Page 1

ORDER NO. MTNC020725A1

B5

Service Manual

Color Television

d

e

i

f

i

S

m

i

l

p

Simplified Manual

(DX3P)

Panasonic

Models

CT-36HL42F AP388

CT-36HL42UF AP388

CT-36HL42CF AP388

This Simplified Service Manual is issued to add listed models to the Main Service Manual order No. MTNC020618C1

(CT36HX42F) of the DX3P family. A set of schematics, unique settings and a complete parts list are included in this

Manual.

Please file and use this Simplified Service Manual together with Main Service Manual order No. MTNC020618C1.

Chassis

“WARNING! This Service Manualis designed for experiencedrepairtechniciansonlyand is not designed for useby the generalpublic.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is requiredtoreadand follow the “Safety Precautions”and“Important Safety Notice” in this Main Manual.

Copyright 2002by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

®

and distributionis a violation of law.

Page 2

Important safety notice

Special components are used in this television set which are important for safety. These parts are identified on the

schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is essential that

these critical parts are replaced with the manufacturer’s specified replacement part to prevent x-ray radiation,

shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety precautions

General guidelines

An Isolation transformer should always be used

during the servicing of a receiver whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the receiver from

being damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices,suchas

fishpaper, isolation resistors and capacitors, and

shields after servicing the receiver. Use only

manufacturer’s recommended rating for fuses, circuits

breakers, etc.

High potentials are present when this receiver is

operating. Operation of the receiver without the rear

cover introduces danger for electrical shock. Servicing

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be practiced when handling the

picture tube. Rough handling may cause it to implode

due to atmospheric pressure. (14.7 lbs per sq. in.). Do

not nick or scratch the glass or subject it to any undue

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture

tube by shorting the anode to chassis ground (not to

the cabinet or to other mounting hardware). When

discharging connect cold ground (i.e. dag ground lead)

to the anode with a well insulated wire or use a

grounding probe.

Avoid prolonged exposure at close range to unshielded

areas of the picture tube to prevent exposure to

x-ray radiation.

The test picture tube used for servicing the chassis at

the bench should incorporate safety glass and

magnetic shielding. The safety glass provide shielding

for the tube viewing area against x-ray radiation as well

as implosion. The magnetic shield limits the x-ray

radiation around the bell of the picture tube in addition

to the restricting magnetic effects. When using a

picture tube test jig for service, ensure that the jig is

capable of handling 50.0kV without causing

x-ray radiation.

Before returning a serviced receiver to the owner,

the service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage current cold check

Unplug the AC cord and connect a jumper between the

two plug prongs.

Measure the resistance between the jumpered AC plug

and expose metallic parts such as screwheads,

antenna terminals, control shafts, etc. If the exposed

metallic part has a return path to the chassis, the

reading should be between 240kΩ and 5.2MΩ. If the

exposed metallic part does not have a return path to

the chassis, the reading should be infinite.

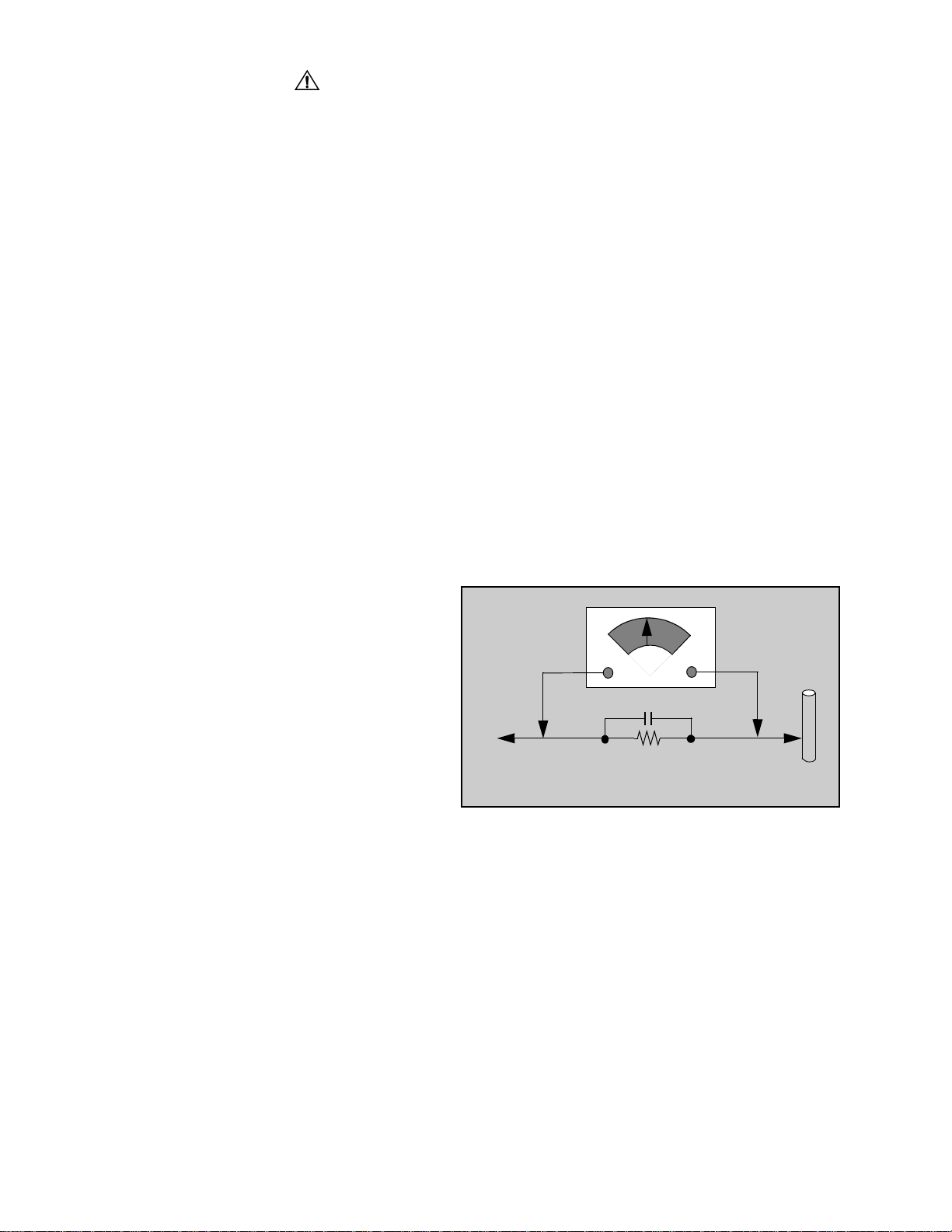

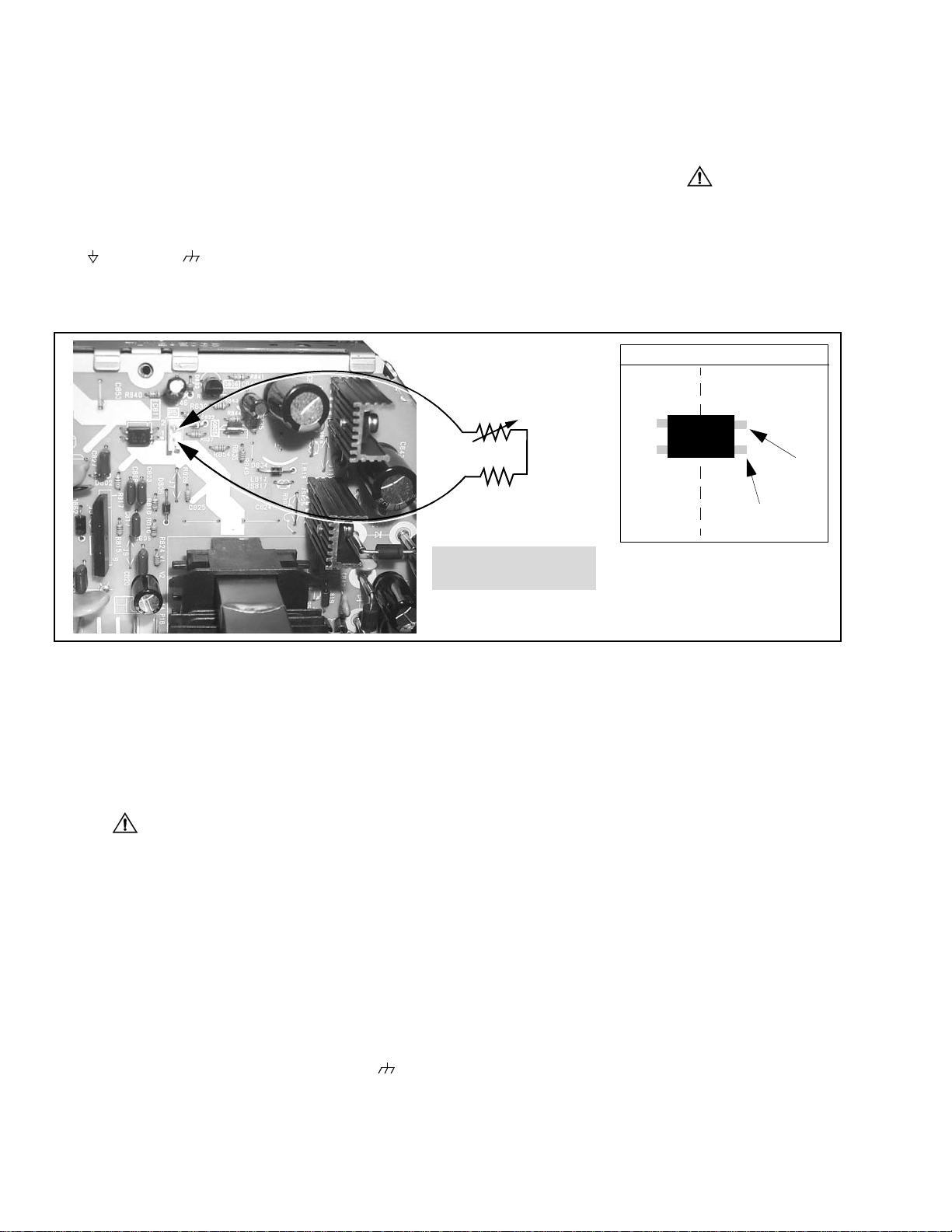

Leakage current hot check (Fig. 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5kΩ 10 watt resistor in parallel with a

0.15µF capacitor between an exposed metallic part

and ground. Use earth ground, for example a

water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other exposed metallic parts.

Verify that any potential does not exceed 0.75 volt

RMS. A leakage current tester (such a Simpson model

229, Sencore model PR57 or equivalent) may be used

in the above procedure, in which case any current

measure must not exceed 0.5 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the receiver must be

repaired and rechecked before it is returned to the

customer.

AC VOLTMETER

COLD

WATER

PIPE

(GROUND)

0.15µF

TO INSTRUMENT’S

EXPOSED METAL

PARTS

1500Ω,10 W

Figure 1. Hot check circuit

X-ray radiation

WARNING: The potential source of x-ray radiation in the

TV set is in the high voltage section and the picture tube.

Note: It is important to use an accurate,

calibrated high voltage meter.

Set the brightness, picture, sharpness and color

controls to minimum.

Measure the high voltage. With a 480i signal the high

voltage should be 33.0kV (± 1.0kV) and with a 1080i

signal the high voltage should be 33.0kV (+1.0kV,

-2.0kV). If the upper limit is out of tolerance,immediate

serviceandcorrectionisrequiredtoinsuresafe

operation and to prevent the possibility of premature

component failure.

Horizontal oscillator disable circuit test

This test must be performed as afinal check before the

receiver is returned to the customer. See horizontal

oscillator disable circuit procedure check in

this manual.

-2-

Page 3

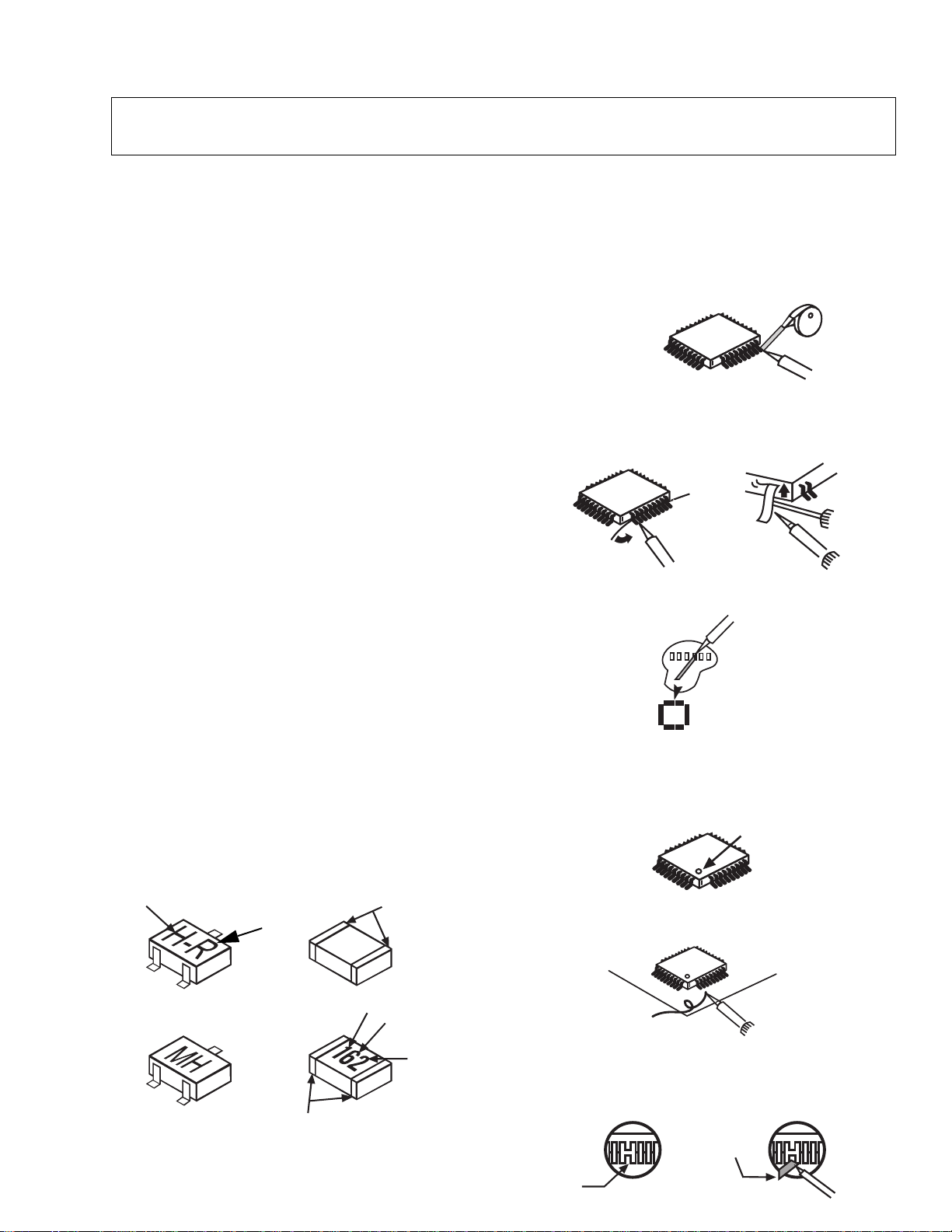

Service notes

Note: These components are affixed with glue. Be careful not to break or damage any foil under

the component or at the pins of the ICs when removing. Usually applying heat to the

component for a short time while twisting with tweezers will break the component loose.

Leadless chip component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in

the board to mount standard transistors or diodes.

Some chips capacitor or resistor board solder pads

may have holes through the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistor have a three digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component removal

1. Use solder wick to remove solder from component

end caps or terminal.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip component installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area with a 30 watt iron

until solder flows. Do not apply heat for more than

3 seconds.

TYPE

Chip components

GRADE

c

SOLDER

CAPS

How to replace Flat-IC

- Required tools -

• Soldering iron • De-solder braids

• Iron wire or small awl • Magnifier

1. Remove the solder from all of the pins of a Flat-IC

by using a de-solder braid.

De-Solder

Flat-IC

2. Put the iron wire under the pins of the Flat-IC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

Iron

Wire

Pull

Soldering

Iron

Soldering

Iron

3. Remove the solder from all the pads of the Flat-IC

by using a de-solder braid.

Soldering

Iron

De-Solder

Braid

Flat IC

4. Position the new Flat-IC in place (apply the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Properly determine the

positions of the soldering pads and pins by

correctly aligning the polarity symbol.

First pin

123.....

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Braid

Awl

b

ANODES

MH DIODE

e

TRANSISTOR

COMMON

CATHODE

SOLDER

CAPS

CAPACITOR

1ST DIGIT

RESISTOR

2ND DIGIT

MULTIPLIER

=1600 = 1.6k

Soldering

Solder

iron

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

De-Solder

braid

Solder

bridge

Soldering

iron

-3-

Page 4

About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will ref er to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For

service and repair work, we’d suggest the use of Pb free solder as well, although Pb solder may be

used.

PCBs manufactured using lead free solder will have the “PbF” or a leaf symbol stampedon the

back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting

point is 50 ~ 70 °F(30~40°C) higher. Please use a high temperature soldering iron

and set it to 700 ± 20 °F(370± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °For600°C).

If you must use Pb solder, please completely remove all of the Pb free solder on the

pins or solder area before applying Pb solder. If this is not practical, be sure to heat the

Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side

for excess solder which may flow onto the opposite side. (see figure below)

remove all of the

excess solder

component

pin

component

slice view

solder

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu

(tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder

canalsobeused.

0.3mm X 100g

0.6mm X 100g 1.0mm X 100g

-4-

Page 5

Importantsafetynotice................... 2

Safetyprecautions................. 2

Generalguidelines................. 2

Leakage current cold check . . . . . . . . . . 2

Leakage current hot check . . . . . . . . . . . 2

X-rayradiation .................... 2

Horizontal oscillator disable circuit test. . 2

Servicenotes........................... 3

Leadless chip component

(surfacemount)................ 3

Componentremoval................ 3

Chip component installation . . . . . . . . . . 3

HowtoreplaceFlat-IC.............. 3

About lead free solder (PbF) .............. 4

HHSreferenceadjustment........... 6

Horizontal oscillator disable circuit . . . . . 6

Receiverfeaturetable.................... 7

Boarddesignation....................... 8

Locationofcontrols(receiver)............. 9

Quick reference control operation . . . . . 9

Remote-locationofcontrols............. 10

Auto diagnosis feature . . . . . ............. 11

Boardconnections..................... 15

Description of connectors . . . . . . . . . . ..... 16

Identification of components . . . . . . . . ..... 18

Partslist.............................. 24

Partslistabbreviations.................. 35

Foldoutsnotes......................... 36

Schematics & v oltages

G-Boardschematic................ 38

G-Boardvoltages................. 41

K-Boardschematic................ 42

Layouts

G-PCB ......................... 44

K-PCB.......................... 46

Disassemblyforservice................. 12

Backcover...................... 12

A-Board-Mainchassis ............ 12

L-Board-CRToutput.............. 12

DG-Board ...................... 12

P-Board ........................ 12

G-Board........................ 12

K-Board ........................ 13

Speakers ....................... 13

Disassembly for CRT replacement . . . . . . . . 13

CRTreplacement................. 13

Backcoverremoval..................... 14

-5-

Page 6

Service notes (continued)

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires and CRT DAG wire

are securely connected.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when servicing the receiver to

avoid damage to the test equipment or to the chassis.

