Page 1

Operating Instructions

Bedienungsanleitung

Cordless Multi Purpose Cutter

Akku-Mehrzwecksäge

Model No: EY4542

Before operating this unit, please read these instructions completely and save this manual for future use.

Vor Inbetriebnahme des Gerätes die Betriebsanleitung bitte gründlich durchlesen und diese Broschüre zum

späteren Nachschlagen sorgfältig aufbewahren.

- 1 -

Page 2

Index/Index

English: Page 4

Deutsch: Seite 21

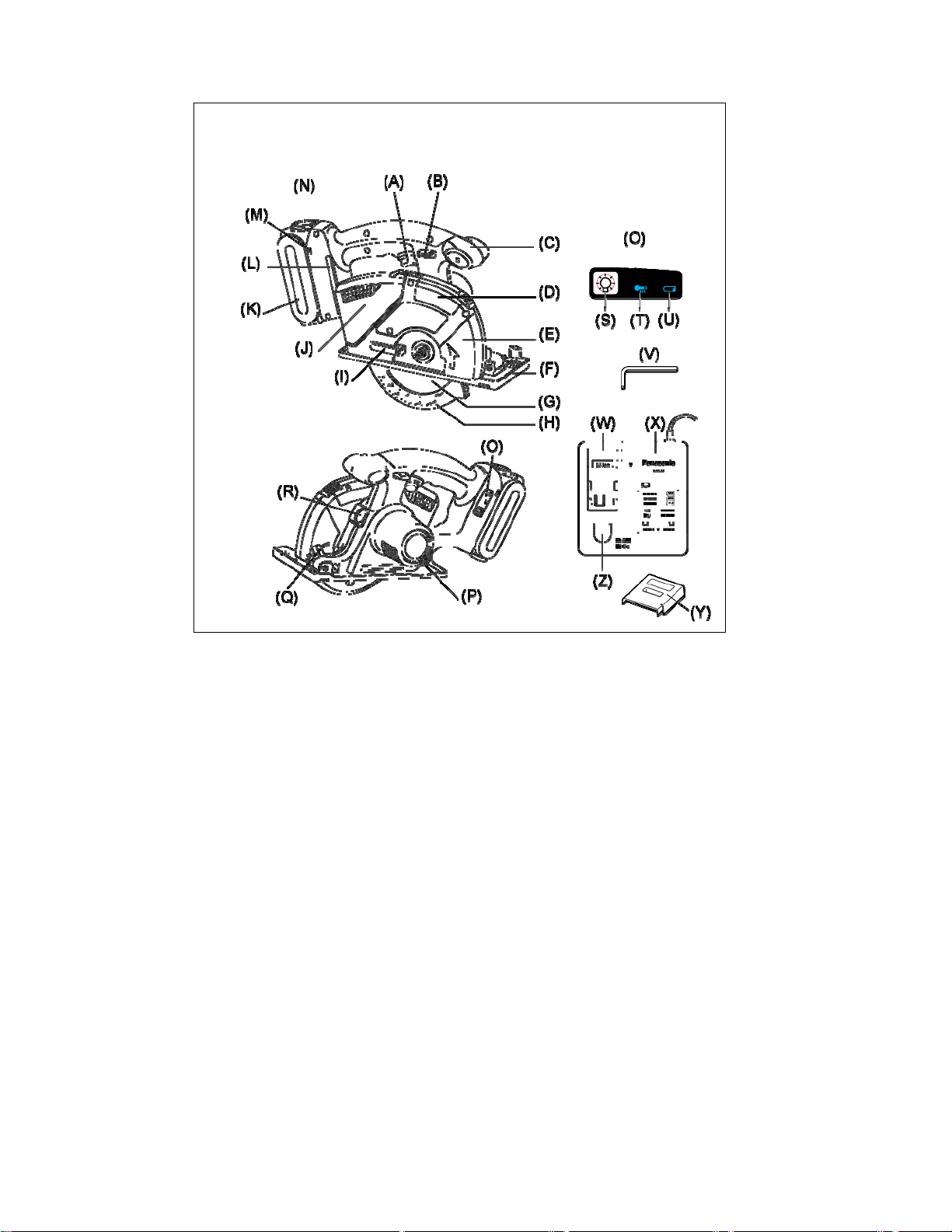

FUNCTIONAL DESCRIPTION

FUNKTIONSBESCHREIBUNG

Fig. 1

- 2 -

Page 3

A Power switch B Switch lock lever C Front grip

Betriebsschalter Schalter-Verriegelungshebel Vorderer Griff

D Front cover E Transparent guard F Shoe

Frontabdeckung Klarsichthaube Gleitschuh

G Blade (EY9PM13C) H Lower guard I Retracting handle

Blatt (EY9PM13C) Untere Schutzvorrichtung Rückzughebel

J Dust case K Battery pack (EY9L40) L Storage slot for hex wrench

Staubgehäuse Akkupack (EY9L40) Schlüsseldepot

M

Battery pack alignment mark

Akku-Ausrichtmarke

P Depth adjustment nut Q LED light R Spindle lock button

Tiefeneinstellmutter LED-Leuchte Spindelarretierknopf

S

LED light on/off button

LED-Leuchten-EIN/AUS-Taste

V Hex wrench W Li-ion battery pack dock X Battery charger (EY0L80)

Inbusschlüssel Li-Ion-Akkuladeschacht Ladegerät (EY0L80)

Y Pack cover Z

Akkuabdeckung

N Battery pack release button O Control panel

Akku-Entriegelungsknopf Bedienfeld

Overheat warning lamp

T

(battery)

Überhitzungs-Warnlampe

(Akku)

Ni-MH/Ni-Cd battery pack

dock

Ni-MH/Ni-Cd-Akkuladeschacht

U Battery low warning lamp

Akkuladungs-Warnlampe

- 3 -

Page 4

I. INTRODUCTION

This tool is a Multi Purpose Cutter. By changing

the blade, it can be used to cut wood, metal, and

plastic. Dust can be collected by an integrated

dust case or via a connected vacuum (by attaching the hose to the cutter).

DANGER

This product is a cutting tool, designed to cut

through metal and wood. It has a rotating blade

which is capable of cutting you deeply, causing

serious injury or death. As a result, please read

this manual and the cautionary markings on the

tool carefully, and obey all of the Safety Instructions to avoid such injury.

