CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Operator Interface Stations

USER’S MANUAL

Setup & Operation

CONTENTS

For Toshiba PLCs

& Other Automation Equipment

Toshiba International Corporation

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Thank you for purchasing the OIS (Operator Interface Station) Series product from

Toshiba International Corp. OIS Series products are versatile operator interfaces which

are configured with Microsoft Windows® based software.

Manual’s Purpose and Scope

This manual provides information on how to safely install, operate, and

maintain your TIC OIS (Operator Interface Station). This manual includes a

section of general safety instructions that describes the warning labels and

symbols that are used throughout the manual. Read the manual completely

before installing, operating, or performing maintenance on this equipment.

This manual and the accompanying drawings should be considered a

permanent part of the equipment and should be readily available for reference

and review. Dimensions shown in the manual are in metric and/or the English

equivalent.

Toshiba International Corporation reserves the right, without prior notice, to

update information, make product changes, or to discontinue any product or

service identified in this publication.

TOSHIBA is a registered trademark of the Toshiba Corporation. All other

product or trade references appearing in this manual are registered

trademarks of their respective owners.

Toshiba International Corporation (TIC) shall not be liable for technical

or editorial omissions or mistakes in this manual, nor shall it be liable

for incidental or consequential damages resulting from the use of

information contained in this manual.

This manual is copyrighted. No part of this manual may be photocopied or

reproduced in any form without the prior written consent of Toshiba

International Corporation.

© Copyright 2004 Toshiba International Corporation.

© Copyright 2004 Renu Electronics Pvt. Ltd.

All rights reserved.

Printed in the U.S.A.

Page ii

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Important Notice

The instructions contained in this manual are not intended to cover all details

or variations in equipment types, nor may it provide for every possible

contingency concerning the installation, operation, or maintenance of this

equipment. Should additional information be required contact your Toshiba

representative.

The contents of this manual shall not become a part of or modify any prior or

existing agreement, commitment, or relationship. The sales contract contains

the entire obligation of Toshiba International Corporation. The warranty

contained in the contract between the parties is the sole warranty of Toshiba

International Corporation and any statements contained herein do not create

new warranties or modify the existing warranty.

Any electrical or mechanical modifications to this equipment without prior

written consent of Toshiba International Corporation will void all warranties

and may void the 3rd party (CE, UL, CSA, etc) safety certifications.

Unauthorized modifications may also result in a safety hazard or equipment

damage.

Contacting Toshiba’s Customer

Support Center

Toshiba’s Customer Support Center may be contacted to obtain help in

resolving any system problems that you may experience or to provide

application information.

The center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The

Support Center’s toll free number is US 800-231-1412 Fax 713-466-8773

— Canada 800-527-1204 — Mexico 01-800-527-1204.

You may also contact Toshiba by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: PLC Marketing

or

plc@tic.toshiba.com

Page iii

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Manual Revisions

Please have the following information available when contacting Toshiba International

Corp. about this manual.

Name: OIS User’s Manual

Document: UMAN\OIS

Revision:

Rev No. Date Description

0 2003/06 Initial Issue (for OIS60)

1 2006/06 EV3 Upgrade Documentation

Add OIS40/50/120

3 2008/02 Upgrade for OISetup32 V3.12 Features

Page iv

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Table of Contents

0. General Safety Instructions and Information ............................................ 1

0.1 Warning Labels Within Manual....................................................................................2

0.2 Equipment Warning Labels. .........................................................................................4

0.3 Preparation........................................................................................................................5

0.4 Installation Precautions.................................................................................................6

0.5 Connection, Protection & Setup..................................................................................8

0.6 System Integration Precautions................................................................................10

0.7 3rd Party Safety Certifications....................................................................................11

1. Introduction ........................................................................................................ 12

1.1 Purpose of this Manual...........................................................................................13

1.1.1 OIS Basics.........................................................................................................13

1.1.2 Hardware Requirements.................................................................................14

1.2 OIS Overview ..................................................................................................................15

1.2.1 What is an OIS?......................................................................................................15

1.2.2 How the OIS Works................................................................................................16

1.2.3 Specifi cations of OIS Series......................................................................20

1.2.4 Comparison Between Keypad Based OIS Operator Panels .............20

1.2.5 Comparison Between Touchscreen Based OIS Panels.....................21

2. Hardware ............................................................................................................. 28

2.1 Unpacking The Unit..............................................................................................29

2.2 Managing Electrostatic Discharge..............................................................29

2.3 CE Compliance.......................................................................................................29

2.4 Environmental Rating .......................................................................................29

2.5 Environmental Consideration........................................................................29

2.6 Safety Precaution...............................................................................................30

2.7 Installation Instructions...................................................................................30

2.7.1 Panel Cutouts for OIS Models .......................................................................31

2.7.2 Not Included at This Time. .........................................................................................33

2.8 Wiring Diagrams.........................................................................................................34

2.9 Communication Ports...............................................................................................34

3. Before You Begin .............................................................................................. 35

3.1 Connecting the OIS to a Computer.......................................................................36

3.2 Starting OISetup32 Software..................................................................................37

3.2.1 Installing OISetup32 Softw

3.2.2 Steps for starting OISetup32 Software........................................................39

3.2.3 Uninstallin

3.3 Setting Network Configuration ...........................................................................40

4. Using OISetup32 Software............................................................................. 45

4. 1 OIS Menu Structure.......................................................................................................46

4.1.1 File Menu ..................................................................................................................49

4.1.2 Define Menu.............................................................................................................49

4.1.3 Communicate Menu...............................................................................................50

4.1.4 Utilities Menu...........................................................................................................50

4.1.5 Help Menu.................................................................................................................51

g OISetup32 Software..................................................................39

are............................................................................37

Page v

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

4. 2 Creating a New Application.......................................................................................51

4.3 Creating Screens...........................................................................................................58

4.3.1 Protecting OIS Application..................................................................................59

4.3.2 Protecting OIS Screen...........................................................................................59

4.4 Data Entry Object..........................................................................................................60

4.5 Display OIS Or PLC Data Object................................................................................60

4.6 Global And Power On Task.........................................................................................60

4 . 7 Global Keys....................................................................................................................62