Connect the test equipment to the proper ground

(hot ) or (cold ) when servicing, or incorrect

voltages will be measured.

WARNING: This receiver has been designed to meet

or exceed applicable safety and x-ray radiation

protection as specified by government agencies and

independent testing laboratories.

To maintain original product safety design standards

relative to x-ray radiation and shock and fire hazard,

parts indicated with the symbol on the schematic

must be replaced with identical parts. Order parts from

the manufacturer’s parts center using the parts

numbers shown in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and reliability, all other parts

should be replaced with components of

identical specification.

Alternative test points

Horizontal oscillator disable circuit

This chassis employs a special circuit to protect

against excessive high voltage and beam current. If, for

any reason, the high voltage and beam current exceed

a predetermined level this protective circuit activates

and detunes the horizontal oscillator that limits the high

voltage. The over-voltage protection circuit is not

adjustable. However, if components indicated by the

symbol on the schematic in either the horizontal

sweep system or the over-voltage protection circuit

itself are changed, the operation of the circuit should be

checked using the following procedure:Equipment

needed to check the disabled circuit:

1. High voltage meter (0- 50kV)

2. Variac or isolation transformer

3. 1k ohm VR

4. DC Ammeter

Preparation

1. Connect receiver to AC 120 Volts. Do not turn ON.

2. Connect HIGH VOLTAGE meter to 2nd anode

(H.V. button).

negative lead.

3. Connect the ammeter serial from the flyback anode

lead to the picture tube anode socket.

4. Prepare HHS jig to be connected between TPD50

and TPD51 on P-Board as shown above.

Note:Use cold ground ( ) for

TPD51 (P5-2)

1kΩ

HOT

GROUND

COLD

GROUND

HHS Jig

IC811

100Ω

TPD50 (P5-1)

(OPTO)

TPD51

(Led cathode)

TP labels are located

on bottom of board

Figure 2. Power supply jig detail (D-Board)

Procedure

:

1. Open connector A17.

2. Turn power ON and apply a white pattern.

3. Set current within 50-100µΑ

by changing the

picture and bright controls.

4. Turn power OFF.

5. Connect HHS jig between TPD50 and TPD51 on

P-Board as shown above (VR should be turn fully

clockwise).

6. Turn power on.

7. Using the variable resistor slowly increase the

current until the horizontal sync frequency abruptly

increases indicating that the horizontal frequency is

just beginning to pull out of sync. Maintain the

current within

50-100µΑ by changing the picture

and bright controls

8. Observe the high voltage meter. High voltage

should read less than 38.4kV.

9. Turn power OFF, remove HHS jig, HV meter,

ammeter and connect A17 connector.

10. Turn power ON. Reset PICTURE and

BRIGHTNESS controls. Confirm B+ 144V±1.5V

with 120V AC applied.

Note: If high voltage is not within the

specified limit the cause must be

determined before the receiver is

returned to the owner.

-6-

TPD50

(Led anode)

Page 7

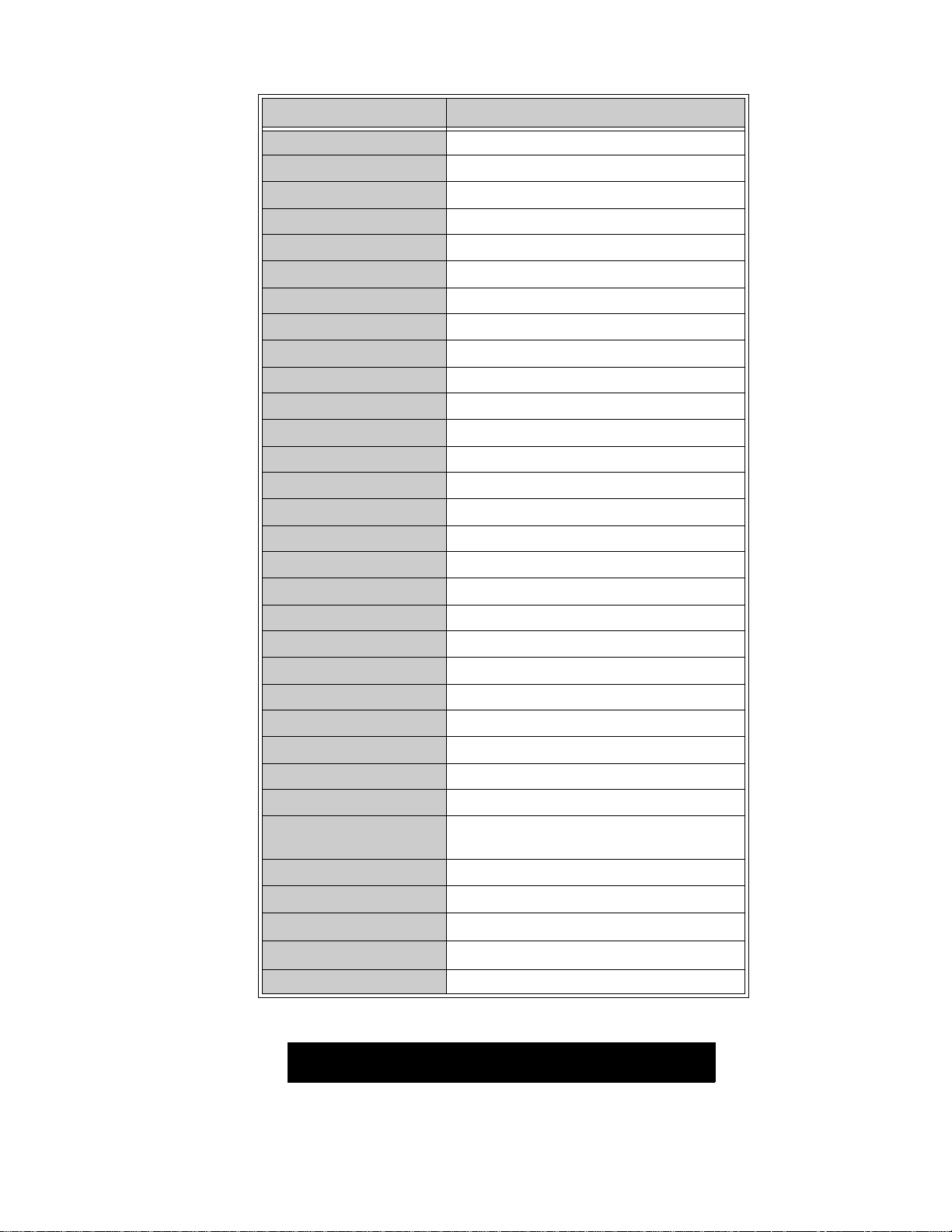

Receiver feature table

FEATURE\MODEL CT-36HL42F/UF/CF

Chassis DX3P

Number of channels 181

Menu language ENG/SPAN/FR

Closed caption X

V-Chip (USA/CANADA) X

Picture in Picture PIP 2T

2RF X

Remote model number EUR7603Z30

Picture tube A90LSW295X

PureFlat PF (4:3)

Comb ADV 3D Y/C

VM X(DIGITAL)

Color Temp X

V/A norm (X=both) X

MTS/SAP/DBX X

Built-in audio power 10W x 3

Number of speakers 2 w/subwoofer

Bass/Bl/Treble Control X

AI Sound X

SURROUND/BBE X

A/V in (rear/front) 4(3/1)

A/V Prog out X

Component Input 2

Audio Out (FAO,VAO) F,V

S-VHS input (rear/front) 2/1

EPJ/HPJ/MISC HPJ

Dimensions mm

(HxWxD) in

Weight (kg/lbs) 98/216.05

Power source (V/Hz) 120/60

Anode voltage

Video input jack

Audio input jack 500mV RMS 47kΩ

891x1094x742

35.07x43.07x29.21

31.0kV

1V

± 1.0kV

75Ω phono jack

p-p

Table 1. Receiver features

Specifications are subject to change without notice or obligation.

Dimensions and weights are approximate.

-7-

Page 8

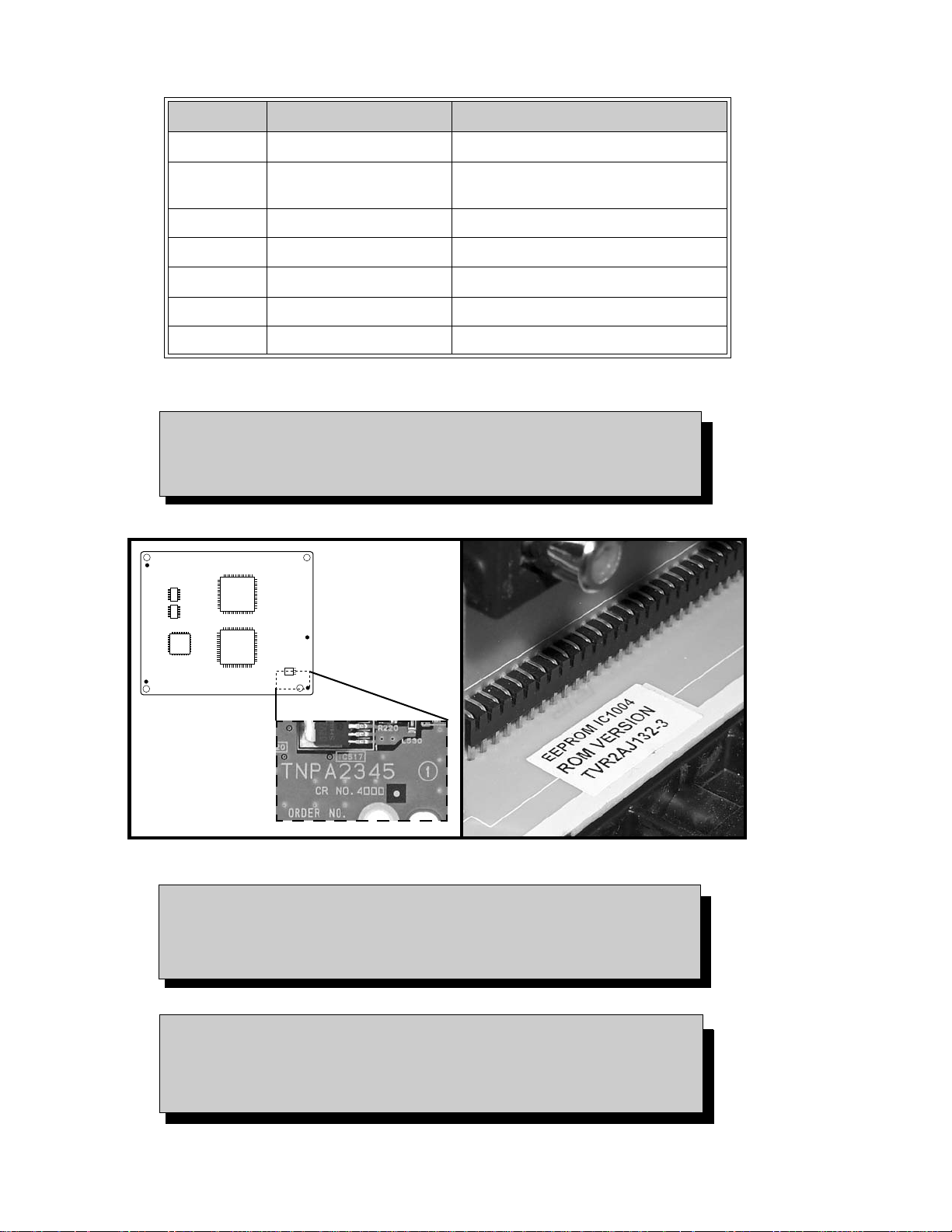

Board designation

Board Board number Description

A-Board TNPH0465 Main panel

DG-Board**

L-Board TNPA2346 CRT board

D-Board TNPH0466 High voltage and deflection panel

P-Board TNPA2344 Power supply panel

G-Board TNPA2347 Front A/V inputs, speaker conectors.

K-Board TNPA2414 Keyboard, LED and IR Sensor Panel.

** IMPORTANT:

TNPA2345/

TNPA2345AC

MPU, Digital video board, PIP processing,

Since two different versions of DG-boards are available for

the CT-36HL42 models, please check board number printed on the lower

right corner (fig. 3a) when replacing DG-Board. Refer to label on chassis for

EEPROM p art number that is used (see fig. 3b for label location).

Panasonic

Panasonic

TNPA2345

Top side

a)

Figure 3. a)DG-Board number location b)EEPROM label on A-Board below A/V jacks.

Note: The DG-Board (TNPA2345 or TNPA2345AC) is non-serviceable.

If this board is defective replace it with a new one. Each version of

DG-Board must be matched with correct version of EEPROM.

Confirm the EEPROM part number before replacing.

Notice: When ordering any board, add and ” S” after the board suffix

application.

Example: If ordering D-Board, should be ordered as:

b)

TNPH0466

S.

-8-

Page 9

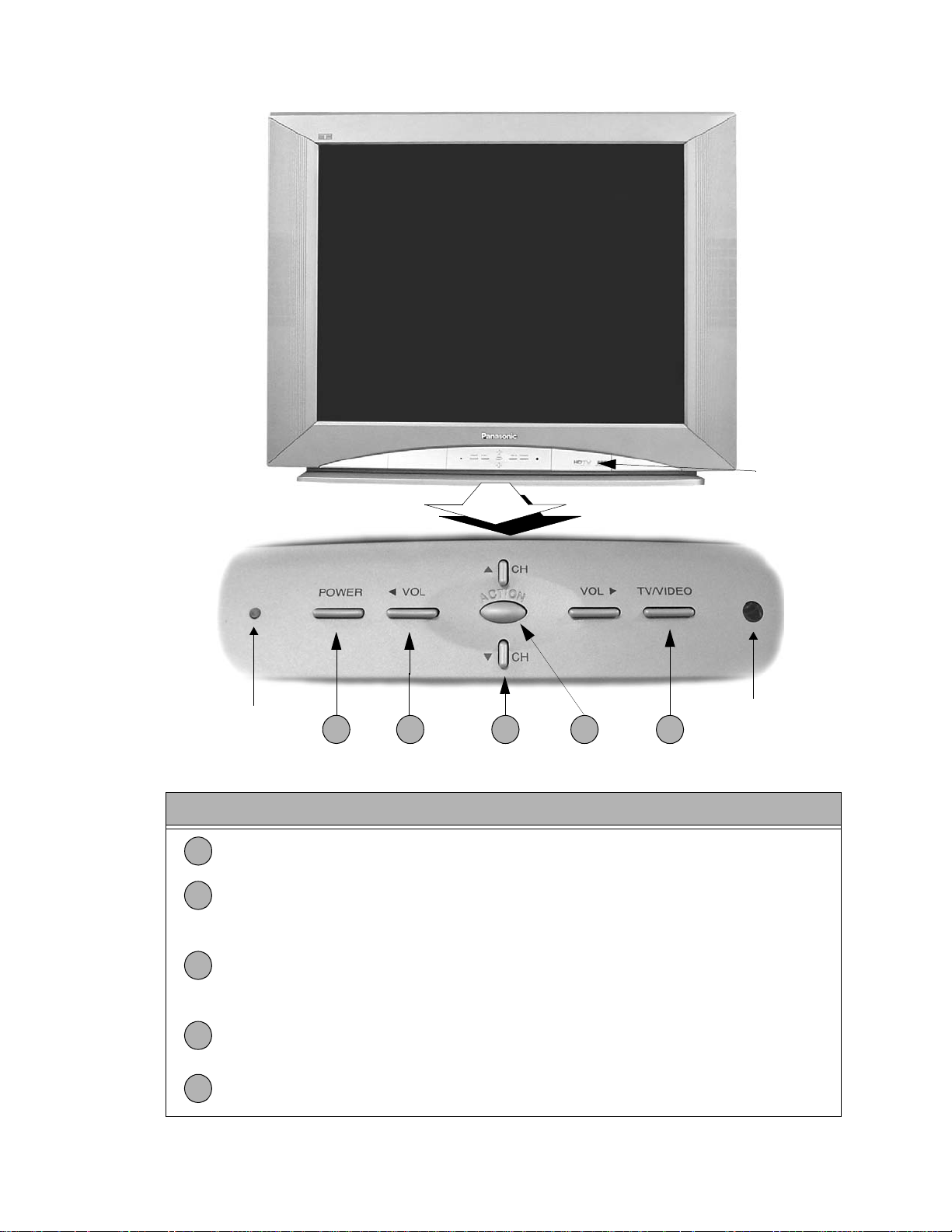

Location of controls (receiver)

A/Vinputsinside

front door

LED

1

2 4 53

Remote control

sensor

Figure 4. Location of controls receiver

Quick reference control operation

1

POWER button - Press to turn ON or OFF.

VOLUME buttons - Press to adjust sound level, or to adjust audio menus, video

2

menus, and select operating features when menus are displayed

CHANNEL buttons - Press to select programmed channels. Press to highlight desired

features when menus are displayed. Also use to select cable converter box channels

3

after programming remote control infrared codes (the TV/AUX/CABLE switch must be

set in CABLE position).

ACTION button - Press to display main menu and access on screen feature and

4

adjustment menus.

TV/VIDEO button - Press to select TV or one of two video inputs, for the main picture

5

or the PIP frame (when PIP frame is displayed).

-9-

Page 10

Remote - location of controls

POWER button

Press to turn ON and OFF.

MUTE button

Press to mute sound.

A second press resumes sound. Press also to

access and delete Closed Caption display.

TV, VCR, DVD, DTV,AUX, CBL,RCVR, DBS

buttons

Component function buttons

VOL (volume) buttons

Press to adjust TV sound level. Use with

channel buttons to navigate in menus.

R-TUNE (rapid tune) button.

Press to switch to theprevious

channel.

ACTION button

Press to display main menu and access or exit

On Screen features and Adjustment Menus.

REW,PLAY, FF, TV/VCR, STOP, PAUSE, REC

& VCR CHANNEL buttons

Component function buttons.

DBS EXIT& DBS GUIDE buttons

DBS function buttons.

LIGHT button

Press to light remote control buttons.

