Panasonic DVDS-31-EG, DVDS-35-EB, DVDS-35-E, DVDS-35-EG Service manual

Specifications

ORDER NO: MAD0303001C2

DVD Player

DVD-S35E

DVD-S35EB

DVD-S35EG

DVD-S31EG

Colour

(S).......................Silver Type

(K).......................Black Type

Power supply: AC220-240 V, 50 Hz

Power consumption: 13 W +/-1,3W

standby mode: 2W+/-0,4W

Dimensions: 430 (W)×260 (D)×60 (H) mm

(excluding protrusions)

Mass: 2.2 kg

Signal system: PAL625/50, PAL525/60, NTSC

Operating temperature range: +5 to +35°C

Operating humidity range: 5 to 90% RH (no condensation)

Region number: Region No.2

Playable disctype:

(1) DVD-Video, DVD-RAM, DVD-Audio, DVD-R (R4.7)

(2) CD-Audio (CD-DA) (3) Video CD

(4) CD-R/CD-RW (CD-DA, Video CD formatted discs)

(5) MP3 (audio), WMA (audio), JPG (picture)

Maximum number of tracks and groups recognizable:

999 tracks and 99 groups

Compatible compression rate: between 32 kbps and 320 kbps

Video output:

Output level: 1 Vp-p (75Ω)

Output terminal: Pin jack/ AV

Number of terminals: 1 system

S video output:

Y output level: 1 Vp-p (75Ω)

C output level: NTSC: 0.286 Vp-p (75Ω)

PAL: 0.300 Vp-p (75Ω)

Output terminal: S terminal/AV

Number of terminals: 1 system

RGB video output:

R output level: 0.7 Vp-p (75Ω) +/-10%

G output lebel: 0.7 Vp-p (75Ω) +/-10%

B output level 0.7 Vp-p (75Ω) +/-10%

Output terminal: AV

Number of terminals: 1 system

Audio output:

Output level: 2 Vrms (1 kHz, 0 dB)

Output terminal: Pin jack/ AV

Number of terminals: 2CH 1system

Audio performance:

(1) Frequency response: DVD (linear audio):

4 Hz-22 kHz (48 kHz sampling)

4 Hz-44 kHz (96 kHz sampling)

CD audio: 4 Hz-20 kHz

(2) S/N ratio: CD audio: 115 dB

(3) Dynamic range: DVD (linear audio): 97 dB

CD audio: 97 dB

(4) Total harmonic distortion: CD audio: 0.0025%

Digital audio output:

Optical digital output: Optical terminal

Pickup:

Wave length: 658 nm/790 nm

Laser power: CLASS 2/CLASS 1

Note:

Specifications are subject to change without notice.

Mass and dimensions are approximate.

© 2003 Matsushita Electric Industrial CO., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

