Sample and Hold

Model 9752

Assembly and Using Manual

This second-generation 9700-series processing

element for modular sound synthesizers is

designed to provide great sound and excellent

value.

The 9752 monitors the input signal voltage and

copies it to the output, synchronized to changes in

an input control voltage (CV) or an input clock, or

synchronized to an internal clock if there is no

external input. The input may be an audio or

control signal. One typical application uses noise

as an input signal and a variable rate clock to

control sampling. This provides a random control

voltage source from the module output.

The module's use with audio signals is enhanced

by a switch option to change the function from

"sample and hold" to "gate and hold", where the

output tracks the input signal as long as the

control input voltage is above a threshold (or, if

selected, the internal clock rises). After the control

voltage drops, the output voltage freezes until the

next high-going transition of the control voltage (or

the internal clock rises again).

© 2009 PAiA Corporation

This high-performance module is designed to be

compatible with most modular synthesizer

systems with little or no modification. Most active

components are already mounted, making

assembly a snap.

ASSEMBLING THE 9752 Sample and Hold

Before beginning assembly, go through the manual. Look at the drawings.

Feel the parts. You're naturally eager to plunge right in, but take a few

deep breaths first. Check the parts supplied against the packing list at the

back of this manual.

In some cases, notes packed with the parts will be used to call your attention

to special situations. If parts are missing, please notify PAiA at

missing@paia.com or by phone at (405) 340-6300, fax (405) 340-6378. A

NOTES page is included at the end of this manual.

Notice that each step in the manual is marked with a

checkoff box like this:

DESIGNATION DESC. MARKING

( ) R27 100ohm brn-blk-brn-gld

Checking off each step as you do it may seem silly and ritualistic, but it

greatly decreases the chance of omitting a step and also provides some

gratification and reward as each step is completed.

Numbered figures are printed in the Illustrations Supplement in the center of

this manual. These pages may be removed for easy reference during

assembly.

THE CIRCUIT BOARD

The 9752 Sample and Hold is built on a double-sided circuit board. Note the

“top” side of the board has the connector and control placement designators.

Surface-mounted components are on the “bottom” of the board. Install parts

to the top of the board and solder them on the bottom.

TOOLS

You'll need a minimum of tools to assemble the kit – a small pair of diagonal

wire cutters, pliers, screwdriver, soldering iron, and solder.

2

Modern electronic components are small (in case you hadn't noticed) and

values marked on the part are often difficult to see. Another handy tool for

your bench will be a good magnifying glass. Also use the magnifier to

examine each solder joint as it is made to make sure that is doesn't have

any of the problems in the SOLDERING section which follows.

SOLDERING

Select a soldering iron with a small tip and a power rating of not more than

35 watts. Soldering guns are completely unacceptable for assembling

solid-state equipment because the large magnetic field they generate can

damage components.

Use only a high quality electronic solder. Your kit is compatible with leadfree and/or tin-lead flux-core solders made especially for electronic

assembly. Plumbing solder will destroy your kit with its acid core. Jewelry

solder (silver solder) will destroy your kit with its high working heat. Neither

is for electronics work.

A proper solder joint has just enough solder to cover the soldering pad and

about 1/16-inch of the lead passing through it.

There are two improper connections to be aware of: Using too little solder

will sometimes result in a connection which appears to be soldered when

actually there is a thin layer of flux insulating the component lead from the

solder bead. This situation can be cured by reheating the joint and applying

more solder.

Too much solder may produce a conducting bridge of excess solder

between adjacent pads causing a short-circuit. Continued feeding of solder

into a hot joint can result in accumulation on the underside of the board and

may cause bridges or impede the action of mechanical components. If you

see this, position the board above the iron tip and the excess will flow to the

tip.

Use care when mounting all components. Never force a component into

place.

