Panasonic CS-VA70KE, CS-VA90KE, CU-VA70KE, CU-VA90KE, CS-VA120KE Service Manual

...

© 1999 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

CS-VA70KE

CU-VA70KE

CS-VA90KE

CU-VA90KE

CS-VA120KE

CU-VA120KE

Room Air Conditioners

Order number RAC9911056C2

1 Features 3

2 Functions

4

2.1. REMOTE CONTROL

4

2.2. INDOOR UNIT

5

2.3. OUTDOOR UNIT

6

3 Product Specifications

7

3.1. CS-VA70KE / CU-VA70KE

7

3.2. CS-VA90KE / CU-VA90KE

9

3.3. CS-VA120KE / CU-VA120KE

11

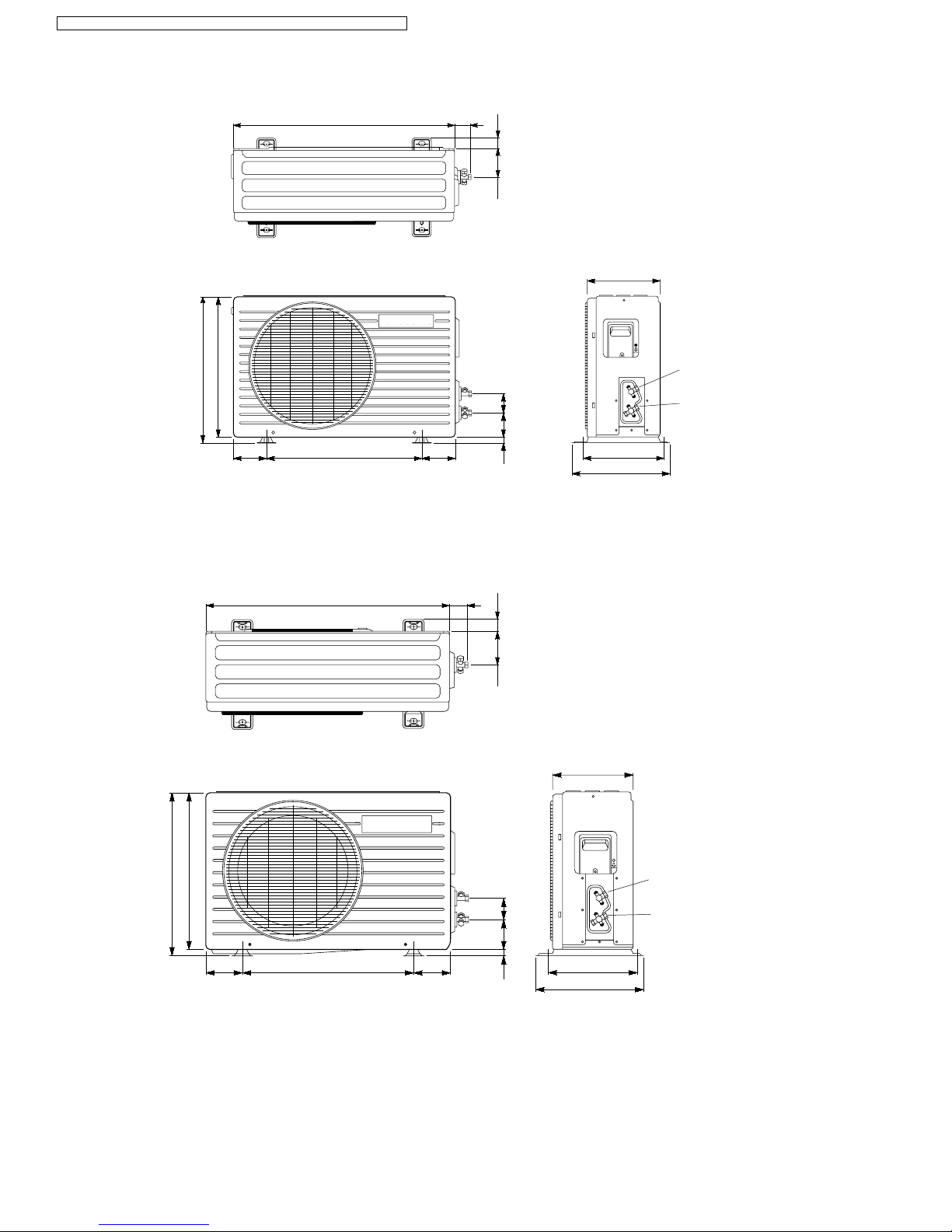

4 Dimensions

13

4.1. CS-VA70KE / CS-VA90KE / CS-VA120KE (INDOOR

UNIT)

13

4.2. CU-VA70KE / CU-VA90KE (OUTDOOR UNIT)

14

4.3. CU-VA120KE(OUTDOOR UNIT)

14

5 Refrigeration Cycle Diagram

15

5.1. CS-VA70KE / CU-VA70KE, CS-VA90KE / CU-VA90KE

15

5.2. CS-VA120KE / CU-VA120KE

16

6 Block Diagram

17

7 Wiring Diagram

18

8 Operation Details

19

8.1. COOLING MODE OPERATION

19

8.2. SOFT DRY MODE OPERATION

21

8.3. HEATING MODE OPERATION

23

8.4. AUTOMATIC MODE OPARATION

27

8.5. SLEEP MODE AUTO OPERATION

27

8.6. AUTO RESTART CONTROL

28

8.7. INDOOR FAN MOTOR CONTROL

28

8.8. AIRFLOW DIRECTION CONTROL

29

8.9. DELAY ON TIMER CONTROL

29

9 Installation And Servicing Air Conditioner Using R410A

30

9.1. OUTLINE

30

9.2. TOOLS FOR INSTALLING/SERVICING REFRIGERANT

PIPING

31

9.3. REFRIGERANT PIPING WORK

35

9.4. INSTALLATION, TRANSFERRING SERVICING

37

10 Installation Information

41

10.1. ATTACHED ACCESSORIES

41

10.2. SELECT THE BEST LOCATION

41

10.3. INDOOR/OUTDOOR UNIT INSTALLATION DIAGRAM

42

11 2-WAY / 3-WAY VALES

43

11.1. EVACUATION OF INSTALLATION

44

11.2. PUMPING DOWN

45

11.3. EVACUATION OF RE-INSTALLATION

46

11.4. BALANCE REFRIGERANT OF THE 2-WAY, 3-WAY

VALVE

47

11.5. EVACUATION

48

12 Servicing Information

49

12.1. INSPECTION POINTS FOR THE INDOOR ELECTRONIC

CONTROLLER

49

12.2. INDOOR FAN MOTOR REMOVAL PROCEDURE

49

12.3. CROSS FLOW FAN REMOVAL PROCEDURE

51

12.4. OUTDOOR UNIT SERVICING

52

12.5. REMOTE CONTROL RESET

52

12.6. CHANGING THE WIRELESS REMOTE CONTROL

TRANSMISSION CODE

53

13 Troubleshooting Guide

54

13.1. RELATIONSHIP BETWEEN THE CONDITION OF THE

AIR CONDITIONER AND GAS PRESSURE AND

ELECTRIC CURRENT

55

13.2. DIAGNOSIS METHODS OF A MALFUNNCTION OF A

COMPRESSOR AND A 4-WAY VALVE

55

14 Technical Data

56

14.1. THERMOSTAT CHARACTERISTICS

56

14.2. OPERATION CHARACTERISTICS

57

15 Electronic Circuit Diagram

60

15.1. HOW TO USE ELECTRONIC CIRCUIT DIAGRAM

60

15.2. ELECTRONIC CIRCUIT DIAGRAM

61

15.3. CHARACTERISTICS CHART

63

15.4. REMOTE CONTROLLER

64

15.5. TIMER TABLE

65

16 Printed Circuit Board

66

16.1. INDOOR UNIT (MAIN)

66

17 Exploded View & Replacement Parts List

67

17.1. CS-VA70KE / CS-VA90KE

67

17.2. CS-VA120KE

69

17.3. CU-VA70KE / CU-VA90KE

71

17.4. CU-VA120KE

73

18 Electronic Parts List

75

CONTENTS

Page Page

2

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

·

R410A

No Ozone Layer Damage

Our new models use R410A as its refrigerant.

This Refrigerant does not contain chlorine, so there´s no

danger of damage to the ozone layer.

·

Compact Design

·

Comfort Improvement

−

− −

−

Wider range of horizontal discharge air

−

− −

−

Longer hours of sleep mode operation

·

Auto Restart

−

− −

−

Auto restart operation after power failure

·

Removable and Washable Front Panel

·

Deodorizing Air Purifying Filter

−

− −

−

Air Purifying Filter features a deodorizing function that

removes unpleasant odors from the air.

·

Installation Work Improvement

−

− −

−

Long piping up to 10 m (CS-VA70KE / CS-VA90KE)

−

− −

−

Long piping up to 15 m (CS-VA120KE)

·

Quality Improvement

−

− −

−

Low voltage protection

−

− −

−

Gas leakage protection

−

− −

−

Prevent compressor reverse cycle

−

− −

−

2-stage OLP to protect compressor

(CS-VA90KE / CS-VA120KE)

