Page 1

2 mode Noise Filters

Typ e:

EXC24CB/CP

EXC24CN

2 mode Noise Filters

■ Features

● Burst/radiation noise fi ltering for audio circuits

● The optimally magnetic-coupled ferrite beads allow for

the fi ltering of both common and normal mode noises

● The strong multi-layer structure provides high resistance

to refl ow soldering heat and a high mounting reliability

● Magnetic shield type

● High Impedance : 220 to 1 k액(EXC24CB type)

● Low Resistance Value : 0.4 액 max. (EXC24CP type)

● High Impedance : 600 액,

Low Resistance Value : 0.9 액 max. (EXC24CN type)

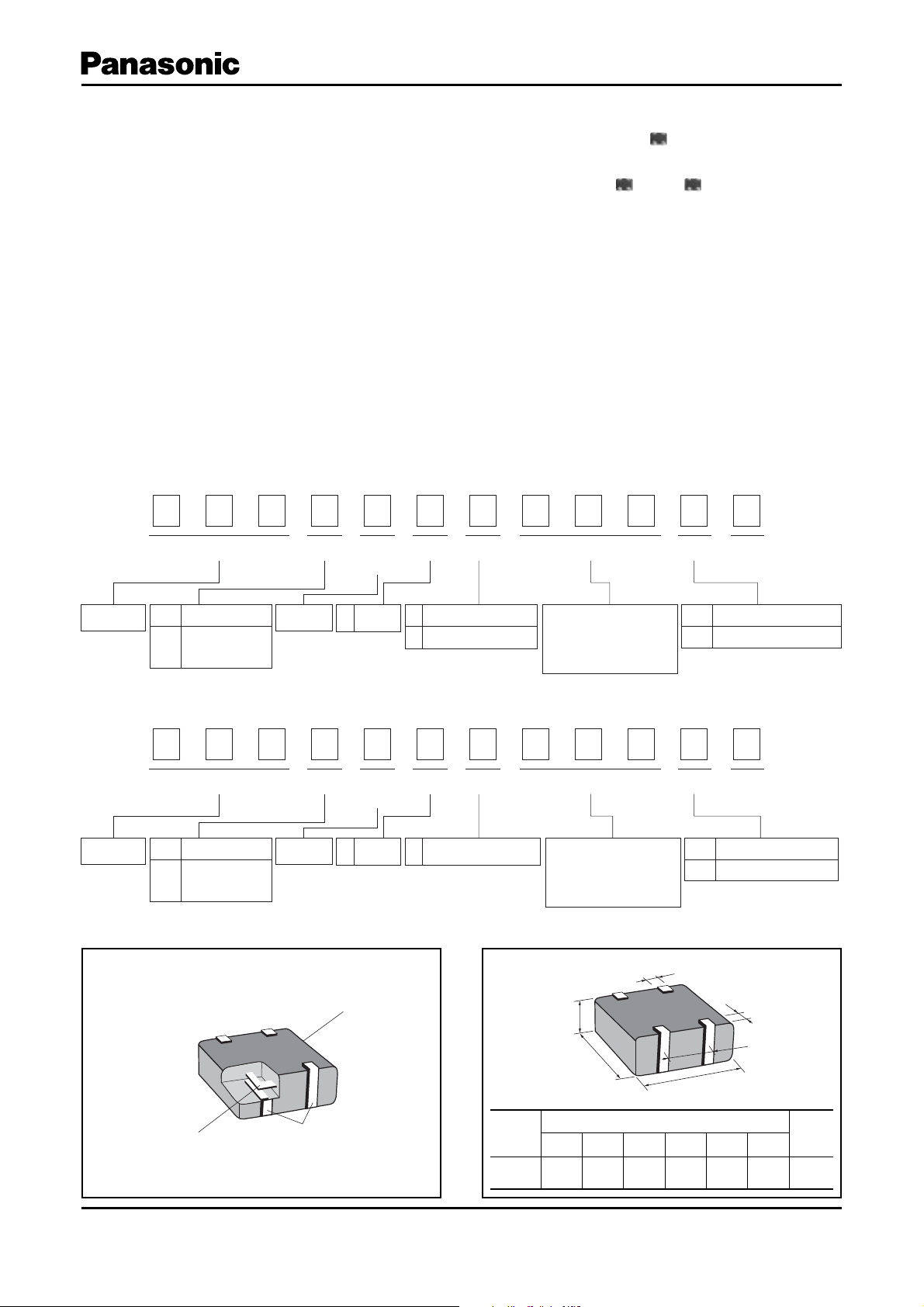

■ Explanation of Part Numbers

EXC24CB/CP Type

●

Noise Filter

1

E

Code

2

2

X

Product Code Type

Dimensions(mm)

