Multi Air Conditioner

CS-ME7CB1P

CS-ME10CB1P

CS-ME12CB1P

CS-ME14CB1P

CS-ME10CD3P

CS-ME14CD3P

ORDER NO. RAC0312001A8

Please file and use this manual together with the service manual for Model No. CS-ME7CKPG, CSME10CKPG, CS-ME12CKPG, CS-ME14CKPG, CS-ME18CKPG, CU-2E15CBPG, CU-2E18CBPG, CU3E23CBPG, CU-4E27CBPG, Order No. RAC0209005C2.

CONTENTS

Page Page

1 Features 3

2 About Lead Free Solder (PbF)

2.1. DISTINCTION OF PbF P.C. BOARD

2.2. CAUTION

3 Functions

3.1. REMOTE CONTROL

3.2. INDOOR UNIT

4 Product Specifications

5 Dimensions

3

3

3

4

4

5

7

8

5.1. Cassette Type 8

5.2. Grille

5.3. Duct Type

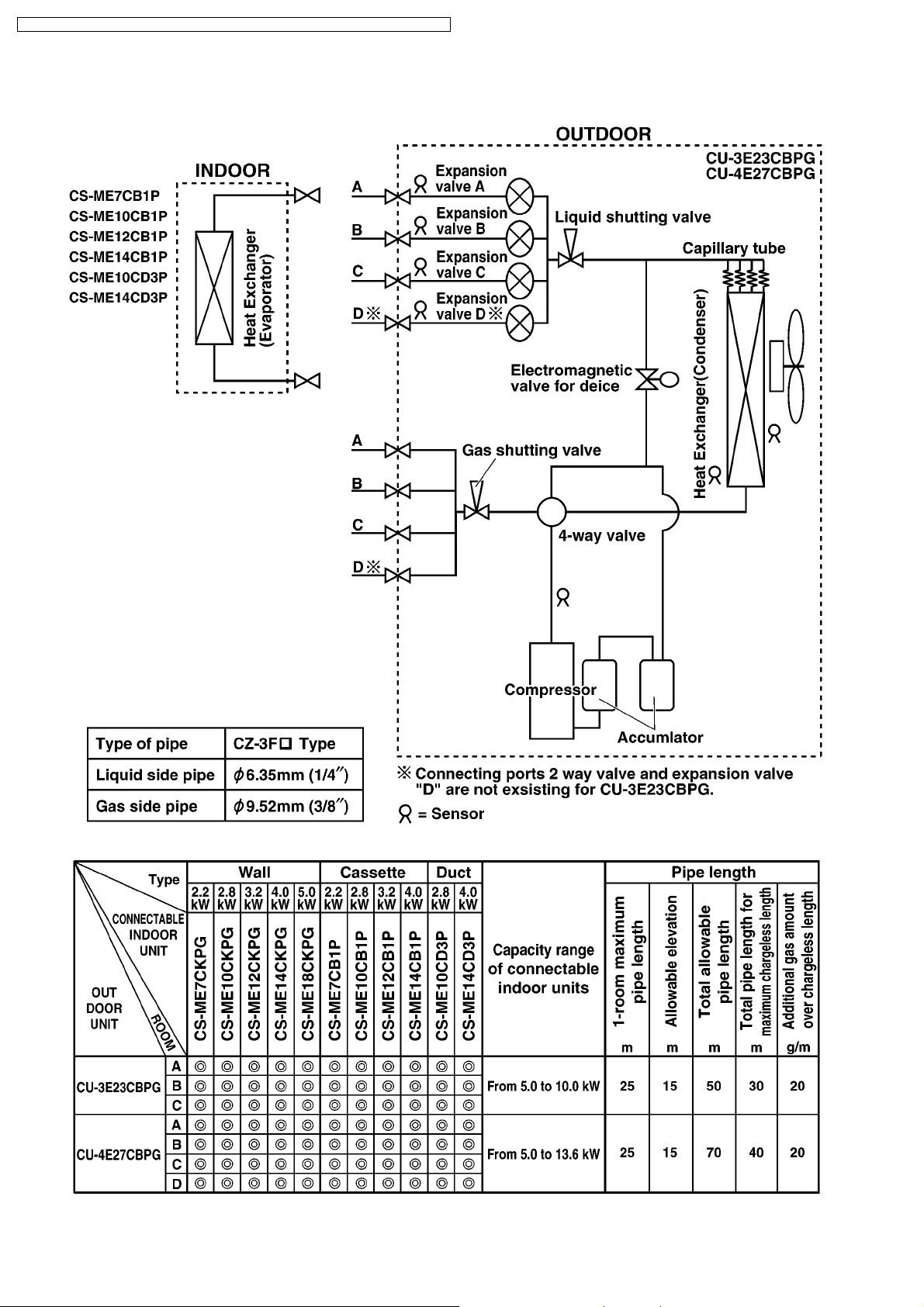

6 Refrigeration Cycle Diagram

7 Block Diagram

8 Wiring Diagram

8.1. Cassette Type (CS-

ME7CB1P/ME10CB1P/ME12CB1P/M E14CB1P)

8.2. Duct Type (CS-ME10CD3P/ME14CD3P)

10

11

12

13

14

14

15

© 2003 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9 Operation Details (Functions & Protection) 16

9.1. Simultaneous Operation Control

9.2. Airflow Direction Control (Cassette Type only)

9.3. Indoor Fan Control

9.4. Drain Pump Control

9.5. Auto Restart Control

9.6. Other Indoor Unit Operation Functions

10 Installation Instructions

10.1. Cassette Type

10.2. Duct Type

11 Operating Instructions

12 Disassembly of Parts

16

17

18

20

21

22

30

30

35

41

53

12.1. Cassette Type (Indoor Unit: CS-

ME7CB1P/ME10CB1P/ME12CB1P/M E14CB1P)

12.2. Duct Type (Indoor Unit: CS-ME10CD3P/ME14CD3P)

13 Technical Data

13.1. OPERATION CHARACTERISTICS

14 Electronic Circuit Diagram

14.1. REMOTE CONTROL

14.2. Cassette Type

14.3. Duct Type

15 Exploded View & Replacement Parts List

15.1. CS-ME7CB1P/ME10CB1P/ME12CB1 P/ME14CB1P

15.2. CS-ME10CD3P/ME14CD3P

53

57

59

59

63

63

64

65

66

66

68

2

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

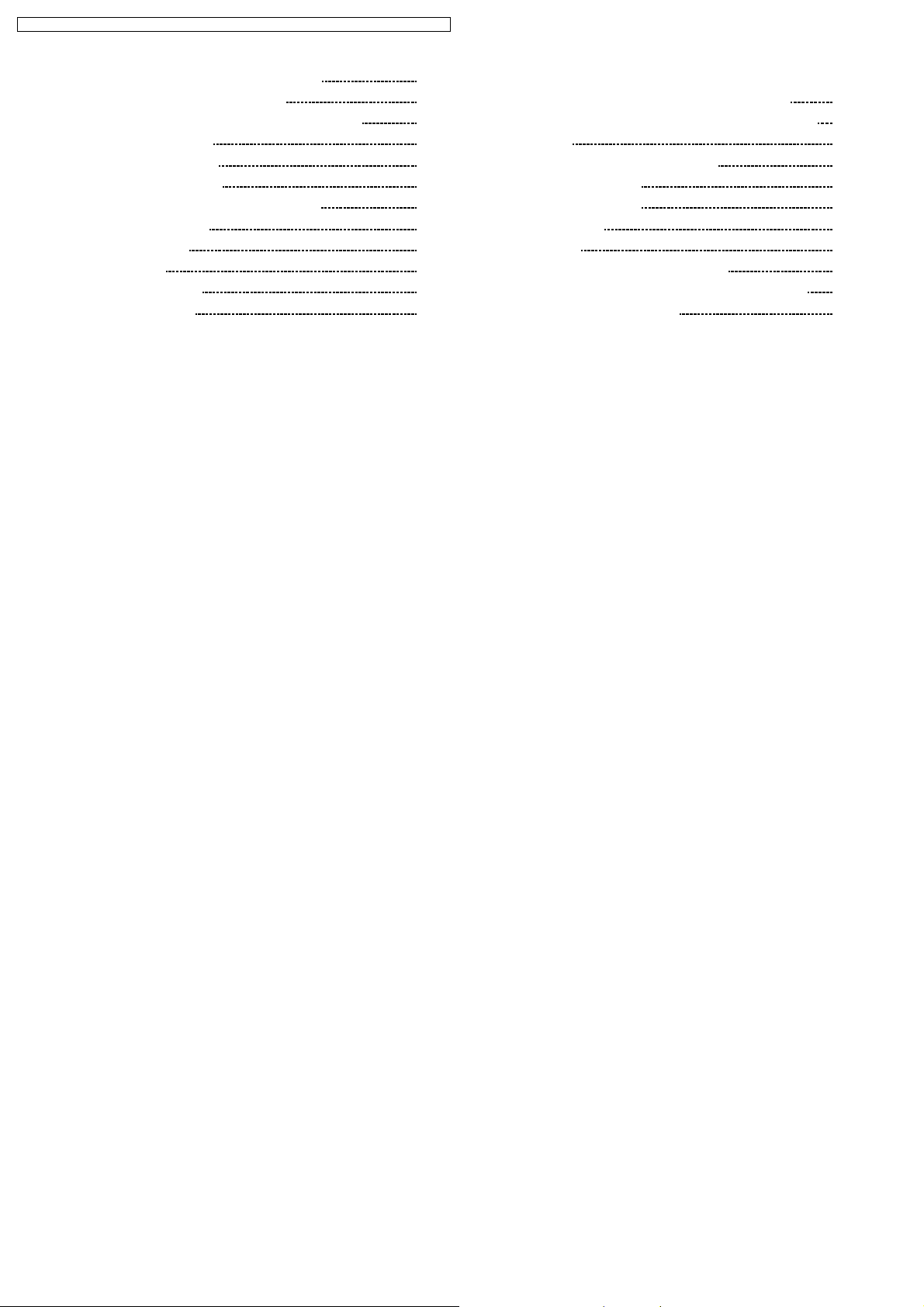

1 Features

· Product

−

− A single OUTDOOR unit enables air conditioning of up to four separate rooms

− −

Remarks:

1. At least two indoor units must be connected.

2. The total nominal cooling capacity of indoor units that will be connected to outdoor unit must be within connectable

capacity range of outdoor unit. (Shown in the above table)

Example: The below indoor units combination is not possible to connect CU-3E23CBPG. (Total nominal capacity

of indoor unit is between 5.0kW and 10.0kW)

1) Two CS-ME7CB1P only. (Total nominal cooling capacity is 4.4kW)

2) Three CS-ME14CB1P only. (Total nominal cooling capacity is 12.0kW )

−

− Inverter controlled for High energy efficiency and optimal comfort

− −

−

− New refrigerant R410A is used for protecting ozone layer

− −

−

− Lead - free P.C. Board

− −

· Serviceability

−

− Self diagnosis

− −

−

− Test Run at both Cooling and Heating rated frequency

− −

· Built-in drain pump (Cassette and Duct type)

−

− A drain pump is built in.

− −

The pipe can rise to 200 mm above the drain outlet.

2 About Lead Free Solder (PbF)

2.1. DISTINCTION OF PbF P.C. BOARD

P.C. Boards (manufactured) using lead free solder will have a PbF stamp on the P.C. Board.

2.2. CAUTION

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70 °F (30 - 40 °C) higher.

Please use a high temperature solder iron and set it to 700 ± 20 °F (370 ± 10 °C).

· Pb free solder will tend to splash when heated too high (about 1100 °F/ 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