CONTENTS

Page Page

1 SAFETY PRECAUTIONS 3

1.1. GENERAL GUIDELINES

2 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

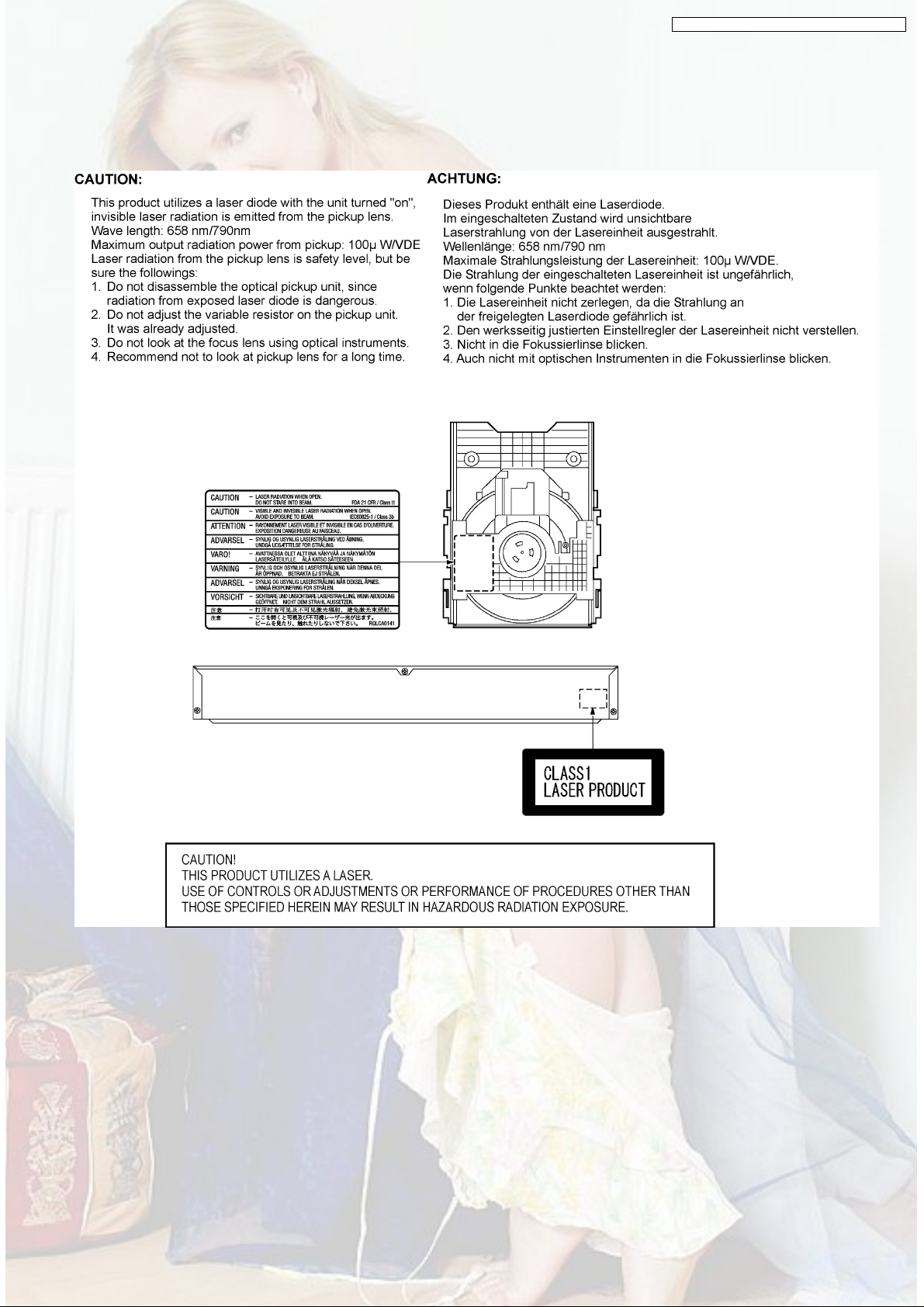

3 Precaution of Laser Diode

3.1. About lead free solder (PbF)

4 General Description

4.1. Operating instructions

5 PREVENTION OF STATIC ELECTRICITY DISCHARGE

5.1. Grounding for electrostatic breakdown prevention

5.2. Handling Precautions for Traverse Unit (Optical Pickup)

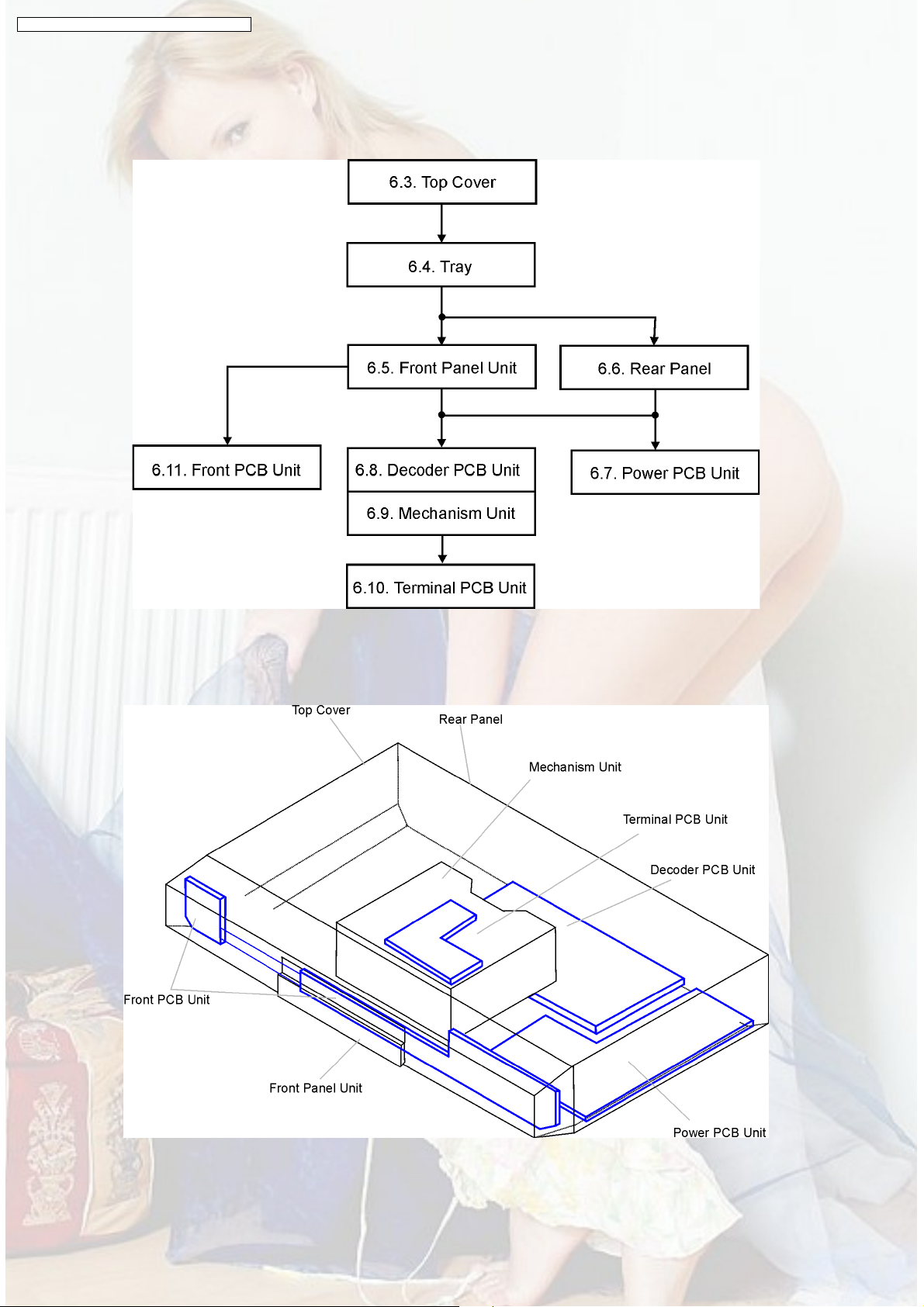

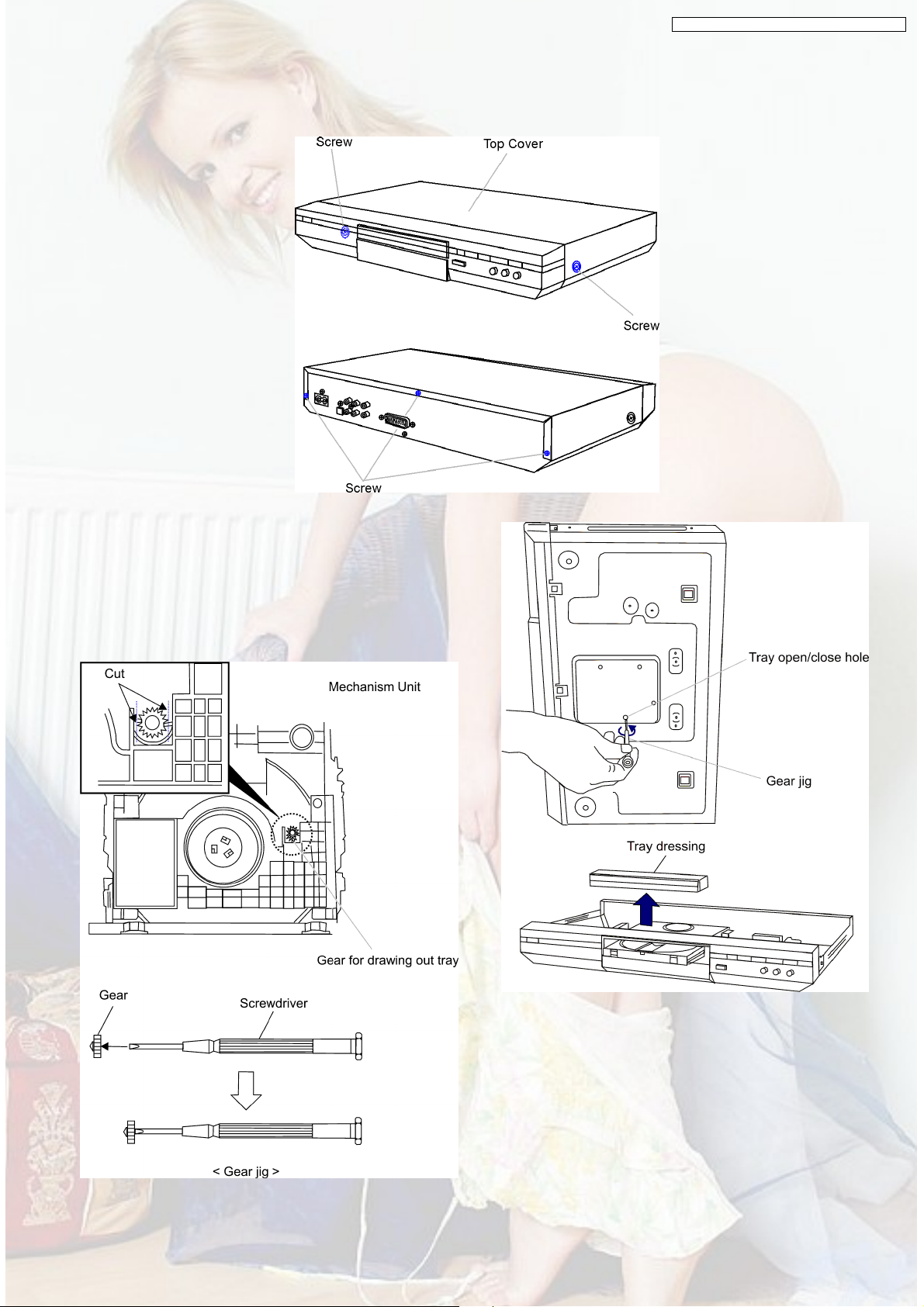

6 Disassembling the Casing and Checking PCBs

6.1. Dissasembly Procedure

6.2. Casing Parts and PCB Positions

6.3. Top Cover

6.4. Tray

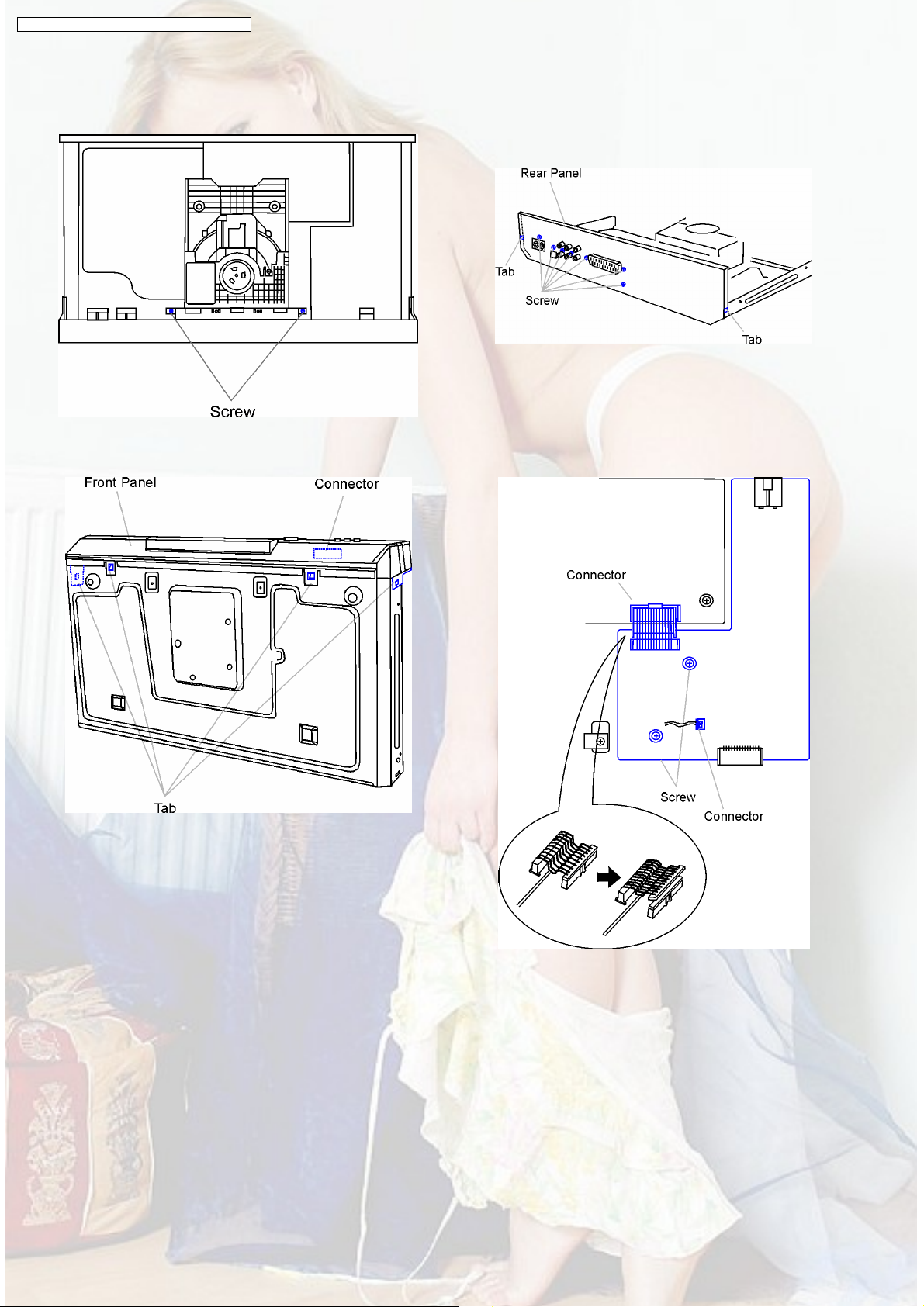

6.5. Front Panel Unit

6.6. Rear Panel

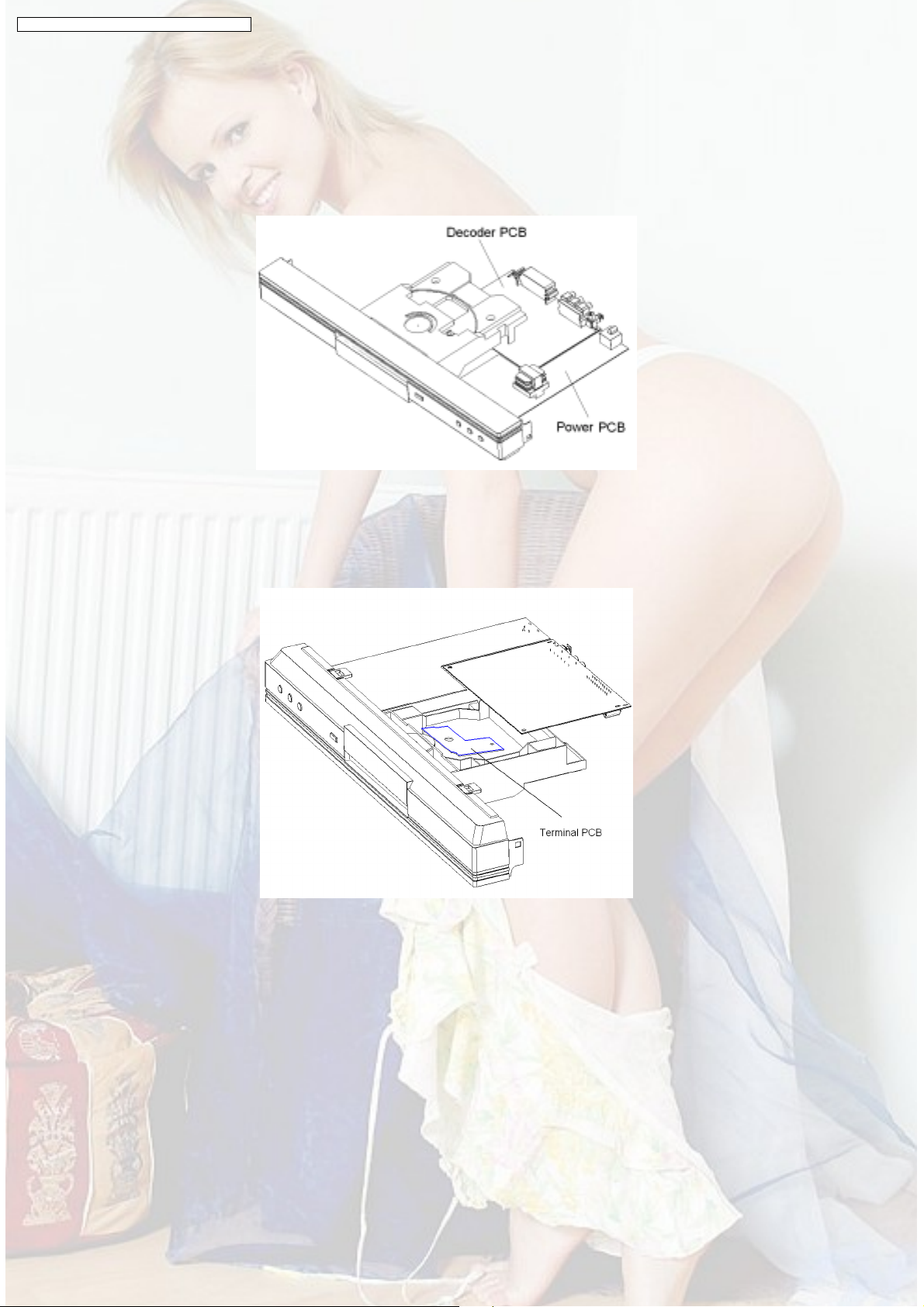

6.7. Power PCB Unit

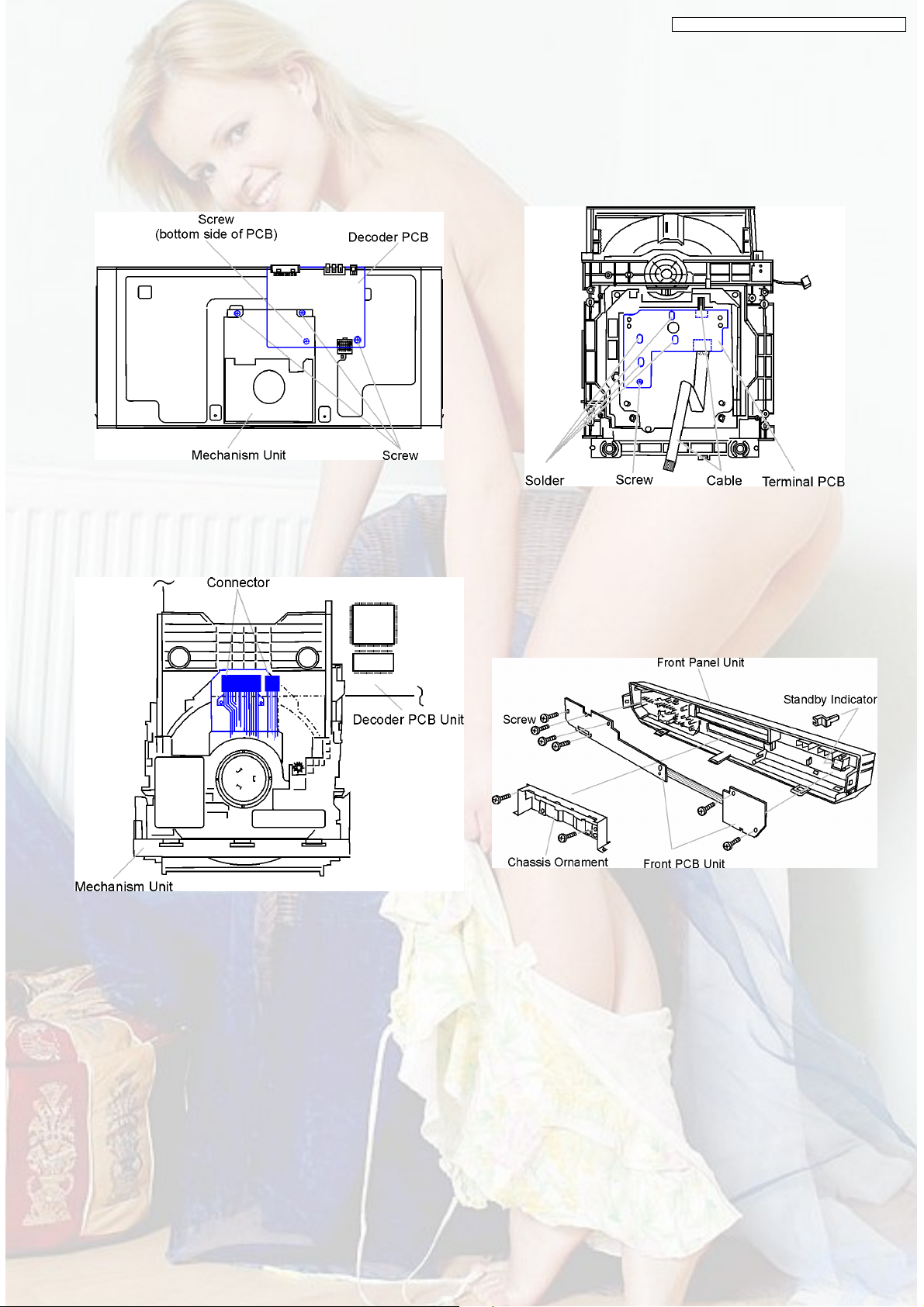

6.8. Decoder PCB

6.9. Mechanism Unit

6.10. Terminal PCB

6.11. Front Panel PCB Unit

6.12. Servicing Position

7 OPTICAL PICKUP SELF-DIAGNOSIS AND REPLACEMENT

PROCEDURE

7.1. Self-diagnosis

7.2. Cautions to be used before replacing the Optical Pickup

Unit and Spindle Motor assembly

8 Self-Diagnosis Function and Service Modes

8.1. Service Mode Table 1

8.2. DVD Self Diagnostic Function-Error Code

8.3. Last Error Code saved during NO PLAY

8.4. Service mode table 2

8.5. Overview of each function

8.6. Sales demonstration lock function

8.7. Handling After Completing Repairs

8.8. Service Precautions

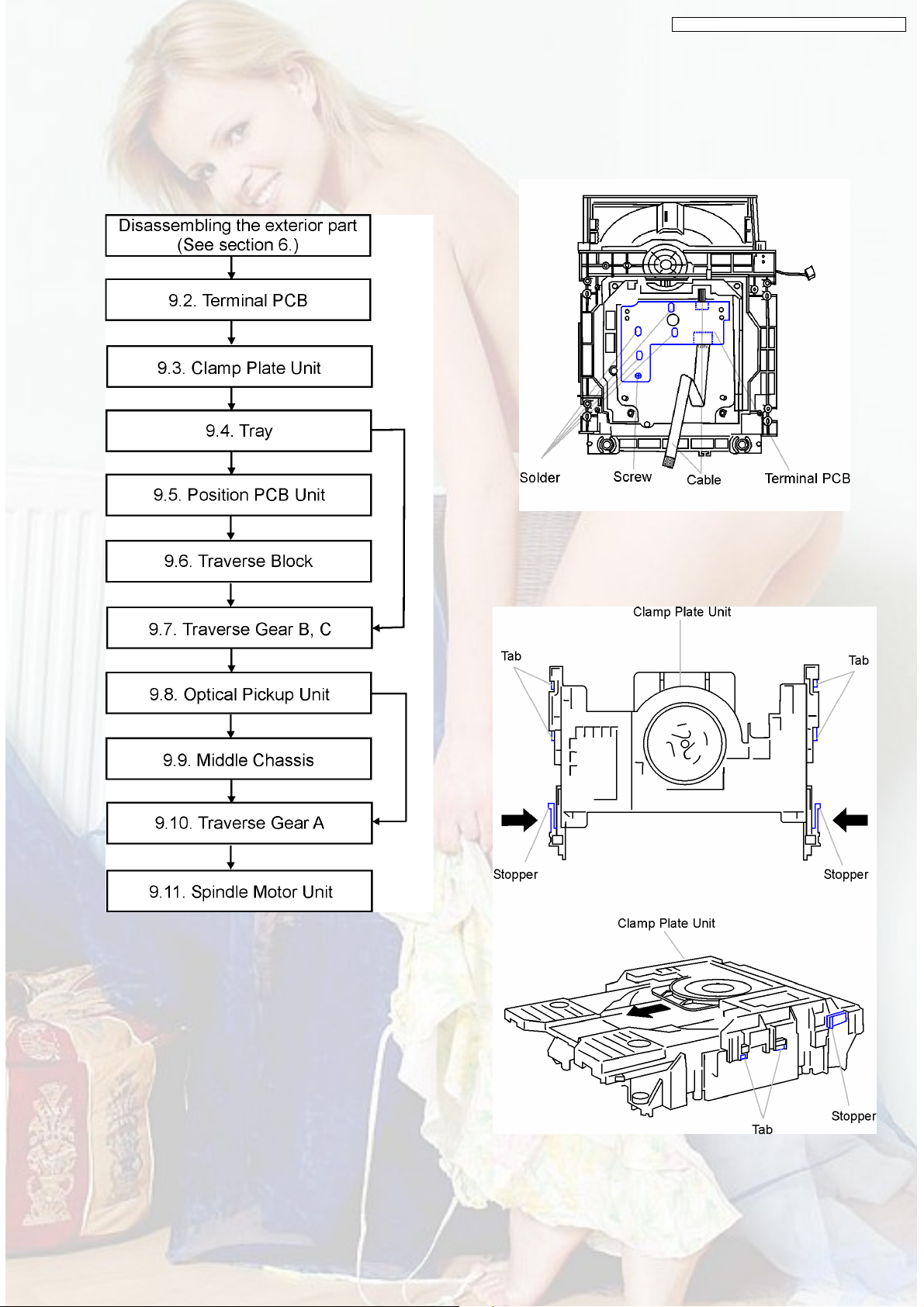

9 ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT

9.1. Disassembly Procedure

9.2. Terminal PCB

9.3. Clamp Plate Unit

10

10

10

11

11

11

11

12

13

13

14

15

15

15

16

17

19

19

19

20

21

21

21

21

3

4

5

5

6

6

7

7

7

8

8

8

9

9

9.4. Tray

9.5. FG PCB Unit

9.6. Traverse Block

9.7. Traverse Gear

9.8. Optical Pickup Unit

9.9. Disassembling the Middle Chassis

9.10. Disassembling the Traverse Gear A

9.11. Disassembling the Spindle Motor Unit

10 ADJUSTMENT PROCEDURES