SAP button

Access secondary audio program

ASPECT button

Select picture size (ratio) to match

programmingformat (DTV-STB and DBS only).

PROG button

Press to enter minor number in a compound

number.

MOVE, PIP, SPLIT/SIZE, FREEZE, SWAP,

SEARCH, PIP CHANNEL, PIP MIN, PIP MAX

PIP function buttons.

Figure 5. Location of controls (EUR7603Z30 remote)

For additional information for this remote please refer to the owner’s

manual section remote operation, part number listed on parts list section.

-10-

Page 11

Auto diagnosis feature

This receiver incorporates a new auto-diagnosis

feature. With this new feature will be easier for the

repair technician to detect the failures. There is a LED

located on the A-Board by the DG-Board, this LED will

start flashing when a failure is detected by the circuits

located in a specific area, depending on how many

times the LED is flashing, this will tell you what circuit

should be checked.

After the count:

Proceed to check that area, verify what board is the

problem located, this way the area to check will be

reduced until the failure is found.

Make a count of flashing and see Table 1.

Please use this feature effectively especially for

intermittent problems.

NUMBER OF

FLASHES

1 +140 (POWER)

2LOWDC(+B)

4 HHS (HIGH VOLTAGE)

5IC4511

6 IC4518

Table 1: SOS of diagnosis LED

Refer to Fig. 6 for DIAGNOSIS LED location.

POSSIBLE CIRCUIT

LED

Figure 6. Diagnosis LED location

-11-

Page 12

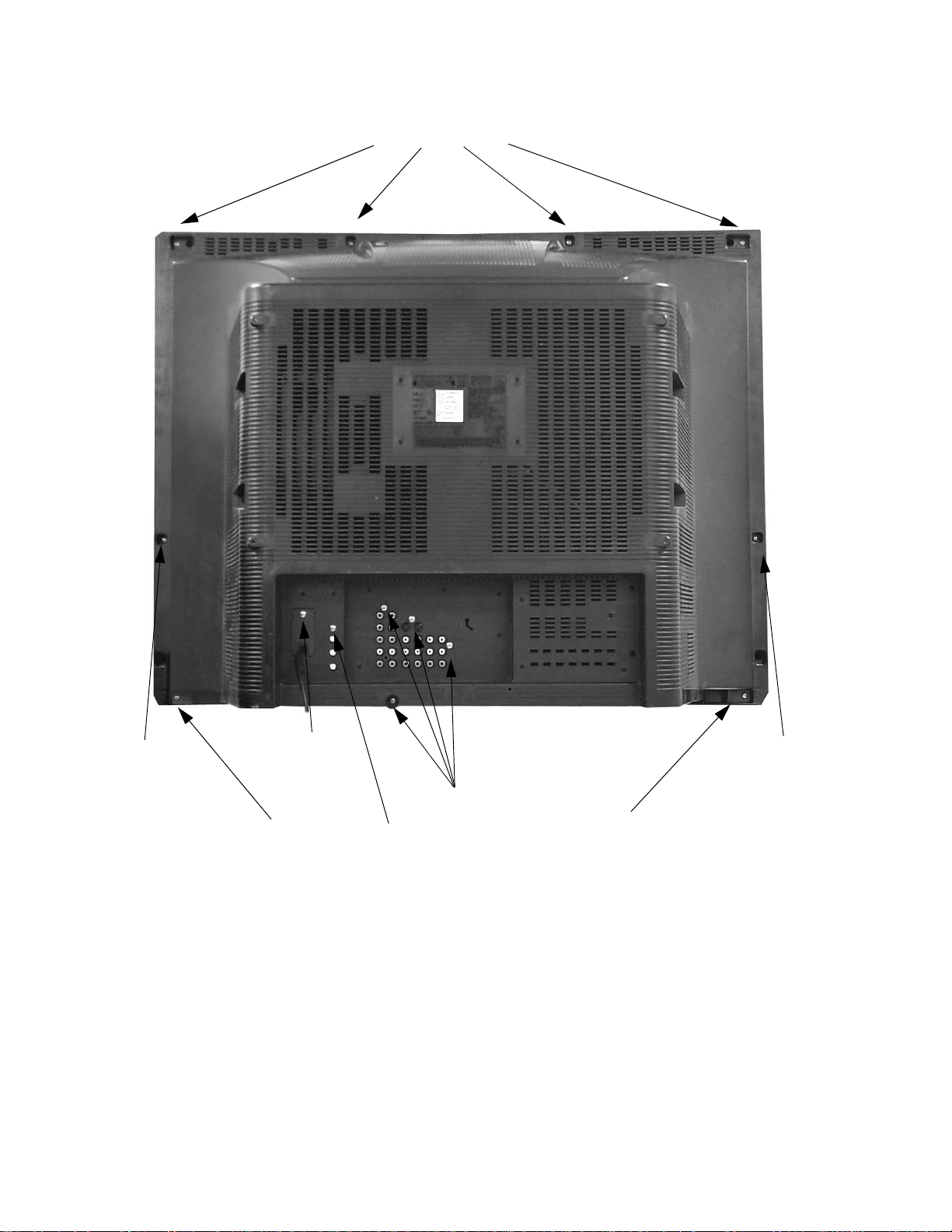

Disassembly for service

Back cover

Remove all the screws marked with an arrow( )

from the back of the receiver (see Fig. 12):

• 4 screws at the top edgeof the receiver.

• 3 screw by the A/V jacks.

• 1 screw by the RF jacks.

• 1 screw at each lower corner of the receiver.

• 1 screw by the retainer plate of the AC power cord.

• 1 screw at each lower side of the receiver.

• 1screw below the A/V jacks

Note: Extensions for board connectors may

be needed to test voltages on

P-Board, please see parts list section

for part numbers in this service

manual.

A-Board - Main chassis (see Fig. 14)

The DG-Board is assembled on the main chassis

(A-Board). The A-Board assembly rest on a chassis

tray along with the D-Board.

Slide chassis tray out. Gently lift, tray and pull out.

Disconnect plug connectors; release wire ties and

holders as required for complete chassis removal.

A. A-Board is secured to the chassis tray with five

screws.

B. The D-Board is secured to the chassis tray with

three screws

C. The A-Board is mated to the D-Board by four

flexible connectors: A4, A5, A6 & A7 (D4, D5, D6 &

D7 on the D-Board, respectively). To remove either

boards, unplug the connectors on the A-Board.

Note: Some tie-wraps that secure the wire

dressings may need to be unfastened

for chassis removal.

Insert wire then

pull upwards

Note: To realease the

GND cable from

D13 connector

insert a wire in

both cavities of

connector, then

pull up the

cable.

Figure 7. D-Board D13 GND connector.

L-Board - CRT output

Plugs into the socket on the CRT neck.

To remove this board, first unplug the board from

the CRT neck, then disconnect L1, L2 and L3

connectors, to disconnect the focus F1(red cable)

& F2 (white cable) cables, pull the tab and release

the cables (see Fig. 8), finally disconnect the

screen cable from the D-Board D16 (screen and

heater).

To reinsert back the cables, remember the original

position of cables, F1 (red cable) goes to A on the

CRT socket and F2 (white cable) goes to B on the

CRT socket.

Figure 8. F1 & F2 cables release

To release screen GND cables from L-Board L11 &

L12 connectors, insert a wire in both sides of connector

and pull upwards the cable, then remove the wire

(see Fig. 9)

Insert wire

Figure 9. L-Board screen GND cables release

Press tab

leftward to

release cables

Pull cables

upwards

Pull cables upwards

DG-Board

Plugs onto the A-Board at the A21, A22 and A23

(DG21, DG22 and DG23 respectively) connectors.

Note: This board is not-serviceable.

When removing this board pull carefully.

P-Board

Plugs onto the right side of the D-Board at D3, D2,

D11 & D12 connectors (P3, P2, P11 & P12 on

P-Board, respectively); First remove the three

screws that holds the metal board, one from the

flyback and two from the chassis tray and then use

a flat head screwdriver to release the connector

locking tabs and pull upwards the board.

-12-

G-Board

Mated to A-Board by three flexible connectors (A1,

A2, A3) and D-Board by one flexible connector

(D40). To remove this board, first unplug the four

flexible connectors, then RT4 and G4 connectors,

then pull upwards the board while unlock the tabs

from the chassis tray.

Page 13

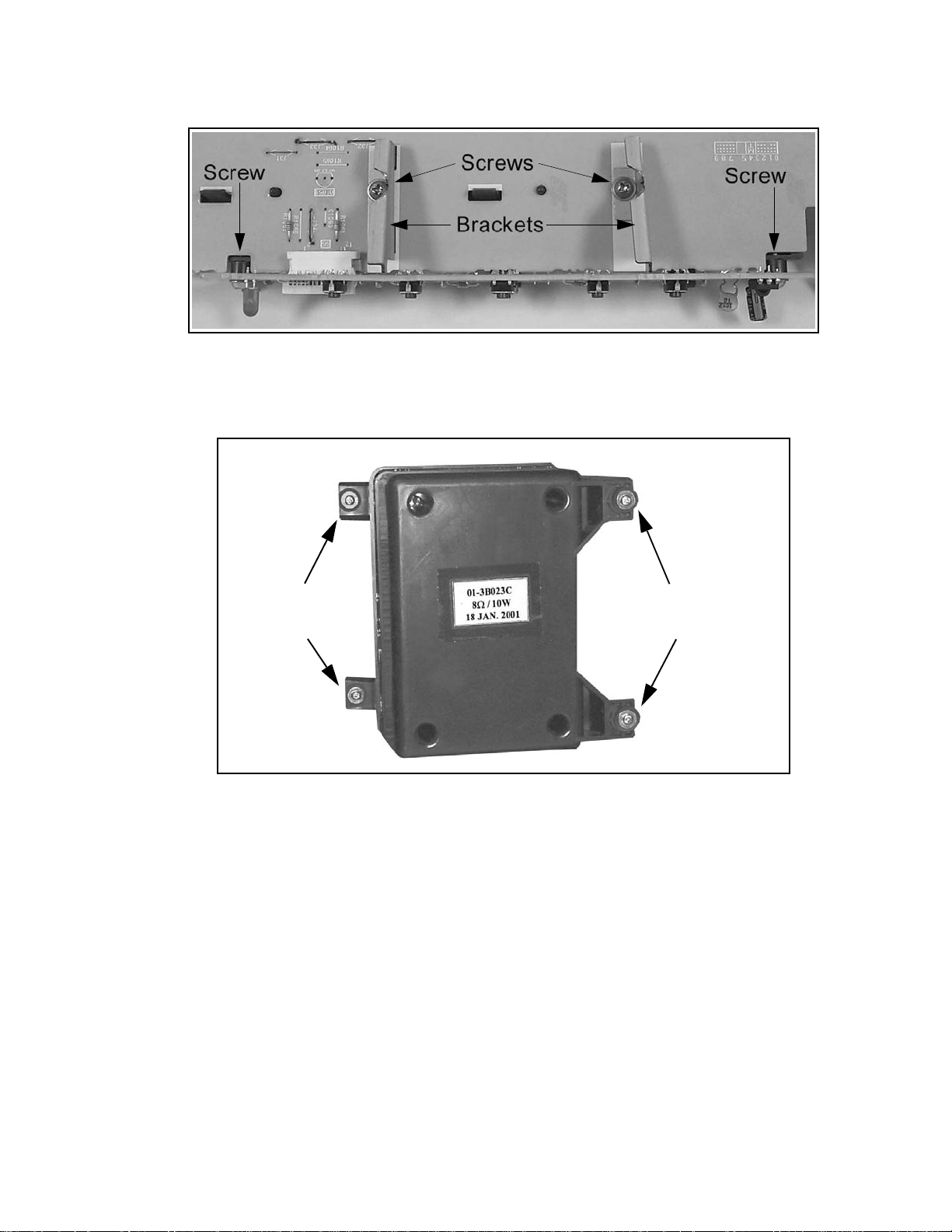

K-Board

Is fastened to the G-Board by two metal brackets that are secured by a screw (each one). Plugs into the front

of G-Board by connector K1 to G6,and is fastened to the chassis tray assembly by 2 screws on each lower

corner.(Fig. 9).

G-Board

K-Board

Figure 10. K-Board toG-Board Assembly (Top View).

Speakers

Each speaker is secured to a plastic base with 4 screws, and each plastic base is secured to a second base

with two screws, and assembled to the cabinet with two screws.

The subwoofer speaker is assembled within the backcover of the television set by 4 screws (Fig. 10).

Screws secured

to back cover

Figure 11. Subwoofer speaker

Note: Be sure to reconnect the speaker wires to the correct speaker lead (+) (-)

Screws secured

to back cover

-13-

Page 14

Back cover removal

4screws

at the top edge

1screw

at the lower side

1screwby

the AC cord

1screw

at the lower corner

Figure 12. Back cover removal.

1 screw by

the RF jacks

1screw

at the lower side

4 screws

1screw

at the lower corner

-14-

Page 15

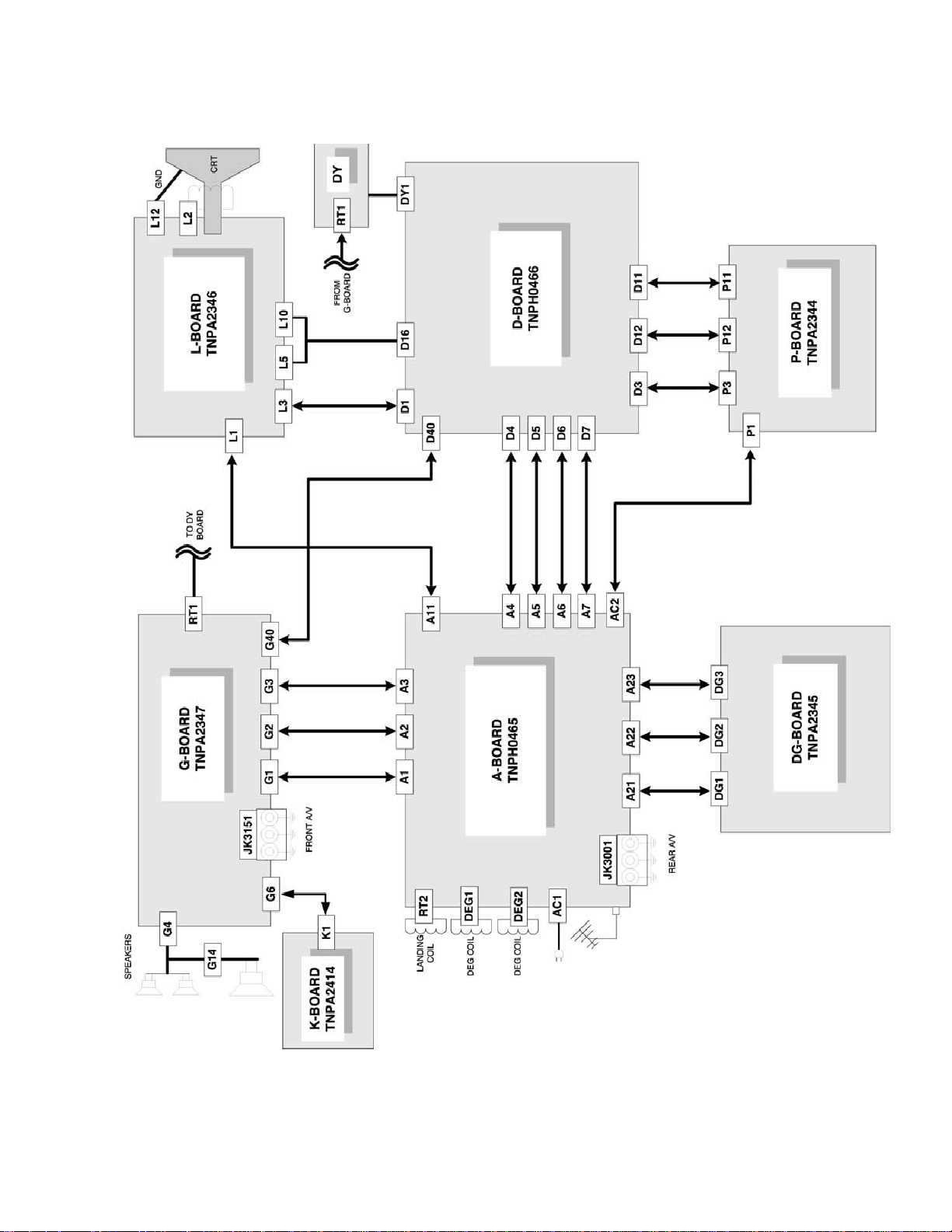

Board connections

Figure 13. Board connections.

-15-

Page 16

Description of connectors

AC2--P1

1

3

5

A15--Factory

1

2

3

4

5

6

7

8

SDA1 (EEPROM)

A12--2RF

1

2

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

AC N.C.

AC +

STB 7V

FA1

FA2 (GND)

SCL1 (EEPROM)

SCL2

SDA2

REMOTE

9V

RF SW

A3--G3

Y4

LV4

V4

RV4

GND

GND

ROUT

RGND

LGND

ROUT

D2--P2

N.C.

N.C.

N.C.

N.C.

N.C.

A2--G2

GND

SDA

SCL

GND

N.C.

HP MUTE

N.C.

AGND

S-4

S2-4 C-4

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

A1--G1

STB 3.3V

REMOTE

KEY SCAN1

KEY SCAN2

A23--DG3

STB GND

AC SW

DEG SW

AFC 1

AFC 2

LANDING

KEY SCAN 2

KEY SCAN 1

STB 3.3 V

MOMENT B SW

140 SW

V RASTER

HHS DET

HD SD SW

H RASTER

SOS 2

SYSCLK

2RFSW

REMOTE

SP SW

AUDIO MUTE

INPUT MUTE

STB 7V

STB GND

A11--L1

GND

GND

N.C.

9V

12V

GND

SOS

TILT

GND

GND

FA1

N.C.

VM

GND

GND

12 V

GND

A21--DG1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

SOS LED

SDA2

SCL2

SDA1

SCL1

N.C.

WP

NTSC VY1

VGND

C1

VGND

NTSC VY2

VGND

C2

VGND

AGND

DTVY2

AGND

PB2

AGND

PR2

AGND

DTVY1

AGND

PB1

AGND

PR1

AGND

STB 3.3V

HHS REF

D10--TESTPIN

1

2

3

4

5

FBP

EHT-DEF

HHS REF

GND

H DRIVE

A7--D7

1

2

3

4

5

6

R

G

B

7

8

9

10

11

12

13

14

15

16

HHS REF

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

ABL

N.C.

VDAF

N.C.

HDAF

N.C.

EHT DET

N.C.

