Panasonic CT-20G7DF, TC-20G7, CT-20D12DF Schematic

ORDER NO. MT NC020515A1

B1

Service Manual

Color Television

d

e

i

S

m

i

p

l

i

f

Simplified Manual

(NA7DM)

Panasonic

Models

CT-20G7DF AP391

CT-20D12DF BP391

This supplement service manual is issued to add the modelss of the NA7DM family listed above to the main service

manual order No. MTNC010305C1 (CT-20D11E). Included in this supplement service manual are unique

characteristics and a complete parts list. Please file and use this simplified service manual together with main service

manual order No. MTNC010305C1

Chassis

“WARNING! This ServiceManualis designed forexperiencedrepairtechnicians only and is not designedfor use bythe general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Productspowered byelectricityshouldbeservicedorrepairedonlybyexperiencedprofessionaltechnicians.Anyattempttoservice

or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is requiredtoreadand follow the “safety precautions”and“important safety notice” in this main manual.

Copyright2002by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

and distribution is a violation of law.

Important safety notice

Special components are used in this television set which are important for safety. These parts are identified on the

schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is essential that

these critical parts are replaced with the manufacturer’s specified replacement part to prevent X-ray radiation,

shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety precautions

General guidelines

AnIsolationTransformershouldalwaysbe usedduring

the servicing of a receiver whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the receiver from

being damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices,suchas

fishpaper, isolation resistors and capacitors, and

shields after servicing the receiver. Use only

manufacturer’s recommended rating for fuses, circuits

breakers, etc.

High potentials are present when this receiver is

operating. Operation of the receiver without the rear

cover introduces danger for electrical shock. Servicing

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be practiced when handling the

picture tube. Rough handling may cause it to implode

due to atmospheric pressure. (14.7 lbs per sq. in.). Do

not nick or scratch the glass or subject it to any undue

pressure. When handling, use safety goggles and

heavygloves forprotection.Discharge the picture tube

by shorting the anode to chassis ground (not to the

cabinet or to other mounting hardware). When

discharging connect cold ground (i.e. dag ground lead)

to the anode with a well insulated wire or use a

grounding probe.

Avoid prolonged exposure at close range to unshielded

areas of the picture tube to prevent exposure to

X-ray radiation.

The test picture tube used for servicing the chassis at

the bench should incorporate safety glass and

magnetic shielding. The safety glass provide shielding

for the tube viewing area against X-ray radiation as

well as implosion. The magnetic shield limits the X-ray

radiation around the bell of the picture tube in addition

to the restricting magnetic effects. When using a

picture tube test jig for service, ensure that the jig is

capable of handling 35kV without causing

X-ray radiation.

Beforereturning a servicedreceiver totheowner,the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage current cold check

Unplug the AC cord and connecta jumper between the

two plug prongs.

Measure the resistance between the jumpered AC plug

and expose metallic parts such as screwheads,

antenna terminals, control shafts, etc.

If the exposed metallic part has a return path to the

chassis, the reading should be between 240kΩ and

5.2MΩ. If the exposed metallic part does not have a

return path to the chassis, the reading should be

infinite.

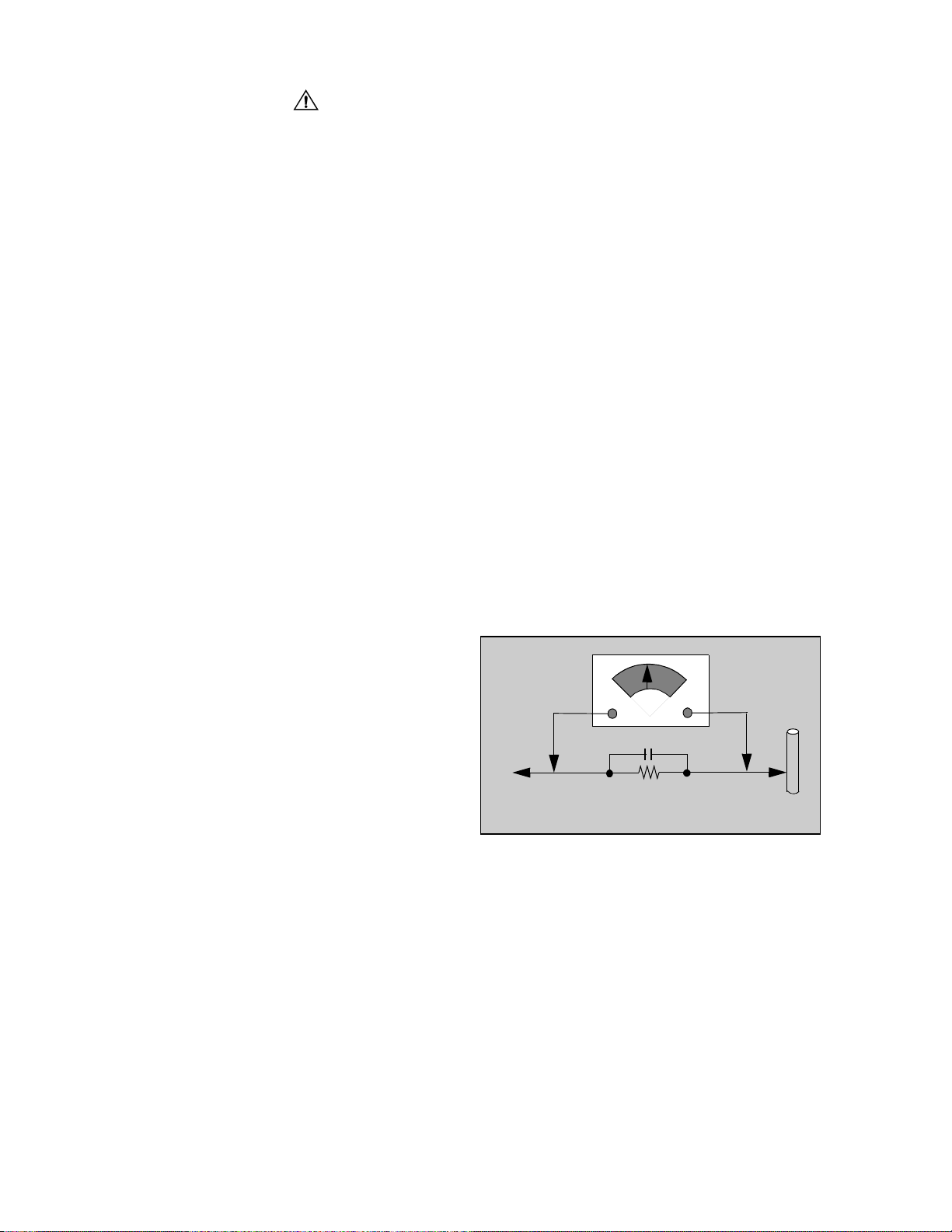

Leakage current hot check (Fig. 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5kΩ 10 watt resistor in parallel with a

0.15µF capacitor between an exposed metallic part

and ground. Use earth ground, for example a

water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other exposed metallic parts.