·

Service Improvement

−

− −

−

Easy fan motor replacement procedure

−

− −

−

Front side servicing for outdoor unit

1 Features

3

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

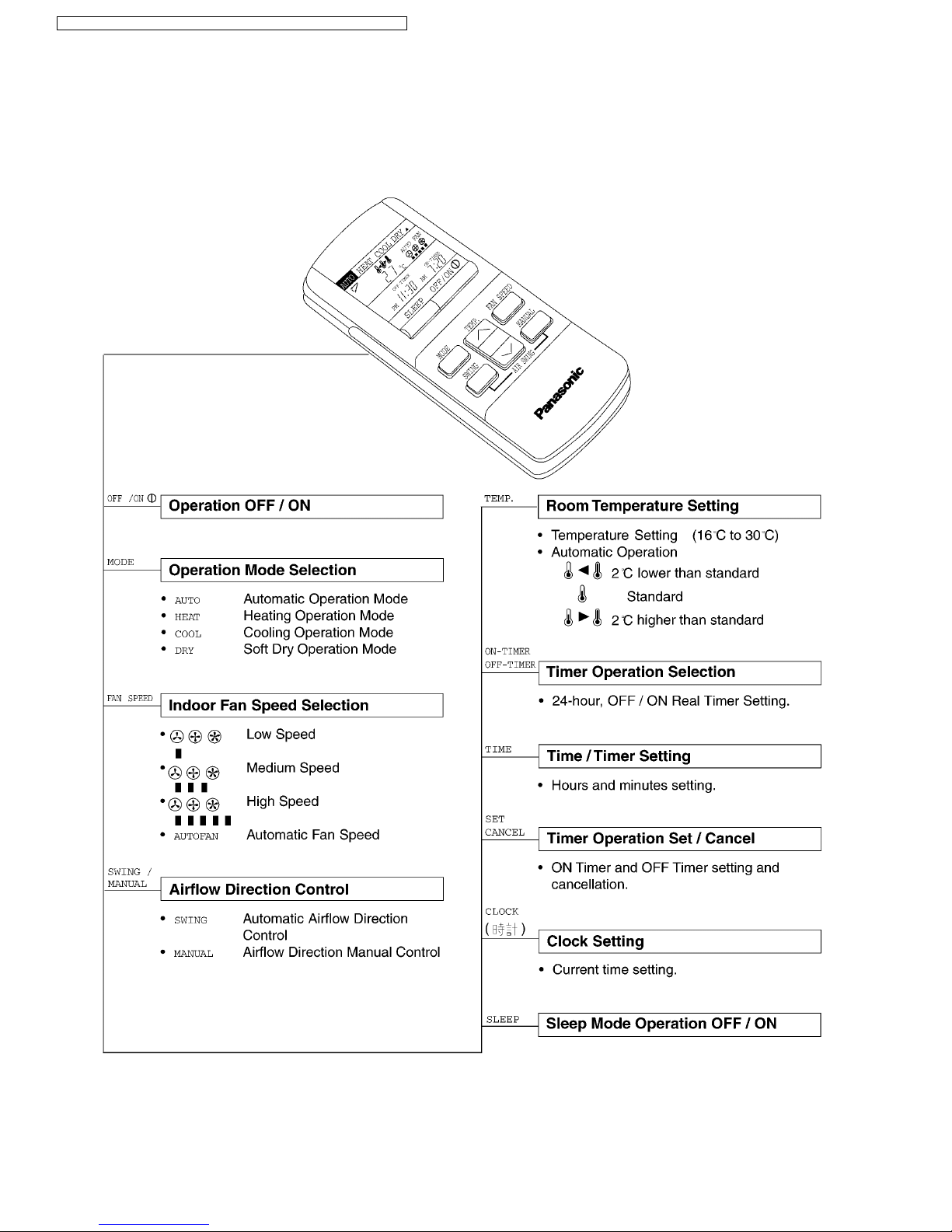

2 Functions

2.1. REMOTE CONTROL

4

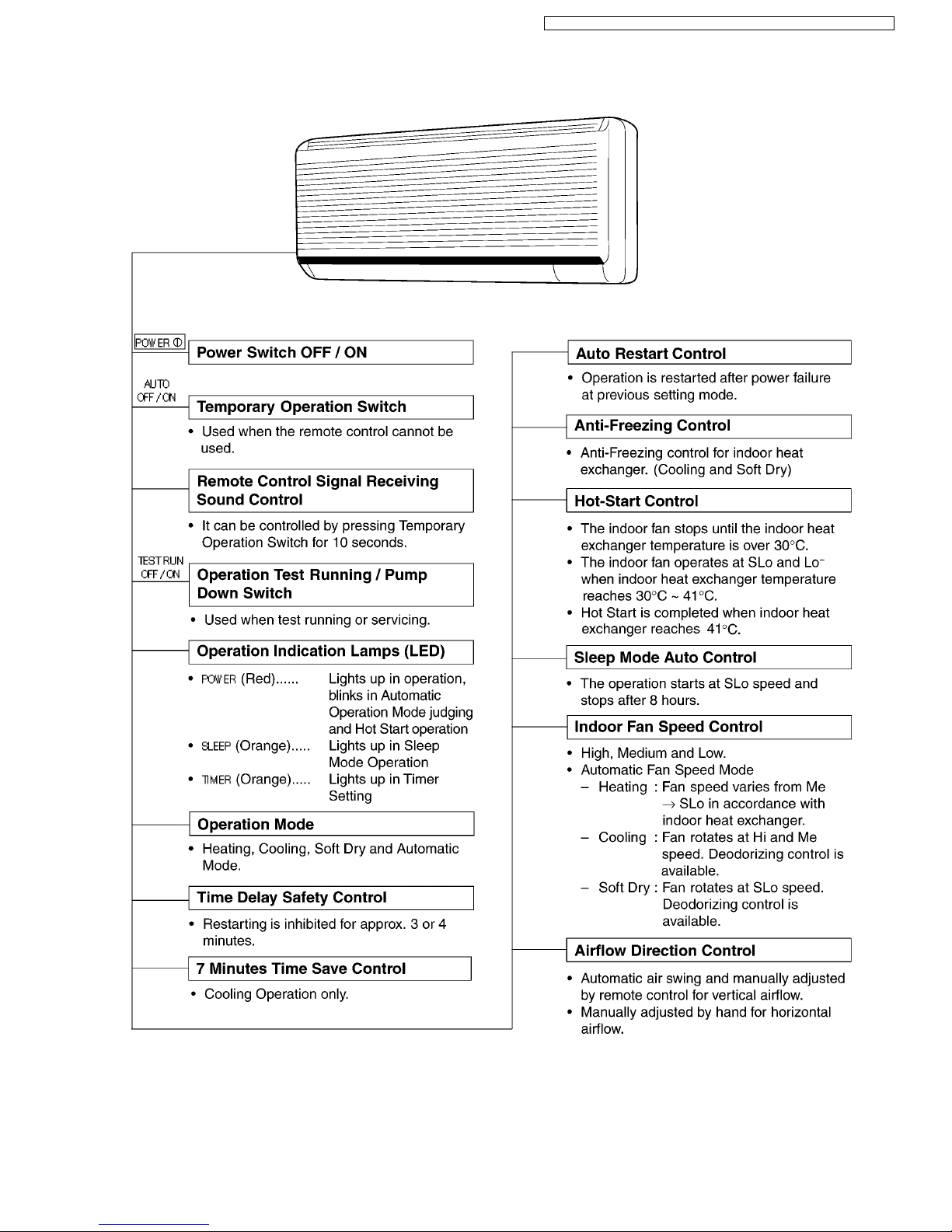

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

2.2. INDOOR UNIT

5

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

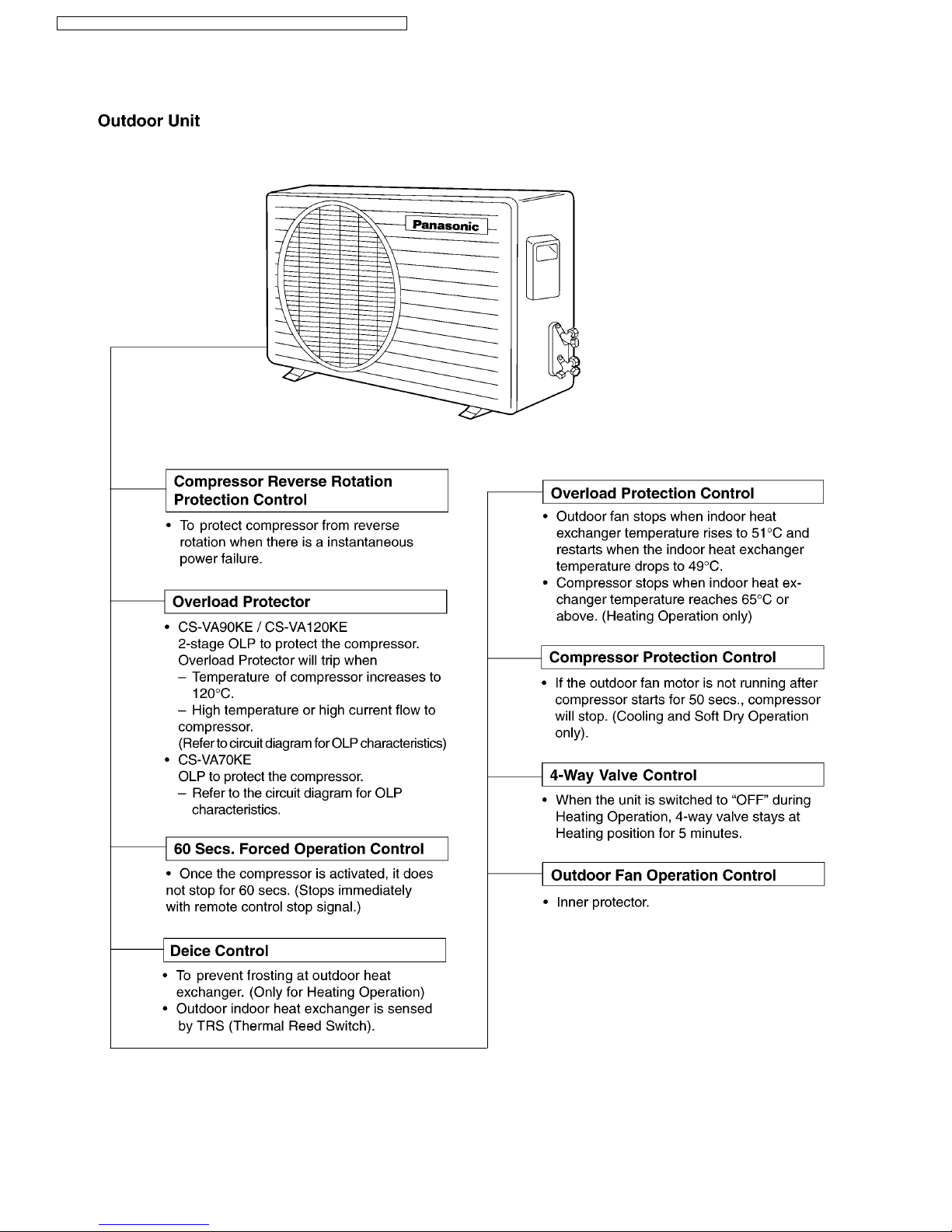

2.3. OUTDOOR UNIT

6

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120 KE

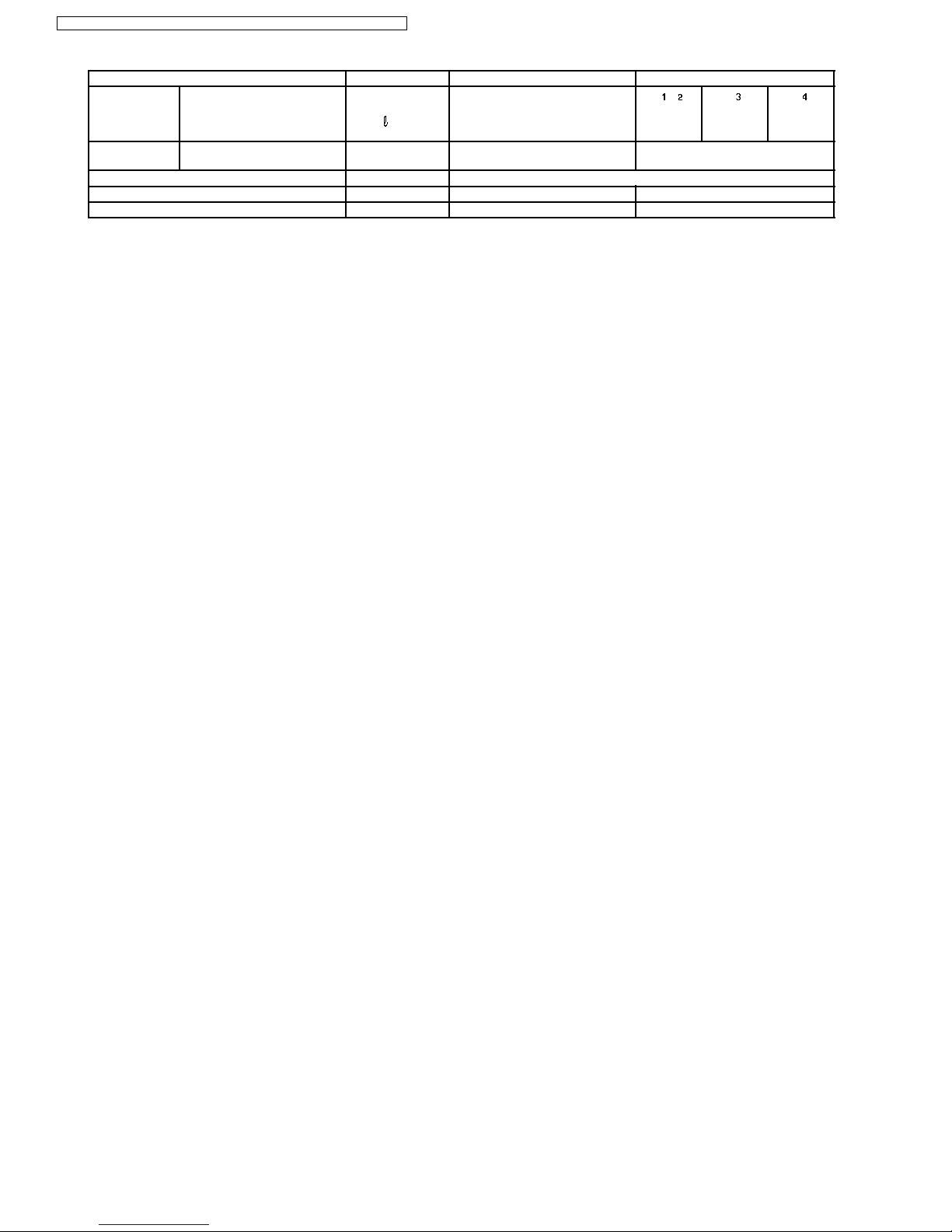

3 Product Specifications

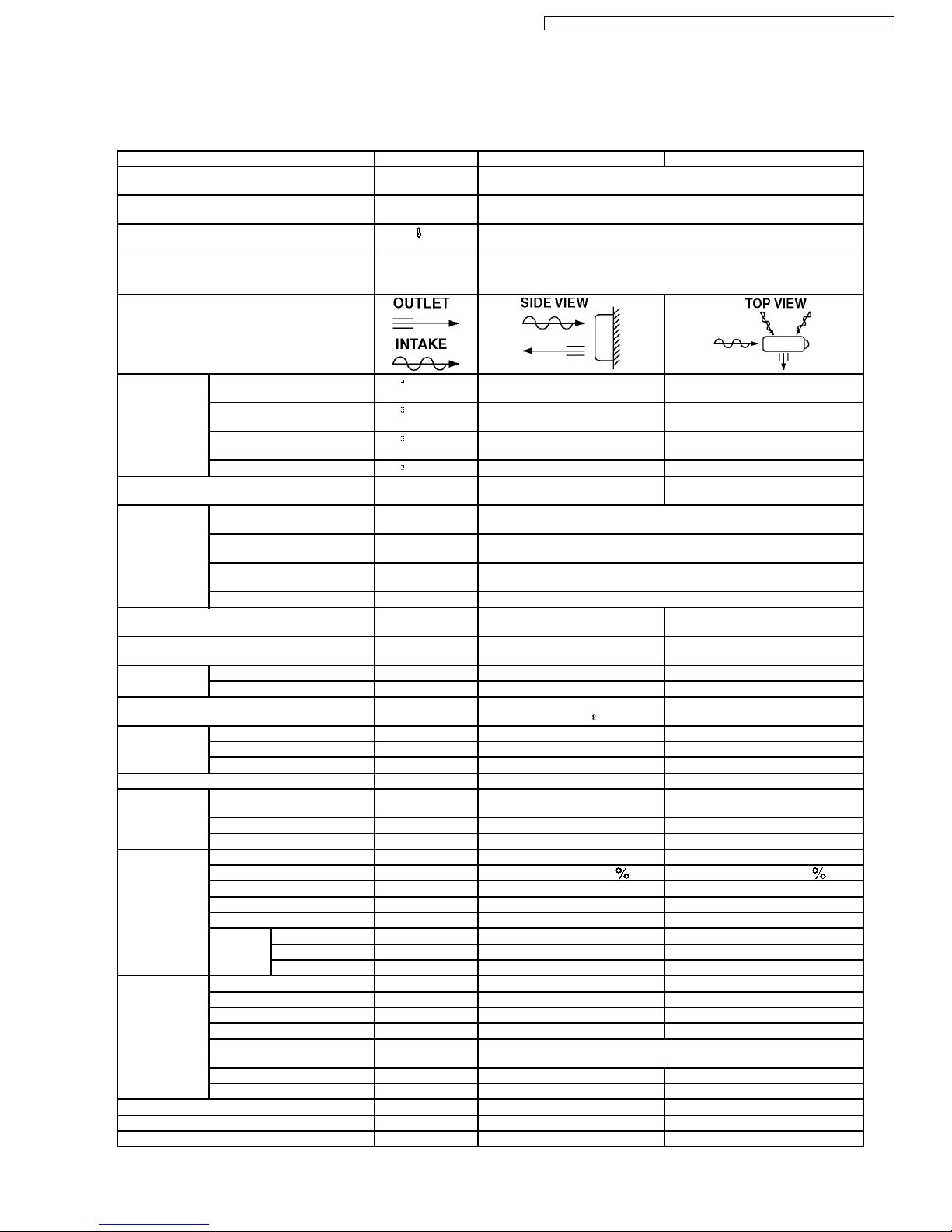

3.1. CS-VA70KE / CU-VA70KE

Unit CS-VA70KE CU-VA70KE

Cooling Capacity kW

Btu/h

2.20

7,500

Heating Capacity kW

Btu/h

2.35

8,000

Moisture Removal /h

Pint/h

1.3

2.7

Power Source Phase

V

Cycle

Single

230

50

Airflow Method

Air Volume Indoor Air(Lo) m / min(cfm) Cooling ; 5.5(190)

