Panasonic cs-ks12nb41 installation

INSTALLATION INSTRUCTIONSAPPENDIX B

CS-KS12NB41 & CZ-18BT1U + CU-KS12NK1A

CS-KS18NB4UW & CZ-18BT1U + CU-KS18NKU

CS-KS18NB4UW & CZ-18BT1U + CU-KS18NKUA

(852-6-4190-574-00-1)

A-2

INSTALLATION INSTRUCTIONS

Split System Air Conditioner

This air conditioner uses the refrigerant R410A.

NOTE

External diameter of service port R410A: 5/16"

Model Combinations

Combine indoor and outdoor units only as listed

below.

Model No.

Indoor Unit Outdoor Unit

CS-KS12NB41 CU-KS12NK1A

Power Source:

60 Hz, single-phase, 115 V

CS-KS18NB4UW CU-KS18NKU

CU-KS18NKUA

Power Source:

60 Hz, single-phase, 230/208 V

Ceiling Panel

CZ-18BT1U

Contents

Page

IMPORTANT!

Please Read Before Starting .................................. 2

1. GENERAL .......................................................... 4

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Optional Copper Tubing Kit

1-4. Type of Copper Tube and Insulation Material

1-5. Additional Materials Required for Installation

2. INSTALLATION SITE SELECTION ................... 5

2-1. Indoor Unit

2-2. Outdoor Unit

2-3. Baffle Plate for the Outdoor Unit

3. HOW TO INSTALL THE INDOOR UNIT ........... 12

3-1. Preparation for Suspending

3-2. Suspending the Indoor Unit

3-3. Placing the Unit Inside the Ceiling

3-4. Installing the Drain Piping

3-5. Checking the Drainage

3-6. How to Install the Ceiling Panel

3-7. Wiring Instructions

3-8. Recommended Wire Length and Diameter

3-9. Wiring Instructions for Inter-unit Connections

4. HOW TO INSTALL THE OUTDOOR UNIT ....... 20

4-1. Wiring Instructions for the Outdoor Unit

5. REFRIGERANT TUBING .................................. 21

5-1. Use of the Flaring Method

5-2. Flaring Procedure with a Flare Tool

5-3. Caution before Connecting Tubes Tightly

5-4. Connecting Tubing between Indoor and

Outdoor Units

5-5. Insulation of Refrigerant Tubing

5-6. Taping the Tubes

5-7. Finishing the Installation

6. AIR PURGING................................................... 23

Air Purging with a Vacuum Pump (for Test Run)

Basic Functions of the Service Valves

Pump Down

Service Valve Connections

7. REMOTE CONTROLLER INSTALLATION

POSITION ......................................................... 27

7-1. Mounting on a Wall

8. ADDRESS SWITCH .......................................... 28

8-1. Address Setting of the Remote Controller

85264190574001 2011

CV6233187785

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating

standards. As the installer or service person, it is an important

part of your job to install or service the system so it operates

safely and efficiently.

When Transporting

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend your knees when

lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner can cut your fingers.

When Installing…

For safe installation and trouble-free operation, you

must:

Carefully read this instruction booklet before beginning.

Follow each installation or repair step exactly as shown.

Observe all local, state, and national electrical codes.

Pay close attention to all warning and caution notices

given in this manual.

This symbol refers to a hazard

WARNING

CAUTION

or unsafe practice which can

result in severe personal injury

or death.

This symbol refers to a hazard

or unsafe practice which can

result in personal injury or product or property damage.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for improper installation or maintenance service, including failure to

follow the instructions in this document.

SPECIAL PRECAUTIONS

Select an installation location which is rigid and strong

enough to support or hold the unit, and select a location for

easy maintenance.

…In a Ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

unit’s weight. It may be necessary to construct a strong

wood or metal frame to provide added support.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

Keep the fire alarm and the air

CAUTION

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

outlet at least 1.5 m away from

the unit.

WARNING

'RQRWVXSSO\SRZHUWRWKHXQLWXQWLODOOZLULQJDQGWXELQJ

are completed or reconnected and checked.

+LJKO\GDQJHURXVHOHFWULFDOYROWDJHVDUHXVHGLQWKLV

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or

death.

*URXQGWKHXQLW following local electrical codes.

&RQQHFWDOOZLULQJWLJKWO\/RRVHZLULQJPD\FDXVHRYHU

heating at connection points and a possible fire hazard.

7RSUHYHQWSRVVLEOHKD]DUGVIURPLQVXODWLRQIDLOXUH

the unit must be grounded.

When Wiring

ELECTRICAL SHOCK CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED ELECTRICIAN

SHOULD ATTEMPT TO WIRE THIS SYSTEM.