-16-

Page 17

D3--P3

A6--D6

D12--P12

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

AUDIO -16V

AUDIO -16V

AUDIO GND

AUDIO GND

AUDIO +16V

AUDIO +16V

+B ON/OFF

D1-L3

A22--DG2

MAIN 5V

V DRIVE

H DRIVE

EW DRIVE

EHT DET

SERVICE SW

N.C.

+B 140V

N.C.

- 220V

N.C.

GND

GND

GND

SCL2

SDA2

GND

GND

GND

GND

GND

VM

9V

D2.5V

D2.5V

GND

GND

SUB 5V

N.C.

N.C.

FBP

HDAF

VDAF

ABL

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

HDRIVEGC

VL NEK PRO

FBP

GND

EW DRIVE

GND

GND

N.C.

GND

H RASTER

GND

HD SD SW

GND

HHS DET

GND

GND

A5--D5

1

2

3

4

5

6

7

B

G

R

8

9

10

11

12

13

14

15

16

SERVICEC SW

V DRIVE GC

140V SW ON/OFF

MOMENT B

N.C.

SCL2

SDA2

TILT

GND

V RASTER

GND

GND

SOS

GND

GND

12 V

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

UNREG +25V

UNREG +25V

GND

GND

UNREG -15V

GND

UNREG +15V

UNREG +15V

D11--P11

+B 144V

+B 144V

+B 144V

N.C.

N.C.

GND

GND

GND

D40--G40

VSAW

GND

SDA2

GND

SCL2

GND

TILT

+ 15V

GND

- 15V

G6--K1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A4--D4

UNREG 15V

UNREG 15V

GND

UNREG 23V

UNREG 23V

GND

BTL 30V

GND

STBY 5V

GND

AUDIO +20V

AUDIO +20V

AUDIO GND

AUDIO GND

AUDIO -20V

AUDIO -20V

1

2

3

4

5

6

7

8

9

10

11

12

STBY 3.3V

5V

STBY 3.3V

5V

KEYSCAN 2

GND

KEYSCAN 1

GND

GND

GND

12VR

RMT

-17-

Page 18

Identification of components

CRT (Secured To Cabinet

By 4 Screws On Corners)

Geomagnetic Coil

Anode

(High Voltage)

D.Yoke

Deg. Coil

L-Board

Speaker

(4 Screws)

Tuners

DG-Board

A/V-Board

A-Board

(main chassis)

Note:

D-Board

After servicing the receiver,remember

to dress the cables, as shown above.

Figure 14. Rear view.

Speaker

(4 Screws)

Flyback

(T551)

P-Board

(power supply)

-18-

Page 19

Identification of components (cont....)

D801

Q801

IC811

P2 P11 P3

RL804

Q806

Q805

D834

P12

T801

IC802

Q952

Figure 15. P-Board

IC3803

Q956

IC3801

Q955

Q951

IC3802

CRT Socket

Figure 16. L-Board

-19-

Page 20

IC515

IC529

IC002

Identification of components (cont....)

IC511

IC506

IC517

IC6502

IC802

DG1

Board Number

IC518

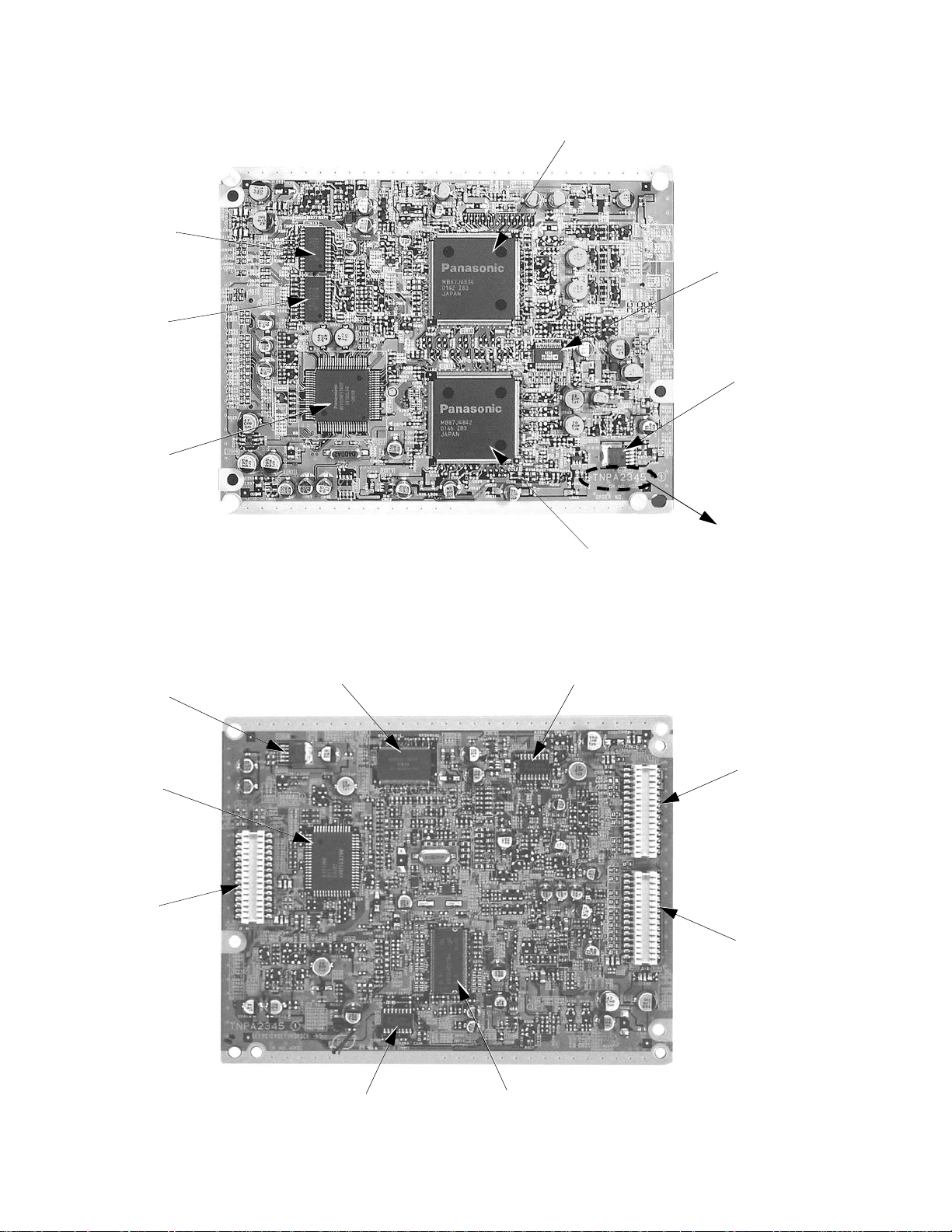

Figure 17. DG-Board top-side

IC507 IC530

DG2

DG3

IC521

Figure 18. DG-Board bottom-side

-20-

IC525

Page 21

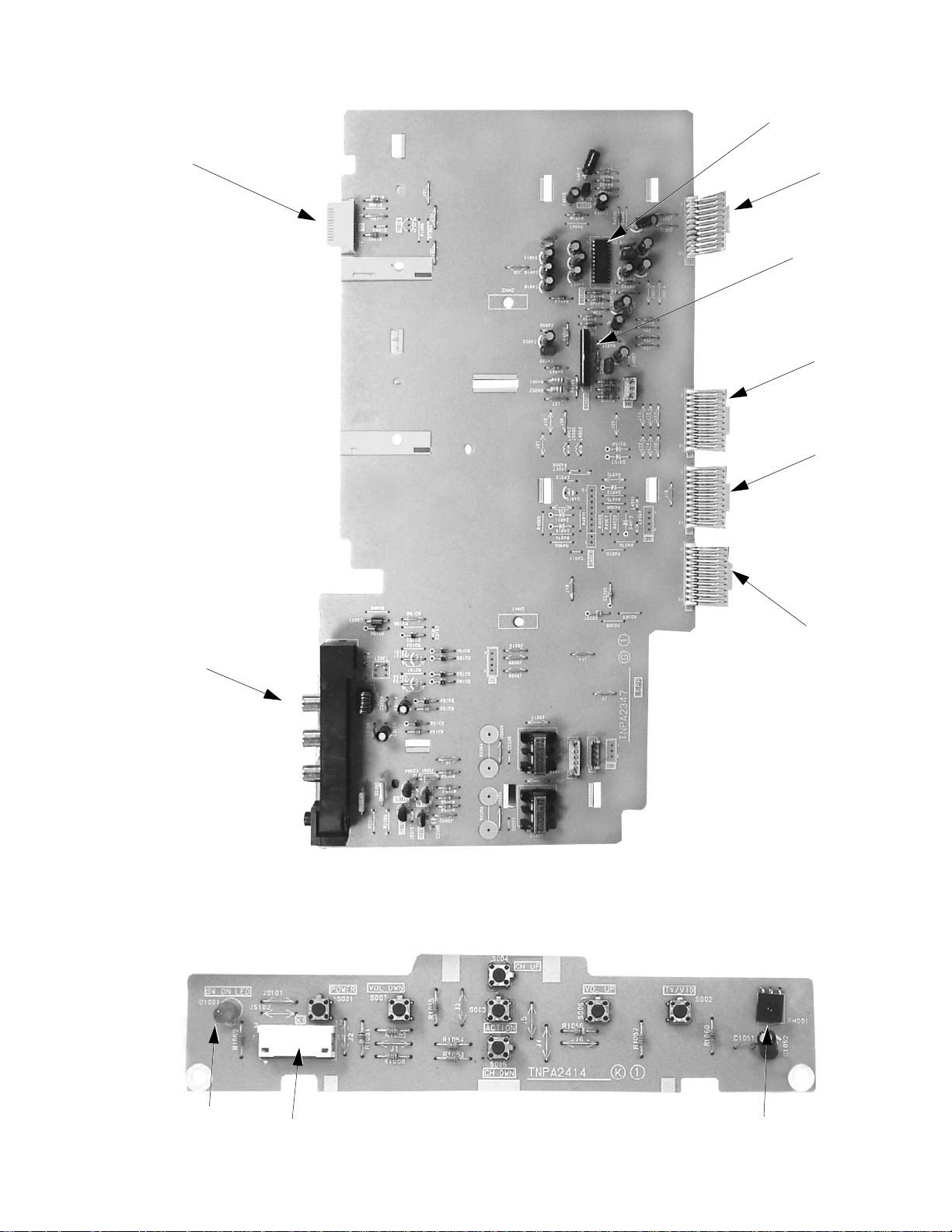

G6

Identification of components (cont....)

IC4805

G40

IC4804

G1

G2

FRONT A/V

G3

Figure 19. G-Board

LED

K1

IR Sensor

Figure 20. K-Board

-21-

Page 22

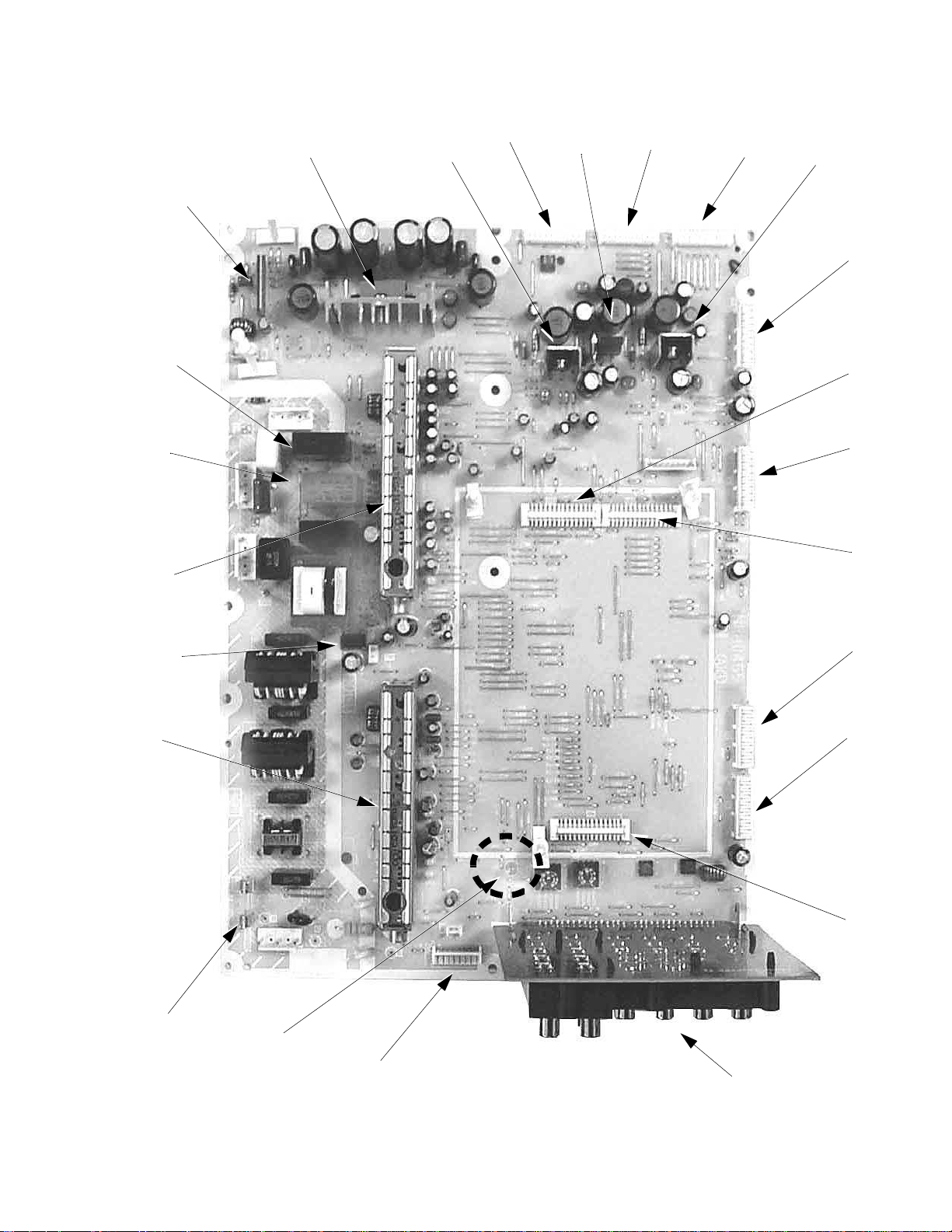

Identification of components (cont....)

D40

D5

D4

D503

IC500

L554

IC752

RL451

IC451

D3

D12

D6

D7

T1501

D11

Q551

D2

T551

FLY-BACK

Figure 21. D-Board

-22-

Page 23

Identification of components (cont....)

