Panasonic CT-36SL13G, CT-3663G, CT-32SL13G, CT-36SC13G, CT-32SC13G Schematic

...

36sl13g.html

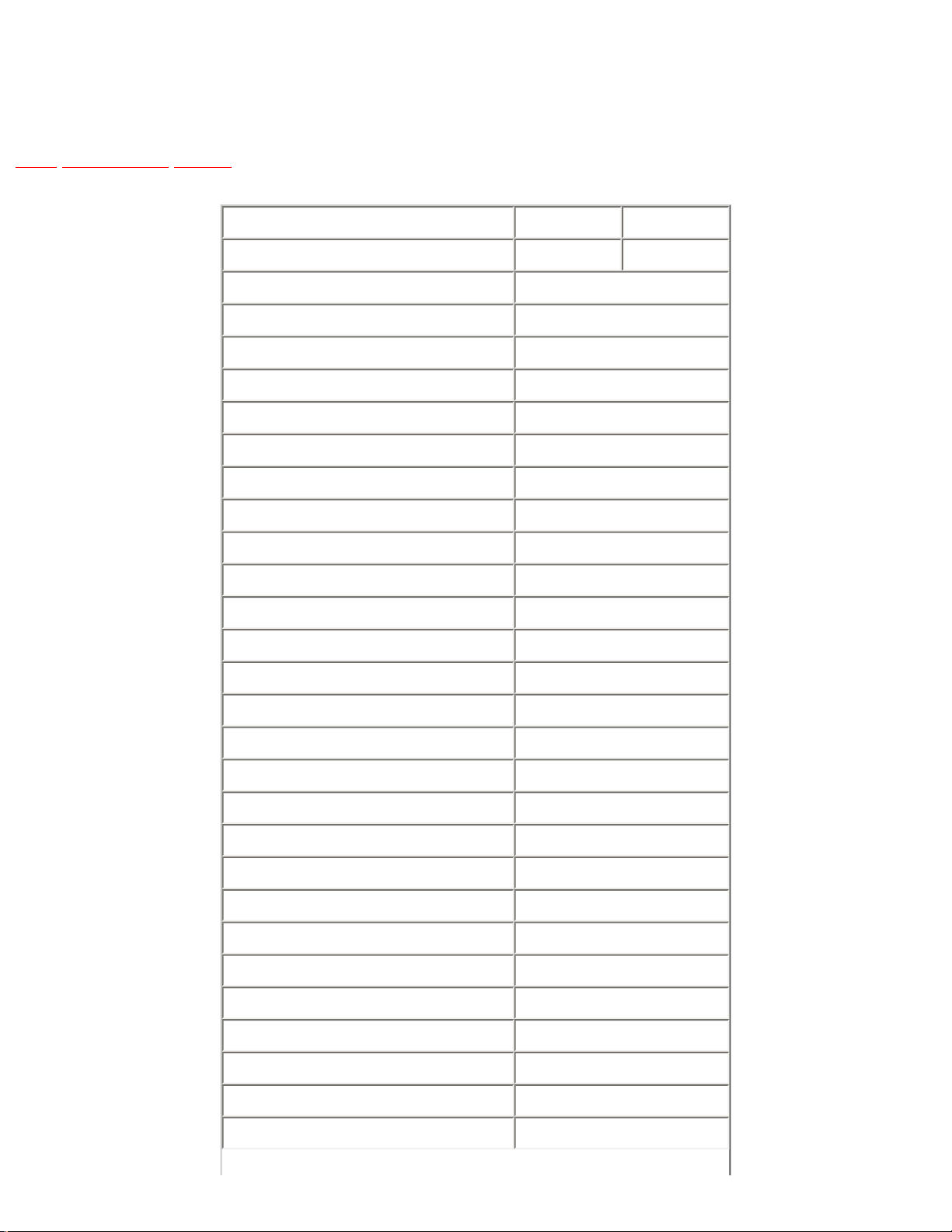

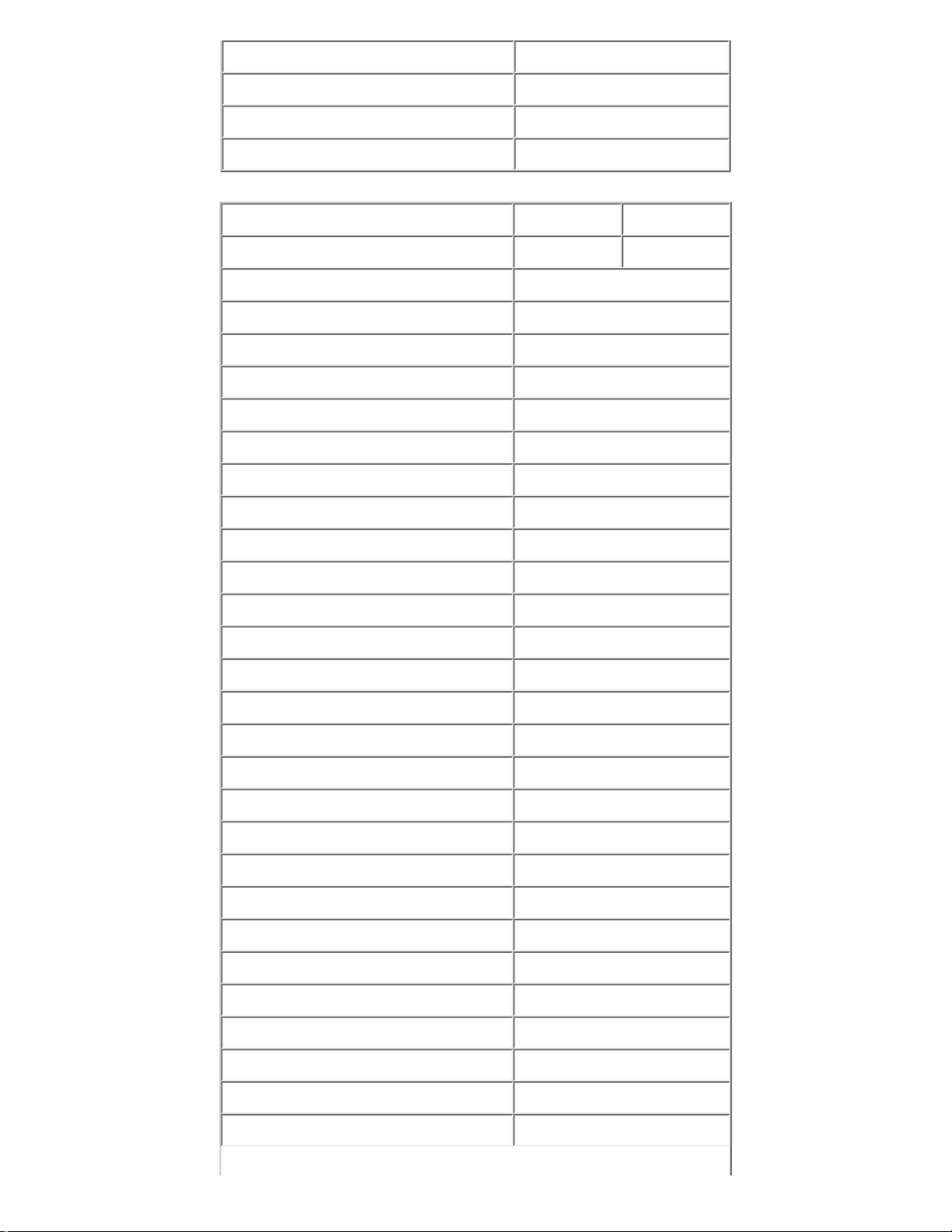

Table Of Contents

COVER

1 Safety precautions

2 Service notes

2.1 X-Ray Protection Circuit Check& Adjustments

3 EEPROM replacement

4 About lead free solder (PbF)

5 Receiver feature table

6 Board description table

7 TV Location of controls

8 Location of controls (EUR7613Z60 remote)

9 Location of controls (EUR7713010 remote)

10 Dissasembly for service

10.1 Disassembly for CRT replacement

11 Chassis service adjustment procedures

12 Purity and convergence procedure

12.1 DYNAMIC CONVERGENCE ADJUSTMENT

12.2 Permalloy convergence corrector strip (Part No. 0FMK014ZZ)

12.3 DAF adjustment(Dynamic focus adjustment)

13 Service mode (electronic adjustments)

13.1 Service adjustment default values for items

13.2 Instructional flow chart for service mode

13.3 Instructional flow chart for service mode (continued).

14 Service adjustments (electronic controls)

14.1 Sub-Brightness and ContrastService DAC adjustment (BRIGH, CONT)

14.2 Color output adjustmentService DAC adjustment (COLOR, TINT)

14.3 Color output adjustmentService DAC adjustment(COLOR, TINT, B-Y_G)

14.4 Color temperature adjustment(B/W Tracking)Service DAC Adjust.(CUT R) (CUT G) (CUT B) (R DR) (B DR)

14.5 Deflection adjustments

14.5.1 H-Center adjustment

14.5.2 H-Width adjustment

14.5.3 Trapezoid adjustment

14.5.4 Parallelogram adjustment

14.5.5 E-W PCC balance adjustment

14.5.6 Vertical linearity(V-C), V-Size and V-Position adjustment

14.5.7 V-S Correction adjustment

14.6 MTS circuit adjustments

14.7 Clock adjustment (CLOCK)

14.8 Service Adjustments Mechanical Controls

15 Identification of Components

15.1 A-Board components

15.1.1 D-Board components

15.1.2 G-Board components

15.1.3 L-Board components

16 Reference for PDF colors

17 Conductor views

17.1 A-Board printed circuit 1 of 2

17.2 A-Board printed circuit 2 of 2

17.3 D-Board printed circuit 1 of 2

17.4 D-Board printed circuit 2 of 2

17.5 G-Board (SC models) printed circuit 1 of 2

17.6 G-Board (SC models) printed circuit 2 of 2

17.7 G-Board (SL models) printed circuit 1 of 2

17.8 G-Board (SL models) printed circuit 2 of 2

17.9 L-Board printed circuit

Service Manual

TOP NEXT

MTNC030729C1

B05

Color Television

● CT-36SL13G

CT-32SL13G

CT-36SC13G

CT-32SC13G

CT-3653G

NA10FL

Copyright 2003 Matsushita Electric Corporation of America. All rights reserved. Unauthorized copying and distribution is a

violation of law.

