Page 1

ORDER No.AED02110467

AUTOMOTIVE ELECTRONICS

GM

CX-CG0260Z

6-Disc In-Dash CD Changer

GM PART No. :15055250

VEHICLE : Denali/ GMT820D

Grand Surb/ GMT

Escalade/ GMT820C

Cadillac/ GMT806

DESTINATION : North America

PRODUCED AFTER: Jan., 2002

I0

Specifications*

General

Power Supply DC 12V (11V - 16V)

Test Voltage 13.2V

Negative ground

Current Consumption Less than 1.0A

Output Level 1.25Vrms

Channel Separation 65dB min. (at 100kΩ Load)

Cannel Balance 1.0dB max. (at 1kHz)

Signal to Noise Ratio 75dB min.

THD 0.1% max. (at 1kHz)

Dimensions** (W×H×D) 178 × 50 × 177.5 (mm)

(not including connector protrusion or

brackets)

Weight** 2.0kg

* Specifications and the design are subject to possible modification

without notice due to improvements.

** Dimensions and Weight shown are approximate.

•

• Above specifications comply with EIA standards.

• •

© 2002 Matsushita Communication Industrial Co.,

Ltd. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

GM / CX-CG0260Z

CONTENTS

Page Page

1 FEATUERS 2

2 LASER PRODUCTS

3 REAR VIEW AND CONNECTORS

4 FRONT VIEW AND FUNCTIONS

5 WIRING CONNECTIONS

6 BLOCK DIAGRAM

7 TERMINALS DESCRIPTION

8 CD DISC CENTERING ALIGNMENT

9 PACKAGE AND IC BLOCK DIAGRAM

10 REPLACEM ENT PARTS LIST 13

2

11 EXPLODED VIEW (Unit)

3

12 CD CHANGER PARTS LIST

13 EXPLODE D VIEW (CD Deck-1)

3

4

14 EXPLODE D VIEW (CD Deck-2)

5

15 EXPLODE D VIEW (CD Deck-3)

16 WIRING DIAGRAM

7

9

17 SCHEMAT IC DIAGRAM

10

1 FEATUERS

•

•

6-Disc CD changer capacity

• •

•

•

1 DIN size.

• •

•

•

Includes Illumination circuit to improve neght visibility.

