Page 1

Order No: PAPAMY1503095CE

TEM P

O

TIMER

S

O

N

O

1

2

C

K

Installation Manual

Air Conditioner

Indoor Unit Outdoor Unit

CS-E12RB4UW

CS-E18RB4UW

CU-E12RB4U

CU-E18RB4U

E

S

O

L

C

N

E

P

O

N

E

P

O

E

S

O

L

C

O

F

F

/

O

N

A

I

R

T

I

S

M

P

W

O

E

R

W

I

N

E

G

R

AUTO

HEAT

COOL

DRY

FAN

MODE

POWERFUL/

QUIET

TIMER

123

FF

SETCHECK CLOCK RESET

FAN

SPEED

AIR

SWING

OFF/ON

FF/ON

TEMP

AIRSWING

FANSPEED

ET

SET

3

CANCEL

CANCELONOFF

AC RC

HEC

Destination

USA

Canada

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2015

Page 2

11. Installation Instruction

11.1 Indoor Unit

11.1.1 Selecting the Location for the Indoor Unit

Provide a check port on the piping side ceiling for repair and maintenance.

Install the indoor unit once the following conditions are satisfied and after receiving the customer approval.

1 The indoor unit must be within a maintenance space.

2 The indoor unit must be free from any obstacles in path of the air inlet and outlet, and must allow spreading

of air throughout the room.

3 Mount with the lowest moving parts at least 8 ft (2.4 m) above floor or grade level.

"

16

/

13

/16"

11

(300) or less

(Unit: inch (mm))

(Unit: inch (mm))

Obstacles

3

/8"

39

(1000)

or more

11

/16"

Floor

19

(500) or

more

"

8

/

1

96"–118

(2400 – 30 00)

1911/16"

(500) or

more

11

19

(500) or

more

* If the height from the floor to ceiling ex

ecreased

d

.

ceeds three meters, air flow distribution deteriorates a

nd the effect is

4 The installation position must be able to support a load four times the indoor unit weight.

5 The indoor unit must be away from heat and steam sources, but avoid installing it near an entrance.

6 The indoor unit must allow easy draining.

7 The indoor unit must allow easy connection to the outdoor unit.

8 Place the indoor unit according to the height from the ceiling shown in the illustration below.

9 The indoor unit must be from at least 9.8 ft (3 m) away from any noise-generating equipment. The electrical

wiring must be shielded with a steel conduit.

10 If the power supply is subject to noise generation, add a suppressor.

11 Do not install the indoor unit in a laundry. Electric shocks may result.

Note

Thoroughly study the following installation locations

1

In such places as restaurants and kitchens, considerable amount of oil steam and flour adhere to the turbo

fan, the fin of the heat exchanger and the drain pump, resulting in heat exchange reduction, spraying,

dispersing of water drops, drain pump malfunction, etc.

In these cases, take the following actions:

o Make sure that the ventilation fan for smoke-collecting hood on a cooking table has sufficient capa

that it draws oily steam wh

o Make enough distance from the cooking room to install the air conditioner in such place wher

su

ck in oily steam.

Air conditioner

ich should not flow into the suction of the air conditioner.

e it may not

city so

Ensure ample

distance

2 Avoid installing the air conditioner in such

circumstances where cutting oil mist or iron

powder exist especially in factories, etc.

3 Avoid places where inflammable gas is

generated, flows-in, contaminated, or leaked.

4 Avoid places where sulphurous acid gas or

corrosive gas can be generated.

5 Avoid places near high frequency generators.

Cooking table

29

Use the ventilation fan for smokecollection hood with sufficient capacity.

collectionhoodwithsufficientcapacity.