file:///C|/Documents and Settings/eDOK/Рабочий стол/NA10FL Ch_CT-36SL13G_32SL13G_36SC13G_32SC13G_3653G.htm (1 of 2)04.12.2008 23:59:58

36sl13g.html

17.10 K-Board printed circuit

18 Block diagrams

18.1 Video signal block diagram

18.2 Audio signal block diagram

19 Schematics

19.1 English schematic notes

19.2 Notas de esquemáticos en español

19.3 A-Board schematic TNP2AH052NIL/AA (1 of 3)

19.4 A-Board schematic TNP2AH052NIL/AA (2 of 3)

19.5 A-Board schematic TNP2AH052NIL/AA (3 of 3)

19.6 D-Board schematic TNP2AH053NIL/AB (1 of 2)

19.7 D-Board schematic TNP2AH053NIL/AB (2 of 2)

19.8 G-Board (SC models) schematic TNP2AA141 (1 of 2)

19.9 G-Board (SC models) schematic TNP2AA141 (2 of 2)

19.10 G-Board (SL models) schematic TNP2AA142AB (1 of 2)

19.11 G-Board (SL models) schematic TNP2AA142AB (2 of 2)

19.12 L-Board schematic TNPA1673AE (1 of 2)

19.13 L-Board schematic TNPA1673AE (2 of 2)

19.14 K-Board schematic TNP2AA143

19.15 Voltages

19.16 Waveforms

20 Parts Location

21 Parts List

21.1 Parts List Notes

21.2 Parts List

TOP NEXT

file:///C|/Documents and Settings/eDOK/Рабочий стол/NA10FL Ch_CT-36SL13G_32SL13G_36SC13G_32SC13G_3653G.htm (2 of 2)04.12.2008 23:59:58

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0000000000.html

Service Manual

TOP NEXT

MTNC030729C1

B05

Color Television

● CT-36SL13G

CT-32SL13G

CT-36SC13G

CT-32SC13G

CT-3653G

NA10FL

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0000000000.html (1 of 2)05.12.2008 0:00:05

TOP NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0000000000.html (2 of 2)05.12.2008 0:00:05

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html

1 Safety precautions

TOP PREVIOUS NEXT

General guidelines

An isolation transformer should always be used during the servicing of a receiver whose chassis is not

isolated from AC power line. Use a transformer of adequate power rating as this protects the technician

from accidents resulting in personal injuryfrom electrical shocks. It will also protect the receiver from

being damaged by accidental shorting that may occur during servicing.

When servicing, observe the original lead dress, especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of overheating.)

Always replace protective devices, such as fish paper, isolation resistors and capacitors, and shields after

servicing the receiver. Use only manufacturer’s recommended rating for fuses, circuits breakers, etc.

High potentials are present when this receiver is operating. Operation of the receiver without the rear

cover introduces danger for electrical shock. Servicing should not be performed by anyone who is not

thoroughly familiar with the necessary precautionswhen servicing high voltage equipment.

Extreme care should be practiced when handling the picture tube. Rough handling may cause it to

implode due to atmospheric pressure. (14.7 lbs per sq. in.). Do not nick or scratch the glass or subject it

to any undue pressure. When handling, usesafety goggles and heavy gloves for protection. Discharge the

picture tube by shorting the anode to chassis ground (not to the cabinet or to other mounting hardware).

When discharging connect cold ground (i.e. dag ground lead) to the anode with a wellinsulated wire or

use a grounding probe.Avoid prolonged exposure at close range to unshielded areas of the picture tube

to prevent exposure to x ray radiation.

The test picture tube used for servicing the chassis at the bench should incorporate safety glass and

magnetic shielding. The safety glass provide shielding for the tube viewing area against x ray radiation

as well as implosion. The magnetic shieldlimits the x ray radiation around the bell of the picture tube in

addition to the restricting magnetic effects. When using a picture tube test jig for service, ensure that the

jig is capable of handling 50kV without causing x ray radiation.

Before returning a serviced receiver to the owner, the service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a line isolation transformer when testing.

Leakage current cold check

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html (1 of 3)05.12.2008 0:00:16

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html

Unplug the A.C. cord and connect a jumper between the two plug prongs.Measure the resistance

between the jumpered AC plug and expose metallic parts such as screwheads, antenna terminals, control

shafts, etc. If the exposed metallic part has a returnpath to the chassis, the reading should be between

240kΩ and 5.2MΩ. If the exposed metallic part does not have a return path to the chassis, the reading

should be infinite.

Leakage current hot check

Plug the AC cord directly into the AC outlet. Do not use an isolation transformer during the check.

Connect a 1.5kΩ 10 watt resistor in parallel with a 0.15μF capacitor between an exposed metallic part

and ground. Use earth ground, for example a water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage present with all other exposed metallic parts.

Verify that any potential does not exceed 0.75 volt RMS. A leakage current tester (such a Simpson

model 229, Sencore model PR57 or equivalent) may be used in the above procedure, in which case any

current measure must not exceed 0.5 milliamp. Ifany measurement is out of the specified limits, there is

a possibility of a shock hazard and the receiver must be repaired and rechecked before it is returned to

the customer.

Hot check circuit

Insulation test

Connect an insulation tester between an exposed metallic part and A.C. line. Apply 1080VAC/60Hz for

1 second. Confirm that the current measurement is 0.5mA ~ 2.0mA. Repeat test with other metallic

exposed parts.

X ray radiation

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html (2 of 3)05.12.2008 0:00:16

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html

WARNING

The potential source of x ray radiation in the TV set is in the high voltage section and the picture tube.

NOTE

It is important to use an accurate, calibrated high voltage meter.

Set the brightness, picture, sharpness and color controls to minimum.

Measure the high voltage. The high voltage should be 33.0 ± 1.0kV. If the upper limit is out of

tolerance, immediate service and correction is required to insure safe operation and to prevent the

possibility of prematurecomponent failure.

Horizontal oscillator disable circuit test

This test must be performed as a final check before the receiver is returned to the customer. See

horizontal oscillator disable circuit procedure check in this manual.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0100000000x.html (3 of 3)05.12.2008 0:00:16

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html

2 Service notes

TOP PREVIOUS NEXT

NOTE

These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the componentloose.

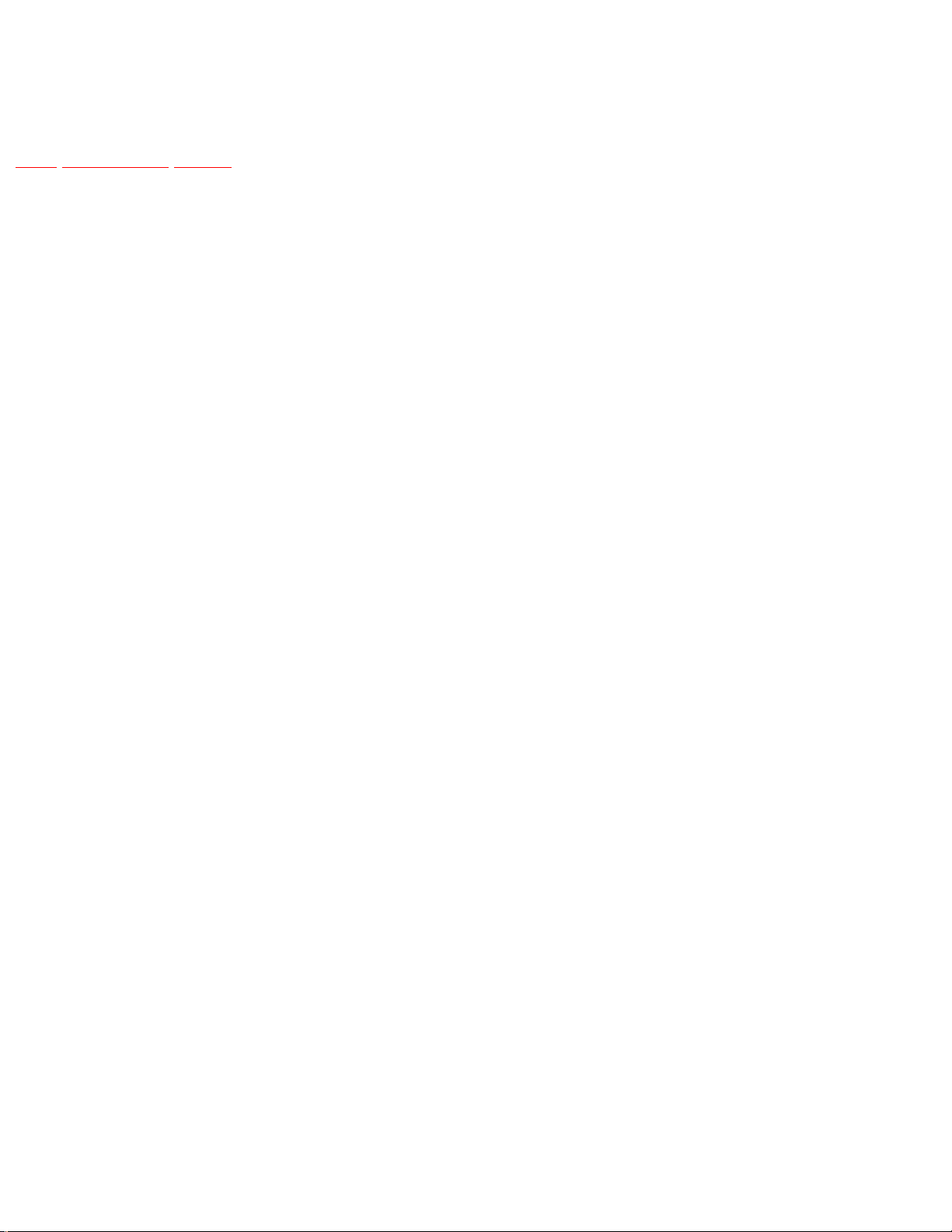

Leadless chip component (surface mount)

Chip components must be replaced with identical chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or diodes. Some chips capacitor or resistor board solder

pads may have holes through the board,however the hole diameter limits standard resistor replacement

to 1/8 watt. Standard capacitor may also be limited for the same reason. It is recommended that identical

components be used.

