLU5 LED5 : LED driving pin 5

P86 LED6 in/out P8DIR6 P8PLU6 LED6 : LED driving pin 6

P87 LED7 in/out P8DIR7 P8PLU7 LED7 : LED driving pin 7

PA0 AN0 PAPLUD0 AN0 : Analog 0 input

PA1 AN1 PAPLUD1 AN1 : Analog 1 input

PA2 AN2 PAPLUD2 AN2 : Analog 2 input

PA3 AN3 PAPLUD3 AN3 : Analog 3 input

PA4 AN4 PAPLUD4 AN4 : Analog 4 input

PA5 AN5 PAPLUD5 AN5 : Analog 5 input

PA6 AN6 PAPLUD6 AN6 : Analog 6 input

Function

SDA4B

SBI3

SBO3

SDA4A

SCL4A

SDO2

SDO4

SDO5

SDO6

SDO7

SBO0B

SBI0B

SBT0B

SBO1B

SBI1B

SBT1B

TCIO1

TCIO5

SCL4B

TXD0A

RXD0A

RMOUTB

ACZ

SDA3

SCL3

KEY0

KEY1

KEY2

KEY3

KEY4

KEY5

KEY6

KEY7

TXD0B

RXD0B

TXD1B

RXD1B

DA0

DA1

Input/output

in/out

in/out

in/out

in/out

in/out

in/out P5DIR0 P5PLU0 SBO3 : Serial 3 reception data output

in/out P5DIR1 P5PLU1 SBI3 : Serial interface 3 ransmission data input

in/out P6DIR3 P6PLU3 KEY3 : KEY interrupt input 3

in/out

in/out P6DIR5 P6PLU5 KEY5 : KEY interrupt input 5

in/out

in/out

in/out

in/out

in/out

in/out

in/out

in/out

in/out

Direction

control

P1DIR4 P1PLU4 TCIO7 : Timer 7 I/O

P2DIR0

P2DIR1

P2DIR2

P2DIR3

P2DIR4

P6DIR4

P6DIR6

P6DIR7 P6PLU7 KEY7 : KEY interrupt input 7

PADIR0

PADIR1

PADIR2

PADIR3

PADIR4

PADIR5

PADIR6

Pin control

SDA4B :

Serial Interface 4

P1PLU0 TCIO0A : Timer 0 output

SDA4A : Serial interface 4 data I/O

SCL4A : Serial interface 4 clock I/O

SDO0 : Timer synchronous output 0

SDO1 : Timer synchronous output 1

SDO2 : Timer synchronous output 2

SDO3 : Timer synchronous output 3

SDO4 : Timer synchronous output 4

P6PLU4

SDO5 : Timer synchronous output 5

SDO6 : Timer synchronous output 6

P6PLU6

SDO7 : Timer synchronous output 7

SBO0B : Serial interface 0 transmission data output

SBI0B : Serial interface 0 reception data input

SBT0B : Serial interface 0 clock I/O

SBO1B : Serial interface 1 transmission data output

SBI1B : Serial interface 1 reception data input

SBT1B : Serial interface 1 clock I/O

TCIO1 : Timer 1 I/O

TCIO5 : Timer 5 I/O

Descreption

data I/O

RXD1A : UART 1 reception data output

SCL4B :

Serial Interface 4 clock I/O

TXD0A : UART 0 transmission data output

RXD0A : UART 0 reception data input

RMOUTA : Remote control carrier output

RMOUTB : Remote control carrier output

ACZ : AC zero bolt detection input

SDA3 :

Serial Interface 3 data I/O

SCL3 :