Verify that any potential does not exceed 0.75 volt

RMS. A leakage current tester (such a Simpson model

229, Sencore model PR57 or equivalent) may be used

in the above procedure, in which case any current

measure must not exceed 0.5 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the receiver must be

repaired and rechecked before it is returned to the

customer.

AC VOLTMETER

COLD

WATER

PIPE

(GROUND)

0.15µF

TO

INSTRUMENT’S

EXPOSED METAL

PARTS

1500Ω,10 W

Figure 1. Hot check circuit

X-ray radiation

WARNING: The potential source of X-ray radiation in the

TV set are the High Voltagesection and the picture tube.

Refer to X-RAY protecton circuit check in service

notes in this manual to confirm HHS voltage.

High voltage (crt anode)

Confirm Anode voltage is within limits:

Set the BRIGHTNESS, PICTURE, SHARPNESS and

COLOR to minimum (To obtaina dark image). Measure

high voltage. It should be:

26.60

± 1.25kV.

If the upper limit is out of tolerance, immediate service

and correction is required.

Note: It is important to use an accurate, calibrated

high voltage meter.

-2-

Importantsafetynotice................... 2

Safetyprecautions................. 2

Generalguidelines................. 2

Leakage current cold check . . . . . . . . . . 2

Leakage current hot check . . . . . . . . . . . 2

X-rayradiation.................... 2

Highvoltage(crtanode)............. 2

Servicenotes........................... 4

Leadless chip component

(surfacemount)................ 4

Componentremoval................ 4

Chip component Installation . . . . . . . . . . 4

HowtoreplaceFlat-IC.............. 4

X-rayprotectioncircuitcheck......... 5

Receiverfeaturetable.................... 6

Chasis service adjustment procedures. . . . . . 7

130.0V B+ voltage confirmation . . . . . . . 7

Sourcevoltagechart................ 7

Highvoltagecheck................. 7

Audiosignalpathblockdiagram........... 8

Videosignalpathblockdiagram........... 9

Partslist.............................. 10

Foldouts, voltages & waveforms . . . . . . . 18~31

-3-

Service notes

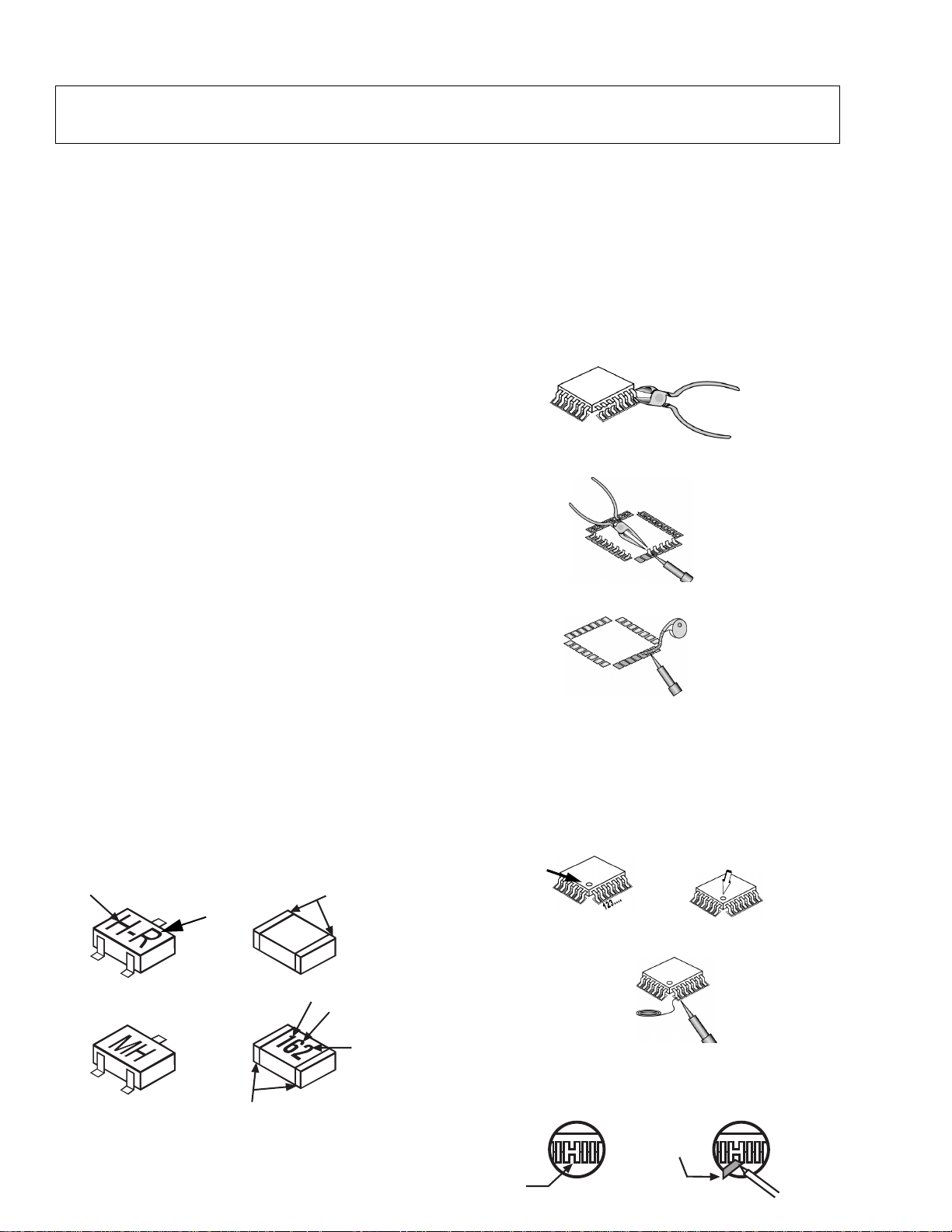

Note: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short time

while twisting with tweezers will break the component loose.

Leadless chip component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil track spacing. There are no holes in

the board to mount standard transistors or diodes.

Some chips capacitor or resistor board solder pads

may have holes through the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistor have a three digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component removal

1. Use solder wick to remove solder from component

end caps or terminal.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area with a 30 watt iron

until solder flows. Do not apply heat for more than

3 seconds.

TYPE

b

e

ANODES

MH DIODE

Chip components

GRADE

c

TRANSISTOR

COMMON

CATHODE

SOLDER

CAPS

CAPACITOR

1ST DIGIT

RESISTOR

SOLDER

CAPS

2ND DIGIT

MULTIPLIER

=1600 = 1.6k

How to replace Flat-IC

- Required tools -

• Soldering iron • De-solder braids

• Sharpen pliers (wire

cutters and long nose)

1. Cut the pins ofthe defective IC with the wire cutters

pliers, and remove it completely away from the

board. If the IC is glued to the board, apply hot air

to complete the removal. CAUTION- Do not pull or

twist the pliers, may damage the soldering pads in

the board.