4.8 Screen Keys...................................................................................................................63

5. Representing Data by Objects and Objects ............................................. 64

5.1 Alphanumeric Objects...................................................................................................65

5.1.1 Text Object..........................................................................................................65

5.1.2 Data Entry Object..............................................................................................65

5.1.3 Display OIS Or PLC Data Object Procedure ..........................................67

5.1.4 Time..........................................................................................................................70

5.1.5 Date..........................................................................................................................70

5. 2 Graphic Objects............................................................................................................75

5.2.1 Line...........................................................................................................................76

5.2.2 Rectangle.................................................................................................................76

5.2.3 Ellipse ......................................................................................................................77

5.2.4 Rounded Rectangle .......................................................................................77

5.2.5 Bargraph..................................................................................................................78

5.2.6 Bitmap......................................................................................................................78

5.3 Wizards............................................................................................................................81

5.3.1 Bit Button ................................................................................................................82

5.3.2 Word Button.......................................................................................................86

5.3.3 Bit Lamp..................................................................................................................89

5.3.4 Word Lamp .........................................................................................................93

5.3.5 Multiple Bargraph..................................................................................................95

5.3.6 Analog Meter ...................................................................................................101

5.3.7 Real Time Trend ............................................................................................107

5.3.8 Numeric Keypad ............................................................................................112

5.3.9 ASCII Keypad..........................................................................................................115

6. Task Management........................................................................................... 117

6. 1 Application Task List .................................................................................................118

6. 2 Screen Task List.........................................................................................................119

6.3 Key Task List................................................................................................................121

6.3.1 For Keypad Products .........................................................................................122

6.3.2 For Touch Screen Products .....................................................................123

6.4 Description of Tasks..................................................................................................124

7. Using Languages............................................................................................. 141

7.1 Language Conversion Utility....................................................................................142

7.1.1 File Menu ................................................................................................................142

7.1.2 Edit Menu................................................................................................................145

7.1.3 View Menu ..........................................................................................................145

7.2 Multi-Language Text Wizard.....................................................................................145

7.2.1 Configure Languages.........................................................................................146

7.2.2 Displaying Multiple Languages in Unit..........................................................148

Page vi

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

8. DownLoading & UpLoading from the OIS................................................ 149

8.2 Download.......................................................................................................................152

9. Alarms................................................................................................................. 156

9.1 Defining Alarms...........................................................................................................157

9.2 Alarm Definition...........................................................................................................158

9.3 Alarm Object............................................................................................................159

9.4 Alarm Type....................................................................................................................160

10. Trending........................................................................................................... 161

10.1 Real Time Trending..................................................................................................162

10.2 Data Logger................................................................................................................167

10.3 Historical Trend.........................................................................................................171

11. {Section Not Included at this Time}........................................................ 177

12. Printing............................................................................................................. 178

12.1 Printing from OIS Unit............................................................................................179

12.2 Printing from OISetup32 Software.......................................................................180

12.3 Printer Port Setup.....................................................................................................181

13. Miscellaneous................................................................................................ 184

13.2 Font Editor..................................................................................................................186

13.3 Associate a Screen ..................................................................................................190

13.4 Real Time Clock........................................................................................................191

13.5 On-Line Ladder Monitor..........................................................................................193

13.6 On-Line Screen Monitor...........................................................................................198

13.7 Convert Application..................................................................................................205

13.8 Ethernet Settings.......................................................................................................206

14. Diagnostics & Maintenance...................................................................... 215

14 . 1 Diagnostics................................................................................................................216

14.1.1 Erase Keys..........................................................................................................216

14.1.2 Touchscreen Calibration.................................................................................218

14.2 Maintenance................................................................................................................218

Appendix.................................................................................................................. 219

A. Communication Cable Diagrams..............................................................................220

C. Order Numbers..............................................................................................................232

D. Description of Tool Icons............................................................................................233

E. List of Supported Devices.........................................................................................236

16. Frequently Asked Questions..................................................................... 237

Index ......................................................................................................................... 239

Page vii

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page viii

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

0. General Safety Instructions and Information

Warning Labels Within Manual

Equipment Warning Labels

Preparation

Installation Precautions

Connection, Protection & Setup

System Integration Precautions

3rd Party Safety Certifications

Page 1

0.1 Warning Labels Within Manual

R

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

DO NOT attempt to install, operate, maintain, or dispose of this equipment

until you have read and understood all of the product warnings and user

directions that are contained in this instruction manual.

Listed below are the signal words that are used throughout this manual

followed by their descriptions and associated symbols. When the words

DANGER, WARNING, and CAUTION are used in the manual, they will be

followed by important safety information that must be carefully adhered to.

DANGER — The danger symbol is an exclamation mark enclosed in a triangle

that precedes the word DANGER. The danger symbol is used to indicate an

imminently hazardous situation that will result in serious injury, possible

severe property and equipment damage, or death if the instructions are not

followed.

DANGE

UMAN/OIS

WARNING — The warning symbol is an exclamation mark enclosed in a

triangle that precedes the word WARNING. The warning symbol is used to

indicate a potentially hazardous situation that can result in serious injury, or

possibly severe property and equipment damage, or death, if the instructions

are not followed.

WARNING

CAUTION — The caution symbol is an exclamation mark enclosed in a

triangle that precedes the word CAUTION. The caution symbol is used to

indicate situations that can result in minor or moderate operator injury, or

equipment damage if the instructions are not followed.

CAUT ION

Page 2

UMAN/OIS

L

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

To identify special hazards, other symbols may appear in conjunction with the

DANGER, WARNING, and CAUTION symbols. These warnings describe

areas that require special care and/or strict adherence to the procedures to

prevent serious injury and possible death.

Electrical Hazard — The electrical hazard symbol is a lightning bolt enclosed

in a triangle. The electrical hazard symbol is used to indicate high voltage

locations and conditions that may cause serious injury or death if the proper

precautions are not observed.

ELECTRICA

HAZARD

Explosion Hazard — The explosion hazard symbol is an explosion image

enclosed in a triangle. The explosion hazard symbol is used to indicate

locations and conditions where molten exploding parts may cause serious

injury or death if the proper precautions are not observed.

