Page 1

PRINTED IN JAPAN

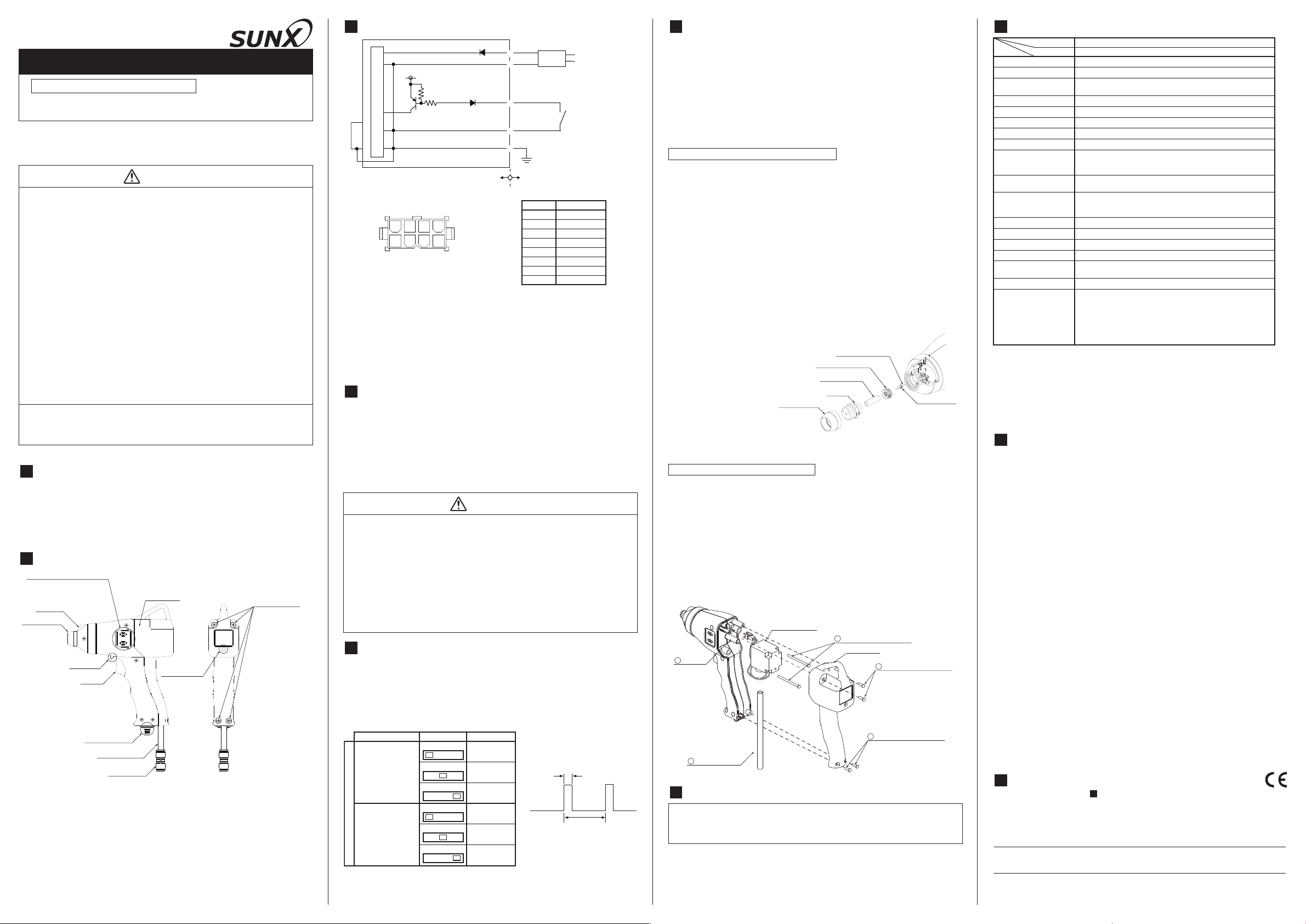

Overseas Sales Division (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

Europe Headquarter: Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

Phone: +49-8024-648-0

US Headquarter: Panasonic Electric Works Corporation of America

629 Central Avenue New Providence, New Jersey 07974 USA Phone: +1-908-464-3550

URL: sunx.com

SUNX Limited

INSTRUCTION MANUAL

White LED

Nozzle guard

Trigger

Lock knob

Solenoid valve

indicator

Cable connector

ø8mm air tube

Straight joint

Mode select switches

Upper: Pulse air mode selection

Lower: LED illumination mode selection

M3×10

mounting screw

Back cover

D

D: Power supply reverse connection

protection diode

Internal circuit

Users’ circuit

AC adapter (accessory)

24V

0V

GND (connected internally to 0V,

COM (-) and nozzle metallic parts)

External input

100 to 240V AC

4.7kΩ

5V

COM(-)