Flat-IC

2. Using the soldering Iron and the long nose pliers,

remove the IC pins that still attached to the board.

3. Using the de-solder braid and the soldering iron,

remove the solder from the board soldering pads.

4. Position the new Flat-IC in place (apply the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Properly determine the

positions of the soldering pads and pins by

correctly aligning the polarity symbol. Start aligning

and soldering pin no.1, then align and solder the

pin in the apposite corner of the IC, this will help to

align the rest of the pins.

Polarity

symbol

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Solder

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

Solder

bridge

-4-

• Magnifier

Soldering

iron

De-Solder

braid

Soldering

iron

Soldering

iron

De-Solder

braid

Soldering

iron

Service notes (continued)

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires and CTR DAG wire

are securely connected.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when servicing the receiver to

avoid damage to the test equipment or to the chassis.

Connect the test equipment to the proper ground ( ) or

( ) when servicing, or incorrect voltages will be

measured.

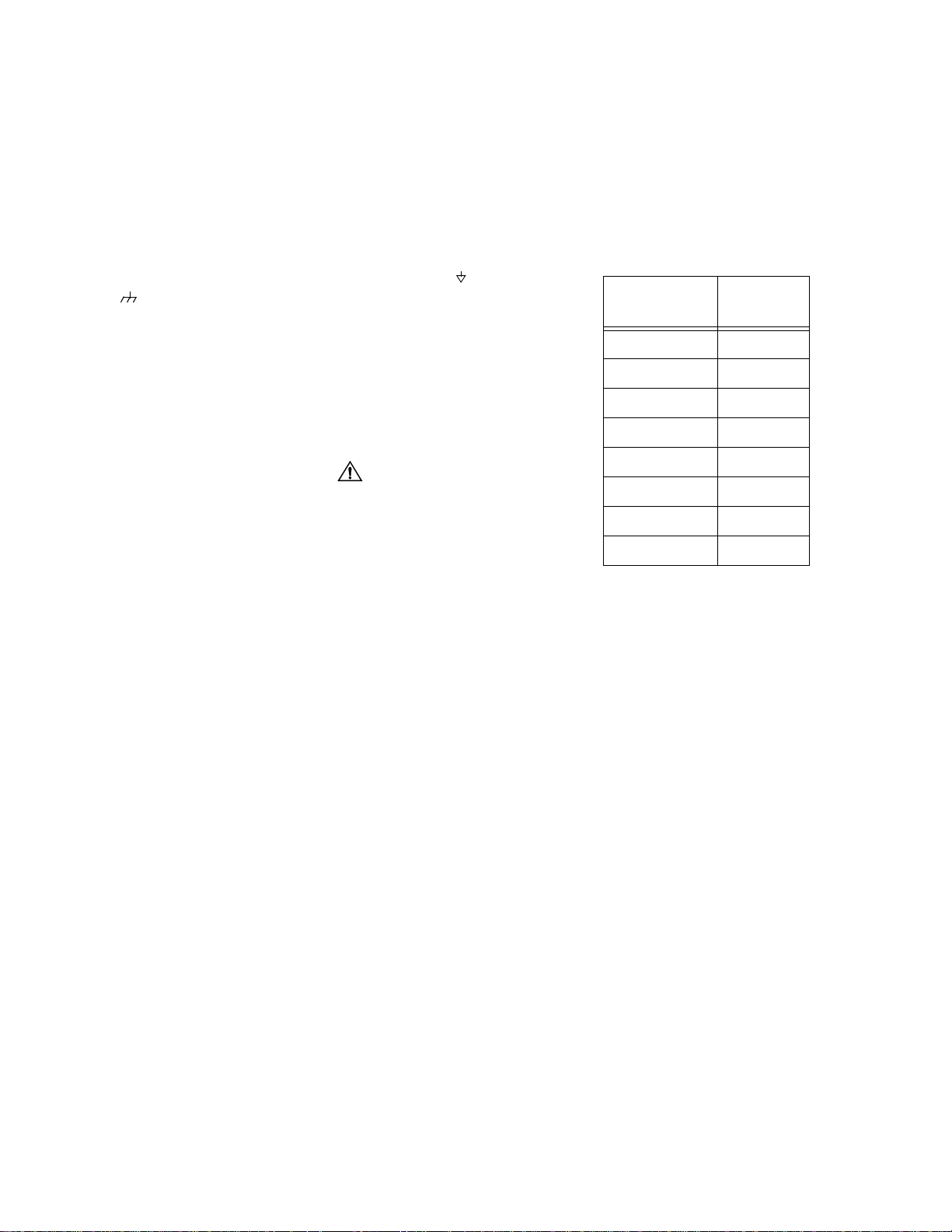

Procedure:

1. Connect receiver to isolator transformer.

2. Apply a monoscope pattern.

3. In service mode. (Refer to service mode section)

select register C0b.

4. Measure TP5 (TPs port close to tuner). Compare

the measure of TP5 and set the data for C0b

according the following table

TP5

MEASURE (V)

DATA TO

C0b (Hex)

WARNING: This receiver has been designed to meet

or exceed applicable safety and x-ray radiation

protection as specified by government agencies and

independent testing laboratories.

To maintain original product safety design standards

relative to x-ray radiation and shock and fire hazard,

parts indicated with the symbol on the schematic

must be replaced with identical parts. Order parts from

the manufacturer’s parts center using the parts

numbers shown in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and reliability, all other parts

should be replaced with components of

identical specification.

X-ray protection circuit check

This test must be performed as final check before the

receiver is returned to the customer. If voltage is out of

tolerance, immediate service and correction is required

to insure safe operation and to prevent the possibility of

premature component failure.

Equipment needed to check the protection circuit:

1. Isolator transformer.

2. High voltage meter.

3. Short jumper.

4. Diode connection jumper.

Use similar diode than D823, refer to parts list for

part No., (diode should support at least 150V.)

0 ~ 0.93 00

0.93 ~ 0.97 01

0.97 ~ 1.01 02

1.01 ~ 1.05 03

1.05 ~ 1.09 04

1.09 ~ 1.13 05

1.13 ~ 1.17 06

1.17 ~ 1.21 07

5. Exit service mode and turn receiver OFF.

6. Connect a jumper from TPD16 to TPD17.

7. Connect the

diode jumper

, cathode to TPD14

(cold GND), anode to TPD15 (hot GND).

Note: Refer to Fig. 2 for test point location.

8. Apply 75V AC to the AC input of the Insulator

transformer.Turn receiver ON.