EXPLOSION

HAZARD

Page 3

0.2 Equipment Warning Labels.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

DO NOT attempt to install, operate, maintain, or dispose of this equipment

until you have read and understood all of the product warnings and user

directions that are contained in this instruction manual.

Shown below are examples of warning labels that may be found attached to

the equipment. DO NOT remove or cover any of the labels. If the labels are

damaged or if additional labels are required, contact your Toshiba

representative for additional labels.

The following are examples of the warning labels that may be found on the

equipment and are there to provide useful information or to indicate an

imminently hazardous situation that may result in serious injury, severe

property and equipment damage, or death if the instructions are not followed.

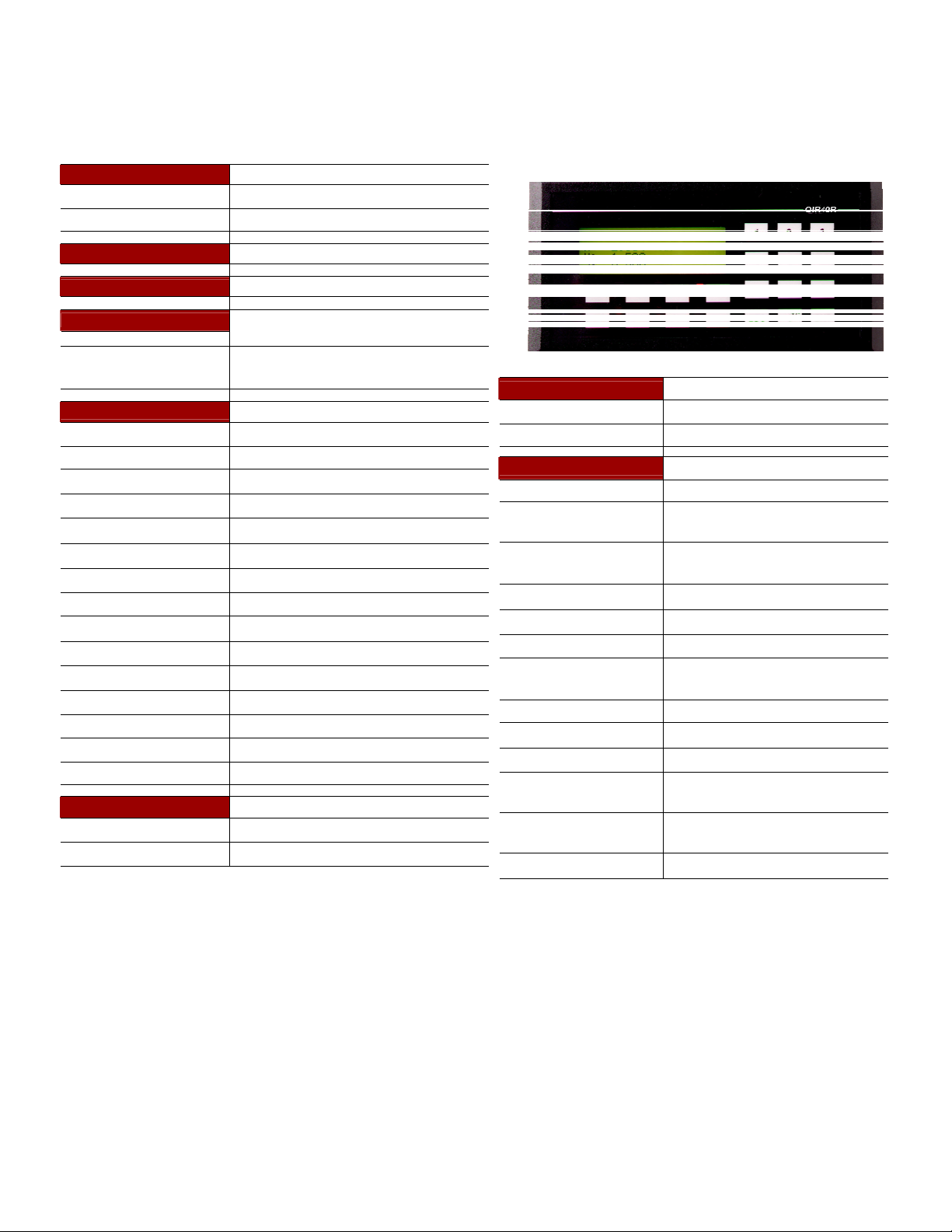

Examples of labels that may be found on the equipment.

UMAN/OIS

Page 4

0.3 Preparation

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Qualified Person

A Qualified Person is one that has the skills and knowledge relating to the

construction, installation, operation, and maintenance of the electrical

equipment and has received safety training on the hazards involved (Refer to

the latest edition of NFPA 70E for additional safety requirements).

Qualified Personnel shall:

• Have carefully read the entire operation manual.

• Be trained and authorized to safely energize, de-energize, ground, lockout

and tag circuits and equipment, and clear faults in accordance with

established safety practices.

• Be trained in the proper care and use of protective equipment such as

safety shoes, rubber gloves, hard hats, safety glasses, face shields, flash

clothing, etc., in accordance with established safety practices.

• Be trained in rendering first aid.

UMAN/OIS

For further information on workplace safety visit www.osha.gov.

Equipment Inspection

• Upon receipt of the equipment inspect the packaging and equipment for

shipping damage.

• Carefully unpack the equipment and check for parts that were damaged

from shipping, missing parts, or concealed damage. If any discrepancies

are discovered, it should be noted with the carrier prior to accepting the

shipment, if possible. File a claim with the carrier if necessary and

immediately notify your Toshiba representative.

• DO NOT install or energize equipment that has been damaged. Damaged

equipment may fail during operation resulting in further equipment damage

or personal injury.

• Check to see that the model number specified on the nameplate conforms

to the order specifications.

• Modification of this equipment is dangerous and must not be performed

except by factory trained representatives. When modifications are required

contact your Toshiba representative.

• Inspections may be required before and after moving installed equipment.

• Keep the equipment in an upright position as indicated on the shipping

carton.

• Contact your Toshiba representative for assistance if required.