1.25 ҂ 1.00 ҂ 0.50

(L) ҂ (W) ҂ (H)

3

C

4Terminals

4

2

Size Nominal Impedance Form Suffix

Number of

Terminals

Coupled

C

type

5

4

6

C

High Impedance Type

B

Low DCR Type

P

■ Recommended Applications

● Receiver lines, speaker lines, microphone lines and

headset of mobile phones.

● Audio signal lines of Portable audio equipment, PCs,

PDAs.

7

B

Characteristics

8

1

9

0

The first two digits are

significant figure of

impedance value, and the

third one denotes the

number of zeros following

10

2

11 12

U

Code

U

Packing

Embossed Carrier Taping

EXC24CN Type

●

Noise Filter

1

E

Code

2

2

X

Product Code Type

Dimensions(mm)

1.25 ҂ 1.00 ҂ 0.50

(L) ҂ (W) ҂ (H)

3

C

4Terminals

4

2

Size Nominal Impedance Form Suffix

Number of

Terminals

Coupled

C

type

5

4

6

C

High Impedance Type

N

and Low DCR Type

7

N

Characteristics

8

6

9

0

The first two digits are

significant figure of

impedance value, and the

third one denotes the

number of zeros following

10

1

11 12

X

Code

X

■ Construction ■ Dimensions in mm (not to scale)

F

Inner Conductor

Electrode

Ferrite

Type

(inches)

EXC24C

(0504)

C

A

B

Dimensions (mm)

ABCDE F

1.00±0.15 1.25±0.15 0.50±0.10 0.20±0.15 0.65±0.10 0.35±0.10

Packing

Pressed Carrier Taping

D

E

Mass

(Weight)

[mg/pc.]

3

Design and spec ifi cations are e ach subj ect to change w ithout notic e. Ask f actory for t he cur rent technical speci fi cations before purchase and/or use.

Should a sa fet y concern ar ise reg arding th is product, please be sure to c ontac t us immediately.