Chip resistor have a three digit numerical resistance code, 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The first letter indicates the type and the second

letter, the grade of transistor.

Chip diodes have a two letter identification code as per the code chart and are a dual diode pack with

either common anode or common cathode. Check the parts list for correct diode number.

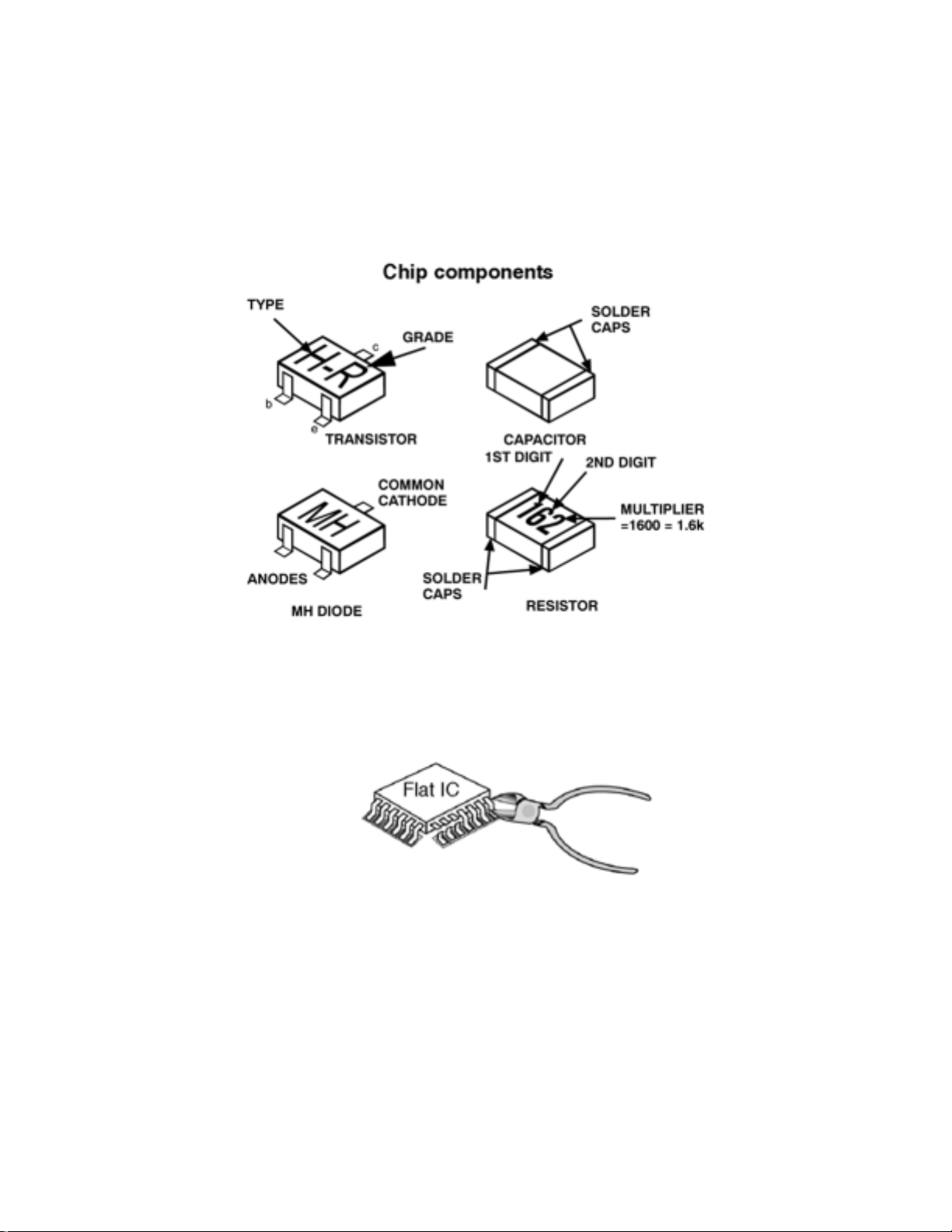

Component removal

1. Use solder wick to remove solder from component end caps or terminal.

2. Without pulling up, carefully twist the component with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip components since they are subject to stress fracture during

removal.

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html (1 of 4)05.12.2008 0:00:25

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html

Chip component installation

1. Put a small amount of solder on the board soldering pads.

2. Hold the chip component against the soldering pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt iron until solder flows. Do not apply heat for

more than 3 seconds.

How to replace flat ic (required tools)

1. Remove the solder from all of the pins of a Flat IC by using a desolder braid

2. Put the iron wire under the pins of the Flat IC and pull it in the direction indicated while heating

the pins using a soldering iron. A small awl can be used instead of the iron wire.

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html (2 of 4)05.12.2008 0:00:25

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html

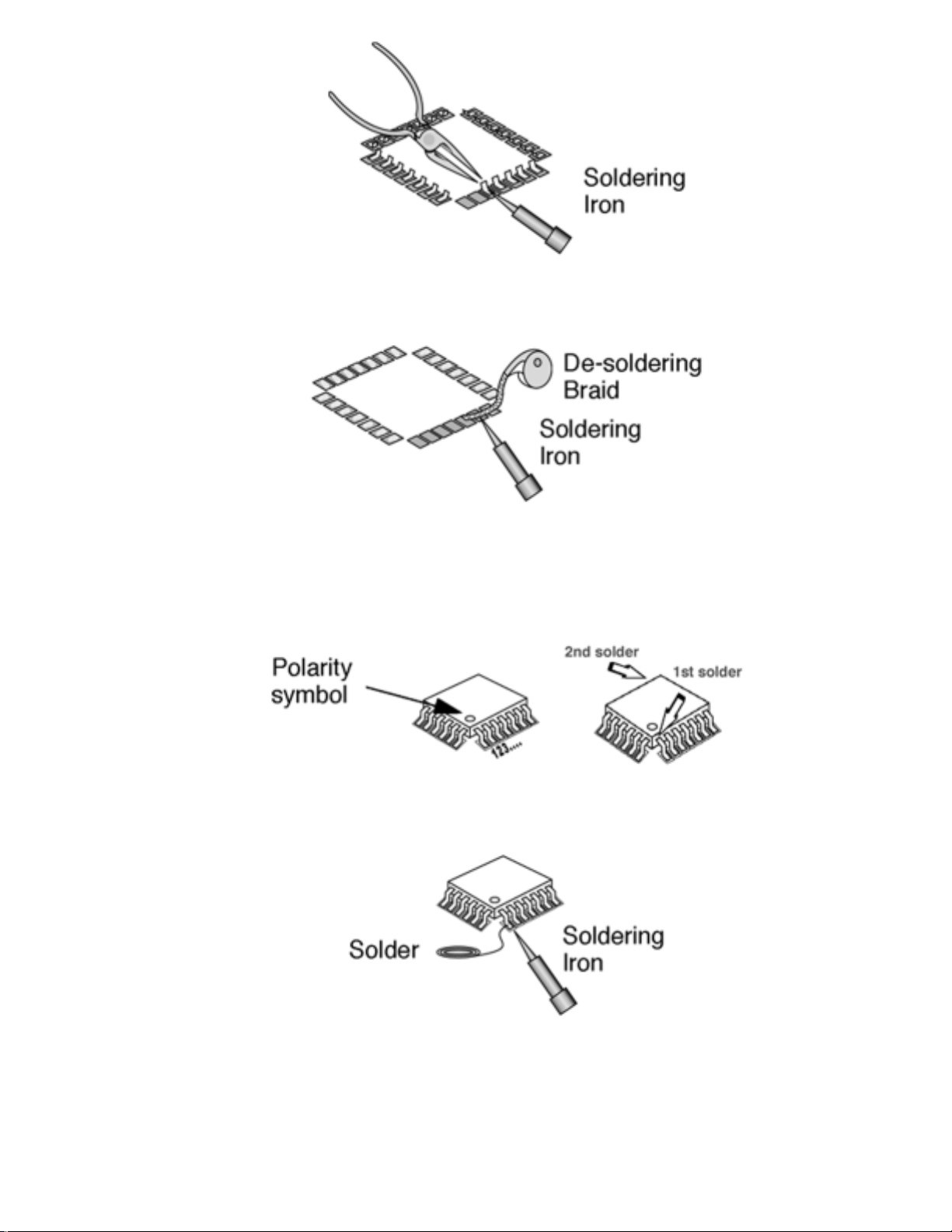

3. Remove the solder from all the pads of the Flat IC by using a de solder braid

4. Position the new Flat IC in place (apply the pins of the Flat IC to the soldering pads where the

pins need to be soldered). Properly determine the positions of the soldering pads and pins by