Page 5

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Handling and Storage

• Use proper lifting techniques when moving the OIS; including properly

sizing up the load, and getting assistance if required.

• Store in a well-ventilated covered location and preferably in the original

carton if the equipment will not be used upon receipt.

• Store in a cool, clean, and dry location. Avoid storage locations with

extreme temperatures, rapid temperature changes, high humidity, moisture,

dust, corrosive gases, or metal particles.

• Do not store the unit in places that are exposed to outside weather

conditions (i.e., wind, rain, snow, etc.).

• Store in an upright position as indicated on the shipping carton.

• Include any other product-specific requirements.

Disposal

Never dispose of electrical components via incineration. Contact your state

environmental agency for details on disposal of electrical components and

packaging in your area.

0.4 Installation Precautions

Location and Ambient Requirements

• Adequate personnel working space and adequate illumination must be

provided for adjustment, inspection, and maintenance of the equipment

(refer to NEC Article 110-34).

• Avoid installation in areas where vibration, heat, humidity, dust, fibers,

steel particles, explosive/corrosive mists or gases, or sources of electrical

noise are present.

• The installation location shall not be exposed to direct sunlight.

• Allow proper clearance spaces for installation. Do not obstruct the

ventilation openings. Refer to the recommended minimum installation

dimensions as shown on the enclosure outline drawings.

• The ambient operating temperature shall be between 0° and 50° C (32°

and 122° F).

Mounting Requirements

• Only Qualified Personnel should install this equipment.

• Install the unit in a secure upright position in a well-ventilated area.

• A noncombustible insulating floor or mat should be provided in the area

immediately surrounding the electrical system at the place where

maintenance operations are to be performed.

Page 6

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

• As a minimum, the installation of the equipment should conform to the

NEC Article 110 Requirements For Electrical Installations, OSHA, as well

as any other applicable national, regional, or industry codes and standards.

• Installation practices should conform to the latest revision of NFPA 70E

Electrical Safety Requirements for Employee Workplaces.

Conductor Routing and Grounding

• Use separate metal conduits for routing the input power, and control

circuits.

• A separate ground cable should be run inside the conduit with the input

power, and control circuits.

• DO NOT connect control terminal strip return marked CC to earth ground.

• Always ground the unit to prevent electrical shock and to help reduce

electrical noise.

The Metal Of Conduit Is Not An Acceptable

Ground.

Page 7

0.5 Connection, Protection & Setup

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Personnel Protection

• Installation, operation, and maintenance shall be performed by Qualified

Personnel Only.

• A thorough understanding of the OIS will be required before the installation,

operation, or maintenance of the OIS.

• Rotating machinery and live conductors can be hazardous and shall not

come into contact with humans. Personnel should be protected from all

rotating machinery and electrical hazards at all times. Depending on its

program, the OIS can initiate the start and stop of rotating machinery.

• Insulators, machine guards, and electrical safeguards may fail or be

defeated by the purposeful or inadvertent actions of workers. Insulators,

machine guards, and electrical safeguards are to be inspected (and tested

where possible) at installation and periodically after installation for potential

hazardous conditions.

• Do not allow personnel near rotating machinery. Warning signs to this

effect shall be posted at or near the machinery.

UMAN/OIS

• Do not allow personnel near electrical conductors. Human contact with

electrical conductors can be fatal. Warning signs to this effect shall be

posted at or near the hazard.

• Personal protection equipment shall be provided and used to protect

employees from any hazards inherent to system operation or maintenance.

System Setup Requirements

• When using the OIS as an integral part of a larger system, it is the

responsibility of the OIS installer or maintenance personnel to ensure that

there is a fail-safe in place (i.e., an arrangement designed to switch the

system to a safe condition if there is a fault or failure).

• System safety features should be employed and designed into the

integrated system in a manner such that system operation, even in the

event of system failure, will not cause harm or result in personnel injury or

system damage (i.e., E-Off, Auto-Restart settings, System Interlocks, etc.).

• The programming setup and system configuration of the OIS may allow it

to start a motor unexpectedly. A familiarity with Auto-restart settings is a

requirement to use this product.

• Improperly designed or improperly installed system interlocks may render

the motor unable to start or stop on command.

Page 8

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

• The failure of external or ancillary components may cause intermittent

system operation, i.e., the system may start a motor without warning or

may not stop on command.

• There may be thermal or physical properties, or ancillary devices

integrated into the overall system that may allow the OIS to start a motor

without warning. Signs at the equipment installation must be posted to this

effect.

• The operating controls and system status indicators should be clearly

readable and positioned where the operator can see them without

obstruction.

• Additional warnings and notifications shall be posted at the equipment

installation location as deemed required by Qualified Personnel.

Page 9

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

0.6 System Integration Precautions

The following precautions are provided as general guidelines for using an OIS

in an industrial or process control system.

• The Toshiba OIS is a general-purpose product. It is a system component

and is used in conjunction with other items of industrial equipment such as

PLCs, Loop Controllers, Adjustable Speed Drives, etc.

• A detailed system analysis and job safety analysis should be

performed by the systems designer or systems integrator before

including the OIS in any new or existing system. Contact Toshiba for

options availability and for application-specific system integration

information if required.

• The OIS may be used to control an adjustable speed drive connected to

high voltage sources and rotating machinery that is inherently dangerous if

not operated safely. Interlock all energy sources, hazardous locations,

and guards in order to restrict the exposure of personnel to hazards. The

adjustable speed drive may start the motor without warning. Signs at the

equipment installation must be posted to this effect. A familiarity with Autorestart settings is a requirement when controlling adjustable speed drives.

Failure of external or ancillary components may cause intermittent system

operation, i.e., the system may start the motor without warning or may not

stop on command. Improperly designed or improperly installed

system interlocks and permissives may render a motor unable to

start or stop on command

UMAN/OIS

• Control through serial communications can fail or can also override local

controls, which can create an unsafe condition. System safety features

should be employed and designed into the integrated system in a manner

such that system operation, even in the event of system failure, will not

cause harm or result in personnel injury or system damage. Use of the

built-in system protective features and interlocks of the equipment being

controlled is highly recommended (i.e., emergency-off, overload protection,

etc.)