IC4803

RL803

RL802

TNR002

IC2302

IC875

A3

IC872

A2

A1

IC871

A4

DG2

A5

DG3

IC804

TNR001

FUSE

DIAGNOSIS

LED

A6

A7

DG1

A15

REAR A/V

Figure 22. A-Board

-23-

Page 24

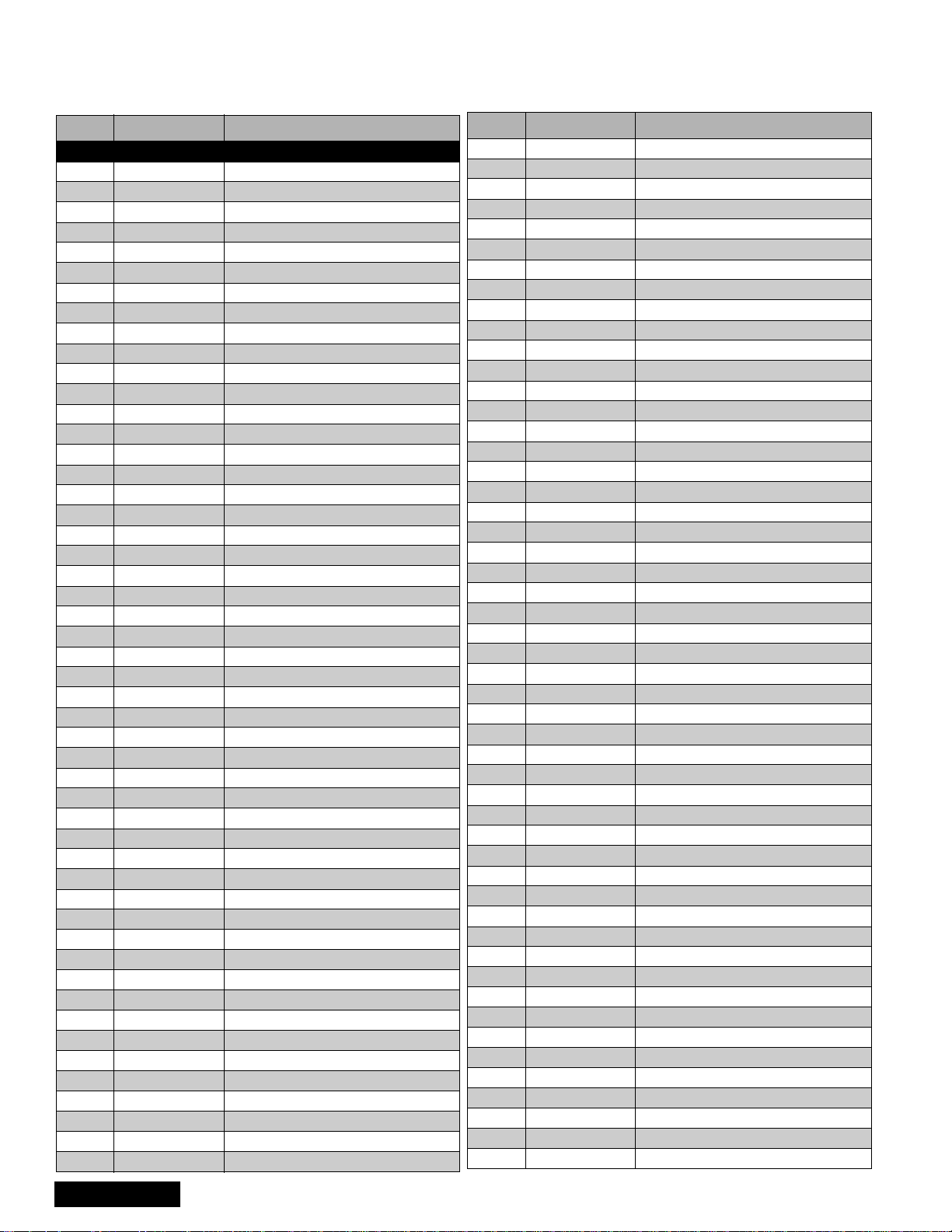

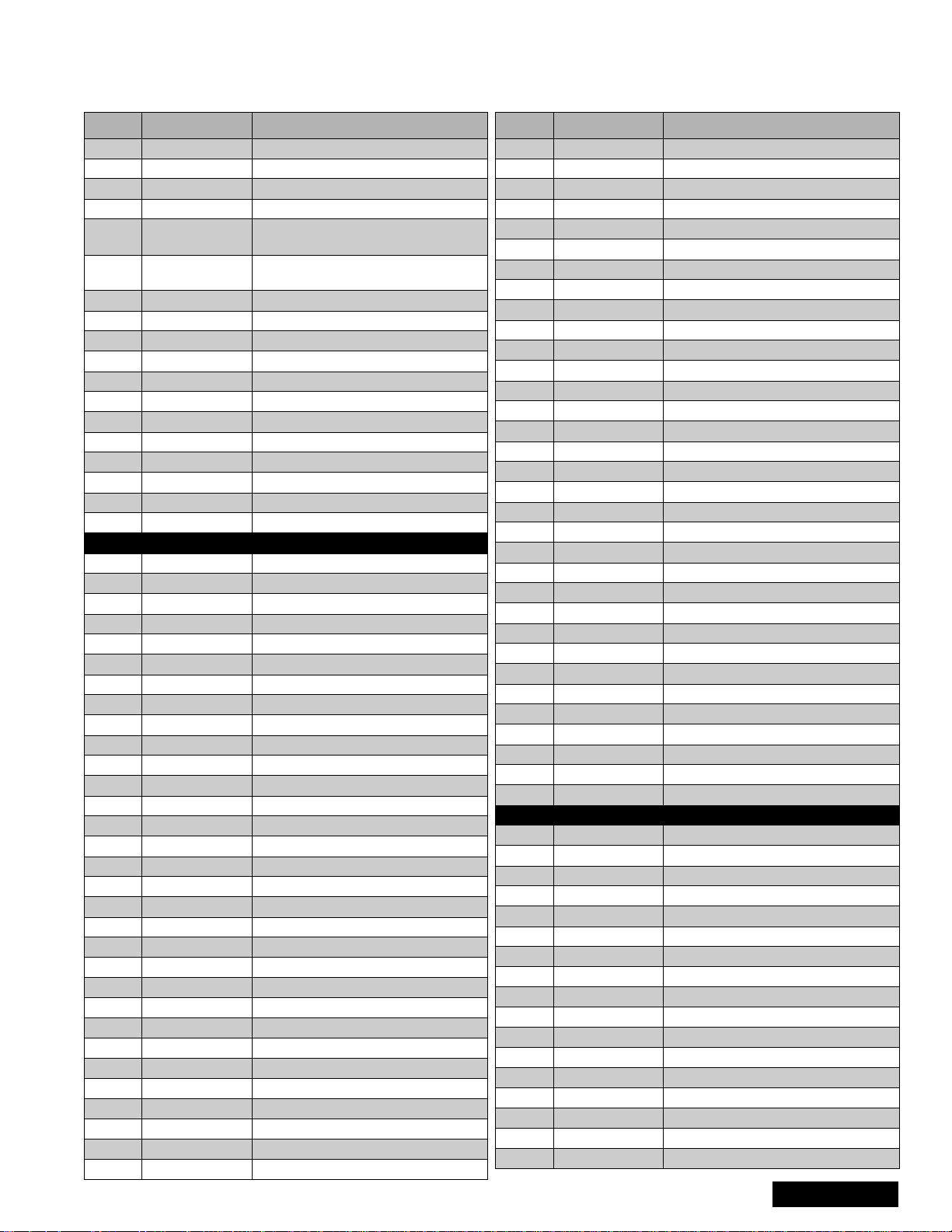

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When

replacingany of thesecomponents use only manufacturer’sspecified parts.

REF NO. PART NO. DESCRIPTION

CAPACITORS

C038 EEUFC1A471B CAP,E 470UF-10V

C039 ECA1HM4R7B CAP,E4.7UF-50V

C040 ECA1VM470B CAP,E 47UF/35V

C041 ECA1HM2R2B CAP,E2.2UF-50V

C042 ECA1VM470B CAP,E 47UF/35V

C043 ECA1HM4R7B CAP,E4.7UF-50V

C044 ECA1VM470B CAP,E 47UF/35V

C045 ECA1HM2R2B CAP,E2.2UF-50V

C047 ECA1HM010B CAP,E1UF-50V

C050 TCJ2VC1H101J CAP,C 100PF-J-50V

C051 TCJ2VC1H101J CAP,C 100PF-J-50V

C058 ECA1HMR22B CAP,E .22UF-50V

C059 ECA1HMR22B CAP,E .22UF-50V

C060 ECA1HM4R7B CAP,E4.7UF-50V

C405 ECA1HM102E CAP,E1000UF-50V

C406 ECQV1H105JL3 CAP,P 1.0UF-J-50V

C407 ECKR1H103ZF5 CAP,C .01UF-Z-50V

C408 ECA1VM102E CAP,E 1000UF-35V

C409 ECA1VM102E CAP,E 1000UF-35V

C411 ECQB1H472JF3 CAP,P 4700PF-J-50V

C412 ECQB1224KF3 CAP,P .22UF-K-100V

C413 ECA1HM010B CAP,E 1UF-50V

C414 ECQB1H272JF3 CAP,P 2700PF-J-50V

C415 ECQB1473KF3 CAP,P .047UF-K-100V

C416 ECQB1H472JF3 CAP,P 4700PF-J-50V

C419 EEUNA1A470B CAP,E 47UF-125V

C420 ECA1CM101B CAP,E100UF/16V

C421 ECA1CM101B CAP,E100UF/16V

C422 ECA1HM010B CAP,E1UF-50V

C434 ECA1HM100B CAP,E10UF/50V

C438 ECQB1H102JF3 CAP,P 1000PF-J-50V

C439 TCJ2VB1H103K CAP,C .01UF-K-50V

C440 ECA1HM100B CAP,E10UF/50V

C457 ECEA1EN4R7UB CAP,E 4.7UF-25V

C501 ECA1VM101B CAP,E 100UF-35V

C502 ECQV1H104JL3 CAP,P .10UF-J-50V

C503 ECKR2H102KB5 CAP,C 1000PF-K-500V

C506 ECA1CM471B CAP,E470UF-16V

C509 ECKR3A222KBP CAP,C .0022UF-K-1KV

C510 TCJ2VC1H221J CAP,C 220PF-J-50V

C511 ECWH20562JVB CAP,P 5600PF-J-2KV

C513 ECQF6103JZH CAP,P .010UF-J-630V

PARTS LIST

C514 ECWH20272JVY CAP,P 2700PF-J-2KV

C515 ECKR3A222KBP CAP,C .0022UF-K-1KV

C516 ECWF2224JSR CAP,M .22UF-J-200V

C517 ECWF2684JSR CAP,M .26UF-J-200V

C518 ECKW3D681KBR CAP,C 680PF-K-2KV

C519 ECKW3D681KBR CAP,C 680PF-K-2KV

C520 ECQB1H183JF3 CAP,P .018UF-J-50V

C521 ECWF2224JSR CAP,M .22UF-J-200V

REF NO. PART NO. DESCRIPTION

C522 ECWH20222JVY CAP,P 2200PF-J-2KV

C523 ECWH20272JVY CAP,P 2700PF-J-2KV

C524 ECQB1224JF3 CAP,P .22UF-J-100V

C525 EEUNA1E220B CAP,E22UF-25V

C526 ECA2EM470E CAP,E 47UF-250V

C527 ECKR2H102KB5 CAP,C 1000PF-K-500V

C528 ECA1HM4R7B CAP,E 4.7UF-50V

C530 ECQE2155JFB CAP,P 1.5UF-J-200V

C531 ECA160V33UE CAP,E 33UF/160V

C532 ECQF6472JZH CAP,P .0047UF-J-630V

C535 ECA1HM471E CAP,E 470UF-50V

C536 ECEA1HN100UB CAP,E 10UF/50V

C537 ECQB1H473JF3 CAP,P .047UF-J -50V

C538 ECA1CM471B CAP,E 470UF-16V

C539 ECA1CM471B CAP,E 470UF-16V

C541 ECQE2333JFB CAP,P .033UF-J-200V

C573 ECQB1H104JF3 CAP,P .10UF-J -50V

C574 ECA1CM470B CAP,E 47UF/16V

C575 ECKR1H103ZF5 CAP,C.01UF-Z-50V

C701 ECQB1H182JF3 CAP,P 1800PF-J-50V

C704 ECQB1H152JF3 CAP,P 1500PF-J-50V

C705 TCJ2VC1H221J CAP,C 220PF-J-50V

C706 ECKW3D271JBN CAP,C 270PF-J-2KVDC

C709 ECQE1106KFB CAP,P 100UF-K-1KV

C712 ECKR1H221KB5 CAP,C 220PF-K-50V

C713 ECKR1H221KB5 CAP,C 220PF-K-50V

C714 ECA1HM2R2B CAP,E 2.2UF-50V

C759 ECQM2104KZW CAP,P .1UF-K-200V

C801 ECQU2A104BN9 CAP,P .10UF-B-250V

C802 ECQU2A823BN9 CAP,P .082UF-B-250V

C803 ECQU2A823BN9 CAP,P .082UF-B-250V

C804 ECQU2A823BN9 CAP,P .082UF-B-250V

C805 ECKW2H472PU7 CAP,C 4700PF-P-500V

C806 ECKW2H472PU7 CAP,C 4700PF-P-500V

C807 ECKW2H472PU7 CAP,C 4700PF-P-500V

C808 ECQB1H102JF3 CAP,P 1000PF-J-50V

C809 ECQB1H333JF3 CAP,P .033UF-J -50V

C810 EC0S2DA821DB CAP,E 820UF-200V

C811 EC0S2DA821DB CAP,E 820UF-200V

C812 ECA1CM471B CAP,E 470UF-16V

C813 ECA1HM010B CAP,E 1UF-50V

C814 ECKW2H472PU7 CAP,C 4700PF-P-500V

C815 ECA1EM471B CAP,E 470UF-25V

C816 ECKW3A272KBP CAP,C 2700PF-K-1KV

C817 ECQB1H332JF3 CAP,P 3300PF-J-50V

C819 TACCQ221T50V CAP,C 220PF/50V

C820 ECA1EHG221B CAP,E 220UF-25V

C821 ECKW3D272KBP CAP,C 2700PF-K-2KV

C822 ECQB1H393JF3 CAP,P .039UF-J -50V

C823 ECQB1H222JF3 CAP,P 2200PF-J-50V

C826 ECA1VM221B CAP,E 220UF-35V

Parts List

-24-

179-02

Page 25

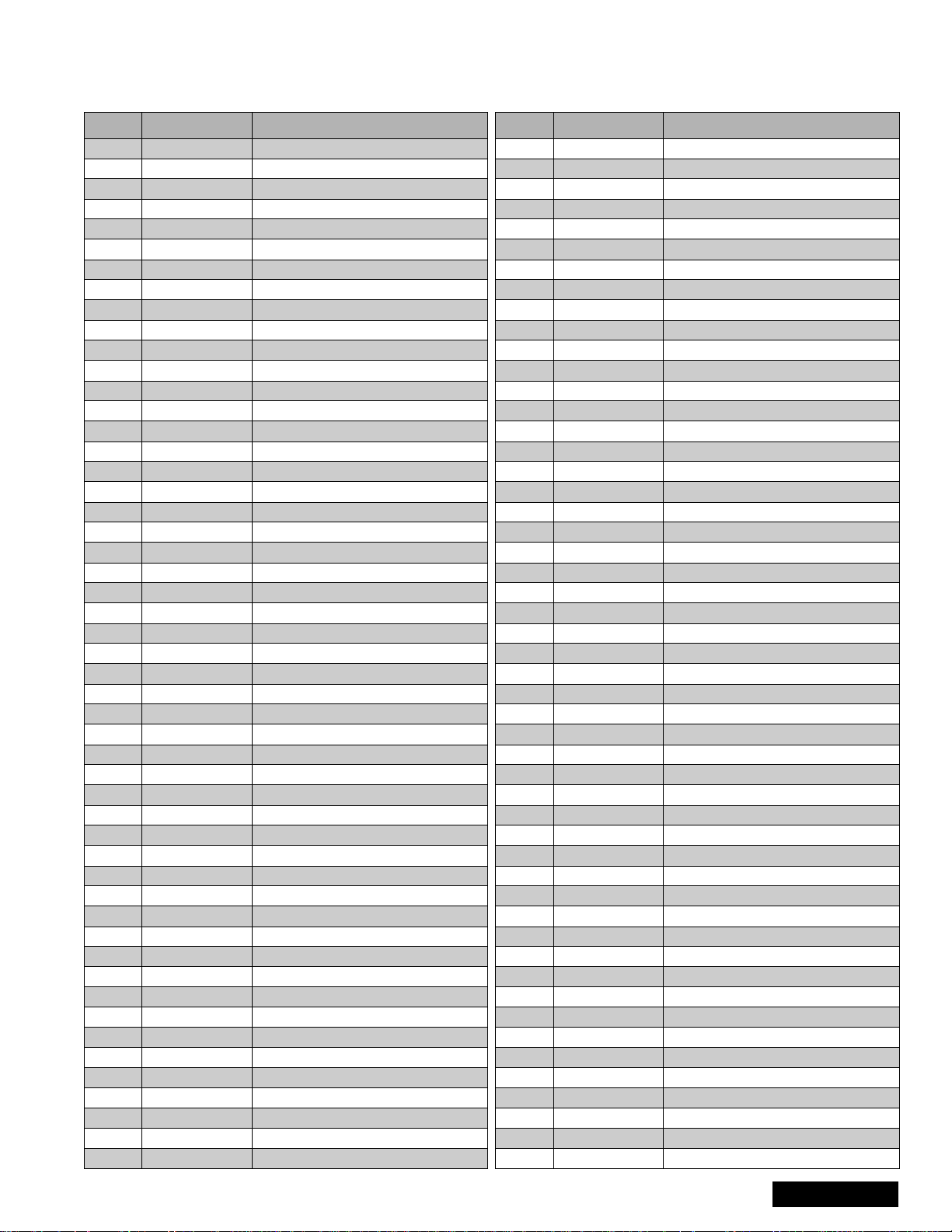

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF.

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

C827 ECQB1H333JF3 CAP,P .033UF-J-50V

C828 ECKR3A331KBP CAP,C 330PF-K-1KVDC

C830 EETHC2C102H CAP,E 1000UF-160V

C831 ECKR3A102KBP CAP,C 1000PF-K-1KV

C832 ECA1VHG102E CAP,E 1000UF/35V

C833 ECKR3A471KBP CAP,C 470PF-K-1KV

C834 EEUFC1V222E CAP,E 2200UF-35V

C838 EEUFC1E272E CAP,E 2700UF-25V

C839 ECKR3A151KBP CAP,C 150PF-K-1KV

C840 ECA1EMH471B CAP,E 470UF-25V

C841 ECA1EHG102E CAP,E 1000UF-25V

C842 ECKR3A331KBP CAP,C 330PF-K-1KVDC

C843 ECA1VHG102E CAP,E 1000UF/35V

C844 ECKR3A471KBP CAP,C 470PF-K-1KV

C845 ECA1CM101B CAP,E 100UF/16V

C846 ECA1HM010B CAP,E 1UF-50V

C847 ECA1VM470B CAP,E 47UF/35V

C848 ECA1CM101B CAP,E 100UF/16V

C850 EEUFC1E272E CAP,E 2700UF-25V

C851 ECA1CM221B CAP,E 10UF-16V

C856 ECQU2A103MNB CAP,P .010UF-M-250V

C857 TCJ2VB1H103K CAP,C .01UF-K-50V

C859 ECA1VHG471B CAP,E 470UF-35V

C860 ECKCNA222MEB CAP,C 2200PF-M-125V

C861 ECKCNA222MEB CAP,C 2200PF-M-125V

C876 ECA1EM471B CAP,E 470UF-25V

C877 EEUFC1A471B CAP,E 470UF-10V

C878 ECA1EM221B CAP,E 220UF-25V

C879 EEUFC1A471B CAP,E 470UF-10V

C880 TCJ2VB1H103K CAP,C .01UF-K-50V

C885 ECA1VM471B CAP,E 470UF-35V

C886 EEUFC1C471B CAP,E 470UF-16V

C887 ECA1CM471B CAP,E 470UF-16V

C888 ECA1EM101B CAP,E 100UF-25V

C889 ECA1CM101B CAP,E 100UF/16V

C890 ECA1CM221B CAP,E 10UF-16V

C891 TCJ2VB1H103K CAP,C .01UF-K-50V

C892 ECA0JM221B CAP,E 220UF-6.3V

C893 TCJ2VB1H103K CAP,C .01UF-K-50V

C894 ECA1VM101B CAP,E 100UF-35V

C895 ECA1CM221B CAP,E 10UF-16V

C896 TCJ2VB1H103K CAP,C .01UF-K-50V

C897 ECA1EM471B CAP,E 470UF-25V

C898 TCJ2VB1H103K CAP,C .01UF-K-50V

C899 TCJ2VB1H103K CAP,C .01UF-K-50V

C901 ECQB1H103JF3 CAP,P .01UF-J -50V

C906 ECEA1CN100UB CAP,E 10UF-16V

C952 ECA1CM221B CAP,E 10UF-16V

C953 ECA1CM471B CAP,E 470UF-16V

C955 ECQB1223KF3 CAP,P .22UF-K-100V

C956 ECQE2103KF3 CAP,P .010UF-K-200V

REF NO. PART NO. DESCRIPTION

C957 ECQE2103KF3 CAP,P .010UF-K-200V

C959 ECQB1223KF3 CAP,P .22UF-K-100V

C961 ECA2CM4R7B CAP,E 4.7UF-160V

C962 ECQE2103KF3 CAP,P .010UF-K-200V

C964 ECA1CM101B CAP,E 100UF/16V

C966 ECA1CM101B CAP,E 100UF/16V

C967 ECA2CHG330E CAP,E 33UF-160V

C970 ECQB1H103JF3 CAP,P .01UF-J-50V

C971 ECQB1H103JF3 CAP,P .01UF-J -50V

C973 ECQE2103KF3 CAP,P .010UF-K-200V

C1024 TCJ2VB1H103K CAP,C .01UF-K-50V

C1025 ECA0JM222B CAP,E 2200UF-6.3V

C1051 ECKR1H103ZF5 CAP,C .01UF-Z-50V

C1052 ECA1AM470B CAP,E 47UF-10V

C1504 ECQB1H103JF3 CAP,P .01UF-J-50V

C1505 ECA1CM470B CAP,E 47UF/16V

C1506 TCJ2VF1H102Z CAP,C 1000PF-Z-50V

C1507 ECA1CM220B CAP,E 22UF-16V

C1508 ECKW3D151KBP CAP,C 150PF-K-2KV

C1509 ECQM6223KZW CAP,P.022UF-K-600V

C1510 ECQM4223KZW CAP,P .022UF-K-400V

C1511 ECA1HM010B CAP,E 1UF-50V

C1512 ECKW3D102KBP CAP,C 1000PF-K-2KV

C1513 ECKR3A471KBP CAP,C 470P F-K-1KV

C1515 ECKR3A152KBP CAP,C 1500PF-K-1KVDC

C1516 ECKR3A561KBP CAP,C 470P F-K-1KV

C1517 ECKR3A151KBP CAP, C 150PF-K-1KV

C1518 ECKR3A102KBP CAP,C 1000PF-K-1KV

C1519 ECA1VM470B CAP,E47UF/35V

C1520 ECA1HM100B CAP,E 10UF/50V

C1521 ECA0JM331B CAP,E 330UF-6.3V

C2202 ECEA1HKA2R2B CAP,E 2.2UF-50V

C2203 ECEA1HKA4R7B CAP,E 4.7UF-50V

C2204 AP106K016CAE CAP, T 10UF/16V

C2205 ECA1HM010B CAP,E 1UF-50V

C2206 ECQB1H223JF3 CAP,P.022UF-J-50V

C2207 AP335K016CAE CAP,T 3.3UF/16V

C2208 TCJ2VB1C104K CAP,C .1UF-K-16V

C2209 TCJ2VB1C104K CAP,C .1UF-K-16V

C2210 TCJ2VB1C104K CAP,C .1UF-K-16V

C2211 ECA1HM100B CAP,E 10UF/50V

C2212 ECQB1H473JF3 CAP,P.047UF-J-50V

C2215 ECA1CM101B CAP,E 100UF/16V

C2218 ECA1HMR47B CAP,E .47UF-50V

C2303 ECA1EM101B CAP,E100UF-25V

C2304 TCJ2VB1H103K CAP,C .01UF-K-50V

C2330 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2331 ECA1HM100B CAP,E 10UF/50V