• •

16

17

20

21

22

23

27

2 LASER PRODUCTS

2

Page 3

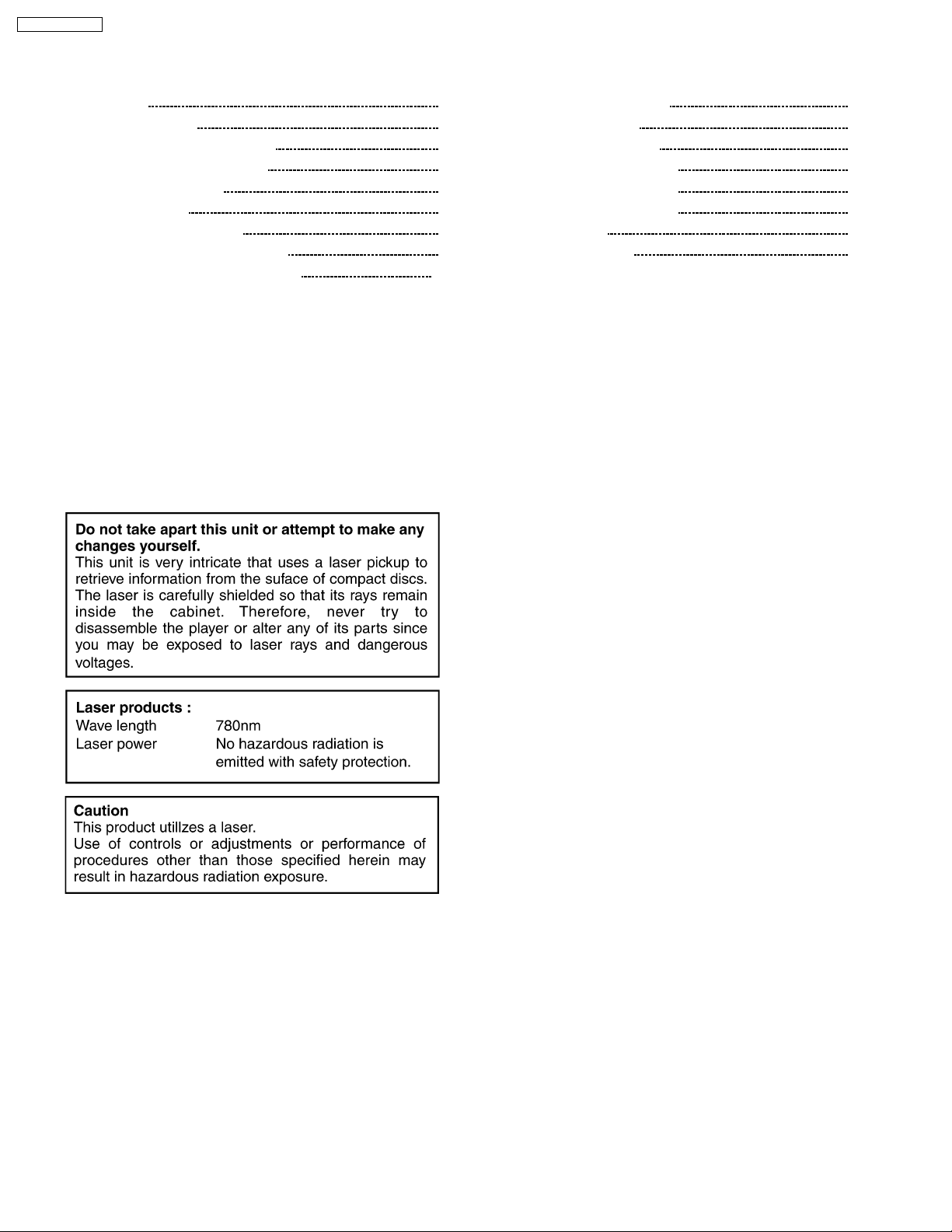

3 REAR VIEW AND CONNECTORS

4 FRONT VIEW AND FUNCTIONS

GM / CX-CG0260Z

3

Page 4

GM / CX-CG0260Z

5 WIRING CONNECTIONS

4

Page 5

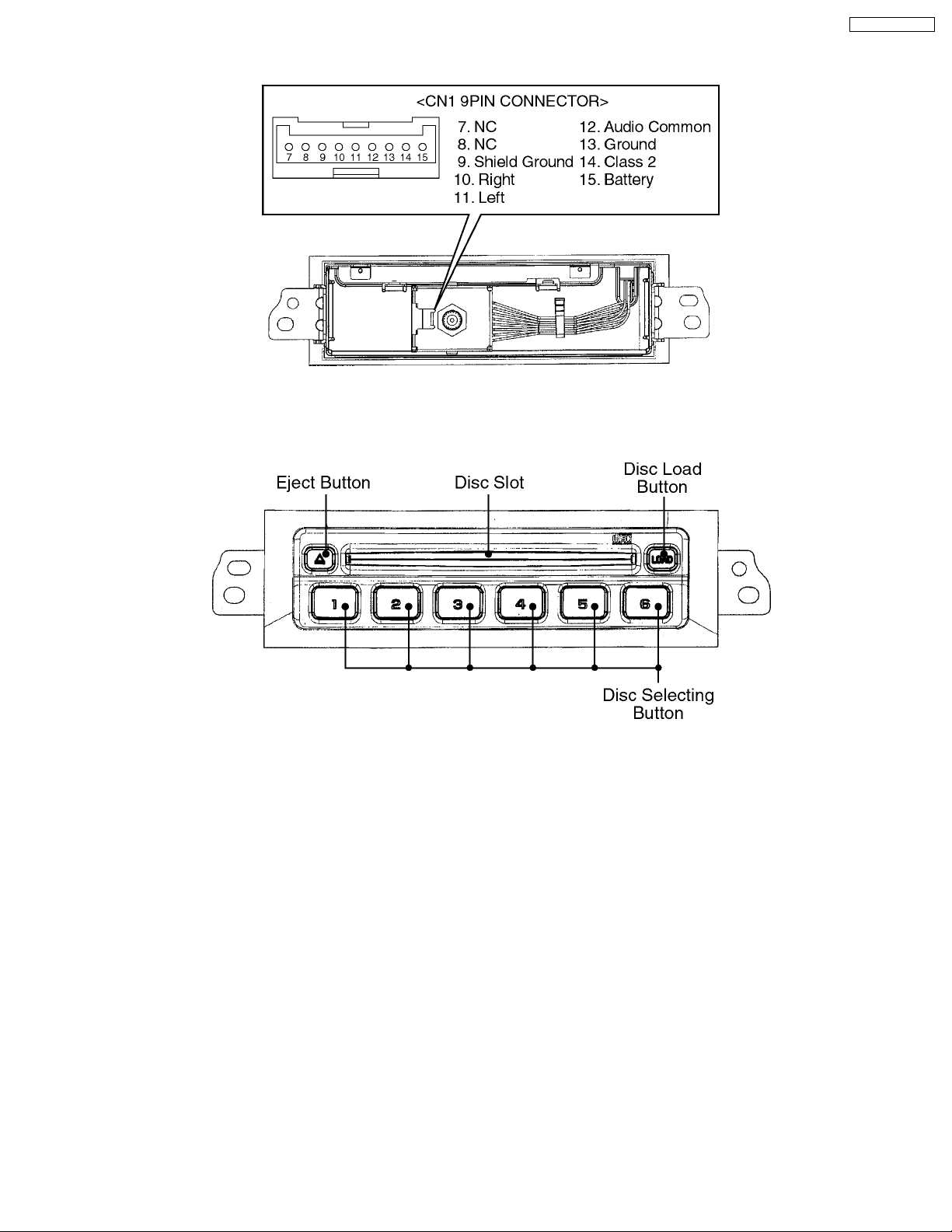

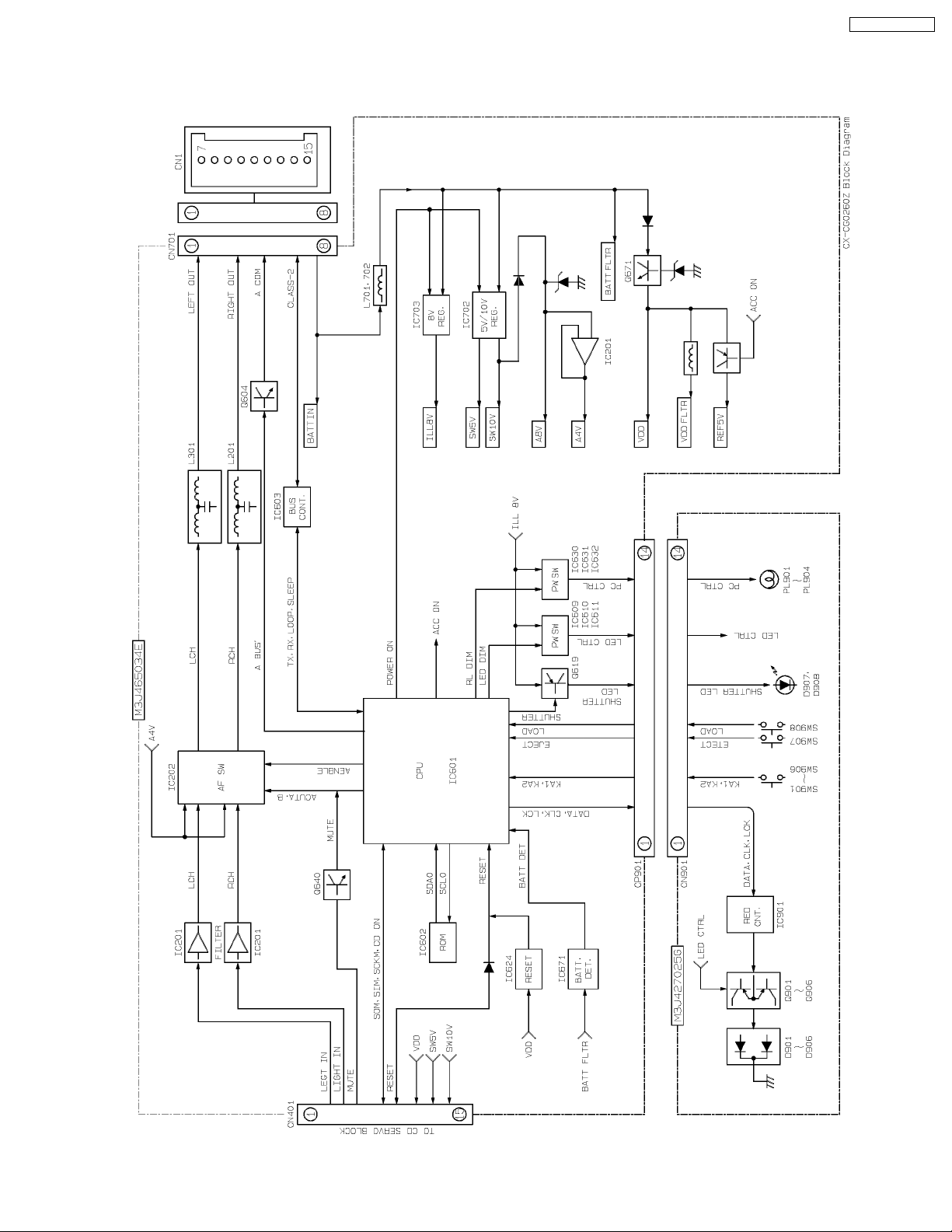

6 BLOCK DIAGRAM

6.1. Main/ Display Block

GM / CX-CG0260Z

5

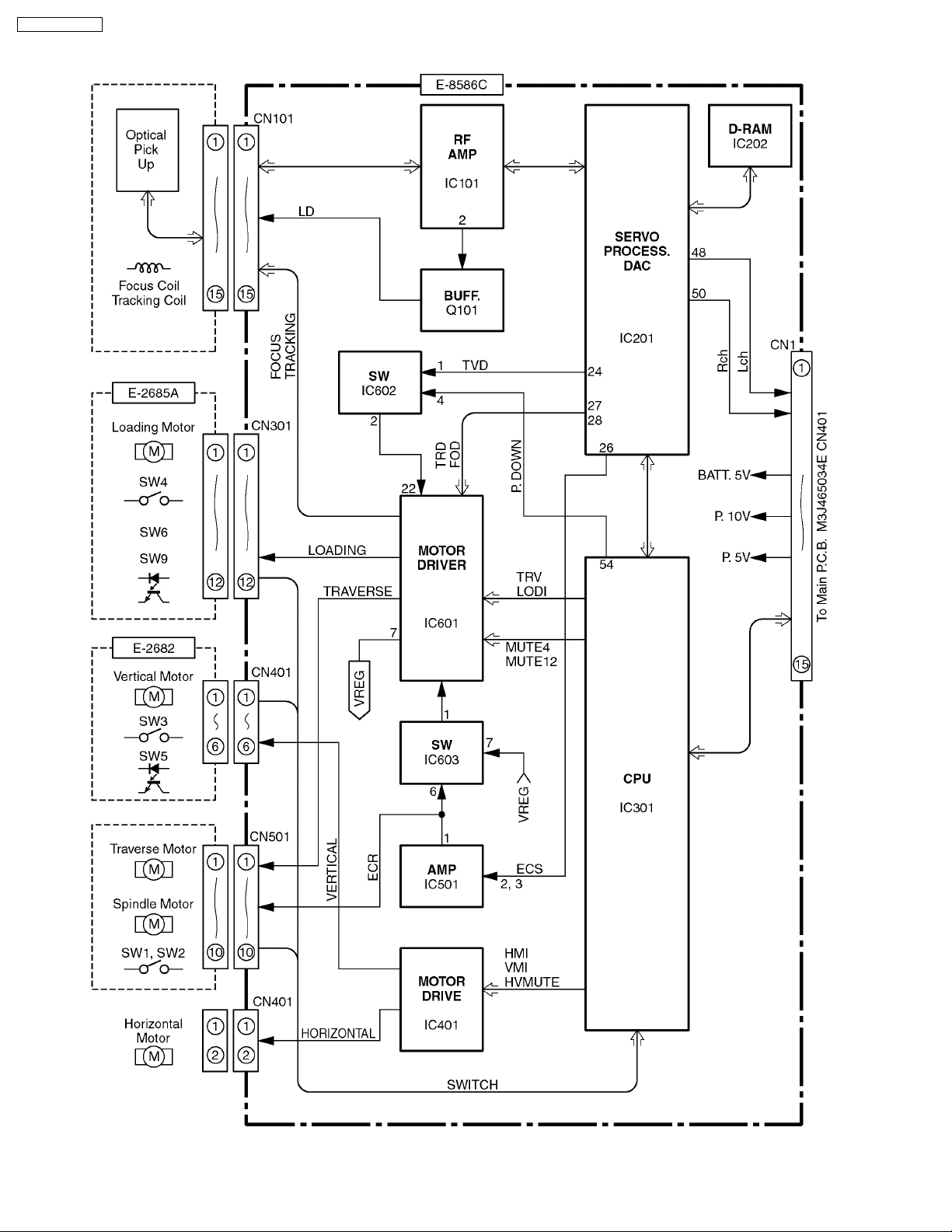

Page 6

GM / CX-CG0260Z

6.2. CD Servo Block

6

Page 7

7 TERMINALS DESCRIPTION

GM / CX-CG0260Z

7.1. Main Block

IC601 : UC2BBGF00008

Pin No. Port Description I/O

1 (NC) - 2 SDA Serial Data I/O

3 SCL Clock for serial data O

4 (NC) - 5 (NC) - 6 (NC) - 7 BATT DET Battery Voltage Detection I

8 RD ON (+5V pull up) -

9 EJECT EJECT Switch signal I

10 LOAD LOAD Switch signal I

11 AVREF1 +5V power supply 12 K2A Key Switch signal 2 I

13 K1A Key Switch signal 1 I

14 (NC) - 15 (NC) - 16 (NC) - 17 (NC) - 18 (NC) - 19 (NC) - 20 AVSS Ground 21 (NC) - 22 A BUS A BUS out O

23 ACC ON ACC On signal O

24 (NC) - 25 (NC) - 26 (NC) - 27 RESET Reset input I

28 CD ON CD On signal O

29 SOM CD changer serial data I

30 SIM CD changer serial data O

31 SCKM Clock for serial data O

32 VDD +5V power supply 33 VSS Ground 34 SMUTTER Shatter LED O

35 (NC) - 36 (NC) - 37 (NC) - 38 (NC) - 39 (NC) - 40 (NC) - 41 ACNTA Audio switch control A O

42 ACNTB Audio switch control B O

43 AENBL Audio switch enable O

44 POWER ON Power On signal O

45 LCK LED Driver LCK O

46 (NC) - 47 DATA LED Driver data O

48 CLK LED Driver clock O

49 (NC) - 50 (NC) - 51 (NC) - 52 (NC) - 53 (NC) - 54 (NC) - 55 (NC) - 56 LED DIM LED dimer signal O

57 PL DIM Pilot Lamp dimmer control O

58 (NC) - 59 (NC) - 60 SLEEP Class2 transeiver sleep O

61 LOOP Class2 transeiver loop O

Pin No. Port Description I/O

62 C2RX Class2 transeiver RX I

63 C2TX Class2 transeiver TX O

64 RESET Reset input I

65 IC(VPP) (TP1) #REF!

66 X2 Crystal osillator 67 X1 Crystal osillator 68 VSS1 Ground 69 VDD1 +5V power supply 70 VDD0 +5V power supply 71 AVREF0 +5V power supply 72 (NC) - 73 (NC) - 74 (NC) - 75 (NC) - 76 (NC) - 77 (NC) - 78 (NC) - 79 (NC) - 80 AVSS1 Ground -

Note :

Voltage measuerments are with respect to ground, with a

voltmeter (Internal resistance : 10M ohms.)