Model Name Height in the ceiling

E12***

E18***

11" (280 mm) or

more

Page 3

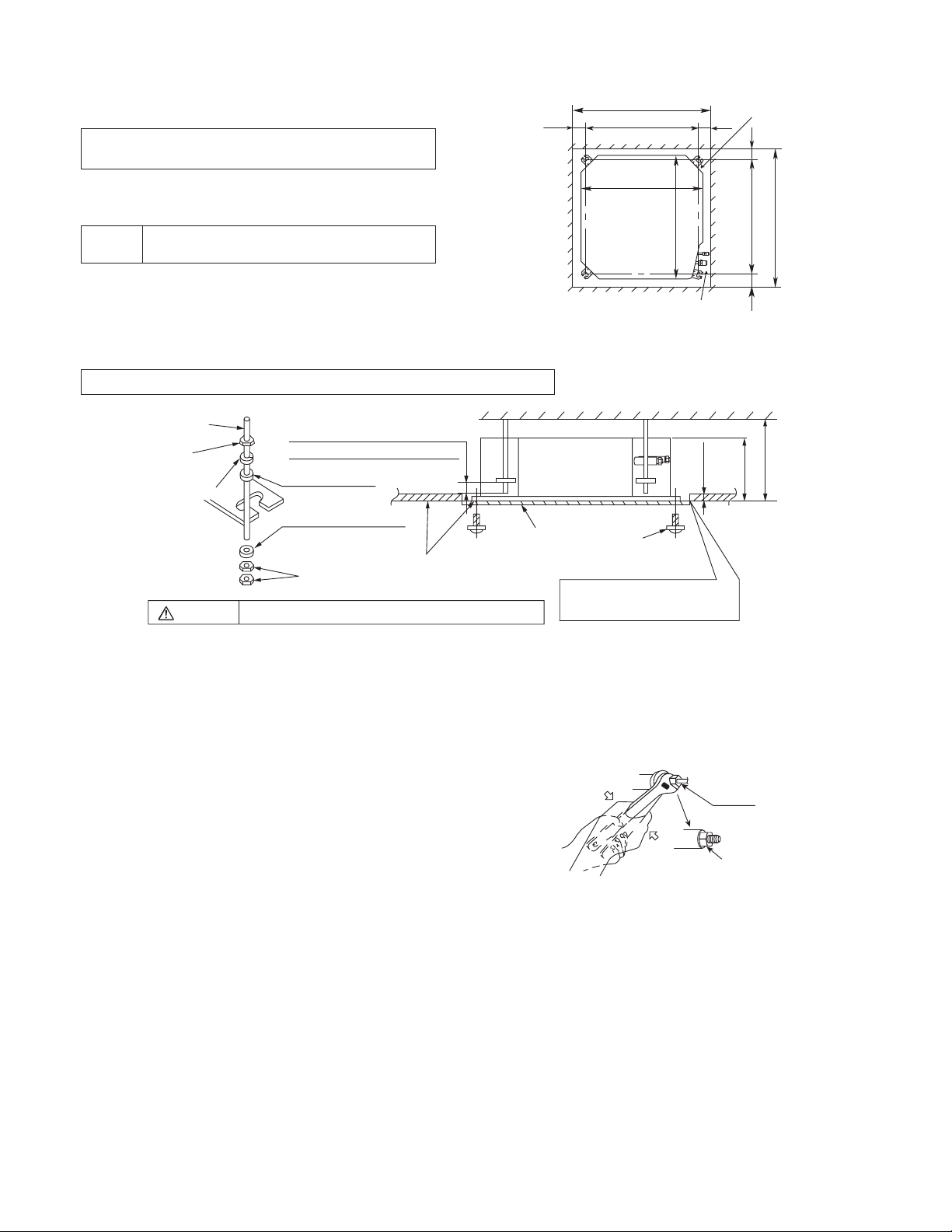

11.1.2 Installation of Indoor Unit

n

nch

H

andabove

piping

This air conditioner uses a drain up motor.

Horizontally install the unit using a level gauge.

CEILING OPENING DIMENSIONS AND

BOLT LOCATION

The paper model for installation expand or shrink

according to temperature and humidity.

Check on dimensions before using it.

Caution

During the installation, care must be taken

not to damag

e electric wires.

The dimensions of the paper model for installation

are the same

imensions

d

Be sure to discuss the ceiling drilling work

worke

rs concerne

as those of the ceiling opening

.

d.

POSITIONS OF AIR CONDITIONER BODY AND CEILING SURFACE

HANGING

with the

259/16" (650) (Ceiling opening)

23/8"

(60)

7

/8" (530)

20

(Hanging bolt)

2213/16" (580)

(Unit size)

(U

" (580)

16

/

13

(Unit size)

22

Refrigerant pipe

2

(60)

it: i

3

/8"

Drain pipe

23/8"

(60)

" (530)

8

/

7

20

(Hanging bolt)

"

8

/

3

(mm))

(60)

9

" (650) (Ceiling opening)

16

/

25

angingbolt

(W3/8 or M10)

Nut

(W3/8 or M10)

M10Springwasher

Warning

Keep the length of the bolt from

9

the bracket to 1

Flat washer for M10

(accessory)

Flat washer for M10

(accessory)

Nut

(W3/8 or M10)

/16" (40 mm)

Ceiling

Adjust to the same height

Paper model

for installation

Tighten the nut and bolt to prevent unit from falling

Air conditioner body

Set screw for paper

model (4 pieces)

Open the ceiling board a long the

outer edge of the pa per model.

