Panasonic EY3552 User Manual

Cordless Metal Cutter

Scie circulaire à batterie à couper les métaux

Sierra para metales inalámbrica

Operating Instructions

Instructions d'utilisation

Manual de instrucciones

Model No : EY3552

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index/Index/Indice

English: Page 3

Français: Page 18

Español: Página 33

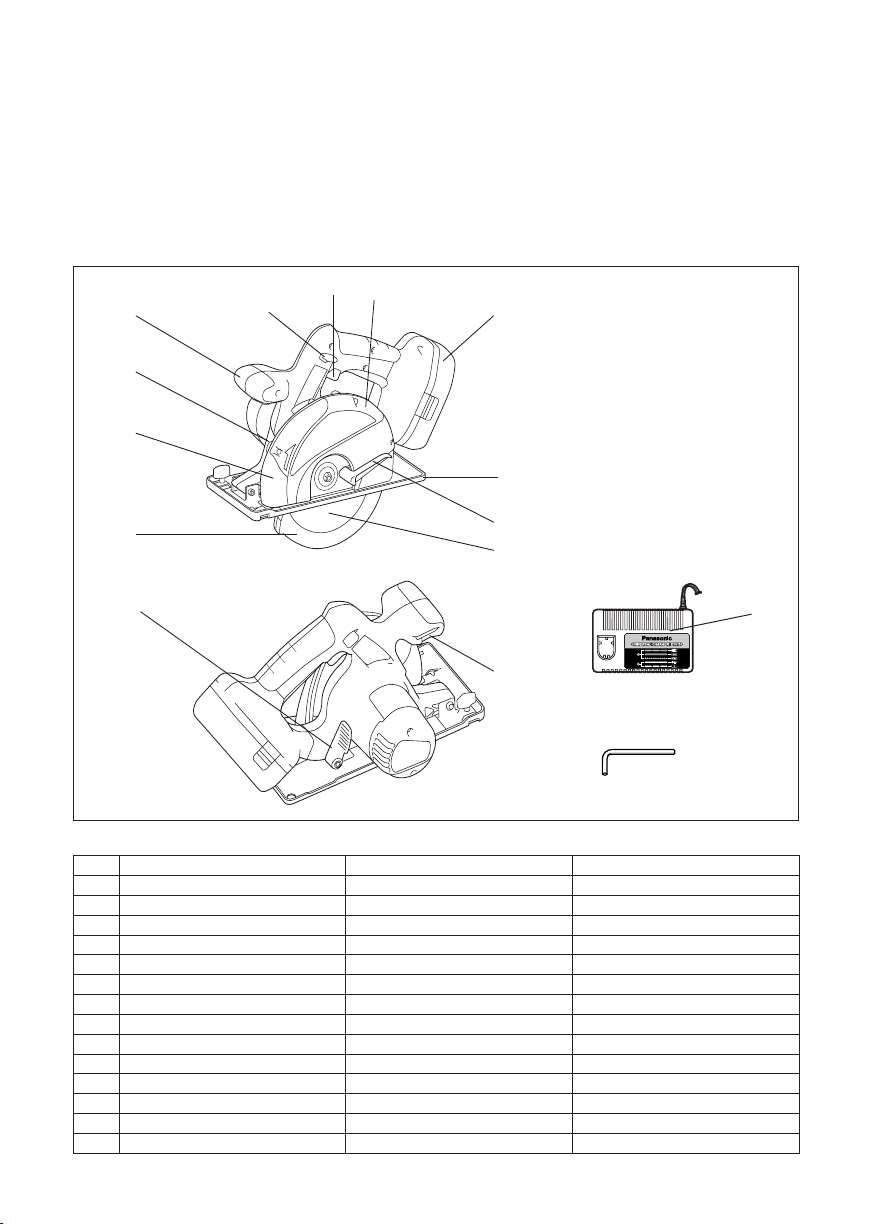

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

M

L

J K

I

H

A

B

G

C

D

F

N

E

O

Fig.1

A Battery pack (EY9251) Batterie autonome (EY9251) Batería (EY9251)

B Shoe Sabot Zapata

C Lower guard lift lever

D Blade (EY9PM17A) Lame de scie (EY9PM17A) Cuchilla (EY9PM17A)

E Storage slot for hex wrench

F Depth adjustment lever

G Lower guard Protège-lame inférieur Protector inferior de la cuchilla

H Transparent guard Protège-lame transparent Protector transparente

I Spindle lock button

J Front grip Bouton avant Asidera delantera

K Switch lock lever

L Power switch Interrupteur d’alimentation Interruptor de alimentación

M Upper blade cover Couvercle de lame supérieur Cubierta superior de la cuchilla

N Battery charger (EY0110) Chargeur de batterie (EY0110) Cargador de batería (EY0110)

O Hex wrench Clé hexagonale Llave hexagonal

Levier de relevage de protège-lame inférieur

Fente de rangement de clé hexagonale

Levier d'ajustement de la profondeur

Bouton de verrouillage de broche

Levier de verrouillage d’interrupteur

Palanca de elevación del protector inferior

Ranura para guardar la llave hexagonal

Palanca de ajuste de profundidad

Botón de bloqueo del husillo

Palanca de bloqueo del interruptor

-

2 -

I. INTRODUCTION

Thank you for purchasing the Panasonic Metal

Cutter. The powerful cutting action of this cutter,

combined with the convenience of its rechargeable battery pack, provides you with great metal

cutting performance.

This Metal Cutter is only to be used for cutting

unhardened ferrous metal.

DANGER

This product is a cutting tool, designed to cut

through metal. It has a rotating blade which is

capable of cutting you deeply, causing serious

injury or death. As a result, please read this

manual and the cautionary markings on

the tool carefully, and obey all of the Safety

Instructions to avoid such injury.

WARNING

To avoid injury, never insert your finger or any

other object into any opening of the metal cutter.

How to Use This Manual

•Please read this manual completely before starting to cut with your metal cutter. If you let someone else use the metal cutter, make sure they

either read this manual or are fully instructed in

the proper use and all safety precautions concerning the metal cutter.

•Please keep this manual for future reference. It

contains important safety information that you

must follow to use the metal cutter safely.

•This manual and product use the following signal

words:

NOTE

Notes provide additional information that you

should know about the metal cutter.

CAUTION

Caution indicates a potentially hazardous situation, which could result in minor or moderate

injury if not avoided. Cautions also alert you to

unsafe practices to be avoided.

WARNING

Warning indicates a potentially hazardous situation, which could result in serious injury or death

if not avoided.

DANGER

Danger indicates a imminent hazard which will

result in serious injury or death if not avoided.

II. SAFETY INSTRUC-

TIONS

General Safety Rules

WARNING! Read all instructions

Failure to follow all instructions listed below

may result in electric shock, fire and/or

serious injury. The term "power tool" in all of

the warnings listed below refers to your mains

operated (corded) power tool and battery

operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

2) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

Power tools create sparks which may ignite

the dust or fumes.

3) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

2) Avoid body contact with earthed or

grounded surfaces such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

3) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the

risk of electric shock.

4) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase the risk

of electric shock.

5) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

-

3 -

-

4 -

Personal safety

1)

Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication.

A moment of inattention while operating power

tools may result in personal injury.

2) Use safety equipment. Always wear eye

protection.

Safety equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

3)

Avoid accidental starting. Ensure the switch

is in the off position before plugging in.

Carrying power tools with your finger on the

switch or plugging in the power tools that have

the switch on invites accidents.

4) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a rotating part

of the power tool may result in personal injury.

5) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

6) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

7)

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of these devices can reduce dust related hazards.

Power tool use and care

1) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was designed.

2) Do not use the power tool if the switch

does not turn it on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

3)

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the

risk of starting the power tool accidentally.

4) Store idle power tools out of the reach of

children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

5)

Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool repaired before

use.

Many accidents are caused by poorly maintained power tools.

6) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

7) Use the power tool, accessories and tool

bits etc. in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into

account the working conditions and the

work to be performed.

Use of the power tool for operations different

from those intended could result in a hazardous situation.

Battery tool use and care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools that

have the switch on invites accidents.

2) Recharge only with the charger specified

by the manufacturer.

A charger that is suitable for one type of battery pack may create a risk of fire when used

with another battery pack.

3) Use power tools only with specifically

designated battery packs.

Use of any other battery packs may create a

risk of injury and fire.

4) When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may

cause burns, or a fire.

5) Under abusive conditions, liquid may be

ejected from battery; avoid contact. If contact accidentally occurs, flush with water.

If liquid contacts eyes, additionally seek

medical help.

Liquid ejected from the battery may cause

irritation or burns.

Service

1) Have your power tool serviced by a qualified repair person using only identical

replacement parts.

-

5 -

This will ensure that the safety of power tool is

maintained.

WARNING

To reduce the risk of injury, user must read

instruction manual.

Safety Instructions for

All Saws

DANGER

• Keep hands away from cutting area and

the blade. Keep your second hand on

auxiliary handle, or motor housing. If both

hands are holding the saw, they cannot be

cut by the blade.

• Do not reach underneath the workpiece.

The guard cannot protect you from the

blade below the workpiece.

• Adjust the cutting depth to the thickness

of the workpiece. Less than a full tooth of

the blade teeth should be visible below the

workpiece.

• Never hold piece being cut in your hands

or across your leg. Secure the workpiece

to a stable platform. It is important to sup-

port the work properly to minimize body

exposure, blade binding, or loss of control.

• Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with

a “live” wire will also make exposed metal

parts of the power tool “live” and shock the

operator.

• When ripping always use a rip fence or

straight edge guide. This improves the

accuracy of cut and reduces the chance of

blade binding.

• Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the mount-

ing hardware of the saw will run eccentrically, causing loss of control.

• Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your saw,

for optimum performance and safety of

operation.

Further Safety Instructions for All Saws

Causes and operator prevention of kickback:

- kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the workpiece toward the operator;

- when the blade is pinched or bound tightly

by the kerf closing down, the blade stalls and

the motor reaction drives the unit rapidly back

toward the operator;

- if the blade becomes twisted or misaligned

in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and

jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given

below.

1) Maintain a firm grip with both hands on the

saw and position your arms to resist kickback forces. Position your body to either

side of the blade, but not in line with the

blade.

Kickback could cause the saw to jump backwards, but kickback forces can be controlled

by the operator, if proper precautions are

taken.

2) When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the

material until the blade comes to a complete stop. Never attempt to remove the

saw from the work or pull the saw backward while the blade is in motion or kickback may occur.

Investigate and take corrective actions to eliminate the cause of blade binding.

3) When restarting a saw in the workpiece,

centre the saw blade in the kerf and check

that saw teeth are not engaged into the

material.

If saw blade is binding, it may walk up or kickback from the workpiece as the saw is restarted.

4) Support large panels to minimize the risk

of blade pinching and kickback.

Large panels tend to sag under their own

weight. Supports must be placed under the

panel on both sides, near the line of cut and

near the edge of the panel.

5) Do not use dull or damaged blades.

Unsharpened or improperly set blades produce narrow kerf causing excessive friction,

-

6 -

blade binding and kickback.

6) Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut.

If blade adjustment shifts while cutting, it may

cause binding and kickback.

7) Use extra caution when making a “plunge

cut” into existing walls or other blind

areas.

The protruding blade may cut objects that can

cause kickback.

Safety Instructions for

This Saw

1) Check lower guard for proper closing

before each use. Do not operate the saw if

lower guard does not move freely and close

instantly. Never clamp or tie the lower guard

into the open position.

If saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with

the Lower Guard Lift Lever and make sure it

moves freely and does not touch the blade or

any other part, in all angles and depths of cut.

2) Check the operation of the lower guard

spring. If the guard and the spring are not

operating properly, they must be serviced

before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a buildup of debris

3) Lower guard should be retracted manually

only for special cuts such as “plunge cuts”

and “compound cuts.” Raise lower guard

by Lower Guard Lift Lever and as soon as

blade enters the material, the lower guard

must be released.

For all other sawing, the lower guard should

operate automatically.

4) Always observe that the lower guard is

covering the blade before placing saw

down on bench or floor.

An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in

its path. Be aware of the time it takes for the

blade to stop after switch is released.

5) Do not use any abrasive wheels.

6) Wear a dust mask, if the work causes dust.

7) Use saw blades recommended by Manufacture.

8) Wear ear protectors when using the tool for

extended periods.

9) The risk of kickback increases as the battery pack discharges.

10) Be sure to inspect material. Avoid cutting

other different material.

11) Be careful not to drop Metal Cutter.

12) Never swing Metal Cutter.

13) Never cover the ventilation slots, and keep

them free from dust or other material.

14) Do not clamp Metal Cutter in a vise. Never

cut with Metal Cutter held upside down in a

vise. This is extremely dangerous and can

lead to serious accidents.

15) Never wear knitted gloves.

16) Be sure no one is below when using Metal

Cutter in high locations.

17) Do not touch the blade immediately after

operation. It may be hot and could burn

your skin.

18) Do not touch material after it has been cut.

Cut material may be very hot.

19) Do not use cutting oil. This use of cutting oil

may cause a fire.

20) Do not cut workpieces covered or stained

with gas, oil, solvents, thinners, etc.

Exposure to these materials may damage

the transparent guard.

21) Do not remove the transparent and lower

guards. If the transparent and lower guards

is damaged or missing, return tool to authorized service center for replacement.

22) Do not start the blade when in contact with

workpiece. Wait for blade to reach full speed

before beginning cut.

Symbol

Symbol

V

n

0

··· / min

A

Revolutions or reciprocations

per minute

Meaning

Volts

Direct current

No load speed

Amperes

-

7 -

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

* Lead from lead-based paints

* Crystalline silica from bricks and cement and

other masonry products

* Arsenic and chromium from chemically-

treated lumber.

To reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as dust

masks that are specially designed to filter out

microscopic particles.