9. Set PICTURE and BRIGTHNESS to minimum.

10. Increase the AC voltage at the input of Insulator

transformer and confirm the HHS voltage is

32.0kV, at the point set starts to loose sync,

11. Reset picture controls to original levels.

12. Turn the set OFF, and remove all jumpers and

connections from chassis.

-5-

Receiver feature table

FEATURE\MODEL CT-20G7DF CT-20D12DF

Chassis No AP391 BP391

Family NA7DM

Number of channels 181

Menu language Eng/Span/Fr

Closed Caption X

V-Chip X

75 Ω input X

Remote Model number EUR501450 EUR51 1502

Picturetubetype PANABLACK

Picture tube Supplier SAMSUNG

Comb Filter 2DIG

V/A norm V

FM Radio ---- X

MTS/SAP/DBX X

Built-in audio power 1.5Wx2 (10%)

Number of speakers 2

AI Sound X

A/V in (rear/front) 1(1/1)

Audio Out (F:FAO/V:VAO) --- F,V

S-VHS In (rear/front) --- 1/0

EPJ/HPJ/MISC HPJ

Dimensions mm

(WxDxH) in

Weight (kg/lbs) 18/39.6

Anode voltage

Video input jack 1Vp-p 75Ω, phono

Audio input jack 500mV rms, 47KΩ

A-Board TNP2AH040 DH* DK*

C-Board TNP2AA106 AF*

515.7x490.5x461.7

20.30x19.31x18.17

± 1.25 kV

26.60

Table 1. Receiver features

*Note: When ordering a board, add and ” S” after the board suffix application.

Example, If order A-Board for CT-20G7DF, should be ordered as:

TNP2AH040

DHS.

Specifications are subject to change without notice or obligation.

Dimensions and weights are approximate.

-6-

Chasis service adjustment procedures

All service adjustments are factory preset and should not require adjustment unless controls and/or

associated components are replaced.

Note: Connect the (-) lead of the voltmeter to the appropriate ground. Use IC801’s heat sink when the HOT

ground symbol ( ) is used. Otherwise, use COLD ground ( ) — tuner shield, IC451’s heat sink or FA2.

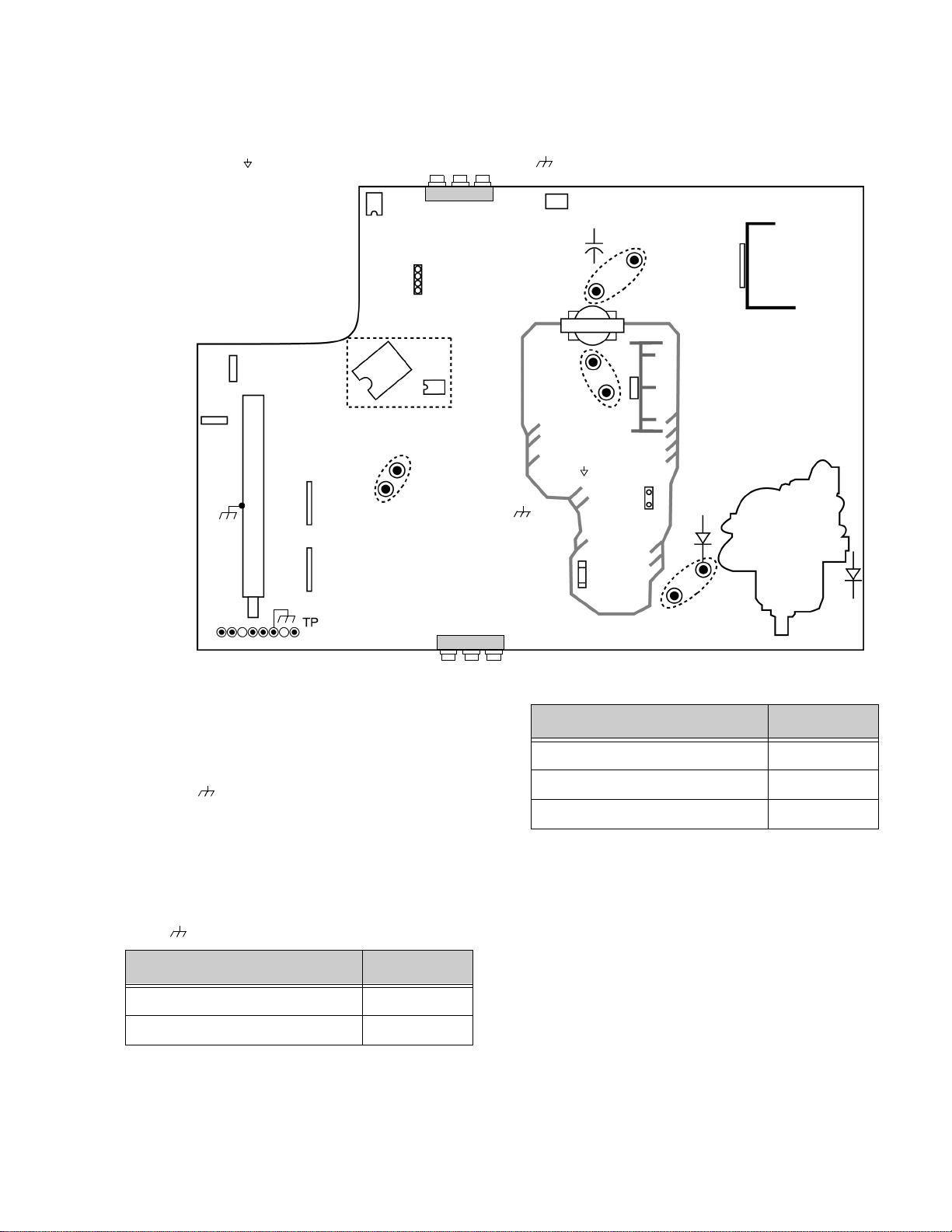

Figure 2. A-Board main

components

and test points

IC552

IC551

T

U

N

E

R

FA1

CLK

DATA

FA2

IC2302

IC2301

IC002

IC001

A11

TPE10

TPE11

IC050

COLD ( )

IC003

C825

TPD17

TPD15

TPD16

HOT ( )

F801

IC801

TPD14

CRT

GND

TPD9

IC451

D561

TPD8

D554

SCREENFOCUS

COMPONENTS WITHIN DOT LINES ARE LOCATED AT THE OPOSITESIDE OF BOARD.

130.0V B+ voltage confirmation

1. Set the BRIGHT and the PICTURE to minimum by

using the PICTURE menu.

2. Connect the DVM between C825 (+ side) and cold

ground ( ).

3. Confirm that B+ voltage is 130.0V ± 2.5V.This

voltage supplies B+ to the horizontal output &

flyback circuits.