correctly aligning the polarity symbol

5. Solder all pins to the soldering pads using a fine tipped soldering iron

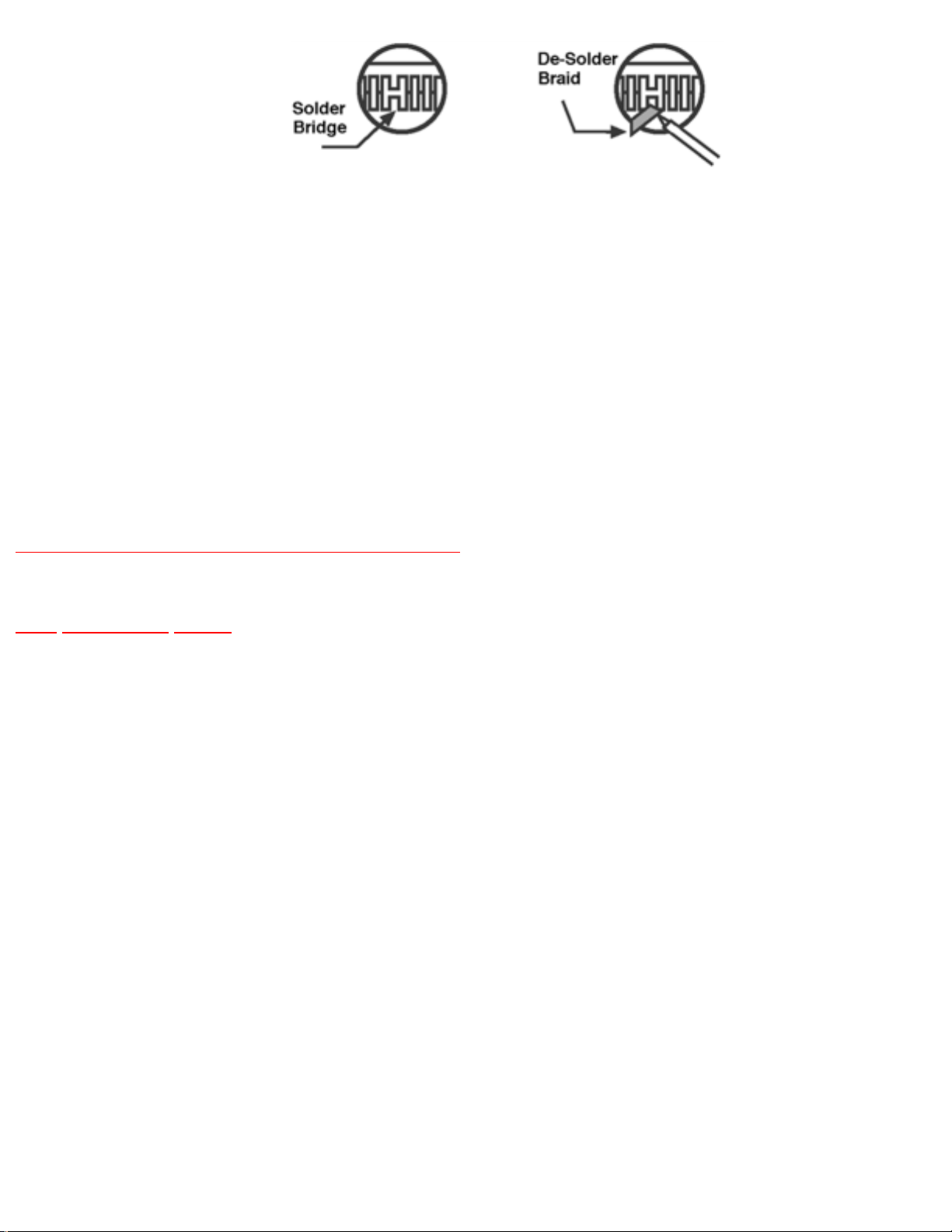

6. Check with a magnifier for solder bridge between the pins or for dry joint between pins and

soldering pads. To remove a solder bridge, use a de solder braid as shown in the figure below

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html (3 of 4)05.12.2008 0:00:25

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html

IMPORTANT

To protect against possible damage to the solid state devices due to arching or static discharge, make

certain that all ground wires and CRT DAG wire are securely connected.

CAUTION

The power supply circuit is above earth ground and the chassis cannot be polarized. Use an isolation

transformer when servicing the receiver to avoid damage to the test equipment or to the chassis. Connect

the test equipment to the proper ground(hot) or (cold) when servicing, or incorrect voltages will be

measured.

2.1 X-Ray Protection Circuit Check& Adjustments

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0200000000x.html (4 of 4)05.12.2008 0:00:25

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0201000000.html

2.1 X-Ray Protection Circuit Check& Adjustments

TOP PREVIOUS NEXT

This test must be performed as final check before the receiver is returned to the customer. If voltages are

out of tolerance, immediate service and correction is required to insure safe operation and to prevent the

possibility of premature componentfailure.

Equipment:

1. Isolation transformer.

2. High voltage meter.

3. D.C. Ammeter

4. Short jumper.

5. HHS jig (See figure below).

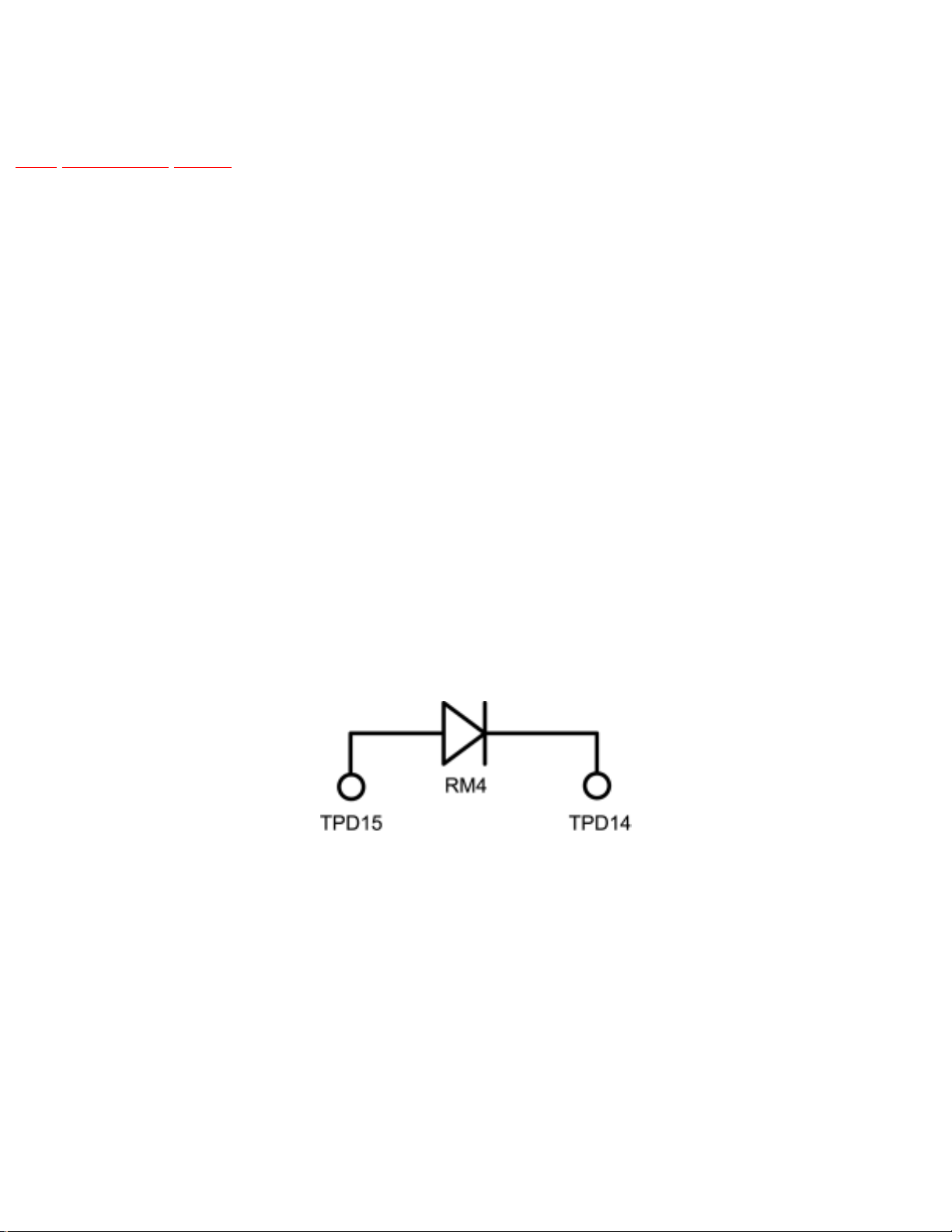

Diode Connection Jumper.

Preparation:

1. Make sure the receiver is turned off.

2. Connect the receiver to an isolation transformer.

3. Connect the ammeter serial from the flyback anode lead to the picture tube anode socket.

4. Prepare short jumper and HHS jig.

Procedure:

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0201000000.html (1 of 2)05.12.2008 0:00:36

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0201000000.html

1. Connect the short jumper between TPD16 & TPD17.

2. Connect the jumper diode between TPD14 and TPD15 (anode connected to TPD15 and cathode

to TPD14).

3. Apply 75VAC to AC input of isolation transformer.

4. Turn the receiver on.

5. Apply a monoscope pattern.

6. Set customer picture and brightness controls to the minimum.

7. tSet current within 50μA to 100μA by changing the picture and bright controls.

8. Slowly increase AC voltage at the input of the isolation transformer and confirm HHS voltage

measure 36kV .