C2332 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2333 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2334 TCJ2VB1H103K CAP,C .01UF-K-50V

PARTS LIST

179-02

-25-

Parts List

Page 26

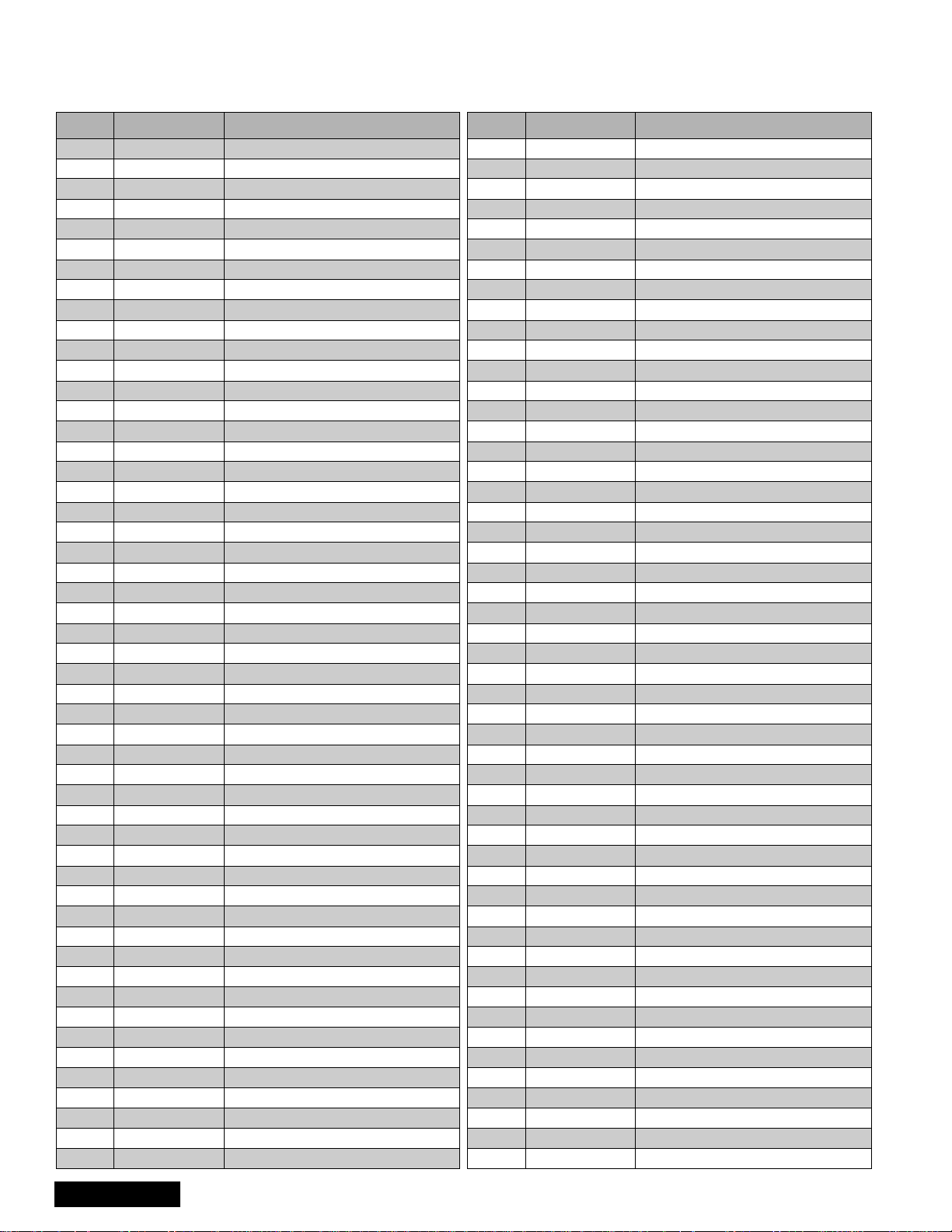

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When

replacingany of thesecomponents use only manufacturer’sspecified parts.

REF NO. PART NO. DESCRIPTION

C2335 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2342 TCJ2VB1H333K CAP,C .033UF-K-50V

C2343 ECEA1CN100UB CAP, E 10UF-16V

C2344 ECQB1H224JF3 CAP,P .22UF-J-50V

C2345 EEUFC1E222E CAP,E 2200UF-25V

C2346 TCJ2VB1H561K CAP,C 560PF-K-50V

C2347 ECJ3VB1H104K CAP,C .1UF -K-50V

C2348 ECA1HM100B CAP,E 10UF/50V

C2349 ECEA1CN100UB CAP, E 10UF-16V

C2351 TCUY1C225ZFN CAP,C 2.2UF-Z-16V

C2352 EEUFC1E222E CAP,E 2200UF-25V

C2353 EEUFC1E222E CAP,E 2200UF-25V

C2354 TCJ2VB1H471K CAP,C 470PF-K-50V

C2355 TCJ2VC1H270J CAP,C 27PF-J-50V

C2356 TCJ2VB1H471K CAP,C 470PF-K-50V

C2357 TCJ2VB1H331K CAP,C 330PF-K-50V

C2358 ECJ3VB1H104K CAP,C .1UF -K-50V

C2359 TCJ2VB1H331K CAP,C 330PF-K-50V

C2360 ECJ3VB1H104K CAP,C .1UF -K-50V

C2361 TCJ2VB1H471K CAP,C 470PF-K-50V

C2362 TCJ2VB1H471K CAP,C 470PF-K-50V

C2363 TCJ2VB1H682K CAP,C 6800PF-K-50V

C2364 ECJ3VB1H104K CAP,C .1UF -K-50V

C2365 ECJ3VB1H104K CAP, C .1UF-K-50V

C2366 EEUFC1E222E CAP,E 2200UF-25V

C2367 ECQB1H224JF3 CAP,P .22UF-J-50V

C2368 TCJ2VB1H333K CAP,C .033UF-K-50V

C2369 TCJ2VB1H561K CAP,C 560PF-K-50V

C2370 ECEA1HN100UB CAP, E 10UF/50V

C2371 ECEA1HN100UB CAP,E 10UF/50V

C2373 TCJ2VB1H682K CAP,C 6800PF-K-50V

C2374 ECEA1HN100UB CAP,E 10UF/50V

C2375 ECEA1HN100UB CAP, E 10UF/50V

C2378 TCJ2VF1H104Z CAP,C .1UF-Z-50V

C2380 ECA1HM010B CAP,E 1UF-50V

C2451 ECA1CM101B CAP,E 100UF/16V

C2452 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2453 TCJ2VB1C104K CAP,C .1UF-K-16V

C2454 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C2455 TCJ2VB1C104K CAP,C .1UF-K-16V

C2456 TCJ2VC1H222J CAP,C 2200PF-J-50V

C2457 TCJ2VB1H333K CAP,C .033UF-K-50V

C2458 TCJ2VB1H333K CAP,C .033UF-K-50V

PARTS LIST

C2459 ECEA1CN100UB CAP,E 10UF-16V

C2460 TCJ2VB1H332K CAP,C .0033UF-K-50V

C2461 ECEA1CN100UB CAP,E 10UF-16V

C2462 ECA1HM4R7B CAP,E 4.7UF-50V

C2463 ECEA1HKA4R7B CAP,E 4.7UF-50V

C2464 TCJ2VB1H332K CAP,C .0033UF-K-50V

C2465 TCJ2VB1H333K CAP,C .033UF-K-50V

C2466 TCJ2VB1H333K CAP,C .033UF-K-50V

REF NO. PART NO. DESCRIPTION

C2467 TCJ2VB1H102K CAP,C 1000PF-K-50V

C2468 TCJ2VB1H102K CAP,C 1000PF-K-50V

C2469 TCJ2VB1H103K CAP,C .01UF-K-50V

C2473 ECEA1HKA4R7B CAP,E 4.7UF-50V

C2474 ECA1CM101B CAP,E 100UF/16V

C2475 ECA1HM4R7B CAP,E 4.7UF-50V

C3001 ECA1CM470B CAP,E 47UF/16V

C3002 TCJ2VB1H103K CAP,C .01UF-K-50V

C3003 TCJ2VB1H103K CAP,C .01UF-K-50V

C3004 ECA1CM470B CAP,E 47UF/16V

C3006 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3007 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3008 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3055 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3056 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3063 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3064 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3071 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3072 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3073 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3074 TCJ2VB1H103K CAP,C .01UF-K-50V

C3077 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3078 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3079 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3080 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3081 TCJ2VB1H103K CAP,C .01UF-K-50V

C3084 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3085 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3086 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3087 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3088 ECA1CM471B CAP,E 470UF-16V

C3089 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3090 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3091 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3092 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3093 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3094 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3095 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3096 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3097 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3098 TCJ2VB1H152K CAP,C 1500PF-K-50V

C3105 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3106 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3107 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3108 TCJ2VF1C105Z CAP,C 1.0UF-Z-16V

C3154 ECA1HM010B CAP,E 1UF-50V

C3155 ECA1HM010B CAP,E 1UF-50V

C3158 ECKR1H152KB5 CAP,C 1500PF-K-50V

C3159 ECKR1H152KB5 CAP,C 1500PF-K-50V

C3804 ECQE2104KFW CAP,P .10UF-K-200V

C3807 ECCR1H100DC5 CAP, C 10PF-D-50V

Parts List

-26-

179-02

Page 27

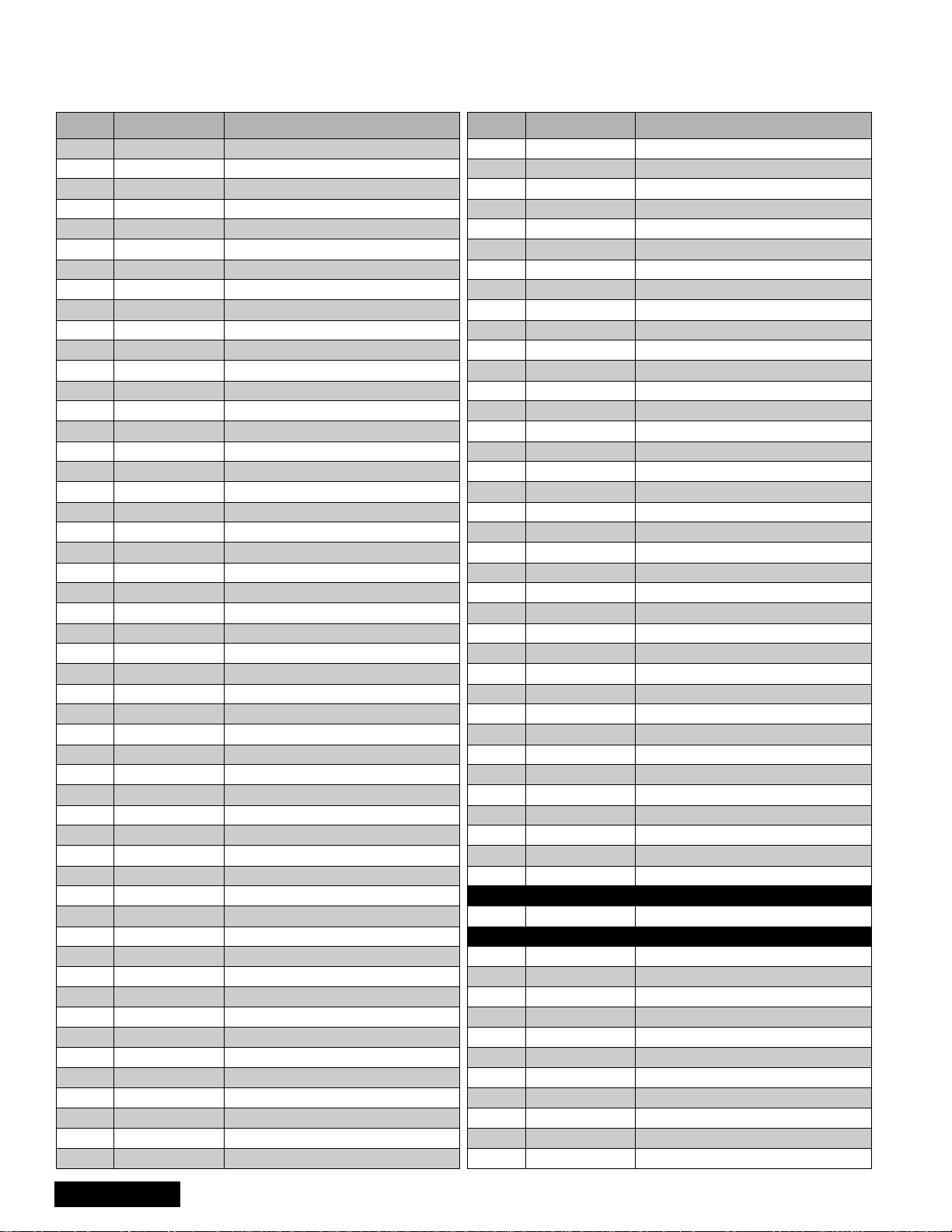

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF.

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

C3814 ECQE2104KFW CAP,P.10UF-K-200V

C3816 ECA2EM470E CAP,E 47UF-250V

C3817 ECCR1H220JC5 CAP.C 22P F- J-50V

C3824 ECQE2104KFW CAP,P .10UF-K-200V

C3826 ECA2EM101E CAP,E 100UF-250V

C3827 ECCR1H270JC5 CAP,C 27PF- J-50V

C3833 ECA2EM101E CAP,E 100UF-250V

C3836 ECKC3D332KBN CAP,C 3300PF-K-2KV

C4805 ECA1CM470B CAP,E 47UF/16V

C4806 ECQV1H334JL3 CAP, P .33UF-J-50V

C4810 ECEA1CN220UB CAP,E 22UF-16V

C4811 ECEA1CN220UB CAP,E 22UF-16V

C4812 ECA1HM0R1B CAP,E 0.1UF/50V

C4813 ECKR1H472KB5 CAP,C 4700PF-K-50V

C4814 ECA1HM4R7B CAP,E 4.7UF-50V

C4815 ECA1HM4R7B CAP,E 4.7UF-50V

C4816 ECA1HM4R7B CAP,E 4.7UF-50V

C4817 ECA1HMR47B CAP,E .47UF-50V

C4818 ECA1HM100B CAP,E 10UF/50V

C4819 ECEA1CN100UB CAP,E 10UF-16V

C4913 ECEA1CN100UB CAP,E 10UF-16V

C4914 ECA1HM0R1B CAP,E 0.1UF/50V

C4915 ECKR1H472KB5 CAP,C 4700PF-K-50V

C4916 ECA1CM470B CAP,E 47UF/16V

C4917 ECQB1H104JF3 CAP,P.10UF-J-50V

C4918 ECA1HM0R1B CAP,E 0.1UF/50V

C4919 ECA1HM4R7B CAP,E 4.7UF-50V

C4920 ECKR1H103ZF5 CAP,C .01UF-Z-50V

C4921 ECA1CM470B CAP,E 47UF/16V

C4922 ECQB1H104JF3 CAP,P.10UF-J-50V

C4923 ECA1VM470B CAP,E 47UF/35V

C4924 ECA1VM470B CAP,E 47UF/35V

C4925 ECQB1H104JF3 CAP,P.10UF-J-50V

C4930 EEUFC1E470B CAP,E 47UF-25V

DIODES

D006 MA4300HTA DIODE

D009 MA165TA5VT DIODE, SWITCHING

D010 MA4030MTA DIODE

D014 LN21RCPHL DIODE, LED

D402 MA4270MTA DIODE

D405 ERA15-02V3 DIODE

D406 ERA15-02V3 DIODE

D407 MA165TA5VT DIODE, SWITCHING

D408 MA165TA5VT DIODE , SWITCHING

D410 MA165TA5VT DIODE, SWITCHING

D411 MA165TA5VT DIODE, SWITCHING

D412 MA165TA5VT DIODE, SWITCHING

D452 MA165TA5VT DIODE , SWITCHING

D468 MA4062MTA DIODE, ZENER

D477 MA29W-BTA DIODE

D501 D1NL40V70 DIODE

REF NO. PART NO. DESCRIPTION

D502 MA4150MTA DIODE

D503 B0KZ00000001 DIODE

D505 MA4033MTA DIODE

D509 MA165TA5VT DIODE, SWITCHING

D510 MA4082MTA DIODE

D511 D1NL40V70 DIODE

D512 D1NL40V70 DIODE

D515 D1NL40V70 DIODE

D516 MA4051LTA DIODE

D517 D1NL40V70 DIODE

D518 D1NL40V70 DIODE

D520 MA167TA5VT DIODE, SWITCHING

D550 RU3NLFA1 DIODE

D703 D1NL40V70 DIODE

D708 MA4150MTA DIODE

D711 ERA22-06V3 DIODE

D751 MA165TA5VT DIODE, SWITCHING

D761 MA165TA5VT DIODE, SWITCHING

D801 D6SB80 DIODE

D802 MA700ATA DIODE

D803 D4DDF1R50001 PTC 5-OHM

D806 AU01ZV0 DIODE

D807 MA165TA5VT DIODE, SWITCHING

D809 ERZV10D391 DIODE

D811 ERA15-01V3 DIODE, RECTIFIER

D814 MA165TA5VT DIODE, SWITCHING

D815 MA165TA5VT DIODE, SWITCHING

D816 MA165TA5VT DIODE, SWITCHING

D817 MA4220LTA DIODE , ZENER

D818 MA4200MTA DIODE

D824 TMPG10G3 DIODE

D825 FMGG2CS DIODE

D826 MA6D90 DIODE

D827 S2L20UP1518 DIODE

D828 MA6D90 DIODE

D829 S2L20UP1518 DIODE

D830 MA6D90 DIODE

D831 MA165TA5VT DIODE, SWITCHING

D832 MA165TA5VT DIODE, SWITCHING

D833 MA4110HTA DIODE, ZENER

D834 AU02ZV0 DIODE

D836 AU02ZV0 DIODE

D839 MA4039MTA DIODE, ZENER

D840 MA165TA5VT DIODE, SWITCHING

D845 MA165TA5VT DIODE, SWITCHING

D846 MA4180MTA DIODE

D847 MA4300MTA DIODE

D848 MA165TA5VT DIODE, SWITCHING

D850 MA165TA5VT DIODE, SWITCHING

D851 MA165TA5VT DIODE, SWITCHING

D861 TVSA81004V3 DIODE

PARTS LIST

179-02

-27-

Parts List

Page 28

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When

replacingany of thesecomponents use only manufacturer’sspecified parts.