For Battery Charger &

Battery Pack

Important Safety Instructions

1) SAVE THESE INSTRUCTIONS-

This manual contains important safety and

operating instructions for battery charger

EY0110.

2) Before using battery charger, read all

instructions and cautionary markings on

battery charger, battery pack, and product

using battery pack.

3) CAUTION-To reduce the risk of injury, charge only Panasonic Battery

Pack as shown in last page.

Other types of batteries may burst causing

personal injury and damage.

4) Do not expose charger and battery pack

to rain or snow.

5) To reduce risk of damaging the electric

plug and cord, pull by plug rather than

cord when disconnecting charger.

6) Make sure cord is located so that it will not

be stepped on, tripped over, or otherwise

subjected to damage or stress.

7) An extension cord should not be used

unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric shock. If

extension cord must be used, make sure:

a. that pins on plug of extension cord are the

same number, size and shape as those of

plug on charger.

b. that extension cord is properly wired and

in good electrical condition.

c. that wire size is large enough for ampere

rating of charger as specified below.

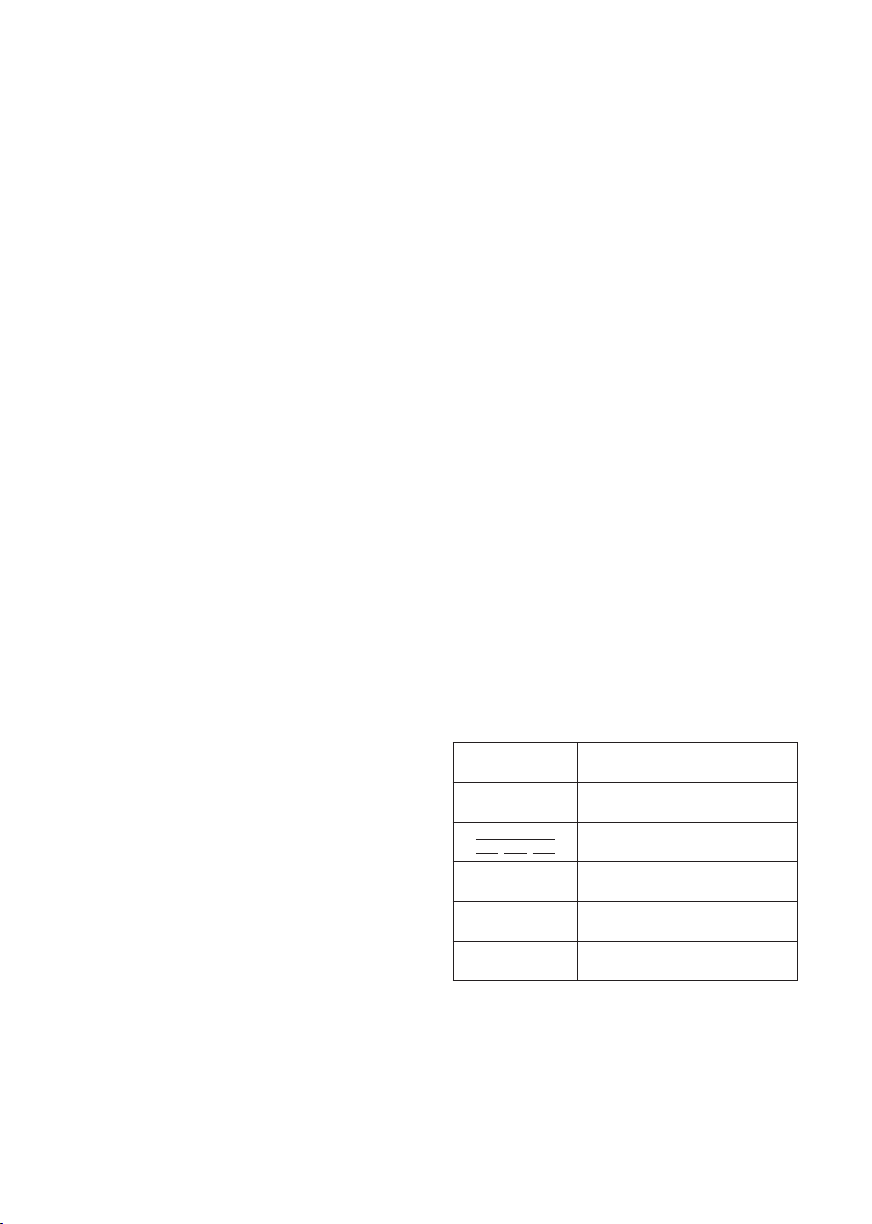

RECOMMENDED MINIMUM AWG SIZE OF

EXTENSION CORDS FOR

AC Input Rating. Amperes AWG Size of Cord

Equal to or

greater than

0 2 18 18 18 16

8) Do not operate charger with damaged cord

or plug — replace them immediately.

9) Do not operate charger if it has received

a sharp blow, been dropped, or otherwise

damaged in any way; take it to a qualified

service personnel.

10) Do not disassemble charger; take it to a

qualified service personnel when service

or repair is required. Incorrect reassembly may result in a risk of electric shock or

fire.

11) To reduce the risk of electric shock, unplug

charger from outlet before attempting any

maintenance or cleaning.

12) The charger and battery pack are specifically designed to work together.

Do not attempt to charge any other cord-

less tool or battery pack with this charger.

13) Do not attempt to charge the battery pack

with any other charger.

14) Do not attempt to disassemble the battery

pack housing.

15) Do not store the tool and battery pack

in locations where the temperature may

reach or exceed 50°C (122°F) (such as a

metal tool shed, or a car in the summer),

which can lead to deterioration of the storage battery.

16) Do not charge battery pack when the temperature is BELOW 0°C (32°F) or ABOVE

40°C (104°F). This is very important in

order to maintain optimal condition of the

battery pack.

17) Do not incinerate the battery pack. It can

explode in a fire.

18) Avoid dangerous environment. Do not use

charger in damp or wet locations.

19) The charger is designed to operate on

standard household electrical power only.

Do not attempt to use it on any other voltage!

20) Do not abuse cord. Never carry charger by

cord or yank it to disconnect from outlet.

Keep cord away from heat, oil and sharp

edges.

BATTERY CHARGERS

But less

than

Length of Cord, Feet

25 50 100 150

-

8 -

21) Charge the battery pack in a well ventilated place, do not cover the charger and battery pack with a cloth, etc., while charging.

22) Use of an attachment not recommended

may result in a risk of fire, electric shock,

or personal injury.

23) Do not short the battery pack. A battery

short can cause a large current flow, over

heating and create the risk of fire or personal injury.

24) NOTE: If the supply cord of this appliance

is damaged, it must only be replaced by

a repair shop authorized by the manufacturer, because special purpose tools are

required.

25) TO REDUCE THE RISK OF ELECTRIC

SHOCK, THIS APPLIANCE HAS A POLARIZED PLUG (ONE BLADE IS WIDER THAN

THE OTHER).

This plug will fit in a polarized outlet only

one way. If the plug does not fit fully in the

outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install

the proper outlet.

Do not change the plug in any way.