WARNING

To avoid injury, never insert your finger or any

other object into any opening of the tool.

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

How to Use This Manual

• Please read this manual completely before

starting to cut with your tool. If you let someone

else use the tool, make sure they either read

this manual or are fully instructed in the proper

use and all safety precautions concerning the

tool.

• Please keep this manual for future reference. It

contains important safety information that you

must follow to use the tool safely.

• This manual and product use the following

signal words:

NOTE

Notes provide additional information that you

should know about the tool.

CAUTION

Caution indicates a potentially hazardous situation, which could result in minor or moderate

injury if not avoided. Cautions also alert you to

unsafe practices to be avoided.

WARNING

Warning indicates a potentially hazardous situation, which could result in serious injury or death

if not avoided.

DANGER

Danger indicates an imminent hazard which will

result in serious injury or death if not avoided.

Read “the Safety Instructions” booklet and

the following before using.

II. ADDITIONAL SAFETY

RULES

Safety instructions for all

saws

DANGER

1) Keep hands away from cutting area and the

blade. Keep your second hand on auxiliar y

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the

blade.

2) Do not reach underneath the workpiece.

The guard cannot protect you from the blade

below the workpiece.

3) A dju st the cutting depth to the t h i c kn e s s o f

the workpiece. Less than a full tooth of the

blade teeth should be visible below the workpiece.

4) Never hold piece being cut in your hands

or across your leg. Secure the workpiece to

a stable platform. It is important to support

the work properly to minimize body exposure,

blade binding, or loss of control.

5) Hold power tool by insulated gripping sur-

faces when performing an operation where

the cutting tool may contact hidden wiring

or its own c ord. Contact with a “live” wire will

also make exposed metal parts of the power

tool “live” and shock the operator.

6) When ripping always use a rip fence or

straight edge guide. This improves the accuracy of cut and reduces the chance of blade

binding.

7) Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the mounting

hardware of the saw will run eccentrically,

causing loss of control.

8) Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum performance and safety of operation.

- 4 -

Page 5

Further safety instructions for all saws

Causes and operator prevention of kickback:

- kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator;

- when the blade is pinched or bound tightly by

the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back toward the operator;

- if the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the blade

can dig into the top surface of the wood causing the blade to climb out of the kerf and jump

back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

1) Maintain a firm grip with both hands on the

saw and position your arms to resist kickback forces. Position your body to either

side of the blade, but no t in line with the

blade.

Kickback could cause the saw to jump backwards, but kickback forces can be controlled

by the operator, if proper precautions are

taken.

2) When blade is binding, or when interrupt-

ing a cut for any reason, rele as e the tri g ge r

and hold the saw motionless in the material

until the blade comes to a complete sto p.

Never attempt to remove the saw from the

work or pull the saw backward while the

blade is in motion or kickback may occur.

Investigate and take corrective actions to

eliminate the cause of blade binding.

3) When restarting a saw in the workpiece,

center the saw blade in the kerf and check

that saw teeth are not engaged into the

material.

If saw blade is binding, it may walk up or kickback from the workpiece as the saw is restarted.

4) Support large panels to minimize the risk of

blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the

panel on both sides, near the line of cut and

near the edge of the panel.

5) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce narrow kerf causing excessive friction,

blade binding and kickback.

6) Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut.

If blade adjustment shifts while cutting, it may

cause binding and kickback.

7) Use extra caution when making a “ plunge

cut” into existing walls or other blind areas.

The protruding blade may cut objects that can

cause kickback.

Safety instructions for

this saw

1) Check lower guard for proper closing before each use. Do not operate the saw if

lower guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position.

If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with the

retracting handle and make sure it moves

freely and does not touch the blade or any

other part, in all angles and depths of cut.

2) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a build-up

of debris.

3) Lower guard should be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard

by retracting handle and as soon as blade

enters the material, the low er guard must

be released.

For all other sawing, the lower guard should

operate automatically.

4) Always observe that the lower guard is

covering the blade before placing saw

down on bench or floor.

An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in

its path. Be aware of the time it takes for the

blade to stop after switch is released.

5) Do not use any abrasive wheels.

6) Wear a dust mask, if the work causes dust.

7) Use saw blades recommended by Manufacture.

8) Wear ear protectors when using the tool for

extended periods.

9) The risk of kickback increases as the battery pack discharges.

10) Be sure to inspect material. Avoid cutting

other different material.

11) Be careful not to drop the tool.

- 5 -

Page 6

12) Never swing the tool.

13) Never cover the ventilation slots, and keep

them free from dust or other material.

14) Do not clamp the tool in a vis e. Never cut

with the tool held upside down in a vise.

This is extremely dangerous and can lead

to serious accidents.

15) Never wear kn itted gloves.

16) Be sure no one is below when using the

tool in high locations.

17) Do not touch the blade immediately after

operation. It may be hot and could burn

your skin.

18) Do not touch material after it has been cut.

Cut material may be very hot.

19) Do not use cutting oil. Th is use of cutt ing oil

may cause a fire.

20) Do not cut workpieces covered or stained

with gas, oil, solvents, thinners, etc.

Exposure to these materials may damage

the transparent guard.

21) Do not remove the transparent and lower

guards. If the transparent and lower guards

is damaged or missing, return tool to authorized service center for replacement.

22) Do not start the blade when in contact with

workpiece. Wait for blade to reach full

speed before beginning cut.

Symbol

Symbol Meaning

V Volts

n

0

-1

··· min

A Amperes

Direct current

No load speed

Revolutions or reciprocations

WARNING

• Do not use other than the Panasonic battery

packs that are designed for use with this rechargeable tool.

• Do not dispose of the battery pack in a fire, or

expose it to excessive heat.

• Do not drive the likes of nails into the battery

pack, subject it to shocks, dismantle it, or attempt to modify it.

• Do not allow metal objects to touch the battery

pack terminals.

• Do not carry or store the battery pack in the

same container as nails or similar metal objects.

• Do not charge the battery pack in a

high-temperature location, such as next to a

fire or in direct sunlight. Otherwise, the battery

may overheat, catch fire, or explode.