Heating ; 5.5(190)

-

Indoor Air(Me) m / min(cfm) Cooling ; 6.0(210)

Heating ; 6.0(210)

-

Indoor Air(Hi) m / min(cfm) Cooling ; 6.7(240)

Heating ; 6.7(240)

-

Outdoor Air m / min(cfm) - 22.4(790)

Noise Level dB(A) Cooling ; High 34,Low 30

heating ; High 33,Low 29

Cooling ; 46

Heating ; 48

Electrical

Data

Input kW Cooling ; 0.64

Heating ; 0.60

Running Current A Cooling ; 3.2

Heating ; 3.0

COP Cooling ; 3.44

Heating ; 3.92

Starting Current A 13

Piping Connection Port

(Flare piping)

inch

inch

G ; Half Union 3/8”

L ; Half Union 1/4”

G ; 3-Way valve 3/8”

L ; 2-Way valve 1/4”

Pipe Size

(Flare piping)

inch

inch

G(gas side) ; 3/8”

L(liquid side) ; 1/4”

G(gas side) ; 3/8”

L(liquid side) ; 1/4”

Drain

Hose

Inner diameter mm 12 Length m 0.7 -

Power Cord length

Number of core-wire

2.1 m

3 (1.0 mm

)

-

-

Dimensions Height inch(mm) 11 - 7/16(290) 18 - 29/32(480)

Width inch(mm) 31 - 15/32(799) 30 - 23/32(780)

Depth inch(mm) 6 - 29/32(175) 9 - 21/32(245)

Net Weight lb(kg) 18(8.0) 64(29.0)

Compressor Type - Rotary(1 cylinder

rolling piston type

Motor Type - Induction(2-poles)

Rated Output W - 550

Air Circularizing Type Cross-flow Fan Propeller Fan

Material AS+Glass Fiber 30 AES+Glass Fiber 12

Motor Type Transiator(4-poles) Induction(6-poles)

Input W - 58.6

rated Output W 20 20

Fan

Speed

Low rpm 950 Medium rpm 1,030 High(heating) rpm 1,550 730

Heat

Exchange

description Evaporator Condenser

Tube material Copper Copper

Fine material Aluminium Aluminium

Fine type Slit Fin Corrugated Fin

Row/Stage (Plate fin configuration, forced draft)

2x12

1x18

FPI 18 18

Size(W x H x L) mm 600 x 252 x 25.4 856 x 457.2 x 22

Refrigerant Control Device - Capillary Tube

refrigeration Oil (c.c) - RB68A(300)

Refrigerant(R410A) g(oz) - 860(30.4)

7

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

Unit CS-VA70KE CU-VA70KE

Thermostat Electronic Control Protection Device - Overload Protector

Capillary Tube

Length

flow Rate

Inner Diameter

mm

/min

mm

-

-

-

C ,C

970

5.0

1.2

C

310

11.3

1.3

C

610

6.5

1.2

Air Filter Material

style

P.P

Honeycomb

-

Capacity Control Capillary Tube

Compressor Capacitor µF,VAC - 25µF,370VAC

Fan motor Capacitor µF,VAC - 1.2µF,400VAC

·

Specifications are subject to change without notice for further improvement.

8

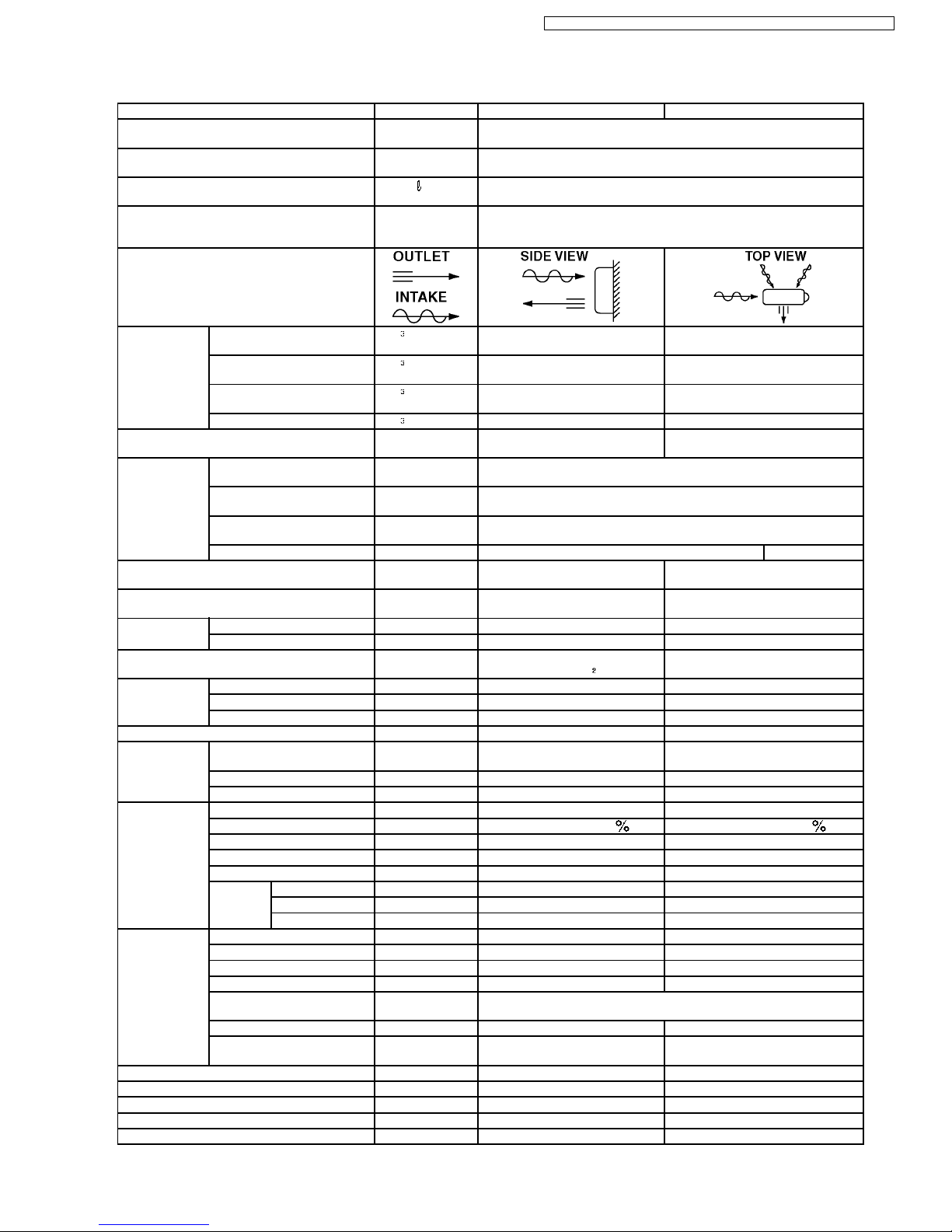

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

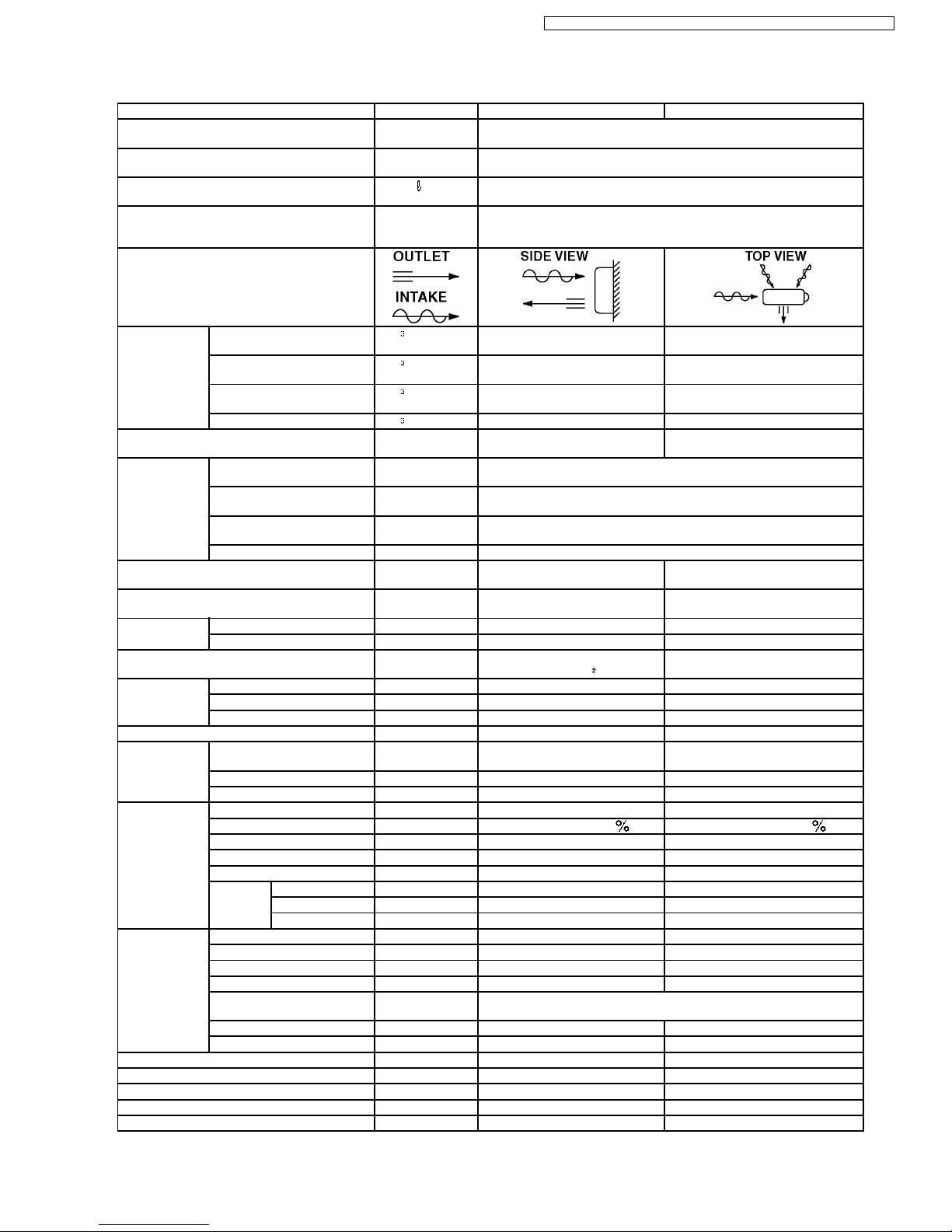

3.2. CS-VA90KE / CU-VA90KE

Unit CS-VA90KE CU-VA90KE

Cooling Capacity kW

Btu/h

2.85

9,700

Heating Capacity kW

Btu/h

3.30

11,300

Moisture Removal /h

Pint/h

1.6

3.4

Power Source Phase

V

Cycle

Single

230

50

Airflow Method

Air Volume Indoor Air(Lo) m / min(cfm) Cooling ; 6.3(220)

Heating ; 6.4(230)

-

Indoor Air(Me) m / min(cfm) Cooling ; 7.4(260)

Heating ; 7.5(260)

-

Indoor Air(Hi) m / min(cfm) Cooling ; 8.5(300)

Heating ; 8.6(300)

-

Outdoor Air m / min(cfm) - 22.4(790)

Noise Level dB(A) Cooling ; High 38,Low 30

heating ; High 38,Low 30

Cooling ; 48

Heating ; 48

Electrical

Data

Input kW Cooling ; 0.94

Heating ; 0.86

Running Current A Cooling ; 4.3

Heating ; 4.0

COP Cooling ; 3.03

Heating ; 3.84

Starting Current A 20

Piping Connection Port

(Flare piping)

inch

inch

G ; Half Union 3/8”

L ; Half Union 1/4”

G ; 3-Way valve 3/8”

L ; 2-Way valve 1/4”