When Connecting Refrigerant Tubing

:KHQSHUIRUPLQJpiping work

do not mix air except for specified refrigerant (R410A) in

refrigeration cycle. It causes

capacity down, and risk of

explosion and injury due to

high tension inside the refrige-

WARNING

9HQWLODWHWKHURRPZHOOLQWKHHYHQWWKDWUHIULJHUDQW

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a flame as this will

cause the generation of poisonous gas.

2

rant cycle.

5HIULJHUDQWJDVOHDNDJHPD\

cause fire.

'RQRWDGGRUUHSODFHUHIULJHUDQW

other than specified type.

It may cause product damage,

burst and injury etc.

8VHWKHIODUHPHWKRGIRUFRQQHFWLQJWXELQJ

$SSO\UHIULJHUDQWOXEULFDQWWRWKHPDWFKLQJVXUIDFHVRI

the flare and union tubes before connecting them,

then tighten the nut with a torque wrench for a leakfree connection.

&KHFNFDUHIXOO\IRUOHDNVEHIRUHVWDUWLQJWKHWHVWUXQ

'RQRWOHDNUHIULJHUDQWZKLOHSLSLQJZRUNIRUDQLQVWDOODWLRQ

or re-installation, and while repairing refrigeration parts.

Handle liquid refrigerant carefully as it may cause frostbite.

When Servicing

7XUQWKHSRZHU2)) DWWKHPDLQSRZHUER[PDLQV

before opening the unit to check or repair electrical

parts and wiring.

.HHS\RXUILQJHUVDQGFORWKLQJDZD\IURPDQ\PRYLQJ

parts.

&OHDQXSWKHVLWHDIWHU\RXILQLVKUHPHPEHULQJWRFKHFN

that no metal scraps or bits of wiring have been left inside

the unit being serviced.

Others

CAUTION

9HQWLODWHDQ\HQFORVHGDUHDVZKHQLQVWDOOLQJRUWHVWLQJ

the refrigeration system. Escaped refrigerant gas, on

contact with fire or heat, can produce dangerously

toxic gas.

&RQILUPXSRQFRPSOHWLQJLQVWDOODWLRQWKDWQRUHIULJHUDQW

gas is leaking. If escaped gas comes in contact with a

stove, gas water heater, electric room heater or other heat

source, it can produce dangerously toxic gas.

'RQRWWRXFKWKHDLULQOHWRUWKHVKDUSDOXPLQXP

fins of the outdoor unit. You may get injured.

'RQRWVLWRUVWHSRQWKHXQLW\RXPD\IDOOGRZQ

accidentally.

'RQRWVWLFNDQ\REMHFWLQWRWKH)$1&$6(

You may be injured and the unit may be damaged.

NOTE

The illustrations are based on the typical appearance of

a standard model. Consequently, the shape may differ

from that of the air conditioner that you are installing.

3

1. General

This booklet briefly outlines where and how to install the air conditioning system. Please read over the entire set of instructions for the indoor and outdoor units and make sure all accessory parts listed are with the system before beginning.

1-1. Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Carpenter’s level

1-2. Accessories Supplied with Unit

Table 1

Parts PartsFigure RemarksQ’ty Figure

Washer

Flare

insulation

Insulation tape

Vinyl tie

Drain hose

insulation

Remote

controller

Remote control

holder

AAA alkaline

battery

Full-scale

installation

diagram

1/8"(T3)

3/16"(T5)

3/32"(T2)

13/32"(T10)

set

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

For temporarily

suspending indoor

8

unit from ceiling

For wide /

2

narrow tube

connection

For wide /

narrow tube /

2

flare nut connection

For flare / drain

insulating

8

connection

For drain tube

1

connection

1

1

2

Printed on

1

container box

Truss head screw

Drain hose

Hose band

Tapping screw

Cushion rubber

Truss head screw

Special screw

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

3/16 13/32"

(5 10mm)

5-1/2"(L140)

Truss-head Phillips

5/32 5/8"

(4 16mm)

5/32 15/32"

(4 12mm)

3/16 1-9/16"

(5 40mm)

Use M10 or 3/8" for suspension bolts.

Suspension bolts and nuts (locally purchased)

For full-scale

installation

4

diagram

For unit & PVC

1

tube connection

For drain hose

2

connection

2

Packed in the

4

outdoor unit

4

Packed in the

ceiling panel

4

RemarksQ’ty

1-3. Optional Copper Tubing Kit

Copper tubing for connecting the outdoor unit to the indoor unit is available in kits which contain the narrow and wide

tubing, fittings and insulation. Consult your nearest sales outlet or air conditioning workshop.