3

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

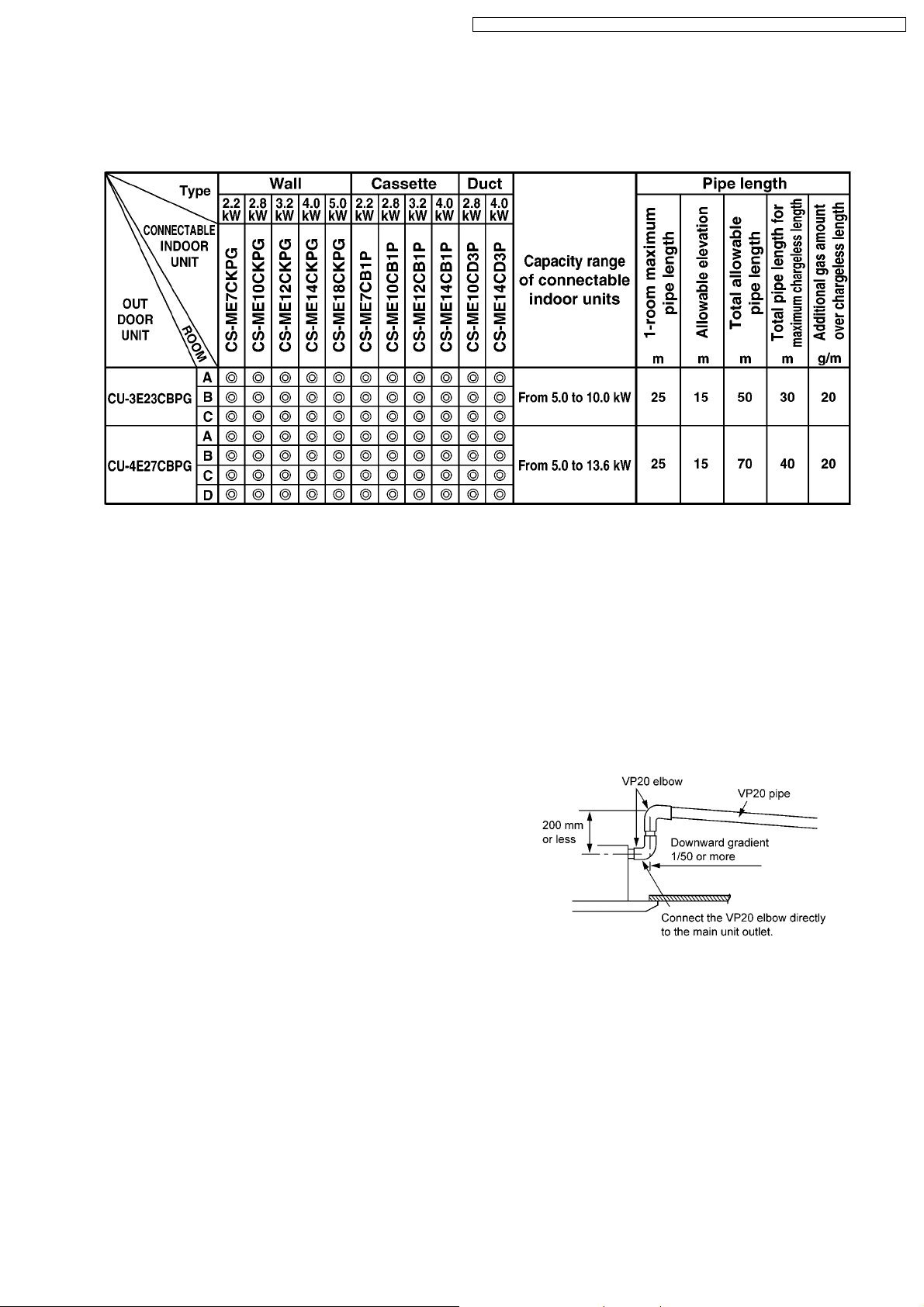

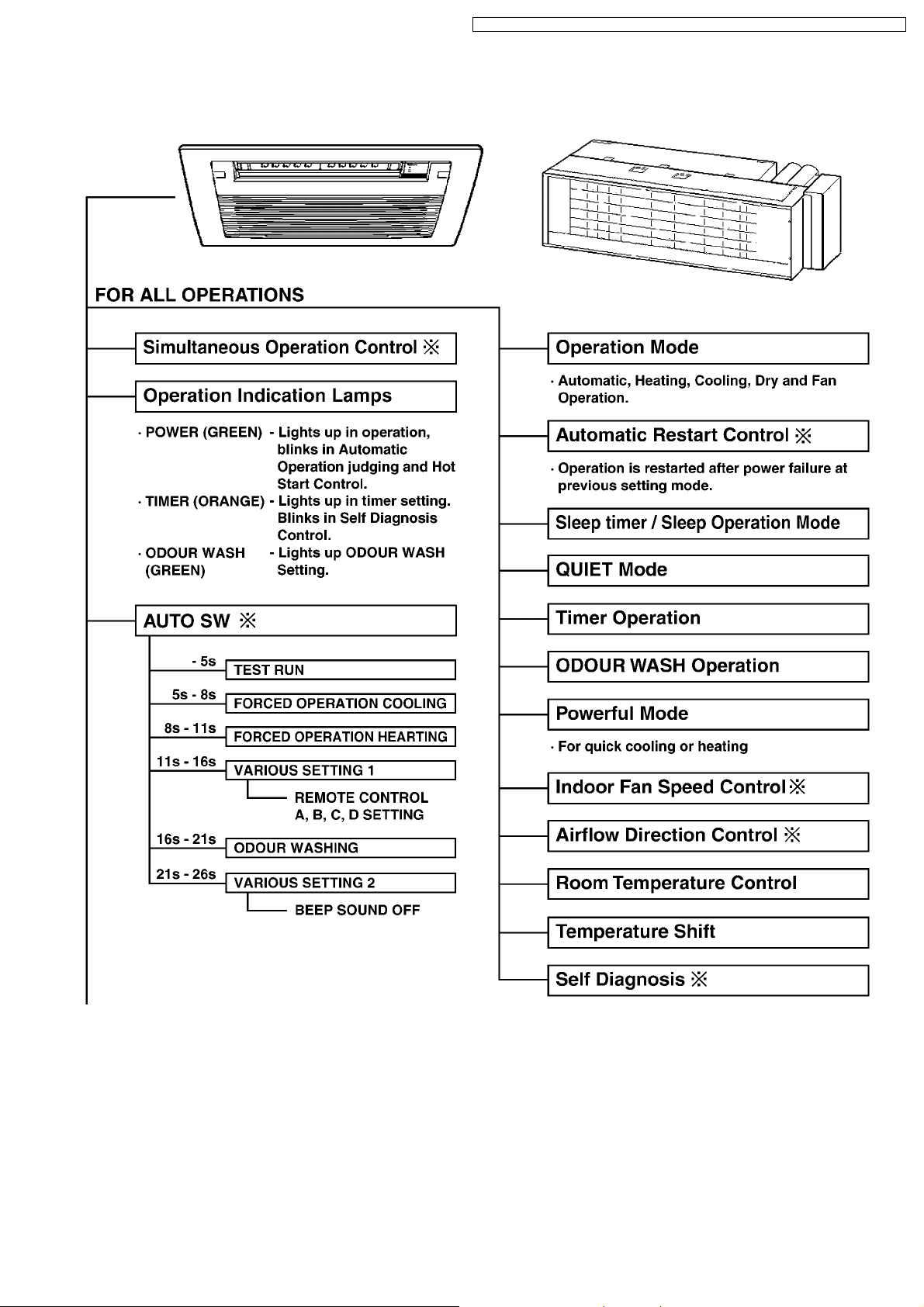

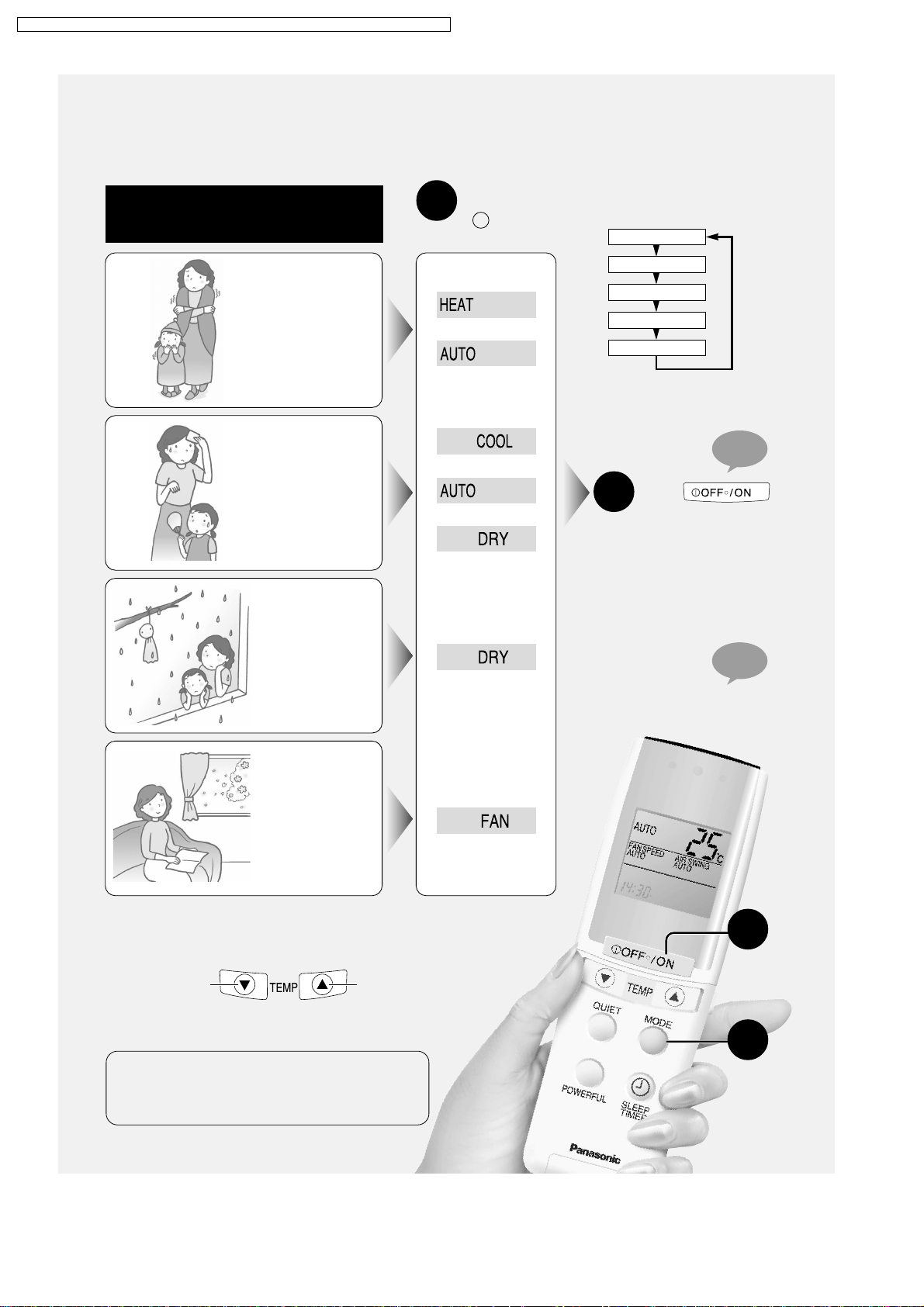

3 Functions

3.1. REMOTE CONTROL

4

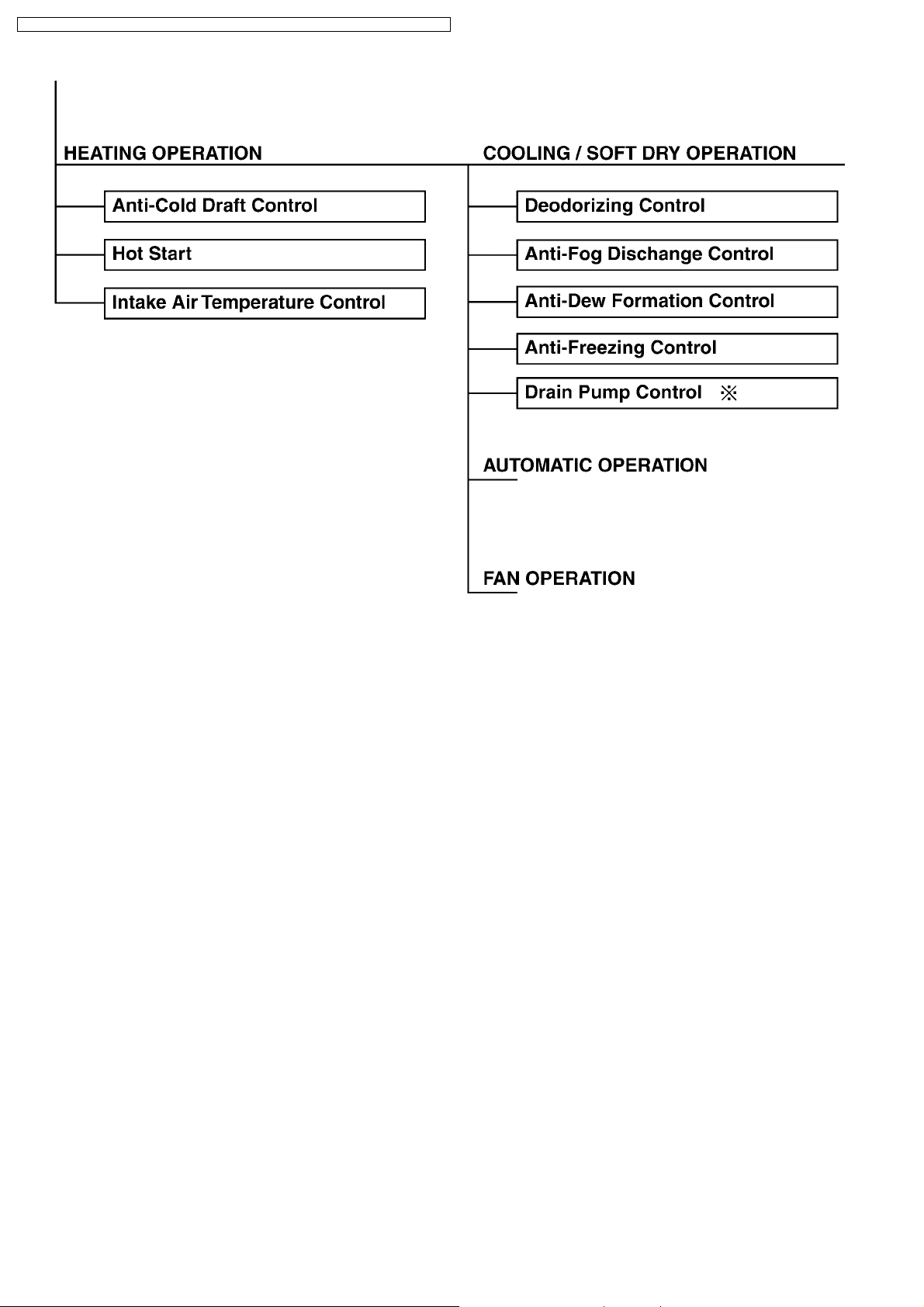

3.2. INDOOR UNIT

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

5

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

6

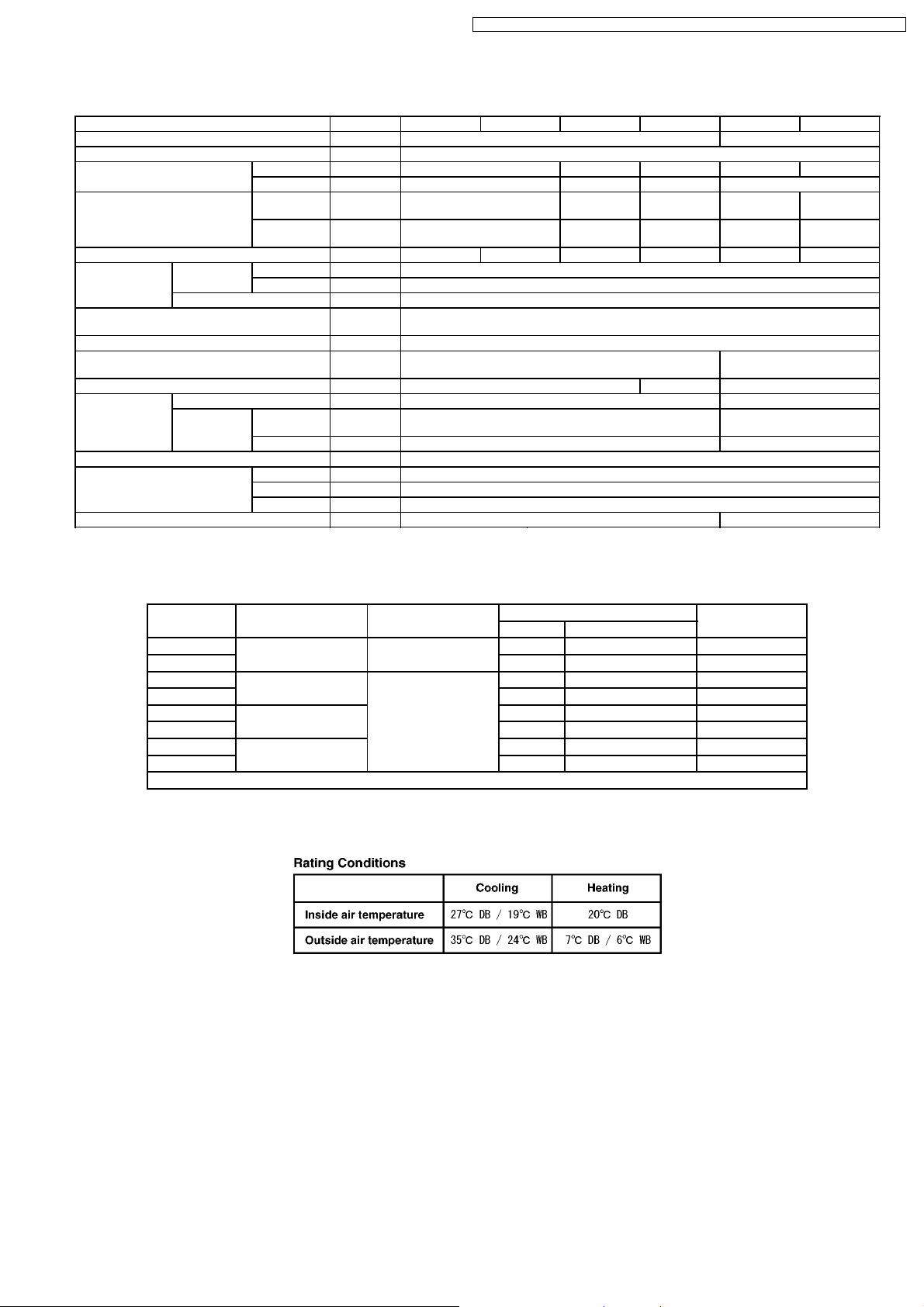

4 Product Specifications

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

Item Cassette Type Duct Type

Power Source Outdoor power (single 230V 50Hz)

Air Volume Cooling m3/min. 9.1 9.6 9.5 7.0 7.8

Noise Level Cooling

Moisture Removal L/h 1.3 1.6 1.8 2.3 1.6 2.3

Refrigeration

piping

Type of Indoor/Outdoor connecting

cable

Drain opening mm VP20

Dimensions mm Height 185 x Width 770 x Depth 360 Height 235 x Width 750

Net Weight kg 9.8 10.5 16.5

Fan Type Cross-flow fan Sirocco fan

Heat exchanger Plate fin forced-draft

Adjustments Switches Wireless remote control

Air filter PP honeycomb -

Connection Liquid mm 6.35 (1/4") Flare to the main unit

Type of pipe CZ-3F

Motor Type DC brushless motor (EHOCM24A4P25) DC brushless motor

Model CS-ME7CB1P CS-ME10CB1P CS-ME12CB1P CS-ME14CB1P CS-ME10CD3P CS-ME14CD3P

Heating m3/min. 9.8 10.2 9.8 8.7

(Power)

Heating

(Power)

Gas mm 9.52 (3/8") Flare to the main unit

Output W 4P 25W 40V A98258 8P 30W 280-340V A981071

Timer Timer with ON and OFF times programmable

Temperature Electronic thermostat

dB(A)

(dB)

dB(A)

(dB)

mm 4 x 1.5 mm2flexible cord, type designation 245 IEC 57 (H05RN-F)

Hi:40(53)

Lo:32(45)

Hi:42(55)

Lo:32(45)

Hi:41(54)

Lo:32(45)

Hi:43(56)

Lo:32(45)

Hi:43(56)

Lo:32(45)

Hi:44(57)

Lo:34(47)

Hi:43(56)

Lo:32(45)

Hi:47(60)

Lo:32(45)

x Depth 370

(ARW31V8P30AC)

Hi:45(58)

Lo:32(45)

Hi:47(60)

Lo:35(48)

Remarks:

The specifications are differ from wall type indoor units when 2.8kW Duct type is connected to CU-2E15CBPG and CU2E18CBPG.