Switch for

external input

Main circuit

Nozzle

⑤

①

③

②

⑧

①

②

③

④

⑧

⑦

⑥

⑤

(From cable insertion side)

Name

Pulse air mode

selection

LED illumination

mode selection

Position Details

Continuous

Pulse 1※

Pulse 2※

Always ON

Synchronized

with trigger

Always OFF

1 2 CONT

1 2 CONT

1 2 CONT

ON SYNC OFF

ON SYNC OFF

ON SYNC OFF

Pulse width

Cycle

※Pulse 1: Pulse ionized air emission cycle approx. 100ms, pulse width approx. 50ms

※Pulse 2: Pulse ionized air emission cycle approx. 100ms, pulse width approx. 10ms

Mode select switches

Discharge needle*

Attachment (Note)

Insulating pipe

Nozzle

Stopper ring*

* Option (sold separately)

EC-GANT : Discharge needle 1 pc

sure that it is facing the correct direction.

If it is installed so that it is facing the

wrong direction, it will not be possible to

fully tighten the nozzle.

Nozzle guard

Back cover

Solenoid valve*

C

M3×45 mounting screw

B ø

8mm air tube

A

M3×10 mounting screw

A

M3×10 mounting screw

D

Air pipe

* Option (sold separately)

EC-GAV: Solenoid valve 1 pc

Static Remover & Dust Remover

Pulse Air-gun Ionizer

EC-G01

Thank you very much for using SUNX products. Please read this Instruction Manual

carefully and thoroughly for the correct and optimum use of this product. Kindly keep

this manual in a convenient place for quick reference.

WARNING

䃂

Never use this product with a device for personnel protection.

In case of using devices for personnel protection, use products which meet laws

or standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable

in each region or country.

䃂

Do not use this product in places where there may be a danger of ammable or

combustible items being present.

䃂

Clean the discharge needle regularly (about once a week), otherwise optimum

charge removal performance may not be obtained and re or operating problems

may occur.

䃂

High voltages are applied to the discharge needle, so never touch the discharge

needle while the power for the product is turned on, otherwise electric shocks may

result.

䃂

If this product is used in an airtight room, ozone emitted from this product may be

detrimental. Therefore, in order for this product to be used in an airtight room, be

sure to keep the room ventilated.

䃂

Do not direct ionized air toward the face. Ozone may cause irritation to places

such as the nose and throat.

䃂

Do not look directly into the white LED spotlight. It may cause injury to the eyes.

䃂

Since the tip of the discharge needle is sharp, take sufcient care in handling the

discharge needle, or injuries may result.

䃂

When air is not being supplied to this product, turn off the power in order to stop

discharging from occurring. If discharging is allowed to continue while air is not

being suppli ed, the ozone concentra tion will rise and acciden ts or o perating

problems may occur.

䃂

This product includes precision components, so do not drop it

or hit it against other objects. If this is not observed, accidents

or problems with operation may occur.

1

OUTLINE

●

This product is an air gun-type electrostatic charge removal and dust removal

device which uses ion generation from corona discharges.

●

This product is equipped with a pulse ionized air emission function for effectively

removing dust and which can be replaced with normal continuous ionized air

emission.

●

It uses a built-in high-illumination white LED spotlight in order to illuminate the

direction in which ionized air is being blown.

2 PART DESCRIPTION

3 I/O CIRCUIT DIAGRAM

●

Pin layout for AC adapter power

supply connector

●

and ⑤ are connected to the AC

①

adapter.

●

Use the accessory connector wiring terminal to connect external input or GND.

When using external input

※

When using external input, ionized air discharging can be carried out using the

same ON/OFF operations as trigger input.

Note: The COM (-) terminal which uses external input is connected internally to 0V, the GND terminal

and the nozzle metallic parts. If external input ON/OFF switching is carried out using an

external control device instead of an independent mechanical-type switch, or if the 0V potential

of the external control device and the grounding potential of the place of use are different (such

as in the case of positive power supply grounding), the external control device used for external

input should have an insulated on/off procedure for the 0V line (such as photocoupler output or

relay output) in order to prevent short-circuits from occurring.

4

WIRING • PIPING

●

Use the accessory relay cable to connect the main unit and the AC adapter.

●

Use the accessory straight joint to connect a suitable air tube to the main unit.

●

Connect the GND terminal of this product to a secure ground when using it.

●

Since the pressure will drop when the air piping from the main pressure supply is

extended or pneumatie-components (e.g., needle valve, speed-controler, minilter)

are added, keep an eye on the pressure supply to the ionizer maiking sure it isn't in

short supply. For the pneumatic-components, select those that can accommodate

the air supply ow rate.

The air supplied should be dry, clean air (air drier: dew point approx. -20°C, air lter:

※

mesh size of approx. 0.01μm).

●

Terminal block diagram

Terminal No.