Serial Interface 3 clock I/O

KEY2 : KEY interrupt input 2

KEY4 : KEY interrupt input 4

KEY6 : KEY interrupt input 6

TXD0B : UART 0 transmission data output

RXD0B : UART 0 reception data output

TXD1B : UART 1 transmission data output

RXD1B : UART 1 reception data output

DA0 : DA0 output

DA1 : DA1 output

I - 10

Pin Description

Page 29

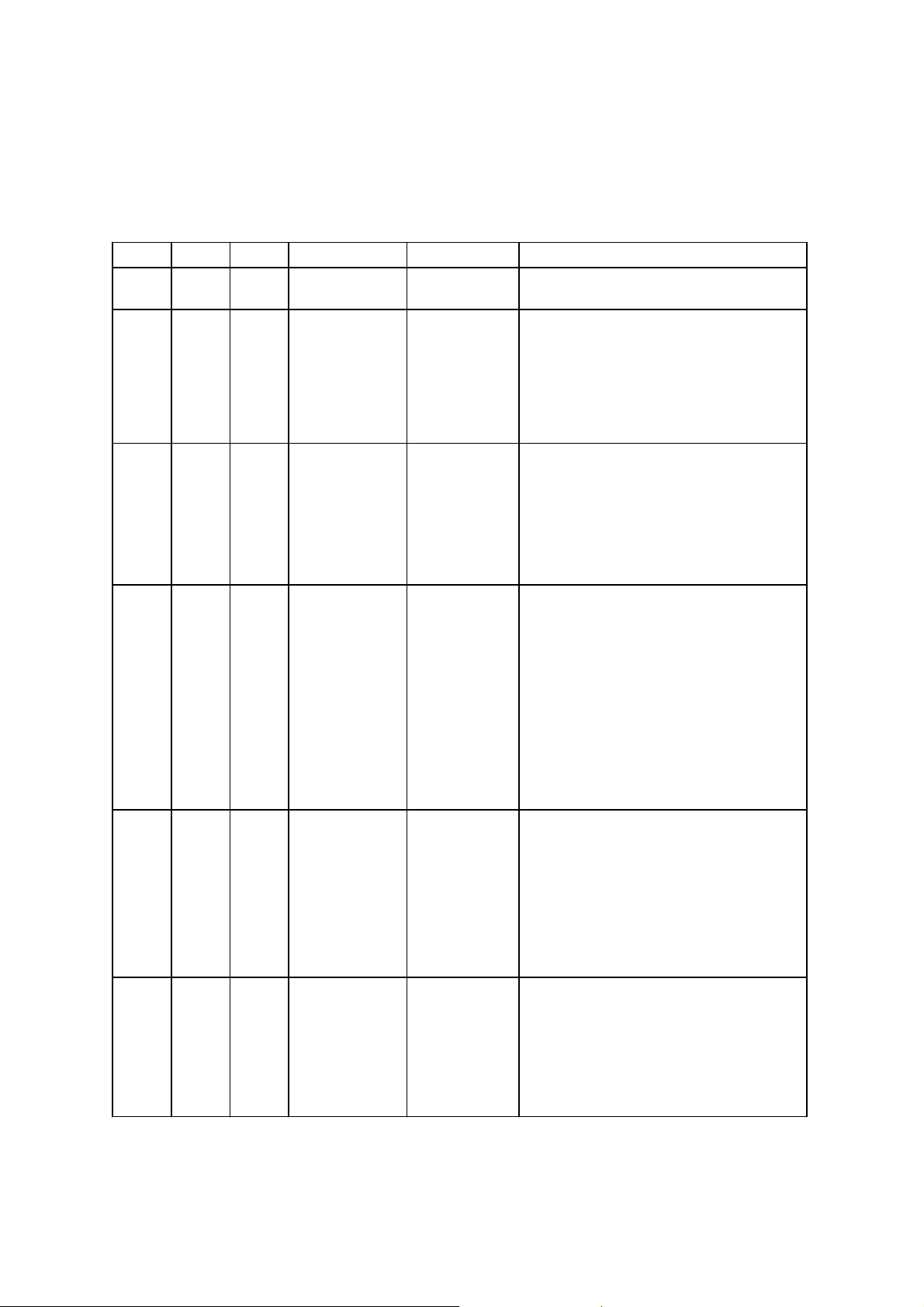

1-3-3 Pin Functions

Table 1-3-3 Pin Function Summary (1/6)

Name No. I/O Funct ion Ot her Funct ion Description

VDD 7 Power supply pin

VSS 10

OSC1 9 Input Clock input pin

OS C 2 8 Output Clock output pin

Supply 1.8 V to 3.6 V to VDD and 0 V to VSS.

Connect these oscillation pins to cer amic or

crystal oscillat ors for high-frequency c loc k

operation.

If the clock is an external input, connect it to OSC1

and leave OSC2 open. T he chip will not oper at e

with an external c lock when using either the

STOP or SLOW modes.