7.2. CD Servo Block

IC201 : MN662783RPW

Pin No. Port Description I/O (V)

1 VDD +5V power supply - 5.0

2 D0 D-RAM data I/O 2.3

3 D1 D-RAM data I/O 1.8

4 /WE D-RAM data write O 4.9

5 /RAS D-RAM row address strobe O 3.4

6 D2 D-RAM data I/O 0.8

7 D3 D-RAM data I/O 0

8 /CAS0 D-RAM columun address strobe O 3.9

9 /CAS1 D-RAM columun address strobe O 0

10 A8 D-RAM address O 0.6

11 A7 D-RAM address O 1.1

12 A6 D-RAM address O 0.7

13 A5 D-RAM address O 0

14 A4 D-RAM address O 1.1

15 A9 D-RAM address O 0.4

16 A0 D-RAM address O 1.0

17 A1 D-RAM address O 1.0

18 A2 D-RAM address O 1.0

19 A3 D-RAM address O 0

20 VSS2 Ground - 0

21 VDD2 +5V power supply - 5.0

22, 23 - Not used - -

24 TVD Traverse motor control O 2.5

25 PC Not used - 26 ECS Spindle motor control O 2.4

27 TRD Tracking coil drive O 2.5

28 FOD Focus coil drive O 2.4

29 FBAL Focus balance O 1.9

30 TBAL Tracking balance O 3.0

31 VREF Reference voltage I 2.5

32 FE Focus error I 2.5

33 TE Tracking error I 2.5

34 RFENV RF envelope I 2.5

35 OFT Off track signal I 0

36 /RFDET RF detecting signal I 0

7

Page 8

GM / CX-CG0260Z

37 BDO Drop-out signal I 0

38 LDON Laser on signal O 4.5

39 ARF RF signal I 2.5

40 IREF Reference current input I 1.2

41 DRF Biase for DSL I 2.4

42 DSLF Loop filter for DSL I/O 2.5

43 SDLF2 Loop filter for DSL I/O 2.2

44 PLLF Loop filter for PLL I/O 1.4

45 VCOF Not used - 46 AVDD2 +5V power supply - 5.0

47 AVSS2 Ground - 0

48 OUTL L channel output O 2.3

49 AVSS1 Ground - 0

50 OUTR R channel output O 2.3

51 AVDD1 +5V power supply - 4.7

52-54 - (Connecting to ground) - 0

55 FLAG Flag output O 0

56 FCLK Frame clock O 0

57-59 - Not used - -

60 TX Not used - 61 MCLK Clock for I/F command I 1.0

62 MDATA Data for I/F command I 3.1

63 MLD I/F command load I 5.0

64 BLKCK Subcode block clock O 0

65 SQCK Ext. clock for sub code-Q I 5.0

66 SUBQ Code for sub. code-Q O 3.8

67 DMUTE Mute input I 0

68 STAT Status signal O 5.0

69 /RST Reset input I 5.0

70 CSEL (Connecting to ground) - 0

71 PMCK PM clock O 2.5

72 SMCK SM clock O 2.5

73 SUBC Serial data of sub code O 0

74 SBCK Shift clock for SUBC I 0.6

75 /CLDCK Not used - 76 /TEST (Connecting to VDD) - 5.0

77 X1 Crystal oscillator - 0.4

78 X2 Crystal oscillator - 3.2

79 VDD1 +5V power supply - 5.0

80 VSS1 Ground - 0

24 SUBQ Code for sub. code-Q I 1.6

25 - Not used - 5.0

26 - (Ground pull-down) - 0

27 CD.ON CD changer start/stop I 5.0

28 - Not used - 5.0

29 BLKCK Sub. code block clock I 0

30 P.ON Not used - 5.0

31 MUTE Mute output O 5.0

32 - (Ground pull-down) - 0

33 SENS Servo status O 0

34 CLVS Servo status O 5.0

35 FLOCK Focus servo lock O 0.2

36 TLOCK Tracking servo lock O 0

37 VMI Horizontal motor control O 2.5

38 HMI Vertical motor control O 0

39 HVMUTE H/V motor mute O 0

40-42 - (Ground pull-down) - 0

43 SW9 Disc-in (B) SW I 0

44 SW8 Disc-in (L) SW I 0

45 SW7 Disc-in (F) SW I 0

46 SW6 Disc push SW I 0

47 SW5 Tray hight SW I 4.5

48 BDO Drop-out signal I 0

49 DQSY Not used - 50 /RST Reset output O 5.0

51 STAT Status signal I 2.1

52 DMUTE Mute output O 0

53 XE Not used - 54 P.DOWN Power down signal O 0

55 - No connection - 56 MLD I/F command load O 5.0

57 MDATA Data for I/F command O 3.1

58 MCLK Clock for I/F command O 4.1

59 SPMT Spindle mute O 5.0

60 MUTE12 Focus/Tracking mute O 0

61 MUTE4 Loading motor mute O 4.8

62 LDOI Loading motor control I/O 2.5

63 TRV Forced traverse control I/O 2.4

64 SYNC Not used - -

IC301 : MN1873260AB4

Pin

No.

1 VDD +5V power supply - 5.0

2 OSC2 Crystal oscillator - 2.2

3 OSC1 Crystal oscillator - 2.1

4 VSS Ground - 0

5 XI (Connecting to ground) - 0

6 XO Not used - 7 CM (Connecting to ground) - 0

8 VREFH Reference voltage I 5.0

9 SW13 Shuter SW I 4.9

10 SW12 Horizontal origin I 4.9

11 SW11 Clump SW I 0

12 SW10 Play SW I 0

13 SW4 Shuter SW I 4.9

14 SW3 Tray origin SW I 0

15 SW2 Inner SW I 4.8

16 SW1 Outer SW I 4.9

17 VREFL Reference voltage I 0

18 /RESET Reset input I 4.9

19 - (Ground pull-down) - 0

20 SCKM Clock for serial data I 5.0

21 SIM CD changer serial data I 1.3

22 SOM CD changer serial data O 4.3

23 SQCK Ext. clock for sub. code-Q O 5.0

Port Description I/O (V)

8

Page 9

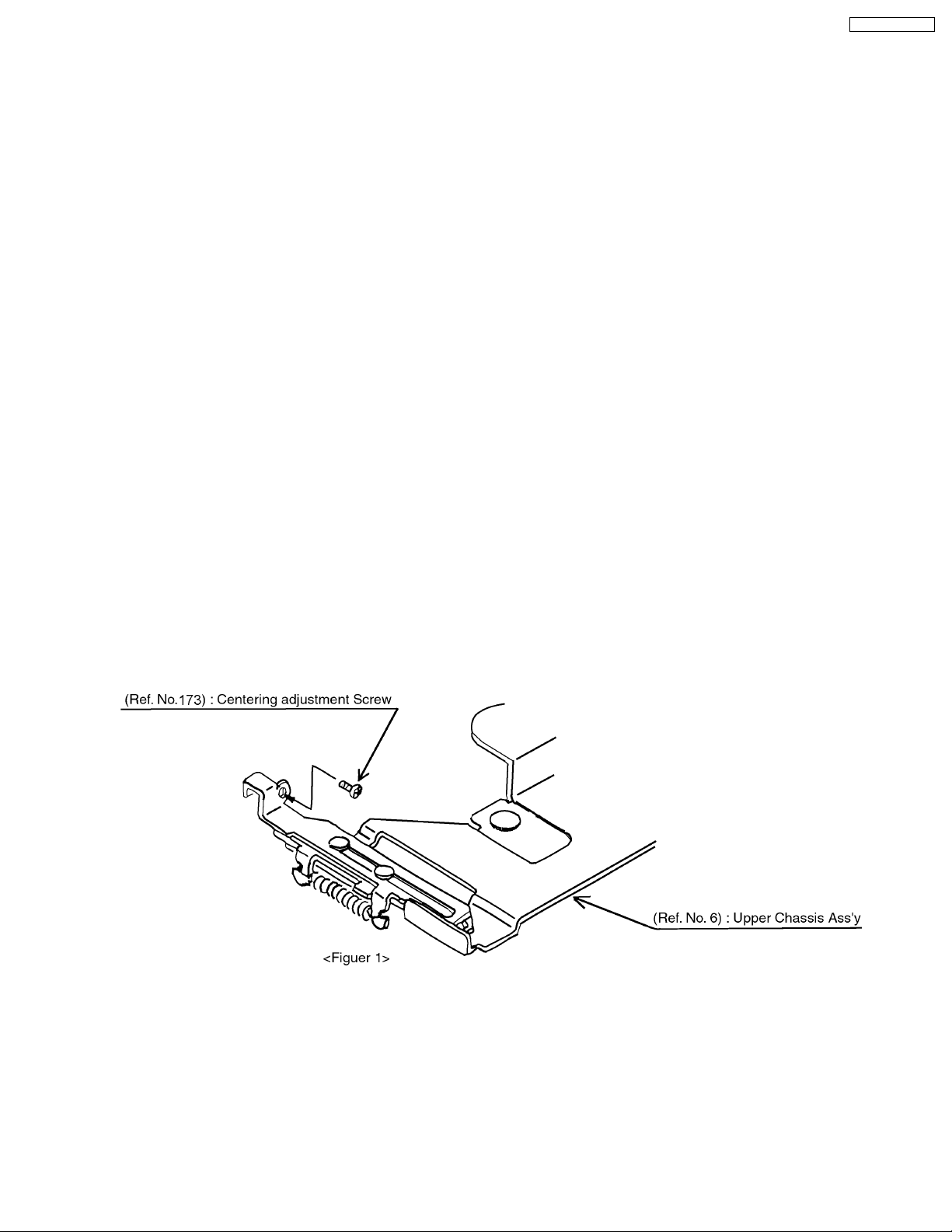

8 CD DISC CENTERING ALIGNMENT

•

•

This adjustment is for assuring that compact discs will be placed in the center of the turntable.