Source voltage chart

120V AC line input. Set the BRIGHT and the PICTURE

to minimum by using the PICTURE menu. Use cold

ground

(

) for the (-) lead of the DVM.

LOCATION VOLTAGE

TPD8 26.0V ± 2V

TPD9 25.0V ± 2V

LOCATION VOLTAGE

IC552 Pin3 5.0V ± 0.25V

IC551 Pin3 9.0V ± 0.25V

D554 Cathode 200V ± 15V

Adjust PICTURE menu for normalized video

adjustments.

High voltage check

1. Select an active TV channel and confirm that the

horizontal is in sync.

2. Adjust BRIGHTNESS and PICTURE using picture

icon menu, so video just disappears.

3. Confirm B+ 130V is within limit.

4. Using a high voltage meter confirm that the high

voltage is:

26.60kV±1.25kV

-7-

Audiosignalpathblockdiagram

A-BOARD

LEFT

SPEAKER

-

+

OUT

LEFT

5

10

OUT

VAO

LEFT

AUDIO AMP

LEFT CHANNEL

TV IN

3

LEFT

VOL

6

SP SW

RIGHT

TV IN

3

RIGHT

SPEAKER

-

+

OUT

RIGHT

10

OUT

RIGHT

VOL

699

5

VAO

AUDIO AMP

RIGHT CHANNEL

SP SW

JK3002

REAR A/V

OUT

AUDIO

67

SP / CP

64

VOL

IC001

MPU/VCJ

M65580MAP10

only for CT-20D12DF

TNR001

MAIN TUNER

MTS

22

OUT

RIGHT

IN

RIGHT

IN

LEFT

ANN5829S-E1V.