"

"

8

/

16

1

/

7

11

4

(282 mm)

(113 mm)

11.1.3 Refrigerant Piping

Refrigerant is charged to the outdoor unit. For details, see the manual for installation work of outdoor unit.

(Additional charging, etc.)

1 Brazing for piping.

a. Execute brazing before tightening the flare

nut.

b. Brazin

g must be executed whil

n gas. (This prevents generatio

nitroge

oxidized scale in copper pipe.)

2

When there is a lot of brazings for long piping,

install a strainer midway of the piping. (The

strainer is locally supplied.)

3 Use clean copper pipe with inner wall surface

free from mist and dust. Blow nitrogen gas or

air to blow off dust in the pipe before

connection.

4 Form the piping according to its routing. Avoid

bending and bending back the same piping

point more than three times. (This will result in

hardening of the pipe).

5 After deforming the pipe, align centers of the

union fitting of the indoor unit and the piping,

and tighten them firmly with wrenches.

6 Connect pipe to the service valve or ball valve

which is located below the outdoor unit.

7 After completed the piping connection, be sure to check if there is gas leakage in indoor and outdoor

connection.

e blowing

n of

Red mar k

Con• rm the red mark of the union (thin side)

•

is always at lower direction after connecting

.

Union

" (292 mm)

2

/

1

11

30

Page 4

Vacuum drying

r

w

henconnectingwithth

D

After completing the piping connection, execute vacuum drying for the connecting piping and the indoor unit.

The vacuum drying must be carried out by using the service ports of both the liquid and gas side valves.

CAUTION

Use two wrenches and tighten with regular torque.

Do not overtighten, overtightening may cause gas leakage.

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf•ft [18 N•m (1.8 kgf•m)]

3/8" (9.52 mm) 31.0 Ibf•ft [42 N•m (4.3 kgf•m)]

1/2" (12.7 mm) 40.6 Ibf•ft [55 N•m (5.6 kgf•m)]

5/8" (15.88 mm) 47.9 Ibf•ft [65 N•m (6.6 kgf•m)]

3/4" (19.05 mm) 73.8 Ibf•ft [100 N•m (10.2 kgf•m)]