• Never use the OIS units to perform emergency stops. Separate

switches outside the OIS, the PLC, and the ASD should be used for

emergency stops.

• Changes or modifications to the OIS program should not be made without

the approval of the system designer or systems integrator. Minor changes

or modifications could cause the defeat of safety interlocks and

permissives. Any changes or modifications should be noted and included

with the system documentation.

Page 10

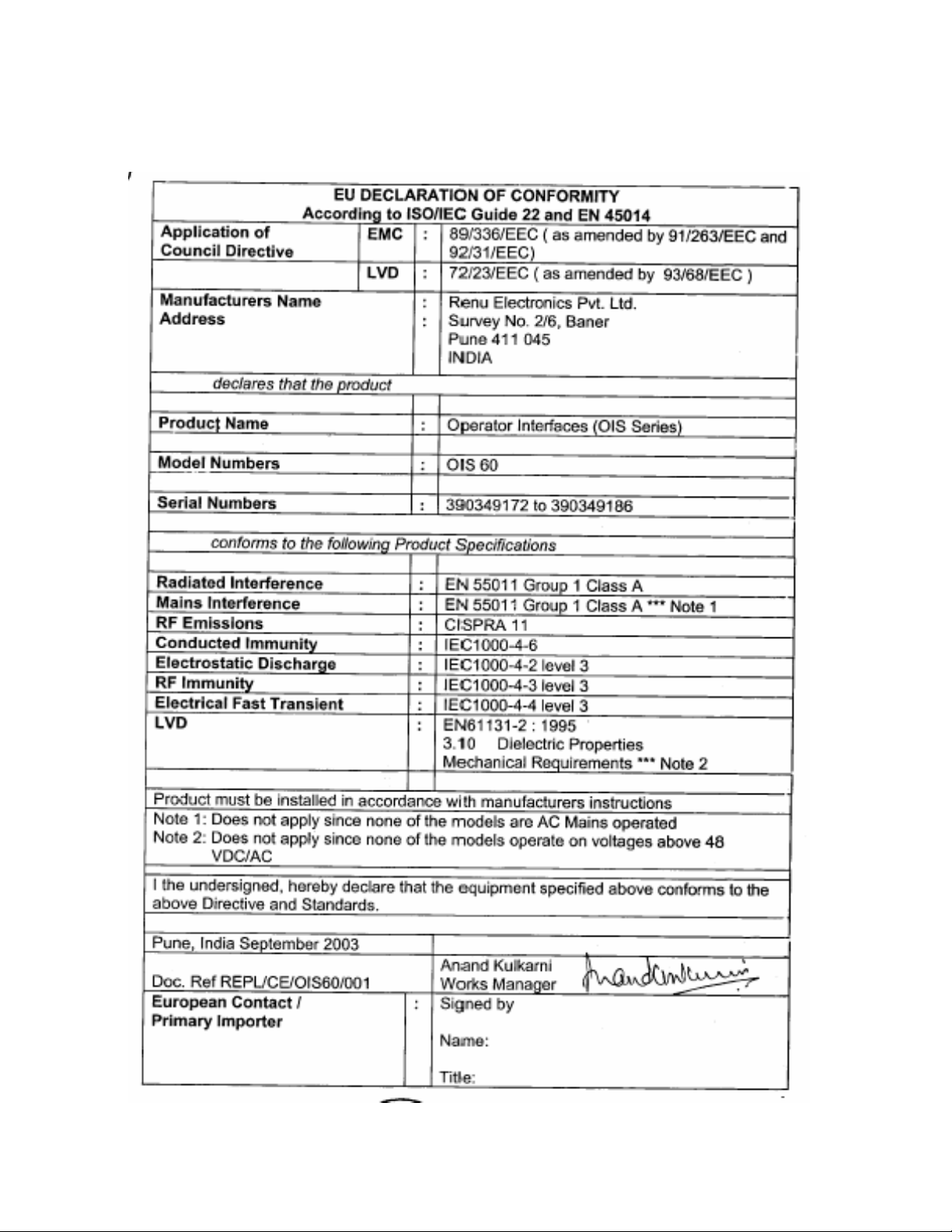

0.7 3rd Party Safety Certifications.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

UMAN/OIS

CE Marking

Page 11

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. Introduction

Purpose of Manual

OIS Basics

Hardware Configuration

OIS Overview

What is OIS

OIS Specifications

Page 12

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.1 Purpose of this Manual

Thank you for purchasing OIS EV3 Series Products from Toshiba International

Corp.. OIS Series Products are versatile operator interfaces with Microsoft

Windows based configuration Software.

This Manual explains the operation of the OIS Series and how to implement

available features using the OIS32 Soft-ware. This manual will help you to install,

configure and operate your OIS product.

1.1.1 OIS Basics

Operator Interface Terminals (OISs) provide much more versatility than traditional

mechanical control panels. An OIS allows a plant floor operator to monitor current

conditions of a control system and, if necessary, to initiate a change in the operation of the system. OISs connect to programmable logic controllers (PLCs) typically

through the serial communications port. The OIS can be programmed to monitor

and/or change current values stored in the data memory of the PLC.

UMAN/OIS

OISs can have either text or graphics based displays. A text based OIS can

display printable text characters but can not print graphics.

Some OISs use touch screen displays while others use a PCB based keypad. PCB

based keypads are best used in applications in which the keypad is likely to

become dirty. A touch screen OIS provides much more flexibility than typical PCB

based keypad displays. Keys can be created in a touch screen OIS that can be

made visible only when needed. The OIS Series OISs are available in both text

display based OIS and graphics display based OISs.

What is a Project?

A project is an user created application in OIS32 Software. A project contains

information such as OIS model, Network Configuration, Screen information, Task

information et c.

What is a Screen?

A screen is a visual representation of objects placed on the OIS screen. Any

partially sized window is usually referred to as a popup screen or window. The user

can create his customized screen according to his requirements. Popup wind ows

can also appear on the OIS display by pressing buttons on the touch screen . The

maximum number of screens in an application is only limited by the application

memory size. A more in depth discussion on screens is covered in chapter 4.

Page 13

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

What is an Object?