Indoor unit

Combination

Cooling 22 + 28 CU-2E15CBPG 1.39 0.25 - 1.73 6.50

Heating 1.36 0.21 - 1.67 6.05

Cooling 22 + 28 CU-2E18CBPG 1.39 0.25 - 1.73 6.50

Heating 1.36 0.21 - 1.67 6.05

Cooling 28 + 28 (*) 1.56 0.25 - 1.73 7.25

Heating 1.47 0.21 - 1.74 6.50

Cooling 28 + 32 1.67 0.25 - 1.80 7.80

Heating 1.39 0.21 - 1.72 6.15

(*) The combination 2.8kW Duct type X 2 and 2.8kW Duct type + 2.8kW Wall type are same value.

Outdoor unit Power Input (kW) Current (A)

min. - max

* Specifications are subject to change without notice for further improvement.

7

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P9CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

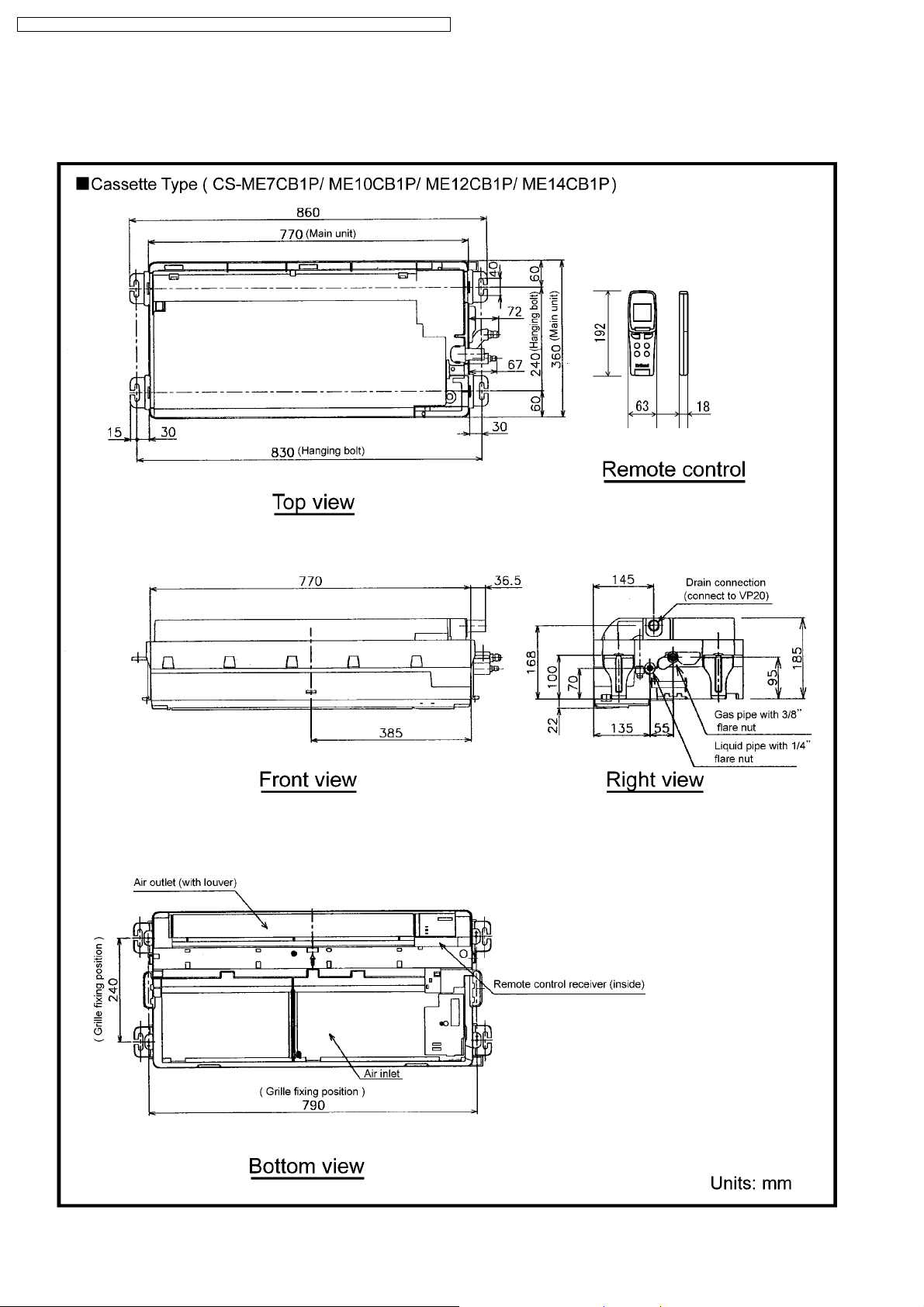

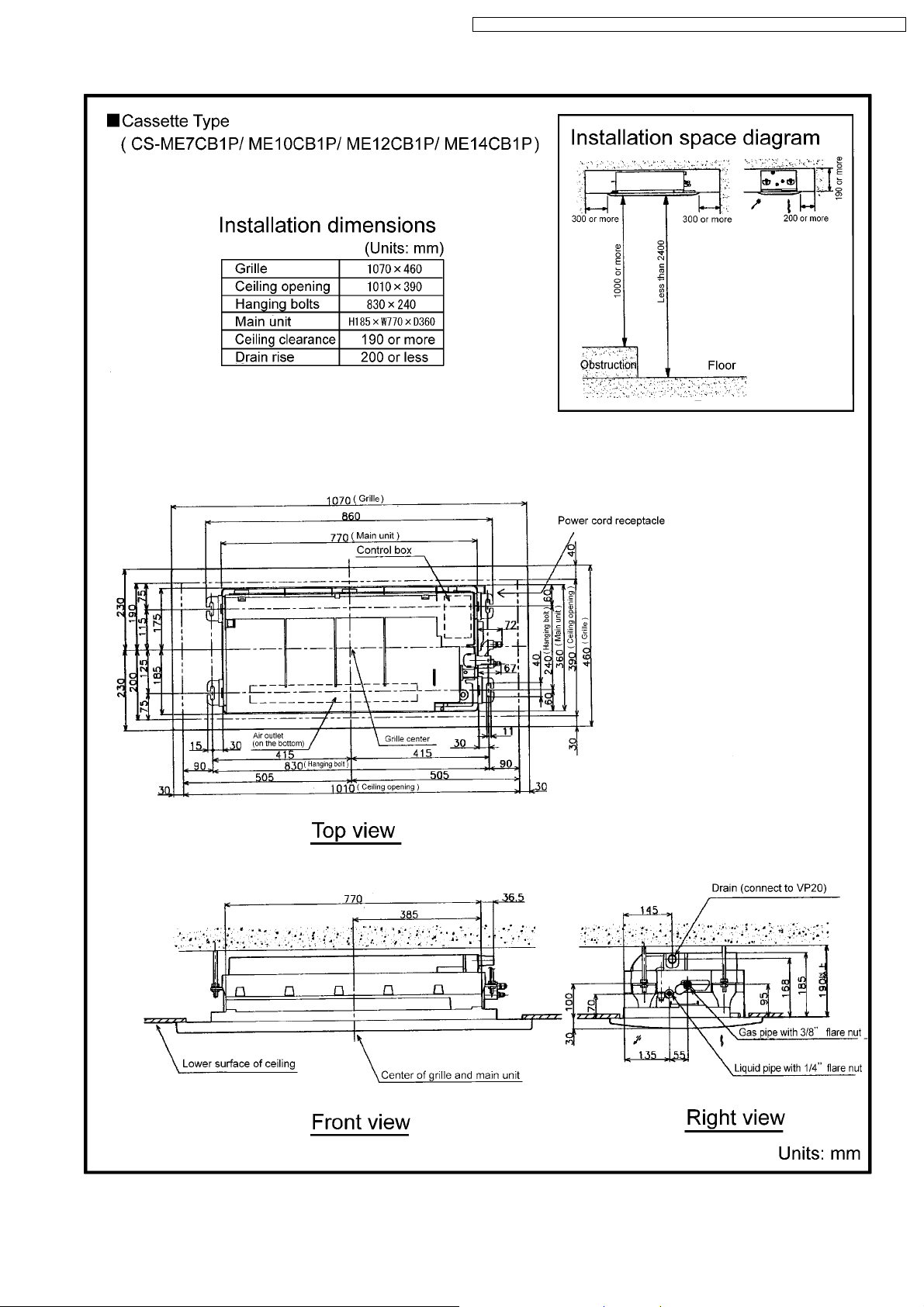

5 Dimensions

5.1. Cassette Type

8

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