REF NO. PART NO. DESCRIPTION

D862 TVSA81004V3 DIODE

D874 RK34LFC4 DIODE

D875 RK34LFC4 DIODE

D876 MA165TA5VT DIODE , SWITCHING

D877 MA165TA5VT DIODE, SWITCHING

D878 RK34LFC4 DIODE

D881 TMPG10G3 DIODE

D883 TMPG10G3 DIODE

D884 TMPG12G3 DIODE

D889 MA165TA5VT DIODE , SWITCHING

D893 MA165TA5VT DIODE, SWITCHING

D894 MA165TA5VT DIODE , SWITCHING

D898 MA165TA5VT DIODE, SWITCHING

D899 MA165TA5VT DIODE , SWITCHING

D954 MA165TA5VT DIODE, SWITCHING

D957 MA165TA5VT DIODE , SWITCHING

D1001 LN81RPH DIODE

D1501 MA4075HTA DIODE

D1503 MA4030HTA DIODE

D1504 MA4020HTA DIODE

D1505 RP1HLFA5 DIODE

D1508 MA165TA5V T DIODE, SWITCHING

D1509 AU02AV0 DIODE

D1510 AU02AV0 DIODE

D1513 MA165TA5V T DIODE, SWITCHING

D2320 MA4390MTA DIODE

D2321 MA4390MTA DIODE

D2322 MA152KTX DIODE

D2324 MA152KTX DIODE

D2325 MA152KTX DIODE

D2326 MA4270MTA DIODE

D2327 MA4270MTA DIODE

D3051 MA3110MTX DIODE, ZENER

D3052 MA3110MTX DIODE, ZENER

D3053 MA3110MTX DIODE, ZENER

D3054 MA3110MTX DIODE, ZENER

D3055 MA3110MTX DIODE, ZENER

D3056 MA3110MTX DIODE, ZENER

D3057 MA3110MTX DIODE, ZENER

D3058 MA3110MTX DIODE, ZENER

D3059 MA3110MTX DIODE, ZENER

D3060 MA3110MTX DIODE, ZENER

D3061 MA3110MTX DIODE, ZENER

PARTS LIST

D3062 MA3110MTX DIODE, ZENER

D3063 MA3110MTX DIODE, ZENER

D3064 MA3110MTX DIODE, ZENER

D3065 MA3110MTX DIODE, ZENER

D3066 MA3110MTX DIODE, ZENER

D3067 MA3110MTX DIODE, ZENER

D3068 MA3110MTX DIODE, ZENER

D3069 MA3110MTX DIODE, ZENER

REF NO. PART NO. DESCRIPTION

D3070 MA3110MTX DIODE , ZENER

D3071 MA3110MTX DIODE, ZENER

D3072 MA3110MTX DIODE , ZENER

D3073 MA3110MTX DIODE, ZENER

D3074 MA3110MTX DIODE , ZENER

D3075 MA3110MTX DIODE, ZENER

D3077 MA3110MTX DIODE , ZENER

D3078 MA3110MTX DIODE, ZENER

D3079 MA3110MTX DIODE , ZENER

D3080 MA3110MTX DIODE, ZENER

D3081 MA3110MTX DIODE , ZENER

D3082 MA3110MTX DIODE, ZENER

D3084 MA3110MTX DIODE , ZENER

D3085 MA3110MTX DIODE, ZENER

D3086 MA3110MTX DIODE , ZENER

D3087 MA3110MTX DIODE, ZENER

D3088 MA3110MTX DIODE , ZENER

D3151 MA4140MTA DIODE

D3152 MA4140MTA DIODE

D3153 MA4140MTA DIODE

D3154 MA4140MTA DIODE

D3155 MA4140MTA DIODE

D3156 MA4140MTA DIODE

D3159 MA4140MTA DIODE

D3160 MA4140MTA DIODE

D3809 ERZV07D361 VARISTOR

D3824 MA4120MTA DIODE , ZENER

D3825 MA4120MTA DIODE, ZENER

D3826 MA4120MTA DIODE , ZENER

D3831 B0HALP000002 DIODE

D3832 B0HALP000002 DIODE

D3833 B0HALP000002 DIODE

D3834 B0HALP000002 DIODE

D3835 B0HALP000002 DIODE

D3836 B0HALP000002 DIODE

D4805 MA165TA5VT DIODE, SWITCHING

D4806 MA165TA5VT DIODE, SWITCHING

FUSES

F801 XBA2A00101 FUSE 6.3A 125V

INTEGRATED CIRCUITS

IC432 AN6562S-E1 V SAW

IC433 AN6562S-E1 VERTICAL DRIVE AMP

IC451 LA7876N VERTICAL OUT

IC500 LA6510 RASTER SHIFT

IC511 AN6914S-E1 RASTER POSITION AMP

IC751 AN6914S-E1 INNER PIN AMP

IC752 IR2117 PCC AMP

IC801 AN8029 MAIN REG

IC802 SE130NLF4 ERROR AMP

IC804 TVSS1WBS20 DIODE, BRIDGE RECTIFIER

IC811 PC123FY2 OPTOISOLATOR

Parts List

-28-

179-02

Page 29

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF.

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

IC871 SI-8050S 5V REGULATOR

IC872 C0DAAZG00006 2.5V REGULATOR

IC875 SI-8090S 9V REGULATOR

IC876 PQ12RD1B 12V REGULATOR

IC1004 TVR2AJ144S

IC1004 TVR2AJ146S

IC1501 AN6562S-E1 HHS AMP

IC2201 AN5849S-E1V MTS AUDIO

IC2302 TDA7490 AUDIO AMP L/R

IC2304 BA15218F-E2 VAO AUDIO AMP

IC2451 C1BB00000621 BBE AUDIO

IC3003 CX A2069Q SW AUDIO VIDEO

IC3801 C1AA00000648 RED AMP

IC3802 C1A A00000648 GREEN AMP

IC3803 C1AA00000648 BLUE AMP

IC4803 LA6510 LANDING CORRECTION

IC4804 LA6510 TILT CORRE CTION

IC4805 CXA2021S H-TRAPEZOID CONTROL

ADJUSTED MPU EEPROM FOR

DG-BOARD TNPA2345

ADJUSTED MPU EEPROM FOR

DG-BOARD TNPA2345AC

COILS

L009 ELESN330JA COIL, PEAKING 33UH

L010 ELESN330JA COIL, PEAKING 33UH

L011 ELESN330JA COIL, PEAKING 33UH

L012 ELESN330JA COIL, PEAKING 33UH

L401 EXCELSA39V FERRITE BEAD

L431 ELESN101KA COIL, PEAKING 100UH

L432 EXCELDR25V FERRITE BEAD

L500 TALL08TR56MA COIL

L503 TALL13N103JB COIL

L506 EXCELSA24T FERRITE BEAD

L551 ELH5L7720 COIL

L553 ELH5L8110 COIL

L711 ELESN100KA COIL, PEAKING 10UH

L751 ELC18B121F COIL

L752 TALFP15B152K COIL

L759 EXCELSA35T FERRITE BEAD

L801 G0B650H00002 COIL

L802 G0B332H00002 COIL

L803 G0B332H00002 COIL

L804 G0B102H00009 COIL

L807 EXCELDR35V FERRITE BEAD

L812 EXCELSA35B FERRITE BEAD

L813 EXCELSA39E FERRITE BEAD

L814 TALL08T101KA COIL, PEAKING

L815 EXCELSA39E FERRITE BEAD

L816 EXCELSA39E FERRITE BEAD

L819 EXCELSA24T FERRITE BEAD

L820 EXCELSA24T FERRITE BEAD

L821 EXCELDR35V FERRITE BEAD

L824 EXCELDR35V FERRITE BEAD

L825 G0A151D00002 COIL

179-02

REF NO. PART NO. DESCRIPTION

L826 TLUADTB820K COIL

L827 TALL08T470KA COIL

L829 EXCELDR35V FERRITE BEAD

L850 ELESN 101JA COIL, PEAKING 100UH

L875 G0A151ZA0004 COIL

L876 G0A221ZA0004 COIL

L878 G0A221ZA0004 COIL

L882 G0A470F00004 COIL

L885 TALL08T220KA TRANSFORMER, LINE FILTER

L886 TALL08T221KA COIL

L887 G0A330G00010 COIL

L888 EXCELSA24T FERRI TE BEAD

L889 EXCELSA24T FERRITE BEAD

L890 EXCELSA24T FERRI TE BEAD

L891 G0A101E00003 COIL

L892 G0A101E00003 COIL

L904 TLTABT560K COIL

L957 EXCELSA35T FERRI TE BEAD

L1501 TALFP15B222K COIL

L2201 ELESN100JA COIL, PEA KI N G 10UH

L2331 ELC12E390 COIL

L2332 ELC12E390 COIL

L2334 EXCELDR35V FERRITE BEAD

L2335 EXCELDR35V FERRITE BEAD

L2336 G0B800H00001 COIL

L2337 G0B800H00001 COIL

L2341 G0A330G00010 COIL

L2342 G0A330G00010 COIL

L3001 EXCELSA35T FERRITE BEAD

L3801 TALV35VB1R0J COIL, PEAKING

L3802 TALV35VB1R0J COIL, PEAKING

L3803 TALV35VB1R0J COIL, PEAKING

L3810 EXCELSA24T FERRITE BEAD

TRANSISTORS

Q007 2SD601ARTX TRANSISTOR

Q404 2SD601ASTX TRANSISTOR

Q405 2SA1309ATA TRANSISTOR

Q406 2SD601ARTX TRANSISTOR

Q501 2SK2962TPE6 TRANSISTOR

Q502 2SK2847LBMAT TRANSISTOR

Q503 2SD601ARTX TRANSISTOR

Q509 2SC1473QR TRANSISTOR

Q510 2SC1473QR TRANSISTOR

Q512 2SC1685QRSTA TRANSISTOR

Q513 2SD601ARTX TRANSISTOR

Q551 2SC5612LB228 TRANSISTOR

Q562 2SC1473QRTA TRANSISTOR

Q751 2SK2538000LB TRANSISTOR

Q752 2SD601ARTX TRANSISTOR

Q754 2SD601ARTX TRANSISTOR

Q755 FS10KM-06-AV TRANSISTOR

-29-

PARTS LIST

Parts List

Page 30

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When

replacingany of thesecomponents use only manufacturer’sspecified parts.

REF NO. PART NO. DESCRIPTION

Q801 2SK2917LB TRANSISTOR

Q802 2SC1685QRSTA TRANSISTOR

Q803 2SC1685QRSTA TRANSISTOR

Q804 2SA1309ATA TRANSISTOR

Q805 2SC1685QRSTA TRANSISTOR

Q806 2SC1685QRSTA TRANSISTOR

Q808 2SC1685QRSTA TRANSISTOR

Q854 2SA19610QAHW TRANSISTOR

Q860 2SD601ARTX TRANSISTOR

Q861 2SD601ARTX TRANSISTOR

Q862 2SD601ARTX TRANSISTOR

Q863 2SD601ARTX TRANSISTOR

Q880 2SB709ARTX TRANSISTOR

Q902 2SC1685QRSTA TRANSISTOR

Q951 2SA1309ATA TRANSISTOR

Q952 2SC1685QRSTA TRANSISTOR

Q955 2SB1569AF51E TRANSISTOR

Q956 2SD2400AF51E TRANSISTOR

Q961 2SB621ATA TRANSISTOR

Q963 2SD592A TRANSISTOR

Q1501 B1DEDR000005 TRANSISTOR

Q1502 B1DEDR000005 TRANSISTOR

Q1503 2SC 5460LB TRANSISTOR

Q1504 2SC1685Q RSTA TRANSISTOR

Q1505 2SC 1685QRSTA TRANSISTOR

Q1506 2SD601ARTX TRANSISTOR

Q2301 2SB709ARTX TRANSISTOR

Q2302 2SB709ARTX TRANSISTOR

Q2304 2SD601ARTX TRANSISTOR

Q2306 2SD601ARTX TRANSISTOR

Q2307 2SB709ARTX TRANSISTOR

Q2313 2SD601ARTX TRANSISTOR

Q2314 2SD601ARTX TRANSISTOR

Q2334 2SD601ARTX TRANSISTOR

Q2335 2SD601ARTX TRANSISTOR

Q2336 2SB709ARTX TRANSISTOR

Q2337 2SD601ARTX TRANSISTOR

Q2338 2SD601ARTX TRANSISTOR

Q2339 2SD601ARTX TRANSISTOR

Q2340 2SB709ARTX TRANSISTOR

Q2451 2SD601ARTX TRANSISTOR

Q2452 2SD601ARTX TRANSISTOR

Q3026 2SB709ARTX TRANSISTOR

PARTS LIST

Q3027 2SD601ARTX TRANSISTOR

Q3157 2SC 1685QRSTA TRANSISTOR

Q3158 2SC1685Q RSTA TRANSISTOR

Q4901 2SC 1685QRSTA TRANSISTOR

RELAYS

RL451 TSE10814 RELAY

RL801 TSEH8011 RELAY

RL802 TSE10814 RELAY

REF NO. PART NO. DESCRIPTION

RL803 TSEH0005 RELAY

RL804 K6B1CGA00075 RELAY

RESISTORS

R050 ERJ6GEYJ101V RES ,M 100-J-1/10W

R051 ERJ6GEYJ101V RES,M 100- J-1/10W

R052 ERJ6GEYJ101V RES ,M 100-J-1/10W

R053 ERJ6GEYJ101V RES,M 100- J-1/10W

R078 ERJ6GEYJ103V RES ,M 10K-J-1/10W

R079 ERJ6GEYJ223V RES,M 22K -J-1/10W

R080 ERJ6GEYJ220V RES ,M 22-J-1/10W

R081 ERDS2TJ220T RES,C 22-J-1/4W

R407 ERJ6GEYJ473V RES ,M 47K-J-1/10W

R408 ERDS2TJ272T RES,C 2.7K-J-1/4W

R409 ERJ6GEYJ563V RES ,M 56K-J-1/10W

R410 ERJ6GEYJ224V RES,M 220K -J-1/10W

R411 ERJ6GEYJ332V RES,M 3. 3 K-J-1/10W

R412 ERJ6GEYJ472V RES,M 4.7K-J-1/10W

R413 ERDS2TJ104T RES,C 100K-J-1/4W

R414 ERX1SJR82P RES,M .82-J-1/2W

R415 ERG3FJ331H RES,M 330-J-3W

R417 ERJ6GEYJ272V RES,M 2.7K-J-1/10W

R418 ERJ6GEYJ473V RES ,M 47K-J-1/10W

R419 ERJ6GEYJ472V RES,M 4.7K-J-1/10W

R420 ERJ6GEYJ272V RES,M 2.7 K-J-1/10W

R421 ERJ6ENF1602V RES,M 16K-F-1/4W

R422 ERJ6ENF2001V RES,M 2K-F-1/10W

R423 ERJ6GEYJ103V RES,M 10K -J-1/10W

R424 ERJ6GEYJ472V RES,M 4.7 K-J-1/10W

R425 ERDS1FJ1R0P RES,C 1.0-J-1/2W

R426 ERJ6GEYJ123V RES ,M 12K-J-1/10W

R427 ERJ6GEYJ102V RES,M 1K-J-1/10W

R428 ER0S2THF9761 RES,M 9.76K-F-1/4W

R429 ERJ6GEYJ182V RES,M 1.8K-J-1/10W

R430 ER0S2THF1500 RES,M 150-F-1/4W

R431 ER0S2THF2000 RES,M 200-F-1/4W

R434 ERX12SJ1R8P RES,M 1.8-J-1/2W

R435 ERX12SJ2R2P RES,M 2.2-J-1/2W

R436 ERJ6GEYJ103V RES ,M 10K-J-1/10W

R440 ERG1SJ102P RES,M 1K-J-1W

R441 ERX1SJ1R0P RES,M 1.0-J-1W

R444 ERJ6GEYJ103V RES,M 10K -J-1/10W

R445 ERX1SJ1R0P RES,M 1.0-J-1W

R447 ERJ6ENF6800V RES,M 680-F-1/10W

R449 ERJ6ENF3901V RES,M 3.9K-F-1/10W

R464 ERJ6GEYJ103V RES,M 10K -J-1/10W

R465 ERJ6ENF2201V RES,M 2.2K-F-1/10W

R470 ERJ6GEYJ683V RES,M 68K -J-1/10W

R471 ERJ6ENF1003V RES,M 100K-F-1/10W

R472 ERJ6ENF2002V RES,M 20K-F-1/10W

R476 ERJ6GEYJ823V RES ,M 82K-J-1/10W

R479 ERJ6GEYJ821V RES,M 820- J-1/10W

Parts List

-30-

179-02

Page 31

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF.