9. Turn power off and remove jigs.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0201000000.html (2 of 2)05.12.2008 0:00:36

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0300000000x.html

3 EEPROM replacement

TOP PREVIOUS NEXT

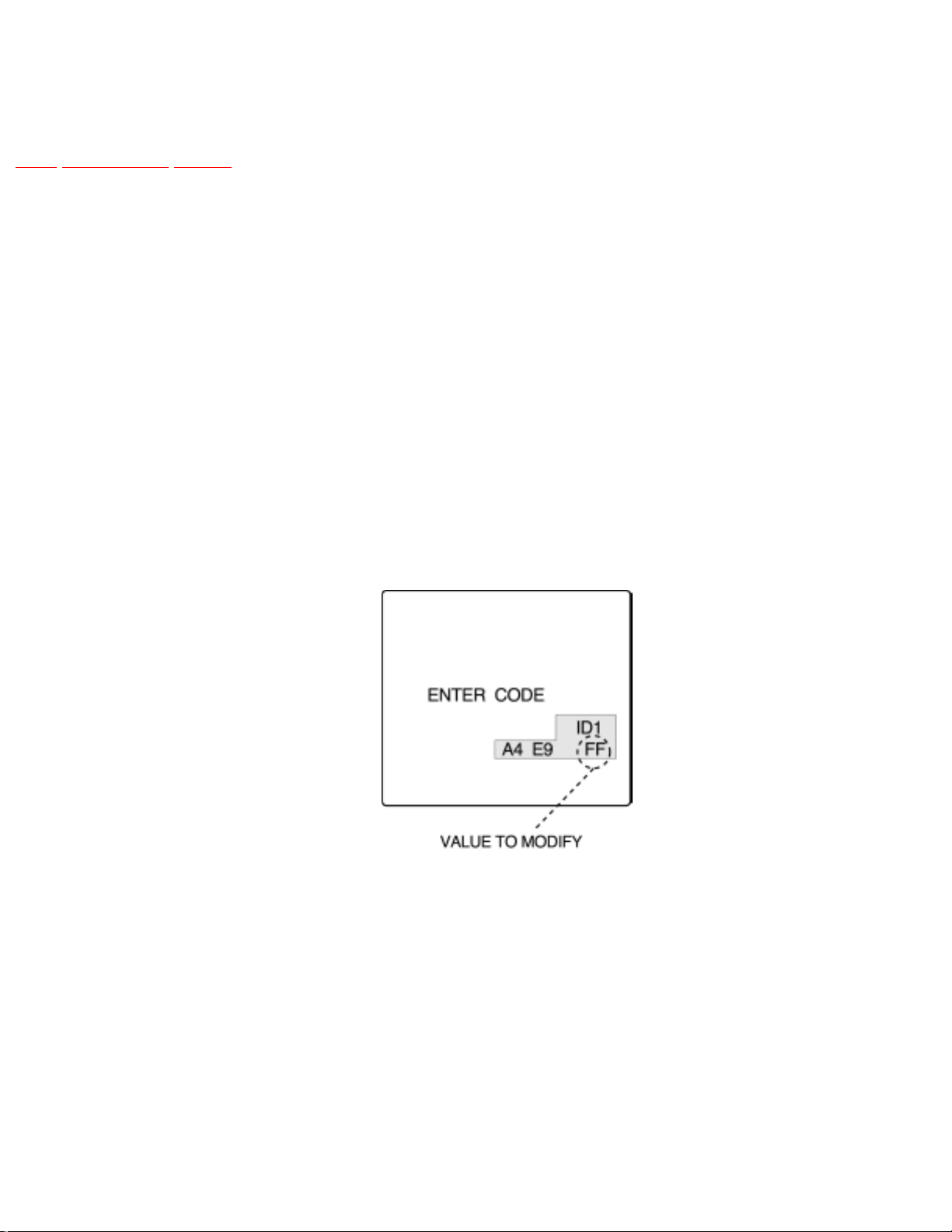

If a new EEPROM integrated circuit is replaced for servicing, follow the next procedure once that the

memory is properly assembled:

1. Turn the TV set ON.

2. Enter to service mode.

3. Once inside service mode the first image that appears on-screen is the ID1 register with the

respective address value (FF) like the image below.

Note:

All 3 registers (ID1,ID2,ID3) should appear with FF values if a new EEPROM is assembled.

4. With “VOL” keys adjust the correct value according with the service adjustment table (see

“Service Mode” section in page 15).

5. Change to the next ID switch register with “CH” keys and repeat the same procedure as step 4.

6. When replacing a new EEPROM be sure to set the correct ID switch values for each model.

7. Once that all 3 registers are set with the correct address value, perform all of the remaining

adjustments and servicing.

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0300000000x.html (1 of 2)05.12.2008 0:00:41

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0300000000x.html

IMPORTANT:

Correct ID switch configuration should be input when replacing EEPROM for each television model,

otherwise if wrong values are configured, the television software will not function accordingly and

properly.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0300000000x.html (2 of 2)05.12.2008 0:00:41

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0400000000x.html

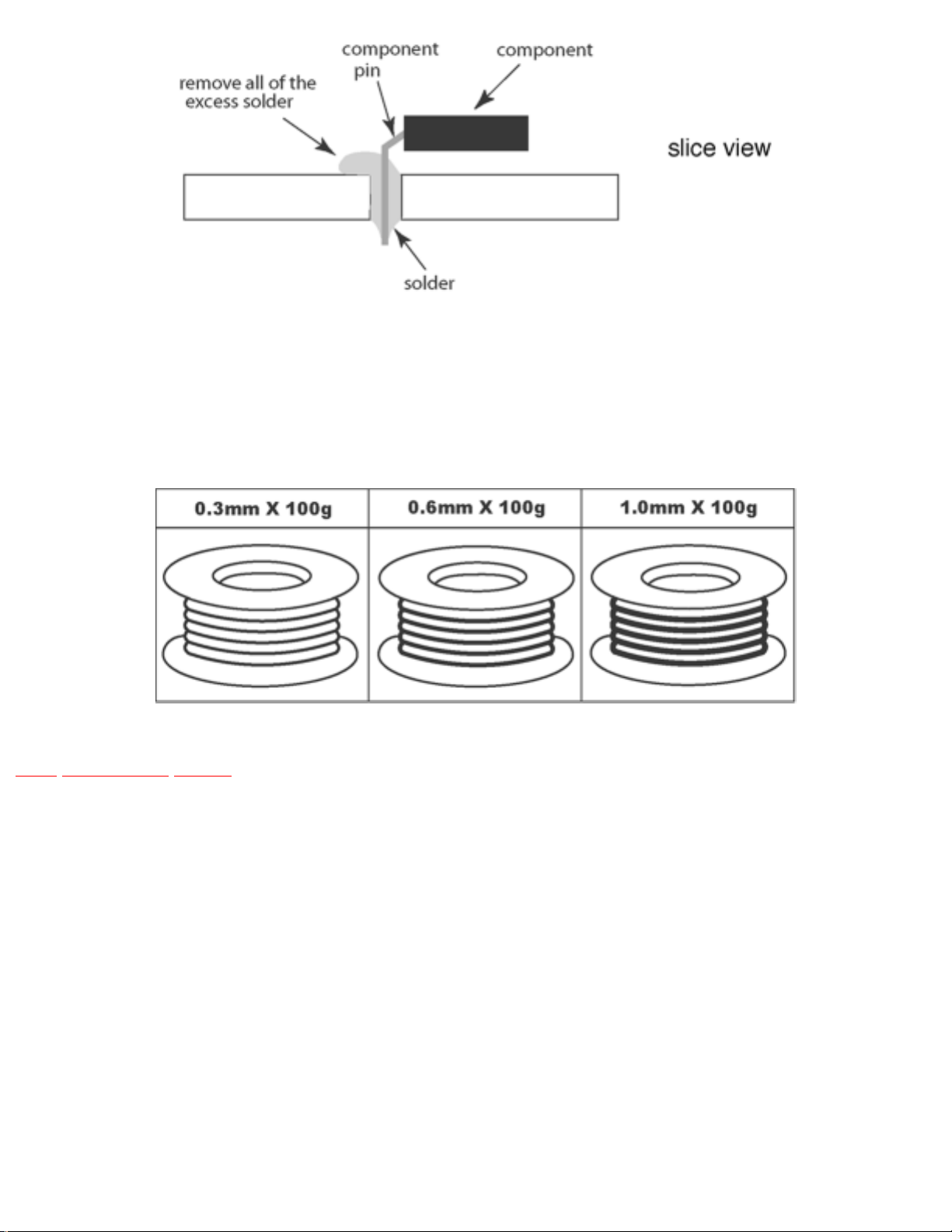

4 About lead free solder (PbF)

TOP PREVIOUS NEXT

NOTE

Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to lead solder, and PbF will refer to Lead Free Solder.

The lead free solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

Thatis Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For

service and repair work, we’d suggest the use of Pb free solder as well, although Pb solder may be

used.

PCBs manufacturedusing lead free solder will have the “PbF” or a leaf symbol stamped on the

back of PCB.

CAUTION

● Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~

70 °F (30 ~ 40 °C) higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F

(370 ± 10 °C).

● Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder

area before applying Pb solder. If thisis not practical, be sure to heat the Pb free solder until it

melts, before applying Pb solder.

● After applying PbF solder to double layered boards, please check the component side for excess

solder which may flow onto the opposite side.

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0400000000x.html (1 of 2)05.12.2008 0:00:49

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0400000000x.html

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin,

silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also

beused.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0400000000x.html (2 of 2)05.12.2008 0:00:49