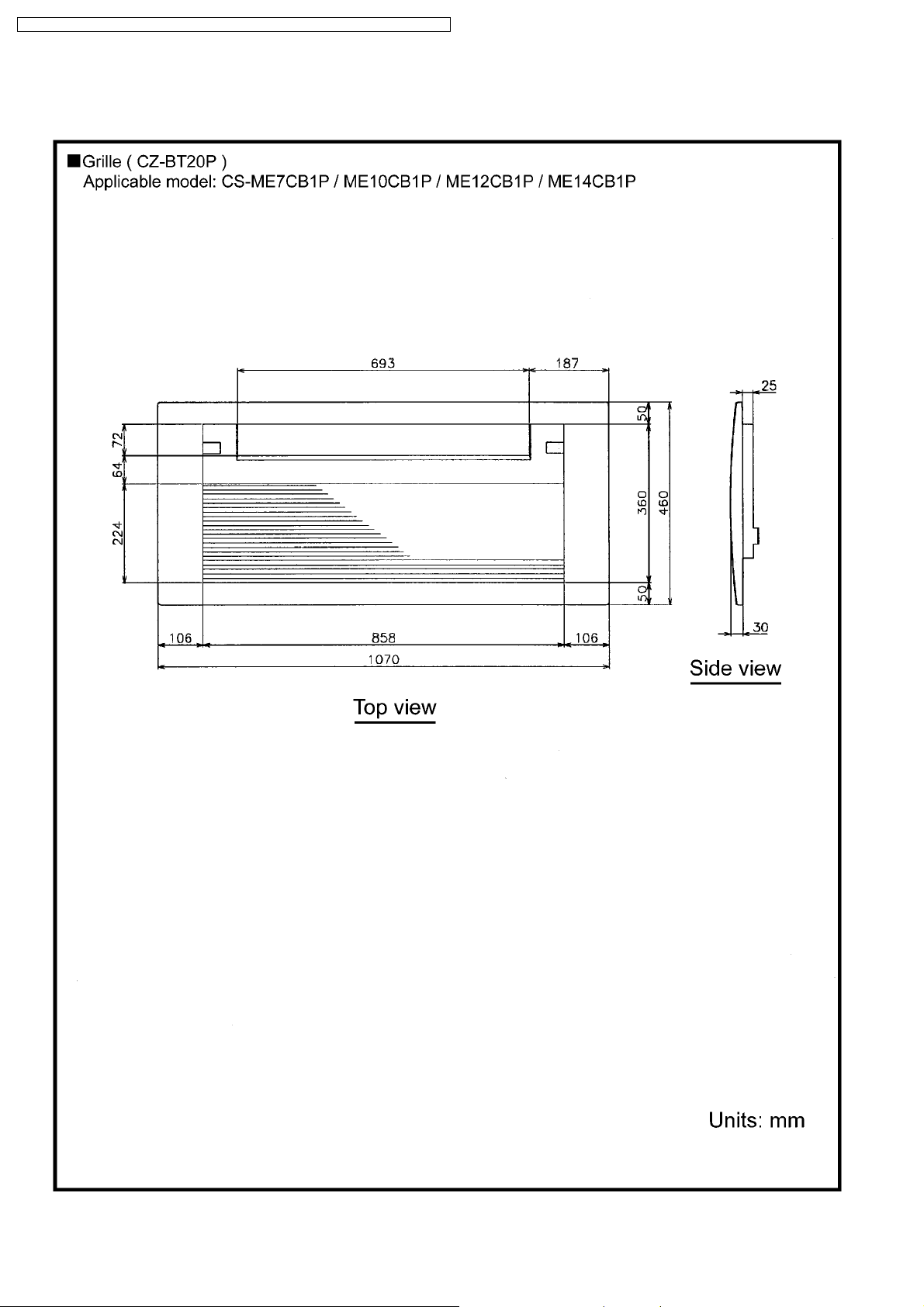

5.2. Grille

10

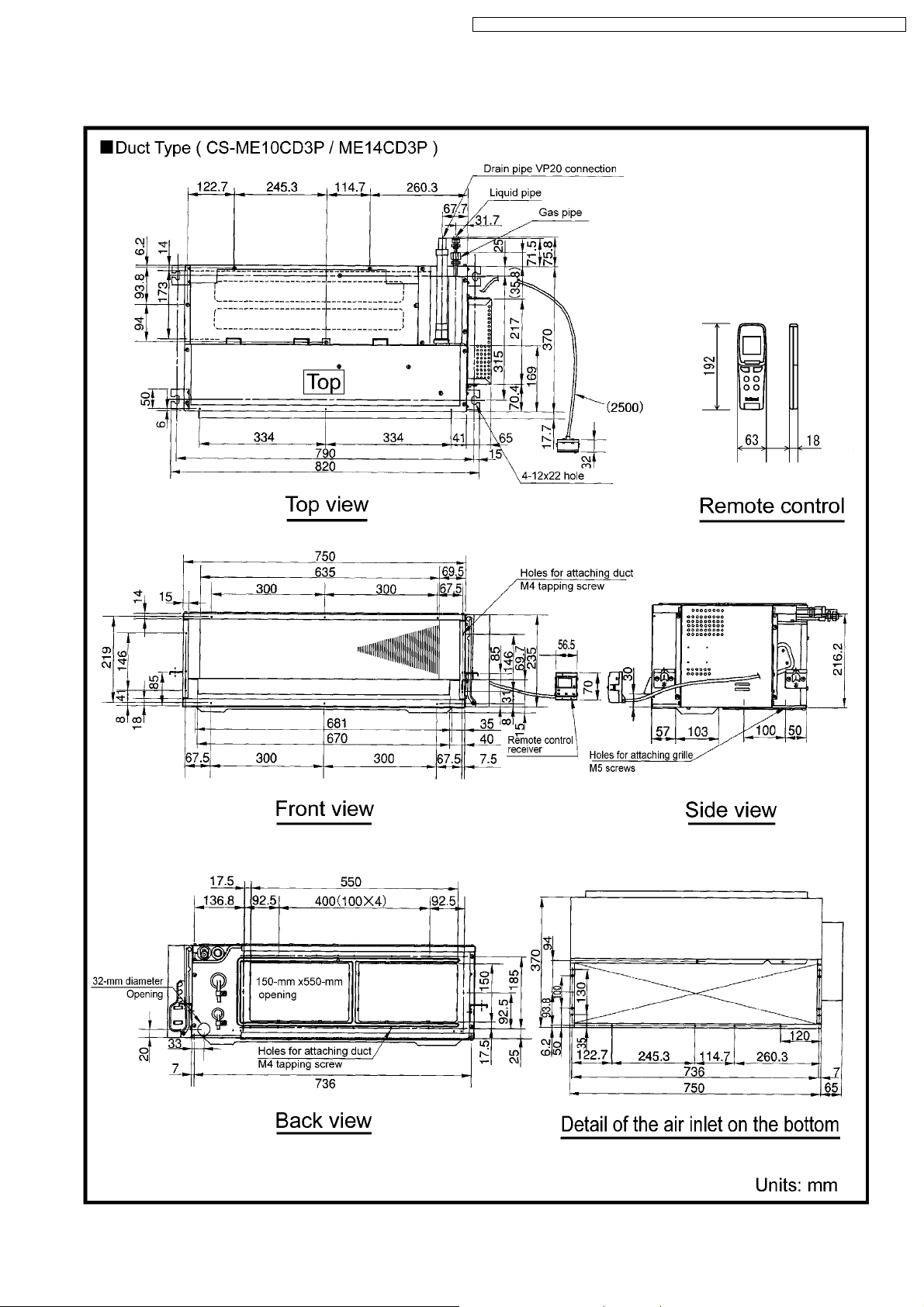

5.3. Duct Type

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

11

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

6 Refrigeration Cycle Diagram

12

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

7 Block Diagram

CS-ME7CB1P/ME10CB1P/ME12CB1P/ME14CB1P/ME10CD3P/ME14CD3P

13

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

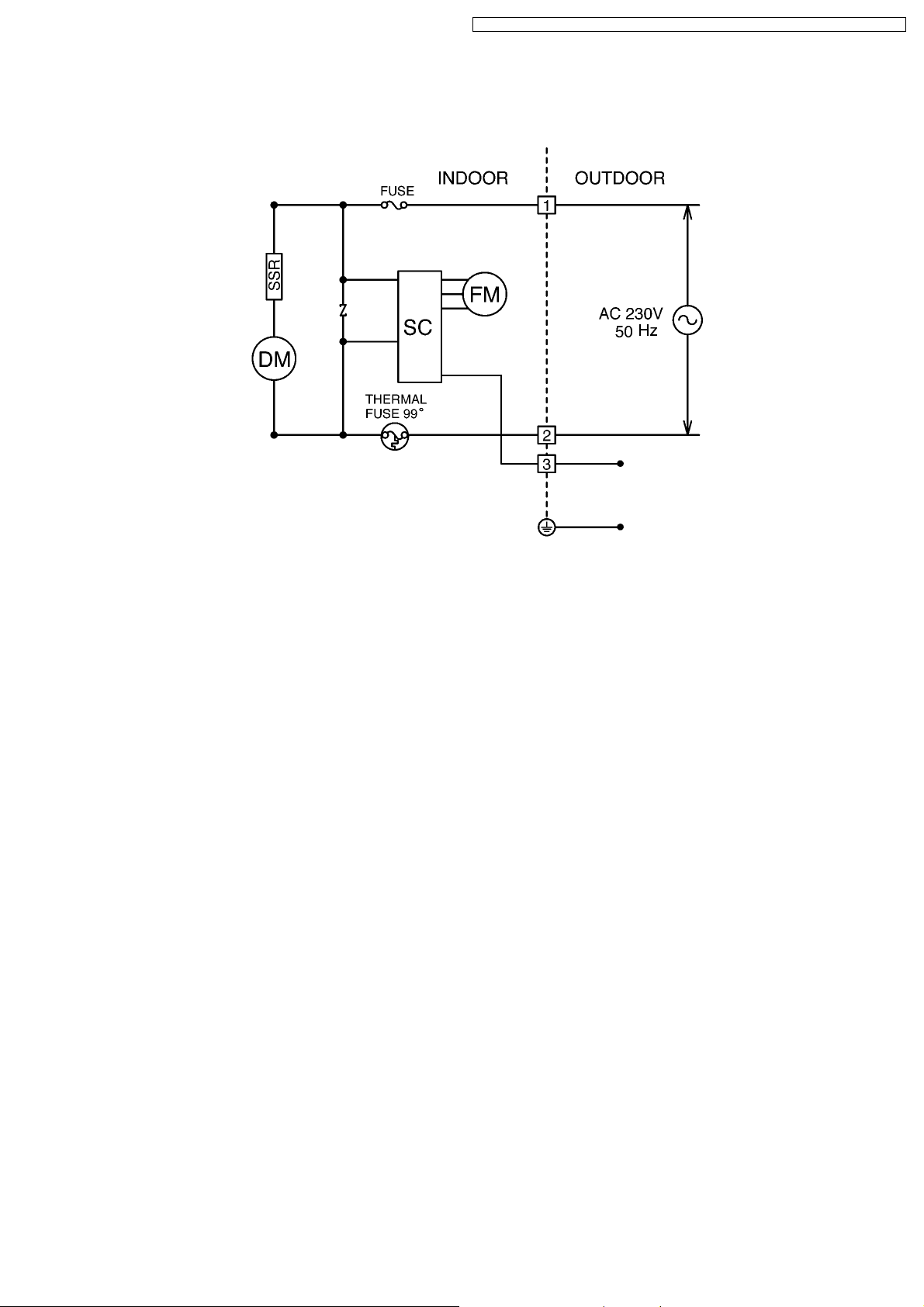

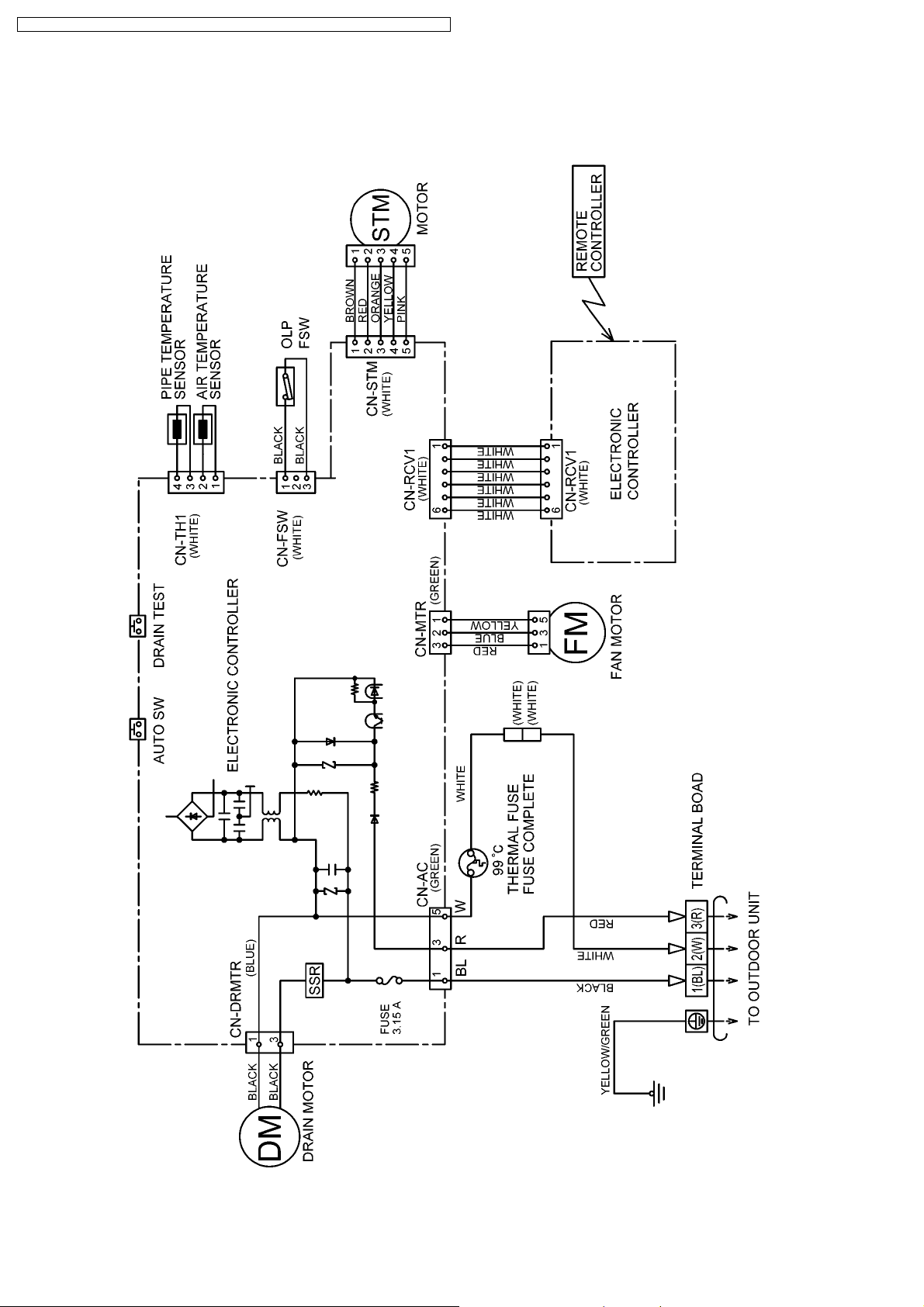

8 Wiring Diagram

8.1. Cassette Type (CS-ME7CB1P/ME10CB1P/ME12CB1P/ME14CB1P)

14

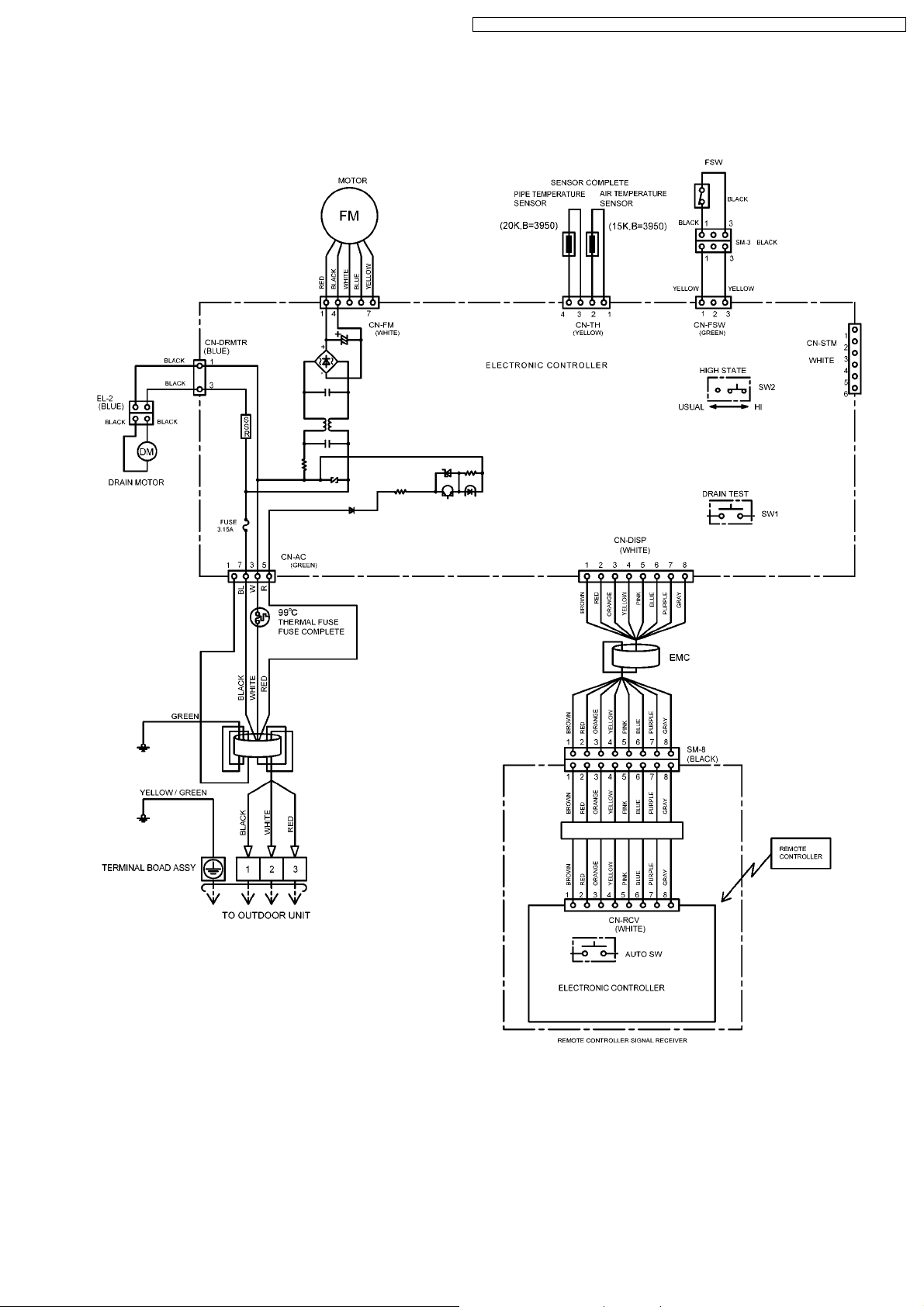

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

8.2. Duct Type (CS-ME10CD3P/ME14CD3P)

15

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9 Operation Details (Functions & Protection)