1-4. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately from a local source, you will need:

1. Deoxidized annealed copper tube for refrigerant tubing as detailed in Table 2.

Cut each tube to the appropriate lengths 1' to 1'4" (30 cm to 40 cm) to dampen vibration between units.

2. Foamed polyethylene insulation for the specified copper tubes as required to precise length of tubing. Wall thickness

of the insulation should be not less than 5/16" (8 mm).

3. Use insulated copper wire for field wiring. Wire size varies with the total length of wiring. Refer to 3-7. Wiring

Instructions for details.

CAUTION

Table 2

Model

CS-KS12NB41 1/4" (6.35 mm) 0.0314" (0.8 mm) 3/8" (9.52 mm) 0.0314" (0.8 mm)

CS-KS18NB4UW 1/4" (6.35 mm) 0.0314" (0.8 mm) 1/2" (12.70 mm) 0.0314" (0.8 mm)

Outer Dia. Thickness Outer Dia. Thickness

Narrow Tube Wide Tube

4

Check local electrical codes

and regulations before

obtaining wire. Also, check

any specified instructions or

limitations.

1-5. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See local codes)

3. Putty

4. Refrigeration lubricant

5. Clamps or saddles to secure refrigerant tubing

2. Installation Site Selection

2-1. Indoor Unit

WARNING

To prevent abnormal heat generation and the possibility of fire, do

not place obstacles, enclosures

and grilles in front of or surrounding the air conditioner in a way

that may block air flow.

AVOID:

direct sunlight.

nearby heat sources that may affect performance of the unit.

areas where leakage of flammable gas may be expected.

places where large amounts of oil mist exist.

DO:

select an appropriate position from which every corner of

the room can be uniformly cooled.

select a location that will hold the weight of the unit.

select a location where tubing and drain hose have the

shortest run to the outside.

3.3 ft.

(1m)

3.3 ft.

(1m)

Fig. 1

3.3 ft.

(1m)

3.3 ft.

(1m)

3.3 ft.

(1m)

Indoor unit

allow room for operation and maintenance as well as unre-

stricted air flow around the unit. (Fig. 1)

install the unit within the maximum elevation difference (H)

above or below the outdoor unit and within a total tubing length

Outdoor unit

Tubing length (L)

Elevation difference (H)

Fig. 2

(L) from the outdoor unit as detailed in Table 3 and Fig. 2.

install the indoor unit more than 3.3' (1 m) away from any

antenna or power lines or connecting wires used for television,

radio, telephone, security system, or intercom. Electrical noise

from any of these sources may affect operation.

CAUTION

Air delivery will be degraded if the distance

from the floor to the ceiling is greater than

10 ft. (3 m).

Table 3

Max. Allowable Tubing Limit of Tubing Limit of Elevation Required Amount of

Model Length at Shipment Length (L) Difference (H) Additional Refrigerant

(ft.) (ft.) (ft.) (oz./ft.)*

CS-KS12NB41 25 65 23 0.16

CS-KS18NB4UW 25 100 50 0.27

* If total tubing length becomes 25 to 65 ft. (Max.) or 25 to 100 ft. (Max.), charge additional refrigerant (R410A) by 0.16 or 0.27 oz./ft.

No additional charge of compressor oil is necessary. For more detailed charging information, refer to the Technical & Service Manual.

5

2-2. Outdoor Unit

AVOID:

heat sources, exhaust fans, etc. (Fig. 3)

damp, humid or uneven locations.

DO:

choose a place as cool as possible.

choose a place that is well ventilated.

install in a location where at least two sides are unob-

structed, so that the flow of air at the intake port or

exhaust port is not blocked, and so that sufficient

space is ensured for maintenance to be carried out

without trouble. In general the top also must be unobstructed. (Figs. 4a and 4b)

provide a solid base (level concrete pad, concrete

block, 4" 1'4" (10 40 cm) beams or equal), a minimum of 4" (10 cm) above ground level to reduce

humidity and protect the unit against possible water

damage and decreased service life. (Fig. 5a)

install cushion rubber under unit’s feet to reduce

vibration and noise. (Fig. 5b)

use lug bolts or equal to bolt down unit, reducing

vibration and noise.

install in a location where no antenna of a television

or radio exists within 10' (3 m).

NO

Hot air

Outdoor unit

Fig. 3

(CU-KS12NK1A)

Air intake Min. 2" (5 cm)

Min.

2" (5 cm)

Air discharge

(CU-KS18NKU, CU-KS18NKUA)

Air intake Min. 4" (10 cm)

Min.