①

②

③

④

⑤

⑥

⑦

⑧

Terminal name

0V

COM (-)

External input

N.C. (not used)

24V

N.C. (not used)

N.C. (not used)

GND

CAUTION

䃂

Turn off the power and air and make sure that the supply of air has been fully

shut off before carrying out any wire and tube connection work. If this is not done,

accidents or problems with operation may occur.

䃂

The metal parts of the nozzle are connected inside the product to the 0V and GND

terminal. Do not connect it to objects with a different electrical potential such as

the conductive parts of external devices.

䃂

If the supplied air contains any particles other than air or any corrosive gases,

accidents or problems with operation may occur. In addition, if air which contains

impurities su ch as carbon dus t or air which contains moistu re or oil is used,

accidents or problems with operation may also occur.

䃂

Do not modify the nozzle or install the nozzle to any other appliances, otherwise

correct charge removal performance may not be obtained, and a ccidents or

problems with operation may occur.

5 OPERATION

Use the mode select switches to select the required settings.

①

Face the ionizer toward the electrostatically-charged object and pull the trigger.

②

When the trigger is pulled, dust removal operation will start, and when the trigger is

released, dust removal operation will stop.

䃂

If the lock knob is pushed to the trigger side while the trigger is being pulled, the

trigger will be locked in that position, and discharging operation will be carried out

continuously even after you release your finger from the trigger. To release the

lock, pull the trigger once more and return the lock knob.

6 CARE AND MAINTENANCE

䃂

Be sure to turn off the power and air before carrying out cleaning and maintenance.

Make sure that the supply of air has been fully shut off and that all pressures at the

product and inside the tubes are at zero before continuing. If this is not done, air

pressure may cause operating problems or accidents.

䃂

The discharge needle has a sharp point, so be very careful when cleaning the

needle.

䃂

Clean the discharge needle regularly about once a week, otherwise optimum

charge removal performance may not be obtained and accidents or operating

problems may occur.

䃂

The discharge needle is a consumable part. If charge removal performance does

not return to normal after the discharge needle has been cleaned, then the needle

should be replaced.

Cleaning and replacing the discharge needle

Turn off the power and check that the air pressure inside the air tube has dropped to

①

zero.

②Remove the

Remove the insulating pipe and the attachment.

③

When carrying out cleaning, use a cotton swab moistened in alcohol or similar to

④

remove any dirt from the needle and the area around it.

(If replacing the discharge needle, use needle nose pliers or a similar tool to pull out

④

the needle, and then insert a new needle as far as it will go.)

After cleaning or replacing the needle, return the attachment, insulating pipe and

⑤

nozzle to their normal installation positions. Turn the nozzle clockwise to install it.

The tightening torque for the nozzle at this time should be 3 N•m or less.

④

Lastly, afx the nozzle guard.

④

Do not touch the tip of the di sch arge needl e against tools or any othe r hard

※

surfaces. If the discharge needle is damaged, optimum charge removal performance

nozzle guard, turn the nozzle counterclockwise and remove it.

may not be obtained and accidents or pro ble ms with operation may occ ur. In

addition, do not touch the stopper ring area, otherwise the stopper ring may slip out

of position, and it may not be possible to reinstall it.

When handling the discharge needle with tools, hold the discharge needle at the

※

middle and avoid applying excessive force to the needle.

䃂

The solenoid valve is a consumable part (open/close operations: approx.

8,000,000). If it no longer opens and closes normally, stop using the ionizer and

replace the solenoid valve.

Solenoid valve replacement procedure

Check that the power is turned off and that the air pressure inside the air tube has

①

dropped to zero.

Remove the back cover.

②

Remove the four M3 mounting screws. (A in diagram below)

Disconnect the air tube from the solenoid valve. (B in diagram below)

③

Disconnect the solenoid valve lead wire connector.

④

Remove the two M3 mounting screws. (C in diagram below)

⑤

Disconnect the air pipe from the solenoid valve. (D in diagram below)

⑥

Install the new solenoid valve, and then install the M3×45 mounting screws and

⑦

connect the air tubes and the solenoid valve lead wire connector. Tighten the M3×45

mounting screws at a torque of 0.2 N•m or less.

Install the back cover. Be careful not to clamp the lead wire. Tighten the M3×10

⑧

mounting screws at a torque of 0.4 N•m or less.

7 TROUBLESHOOTING

䃂

When an error is detected, the white LED ashes. (It also ashes even when the

LED illumination mode is set to “Always OFF”.) If the white LED is ashing, carry

out the following checking operations. When checking the discharge area, always

be sure to turn off the power before carrying out the checking.

䃂

Turn off the power and che

dirt on it, and that the needle is installed correctly.

䃂

Check that there are no foreign objects inside the nozzle.

䃂

Check that the nozzle is installed correctly.