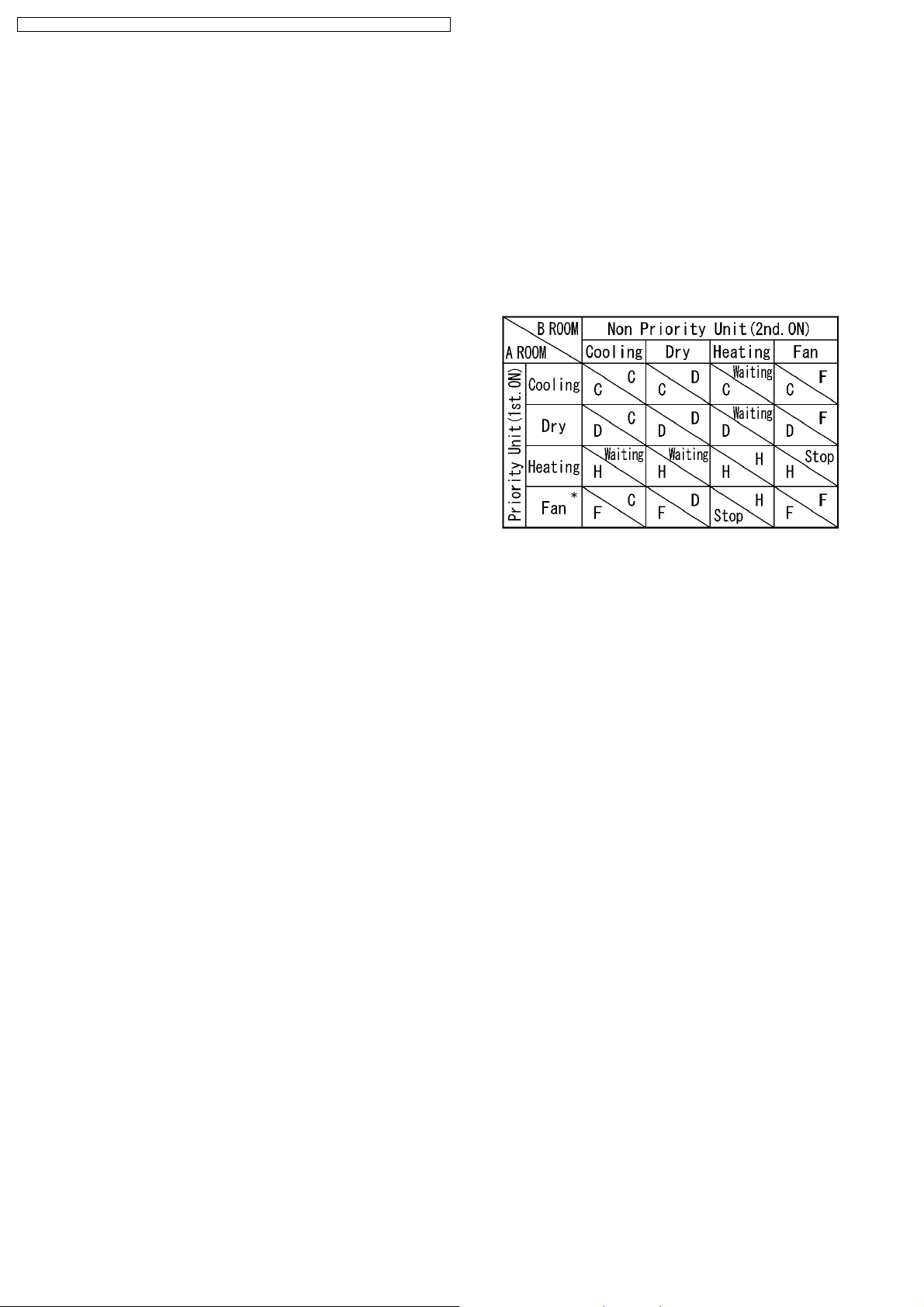

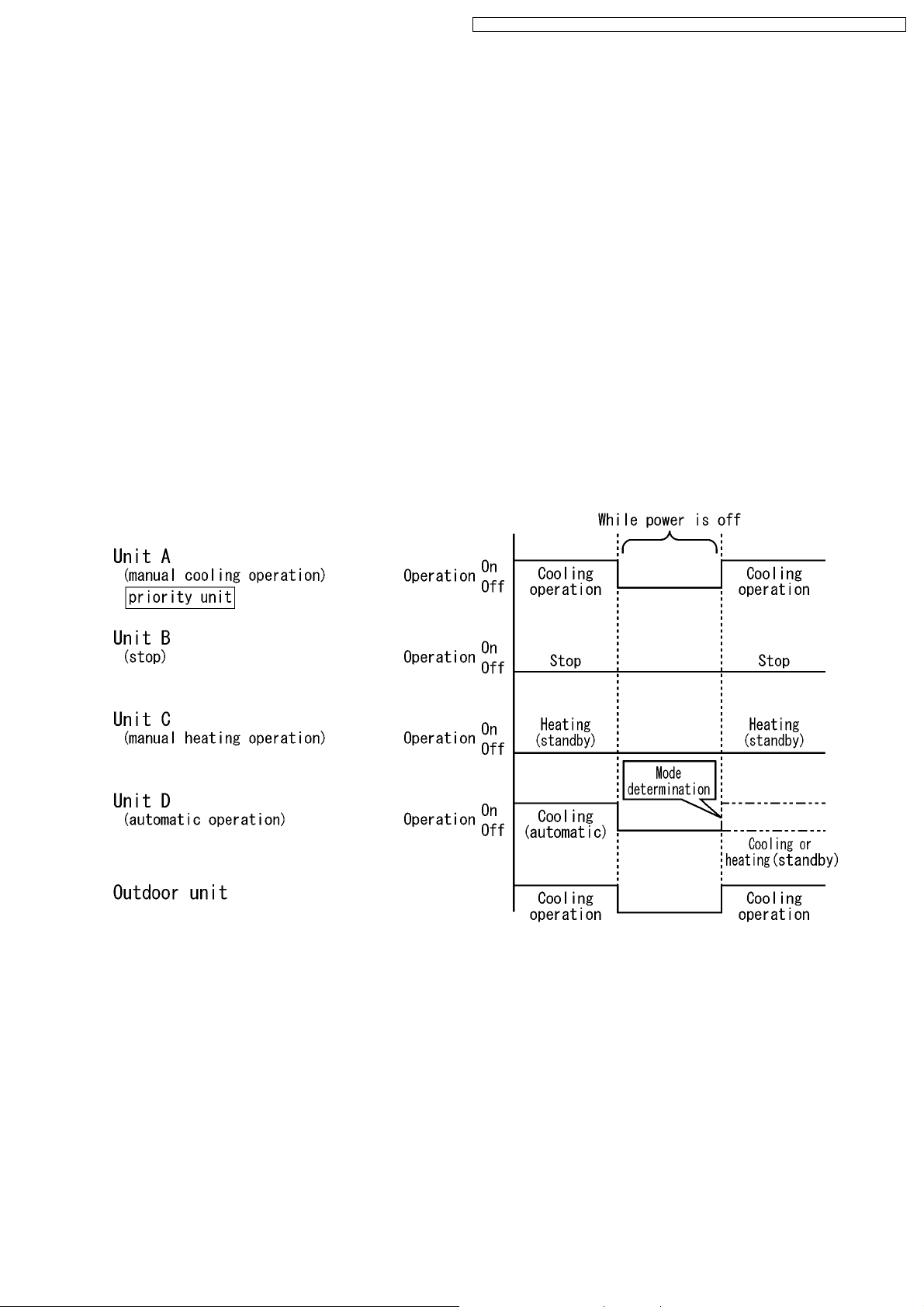

9.1. Simultaneous Operation Control

1. Operation modes which can be selected using the remote

control unit: Automatic, Cooling, Dry, Heating, Fan operation mode.

2. Types of operations modes which can be performed

simultaneously

· Cooling operation and cooling, Dry or fan operation

· Heating operation and heating operation

3. Types of operation modes which cannot be performed

simultaneously

· While a cooling operation is in progress, a heating operation

cannot be performed by an indoor unit in another room.

In the room where the operation button for cooling was pressed

first, the operation is continued. In the room where the operation

button for heating was pressed afterward, the operation lamp of

the indoor unit blinks, where the attempt is made to establish the

heating operation. Its fan is stopped, and the air does not

discharged.

· While a heating operation is in progress, a cooling operation

cannot be performed by an indoor unit in another room.

In the room where the operation button for heating was pressed

first, operation is continued. In the room where the operation

button for cooling was pressed afterward, the operation lamp of

the indoor unit blinks, where the attempt is made to establish the

cooling operation. Its fan is stopped, and the air does not

discharged.

4. Operation mode priority control

· The operation mode designated first by the indoor unit has

priority.

· If the priority indoor unit stops operation or initiates the fan

operation, the priority is transferred to other indoor units.

“Waiting” denotes the standby status in which the operation

lamp LED blinks (ON for 2.5 sec. and OFF for 0.5 sec.), and

the fan is stopped.

* In the fan mode, priority is transferred to a non-priority unit.

Note

C: Cooling operation mode

D: Dry operation mode

H: Heating operation mode

F: Fan operation mode

16

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

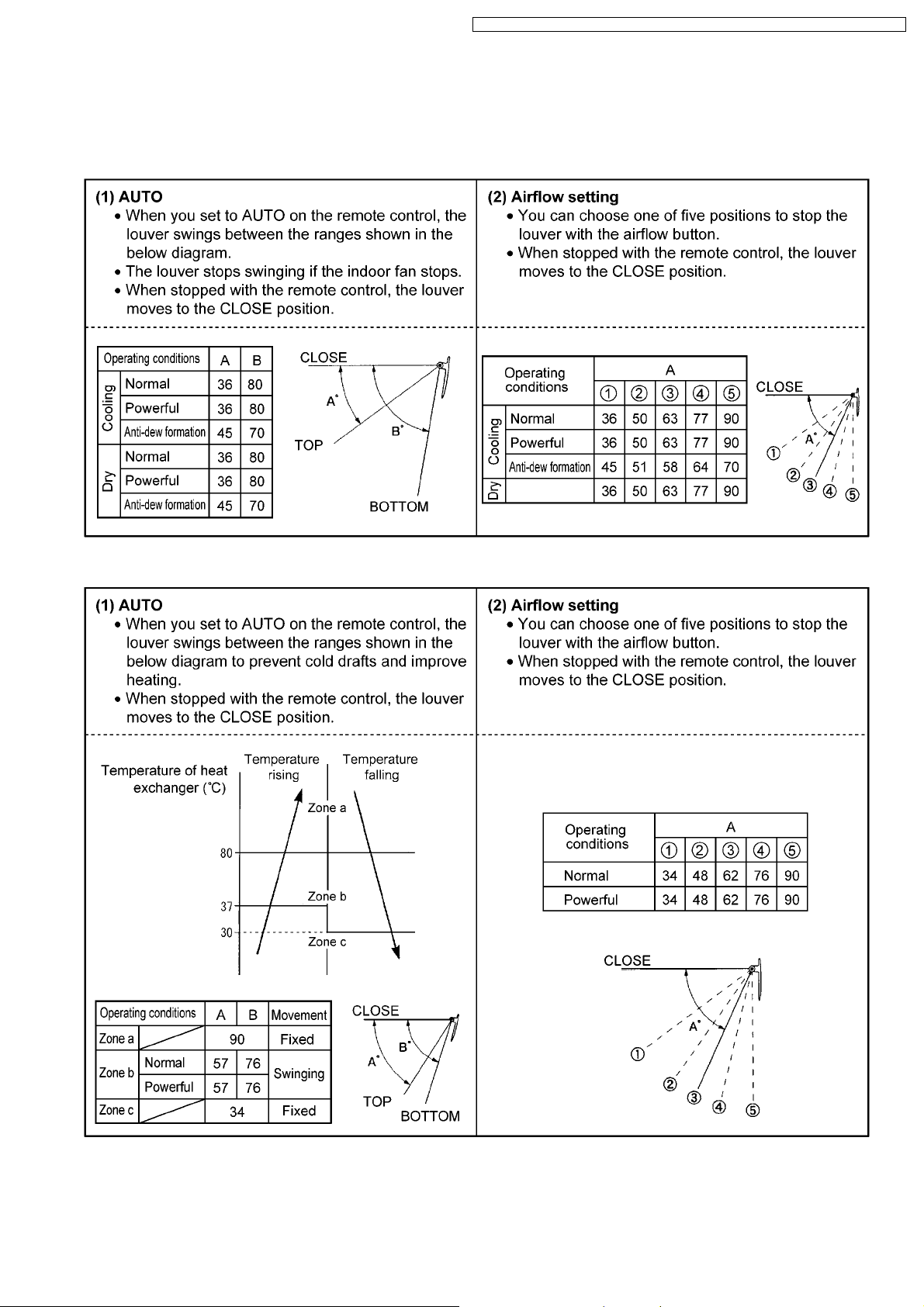

9.2. Airflow Direction Control (Cassette Type only)

The following shows how louver operation changes depending on the direction set with the AIR SWING button and other operating

conditions.

Cooling and Dry

Heating

· The louver stops at the CLOSE position when the power switch or breaker is ON.

· The louver stops at their current position when the power switch or breaker is OFF.

· Move the horizontal airflow direction control louver manually.

17

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P19CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

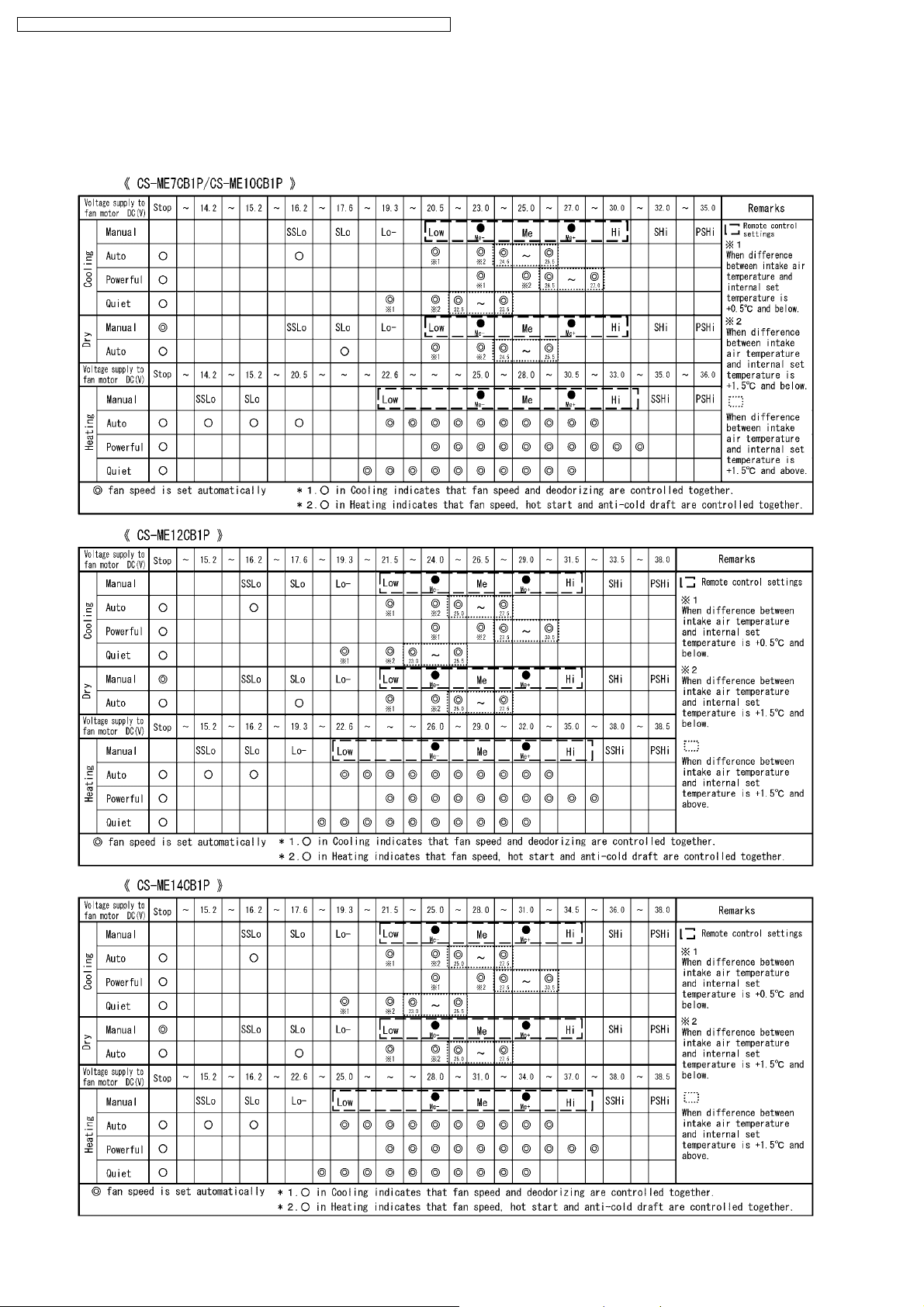

9.3. Indoor Fan Control

· The following shows how fan speed changes depending on the setting made with the FAN SPEED button and other operating

conditions.

· Actual fan speed may differ from that you set with remote control.

18

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

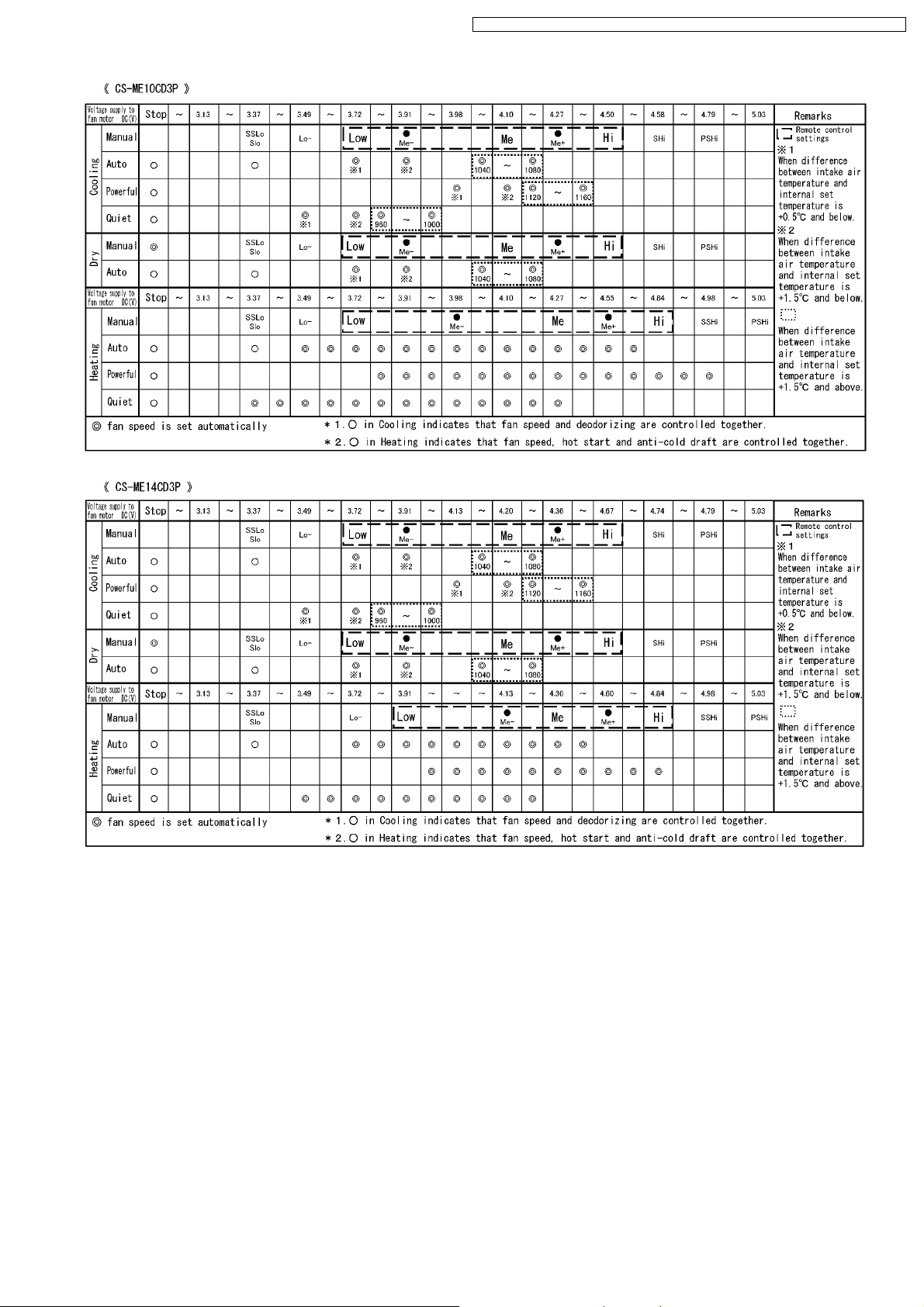

9.4. Drain Pump Control

Basic operation

· The drain pump starts 50 seconds after the indoor unit starts or the thermostat comes on (i.e., 10 seconds after the fan

motor starts).