• Never use other than the dedicated charger to

charge the battery pack. Otherwise, the battery may leak, overheat, or explode.

• After removing the battery pack from the tool

or the charger, always reattach the back

cover. Otherwise, the battery contacts could

be shorted, leading to a risk of fire.

III. ASSEMBLY

Attaching or Removing Battery

Pack

CAUTION:

Before inserting battery pack, check that the

power switch in the tool actuates properly and

returns to the “OFF” position when released.

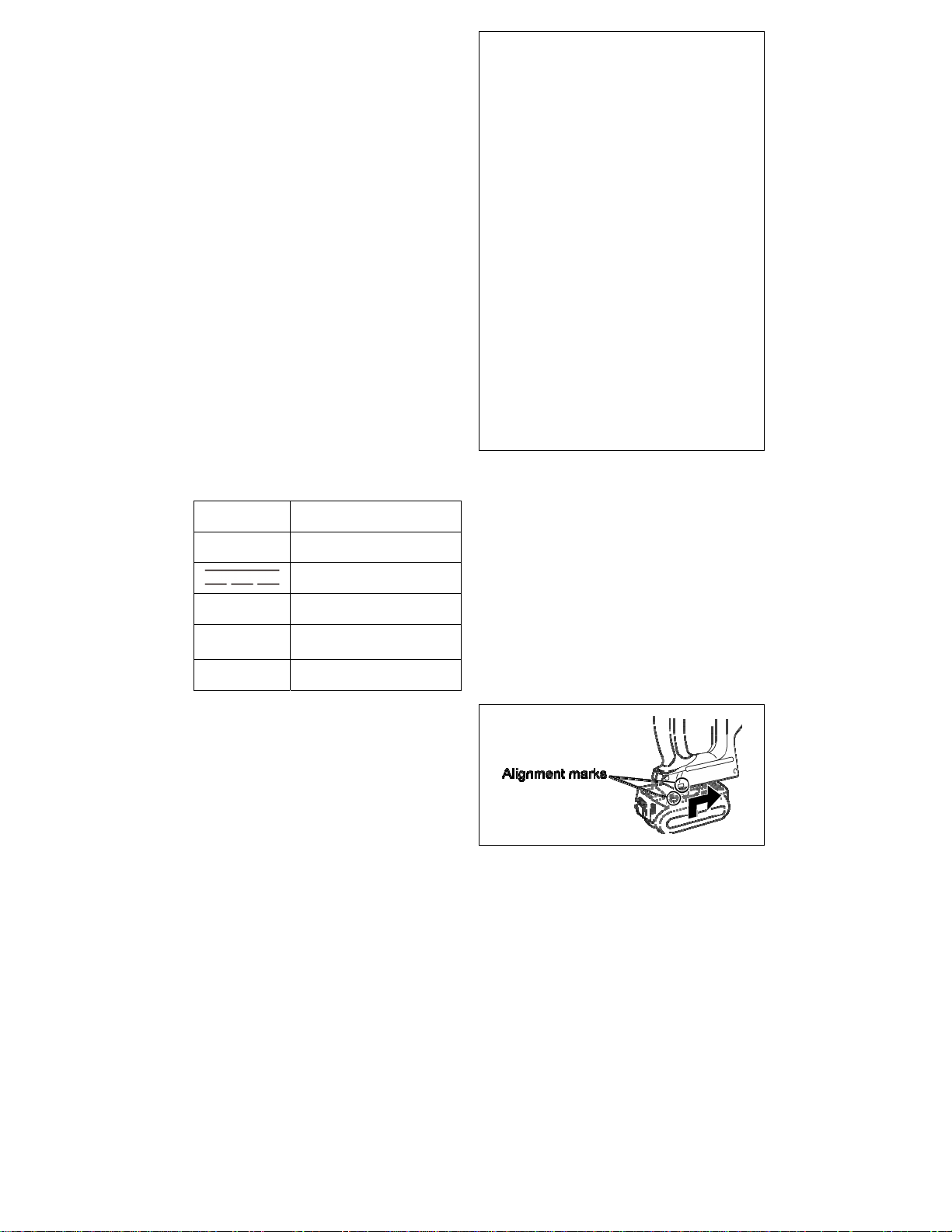

1. To connect the battery pack (See Fig. 2)

Line up the alignment marks and attach the

battery pack.

• Slide the battery pack until it locks into

position.