2" (5 cm)

Air discharge

Valve

side

Min. 10"

(25 cm)

Min.

8" (20 cm)

Fig. 4a

Valve

side

Min. 10"

(25 cm)

Min.

1'4" (40 cm)

Exhaust fan

Heat source

Obstacle above

Ground

Obstacle above

Min.

7' (2 m)

Air discharge

Min. 2" (5 cm)

Air intake

Min.

7' (2 m)

Air discharge

Min.

7' (2 m)

Obstacle

Min.

7' (2 m)

Obstacle

Air intake

Concrete

or equal

About 1'4" (40 cm)

Anchor bolts

(4 pcs.)

Min. 4" (10 cm)

About 4" (10 cm)

Fig. 4b

Fig. 5a Fig. 5b

6

Ground

Cushion rubber

Min. 4" (10 cm)

Air intake

2-3. Baffle Plate for the Outdoor Unit

(Low Ambient Cooling models only)

Air intake baffle

NOTE

It is recommended to use baffle plates for models

CU-KS12NK1A and CU-KS18NKUA. The baffle plates

are not normally required for the other models.

When the outdoor unit is installed in a position exposed

to strong wind (such as seasonal winds with low air temperature in winter), baffle plates must be installed on the

outdoor unit. (Fig. 5c)

This unit is designed so that the fan of the outdoor unit

runs at low speed when the air conditioner is operated at

low outdoor air temperatures. When the outdoor unit is

exposed to strong wind, the system pressure drops

because of the freeze protector.

Install a pair of windbaffle plates at the front and back of

the outdoor unit if it will be subject to strong wind during

the winter. (Figs. 5c to 5k)

Wind

Back

No air intake baffle

required on

this side.

Front

Wind

Air discharge baffle

Fig. 5c

7

CU-KS12NK1A

(1) Recommended dimensions of the baffle plates

Air Intake Baffle

C

E

D

B

F

A

2- 1/4"

(2- 6.5 mm)

Fig. 5d

2- 15/64"

(2- 6 mm)

Q

P

Air Discharge Baffle

N

H

I

B

H

J

G

4- 1/4"

(4- 6.5 mm)

L

K

G

I

E

A

G

F

D

Fig. 5e

J

C

M

K

For Air Intake

Dimensions

Model

CU-KS12NK1A

(inch)

(mm) 550 20 55 440 330 10 15 9 7.5 441 10 150 20 20

ABCDEFGH I J KNPQ

21-21/32

25/32 2-5/32 17-5/16 13 25/64 19/32 23/64 19/64 17-3/8 25/64 5-29/32 25/32 25/32

For Air Discharge

Dimensions

Model

CU-KS12NK1A

(inch)

(mm) 485 510 350 150 445 20 55 370 70 85 15 35 35

ABCDEFGH I J KLM

19-3/32 20-3/32

13-25/32

5-29/32

17-17/32

25/32 2-5/32 14-9/16 2-3/4 3-11/32 19/32 1-3/8 1-3/8

Material to be used: Metal plate with corrosion protection treatment

Plate thickness: 0.0394 to 0.0472" (1.0 to 1.2 mm)

(2) Parts required (locally purchased except for screws)

Air Intake Baffle

Item Q’ty Remarks

Baffle plate 1

Screw 5/32 15/32" (4 12 mm) tapping 2 Attached to outdoor unit

Bolt 15/64 19/32 – 25/32" (M6 15 – 20 mm) 2

Nut 15/64" (M6) 2

Washer 2

Spring washer 2

Air Discharge Baffle

Item Q’ty Remarks

Baffle plate 1

Bolt 15/64 13/32 – 19/32" (M6 10 – 15 mm) 4

Nut 15/64" (M6) 4

Washer 4

Spring washer 4

8

CU-KS18NKUA

(1) Recommended dimensions of the baffle plates

Air Intake Baffle

C

E

D

F

B

G

Air Discharge Baffle

H

O

A

2- 15/64"

(2- 6 mm)

J

3- 1/4"

(3- 6.5 mm)

R

Q

Fig. 5f Fig. 5g

L

I

K

E

A

F

D

B

(4- 6.5 mm)

G

G

H

4- 1/4"

I

J

C

K

For Air Intake

Dimensions

Model

CU-KS18NKUA

(inch)

(mm) 620 20 45 565 235 235 10 20 15 587 7.5 10 150 20 20

ABCDEFGH I J KLOQR

24-13/32

25/32 1-25/32 22-1/4 9-1/4 9-1/4 25/64 25/32 19/32 23-1/8 19/64 25/64 5-29/32 25/32 25/32