Feb. 2008

Page 2

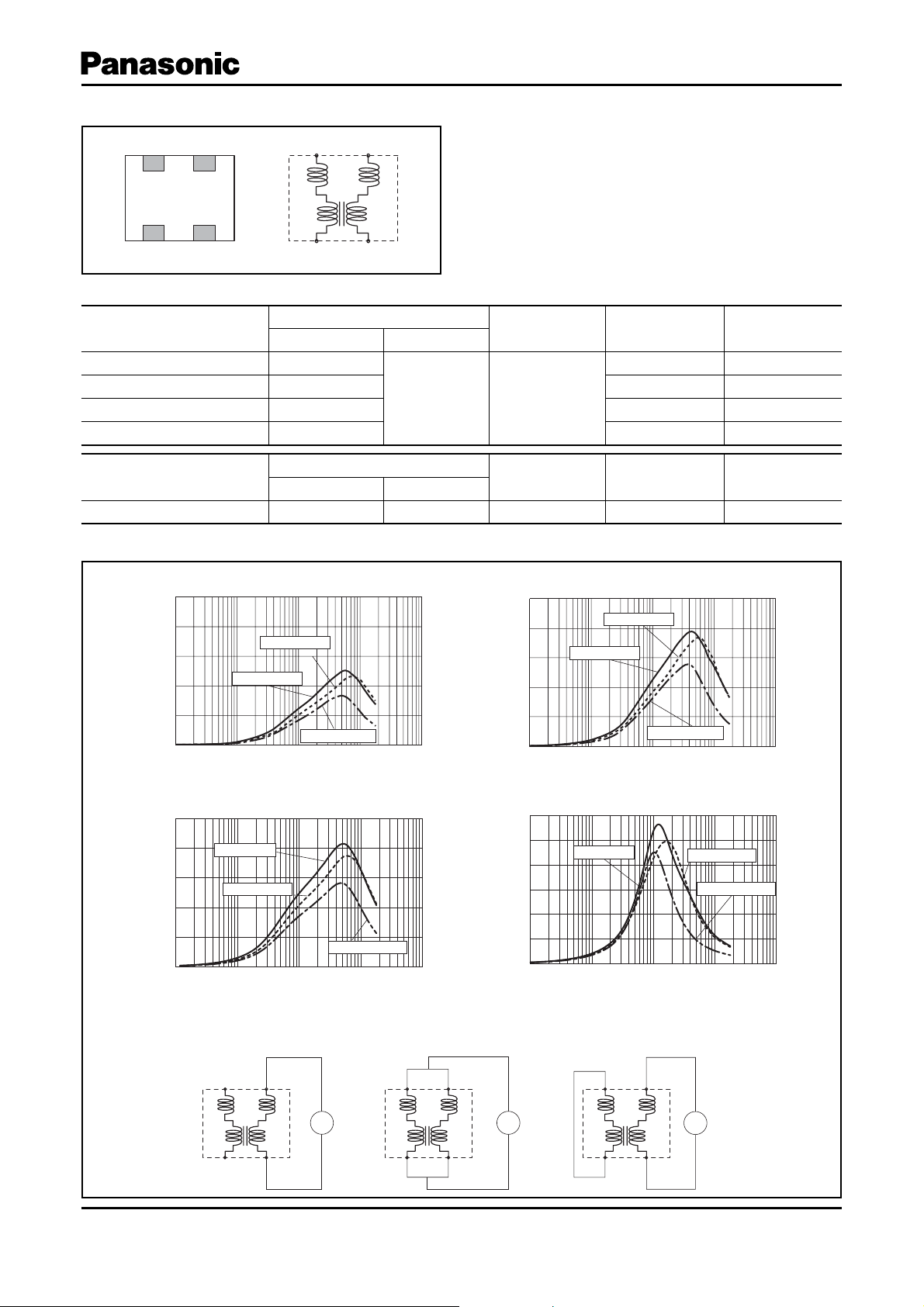

■ Circuit Confi guration (No Polarity)

2 mode Noise Filters

43

12

43

12

■ Ratings

Part Number

EXC24CP121U

EXC24CP221U

EXC24CB221U

EXC24CB102U

Part Number

EXC24CN601X

Impedance (Open mode)

(액) at 100 MHz Tolerance(%)

120

220 350 0.4

220 100 0.7

1000 50 1.5

Impedance (Common mode)

(액) at 100 MHz Tolerance(%)

600 ±25 5 200 0.9

■ Impedance Characteristics (Typical)

EXC24CP121U

●

500

400

300

200

Impedance(액)

100

0

EXC24CB221U

●

500

400

300

200

Impedance(액)

100

0

110100 1000 10000

Open mode

110100 1000 10000

Normal mode

Open mode

Common mode

Frequency(MHz)

Normal mode

Common mode

Frequency(MHz)

Rated Voltage

(V DC)

±25 5

Rated Voltage

(V DC)

EXC24CP221U

●

500

400

300

200

Impedance(액)

100

0

110100 1000 10000

EXC24CB102U

●

1200

1000

800

600

400

Impedance(액)

200

0

110100 1000 10000

Rated Current

(mA DC)

500 0.3

Rated Current

(mA DC)

Normal mode

Open mode

Common mode

Frequency(MHz)

Open mode

Frequency(MHz)

Normal mode

Common mode

DC Re sis tance

(액) max.

DC Re sis tance

(액) max.

Measurement Circuit

●

(A)Open Mode (B)Common Mode (C)Normal Mode

Z

Design and spec ifi cations are e ach subj ect to change w ithout notic e. Ask f actory for t he cur rent technical speci fi c ations before purchase and/or use.

Should a sa fet y concern ar ise reg arding th is product, please be sure to c ontac t us immediately.

Z

Z

Feb. 2008

Page 3

(A)Open Mode

(C)Differential Mode

(B)Common Mode

Z

Z

Z

■ Impedance Characteristics (Typical)

2 mode Noise Filters

EXC24CN601X

●

1600

1400

1200

1000

800

600

Impedance(액)

400

200

–

110100 1000 10000

Differential mode

Open mode

Common mode

Frequency(MHz)

Measurement Circuit

●

■ Packaging Methods (Taping)