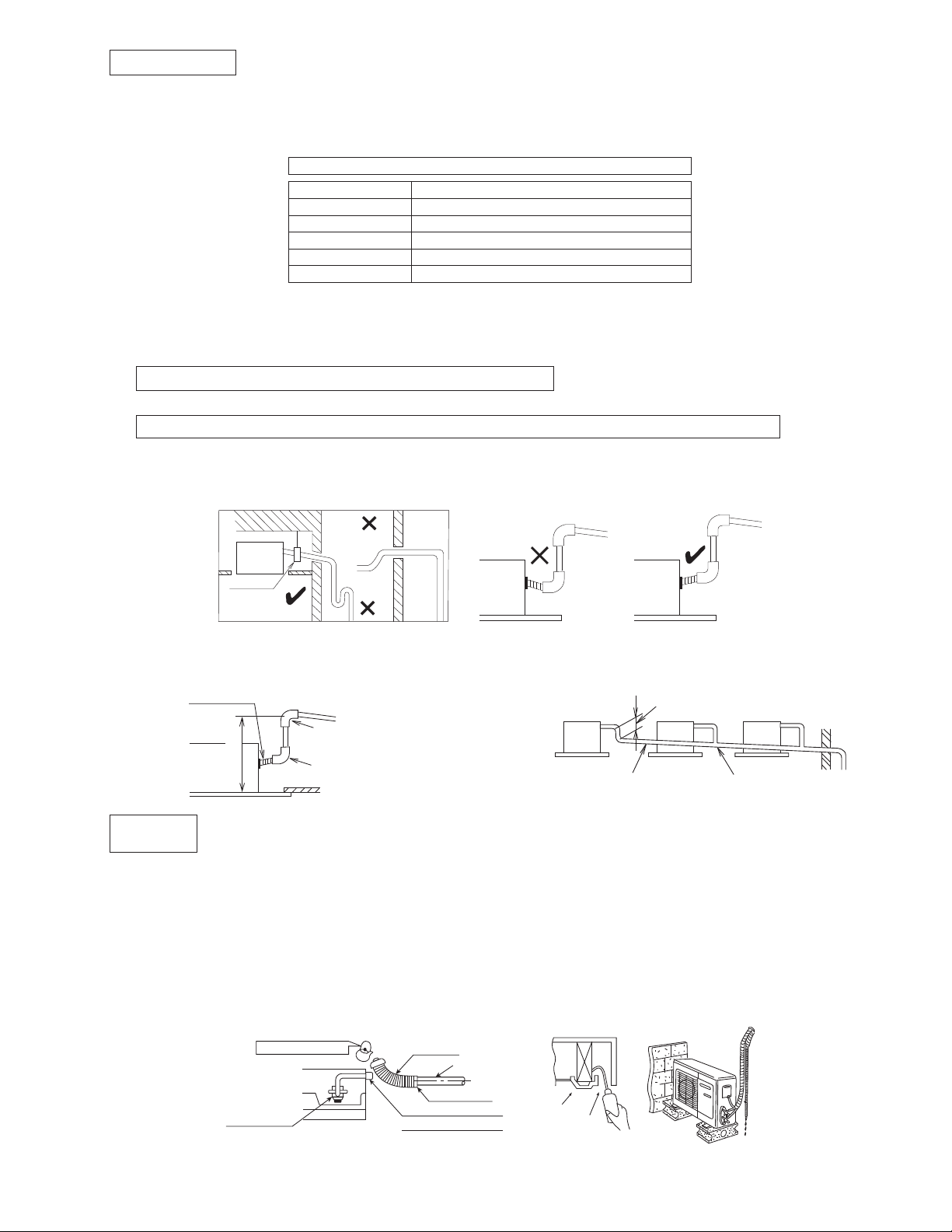

11.1.4 Indoor Unit Drain Piping

During drain piping connection, be careful not to exert extra force on the drain port at the indoor unit.

The outside diameter of the drain connection at the indoor unit is 1-1/4" (32 mm).

Piping material: Polyvinyl chloride pipe VP-25 and pipe fittings.

Be sure to perform heat insulation on the drain piping.

Heat insulation material: Polyethylene foam with thickness more than 5/16" (8 mm) (local supply).

Drain piping must have down-slope (1/50 to 1/100); be sure not to provide up-and-down slope to prevent reversal

flow.

Be sure to check no air trap on drain hose and to ensure smooth water flow and no abnormal sound.

ow.

Upward-slope

No Air Trap

Apply thehead

confluence pipe. (about 3

Use VP30 or more confluence

nd.

mplete.

the

15

/16" (100 mm))

e

Indoor

unit

Pipe clamp

Down-slope

The height of drain may be possibl

(750 mm

Drain Test

Connect the main drain pipe to exterior and leave it provisionally until the test comes to an e

Feed water to the flexible drain hose and check the piping for leaka

Be sure to check the drain up motor for normal operating and noise when electric wiring is co

When the test is complete, connect the flexible drain hose to the drain port.

).

ainport

D

Indoor unit

" (750 mm)

or less

2

/

1

29

The air conditioner uses a drain up motor to drain water. Use the following procedure to test the drain

up motor o

Upward routin g

Tra p

e up to 29-1/2"

Down-slope (1/50 ~ 1/100)

Elbow

Elbow

peration.

Down-slope

Air Trap

When drain set piping, install as shown in

figure bel

Indoor

unit

own-slope (1/50 ~ 1/100)

ge.

Pour about 600-700cc of water in the drain pan of the indoor unit. (Pour from the position specified in the drawing

by using a

Press the drain pump test run on PCB to start the drain motor, and verify water drainage.

water supply bottle or other su

itable tool.)

(The drain motor will automatically stop after operating for about five minutes.)

Feed water

Drain up motor

Drain hose

Main drain pipe

Drain

Glue the joint

port

Drain hose connection

Use the clip (accessory)

Drain pan

Air outlet vent

31

Page 5

11.1.5 Heat Insulation

u

n

pedow

n

Be sure to perform heat insulation on the drain, liquid and gas piping. Imperfection in heat insulation

work leads to water leakage.

1 Use the heat insulation material for the refrigerant piping which has an excellent heat-resistance (over 248°F

(120°C)).

Overlapwithheat

insulator for piping.