For Air Discharge

Dimensions

Model

CU-KS18NKUA

(inch)

(mm) 530 560 350 150 460 35 55 440 60 85 25

ABCDEFGH I J K

20-7/8 22-1/16

13-25/32

5-29/32 18-1/8 1-3/8 2-5/32 17-5/16 2-3/8 3-11/32 31/32

Material to be used: Metal plate with corrosion protection treatment

Plate thickness: 0.0394 to 0.0472" (1.0 to 1.2 mm)

(2) Parts required (locally purchased except for screws)

Air Intake Baffle

Item Q’ty Remarks

Baffle plate 1

Screw 5/32 15/32" (4 12 mm) tapping 2 Attached to outdoor unit

Bolt 15/64 19/32 – 25/32" (M6 15 – 20 mm) 3

Nut 15/64" (M6) 3

Washer 3

Spring washer 3

Air Discharge Baffle

Item Q’ty Remarks

Baffle plate 1

Bolt 15/64 13/32 – 19/32" (M6 10 – 15 mm) 4

Nut 15/64" (M6) 4

Washer 4

Spring washer 4

9

(3) Installation procedure

CU-KS12NK1A

1. Air Intake Baffle

(1) Left side

1. Remove the front panel from the unit.

2. Remove the panel side L, and drill 2 holes of ø1/4 inch

(6.5 mm) at the prescribed position.

3. Install the windbaffle on the unit using field supply bolts

and nuts.

4. Recommended bolts to be used are 15/64" (M6 ISO

standard), and the recommended length of the bolts is

between 19/32 – 25/32 inch (15 – 20 mm).

5. Use washers and spring washers to tightly fasten the

windbaffle to the unit.

(2) Right side

1. Remove the front panel from the unit.

2. Use 2 preholes on the panel side R to install the baffle

plate.

3. Remove the panel side R from the unit by removing the

screws. These screws are used in step 4 below.

4. Put (sandwich) the windbaffle between the unit and the

panel side R, then install the windbaffle on the unit using

the above screws. Be careful not to damage the screw

holes.

2. Air Discharge Baffle

1. Remove the panels front, side L and R from the unit

and drill 4 holes of ø1/4 inch (6.5 mm) at the

prescribed positions.

2. Install the windbaffle on the unit using field supply

bolts and nuts.

3. Recommended bolts to be used are 15/64" (M6 ISO

standard), and the recommended length of the bolts

is between 13/32 – 19/32 inch (10 – 15 mm).

4. Use washers and spring washers to tightly fasten the

windbaffle to the unit.

Panel side R

Fig. 5h

Panel front

Panel side L

Panel side L

Fig. 5i

Panel side R

Panel front

NOTE

In order to prevent contact of the bolts and heat exchanger and other parts inside the unit, install the windbaffle using

bolts from inside the unit and fasten the bolts with nuts from outside the unit.

When the windbaffle is installed on the unit, the unit has higher wind resistance. In order to prevent the unit from

falling over, anchor the legs of the unit using anchor bolts (or similar method).

10

CU-KS18NKUA

1. Air Intake Baffle

(1) Left side

1. Remove the top panel from the unit.

2. Remove the panel side L, and drill 3 holes of ø1/4 inch

(6.5 mm) at the prescribed positions.

3. Install the windbaffle on the unit using field supply bolts

and nuts.

4. Recommended bolts to be used are 15/64" (M6 ISO

standard), and the recommended length of the bolts is

between 19/32 – 25/32 inch (15 – 20 mm).

5. Use washers and spring washers to tightly fasten the

windbaffle to the unit.

(2) Right side

1. Remove the top panel from the unit.

2. Use 2 preholes on the panel side R to install the baffle plate.

3. Remove the panel side R from the unit by removing the

screws. These screws are used in step 4 below.

4. Put (sandwich) the windbaffle between the unit and the

panel side R, then install the windbaffle on the unit using the

above screws. Be careful not to damage the screw holes.

Panel top

Panel front

2. Air Discharge Baffle

1. Remove the panels front, top, side L and R from the

unit and drill 4 holes of ø1/4 inch (6.5 mm) at the

prescribed positions.

2. Install the windbaffle on the unit using field supply

bolts and nuts.

3. Recommended bolts to be used are 15/64" (M6 ISO

standard), and the recommended length of the bolts

is between 13/32 – 19/32 inch (10 – 15 mm).

4. Use washers and spring washers to tightly fasten the

windbaffle to the unit.

Panel side R

Panel top

Panel side R

Panel front

Panel side L

Panel side L

Fig. 5j

Fig. 5k

NOTE

In order to prevent contact of the bolts and heat exchanger and other parts inside the unit, install the windbaffle using

bolts from inside the unit and fasten the bolts with nuts from outside the unit.