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html

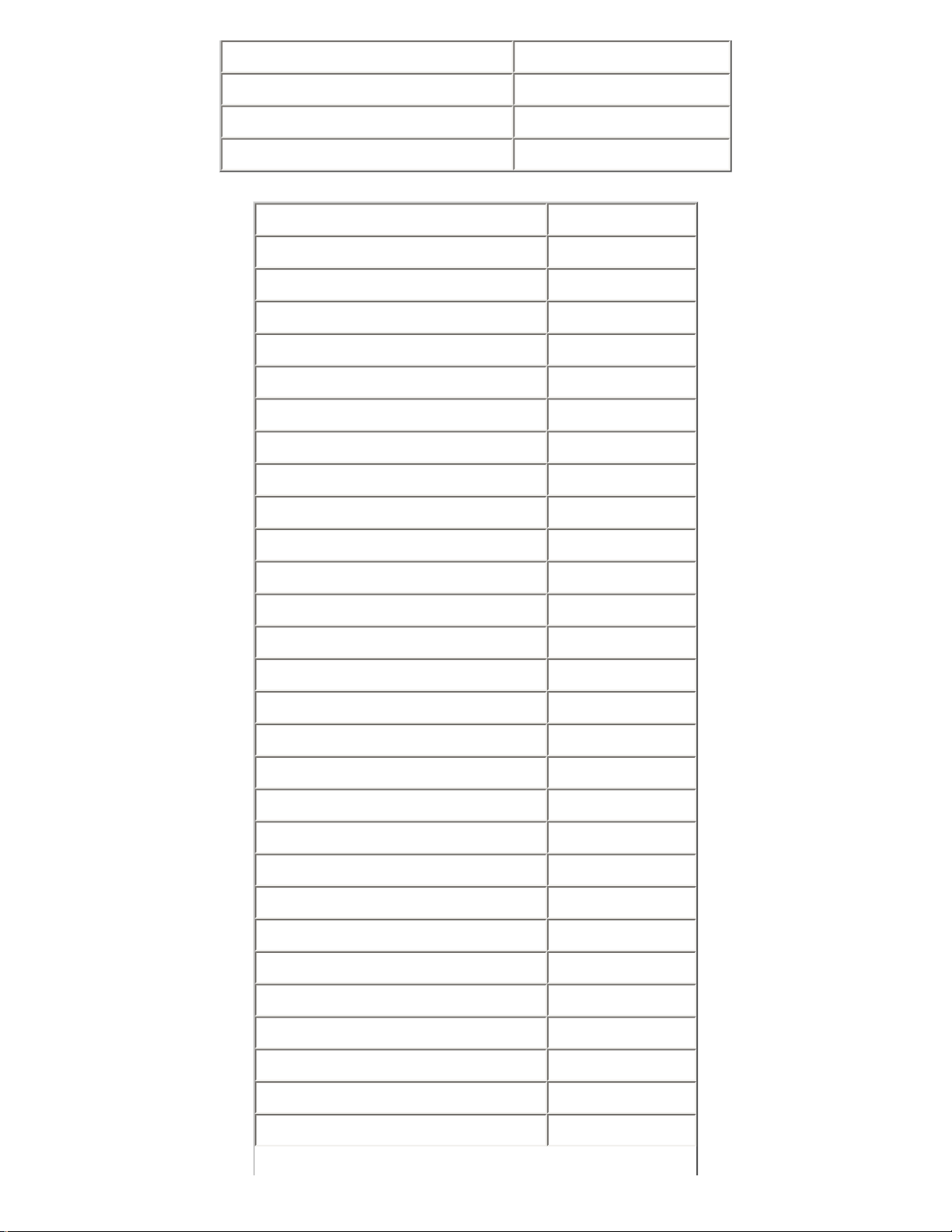

5 Receiver feature table

TOP PREVIOUS NEXT

FEATURE/MODEL CT-32SL13G CT-36SL13G

CHASSIS AP411 AP412

MICRO 128K

MENU LANGUAGE ENG/SPAN/FR

CLOSED CAPTION X

V-CHIP (USA/CANADA) X

CHANNEL COUNT 181

CHANNEL INFO BANNER X

VIDEO INPUT SKIP X

75 OHM INPUT X

REMOTE CONTROL EUR7613Z60

CRT SUPPLIER MDDA FLAT (4:3)

CHASSIS NA10FL

COMB FILTER MOTION ADP 3 DIG

HEC/VEC (X=BOTH) X

VM X (DIGITAL)

V/A NORM (X=BOTH) X

COLOR TEMP X

PRESET/INPUT LABELING X

VIDEO PICTURE MEMORY X

MTS/SAP/DBX X

BUILT-IN AUDIO POWER 10Wx2

No. OF SPEAKERS 2

BASS/BALANCE/TREBLE CONTROL X

AI SOUND X

SURROUND X

SPATIALIZER/BBE BBE

A/V IN (REAR/FRONT) 3(2/1)

A/V PROGRAM OUT X

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html (1 of 4)05.12.2008 0:00:53

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html

AUDIO OUT (FAO:F, VAO:V) F, V

COMPONENT INPUT (Y, Pb, Pr) 1

S-VIDEO INPUT (REAR/FRONT) 1/1

EPJ/HPJ/MISC HPJ

FEATURE/MODEL CT-32SC13G CT-36SC13G

CHASSIS BP411 BP412

MICRO 128K

MENU LANGUAGE ENG/SPAN/FR

CLOSED CAPTION X

V-CHIP (USA/CANADA) X

CHANNEL COUNT 181

VIDEO INPUT SKIP X

75 OHM INPUT X

75 OHM INPUT X

REMOTE CONTROL EUR7613Z60

CRT SUPPLIER MDDA FLAT (4:3)

CHASSIS NA10FL

COMB FILTER 3-LINE

HEC/VEC (X=BOTH) X

VM X (DIGITAL)

V/A NORM (X=BOTH) X

COLOR TEMP X

PRESET/INPUT LABELING X

VIDEO PICTURE MEMORY X

MTS/SAP/DBX X

BUILT-IN AUDIO POWER 5Wx2

No. OF SPEAKERS 2 (DOME)

BASS/BALANCE/TREBLE CONTROL X

AI SOUND X

SURROUND X

SPATIALIZER/BBE BBE

A/V IN (REAR/FRONT) 3(2/1)

A/V PROGRAM OUT X

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html (2 of 4)05.12.2008 0:00:53

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html

AUDIO OUT (FAO:F, VAO:V) F, V

COMPONENT INPUT (Y, Pb, Pr) 1

S-VIDEO INPUT (REAR/FRONT) 1/1

EPJ/HPJ/MISC HPJ

FEATURE/MODEL CT-3653G

CHASSIS BP412

MICRO 128K

MENU LANGUAGE ENG/SPAN/FR

CLOSED CAPTION X

V-CHIP (USA/CANADA) X

CHANNEL COUNT 181

VIDEO INPUT SKIP X

75 OHM INPUT X

75 OHM INPUT X

REMOTE CONTROL EUR7613Z60

EXTRA REMOTE CONTROL EUR7713010

CRT SUPPLIER MDDA FLAT (4:3)

CHASSIS NA10FL

COMB FILTER 3-LINE

HEC/VEC (X=BOTH) X

VM X (DIGITAL)

V/A NORM (X=BOTH) X

COLOR TEMP X

PRESET/INPUT LABELING X

VIDEO PICTURE MEMORY X

MTS/SAP/DBX X

BUILT-IN AUDIO POWER 7.5Wx2

No. OF SPEAKERS 2 (DOME)

BASS/BALANCE/TREBLE CONTROL X

AI SOUND X

SURROUND X

SPATIALIZER/BBE BBE

A/V IN (REAR/FRONT) 3(2/1)

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html (3 of 4)05.12.2008 0:00:53

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html

A/V PROGRAM OUT X

AUDIO OUT (FAO:F, VAO:V) F, V

COMPONENT INPUT (Y, Pb, Pr) 1

S-VIDEO INPUT (REAR/FRONT) 1/1

EPJ/HPJ/MISC HPJ

Note:

Specifications are subject to change without notice or obligation.

NOTE:

CT-3653G includes EUR7613Z60 remote control and an extra remote control with part number

EUR7713010

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0500000000x.html (4 of 4)05.12.2008 0:00:53