Heat insulator

for piping

(Local supply)

Heat insulator

(Accessory)

Indoor

nit

Band

(Accessory)

2 Precautions in high humidity circumstance.

This air conditioner has been tested according to the “JIS Standard Conditions with Mist” and have been

confirmed that there are no faults. However, if it is operated for a long time in high humid atmosphere (dew

point temperature: more than 73.4°F (23°C)), water drops are liable to fall. In this case, add heat insulation

material according to the following procedure:

o Heat insulation material to be prepared… Adiabatic glass wool with thickness 3/8" to 1 3/16" (10 to

20 mm).

o Stick glass wool on all air conditioners that are located in ceiling atmosphere.

o In addition to the normal heat insulation (thickness: more than 5/16" (8 mm) for refrigerant piping (gas

piping: thick piping) and drain piping, add a further of 3/8" (10 mm) to 1 3/16" (30 mm) thicknes

material.

Wall seal

When the outdoor unit is installed on a higher

positio

n than the indoor unit, install the trap so as

not to instill rain water into the wall by transmitting

in piping.

Stuff the space among piping, the electric

and- the d

rain hose with “Putty” and se

wire,

al the

penetration wall hole.

sure that rain water do not instill in

Make

to the

wall.

Hose clip (Accessory)

Heat insulator (Local supply)

(The thickness must be at

5

least

/16" (8 mm).)

It may be required to take off this par t for checking or

servicing the drain up motor. Please do not glue.

Make sure that there is no clearance here.

Pi

Put the incision at the trap part of the heat

i

Flexible hose with

heat insulator

(Accessory)

To be glued

Indoor

unit

Drain pipe

sulator (for waterdrain)

PVC pipe

(O.D. ø1"

(ø26)

(Local

supply)

Putty

Pipe

s

Trap

Incision

32

Page 6

11.1.6 Connecting the Cable to the Indoor

cre

w

C

a

e

r

Open the control board cover by removing 2 pcs of screw.

Unscrew and open the conduit cover upper case. Remove the plug and fix the conduit connector to cond

with lock

nut.

Connecting wire between indoor unit and outdoor unit should be UL listed or CSA approved 4 conductor UL listed

or CSA app

nection cable length of each indoor unit shall be 98.4 ft (30 m) or less.

con

Secure the connection cable onto the control board with the holder (clamp

Ensure the colour of wires of outdoor unit and the terminal Nos. are the same to the indoor’s resp

roved 4 conductor wires minimum AWG16 in accordance with local electric codes. Allowabl

er).

ectively.

Earth wire shall be Yellow/Green (Y/G) in colour and longer than other AC wires for safety reason.

S

s

Terminals on the indoor unit 1 2 3

Colour of wires

Terminals on the outdoor unit 1 2 3

Wire inser tion hole

uit cover

e

WARNING

This equipment must be properly earthed.

WIRE STRIPPING,

CONNECTING

REQUIREMENT

No loose strand

when inserted

Indoor/outdoor

connection

terminal

board

7/32" (5 mm)

or more

(gap between wires)

WARNING

Do not joint wires

RISK OF FIRE

JOINING OF WIRES

MAY CAUSE

OVERHEATING AND

FIRE.

Conductor

fully inserted

ACCEPT PROHIBITED PROHIBITED

Wire stripping

(10±1 mm)

13/32" ±1/16"

Conductor

over inserted

Conductor not

fully inserted

OROR

Screw

Lock nut

Connector

inlet hole

Terminal

Installer should

open the ear th

wire screw on

the metal par t

when necessary

for installation or

service purpose.

Control box cover

Conduit Cover

upper ca se

Connector

Indoor

123

OR

Plug

Indoor-Outdoor

connection w ire

inlet

Use complete wire without joining.

Use approved socket and plug with earth pin.

Wire conn e ction in this area m ust follow t o

national wiring rules.

11.1.7 Installation of Decorative Panel

The decorative panel has its installation direction. Confirm the direction by displaying the piping side.

1 Remove the air inlet grille by moving the catchers to center.

Air inlet grill

tch

Decorative panel

Hinge

Air inlet grill

* Hang the hinge on the hole of

decorative panel. (The direction of

the insta lla tion is free.)

33

Page 7

2 Fitting the decorative panel

ram

e

C

N-STM

2

r

o Temporarily secure the fixing scre

pcs.) before fitting the decorative panel.

ws (3

Securing the tentative

fixing screw

Approx. 3/4" (20 mm)

(For temporarily securing the front grille.)

o

Place decorative panel on the scre

pcs.) befo

panel a

sc

rews (4 pcs.

Check beforehand the height from the ce

re fitting, move decor

s illustrated and tigh

).

ws (3

ative

ten all the

iling to

Piping

direction

the unit.

The front grille fitting direction is determi

the unit direction.