3

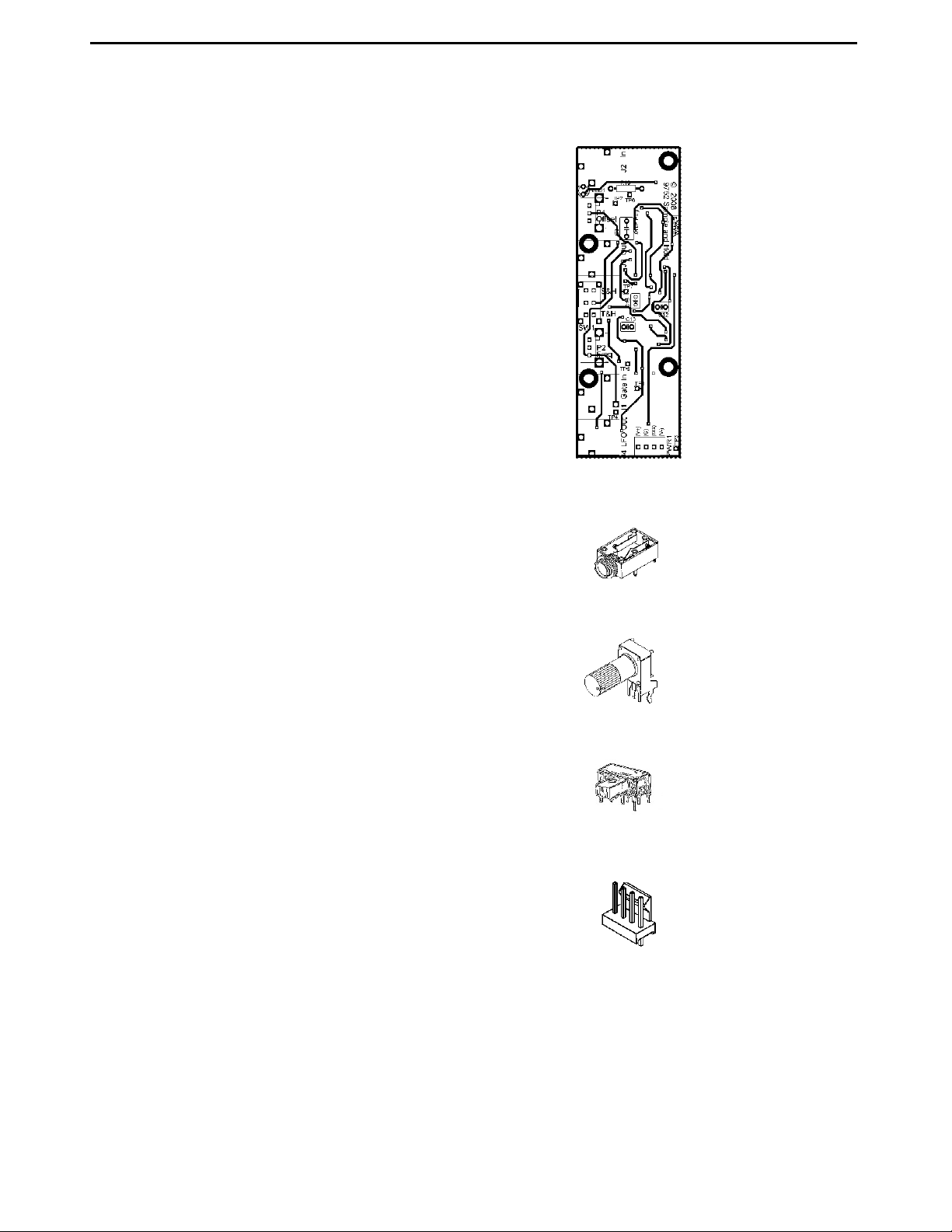

CONTROLS AND CONNECTORS

Controls and connectors will be installed on the top

side of the board with the placement designators as

shown in the illustration to the right.

Miniature phone connectors referenced as “stereo

phone jacks” in the manual parts list are specified

below with the contact/terminal names, Tip, Ring and

Sleeve (TRS) and are labeled on the board and

schematic as such.

The potentiometers have tabs extending from their body

for stability. They have a snap-fit to the board. Align

the tabs and pins with their holes and press them into

place. There is no need to bend the tabs or terminals.

To ensure the best alignment with these parts with the

front panel, begin by soldering only one of the multiple

terminals associated with each of the following parts

as it is installed. Then, if a part is tilted or crooked, it

is only a matter of reheating the joint as the part is

aligned.

Match the tab of the polarized power connector with the

corresponding board marking.

Top of circuit board

DESIG. DESC. MARKING

( ) J1 TRS socket, c.c. 4 terminals

( ) J2 TRS socket 3 terminals

( ) J3 TRS socket 3 terminals

( ) J4 TRS socket 3 terminals

( ) P1 100K ohm B100K

potentiometer, linear

( ) P2 1M ohm A1M

potentiometer, audio

( ) SW1 Slide Switch

( ) PWR1 Header

TRS socket

“stereo phone jack”

Potentiometer

Slide Switch

Header

4

Loading...

Loading...