When the windbaffle is installed on the unit, the unit has higher wind resistance. In order to prevent the unit from

falling over, anchor the legs of the unit using anchor bolts (or similar method).

(4) Precautions for installation

1. Be sure not to damage painted surfaces.

2. Finish the edges of the windbaffle to avoid cuts or injury.

3. Drilling of holes must be carefully done so that no damage is caused to external or internal parts of the unit.

Particular care must be taken that drill chips do not drop into the unit.

11

3. How to Install the Indoor Unit

3-1. Preparation for Suspending

This unit uses a drain pump. Use a carpenter’s level to

check that the unit is level.

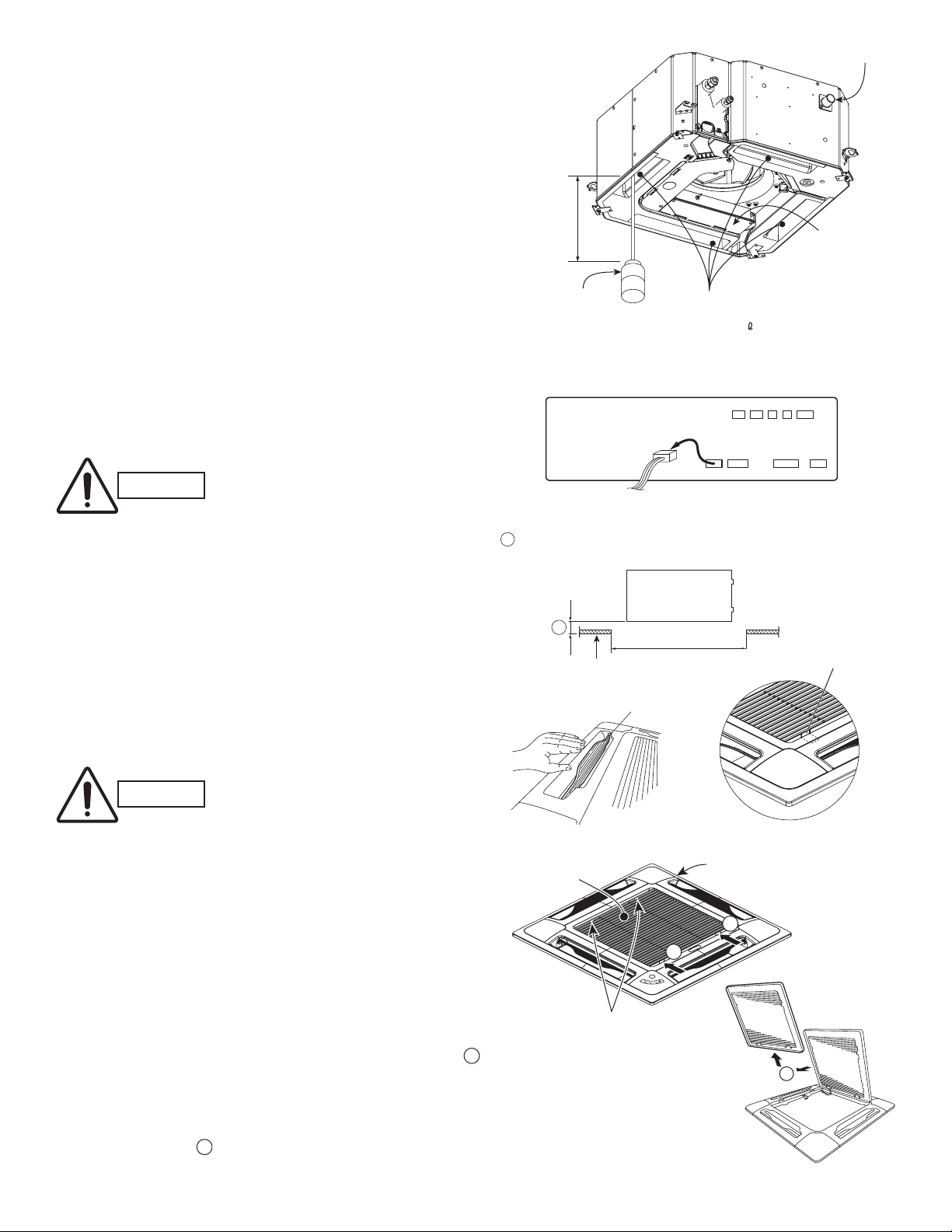

3-2. Suspending the Indoor Unit

(1) Fix the suspension bolts securely in the ceiling using

the method shown in the diagrams, by attaching

them to the ceiling support structure, or by any other

method that ensures that the unit will be securely

and safely suspended. (Fig. 6-1)

(2) Follow the diagram to make the holes in the ceiling.