-

9 -

III. SETTING UP

Charging Battery Pack EY9251

Charge the battery pack when the cutting speed

becomes too slow for effective cutting.

If you have two battery packs, you can use one to

continue working while charging the other one.

NOTE:

When you charge the battery pack for the first

time, or after prolonged storage, charge it for

about 24 hours to bring the battery up to full

capacity.

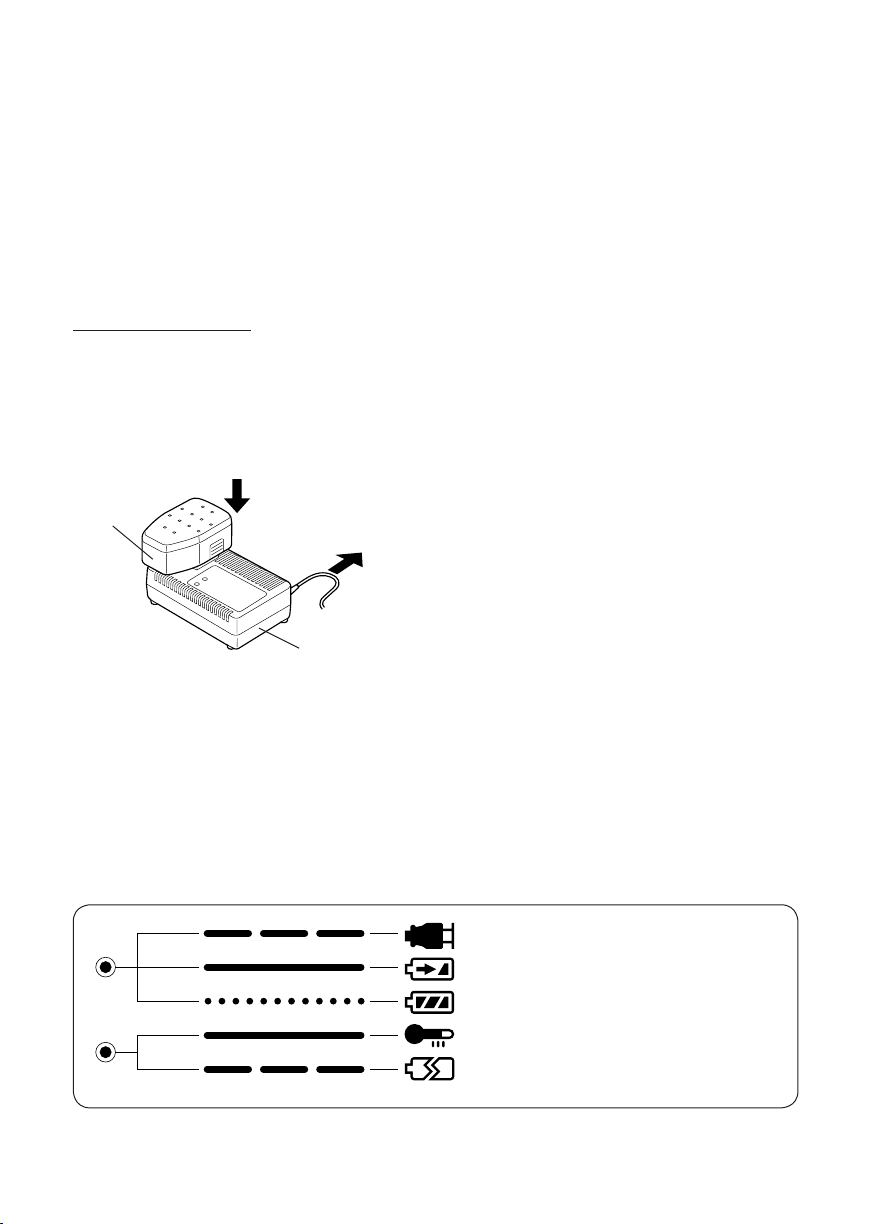

Battery charger (EY0110)

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the plug is

inserted into the AC power supply, but this is

not a problem in terms of safety.

2. Insert the battery pack firmly into the charger.

2

Battery

pack

3. During charging, the charging lamp will be lit.

When charging is completed, an internal electronic switch will automatically be triggered to

prevent overcharging.

• Charging will not start if the battery pack

is warm (for example, immediately after

heavy-duty operation).

To AC

outlet

1

Battery

charger

The orange standby lamp will be lit until the

battery cools down. Charging will then begin

automatically.

4. When charging is completed, the charging

lamp will start flashing quickly in green color.

5. When in any of the conditions that battery

pack is too cool, or the battery pack has not

been used for a long time, the charging lamp

is lit. In this case, charging takes longer to fully

charge the battery pack, than the standard

charging time.

• If a fully charged battery pack is inserted

into the charger again, the charging lamp

lights up. After several minutes, the charging lamp may flash quickly to indicate the

charging is completed.

6. If the charging lamp does not light immediately

after the charger is plugged in, or if after the

standard charging time the lamp does not go

off, consult an authorized dealer.

NOTE:

• When charging a cool battery pack (below 5°C

(41°F)) in a warm place, leave the battery pack

at the place and wait for more than one hour to

warm up the battery to the level of the ambient

temperature. Otherwise battery pack may not

be fully charged.

• Cool down the charger when charging more

than two battery packs consecutively.

• Do not insert your fingers into contact hole,

when holding charger or any other occasions.

CAUTION:

To prevent damage or risk of fire:

• Do not use power source from an engine gen-

erator.

• Do not cover vent holes on the charger and the

battery pack.

• Unplug the charger when not in use.

Lamp Indications

Red Flashing

Red Lit

Green Flashing quickly

Orange Lit

Orange Flashing

Charger is plugged into the AC outlet.

Ready to charge.

Now charging

Charging is completed.

Battery pack is warm. Charging will begin

when temperature of battery pack drops.

Charging is not possible. Clogged with

dust or malfunction of the battery pack.