Only use the screws with the length of 1-3/8"

(35 mm) which is provided,

to fix the decorative

panel.

Do not use other screw which is longe

se damage to the drain-pan and othe

cau

ned by

r it may

r

Decorative

Pane l m ovin g

direction

Front grille fixing

scews (4 pcs.)

Tighten this

screw first

after hanging

the grille

f

components.

3 Fit the decorative panel and ceiling wall together and confirm no gap in between. Readjust indoor unit heigh

if there is a g

ap between ceiling wall and decorative panel.

t,

Good example

Air conditioner

Air

Fit the insulator (this part) and

be careful for cool air leakage.

unit

Ceiling

Decorative

panel

4 Open the indoor control box cover by

removing 2 pcs of screw.

5 Insert firmly the connector of cosmetic louver

to indoor pcb CN-STM1, CN-STM2 and

CN-DISP.

Be caution not to clamp the cord in between

control board and control board cover.

6 After complete, install back removed part

follow opposite procedure.

Be sure to hook the air inlet grill string,

to prevent gril

l from falling and causing

injury from it.

Bad example

Cool air leakage

(no good)

Air conditioner

Air

unit

Decorative

panel

CN-STM1

CN-DISP

Clamp lead

wire with band

here

Ceiling

Hang the

string

Air inlet grille

Catcher

Catche

34

Page 8

11.2 Outdoor Unit

•

11.2.1 Select the Best Location

If an awning is built over the unit to prevent direct

sunli

ght or rain, be careful that heat radiat

the con

denser is not obstructed.

There should not be any animal or plant which

coul

d be affected by hot air discharged.

Keep the spaces indicated by arrows from

ceiling, fence or other obstacles.

Do not place any obstacles

rt circuit of the discharged air.

sho

which may cause a

If piping length is over the [piping length for

addition

adde

Model

E12*** 11900

E18*** 17500

Example: For E12***

al gas], additional refrigerant sh

d as shown in the tabl

Capacity

(Btu/h)

Piping size

Gas Liquid

1/2"

(12.7mm)

1/4"

(6.35mm)

Std.

Length

24.6 ft

(7.5 m)

Elevation

49.2 ft

(15 m)

49.2 ft

(15 m)

Max.

e.

Piping

Length

Min.

9.8 ft

(3 m)

9.8 ft

(3 m)

Max.

Piping

Length

65.6 ft

(20 m)

100 ft

(30.5 m)

If the unit is installed at 32.8 ft (10 m) distance, the

quantity of additional refrigerant should be 1.64 oz

(50 g) .... (32.8 - 24.6) ft x 0.2 oz/ft = 1.64 oz.

((10 - 7.5) m x 20 g/m = 50 g).

ion from

wall,

ould be

Additional

Refrigerant

0.2 oz/ft

(20 g/m)

0.3 oz/ft

(25 g/m)

Piping

Length for

add. gas

24.6 ft

(7.5 m)

32.8 ft

(10 m)

11.2.1.1 Indoor/Outdoor Installation

Diagram

Installation par ts you

or more

8ft(2.4m)

FloororGradelevel

Attaching the remote control holder to the wall

Remote control holder fixing screws

Remote

control

Remote contro l holder

Indoor unit

a

Outdoor

b

unit

3

1

(

5

1

0

/

1

0

6

o

"

r

m

m

m

o

)

r

Itisadvisabletoavoid

more than 2 blockage

directions.For better

ventilation & multipleoutdoor installation,

please consult

authorized dealer/

specialist.

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

e

"

)

8

/

m

3

m

e

9

r

0

3

o

0

0

m

1

r

(

o

should purchase (

Sleeve ( )

Bushing-Sleeve (

Putty (Gum Type Sealer) (

Bend the pipe as

closely on the wall as

possible, but be careful

that it doesn’t break.

Vinyl tape (Wide) (

• Apply after carrying

out a drainage test.

Saddle (

Power supply cable (

Connection cable (

1/4" Liquid side

m

m

)

r

o

e

1

1

(3

1

3

0

/

0

o

1

r

m

m

m

o

r

e

piping (

Gas side piping (

Additional drain

hose (

6

"

)

"

6

1

/

5

m

1

0

3

0

r

1

(

o

)

)

)

)

)

)

)

)

)

)

11.2.2 Install the Outdoor Unit

After selecting the best location, start installation

according to Indoo

ram.

Diag

r/Outdoor Unit Installati

1 Fix the unit on concrete or rigid fram

and ho

rizontally by bolt nut (ø10 mm).