Hole-in-anchor

Hole-in-plug

Ceiling opening dimensions

21-1/32"(534

Suspension bolt pitch

Concrete Insert

Suspension bolt (M10 or 3/8")

(locally purchased)

Fig. 6-1

23-5/8"(600mm)

mm

)

(3) Determine the pitch of the suspension bolts using

the supplied full-scale installation diagram. The diagram shows the relationship between the positions

of the suspension fitting, unit, and panel. (Fig. 6-2)

3-3. Placing the Unit Inside the Ceiling

(1) Be sure to remove the fan protection (4pcs) for

transportation before hanging up the indoor unit.

(2) When placing the unit inside the ceiling, determine

the pitch of the suspension bolts using the supplied

full-scale installation diagram. (Fig. 6-3)

Tubing and wiring must be laid inside the ceiling

when suspending the unit. If the ceiling is already

constructed, lay the tubing and wiring into position

for connection to the unit before placing the unit

inside the ceiling.

(3) The length of suspension bolts must be appropriate

for a distance between the bottom of the bolt and the

bottom of the unit of more than 19/32" (15 mm) as

shown in the diagram. (Fig. 6-3)

(4) Thread the 3 hexagonal nuts (locally purchased) and

2 supplied washers onto each of the 4 suspension

bolts as shown in the diagram. Use 1 nut and 1

washer for the upper side, and 2 nuts and 1 washer

for the lower side, so that the unit will not fall off the

suspension lugs. (Fig. 6-4)

(5) Adjust so that the distance between the unit and the

ceiling bottom is 1/2" (13 mm) to 23/32" (18 mm).

Tighten the nuts on the upper side and lower side of

the suspension lug. (Fig. 6-4)

)

mm

(45

1-25/32"

)

)

mm

mm

4-19/32"

(45

1-25/32"

(117

Power supply port

)

mm

Over 19/32" (15

Supplied screw

Nuts and washers

(used for upper and lower)

22-5/8"(575mm)

6-5/16"2-3/32"

6-11/16"

mm

)(160mm)(53mm)

(170

Refrigerant tubing joint

(narrow tube side)

1/4( 6.35mm) (flared)

Fig. 6-2

Full-scale installation diagram

(printed on top of container box)

Fig. 6-3

Suspension bolt

)

)

mm

mm

23-5/8"(600

21-1/32"(534

Suspension bolt pitch

Ceiling opening dimensions

Drain tube

connection port

(outer dia 1-1/32"( 26mm))

)

mm

)

mm

(215

8-15/32"

11-5/32"(283

)

mm

1-3/16"

(30

)

mm

1/2" – 23/32" (13~18

Suspension lug

12

Double nut

1/2" – 23/32"

(13~18

mm

Fig. 6-4

Notch

)

3-4. Installing the Drain Piping

(1) Prepare standard hard PVC pipe (locally purchased O.D.

1-1/32" (26 mm)) for the drain and use the supplied hose

band to prevent water leaks. (Fig. 6-5)

(2) To install the drain hose, first place 1 of the 2 hose bands

over the unit drain port and the other hose band over the

hard PVC pipe (not supplied). Then connect both ends of

the supplied drain hose. (Fig. 6-5)

(3) On the unit drain side, grasp the hose band with pliers

and insert the drain hose all the way to the base.

If other commercially available hose bands are used, the

drain hose may become pinched or wrinkled and there is

danger of water leakage. Therefore be sure to use the

supplied hose bands. When sliding the hose bands, be

careful to avoid scratching the drain hose.

Do not use adhesive when connecting the supplied drain

hose to the drain port (either on the main unit or the PVC

pipe).

Reasons: a) It may cause water to leak from the connec-

tion. Since the connection is slippery just

after the adhesive has been applied, the

pipe easily slips off.

b) The pipe cannot be removed when mainte-

nance is needed.

Twist tie

(4 vinyl ties, supplied)

3/16"

(5

mm

mm

)

Drain hose

insulation

(supplied)

)

5-1/2"(140

Drain port

15/16"

(25

Unit

CAUTION

Hard PVC pipe

(equivalent to

O.D. 1-1/32" (26mm))

(locally purchased)

3/16"

(5mm)

15/16"

(25mm)

mm

)

Drain hose

(supplied)

Hose band

(2 bands, supplied)

Position to

fasten hose

bands

Fig. 6-5

Attach so that the hose band

fastener is on the side of the

drain port.