Chapter 1 Overview

XI 11 Input Clock input pin

XO 12 Out put Clock output pin

NRST 14 I/O Reset pin P27 This pin resets the chip when power is turned on,

P00 15 I/O I/O port 0 SBO1A, TXD1A

P01 16 SBI1A, RXD1 A

SDA4B

P02 17 SBT1A , SCL4B

P03 18 SBO0A , T XD0A

P04 19 SBI0A, RXD0 A

P05 20 SBT0A

P06 21 BUZZER

P10 22 I/O I/O port 1 TCO0A, RMOUTA

P11 23 TCIO0B, RMOUTB

P12 24 TCO4A

P13 25 TCIO4B

P14 26 TCI07

Connect these oscillation pins to cer amic

oscillators or crystal oscillators for low-fr equency

clock operation.

If the clock is an external input, connect it to XI

and leave XO open. The c h ip will not operate with

an ex ternal clock when using the STOP mode. If

these pins are not used, connect XI to VSS and

leav e XO open.

is allocated as P27 and contains an internal pullup resistor. S etting this pin low initializes the

internal state of the device. Thereafter, setting the

input to high r eleases the reset. The hardware

waits for t he sy stem clock to stabilize, then

processes the reset int errupt. Also, if ""0" " is

written to P27 and the reset is initiated by

softwar e, a low level will be out put. The output

has an n-channel open-drain configur ation. I f a

capacitor is to be inserted between NRST and

VDD, it is recommended that a discharge diode

be placed between NRST and VDD.

7-Bit CMOS tri-state I/O port.

Eac h bi t can b e set in di vi dual l y as either an in put

or output by the P0DIR register. A pull-up resistor

for eac h bit c an be selected individually by the

P0PLU register.

At reset, the input mode is selected and pull-up

resistors are disabled (high impedance output) .

5-Bit CMOS tri-state I/O port.

Eac h bi t can b e set in di vi dual l y as either an in put

or output by the P1DIR register. A pull-up resistor

for eac h bit c an be selected individually by the

P1PLU register.

At reset, the input mode is selected and pull-up

resistors are disabled (high impedance output) .

Pin Description

I - 11

Page 30

Chapter 1 Overview

Table 1-3-4 Pin Function Summary (2/6)

Name No. I/O F unctio n Other Function Description

P20 27 I/O I/O port 2 IRQ0

P21 28 IRQ1, ACZ

P22 29 IRQ2

P23 30 IRQ3

P24 31 IRQ4

P27 14 Input I /O port 2 NRST P27 has an n-channel open-drain configurati on.

P50 32 I/O I/O port 5 SBI3

P51 33 SBO3,

P52 34 SBT3

P53 35 SDA4A

P54 36 SCL4A

P60 37 I/O I/O port 6 SDO0, KEY0

P61 38 SDO1, KEY 1

P62 39 SDO2, KEY 2

P63 40 SDO3, KEY 3

P64 41 SDO4, KEY 4

P65 42 SDO5, KEY 5

P66 43 SDO6, KEY 6

P67 44 SDO7, KEY 7

P70 45 I/O I/O port 7 SBO0B, TXD0B

P71 46 SB I0B, RXD0B

P72 47 SBT0B

P73 48 SBO1B, TX D1B

P74 49 SB I1B, RXD1B

P75 50 SBT1B

P76 51 TCI01

P77 52 TCI05

P80 60 I/O I/O port 8 LED0

P81 59 LED1

P82 58 LED2

P83 57 LED3

P84 56 LED4

P85 55 LED5

P86 54 LED6

P87 53 LED7

PA0 62 I/O I/O port A AN0, DA0

PA1 63 AN1, DA1

PA2 64 AN2

PA3 1 AN3

PA4 2 AN4

PA5 3 AN5

PA6 4 AN6

5-Bit CMOS tri-state I/O port.

A pull-up resistor for each bi t can be select e d

individually by the P2PLU register .

At reset, pull-up r esistor s are d isabled

(high impedance output ) .

When "0" is written and the reset is initiated by

softwar e, a low level will be out put.

5-Bit CMOS tri-state I/O port.

Each bit can be set individually as either an input

or output by the P5 DIR register . A pul l-up resistor

for eac h bit c an be selected individually by the

P5PLU register. At reset, the P50t o P54 input

mode is selected and pull- up resistors are

disabled. (high impedance output)

8-Bit CMOS tri-state I/O port.

Each bit can be set individually as either an input

or output by the P6 DIR register . A pul l-up resistor

for eac h bit c an be selected individually by the

P6PLU register.

At reset, the P60 to P67 input mode is selected

and pull- up resistors are disabled.

(high impedance output )

8-Bit CMOS tri-state I/O port.