- 6 -

Fig. 2

Page 7

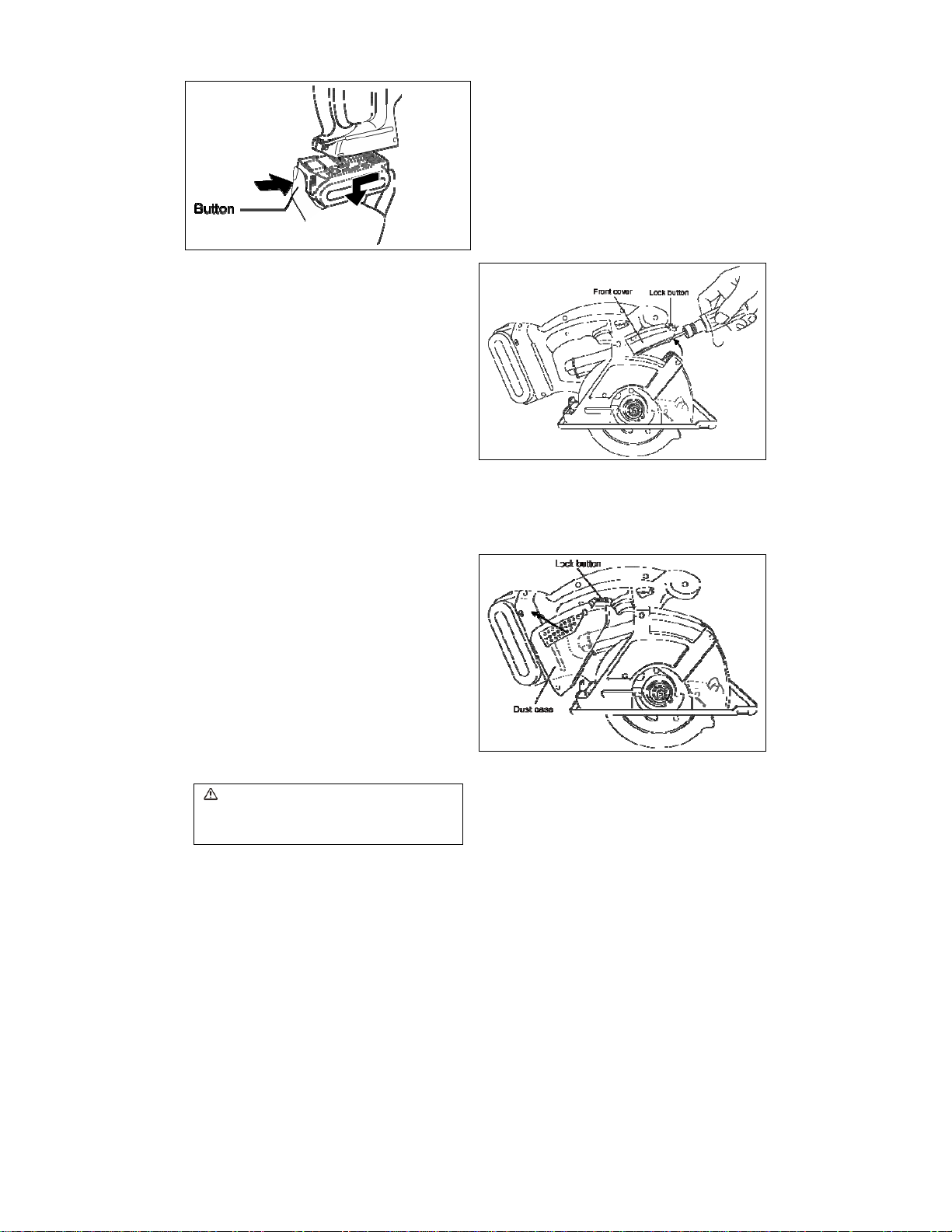

2. To remove the battery pack (See Fig. 3)

Push on the button from the front to release

the battery pack.

Fig. 3

IV. OPERATION

Before Using the Tool

This tool is intended for cutting unhardened ferrous metal, nonferrous metal, wood, and plastic.

Refer to the “Accessories” section for a list of

blades to be used for the proper applications of

this tool. The following precautions must be followed to reduce the risk of injury;

• Do not cut stacked materials. Cut one piece at

a time.

• Do not cut hardened steel.

• Cut materials with the wider edge of the shoe

over the clamped side of the material.

• Do not touch the saw blade, workpiece, or

cutting chips with bare hands immediately after

cutting; they may be hot and could burn skin.

Each time you use the tool, you must make sure

it is in good operating condition.

Use the following checklist:

1. Is the blade installed in the correct direction?

The arrow on the blade must point in the same

direction as the arrow on the upper blade cover.

2. Is the blade installed properly?

Make sure the hex bolt is tightened securely.

(See Fig. 6)

3. Does the blade look alright?

Replace the blade immediately if there are any

cracks in it or if any teeth are broken.

4. Does the lower guard close properly?

WARNING

To avoid injury, do not use the tool if the lower

guard does not close quickly over the blade.

6. Is the battery pack charged and inserted firmly

to the tool?

7. Is the depth adjustment nut for cutting securely

tightened?

8. Is the workpiece securely clamped on a saw

horse or bench?

9. Is the dust case or front cover clogged with

dust?

Disengage the front cover lock button and

remove any dust that has become clogged inside the cover. If the cover is clogged, use a

long object such as a manual screwdriver to

unclog it. After doing so, close the front cover.

(See Fig. 4)

Fig. 4

If there is dust inside the dust case, disengage

the dust case lock button, detach the dust case,

and remove the dust. After doing so, reattach

the dust case. (See Fig. 5)

Fig. 5

5. Is the transparent guard securely installed?

- 7 -

Page 8

Installing Blade

Follow these steps:

1. Remove the battery pack from the tool.

2. Remove any cutting debris from blade area.

3. Use the retracting handle to retract (open) the

lower guard.

4. Install the blade as illustrated. (See Fig. 6)

Make sure that both the direction arrow on the

blade and the direction arrow on the upper

blade cover point in the same direction.

5. Set the outer washer in place.

6. Insert the hex bolt.

7. Hold the spindle lock button down. This prevents the blade from rotating.

8. Tighten the hex bolt securely with the provided

hex wrench. Store the hex wrench.

NOTE:

Keep the hex wrench in the storage slot on the

cutter’s body when not using it.

WARNING

Failure to follow these instructions can result in

serious personal injury.

Removing Blade

CAUTION:

The blade will be hot right after cutting. Be sure

to let the blade cool down before removing it.

Follow these steps:

1. Remove the battery pack from the tool.

2. Hold the spindle lock button down. This prevents the blade from rotating.

3. Use the provided hex wrench to loosen the hex

bolt.

NOTE:

Keep the hex wrench in the storage slot on the

cutter’s body when not using it.

4. Remove the hex bolt and outer washer.

5. Use the retracting handle to retract (open) the

lower guard.

6. Carefully remove the blade.

7. Clean the tool if necessary.

CAUTION:

Be careful to avoid cutting your hands on the

blade.

• When disposing of a blade, secure it inside

heavy or corrugated paper. This will help

prevent anyone from being cut by the discarded blade.

Fig. 6

- 8 -

Page 9

Using the Tool

CAUTION:

To reduce the risk of injury read the Safety Instructions at the front of this manual before using

the tool.

WARNING

To reduce the risk of injury, wear safety goggles or glasses with side shields while using

the cutter. Additionally, wear a dust mask

when cutting materials that generate excessive particulate matter. Do not use cutter in

the rain. Doing so may result in electric shock

or cause the cutter to emit smoke.

Do not cut materials on which there is any

paint thinner, gasoline, oil, or similar build-up.

Doing so may cause the dust case to crack,

resulting in injury.

Follow these steps:

Hold the tool with both hands. (See Fig. 8) Do not

attempt to remove cut material when blade is

moving.

1. Line up the sight line on shoe with your cutting

line. (See Fig. 7)

Alignment with cutting line

• Position the notch on the shoe over the cutting

line, aligning the top and bottom corners of the

diamond-shaped opening with the line.

As the cutting position may differ depending on

the blade, do a trial cut beforehand.