-

10 -

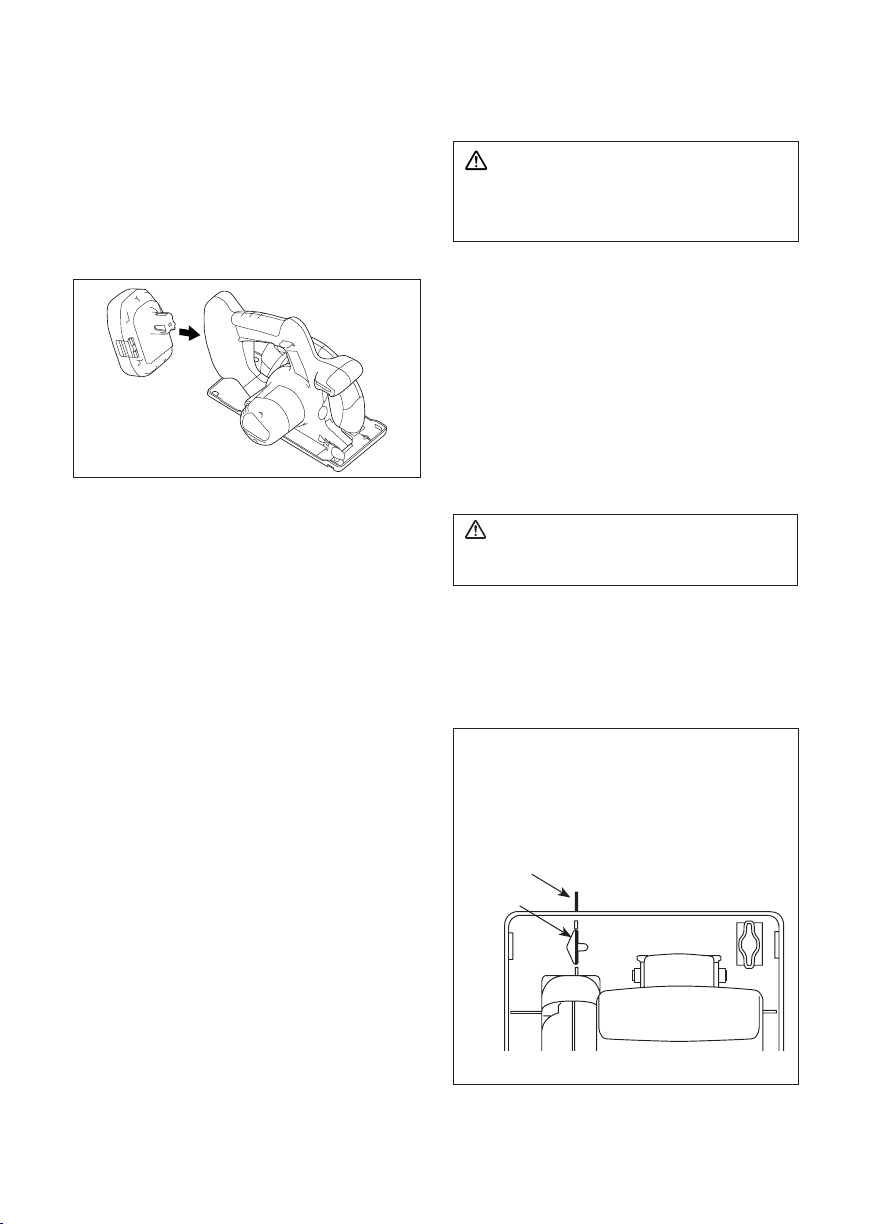

Inserting Battery Pack

CAUTION:

Before inserting battery pack, check that the

power switch in the Metal Cutter actuates properly

and returns to the “OFF” position when released.

1.To insert the battery pack: (See Fig.2)

Slide the battery pack in place at the rear of the

metal cutter. The battery should snap into place.

If the battery is loose, it has not been properly

connected.

Fig.2

2.To remove the battery pack:

Press the two tabs on the sides of the battery

pack. Slide the battery pack out of the metal

cutter body.

IV. OPERATION

Before Using Metal Cutter

This tool is intended for cutting unhardened ferrous metal and nonferrous metal. Refer to the

“Accessories” section for a list of blades to be

used for the proper applications of this tool. The

following precautions must be followed to reduce

the risk of injury;

•Do not cut stacked materials. Cut one piece at a

time.

•Do not cut hardened steel.

•Cut materials with the wider edge of the shoe

over the clamped side of the material.

•Do not touch the saw blade, workpiece, or cutting

chips with bare hands immediately after cutting;

they may be hot and could burn skin.

Each time you use the metal cutter, you must

make sure it is in good operating condition.

Use the following checklist:

3.Does the blade look alright?

Replace the blade immediately if there are any

cracks in it or if any teeth are broken.

4.Does the lower guard close properly?

WARNING

To avoid injury, do not use the metal cutter if

the lower guard does not close quickly over

the blade.

5.Is the transparent guard securely installed?

6.Is the battery pack charged and inserted firmly to

the metal cutter?

7.Is the depth adjustment lever for cutting securely

tightened?

8.Is the workpiece securely clamped on a saw

horse or bench?

Using Metal Cutter

CAUTION:

To reduce the risk of injury read the Safety

Instructions at the front of this manual before using

the metal cutter.

WARNING

To reduce the risk of injury, wear safety goggles

or glasses with side shields.

Follow these steps:

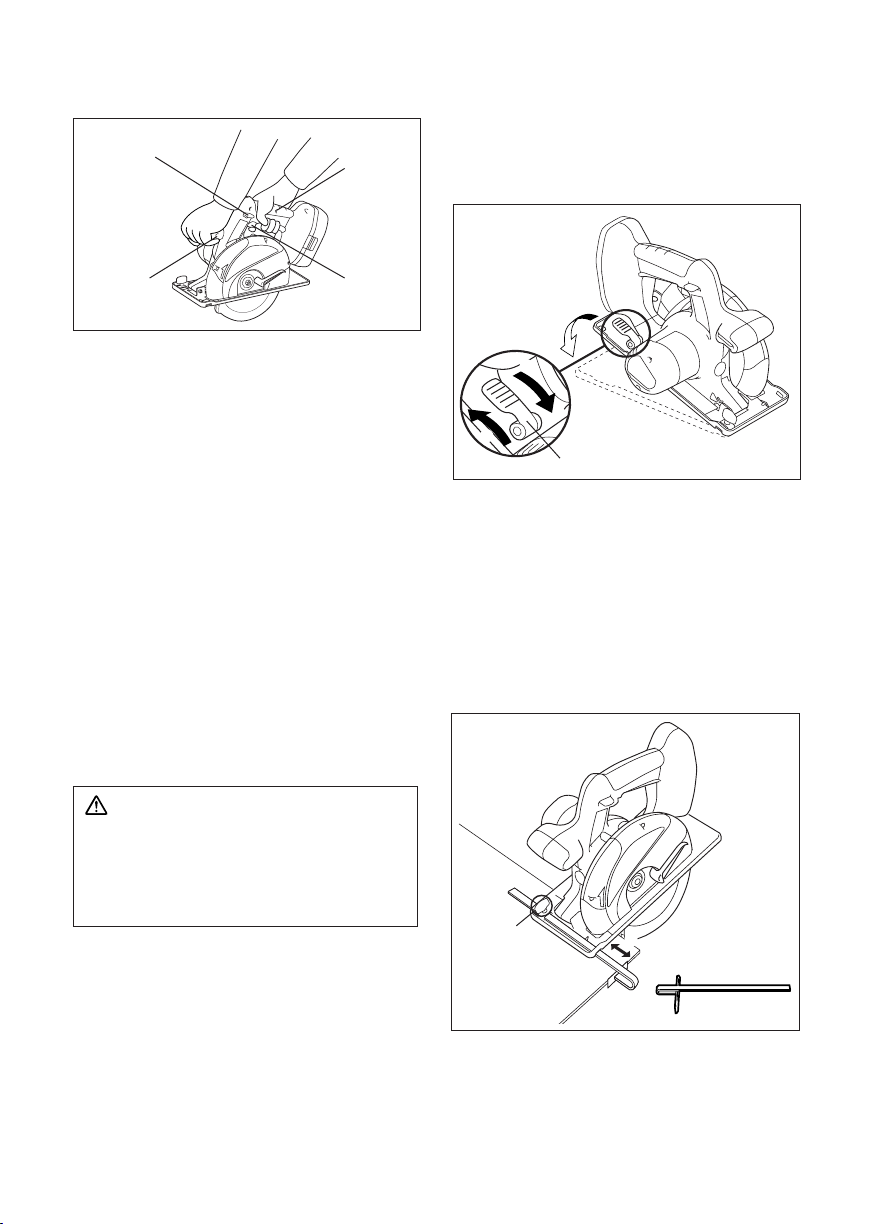

Hold the metal cutter with both hands. (See Fig.4)

Do not attempt to remove cut material when blade

is moving.