10.1. Service Tools and Equipment

10.2. Important points in adjustment

10.3. Storing and Handling Test Discs

10.4. Optical adjustment

11 Abbreviations

12 Voltage Chart

13 BLOCK DIAGRAM

13.1. OVERALL BLOCK DIAGRAM

13.2. POWER BLOCK DIAGRAM

13.3. FRONT PANEL BLOCK DIAGRAM

13.4. SERVO BLOCK DIAGRAM (Decoder PCB)

14 SCHEMATIC DIAGRAM

14.1. INTERCONNECTION SCHEMATIC DIAGRAM

14.2. POWER PCB UNIT

14.3. FRONT PANEL PCB UNIT

14.4. DECODER INTERCONNECTION

14.5. DECODER PCB (AV DECODER)

14.6. DECODER DRIVE CONNECTION

14.7. DECODER FLASH MEMORY

14.8. DECODER AV INTERFACE

14.9. DECODER AUDIO DAC

14.10. TERMINAL PCB

15 PRINT CIRCUIT BOARD

15.1. Decoder PCB Unit

15.2. Power PCB Unit

15.3. TERMINAL PCB

15.4. Front PCB Unit

16 EXPLODED VIEWS

16.1. Casing Parts& Mechanism Section Exploded View

16.2. Mechanism Section Exploded View

16.3. Packing& Accessories Section Exploded View

17 REPLACEMENT PARTS LIST

18 All Schematic Diagram for printing with A4

22

23

23

24

24

29

29

29

30

30

30

30

31

32

34

37

37

38

39

40

41

41

42

43

44

45

46

47

48

49

50

51

51

52

53

54

55

55

56

57

58

64

2

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

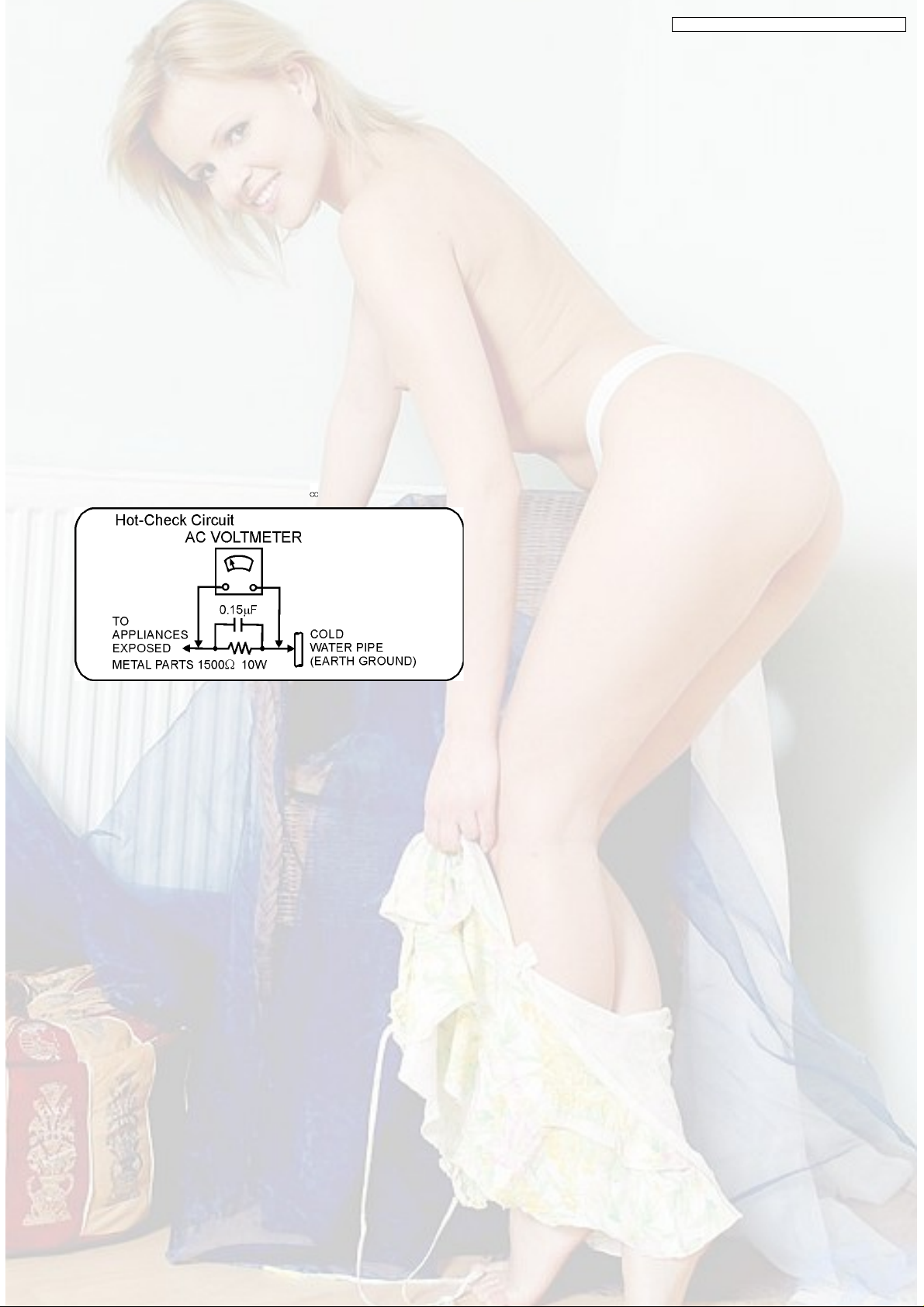

1.1.2. LEAKAGE CURRENT HOT CHECK

(See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitor, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

3

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

2 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

3 Precaution of Laser Diode

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

3.1. About lead free solder (PbF)

This model uses lead free solder (PbF). For repair use only lead free handsolder.

Caution:

Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 +/-20°F (370

+/-10°C). Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C). When soldering or unsoldering, please

completely remove all of the solder on the pins or solder area and be sure to heat the soldering points with the Pb free solder

until it melts enough.