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0600000000x.html

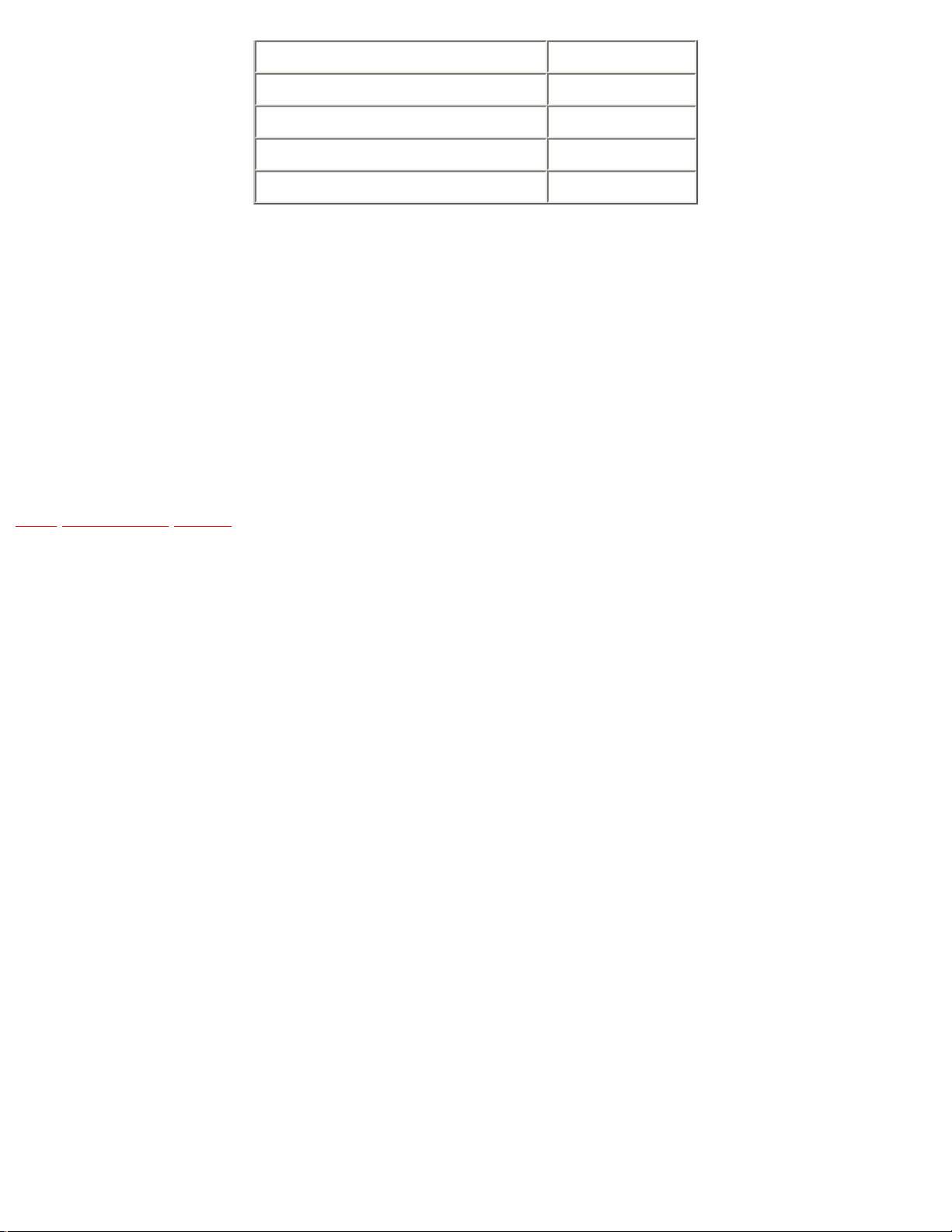

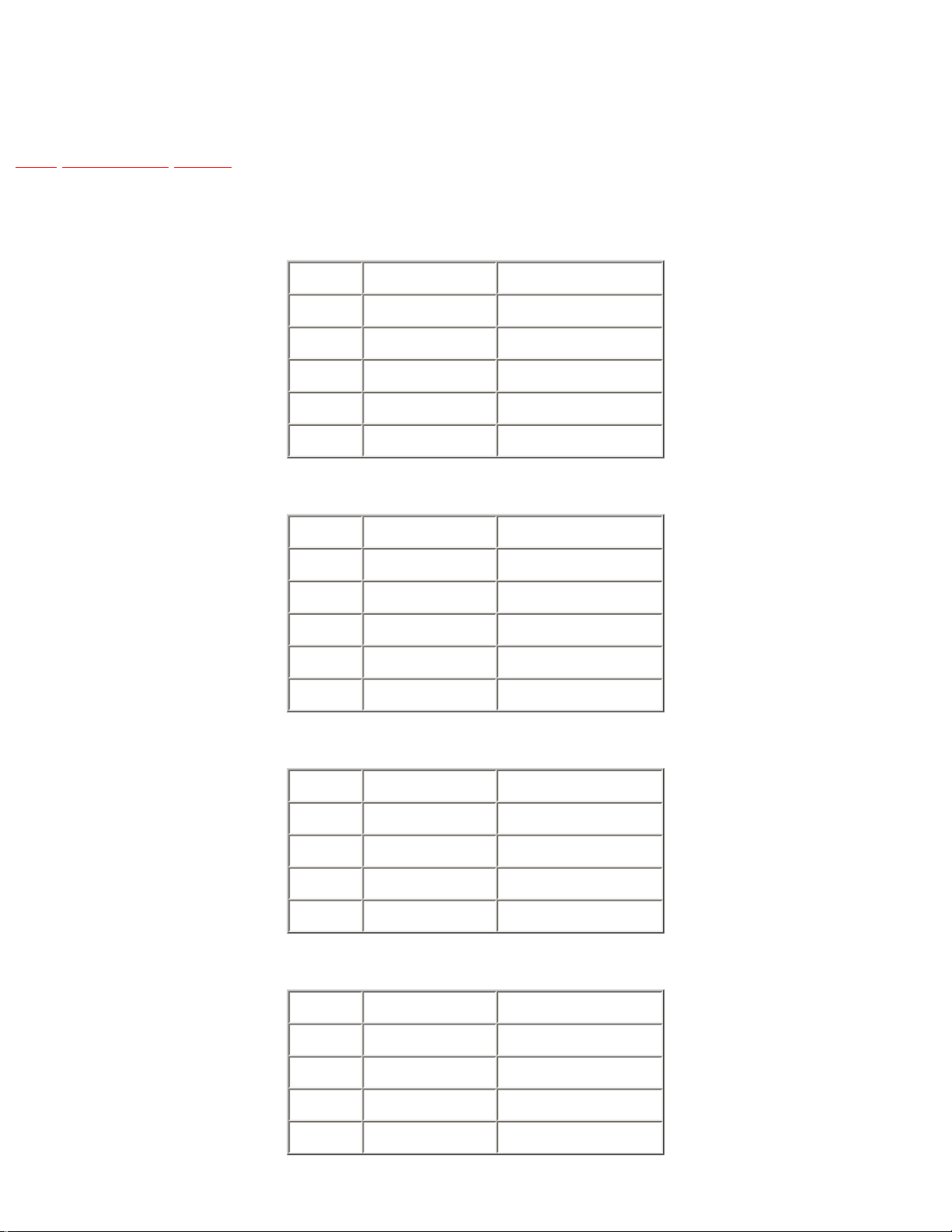

6 Board description table

TOP PREVIOUS NEXT

CT-32SL13G

BOARD PART NUMBER DESCRIPTION

A TNP2AH052AA MAIN BOARD

D TNP2AH053AB POWER SUPPLY

G TNP2AA142AB FRONT A/V BOARD

K TNP2AA143 KEY BOARD

L TNPA1673AE CRT BOARD

CT-36SL13G

BOARD PART NUMBER DESCRIPTION

A TNP2AH052 MAIN BOARD

D TNP2AH053 POWER SUPPLY

G TNP2AA142AB FRONT A/V BOARD

K TNP2AA143 KEY BOARD

L TNPA1673AE CRT BOARD

CT-32SC13G

BOARD PART NUMBER DESCRIPTION

A TNP2AH052AA MAIN BOARD

D TNP2AH053AB POWER SUPPLY

G TNP2AA141 FRONT A/V BOARD

L TNPA1673AE CRT BOARD

CT-36SC13G and CT-3653G

BOARD PART NUMBER DESCRIPTION

A TNP2AH052 MAIN BOARD

D TNP2AH053 POWER SUPPLY

G TNP2AA141 FRONT A/V BOARD

L TNP1673AE CRT BOARD

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0600000000x.html (1 of 2)05.12.2008 0:01:03

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0600000000x.html

NOTE

When ordering a replacement board assembly, append an “S” to the board number

EXAMPLE

To order the A Board, the replacement board is TNP2AH052AAS.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0600000000x.html (2 of 2)05.12.2008 0:01:03

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0700000000x.html

7 TV Location of controls

TOP PREVIOUS NEXT

NOTE:

Front cabinet may vary depending on the model

User controls are inside the front door

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0700000000x.html (1 of 2)05.12.2008 0:01:10

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0700000000x.html

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0700000000x.html (2 of 2)05.12.2008 0:01:10