Attach the hose bands so that

each is approximately 3/16"

(5 mm) to 15/16" (25 mm) from

the end of the supplied drain

hose.

(4) Wrap the hose with the supplied drain hose insulation

and use the 4 twist ties so that the hose is insulated with

no gaps.

Do not bend the supplied drain hose 90° or more. The

hose may slip off.

NOTE

Make sure the drain pipe has a downward gradient (1/100 or

more) and that there are no water traps.

CAUTION

In cases where it is necessary to raise the height of the

drain piping, the drain piping can be raised to a maximum

height of 2.78 ft. (850 mm) above the bottom surface of

the ceiling. Under no conditions attempt to raise it higher

than 2.78 ft. (850 mm) above the bottom surface of the

ceiling. Doing so will result in water leakage. (Fig. 6-7)

Do not use natural drainage.

Do not install the pipe with an upward gradient from the

connection port. This will cause the drain water to flow

backward and leak when the unit is not operating.

(Fig. 6-8)

Do not apply force to the piping on the unit side when

connecting the drain pipe. The pipe should not be

allowed to hang unsupported from its connection to the

unit. Fasten the pipe to a wall, frame, or other support as

close to the unit as possible. (Fig. 6-9)

Provide insulation for any pipes that are run indoors.

Air bleeder prohibited

Fig. 6-6

CAUTION

Do not install an air bleeder as

this may cause water to spray

from the drain pipe outlet.

(Fig. 6-6)

1 ft.(300mm) or less

0 - 45

* Length of supplied drain hose = 5-1/2"(140mm)

2.78 ft.(850

Fig. 6-7

Uphill slope

Fig. 6-8

Support

bracket

mm

) or less

13

Fig. 6-9

3-5. Checking the Drainage

A

After wiring and drain piping are completed, use the following procedure to check that the water will drain smoothly. For this, prepare a bucket and wiping cloth to catch and wipe up spilled water.

Be sure to do the wiring between the units before installing the

ceiling panel. (Refer to 3-9. Wiring Instructions for Inter-unit

Connections)

(1) Turn on the power. (Here, “power” refers to the power supply

from the outdoor unit.)

(2) Slowly pour approx. 16 ounces (500 ml) of water into the drain

pan to check drainage. (Fig. 6-10a)

(3) Remove the 2 screws from the control box cover, then open

the cover. Be careful not to drop the cover at this time.

(4) Disconnect the FS 3P connector (red) on the control PCB and

operate the drain pump. (Fig. 6-10b) Check the water flow

through the transparent drain pipe and see if there is any

leakage.

(5) When the check of drainage is complete, reconnect the FS

3P connector and remount the control cover.

Over 4"

(100mm)

Plastic container

for water intake

Water drain

Control box

Drain pan outlet

Water

(Approx. 16 ounces (500m ) )

Fig. 6-10a

Control box

FLAP

The drain pump will continue to

CAUTION

operate for a minimum of 6 minutes after the FS 3P connector is

reconnected.

3-6. How to Install the Ceiling Panel

Checking the unit position

(1) Check that the ceiling hole is 23-5/8" (600 mm) 23-5/8"

(600 mm) (Fig. 6-11)

(2) Confirm that the position of the indoor unit and the ceiling

as shown in the diagram. If the positions of the ceiling surface and unit do not match, air leakage, water leakage, flap

operation failure, or other problems may occur. (Fig. 6-11)

CAUTION

Never place the panel face-down. Neither hang it ver-

tically nor place it on top of a projecting object. Placing it face-down will damage the surface.

Do not touch the flap or apply force to it. (This may

cause flap malfunction.) (Fig. 6-12)

3-6-1. Before Installing the Ceiling Panel

FS

RCIND

Fig. 6-10b

must be within the range of 1/2"(13mm) to 23/32"(18mm). (Fig. 6-11)

A

If not within this range, malfunction or other trouble may occur.

Indoor unit

A

Ceiling side

Ceiling opening

dimension

Fig. 6-11

NO

Flap

Fig. 6-12 Fig. 6-13

ir-intake grille

Ceiling panel

1

1

Latch

(1) Remove the air-intake grille and air filter from the ceiling

panel.

a) Press on and slide the two latches of the air-intake grille

with your thumb in the direction shown by the arrow

to open the grille. (Figs. 6-13 and 6-14)

1

Air-intake grille hinge

Fig. 6-14

2

b) With the air-intake grille opened, remove the grille hinge

from the ceiling panel by sliding it in the direction shown

by the arrow . (Fig. 6-15)

2

Fig. 6-15

14

Loading...

Loading...