An object placed on OIS screen can perform actions such as displaying text

messages, writing a value to a PLC register, or displaying an alarm. An object can

be classified as a text or graphical object.

A text object is used to display the text on the OIS and can also used to perform

some action. For example, a data entry object tells the OIS to continuously monitor

a PLC register and allows the user to change the value in the register. Some

objects can display graphics whose shape depends on the value of a register.

These objects may also change the value of a PLC tag. An example is a Bit Button

Object that creates a graphic object on the OIS. When pressed, it activates a bit in

the PLC.

1.1.2 Hardware Requirements

The following basic PC hardware configuration is needed to configure and operate your

OIS32 Software.

DEVICE MINIMUM REQUIREMENT

IBM Compatible PC with

Pentium Processor

Operating System Windows® 2000 and above

System RAM

Hard Disk 150 MB Free Memory Space

VGA Monitor Color

Setting Resolution

Serial Port

Mouse

Keyboard Required

266MHz Pentium® II or higher Pentium

compatible CPU

At least 64 megabytes (MB) of RAM, more

memory generally improves responsiveness

800 x 600 with 24 bit True Color

Serial Port for Downloading

Microsoft® Mouse or compatible pointing device

These are the minimum system requirements for a computer running the OISetup32 software.

Page 14

1.2 OIS Overview

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2.1 What is an OIS?

OIS provide Human-Machine Interface to the Pr ogrammable L ogic Cont roller. These OISs

communicate with PLCs using their serial communications ports.

Configuration of OIS:

Each OIS unit has to be configured using the OISetup32 Software before connecting it to the PLC.

Normal Operation:

UMAN/OIS

Connect OIS unit to PLC using the correct PLC-OIS cable. The OIS can communicate with any

device without making any additional hardware settings on the unit.