Each bit can be set individually as either an input

or output by the P7 DIR register . A pul l-up/pulldown resistor for each bit can be selected

individually by the P7PLU r e gist e r . Howev er,

pull-up and pull-down resistors cannot be mixed.

At reset, the P70to P77 input mode is selected

and pull- up resistors are disabled. (high

impedance output )

8-Bit CMOS tri-state I/O port. Each bit can be set

individu al ly as either an input or output by the

P8DIR register. A pull-up resistor for each bit c an

be selected individually by the P8PLU register.

When c o nfigured as out puts, these pins can

drive LEDs directly. A t reset, the P80to P 87 input

mode is selected and pull- up resistors are

disabled. (high impedance output)

6-Bit I/O port. A pull-up or pull-down resistor for

each bi t can be selected individually by the

PAPLUD resister. However, pull-up and pulldown resistors cannot be mixed. At reset, the

PA0 to PA 6 input mode is selected and pull- up

resistor s are di sabled. (high impedance ou tput)

I - 12

Pin Description

Page 31

Table 1-3-5 Pin Function Summary (3/6)

Name No. I/O Function Other Function Description

SBO 0A 18 Output P03, TXD0A

SBO0B 48 P70, TXD0B

SBO1A 15 P00, TXD1A

SBO1B 45 P73, TXD1B

SBO3 33 P51, SDA3

SBI 0A 19 Input P04, RXD0A

SBI0B 49 P71, RXD0B

SBI1A 16 P01, RXD1A

SBI1B 46 P74, RXD1B

SBI3 32 P50

Serial interface

transmission data

output pins

Serial interface

recept ion dat a input

pins

SDA4A

Transmission data output pins for serial

interfaces 0 , 1, 3. The output configuration,

eit her CMOS push-pull or n-channel op en-drain

can be selected. Pull-up r esistors can be

selected by the P0PLU register, the P5PLU

register and the P7PLUD r egister. S elec t output

mode by the P0DI R register , the P5DI R register

and the P7DI R r egister, and serial data output

mode by serial mode register 1 ( S C0MD1,

SC1M D1, SC3MD1). These can be used as

normal I/O pins when the serial interfac e is not

used .

Reception data input pins for serial inter faces 0,

1, 3. Pll-up resistors can be selected by the

P0PLU register, the P5PLU register and the

P7PLUD register. Select input mode by the

P0DIR register, the P5DI R r egister, the P7DIR

register and serial input mode by the serial mode

regist er 1 ( S C0MD1, S C1 MD1, S C 3MD1). These

can be u sed as normal I /O pins when t he seri al

interface is not used.

Chapter 1 Overview

SBT0A 20 I/O P50

SBT0B 50 P72

SBT1A 17 P02, SCL4A

SBT1B 47 P75

SBT3 34 P52, SCL3

TXD0A 18 Output SBO0A, P03

TXD0B 48 SBO0B, P70

TXD1A 15 SBO1A, P00

TXD1B 45 SBO1B, P73

Serial interface

clock I/O pins

UART tr an smission

data output pins

Clock I /O pins for serial interf ac es 0, 1, 3. The

output configuration, either CMOS push-pull or nchannel op en - drain can be selected. Pull - up

resist o rs ca n be selected by the P0P LU re sister

and the P5PLU register and t he P 7PLUD

register. Select clock I/O for each communication

mode by the P0DI R register , the P5DI R register ,

the P7DIR register and serial mode register 1

( SC0MD1, SC1M D1, S C3MD1). T hese can be

used as normal I/O pins when the serial interf ace

is not used.

In the serial interface in UART mode, these pins

are configured as the transmission data output

pins. The output configurati on, either CMOS

push-pull or n-channel open -drain can be

selected. Pull-up resistors can be selected by

the P0PLU r egister and t he P 7PLUD register.

Select out put mode by the P0DIR register and the

P7DIR register, and serial data output by serial

interface 1 mode register 1 ( SC0MD1, SC1MD1).

These can be used as normal I/O pins when the

serial interfac e i s not used.

Pin Description

I - 13

Page 32

Chapter 1 Overview

Table 1-3-6 Pin Function Summary (4/6)

Name No. I/O Function Other Function Description

RX D0A 19 Input S B I 0A, P04

RXD0B 49 SBI0B, P71

RXD1A 16 SBI1A, P01

RXD1B 46 SBI1B, P74

UART reception

data input pin

SDA4A

In t he serial interfac e in UART mode, these pins