1.Line up the sight line on shoe with your cutting

line. (See Fig.3)

Alignment with cutting line

•Use the notch as guide to establish cutting

position. Align the notch with cutting line.

As the cutting position may differ depending on

the blade, do a trial cut beforehand.

Cutting line

Notch

1.Is the blade installed in the correct direction?

The arrow on the blade must point in the same

direction as the arrow on the upper blade cover.

2.Is the blade installed properly?

Make sure the hex bolt is tightened securely.

(See Fig.12)

Guide line of blade front

Fig.3

-

11 -

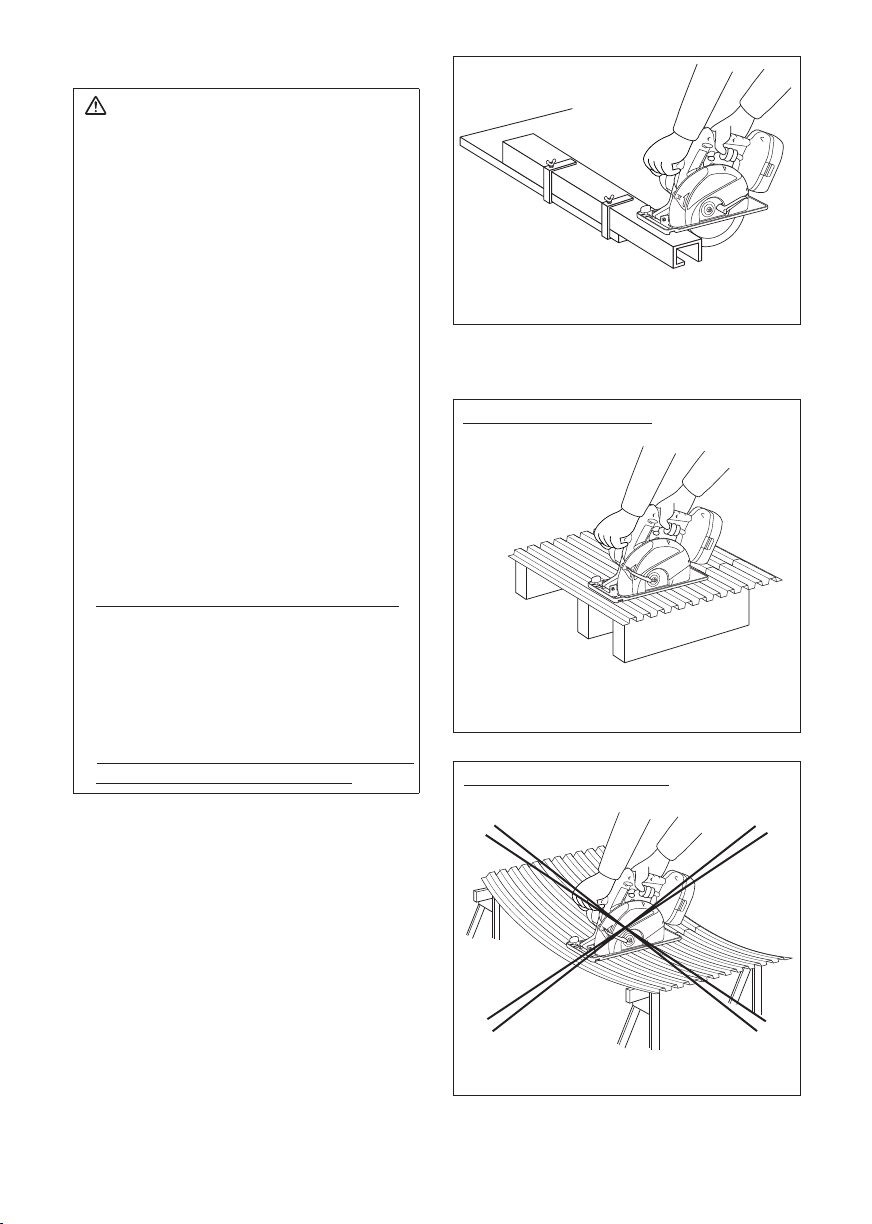

2.Press the switch lock lever down, then squeeze

the power switch to start the motor, and then

release the switch lock lever.

Switch

lock lever

Handle

Cutting depth adjustment

•Remove battery pack.

•Loosen the depth adjustment lever by pushing it

and adjust the cutting depth.

Tighten the depth adjustment lever securely by

lifting it up towards the motor housing at the

desired cutting depth.

Front grip

Fig.4

CAUTION:

• Check that the switch lock lever works.

If power switch can be activated without

depressing the switch lock lever, discontinue

use immediately. Take the tool to an authorized service center.

• Always hold the handle with one hand and the

front grip with the other. (See Fig.4) Maintain a

firm grip and depress the switch fully.

• The blade should not touch the cutting material before you start the motor. Wait until the

blade reaches full speed before starting a cut.

• This tool has no provision to lock the power

switch in the “ON” position, and you must not

attempt to secure it in the “ON” position.

3.Start cutting when the blade reaches full speed.

4.During cutting, keep your cutting line straight.

Move the metal cutter forward at a steady speed,

while looking at the tip of the blade through the

transparent guard.

Power

switch

WARNING

• To prevent dangerous kickback, keep the

shoe of the metal cutter flat on the surface of

the material being cut.

• Never force the cutter. Use light and continu-

ous pressure.

5.If the motor starts to feel too warm, stop cutting.

Let the metal cutter cool down before continuing

work.

6.It is always a safe practice to remove the battery

pack after use and before storing the metal cutter.