Fig. 7

2. Press the switch lock lever down, then

squeeze the power switch to start the motor,

and then release the switch lock lever.

Fig. 8

CAUTION:

• Check that the switch lock lever works.

If power switch can be activated without de-

pressing the switch lock lever, discontinue use

immediately. Take the tool to an authorized

service center.

• Always hold the handle with one hand and the

front grip with the other. (See Fig. 8) Maintain a

firm grip and depress the switch fully.

• The blade should not touch the cutting material

before you start the motor. Wait until the blade

reaches full speed before starting a cut.

• This tool has no provision to lock the power

switch in the “ON” position, and you must not

attempt to secure it in the “ON” position.

3. Start cutting when the blade reaches full

speed.

4. During cutting, keep your cutting line straight.

Move the tool forward at a steady speed, while

looking at the tip of the blade through the

transparent guard.

WARNING

• To prevent dangerous kickback, keep the

shoe of the tool flat on the surface of the material being cut.

• Never force the tool. Use light and continuous

pressure.

5.If the motor starts to feel too warm, stop cutting.

Let the tool cool down before continuing work.

6. It is always a safe practice to remove the battery pack after use and before storing the tool.

Cutting depth adjustment

• Remove battery pack.

• Loosen the depth adjustment nut and adjust

the cutting depth, using the graduations on the

lower guard to gauge the depth. Once finished

adjusting the depth, tighten the depth adjust-

- 9 -

Page 10

ment nut securely.

* When wood material is 10 mm (3/8") or less

thick, adjust the cutting depth so that the blade

protrudes approx. 5 mm (3/16") from the bottom of the material.

Fig. 9

Rip fence (EY3500B7727)

(Available as an accessory, not included)

Rip fence is convenient for rip cuts and repeated

cuts of uniform width.

• Remove battery pack.

• Insert rip fence and adjust cutting width. (See

Fig. 10)

• Fasten screw securely to fix rip fence.

jury.

* When cutting metal materials, do not attach a

vacuum cleaner.

Sparks and hot metal chips may cause the

vacuum to be caught in fire. Operate the vacuum cleaner in accordance with its instructions.

(1) Collect dust in the dust case.

* Empty the dust case when it is filled up with

dust.

* Empty the dust case before storing the

cutter.

* Dust case capacity

• When cutting electrical conduit with a

diameter of 25 mm (1"), approximately xx

cuts

• When cutting 45 mm (25/32") x 45 mm

(25/32") lumber, approximately xx cuts

NOTE

The unique physical properties of some materials

may cause dust to become clogged inside the

front cover when cutting those materials.

Fig. 10

Collecting Dust

WARNING

* Before cutting metal materials, always empty

the dust case, open the front cover and remove

the dust.

• Use the cutter with the flammable materials in

the dust case to cut metal materials may result in fire.

* When cutting metal materials, always use the

cutter with the dust case attached.

• Flying sparks and metal chips may cause in-

Fig. 11

(2) Use with vacuum cleaner to collect dust.

* Connect the cutter to the hose using the

EY9X012E vacuum cleaner hose adapter

(sold separately).

Compatible hose inner diameter: 25 mm

(1") to 38 mm (2/1")

* Operate the vacuum cleaner obeying its in-

structions.

- 10 -

Page 11

Fig. 12

NOTE

When the cutter has difficulty ejecting or collecting dust.

The cutter outlet may be clogged with dust. Open

the front cover and remove any dust.

flashlight, since it does not have enough

brightness.

• Power automatically turns off immediately after

the battery pack is installed or when the LED

light is on and the driver has not been used for

5 minutes or more or when the LED light is

turned off and the driver has not been used for

1 minute or more. Please depress the switch to

operate the drill again.

This tool has the built-in LED light.

This tool is classified into “Class 1 LED Product”

to IEC (EN) 60825-1:2001.

Class 1 LED Product

Caution

Use of controls or adjustments or performance of

procedures other than those specified herein

may result in hazardous radiation exposure.

: DO NOT STARE INTO BEAM.

Control Panel

(1) LED light

Fig. 13

Pressing

the LED light on and off.

The light illuminates with

does not adversely affect the performance of the

tool during use or its battery capacity.

CAUTION:

• The built-in LED light is designed to illuminate

the small work area temporarily.

• Do not use it as a substitute for a regular

(LED light ON/OFF button) toggles

very low current, and it

(2) Overheat warning lamp

The overheating protection feature halts tool

operation to protect the battery pack in the

event of overheating. The overheat warning

lamp on the control panel flashes when this

feature is active.

• If the overheating protection feature activates, allow the tool to cool thoroughly (at

least 30 minutes). The tool is ready for use

when the overheat warning lamp goes out.

• Avoid using the tool in a way that causes

the overheating protection feature to activate repeatedly.

(3) Battery low warning lamp

Excessive (complete) discharging of lithium

- 11 -

Page 12

ion batteries shortens their service life dramatically. The tool includes a battery protection feature designed to prevent excessive

discharging of the battery pack.

• The battery protection feature activates

immediately before the battery loses its

charge, causing the battery low warning

lamp to flash.

• If you notice the battery low warning lamp

flashing, charge the battery pack immediately.

For Proper Use (Further Detail)

WARNING

To prevent the risk of serious personal injury:

It is important to use an appropriate device

to hold the material being cut properly, and

to hold the cutter firmly with both hands to

prevent loss of control which could cause

personal injury.

• Figure 14 shows proper cutting position.

• Note that hands are kept away from cutting

area.

• Make sure bystanders are away from work

area and from underneath of workpiece.

• When cutting, do not try to hold the material

with your hand.

Cutting large sheets;

Support large sheets. Be sure to set the

depth of the cut so that you only cut through

the workpiece, not through the supports.

(See Fig. 15)

Large sheets sag or bend if they are not correctly supported. If you attempt to cut without

levelling and properly supporting the workpiece, the blade will tend to bind, causing

kickback. (See Fig. 16)

• Don’t support the material away from the

cut.

Cutting thin or corrugated materials;

Cut thin and corrugated materials at least 1"

from the edge of the workpiece to avoid injury or damage to the tool caused by thin

strips of metal being pulled into the upper

guard.