● Standard Quantity

Part Number Kind of Taping Pitch (P1)Quantity

EXC24CP

EXC24CB

EXC24CN

Embossed Carrier Taping

●

t1

Sprocket hole Compartment

t2

Chip component

첸첸첸

첸첸첸

첸첸첸

U

U

X

Embossed Carrier Taping 4 mm 5000 pcs./reel

Pressed Carrier Taping 2 mm 10000 pcs./reel

Pressed Carrier Taping

●

φD0

A

B

P1 P2 P0

FE

W

Ta pe running direction

Sprocket hole

B

A

t2

Chip component

P0 P2

P1

Tape running direction

Compartment

φD0

E

F

W

●

Embossed Carrier Dimensions (mm)

Pressed Carrier Dimensions (mm)

Standard Reel Dimensions (mm)

Design and spec ifi cations are e ach subj ect to change w ithout notic e. Ask f actory for t he cur rent technical speci fi c ations before purchase and/or use.

Should a sa fet y concern ar ise reg arding th is product, please be sure to c ontac t us immediately.

Ta ping Reel

Part Number

EXC24CP

EXC24CB

Part Number

EXC24CN

Part Number

EXC24C

첸첸첸첸

E

φA

U

첸첸첸

첸첸첸

첸첸첸

1.20±0.15 1.45±0.15 8.0±0.2 3.5±0.1 1.75±0.10 4.0±0.1 2.0±0.1 4.0±0.1 1.5±0.1 0.25±0.05 0.90±0.15

U

X

1.20±0.15 1.45±0.15 8.0±0.2 3.5±0.1 1.75±0.10 2.0±0.1 2.0±0.1 4.0±0.1 1.5±0.1 0.68±0.10

U

180.0±3.0 60.0±1.0 13.0±0.5 21.0±0.8 2.0±0.5 9.0±0.3 11.4±1.5 1.2±0.2

T

φC

φD

ABWFEP

ABWFEP

φB

W

t

1

P

1

A

φ

B

φ

C

φ

DE W T t

φ

2

P

0

P

2

D

φ

0

P

0

t

1

D

φ

0

t

2

t

2

Feb. 2008

Page 4

■ Recommended Land Pattern Design

B

EF E

A

DCD

■ Recommended Soldering Conditions

Recommendations and precautions are described below.

Recommended soldering conditions for refl ow

●

· Refl ow soldering shall be performed a maximum of

two times.

· Please contact us for additional information when

used in conditions other than those specifi ed.

· Please measure the temperature of the terminals

and study every kind of solder and printed circuit

board for solderability be fore ac tu al use.

Peak

2 mode Noise Filters

Dimension (mm)

A 1.50 to 1.90

B 1.10

C 0.50

D 0.50 to 0.70

E 0.40

F 0.30

For soldering (Example : Sn- 37Pb)

Temp erature Time

Preheating 140 °C to 160 °C 60 s to 120 s

Main heating Above 200 °C 30 s to 40 s

Peak 235 ± 10 °C max. 10 s

Preheating

For lead-free soldering (Example : Sn/3Ag/0.5Cu)

Temp erature Time

Temperature

Heating

Preheating 150 °C to 170 °C 60 s to 120 s

Main heating Above 230 °C 30 s to 40 s

Peak max. 260 °C max. 10 s

Time

<Repair with hand soldering>

Preheat with a blast of hot air or similar method. Use a soldering iron with a tip temperature of 350 °C or less. Solder

●

each electrode for 3 seconds or less.

Never touch this product with the tip of a soldering iron.

●

Safety Precautions

The following are precautions for individual products. Please also refer to the precautions common to EMI Filters,

ESD Suppressors, Fuses, and MR Sensors shown on page EL113 of this catalog.

1. When possible, do not mount 2 mode Noise Filters (hereafter called the fi lters) by fl ow soldering. It is highly

possible that fl ow soldering may cause bridges between the electrodes.

2. Use rosin-based fl ux or halogen-free fl ux.

3. For cleaning, use an alcohol-based cleaning agent. Before using any other type, consult with our sales person

in advance.

4. Do not apply shock to the fi lters or pinch them with a hard tool (e.g. pliers and tweezers). Otherwise, their bodies

may be chipped, affecting their performance. Excessive me chanical stress may damage the fi lters. Handle

with care.

5. Store the fi lters in a lo ca tion with a temperature ranging from −5 °C to +40 °C and a relative humidity of 40 % to 60 %,

where there are no rapid changes in temperature or humidity.