(Including the attachment and the insulating pipe)

䃂

Check that the air pressure is within the specication range.

ck that the tip of the needle is intact and that there is no

8 SPECIFICATIONS

Item Model No. EC-G01

Charge removal time 0.5 sec. or less (1,000V → 100V) (Note 1)

Ion balance ±10V or less (Note 1)

Power supply voltage

Power consumption 30VA or less

Discharge method High-frequency AC method

Discharge output voltage 2000V approx.

Ozone generation 0.02ppm or less (Note 2)

Applicable uid Air (dried clean air)

External input

Indicators

Error detection function

Ambient temperature 0 to + 50°C (No dew condensation) AC adapter: 0 to +40°C

Ambient humidity 35% to 65% RH (No dew condensation)

Supplied air ow Max. 300 ℓ/min. (ANR) or less

Air pressure range 0.05 to 0.50 MPa

Material

Weight 270g approx. (main unit only)

Accessories

Notes: 1) Typical value for continuous pulse air mode at 100mm from end of discharge nozzle at an

applied air pressure of 0.50MPa

Notes: 2) Typical value for continuous pulse air mode at 300mm from end of discharge nozzle at an

applied air pressure of 0.25MPa

Notes: 3) Once an error is detected, the error status is maintained until the power is turned off and

back on again.

Notes: 3) Remove the cause of the error and then turn the power back on.

Notes: 3) If the cause of the error is not removed, the error will occur once more.

Notes: 4) At the time of shipment from the factory, ø8mm-ø8mm type is attached.

9

CAUTIONS

䃂

This product has been developed / produced for industrial use only.

䃂

Do not use this product for any purpose other than charge removal and dust

removal.

䃂

Do not use this product in enviroments which are outside the specication range,

otherwise operating problems or damage may occur. In addition, the operating life

of the product may become signicantly reduced.

䃂

Never disassemble, repair or modify this product, otherwise operating problems or

accidents may occur.

䃂

Do not dispose of this product by burning it, otherwise it may explode or toxic

fumes may be generated.

䃂

This product generates ozone, so be sure to provide adequate ventilation if using it

in a conned space.

䃂

Do not run the wires together with high-voltage lines or power lines or put them in

the same raceway. This can cause malfunction due to induction.

䃂

Be sure to turn off the air and the power supply before carrying out any cable

connection or inspection work. If this is not done, operating problems, damage or

electric shocks may occur.

䃂

After connecting the cables, check that the air piping and power supply connections

are correct before turning on the power. If the wires or cables are connected

incorrectly, operating problems or accidents may occur.

䃂

Verify that the supply voltage variation is within the rating.

䃂

Do not turn the power back on immediately after it has been turned off, otherwise

operating problems or accidents may occur. In addition, the operating life of the

product may become signicantly reduced. Wait at least 2 seconds before turning

the power back on again.

䃂

Do not use the power plug of the AC adapter if it has become dusty, otherwise re may occur.

䃂

Do not use any cables which have any damage (such as splitting or cracking),

otherwise operating problems or accidents may occur.

䃂

Avoid using the product in places where there are high levels of steam or dust in

the air or where it might be directly exposed to water, oil or welding spatter.

䃂

Do not touch the discharge needle with hard objects such as tools. If the discharge

needle becomes broken, it will not provide sufcient charge removal performance,

and moreover operating problems or accidents may occur.

䃂

If this product ceases functioning or is no longer required, dispose of it according to

appropriate local waste disposal regulations.

䃂

This product is a high-precision device, and should be handled with care.

10

PRODUCTS CONFORMING TO CE MARKING

䃂

The models listed under ‘

As for all other models, please contact our ofce.

Type Pulse Air-gun Ionizer

Accessory AC adapter INPUT: 100 to 240V AC±10% 50/60Hz

Ionized air emission operation ON/OFF using OR control with trigger switch

Ionized air emission operation ON: Short-circuited to COM (-)

Ionized air emission operation OFF: Open

Valve illumination: Illuminated when solenoid valve is ON (open)

When an abnormal discharge (short-circuited, etc.) occurs,

discharge is forcibly stopped and the spotlight ashes

(reset when the power is turned off and back on) (Note 3)

Enclosure: ABS

Discharge needle: Tungsten

• AC adapter 1 pc

• Exdusive intermediate cable 1 pc

oil-proof · heat-proof · winding-proof type length 2m 1 pc

• Straight joints

Tube outer diameter ø8mm-ø8mm compatible type 1 pc (Note 4)

Tube outer diameter ø8mm-ø6mm compatible type 1 pc

• Connector connection terminal (manufactured by Molex) 3 pcs

8

SPECIFICATIONS’ are conforming to CE Marking.

(OUTPUT: 24V DC)

(orange LED)

Nozzle: Stainless steel

Nozzle guard: NBR

Loading...

Loading...