2 When installing at roof, please consider strong

wind and earthquake.

Please fasten the installation stand firmly with

bolt or nails.

on

e firmly

35

AB

C

D

Model A B C D

"

E12***

E18***

22-7/16

(570 mm)

24-1/8"

(613 mm)

4-1/8"

(105 mm)

5-5/32"

(131 mm)

23/32"

(18.5 mm)

5/8"

(16 mm)

12-19/32

(320 mm)

14-3/16"

(360.5 mm)

"

Page 9

11.2.3 Connect the Piping

andPipeS

r

H

allU

nion

11.2.3.1 Connecting the Piping to Indoor Unit

Please make flare after inserting flare nut (locate at

joint portion of tube assembly) onto the copper pipe.

(In case of using long piping)

Connect the piping

Align the center of piping and suffici

the flare nut

with fingers.

ently tighten

Further tighten the flare nut with torque wrench in

spe

cified torque as stated in the table.

Do not overtighten, overtightening may cause gas leakage

Piping size Torque

1/4" (6.35 mm) 13.3 Ibf•ft [18 N•m (1.8 kgf•m)]

3/8" (9.52 mm) 31.0 Ibf•ft [42 N•m (4.3 kgf•m)]

1/2" (12.7 mm) 40.6 Ibf•ft [55 N•m (5.6 kgf•m)]

5/8" (15.88 mm) 47.9 Ibf•ft [65 N•m (6.6 kgf•m)]

3/4" (19.05 mm) 73.8 Ibf•ft [100 N•m (10.2 kgf•m)]

11.2.3.2 Connecting the Piping to Outdoor Unit

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge. Make flare after

inserting the flare nut (locate at valve) onto the copper

pipe. Align center of piping to valve and then tighten

with torque wrench to the specified torque as stated in

the table.

Spanner

or Wrench

Torque wrench

11.2.3.3 Connecting the Piping to Outdoor Multi

Decide piping length and then cut by using pipe cutter. Remove burrs from cut edge. Make flare after inserting the

flare nut (locate at valve) onto the copper pipe. Align center of piping to valve and then tighten with torque wrench to

the specified torque as stated in the table.

Female sideMale side

Flare Nut

Female side

(Connection pipe)

Applicable to

Liquid side of

CS-E12***

CS-E18***

Applicable to

Gas side of

CS-E12***

CS-E18***

(Auxiliary pipe)

Wrench (Adjustable Wrench)

Male side

(Auxiliary pipe)

Wrench (Adjustable Wrench)

Torque Wrench for Flare Nut

izeReduce

Hall Union

Flare Nut

(Connection pipe)

Torque Wrench for Flare Nut

Pipe Size

Packi ng

Reducer

11.2.3.4 Gas Leak Checking

Pressure test to system to 400 PSIG with dry nitrogen, in stages. Thoroughly leak check the system.

If the pressure holds, release the nitrogen and proceed to section 11.2.4.

36

Page 10

11.2.4 Evacuation of the Equipment

r

U

r

U

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND

PIPES in the following procedure.

Liquid side

Gas side

Two-way valve

Close

Three-way valve

Close

Outdoor unit

Vacuum

pump

Indoor unit

1 Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way

valve.

2 Connect the micron gauge between vacuum pump and service port of outdoor units.

3 Turn on the power switch of the vacuum pump and make sure that connect digital micron gauge and to pull

down to a value of 500 microns.

4 To make sure micron gauge a value 500 microns and close the low side valve of the charging set and turn off

the vacuum pump.

5 Disconnect the vacuum pump house from the service port of the 3-way valve.

6 Tighten the service port caps of the 3-way valve at a torque of 13.3 Ibf•ft (18 N•m) with a torque wrench.

7 Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to “Open”

using a hexagonal wrench (5/32" (4 mm)).

8 Mount valve caps onto the 2-way valve and the 3-way valve.

o Be sure to check for gas leakage.

If micron gauge value does not descend 500 microns, take the following measures:

If the leak stops when the piping connections are tightened further, continue working from step 3

If the leak does not stop when the connections are retightened, re

-

-

Do not release refrigerant during piping work for installation and reinstallation.

pair location of leak.

.

- Be careful with the liquid refrigerant, it may cause frostbite.