• •

<Adjustment Condition / Jig>

•

•

Power Supply Voltage : 13.2V

• •

•

•

Test Disc : TCD-792A

• •

<Adjustment Procedures>

1. Attach the adjusting screw to the upper chassis (See Figure 1.).

2. Insert the test CD (TCD-792A) into the disc No.1 position and play it.

3. After checking whether the disc is centered on the turntable, turn the adjusting screw unit it is in the center.

<Check Items>

•

•

Check that the disc is correctly centered.

• •

•

•

Check that the disc is securely clamped.

• •

•

•

Check that no abnormal noise is produced when clamping the disc.

• •

GM / CX-CG0260Z

[Directions of Turning the Adjusting Screw]

•

•

CD stops before its proper position : Turn the screw counterclockwise.

• •

•

•

CD overruns : Turn the screw clockwise.

• •

4. After the adjustment, lock the screw.

9

Page 10

GM / CX-CG0260Z

9 PACKAGE AND IC BLOCK DIAGRAM

9.1. Main / Display Block

IC201 YEAMPC4574E1

IC702 YEAM61W12ST

IC202 YEAMPD4052E1

IC604, 671 MN1382QTX

IC901 BU2092FV

10

Page 11

9.2. CD Servo Block

GM / CX-CG0260Z

IC603 : YEAMT4W53FUL

IC101 : C1BB00000173

IC202 : C3ABMB000010

IC401 : YEAMBA6792FY

11

Page 12

GM / CX-CG0260Z

IC601 : C0GBY0000004

IC501 : YEAMPC358G2T

12

Page 13

10 REPLACEMENT PARTS

LIST

Notes :

1. Be sure to make your orders of replacement parts

according to this list.

2. Important safety notice: Components, identified by

mark have special characteristics important for safety.

When replacing any of these components, use only

manufacturer´s specified parts.

3. Location keys in the remarks column indicates the general

location of the parts shown in the exploded drawing, as in a

road map.

4. The marking (RTL) indicates that Retention Time is limited

for this item. After the discontinuation of assembly in

production, the item will continue to be available for a

specific period of time. The retention period of availability is

dependent on the type of assembly, and in accordance with

the laws governing part and product retention. After the end

of this period, the assembly will no longer be available.

5. "MCC" marks in remarkscolumn are indicated supply parts

of Matsushita Communication Industrial Corp. of America

(MCC).

Ref.

No.

[M3J465034E] Main Block

IC´s and TRANSISTORs

IC201 YEAMPC4574E1 IC

IC202 YEAMPD4052E1 IC MCC

IC601 UC2BBGF00008 IC, CPU MCC

IC602 UC3EBE000001 IC MCC

IC603 MC33390 IC MCC

IC604 MN1382QTX IC

IC671 MN1382QTX IC

IC702 YEAMA61W12ST IC, REG

IC703 YEAMBA09ST IC, REG MCC

Q604 2SD1382STTX Transistor

Q609 B1GBCFJN0005 Transistor

Q610 2SB1440TX Transistor

Q611 2SD1030TX Transistor

Q619 B1GDCFJN0005 Transistor

Q629 B1GDCFJN0005 Transistor

Q630 B1GBCFJN0005 Transistor

Q631 2SB1440TX Transistor

Q632 2SD1030TX Transistor

Q671 YEANC3618 Transistor

DIODEs

D601 UJ0LB0000001 Diode, Surge Protect MCC

D606 MA151KTX Diode

D671 YEADRD56M2T1 Diode, Zenner

D672 MA8051HTX Diode, Zenner MCC

D673 MA151KTX Diode

D674 MA151KTX Diode

D701 YEAD30D2FC6 Diode

D702 YEADDSA3A2B Diode

D703 YEADRD82M2T1 Diode, Zenner

D704 MA151KTX Diode

D705 MA151KTX Diode

CAPACITORs

C201 EEVMC1C100R Electrolytic, 10µF 16WV

C202 YECUS1H392KX Ceramic, 3900pF 50WV

C203 YECUS1H682KX Ceramic, 6800pF 50WV

C204 F1J1H182A509 Ceramic, 1800pF 50WV

C205 EEVMC1C100R Electrolytic, 10µF 16WV

Part No. Part Name & Description Remarks

Ref.

No.

C206 EEVMC1C220R Electrolytic, 22µ:F 16WV

C213 YECUS1H102KX Ceramic, 1000pF 50WV

C301 EEVMC1C100R Electrolytic, 10µF 16WV

C302 YECUS1H392KX Ceramic, 3900pF 50WV

C303 YECUS1H682KX Ceramic, 6800pF 50WV

C304 F1J1H182A509 Ceramic, 1800pF 50WV

C305 EEVMC1C100R Electrolytic, 10µF 16WV

C306 EEVMC1C220R Electrolytic, 22µ:F 16WV

;

C313 YECUS1H102KX Ceramic, 1000pF 50WV

C602 YECUS1H221JM Ceramic, 220pF 50WV

C603 YECUS1C104KX Ceramic, 0.1µF 16WV

C604 YECUS1C104KX Ceramic, 0.1µF 16WV

C605 YECUS1H101JM Ceramic, 100pF 50WV

C609 YECUS1C104KX Ceramic, 0.1µF 16WV

C610 YECUS1C104KX Ceramic, 0.1µF 16WV

C611 F1H1H1020001 Ceramic, 1000pF 50WV

C612 F1H1H101A231 Ceramic, 100pF 50WV

C613 F1H1H680A231 Ceramic, 68pF 50WV

C614 F1H1H680A231 Ceramic, 68pF 50WV

C615 F1H1H680A231 Ceramic, 68pF 50WV

C620 YECUS1H103KX Ceramic, 0.01µF 50WV

C621 YECUS1H103KX Ceramic, 0.01µF 50WV

C622 F1J1C1050016 Ceramic, 1µF 16WV MCC

C624 F1J1C1050016 Ceramic, 1µF 16WV MCC

C627 F1J1C1050016 Ceramic, 1µF 16WV MCC

C629 F1J1C1050016 Ceramic, 1µF 16WV MCC

C630 YECUS1H102KX Ceramic, 1000pF 50WV

C671 F1H1C1040002 Ceramic, 0.1µF 16WV

C672 EEVMC1C470P Electrolytic, 47µF 16WV

C673 EEVMC1C470P Electrolytic, 47µF 16WV

C674 YECUS1H104KX Ceramic, 0.1µF 50WV

C675 YECUS1H103KX Ceramic, 0.01µF 50WV

C680 YECUS1H104KX Ceramic, 0.1µF 50WV

C681 F1J1C224A006 Ceramic, 0.22µF 16WV

C682 F1J1C224A006 Ceramic, 0.22µF 16WV

C683 YECUS1H103KX Ceramic, 0.01µF 50WV

C684 YECUS1H104KX Ceramic, 0.1µF 50WV

C705 EEVHA1C331P Electrolytic, 330µF 16WV MCC

C706 EEVFC1C101P Electrolytic, 100µF 16WV

C707 YECUS1H104KX Ceramic, 0.1µF 50WV

C708 EEVMC1C220R Electrolytic, 22µ:F 16WV

C710 YECUS1H104KX Ceramic, 0.1µF 50WV

C711 EEVMC1C470P Electrolytic, 47µF 16WV

C713 EEVMC1C470P Electrolytic, 47µF 16WV

C714 YECUS1H104KX Ceramic, 0.1µF 50WV

C718 YECUS1H104KX Ceramic, 0.1µF 50WV

C723 YECUS1H104KX Ceramic, 0.1µF 50WV

C726 EEVMC1C220R Electrolytic, 22µ:F 16WV

C727 EEVMC0J101P Electrolytic, 100µF 6.3WV

C728 EEVHA1C331P Electrolytic, 330µF 16WV MCC

C751 YECUS1H103KX Ceramic, 0.01µF 50WV

C752 YECUS1H103KX Ceramic, 0.01µF 50WV

C797 EEVHA1C331P Electrolytic, 330µF 16WV MCC

C798 EEVHA1C331P Electrolytic, 330µF 16WV MCC

C799 EEVMC1C470P Electrolytic, 47µF 16WV

COILs

L201 YECCL60R471T Coil

L301 YECCL60R471T Coil

L601 YELT03N470JT Coil

L602 YELTBLM21A10 Coil

L701 YETQ012G157 Coil

L702 YECCL60R471T Coil

RESISTORs

R201 ERJ6GEYJ101V Chip, 100

R202 ERJ6GEYJ102V Chip, 1k

R203 ERJ6GEYJ333V Chip, 33k

R204 ERJ6GEYJ102V Chip, 1k

R205 ERJ6GEYJ102V Chip, 1k

R207 ERJ6GEYJ474V Chip, 470k

Part No. Part Name & Description Remarks

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

GM / CX-CG0260Z

13

Page 14

GM / CX-CG0260Z

Ref.

No.