Pipe Size

(Flare piping)

inch

inch

G(gas side) ; 3/8”

L(liquid side) ; 1/4”

G(gas side) ; 3/8”

L(liquid side) ; 1/4”

Drain

Hose

Inner diameter mm 12 Length m 0.7 -

Power Cord length

Number of core-wire

2.1 m

3 (1.0 mm

)

-

-

Dimensions Height inch(mm) 11 - 7/16(290) 18 - 29/32(480)

Width inch(mm) 31 - 15/32(799) 30 - 23/32(780)

Depth inch(mm) 6 - 29/32(175) 9 - 21/32(245)

Net Weight lb(kg) 18(8.0) 71(32.0)

Compressor Type - Rotary(1 cylinder

rolling piston type

Motor Type - Induction(2-poles)

Rated Output W - 750

Air Circularizing Type Cross-flow Fan Propeller Fan

Material AS+Glass Fiber 30 AES+Glass Fiber 12

Motor Type Transiator(4-poles) Induction(6-poles)

Input W - 58.6

rated Output W 20 20

Fan

Speed

Low rpm 980 Medium rpm 1,150 High(heating) rpm 1,310 730

Heat

Exchange

description Evaporator Condenser

Tube material Copper Copper

Fine material Aluminium Aluminium

Fine type Slit Fin Corrugated Fin

Row/Stage (Plate fin configuration, forced draft)

2x12

1x18

FPI 18 19

Size(W x H x L) mm 600 x 252 x 25.4 856 x 457.2 x 22

Refrigerant Control Device - Capillary Tube

refrigeration Oil (c.c) - RB68A(350)

Refrigerant(R410A) g(oz) - 880(31.1)

Thermostat Electronic Control Protection Device - Overload Protector

9

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

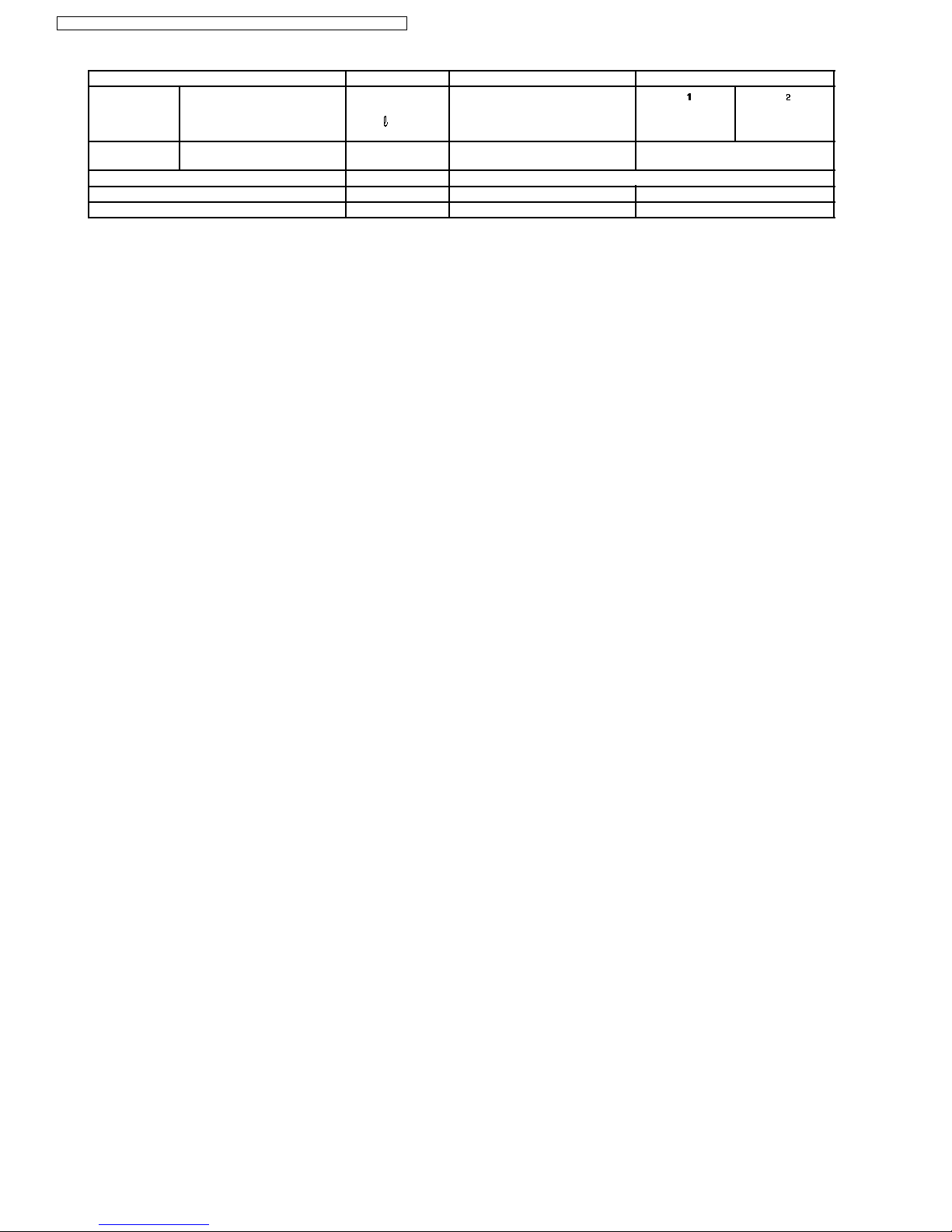

Unit CS-VA90KE CU-VA90KE

Capillary Tube

Length

flow Rate

Inner Diameter

mm

/min

mm

-

-

-

C ,C

970

5.0

1.2

C

750

15.4

1.7

C

590

8.2

1.3

Air Filter Material

style

P.P

Honeycomb

-

Capacity Control Capillary Tube

Compressor Capacitor µF,VAC - 25µF,370VAC

Fan motor Capacitor µF,VAC - 1.2µF,400VAC

·

Specifications are subject to change without notice for further improvement.

10

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

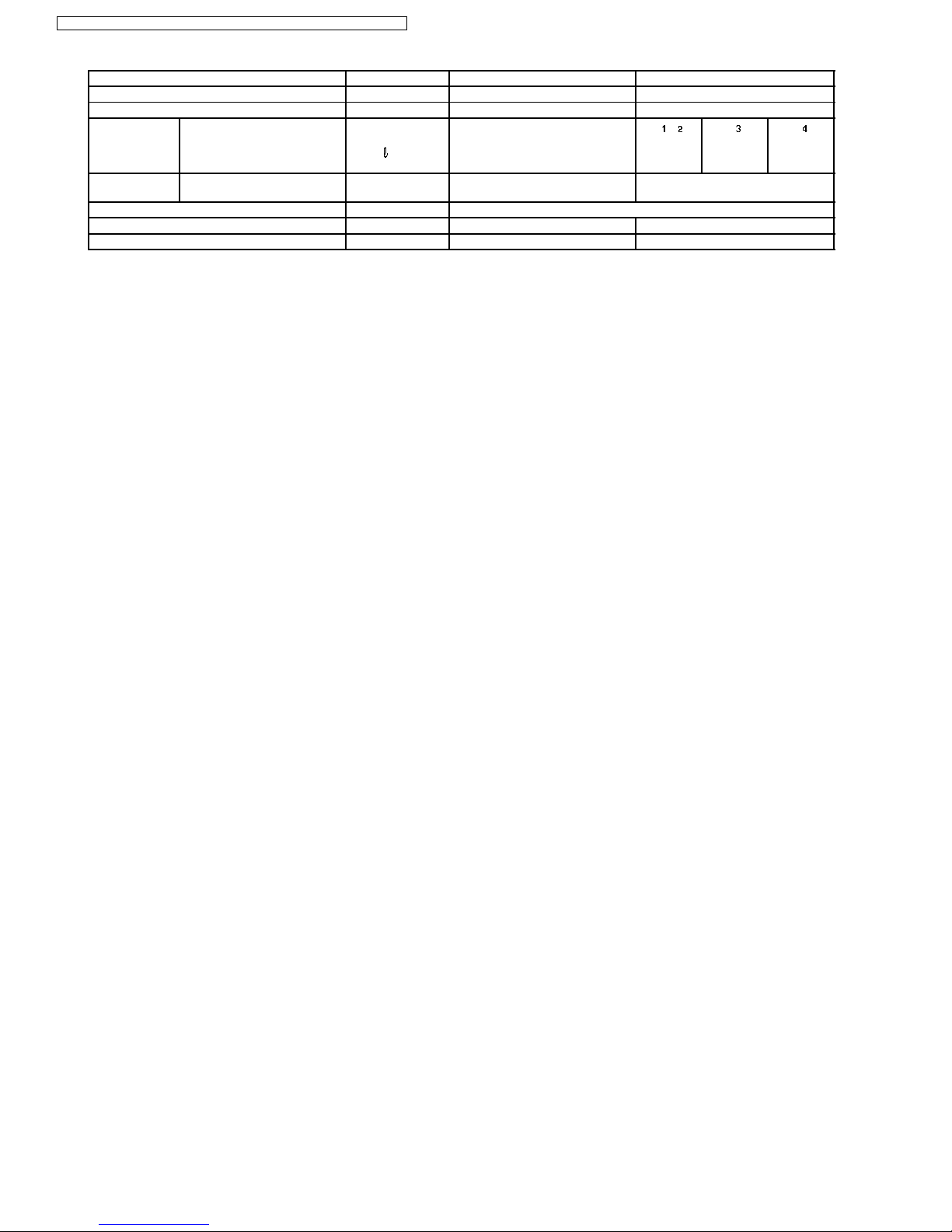

3.3. CS-VA120KE / CU-VA120KE

Unit CS-VA120KE CU-VA120KE

Cooling Capacity kW

Btu/h

3.55

12,000

Heating Capacity kW

Btu/h

4.00

13,600

Moisture Removal /h

Pint/h

2.0

4.2

Power Source Phase

V

Cycle

Single

230

50

Airflow Method

Air Volume Indoor Air(Lo) m / min(cfm) Cooling ; 7.5(260)

Heating ; 7.8(280)

-

Indoor Air(Me) m / min(cfm) Cooling ; 8.4(300)

Heating ; 8.7(310)

-

Indoor Air(Hi) m / min(cfm) Cooling ; 9.3(330)

Heating ; 9.7(340)

-

Outdoor Air m / min(cfm) - 22.0(780)

Noise Level dB(A) Cooling ; High 42,Low 38

heating ; High 42,Low 38

Cooling ; 49

Heating ; 49

Electrical

Data

Input kW Cooling ; 1.24

Heating ; 1.18

Running Current A Cooling ; 5.6

Heating ; 5.4

COP Cooling ; 2.86

Heating ; 3.39

Starting Current A 25

Piping Connection Port

(Flare piping)

inch

inch

G ; Half Union 1/2”

L ; Half Union 1/4”

G ; 3-Way valve 1/2”

L ; 2-Way valve 1/4”

Pipe Size

(Flare piping)

inch

inch

G(gas side) ; 1/2”

L(liquid side) ; 1/4”

G(gas side) ; 1/2”

L(liquid side) ; 1/4”

Drain

Hose

Inner diameter mm 12 Length m 0.7 -

Power Cord length

Number of core-wire

2.1 m

3 (1.0 mm

)

-

-

Dimensions Height inch(mm) 11 - 7/16(290) 19 - 29/32(505)

Width inch(mm) 31 - 15/32(799) 30 - 23/32(780)

Depth inch(mm) 6 - 29/32(175) 9 - 21/32(245)

Net Weight lb(kg) 18(8.0) 83(38.0)

Compressor Type - Rotary(1 cylinder

rolling piston type

Motor Type - Induction(2-poles)

Rated Output W - 1100

Air Circularizing Type Cross-flow Fan Propeller Fan

Material AS+Glass Fiber 30 AES+Glass Fiber 12

Motor Type Transiator(4-poles) Induction(6-poles)

Input W - 60.2

rated Output W 20 25

Fan

Speed

Low rpm 1200 Medium rpm 1,330 High(heating) rpm 1,500 730

Heat

Exchange

description Evaporator Condenser

Tube material Copper Copper

Fine material Aluminium Aluminium

Fine type Slit Fin Corrugated Fin

Row/Stage (Plate fin configuration, forced draft)

2x12

2x19

FPI 21 16

Size(W x H x L) mm 600 x 252 x 25.4 706 x 457.2 x 44

670 x 457.2 x 44

Refrigerant Control Device - Capillary Tube

refrigeration Oil (c.c) - RB68A(430)

Refrigerant(R410A) g(oz) - 1150(40.6)

Thermostat Electronic Control Protection Device - Overload Protector

11

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120 KE

Unit CS-VA120KE CU-VA120KE

Capillary Tube

Length

flow Rate

Inner Diameter

mm

/min

mm

-

-

-

C

600

12.2

1.5

C

540

10.4

1.4

Air Filter Material

style

P.P

Honeycomb

-

Capacity Control Capillary Tube

Compressor Capacitor µF,VAC - 30µF,370VAC

Fan motor Capacitor µF,VAC - 1.2µF,400VAC

·

Specifications are subject to change without notice for further improvement.