6. Use the fi lters within half a year after the date of the outgoing inspection indicated on the packages.

Design and spec ifi cations are e ach subj ect to change w ithout notic e. Ask f actory for t he cur rent technical speci fi c ations before purchase and/or use.

Should a sa fet y concern ar ise reg arding th is product, please be sure to c ontac t us immediately.

Jul. 2008

Page 5

Safety Precautions (Common precautions for EMI Filters, ESD Suppressors, Fuses, and MR Sensors)

• When using our products, no matter what sort of equipment they might be used for, be sure to make a written

agreement on the specifi cations with us in advance. The design and specifi cations in this catalog are subject

to change without prior notice.

• Do not use the products beyond the specifi cations described in this catalog.

• This catalog explains the quality and performance of the products as individual components. Before use, check

and evaluate their operations when installed in your products.

• Install the following systems for a failsafe design to ensure safety if these products are to be used in equip ment

where a defect in these products may cause the loss of human life or other signifi cant dam age, such as damage to

vehicles (automobile, train, vessel), traffi c lights, medical equipment, aerospace equipment, electric heating

appliances, combustion/gas equipment, rotating equipment, and disaster/crime prevention equipment.

Systems equipped with a protection circuit and a protection device

✽

Systems equipped with a redundant circuit or other system to prevent an unsafe status in the event of a sin gle fault

✽

(1) Precautions for use

• These products are designed and manufactured for general and standard use in general elec tron ic equipment

(e.g. AV equipment, home electric appliances, offi ce equipment, information and communication equipment)

• These products are not intended for use in the following special conditions. Before using the products,

carefully check the effects on their quality and performance, and determine whether or not they can be used.

1. In liquid, such as water, oil, chemicals, or organic solvent

2. In direct sunlight, outdoors, or in dust

3. In salty air or air with a high concentration of corrosive gas, such as Cl

4. Electric Static Discharge (ESD) Environment (except ESD Suppressors)

These components are sensitive to static electricity and can be damaged under static shock (ESD).

Please take measures to avoid any of these environments.

Smaller components are more sensitive to ESD environment.

5. Electromagnetic Environment

Avoid any environment where strong electromagnetic waves exist.

6. In an environment where these products cause dew condensation

7. Sealing or coating of these products or a printed circuit board on which these products are mounted, with

resin or other materials

• These products generate Joule heat when energized. Carefully position these products so that their heat will

not affect the other components.

• Carefully position these products so that their temperatures will not exceed the category temperature range due

to the effects of neighboring heat-generating components. Do not mount or place heat-generating components

or infl ammables, such as vinyl-coated wires, near these products (except Thermal Cutoffs).

• Note that non-cleaning solder, halogen-based highly active fl ux, or water-soluble fl ux may deteriorate the

performance or reliability of the products.

• Carefully select a fl ux cleaning agent for use after soldering. An unsuitable agent may deteriorate the performance

or reliability. In particular, when using water or a water-soluble cleaning agent, be careful not to leave water

residues. Otherwise, the insulation performance may be deteriorated.

, H2S, NH3, SO2, or NO

2

2

(2) Precautions for storage

The performance of these products, including the solderability, is guaranteed for a year from the date of ar riv al

at your company, provided that they remain packed as they were when delivered and stored at a tem per a ture

of 5 °C to 35 °C and a relative humidity of 45 % to 85 %. (Micro Chip Fuses: Guaranteed for 6 months from the

date of arrival at your company)

The performance of EMI Filters is guaranteed for 6 months or a year from the out go ing inspection date indicated on

the packages, provided that they are stored at a temperature of -5 °C to +40 °C and a relative humidity of 40 %

to 60 %. Check the guarantee period in the specifi cations. The performance of Thermal Cut offs is guaranteed for a

year from the outgoing inspection date indicated on the packages, provided that they are stored at a temperature of

-10 °C to +40 °C and a relative humidity of 30 % to 75 %.

Even within the above guarantee periods, do not store these products in the following conditions. Otherwise,

their electrical performance and/or solderability may be deteriorated, and the packaging materials (e.g. taping

materials) may be deformed or deteriorated, resulting in mounting failures.

1. In salty air or in air with a high concentration of corrosive gas, such as Cl

, H2S, NH3, SO2, or NO

2

2

2. In direct sunlight

<Package markings>

Package markings include the product number, quantity, and country of origin.

In principle, the country of origin should be indicated in English.

Jan. 2008

– EL113 –

Loading...

Loading...