•Use sharp blades only. Clean and sharp

blades minimize stalling and kickback.

Fig. 14

Fig. 15

Fig. 16

- 12 -

Page 13

WARNING

To prevent the risk of serious personal injury:

• When making an incomplete cut or cutting is interrupted, or blade is binding or cutter is stalling; release the power switch immediately and hold the cutter motionless in the material until the blade

comes to a complete stop.

• To avoid kickback, never attempt to remove the cutter from the work or pull the cutter backward while

the blade is in motion. Make sure the blade has come to a complete stop, then remove cutter from

cut.

• To resume cutting, start cutter, allow the blade to reach full speed, reenter the cut slowly and resume

cutting.

1. Place the wider part of the shoe on the part of the work piece which is solidly supported (See Fig. 17),

never on the section that will fall off when the cut is made. (See Fig. 18)

Hold the cutter firmly to prevent loss of control. Working carelessly can cause severe personal injury.

Fig. 17 Fig. 18

2. Make sure the blade stops.

Even though your tool has a brake, before setting the tool down, make sure the blade has come to a

complete stop and the lower guard has closed.

3. Do not use if anything seem unusual. Remove battery pack immediately.

If the tool body becomes very hot, or does not work properly, remove the battery pack and do not use.

Have it checked by an authorized service center.

WARNING

To prevent the risk of serious personal injury or fire, do not try to repair the tool by yourself. Never

disassemble or modify the tool body. There are no user-repairable parts inside.

4. NEVER ALLOW THE CUTTER TO COME IN CONTACT WITH YOUR BODY.

After completing a cut, do not allow the cutter to brush against your leg or side.

Since the lower guard is retractable, it could catch on your clothing and expose the blade. Keep

clothing away from tool. Be aware of the exposed blade sections that exist in both the upper and

lower guard areas.

WARNING

Because cutting metal creates sparks;

• Always use safety goggles.

• Do not use tool near any flammable substance or in an area where flammable substances are used.

Fire and burn injury could result.

5. Never engage the spindle lock while blade is running, or engage in an effort to stop the tool. Never

turn the switch on when the spindle lock is engaged. Serious damage to your tool will result.

- 13 -

Page 14

[Battery Pack]

For Appropriate Use of

Battery pack

Li-ion Battery pack (EY9L40)

• For optimum battery life, store the Li-ion bat-

tery pack following use without charging it.

• When charging the battery pack, confirm that

the terminals on the battery charger are free of

foreign substances such as dust and water etc.

Clean the terminals before charging the battery

pack if any foreign substances are found on

the terminals.

The life of the battery pack terminals may be

affected by foreign substances such as dust

and water etc. during operation.

• When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects that can make a connection from one

terminal to another.

Shorting the battery terminals together may

cause sparks, burns or a fire.

• When operating the battery pack, make sure

the work place is well ventilated.

• When the battery pack is removed from the

main body of the tool, replace the battery pack

cover immediately in order to prevent dust or

dirt from contaminating the battery terminals

and causing a short circuit.

[Battery Charger]

Charging

Cautions for the Li-ion Battery

Pack

• If the temperature of the battery pack falls

approximately below −10°C (14°F), charging

will automatically stop to prevent degradation

of the battery.

Common Cautions for the Liion/Ni-MH/Ni-Cd Battery Pack

• The ambient temperature range is between

0°C (32°F) and 40°C (104°F).

If the battery pack is used when the battery

temperature is below 0°C (32°F), the tool may

fail to function properly.

• When charging a cool battery pack (below 0°C

(32°F)) in a warm place, leave the battery pack

at the place and wait for more than one hour to

warm up the battery to the level of the ambient

temperature.

•

Cool down the charger when charging more than

two battery packs consecutively.

• Do not insert your fingers into contact hole,

when holding charger or any other occasions.

CAUTION:

To prevent the risk of fire or damage to the battery charger.

• Do not use power source from an engine gen-

• Do not cover vent holes on the charger and the

• Unplug the charger when not in use.

erator.

battery pack.

Battery Pack Life

The rechargeable batteries have a limited life. If

the operation time becomes extremely short after

recharging, replace the battery pack with a new

one.

Battery Recycling

ATTENTION:

For environmental protection and recycling of

materials, be sure that it is disposed of at an

officially assigned location, if there is one in your

country.

Li-ion Battery Pack

NOTE:

Your battery pack is not fully charged at the time

of purchase. Be sure to charge the battery before

use.

Battery charger (EY0L80)

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the plug is inserted into the AC power supply, but this is not

a problem in terms of safety.

2.

Insert the battery pack firmly into the charger.

1. Line up the alignment marks and place the

battery onto the dock on the charger.

2. Slide forward in the direction of the arrow.

- 14 -

Page 15

During charging, the charging lamp will be lit.

3.

When charging is completed, an internal elec-

tronic switch will automatically be triggered to

prevent overcharging.

• Charging will not start if the battery pack is

warm (for example, immediately after

heavy-duty operation).

The orange standby lamp will be flashing un-

til the battery cools down.

Charging will then begin automatically.

4. The charge lamp (green) will flash slowly once

the battery is approximately 80% charged.

5. When charging is completed, the charging lamp

will start flashing quickly in green color.

6. If the temperature of the battery pack is 0°C or

less, charging takes longer to fully charge the

battery pack than the standard charging time.

Even when the battery is fully charged, it will

have approximately 50% of the power of a fully

charged battery at normal operating temperature.

7.

If the power lamp does not light immediately

after the charger is plugged in, or if after the

standard charging time the charging lamp does

not flash quickly in green, consult an authorized

dealer.

8. If a fully charged battery pack is inserted into

the charger again, the charging lamp lights up.

After several minutes, the charging lamp may

flash quickly to indicate the charging is completed.

Ni-MH/Ni-Cd Battery Pack

NOTE:

When you charge the battery pack for the first

time, or after prolonged storage, charge it for

about 24 hours to bring the battery up to full

capacity.

Battery charger (EY0L80)

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the plug is inserted into the AC power supply, but this is not

a problem in terms of safety.

2.

Insert the battery pack firmly into the charger.

3. During charging, the charging lamp will be lit.

When charging is completed, an internal elec-

tronic switch will automatically be triggered to

prevent overcharging.