Tighten

1

2

Loosen

Depth adjustment lever

Fig.5

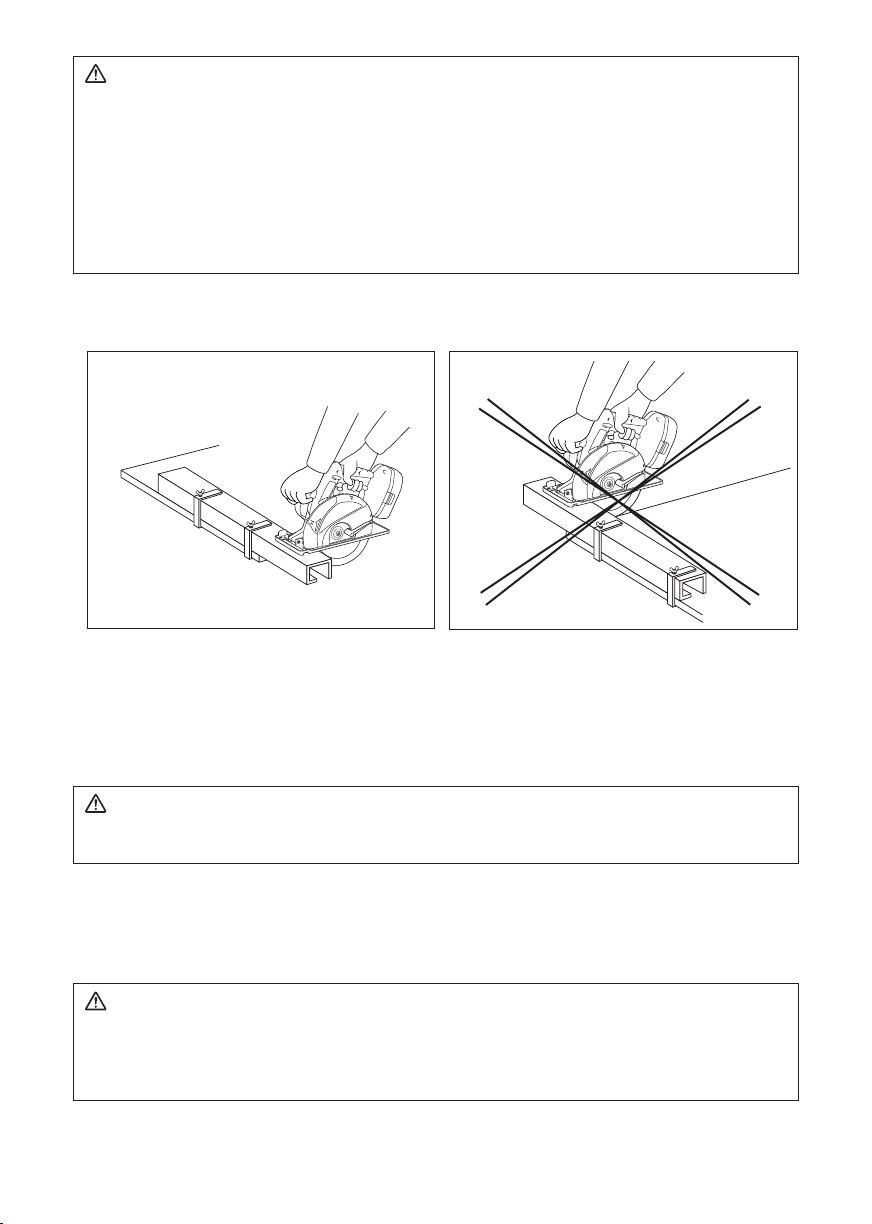

Rip fence (EY3500B7727)

(Available as an accessory, not included)

Rip fence is convenient for rip cuts and repeated

cuts of same width.

•Remove battery pack.

•Insert rip fence and adjust cutting width. (See

Fig.6)

•Fasten screw securely to fix rip fence.

2

Fasten screw

1

Insert and adjust

Fig. 6

Rip Fence

-

12 -

For Proper Use (Further Detail)

WARNING

To prevent the risk of serious personal injury:

l It is important to use an appropriate device

to hold the material being cut properly, and

to hold the cutter firmly with both hands to

prevent loss of control which could cause

personal injury.

• Figure 7 shows proper cutting position.

• Note that hands are kept away from cutting

area.

• Make sure bystanders are away from work

area and from underneath of workpiece.

• When cutting, do not try to hold the material

with your hand.

Fig.7

Cutting large sheets;

Support large sheets. Be sure to set the depth

of the cut so that you only cut through the workpiece, not through the supports. (See Fig.8)

Large sheets sag or bend if they are not

correctly supported. If you attempt to cut

without leveling and properly supporting the

workpiece, the blade will tend to bind, causing

kickback. (See Fig.9)

• Don’t support the material away from the cut.

Cutting thin or corrugated materials;

Cut thin and corrugated materials at least

1" from the edge of the workpiece to avoid

injury or damage to the tool caused by thin

strips of metal being pulled into the upper

guard.

•Use sharp blades only. Clean and sharp

blades minimize stalling and kickback.

Proper Support of Material

Fig.8

Improper Support of Material

Fig.9

-

13 -

WARNING

To prevent the risk of serious personal injury:

• When making an incomplete cut or cutting is interrupted, or blade is binding or cutter is stalling;

release the power switch immediately and hold the cutter motionless in the material until the blade

comes to a complete stop.

• To avoid kickback, never attempt to remove the cutter from the work or pull the cutter backward while

the blade is in motion. Make sure the blade has come to a complete stop, then remove cutter from

cut.

• To resume cutting, start metal cutter, allow the blade to reach full speed, reenter the cut slowly and

resume cutting.

1.Place the wider part of the shoe on the part of the work piece which is solidly supported (See Fig.10),

never on the section that will fall off when the cut is made. (See Fig.11)

Hold the cutter firmly to prevent loss of control. Working carelessly can cause severe personal injury.

RIGHT

Fig.10

2.Make sure the blade stops.

Even though your metal cutter has a brake, before setting the metal cutter down, make sure the blade

has come to a complete stop and the lower guard has closed.

3.Do not use if anything seems unusual. Remove battery pack immediately.

If the metal cutter body becomes very hot, or does not work properly, remove the battery pack and do not

use. Have it checked by an authorized service center.

WRONG

Fig.11

WARNING

To prevent the risk of serious personal injury or fire, do not try to repair the metal cutter by yourself.

Never disassemble or modify the metal cutter body. There are no user-repairable parts inside.

4.NEVER ALLOW THE CUTTER TO COME IN CONTACT WITH YOUR BODY.

After completing a cut, do not allow the cutter to brush against your leg or side.

Since the lower guard is retractable, it could catch on your clothing and expose the blade. Keep clothing

away from metal cutter. Be aware of the exposed blade sections that exist in both the upper and lower

guard areas.

WARNING

Because cutting metal creates sparks;

• Always use safety goggles

• Do not use metal cutter near any flammable substance or in an area where flammable substances

are used. Fire and burn injury could result.

5.Never engage the spindle lock while blade is running, or engage in an effort to stop the tool. Never turn

the switch on when the spindle lock is engaged. Serious damage to your metal cutter will result.

-

14 -

V. MAINTENANCE

WARNING

To avoid severe personal injury, always

remove the battery pack from the metal cutter

before starting any maintenance procedure.

CAUTION:

To assure product SAFETY and RELIABILITY,

servicing should be performed by an authorized

service center. Always insist on genuine Panasonic

replacement parts.