CHANNELS

LEFT&RIGHT

21

OUT

LEFT

14

MPX IN

IC2201

Figure 3. Audio signal block diagram

A/V 2

2 3

RIGHT RIGHT

LEFT LEFT

JK3002

REAR A/V

JK3001

A/V 1

FRONT A/V

-8-

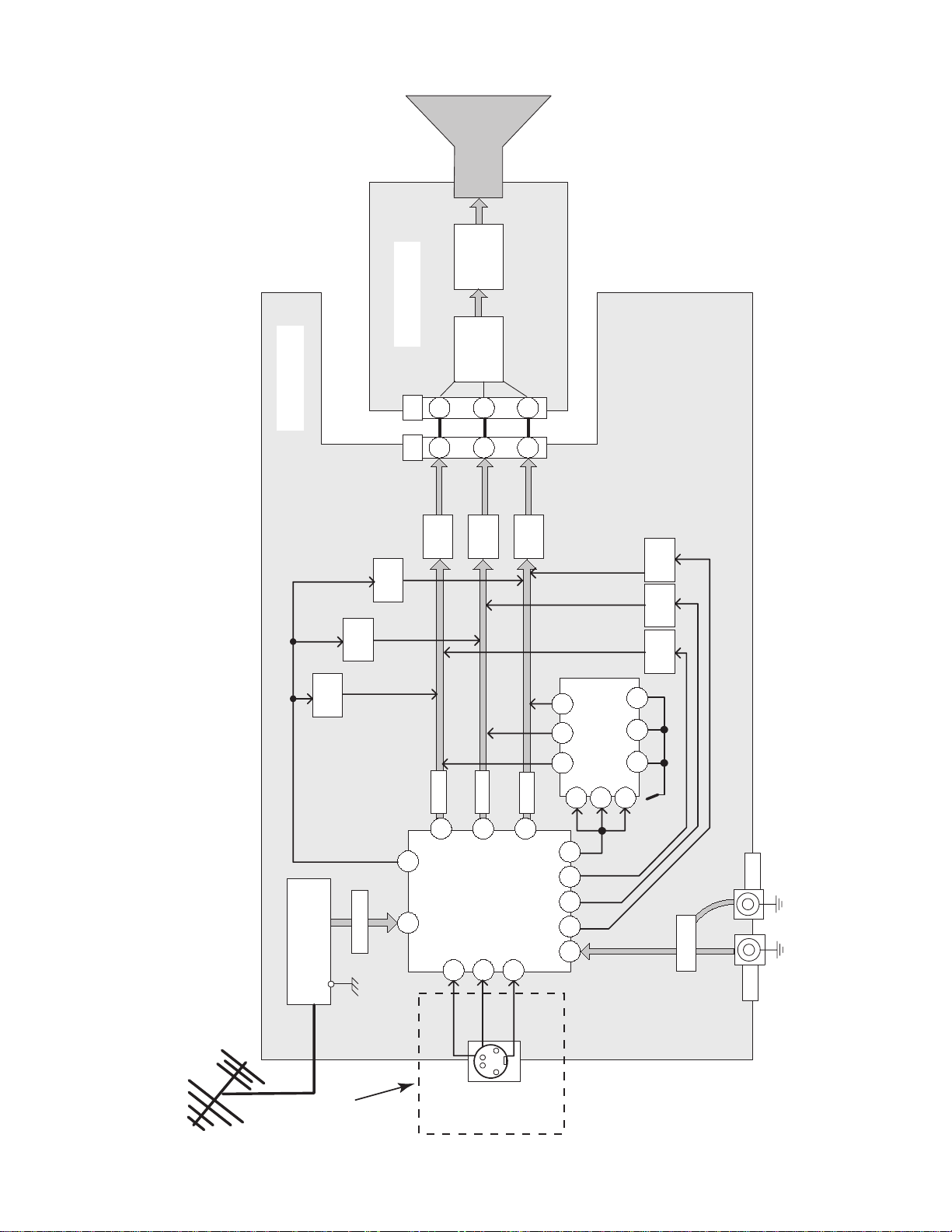

Videosignalpathblockdiagram

Q353 -B

Q351 -R

Q352 -G

C-BOARD

Q356 -B

Q354 -R

Q355 -G

1

2

A-BOARD

C1

A11

1

3

2

3

Q053

TNR001

MAIN TUNER

Q055

Q054

V IDEO IN

Q006

Q007

Q008

Q050 Q053 Q053

R

41 8

IC050

2 3 9

HALFTONE

6

TONE

HALF-

R

GB

OSD

EXT

5

59

48 49 51

20

R-OUT

G-OUT

B-OUT

28

28

FB

IC001

26

TV IN

Y IN

22

32

30

MPU/VCJ

M65580MAP10

C IN

SSW

24

72

13

3.3V

A/V 2

JK3002

REAR A/V

V IDEO IN

A/V 1

JK3001

FRONT A/V

JK3001

only for CT-20D12DF

Figure 4. Video signal block diagram

-9-

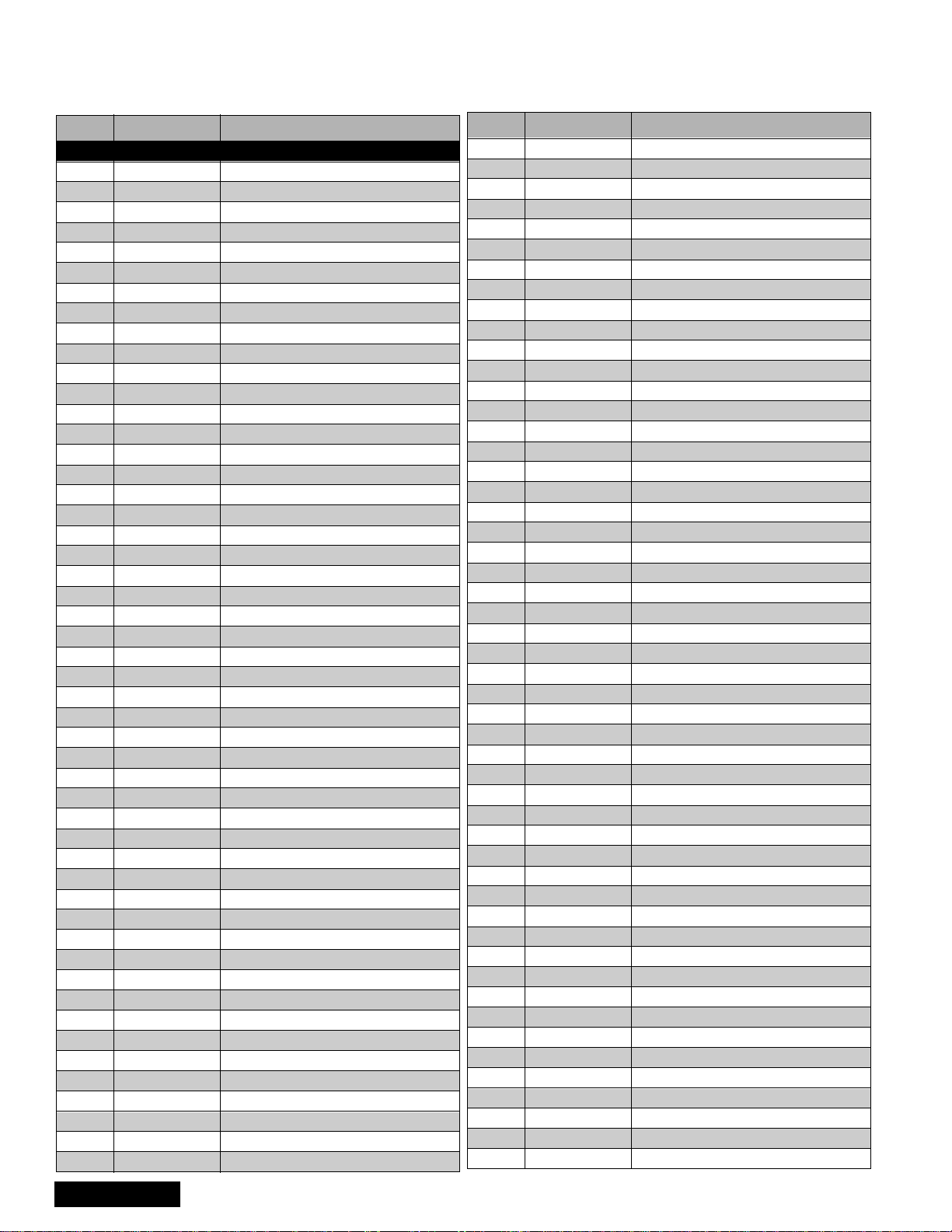

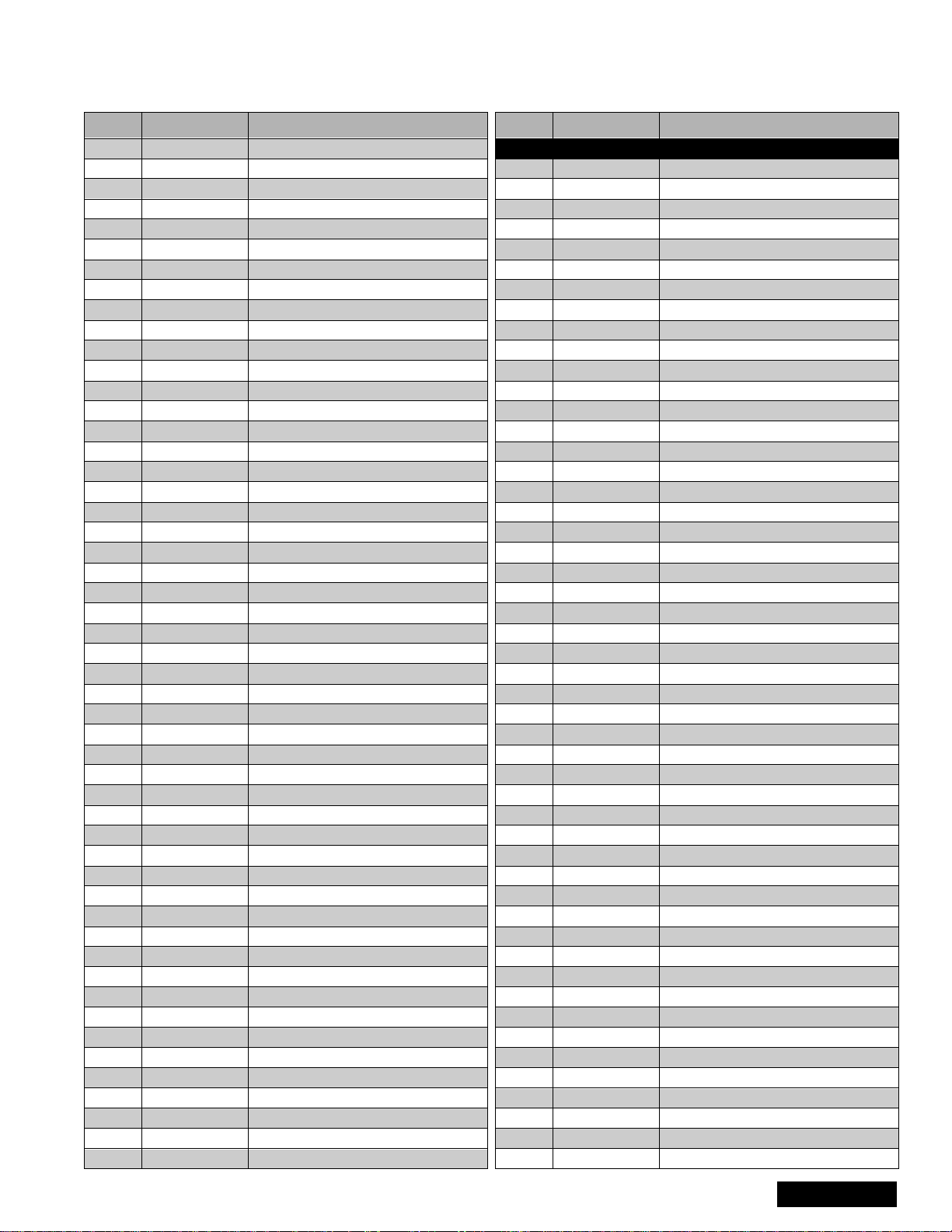

REPLACEMENT PARTS LIST

Models: CT-20D12DF, CT-20G7DF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