R208 ERJ6GEYJ474V Chip, 470k

R209 ERJ6GEYJ103V Chip, 10k

R210 ERJ6GEYJ152V Chip, 1.5k

R301 ERJ6GEYJ101V Chip, 100

R302 ERJ6GEYJ102V Chip, 1k

R303 ERJ6GEYJ333V Chip, 33k

R304 ERJ6GEYJ102V Chip, 1k

R305 ERJ6GEYJ102V Chip, 1k

R307 ERJ6GEYJ474V Chip, 470k

R308 ERJ6GEYJ474V Chip, 470k

R309 ERJ6GEYJ103V Chip, 10k

R310 ERJ6GEYJ152V Chip, 1.5k

R601 ERJ3EKF3401V Chip, 3.4k

R602 ERJ3EKF3401V Chip, 3.4k

R607 ERJ6GEYJ472V Chip, 4.7k

R608 ERJ6GEYJ474V Chip, 470k

R609 ERJ6GEYJ182V Chip, 1.8k

R614 ERJ6GEYJ102V Chip, 1k

R621 ERJ6EKF1072V Chip, 10.7k

R623 ERJ6GEYJ223V Chip, 22k

R624 ERJ6GEYJ223V Chip, 22k

R625 ERJ6GEYJ223V Chip, 22k

R629 ERJ3GEYJ103V Chip, 10k

R631 ERJ6GEY0R00V Chip, 0

R632 ERJ6GEY0R00V Chip, 0

R633 ERJ6GEY0R00V Chip, 0

R634 ERJ6GEYJ104V Chip, 100k

R635 ERJ6GEYJ104V Chip, 100k

R637 ERJ3GEYJ103V Chip, 10k

R638 ERJ3GEYJ473V Chip, 47k

R639 ERJ3GEYJ103V Chip, 10k

R640 ERJ3GEYJ153V Chip, 15k

R641 ERJ3GEYJ103V Chip, 10k

R642 ERJ3GEYJ103V Chip, 10k

R671 ERJ6GEYJ473V Chip, 47k

R674 ERJ6GEYJ563V Chip, 56k

R675 ERJ6GEYJ100V Chip, 10

R676 ERJ6GEYJ473V Chip, 47k

R678 ERJ6GEYJ474V Chip, 470k

R679 ERJ6GEYJ474V Chip, 470k

R707 ERJ6GEYJ680V Chip, 68

R708 ERJ6GEYJ103V Chip, 10k

R709 ERJ6GEYJ103V Chip, 10k

R710 ERJ6GEY0R00V Chip, 0

R711 ERJ6GEY0R00V Chip, 0

R712 ERJ6GEY0R00V Chip, 0

R713 ERJ6GEYJ101V Chip, 100

RESISTOR NETWORKs

R626 EXBV8V102JV Resistor Network, 1k

R627 EXBV8V102JV Resistor Network, 1k

R628 EXBV8V102JV Resistor Network, 1k

R630 EXBV8V102JV Resistor Network, 1k

Part No. Part Name & Description Remarks

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/16W MCC

ΩΩΩΩ

1/16W MCC

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/16W MCC

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/16W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

x4

x4

x4

x4

Ref.

No.

Q903 FMA8ASMT5 Transistor MCC

Q904 FMA8ASMT5 Transistor MCC

Q905 FMA8ASMT5 Transistor MCC

Q906 FMA8ASMT5 Transistor MCC

DIODEs

D901 M1Z427084 LED, w/Spacer MCC

D902 M1Z427084 LED, w/Spacer MCC

D903 M1Z427084 LED, w/Spacer MCC

D904 M1Z427084 LED, w/Spacer MCC

D905 M1Z427084 LED, w/Spacer MCC

D906 M1Z427084 LED, w/Spacer MCC

D907 MEADHAY1105W LED, Amber MCC

D908 MEADHAY1105W LED, Amber MCC

CAPACITORs

C901 YECUS1H104KX Ceramic, 0.1µF 50WV

C902 YECUS1H104KX Ceramic, 0.1µF 50WV

C907 YECUS1H103KX Ceramic, 0.01µF 50WV

C908 YECUS1H103KX Ceramic, 0.01µF 50WV

RESISTORs

R901 ERJ14YJ221H Chip, 220

R902 ERJ14YJ221H Chip, 220

R903 ERJ14YJ221H Chip, 220

R904 ERJ14YJ221H Chip, 220

R905 ERJ14YJ221H Chip, 220

R906 ERJ14YJ221H Chip, 220

R907 ERJ14YJ221H Chip, 220

R908 ERJ6GEYJ272V Chip, 2.7k

R909 ERJ6GEYJ222V Chip, 2.2k

R910 ERJ6GEYJ152V Chip, 1.5k

R911 ERJ6GEYJ102V Chip, 1k

R912 ERJ6GEYJ272V Chip, 2.7k

R913 ERJ6GEYJ222V Chip, 2.2k

R914 ERJ6GEYJ152V Chip, 1.5k

R915 ERJ6GEYJ102V Chip, 1k

R916 ERJ14YJ221H Chip, 220

CONNECTORs

CN901 K1MQ14A00003 Connector, 14P MCC

SWITCHes

SW901 MEPBSKQMAG Switch MCC

SW902 MEPBSKQMAG Switch MCC

SW903 MEPBSKQMAG Switch MCC

SW904 MEPBSKQMAG Switch MCC

SW905 MEPBSKQMAG Switch MCC

SW906 MEPBSKQMAG Switch MCC

SW907 MEPBSKQMAG Switch MCC

SW908 MEPBSKQMAG Switch MCC

Part No. Part Name & Description Remarks

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/4W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/10W

ΩΩΩΩ

1/4W

CONNECTORs

CN401 YEAE5227115 Connector, 15P

CN701 UK1KA08B0002 Connector, 8P MCC

CP901 YEAE0114TKCX Connector, 14P

CRYSTAL

XL601 H2D838400003 Ceramic Oscillator

[M3J427025G] Display Block

IC´s and TRANSISTORs

IC901 BU2092FV IC MCC

Q901 FMA8ASMT5 Transistor MCC

Q902 FMA8ASMT5 Transistor MCC

LAMPs

PL901 M1Z427062 Pilot Lamp, Blue MCC

PL902 M1Z427062 Pilot Lamp, Blue MCC

PL903 M1Z427062 Pilot Lamp, Blue MCC

PL904 M1Z427062 Pilot Lamp, Blue MCC

Mechanical Parts

MISCELLANEOUS

AE1 YEAES15B040A Connector, 15P

CN1 M3Z465060 Power Cord w/Connectors MCC

1 M4G427052C Top Cover MCC

2 M4G427035A Bracket, Main PCB MCC

3 M1C427069 Tape, Urethane MCC

14

Page 15

Ref.

No.

4 M4G427051B Bracket, Rear MCC

5 M4G427017 Bracket, IC MCC

6 ZZ65034MP3 PCB w/Component, Main MCC,

7 ZZ27025MP3 PCB w/Component, Display MCC,

8 M4A465051B Escucheon Ass´y MCC

9 M1Z427063 Insulator MCC

10 M1D465058 Clamper, Power Cord MCC

11 M2A465055 Bracket, Power Cord MCC

12 M3A465057 Chassis Ass´y MCC

21 XTB2+6GFX Screw, M2X6mm

22 YEJT03015 Screw, M3X6mm

23 XTB3+6FFX Screw, M3X6mm

24 XTB3+5FFX Screw, M3X5mm

25 YEJS06093 Screw, M3X6mm

Part No. Part Name & Description Remarks

RTL

RTL

GM / CX-CG0260Z

15

Page 16

GM / CX-CG0260Z

11 EXPLODED VIEW (Unit)

16

Page 17

12 CD CHANGER PARTS

LIST

Ref.

No.