12

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

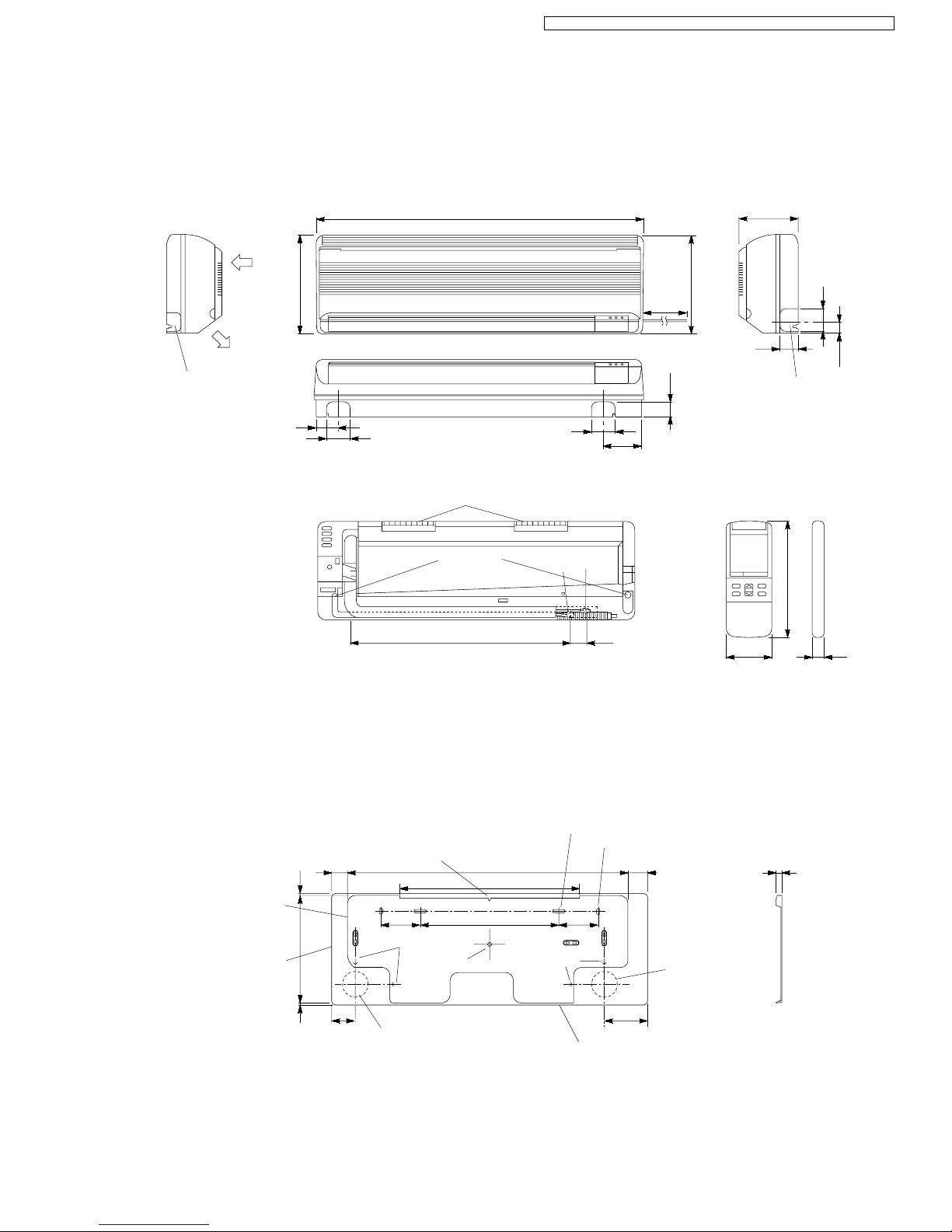

4 Dimensions

4.1. CS-VA70KE / CS-VA90KE / CS-VA120KE (INDOOR UNIT)

Relative position between the indoor unit and the installation plate <Front View>

799

48.5

60

290

<Front View>

175

61

34.5

52

direction

Air intake

Air outlet

direction

Left piping hole

Right piping hole

290

115

55

60

2100

57

142

16

Remote control transmitter

(45)(410)

<Back View>

Installation plate hooks

Drain ports

Gas

side

Liquid

side

(40)

710

(40)

276

7

(60)

(110)

100 100

Slot (2 places)

Slot (2 places)

Centre notch

Indoor unit external

dimensions line

Installation plate

Left piping hole

Arrow

Arrow

Centre

Right piping hole

Installation plate positioning gauge

350

7

457

13.5

13

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

4.2. CU-VA70KE / CU-VA90KE (OUTDOOR UNIT)

67

77

105105 570

467

480

280

312

245

2-way valve

at Liquid side

13

at Gas side

3-way valve

93

27.5

780 57

Panasonic

4.3. CU-VA120KE(OUTDOOR UNIT)

67

93

105105 570

494

505

280

312

245

2-way valve

at Liquid side

11

at Gas side

3-way valve

112

27.5

780 57

14

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

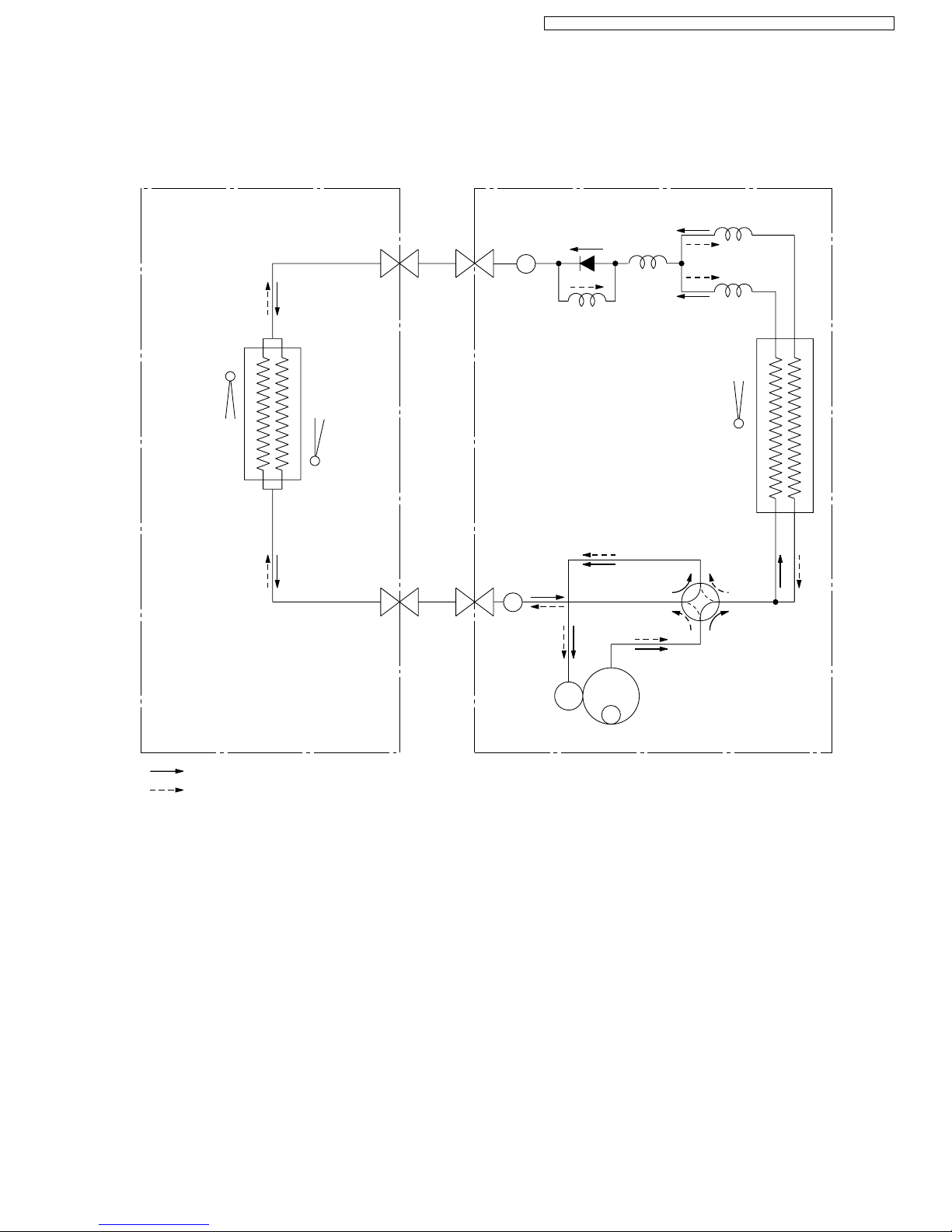

5 Refrigeration Cycle Diagram

5.1. CS-VA70KE / CU-VA70KE, CS-VA90KE / CU-VA90KE

COMP.

4-WAY VALVE

C1

C4

C2

CHECK VALVE

DRYER

PIPE

TEMP.

SENSOR

(T.R.S)

SENSOR

TEMP.

INTAKE

PIPE

TEMP.

SENSOR

INDOOR OUTDOOR

COOLING

HEATING

HEAT EXCHANGER

(EVAPORATOR)

HEAT EXCHANGER

(CONDENSER)

2-WAY

VALVE

VALVE

3-WAY

C3

STRAINER

C1,C2,C3,C4; CAPILLARY TUBE

15

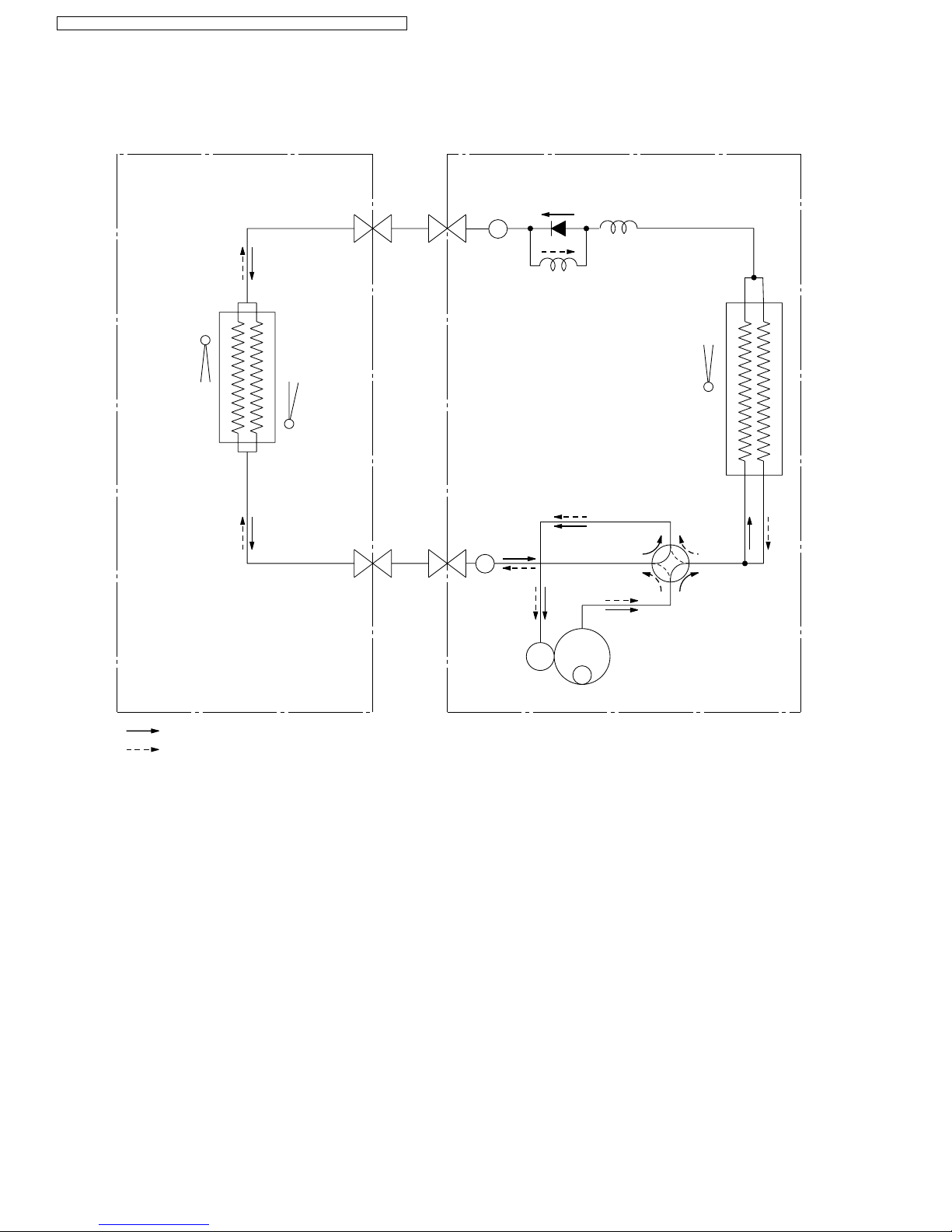

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

5.2. CS-VA120KE / CU-VA120KE

COMP.

4-WAY VALVE

C2

CHECK VALVE

DRYER

PIPE

TEMP.

SENSOR

(T.R.S)

SENSOR

TEMP.

INTAKE

PIPE

TEMP.