5

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

4 General Description

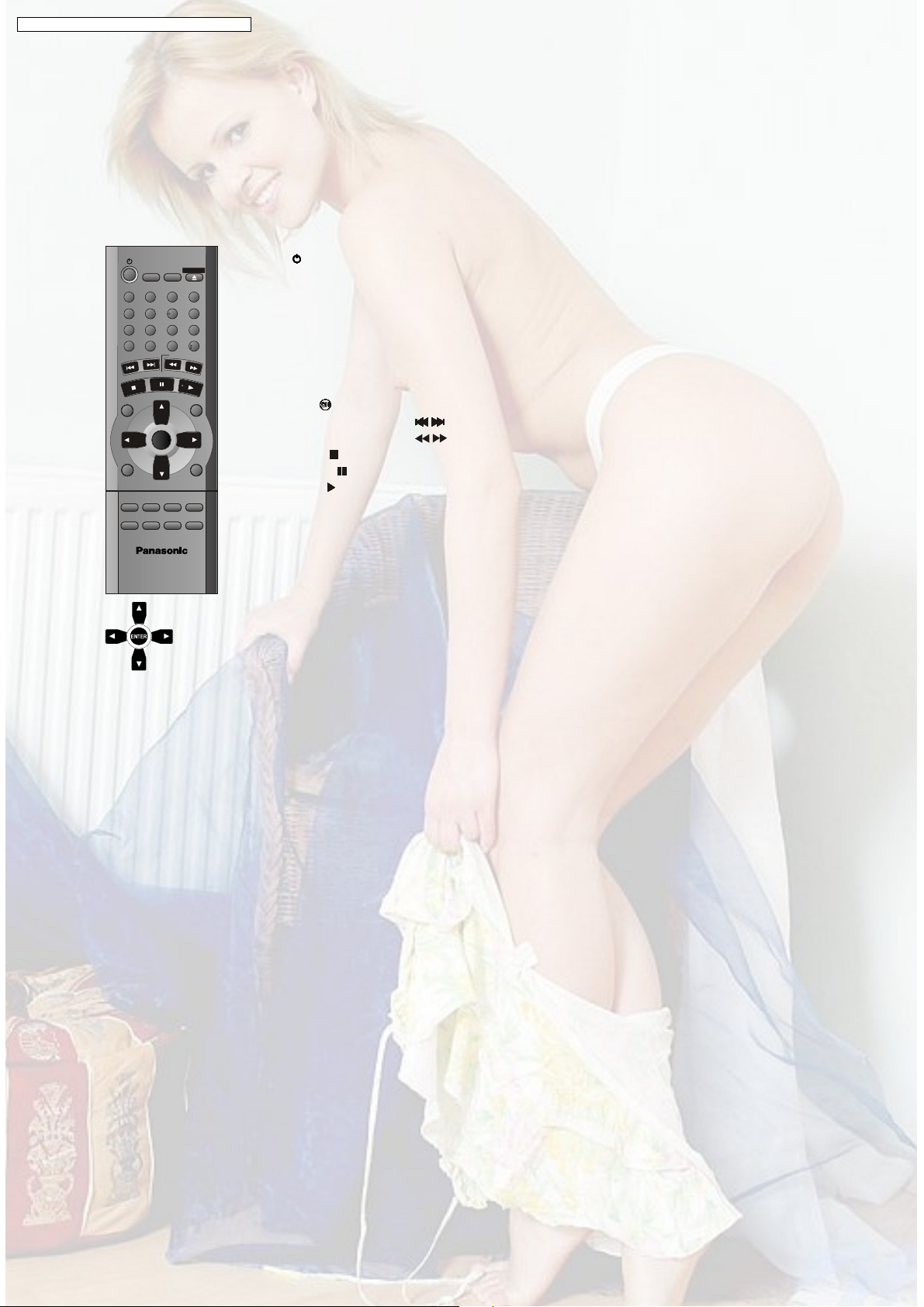

4.1. Operating instructions

The remote control unit

OPEN/CLOSE

SLEEP SETUP

A.SRD

123

CINEMA

4

6

789

CANCEL

IPK

S

PAUSE

STOP

ENTER

AUDIO

ZOOM

DVD PLAYER

N2QAJB000069

5

0

ANGLE/PAGE

REPEAT

/SLO ARWSE C

PLA

PLAY LIST

QUICK REPLAY

POSITION

MEMORY

10

H

Y

MENU

D.ENH

GROUP

DIRECT NAVIGATOR

TOP

MENU

DISPLAY RETURN

SUBTITLE

PLAY MODE

Cursor keys

ENTER to accept the menu

function you selected

Switches on and off the DVD player from stand-by mode

SLEEP Switches off the unit at the set time

SETUP Displays the DVD player menus

OPEN/CLOSE Opens and closes the disc tray

A.SRD

ADVANCED SURROUND: Provides something similar to a surround effect

CINEMA Enhances the contrast of dark scenes

D.ENH

DIALOGUE ENHANCER: Puts up the volume of the dialogue tone

GROUP Displays on-screen any groups of MP3 tracks

CANCEL Undoes entries or selections

0...9

SKIP

SLOW/SEARCH

STOP

PAUSE

PLAY

DIRECT NAVIGATOR/

Numeric key pad; press 0 to input two-digit numbers

Press to skip chapters or CD tracks

Slow motion and search function

Press to stop playback

Press to pause playback

Press to start playback

TOP MENU Displays the main menu of a DVD, RAM disc or MP3

PLAY LIST/MENU Displays the menu screen of a DVD or the MP3 menu

DISPLAY Enables the on-screen display

RETURN Hides the menu and resumes playback

SUBTITLE Selects the language of subtitles during playback

AUDIO Changes the sound track language during playback

ANGLE/PAGE Chooses from various camera angles during playback

QUICK REPLAY Repeats the last 7 seconds of a film

PLAY MODE Programme memory

ZOOM ZOOM function during playback

REPEAT REPEAT function

POSITION MEMORY Resumes playback at stored position following an interruption

6

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

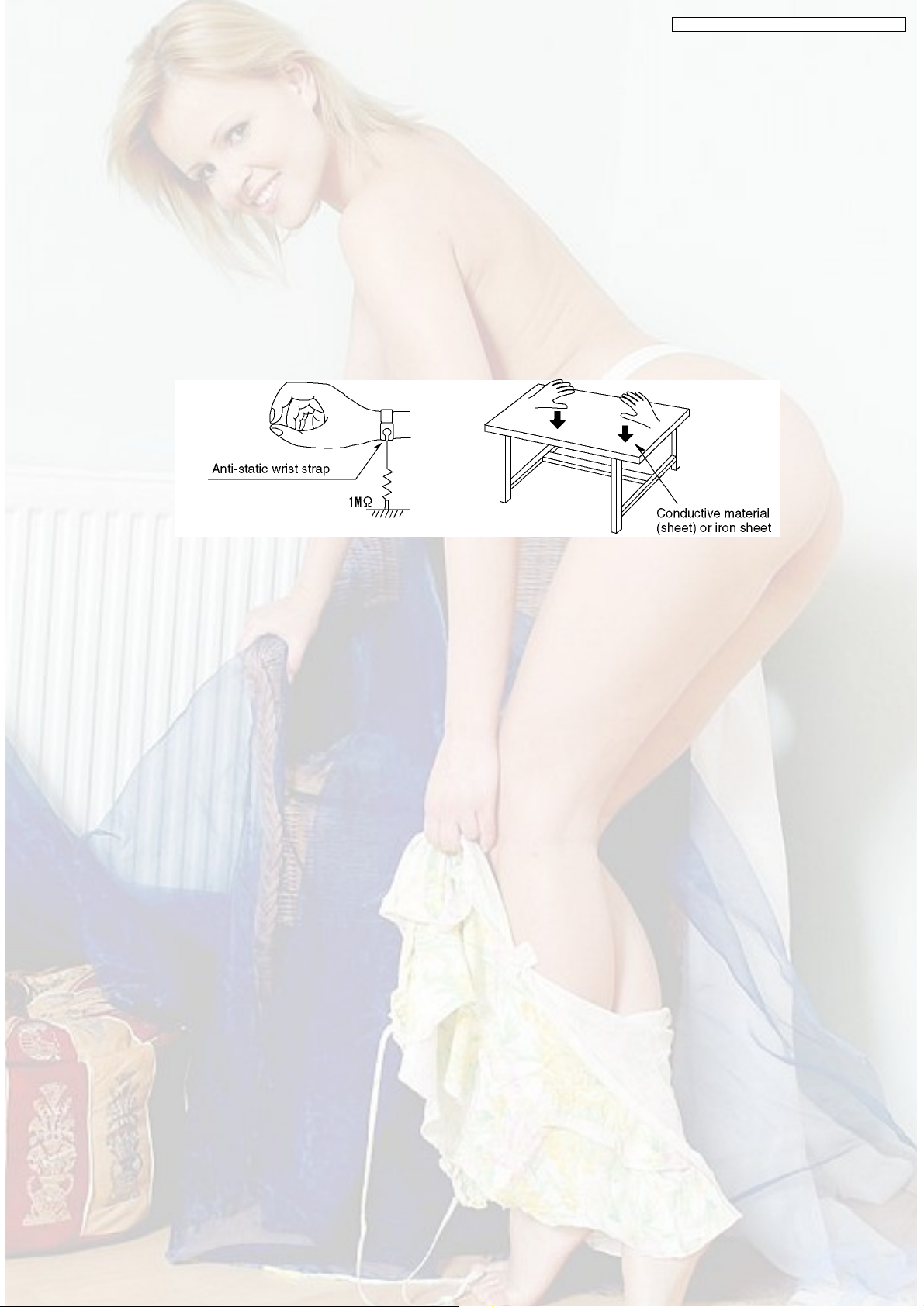

5 PREVENTION OF STATIC ELECTRICITY DISCHARGE

The laser diode in the traverse unit (optical pickup) may brake down due to static electricity of clothes or human body. Use due

caution to electrostatic breakdown when servicing and handling the laser diode.

5.1. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

5.1.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

5.1.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

5.1.3. Handling of optical pickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before installation, the both ends of

the laser diode are short-circuited. After replacing the parts with new ones, remove the short circuit according to the correct

procedure. (See this Technical Guide.)

2. Do not use a tester to check the laser diode for the optical pickup. Failure to do so willdamage the laser diode due to the power

supply in the tester.

5.2. Handling Precautions for Traverse Unit (Optical Pickup)

1. Do not give a considerable shock to the traverse unit (optical pickup) as it has an extremely high-precise structure.

2. When replacing the optical pickup, install the flexible cable and cut its short land with a nipper. See the optical pickup

replacement procedure in this Technical Guide. Before replacing the traverse unit, remove the short pin for preventing static

electricity and install a new unit. Connect the connector as short times as possible.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the cable.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

7

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

6 Disassembling the Casing and Checking PCBs

6.1. Dissasembly Procedure

6.2. Casing Parts and PCB Positions

8

6.3. Top Cover

1. Unscrew the screws.

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

6.4. Tray

1. Pull the tray out of the mechanism unit. Remove the gear

and install it onto a screwdriver to make a gear jig.

2. Insert the gear jig into the tray open/close hole.

3. Turn the gear jig counterclockwise to open the tray.

4. Remove the tray dressing from the tray section.

9

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

6.5. Front Panel Unit

1. Remove the screws.

2. Release the tabs.

3. Release the connector (inside).

6.6. Rear Panel

1. Unscrew the screws

2. Release the tabs.

6.7. Power PCB Unit

1. Unscrew the screws.

2. Remove the connectors.

3. Pull out the Power PCB Unit vertically.

10

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

6.8. Decoder PCB

1. Unscrew the screws.

2. Pull out the Mechanism Unit together withthe Decoder PCB

Unit.

3. Unscrew the Screw bottom side of the Decoder PCB Unit.

6.9. Mechanism Unit

1. Remove the connectors between

Mechanism Unit and Decoder PCB Unit.

6.10. Terminal PCB

1. Unscrew the screw.

2. Remove the solders.

3. Remove the connector.

6.11. Front Panel PCB Unit

1. Unscrew the screws.

2. Remove the Chassis Ornament.

3. Remove the Front PCB Unit.

11

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

6.12. Servicing Position

6.12.1. Servicing position of the Decoder PCB and Power PCB (from top side without

chassis parts).

6.12.2. Servicing position of the Terminal PCB (from bottom side).

12

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

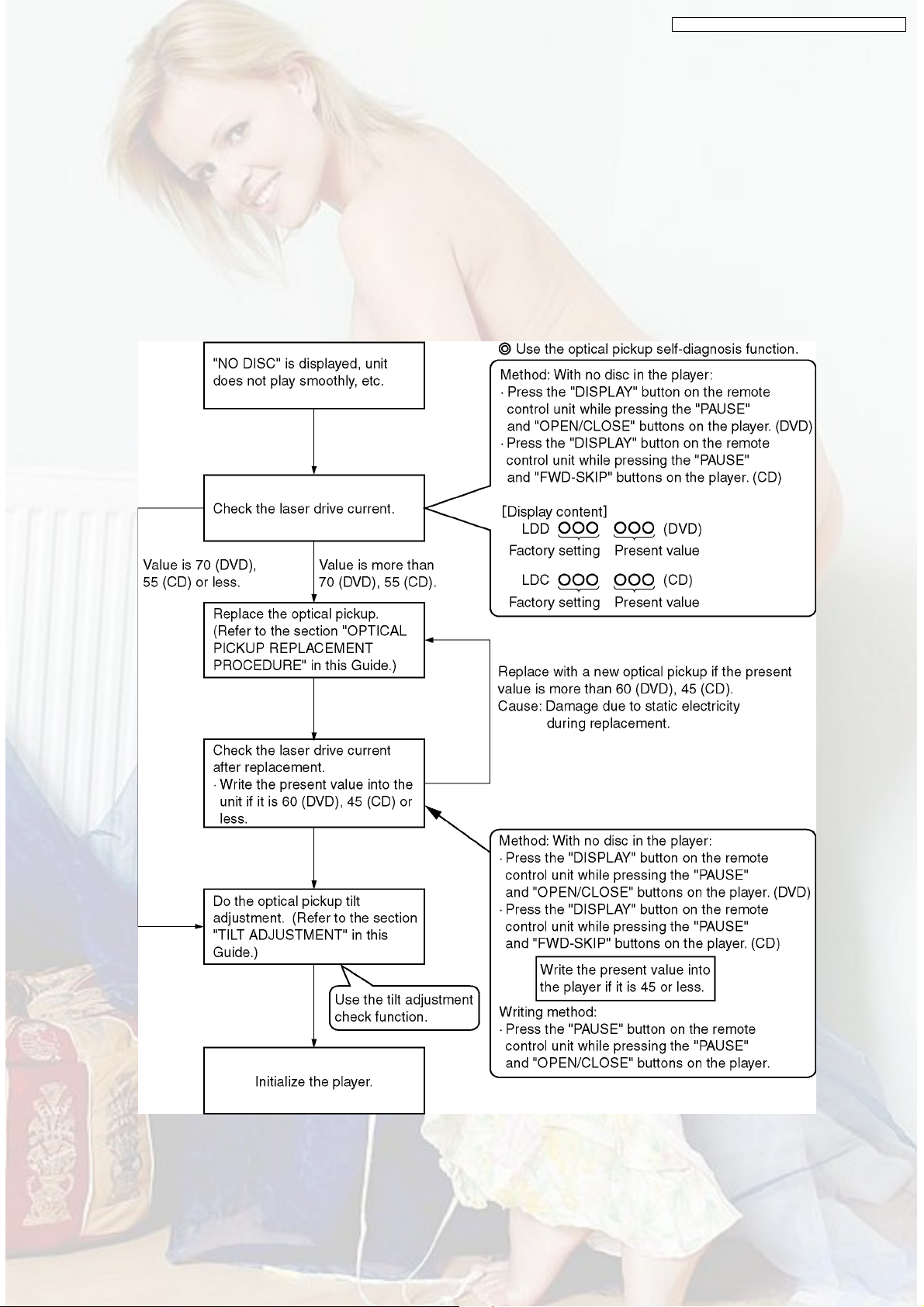

7 OPTICAL PICKUP SELF-DIAGNOSIS AND

REPLACEMENT PROCEDURE

7.1. Self-diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing, use

the following procedure for effective Self-diagnosis and tilt adjustment. Be sure to use the self-diagnosis function before replacing

the optical pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup when the value of the laser

drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up. (Otherwise,

the result will be incorrect.)