[E8586C] CD Servo Block

IC´s and TRANSISTORs

IC101 C1BB00000173 IC

IC201 MN662783RPW IC

IC202 C3ABMB000010 IC

IC301 MNS73260ACBL IC

IC401 YEAMBA6792FY IC

IC501 YEAMPC358G2T IC

IC601 C0GBY0000004 IC

IC602 C0JBAS000051 IC

IC603 YEAMT4W53FUL IC

Q101 2SB766ATX Transistor

DIODE

D301 MA152WKTX Diode

CAPACITORs

C100 ECEV1CA470SP Electrolytic, 47µF 16WV

C101 YECUS1C104KX Ceramic, 0.1µF 16WV

C102 YECUS1C104KX Ceramic, 0.1µF 16WV

C103 F3H0J1070005 Tantalum, 100µF 6.3WV

C104 YECUS1C104KX Ceramic, 0.1µF 16WV

C105 F3E0J475A001 Tantalum, 4.7µF 6.3WV

C106 YECUS1E273KX Ceramic, 0.027µF 25WV

C107 YECUS1H152KX Ceramic, 1500PF 50WV

C108 YECUS1H472KX Ceramic, 4700PF 50WV

C109 YECUS1H102KX Ceramic, 1000PF 50WV

C110 YECUS1H102KX Ceramic, 1000PF 50WV

C111 YECSW1C106MS Tantalum, 10µF 16WV

C112 YECUS1C104KX Ceramic, 0.1µF 16WV

C113 YECUS1C104KX Ceramic, 0.1µF 16WV

C114 YECSW1C106MS Tantalum, 10µF 16WV

C115 YECUS1H102KX Ceramic, 1000PF 50WV

C116 YECUS1H102KX Ceramic, 1000PF 50WV

C118 YECUS1H391JM Ceramic, 390PF 50WV

C120 YECUS1H561JM Ceramic, 560PF 50WV

C122 YECUS1C104KX Ceramic, 0.1µF 16WV

C202 YECUS1H123KX Ceramic, 0.012µF 50WV

C203 YECUS1C334KX Ceramic, 0.33µF 16WV

C204 YECUS1C104KX Ceramic, 0.1µF 16WV

C205 YECSW1C106MS Tantalum, 10µF 16WV

C206 ECEV0JA470SR Electrolytic, 47µF 6.3WV

C207 YECUS1C104KX Ceramic, 0.1µF 16WV

C208 YECUS1C104KX Ceramic, 0.1µF 16WV

C209 YECSW1C106MS Tantalum, 10µF 16WV

C210 YECUS1C104KX Ceramic, 0.1µF 16WV

C211 YECUS1A105KX Ceramic, 1µF 10WV

C301 YECUS1C104KX Ceramic, 0.1µF 16WV

C302 YECSW1C106MS Tantalum, 10µF 16WV

C305 YECUS1H103KX Ceramic, 0.01µF 50WV

C401 YECUS1C104KX Ceramic, 0.1µF 16WV

C402 ECEV1CA470SP Electrolytic, 47µF 16WV

C403 YECUS1C104KX Ceramic, 0.1µF 16WV

C501 YECUS1C104KX Ceramic, 0.1µF 16WV

C503 YECUS1E273KX Ceramic, 0.027µF 25WV

C504 YECUS1E393KX Ceramic, 0.039µF 25WV

C601 YECUS1C104KX Ceramic, 0.1µF 16WV

C602 ECEV1CA470SP Electrolytic, 47µF 16WV

C603 YECUS1C104KX Ceramic, 0.1µF 16WV

C604 YECUS1C104KX Ceramic, 0.1µF 16WV

C605 F1H1H821A190 Ceramic, 820PF 50WV

Part No. Part Name & Description Remarks

Ref.

No.

R102 ERJ12YJ330H Chip, 33

R103 ERJ6GEYJ683 Chip, 68k

R104 ERJ6GEYJ683 Chip, 68k

R105 ERJ6GEYJ333 Chip, 33k

R106 ERJ6GEYJ184 Chip, 180k

R107 ERJ6GEYJ184 Chip, 180k

R108 ERJ6GEYJ823 Chip, 82k

R109 ERJ6GEYJ334 Chip, 330k

R110 ERJ6GEYJ102 Chip, 1k

R111 ERJ6GEYJ102 Chip, 1k

R112 ERJ6GEYJ393 Chip, 39k

R113 ERJ6GEYJ333 Chip, 33k

R201 ERJ6GEYJ124 Chip, 120k

R202 ERJ6GEYJ473 Chip, 47k

R203 ERJ6GEYJ334 Chip, 330k

R204 ERJ6GEYJ473 Chip, 47k

R205 ERJ6GEYJ331 Chip, 330

R206 ERJ6GEYJ470 Chip, 47

R207 ERJ6GEYJ472 Chip, 4.7k

R208 ERJ6GEYJ472 Chip, 4.7k

R209 ERJ6GEYJ472 Chip, 4.7k

R210 ERJ6GEYJ472 Chip, 4.7k

R211 ERJ6GEYJ472 Chip, 4.7k

R212 ERJ6GEYJ472 Chip, 4.7k

R213 ERJ6GEYJ472 Chip, 4.7k

R301 ERJ6GEYJ472 Chip, 4.7k

R302 ERJ6GEYJ472 Chip, 4.7k

R303 ERJ6GEYJ472 Chip, 4.7k

R304 ERJ6GEYJ472 Chip, 4.7k

R305 ERJ6GEYJ563 Chip, 56k

R306 ERJ6GEYJ563 Chip, 56k

R307 ERJ6GEYJ473 Chip, 47k

R308 ERJ6GEYJ472 Chip, 4.7k

R309 ERJ6GEYJ472 Chip, 4.7k

R310 ERJ6GEYJ472 Chip, 4.7k

R311 ERJ6GEYJ472 Chip, 4.7k

R312 ERJ6GEYJ473 Chip, 47k

R313 ERJ6GEYJ473 Chip, 47k

R314 ERJ6GEYJ823 Chip, 82k

R315 ERJ6GEYJ823 Chip, 82k

R316 ERJ6GEYJ823 Chip, 82k

R317 ERJ6GEYJ471 Chip, 470

R318 ERJ6GEYJ471 Chip, 470

R319 ERJ6GEYJ471 Chip, 470

R320 ERJ6GEYJ471 Chip, 470

R321 ERJ6GEYJ471 Chip, 470

R322 ERJ6GEYJ473 Chip, 47k

R324 ERJ6GEYJ473 Chip, 47k

R325 ERJ6GEYJ473 Chip, 47k

R326 ERJ6GEYJ473 Chip, 47k

R327 ERJ6GEYJ473 Chip, 47k

R328 ERJ6GEYJ473 Chip, 47k

R401 ERJ6GEYJ222 Chip, 2.2k

R402 ERJ6GEYJ222 Chip, 2.2k

R501 ERJ6GEYJ101 Chip, 100

R502 ERJ6GEYJ103 Chip, 10k

R503 ERJ6GEYJ103 Chip, 10k

R504 ERJ6GEYJ222 Chip, 2.2k

R505 ERJ6GEYJ103 Chip, 10k

R601 ERJ6GEYJ123 Chip, 12k

R602 ERJ6GEYJ103 Chip, 10k

R603 ERJ6GEYJ273 Chip, 27k

R604 ERJ6GEYJ103 Chip, 10k

R605 ERJ6GEYJ183 Chip, 18k

R606 ERJ6GEYJ393 Chip, 39k

R607 ERJ6GEYJ103 Chip, 10k

R608 ERJ6GEYJ472 Chip, 4.7k

R609 ERJ6GEYJ472 Chip, 4.7k

Part No. Part Name & Description Remarks

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

1/2W

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

1/10W

1/10W

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

1/10W

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

ΩΩΩΩ

GM / CX-CG0260Z

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

1/10W

RESISTORs

R100 ERJ6GEYJ334 Chip, 330k

R101 ERJ6GEYJ101 Chip, 100

ΩΩΩΩ

ΩΩΩΩ

1/10W

1/10W

CONNECTORs

CN1 YEAE5220715 Connector, 15P

CN101 YEAE5220715 Connector, 15P

17

Page 18

GM / CX-CG0260Z

Ref.

No.

CN301 YEAE5227112 Connector, 12P

CN401 YEAE5220706 Connector, 6P

CN402 YEAE5326102 Connector, 2P

CN501 YEAE5227110 Connector, 10P

SWITCHEs

SW10 ESE102MH4 Switch

SW11 ESE102MH4 Switch

SW12 ESE102MH4 Switch

SW13 ESE102MH4 Switch

COIL

L101 YELTLM41P750 Coil

CRYSTALs

XL201 H2D169500001 Crystal

XL301 YEXLSTCC737T Crystal

[E2682]

DIODE

D1 ON1004 Diode

SWITCHE

SW1 ESE102MH4 Switch

[E2684B]

DIODEs

D1 LN01201C Diode

D2 LN01201C Diode

D3 LN01201C Diode

[E2685B]

IC´s and TRANSISTORs

Q1 PNZ14700R Transistor

Q2 PNZ14700R Transistor

Q3 PNZ14700R Transistor

DIODE

D1 ON1004 Diode

SWITCHE

SW4 ESE102MH4 Switch

CONNECTOR

JD1 YEAE5227106 Connector, 6P

Mechanical Parts

MISCELLANEOUS

3 K1LA02A00021 Cord w/Connector (4-A)

4 YEAP2683 Suspension FPC (1-E)

5 YEATSD00405 Terminal (1-F)

6 YEFA011711G Upper Chassis Ass´y (3-B)

7 YGFA011713A Side Chassis (R) (1-C)

8 YEFA011714D Side Chassis (L) Ass´y (4-A)

9 YEFA011716 Suspension Chassis Ass´y (1-D)

10 YEFA011718A Suspension Chassis(Bottom)

11 YEFA011720B Swing Chassis Ass´y (3-D)

Part No. Part Name & Description Remarks

Ass´y

(1-D)

Ref.

No.