SENSOR

INDOOR OUTDOOR

COOLING

HEATING

HEAT EXCHANGER

(EVAPORATOR)

HEAT EXCHANGER

(CONDENSER)

2-WAY

VALVE

VALVE

3-WAY

C1

STRAINER

C1,C2 ; CAPILLARY TUBE

16

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

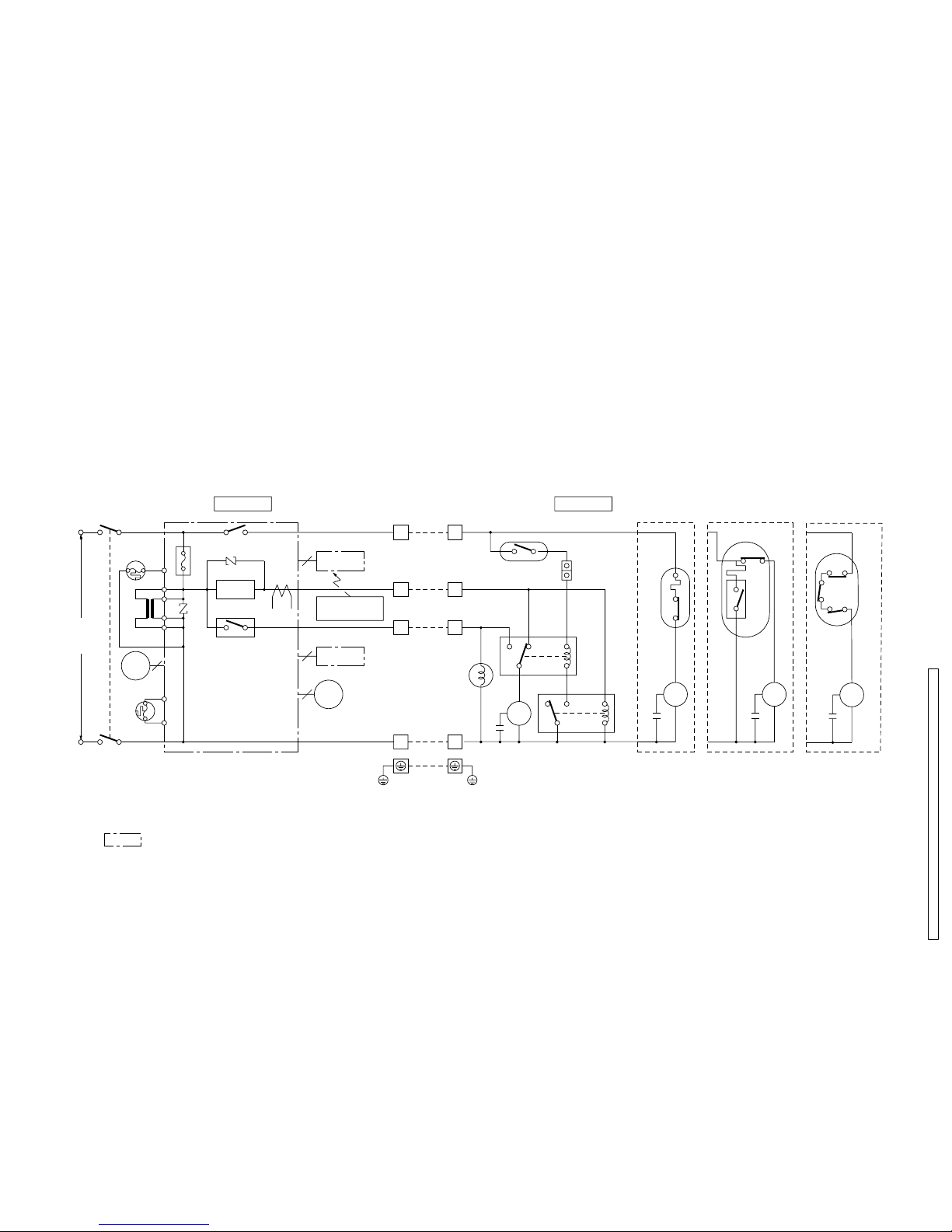

6 Block Diagram

FUSE

ZNR1

ZNR2

3

4

1

TRANSFORMER

FM

CT1

STEPPING

3C

4C

5C

RECEIVER

P.C.B.

INDICATOR

P.C.B.

WIRELESS

REMOTE CONTROL

TRANSMITTER

22

1

4

3

FM

RELAY

B

RELAY A

COMP

COMP

O.L.P.

O.L.P.

FOR

CU-VA90KE

FOR

CU-VA70KE

MAIN

POWER SWITCH

SSR1

RY-HOT

SINGLE

50Hz

AC 230V

PHASE

INDOOR UNIT OUTDOOR UNIT

CS/CU-VA70KE/VA90KE/VA120KE

A-008.DWG

P.C.B.

MOTOR

TRS

4-WAY

VALVE

(3.15A)

3C

THERMAL FUSE

(102°C)

INDOOR

FAN MOTOR

THERMAL FUSE

(99°C)

RY-PWR

CS-VA70KE / CU-VA70KE

CS-VA90KE / CU-VA90KE

CS-VA120KE / CU-VA120KE

"C"

Indicates the electronic control unit.

Indicates the number of core wires. (Example:5C=5 core wires).

**

COMP

O.L.P.

FOR

CU-VA120KE

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

17

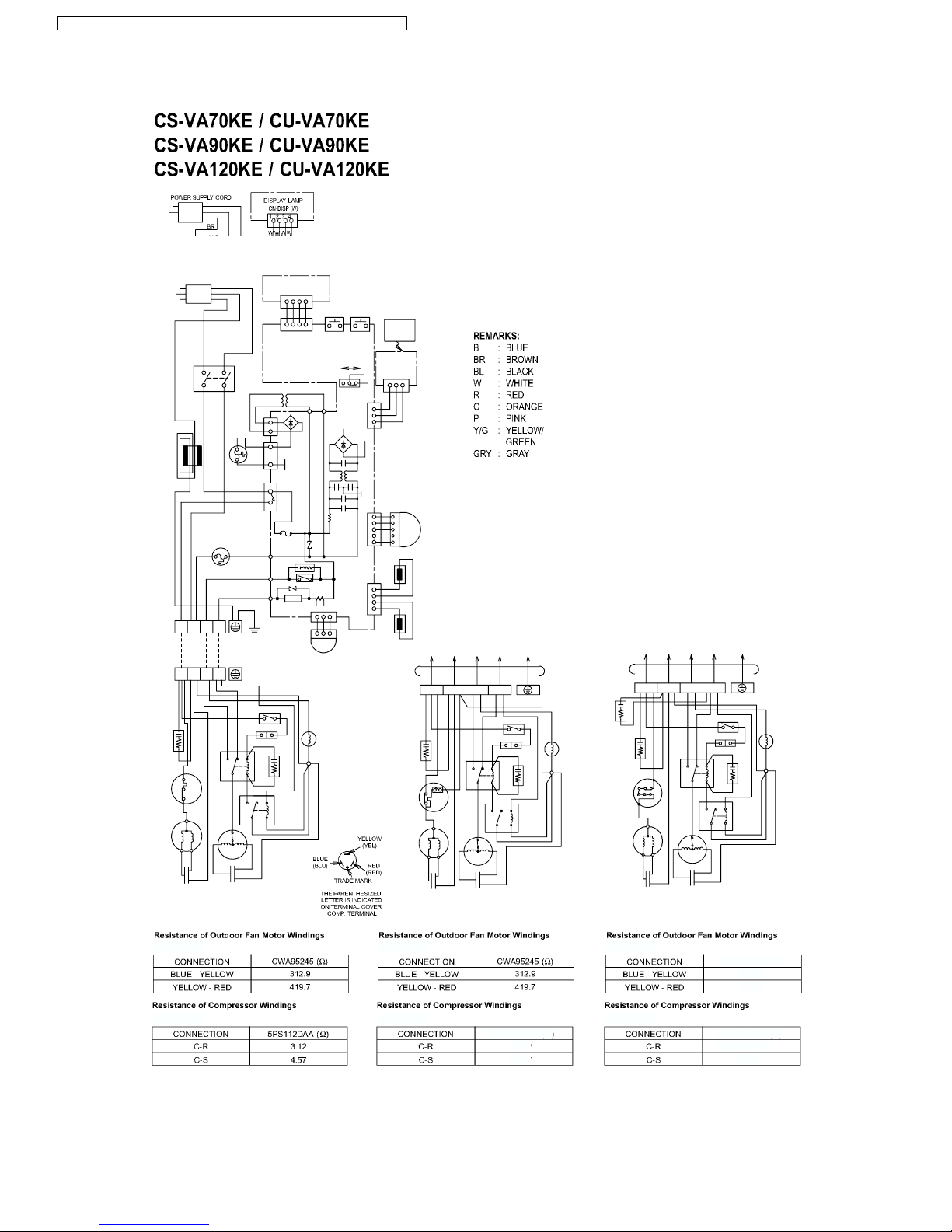

7 Wiring Diagram

POWER SUPPLY CORD

DISPLAY LAMP

Y/G

B

BL

FUSE

(Y2A L250W)

R

R

B

B1

3

2

2

3

1

1

1

2

3

4

2

MOTOR

(FLAP)

3

4

5

1

BR

R

O

Y

P

2

3

4

5

B

B

A

T(BL) T(BL)

R

R

1

3

TRANSFORMER BL

2

MAIN SW.

143

BR

BR

CORE

CN-STM (G)CN-TH (Y)

SENSOR

(PIPE TEMP .)

SENSOR

(INTAKE TEMP.)

THERMAL FUSE

(102°C)

CN FUSE

(B)

CN-T (W)

WIRELESS

REMOTE

CONTROL

ELECTRONIC

CONTROLLER

(RECEIVER)

CN-RCV (W)

1234

4321

WWWW

CN-DISP (W)

CN-DISP (W)

ELECTRONIC

CONTROLLER

PUMP

DOWN SW

(TEST RUN)

REMOTE

CONTROL NO.

AUTO

SW.

1

234

1

234

INDOOR UNIT

TERMINAL

OUTDOOR UNIT

TERMINAL

CAPACITOR CAPACITOR

3

2

1

FAN MOTOR

YELLOW

BROWN

BLACK

BLACK

BLUE

BLACK

GRAY

BLUE

BLUE

COIL

REVERSING VALVE

BLUE

BLUE

RED

BLACK

WHITE

TRS

4

R

B

FM (B)

HD1(R)

NV-HD1

AC(W)

BR

321

Y

W

L

P

AC

(BR)

COMP

(BL)

THERMAL FUSE

(99°C)

BL

W

W

28

76

428

76

BLACK

BLACK

BLACK

YELLOW

GRAY

RED

RED

GRAY

COMPRESSOR

OVER LOAD

PROTECTOR

ELECTROLYTIC

CAPACITOR

MAGNETIC RELAY A

MAGNETIC RELAY B

ELECTROLYTIC

CAPACITOR

Y/G

ZNR1

CR1

CT1

ZNR2

SSR1

CN-MTR (G)

MOTOR

135

CN-RCV(W)

CU-VA70KE

CU-VA70KE

CU-VA90KE

CU-VA90KE

CU-VA120KE

CU-VA70KE

CU-VA90KE

CU-VA120KE

CU-VA120KE

5PS112DAA(Ω) 5KS150DAA(Ω)

3.12

4.57

2.21

3.53

CWA95230(Ω)

312.9

419.5

123

CAPACI TOR

CAPACITOR CAPACITOR CAPACITOR

4

BLUE

RED

COMPRESSOR

COMPRESSOR

TERMINAL

TERMINAL

ELECTROLYTIC

CAPACITOR

ELECTROLYTIC

CAPACITOR

2

1

2

4

6

8

7

F

A

N

M

O

T

O

R

F

A

N

M

O

T

O

R

M

A

G

N

E

T

I

C

R

E

L

A

Y

M

A

G

N

E

T

I

C

R

E

L

A

Y

M

A

G

N

E

T

I

C

R

E

L

A

Y

M

A

G

N

E

T

I

C

R

E

L

A

Y

4

6

872

COI L

REVERSING VAL VE

COI L

REVERSING VAL VE

TO INDOOR UNIT TO INDOOR UNIT

ELECTROL YTIC

CAPA CITO

R

OVER LOA D

PROTECTOR

TRS

WHITE

BLUE

RED

WHITE

YELLOW

YELLOW

BLUE

BLUE

RED

BLACK

BLACK

BLACK

BLACK

BROWN

BLACK

BLACK

GRAY

RED

RED

GRAY

GRAY

WHI TE

WHITE

GRAY

BLUE

B

L

UE

BLACK

BLACK

A

1234

2

4

6

8

7

4

6

872

ELECT ROLYTI C

CAPA CI T OR

OVER L OAD

PROTECTOR

TRS

YELL O W

YELL O W

BLUE

BLUE

R

ED

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

GRAY

WHITE

GRAY

BLUE

BLUE

B

B

A

4

1

BLACK BL ACK

BLACK

BLACK

18

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120 KE

8 Operation Details

8.1. COOLING MODE OPERATION

Cooling in operation according to the remote control setting.