13

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

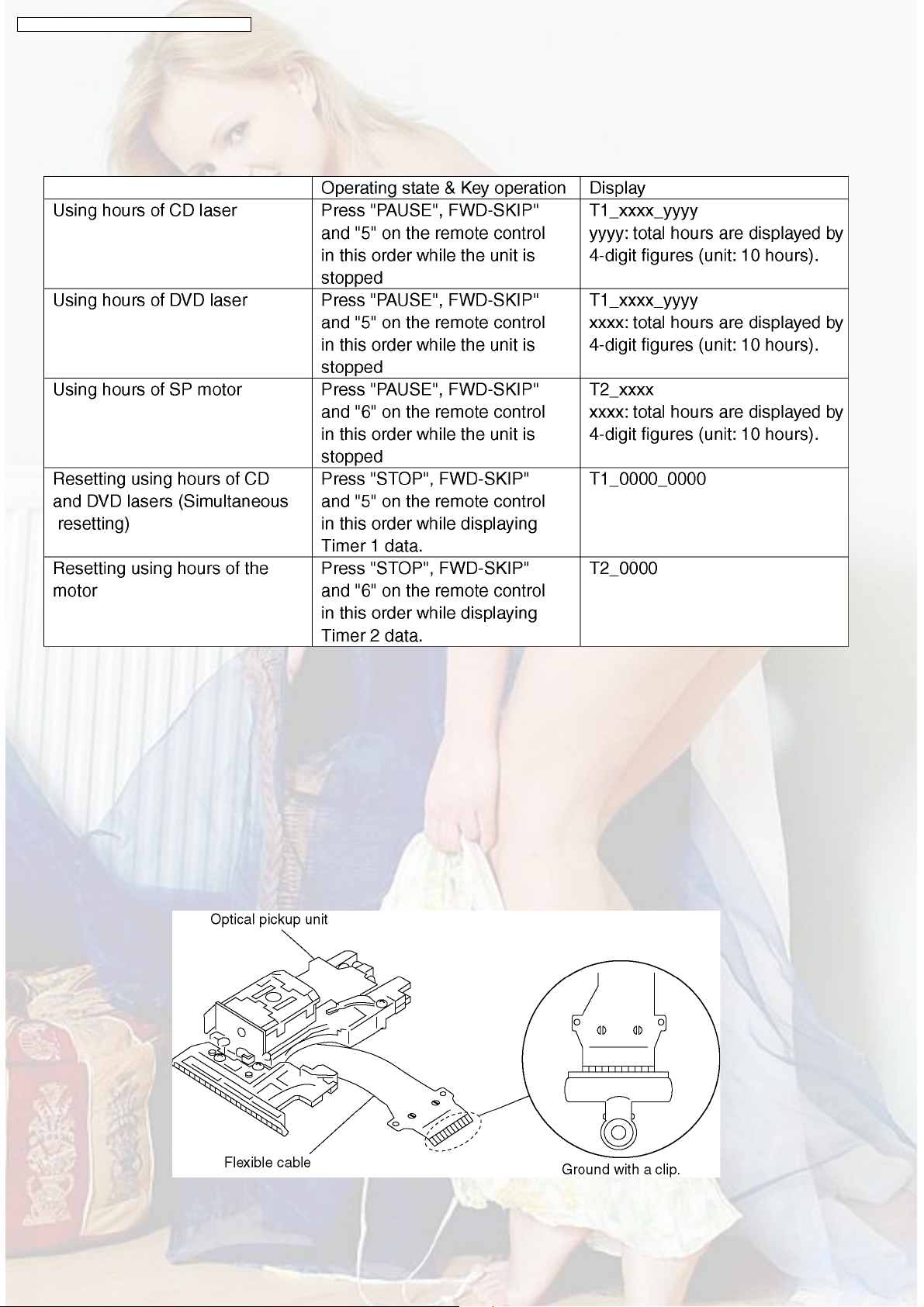

7.2. Cautions to be used before replacing the Optical Pickup Unit and

Spindle Motor assembly

Before replacing the optical pickup unit and spindle motor assembly, check the total using hours for each of them. The checking

method is as follows:

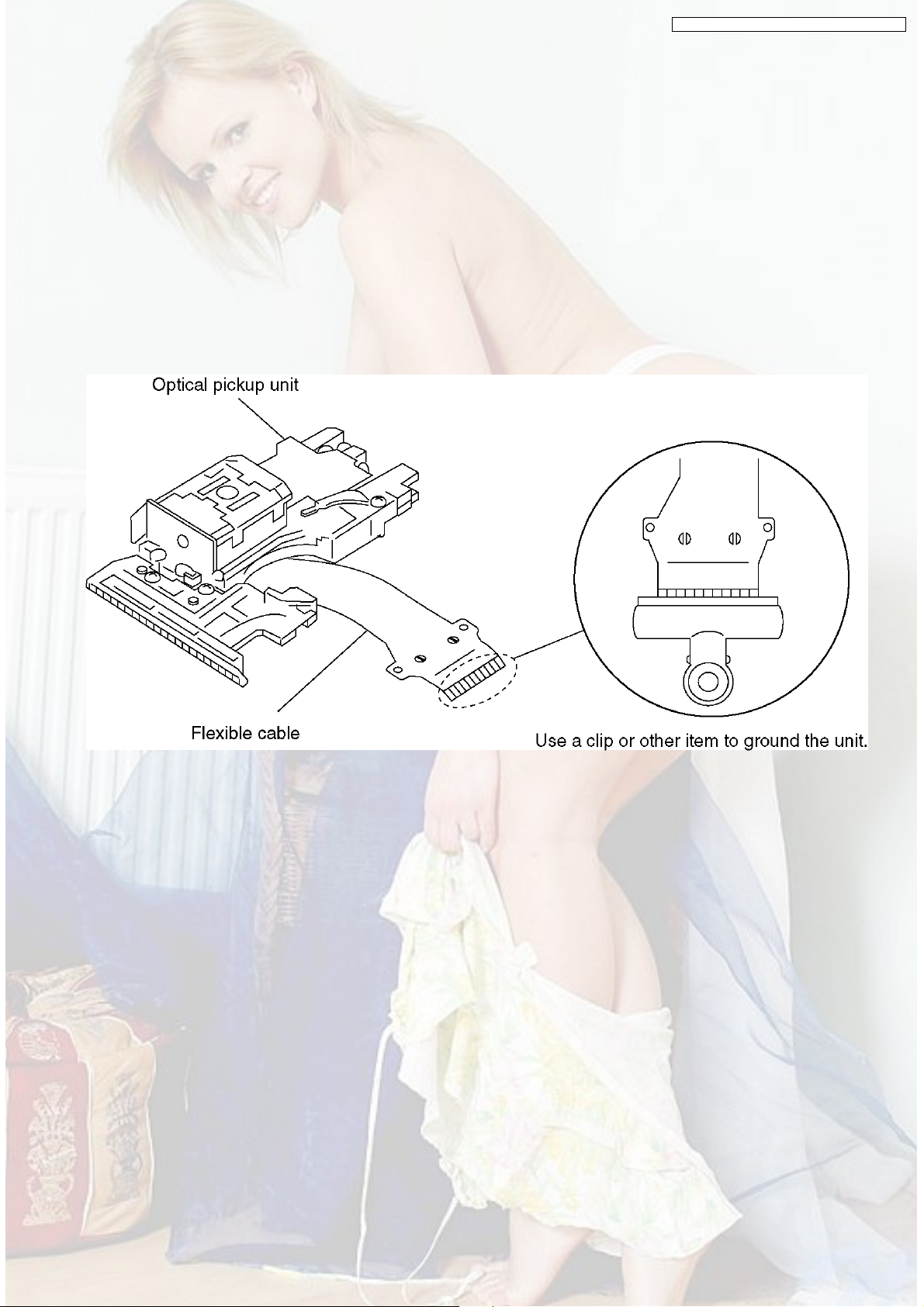

Cautions to be taken when replacing the optical pickup

The optical pickup may break down due to the static

electricity of human body. Take proper protection measures

against static electricity before repairing the parts around

the optical pickup. (See the page describing the

PREVENTION OF STATIC ELECTRICITYDISCHARGE.)

1. Do not touch the areas around the laser diode and

actuator.

2. Do not judge the laser diode with a tester. (The tester

will be damaged easily.)

3. It is recommended to use a destaticized soldering iron

for short-circuiting or removing the laser diode.

(Recommended soldering iron) HAKKO ESD Product

4. Solder the land of the flexible cable in the optical pickup.

Note:

•

• When using a soldering iron which is not

• •

destaticized, short-circuit the terminal face of the

flexible case with a clip. After that, short-circuit

the land.

•

• After the repairing work is completed, remove the

• •

solder according to the correct procedure shown

in this Technical Guide.

14

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

8 Self-Diagnosis Function and Service Modes

8.1. Service Mode Table 1

The service modes can be activated by pressing various button combination on the player and remote control unit.

Player buttons Remote control unit buttons Application Note

PAUSE

+

OPEN/CLOSE

PAUSE

SKIP/SEARCH<<

OPEN/CLOSE

0 Displaying the UHF display F_ _ _ Refer to section 8.2. Self-

5 Jitter check, tilt adjustment

*Display shows J_xxx_yyy_zz

"yyy" and "zz" shown tothe righthave nothing to do with the jitter

value. "yyy" is the error counter, while "zz" is the focusdrive

value.

Refer to section 10.4. for Optical Pickup Tilt Adjustment

Procedure.

6 Checking the region numbers and broadcast system

7 Checking the program version

9 Lighting Confirmation Function of Display Tube

DISPLAY Checking the laser drive current Refer to section 9

PAUSE Writing the laser drive current value after replacing the optical

pickup (do not use for anything other than optical pickup

replacement)

Initializing the DVD player

(restoring factory preset settings)

Diagnosis Function (UHF

Display).

Refer to section 10.4.

Optical Pickup Tilt

Adjustment

Optical Pickup

Replacement Procedure.

Refer to section 8.4.

Initializing the DVD

player.

8.2. DVD Self Diagnostic Function-Error Code

Error Code Error Content Additional error explanation

U11 Focus error

H01 Tray loading error

H02 Spindle servo error (Spindle servo, DSC SP motor, CLV servo error)

H03 Traverse servo error

H04 Tracking servo error

H05 Seek error

H06 Power error Cannot switch off the power because of the panel

H07 Spindle motor drive

error

F103 Illegal highlight Position Big possibility of disc specification violation during

F498 No communication

between Front Micro

Computer and Main

Micro Computer after

power on

F499 No response from Main

Micro Computer when

key code is sent from

Front Micro Computer to

Main Micro Computer

F4FF Force initialize failure

(time out)

F500 DSC error DSC stops in the occurence of servo error (starup,

F501 DSC not Ready DSC-system computer communication error

F502 DSC Time out error Similar disposal as F500

F503 DSC communication

Failure

F505 DSC Attention error Similar disposal as F500

F506 Invalid media Disc is flipped over, TOC unreadable,

F600 Access failure to

management

information caused by

demodulation error

and system computer communication error

highlight display

Main Micro Computer hangs up

focus error, etc)

(Communication failure caused by idling of DSC)

Communication error (result error occured

although communication command was sent)

incompatible disc

Operation stopped because navigation data is not

accessible caused by the demodulation defect

15

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

Error Code Error Content Additional error explanation

F601 Indeterminate sector ID

F602 Access failure to LEAD-

F603 Access failure to

F610 ODC abnormality No permission for command execution

F611 6626 QCODE don’t

F612 No CRC OK for a

F630 No reply to KEY DET

F631 CPPM KEY DET is not

F632 CPPM KEY DET is not

F103 Illegal highlight Position Big possibility of disc specification violation during

F700 MBX overflow When replying message to disc manager

F701 Message command

F702 Message command

F880 Task number is not

F890 Sending message when

F891 Message couldn’t be

F893 FROM falsification

F894 EEPROM abnormality

F895 Language area

F896 No existence model Firm version agreement check for factory preset

F897 Initialize is not

F8A0 Message command is

requested

IN caused by

demodulation error

KEYDET caused by

demodulation error

read Error

specific time

enquiry

available till the FILE

terminal

available

does not end

changes

appropriate

message is being sent

to AV task

sent to AV task

abnormality

completed

not appropriate

Operation stopped caused by the request to

access abnormal ID data

LEAD IN data unreadable

Access failure to CSS data of disc

Access failure to seek address in CD series

Access failure to ID data in DVD series

(for internal use only)

(CPPM file system is unreadable caused by

scratches)

Been revoked or falsified

highlight display

Next message is sent before replying to disc

manager

Message is changed before it is sent as a reply to

disc manager

Message coming from a non-existing task

Sending message to AV task

Begin sending message to AV task

Firm version agreement check for factory preset

setting failure prevention

setting failure prevention

Initialize completion check for factory preset

setting failure prevention

Begin sending message to AV task

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

8.3. Last Error Code saved during NO PLAY

Error code Error Content System computer Setting task System computer internal error code