12 YEFA011722 Stocker Plate Ass´y (4-F)

13 YGFA011858B Main Chassis Ass´y (3-E)

14 YEFS04707 Damper (4-D)

16 YEFV011897 Insulator (2-F)

17 YEFW04158 Bearing (3-D)

18 YEFW04159A Roller Shaft Holder(L) (2-B)

19 YEFX04161A Feed Screw Housing (1-E)

20 YGFW05412 Disc Collar (2-B)

22 YEFW062351 Disc Roller Shaft (2-A)

23 YEFX062461B Roller Shaft Ass´y (2-B)

24 YEFX003872 Elevator Gear(1) (3-F)

25 YEFX003873 Elevator Gear(2) (2-F)

26 YEFX003874 Elevator Gear(3) (3-E)

27 YEFX003875 Elevator Gear(4) (3-E)

28 YEFX003877 Traverse Gear(2) (2-D)

29 YEFX003878A Traverse Gear(3) (2-D)

30 YEFX003879 Traverse Gear(4) (1-D)

31 YEFX003882A Stocker Cam Gear(1) (3-F)

32 YEFX003883B Stocker Cam Gear(2) (3-E)

33 YEFX003884 Stocker Cam Gear(3) (3-E)

34 YGFX0031007 Disc Hold Gear (3-F)

35 YEFX0031057 Load Gear (3-B)

36 YEFX003891A Push Gear(1) (3-B)

37 YEFX0031003 Push Gear(2) (3-B)

38 YEFX003894 Horizontal Cam Gear(1) (3-D)

39 YEFX003895 Horizontal Cam Gear(2) (2-E)

40 YEFX003896 Horizontal Gear(1) (3-E)

41 YEFX003897A Horizontal Gear(2) (3-E)

42 YEFX003898 Horizontal Gear(3) (3-E)

43 YEFX003899B Horizontal Gear(4) (3-D)

44 YEFX003929 Horizontal Cam Gear(3) (3-E)

45 YEFX003931 Horizontal Gear(5) (3-D)

46 YEFX003932A Push Cam Gear (3-B)

47 YEFX0052269 FPC Hold Spring (2-D)

48 YEFX0052272 Guide Spring(B) (1-B)

49 YEFX0052274B Suspension Lock Spring (3-D)

50 YEFX0052275A Swing Spring (3-D)

51 YEFX0052276A Stocker Spring(1) (4-D)

52 YEFX0052277 Stocker Spring(2) (4-D)

53 YEFX0052278 Thrust Spring (1-E)

54 YEFX0052279 Sencer Lever Spring (1-E)

55 YGFX0052449A Damper Spring (4-D)

56 YEFX0052447 Balance Spring(1) (3-D)

57 YEFX0052284 Push Spring (3-A)

58 YEFX0052285A Spring (4-B)

59 YGFX0052499 Roller Hold Spring(L) (2-B)

60 YEFX0052527 Roller Hold Spring(R) (2-B)

61 YEFX0052289A Push Lever Spring (4-E)

62 YEFX0052290A Feeder Spring (4-B)

63 YEFX0052291B Push Plate Spring (3-B)

64 YEFX0052292A Change Spring (1-D)

65 YEFX0052335 Guide Spring(F) (2-B)

66 YGFX0052595 Stocker Thrust Spring (4-E)

67 YEFX0052495 Damper Spring (R ) (4-D)

68 YGFX0052494 Damper Spring (L) (4-D)

69 YEFX0052445 Lock Spring (3-A)

70 YEFX018552 Travese Motor Bracket Ass´y (2-E)

71 YEFX018553D Guide(F) Bracket (3-E)

72 YEFX018595 Guide(B) (3-D)

73 YEFX018556 Bearing Bracket (3-D)

74 YEFX018596 Stopper Plate (1-D)

75 YEFX018638 Gear Bracket Ass´y (2-D)

76 YEFX018600A Elevator Motor Bracket (3-F)

77 YEFX0461903A Guide Lever (B) Ass´y (3-D)

78 YEFX0461905A Guide Lever (F) Ass´y (3-E)

79 YEFX0461914B Senser Cover (1-F)

Part No. Part Name & Description Remarks

(3-F)

(2-F)

(2-F)

(2-F)

(2-D)

(4-E)

(4-E)

(1-F)

(3-F)

18

Page 19

Ref.

No.

80 YEFX0461917 Stocker Rack (4-F)

81 YEFX0461918 Senser Lever(B) (2-E)

82 YEFX0461919A Sneser Lever(FA) (1-F)

83 YEFX0461922D Feeder Plate (2-B)

84 YGFX0462143 Push Lever (3-A)

85 YEFX0461926A Rack Lever (3-F)

86 YEFX0461931A Push Lever (4-E)

87 YGFX0462062B Escape Lever(1) (3-A)

88 YEFX219129 Guide (F) (2-B)

90 YEFX0462002C Guide Cam Plate(F) (1-B)

91 YEFX0462003B Guide Cam (B) Plate Ass´y (1-B)

92 YEFX0462026 Lever Guide Plate Ass´y (2-D)

93 YEFS02342 Felt (4-A)

94 YEFX0462029 Feeder Guide Plate Ass´y (2-B)

95 YEFX206135C Guide(BL) (1-B)

96 YEFX206136D Guide(BU) (1-B)

97 YEFX206137A Guide(FL) (2-B)

98 YEFX206138C Guide(FU) (2-B)

99 YEFX206139E Disc Guide (2-A)

100 YEFX206140 Traverse Guide (1-D)

101 YEFX206141A FPC Guide (1-D)

102 YEFX206143 Disc Guide(S) (2-D)

103 YEFX206144 Disc Guide(U) (3-B)

104 YEFX218296 Disc Roller (2-A)

105 YEFX218299 Disc Roller (2-B)

106 YEFX219124A Guide (B) Base Ass´y (1-B)

107 YEFX219126D Guide Base (F) Ass´y (2-B)

108 YEFX233504A Stocker Tray Housing (4-D)

109 YGFX233521 Disc Holder(L) (3-F)

110 YEFX233506 Disc Holder(U) (4-E)

111 YEFX234192 Elevator Cam (2-E)

112 YEFX249486 Feeder Arm Ass´y (1-A)

113 YEFX9992184 Suspension Balancer 1 (1-D)

114 YEFX9992237 Stocker Tray (4-D)

115 YEFX9991903 Feed Screw Guide (1-E)

120 YEJT03220 Feed Screw Ass´y (1-D)

121 YEP0FX4078 Optical Pick-up Ass´y (1-E)

122 YGP0FX3633 Spindle Motor Ass´y (1-E)

123 YEP0FX3661S Horizontal Motor Ass´y (4-A)

124 YEP0FX3660S Vertical Motor Ass´y (3-F)

125 YEP0FX3662S Loading Motor Ass´y (3-C)

126 YEP0FX3663S Traverse Motor Ass´y (2-E)

134 YEFX218308 Roller (1-A)

135 YEFX0031053 Load Gear (2-B)

136 YEFX0031054 Load Gear (2-C)

137 YEFX014040 Retaining Ring, 2mm (2-C)

138 YGP0PT8586A2 PCB w/Component RTL

139 YGP0PT2682A0 PCB w/Component RTL

140 YGP0PT2684A0 PCB w/Component RTL

141 YGP0PT2685A0 PCB w/Component RTL

142 YEFX0052448 Spring (3-D)

143 YEFX9992193 Suspension Balancer 3 (1-D)

144 YEFX9992192A Suspension Balancer 2 (1-D)

145 YGFS011864 Pad (3-C)

146 YEFW04181 Guide Plate Collar (1-B)

Part No. Part Name & Description Remarks

Ref.

No.

166 XSB2+4FX Screw, 2mm * 4mm

167 XYN2+J5FX Screw, 2mm * 5mm

168 XYN2+C6FX Screw, 2mm * 6mm

169 XYN2+C10FX Screw, 2mm * 10mm

170 XQN2+C2FX Screw, 2mm * 2mm

171 YEJT03129 Tapping Screw, 2mm * 4mm

173 YEJS06244 Screw

174 YEJS06242 Screw

175 XYN2+C8FX Screw, 2mm * 8mm

176 YGFX0051590 Retaining Ring

Part No. Part Name & Description Remarks

GM / CX-CG0260Z

150 XUC2V Retaining Ring, 2mm

151 YGJE01044 Retaining Ring

152 XUC15V Retaining Ring, 1.5mm

153 YGFX014047 Retaining Ring

154 YEJS06097A Screw, 2mm * 2.5mm

155 YEJS06173 Screw

156 YEJS06220 Screw

157 YEJT03216 Tapping Screw

158 XQN14+C18FX Screw, 1.4mm * 1.8mm

159 XQN17+A2FX Screw, 1.7mm * 2mm

160 XQN2+A2FX Screw, 2mm * 2mm

161 XQN2+C25FX Screw, 2mm * 2.5mm

162 XSB2+3FX Screw, 2mm * 3mm

163 XSB26+3FX Screw, 2.6mm * 3mm

164 XYN2+C3FX Screw, 2mm * 3mm

165 XYN2+C4FX Screw, 2mm * 4mm

19

Page 20

GM / CX-CG0260Z

13 EXPLODED VIEW (CD Deck-1)

20

Page 21

14 EXPLODED VIEW (CD Deck-2)

GM / CX-CG0260Z

21

Page 22

GM / CX-CG0260Z

15 EXPLODED VIEW (CD Deck-3)

22

Page 23

16 WIRING DIAGRAM

16.1. Main Block

CP901

Q609

R639

1

TP4

80

61

C612

D673

R208

IC603

C313

2

R676

R628

3

C604

R601

TP1

D674

C622

IC671

R602

R675

R607

D606

4

1

C

R637

IC602

9

8

C206

L201

1

CN701

BE

D671

14

85

L602

R629

IC604

C673

C713

R621

C610

C708

R201

R626

C676

R303

R302

R609

R614

C615

C714

R709

14

IC201

R310

R309

D607

TP6

1

C798

TP7

C675

C304

R305

C303

R304

R203

C302

C301

Q610

R713

C

B

E

Q619

C620

C

Q629

B

E

20

21

IC601

TP5

40

41 60

C609

Q640

1

2

5

3

R708

C610

8

R707

7

R210

C203

R205

C204

R204

R202

C201

C202

C305

C705

C728

C683

C682

C681

C706

D703

C718

C602

3

2

1

R630

R627

C613

C674

D672

D705

R209

R308 R712

C205

L702

D701

C680

R710

BE

C624

Q611

C

R632

R631

R635 R633R634R621

R674 R671

C630

R673

C603

1

Q671

C611

C614

3

2

1

R623 R625 R624

16

D704

IC201

1

R678

R307

R207

C306

C797

5

C707

8

D702

L701

C213

R679

C752

R640

R672

C605

1 3

Q604

E

C601

R638

R671

2

C

5

1

5

1

B

L601

R301

C

TP3

TP2

C723

L301

3

Q631

E

C727

XL601

C711

C726

IC703

4

2

4

2

C629

2

1

R641

Q630

C672

R608

C799

IC702

C751

C602

C631

C

R711

D601

BBE

R627

GM / CX-CG0260Z

Q632

R642

PLACE BER

CN401

C608

8

CODE HERE

[M3J465034E] [Top View] [M3J465034E] [Bottom View]

CX-CG0260Z MAIN P.C.B

23

Page 24

GM / CX-CG0260Z

16.2. Display Block

[M3J427025G] [Top View]

[M3J427025G] [Bottom View]

CX-CG0260Z ESC P.C.B

24

Page 25

16.3. CD Servo Block

Horizontal Motor

BCE

GM / CX-CG0260Z

[E-8586C] [Top Vew]

28

22

3

16

17

32

33

1

64

21

8

7

19

8

21

6

To E-8580A CN501

20

16

21

40

41

1

80

61

60

25

[E-8586C] [Bottom View]

Page 26

GM / CX-CG0260Z

26

Page 27

17 SCHEMATIC DIAGRAM

17.1. Main Block

GM / CX-CG0260Z

RIGHT CHANNEL AUDIO

LEFT CHANNEL AUDIO

BATT IN

C683

0.01

D701

1

2

BATT FLTR

1

NC

2

D674

LEFT IN

L

D706

68

0.1

C673

GND

C301

—

10

C201

—

R302

+

1.0K

MAIN POWER

—

C705

D703

R675

10

47

MTH1MTH3MTH2

+

10

A4V

330

10V

GNDPGND

RIGHT IN

R

L701 L702

D702

2

1

3

4

NC

R707

3

C710

D704

3

+

47

—+—

C672

GND

The following symbols are

shown on the schematic diagram.