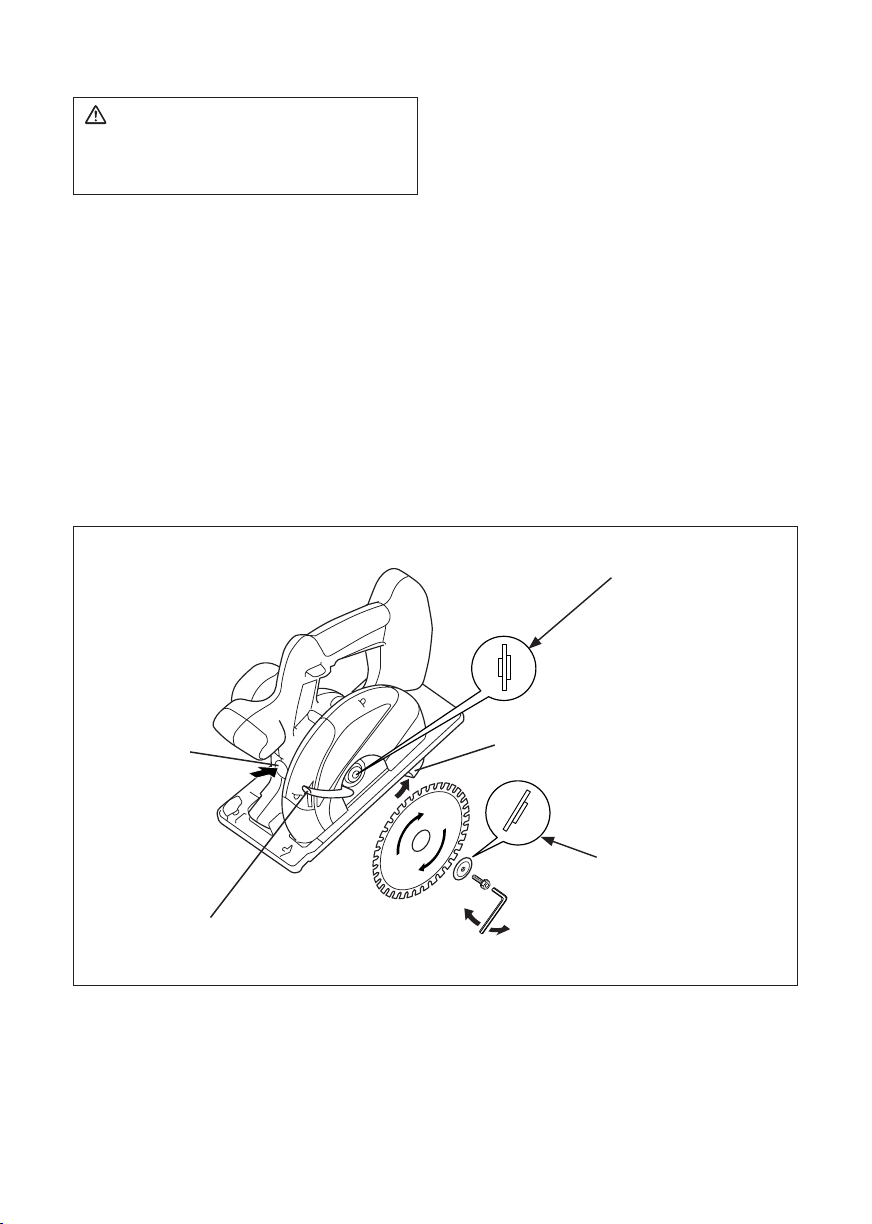

Removing Blade

CAUTION:

The blade will be hot right after cutting. Be sure to

let the blade cool down before removing it.

Follow these steps:

1.Remove the battery pack from the metal cutter.

2.Hold the spindle lock button down. This prevents

the blade from rotating.

3.Use the provided hex wrench to loosen the hex

bolt.

NOTE:

Keep the hex wrench in the storage slot on the

metal cutter’s body when not using it.

4.Remove the hex bolt and outer washer.

5.Use the lower guard lift lever to retract (open) the

lower guard.

6.Carefully remove the blade.

7.Clean the metal cutter if necessary.

CAUTION:

Be careful to avoid cutting your hands on the

blade.

• When disposing of a blade, secure it inside

heavy or corrugated paper. This will help prevent

anyone from being cut by the discarded blade.

Place the inner washer

with cut-out facing you.

Spindle lock

button

Lower guard lift lever

Loosen

Fig.12

Inner washer

Lower guard

Outer washer

Hex bolt

Tighten

Place the protrusion of

the outer washer into the

position of the washer.

-

15 -

Installing Blade

Follow these steps:

1.Remove the battery pack from the metal cutter.

2.Remove any cutting debris from blade area.

3.Use the lower guard lift lever to retract (open) the

lower guard.

4.Install the blade as illustrated. (See Fig. 12)

Make sure that both the direction arrow on the

blade and the direction arrow on the upper blade

cover point in the same direction.

5.Set the outer washer in place.

6.Insert the hex bolt.

7.Hold the spindle lock button down. This prevents

the blade from rotating.

8.Tighten the hex bolt securely with the provided

hex wrench. Store the hex wrench.

NOTE: Keep the hex wrench in the storage slot on

the metal cutter’s body when not using it.

WARNING

Failure to follow these instructions can result

in serious personal injury.

For Appropriate use of Battery

pack

Ni-MH Battery pack (EY9251)

• Charge the Ni-MH battery fully before storage

in order to ensure a longer service life.

• The ambient temperature range is between 0°C

(32°F) and 40°C (104°F).

If the battery pack is used when the battery

temperature is below 0°C (32°F), the tool may

fail to function properly. In that case, charge the

battery until charging is completed for appropriate functioning of the battery.

• When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal

to another.

Shorting the battery terminals together may

cause sparks, burns or a fire.

• When operating with a Ni-MH battery pack,

make sure the place is well ventilated.

Battery Pack Life

The rechargeable batteries have a limited life. If

operation time becomes extremely short after

recharging, replace the battery pack with a new one.

NOTE:

•Use under extremely hot or cold conditions will

reduce operating capacity per charge.

•Even if you don’t use the Metal Cutter, charge

the battery pack at least once every six months.

Battery Recycling

ATTENTION:

A nickel metal hydride battery that is recyclable

powers the product you have purchased.

Please call 1-800-8-BATTERY for information on

how to recycle this battery.

Cleaning Metal Cutter

Keep your metal cutter clean for good cutting performance, and to help keep it safe to use.

Follow these steps:

1.Remove the battery pack from the metal cutter.

2.Wipe the metal cutter with a dry, soft cloth. Do

not use a wet cloth or cleaning liquids.

They could damage the metal cutter’s finish.

3.Be sure to rub off any oil or grease which could

make the metal cutter slippery or hard to handle.

4.Remove the blade and brush off any dust.

CAUTION:

To avoid injury or damage to the unit, never

immerse any part of the tool in a liquid.

Transparent Guard

WARNING

If the guard is cracked, or is broken, take the

metal cutter to an authorized service center

for replacement. Do not attempt to operate

cutter. It could result in serious personal injury.

Never use your metal cutter with a damaged

transparent guard or without the transparent

guard installed. Flying chips could result in

serious injury.

Loading...

Loading...