• Charging will not start if the battery pack is

warm (for example, immediately after

heavy-duty operation).

The orange standby lamp will be flashing un-

til the battery cools down. Charging will then

begin automatically.

4.

When charging is completed, the charging lamp

will start flashing quickly in green color.

5.

If the charging lamp does not light immediately

after the charger is plugged in, or if after the

standard charging time the charging lamp does

not flash quickly in green, consult an authorized

dealer.

6. If a fully charged battery pack is inserted into

the charger again, the charging lamp lights up.

After several minutes, the charging lamp may

flash quickly to indicate the charging is completed.

- 15 -

Page 16

LAMP INDICATIONS

Green Lit

Information for Users on Collection and Disposal of Old Equipment and used Batteries

These symbols on the products, packaging, and/or accompanying docu-ments mean

that used electrical and electronic products and batteries should not be mixed with

general household waste.

For proper treatment, recovery and recycling of old products and used bat-teries,

please take them to applicable collection points, in accordance with your national

legislation and the Directives 2002/96/EC and 2006/66/EC.

By disposing of these products and batteries correctly, you will help to save valuable

resources and prevent any potential negative effects on human health and the environment which could otherwise arise from inap-propriate waste handling.

For more information about collection and recycling of old products and bat-teries,

please contact your local municipality, your waste disposal service or the point of sale

where you purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in ac-cordance with

national legislation.

Charger is plugged into the AC outlet.

Ready to charge.

Green Flashing Quickly

Charging is completed. (Full charge.)

Green Flashing

Battery is approximately 80% charged. (Usable charge. Li-ion only.)

Green Lit

Now charging.

Orange Lit

Battery pack is cool.

The battery pack is being charged slowly to reduce the load on the battery. (Li-ion only.)

Orange Flashing

Battery pack is warm. Charging will begin when temperature of battery pack drops.

If the temperature of the battery pack is –10°C or less, the charging status lamp (orange)

will also start flashing. Charging will begin when the temperature of the battery pack goes

up (Li-ion only).

Charging Status Lamp

Left: green Right: orange will be displayed.

Both Orange and Green Flashing Quickly

Charging is not possible. Clogged with dust or malfunction of the battery pack.

For business users in the European Union

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for

further information.

[Information on Disposal in other Countries outside the European Union]

These symbols are only valid in the European Union. If you wish to discard these items, please contact your local authorities or dealer and ask for the correct method of disposal.

Note for the battery symbol (bottom two symbol examples):

This symbol might be used in combination with a chemical symbol. In this case it complies with the

requirement set by the Directive for the chemical involved.

- 16 -

Page 17

V. MAINTENANCE

. ACCESSORIES

VI

WARNING

To avoid severe personal injury, always remove

the battery pack from the tool before starting any

maintenance procedure.

CAUTION:

To assure product SAFETY and RELIABILITY,

servicing should be performed by an authorized

service center. Always insist on genuine

Panasonic replacement parts.

Cleaning Tool

Keep your tool clean for good cutting performance, and to help keep it safe to use.

Follow these steps:

1. Remove the battery pack from the tool.

2. Wipe the tool with a dry, soft cloth. Do not

use a wet cloth or cleaning liquids.

They could damage the cutter’s finish.

3. Be sure to rub off any oil or grease which

could make the tool slippery or hard to handle.

4. Remove the blade and brush off any dust.

CAUTION:

To avoid injury or damage to the unit, never immerse any part of the tool in a liquid.

Transparent Guard

WARNING

If the guard is cracked, or is broken, take the tool

to an authorized service center for replacement.

Do not attempt to operate cutter. It could result in

serious personal injury.

Never use your tool with a damaged transparent

guard or without the transparent guard installed.

Flying chips could result in serious injury.

WARNING

• The use of any accessories not specified in

this manual may result in fire, electric shock,

or personal injury. Use recommended accessories only.

• Use of a blade on material that is thicker or

thinner than that recommended for that

blade will result in a rough cut, and could

increase the risk of “kickback

jury.

Carbide-tipped Blade for Metal

• EY9PM13C

For cutting unhardened ferrous material

Carbide-tipped Blade for Thin Metal (Optional

accessory)

• EY9PM13D

For cutting unhardened thin ferrous material

Carbide-tipped Blade for Wood (Optional ac-

cessory)

• EY9PW13A

For cutting wood

Carbide-tipped Blade for Thin Wood (Optional

accessory)

• EY9PW13B

For cutting thin wood

Carbide-tipped Blade for Plastic (Optional ac-

cessory)

• EY9PP13B

For cutting plastic material

Vacuum hose adaptor (Optional accessory)

• EY9X012E

Rip Fence (Optional accessory)

• EY3500B7727

For convenience of rip cuts and repeated cut

of uniform width

” or other in-

- 17 -

Page 18

VII. SPECIFICATIONS

Motor voltage 14.4 V DC

Blade speed XX min-1 (rpm)

Blade size

Outside diameter

Arbor size

Maximum cutting depth 0 – 46 mm (0" – 1-13/16") (φ 165 mm blade)

Overall length 329 mm (12-61/64")

Weight (with battery pack) 2.6 kg (5.7 lbs)

135 mm (5-5/16")

BATTERY PACK

Model EY9L40

Storage battery Li-ion Battery

Battery voltage 14.4 V DC (3.6 V × 4 cells)

Capacity 3 Ah

BATTERY CHARGER

Model EY0L80

Electrical rating See the rating plate on the bottom of the charger.

Weight 0.95 kg (2.1 lbs)

20 mm (25/32")

[Li-ion battery pack]

Charging

time

3 Ah

14.4 V 21.6 V 28.8 V

EY9L40

Usable: 35 min.

Full: 50 min.

Usable: 45 min.

- 18 -

EY9L60

Full: 60 min.

EY9L80

Usable: 55 min.

Full: 70 min.