+B

10V

10V

8V

8V

5V

5V

CD(L,R)

R303

1

+—+

C713

AGND

GND

R209

R210

10K

C203

6800PF

R204

1.0K

C202

3900PF

33K

C303

6800PF

R304

1.0K

C302

3900PF

ILLGND

BATT FLTR

31

+

0.1

330

—

C797

C707

PGND

A8V

8V

13

12

YEAMPC4574E1

C675

0.01

3

112

NC

3

D672

GND

+

VDD

IC201(d)

10K

10K

Q671

D673

R205

1.0K

R309

10K

2

R305

3

1.0K

C304

1800PF

AGND

2

IC703

YEAMBA09ST

0.1

C723

2

IC702

YEAMA61W12ST

35

GND

14

B

C676

A

AGND

5V 5V

C728

330

YEANA114YKTX

E

33K

+

R202

—

1.0K

C798

5V

47

R676

C674

R203

A4V

IC703

8V REG

2

330

R708

R709

YEANC3618T1

2

47K

0.1

6

5

C204

1800PF

AGND

R310

1.5K

IC201(a)

-

1

+

YEAMPC4574E1

1

4

35

4

C708

22

IC201(d)

BIAS

GEN

A4V

OPEN

OPEN-0805-CAP

L602

+

—

Q629

C

B

5V

1.5K

IC201(b)

-

+

YEAMPC4574E1

+

—

5V

+—+

C727

100

7

IC201(a)

AMP

C305

—

+

10

8V

C726

22

10V

—

+

—

R679

A4V

C706

100

5V

/RESET

IC201(b)

AMP

C205

—

+

10

L

470K

ILL8V

IC702

5V,10V

REG

SW5V

SW10V

C714

0.1

GND

R678

A4V

AGND

1

2

470K

VDD FLTR

REF5V

NC

3

D606

L

R307

R

1

2

3

4

5

6

7

8

C306

—

+

22

470K

IC202

Y0

Y2

YOUT

Y3

Y1

INHIBIT

Vcc

Vss

YEAMPD4052E1

IC202

AUDIO

SWITCH

MUTE

5

4

3

BATT FLTR

ILL8V

1

AGND

R308

470K

AGND

Vdd

16

X2

15

X1

14

XOUT

13

X0

12

X3

11

A

10

9

B

Q640

L

8V

Q630

YEANC114YKTX

IC604

MN1382QTX

321

GND

L301

2

1

2

R

8V

47K

R638

C

B

E

Q609

YEANC114YKTX

15K

R640

C

B

E

C605

100PF

GND

R301

3

100

R

R207

470K

AGND

ACNTA

ACNTB

AENBL

R671

47K

R672

AB

OPEN

8V

R637

10K

C622

1.0

8V

R641

10K

C627

1.0

IC604

RESET

CONTROL

R607

4.7K

M3J465034E

C206

—

+

22

R208

470K

AGND

22K

22K

R625

R624

IC671

BATTERY

DETECTION

56K

R674

GND

Q610

2SB1440TX

Q611

2SD1030TX

R639

B

10K

C624

1.0

2SB1440TX

Q632

2SD1030TX

R642

B

10K

C629

1.0

RESET

1

D671

3

3

R623

E

Q631

E

AGND

3

22K

1

C

ILL GND

1

C

ILL GND

L201

2

D705

2

1

NC

IC671

MN1382QTX

GND

R673

AB

OPEN

C671

0.1

2

C626

OPEN

2

C631

OPEN

3

123

LED CTRL

R201

100

PL CTRL

C718

0.1

BATT DET

LED DIM

RL DIM

C613

68PF

C611

1000PF

LEFT OUT

RIGHT OUT

A8V

11

AGND

TP1

IC201

4

YEAMPC4574E1

POWER ON

DATA

CLK

GND

GND

Vpp

10K

R629

GND

VDD FLTR

IC601

CPU

ACNTA

ACNTB

AENBL

C614

68PF

C612

100PF

1Kx4

R628

A BUS

L

LCK

GND

10

A4V

R609

1.8K

2SD1328STTX

P52

P53

41

42

P54

43

P55

P56

44

45

P57

P20/SI31

46

P21/SO31

47

48

P22/SCK31

49

P04/INTP4

50

P05/INTP5

51

P07/INTP7

52

P07/INTP7

53

P23

54

P24/RXD0

55

P25/TXD0

56

P26/ASCK0

57

P27

P64

58

P65

59

P66

60

P67

1234

TP2

8765

9

C609

R

0.1

IC201(c)

8

YEAMPC4574C1

Q604 3

1

AGND

GND

P51

P50

PT1010

C2RX

C2TX

RESET

RESET

0.1

C610

GND

2

R626

1Kx4

C615

68PF

8V

P33

P34/TD00

P35/T1000

IC(Vpp)X2X1

3

1

2

XL601

5

6

7

8

UC1BB0000001

MISC.POWER & GROUND

C799

—

+

47

C711

—

+

47

470K

R608

1234

8765

Vss

Vdd

P30/SI30

P31/SD30

P32/SCK30

IC601

UC2BBGF00008

P74/TI001

P73/TO01

P72/SCL0

P71/SDA0

P70/FCL

Vss1

Vdd1

Vdd0

AVretto

P90/ANI00

GND

BATT FLTR

IC603

BUS

Vbat

LOAD

4x/LOOP

GND

TX(DI)

SLEEP

RX(DO)

A COM

TP5

1K

R614

TP6

TP7

ACC ON

P47

P46

P45

P44

P43

P42

P87/ANI71

P86/ANI61

P85/ANI51

P84/ANI41

P83/ANI31

P82/ANI21

P81/ANI11

P80/ANI01

AV/REF1

P03/INTP3

P02/INTP2

P01/INTP1

P00/INTP0

P75/TI011

P91/ANI10

P92/ANI20

P93/ANI30

P94/ANI40

P95/ANI50

P96/ANI60

C604

0.1

IC603

CLASS2

TRANSCEIVER

4

R621

3

10.7K

2

1

OPEN 220PF

ILL8V

A BUS

SMUTTER

2122232425262728293031323334353637383940

P41

AVSS1

P97/ANI70

8079787776757473727170696867666564636261

C601

P40

AVss1

GND

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TP4

MH1

PGND

R710

R711

0

R712

0

YEANA114YKTX

EC

GND

BATT DET

RD ON

R601

VDD FLTR

TP3

L601

47 H

GND

0

Q619

3.4K

C602

AGND

B

R602

ILL GND

REF5V

R627

1Kx4

1

2

3

4

3.4K

MH2

PGND

DECK GND

VDD

SW10V

SW5V

L

100

R713

8

7

6

5

VDD FLTR

SDA

5

SCL

6

WP

7

8

VCL

UCSEBE000001

C603

0.1

D601

IC602

L

8V

VSS

CN701

1

GND

C752 0.01

GND

GND

C630

C682 0.22

1000PF

GND

2

RIGHT OUT

3

LEFT OUT

4

A COM

5

SHIELD GND

6

CLASS-2

7

BATT IN

8

CN401

MUTE

1

2

SOM

3

SIM

SCKM

4

5

CD ON

6

/RESET

NC

7

8

VDD

9

SW10V

SW5V

10

11

DECK GND

12

DECK GND

13

LEFT IN

AGND

14

15

RIGHT IN

To

E-8586C

CN1

14

VDD FLTR

5V

13

DATA

CLK

12

LCK

11

GND

10

LED CTRL

9

SHTR LED

8

7

PL CTRL

ILL GND

6

REF5VA

5

K1A

4

K2A

3

EJECT

2

LOAD

1

CP901

To

M3J427025G

CN901

R

BATT IN

C751 0.01

C313 1000PF

C213 1000PF

5V

10V

5V

R

AGNDDECK GND

C681 0.22

C684 0.1

C680 0.1

VDD FLTR

R632

0

C621 0.01

CLASS-2

GND

GND

0.01

C620

ILL GND

VDD FLTR

54

63

72

81

R630

1Kx4

R631

5V

0

0

R633

100K

100K

R634

R635

4

A2

3

A1

2

1

A0

GND

27

CX-CG0260Z Main Block

Page 28

GM / CX-CG0260Z

17.2. Display Block

M3J472025G

28

5V

5V5V

8V

5V

The following symbols are

shown on the schematic diagram.

8V

8V

5V

5V

CX-CG0260Z ESC BIOCK

To

M3J465034E

CP901

Page 29

17.3. CD Servo Block

GM / CX-CG0260Z

M3J465035E CN401

TO

29

Printed in Japan (K) 2002.11 (Recycled Paper)

Loading...

Loading...