CAPACITORS

C001 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C002 TCJ2VB1H471K CAP,C 470PF-K-50V

C003 ECA1HM4R7B CAP,E 4.7UF-50V

C004 TCJ2VC1H150J CAP,C 15PF-J-50V

C005 TCJ2VC1H150J CAP,C 15PF-J-50V

C008 TCJ2VF1H104Z CAP,C .1UF-Z-50V

C009 ECA1AM470B CAP,E 47UF-10V

C010 TCJ2VF1H104Z CAP,C .1UF-Z-50V

C011 ECA1AM101B CAP,E 100UF-10V

C015 ECJ2VB1C224K CAP,C .22UF-K-16V

C016 TCJ2VC1H101J CAP,C 100PF-J-50V

C017 TCJ2VB1C104K CAP,C .1UF-K-16V

C018 TCJ2VC1H151J CAP,C 150PF-J-50V

C020 TCJ2VB1C104K CAP,C .1UF-K-16V

C022 TCJ2VC1H101J CAP,C 100PF-J-50V

C023 TCJ2VC1H151J CAP,C 150PF-J-50V

C024 ECA1AM470B CAP,E 47UF-10V

C025 TCJ2VB1C104K CAP,C .1UF-K-16V

C026 TCJ2VB1C104K CAP,C .1UF-K-16V

C027 TCJ2VC1H391J CAP,C 390PF-J-50V

C028 TCJ2VB1C104K CAP,C .1UF-K-16V

C029 ECQB1H333JF3 CAP,P .033UF-J-50V

C031 ECA1HMR22B CAP,E .22UF-50V

C032 ECA1AM470B CAP,E 47UF-10V

C033 TCJ2VC1H390J CAP,C 39PF-J-50V

C034 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C035 ECA1HM010B CAP,E 1UF-50V

C036 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C037 ECA1HM0R1B CAP,E 0.1UF/50V

C038 ECA1AM470B CAP,E 47UF-10V

C040 ECA1AM470B CAP,E 47UF-10V

C041 ECA1HM2R2B CAP,E 2.2UF-50V

C042 TCJ2VF1H104Z CAP,C .1UF-Z-50V

C043 ECA1AM470B CAP,E 47UF-10V

C044 TCJ2VC1H471J CAP,C 470PF-J-50V

C045 ECA1HM0R1B CAP,E 0.1UF/50V

C046 TCJ2VB1C104K CAP,C .1UF-K-16V

C047 TCJ2VC1H220J CAP,C 22PF-J-50V

C048 TCJ2VC1H220J CAP,C 22PF-J-50V

C050 ECA1AM101B CAP,E 100UF-10V

C051 TCJ2VF1H104Z CAP,C .1UF-Z-50V

C054 TCJ2VF1H103Z CAP,C .01UF-Z-50V

PARTS LIST

C055 TCJ2VC1H560J CAP,C 56PF-J-50V

C057 ECKR1H471KB5 CAP,C470PF-K-50V

C103 ECA0JM331B CAP,E 330UF-6.3V

C104 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C105 ECA0JM101B CAP,E 100UF-6.3V

C350 ECA1CM101B CAP,E 100UF/16V

C351 TCJ2VB1H391K CAP,C 390PF-K-50V

C352 TCJ2VB1H391K CAP,C 390PF-K-50V

CT-20D12DF

CT-20D12DF

REF NO. PART NO. DESCRIPTION

C353 TCJ2VB1H471K CAP,C 470PF-K-50V

C354 ECKW3D102KBN CAP,C .001UF-K-2KVDC

C357 EEANA1E1R0B CAP,E 1.0U F- 25V

C361 TCJ2VC1H151J CAP,C 150PF-J-50V

C362 TCJ2VC1H151J CAP,C 150PF-J-50V

C363 TCJ2VC1H151J CAP,C 150PF-J-50V

C451 ECA1CHG470B CAP,E 47UF-16V

C452 ECSF1EE105VB CAP,E 1.0UF-25V

C453 ECEA1HFS2R2B CAP,E 2.2UF-50V

C454 ECA1EM102E CAP,E 1000UF-25V

C455 ECA1EHG101B CAP,E 100UF -25V

C456 ECQB1H103JF3 CAP,P .01UF-J-50V

C459 ECA1VHG471B CAP,E 470UF -35V

C462 ECA1HM4R7B CAP,E 4.7UF-50V

C502 TCJ2VC1H471J CAP,C 470PF-J-50V

C503 TCJ2VB1C104K CAP,C.1UF-K-16V

C504 TCJ2VB1C104K CAP,C .1UF-K-16V

C510 ECCR2H100D5 CAP,C 10PF-D-500V

C511 ECKR2H821KB5 CAP,C 820PF-K-500V

C512 ECKR2H101KB5 CAP,C 100UF-K-500V

C531 ECA1EM220B CAP,E 22UF-25V

C551 ECA1VM331B CAP,E 330UF-35V

C554 ECKR2H561KB5 CAP,C 560PF-K-500V

C555 ECA2EM220E CAP,E 22UF-250V

C556 ECA1CM471B CAP,E 470UF-16V

C557 ECKR2H222KB5 CAP,C 2200PF-K-500V

C560 ECEA1HN010UB CAP,E 1UF/50V

C561 ECKR2H561KB5 CAP,C 560PF-K-500V

C563 ECWH12H362JS CAP,P 3600PF-J-1250 VDC

C564 ECWH12H562JS CAP,P .0056UF-J-1.2KV

C565 ECKW3D331JBR CAP,C 330PF-J-2KV

C566 ECKW3D181JBP CAP,C 180PF-J-2KV

C568 ECQM4473JZW CAP,P .047UF-J-400V

C569 ECWF2394JBB CAP,P .39UF-J-200V

C570 ECA1CM222E CAP,E 2200UF-16V

C571 ECA1EM220B CAP,E 22UF-25V

C572 ECA1CM100B CAP,E 10UF-16V

C573 ECA1CM101B CA P,E 100UF/16V

C575 ECA0JM222B CAP,E 2200UF-6.3V

C577 ECA1CM101B CA P,E 100UF/16V

C578 ECA0JM332B CAP,E 3300PF-6.3V

C579 TCJ2VC1H100D CAP,C 10PF-J-50V

C580 ECKR2H152KB5 CAP,C .0015UF-K-500V

C605 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C606 ECA0JM221B CAP,E 220UF-6.3V