11.2.5 Connect the Cable to the Outdoor Unit

1 Remove control board cover (Plastic and Metal), follow by particular plate (for E18*** model).

2 Remove top panel, follow by Control Board Cover (Plastic and Metal) (for E12*** model).

3 Remove plugs.

4 Fix the conduit connectors to the knockout holes with lock-nuts, then secure them against the side panel.

5 All wires pass through conduits & particular plate’s opening hole.

6 Connecting wire between indoor unit and outdoor unit should be UL listed or CSA approved 4 conductor

wires minimum AWG16 in accordance with local electric codes.

7 Wire connection to the power supply (208/230V 60Hz) through circuit breaker.

o Connect the UL listed or CSA approved wires minimum AWG14 (for E12***) and AWG12 (for

the terminal b

8 Connect the power supply cord and connecting wire between indoor unit and outdoor unit according to the

diagram below.

oard, and connect the other end of the wires to EL

Indoo

nit

1

2

3

208/230V min AWG16

208/230V min AWG16

208/230V min AWG16

GroundingwireminAWG16

* The wires between the indoor and

outdoor unit can be installed in the

same conduit but the power supply

for the outdoor unit must be in a

separate conduit to prevent potential

communication problems.

Outdoo

1

2

3

L1

L2

nit

lanimreTlanimreT

Disconnect

Switch

Field supply

Grounding wire

CB / GFCI.

Power Supply Single

Phase 208/230V 60Hz

min AWG14 (for E12***)

and AWG12 (for E18***)

E18***) to

37

Page 11

9 Secure the wire onto the control board with the holder (clamp).

C

e

c

r

e

e

arefullyche

are

mproperfla

rin

g

10 After completing wiring connections, reattach the particular plate and control board cover (metal and plastic)

to the original position with the screws.

11 For wire stripping and connection requirement, refer to instruction 11.1.6 of indoor unit.

Front Panel

Particular Plate

Lock Nuts

Knockout

Holes

WARNING

This equipment must be properly earth grounded.

Ground lead wire shall be Yellow/Green (Y/G) in colour and longer

•

than other lead wires for electrical safety in case of the slipping.

onn

tingWi

s

Control Board

Cover (Metal)

Control Board Cover (Plastic)

wire clip

Plugs

Connectors

Particular Plate’s

opening holes

applicable for E18***

Terminal

Board

Ground

wire longer

than other

AC wir es

for sa fety

reasons

Holder

Make sure all power

•

supply and indoor

outdoor connecting

wires are guided

through wire clip which

is located near opening

hole internally.

Make sure all wires do

•

not have excess length

internally.

Power supply

cord

Control Board

Cover (Plastic)

Indoor & outdoor

connection cable

Control Board

Metal Cover

Term i nal

Board

Ground

wire longer

than other

AC wir es

for safety

reasons

Holder

Top Panel

Connectors

applicable for E12***

Connecting

Wires

Lock Nuts

Knockout

Holes

Plugs

Side Panel

11.2.6 Pipe Insulation

1 Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation

Diagram. Please wrap the insulated piping end to prevent water from going inside the piping.

2 If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by

using POLY-E FOAM with thickness 1/4" (6 mm) or above.

11.2.6.1 Cutting and Flaring the Piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

1. To cut

Pipe

Reamer

Poin t down

Bar

Clamp handle

2. To remove burrs 3. To flare

Handle

Yo ke

Core

Red arrow mark

Bar

1

/32"

0–

(0-0.5 mm)

Copper pipe

ŶI

Inclined Surface

When properly flared, the internal surface of the flare will evenly shine

and be of even thickness. Since the flare part comes into contact with

th

connections, c

damaged

ck thefl

Ŷ

Cracked Uneven

thickness

finish.

38

Page 12

11.2.7 Disposal of Outdoor Unit Drain Water

r

“AUT

O

If a drain elbow is used, the unit should be placed on a stand which is taller than 1-3/16" (3 cm).

If the unit is used in an area where temperature falls below 32°F (0°C) for 2 or 3 days in successi

recomme

nded not to use a drain elbow, for the drain water freezes and the fan will not rotate

Install the hose at an

angle so that the wate

Drain elbow

Hose

smoothly flows out.

.

11.2.8 Auto Switch Operation

The following operations can be performed by

pressing the “AUTO” switch.

1 AUTO OPERATION MODE

The Auto operation will be activated

immediately once the Auto Switch is pressed.

2 TEST RUN OPERATION (FOR PUMP

DOWN/SERVICING PURPOSE)

The Test Run operation will be activated if the

Auto Switch is pressed continuously for more

than 5 sec. to below 8 sec. A “pep” sound will

occur at the fifth sec., in order to identify the

starting of Test Run operation.

”switch

on, it is

39

Loading...

Loading...