Page 15

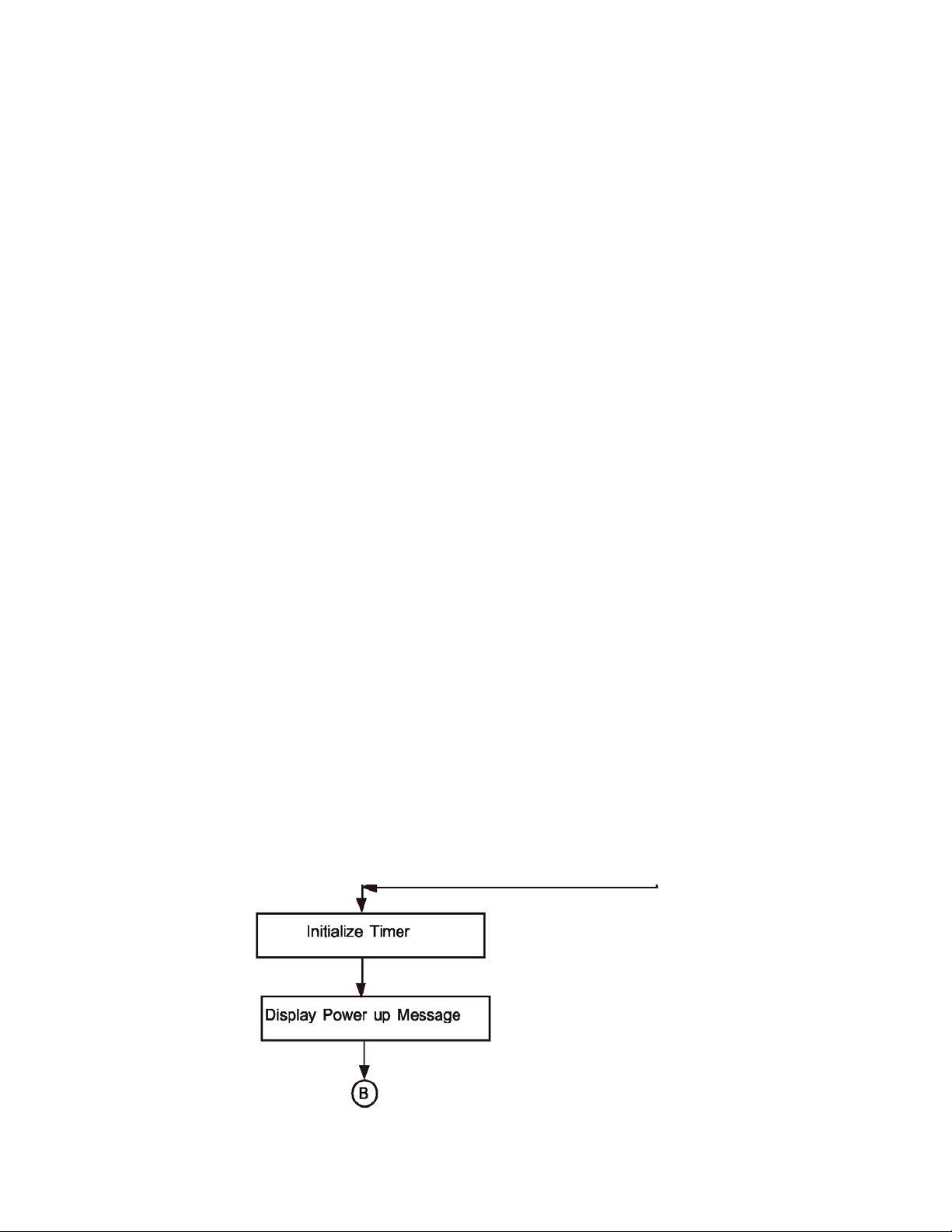

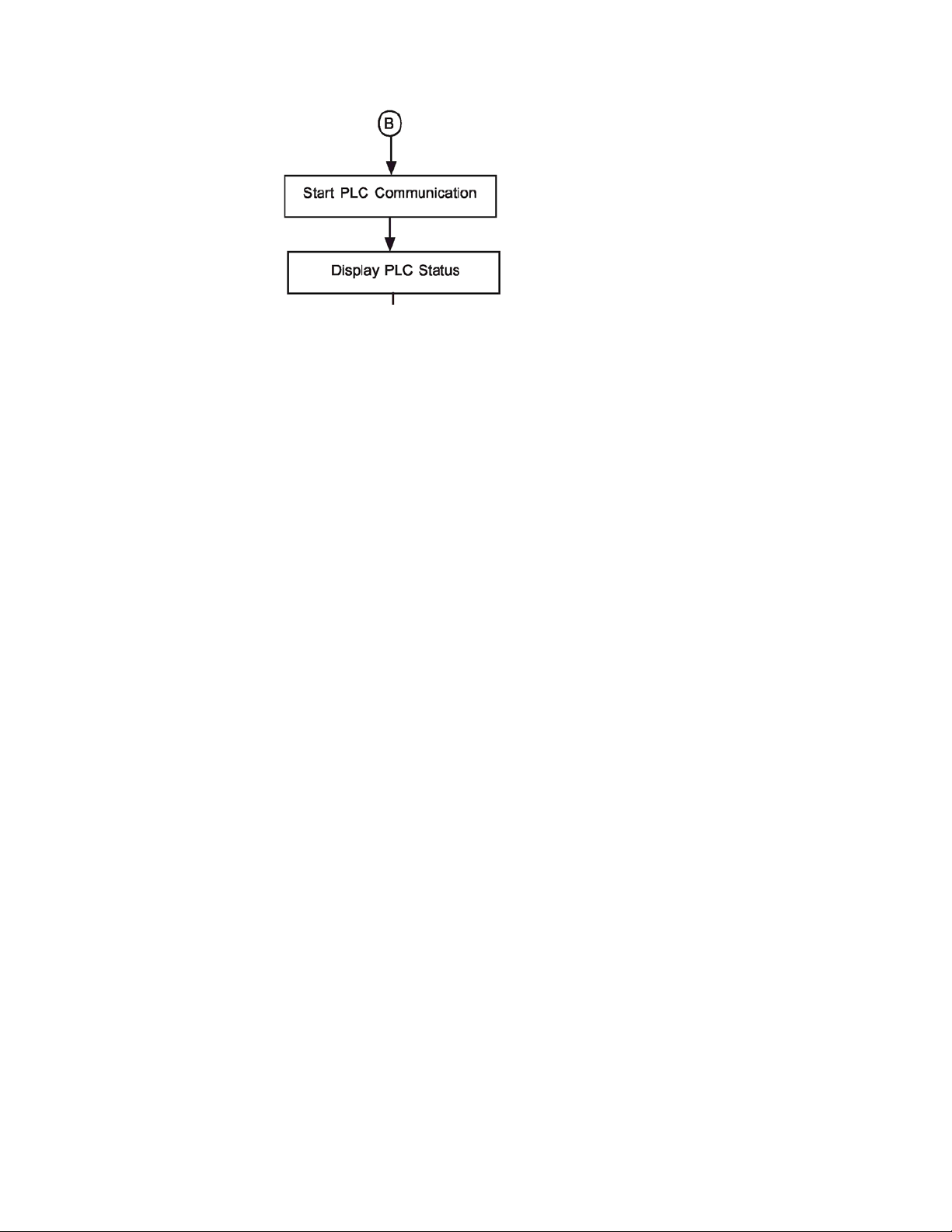

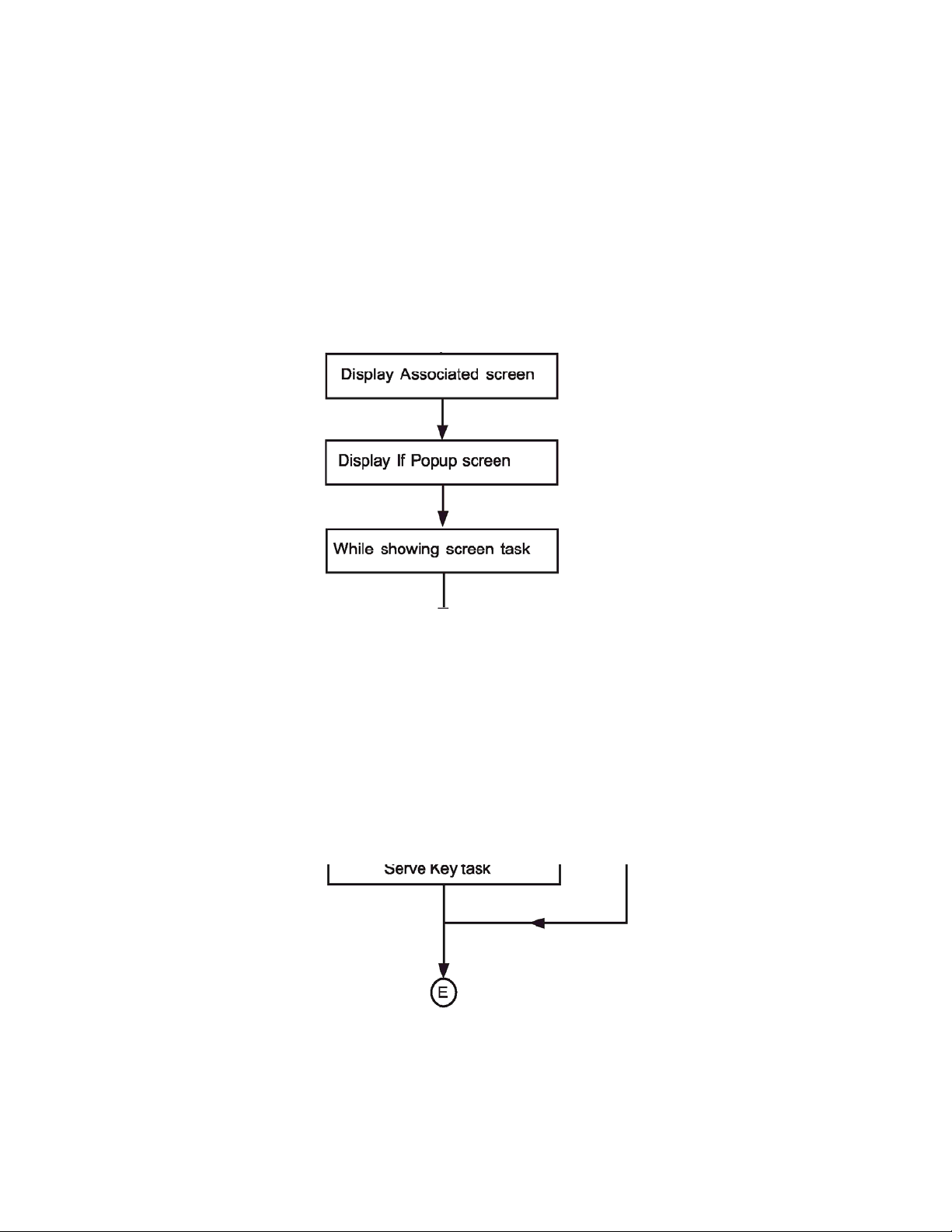

1.2.2 How the OIS Works

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The OIS follows a specific sequence for performin g the ta sks defined by the user in the

application. The sequence is as shown below:

UMAN/OIS

Page 16

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 17

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 18

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 19

UMAN/OIS

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2.3 Specifications of OIS Series

OIS series models are Human Machine Interfaces with optional Input/Output capability. OISs with

Input/Output capability are termed as HIO. OIS series OISs can be powered either from the PLC or from an

external power supply. PLC powered units are referred to as IOP, whereas externally powered units are

referred to as OIS. HIO units can not be powered from a PLC. HIO models can be externally from a DC or

AC source.

OIS models need +24VDC power from an external supply. HIO can either be external +24VDC powered or

85-265, 50/ 60Hz VAC powered.

Models included in the OIS Series are as follows:

OIS40/40R OIS50 OIS55 OIS60 OIS120

The functionality of OIS and HIO products is exactly the same. The only difference between a OIS

product and an HIO product is the addition of real I/O to the HIO unit. A OIS application can be

downloaded to a corresponding HIO model. All of the OIS EV3 series models have ladder functionality

built in.

All OIS EV3 series models have two serial communication ports. They can communicate with two

different PLCs simultaneously.

1.2.4 Comparison Between Keypad Based OIS Operator Panels

Model OIS40 OIS40R

Display 128 X 64 Pixels 128 X 64 Pixels

Keys Function 8 User Definable 8 User Definable

LEDs 8 8

Memory Total 512 KB 512 KB

Data Logging N. A. N. A.

Trending N. A. N. A.

Alarms Real Time

Recipes Yes Yes

Password Yes Yes Yes

Dimensions 101 HX183WX37D 101 HX183WX37D 101 HX183WX37D

Numeric 12 12

Application 120 KB 120 KB

Ladder 62 KB 62 KB

Historical

Yes Yes Yes

163W X 77H mm 163W X 77H mm 163W X 77H mm

Real Time

Historical

Page 20

1.2.5 Comparison Between Touchscreen Based OIS Panels

*

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Model OIS50 OIS55 OIS60 OIS120

Display

Type

Resolution 192 X 62 Pixels 320 X 240 Pixels 320 X 240 Pixels 800 X 600 Pixels

Brightness

Control

Touchscree

n

Total 512 KB 3 MB 4 MB 32 MB

Applicati

on

Ladder 62 KB 512 KB 128 KB 2 MB

Memory

Data

Logging

Data

Logging

Trending N.A. Real Time

4.1” Yellow Backlit

LCD

Graphical Display

Standard Through

Pot

Analog Resistive Analog Resistive Analog Resistive Analog Resistiv

120 KB 2.56 MB 3 MB Maximum* 25 MB Maximum

N.A. N.A. 2 MB* 2 MB*

N.A. N.A. Yes Yes

3.5" TFT Graphical

Color Display,

6 Function Keys

5.7” STN CCFL

QVGA

Graphical Color

Standard Through

Pot

Real Time +

Historical

12.1: TFT CCFL

Graphical Color

Standard Thru.

Pot

Real Time +

Historical

UMAN/OIS

Alarms

Recipes Yes Yes Yes Yes

ScreenSave

r

Screen Yes Yes Yes Yes

P

W

Applicati

on

External

Dimensi

Di

ons

m

Panel

Cutout

Real Time +

Historical

N.A. Yes Yes Yes

Yes Yes Yes Yes

77HX140WX32D 91Hx136W x29D 139HX197WX58.5D 246HX312WX47

132W X 69H mm 127W x 77H 184W X 126H mm 295W X 227H mm

Real Time +

Historical

Real Time +

Historical

Real Time +

Historical

Note: Total memory can be adjusted between application memory, ladder memory, and

data logging memory.

D

Page 21

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

OIS40/40R

Power Supply OIS40, from PLC OIS40R, 24VDC

Voltage Rating 24 VDC + 10%

Power Rating 3W Maximum

Approvals CE Certified and UL Listed 58DN

Bezel IP65 Rated Keypad

Keypad

Number Of Keys

Memory

Total Memory 512KB

Application Memory 120KB

Ladder Memory 62KB

Data Register 1000

Retentive Register 1400

System Register 64

System Coil 100

Internal Coil 5000

Input Coil 100

Output Coil 100

Internal Register 313

Input Register 7

Output Register 7

Timer Register 128

Counter Register 178

Display LCD Text Display

Display Type 4 lines of 16 characters Backlit LCD

LEDs 8 LEDs

PCB based Keypad With Tactile

Feedback Keys, Insertable Legend

8 User Definable keys and 12 Numeric

Keys

UMAN/OIS

Communication

Number of Ports

Type RS232 / RS485 / RS422 / CMOS

Miscellaneous

External Dimension 101 H X 183 W X 37 D mm

Battery

Battery Backup

Operating Temperature 0 0C to 50 0C

Storage Temperature -25 0C to 80 0C

Mounting Method Panel Mounting

Clock(RTC)

Humidity 10% To 90% (Noncondensing)

Immunity to ESD Level 3 as per IEC1000-4-2

Immunity to Transients Level 3 as per IEC1000-4-4

Immunity to Radiated

RF

Immunity to Conducted

RF

Emission EN55011 CISPRA

2

Coin Type, 3V Lithium Battery

614-CR1225FH

Minimum 5 years battery backup for

RTC and System data

Real Time Clock Function(Date &

Time)

Level 3 as per IEC1000-4-3

Level 3 as per IEC1000-4-6

Page 22

Loading...

Loading...