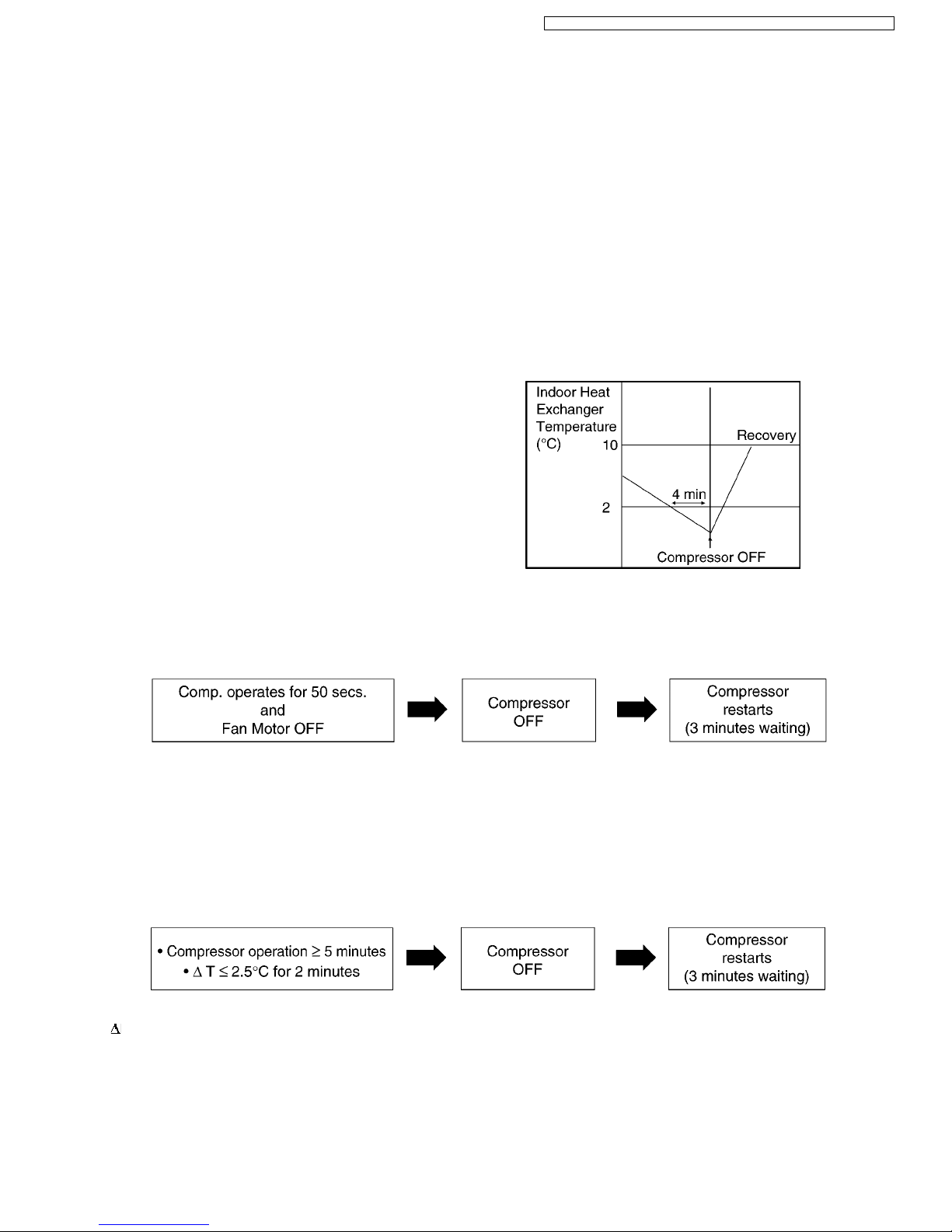

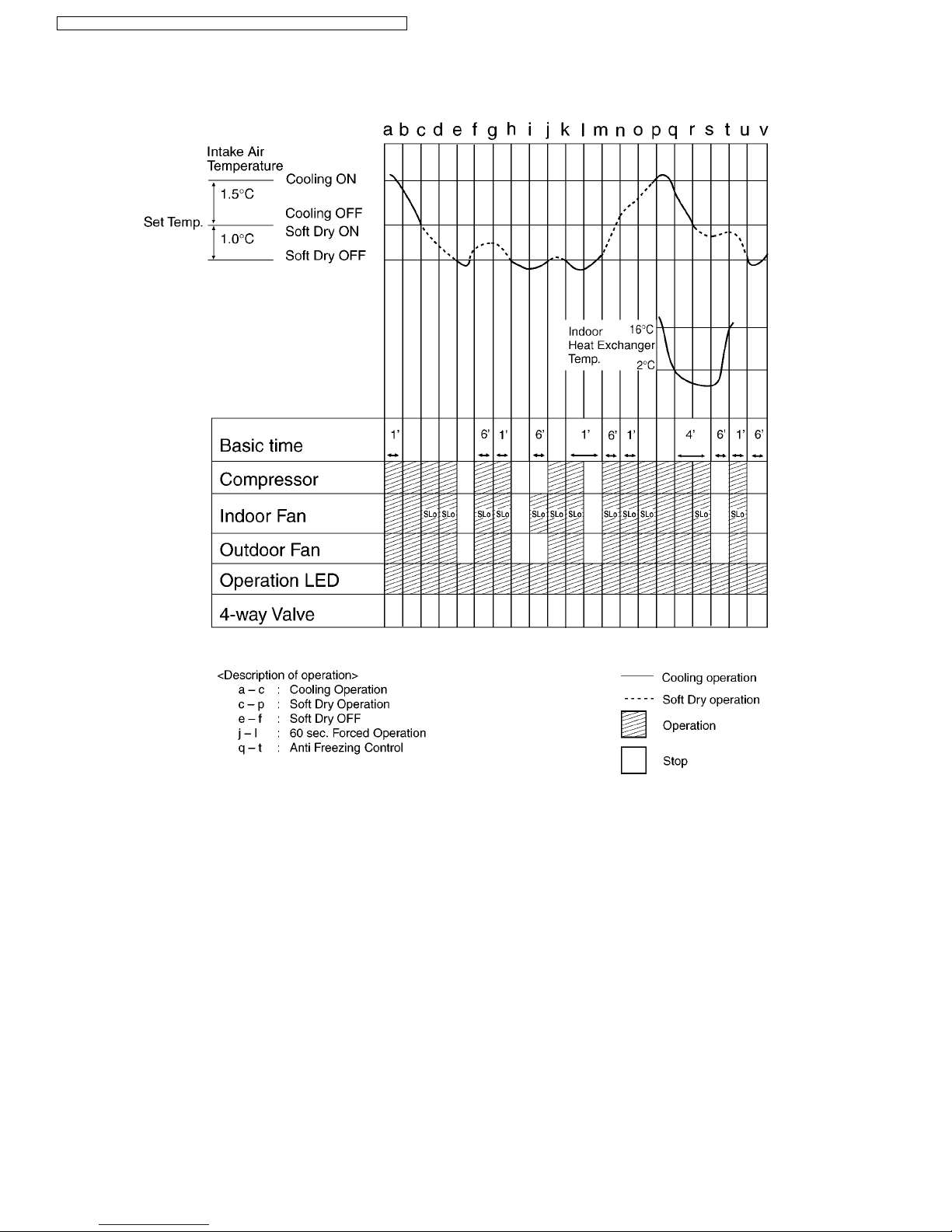

8.1.1. Time Delay Safety Control (3 minutes)

· When the compressor is stopped by Power Switch, Remote Control or when there is a power failure, it restarts after 3 minutes

when the Power Switch, Remote Control is turned ON or when the power supply is resumed.

· When the setting temperature is reached during cooling operation, the compressor stops and it will not start for 3 minutes.

8.1.2. 7 Minutes Time Save Control

· The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is below the compressor

ON temperature.

8.1.3. Anti-Freezing Control

·

If the temperature of the indoor heat exchanger falls

continously below 2°C for 4 minutes, the compressor turns off

to protect the indoor heat exchanger from freezing.The fan

speed setting remains the same.

·

Compressor recommences when the indoor heat exchanger

temperature rises to 10 °C (Recovery).

*3 minutes waiting of Time Delay Safety Control is valid for

Cooling Operation.

8.1.4. Compressor Protection Control

· After the compressor operates for 50 seconds but the outdoor fan motor is still OFF, the compressor will stop and restart

automatically.(Time Delay Safety Control is valid).

· If the above phenomenon is repeated 3 times, the compressor will stop.

· The above phenomenon is reset when there is a change to heating mode or stopped by Remote Control Switch.

8.1.5. Compressor Reverse Rotation Protection Control

· If the compressor is operating continually for 5 minutes or longer and the temperature difference between intake air and indoor

heat exchanger is 2.5 °C or less for 2 minutes, the compressor will stop and restart automatically.

(Time Delay Safety Control is valid).

T =Intake air temperature - Indoor heat exchanger temperature

This is to protect the compressor against reverse rotation when there is an instantaneous power failure.

19

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

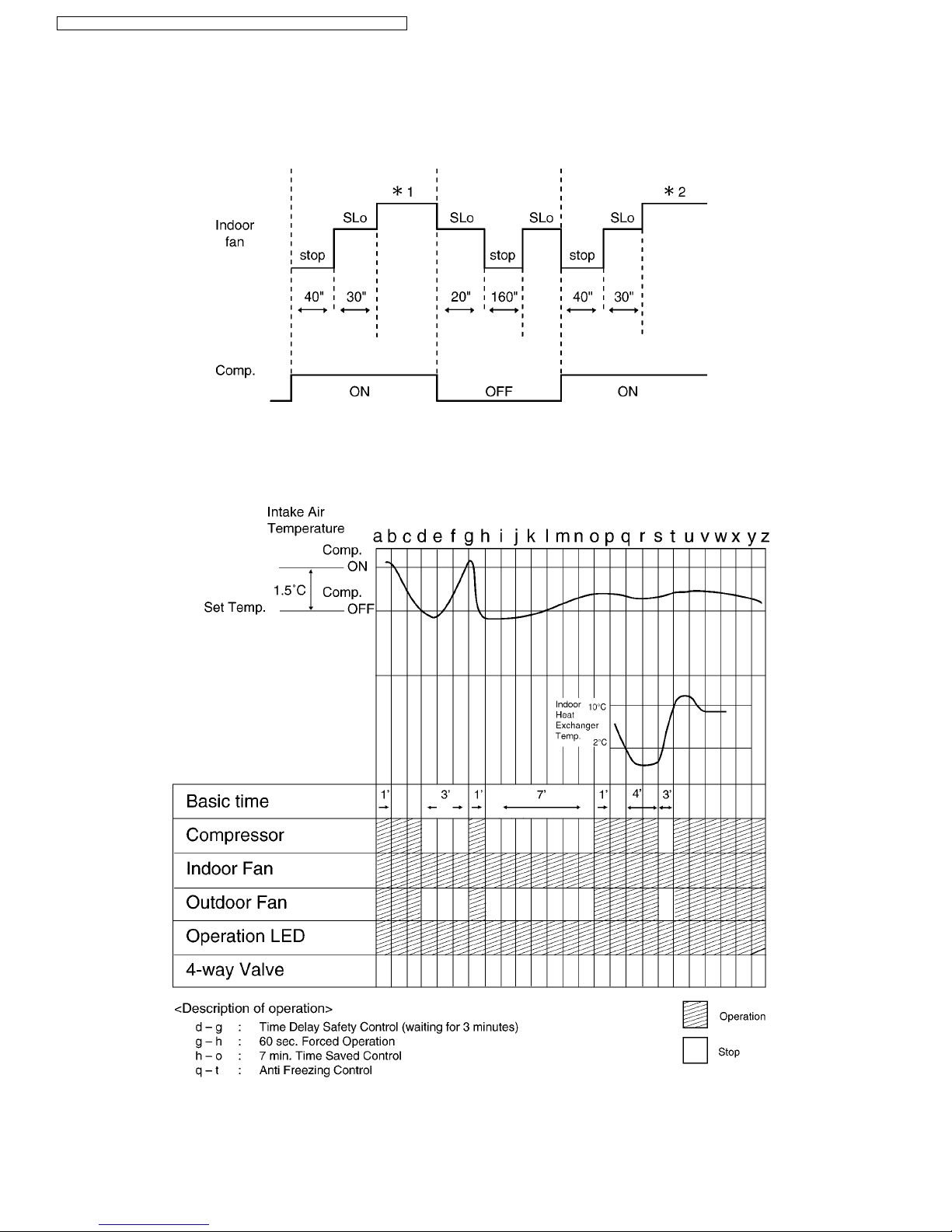

8.1.6. Automatic Fan Speed Mode

When Automatic Fan Speed is selected on the remote control during cooling operation.

· Fan speed rotates in the range of Hi to Me.

· Deodorizing Control.

*1 Fan Speed is Hi until the compressor stops (when the set temperature is reached).

*2 Fan Speed is Me after the compressor restarts.