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0800000000x.html

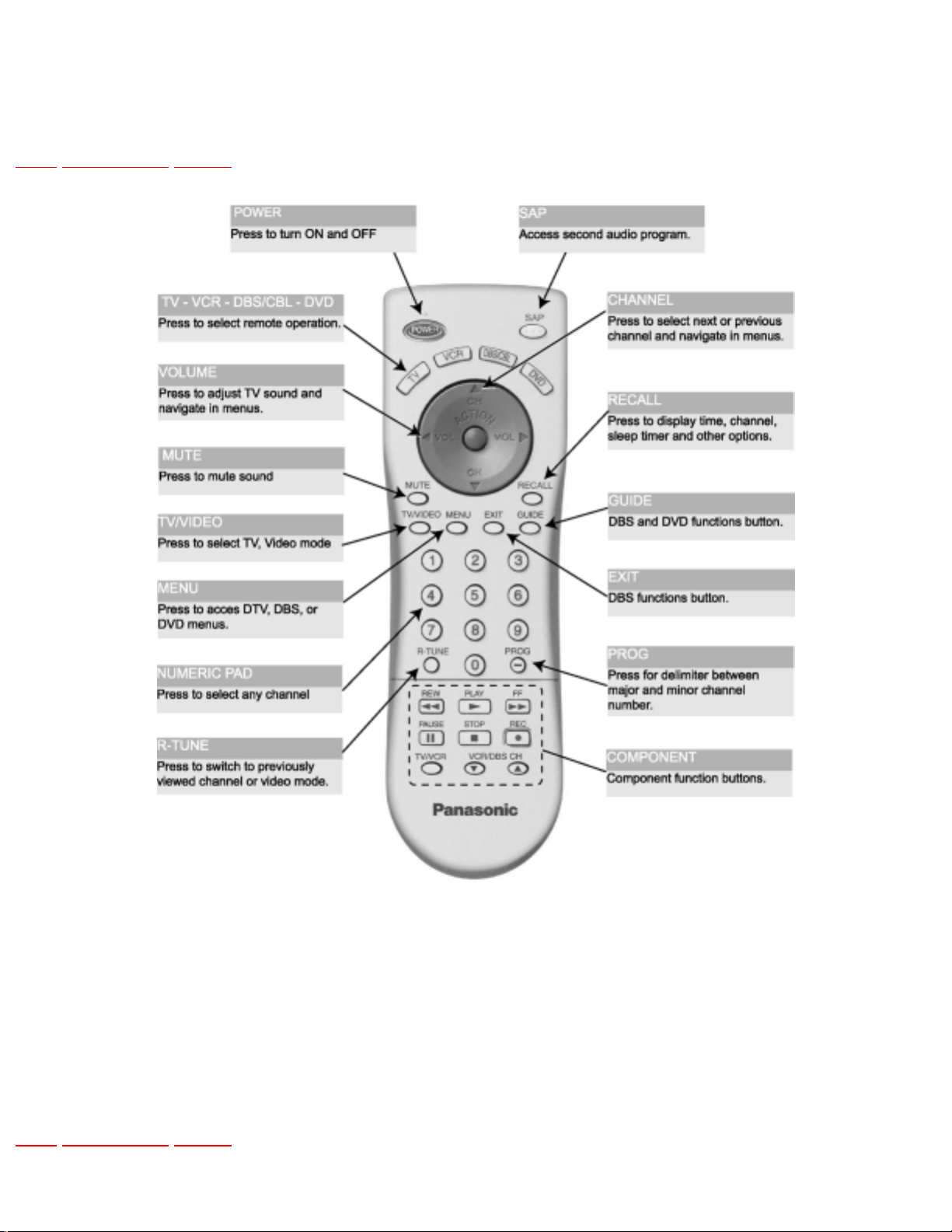

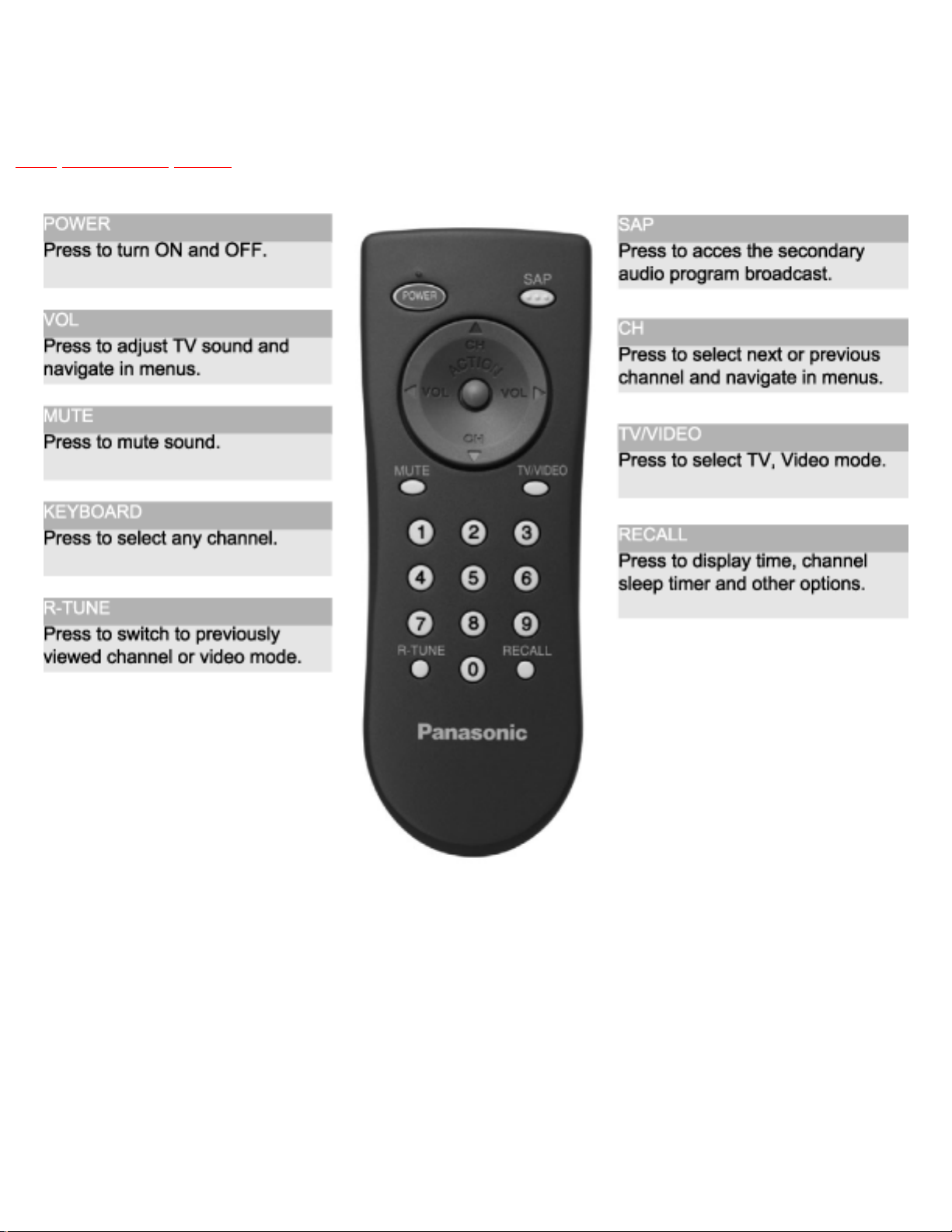

8 Location of controls (EUR7613Z60 remote)

TOP PREVIOUS NEXT

Note:

For additional information about this remote please refer to the owner’s manual section remote

operation, listed on the parts list section.

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0800000000x.html05.12.2008 0:01:19

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0900000000x.html

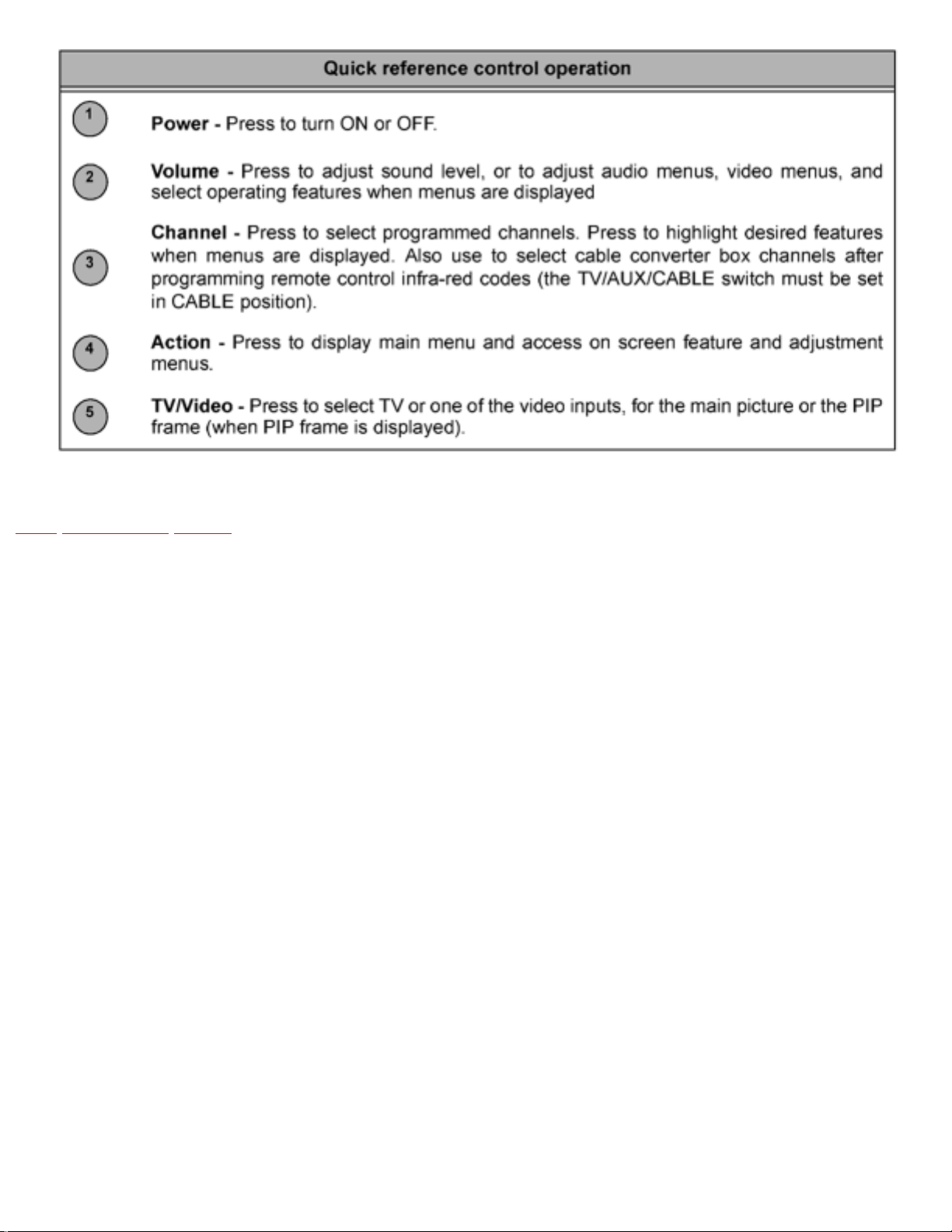

9 Location of controls (EUR7713010 remote)

TOP PREVIOUS NEXT

Note:

For additional information about this remote please refer to the owner’s manual section remote

operation, listed on the parts list section.

NOTE:

CT-3653G includes EUR7613Z60 remote control and an extra remote control with part number

EUR7713010

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0900000000x.html (1 of 2)05.12.2008 0:01:24

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0900000000x.html

TOP PREVIOUS NEXT

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s0900000000x.html (2 of 2)05.12.2008 0:01:24

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s1000000000x.html

10 Dissasembly for service

TOP PREVIOUS NEXT

Back cover

Remove all the screws marked with an arrow (←) from the back of the receiver

NOTE

Screw location and quantity may vary depending on the model of the receiver serviced and the

application; various models are covered in this manual. Use same hardware when reassembling the

receiver.

● 4 screws at the top edge of the receiver.

● 4 screw by the A/V jacks.

● 1 screw by the antenna jacks.

● 1 screw at the lower part of TV.

● 1 screw at each lower corner of the receiver.

● 1 screw by the retainer plate of the AC power cord.

● 1 screw by the A.C. cord assembly.

NOTE

Extensions for board connectors may be needed to take voltages on some boards, please see parts list

section for part numbers in this service manual.

A-Board - Main chassis

The A-Board assembly rest on a chassis tray along with the D-Board.

Slide chassis tray out. Gently lift the tray and pull out. Disconnect plug connectors; release wire ties and

holders as required for complete chassis removal.

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s1000000000x.html (1 of 4)05.12.2008 0:01:30

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s1000000000x.html

1. A-Board is secured to the chassis tray with screws.

2. The A-Board is mated to the D-Board by three flexible connectors: A5, A6 & A7 (D5, D6 & D7

on the D-Board, respectively). To remove either boards, unplug the connectors on the A-Board.

NOTE

Some tie-wraps that secure the wire dressings may need to be unfastened for chassis removal

D-Board - Deflection

The D-Board assembly rest on a chassis tray along with the A-Board.

Slide chassis tray out. Gently lift the tray and pull out. Disconnect plug connectors; release wire ties and

holders as required for complete chassis removal.

1. D-Board is secured to the chassis tray with screws.

2. The D-Board is mated to the A-Board by three flexible connectors: D5, D6 and D7 (A5, A6 &

A7 on the A-Board, respectively). To remove either boards, unplug the connectors on the ABoard.

NOTE

Some tie-wraps that secure the wire dressings may need to be unfastened for chassis removal

L-Board - CRT output

Plugs into the socket on the CRT neck.

To remove this board, first unplug the board from the CRT neck, then disconnect L1, L2 and L3

connectors, to disconnect the focus F1(red cable) & F2 (white cable) cables from the CRT socker, pull

the tab and release the cables (see figure),finally disconnect the screen cable from the D-Board D16

(screen and heater).

To reinsert back the cables, remember the original position of cables, F1 (red cable) goes to A on the

CRT socket and F2 (white cable) goes to B on the CRT socket.

F1 and F2 cables release

http://tsn.pstc.panasonic.com/viewing/NA/CT-36SL13G/SVC/s1000000000x.html (2 of 4)05.12.2008 0:01:30

Loading...

Loading...