The drain pump stops 30 seconds after the indoor unit stops or the thermostat turns off.

· The drain pump repeats a cycle of on for 30 seconds then off for between 50 and 90 seconds as long as the unit is

operating. Operation while the unit is off is determined by the difference between the temperature setting and the room

temperature.

Float switch operation

· W hen the float switch turns on for 10 seconds continuously, the thermostat of the indoor unit turns off and the drain pump

operates continuously.

· W hen the float switch stays on for 150 seconds continuously, the drain pump and indoor unit stop and the timer lamp

flashes indicating an H21 error.

20

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9.5. Auto Restart Control

· if there is a power failure, operation will automatically be restarted when the power is resumed. It will start with the previous

operation mode and airflow direction. (Time Delay Safety Control is valid)

1. Control start conditions

<1> The 24-hour timer must not be set.

<2> The sleep timer must not be set.

Auto restart control is not available when timer or sleep mode is set.

2. Description of control

<1> In the case of manual operation, the operation mode, temperature setting, fan speed and airflow direction before the power

is turned off are restored.

<2> In the case of automatic operation, after the power is restored operation starts with the determination of the mode.

<3> While the air conditioner odour clear timer has been set, the setting is cancelled, and operation is transferred to the mode

before the power is turned off.

<4> While the air conditioner odour clear operation (with timer / without timer setting) are being performed, both of these

operations are completed, and operation is transferred to the operation mode prior to these operations.

Example: When the power is turned off during an outdoor unit cooling operation

21

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9.6. Other Indoor Unit Operation Functions

9.6.1. Auto button

Proceed with operation when the air conditioner is stopped.

(When the auto button is pressed during operation, the air conditioner is stopped.)

1. Emergency operation

Press the auto button and release it within 5 seconds to perform emergency operation.

Under normal condition (failure is not occurred) automatic operation is perform ed. In the event of a failure that still enables

operation to be performed, emergency operation is performed.

2. Forced cooling operation

Press the auto button about 5-8 seconds (1 beep sound) to perform the forced cooling operation.

The air conditioner does not operate for 2 minutes if the room temperature is low (intake temperature below 16 °C) so

just wait. The forced operation is performed after the 2 minutes have elapsed.

3. Forced heating operation

Press the auto button about 8-11 seconds (2 beeps sound) to perform the forced heating operation.

4. Setting modes (Remote control transmission code, current switch ing mode)

The remote control transmission code selection mode is established by pressing the AUTO button about 11-16 seconds (3

beeps sound).

22

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

CHANGING THE REMOTE CONTROL TRANSMISSION CODE

· W hen installing two air conditioners in one room, each air conditioner can be synchronized to the remote control.

In order to operate separately, open the rear cover of one of the remote control and set to “B”.

Set “B” on the remote control.

This can be achieved by cutting the jumper wire of the remote control with a cutter.

Setting the air conditioner unit to “B”

1. Press the “AUTO” button for about 11 to 15 seconds. When you hear three short beeps, release the button.

Note: you will hear one beep in about 5 seconds, and then two beeps in about 8 seconds.

2. Press again the “AUTO” button within 60 seconds. Every press the “AUTO” button, you pressing the “AUTO” button,

which achieves “B” setting.

If you stop pressing the “AUTO” button midway at the short beep, this will achieve “A” setting.

3. After 60 seconds or longer of the above setting, use the “B” set remote control to confirm successful operation.

4. Set, A, B, C or D transmission code at remote control. (Fig.1)

5. Odour clear setting mode

The odour clear inhibit mode is established by pressing the AUTO button 16-21 seconds (4 beeps sound).

6. Individual setting mode

The H14 error detection selection mode is established by pressing the auto button about for 21 seconds (5 beeps sound). Now

remove the remote control unit´s battery cover, and short the “SET” terminals to establish the beep sound mute mode.

* If the auto button is pressed and 26 seconds or so are allowed to elapse, the auto button operation mode is restored.

When nothing happens for 60 seconds in the “Setting mode”, “Odour clear setting mode” or “individual setting mode”

or if a remote control code is received, the mode concerned is canceled.

23

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9.6.2. Drain Test (SW1)

When installing the unit and you want the drain pump to operate independently, press the DRAIN TEST switch to operate it for

about 5 minutes.

9.6.3. High Static Pressure Switch (High state switch SW2) (For Duct Type)

To increase the fan speed, open the control box and on the control board switch the HIGH STATE switch (SW2) to “HI”.

24

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1 P / CS-ME10CD3P / CS-ME14CD3P

9.6.4. Self Diagnosis display

The diagnostic displays that appear when trouble has occurred can be checked using the remote control unit.

When trouble occurs, operation is stopped automatically, and the timer lamp blinks. The diagnosis time has been reduced by

warning the user by means of the blinking of the timer lamp.

· When trouble occurs, operation is stopped automatically , and the timer

lamp blinks.

· The timer lamp will go off if the power is turned off, but it will start

blinking again if the air conditioner is operated with the trouble left

unremedied.

· No diagnostic displays will appear when the unit is operated after the

trouble has been remedied. However, the last diagnostic symbol is

stored in the IC´s memory. (This symbol can be cleared.)

· When the air conditioner protection operation is triggered because the

air conditioner is being operated under overload conditions, its heat

radiation is being interfered with or anti-freezing operation is initiated or

because its supply voltage has dropped or its power has been turned

off and then back on during operation, for instance, no diagnostic

displays will appear. However, F99 and other such information are

stored in the IC´s memory: this is normal and not indicative of

malfunctioning.

· The diagnostic displays appear automatically when trouble

occurs.

1. Operation is stopped automatically.

2. The timer lamp of the display unit on the indoor unit blinks.

3. The timer lamp goes off when the power is turned off.

· To display the trouble (or protection operation) status stored in

the memory

1. Turn on the power.

2. Open the remote control unit´s door, and press the timer setting

“UP-ARROW” button for 5 seconds.

3. Press the “UP-ARROW” button slowly and repeatedly until 4 beeps

are heard continuously from the indoor unit.

4. The 3-digit alphanumeric display on the remote control unit

indicates the trouble which has occurred.

* If the 3-digit alphanumeric display on the remote control unit

and the nature of the trouble match, the operation lamp

(green) will light.

· To clear the trouble (or protection operation) status stored in the

memory after remedial action has been taken

1. Set forced cooling operation by pressing Auto button 5 to 8

seconds.

2. Remove the battery cover from remote control.

3. The air conditioner can then be forcibly reset by shorting the

RESET terminals toward the main unit. (one short receiving beep)

The procedure is applied to all of Cassette, Duct and Wall type models.

· Concerning emergency operation (which can be performed in

some of the trouble conditions)

1. Using the remote control unit, select COOL or HEAT, and press

the operation OFF/ON button. (4 receiving beeps are heard, and

the timer lamp blinks.)

2. The air conditioner can now be used temporarily until its trouble is

remedied.

25

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1P / CS-ME10CD3P / CS- ME14CD3P

9.6.4.1. Error Cord

Symbol Diagnosis Diagnosis method

H11 Indoor/Outdoor

abnormal

communication

H12 Indoor unit capacity

unmatched

H14 Intake air temp.

sensor

H16 Outdoor Current

Transformer

H19 Indoor fan motor

mechanism lock

H21 Indoor float switch

abnormality

H23 Indoor heat

exchanger temp.

sensor

H27 Outdoor air temp.

sensor

H28 Outdoor heat

exchanger temp.

sensor 1

This trouble display appears when indoor/outdo or unit communication fails to be established after 30 or more

seconds.

<Diagnosis checkpoint>

1. Measure the voltages of the indoor/outdo or unit communication cables, and check whether the voltage is

being supplied properly to the outdoor unit or whether it is being returned from the outdoor unit to the

indoor units.

This trouble display appears when wrong in the total connection capacity and wrong connection in each

capacity.

The trouble is determined within 2 minutes after the power is turned on.

<Diagnosis checkpoint>

1. Check the total capacity of the units connected and check that the models are compatible for connection.

This trouble display appears when the intake air temperature has exceeded above 46 °C continuously for 2

minutes or dropped below -54 °C continuously for 5 seconds during operation.

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 6.5 kΩ) is not

found, defective contact of the connector is to blame.

When the total current has dropped below the set current level continuously for 20 seconds during operation

beyond the set capacity, operation is stopped. Three minutes later, operation is started up again, and when the

trouble occurs on 4 successive occasions, the trouble display appears (the timer lamp blinks).

<Diagnosis checkpoint>

1. Check the refrigerating cycle: Gas may be leaking (the amount of refrigerant is extremely low).

2. Check the control P.C. Board: Check for a broken wire (open circuit) in the current transformer. (If an open

circuit is found, replace the control P.C. Board.)

In the case of a scroll compressor (DC motor), H16 is detected only when the regular compressor is

operating.

· High-voltage PWM: When a state in which the fan motor speed is not synchronized with the control signal

has been detected on 7 successive occasions:

· Low-voltage PAM: When the fan lock detection signal has been detected on 7 successive occasions or it

has been detected continuously for 25 seconds or when a state in which the fan motor speed is not

synchronized with the control signal has been detected on 7 successive occasions:

The trouble display appears (the timer lamp blinks).

<Diagnosis checkpoint>

1. Check the nature of the fan lockup trouble.

2. Check for disconnections of the fan motor connectors and for defects in contact, in the fan motor and in

the control P.C. Board.

Error appears when the float switch is open for 150 seconds.

<Diagnosis checkpoint>

1. Drain blockage

2. Check the conductivity of float switch.

3. Check that the resistance of the drain motor is about 200 Ω

This trouble display appears when a temperature of under approximately -40 °C or above approximately 80 °C

has been detected by the heat exchanger temperature sensor continuously for 5 seconds.

(This trouble is not detected during de-icing.)

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 2.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

This trouble display appears when a temperature of under approximately -40 °C or above approximately 150

°C has been detected by the outside air temperature sensor for 2 to 5 seconds. (This trouble is not detected

during de-icing.)

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

This trouble display appears when a temperature of under approximately -60 °C or above approximately 110

°C has been detected by the heat exchanger temperature sensor for 2 to 5 seconds. (This trouble is not

detected during de-icing.)

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

26

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1P / CS-ME10CD3P / CS- ME14CD3P

Symbol Diagnosis Diagnosis method

H30 Outdoor discharge

pipe temp. sensor

Disconnected discharge sensor

· When the condensation temperature is higher than the discharge temperature + (plus) 6 °C, a sensor

disconnection is detected, operation stops, and the trouble display appears (the timer lamp blinks).

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

H32 Outdoor heat

exchanger temp.

sensor 2

(discharge pipe

temp.)

This trouble display appears when a temperature of under approximately -60 °C or over approximately 110 °C

has been detected continuously for 2 to 5 seconds by the outlet temperature sensor of the heat exchanger.

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

H34 Outdoor heat sink

temp. sensor

This trouble display appears when a temperature of under -43 °C or above 80 °C has been detected by the

outdoor unit radiator fin sensor continuously for 2 seconds.

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

H35 Drainage or drain

pump abnormality

This error appears if the float switch is open three times for ten seconds or more during a twenty-minute

period.

<Diagnosis checkpoint>

1. Drain blockage

2. Check the conductivity of float switch.

3. Check that the resistance of the drain motor is about 200 Ω

H36 Outdoor gas pipe

temp. sensor

This trouble display appears when a temperature of under approximately -45 °C or above approximately 149

°C has been detected by the outdoor unit gas side pipe temperature sensor continuously for 2 to 5 seconds.

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

H37 Outdoor liquid pipe

temp. sensor

This trouble display appears when a temperature of under -45 °C or above 149 °C has been detected by the

outdoor unit liquid side pipe temperature sensor continuously for 2 seconds.

<Diagnosis checkpoint>

1. This trouble display appears when a temperature which is impossibly high or low from a normal standpoint

has been detected.

Check the sensor, and if open-circuiting (more than 500 kΩ) or short-circuiting (less than 0.5 kΩ) is not

found, defective contact of the connector or a defective control P.C. Board is to blame.

H39 Abnormal indoor

operating unit or

standby units

H41 Abnormal wiring or

piping connection

This display appears in rooms other than one in which indoor freezing trouble has occurred when the pipes

have been connected incorrectly, when an outdoor expansion valve is defective or when an expansion valve

connector has become disconnected .

CU-2E only

This display appears when this kind of trouble is detected 3 minutes after a forced cooling operation was

conducted for one room during the initial operation after the power was turned on. It appears when:

· The indoor unit pipe temperature in a room without the capacity supply available at an outside air

temperature above 5 °C has dropped by more than 20 °C to 5 °C or lower 3 minutes after the compressor

started up.

· The outdoor unit gas pipe temperature in a room without the capacity supply available has dropped by

more than 5 °C to 5 °C or lower 3 minutes after the compressor started up.

H97 Outdoor fan motor

mechanism lock

When the fan motor speed detected when its maximum output is demanded is below 30 rpm continuously for

15 seconds, the fan motor stops for 3 minutes and then restarted.

When this happens on 16 occasions (the trouble display is cleared when the value is normal for 5 minutes),

the H97 diagnostic symbol is stored in the memory, and the fan motor stops.

<Diagnosis checkpoint>

1. Check the nature of the fan lockup trouble.

2. Check for disconnections of the fan motor connectors and for defects in contact, in the fan motor and in

the control P.C. Board.

H98 Indoor high pressure

protection

The restriction on the compressor frequency is started when the temperature of the indoor unit heat exchanger

source is between 50 °C and 52 °C, the compressor stops at a temperature from 62 °C to 65 °C, it is restarted

3 minutes later at below 62 °C to 65 °C, and the restriction on the compressor frequency is released at a

temperature between 48 °C and 50 °C. (No trouble display appears.)

<Diagnosis checkpoint>

1. Check the indoor unit heat exchanger temperature sensor (check for changes in its characteristics and

check its resistance): Symptoms include no hot start when operation is started, a failure of the thermostat

to turn on (no outdoor unit operation). And frequent repetition of stopping and startup.

2. Check also for short circuits indoors and clogging of the air filters.

27

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1P / CS-ME10CD3P / CS- ME14CD3P

Symbol Diagnosis Diagnosis method

H99 Indoor operating unit

freezing

The restriction on the compressor frequency is started when the indoor unit heat exchanger temperature is

between 8 °C and 12 °C. Operation stops if a temperature below 0 °C continues for 6 minutes. Three minutes

later, operation is started up at a temperature from 3 °C to 8 °C. The restriction on the compressor frequency

is released at a temperature between 13 °C and 14 °C.

<Diagnosis checkpoint>

1. A cooling or dry mode operation conducted at a low outside air temperature is mainly to blame:

this is not indicative of any malfunctioning.

If the outside air temperature rises during automatic operation in the winter months, the dry mode

operation is selected. The H99 diagnostic display also appears at such a time.

2. Check the refrigerating cycle: Gas may be leaking (the amount of refrigerant is low) or a pipe may be

broken, etc.

3. Check also for short circuits indoors and clogging of the air filters.

F11 4-way valve switching

failure

When a difference of 0 °C to 5 °C has been detected between the outdoor unit heat exchanger temperature

and liquid side pipe temperature on 5 occasions, the trouble display appears.