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

R481 ERJ6GEYJ102V RES,M 1K-J-1/10W

R495 ERJ6ENF2203V RES,M 220K-J-1/10W

R501 ERDS2TJ104T RES,C 100K-J-1/4W

R502 ERDS2TJ680T RES,C 68-J-1/4W

R503 ERG3FJ181H RES,M 180-J-3W

R504 ERG1SJ102P RES,M 1K-J-1W

R505 ERG1SJ100P RES,M 10-J-1W

R510 ERG2FJ331H RES,M 330-J-2W

R512 ERJ6GEYJ103V RES,M 10K-J-1/10W

R513 ERC12GK103D RES,C 10K-K-1/2W

R514 ER0S2THF3242 RES,M 32.4K-F-1/4W

R515 ER0S2THF2612 RES,M 26.1K-F-1/4W

R516 ERDS2TJ101T RES,C 100-J-1/4W

R517 ERG1SJ103P RES,M 10K-J-1W

R518 ERDS1FJ1R5T RES,C 1.5-J-1/2W

R520 ERQ14AJ2R2E RES,F 2.2-J-1/4W

R521 ERJ6ENF6041V RES,M 6.04K-F-1/10W

R522 ERJ6ENF2321V RES,M 2.32K-F-1/10W

R524 EVMEAGA00B14 CONTROL 10K

R525 ERJ6GEYJ103V RES,M 10K-J-1/10W

R526 ERQ12HJ1R0P RES,F 1.0-J-1/2W

R527 ERDS2TJ472T RES,C 4.7K-J-1/4

R528 ERQ1CJP120S RES,F 12-J-1W

R529 ERDS2TJ273T RES,C 27K-J-1/4W

R530 ERDS2TJ123T RES,C 12K-J-1/4W

R531 ERDS2TJ221T RES,C 220-J-1/4W

R532 ERDS1FJ1R0P RES,C 1.0-J-1/2W

R533 ERDS1FJ1R0P RES,C 1.0-J-1/2W

R534 ER0S2THF9102 RES,M 91K-F-1/4W

R535 ERJ6GEYJ562V RES,M 5. 6K-J-1/10W

R536 ERDS2TJ101T RES,C 100-J-1/4W

R538 ERJ6GEYJ101V RES,M 100- J-1/10W

R540 ERJ6GEYJ272V RES,M 2.7 K-J-1/10W

R541 ERJ6GEYJ103V RES,M 10K-J-1/10W

R550 ER0S2THF5361 RES,M 5.36K-F-1/4W

R560 ERJ6GEYJ101V RES,M 100- J-1/10W

R561 ERJ6GEYJ103V RES,M 10K-J-1/10W

R562 ERJ6GEYJ104V RES,M 100K -J-1/10W

R586 ERJ6GEYJ103V RES,M 10K-J-1/10W

R587 ERJ6GEYJ101V RES,M 100- J-1/10W

R588 ERJ6GEYJ103V RES,M 10K-J-1/10W

R589 ERJ6GEYJ101V RES,M 100- J-1/10W

R595 ERDS2TJ273T RES,C 27K-J-1/4W

R701 ERJ6GEYJ153V RES,M 15K-J-1/10W

R702 ERJ6GEYJ101V RES,M 100-J-1/10W

R703 ERJ6GEYJ101V RES,M 100- J-1/10W

R704 ERJ6GEYJ202V RES,M 2K-J-1/10W

R705 ERJ6GEYJ103V RES,M 10K-J-1/10W

R706 ERJ6GEYJ152V RES,M 1.5 K-J-1/10W

R707 ERJ6GEYJ102V RES,M 1K-J-1/10W

R708 ERJ6GEYJ183V RES,M 18K-J-1/10W

REF NO. PART NO. DESCRIPTION

R709 ERDS1FJ680T RES,C 68-J-1/2W

R711 ERJ6GEYJ682V RES,M 6. 8 K-J-1/10W

R712 ERJ6GEYJ102V RES,M 1K-J-1/10W

R714 ERJ6GEYJ473V RES ,M 47K-J-1/10W

R715 ERJ6GEYJ103V RES,M 10K -J-1/10W

R717 ERF5AK4R7H RES,W 4.7-K-5W

R718 ERJ6GEYJ102V RES,M 1K-J-1/10W

R720 ERJ6GEYJ152V RES,M 1.5 K-J-1/10W

R787 ERQ14AJ220P RES,F 22-J-1/4W

R788 ERDS2TJ473T RES,C 47K-J-1/4W

R800 ERU5TCK1R5T RES,F 1.5-K-5W

R801 ERC14GK824D RES,C 820K-K-1/4W

R803 ERDS2TJ680T RES,C 68-J-1/4W

R804 ERDS2TJ331T RES,C 330-J-1/4W

R806 ERDS2TJ473T RES,C 47K-J-1/4W

R807 ERDS2TJ820T RES,C 82-J-1/4W

R808 ERDS2TJ680T RES,C 68-J-1/4W

R809 ERDS2TJ472T RES,C 4.7K-J-1/4

R810 ERDS2TJ473T RES,C 47K-J-1/4W

R811 ERDS2TJ472T RES,C 4.7K-J-1/4

R812 ERDS2TJ473T RES,C 47K-J-1/4W

R813 ERDS1FJ152T RES,C 1.5K-J-1/2W

R814 ERG3FJ223 RES,M 22K-J-3W

R815 ERDS2TJ331T RES,C 330-J-1/4W

R816 ERDS2TJ471T RES,C 470-J-1/4W

R817 ER0S2THF1371 RES,M 1.37K-F-1/4W

R818 ERDS2TJ220T RES,C 22-J-1/4W

R819 ERDS1FJ390T RES,C 39-J-1/2W

R820 ERDS1FJ120T RES,C 12-J-1/2W

R821 ERX12SJ1R8P RES,M 1.8-J-1/2W

R822 ERX12SJ1R8P RES,M 1.8-J-1/2W

R823 ERDS2TJ102T RES,C 1K-J-1/4W

R824 ERDS2TJ153T RES,C 15K-J-1/4W

R825 ERDS2TJ104T RES,C 100K-J-1/4W

R826 ERDS2TJ103T RES,C 10K-J-1/4W

R828 ERDS2TJ103T RES,C 10K-J-1/4W

R829 ERJ6GEYJ103V RES,M 10K -J-1/10W

R830 ERJ6GEYJ272V RES,M 2.7 K-J-1/10W

R831 ERDS2TJ332T RES,C 3.3K-J-1/4W

R832 ERD75TAJ825 RES,C 8.2MEG-J-3/4W

R833 ERDS2TJ104T RES,C 100K-J-1/4W

R834 ERDS2TJ104T RES,C 100K-J-1/4W

R835 ERDS2TJ101T RES,C 100-J-1/4W

R836 ERJ6GEYJ102V RES,M 1K -J-1/10W

R837 ERDS2TJ222T RES,C 2.2K-J-1/4W

R838 ERDS1FJ330T RES,C 30-J-1/2W

R839 ERDS2TJ222T RES,C 2.2K-J-1/4W

R840 ERDS2TJ470T RES,C 47-J-1/4W

R841 ERDS2TJ104T RES,C 100K-J-1/4W

R842 ERDS2TJ223T RES,C 22K-J-1/4W

R843 ERDS2TJ681T RES,C 680-J-1/4W

PARTS LIST

179-02

-31-

Parts List

Page 32

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When

replacingany of thesecomponents use only manufacturer’sspecified parts.

REF NO. PART NO. DESCRIPTION

R844 ERDS2TJ104T RES,C 100K-J-1/4W

R845 ERDS2TJ332T RES,C 3.3K-J-1/4W

R846 ERJ6GEYJ182V RES,M 1.8K-J-1/10W

R847 ERDS1FJ473T RES,C 47K-J-1/2W

R852 ERDS1FJ562T RES,C 56K-J-1/2W

R854 ERDS2TJ102T RES,C 1K-J-1/4W

R855 ERDS2TJ913T RES,C 91K-J-1/4W

R856 ERDS2TJ123T RES,C 12K-J-1/4W

R857 ERX1SJ1R0P RES,M 1. 0-J-1W

R858 ERX1SJ1R0P RES,M 1.0-J- 1 W

R859 ERDS2TJ272T RES,C 2.7K-J-1/4W

R860 ERDS1FJ102T RES,C 1K-J-1/2W

R861 ERX12SJR22P RES,M .22-J-1/2W

R862 ERX12SJR22P RES,M .22-J-1/2W

R863 ERX12SJR22P RES,M .22-J-1/2W

R865 ERDS2TJ102T RES,C 1K-J-1/4W

R867 ERJ6GEYJ101V RES,M 100-J-1/10W

R868 ERJ6GEYJ223V RES,M 22K-J-1/10W

R869 ERJ6GEYJ101V RES,M 100-J-1/10W

R870 ERJ6GEYJ223V RES,M 22K-J-1/10W

R875 ERJ6GEYJ473V RES,M 47K-J-1/10W

R876 ERJ6GEYJ393V RES,M 39K-J-1/10W

R877 ERJ6GEYJ473V RES,M 47K-J-1/10W

R878 ERJ6GEYJ393V RES,M 39K-J-1/10W

R888 ERJ6ENF1501V RES,M 1.5K-F-1/10W

R889 ERJ6ENF1581V RES,M 158-F-1/10W

R890 ERJ6ENF30R0V RES,M 30.0-F-1/10W

R891 ERJ6ENF5600V RES,M 560-F-1/10W

R894 ERJ6GEYJ103V RES,M 10K-J-1/10W

R895 ERJ6GEYJ104V RES,M 100K-J-1/10W

R896 ERJ6GEYJ473V RES,M 47K-J-1/10W

R899 ERG1SJ273P RES,M 27K-J-1W

R902 ERDS2TJ223T RES,C 22K-J-1/4W

R904 ERDS2TJ101T RES,C 100-J-1/4W

R905 ERDS2TJ223T RES,C 22K-J-1/4W

R906 ERDS2TJ472T RES,C 4.7K-J-1/4

R908 ERDS2TJ471T RES,C 470-J-1/4W

R953 ERQ14AJ101P RES,F 100-J-1/4W

R954 ERDS2TJ472T RES,C 4.7K-J-1/4

R961 ERQ1CJP331S RES,F 330-J-1W

R962 ERDS2TJ822T RES,C 8.2K-J-1/4W

R964 ERDS2FJ561T RES,C 560-J-1/4W

R965 ERDS2TJ683T RES,C 68K-J-1/4W

PARTS LIST

R966 ERG3FJ331H RES,M 330-J-3W

R967 ERDS2TJ822T RES,C 8.2K-J-1/4W

R968 ERDS2FJ561T RES,C 560-J-1/4W

R969 ERQ14AJ120P RES,F 12-J-1/4W

R970 ERQ14AJ2R2P RES,F 2.2-J-1/4W

R971 ERQ14AJ2R2P RES,F 2.2-J-1/4W

R972 ERQ14AJ120P RES,F 12-J-1/4W

R975 ERDS2TJ683T RES,C 68K-J-1/4W

REF NO. PART NO. DESCRIPTION

R976 ERDS2TJ100T RES,C 10-J-1/4W

R977 ERDS2TJ100T RES,C 10-J-1/4W

R991 ERDS2TJ470T RES,C 47-J-1/4W

R995 ERDS2TJ150T RES,C 15-J-1/4W

R1025 ERJ6GEYJ101V RES,M 100-J-1/10W

R1026 ERJ6GEYJ101V RES,M 100-J-1/10W

R1051 ER0S2THF1002 RES,M 10K-F-1/4W

R1052 ERDS2TJ222T RES,C 2.2K-J-1/4W

R1053 ERDS2TJ222T RES,C 2.2K-J-1/4W

R1054 ERDS2TJ332T RES,C 3.3K-J-1/4W

R1055 ERDS2TJ512T RES,C 5.1K-J-1/4W

R1056 ERDS2TJ912T RES,C 9.1K-J-1/4W

R1057 ERDS2TJ223T RES,C 22K-J-1/4W

R1058 ERDS2TJ103T RES,C 10K-J-1/4W

R1059 ERDS2TJ102T RES,C 1K-J-1/4W

R1060 ERDS2TJ470T RES,C 47-J-1/4W

R1061 ERDS2TJ101T RES,C 100-J-1/4W

R1062 ERDS2TJ182T RES,C 1.8K-J-1/4W

R1501 ERJ6GEYJ102V RES,M 1K-J-1/10W

R1503 ERJ6GEYJ222V RES,M 2.2K-J-1/10W

R1504 ERJ6GEYJ102V RES,M 1K-J-1/10W

R1505 ERJ6GEYJ103V RES,M 10K-J-1/10W

R1506 ERJ6GEYJ102V RES,M 1K-J-1/10W

R1507 ERJ6GEYJ102V RES,M 1K-J-1/10W

R1508 ERJ6GEYJ332V RES,M 3.3K-J-1/10W

R1514 ERJ6GEYJ331V RES,M 330-J-1/10W

R1515 ERJ6GEYJ103V RES,M 10K-J-1/10W

R1521 ERDS2TJ104T RES,C 100K-J-1/4W

R1522 ERDS2TJ104T RES,C 100K-J-1/4W

R1523 ERDS2TJ104T RES,C 100K-J-1/4W

R1525 ERJ6GEYJ122V RES,M 1.2K-J-1/10W

R1526 ERJ6GEYJ101V RES,M 100-J-1/10W

R1527 ERC14GK334D RES,C 330K-K-1/4W

R1528 ERJ6GEYJ473V RES,M 47K-J-1/10W

R1529 ERG1SJ332P RES,M 3300-J-1W

R1530 ERG3FJ331H RES,M 560-J-3W

R1531 ERG3FJ681H RES,M 680-J-3W

R1532 ERC12GK104D RES,C 100K-K-1/2W

R1533 ERDS2TJ125T RES,C 1.2M-J-1/4W

R1534 ERDS2TJ125T RES,C 1.2M-J-1/4W

R1535 ERJ6GEYJ203V RES,M 20K-J-1/10W

R1536 ERG2FJ123H RES,M 12K-J-2W

R1537 ERJ6GEYJ101V RES,M 100-J-1/10W

R1538 ERJ6GEYJ103V RES,M 10K-J-1/10W

R1539 ERJ6GEYJ103V RES,M 10K-J-1/10W

R1540 ERJ6GEYJ560V RES,M 56-J-1/10W

R2203 ERJ6GEYJ751V RES,M 750-J-1/10W

R2206 ERJ6GEYJ102V RES,M 1K-J-1/10W

R2207 ERJ6GEYJ102V RES,M 1K-J-1/10W

R2221 ERJ6GEYJ101V RES,M 100-J-1/10W

R2301 ERJ6GEYJ102V RES,M 1K-J-1/10W

Parts List

-32-

179-02

Page 33

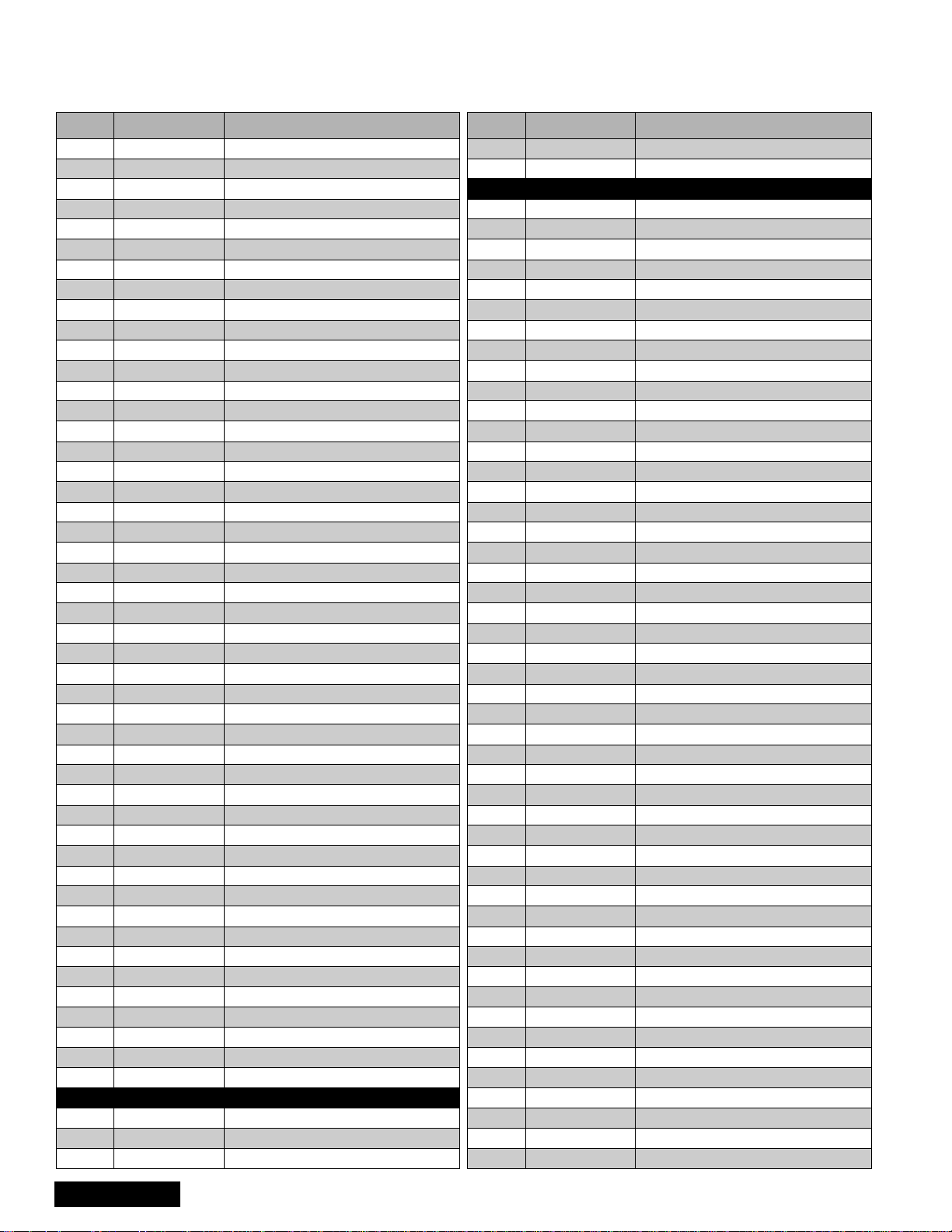

REPLACEMENT PARTS LIST

Models: CT-36HL42F, CT-36HL42CF, CT-36HL42UF.

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

R2302 ERJ6GEYJ392V RES,M 3.9K-J-1/10W

R2303 ERJ6GEYJ271V RES,M 270-J-1/10W

R2304 ERJ6GEYJ473V RES,M 47K-J-1/10W

R2305 ERJ6GEYJ223V RES,M 22K-J-1/10W

R2307 ERJ6GEYJ223V RES,M 22K-J-1/10W

R2308 ERJ6GEYJ183V RES,M 18K-J-1/10W

R2309 ERJ6GEYJ103V RES,M 10K-J-1/10W

R2313 ERJ6GEYJ102V RES,M 1K-J-1/10W