C800 ECKR3A391KBP CAP,C 390PF-K-1KVDC

C801 ECKWAE472ZED CAP,C4700PF-Z-500V

C802 ECKWAE472ZED CAP,C 4700PF-Z-500V

C803 ECKWAE472ZED CAP,C4700PF-Z-500V

C805 EC0S2DA221BB CAP,E 220UF/200V

C806 ECQM4103KZW CAP,P .01UF-K-400V

Parts List

-10-

120-02

REPLACEMENT PARTS LIST

Models: CT-20D12DF, CT-20G7DF

Important Safety Notice: Components printed in BOLD TYPE have special characteristics important for safety. When replacing

any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

C807 ECKR3A821KBP CAP,C 820PF-K-1KV

C808 ECA1VM101B CAP,E 100UF-35V

C809 ECKR1H101KB5 CAP,C100PF-K-50V

C810 ECKR1H471KB5 CAP,C470PF-K-50V

C812 ECQU2A224MVA CAP,P .22UF-M-250VAC

C813 ECQU2A153MVA CAP,P .015UF-M-250VAC

C814 ECQU2A153MVA CAP,P .015UF-M-250VAC

C820 ECA1CM101B CAP,E 100UF/16V

C821 TCJ2VF1H103Z CAP,C .01UF-Z-50V

C822 ECKR3A221KBP CAP,C 220PF-K-1KV

C823 ECA1VM471E CAP,E 470UF-35V

C824 ECKR3A102KBP CAP,C 1000PF-K-1KV

C825 EEUMG2C221S CAP,E 220UF-160V

C826 ECKR3A471KBP CAP,C 470PF-K-1KV

C827 ECA1CM471B CAP,E 470UF-16V

C828 ECA160V33UE CAP,E 33UF/160V

C2201 ECA1HM4R7B CAP,E 4.7UF-50V

C2202 ECA1HM2R2B CAP,E 2.2UF-50V

C2203 ECA1HM4R7B CAP,E 4.7UF-50V

C2204 AP106K016CAE CAP,T 10UF/16V

C2205 ECA 1HMR33B CAP,E .33UF-50V

C2206 ECQB1H223JF3 CAP,P .022UF-J-50V

C2207 AP335K016CAE CAP,T 3.3UF/16V

C2208 TCJ2VB1C104K CAP,C .1UF-K-16V

C2209 TCJ2VB1C104K CAP,C .1UF-K-16V

C2210 TCJ2VB1C104K CAP,C .1UF-K-16V

C2212 ECQB1H473JF3 CAP,P .047U F-J-50V

C2213 ECA1HMR47B CAP,E .47UF-50V

C2214 ECA1AM101B CAP,E 100UF-10V

C2215 EEANA1E100B CAP,E 10UF-25V

C2216 TCJ2VC1H100D CAP,C 10PF-J-50V

C2301 ECA1EM102E CAP,E 1000UF-25V

C2302 ECEA1HN010UB CAP,E 1UF/50V

C2303 ECA1EM101B CAP,E 100UF-25V

C2304 ECA1CM100B CAP,E10UF-16V

C2307 ECA1CM102B CAP,E1000UF/16V

C2309 ECA1HM010B CAP,E 1UF-50V

C2311 ECA1EM102E CAP,E 1000UF-25V

C2312 ECEA1HN010UB CAP,E 1UF/50V

C2313 ECA1EM101B CAP,E 100UF-25V

C2314 ECA1CM100B CAP,E10UF-16V

C2317 ECA1CM102B CAP,E1000UF/16V

C2319 ECA1HM010B CAP,E 1UF-50V

C2320 ECA1CM100B CAP,E10UF-16V

C2330 ECA1CM100B CAP,E10UF-16V

C2350 ECA1HM100B CAP,E10UF/50V

C3001 ECA1HM0R1B CAP,E 0.1UF/50V

C3012 ECA1HM010B CAP,E1UF-50V

C3018 ECA1HM010B CAP,E 1UF-50V

C3050 TCJ2VF1H103Z CAP,C.01UF-Z-50V

C3051 TCJ2VF1H103Z CAP,C.01UF-Z-50V

CT-20D12DF

CT-20D12DF

CT-20D12DF

CT-20D12DF

REF NO. PART NO. DESCRIPTION

DIODES

D002 MA165TA5VT DIODE, SWITCHING

D006 MA4330HTA DIODE

D052 MA4068MTA DIODE, ZENER

D053 MA4056MTA DIODE

D055 MA4056MTA DIODE

D451 ERA15-01V3 DIODE, RECTIFIER

D452 MA4047MTA DIODE

D453 MA165TA5VT DIODE, SWITCHING

D454 MA165TA5VT DIODE, SWITCHING

D456 MA4047MTA DIODE

D502 MA4047MTA DIODE

D531 AS01V0 DIODE

D551 D1NL20UV70 DIODE

D554 AU02V0 DIODE

D558 RS3FS DIODE

D559 BYD33G-113 DIODE

D561 AU02V0 DIODE

D571 MA165TA5VT DIODE, SWITCHING

D606 MA165TA5VT DIODE, SWITCHING

D607 MA152KTX DIODE

D608 MA152KTX DIODE

D609 MA152KTX DIODE

D801 D3SBA60-4103 DIODE

D806 TAP2AA0001 PTC 5-OHM

D808 SARS01V1 DIODE

D809 AG01V0 DIODE

D810 AG01V0 DIODE

D811 AG01V0 DIODE

D812 MA4068MTA DIODE, ZENER

D820 MA165TA5VT DIODE, SWITCHING

D821 MA4047HTA DIODE

D822 RN1ZLF-B1 DIODE

D823 S3L60P154004 DIODE

D824 D1NL20UV70 DIODE

D2305 MA3110MTX DIODE, ZENER

D2306 MA3110MTX DIOD E, ZENER

D2307 MA3110MTX DIODE, ZENER

D2308 MA3110MTX DIOD E, ZENER

D2350 MA4068MTA DIODE, ZENER

D2351 MA165TA5VT DIODE, SWITCHING

D2352 MA165TA5VT DIODE, SWITCHING

D2353 MA165TA5VT DIODE, SWITCHING

D2354 MA4091MTA DIODE

D3001 MA3110MTX DIOD E, ZENER

D3003 MA3110MTX DIODE, ZENER

D3004 MA3110MTX DIOD E, ZENER

D3005 MA3110MTX DIODE, ZENER

D3006 MA3110MTX DIOD E, ZENER

D3017 MA3110MTX DIODE, ZENER

D3018 MA3110MTX DIOD E, ZENER

CT-20D12DF

CT-20D12DF

CT-20D12DF

CT-20D12DF

PARTS LIST

120-02

-11-

Parts List

Loading...

Loading...