F0BF 6) Cannot playback because

physical layer is not recoginizable

F0C0 8) DVD: Cannot playback because it

is not DVD Video/Adio/VR

F0C1 9) DVD: Prohibited by the restricted

region code

F0C2 A) DVD: PAL restricted playback PCND_NOPLAY PAL 0x90 DiscManager 0xDOC2

F0C3 B) DVD: Parental lock setting

prohibits the playback of the entire

title

F0C4 C) VCD: Prohibited because it is in

PHOTO CD fromat

F0C5 VCD/CD: Prohibited because it is

CDROM without CD-DA

PCND_NOPLAY PHYSICAL

0x50

PCND_NOPLAY VIDEO 0x70 DiscManager 0xDOC0

PCND_NOPLAY RCD 0x80 DiscManager 0xDOC1

PCND_NOPLAY PTL 0xA0 DiscManager 0xDOC3

PCND_NOPLAY PHOTO CD

0xB0

PCND_NOPLAY CDROM 0xC0 DiscManager 0xDOC5

DiscManager 0xDOBF

DiscManager 0xDOC4

16

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

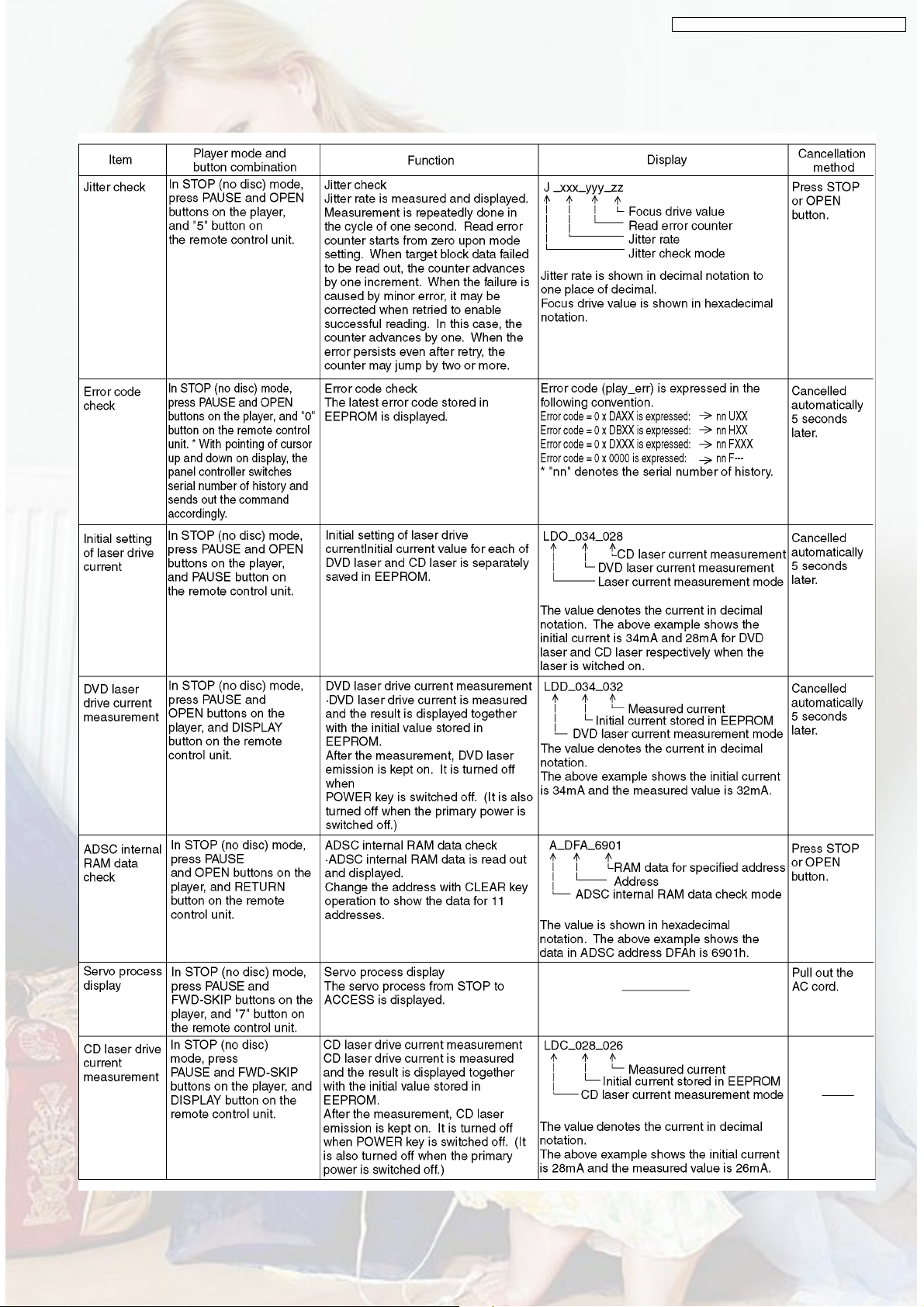

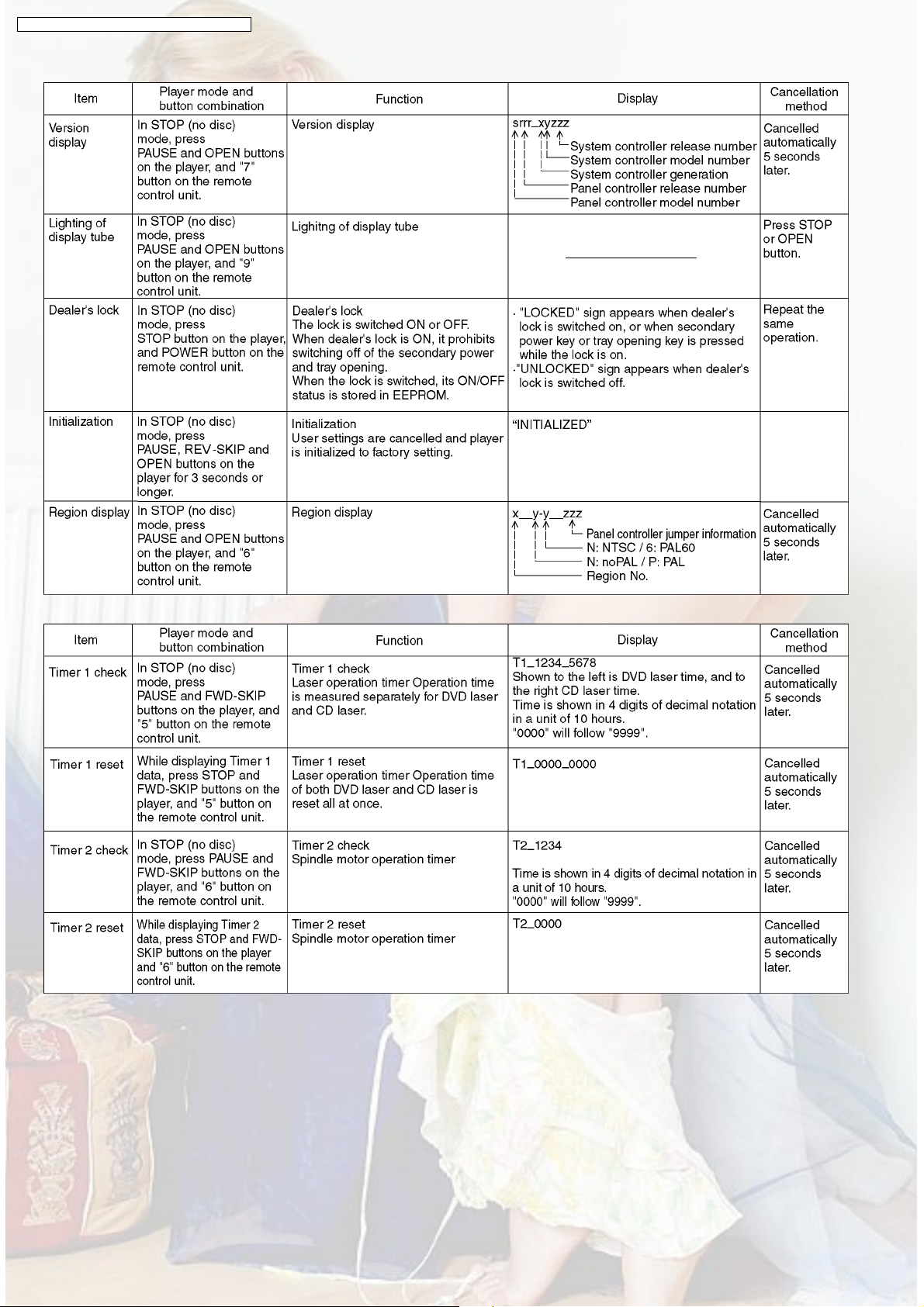

8.4. Service mode table 2

Pressing various button combinations on the player and remote control unit can activate the service modes.

17

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

18

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

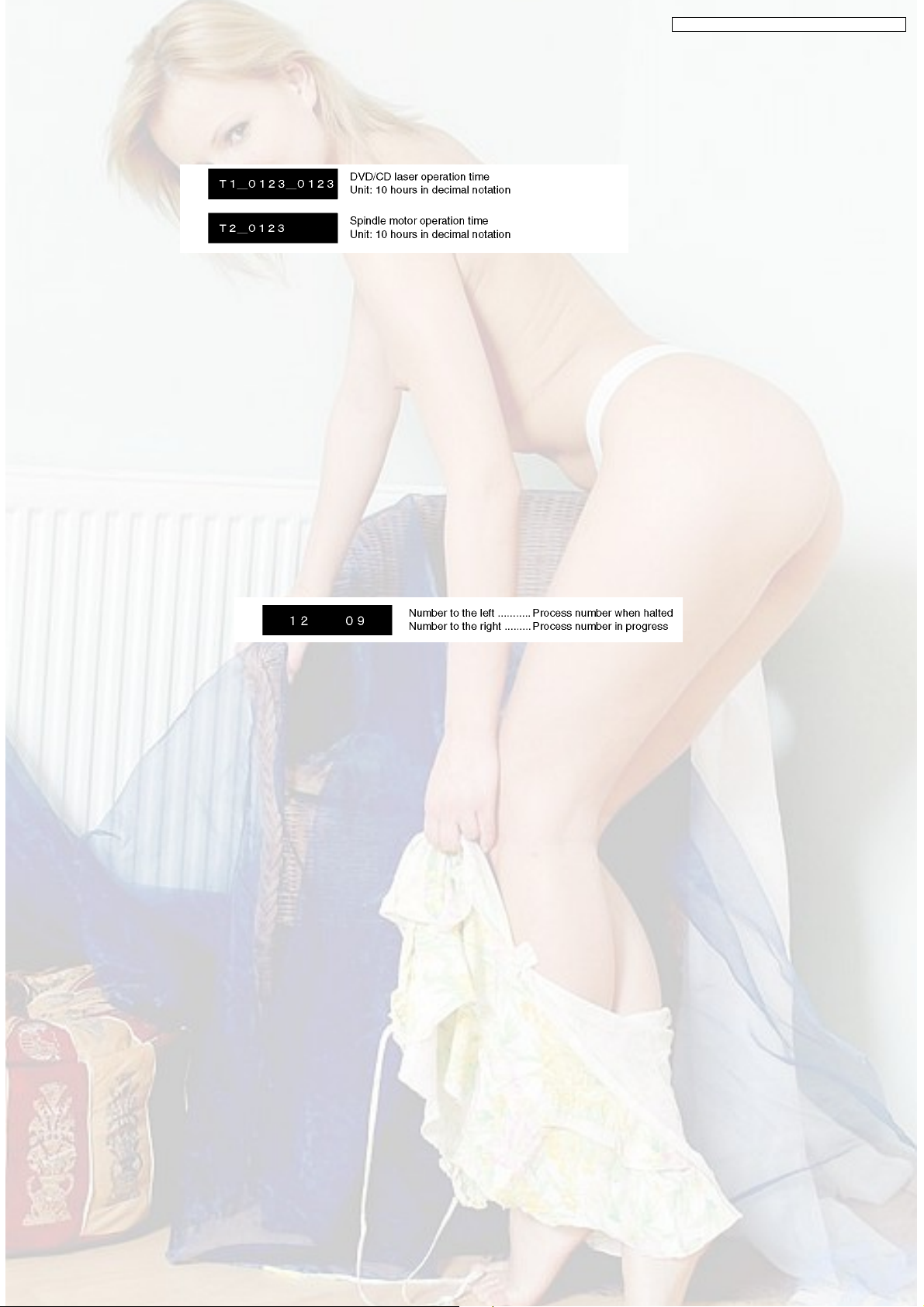

8.5. Overview of each function

8.5.1. Cumulative operation time display

1. Operation/display

Key operations are as follows.

Laser operation time ............. In STOP mode, main unit PAUSE+FWD-SKIP+ remote controller [5]

Spindle motor operation time ..... In STOP mode, main unit PAUSE+FWD-SKIP+ remote controller [6]

To reset the timer, perform the following while displaying the time with above key operation.

Laser operation time ............. In STOP mode, main unit STOP+FWD-SKIP+ remote controller [5]

Spindle motor operation time ..... In STOP mode, main unit STOP+FWD-SKIP+ remote controller [6]

2. How to utilize

Reference information in fault diagnosis of laser or spindle motor system

Review of faulty point in repeated repair

8.5.2. Servo process display

1. Operation/display

While the player is in STOP mode, perform the specified key operation to display the servo process number on FL.

When the display does not change from the error indication, press Open/Close key to show the servo process number.

Key operation: In STOP mode, main unit PAUSE+FWD- SKIP+ remote controller [7]

8.6. Sales demonstration lock function

This function prevents discs from being lost when the unit is used for sales demonstrations by disabling the disc eject function.

"LOCKED" is displayed on the unit, and ordinary operation is disabled.

8.6.1. Setting

The sales demonstration lock is set by simultaneously pressing STOP button on the player and POWER button on the remote

control unit.

8.6.2. Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCKED" is displayed on cancellation. Disconnecting

the power cable from power outlet does not cancel the lock.)

8.7. Handling After Completing Repairs

Use the following procedure after completing repairs.

8.7.1. Precautions

Do not disconnect the power plug from the outlet with the tray still open, then close the tray manually.