<Diagnosis checkpoint>

1. Check the 4-way valve coil: Check that no power is supplied to the coil during cooling and dry mode

operations, and that power is supplied during heating operations. Inspect the coil for broken wires (open

circuits).

2. If the coil is trouble-free, the switching action of the 4-way valve may be defective.

F17 Indoor standby units

freezing

When the difference of an intake temperature (room temperature sensor) and the indoor unit heat exchanger

temperature (piping sensor) is higher than 10 °C or an indoor unit heat exchanger temperature of below -1 °C

has been detected continuously for 5 minutes, operation stops. Three minutes later, it is started up, and the

trouble display appears when this has occurred on 3 consecutive occasions.

<Diagnosis checkpoint>

1. Check the refrigerating cycle: Expansion valve leakage

2. Check the indoor unit pipe temperature sensor (check for changes in its characteristics and check its

resistance).

F90 PFC circuit protection When a DC voltage over 393V to 424V has been detected on 16 occasions, this trouble display appears.

<Diagnosis checkpoint>

1. To check whether the shutting valve has been left close by mistake, operation is performed for one to

several minutes after the compressor has started up, F93 is stored in the memory as the symptom, and

operation stops.

2. Check the inverter circuit (for open circuits) in the control P.C. Board: Check the IPM base current (6

locations) within 3 minutes after the power has been turned back on. As the symptom, F93 is stored in the

memory 30 seconds after the compressor has started up, and operation stops. The trouble display

appears after 4 restarts.

3. Check for broken wires (open circuits) in the compressor winding: Approximately 1 ohm under normal

conditions for each phase (same symptom as in 2.)

4. Check the power supply voltage has been fluctuating or not.

F91 Refrigeration cycle

abnormality

When the compressor frequency is above 55 Hz and the current drops below the prescribed level continuously

for 7 minutes, operation stops, and it is restarted 3 minutes later.

When the compressor discharge temperature has exceeded the setting and the expansion valve has remained

fully open for 80 seconds, operation stops, and it is restarted 3 minutes later.

When the stopping described above has occurred on 4 occasions, operation stops, and the trouble display

appears.

<Diagnosis checkpoint>

1. Check the refrigerating cycle: Gas may be leaking (more than one-half of the volume of the gas has gone).

The diagnostic displays resulting from a gas leak generally change in the following sequence depending

on the extent of the gas leak: H99 → F97 → F91 → H16.

The range of this trouble (F91) is limited. (Compressor protection at the start of the season)

F93 Compressor

abnormal revolution

When a state in which the rotation of the compressor is not synchronized with the control signal has been

detected on 8 successive occasions, operation stops, and the trouble display appears.

<Diagnosis checkpoint>

1. To check whether the shutting valve has been left close by mistake, operation is performed for one to

several minutes after the compressor has started up, F93 is stored in the memory as the symptom, and

operation stops.

2. Check the inverter circuit (for open circuits) in the control P.C. Board: Check the IPM base current (6

locations) within 3 minutes after the power has been turned back on. As the symptom, F93 is stored in the

memory 30 seconds after the compressor has started up, and operation stops. The trouble display

appears after 4 restarts.

3. Check for broken wires (open circuits) in the compressor winding: Approximately 1 ohm under normal

conditions for each phase (same symptom as in 2.)

F95 Outdoor high

pressure protection

CU-2E only

When the temperature of the outdoor unit heat exchanger temperature sensor exceeds 62 °C, the F95

diagnostic symbol is stored in the memory, and operation stops. 13 minutes later, operation is restarted at a

temperature below 48 °C. This trouble display appears when this happens on 4 occasions in a 20-minute

period.

<Diagnosis checkpoint>

1. Check the outdoor unit heat exchanger temperature sensor (check for changes in its characteristics and

check its resistance).

2. Check whether something is interfering with the dissipation of the heat outdoors.

28

CS-ME7CB1P / CS-ME 10CB1P / CS-ME12CB1 P / CS-ME14CB1P / CS-ME10CD3P / CS- ME14CD3P

Symbol Diagnosis Diagnosis method

F96 IPM (Power transistor

module) or

compressor

overheating

When this trouble is detected from the electrical parts radiation fin temperature sensor and OLP output during

operation, operation stops, and it is restarted 3 minutes later. If the trouble occurs on 4 occasions, operation

stops, and the trouble display appears.

<Diagnosis checkpoint>

1. Something may be interfering with the dissipation of the heat outdoors or the outdoor unit fan may be

defective. (The outdoor unit fan is not running.)

2. Defective IPM (outdoor unit control P.C. Board)

3. Gas leaks. Shutting valve is not opened.

F97 Compressor high

discharge

temperature

This trouble display appears and operation stops when this happens on 6 occasions (it is cleared when the

operation is normal for 20 minutes).

<Diagnosis checkpoint>

1. Check the refrigerating cycle: Gas may be leaking (the amount of refrigerant is low). The stopping of the

outdoor unit from time to time is a symptom of this trouble.

2. When operation steps with this trouble display appearing, check the compressor temperature sensor

(check for changes in its characteristics and check its resistance).

3. Something may be interfering with the dissipation of the heat outdoors or the outdoor unit fan may be

defective. (The fan will not run because of an open circuit.)

(The protection function may be activated by an overload, and the F97 trouble display will remain stored

in the memory.)

F98 Total running current

protection

When the total current exceeds the setting (17A to 20A), frequency control is started, and if it then exceeds the

setting, operation stops, and the trouble display appears.

<Diagnosis checkpoint>

1. Check the AC voltage at the outdoor unit terminal board during operation: The voltage drop must be within

5% of the voltage when operation has stopped (± 110% of rated voltage even during operation). If the

voltage drop exceeds 5% or if the voltage changes suddenly, inspect whether the power supply cord and

indoor/outdoor unit connection cables are too long or too small in diameter, etc.

2. Check whether something is interfering with the dissipation of the heat outdoors (during cooling

operations): Normally, the capacity is limited by the current so that the outdoor unit don’t stop, and the

diagnostic display does not appear.

F99 DC peak detection When “Output current trouble”, which occurs when the prescribed current level is exceeded, has occurred on

16 consecutive occasions, operation stops, and the trouble display appears.

<Diagnosis checkpoint>

1. Check whether the compressor is defective (locked up or shorted winding). Check the outdoor unit control

P.C. Board.

29

10 Installation Instructions

10.1. Cassette Type

Installation Instructions

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

30

Required tools for Installation Works

1. Philips screw driver

2. Level gauge

3. Electric drill, hole core drill

(ø70 mm)

4. Hexagonal wrench (4 mm)

5. Spanner

6. Pipe cutter

7. Reamer

8. Knife

9. Gas leak detector

10. Measuring tape

11. Thermometer

12. Megameter

13. Multimeter

SAFETY PRECAUTIONS

• Read the following “SAFETY PRECAUTIONS” carefully before installation.

• Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main

circuit for the model to be installed.

• The caution items stated here must be followed because these important contents are related to safety. The meaning of

each indication used is as below. Incorrect installation due to ignoring of the instruction will cause harm or damage, and the

seriousness is classified by the following indications.

WARNING

CAUTION

The items to be followed are classified by the symbols:

• Carry out test running to confirm that no abnormality occurs after the installation. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for future

reference.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties only.

Symbol with background white denotes item that is PROHIBITED from doing.

14. Torque wrench

18 N•m (1.8 kgf.m)

42 N•m (4.2 kgf.m)

15. Vacuum pump

16. Gauge manifold

WARNING

1) Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage,

electrical shock or fire.

2) Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical

shock or fire.

3) Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage,

fire or electrical shock.

4) Install at a strong and firm location which is able to withstand the set's weight. If the strength is not enough or

installation is not properly done, the set will drop and cause injury.

5) For electrical work, follow the local national wiring standard, regulation and this installation instruction. An independent

circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will

cause electrical shock or fire.

6) Use the specified cable (1.5 mm

7) Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed

8) When carrying out piping connection, take care not to let air substances other than the specified

8) Otherwise, it will cause lower capacity, abnormal high pressure in the refrigeration cycle, explosion and

9) When connecting the piping, do not allow air or any substances other than the specified refrigerant

10) Do not modify the length of the power supply cord or use of the extension cord, and do not share the

externa

so that no

connection.

perfectly, it will cause heat-up at connection point of terminal, fire or electrical shock.

refrigerant go into refrigeration cycle.

injury.

(R410A) to enter the refrigeration cycle. Otherwise, this may lower the capacity, cause abnormally high

pressure in the refrigeration cycle, and possibly result in explosion and injury.

single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock.

l force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the

2

) and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable

CAUTION

1) This equipment must be earthed. It may cause electrical shock if grounding is not perfect.

2) Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and

accumulates at surrounding of the unit, it may cause fire.

3)

Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and

damage the furniture.

ATTENTION

1) Selection of the installation location.

1) Select a installation location which is rigid and strong enough to support or hold the unit, and select a location for easy

maintenance.

2) Do not release refrigerant.

3) Do not release refrigerant during piping work for installation, reinstallation and during repairing a refrigeration parts. Take

care of the liquid refrigerant, it may cause frostbite.

3) Installation work.

4) It may need two people to carry out the installation work.

4) Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

31

Indoor Unit Accessory Parts

No. No. No.

Accessory part Accessory part Accessory part

Piping insulation

1

Band

2

Remote control

3

Selecting the Installation Location

1

Determine the location with the agreement of the customer.

Indoor unit

The location should be strong enough to support the main unit without vibration.

There should not be any heat or steam sources nearby.

Drainage should be easy. Avoid locating the drain port close to ditches

(domestic wastewater).

Avoid locations above entrances and exits.

Ensure the distances indicated by the marks in the illustration.

Ensure sufficient space for installation and servicing.

The ceiling surface (lower surface) should be level.

Locate the indoor unit at least 1 m or more away from a TV, radio, wireless

equipment, antenna cables and fluorescent lights, and 2 m or more away

from a telephone.

Note that if the air conditioning unit is installed near an electronically lit

fluorescent light (inverter, rapid start type, etc.), it may not receive the

remote control signals.

Qty. Qty. Qty.

Battery

2

4

4

5

1

6

Remote control holder

Remote control holder

fixing screw

2

1

2

Drain joint

7

Pattern

8

Pattern fixing screw

9

Indoor Unit Installation Diagram

30 cm or

more

Wall

Indoor unit

20 cm

or more

Discharge vent

Ceiling

Required Materials

Part name Part number

CZ-BT20P

Decorative grille

(white)

1

1

4

19 cm or

more

Intake

Decorative grille

30 cm or

more

Other Items to be Prepared (Locally Purchased )

Product name Remarks

Rigid PVC pipe

Adhesive

Insulation

Indoor/outdoor

connecting cable

Hanging bolt related parts

VP20 (outer diameter ø26) ; also sockets, elbows and other

parts as necessary

PVC adhesive

For refrigerant piping insulation

(foamed polyethylene with a thickness of 8 mm or more)

For drain piping insulation

(foamed polyethylene with a thickness of 10 mm or more)

2

4×1.5 mm

flexible cord, type designation 245 IEC 57 (H05RN-F)

(See "Connecting the Indoor/Outdoor Connecting Cable".)

Hanging bolts (M10) (4) and nuts (12), Flat washers (8)

Remote control mounting location

Signals may not be transmitted and received correctly when

the remote control is operated while in the holder. Take the

remote control in your hand to operate the unit.

Mount the holder in a location that is not subject to the

effects of heat (direct sunlight and stoves, etc.).

Attaching the remote control holder to the wall

Remote control holder

Remote control

holder

5

fixing screws

6

Remote

control

3

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

Selecting the Piping

2 3

• Prepare the piping set shown in the table

below or equivalent products for the

refrigerant piping.

Liquid side

Gas side

* See the Outdoor Unit Installation

Instructions.

ø 6.35 (1/4") t 0.8

ø 9.52 (3/8") t 0.8

To Drill a Hole in the Wall and

Install a Sleeve of Piping

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes

about 15 mm from the wall.

CAUTION

When the wall is hollow,

please be sure to use the

sleeve for tube ass'y to

prevent dangers caused by

mice biting the connecting

cable.

4. Finish by sealing the sleeve with

putty or caulking compound at the

final stage.

Sleeve for

tube ass'y

ø70 through

hole

Indoor

Wall

Putty or caulking

compound

Outdoor

15 mm

Approx.

5 - 7 mm

Bushing for

tube ass'y

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

32

Installation Dimensions

4

415

505

1010

Drain pan

1070 Grille

860

770 Main unit

Control box position

Grille center

830

Hanging bolt

Ceiling opening

Airflow direction

control vanes

Intake side

Squeeze bottle

Connecting cable

Insertion position

60

72

67

40

240 Hanging bolt

60

11

30

415

90

505

30

36.5770

Installation Dimensions (Unit: mm)

Decorative grille

dimensions

40

Ceiling opening

dimensions

Hanging bolt pitch

dimensions

Grille

Main unit

dimensions

460

Ceiling opening

360 Main unit

Ceiling depth

390

dimension

30

145

70

100

30

55

135

1070 × 460

1010 × 390

830 × 240

H185 × W770 × D360

190 or more

Drain connection port

(connect to VP20)

168

95

Refrigerant piping

(gas side) 3/8"

Refrigerant piping

(liquid side) 1/4"

or more

185

190

Connecting and Insulating the Refrigerant Piping

Tighten the refrigerant piping using the torque

shown in the table to the right.

Cover the piping joint with piping insulation 1 and

tie the insulation firmly using two bands 2 on both

sides. Be sure to adhere the insulation closely so

that there is no gap between the main unit and the

piping insulation.

When the relative humidity inside the ceiling

(indoors) is thought to exceed 80% such as in a

new building during the rainy season or a new

reinforced concrete structure, moisture may

“DRAIN TEST”

switch

“AUTO” switch

condense on the outer surface of the piping

insulation. In this case be sure to add further

insulation to the refrigerant piping.

Half-union

(Auxiliary pipe)

Male side

Wrench

(17 mm and 12 mm end

wrench or adjustable spanner)

• Select the unit position and airflow direction so that the

cool and warm air spreads throughout the whole room.

• Secure the hanging bolts (M10, locally purchased) firmly

in the manners shown below in a location that is

capable of supporting the unit weight.

• When the ceiling materials insufficient strength, it may

be necessary to make an opening in the ceiling and add

a framework or other reinforcing structure to maintain

the levelness of the ceiling and prevent ceiling vibration.

Consult a construction or interior contractor for details.

Wooden structure

(Unit: mm)

Reinforcing materials

(60 to 90 mm square)

Hanging

bolt M10

Connecting the Drain Piping

67

Lay the drain piping so as to ensure drainage.

Use a locally purchased VP20 rigid PVC pipe (outer diameter ø26) for the

drain piping, and connect it to the drain port of the indoor unit using the

drain joint 7 . Coat both sides with a PVC adhesive and adhere them firmly.

Drain piping located indoors should always be insulated by wrapping with locally

purchased insulation (foamed polyethylene with a thickness of 10 mm or more).

The drain piping should have a downward gradient (1/50 or more), and should be

secured using pipe hanging equipment to avoid creating hills or traps partway.

Drain joint 7

Should some obstacle prevent the drain piping from being extended

smoothly, the drain piping can be raised outside the main unit as

shown in the illustration below.

80

Approx.

Ceiling surface

Insulation (thickness

10 mm or more)

Downward gradient

1/50 or more

Roof beam

CAUTION

Absolutely do not install and

extend the drain piping from the

main unit drain water outlet

horizontally or upward or raise it

20cm or more. Doing so may

result in poor drainage or cause

of drain motor failure.

Reinforced concrete

(Unit: mm)

Hanging

bolt M10

20 cm

or less

80

Approx.

Rise

No insulation

VP20 elbow

Downward gradient

1/50 or more

7 cm

or less

Connect the VP20 elbow directly

to the main unit outlet.

Insert hole-in

anchor, etc.

Ceiling surface

Hill

VP20 pipe

230

190

200

230

Tra p

Upward

gradient

or level

75

175

115

125

185

75

Discharge vent

(lower surface)

15

30

90

30

Check the drainage Check after connecting the power supply.