8.1.7. Cooling Operation Time Diagram

20

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

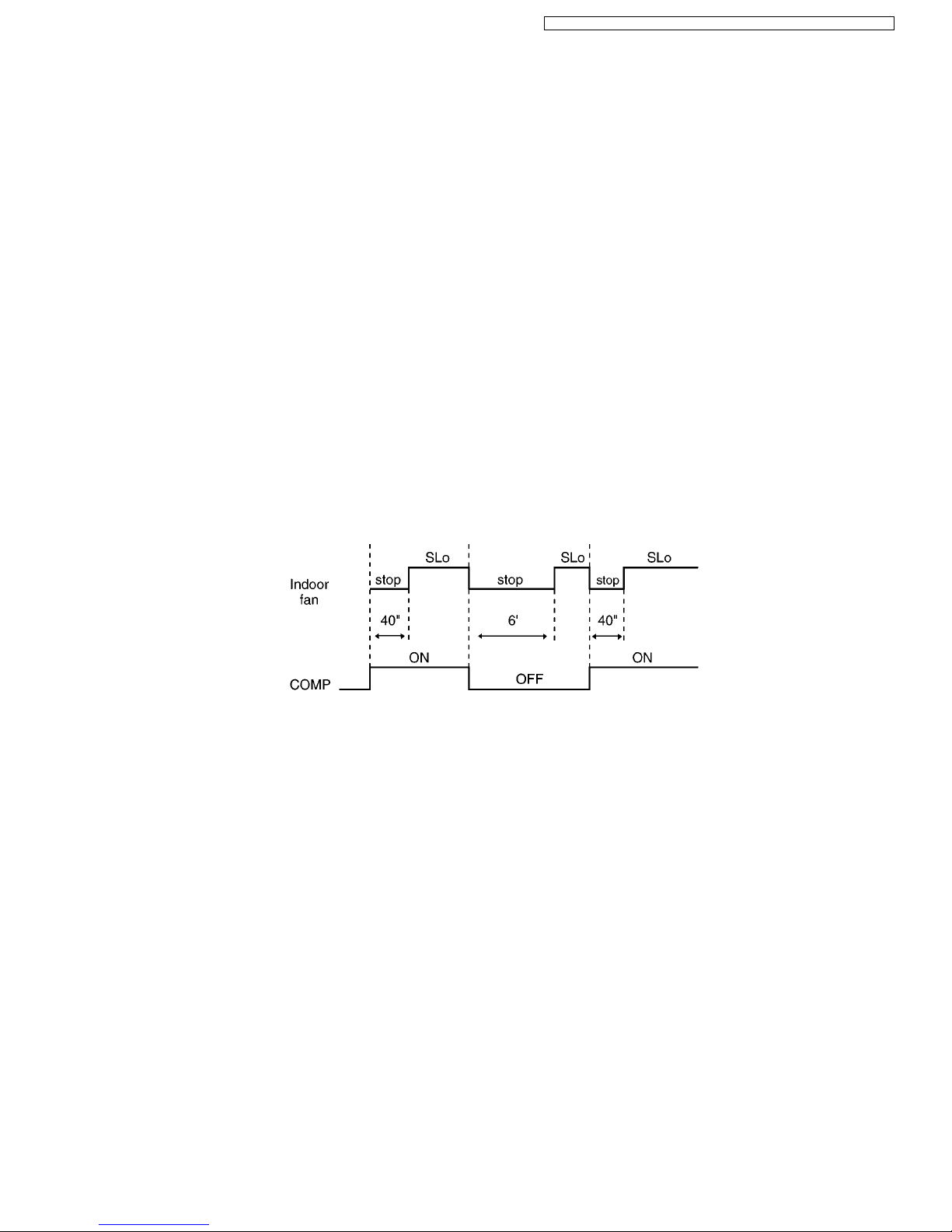

8.2. SOFT DRY MODE OPERATION

· The unit performs cooling operation until the room temperature reaches the setting temperature set on the Remote Contro l, and

then Soft Dry operation will start.

(During Soft Dry operation, the indoor fan operates with SLo speed.)

· Once room temperature reaches below Soft Dry OFF temperature, Indoor Fan, Compressor and Outdoor Fan stop for 6

minutes.

8.2.1. Time Delay Safety Control

· Once the compressor stops, it will not restart for 3 minutes during Cooling operation.

8.2.2. Anti-Freezing Control

· Same as Anti-Freezing Control for Cooling Mode operation.(For Soft Dry operation,6 minutes waiting is valid during compressor

stops.)

8.2.3. Compressor Protection Control

· Same as Compressor Protection Control for Cooling Mode Operation.

8.2.4. Compressor Reverse Rotation Protection

· Same as Compressor Reverse Rotation Protection Control for Cooling Mode Operation.

8.2.5. Automatic Fan Speed Mode

When Automatic Fan Speed is selected on the remote control during Soft Dry Operation.

· Fan speed rotates at SLo.

· Deodorizing Control.

21

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

8.2.6. Soft Dry Operation Time Diagram

22

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

Heating in operation according to the remote control setting.

8.3. HEATING MODE OPERATION

8.3.1. Time Delay Safety Control

· When the compressor is stopped by Power Switch, Remote Control or when there is a power failure, it restarts after 3 minutes

when the Power Switch, Remote Control is turned ON or the power supply is resumed.

· When the setting temperature is reached during heating operation, the compressor stops and it will not restart for 4 minutes.

· Indoor Fan stops for 1 minute 3 minutes after the compressor stopped.Then,it will operate with SLo fan speed.

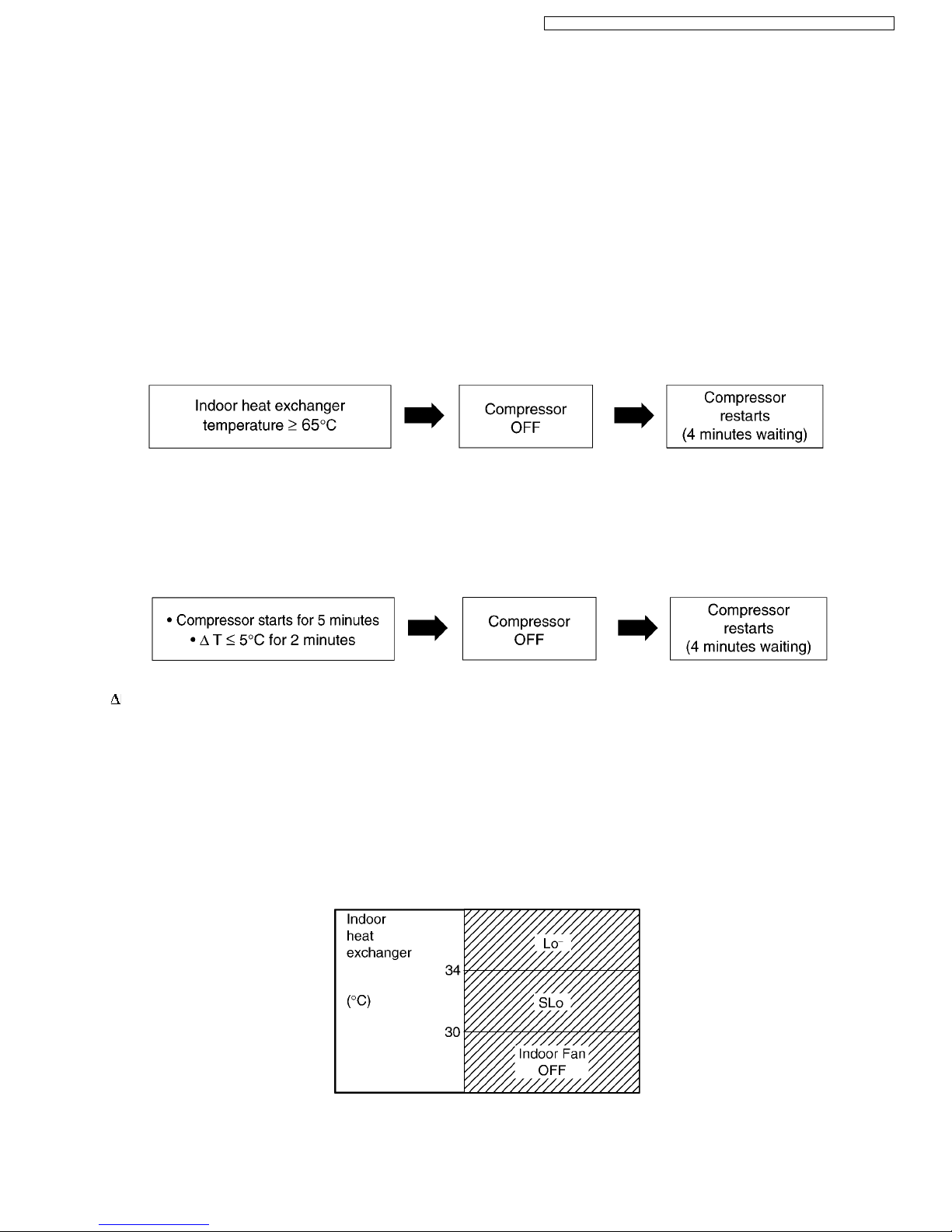

8.3.2. Overload Protection Control

· If the temperature of the indoor heat exchanger rises to 51 °C, Outdoor Fan stops.

The Outdoor Fan restarts when the indoor heat exchanger temperature falls to 49 °C.

· If the indoor heat exchanger becomes 65 °C or more, the compressor will stop and restart automatically.

(Time Delay Safety Control -4 minutes waiting)

8.3.3. Compressor Reverse Rotation Protection Control

· If the compressor is operating continually for 5 minutes or longer and temperature difference between intake air and indoor heat

exchanger is 5 C or less for 2 minutes, the compressor will stop and restart automatically.

(Time Delay Safety Control is valid).

T =Indoor heat exchanger temperature - intake air temperature

This is to protect the compressor against reverse rotation when there is a instantaneous power failure.

8.3.4. 4-way Valve Control

· 4way valve always ON during Heating operation.

· When the unit is switched to "OFF" during Heating operation,4-way valve stays at Heating position for 5 minutes.

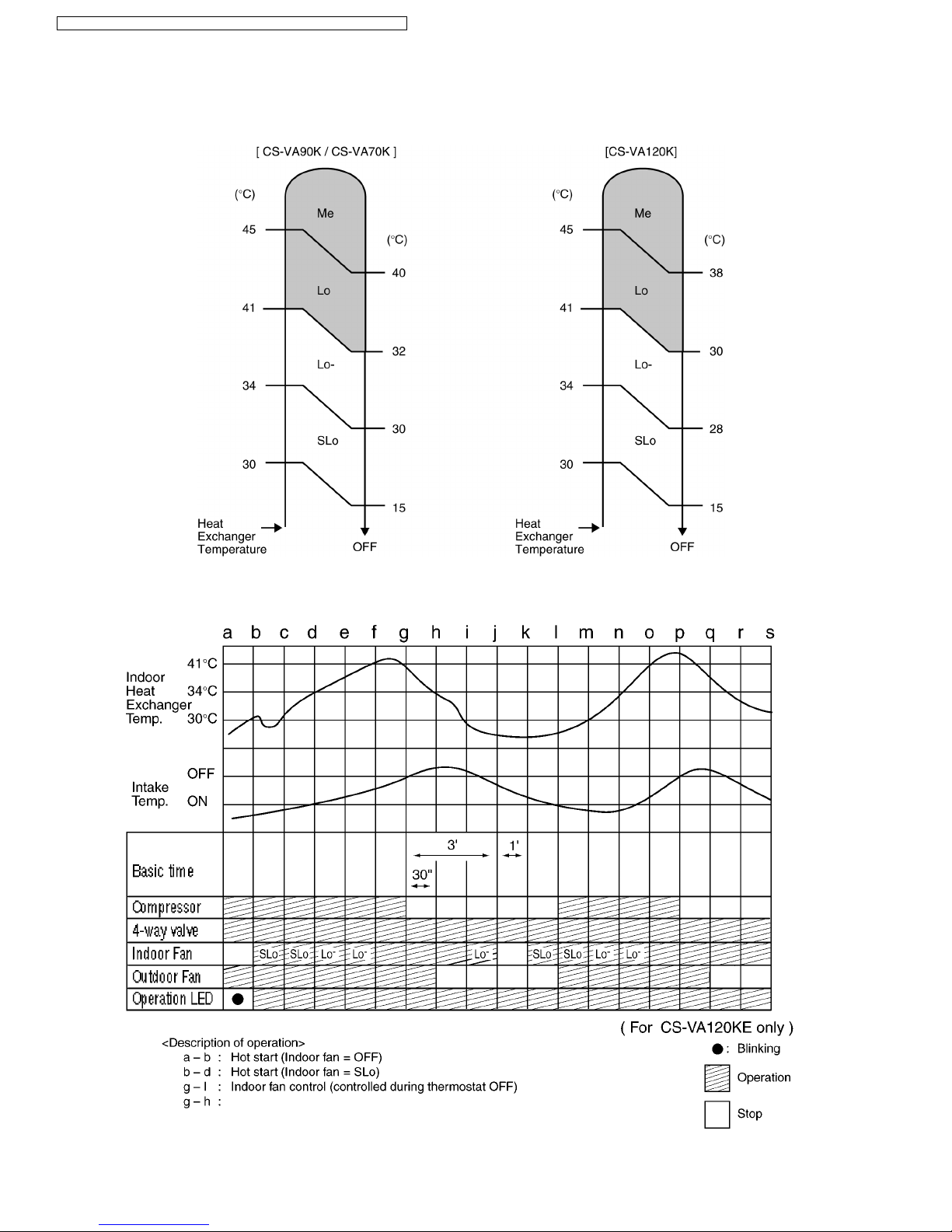

8.3.5. Hot Start Control

When Heating operation starts, Indoor Fan will not start until the indoor heat exchanger reaches 30 °C as shown in the diagram

below.

Hot Start is completed when indoor heat exchanger reaches 41 °C.

23

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

8.3.6. Automatic Fan Speed Mode

When Automatic Fan Speed is selected on the remote control during heating operation.

· Fan speed rotates in the range of Me → SLo according to the heat exchanger temperature.

8.3.7. Heating Operating Time Diagram

24

CS-VA70KE / CU-VA70KE / CS-VA90KE / CU-VA90KE / CS-VA120KE / CU-VA120KE

Loading...

Loading...