8.7.2. Method

Confirm that the power is turned on:

1. Press the "OPEN/CLOSE" button to close the tray.

2. Press the "POWER" button to turn off the power.

3. Disconnect the power plug from the outlet.

19

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

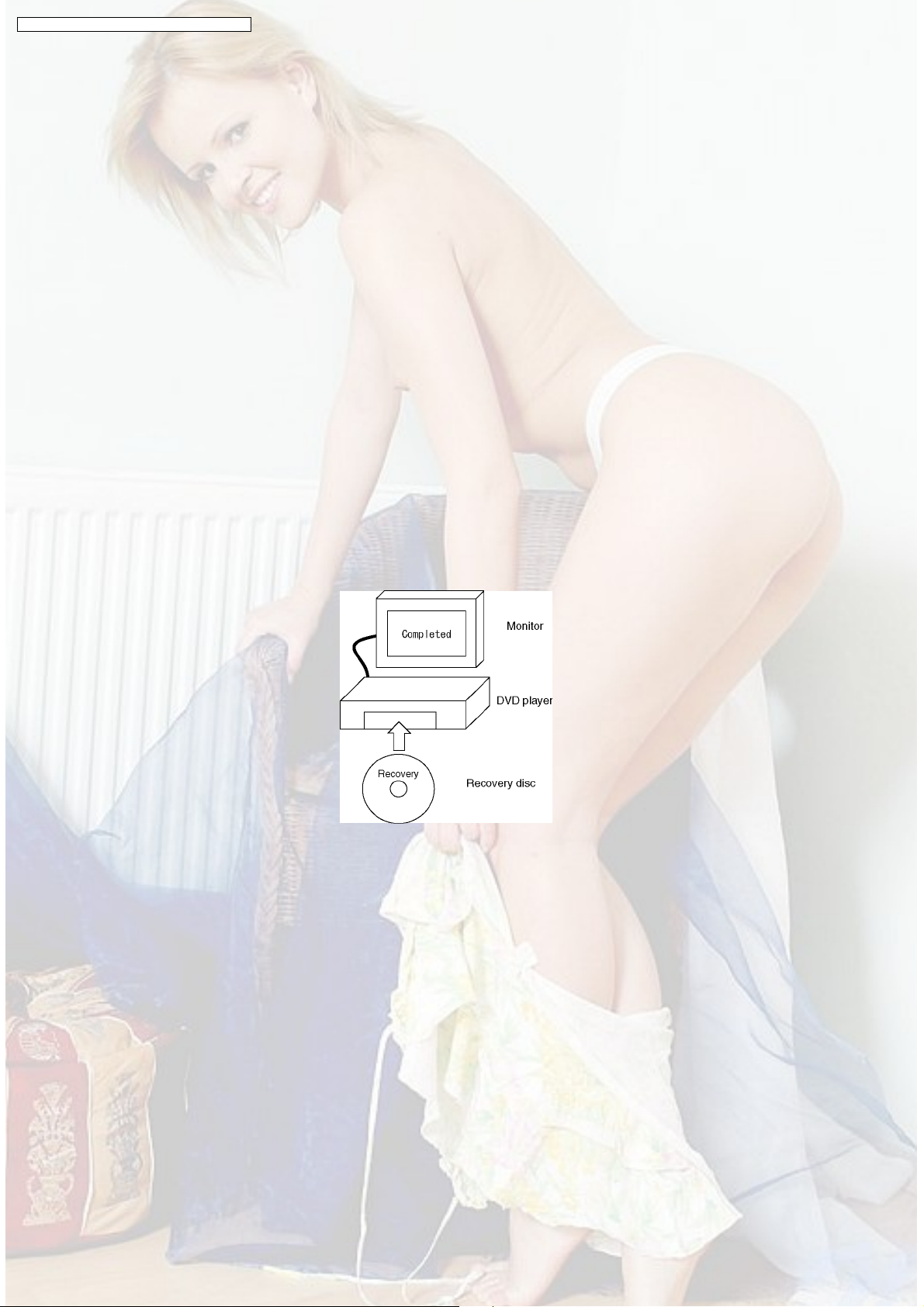

8.8. Service Precautions

Recovery after the dvd player is repaired

When an FROM or an EEPROM on the decoder PCB has replaced, carry out the recovery disc processing to optimize the drive.

Playback the disk to process the recovery automatically.

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired.

When the recovery measures are taken, the customer setting will return to the factory setting as same as the procedure

described in item of "Initialization". Write down the contents of the setting before recovery processing and reset the player.

8.8.1. Firmware version-up of the DVD player

The firmware of the DVD player may be renewed to improve the quality including operationability and playability to the substandard

discs processing to optimize the drive.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out. In such a

case, replace the FROM and carry out the version-up again. The product number of the version-up disc will be noticed when

it is supplied.

8.8.2. Firmware version-up and recovery with disc

•

• Recovery

• •

•

• Firmware updating

• •

Simply run the recovery disc. Then both of the above operations are automatically performed.

Commercially available CD-R can now perform updating and recovery process, making it easier to update the version.

Recovery process: Optimization of player after replacement of FROM and Decoder PCB.

Version updating: Firmware updating for improved operability and performance

8.8.3. How to use recovery disc

8.8.3.1. Performing recovery

1. Load the recovery disc RFKZD03R004 on to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

8.8.3.2. Updating firmware

1. Load the recovery disc RFKZD03R004 on to the player and run it.

2. Firmware version of the player is automatically checked. Appropriate message appears whenever necessary.

3. Using remote controller´s cursor key, select whether version updating is to be done or not. (Selection of Yes/No)

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc according to the message appearing on the screen.

b. Remove the disc according to the message appearing on the screen.

6. Turn off the power.

20

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

9 ASSEMBLING AND

DISASSEMBLING THE

MECHANISM UNIT

9.1. Disassembly Procedure

9.2. Terminal PCB

1. Unscrew the screws.

2. Remove the solders.

3. Remove the connectors.

9.3. Clamp Plate Unit

1. Push the stopper with hand to slide the tabs and remove

the clamp plate unit.

21

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

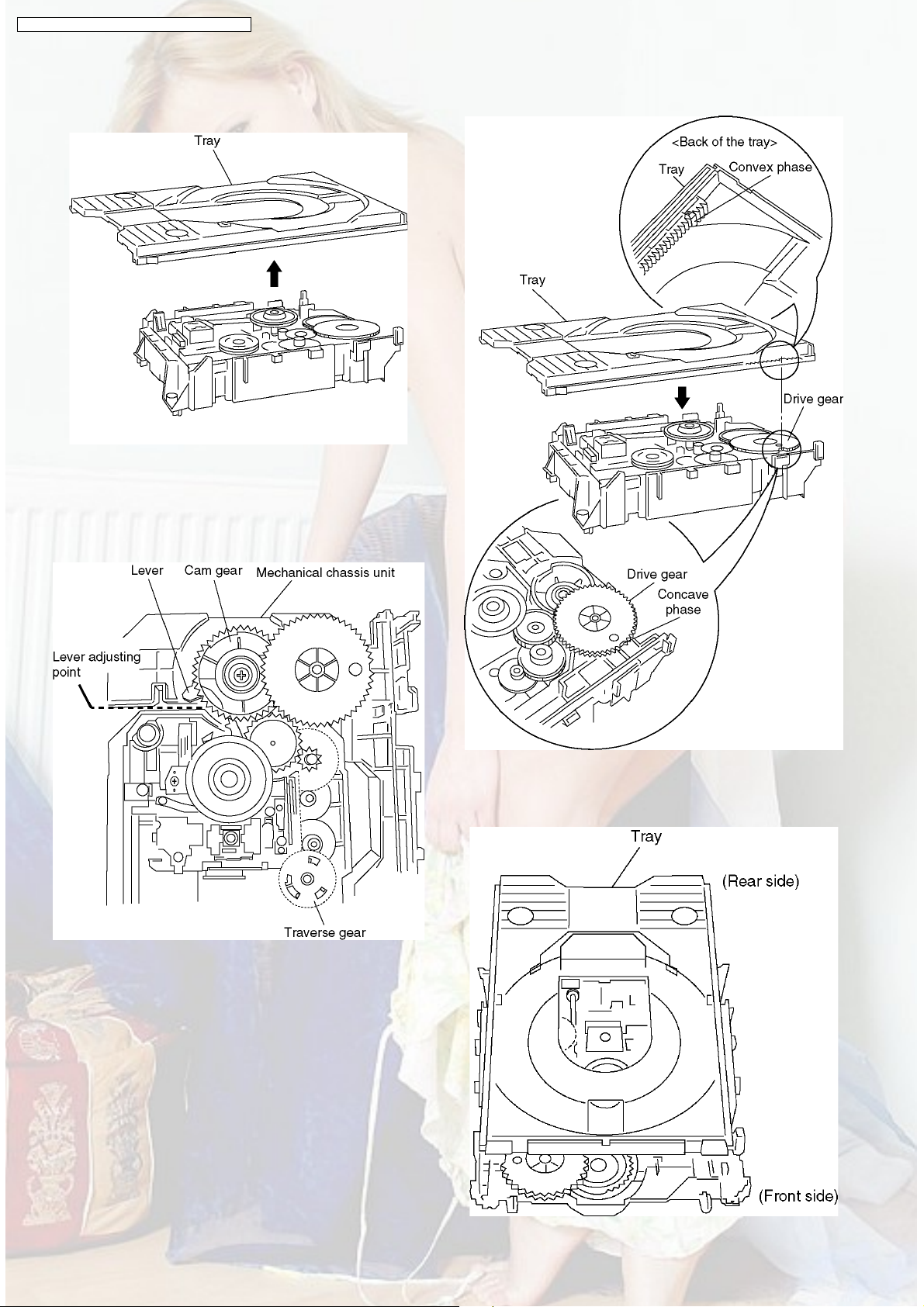

9.4. Tray

1. Lift the tray.

<Precautions in reassembling the tray>

●Reassemble the tray so that it is in the backmost position.

1. Turn traverse gear until cam gear leaver comes to the

lever adjusting position at the end of mechanical chassis

unit.

2. Check the position of convex phase on back of the tray,

and that of concave phase on drive gear.

a. Place the tray on the unit from rearward.

22

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

b. Inch the tray frontward until convex phase and

concave phase mate.

Caution:

Make sure to mate convex phase and concave phase

properly, so that the gap between turntable and tray

becomes 5mm or less.

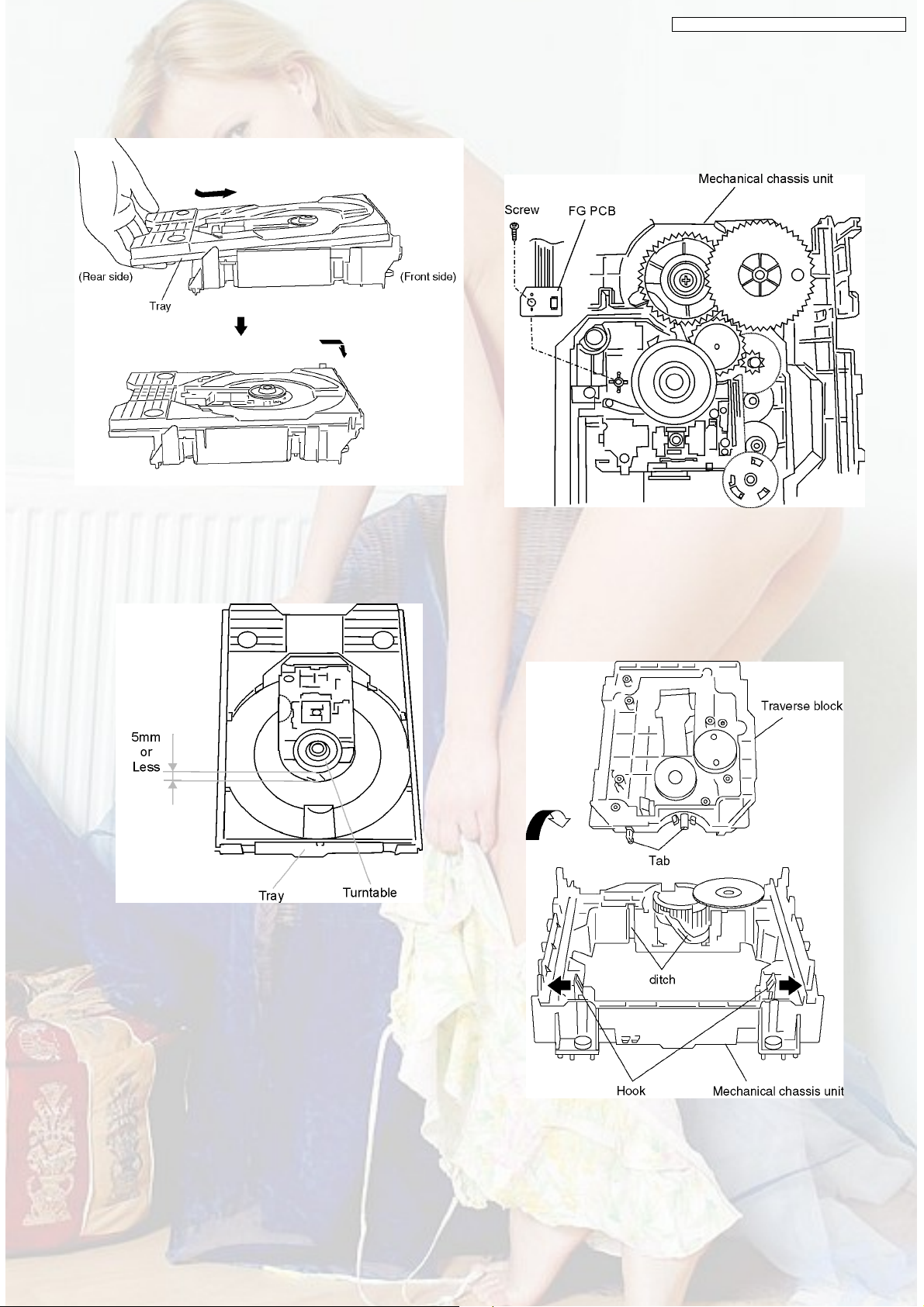

9.5. FG PCB Unit

1. Unscrew the screw.

2. Remove the FG PCB Unit.

9.6. Traverse Block

1. Lift the traverse block while spreading the hook of the

mechanical chassis unit.

2. Disengage the tabs from the holes of the mechanical

chassis unit.