Page 19

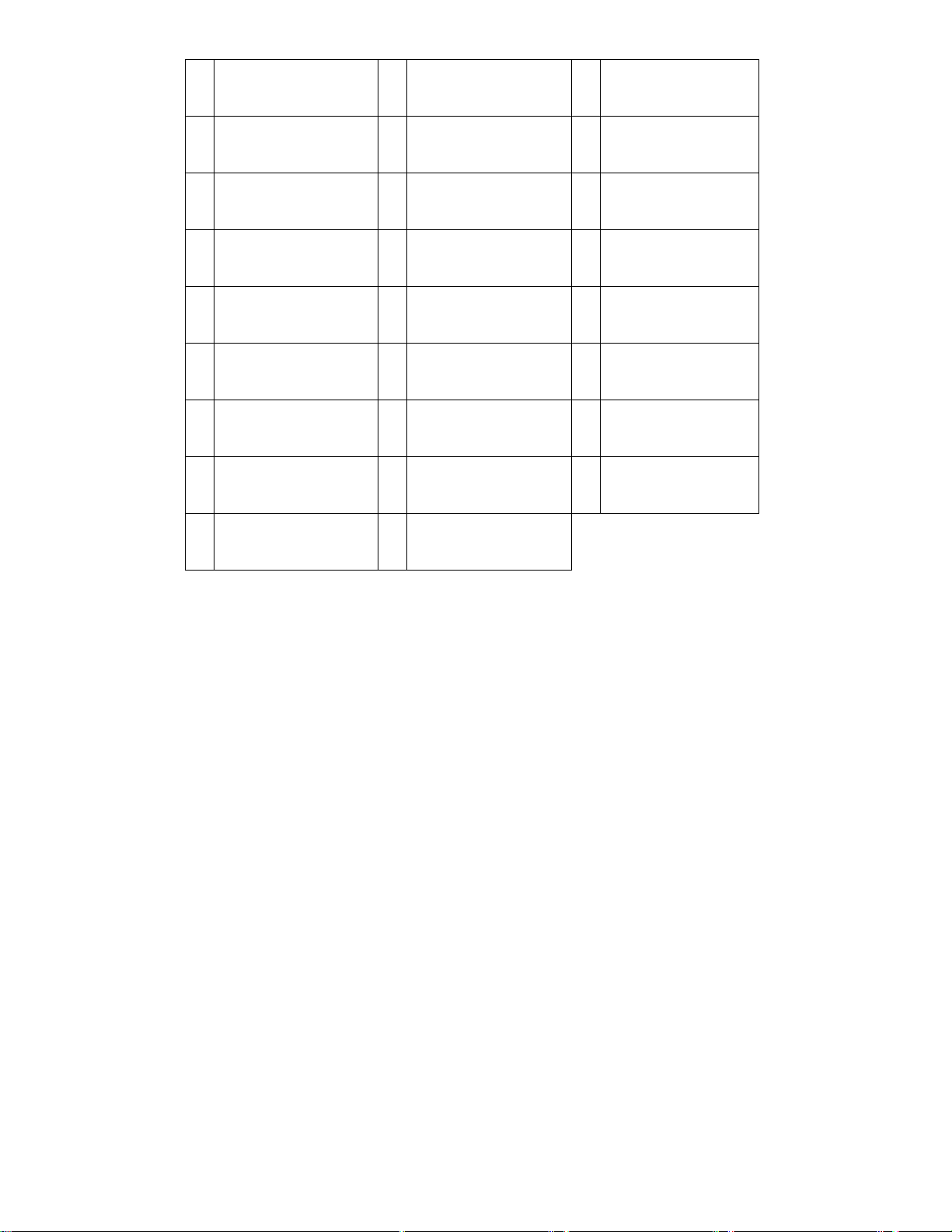

[Ni-Cd/Ni-MH battery pack]

7.2 V 9.6 V 12 V 15.6 V 18 V 24 V

EY9065

1.2 Ah

1.7 Ah

Charging

time

2 Ah

3 Ah

3.5 Ah

NOTE: This chart may include models that are not available in your area.

Please refer to the latest general catalogue.

EY9066

EY9168 EY9188

EY9080

EY9086

20 min.

EY9180

EY9182

EY9001

EY9101

EY9103

25 min.

30 min. 60 min.

EY9106

EY9107

EY9108

EY9200 EY9230 EY9210

EY9201 EY9231 EY9251

55 min.

EY9136

45 min. 90 min.

65 min.

EY9116

EY9117

- 19 -

Page 20

ONLY FOR U.K.

VIII. ELECTRICAL PLUG

INFORMA TION

FOR YOUR SAFETY PLEASE READ

THE FOLLOWING TEXT CAREFULLY

This appliance is supplied with a moulded three

pin mains plug for your safety and convenience.

A 5 amp fuse is fitted in this plug.

Should the fuse need to be replaced please

ensure that the replacement fuse has a rating

of 5 amp and that it is approved by ASTA or BSI

to BS1362.

Check for the ASTA mark

on the body of the fuse.

If the plug contains a removable fuse cover you

must ensure that it is refitted when the fuse is

replaced.

If you lose the fuse cover the plug must not be

used until a replacement cover is obtained.

A replacement fuse cover can be purchased

from your local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE FOR THE SOCKET OUTLET IN

YOUR HOME THEN THE FUSE SHOULD BE

REMOVED AND THE PLUG CUT OFF AND

DISPOSED OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL SHOCK IF THE CUT OFF PLUG IS

INSERTED INTO ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the

wiring code as shown below.

If in any doubt please consult a qualified electrician.

or the BSI mark

IMPORTANT:

The wires in this mains lead are coloured

in accordance with the following code:

Blue: Neutral

Brown: Live

As the colours of the wire in the mains lead of

this appliance may not correspond with the

coloured markings identifying the terminals in

your plug, proceed as follows.

The wire which is coloured BLUE must be

connected to the terminal in the plug which is

marked with the letter N or coloured BLACK.

The wire which is coloured BROWN must be

connected to the terminal in the plug which is

marked with the letter L or coloured RED.

Under no circumstances should either of these

wires be connected to the earth terminal of the

three pin plug, marked with the letter E or the

Earth Symbol

How to replace the fuse: Open the fuse

compartment with a screwdriver and replace

the fuse and fuse cover if it is removable.

- 20 -

.

Page 21

Panasonic Electric Works Co., Ltd.

EN. GR. FR. IT. ND. ES. DN. SW. NR. FN. RUS. Uk

EY971045421 H2007 Printed in China

1048, Kadoma, Osaka 571-8686, Japan

- 21 -

Page 22

- 22 -

Loading...

Loading...