Pour approximately 300 to 400 cc of water into the drain pan of the main unit.

(Pour the water from a squeeze bottle or other vessel as shown in the illustration

below.)

Press the “DRAIN TEST” switch located on the control box to start the drain

motor, and check that the water drains normally.

(The drain motor operates for approximately 5 minutes and then stops automatically.)

Installing the Indoor Unit

5

Attach the nuts and washers to the

hanging bolts, then lift up and hook

the main unit onto the hanging

fixtures.

Adjust the lower surface of the

indoor unit relative to the ceiling

surface as shown in the illustration

below.

Check the levelness using a level or

a vinyl hose filled partially with

water before tightening the nuts.

0 2mm

Flare nut

(Connection pipe)

Female side

Torque wrench

for flare nuts

Ceiling surface

Main

unit

Adhere closely

Hanging bolt (M10)

(Locally Purchased)

Flat washer

(Locally Purchased)

Hexagonal nut (M10)

(Locally Purchased)

CAUTION

Note that if the main unit

is not level or if the

height relative to the

ceiling surface is not

appropriate, water may

leak or condense around

the discharge vent.

0 2mm

CAUTION

Hold the half-union with a

wrench, and do not rotate

the male side.

Pipe diameter

Liquid side

ø6.35 (1/4")

Gas side

ø9.52 (3/8")

Bands 2

Piping

insulation

Tightening

torque

18N • m

(1.8 kgf • m)

42N • m

(4.2 kgf • m)

(locally purchased)

1

8 mm or more

Insulation

Thickness:

Connecting the Indoor/Outdoor Connecting Cable

8

• Remove the control box cover and insert the cable into the main unit

through the cable holder located on the side.

• Check the colors of the wires on the terminal board, and secure

them with screws.

• Secure the outer sheath of the connecting cable with the cord clamp.

• Reattach the control box cover in its original position.

• Connecting cable between indoor unit and outdoor unit shall be

approved polychloroprene sheathed 4 × 1.5 mm

designation 245 IEC 57(H05RN-F) or heavier cord.

• Ensure the color of wires of outdoor unit and the terminal Nos.

are the same to the indoor’s respectively.

• Earth lead wire shall be longer than the other lead wires as

shown in the figure for the electrical safety in case of the slipping

out of the cord from the anchorage.

2

flexible cord, type

33

Indoor/outdoor

connection terminals

Earth wire

Cord clamp

Indoor/outdoor

connecting cable

Control box cover

Attaching the Decorative grille

9

• Lift up the decorative grille from directly below to match it with the main

unit, and tentatively secure it in place.

• Open the intake grille and the screw caps, and secure the decorative

grille using the lock screws (4).

Decorative

grille

temporary

hooks

Air conditioning

unit

Screw cap

Control box cover

lock screw

Air conditioning

unit

Screw cap

Intake grille

Lock screw (4)

(supplied with the decorative grille)

Decorative

grille

temporary

hooks

Decorative

grille

Insert

Cable holder

Indoor/outdoor

connecting cable

Terminals on the indoor unit

Color of wires

Terminals on the outdoor unit

• Secure the cable onto the control board with the holder (clamper).

• Connect the indoor/outdoor connecting cable using the

prescribed cable, and secure it firmly so that external force from

the cable is not transmitted to the terminal connectors.

Opening the Intake Grille

Press the three locations shown

below and open the grille.

Opening the Screw Caps

Press the edge (outside) of the

screw cap to open it.

Press

Decorative grille

Screw cap

1 2 3

1 2 3

• When finishing the ceiling after the air conditioner has been installed, use the pattern

8 to indicate the ceiling opening dimensions as shown below. (The protection sheet

of the pattern is used to prevent the air conditioner discharge vent from becoming

dirty, so wrap it around the discharge vent as shown in the illustration.)

Fold back the protection sheet

and affix using double-sided

adhesive tape

Using the Pattern 8

Air conditioning unit

Discharge vent

Pattern 8

Pattern attachment

hole (small hole)

Pattern fixing screw

9 (4)

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

34

AUTO SWITCH OPERATION

The below operations will be performed by pressing the “AUTO” switch.

1. AUTO OPERATION MODE

1. The Auto operation will be activated

immediately once the

2. TEST RUN OPERATION (FOR PUMP

DOWN/SERVICING PURPOSE)

The Test Run operation will be activated if

the

“AUTO” switch is pressed continuously for

more than 5 sec. to below 8 sec..

1. A short beep sound will occur at the fifth sec.,

in order to identify the starting of Test Run

operation.

“AUTO” switch is pressed.

“DRAIN TEST”

switch

“AUTO” switch

Changing the remote control transmission code

• When installing two air conditioners in one room, each air conditioner can be

synchronized to the remote control.

In order to operate separately, open the rear cover of one of the remote control and set

to “B”.

Set “B” on the remote control.

This can be achieved by cutting

the jumper wire of the remote

control with a cutter.

Setting the air conditioner unit to “B”

1. Press the “AUTO” switch for about 11 to 15 seconds. When you hear three short beeps,

release the switch.

1. Note: you will hear one short beep in about 5 seconds, and then two short beeps in about

8 seconds.

2. Press again the “AUTO” switch within 60 seconds. Every press the “AUTO” switch, you

will hear a short beep. When you hear eventually a long beep, stop pressing the

“AUTO” switch , which achieves “B” setting.

1. If you stop pressing the “AUTO” switch midway at the short beep, this will achieve

“A” setting.

3. After 60 seconds or longer of the above setting, use the “B” set remote control to confirm

successful operation.

Remote control

OPEN

Jumper wire

Side view of jumper

Give two cuts.

The disconnected jumper

wire is “B” setting.

CHECK ITEMS

Is there any gas leakage at

flare nut connections?

Has the heat insulation been carried

out at flare nut connection?

Is the connecting cable being fixed

to terminal board firmly?

Is the connecting cable being

clamped firmly?

Is the drainage ok?

(Refer to “Check the drainage”

section)

Is the earth wire connection

properly done?

Is the power supply voltage

complied with rated value?

Is there any abnormal sound?

Is the cooling / heating operation

normal?

Is the thermostat operation

normal?

Is the remote control’s LCD

operation normal?

MATSUSHITA ELECTRIC INDUSTRIAL CO., LTD.

Web Site : http://www.panasonic.co.jp/global/

ENGLISH

F612424

PRINTED IN JAPAN

10.2. Duct Type

Installation Instructions

35

Required tools for Installation Works

1. Philips screw driver

2. Level gauge

3. Electric drill, hole core drill

(ø70 mm)

4. Hexagonal wrench (4 mm)

5. Spanner

6. Pipe cutter

7. Reamer

8. Knife

9. Gas leak detector

10. Measuring tape

11. Thermometer

12. Megameter

13. Multimeter

SAFETY PRECAUTIONS

• Read the following “SAFETY PRECAUTIONS” carefully before installation.

• Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main

circuit for the model to be installed.

• The caution items stated here must be followed because these important contents are related to safety. The meaning of

each indication used is as below. Incorrect installation due to ignoring of the instruction will cause harm or damage, and the

seriousness is classified by the following indications.

WARNING

CAUTION

The items to be followed are classified by the symbols:

• Carry out test running to confirm that no abnormality occurs after the installation. Then, explain to user the operation,

care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for future

reference.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties only.

Symbol with background white denotes item that is PROHIBITED from doing.

14. Torque wrench

18 N•m (1.8 kgf.m)

42 N•m (4.2 kgf.m)

15. Vacuum pump

16. Gauge manifold

WARNING

1) Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage,

electrical shock or fire.

2) Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical

shock or fire.

3) Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage,

fire or electrical shock.

4) Install at a strong and firm location which is able to withstand the set's weight. If the strength is not enough or

installation is not properly done, the set will drop and cause injury.

5) For electrical work, follow the local national wiring standard, regulation and this installation instruction. An independent

circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will

cause electrical shock or fire.

6) Use the specified cable (1.5 mm

7) Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed

8) When carrying out piping connection, take care not to let air substances other than the specified

8) Otherwise, it will cause lower capacity, abnormal high pressure in the refrigeration cycle, explosion and

9) When connecting the piping, do not allow air or any substances other than the specified refrigerant

10) Do not modify the length of the power supply cord or use of the extension cord, and do not share the

externa

so that no

connection.

perfectly, it will cause heat-up at connection point of terminal, fire or electrical shock.

refrigerant go into refrigeration cycle.

injury.

(R410A) to enter the refrigeration cycle. Otherwise, this may lower the capacity, cause abnormally high

pressure in the refrigeration cycle, and possibly result in explosion and injury.

single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock.

l force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the

2

) and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable

CAUTION

1) This equipment must be earthed. It may cause electrical shock if grounding is not perfect.

2) Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and

accumulates at surrounding of the unit, it may cause fire.

3)

Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and

damage the furniture.

ATTENTION

1) Selection of the installation location.

1) Select a installation location which is rigid and strong enough to support or hold the unit, and select a location for easy

maintenance.

2) Do not release refrigerant.

3) Do not release refrigerant during piping work for installation, reinstallation and during repairing a refrigeration parts. Take

care of the liquid refrigerant, it may cause frostbite.

3) Installation work.

4) It may need two people to carry out the installation work.

4) Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

36

Indoor Unit Accessory Parts

No. No.

Accessory part Accessory part

Piping

insulation

1

Band

2

Remote control

3

Battery

4

Remote control holder

5

Remote control holder

fixing screw

6

Required Materials

• Read the catalog and other technical materials and prepare the required materials.

Qty. Qty.

Drain hose insulation

7

1

Receiver

2

8

Receiver cover

9

1

Receiver mount

10

2

Clamp

11

1

Clamp mounting screw

2

12

Other Items to be Prepared (Locally Purchased)

Product name Remarks

Rigid PVC pipe

Adhesive

Insulation

Indoor/outdoor connecting cable

Hanging bolt related parts

VP20 (outer diameter ø26); also sockets,

elbows and other parts as necessary

PVC adhesive

For refrigerant piping insulation (foamed

polyethylene with a thickness of 8 mm or more)

For drain piping insulation (foamed polyethylene

with a thickness of 10 mm or more)

4 × 1.5 mm2 flexible cord, type designation

245 IEC 57 (H05RN-F)

Hanging bolts (M10) (4) and nuts (12), Flat

washers (8) (when hanging the indoor unit)

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

Selecting the Installation Location

1

1

1

1

2

2

1

Take into consideration the following contents when creating the blueprint.

Indoor unit installation location

The location should be strong enough to support the main unit

without vibration.

There should not be any heat or steam sources nearby.

Drainage should be easy. Avoid locating the drain port close to

ditches (domestic wastewater).

Avoid locations above entrances and exits.

Do not block the intake and discharge.

Select the location so that the cool and warm air spreads

throughout the entire room.

Locate the indoor unit at least 1 m or more away from a TV, radio,

wireless equipment, antenna cables and fluorescent lights, and 2

m or more away from a telephone.

Note that if the air conditioning unit is installed near an

electronically lit fluorescent light (inverter, rapid start type, etc.),

it may not receive the remote control signals.

Selecting the Piping

2

• Prepare the piping set shown in the table

below or equivalent products for the

refrigerant piping.

Liquid side

Gas side

* See the Outdoor Unit Installation

Instructions.

ø 6.35 (1/4") t 0.8

ø 9.52 (3/8") t 0.8

To Drill a Hole in the Wall and

3

Install a Sleeve of Piping

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes

about 15 mm from the wall.

CAUTION

When the wall is hollow,

please be sure to use the

sleeve for tube ass'y to

prevent dangers caused by

mice biting the connecting

cable.

4. Finish by sealing the sleeve with

putty or caulking compound at the

final stage.

Remote control mounting location

Signals may not be transmitted and received correctly when

the remote control is operated while in the holder. Take the

remote control in your hand to operate the unit.

Mount the holder in a location that is not subject to the

effects of heat (direct sunlight and stoves, etc.).

Attaching the remote control holder to the wall

Remote control holder

Remote control

holder

5

fixing screws

Indoor

Sleeve for

tube ass'y

ø70 through

hole

6

Wall

Remote

control

Outdoor

15 mm

Approx.

5 - 7 mm

Bushing for

tube ass'y

Putty or caulking

compound

3

Installing the Indoor Unit (Installation embedded in the ceiling)

4

37

• Always provide sufficient entry and exit space to allow installation work, inspection and unit

replacement.

• Waterproof the rear surface of the ceiling below the unit in consideration of water droplets

forming and dropping.

CAUTION

When cooling operation is performed for an extended period under the following conditions,

water droplets may form and drop. Attach locally purchased insulation (foamed polyethylene

with a thickness of 5 mm or more) to the outside of the indoor unit before installation within

the ceiling for improving the heat insulation.

• Locations with a dew point inside the ceiling of 23 C or more

• Kitchens and other locations that produce large amounts of heat and steam

• Locations where the inside of the ceiling serves as an outside air intake passage

• When installing within a ceiling, select the unit position and the airflow direction so that

the cool air and warm air spread throughout the whole room.

• Do not place objects that might obstruct the air flow within 1 m below the intake grille.

Ceiling Opening and Hanging Bolt Locations

• The relative positions of the ceiling opening and the hanging bolts are shown in the illustration

to the right. When making an inspection opening below the unit, make a 960 mm × 480 mm

opening in the ceiling surface. Also, lead the drain piping, refrigerant piping and indoor/outdoor

connecting cable up to the respective piping and cable connection positions.

• Secure the hanging bolts (M10, Locally Purchased) firmly in a manners capable of supporting

the unit weight.

• Consult your construction or interior contractor for details on finishing the ceiling opening.

Preparing to Install the Indoor Unit

• Fit the drain hose insulation 7 around

the drain hose as shown in the right

figure.

• Attach the discharge chamber.

(10 screws)

• Cut out the intake cut-out portions in the

unit rear panel using cutter or other tools

to make openings.

• Remove the two screws at the rear edge

of the unit top panel, and attach the

intake chamber. (8 screws)

Discharge

chamber

To the

receiver

Drain hose

insulation

7

Intake cut-out

portion

Intake

chamber

(View from below and behind the unit)

Installation Diagram

This diagram shows the unit together

with the purchased components.

Hanging bolt 315

Installation parts you

should purchase

Top view (from above the ceiling)

Front view

300 or more

Installing an Intake and Discharge Duct Type

Allowable

Discharge

side duct

Intake side

duct

177

287.5

Hanging bolt 790

321

Intake chamber for

oval flexible duct

Indoor unit

Top

Discharge chamber for

oval flexible duct

331

310176

Hanging bolt 790

750

331

65

199

370

Hanging bolt 315

30

duct length

5 m or less including

the intake side

1 m or less

(This shows an installation example.)

Intake chamber for

Ø150 flexible duct

65

330 or more

(12)

300 or more

150

65

Duct bends

90 or less

in one location

45 or less

in one location

Discharge chamber for

Ø150 flexible duct

CS-ME7C B1P / CS-ME10CB1 P / CS-ME 12CB1P / CS-ME14CB1 P / CS-ME 10CD3P / CS-ME14 CD3P

Right view

180

Waterproofing

30

235

275

193

44

114

59

38

Securing the Hanging Bolts

Reinforced concrete

(Unit: mm)

Hanging

bolt M10

Approx.

Switching the high state switch

(SW2)

• To increase the air volume, open the

control box and on the control board

switch the high state switch (SW2) to

“HI”.

• See the diagram for “Connecting the

Indoor/ Outdoor Connecting Cable”.

114

Insert hole-in

anchor, etc.

Ceiling surface

Wooden or other structure

(Unit: mm)

(Hanging bolt pitch)

Hanging

bolt M10

Installation in the Ceiling

• Attach the nuts and washers to the hanging bolts, then

lift up and hook the main unit onto the hanging fixtures.

• Check that the unit is level using a level or a vinyl hose

filled partially with water.

990

Hanging bolt

114

Approx.

40

t =2

30

C channel

Hanging fixture

Reinforcing materials

(60 to 90 mm square)

Roof beam

Ceiling surface

Hanging bolt (M10)

(Locally Purchased)

Flat washer

(Locally Purchased)

Hexagonal nut (M10)

(Locally Purchased)

Mounting the Receiver

• Select a ceiling or wall position that does not block reception for the mounting location. Note that