23

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

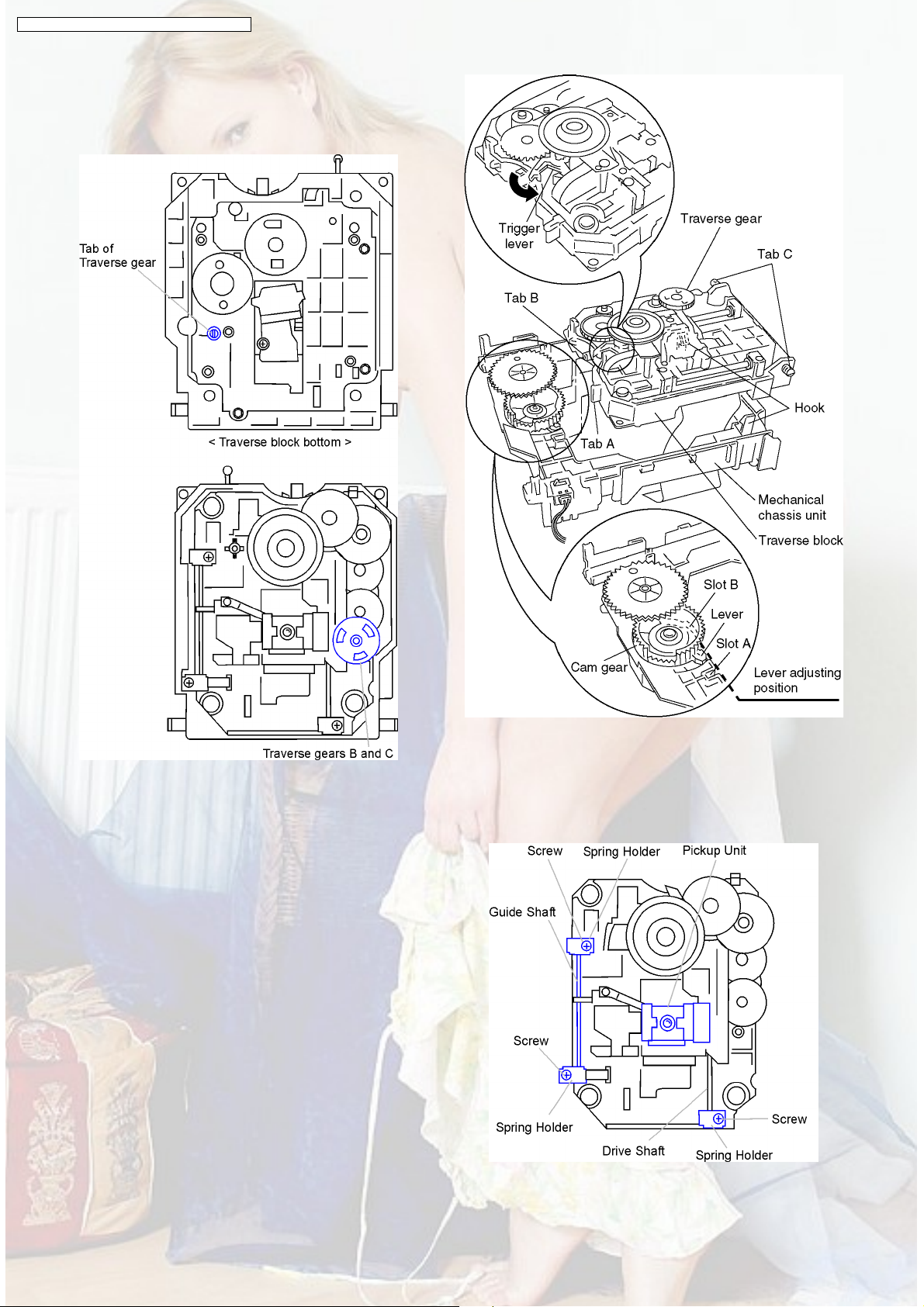

9.7. Traverse Gear

1. Disengage the tabs from the traverse gear.

2. Remove the traverse gears B and C.

<Precautions in reassembling the traverse block>

●Take the following precautions when reassembling the

traverse block.

a. Turn traverse gear on the traverse block to let trigger

lever turn rightward. (Front view)

b. Bring cam gear lever to the lever adjusting position

at the end of mechanical chassis unit.

c. Put tabs A and B into slots A and B respectively.

Place tabs C into hooks to mount the traverse block

on mechanical chassis unit. (Slot A... Mechanical

chassis unit, Slot B... Cam gear)

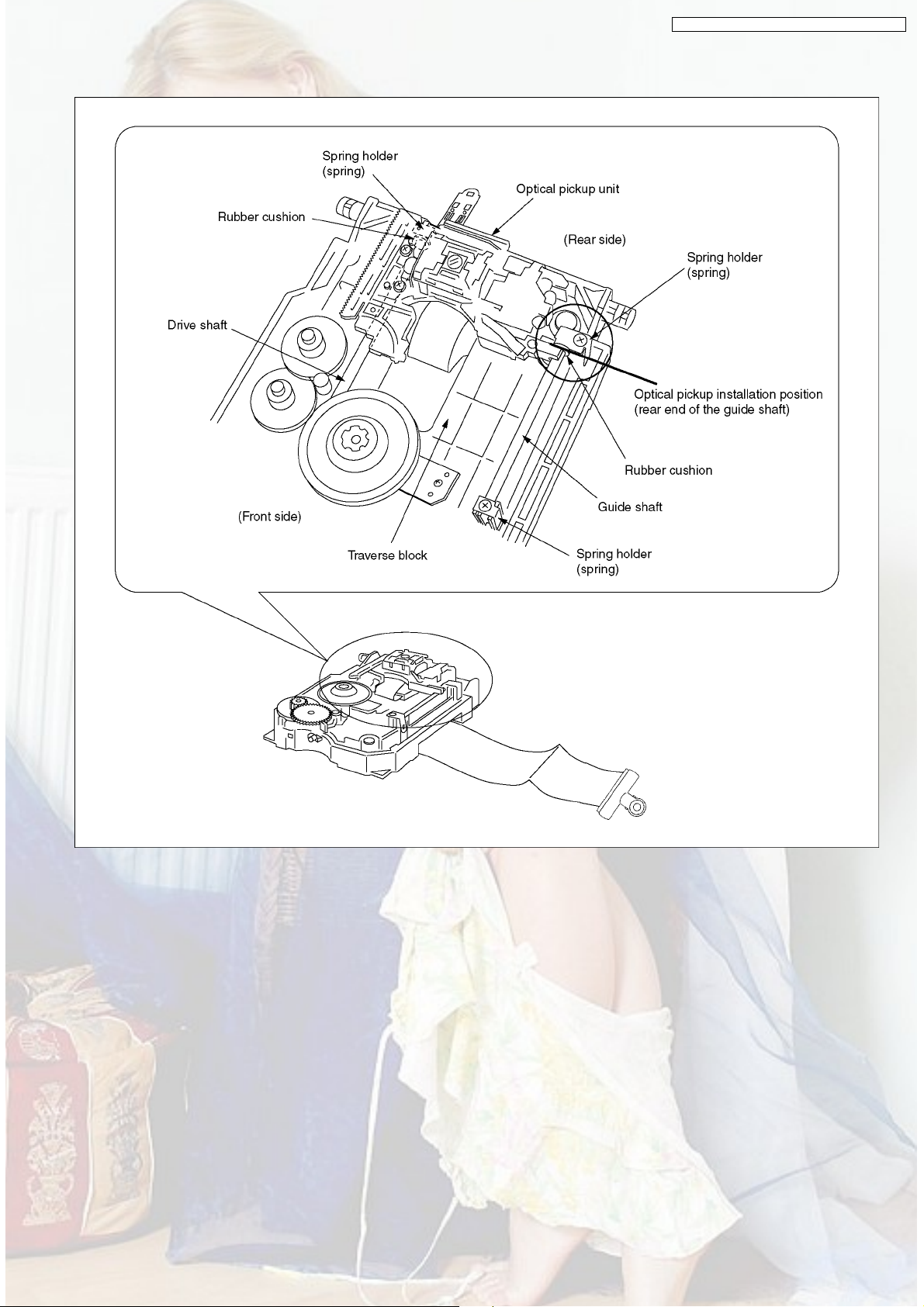

9.8. Optical Pickup Unit

1. Unscrew the screws.

2. Remove the spring holders and the springs.

3. Pull out the drive shaft and guide shaft.

24

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

9.8.1. Precautions in optical pickup replacement

The optical pickup can be damaged by static electricity from your body. Be sure to take static electricity countermeasures

when working around the optical pickup. (Refer to the related page in this Manual about the countermeasures.)

1. Do not touch laser diode, actuator and their peripheries.

2. Do not use tester to check laser diode. (Laser diode can be damaged easily.)

3. The use of soldering iron with anti-static feature is recommended when providing short-circuit to laser diode or when removing

it.

4. Solder the land on flexible cable of optical pickup unit.

Caution

•

• When using the soldering iron without anti-static feature, short-circuit the flexible cable terminal with a clip before short-

• •

circuiting the land.

•

• After intended repair is finished, remove the solder for short-circuit of laser diode in a correct way following the

• •

procedures described in this Manual.

25

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

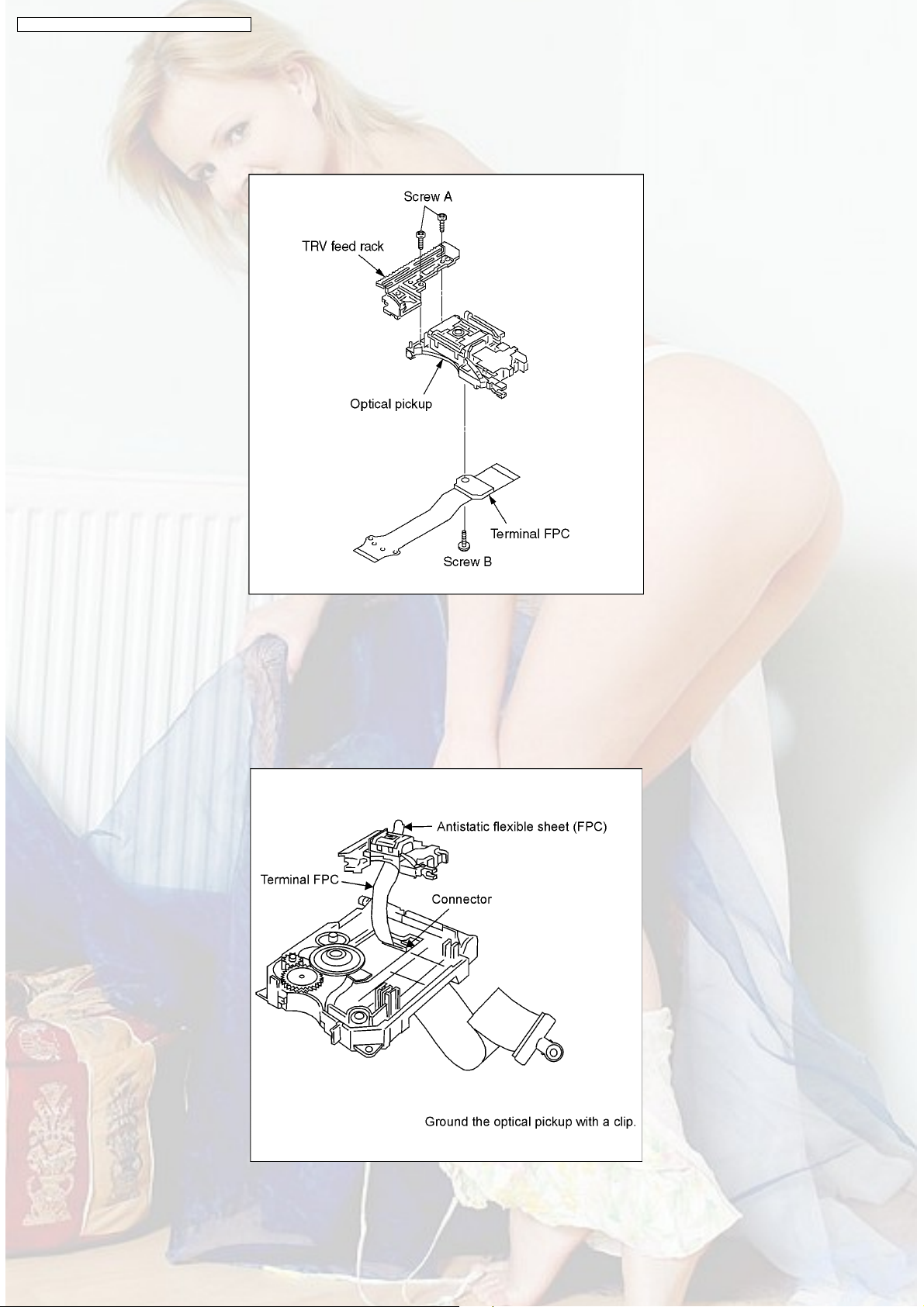

9.8.2. Disassembling the Optical Pickup Unit

1. Remove the 2 screws A and remove the TRV feed rack.

2. Remove the screw B and remove the Terminal FPC.

3. Remove the optical pickup.

Fig. 1

9.8.3. Cautions to be taken when replacing the Optical Pickup

•

• An antistatic flexible sheet (FPC) is connected with the new optical pickup.

• •

Replace the optical pickup according to the following procedure.

1. Install the Terminal FPC, TRV feed rack on the optical pickup. (See Fig. 1)

2. Install the Terminal FPC in the connector on the Intermediate PCB.

Fig. 2

26

DVD-S35E / DVD-S35EB / DVD-S35EG / DVD-S31EG

3. Install the optical pickup unit, spring, drive shaft, guide shaft, rubber cushion, and spring holder on the traverse block.

Fig. 3

Cautions to be taken when assembling the unit: Install the pickup unit so that it is located at the rear end of the guide shaft.

27

Loading...

Loading...